Page 1

eZV-440

Application Guide

Edition 2.6

Page 2

Table of Contents

Copyright 8

About the eZV-440 9

About This Guide 9

Upgrading Firmware 9

Object Restriction Settings (ORS) 10

ORS Troubleshooting 10

About the enteliZONE ORCAview Configuration Graphic 11

Downloading the ORCAview Configuration Graphic 11

Installing the ORCAview Configuration Graphic 11

Opening the ORCAview Configuration Graphic 11

Method 1 (Recommended) 12

Method 2 12

Working with the ORCAview Configuration Graphic 12

Selecting Between Multiple Controllers 12

Save to Flash, Save to PC and Load from PC 13

Shortcuts 13

Configurable and Programmable enteliZONE Controllers 14

Differences Between Configurable and Programmable enteliZONE Controllers 14

LINKnet Devices 14

Data Exchange 15

Alarming 15

Trend Logs 16

Programming 17

eZV-440 Application Guide

Edition 2.6

Page 1 of 84

Page 3

enOcean Integration (firmware 2.2 and higher) 18

Upgrade to Fully Programmable Using Flash Loader (firmware 2.2 and higher) 18

VAV/VVT Programmable Objects 19

VAV/VVT Programmable Objects 19

Relationship Between Algorithm Unit Modules 20

General Tab 22

What is the General Tab? 22

Device Information 22

Network Settings 23

Global Settings 24

Local Inputs Tab 26

Setting Up a Hardwired Temperature Sensor 26

Set Up a Hardwired Temperature Sensor 26

Setting Up a Hardwired Occupancy Input 27

Set Up a Hardwired Occupancy Input 28

Setting Up a Hardwired CO2 Sensor 29

Setting Up Other Supporting Inputs 30

Set Up an Input 30

Setting Up an Airflow Sensor 31

Introduction 31

Setting Up Damper Feedback 31

Local Outputs Tab 33

Setting Up a VAV/VVT Output 33

Introduction 33

Set Up a VAV or VVT Output 33

Page 2 of 84 eZV-440 Application Guide

Edition 2.6

Page 4

Setting Up a Fan Output 34

Set Up a Fan Output 34

Setting Up Other Outputs 36

Set Up an Output 36

Setting Up a Damper Output 37

Set Up a Damper Output 37

LINKnet I/O Tab 38

Configuring an eZNS-T100 Network Sensor 38

Set Up the Temperature Sensor 38

Set Up the Humidity Sensor 39

Set Up the CO2 Sensor 39

Set Up the Occupancy Sensor 39

Assign Functions to the Buttons and Slider 40

Set Up the LCD Display 40

Assigning Buttons and Slider Elements on eZNS-T100 Network Sensor 41

Introduction 41

Set Up the Buttons and Slider Elements 43

Configuring DNS-24L Network Sensor 46

Introduction 46

Set Up the Temperature Sensor 46

Set Up the Humidity Sensor 46

Set Up the CO2 Sensor 47

Set Up the Occupancy Sensor 47

Assign Functions to the Buttons 47

Set Up the LCD Display 47

eZV-440 Application Guide

Edition 2.6

Page 3 of 84

Page 5

Assigning Buttons on DNS-24L Network Sensor 47

Introduction 47

Set Up the Button Elements 48

Setpoints Tab 50

What is the Setpoints Tab? 50

Space Temperature Setpoints 50

Occupied Heating Setpoint (OccHeatingSetpoint) 50

Unoccupied Heating Setpoint (UnOccHeatingSetpoint) 50

Occupied Cooling Setpoint (OccCoolingSetpoint) 50

Unoccupied Cooling Setpoint (UnOccCoolingSetpoint) 50

Occupied Setpoint Offset Range (OccSetpointOffsetRange) 50

Eco Mode Setback (EcoModeSetBack) 51

Standby Setback (StandbySetback) 51

Discharge Air Temperature Limiting Setpoint Differentials 51

Discharge Air Temperature High Limit Setpoint Differential (DATHiLimitSetpointDiff) 51

Discharge Air Temperature Low Limit Setpoint Differential (DATLowLimitSetpointDiff) 51

VAV/VVT Setpoints 51

VAV Box Size (VAVBoxSize) 51

Flow Factor (FlowFactor) 52

Airflow Failure Setpoint (AirflowFailureSetpoint) 52

CoolingMinimum 52

CoolingMaximum 52

HeatingMinimum 52

HeatingMaximum 52

StandbyMinimum 52

Page 4 of 84 eZV-440 Application Guide

Edition 2.6

Page 6

Controllers Tab 53

What is the Controllers Tab? 53

Controller Type 53

Proportional Band 53

Deadband 53

Integral Rate 53

Reset Band 53

Outdoor Air Temperature Heating Lockout Setpoint (OAT Htg Lockout) 54

Heating Demand Limit (Htg Demand Limit) 54

Outdoor Air Temperature Cooling Lockout Setpoint (OAT Clg Lockout) 54

Cooling Demand Limit (Clg Demand Limit) 54

Air Balancing Tab 55

What is the Air Balancing Tab? 55

Variable Air Volume (VAV) System Commissioning 55

Air Balancing 55

To auto zero-calibrate the airflow sensor: 56

To calibrate the airflow factor: 56

Check Duct Heater Airflow Safety 57

enteliZONE Sequence of Operations 58

Introduction 58

Setpoint Control 58

Setpoint Range Limits 58

Occupancy Modes 59

Switching Between Occupancy Modes 60

Setpoints and Occupancy Modes 62

eZV-440 Application Guide

Edition 2.6

Page 5 of 84

Page 7

Heating and Cooling (VAV) 63

Time-Proportional Heating and Cooling 64

Discharge Air Temperature 65

Fan (VAV) 65

Single Speed Parallel Fan Sequence 65

Modulating Speed Parallel Fan Sequence 66

Single Speed Series Fan Sequence 67

Modulating Speed Series Fan Sequence 67

Damper and Airflow Setpoint Control 67

Airflow Setpoints 67

Air Balancing 69

Demand Control Ventilation 70

Open Window Detection 70

enteliZONE Database Configuration Objects 71

Introduction 71

Input Configuration Objects 71

Occupancy Configuration Objects 73

Output Configuration Objects 74

Setpoint Configuration Objects 75

Device Instance/ BACnet Address Object 78

Control Types 79

What are Control Types? 79

Open Source Licensing 81

lwIP 81

ST Microelectronics 82

Page 6 of 84 eZV-440 Application Guide

Edition 2.6

Page 8

Document Revision History 83

eZV-440 Application Guide

Edition 2.6

Page 7 of 84

Page 9

Copyright

Copyright

Copyright © Delta Controls Inc. All rights reserved.

No part of this document may be reproduced, transmitted, transcribed, stored in a retrieval system,

or translated into any language (natural or computer), in any form or by any means, without the

prior written permission of Delta Controls Inc.

Limited permission is granted to reproduce documents released in Adobe® Portable Document

Format (PDF) electronic format in paper format. Documents released in PDF electronic format

may be printed by end-users for their own use using a printer such as an inkjet or laser device.

Authorized distributors of Delta Controls Inc. products (Delta Partners) may print PDF documents

for their own internal use or for use by their customers. Authorized Delta Partners may engage a

printing or copying company to produce copies of released PDF documents with the prior written

permission of Delta Controls Inc.

Information in this document is subject to change without notice and does not represent a

commitment to past versions of this document on the part of Delta Controls Inc. Delta Controls Inc.

may make improvements and/or changes to this document /the associated software/or associated

hardware at any time.

BACspec, BACstat, the Delta logo, ORCAview, ORCAweb, Earthright, enteliWEB, enteliBUS,

enteliMESH, enteliTOUCH, enteliZONE, enteliSTAT, and Virtual Stat are registered trademarks

of Delta Controls Inc.

All other trademarks are the property of their respective owners.

Document edition: 2.6

Published on Wednesday, August 23, 2017

Page 8 of 84 eZV-440 Application Guide

Edition 2.6

Page 10

About the eZV-440

The eZV-440 and eZVP-440 controllers are native BACnet controllers optimized for fan coil

applications. It features line voltage power input with a built-in 24 VAC inverter and line voltage

rated relays eliminating the need for a local control transformer or external relays to switch the fan.

The controller is also designed to be compatible with Delta Controls’ eZNS and DNS-24L network

sensors.

The eZV-440 comes preloaded with algorithms which you configure using a configuration graphic

to match your site’s needs. There are 2 types of eZV-440 controllers: both the configurable (eZV)

and programmable (eZVP) models use the configuration graphic for setup but only the

programmable controller allows you to overwrite the default sequences with General Control

Language (GCL) programming.

You can use ORCAview 3.40R3 and higher or enteliWEB 4.1 and higher to access the

configuration graphic.

About This Guide

This application guide introduces the controller and describes the differences between the

configurable and programmable models. The guide also shows you how to use the configuration

graphic in ORCAview 3.40 R3 and higher to set up your eZV-440 controller. The product name

eZV-440 in this guide refers to both the configurable and programmable models unless stated

otherwise.

The ORCAview configuration graphic version referenced in this guide is B-169041.1.

For help with the eZV-440 configuration page in enteliWEB 4.3 and higher, go to the online help in

enteliWEB. enteliWEB users require the applicable object permissions to change the settings on

the configuration page.

The installation guide for the eZV-440 can be found on the eZV-440 product web page on

the Delta Controls Support web site.

Upgrading Firmware

See the release notes of the firmware version you are upgrading to for more information.

Release notes are available on the Delta Controls Support web site

eZV-440 Application Guide

Edition 2.6

Page 9 of 84

Page 11

About the eZV-440

Object Restriction Settings (ORS)

The Object Restriction Settings (ORS) object allows the user to limit which database objects can be

viewed and edited. This is useful for hiding configuration settings which are not used in day-to-day

operation, to ensure a user cannot inadvertently change the configuration after initial system

commissioning. enteliZONE controllers support permission options of visible, read and write.

However, enteliZONE controllers do not support create or delete permissions as enteliZONE has a

fixed database structure where objects are editable but cannot be created or deleted. enteliZONE

controllers also do not support multiple ORS objects with temporary unlock permissions.

ORS security is turned on and off by locking and unlocking the controller. The ORS is unlocked in

the default database configuration. It must be unlocked in order to configure the controller. If the

controller is in a locked state, a message is displayed asking the user to unlock the controller.

To unlock the controller in ORCAview:

1. In the Navigator tree, right-click on the enteliZONE controller and point to Object Security

and then click Unlock.

2. Enter the unlock username and password. The default username is DELTA and the

password is login.

ORS Troubleshooting

If the controller time does not match the OWS time, the controller cannot be unlocked. To update

the controller time in ORCAview, on the Tools Menu, click Set Controller Time.

Without the correct username and password there is no way to unlock the controller. If the correct

username and password is unavailable, reload a copy of the default database into the controller,

this restores access to the controller, using the default username and password, however any

previous configuration changes will be lost.

Page 10 of 84 eZV-440 Application Guide

Edition 2.6

Page 12

About the enteliZONE ORCAview Configuration Graphic

The enteliZONE controller configuration graphic in ORCAview provides a user-friendly interface to

configure the controller’s algorithm and its corresponding objects and IO points. Each time a

change is made to a field or option,ORCAview updates the corresponding object references. The

topic enteliZONE Database Configuration Objects lists the fields and options, and their object

references.

In enteliWEB, the configuration page is available as a tab on the Object List page.

Downloading the ORCAview Configuration Graphic

You can download the configuration graphic from the enteliZONE controller product web page on

the Delta Controls Support web site and install it on your operator workstation.

Installing the ORCAview Configuration Graphic

To install the configuration graphic in ORCAview:

1. On your operator workstation, go to the graphic folder C:\Users\Public\Delta

Controls\3.40\Sites\<site name>\Graphics. The site name refers to the site where the

enteliZONE controller you are configuring resides.

2. Copy and paste the configuration graphic zip file into the Graphics folder.

3. Unzip the file.

There are 7 configuration (.gpc) files associated with the enteliZONE controller. Each file

corresponds to a tab on the configuration graphic. The balancing file is not enabled on the eZFC424R4-24 or eZ-440R4-230 controller.

Opening the ORCAview Configuration Graphic

There are 2 ways to open the configuration graphic in ORCAview. Make sure the configuration

graphic is installed on your operator workstation before attempting any of these steps.

eZV-440 Application Guide

Edition 2.6

Page 11 of 84

Page 13

About the enteliZONE ORCAview Configuration Graphic

Method 1 (Recommended)

1. In the left window of the ORCAview navigator, right-click on the enteliZONE controller you

want to configure and click Open.

If this is your first time using the configuration graphic, the DEV object dialog opens.

2. On the Configuration tab, click and browse to the graphics folder and select the Main.gpc file

for the enteliZONE controller. Click OK.

3. In the left window of the ORCAview navigator, right-click on the enteliZONE controller again.

Click Open. Because you have set it up in step 2, the configuration graphic window should

open and will open this way each time you select Open from the right-click menu.

Right-clicking does not work if you have changed the name of the configuration

graphic file or if the Controller Graphic field in the Device object (in the controller

database) has been edited.

Method 2

1. In the left window of the ORCAview navigator, open the Graphics folder and double-click on

one of the configuration files. A new graphic window opens. You can access all the

configuration files from this window.

2. In the numerical field at the top of the window, enter the BACnet address of the enteliZONE

controller you want to configure and click Connect.

Working with the ORCAview Configuration Graphic

This graphic is interactive and dynamic in real-time. When you select an option in a field, other fields

and options are displayed in response to the initial option selected. What this also means is that any

changes made to the fields are saved and applied instantly.

Selecting Between Multiple Controllers

If you have multiple enteliZONE controllers of the same kind on the same network, instead of

opening the configuration graphic individually for each controller in the ORCAview navigator, you

can switch between controllers within the configuration graphic.

When you switch between controllers, any changes made in a previous session will be

saved automatically before you switch to the next controller.

Page 12 of 84 eZV-440 Application Guide

Edition 2.6

Page 14

To select between multiple controllers:

In the numerical field at the top of the window, enter the BACnet address of the enteliZONE

controller you want to configure and click Connect.

Save to Flash, Save to PC and Load from PC

These buttons are displayed at the top of the configuration graphic dialog. They minimize the need

to switch between the configuration graphic and the ORCAview Navigator when you are working

with multiple controllers.

The Save to Flash button is used to save the controller database to the controller’s flash memory.

The Save to PC button is used to save the controller database .pdb file to your computer.

The Load from PC button is used to load a controller database .pdb file from your computer onto

the enteliZONE controller.

Both Save to PC and Load from PC allow you to save your configuration graphic settings and copy

them onto multiple enteliZONE controllers using ORCAview.

Shortcuts

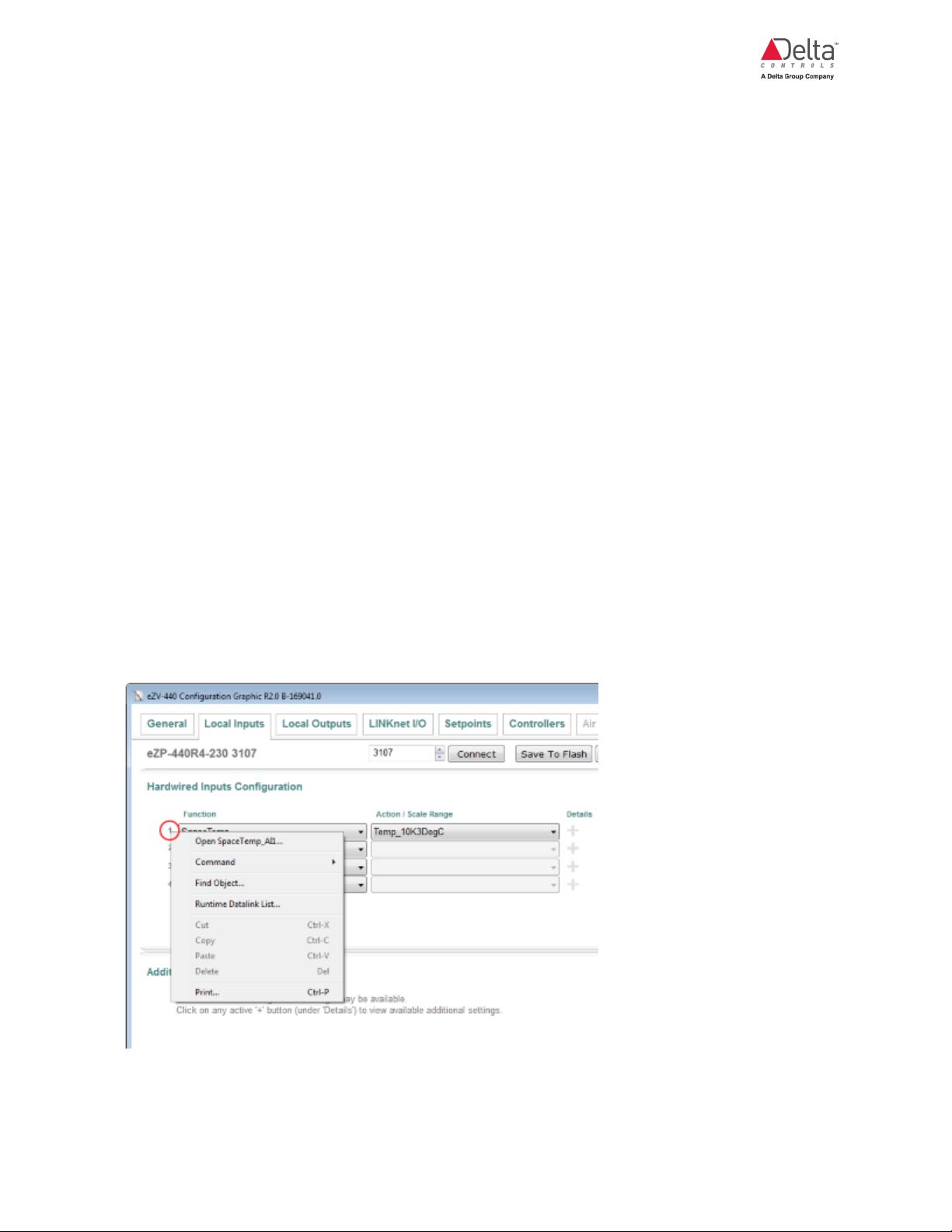

There is a quick way to open the ORCAview object dialogs by right-clicking on the configured input

and output numbers in the configuration graphic.

In the example below, when you right-click on the number 1 and select Open SpaceTemp_AI1,

the AI1 object dialog opens onscreen.

eZV-440 Application Guide

Edition 2.6

Page 13 of 84

Page 15

Configurable and Programmable enteliZONE Controllers

Configurable and Programmable enteliZONE Controllers

Differences Between Configurable and Programmable enteliZONE Controllers

This topic describes the main differences between these 2 types of controllers.

Using the ORCAview or enteliWEB configuration page, variables and setpoints are entered into

the algorithm and written to the appropriate preset objects (100 to 199 range, 1000+ range for

LINKnet device configuration) in the factory controller database.

In the configurable type of controllers, there are no program (PG) objects.

In the programmable controllers, even though it is recommended that you use the configuration

page to set up your programmable controller, local programming can be used to overwrite the

algorithm by writing to the objects in the 800 to 899 range.

There is a limit to the number of specific object types in these controllers. The number limits are

summarized in the table below. You cannot exceed this number by creating any new objects.

Object Type Configurable Programmable

LINKnet objects (LNK) 1 4

Event objects (EV)

Trend Logs (TL) 4 8

Programs (PG) 0 3

Gateway Translation objects (GWT)

(firmware 2.2 and higher)

For a complete list of enteliZONE supported object types and the number of instances allowed for

each object, go to the enteliZONE overview page on the Delta Controls Support web site.

LINKnet Devices

Configurable controllers can only connect to 1 LINKnet device at a time. This LINKnet device has to

have a device address of "1" in order for it to work with the controller algorithm. Multiple LINKnet

devices (up to 4) are only supported by the programmable controllers.

LCD and LINKnet objects are located on the enteliZONE controller and are numbered LCDx001

and LNKx001 respectively where x is the network sensor’s device address.

0 5

0 4

enteliZONE controllers only support eZNS and BACstat LINKnet network sensors. Other LINKnet

devices like Delta Field Modules (DFM) are not supported.

Page 14 of 84 eZV-440 Application Guide

Edition 2.6

Page 16

Data Exchange

This section describes how the enteliZONE controllers accept and initiate data exchanges in the

network.

The enteliZONE controller accepts these data exchange requests:

l Poll. The default data exchange type set up in the Data Exchange Settings object (DES) is

Poll. The poll interval can be adjusted in the DES object, at a recommended minimum of 1

second per MS/TP device on a segment.

l Change of Value (Confirmed and Unconfirmed). The enteliZONE controller is limited to

a maximum of 12 subscriptions (Delta Exchange Local or DEL objects).

The controller does not support the Optimized Broadcast and Broadcast Data Exchange request

types. If a controller attempts to subscribe using any of these exchange types, the exchange types

will fail and revert to polling.

The programmable controllers can initiate up to 12 data exchange polling requests (Delta

Exchange Remote or DER objects). Other types of Data Exchange initiating request types are not

supported.

The DES object for the controller lists the number of DER and DEL requests that are in use.

The controller supports Bulk Data Exchange (BDE) but is limited to 2 BDE objects. Each BDE

object can hold up to 12 tag and object entries on the object’s Transmit Entries tab.

For more information about Data Exchange types, go to the George Support knowledge base

article KBA 1813.

Alarming

The programmable controller supports up to 5 EV objects as well as intrinsic alarming on up to 5

input and output points (see below for more information about intrinsic alarming). These EV objects

support these alarm types:

Alarm

Description

Type

Change of

Used to monitor and alarm a binary value.

State

Command

Failure

Floating

Limit

Used when you have a binary value with feedback. An alarm is generated if

monitored values do not match the feedback value.

Used to alarm when an analog value varies more than a set limit from a variable

setpoint value.

eZV-440 Application Guide

Edition 2.6

Page 15 of 84

Page 17

Configurable and Programmable enteliZONE Controllers

Alarm

Description

Type

Out of

Used to alarm when an analog value varies outside of a set of fixed limits.

Range

The enteliZONE family of controllers does not support Change of Value or Change of Bitstring

alarm types.

Even though the configurable controller versions do not have EV objects, intrinsic alarming can be

enabled on input and output points, specifically analog input (AI), binary input (BI), analog output

(AO) and binary output (BO).

EV objects will send out auto generated messages to notify users about alarms. enteliZONE

controllers do not support alarm acknowledgments.

Custom alarm messages are supported by the following firmware versions:

l eZV-440 controller firmware version 2.1 and higher for EV objects only.

l eZFC-424R4-24 controller firmware version 2.2 and higher for EV objects only.

l eZ-440R4-230 controller firmware version 2.1 and higher for EV objects only.

For more information about how to set up an intrinsic alarm, see the webinar Intrinsic

Alarms in ORCA 3.40 on the Delta Controls support web site.

Trend Logs

A programmable enteliZONE controller supports up to 8 trend logs, 4 of which are user-defined.

The configurable controller version supports 4 trend log objects (TL1 to 4) which are pre configured

in the default database to monitor specific heating and cooling objects. However, all TLs can be

modified to monitor objects other than the default set object. You can also change the method of

data collection (Change of Value or polling) as well as the polling interval. However, fields that

display the maximum and total sample size are read-only.

It is not recommended to use Change of Value for objects that are expected to change at a rate

faster than every 5 seconds. TL objects have a 5-second record limit. Events that occur faster than

this record limit will result in “Log Enabled” or “Log Interrupted” entries that can be hard to interpret.

The default database TL objects are listed in the following table.

Trend Log Monitored Object

1 SpaceTemp (AV1)

2 CurrentHeatSetpoint (AV800)

Page 16 of 84 eZV-440 Application Guide

Edition 2.6

Page 18

Trend Log Monitored Object

3 CurrentCoolSetpoint (AV801)

4 HeatCoolLoad (AV802)

5 User-defined

6 User-defined

7 User-defined

8 User-defined

The enteliZONE trend logs also support Historian archiving. The enteliZONE controllers don’t

support buffer full notification events so make sure the Historian update interval is frequent enough

to avoid missing samples.

Programming

In the programmable controller, the 3 programs that exist alongside the configurable algorithm

allow you to either create your own custom algorithm or override portions of the configurable

algorithm to suit your needs. The maximum size of each program is 5 KB.

The programmable controller also allows you to create new I/O, AV, BV and MV objects in the 900999 range for use in your custom program.

Supported GCL+ Programming Functions, Statements and Operators

The Call Statement is not used in the programmable enteliZONE controllers. Unlike other

programmable Delta Controls controllers, the 3 programs in the programmable enteliZONE

controllers are automatically scanned. The scan rate is also designed to be a constant 10

scans/second.

A list of supported and unsupported GCL+ functions and statements for the enteliZONE

programmable controllers is recorded in KBA 2137 on the George Support web site. The

ORCAview and enteliWEB GCL editors are not aware of these limitations, so using an

unsupported function in an enteliZONE programmable controller will not register a syntax error in

these GCL editors.

Overwriting the Algorithm

You can overwrite the algorithm by programming specific objects numbered in the 800 range. For

example, if you want to change how the algorithm determines the occupancy state, you could write

your own GCL+ program to set the occupancy MV800 state.

Your program must write more frequently than every 5 seconds else the factory algorithm will

recapture control.

eZV-440 Application Guide

Edition 2.6

Page 17 of 84

Page 19

Configurable and Programmable enteliZONE Controllers

Click on a link below to find out more information about these programmable objects.

l VAV/VVT algorithm programmable objects

enOcean Integration (firmware 2.2 and higher)

Gateway Translation (GWT) and Gateway (GW) objects are available on the programmable

enteliZONE controllers so that you can integrate an enteliZONE programmable controller into an

enOcean wireless system using a CON-ENOC enOcean Gateway device.

For more information about how to configure the GWT objects, see the CON-ENOC Application

Guide on the CON-ENOC George Support product page.

Upgrade to Fully Programmable Using Flash Loader (firmware 2.2 and higher)

Delta Controls Flash Loader (Version 3.40 R4) can be used to upgrade controllers from

configurable to fully programmable versions. Flash Loader is part of the ORCAview suite of

software.

Flash Loader connects to and upgrades 1 controller at a time over the BACnet Ethernet network.

This upgrade requires 3 Flash credits on a Flash Loader key. Go to the Flash Loader page

on the George Support web site for more information.

1. Insert a Flash Loader key with sufficient credits into a USB port on your workstation.

2. Download the .FLS upgrade file from the George Support web site onto your workstation.

Save the file in the Flash Loader folder that was created when you installed Flash Loader,

like C:\Program Files(x86)\ Delta Controls\3.40\Flash Loader.

3. Back up the controller database by saving it. Flash Loader does not save the database

before the upgrade.

4. Open Flash Loader version 3.40 R4 on your workstation.

5. In the Filename dropdown list, select the upgrade file on your workstation.

For example, for firmware 2.1, the file name will be eZONE R2.1 B-xxxxxx.fls, where xxxxxx

is the build number.

6. Click the Enables Features box to check it. The eZONE section is displayed.

7. Click the Settings button.

1. In the Protocol dropdown list, select BACnet Network.

2. In the Adapter dropdown list, select the Ethernet adapter that connects the

workstation to the controller network.

Page 18 of 84 eZV-440 Application Guide

Edition 2.6

Page 20

3. Leave the Password field blank unless a password is defined in the Flash Loader

Password field on the Configuration tab of the controller’s DEV object.

4. Click OK to save changes made in the Settings window.

8. In the device Address field, enter the BACnet device address of the controller you want to

flash. This is the address displayed next to the controller in ORCAview Navigator.

9. In the eZONE section, click the Upgrade to Programmable box to check it.

10. Click Add Features.

Flash Loader transmits the new firmware to the controller. The Status and Progress fields in

the Flash Loader window display the status of the transmission.

11. When the upgrade is complete, the Status field displays an Update Complete message.

12. Close the Flash Loader program.

VAV/VVT Programmable Objects

VAV/VVT Programmable Objects

The following table displays all the programmable objects in the VAV/VVT enteliZONE algorithm.

For more information about programmable objects, go to the topic about programmable

controllers.

Algorithm Unit

Unit Module's Function Programmable Object

Module

Airflow Setpoint

Maintains the airflow setpoint in the duct. AV830 AirflowSetpoint

Manager

Box Mode

Controls “box mode” by monitoring the room

temperature and the inlet air temperature.

MV801

VAVDuct1BoxMode

For more information about box mode, see

the Heating and Cooling (VAV) sequence of

operation.

Controller Man-

ager

Cooling Stage

Manager

Determines the heating and cooling load on

the system.

Controls the VAV/VVT cooling sequence.

AV802 HeatCoolLoad

AV808 AirflowDemand

AV810 Fan1

Damper Manager Controls the damper position. AV832 DamperCmd

eZV-440 Application Guide

Edition 2.6

Page 19 of 84

Page 21

Configurable and Programmable enteliZONE Controllers

Algorithm Unit

Module

Duct Status Man-

ager

Flow Loop Man-

ager

Heat Stage Man-

ager

Occupancy Man-

ager

Temperature Set-

point Manager

Unit Module's Function Programmable Object

Determines if there is enough duct air for

BV800 AirflowStatus

heating and cooling.

Controls airflow through the damper. AV831 Damper-

Demand

Controls heating sequences of operations.

AV808 AirflowDemand

AV803 Heat1

AV804 Heat2

AV805 Heat3

AV810 Fan1

Determines the occupancy mode in the

space at any time.

Controls the active heating and cooling set-

points in the space.

MV800 Occu-

pancyMode

AV800

CurrentHeatingSetpoint

Demand Control

Ventilation Man-

ager

Controls the CO2 levels in the space.

See the Demand Control Ventilation

sequence of operation for more information.

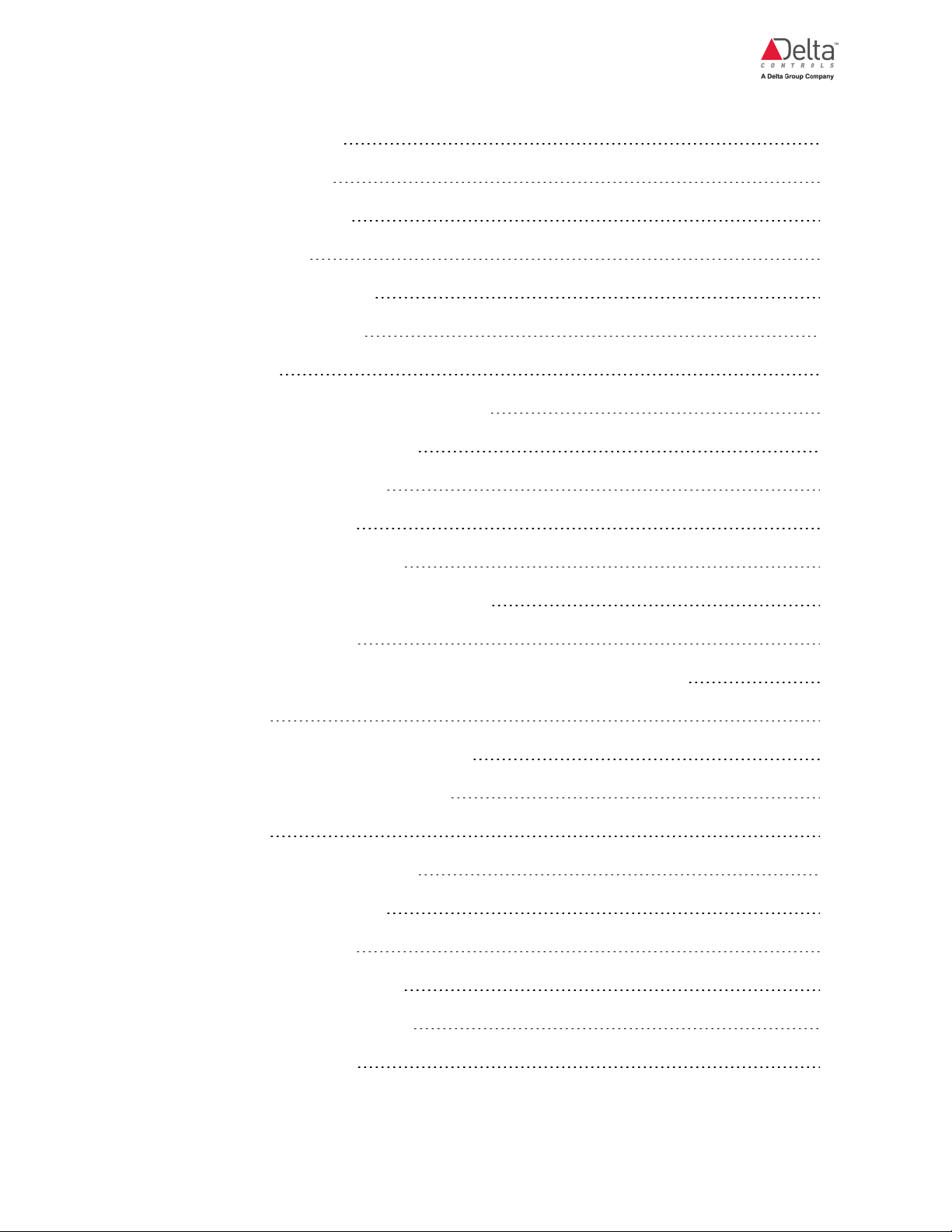

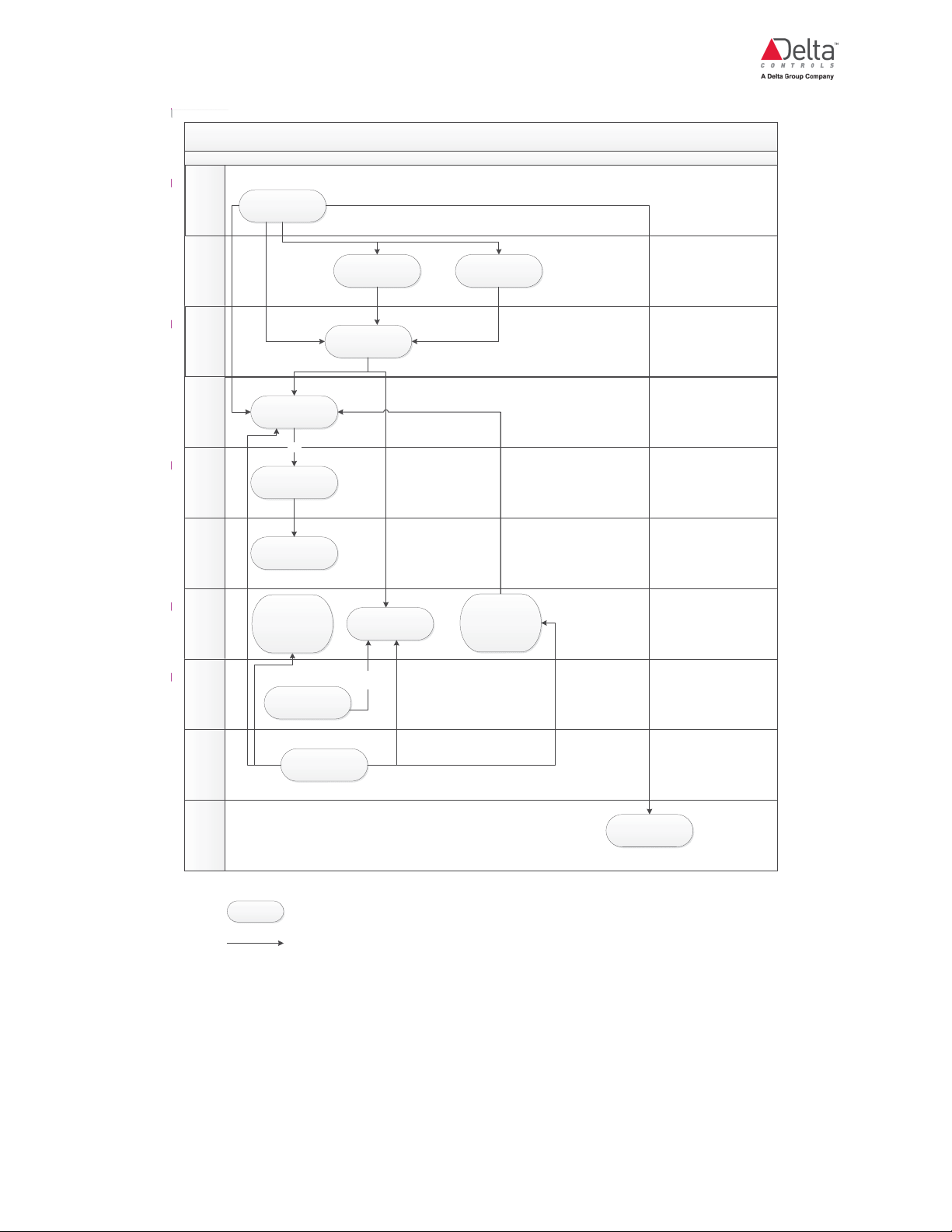

Relationship Between Algorithm Unit Modules

The PDF displays the relationships between unit modules.

AV801

CurrentCoolingSetpoint

AV813

DemandCtrlVent

Page 20 of 84 eZV-440 Application Guide

Edition 2.6

Page 22

enteliZONE VAV Algorithm Flowchart

Temp Setpoint

Manager

Occupancy

Manager

Heat/Cool

Manager

Air Flow

Setpoint

Manager

Flow Loop

Manager

VAV/VVT

Damper

Manager

Heating Staging

Manager

Duct Status

Manager

Box Mode

Manager

Demand Control

Ventilation

MV800 Occupancy

Mode

AV800 CurrentHeating

Setpoint

AV801 CurrentCooling

Setpoint

AV802 HeatCool Load

AV830 Air Flow

Setpoint

AV831 Damper

Demand

VVT

AV832 DamperCmd

AV808 Air Flow

Demand

AV803 Heat1

AV804 Heat2

AV805 Heat3

BV800 Air Flow Status

Hydronic and

Electric Duct

MV801

VAVDuct1BoxMode

Point(s) in each algorithm manager box can be used to override the

algorithm manager

Relationship between points

AV810 Fan1

AV813 DemandCtrlVent

eZV-440 Application Guide

Edition 2.6

Page 21 of 84

Page 23

General Tab

General Tab

What is the General Tab?

The General tab on the enteliZONE controller configuration page is divided into 3 main sections.

The Device Information section contains basic controller information such as model number and

firmware version, and a device description field.

The Network Settings section contains the controller BACnet address, the network number as well

as the network speeds (baud rates).

In the Global Settings section, the options set here are applied to all tabs on the configuration page.

Device Information

The following fields are found in the Device Information section.

Field

Name

Name Displays the name of the controller as it appears in the Device Object.

Model

Name

Application

Version

Firmware

Version

Controller

Graphic

(ORCAview

only)

Device

Description

Description

Displays the controller's Delta Controls model number.

Displays the controller's algorithm version.

In the ORCAview configuration graphic, this field is called the Firmware

Version.

Displays the controller's firmware build number.

In the ORCAview configuration graphic, this field is called the Firmware Build.

Displays the configuration graphic file that opens every time you right-click on

the controller in the ORCAview navigator. You can also enter the name of a

dashboard graphic file and set it as the default graphic.

If you leave this field blank, the Device Object dialog opens instead.

You can enter and modify the controller's text description, up to 64 characters.

Page 22 of 84 eZV-440 Application Guide

Edition 2.6

Page 24

Network Settings

The following fields are found in the Network Settings section.

Field

Name

BACnet

Address

NFC

Password

DNA

Description

Displays the controller's BACnet address. This field is read-only when the DNA

box is checked. If you want to enter a new address, clear the DNA box.

Click here for more information about the BACnet address object.

Displays the password that secures access to the controller’s NFC chip. The

value range is 0 to 65535. The password is stored on the AV96 object.

The Device Password field on the Delta Controls mobile applications must match

the NFC password before any data can be written to the NFC chip.

Turns on or off Derived Network Addressing (DNA) automatic addressing. DNA

is turned on when the box is checked; the BACnet address also becomes readonly. To manually enter a new address, clear the DNA box.

Delta Controls products have the option to use DNA or Derived Network

Addressing, a system of organizing and configuring controllers in a network.

When DNA is enabled, addresses are automatically assigned to a device based

on the BACnet network type and the Delta Controls product type, so that a

device can work out-of-the-box without much set up.

NET1

Protocol

NET1

Speed

NET1

Number

NET1

MAC

Address

NET2

Protocol

NET2

Speed

Displays the network protocol currently enabled for the NET1 port. This is a read-

only field.

Displays the baud rate for the NET1 port. Any changes to the baud rate will be

applied immediately to all Delta Controls controllers in the network.

Displays the controller's BACnet network number.

Displays the controller’s network address typically set up by the controller’s DIP

switches.

Displays the network protocol currently enabled for the NET2 port. This is a read-

only field.

Displays the baud rate for the NET2 port. Any changes to the baud rate will be

applied immediately to all Delta Controls controllers in the network.

eZV-440 Application Guide

Edition 2.6

Page 23 of 84

Page 25

General Tab

Global Settings

The following fields are found in the Global Settings section.

Field Name Description

Application

Type

Temperature

Select the main HVAC system application for this controller. This determines

the algorithm that will be used for the controller.

The options for the eZV-440 are VAV-single duct, VVT and None.

The configurable controller has no functional state until you select an

algorithm.

In a fully programmable controller, when you select an algorithm, you can

override portions of the internal algorithm to suit your needs. See the section

in this guide about overwriting the algorithm. Select None if you want to

program a fully custom sequence of operations. When you select None, the

internal algorithms are disabled and all preconfigured algorithm I/O points and

variables are removed from the default database. Other object types, like AIC,

that were part of the algorithm can be used as is or reconfigured.

If you change an application type for another, the settings of the

previous application type will be deleted. You can save your

controller database before switching application types.

Displays the temperature units used by the controller.

Units

Airflow Units

Child

Controller

(enteliWEB

only)

Displays the airflow units used by the eZV-440 controller. Select between

CFM, l/s or m3/h.

In the configuration graphic, when VVT is selected as the application type, the

units are set to percentages which represent the damper min/max positions.

When VAV is selected as the application type, the AV124 to AV127 objects

and the air flow setpoint will use the units set up in the Airflow Units field.

If this controller reports to a parent controller, select this box. The child

controller polls these variables from its parent controller:

l HeatCoolLoad (AV802)

l OccupancyMode (MV800)

l DemandCtrlVent (AV813)

Page 24 of 84 eZV-440 Application Guide

Edition 2.6

Page 26

Field Name Description

Parent

Address

(enteliWEB

only)

Parent Child

Address

(ORCAview

only)

This field is enabled when the Child Controller box is checked. Enter the

parent's BACnet address in this field. If you are setting up a parent controller,

leave this field at its default zero value.

If the parent’s BACnet address changes in the future, you must manually

update this value to match the new address.

If this controller reports to a parent controller, enter the parent’s BACnet

address in this field. In all other cases, including setting up a parent controller,

leave this field at its default zero value.

If the parent’s BACnet address changes in the future, you must manually

update this value to match the new address.

The child controller polls these variables from its parent controller:

l HeatCoolLoad (AV802)

l OccupancyMode (MV800)

l DemandCtrlVent (AV813)

eZV-440 Application Guide

Edition 2.6

Page 25 of 84

Page 27

Local Inputs Tab

Local Inputs Tab

Setting Up a Hardwired Temperature Sensor

This topic describes how to set up a temperature sensor using the Local Inputs tab on the

configuration page.

Occupancy overrides can share the same input as the temperature sensor.

If you are setting up a LINKnet DNS-24L or eZNS network sensor to provide occupancy

input, use the LINKnet I/O tab on the configuration page.

Set Up a Hardwired Temperature Sensor

1. Wire your sensor to the controller's physical input.

2. Next to the input number that you've assigned to the sensor, in the Function field, select one

of the following options:

Function Select this option if you are using a:

DischargeAirTemp_ Duct temperature sensor that is located downstream from any

local heating or cooling stages that supply the air to that space.

InletAirTemp_ (VAV application type only) Duct temperature sensor that is

located upstream from local heating or cooling stages that

supply the air to that space.

SpaceTemp_ Space temperature sensor, or a network value from a DNS or

eZNS network sensor on LINKnet.

You can set up multiple SpaceTemp inputs and by default the

algorithm will calculate the average of all inputs and assign that

value to the AV1 object.

SpcTemp+

OccOvrdButton_

Space temperature sensor and the occupancy override push

button are wired into the same input.

This can be a normally open contact wired in parallel or a

normally closed contact wired in series with the temperature

sensor.

Page 26 of 84 eZV-440 Application Guide

Edition 2.6

Page 28

Function Select this option if you are using a:

SpcTemp+

OccToggleButton_

Space temperature sensor and the occupancy toggle push

button are wired into the same input.

This can be a normally open contact wired in parallel or a

normally closed contact wired in series with the temperature

sensor.

When setting up a temperature sensor, majority of the cases would require you to select

Temp_10K3DegC or Temp_10K3DegF as an option under Action/Scale, depending on

the temperature units set up on the General tab.

3. If you had selected the DischargeAirTemp_ option, in the additional settings, in the

DATHiLimitSetpointDiff and DATLowLimitSetpointDiff fields, enter the discharge air

temperature high limit and low limit setpoints differentials respectively.

4. (VAV application type only) If you had selected the InletAirTemp_ option, in the additional

settings, in the BoxChangeoverTempDiff field, enter the box changeover temperature

difference.

5. (enteliWEB only) The Input Name field displays the object's name. You can change this

name by clearing the field and entering a new name.

Multiple Space Temperature Inputs

You can set up multiple SpaceTemp inputs and by default the algorithm will calculate the

average of all inputs and assign that value to the AV1 object.

Setting Up a Hardwired Occupancy Input

This topic describes how to set up an occupancy input using the Local Inputs tab on the

configuration page.

Occupancy inputs can either be maintained-contact or momentary contact types. Occupancy

overrides can share the same input as the temperature sensor.

See the sequence of operations topic to learn more about occupancy modes in the algorithm.

If you are setting up a LINKnet DNS-24L or eZNS network sensor to provide occupancy

input, use the LINKnet I/O tab on the configuration page.

eZV-440 Application Guide

Edition 2.6

Page 27 of 84

Page 29

Local Inputs Tab

Set Up a Hardwired Occupancy Input

1. Next to the input number that you've assigned to the input, in the Function field, select one or

more of the following options:

Function Select this option if you are using a:

OccMotion_ Hardwired latching, momentary contact sensor type, or a

network sensor with an integrated motion sensor and want

to enable it for occupancy control.

OccMaintainedContact_ Any maintained contact device like a hotel keycard holder,

manual switch or mechanical time clock input.

OccOvrdButton_ Network sensor button as an occupancy override button.

When pushed during unoccupied mode it starts an

occupancy override timer. When an override has been

activated, pushing the button will extend the override time by

resetting the timer back to its max value.

During scheduled occupancy periods, you cannot switch

occupied to standby mode using the button. However if

occupancy is in standby mode, pressing the button will

switch the room back to occupied mode until the next

occupancy event change.

OccToggleButton_ Network sensor button to toggle between standby and

occupied modes during scheduled occupancy periods.

When pushed during unoccupied mode it starts an

occupancy override timer. When an override has been

activated, pushing the button again will cancel the override

and reset the override timer back to zero.

SpcTemp+

OccOvrdButton_

Space temperature sensor and the occupancy override

push button are wired into the same input.

This can be a normally open contact wired in parallel or a

normally closed contact wired in series with the temperature

sensor.

SpcTemp+

OccToggleButton_

Space temperature sensor and the occupancy toggle push

button are wired into the same input.

This can be a normally open contact wired in parallel or a

normally closed contact wired in series with the temperature

sensor.

In most cases Direct (contact closed = occupied) is the default action.

Page 28 of 84 eZV-440 Application Guide

Edition 2.6

Page 30

2. If you had selected the OccMotion_ option, in the additional settings, in the MotionOvrdTime

field, enter how long the occupancy override should last. This setting allows the use of

momentary contact style occupancy signals.

If you are using maintained-contact occupancy devices, enter zero in this field. In this case,

occupancy state is only based on contact position.

3. If you had selected any occupancy button options, in the additional settings, in the

PushButtonOvrdTime field, enter how long the button override should last.

4. (enteliWEB only) The Input Name field displays the object's name. You can change this

name by clearing the field and entering a new name.

With the OccToggleButton option, With the OccToggleButton option, it is recommended

to display the occupancy status on your network sensor. The occupancy status allows the

user to determine if a button press will start an override or cancel an active override.

Multiple Temp+Occ Inputs

You can set up multiple SpcTemp+OccOvrdButton and SpcTemp+OccToggleButton inputs

and by default the algorithm will calculate the average of all these temperature inputs. With multiple

occupancy inputs, the value will reflect the last value written.

Setting Up a Hardwired CO2 Sensor

This topic describes how to set up a carbon dioxide sensor using the Local Inputs tab on the

configuration page.

If you are setting up a LINKnet DNS-24L or eZNS network sensor to provide occupancy

input, use the LINKnet I/O tab on the configuration page.

Set Up a Hardwired CO2 Sensor

1. Wire your sensor to the controller's physical input.

2. Next to the input number that you've assigned to the input, in the Function field, select

SpaceCO2_. The default option in the Action/Scale column is CO2 0-2000ppm.

3. If you are using demand controlled ventilation with the CO2 sensors, in the additional

settings,

l In the DemandVentEnable field, select Enabled or On (enteliWEB only).

l In the CO2DemandVentSetpoint field, enter the CO2 setpoint value. Levels higher

than this setpoint will maintain the demand for ventilation.

eZV-440 Application Guide

Edition 2.6

Page 29 of 84

Page 31

Local Inputs Tab

4. In the additional settings, if you are using CO2 sensors to determine occupancy,

l (enteliWEB only) In the CO2 Occupancy On Setpoint field, enter the CO2 setpoint

value that will trigger an occupancy event. To disable CO2-based occupancy

detection, set this value to 2000 ppm.

l (enteliWEB only) In the CO2 Occupancy Off Setpoint field, enter the CO2 setpoint

value that will cancel an occupancy event.

5. (enteliWEB only) The Input Name field displays the object's name. You can change this

name by clearing the field and entering a new name.

For more information about demand control ventilation, see the Sequence of Operations topic.

For more information about using CO2 levels to trigger occupancy events, see the Sequence of

Operations topic.

Setting Up Other Supporting Inputs

This topic describes how to set up supporting inputs like fault and window monitoring using the

Local Inputs tab on the configuration page

Set Up an Input

1. Next to the input number that you've assigned to the device, in the Function field, select the

option that applies to your setup:

Function Select this option if you are using a:

AnalogMUX_ Creating an analog input that will be used for monitoring and

will not be used by the algorithm in the controller.

BinaryMUX_ Creating an binary input that will be used for monitoring and

will not be used by the algorithm in the controller.

WindowContact_ Setting up a window contact switch to detect open windows.

When an open window is detected, local heating or cooling

can be disabled as needed to save energy.

FilterStatus_ Adding a filter switch to detect if the fan coil filter is clean or

dirty.

FanStatus_ Adding a current or airflow switch that detects when the zone

supply fan is running.

Fault_ Creating an input to monitor the fault status of an equipment.

SpaceTempSetpoint_ Resistive slider or dial to control the space setpoint. The

resistance range must be within 0 to 20 kohms.

2. Select the associated action/scale option for the input.

Page 30 of 84 eZV-440 Application Guide

Edition 2.6

Page 32

3. If you had selected the SpaceTempSetpoint_ option to set up a resistive slider, in additional

settings, in the SetpointSliderMinResistance field, enter the minimum resistance of the

setpoint slider. In the SetpointSliderMaxResistance field, enter the maximum resistance

of the setpoint slider.

To enter the occupancy setpoint offset range for this resistive slider, go to the Setpoints tab

and enter the ± offset in the OccSetpointOffsetRange field.

4. (enteliWEB only) The Input Name field displays the object's name. You can change this

name by clearing the field and entering a new name.

For a list of input configuration software objects that correspond to each function, see the Input

Configuration Objects topic.

Setting Up an Airflow Sensor

Introduction

This topic describes how to set up an airflow pressure sensor on the eZV-440 controller on the

Local Inputs tab.

On the eZV-440 controller, physical input 6 is reserved for the onboard differential pressure sensor.

Set Up an Airflow Sensor

On the Local Inputs tab, next to input number 6, select VAVAirflow_ in the Function field.

(enteliWEB only) The Input Name field displays the object's name. You can change this name by

clearing the field and entering a new name.

Setting Up Damper Feedback

This topic describes how to set up damper position feedback using the Local Inputs tab on the

configuration page. The actuator must have a position feedback feature.

On the eZV-440 controller, the damper feedback signals should be configured on the controller

input 5.

Set Up Damper Feedback

1. Wire the actuator to the controller's physical input.

2. Next to the input number that you've assigned to the actuator, in the Function field, select

Damper1Feedback_. With the eZV-440 controller, you would use input number 5.

eZV-440 Application Guide

Edition 2.6

Page 31 of 84

Page 33

Local Inputs Tab

If a tristate output is assigned to a damper, the algorithm will use this feedback signal rather

than a calculated damper position based on runtime.

3. In the Action/Scale Range field, select the input scale range that matches your damper

feedback signal. If you do not select a scale range, the default scale range is assumed to be

zero to full scale 0 to 100%.

4. (enteliWEB only) The Input Name field displays the object's name. You can change this

name by clearing the field and entering a new name.

Page 32 of 84 eZV-440 Application Guide

Edition 2.6

Page 34

Local Outputs Tab

Setting Up a VAV/VVT Output

Introduction

This topic describes how to set up a VAV or VVT output on the Local Outputs tab of the enteliZONE

configuration page.

The eZV-440 controllers support the VAV and VVT algorithms, up to 3 heat stages (Heat1, Heat2

and Heat3).

For more information about the enteliZONE algorithm's sequence of operations, go to the

Sequence of operations topic.

Set Up a VAV or VVT Output

1. In the Function field, select the option that applies to your setup:

Function Select this option if you are:

ElectricDuct Setting up an electric duct unit.

ElectricBaseboard_ Setting up an electric baseboard heater.

HydronicDuct_ Setting up a ductal coil unit.

HydronicBaseboard_ Setting up a hydronic baseboard heater.

For a list of output configuration software objects that correspond to each function, see the

Output Configuration Objects topic.

2. In the Stage field, select the corresponding heat stage for the output device. If you are using

ORCAview,select the heat stage in the Output Stage field.

Start a new line for every additional heat stage.

3. In the Control Type field, select the method of control used on the output device signal.

The control types available in the drop-down list will change depending on the option that

was selected in the Function field and the physical output used to connect to the output

device. For more information about control types, see the Control Types topic.

4. In the Action field, choose between direct or reverse control.

5. (enteliWEB only) The Output Name field displays the object's name. You can change this

name by clearing the field and entering a new name.

6. Complete this task by setting up a fan output. You may also need to set up actuator damper

control.

eZV-440 Application Guide

Edition 2.6

Page 33 of 84

Page 35

Local Outputs Tab

Setting Up a Fan Output

This topic describes how to set up fan outputs on the Local Outputs tab of the enteliZONE

configuration page.

The enteliZONE controllers support up to 3 fan stages (Fan1, Fan2 and Fan3). Typically a 3-speed

fan stages uses Fan1, Fan2 and Fan3, and an ECM (Electronically Commutated Motor) fan uses

Fan1.

For more information about the enteliZONE algorithm's sequence of operations, go to the

Sequence of Operations topic.

Set Up a Fan Output

1. In the Function field, select the option that applies to your setup:

Function Select this option if you are:

SeriesFan_ Setting up a series fan in a single duct VAV.

ParallelFan_ Setting up a parallel fan in a single duct VAV.

ExhaustFan_ Setting up a exhaust fan based on occupancy.

For a list of output configuration software objects that correspond to each function, see the

Output Configuration Objects topic.

2. In the Stage field, select the corresponding fan stage for the output device. If you are using

ORCAview,select the heat stage in the Output Stage field.

Start a new line for every additional fan stage.

The ExhaustFan function defaults to OccInterlock or occupancy interlock.

3. In the Control Type field, select the method of control used on the output device signal.

The control types available in the drop-down list will change depending on the option that

was selected in the Function field and the physical output used to connect to the output

device. For more information about control types, see the Control Types topic.

ECM fans may require both an analog speed and a binary stop/start signal. For example, for

a modulating series VAV fan sequence that has both an analog speed and binary stop/start

signal, this is how you should set it up:

Function Output Stage Control Type

Start/Stop Output Series Fan_ Fan1_ Binary

Speed Output Series Fan_ Fan1_ Analog

4. In the Action field, choose between direct or reverse control.

Page 34 of 84 eZV-440 Application Guide

Edition 2.6

Page 36

5. (enteliWEB only) The Output Name field displays the object's name. You can change this

name by clearing the field and entering a new name.

6. In the additional settings available for some fan types:

l Constant Fan Modes. Allows you to select the occupancy mode in which the fan

runs constantly. If you are setting up a parallel fan, select Always Intermittent. In

occupancy modes where the fan is not running constantly, the algorithm assumes the

fan is running intermittently.

Always

Constant

Occupied/

Unoccupied

The fan always runs regardless of the heating or cooling

demand in the space.

The fan runs constantly during the occupied and unoccupied

override occupancy modes. Outside of these modes, the fan

runs intermittently.

Occupied/

Unoccupied

Override/

The fan runs constantly during the occupied, unoccupied

override occupancy and standby modes. Outside of these

modes, the fan runs intermittently.

Standby

Always

Intermittent

l Manual Fan Occupancy Interlock. This field is not applicable for VAV and VVT

The fan does not run constantly at all and only turns on when

heat is required.

systems.

l HeatxFanMin. These fields display the fan speeds that will run at a specific heat ("x" is

the stage number). For ductal heat outputs, with multi-speed fans, "1" is the default

value. With ECM fans, FanMinSpeed (see the section below) is the default value. "0"

is the default value for non-ductal outputs.

When you modify these values, the fan speed associated with that output is changed.

For example, if you enter “3” in Heat2FanMin, the fan will respond to the heating

demand at Heat 2 stage by increasing to fan speed 3.

l FanMinSpeed. The minimum supported supply fan speed. This field is enabled when

you select analog control type for supply fan with a default value of 20%. When you

select a binary control type for a single or multi-speed fan, this field displays the

minimum supported fan speed with a default value of 1 for ductal fans.

l FanMaxSpeed. The maximum supported supply fan speed. This field is enabled

when you select analog control type for supply fan with a default value of 100%. When

you select a binary control type for a single or multi-speed fan, this field displays the

maximum supported fan speed.

eZV-440 Application Guide

Edition 2.6

Page 35 of 84

Page 37

Local Outputs Tab

Setting Up Other Outputs

This topic describes how to set up supporting outputs like occupancy indicator on the Local Outputs

tab of the enteliZONE configuration page.

Set Up an Output

1. In the Function field, select the option that applies to your setup:

Function

Select this option if you

are:

OccIndicator_

Setting up an occupancy

output signal.

Any one of the following: ElectricBaseboard_,

HydronicBaseboard_

Controlling radiant heating

equipment.

GCL-controlled AO_* Creating a custom AO object.

GCL-controlled BO_* Creating a custom BO object.

* Available only with programmable enteliZONE models and only on output terminals that

support AO or BO objects.

For a list of output configuration software objects that correspond to each function, see the

Output Configuration Objects topic.

2. In the Stage field, for the radiant heating equipment, select the radiant heating equipment's

heat stage in the control sequence. If you are using ORCAview,select the heat stage in the

Output Stage field.

Function Stage or Output Stage

OccIndicator_ OccIndicator_ is the default

option.

Any one of the following: ElectricBaseboard_,

HydronicBaseboard_

Select one: Heat1_, Heat2_ or

Heat3_.

GCL-controlled AO_ None_ is the default option.

GCL-controlled BO_ None_ is the default option.

3. In the Control Type field, select the method of control used on the output device signal.

The control types available in the drop-down list will change depending on the option that

was selected in the Function field and the physical output used to connect to the output

device. For more information about control types, see the Control Types topic.

4. In the Action field, choose between direct or reverse control.

Page 36 of 84 eZV-440 Application Guide

Edition 2.6

Page 38

5. (enteliWEB only) The Output Name field displays the object's name. You can change this

name by clearing the field and entering a new name.

Setting Up a Damper Output

This topic describes how to set up damper outputs on the Local Outputs tab of the enteliZONE

configuration page.

Outputs 5 and 6 on the eZV-440 controllers are reserved for the actuator connector (1 Universal

Output, 1 TRIAC Output).

For more information about the enteliZONE algorithm's sequence of operations, go to the

Sequence of Operations topic.

Set Up a Damper Output

1. In the Function field, select the option that applies to your setup:

Function Select this option if you are:

VAV/VVT Damper_ Setting up a damper in a single duct VAV.

For a list of output configuration software objects that correspond to each function, see the

Output Configuration Objects topic.

2. In the Stage field, AirFlowDemand_ is selected automatically for VAV/VVT applications.

3. In the Control Type field, select the method of control used on the damper signal.

For more information about control types, see Control Types.

4. In the Action field, choose between direct or reverse control.

If you are using an analog actuator, in the Action field, choose between direct or reverse

control. For tri-state actuators, use the Control Type field to set the damper’s open and close

direction.

5. If you are setting up a VAV/VVT damper, in the additional settings, in the OP5-6Runtime

field, enter the amount of time it takes to move the damper from fully open to fully closed

positions.

6. If you are setting up a tri-state actuator with damper feedback, set up damper feedback on

the Local Inputs tab in the configuration page.

7. (enteliWEB only) The Output Name field displays the object's name. You can change this

name by clearing the field and entering a new name.

eZV-440 Application Guide

Edition 2.6

Page 37 of 84

Page 39

LINKnet I/O Tab

LINKnet I/O Tab

Configuring an eZNS-T100 Network Sensor

The enteliZONE controller is designed to work with the eZNS network sensor on a LINKnet

network.

This topic describes how to set up the eZNS network sensor's built-in components using the

LINKnet I/O tab on the enteliZONE configuration page.

Configurable controllers can only connect to 1 LINKnet device at a time. This LINKnet

device has to have a device address of "1" in order for it to work with the controller

algorithm. Multiple LINKnet devices (up to 4) are only supported by the programmable

controllers.

On the configuration page, the controller detects the network sensor that is connected to it and

displays only the fields that are relevant for that network sensor.

(enteliWEB only) If you do not have any network sensors online, you can still configure the settings

by selecting your network sensor and model from the Device Information field.

Red Box on LINKnet Tab

(enteliWEB only) When you switch between different network sensor models, active

settings that are not shared between network sensor models become outlined in red. You

need to select the None option to disable these fields.

Set Up the Temperature Sensor

1. In the Sensor Options section, next to Space Temperature sensor type, select the Function

option that is most appropriate for your needs:

Function Select this option if:

None The built-in temperature sensor on the eZNS sensor is not used.

SpaceTempControl

The built-in temperature sensor is used to control the space

temperature. An input object (AI1001) is created the sensor

value which will be used by the algorithm to control space

temperature.

MonitoringOnly

Page 38 of 84 eZV-440 Application Guide

Input object AI1001 created but its value will not be used by the

internal algorithm for space temperature control.

Edition 2.6

Page 40

Set Up the Humidity Sensor

1. In the Sensor Options section, next to Space Humidity sensor type, select the Function

option that is most appropriate for your needs:

Function Select this option if:

None The humidity sensor on the eZNS sensor is not used.

MonitoringOnly

The input object AI1003 is created for monitoring only.

Set Up the CO2 Sensor

1. In the Sensor Options section, next to Space CO2 sensor type, select the Function option

that is most appropriate for your needs:

Function Select this option if:

None The CO2 sensor on the eZNS sensor is not used.

DemandControlVentilation Demand controlled ventilation system is used with the

CO2 sensors.

MonitoringOnly

The input object AI1004 created but its value will not be

used by the internal algorithm for space CO2 control.

2. If you selected DemandControlVentilation, in the additional settings, in the

CO2DemandVentSetpoint field, enter the CO2 demand ventilation setpoint value.

3. If you are using CO2 levels to determine occupancy, in the additional settings,

(enteliWEB only) In the CO2 Occupancy On Setpoint field, enter the CO2 setpoint value that

will trigger an occupancy event. To disable CO2-based occupancy detection, set this value to

2000 ppm.

(enteliWEB only) In the CO2 Occupancy Off Setppoint field, enter the CO2 setpoint value

that will cancel an occupancy event.

Set Up the Occupancy Sensor

1. In the Sensor Options section, next to Occupancy Motion sensor type, select the Function

option that is most appropriate for your needs:

Function Select this option if:

None The occupancy sensor on the eZNS sensor is not used.

OccupancyDetection

The motion sensor on the eZNS network sensor is used to

detect occupancy.

eZV-440 Application Guide

Edition 2.6

Page 39 of 84

Page 41

LINKnet I/O Tab

Function Select this option if:

MonitoringOnly

Input object BI1005 created but its value will not be used by the

internal algorithm.

2. If you selected OccupancyDetection, in the additional settings, in the MotionOvrdTime field,

enter how long the occupancy override should last. This setting allows the use of momentary

contact style occupancy signals.

If you are using maintained-contact occupancy devices, enter zero in this field. In this case,

occupancy statue is only based on contact position.

Assign Functions to the Buttons and Slider

See Assigning Buttons and Slider Elements On eZNS-T100 Network Sensor.

Set Up the LCD Display

You can select which icons are displayed on the network sensor's LCD screen.

1. In the Display Options section, next to Occupancy, select the occupancy symbols you would

like displayed on the LCD screen.

Display

Select this option if you are setting up:

Option

NotDisplayed_ No occupancy status to be displayed.

ManInHouse_

Occupancy status: when a room is occupied, the man in a house icon

is displayed; when the room is unoccupied the icon changes so that

the man appears outside the house. When the occupancy sensor is

disabled, neither icon is displayed.

SunMoon_

Sun or Moon icon to be displayed. These icons can be used to show

day and night occupancy modes.

2. In the Display Setpoints, select how the setpoint of the current heating or cooling stage is

displayed on the LCD screen.

Display

Select this option if you are setting up:

Option

On Button

Press

The setpoint is displayed when the Temp Select, Temp Up or Temp

Down buttons are pressed.

Always The setpoint is always displayed on the LCD in occupied mode.

Page 40 of 84 eZV-440 Application Guide

Edition 2.6

Page 42

3. In the Temp Setpoint Type, select the type of setpoint displayed.

Temperature

Description

Setpoint Type

NotDisplayed_ Setpoint will not be displayed.

DualSetpoint_ Separate setpoints are used during heating mode and cooling mode.

SingleSetpoint_ The average of both the heating and cooling setpoints.

SetpointOffset_

The offset that you can enter to adjust the occupied heating and

cooling setpoints. The range available for this offset is determined by

the OccSetpointOffsetRange field on the Setpoints tab.

4. Complete each option to determine how the backlight should appear onscreen.

Backlight

Do the following:

Options

Backlight

Select a color from the list of available backlight colors.

Color

Backlight On

Intensity

Enter the desired backlight intensity when the screen is turned on with a

button press. 100% is the most intense.

Backlight Off

Intensity

Enter the desired backlight intensity when the network sensor is idle.

100% is the most intense.

Assigning Buttons and Slider Elements on eZNS-T100 Network Sensor

Introduction

The enteliZONE controller is designed to work with the eZNS network sensor on a LINKnet

network.

This topic describes how to assign specific functions to every button and slider element on the

eZNS network sensor using the LINKnet I/O tab on the enteliZONE configuration page.

There are as many as 95 button overlay combinations available for the eZNS network sensor.

Fortunately, all these combinations are based on this single layout which consists of 8 buttons and

the slider element:

eZV-440 Application Guide

Edition 2.6

Page 41 of 84

Page 43

LINKnet I/O Tab

Not all the buttons are used in every button overlay. In some cases, the slider element can be

converted into 2 additional up and down buttons, or omitted. In overlays where there are less than 8

buttons, button areas are merged together and counted as one (see the examples below).

(click to view larger version of image or images)

Page 42 of 84 eZV-440 Application Guide

Edition 2.6

Page 44

For more information about the button overlays, see the Button Overlay Selection Summary

document on George Support.

Set Up the Buttons and Slider Elements

The graphic supports all standard Delta button functions but other custom button behaviors require

GCL programming on a programmable controller. To designate a button to a custom button

behavior, select NotUsed_ from the Function field and refer to the button’s KeyPress property in

the GCL program.

eZV-440 Application Guide

Edition 2.6

Page 43 of 84

Page 45

LINKnet I/O Tab

1. On the LINKnet I/O tab, in the Button Options section, next to the button number that you

want to program, select one of the following functions that you want to assign to that button:

Function Select this option if you want to:

NotUsed_ Designate custom button behavior using GCL or if you want a

blank button.

EcoModeToggle_ Turns on the occupancy eco mode. In eco mode, the setpoints

are widened.

OccupancyOff_ Turn on the standby occupancy mode.

In the additional settings, in the PushButtonOvrdTime field, you

can enter how long the button override should last.

OccupancyOn_ Turn on the occupied mode.

In the additional settings, in the PushButtonOvrdTime field, you

can enter how long the button override should last.

OccupancyToggle_ Toggle between standby and occupied modes during scheduled

occupancy periods.

When pushed during unoccupied mode it starts an occupancy

override timer. When an override has been activated, pushing

the button again will cancel the override and reset the override

timer back to zero.

In the additional settings, in the PushButtonOvrdTime field, you

can enter how long the button override should last.

TempUnitsToggle_ Toggle between displaying the temperature in Celsius and the

temperature in Fahrenheit.

TempDown_ Decrease the temperature setpoint by 0.5 degrees with each

buttonpress. The 0.5 degree amount cannot be changed in the

enteliZONE configurable controller model. In the programmable

controller model, this setting can be overridden using GCL.

In the additional settings, in the OccSetpointOffsetReset field,

you can turn on the Occupancy Setpoint Offset Reset function*.

Page 44 of 84 eZV-440 Application Guide

Edition 2.6

Page 46

Function Select this option if you want to:

TempUp_ Increase the temperature setpoint by 0.5 degrees with each

buttonpress. The 0.5 degree amount cannot be changed in the

enteliZONE configurable controller model. In the programmable

controller model, this setting can be overridden using GCL.

In the additional settings, in the OccSetpointOffsetReset field,

you can turn on the Occupancy Setpoint Offset Reset function*.

TempSelect_ Set up the button to display the current temperature and setpoint

(if enabled). This button is usually used to switch to temperature

display mode from fan mode.

In the additional settings, in the OccSetpointOffsetReset field,

you can turn on the Occupancy Setpoint Offset Reset function*.

FanDown_ Decrease the displayed fan speed or toggle through fan stages

after FanCycle is pressed. With analog fans, fan speed will

change by this amount = (FanMaxSpeed – FanMinSpeed) / 6.

FanUp_ Increase the displayed fan speed or toggle through fan stages

after FanCycle is pressed. With analog fans, fan speed will

change by this amount = (FanMaxSpeed – FanMinSpeed) / 6.

FanCycle_ Set up the button to display the current fan stage. When the up

and down buttons are not available, toggle this button to select a

fan speed.

FanSelect_ Toggle between automatic and manual fan control. Can be used

together with the slider to manually change the fan speed.

Info_ Toggles between all built-in and input sensor measurements that

the eZNS is reading.

* Occupancy Setpoint Offset Range resets the occupancy setpoint offset at the start of a new

occupancy period.

2. In the Slider field, select a function that you want to assign to the slider:

eZV-440 Application Guide

Edition 2.6

Page 45 of 84

Page 47

LINKnet I/O Tab

Function Description

NotUsed_ Designate custom behavior using GCL or if you want a blank

slider icon.

AnalogSlider_ Select this if your button overlay contains a slider. A slider

enables users to set values by moving their finger along the

range.

UpDownButton_ Select this to use the “+” and “-“ icons on the slider as buttons to

increase or decrease values or to toggle between available

options.

Configuring DNS-24L Network Sensor

Introduction

The enteliZONE controller is designed to work with the DNS-24L network sensor on a LINKnet

network.

This topic describes how to set up the DNS-24L network sensor built-in components using the

LINKnet I/O tab on the enteliZONE configuration page.

Configurable controllers can only connect to 1 LINKnet device at a time. This LINKnet

device has to have a device address of "1" in order for it to work with the controller

algorithm. Multiple LINKnet devices (up to 4) are only supported by the programmable

controllers.

On the configuration page, the controller detects the network sensor that is connected to it and

displays only the fields that are relevant for that network sensor.

(enteliWEB only) If you do not have any network sensors online, you can still configure the settings

by selecting your network sensor and model from the Device Information field.

Red Box on LINKnet Tab

(enteliWEB only) When you switch between different network sensor models, active

settings that are not shared between network sensor models become outlined in red. You

need to select the None option to disable these fields.