Page 1

www.deltaww.com

Delta

EtherCAT

Programming Guide

Industrial Automation Headquarters

Delta Electronics, Inc.

Taoyuan Technology Center

No.18, Xinglong Rd., Taoyuan City,

Taoyuan County 33068, Taiwan

TEL: 886-3-362-6301 / FAX: 886-3-371-6301

Asia

Delta Electronics (Jiangsu) Ltd.

Wujiang Plant 3

1688 Jiangxing East Road,

Wujiang Economic Development Zone

Wujiang City, Jiang Su Province, P.R.C. 215200

TEL: 86-512-6340-3008 / FAX: 86-769-6340-7290

Delta Greentech (China) Co., Ltd.

238 Min-Xia Road, Pudong District,

ShangHai, P.R.C. 201209

TEL: 86-21-58635678 / FAX: 86-21-58630003

Delta Electronics (Japan), Inc.

Tokyo Ofce

2-1-14 Minato-ku Shibadaimon,

Tokyo 105-0012, Japan

TEL: 81-3-5733-1111 / FAX: 81-3-5733-1211

Delta Electronics (Korea), Inc.

1511, Byucksan Digital Valley 6-cha, Gasan-dong,

Geumcheon-gu, Seoul, Korea, 153-704

TEL: 82-2-515-5303 / FAX: 82-2-515-5302

Delta Electronics Int’l (S) Pte Ltd.

4 Kaki Bukit Ave 1, #05-05, Singapore 417939

TEL: 65-6747-5155 / FAX: 65-6744-9228

Delta Electronics (India) Pvt. Ltd.

Plot No 43 Sector 35, HSIIDC

Gurgaon, PIN 122001, Haryana, India

TEL : 91-124-4874900 / FAX : 91-124-4874945

Americas

Delta Products Corporation (USA)

Raleigh Ofce

P.O. Box 12173,5101 Davis Drive,

Research Triangle Park, NC 27709, U.S.A.

TEL: 1-919-767-3800 / FAX: 1-919-767-8080

Delta Greentech (Brasil) S.A.

Sao Paulo Ofce

Rua Itapeva, 26 - 3° andar Edicio Itapeva One-Bela Vista

01332-000-São Paulo-SP-Brazil

TEL: 55 11 3568-3855 / FAX: 55 11 3568-3865

Europe

Delta Electronics (Netherlands) B.V.

Eindhoven Ofce

De Witbogt 20, 5652 AG Eindhoven, The Netherlands

TEL : +31 (0)40-8003800 / FAX : +31 (0)40-8003898

*We reserve the right to change the information in this manual without prior notice.

Delta

EtherCAT

Programming Guide

Page 2

March, 2017

Table of Contents

Introduction to API Library

1.1 How to use function libraries? ··············································································· 1-2

1.2 Start a new project ······························································································ 1-2

1.2.1 Using VC ······································································································ 1-2

1.2.2 Using VB ······································································································ 1-2

1.2.3 Using VB.Net ································································································ 1-2

1.2.4 Using C# ······································································································ 1-3

EtherCAT Introduction

2.1 Maximum number of the slave device ····································································· 2-2

2.2 Initialize RTX runtime environment ········································································· 2-3

2.3 Introduction to RTSS Task Manager ······································································· 2-4

EtherCAT Operation Example

3.1 EtherCAT Initialization ························································································· 3-3

3.1.1 Function list ·································································································· 3-3

3.1.2 Application examples ······················································································ 3-3

3.2 Motion control of homing ······················································································ 3-6

3.2.1 Function list ·································································································· 3-6

3.2.2 Application examples ······················································································ 3-6

3.3 Torque control ···································································································· 3-9

3.3.1 Function list ·································································································· 3-9

3.3.2 Application examples ······················································································ 3-9

3.4 Constant speed control ······················································································ 3-12

3.4.1 Function list ································································································ 3-12

3.4.2 Application examples ···················································································· 3-12

3.5 Motion control in PP mode ·················································································· 3-16

3.5.1 Function list ································································································ 3-16

3.5.2 Application examples ···················································································· 3-16

3.6 Motion control in CSP mode ··············································································· 3-20

3.6.1 Function list ································································································ 3-20

3.6.2 Application examples ···················································································· 3-21

3.7 EtherCAT Slave IO control (digital input) ································································ 3-38

Page 3

March, 2017

3.7.1 Function list ································································································ 3-38

3.7.2 Application examples ···················································································· 3-38

3.8 EtherCAT Slave IO control (digital output) ······························································ 3-40

3.8.1 Function list ································································································ 3-40

3.8.2 Application examples ···················································································· 3-40

3.9 Application of EtherCAT analog input module (R1-EC-8124 ) ······································ 3-42

3.9.1 Function list ································································································ 3-42

3.9.2 Application examples ···················································································· 3-42

3.10 Application of EtherCAT analog output module (R1-EC-9144) ··································· 3-44

3.10.1 Function list ······························································································· 3-44

3.10.2 Application examples··················································································· 3-44

3.11 Application of EtherCAT Compare function for PCI card (PCI-L221-B1) ······················· 3-47

3.11.1 Function list ······························································································· 3-47

3.11.2 Appli cation examples ··················································································· 3-48

API List of Dynamic-Link Library

4.1 Data T y pe and Setting Range ··············································································· 4-2

4.2 API list and descriptions ······················································································· 4-2

EtherCAT Master Configuration

5.1 _ECAT_Master_Set_CycleTime············································································· 5-3

5.2 _ECAT_Master_Get_CycleTime ············································································ 5-4

5.3 _ECAT_Master_NodeID_Alias_Enable···································································· 5-5

5.4 _ECAT_Get_SerialNo·························································································· 5-6

5.5 _ECAT_Master_Get_DLL_SeqID ··········································································· 5-7

5.6 _ECAT_Autoconfig_Open_File ·············································································· 5-8

5.7 _ECAT_Autoconfig_Save_File ·············································································· 5-9

5.8 _ECAT_Autoconfig_Set_Slave_DCTime ································································ 5-10

5.9 _EACT_Autoconfig_Clear_ConfigFile ··································································· 5-11

5.10 _ECAT_Autoconfig_Set_NodeID_Alias ································································ 5-12

5.11 _ECAT_Autoconfig_Get_NodeID_Alias ································································ 5-14

5.12 _ECAT_Autoconfig_Save_NodeID_Alias ····························································· 5-15

Master Initialization

6.1 _ECAT_Master_Open ························································································· 6-3

6.2 _ECAT_Master_Initial ·························································································· 6-4

6.3 _ECAT_Master_Reset ························································································· 6-5

6.4 _ECAT_Master_Close ························································································· 6-6

6.5 _ECAT_Master_Get_CardSeq ·············································································· 6-7

Page 4

March, 2017

6.6 _ECAT_Master_Get_SlaveNum ············································································ 6-8

6.7 _ECAT_Master_Get_Slave_Info ············································································ 6-9

6.8 _ECAT_Master_Get_DC_Status ·········································································· 6-11

6.9 _ECAT_Master_Get_Connect_Status ··································································· 6-12

6.10 _ECAT_Master_Get_Api_BufferLength ································································ 6-13

6.11 _ECAT_Master_Get_Cycle_SpendTime ······························································· 6-14

6.12 _ECAT_Master_Check_Initial_Done ··································································· 6-15

6.13 _ECAT_Master_Get_Initial_ErrorCode ································································ 6-16

6.14 _ECAT_Master_Check_Working_Counter ···························································· 6-17

6.15 _ECAT_Master_Get_Return_Code_Message ······················································· 6-18

EtherCAT CoE Standard Communication

7.1 _ECAT_Slave_SDO_Send_Message ····································································· 7-3

7.2 _ECAT_Slave_SDO_Read_Message ····································································· 7-4

7.3 _ECAT_Slave_SDO_Quick_Send_Message ···························································· 7-5

7.4 _ECAT_Slave_SDO_Quick_Read_Message ···························································· 7-6

7.5 _ECAT_Slave_SDO_Read_Response ···································································· 7-7

7.6 _ECAT_Slave_SDO_Wait_All_Done ······································································· 7-8

7.7 _ECAT_Slave_SDO_Get_ErrorCode ······································································ 7-9

7.8 _ECAT_Slave_SDO_Check_Done ······································································· 7-11

7.9 _ECAT_Slave_PDO_Get_OD_Data ····································································· 7-12

7.10 _ECAT_Slave_PDO_Set_OD_Data ···································································· 7-13

7.1 1 _EC AT_Slave_PDO_Get_Information ································································· 7-14

7.12 _ECAT_Slave_PDO_Get_Detail_Mapping ··························································· 7-15

7.13 _ECAT_Slave_PDO_Get_Rx_Data ···································································· 7-16

7.14 _ECAT_Slave_PDO_Get_Tx_Data ····································································· 7-17

7.15 _ECAT_Slave_PDO_Set_Tx_Data ····································································· 7-18

7.16 _ECAT_Slave_PDO_Set_Tx_Detail_Data ···························································· 7-19

General Operation of Motion Axis

8.1 _ECAT_Slave_Motion_Set_Svon ··········································································· 8-3

8.2 _ECAT_Slave_Motion_Ralm ················································································· 8-4

8.3 _ECAT_Slave_Motion_Sd_Stop ············································································ 8-5

8.4 _ECAT_Slave_Motion_Emg_Stop ·········································································· 8-6

8.5 _ECAT_Slave_Motion_Set_Alm_Reaction ······························································· 8-7

8.6 _ECAT_Slave_Motion_Set_Position ······································································· 8-8

8.7 _ECAT_Slave_Motion_Set_Command ···································································· 8-9

8.8 _ECAT_Slave_Motion_Set_MoveMode ·················································· 8-10

8.9 _ECAT_Slave_Motion_Get_MoveMode································································· 8-1 1

8.10 _ECAT_Slave_Motion_Get_ControlWord ····························································· 8-12

Page 5

March, 2017

8.11 _EC AT_Slave_Motion_Get_StatusWord ······························································ 8-14

8.12 _ECAT_Slave_Motion_Get_Mdone ···································································· 8-16

8.13 _ECAT_Slave_Motion_Get_Position ··································································· 8-17

8.14 _ECAT_Slave_Motion_Get_Command ································································ 8-18

8.15 _ECAT_Slave_Motion_Get_T arget_Command ······················································ 8-19

8.16 _ECAT_Slave_Motion_Get_Actual_Position ························································· 8-20

8.17 _ECAT_Slave_Motion_Get_Actual_Command ······················································ 8-21

8.18 _ECAT_Slave_Motion_Get_Current_Speed ························································· 8-22

8.19 _ECAT_Slave_Motion_Get_Torque ···································································· 8-23

8.20 _ECAT_Slave_Motion_Get_Buffer_Length ··························································· 8-24

8.21 _ECAT_Slave_Motion_Set_TouchProbe_Config ···················································· 8-25

8.22 _ECAT_Slave_Motion_Set_TouchProbe_QuickStart ·············································· 8-28

8.23 _ECAT_Slave_Motion_Set_TouchProbe_QuickDone ·············································· 8-30

8.24 _ECAT_Slave_Motion_Set_TouchProbe_Disable ·················································· 8-32

8.25 _ECAT_Slave_Motion_Get_TouchProbe_Status ···················································· 8-33

8.26 _ECAT_Slave_Motion_Get_TouchProbe_Position ················································· 8-35

Cyclic Synchronous Position Mode (CSP)

9.1 _ECAT_Slave_CSP_Start_Move ········································································ 9-5

9.2 _ECAT_Slave_CSP_Start_V_Move ····································································· 9-7

9.3 _ECAT_Slave_CSP_Start_Arc_Move ··································································· 9-8

9.4 _ECAT_Slave_CSP_Start_Arc2_Move ······························································· 9-10

9.5 _ECAT_Slave_CSP_Start_Arc3_Move ······························································· 9-12

9.6 _ECAT_Slave_CSP_Start_Spiral_Move ······························································ 9-14

9.7 _ECAT_Slave_CSP_Start_Spiral2_Move ···························································· 9-15

9.8 _ECAT_Slave_CSP_Start_Sphere_Move ···························································· 9-17

9.9 _ECAT_Slave_CSP_Start_Heli_Move ································································ 9-18

9.10 _ECAT_Slave_CSP_Start_Multiaxes_Move ························································· 9-20

9.11 _EC AT_Slave_CSP_Start_Msbrline_Move ··························································· 9-21

9.12 _ECAT_Slave_CSP_Set_Gear ·········································································· 9-25

9.13 _ECAT_Slave_CSP_Set_Softlimit ······································································ 9-26

9.14 _ECAT_Slave_CSP_TargetPos_Change ····························································· 9-27

9.15 _ECAT_Slave_CSP_Velocity_Change ································································ 9-28

9.16 _ECAT_Slave_CSP_Feedrate_Overwrite ····························································· 9-29

9.17 _ECAT_Slave_CSP_Speed_Continue_Enable ······················································ 9-33

9.18 _ECAT_Slave_CSP_Speed_Continue_Set_Mode ················································· 9-34

9.19 _ECAT_Slave_CSP_Speed_Continue_Set_Combine_ Ratio ···································· 9-37

9.20 _ECAT_Slave_CSP_Scurve_Rate ······································································ 9-38

9.21 _ECAT_Slave_CSP_Liner_Speed_Master ··························································· 9-39

9.22 _ECAT_Slave_CSP_Mask_Axis ········································································ 9-41

Page 6

March, 2017

9.23 _ECAT_Slave_CSP_Sync_Config ······································································ 9-42

9.24 _ECAT_Slave_CSP_Sync_Move ······································································· 9-43

9.25 _ECAT_Slave_CSP_Start_Mabrline_Move ··························································· 9-44

9.26 _ECAT_Slave_CSP_Start_2Segment_Move ························································ 9-46

9.27 _ECAT_Slave_CSP_Start_PVT_Move ································································ 9-48

9.28 _ECAT_Slave_CSP_Start_PVTComplete_Move ··················································· 9-50

9.29 _ECAT_Slave_CSP_Virtual_Set_Enable ····························································· 9-52

9.30 _ECAT_Slave_CSP_Virtual_Set_Command ························································· 9-53

9.31 _ECAT_Slave_CSP_Get_SoftLimit_Status ··························································· 9-54

9.32 _ECAT_Slave_CSP_Pitch_Set_Interval ······························································· 9-55

9.33 _ECAT_Slave_CSP_Pitch_Set_Mode ································································· 9-56

9.34 _ECAT_Slave_CSP_Pitch_Set_Org ··································································· 9-57

9.35 _ECAT_Slave_CSP_Pitch_Set_Rel_T a ble ··························································· 9-58

9.36 _ECAT_Slave_CSP_Pitch_Set_Abs_Table ··························································· 9-59

9.37 _ECAT_Slave_CSP_Pitch_Set_Enable ······························································· 9-60

Cyclic Synchronous Velocity Mode (CSV)

10.1 _ECAT_Slave_CSV_Start_Move ········································································ 10-2

10.2 _ECAT_Slave_CSV_Multi_Start_Move ································································ 10-3

Cyclic Synchronous Torque Mode (CST)

11.1 _EC AT_Slave_CST_Start_Move ········································································ 11-2

1 1.2 _ECAT_Slave_CST_Multi_Start_Move ································································ 11- 3

Homing

12.1 _ECAT_Slave_Home_Config ············································································ 12-3

12.2 _ECAT_Slave_Home_Move ············································································ 12-19

12.3 _ECAT_Slave_Home_Status ··········································································· 12-20

EtherCAT Profile Position Mode (PP)

13.1 _ECAT_Slave_PP_Start_Move ·········································································· 13-3

13.2 _ECAT_Slave_PP_Advance_Config ··································································· 13-4

EtherCAT Profile Velocity Mode (PV)

14.1 _ECAT_Slave_PV_Start_Move ·········································································· 14-3

14.2 _ECAT_Slave_PV_Advance_Config ··································································· 14-4

Page 7

March, 2017

Inverter Motion Control

15.1 _ECAT_Slave_VL_Start_Move ·········································································· 15-2

EtherCAT Profile Torque Mode (PT)

16.1 _ECAT_Slave_PT_Start_Move ·········································································· 16-3

16.2 _ECAT_Slave_PT_Advance_Config ··································································· 16-4

Group Motion Control

17.1 _ECAT_Slave_User_Motion_Control_Set _Enable_Mode ········································17-3

17.2 _ECAT_Slave_User_Motion_Control_Get_Enable_Mode ········································ 17-5

17.3 _ECAT_Slave_User_Motion_Control_Set_T ype ···················································· 17-6

17.4 _ECAT_Slave_User_Motion_Control_Set_Data ···················································· 17-8

17.5 _ECAT_Slave_User_Motion_Control_Clear_Data ·················································· 17-9

17.6 _ECAT_Slave_User_Motion_Control_Get_DataCnt ············································· 17-10

17.7 _ECAT_Slave_User_Motion_Control_Ralm ························································ 17-1 1

17.8 _ECAT_Slave_User_Motion_Control_Svon ························································ 17-12

17.9 _ECAT_Slave_User_Motion_Control_Get_Alm ··················································· 17-13

Operation of DI/DO Module

18.1 _ECAT_Slave_DIO_Get_Input_Value ·································································· 18-3

18.2 _ECAT_Slave_DIO_Get_Output_Value ······························································· 18-4

18.3 _ECAT_Slave_DIO_Set_Output_Val ue ································································ 18-5

18.4 _ECAT_Slave_DIO_Get_Single_Input_Value ························································ 18-6

18.5 _ECAT_Slave_DIO_Get_Single_Output_Value ····················································· 18-7

18.6 _ECAT_Slave_DIO_Set_Single_Output_Value ······················································ 18-8

18.7 _ECAT_Slave_DIO_Set_Output_Error_Mode ······················································· 18-9

18.8 _ECAT_Slave_DIO_Set_Output_Error_Value ····················································· 18-10

Operation of AI/AO Module

19.1 _ECAT_Slave_AIO_Get_Input_Value ·································································· 19-3

19.2 _ECAT_Slave_AIO_Set_Output_Value ································································ 19-4

19.3 _ECAT_Slave_AIO_Get_Output_Value ······························································· 19-5

Operation of Pulse Module (For R1-EC5621D0 Series)

20.1 _ECAT_Slave_R1_EC5621_Set_Output_Mode ····················································· 20-3

20.2 _ECAT_Slave_R1_EC5621_Set_Input_Mode ······················································· 20-4

20.3 _ECAT_Slave_R1_EC5621_Set_ORG_Inverse ···················································· 20-5

20.4 _ECAT_Slave_R1_EC5621_Set_QZ_Inverse ······················································· 20-6

Page 8

March, 2017

20.5 _ECAT_Slave_R1_EC5621_Set_Home_SpMode ·················································· 20-7

20.6 _ECAT_Slave_R1_EC5621_Set_MEL_Inverse ····················································· 20-8

20.7 _ECAT_Slave_R1_EC5621_Set_PEL_Inverse ······················································ 20-9

20.8 _ECAT_Slave_R1_EC5621_Set_Svon_Inverse ·················································· 20-10

20.9 _ECAT_Slave_R1_EC5621_Set_Home _Slow_Down ·········································· 20-11

20.10 _ECAT_Slave_R1_EC5621_Get_IO_Status ····················································· 20-12

20.1 1 _ECAT_Slave_R1_EC56 21_Get_Single_IO_Status ············································ 20-13

Operation of Pulse Module (For R1-ECx62xD0 Series)

21.1 _ECAT_Slave_R1_ECx62x_Set_Output_Mode ····················································· 21-3

21.2 _ECAT_Slave_R1_ECx62x_Set_Input_Mode ······················································· 21-4

21.3 _ECAT_Slave_R1_ECx62x_Set_ORG_Inverse ····················································· 21-5

21.4 _ECAT_Slave_R1_ECx62x_Set_QZ_Inverse ······················································· 21-6

21.5 _ECAT_Slave_R1_ECx62x_Set_Home_SpMode ·················································· 21-7

21.6 _ECAT_Slave_R1_ECx62x_Set_MEL_Inverse ····················································· 21-8

21.7 _ECAT_Slave_R1_ECx62x_Set_PEL_Inverse ······················································ 21-9

21.8 _ECAT_Slave_R1_ECx62x_Set_Svon_Inverse ··················································· 21-10

21.9 _ECAT_Slave_R1_ECx62x_Set_Home_Slow_Down ············································ 21-11

21.10 _ECAT_Slave_R1_ECx62x_Get_IO_Status ······················································ 21-12

21.1 1 _ECAT_Slave_R1_ECx 62x _Get_Single_IO_Status ············································ 21-13

Operation of Delta Servo System

22.1 _ECAT_Slave_DeltaServo_Write_Parameter ························································ 22-3

22.2 _ECAT_Slave_DeltaServo_Read_Parameter ························································ 22-4

22.3 _ECAT_Slave_DeltaServo_Read_Parameter_Info ················································· 22-5

22.4 _ECAT_Slave_DeltaServo_Set_Velocity_Limit ······················································ 22-6

22.5 _ECAT_Slave_DeltaServo_Set_Compare_Enable ················································· 22-7

22.6 _ECAT_Slave_DeltaServo_Get_Compare_Enable ················································· 22-8

22.7 _ECAT_Slave_DeltaServo_Set_Compare_Config ·················································· 22-9

Analog Input Settings (For R1-EC8124D0)

23.1 _ECAT_Slave_R1_EC8124_Set_Input _RangeMode ············································· 23-3

23.2 _ECAT_Slave_R1_EC8124_Set_Input _ConvstFreq_Mode ····································· 23-4

23.3 _ECAT_Slave_R1_EC8124_Set_Input_Enable ····················································· 23-5

23.4 _ECAT_Slave_R1_EC8124_Get_Input _RangeMode ············································· 23-6

23.5 _ECAT_Slave_R1_EC8124_Set_Input _AverageMode ··········································· 23-7

Analog Output Settings (For R1-EC9144D0 Series)

24.1 _ECAT_Slave_R1_EC9144_Set_Output _RangeMode ··········································· 24-3

Page 9

March, 2017

24.2 _ECAT_Slave_R1_EC9144_Set_Output_Enable ··················································· 24-4

24.3 _ECAT_Slave_R1_EC9144_Get_Output _ReturnCode ··········································· 24-5

Auto Recording Function of Motion Axis

25.1 _ECAT_Slave_Record_Set_Type ······································································· 25-3

25.2 _ECAT_Slave_Record_Set_Enable ···································································· 25-4

25.3 _ECAT_Slave_Record_Get_Cnt ········································································ 25-5

25.4 _ECAT_Slave_Record_Read_Data ···································································· 25-6

25.5 _ECAT_Slave_Record_Clear_Data ···································································· 25-7

25.6 _ECAT_Slave_Record_Multi_Set_Enable ···························································· 25-8

25.7 _ECAT_Slave_Record_Multi_Clear_Data ···························································· 25-9

Operation of Local Digital I/O

26.1 _ECAT_GPIO_Set_Output ················································································ 26-3

26.2 _ECAT_GPIO_Get_Output ··············································································· 26-4

26.3 _ECAT_GPIO_Get_Input ·················································································· 26-5

High-Speed Pulse Compare Function

27.1 _ECAT_Compare_Set_Channel_Position ···························································· 27-4

27.2 _ECAT_Compare_Get_Channel_Position ···························································· 27-5

27.3 _ECAT_Compare_Set_Ipulser_Mode ·································································· 27-6

27.4 _ECAT_Compare_Set_Channel_Direction ··························································· 27-7

27.5 _ECAT_Compare_Set_Channel_Trigger_Time ····················································· 27-8

27.6 _ECAT_Compare_Set_Channel_One_Shot ·························································· 27-9

27.7 _ECAT_Compare_Set_Channel_Source···························································· 27-10

27.8 _ECAT_Compare_Set_Channel_Enable ···························································· 27-11

27.9 _ECAT_Compare_Channel0_Position ······························································· 27-12

27.10 _ECAT_Compare_Set_Channel0_Trigger _By_GPIO ········································· 27-13

27.1 1 _ECAT_Compare_S et_Channel1_Output_Enable ·············································· 27-14

27.12 _ECAT_Compare_Set_Channel1_Output_Mode ················································ 27-15

27.13 _ECAT_Compare_Get_Channel1_IO_Status ···················································· 27-17

27.14 _ECAT_Compare_Set_Channel1_GPIO_Out ···················································· 27-18

27.15 _ECAT_Compare_Set_Channel1_Position_Table ·············································· 27-19

27.16 _ECAT_Compare_Set_Channel1_Position _Table_Level ····································· 27-21

27.17 _ECAT_Compare_Get_Channel1_Position _Table_Count ···································· 27-24

27.18 _ECAT_Compare_Set_Channel_Polarity ························································· 27-25

27.19 _ECAT_Compare_Reuse_Channel1_Position _Table ········································· 27-26

27.20 _ECAT_Compare_Reuse_Channel1_Position _Table_Level ································· 27-27

Page 10

March, 2017

Information of EtherCAT Dynamic-Link Library (DLL)

28.1 _ECAT_Master_Get_DLL_Path ········································································· 28-2

28.2 _ECAT_Master_Get_DLL_Version ····································································· 28-3

28.3 _ECAT_Master_Get_DLL_Path_Single ······························································· 28-4

28.4 _ECAT_Master_Get_DLL_Version_Single ···························································· 28-5

Security of Software Protection

29.1 _ECAT_Security_Check_Verify key ····································································· 29-2

29.2 _ECAT_Security_Get_Check_Verifykey_State ······················································ 29-3

29.3 _ECAT_Security_Write_Verifykey ······································································· 29-4

29.4 _ECAT_Security_Get_Write_Verifykey_State ························································ 29-5

29.5 _ECAT_Security_Check_UserPassword ······························································ 29-6

29.6 _ECAT_Security_Get_Check_UserPassword _State ·············································· 29-7

29.7 _ECAT_Security_Write_UserPassword ······························································· 29-8

29.8 _ECAT_Security_Get_Write_UserPassword_State ················································ 29-9

Operating MRAM on PAC

30.1 _ECAT_Master_MRAM_Write_Word_Data ··························································· 30-2

30.2 _ECAT_Master_MRAM_Read_Word_Data ·························································· 30-3

30.3 _ECAT_Master_MRAM_Write_DWord_Data························································· 30-4

30.4 _ECAT_Master_MRAM_Read_DWord_Data ························································ 30-5

Retentive Digital Output of the Module (For 70E2 Series)

31.1 _ECAT_Slave_R1_EC70E2_Set_Output_Enable ·················································· 31-2

Retentive Digital Output of the Module (For 70X2 Series)

32.1 _ECAT_Slave_R1_EC70X2_Set_Output_Enable ·················································· 32-2

MPG Operation (For R1-EC5614D0 Series)

33.1 _ECAT_Slave_R1_EC5614_Set_MJ_Config ························································ 33-3

33.2 _ECAT_Slave_R1_EC5614_Set_MJ_Enable ························································ 33-5

33.3 _ECAT_Slave_R1_EC5614_Get_IO_Status ························································· 33-6

33.4 _ECAT_Slave_R1_EC5614_Get_MPG_Counter ··················································· 33-7

Error Code Description

34.1 List of error code ···························································································· 34-2

34.2 Error code description ···················································································· 34-10

Page 11

March, 2017

(This page is intentionally left blank.)

Page 12

March, 2017 1-1

Introduction to

API Function Library

This chapter introduces APIs of EtherCAT dynamic-link library (DLL). Users can

perform various functions through calling these API libraries. The contents below

provide instructions on how to import API libraries into your developing environment.

1.1 How to use function libraries? ······························································· 1-2

1.2 Start a new project ············································································· 1-2

1.2.1 Using VC ··················································································· 1-2

1.2.2 Using VB ··················································································· 1-2

1.2.3 Using VB.Net ·············································································· 1-2

1.2.4 Using C# ··················································································· 1-3

Page 13

Introduction to API Function Library EtherCAT Programming Guide

1-2 March, 2017

1

1.1 How to use function libraries?

When the installation program is completed, two function libraries will be found in the folder

named “lib”. They can be used in Visual Studio C and Borland C++ respectively.

Function library Development environment

EtherCatDll.lib Visual Studio C++

BCBEtherCAT_DLL.lib Borland C++Builder 6

1.2 Start a new project

1.2.1 Using VC

(1) Place following instructions in the user-built project:

#include “EtherCat_DLL.h”

#include “EtherCat_DLL_Err.h”

(2) Select Project / Setting / Link in Visual C development environment.

Then, type “..\lib\EtherCat_DLL.lib” in Object / Library modules

(3) Setup completed. Users can start to operate EtherCAT DLL with API.

1.2.2 Using VB

Place “EtherCat_DLL.bas” and “EtherCat_DLL_Err.bas” in the project created by users to control

EtherCAT DLL with API.

1.2.3 Using VB.Net

Place “EtherCat_DLL.vb” and “EtherCat_DLL_Err.vb” in the project created by users to control

EtherCAT DLL with API.

Page 14

EtherCAT Programming Guide Introduction to API Function Library

March, 2017

1-3

1

1.2.4 Using C#

Place “EtherCat_DLL.cs” and “EtherCat_DLL_Err.cs” in user-built project to control EtherCAT

DLL with API.

Note: For C# projects, please tick the Enable native code debugging option in the Debug tab. See figure

below. Serious errors (i.e. blue screen) will occur if this option is not ticked.

Figure 1.2.4.1 Settings for C# project

Page 15

Introduction to API Function Library EtherCAT Programming Guide

1-4 March, 2017

1

(This page is intentionally left blank.)

Page 16

March, 2017 2-1

EtherCAT Introduction

This chapter introduces the setting for applying Delta EtherCAT function library,

including the suggested maximum slave number for connection, initialization of RTX

operating system and the description on how to check if the EtherCAT associated DLL

can operate normally in RTS. Please see the contents below for more information.

2.1 Maximum number of the slave device ···················································· 2-2

2.2 Initialize RTX runtime environment ························································ 2-3

2.3 Introduction to RTSS Task Manager ······················································ 2-4

Page 17

EtherCAT Introduction EtherCAT Programming Guide

2-2 March, 2017

2

2.1 Maximum number of the slave device

Delta EtherCAT master has two types of operation system, RTX real-time operating system from

PAC and EtherCAT PCI m otion card. Since the operational efficiency among both differs from

one another, the connected slave number is different.

When EtherCA T master runs in R TX real-time operating system, the default of its comm unication

cycle is 1 ms (1K) and can connect up to remote modules and 64 motion axes, including servo

drives and pulse modules. There is no limitation on quantity of the device that connects to

EtherCAT master. However, if the communication cycle is shorter, the suggested maximum

number of the connected slave will be reduced in accordance with proportion. Please refer to

table 2.1.1 below for the suggested maximum slave quantity to avoid communication instability.

When EtherCAT master runs in PCI motion card, it can connect 64 remote modules and 32

motion axes at most with the default communication cycle 1 ms (1K). Please refer to table 2.1.2.

EtherCAT master runs in RTX real-time operating system of Delta PAC

Communication cycle (ms)

Max. number of the connected

remote module (1 ms)

Max. number of the connected

motion axis (1 ms)

4 ms 100 64

2 ms 100 64

1 ms 100 64

0.5 ms 50 32

0.25 ms 25 16

0.125 ms 22 8

Table 2.1.1 Suggested number of the slave

EtherCAT master runs in Delta PCI EtherCAT motion card

Communication cycle (ms)

Max. number of the connected

remote module (1 ms)

Max. number of the connected

motion axis (1 ms)

4 ms 64 32

2 ms 64 32

1 ms 64 32

0.5 ms 32 16

0.25 ms 16 8

0.125 ms 8 4

Table 2.1.2 Suggested number of the slave

Page 18

EtherCAT Programming Guide EtherCAT Introduction

March, 2017

2-3

2

2.2 Initialize RTX runtime environment

For running the real-time operating system uploaded by synchronous function of EtherCAT

communication, RTX has one CPU and one Ethernet communication port. If you are applying a

Delta EtherCA T motion card, such a s PCI-L221PPI, then there is nothing to do with R TX syst em.

When the host computer has started up, the RTX runtime environment will not be automatically

loaded into the system. It will start running only after instructions related to EtherCAT initialization

API are executed. Or, you can also manually enable RTX. See the steps below.

Once RTX is enabled, you can start to use other related functions and APIs in EtherCAT dynamic

link library.

(1) Open [RTX Properties]

File location: [Start] > [All programs] > [IntervalZero] > [RTX 2012] > [RTX Properties]

(2) Enable RTX devices

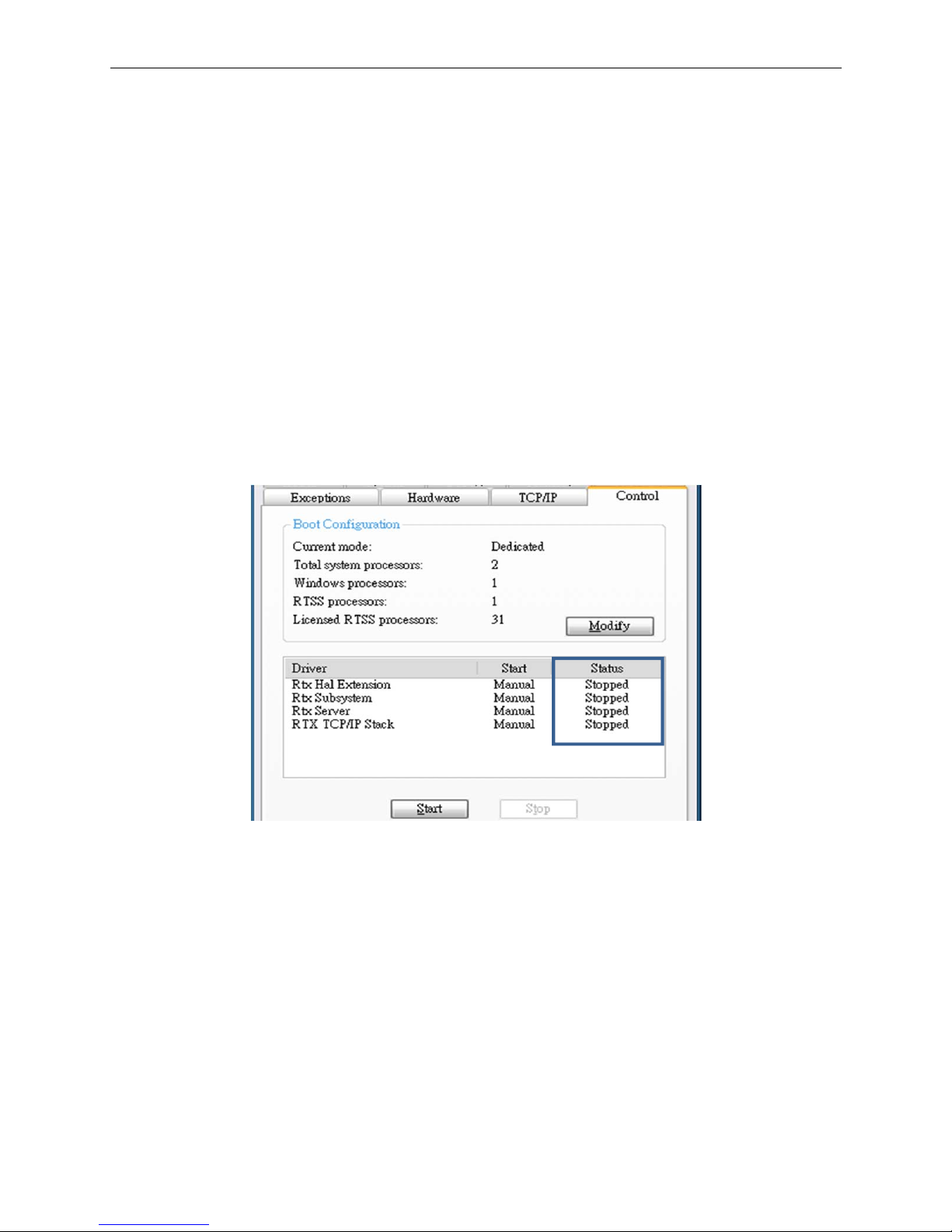

After opening [RTX Properties], select the Control tab and check the Driver status. If the driver

status shows “Stopped”, press the Start key to have the RTX devices start running.

Figure 2.2.1 RTX devices in Stopped status

Page 19

EtherCAT Introduction EtherCAT Programming Guide

2-4

March, 2017

2

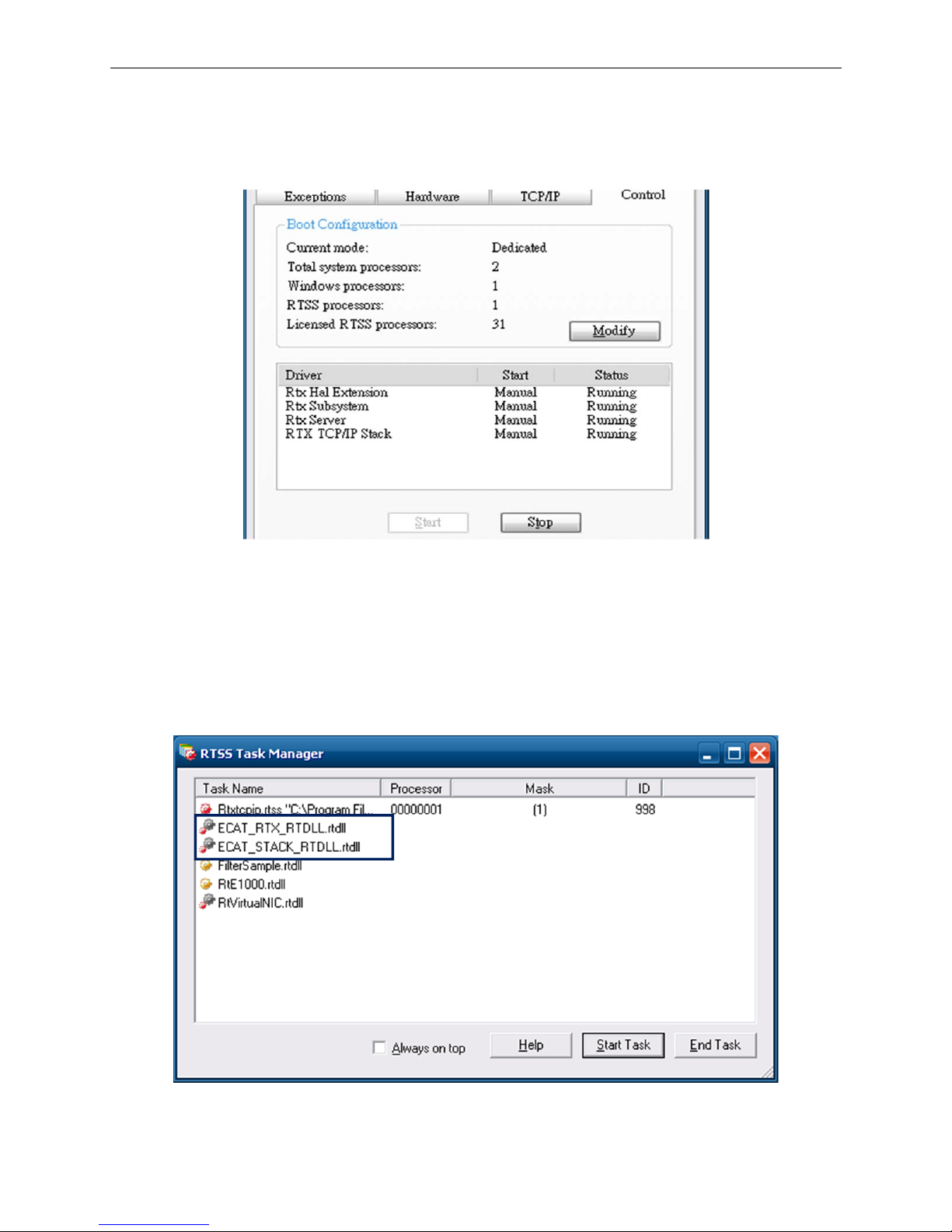

(3) Check the status of RTX devices

When the status of RTX devices shows “Running”, the user can start to use EtherCAT related

functions.

Figure 2.2.2 RTX devices in Running status

2.3 Introduction to RTSS Task Manager

RTSS Task Manager can be used to check whether the EtherCAT associ ated files

(ECA T _RTX_RTDLL.rtdll, ECAT_S TACK_RTDLL.rtdll) are operating normally in RTX.

Figure 2.3.1

Interface of RTSS Task Manager

Page 20

EtherCAT Programming Guide EtherCAT Introduction

March, 2017

2-5

2

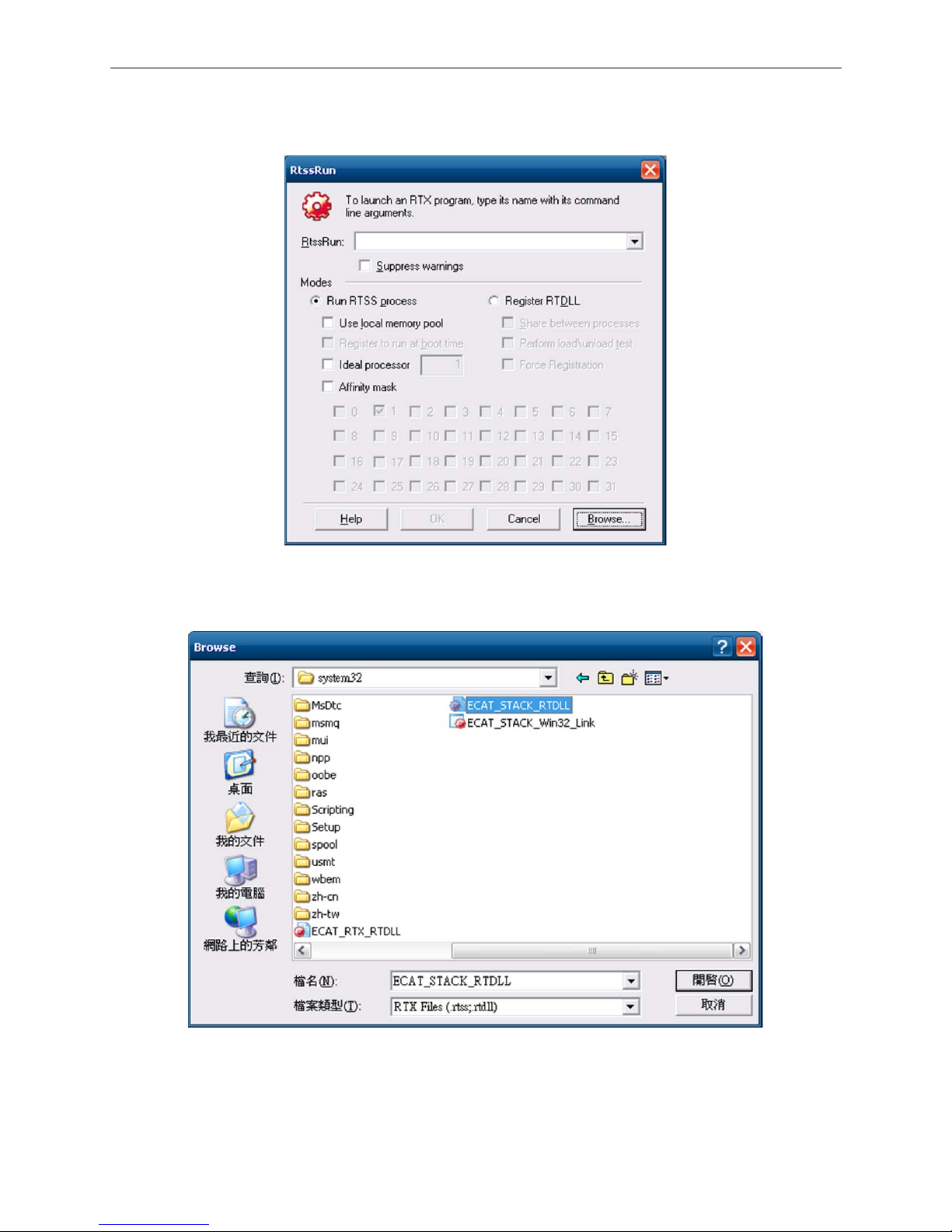

If there is any file missing in Task Manager, users can reload the missing file.

(1) Click the Start T ask key, and the RtssRun window will pop out.

Figure 2.3.2 RtssRun window

(2) Click Browse and select the missing file, which is placed in C:\Windows\system32\.

Figure 2.3.3 Select the missing file

Page 21

EtherCAT Introduction EtherCAT Programming Guide

2-6

March, 2017

2

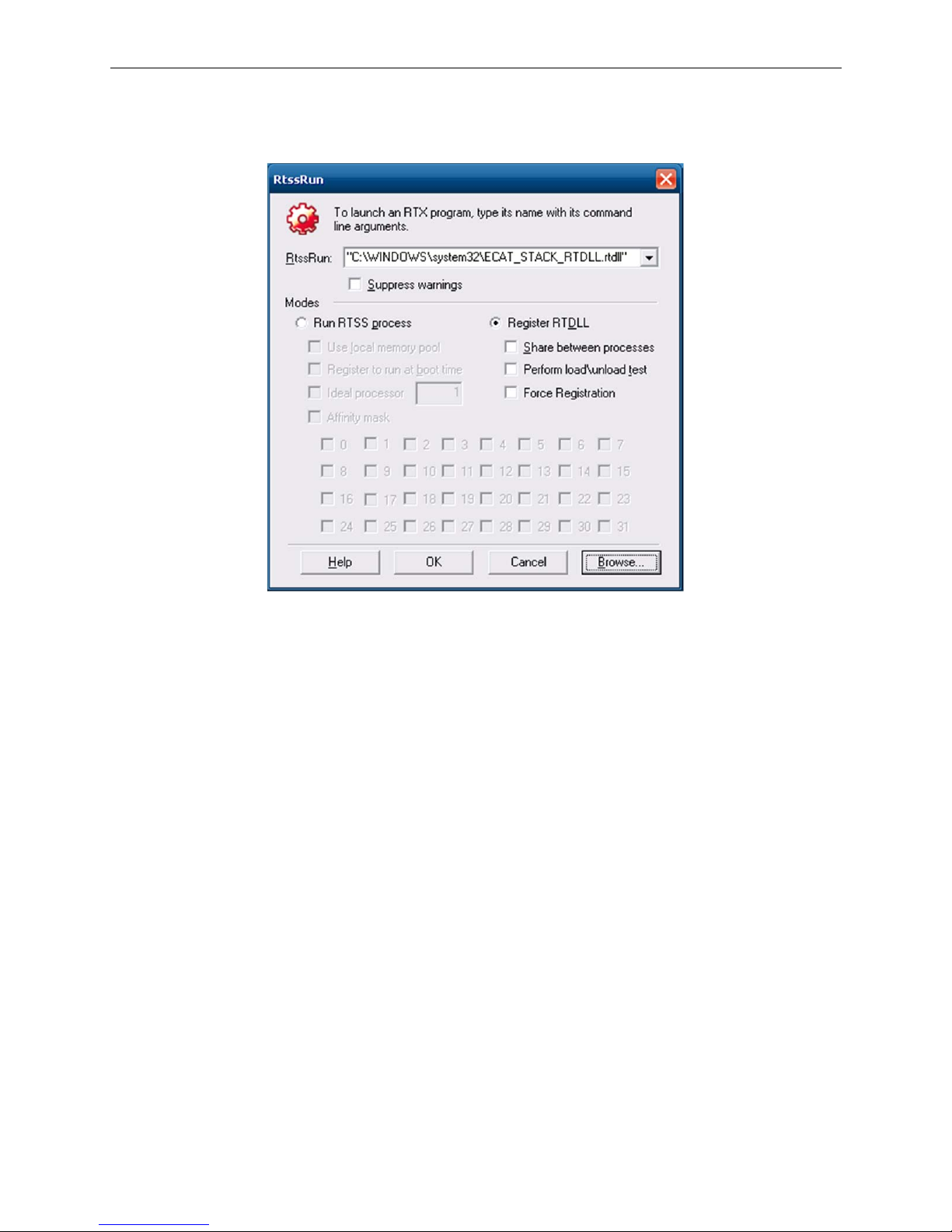

Then, while the other options remain unchanged, press OK and the file will be loaded into RTX

system.

Figure 2.3.4 Load the missing file

Page 22

March, 2017 3-1

EtherCAT Operation

Example

This chapter provides the C/C++ examples of EtherCAT dynamic-link library, including

EtherCAT initialization, homing procedure, PT, PV, PP, CSP modes, remote digital

input/output module, analog input/output, and high-speed pulse compare function.

3.1 EtherCAT Initialization ········································································ 3-3

3.1.1 Function list ················································································ 3-3

3.1.2 Application examples ··································································· 3-3

3.2 Motion control of homing ····································································· 3-6

3.2.1 Function list ················································································ 3-6

3.2.2 Application examples ··································································· 3-6

3.3 Torque control ··················································································· 3-9

3.3.1 Function list ················································································ 3-9

3.3.2 Application examples ··································································· 3-9

3.4 Constant speed control ····································································· 3-12

3.4.1 Function list ·············································································· 3-12

3.4.2 Application examples ································································· 3-12

3.5 Motion control in PP mode ································································· 3-16

3.5.1 Function list ·············································································· 3-16

3.5.2 Application examples ································································· 3-16

3.6 Motion control in CSP mode ······························································· 3-20

3.6.1 Function list ·············································································· 3-20

3.6.2 Application examples ································································· 3-21

3.7 EtherCAT Slave IO control (digital input) ··············································· 3-38

3.7.1 Function list ·············································································· 3-38

3.7.2 Application examples ································································· 3-38

3.8 EtherCAT Slave IO control (digital output) ············································· 3-40

3.8.1 Function list ·············································································· 3-40

3.8.2 Application examples ································································· 3-40

3.9 Application of EtherCAT analog input module (R1-EC-8124) ····················· 3-42

3.9.1 Function list ·············································································· 3-42

3.9.2 Application examples ································································· 3-42

3.10 Application of EtherCAT analog output module (R1-EC-9144) ·················· 3-44

Page 23

EtherCAT Operation Example EtherCAT Programming Guide

3-2 March, 2017

3

3.10.1 Function list ············································································ 3-44

3.10.2 Application examples ································································ 3-44

3.11 Application of EtherCAT Compare function for PCI card (PCI-L221-B1) ······ 3-47

3.11.1 Function list ············································································ 3-47

3.11.2 Application examples ································································ 3-48

Page 24

EtherCAT Programming Guide EtherCAT Operation Example

March, 2017 3-3

3

3.1 EtherCAT initialization

3.1.1 Function list

Function name

_ECAT_Master_Open

_ECAT_Master_Get_CardSeq

_ECAT_Master_Initial

_ECAT_Master_Get_SlaveNum

_ECAT_Master_Reset

_ECAT_Master_Close

_ECAT_Master_Check_Initial_Done

Properties

Hardware

EtherCAT RTX (PAC) EtherCAT motion card

Supported

Y Y

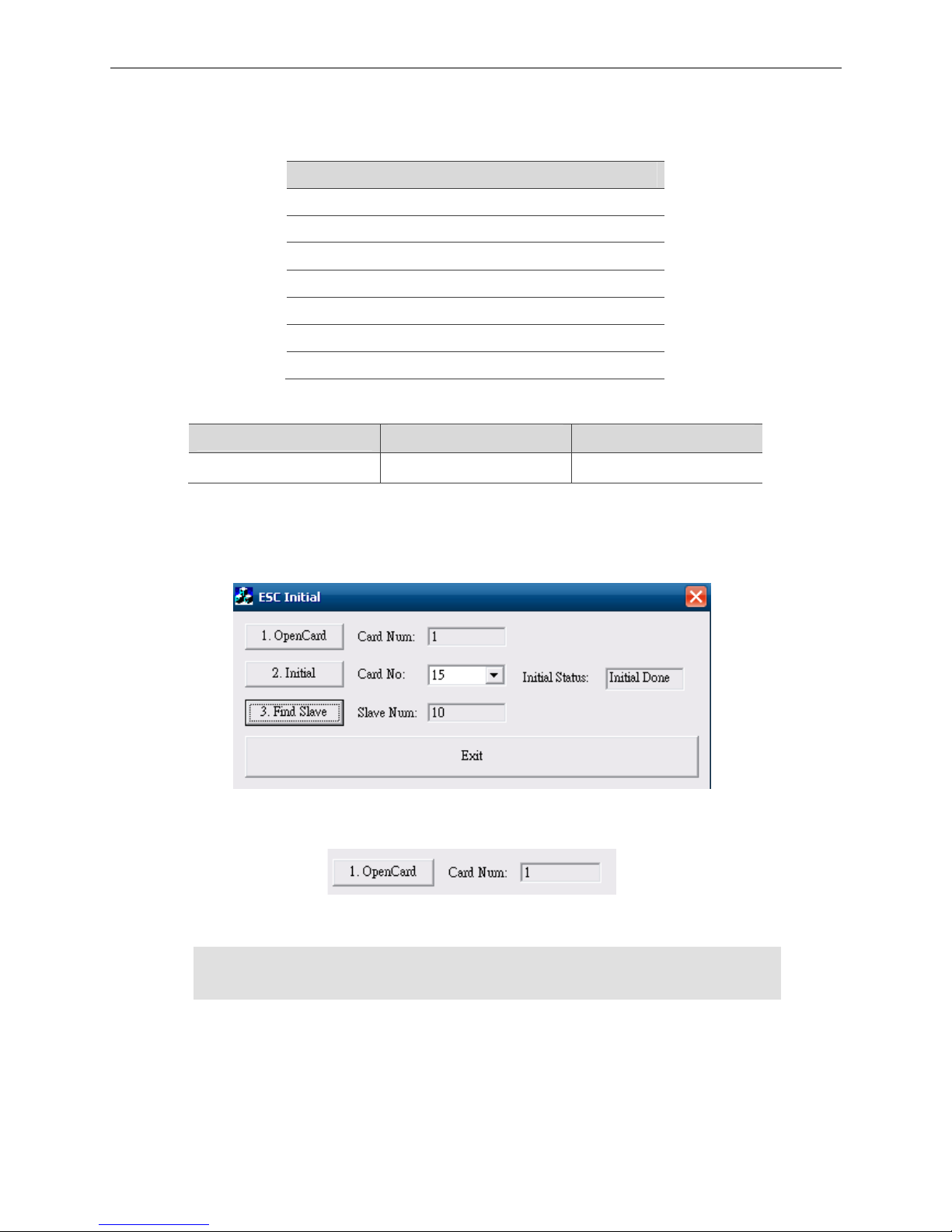

3.1.2 Application examples

Program interface

Figure 3.1.2.1

(1) Activate interface card

Figure 3.1.2.2

Press the OpenCard key to execute the following program:

RetCode = _ECAT_Master_Open(&gESCExistCards);

/* The variable, gESCExistCards, will return EtherCAT motion card number. */

Page 25

EtherCAT Operation Example EtherCAT Programming Guide

3-4 March, 2017

3

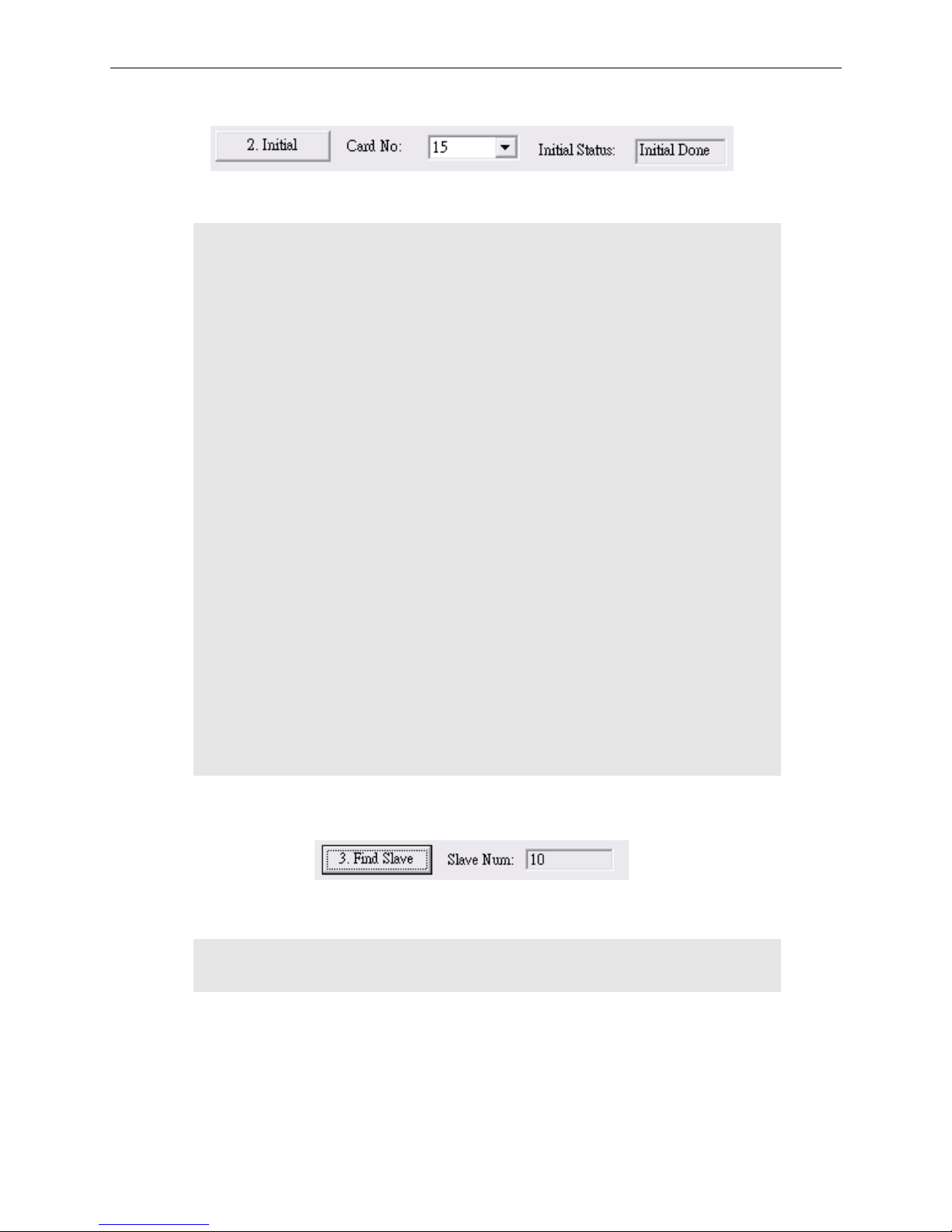

(2) Initialize interface card

Figure 3.1.2.3

Press the Initial key to execute the following program:

for(i=0; i< gESCExistCards; i++)

{

RetCode = _ECAT_Master_Get_CardSeq(i, &CardNo);

/* Get the card No. of the PC interface Card i. This card No. is the dip switch value.

EtherCAT card number in RTX version is 16. */

RetCode = _ECAT_Master_Initial(CardNo);

/* Start to initialize the interface card. */

if(RetCode != 0)

{

strMsg.Format("_ECAT_Master_Initial, RetCode = %d", RetCode);

MessageBox(strMsg);

}

}

RetCode = _ECAT_Master_Check_Initial_Done(gESCCardNo, &InitialDone);

/* Get the Initial status. */

// Display the Initial Status:

// InitialDone = 1: Display “Pre Initial”

// InitialDone = 0: Display “Initial Done”

// InitialDone = 99: Display “Initial Error”

(3) Set the information of the connected modules

Figure 3.1.2.5

Press the Find Slave key to execute the following program:

RetCode = _ECAT_Master_Get_SlaveNum(gESCCardNo, &SlaveNum);

// Get the number of the connected modules.

When the above program completes, the number of the found Slave devices will be

displayed in Slave Num field.

Page 26

EtherCAT Programming Guide EtherCAT Operation Example

March, 2017 3-5

3

(4) Exit program

Figure 3.1.2.6

Press the Exit key to execute the following program:

for(i=0; i< gESCExistCards; i++)

{

_ECAT_Master_Reset(gpESCCardNoList[i]);

// Reset the interface card.

}

_ECAT_Master_Close();

// End the operation of motion control card.

Page 27

EtherCAT Operation Example EtherCAT Programming Guide

3-6 March, 2017

3

3.2 Motion control of homing

3.2.1 Function list

Function name

_ECAT_Slave_Home_Config

_ECAT_Slave_Home_Move

_ECAT_Slave_Motion_Sd_Stop

Properties

Hardware EtherCAT RTX (PAC) EtherCAT motion card

Supported Y Y

3.2.2 Application examples

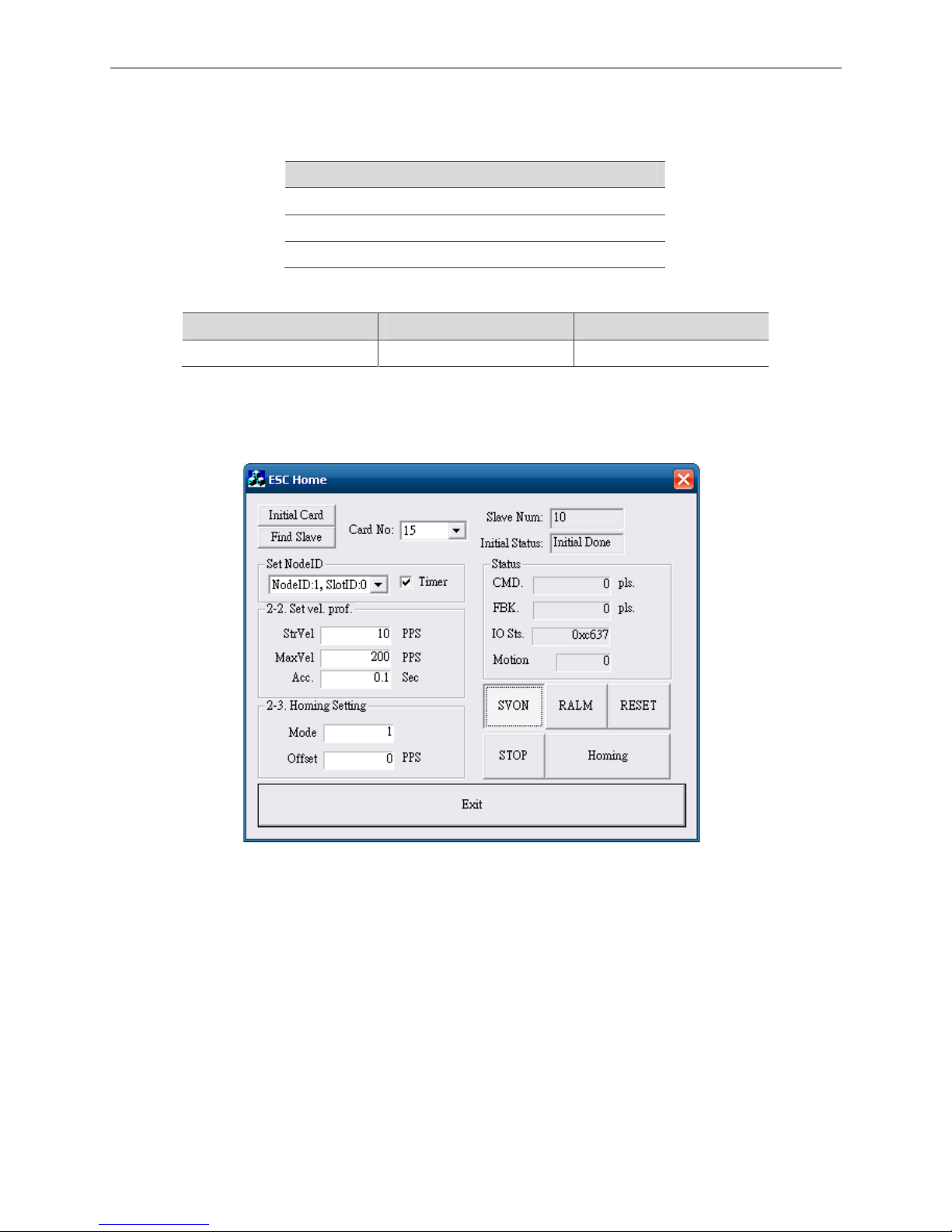

Program interface

Figure 3.2.2.1

(1) Activate and initialize interface card

Press the Initial Card key (as shown in figure 3.2.2.1) to start initializing the interface card.

Press the Find Slave key (as shown in figure 3.2.2.1) to start searching the connecting

modules.

For more information about the interface card initialization, please see “Activate interface

card” and “Initialize interface card” in section 3.1.2.

Page 28

EtherCAT Programming Guide EtherCAT Operation Example

March, 2017 3-7

3

(2) Enter the parameter for motion control

Figure 3.2.2.2

Select Node ID and Slot ID and check the Timer box to display the motion status.

Set NodeID: Specify the Node ID to be executed. The parameters “AxisNo” and “SlotNo”

in the API function.

Timer: Check the Timer box to display the current motion status.

StrVel.: Input motion speed for homing (pulse sent per second). The parameter

“FirstSpeed” in the API function.

MaxVel.: Input the motion speed after homing to the next index pulse (pulse sent per

second). The parameter “SecondSpeed” in the API function.

Acc.: Input the duration to accelerate to the target speed. The parameter “Tacc” in the API

function.

(3) Set the parameters for homing (homing mode and offset value)

Figure 3.2.2.3

Mode: Homing mode 1 ~ 35. The parameter “Mode” in the API function.

Offset: Homing offset. The parameter “Offset” in the API function.

(4) Set the servo motor to ON/OFF state (servo on/servo off)

Figure 3.2.2.4

Press the SVON key (as shown in figure 3.2.2.4) to execute the following program:

RetCode = _ECAT_Slave_Motion_Set_Svon(gESCCardNo, gNodeID, gSlotID,ON_OFF);

// ON_OFF

// 0: Servo OFF

// 1: Servo ON

Page 29

EtherCAT Operation Example EtherCAT Programming Guide

3-8 March, 2017

3

(5) Homing procedures

Press the Homing key (as shown in figure 3.2.2.4) to execute the following program:

RetCode = _ECAT_Slave_Home_Config(gESCCardNo, gNodeID, gSlotID, Mode, Offset,

StrVel, MaxVel, Tacc);

/* Set homing mode: 1 ~ 35, offset and speed parameters, but the servo will not operate

now. */

RetCode = _ECAT_Slave_Home_Move(gESCCardNo, gNodeID, gSlotID);

/* Start homing according to the set parameters. */

(6) Stop homing

To stop homing, press the STOP key (as shown in figure 3.2.2.4) to execute the following

program:

RetCode = _ECAT_Slave_Motion_Sd_Stop(gESCCardNo, gNodeID, gSlotID, Tdec);

/* Interrupt homing process. */

(7) Exit program

Press the Exit key to exit and close the program.

Execute “_ECAT_Master_Reset” and “_ECAT_Master_Close” to exit the function. Detailed

description about these two API is presented in section 3.1.2 Exit program.

Page 30

EtherCAT Programming Guide EtherCAT Operation Example

March, 2017 3-9

3

3.3 Torque control

3.3.1 Function list

Function name

_ECAT_Slave_PT_Start_Move

_ECAT_Slave_Motion_Emg_Stop

Properties

Hardware EtherCAT RTX (PAC) EtherCAT motion card

Supported

Y Y

3.3.2 Application examples

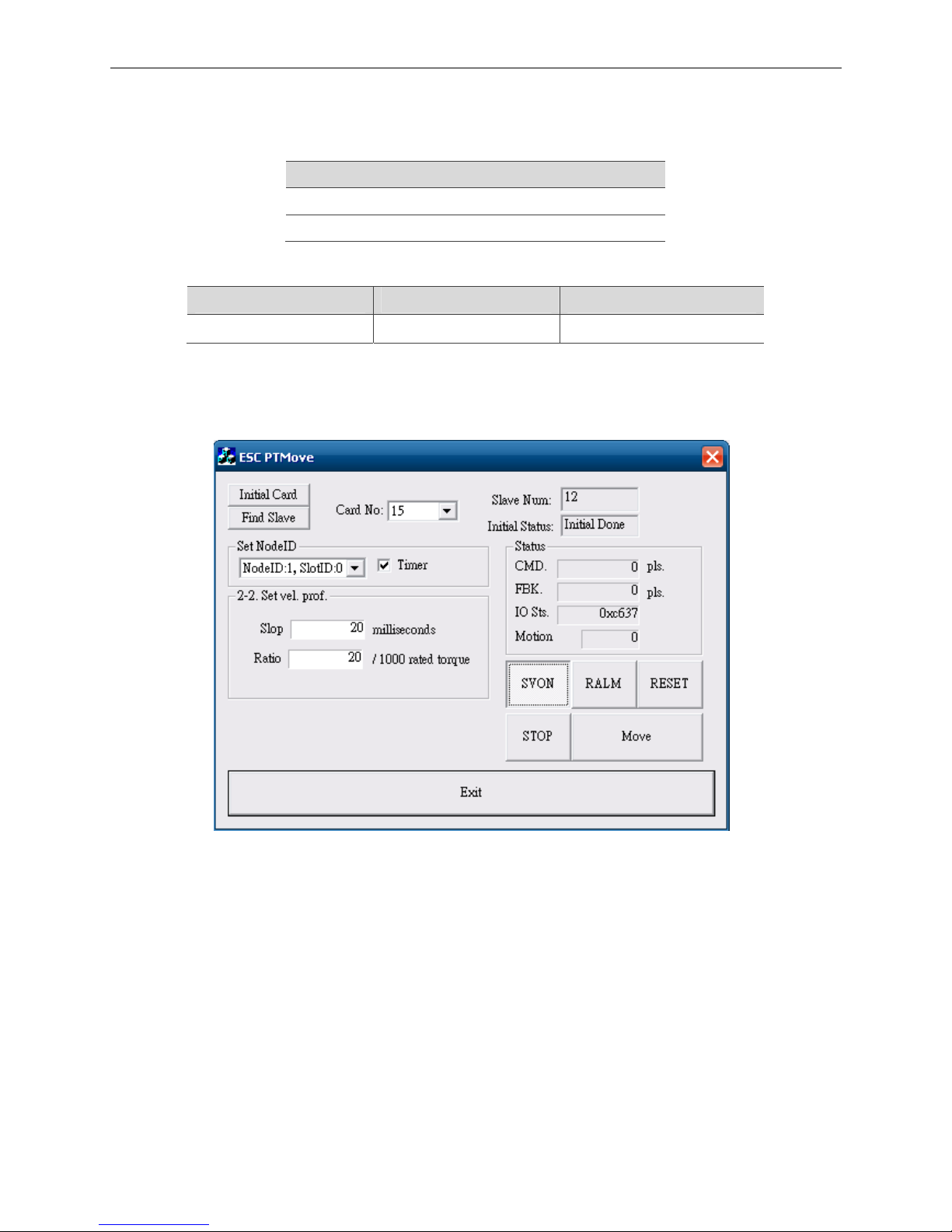

Program interface

Figure 3.3.2.1

(1) Activate and initialize interface card

Press the Initial Card key (as shown in figure 3.3.2.1) to start initializing the interface card.

Press the Find Slave key (as shown in figure 3.3.2.1) to start searching the connecting

modules.

For more information about the interface card initialization, please see “Activate interface

card” and “Initialize interface card” in section 3.1.2.

Page 31

EtherCAT Operation Example EtherCAT Programming Guide

3-10 March, 2017

3

(2) Set Node ID and Slot ID for the servo drive and enable motion status display

Figure 3.3.2.2

Select Node ID and Slot ID and check the Timer box to display the motion status.

Set NodeID: Specify the Node ID to be executed. The parameters “AxisNo.” and “SlotNo”

in the API function.

Timer: Check the Timer box to display the current motion status.

(3) Enter the Slop and Ratio values

Figure 3.3.2.3

Slop: Input the required time for the rated torque. (unit: ms)

Ratio: Input the permillage of the rated torque value. For example, if the ratio value is 20,

the rated torque will be 2%.

(4) Set the servo motor to ON/OFF state (servo on/servo off)

Figure 3.3.2.4

Press the SVON key (as shown in figure 3.3.2.4) to execute the following program:

RetCode = _ECAT_Slave_Motion_Set_Svon(gESCCardNo, gNodeID, gSlotID, ON_OFF);

// ON_OFF:

// 0: Servo OFF.

// 1: Servo ON.

(5) Torque control

Press the Move key (as shown in figure 3.3.2.4) to execute the following program:

RetCode = _ECAT_Slave_PT_Start_Move(gESCCardNo, gNodeID, gSlotID, Torque,

Slope);

/* Set torque parameters and enable torque control. */

// The motor will run in forward direction if the torque value is greater than 0, and run in

reverse direction if the value is smaller than 0.

Page 32

EtherCAT Programming Guide EtherCAT Operation Example

March, 2017 3-11

3

Press the STOP key (as shown in figure 3.3.2.4) to execute the following program:

RetCode = _ECAT_Slave_Motion_Emg_Stop(gESCCardNo, gNodeID, gSlotID);

/* Stop torque control of the motor. */

(6) Status display

Figure 3.3.2.5

Command values of the motion:

RetCode = _ECAT_Slave_Motion_Get_Command(gESCCardNo, gNodeID, gSlotID,

&Cmd);

// Get the command value (CMD. field).

RetCode = _ECAT_Slave_Motion_Get_Position(gESCCardNo, gNodeID, gSlotID, &Pos);

// Get the feedback value of the command (FBK. field).

Motion status:

RetCode = _ECAT_Slave_Motion_Get_StatusWord(gESCCardNo, gNodeID, gSlotID,

&Status);

// Get the current motion status (IO Sts. field).

RetCode = _ECAT_Slave_Motion_Get_Mdone(gESCCardNo, gNodeID, gSlotID,

&MCDone);

// Get the current status of the motor (Motion field).

(7) Reset feedback and clear alarm

Press the RESET key (as shown in figure 3.3.2.4) to execute the following program:

RetCode = _ECAT_Slave_Motion_Set_Position(gESCCardNo, gNodeID, gSlotID, 0);

// Clear feedback first (Value showed in servo drive panel will be set to 0).

RetCode = _ECAT_Slave_Motion_Set_Command(gESCCardNo,gNodeID,gSlotID,0);

// Then, clear the command.

Press the RALM key (as shown in figure 3.3.2.4) to execute the alarm clearing command:

RetCode = _ECAT_Slave_Motion_Ralm(gESCCardNo, gNodeID, gSlotID);

// Clear the alarm of slave station.

(8) Exit program

Press the Exit key to exit and close the program.

Execute “_ECAT_Master_Reset” and “_ECAT_Master_Close” to exit the function. Detailed

description about these two API is presented in section 3.1.2 Exit program.

Page 33

EtherCAT Operation Example EtherCAT Programming Guide

3-12 March, 2017

3

3.4 Constant speed control

3.4.1 Function list

Function name

_ECAT_Slave_PV_Start_Move

_ECAT_Slave_Motion_Sd_Stop

Properties

Hardware EtherCAT RTX (PAC) EtherCAT motion card

Supported

Y Y

3.4.2 Application examples

Program interface

Figure 3.4.2.1

(1) Activate and initialize interface card

Press the Initial Card key (as shown in figure 3.4.2.1) to start initializing the interface card.

Press the Find Slave key (as shown in figure 3.4.2.1) to start searching the connecting

modules.

For more information about the interface card initialization, please see “Activate interface

card” and “Initialize interface card” in section 3.1.2.

Page 34

EtherCAT Programming Guide EtherCAT Operation Example

March, 2017 3-13

3

(2) Set Node ID and Slot ID for the servo drive and enable motion status display

Figure 3.4.2.2

Select Node ID and Slot ID and check the Timer box to display the motion status.

Set NodeID: Specify the Node ID to be executed. The parameters “AxisNo.” and “SlotNo”

in the API function.

Timer: Check the Timer box to display the current motion status.

(3) Enter the acceleration/deceleration time and rotation speed per minute (rpm).

Figure 3.4.2.3

Velocit y: Input the target speed. The parameter “RPM” in the API function. *The actual

rpm value is 0.1 time of the variable Velocity.

Acc: Input the duration from current speed to target speed. The parameter “Tacc” in the

API function.

Dec: Input the duration to decelerate from current speed to 0. The parameter “Tdec” in the

API function.

(4) Set the servo motor to ON/OFF state (servo on/servo off)

Figure 3.4.2.4

Press the SVON key (as shown in figure 3.4.2.4) to execute the following program:

RetCode = _ECAT_Slave_Motion_Set_Svon(gESCCardNo, gNodeID, gSlotID, ON_OFF);

// ON_OFF:

// 0: Servo OFF.

// 1: Servo ON.

Page 35

EtherCAT Operation Example EtherCAT Programming Guide

3-14 March, 2017

3

(5) Speed control

Press the ← or → key (as shown in figure 3.4.2.4) to execute the following program:

RetCode = _ECAT_Slave_PV_Start_Move(gESCCardNo, gNodeID, gSlotID, Velocity,

Tacc, Tdec);

/* Set the parameters of speed mode (the acceleration and deceleration time) and enable

speed control. */

// The servo motor will run in forward direction if the rpm value is greater than 0, and will

run in reverse direction when the rpm value is smaller than 0.

Press the STOP key (as shown in figure 3.4.2.4) to execute the following program:

RetCode = _ECAT_Slave_Motion_Emg_Stop(gESCCardNo, gNodeID, gSlotID);

(6) Status display

Figure 3.4.2.5

Command values of the motion:

RetCode = _ECAT_Slave_Motion_Get_Command(gESCCardNo, gNodeID, gSlotID,

&Cmd);

// Get the command value (CMD. field).

RetCode = _ECAT_Slave_Motion_Get_Position(gESCCardNo, gNodeID, gSlotID, &Pos);

// Get the feedback value of the command (FBK. field).

Motion status:

RetCode = _ECAT_Slave_Motion_Get_Current_Speed(gESCCardNo,gNodeID, gSlotID,

&Spd);

// Get the current moving speed (SPD. field).

RetCode = _ECAT_Slave_Motion_Get_StatusWord(gESCCardNo, gNodeID, gSlotID,

&Status);

// Get the current status (IO Sts. field).

RetCode = _ECAT_Slave_Motion_Get_Mdone(gESCCardNo, gNodeID, gSlotID,

&MCDone);

// Get the current status of the motor. (Motion field)

Page 36

EtherCAT Programming Guide EtherCAT Operation Example

March, 2017 3-15

3

(7) Reset the feedback value and clear the alarm

Press the RESET key (as shown in figure 3.4.2.4) to execute the following program:

RetCode = _ECAT_Slave_Motion_Set_Position(gESCCardNo, gNodeID, gSlotID, 0);

// Clear feedback first (Value showed in servo drive panel will be set to 0).

RetCode = _ECAT_Slave_Motion_Set_Command(gESCCardNo,gNodeID,gSlotID,0);

// Then clear the command.

Press the RALM key (as shown in figure 3.4.2.4) to execute the alarm clearing command:

RetCode = _ECAT_Slave_Motion_Ralm(gESCCardNo, gNodeID, gSlotID);

// Clear the alarm of slave station.

(8) Exit program

Press the Exit key to exit and close the program.

Execute “_ECAT_Master_Reset” and “_ECAT_Master_Close” to exit the function. Detailed

description about these two API is presented in section 3.1.2 Exit program.

Page 37

EtherCAT Operation Example EtherCAT Programming Guide

3-16 March, 2017

3

3.5 Motion control in PP mode

3.5.1 Function list

Function name

_ECAT_Slave_PP_Start_Move

_ECAT_Slave_Motion_Sd_Stop

Properties

Hardware EtherCAT RTX (PAC) EtherCAT motion card

Supported

Y Y

3.5.2 Application examples

Program interface

Figure 3.5.2.1

(1) Activate and initialize interface card

Press the Initial Card key (as shown in figure 3.5.2.1) to start initializing the interface card.

Press the Find Slave key (as shown in figure 3.5.2.1) to start searching the connecting

modules.

For more information about the interface card initialization, please see “Activate interface

card” and “Initialize interface card” in section 3.1.2.

Page 38

EtherCAT Programming Guide EtherCAT Operation Example

March, 2017 3-17

3

(2) Set Node ID and Slot ID for the servo drive and enable motion status display

Figure 3.5.2.2

Select Node ID and Slot ID and check the Timer box to display the motion status.

Set NodeID: Specify the node ID to be executed. The parameters “AxisNo.” and “SlotNo”

in the API function.

Timer: Check the Timer box to display the current motion status.

(3) Enter the parameter for motion control

Figure 3.5.2.3

Dist.: Input the moving distance. The parameter “Dist” in the API function.

StrVel.: Input the initial speed. The parameter “StrVel” in the API function.

*The servo drive accelerates to the initial speed set in StrVel at its max. speed. Then, it

accelerates to the constant speed set in MaxVel with the acceleration time set in Acc.

MaxVel.: Input the constant speed. The parameter “MaxVel” in the API function.

Acc.: Input the duration from initial speed to constant speed. The parameter “Tacc” in the

API function.

Dec.: Input the duration to decelerate from the constant speed to 0. The parameter “Tdec”

in the API function.

ABS.: Check this box to have the motion conducted according to the absolute coordinates

set in Dist.

Page 39

EtherCAT Operation Example EtherCAT Programming Guide

3-18 March, 2017

3

(4) Set the servo motor to ON/OFF state (servo on/servo off)

Figure 3.5.2.4

Press the SVON key (as shown in figure 3.5.2.4) to execute the following program:

RetCode = _ECAT_Slave_Motion_Set_Svon(gESCCardNo, gNodeID, gSlotID, ON_OFF);

// ON_OFF:

// 0: Servo OFF

// 1: Servo ON

(5) Start to control the motion speed

Press the ← or → key (as shown in figure 3.5.2.4) to execute the following program:

RetCode = _ECAT_Slave_PP_Start_Move(gESCCardNo, gNodeID, gSlotID, Dist, StrVel,

MaxVel, Tacc, Tdec, gbIsABS);

// gblsABS

// 0: relative movement

// 1: absolute movement

(6) Stop the motion

Press the STOP key (as shown in figure 3.5.2.4) to enable emergency stop:

RetCode = _ECAT_Slave_Motion_Emg_Stop(gESCCardNo, gNodeID, gSlotID);

In this example, the movement is stopped urgently by setting the deceleration time to 0.

(7) Status display

Figure 3.5.2.5

Command values of the motion:

RetCode = _ECAT_Slave_Motion_Get_Command(gESCCardNo, gNodeID, gSlotID,

&Cmd);

// Get the command value (CMD. field).

RetCode = _ECAT_Slave_Motion_Get_Position(gESCCardNo, gNodeID, gSlotID, &Pos);

// Get the feedback value of the command (FBK. field).

Page 40

EtherCAT Programming Guide EtherCAT Operation Example

March, 2017 3-19

3

Motion status:

RetCode = _ECAT_Slave_Motion_Get_StatusWord(gESCCardNo, gNodeID, gSlotID,

&Status);

// Get the current status (IO Sts. field).

RetCode = _ECAT_Slave_Motion_Get_Mdone(gESCCardNo, gNodeID, gSlotID,

&MCDone);

// Get the current status of the motor (Motion field).

(8) Reset the feedback value and clear the alarm

Press the RESET key (as shown in figure 3.5.2.4) to execute the following program:

RetCode = _ECAT_Slave_Motion_Set_Position(gESCCardNo, gNodeID, gSlotID, 0);

// Clear feedback first (Value showed in servo drive panel will be set to 0).

RetCode = _ECAT_Slave_Motion_Set_Command(gESCCardNo, gNodeID, gSlotID, 0);

// Then, clear the command.

Press the RALM key (as shown in figure 3.5.2.4) to execute the alarm clearing command:

RetCode = _ECAT_Slave_Motion_Ralm(gESCCardNo, gNodeID, gSlotID);

// Clear the alarm of slave station

(9) Exit program

Press the Exit key to exit and close the program.

Execute “_ECAT_Master_Reset” and “_ECAT_Master_Close” to exit the function. Detailed

description about these two API is presented in section 3.1.2 Exit program.

Page 41

EtherCAT Operation Example EtherCAT Programming Guide

3-20 March, 2017

3

3.6 Motion control in CSP mode

3.6.1 Function list

Function name

_ECAT_Slave_Motion_Set_Svon

_ECAT_Slave_CSP_Start_Move

_ECAT_Slave_CSP_Start_V_Move

_ECAT_Slave_CSP_Start_Multiaxes_Move

_ECAT_Slave_CSP_Start_Arc_Move

_ECAT_Slave_CSP_Start_Arc2_Move

_ECAT_Slave_CSP_Start_Arc3_Move

_ECAT_Slave_CSP_Start_Spiral_Move

_ECAT_Slave_CSP_Start_Spiral2_Move

_ECAT_Slave_CSP_Start_Heli_Move

_ECAT_Slave_CSP_Start_Sphere_Move

_ECAT_Slave_Motion_Sd_Stop

_ECAT_Slave_Motion_Set_Position

_ECAT_Slave_Motion_Set_Command

_ECAT_Slave_Motion_Ralm

_ECAT_Slave_Motion_Get_Command

_ECAT_Slave_Motion_Get_Position

_ECAT_Slave_Motion_Get_Current_Speed

_ECAT_Slave_Motion_Get_StatusWord

_ECAT_Slave_Motion_Get_Mdone

_ECAT_Master_Check_Initial_Done

Properties

Hardware EtherCAT RTX (PAC) EtherCAT motion card

Supported

Y Y

Page 42

EtherCAT Programming Guide EtherCAT Operation Example

March, 2017 3-21

3

3.6.2 Application examples

Program interface

Figure 3.6.2.1

(1) Activate and initialize interface card

Press the Initial Card key (as shown in figure 3.6.2.1) to start initializing the interface card.

Press the Find Slave key (as shown in figure 3.6.2.1) to start searching the connecting

modules.

For more information about the interface card initialization, please see “Activate interface

card” and “Initialize interface card” in section 3.1.2.

(2) Select Node ID and Slot ID for the servo drive and enable motion status display

Figure 3.6.2.2

Select Node ID and Slot ID and check the Timer box to display the motion status.

Set NodeID: Specify the Node ID to be executed. The parameters “AxisNo.” and “SlotNo”

in the API function.

Timer: Check the Timer box to display the current motion status.

Page 43

EtherCAT Operation Example EtherCAT Programming Guide

3-22 March, 2017

3

(3) Select the moving mode

Figure 3.6.2.2

Single-axis motion control:

P To P: Point to point movement

Continue: Linear movement

Two-axis motion control:

Line2: Linear interpolation control

Arc: Type 1 arc interpolation control (with the known circle center and angle)

Arc2: Type 2 arc interpolation control (with the known end point and angle)

Arc3: Type 3 arc interpolation control (with the known circle center and end point)

Spiral: Type 1 spiral interpolation control (with the known circle center and angle)

Spiral2: Type 2 spiral interpolation control (with the known end point and circle

number)

Three-axis motion control:

Helix: Helical interpolation control

Line3: Linear interpolation control

Sphere: Three-axis sphere motion control

Page 44

EtherCAT Programming Guide EtherCAT Operation Example

March, 2017 3-23

3

(4) The parameter of single-axis motion control

Figure 3.6.2.3

Dist.: Input the moving distance. The parameter “Dist” in the API function.

StrVel.: Input the initial speed. The parameter “StrVel” in the API function.

ConstVel: Input the constant speed. The parameter “ConstVel” in the API function.

EndVel: Input the end speed when it reaches the target position. The parameter “EndVel”

in the API function.

TPhase1: Input the duration from initial speed to constant speed. The parameter

“TPhase1” in the API function.

TPhase2: Input the duration from constant speed to end speed. The parameter “TPhase2”

in the API function.

S-Curve: Check this box to use S-Curve for the speed curve. Otherwise, it will use

T-Curve.

ABS.: Check this box to have the motion conducted according to absolute coordinates set

in Dist.

(5) Set the servo motor to ON/OFF state (servo on/servo off)

Figure 3.6.2.4

Page 45

EtherCAT Operation Example EtherCAT Programming Guide

3-24 March, 2017

3

Press the SVON key (as shown in figure 3.6.2.4) to execute the following program:

RetCode = _ECAT_Slave_Motion_Set_Svon(gESCCardNo, gNodeID[i], gSlotID[i],

ON_OFF);

// ON_OFF:

// 0: Servo OFF

//1: Servo ON

(6) Select P To P and start the point to point motion control

Press the ← or → key (as shown in figure 3.6.2.4) to execute the following program:

RetCode = _ECAT_Slave_CSP_Start_Move(gESCCardNo, gNodeID[0], gSlotID[0],

Dist[0], StrVel, ConstVel, EndVel, Tacc, Tdec, gbIsSCurve, gbIsABS);

// gblsSCurve

// 1: T-Curve

// 2: S-Curve

// gblsABS

// 0: Relative movement

// 1: Absolute movement

(7) Change the position or speed in P To P mode

Figure 3.6.2.5

Press the ← or → key (as shown in figure 3.6.2.4) to select P To P motion control. To

replace the current position with a new position, press the Change key in Position Change

section (as shown in figure 3.6.2.5) to execute the following program:

RetCode = _ECAT_Slave_CSP_TargetPos_Change(gESCCardNo, gNodeID[0],

gSlotID[0], NewPos);

// Replace the current position with a new position.

To replace the current speed with a new speed, press the Change key in Velocity Change

section (as shown in figure 3.6.2.5) to execute the following program:

RetCode = _ECAT_Slave_CSP_Velocity_Change(gESCCardNo, gNodeID[0], gSlotID[0],

NewSpd, NewTdec);

// Replace the current speed with a new speed.

Page 46

EtherCAT Programming Guide EtherCAT Operation Example

March, 2017 3-25

3

(8) Set the Gear or software limit in P To P mode

Figure 3.6.2.6

Press the ← or → key (as shown in figure 3.6.2.4) to select P To P motion control. To set

the Gear values, press the Set key in the Set Gear section (as shown in figure 3.6.2.6) to

execute the following program:

RetCode = _ECAT_Slave_CSP_Set_Gear(gESCCardNo, gNodeID[0], gSlotID[0],

Numerator, Denominator, Enable);

// Set new gear values.

To set the software limit, press the Set key in the Set Soft Limit section (as shown in figure

3.6.2.6) to execute the following program:

RetCode = _ECAT_Slave_CSP_Set_Softlimit(gESCCardNo, gNodeID[0], gSlotID[0],

MLimit, PLimit, Enable);

// Set software limit values.

(9) Set the value for Feedrate Overwrite in P To P mode.

Figure 3.6.2.7

Press the ← or → key (as shown in figure 3.6.2.4) to execute P To P motion control.

To set the value of Feedrate Overwrite, drag the scrollbar (as shown in figure 3.6.2.7)

to execute the following program:

RetCode = _ECAT_Slave_CSP_Feedrate_Overwrite(gESCCardNo, gNodeID[0],

gSlotID[0], 2, NewSpd, 0.1);

// Mode=2; Users can change the speed and the speed (vector) of all motion commands

whether the command is being executed.

// Speed ratio

Page 47

EtherCAT Operation Example EtherCAT Programming Guide

3-26 March, 2017

3

(10) Select Continue for motion control with constant speed

Press the ← or → key (as shown in figure 3.6.2.4) to execute the following program:

RetCode = _ECAT_Slave_CSP_Start_V_Move(gESCCardNo, gNodeID[0], gSlotID[0], 0,

StrVel, MaxVel, Tacc, gbIsSCurve);

// gblsSCurve

// 1: T-Curve

// 2: S-Curve

(11) Two-axis motion mode (Line2, Spiral, Spiral2) and its settings

Figure 3.6.2.8

Line2 parameter settings: Two-axis linear interpolation

Dist1: Input the moving distance of axis X. The parameter “DistX” in the API function.

Dist2: Input the moving distance of axis Y. The parameter “DistY” in the API function.

StrVel.: Input the initial speed. The parameter “StrVel” in the API function.

ConstVel: Input the constant speed. The parameter “ConstVel” in the API function.

EndVel: Input the end speed when it reaches the target position. The parameter “EndVel”

in the API function.

TPhase1: Input the duration from initial speed to constant speed. The parameter

“TPhase1” in the API function.

TPhase2: Input the duration from constant speed to end speed. The parameter “TPhase2”

in the API function.

S-Curve: Check this box to use S-Curve for the speed curve. Otherwise, it will use

T-Curve.

ABS.: Check this box to have the motion conducted according to absolute coordinates set

in Dist.

Page 48

EtherCAT Programming Guide EtherCAT Operation Example

March, 2017 3-27

3

Spiral parameter settings: Type 1 of spiral interpolation (with the known circle center and

angle)

CenX: Input the X-coordinate of the circle center. The parameter “CenterPoint” in the API

function.

CenY: Input the Y-coordinate of the circle center. The parameter “CenterPoint” in the API

function.

Inter: Input the relative distance between the known spiral pitches. The parameter

“Spiral_Interval” in the API function.

Angle: Input the angle of the spiral movement. The parameter “Angle” in the API function.

StrVel.: Input the initial speed. The parameter “StrVel” in the API function.

ConstVel: Input the constant speed. The parameter “ConstVel” in the API function.

EndVel: Input the end speed when it reaches the target position. The parameter “EndVel”

in the API function.

TPhase1: Input the duration from initial speed to constant speed. The parameter

“TPhase1” in the API function.

TPhase2: Input the duration from constant speed to end speed. The parameter “TPhase2”

in the API function.

S-Curve: Check this box to use S-curve for the speed curve. Otherwise, it will use

T-Curve.

ABS.: Check this box to have the motion conducted according to absolute coordinates set

in Dist.

Spiral2 parameter settings: Type 2 of spiral interpolation (with the know end point and

circle number)

CenX: Input the X-coordinate of the circle center. The parameter “CenterPoint” in the API

function.

CenY: Input the Y-coordinate of the circle center. The parameter “CenterPoint” in the API

function.

EndX: Input the target position of X-coordinate. The parameter “EndPoint” in the API

function.

EndY: Input the target position of Y-coordinate. The parameter “EndPoint” in the API

function.

Num: Input the circle number of the spiral movement. The parameter “CycleNum” in the

API function.

Dir: Input the moving direction (0: Clockwise, 1: Anticlockwise). The parameter “Dir” in the

API function.

StrVel.: Input the initial speed. The parameter “StrVel” in the API function.

ConstVel: Input the constant speed. The parameter “ConstVel” in the API function.

EndVel: Input the end speed when it reaches the target position. The parameter “EndVel”

in the API function.

Page 49

EtherCAT Operation Example EtherCAT Programming Guide

3-28 March, 2017

3

TPhase1: Input the duration from initial speed to constant speed. The parameter

“TPhase1” in the API function.

TPhase2: Input the duration from constant speed to end speed. The parameter “TPhase2”

in the API function.

S-Curve: Check this box to use S-curve for the speed curve. Otherwise, it will use

T-Curve.

ABS.: Check this box to have the motion conducted according to absolute coordinates set

in Dist.

(12) Set the servo motor to ON/OFF state (servo on/servo off)

Press the SVON key (as shown in figure 3.6.2.4) to execute the following program:

RetCode = _ECAT_Slave_Motion_Set_Svon(gESCCardNo, gNodeID[i], gSlotID[i],

ON_OFF);

// ON_OFF:

// 0: Servo OFF

// 1: Servo ON

(13) Select Line2 for two-axis linear motion control

Press the ← or → key (as shown in figure 3.6.2.4) to execute the following program:

RetCode = _ECAT_Slave_CSP_Start_Multiaxes_Move(gESCCardNo, 2, gNodeID,

gSlotID, Dist, StrVel, MaxVel, EndVel, Tacc, Tdec, gbIsSCurve, gbIsABS);

// gblsSCurve

// 1: T-Curve

// 2: S-Curve

// gblsABS

// 0: Relative movement

// 1: Absolute movement

(14) Select Spiral for two-axis arc motion control (center point and angle)

Press the ← or → key (as shown in figure 3.6.2.4) to execute the following program:

RetCode = _ECAT_Slave_CSP_Start_Spiral_Move(gESCCardNo,gNodeID, gSlotID,