Page 1

DELTA WATER ENGINEERING

V05/2009/P1

IINNSSTTAALLLLAATTIIOONN GGUUIIDDEE

EESSCCAALLDDAA

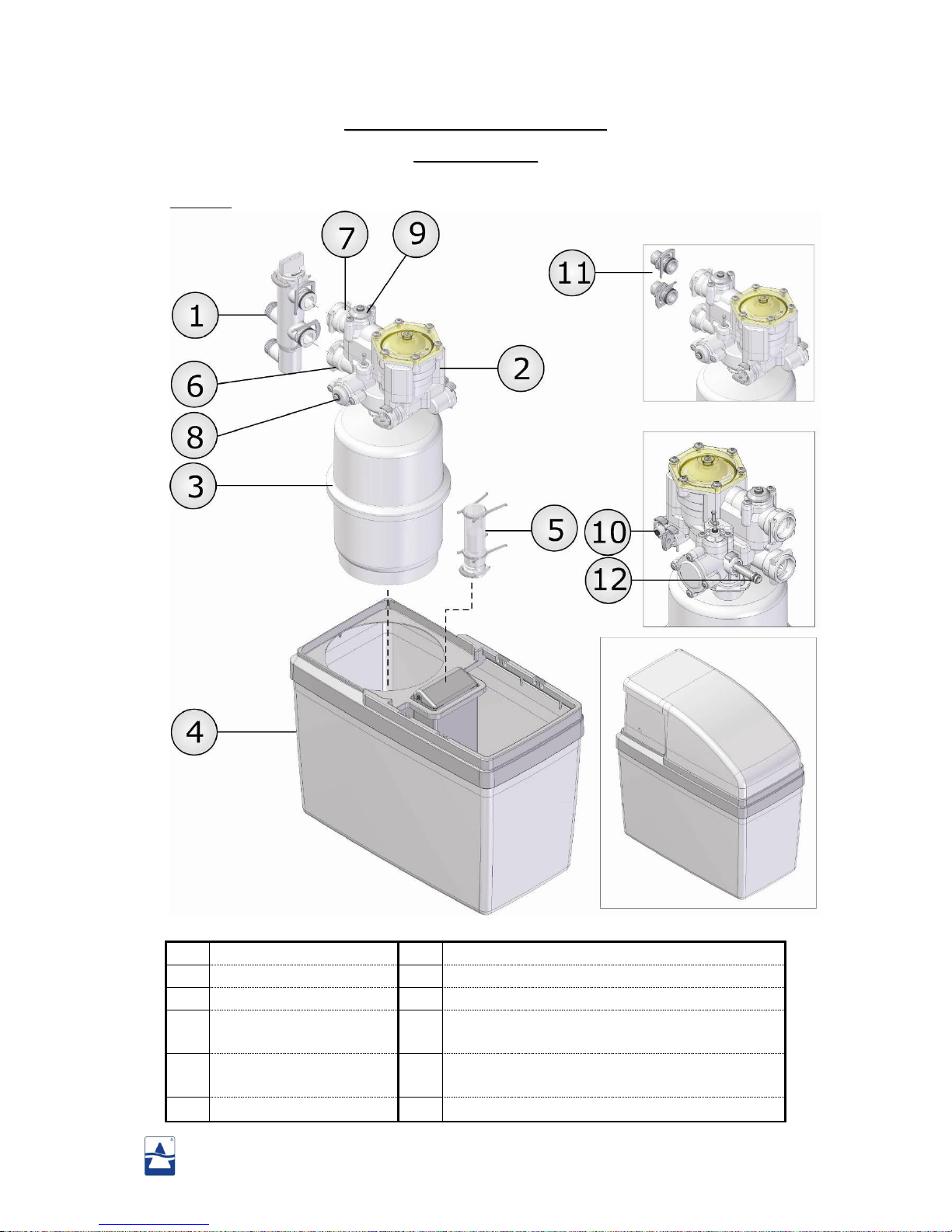

1. Parts:

1.

BYPASS

7.

WATER OUTLET

2.

VALVE HOUSING

8.

BLENDING REGULATOR

3.

RESIN TANK

9.

HARDNESS REGULATOR

4.

CONTAINER FOR

DEVICE AND SALT

10.

TO BRINE VALVE

5.

BRINE VALVE

(floater)

11.

CONNECTIONS (1/2", 3/4”, 1")

6.

WATER INLET

12.

TO DRAIN

Page 2

DELTA WATER ENGINEERING

V05/2009/P2

2. Precautions:

Make sure you have all necessary tools on hand before you begin

with the installation.

Follow all local legal regulations.

Read this manual carefully. If you have any questions or

remarks, please contact your Delta supplier.

Check incoming pressure: minimum 1 bar (dynamic), maximum 8

bar (static) (15 PSI- 116 PSI). If necessary reduce incoming

pressure.

Do not install the Delta Softener close to a heating source

(environment temperature must be below 50°C).

Protect softener and drain (12) against frost.

Make sure you have the latest installation manual at hand. Check

with your Delta supplier.

3. Installation:

3.1 Close main valve and make sure pressure is released from piping.

This can be done by opening at least one tap.

3.2 Cut open main water supply in order to install direct connections to

the Delta Softener or to install the Delta Bypass (recommended).

Follow the arrows on both Bypass and softener for water inlet and

outlet.

Pay attention that the inlet filter doesn’t fall out.

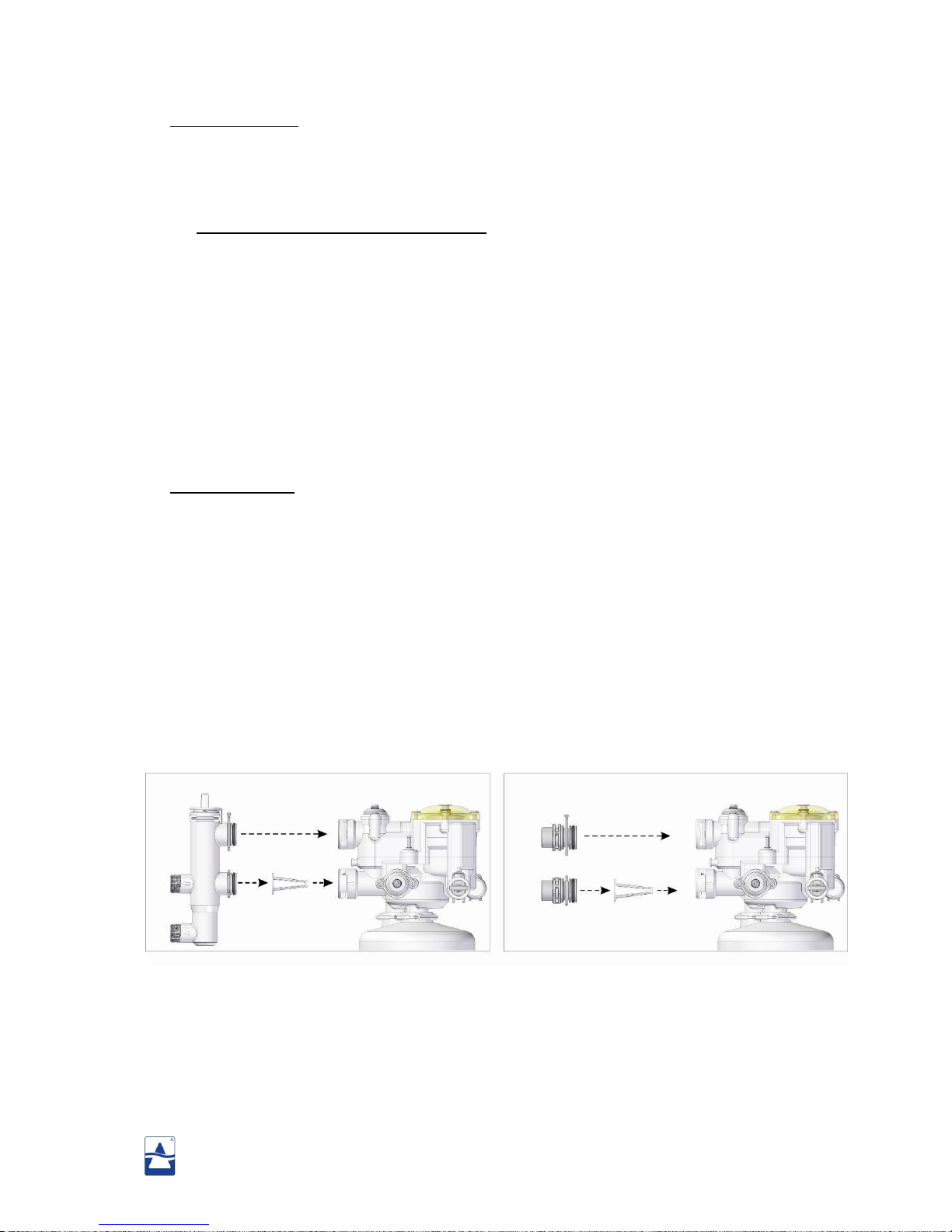

3.2.1

with Delta Bypass with direct connections

The Delta Bypass has a ¾” connection. The direct connections on

the water softener are available in ½”, ¾” and 1”.

Page 3

DELTA WATER ENGINEERING

V05/2009/P3

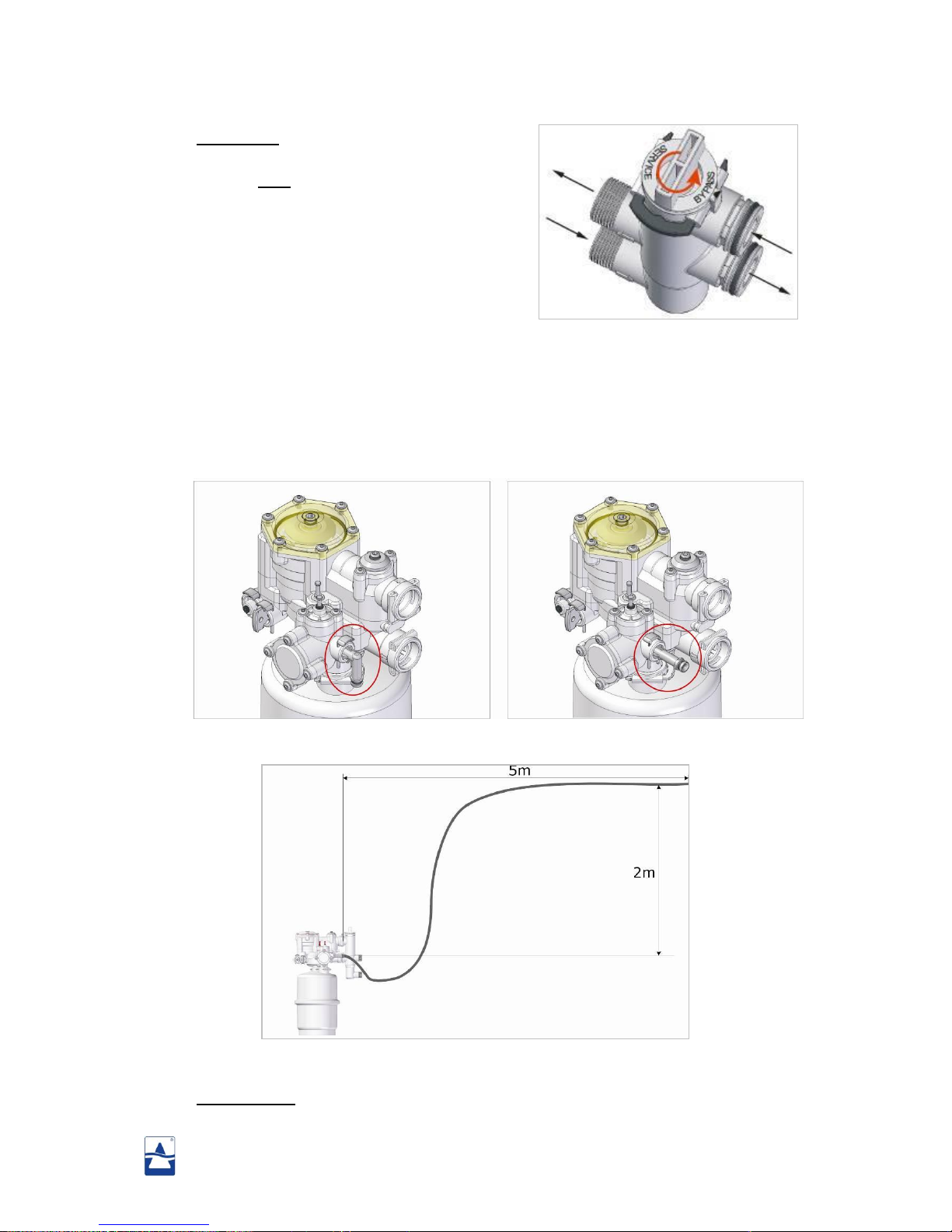

Caution: before installing the

softener, set the Bypass in “bypass”

mode, not in “service”.

3.2.2

Connect elbow or straight outlet (#12) to a local drain by means of

a 13mm flexible drain pipe as supplied by your local supplier. In

order to guarantee that the device will keep on functioning perfectly

in the future, this drain pipe should be spirally reinforced to avoid

later blocking and/or kinks. Please protect the drain against frost

and heat (min. temp. 5°C, max. temp. 50°C).

W

w

w

i

t

h

elbow outlet with straight outlet

maximum height and distance of flexible drain hose

CAUTION: For the installation of the flexible drain hose to the fixed

piping, please follow local legislation.

Page 4

DELTA WATER ENGINEERING

V05/2009/P4

3.2.3

Connect the brine valve (#5) to the softener by means of a Ø4mm

flexible tube. Insert the tube as far as possible (to stop) into the

quick-release couplings. Make sure not to squeeze the tube; avoid

kinks.

Make sure to install the supplied overflow tap. First, pierce a hole

(Ø21mm) in the side wall of the salt bin. The location of the hole is not

important, make sure however that it is approx. 10cm down from the top

edge of the salt bin. Once the hole has been drilled, mount the overflow

tap and secure it with the supplied nut. After drilling, remove all bits of

plastic that have fallen into the salt bin. A separate instruction leaflet with

detailed information has been added to the device.

Page 5

DELTA WATER ENGINEERING

V05/2009/P5

3.3 Place the softener in the salt

bin; use the side with the round

opening (for correct installation,

see 3.4). To install the brine

valve, open the cover by

pressing it gently at both sides.

Now put the brine valve in the

provided space, with the top

side up. Make sure that the

brine valve goes all the way

down to the bottom of the salt

bin. Make sure not to squeeze

the tube; avoid kinks.

Disconnect if necessary, and

reconnect correctly. Close the

cover.

3.4 The device can be installed in the container in three different ways:

at the back, to the left or to the right. The support at the bottom of

the container must be placed accordingly. Please refer to the figures

on the following page.

Page 6

DELTA WATER ENGINEERING

V05/2009/P6

3.4.1 Connections at the back:

The arrow on the support in the container must be pointing to the

back. Place the device in the container with the connections at the

back, as shown below.

3.4.2 Connections to the left:

As in 3.4.1.

Page 7

DELTA WATER ENGINEERING

V05/2009/P7

3.4.3 Connections to the right:

As in 3.4.1.

4. Settings:

4.1 Hardness regulator:

=part number 9 on the illustration on page 1

Measure the hardness of

incoming water by means of a

hardness test kit (not supplied

by Delta). Delta uses ppm

settings of CaCO3. (10 ppm

CaCO3 = 1°fh) (1°dh = 1,78°fh)

Adjust the hardness regulator to

the measured value. This

requires a hex key number 5.

4.2 Blending regulator:

= part number 8 on the illustration on page 1

With the blending regulator, you

can determine the outgoing

hardness. Depending on the

desired residual hardness, set

outgoing hardness with a hex key

number 5. The setting is

proportional, i.e. 1/10 – 1/5 –

1/… of total incoming hardness.

Page 8

DELTA WATER ENGINEERING

V05/2009/P8

5. Start up:

5.1. Leave Bypass in “bypass” mode, open main valve and flush for

several minutes in order to avoid impurities from entering the

softener. When you do not use a Bypass, open the main valve

slowly as described in 5.4.

5.2. Fill salt bin with salt in the

provided space. Use only specific

salt tablets that are suitable for

softeners.

5.3. Add water in the salt bin until the

water level is approx. 10cm (4”)

high. (the floater on the brine

valve must be afloat)

5.4. Turn the bypass slowly to “service” mode. Open the main valve

when you do not use a Bypass.

Page 9

DELTA WATER ENGINEERING

V05/2009/P9

5.5. Open a tap behind the softener so a flow runs through it. Some air

may flow from the tap; this comes from the softener. This will

happen only once; at start-up. Once only water flows from the tap,

and no more air, close the tap.

5.6. Perform a manual regeneration.

5.6.1.

Use a hex key number 5 to turn the program disk (PRG) manually.

T

u

r

n

P

R

G

c

o

u

n

ter clockwise until it is in above position. When the arrow and the

small line on the transparent cover reach the area marked by “B”

(brining), the regeneration will start. Immediately, the PRG will drop

down a little (you will be able to see and hear this). “R” stands for

refill (refilling the container with water at the end of the

regeneration stage). To make sure the softener is in regeneration,

there should be a small water flow to the drain, and the water level

in the container should drop.

5.6.2.

Let regeneration perform until it stops automatically. The estimated

time is approx. 12 minutes. When regeneration has stopped, no

more water flows to the drain. This is a clear indication that the

regeneration stage is over.

5.6.3.

Open a tap behind the softener for several minutes to allow residual

water to be flushed from the tubing.

5.6.4.

Check outgoing hardness with a “hardness test kit” (not supplied by

Delta). Adjust blending if necessary.

B

R

B

R

R

E

E

C

V

I

S

R

E

E

C

V

I

S

Page 10

DELTA WATER ENGINEERING

V05/2009/P10

5.7. Place both lids on the container. First the valve house cover; make

sure the connections fit in the large opening and the drain in the

small opening. Then place the front lid. For future salt refills, only

the front lid has to be removed.

Don’t forget to connect the overflow to the drain.

Page 11

DELTA WATER ENGINEERING

V05/2009/P11

REMARKS:

It is recommended that a water softener is installed by a professional. Although the

DELTA softener is probably the easiest and safest softener on the market, it is imperative

that all necessary precautions are taken and local legislation is followed.

This installation guide is written to help the professional installer keeping in mind that

this person has essential knowledge about hydraulic softeners and domestic plumbing.

Proper working of the softener will be determined by proper installation.

An annual control of your Delta softener will guarantee optimal functioning and a long

operating life.

The DELTA WATER ENGINEERING team is proud of its achievement in having

provided in what we believe to be the best softener available today.

Moreover, we are proud to have you as a customer. We will do our utmost to

deserve your trust.

DELTA WATER ENGINEERING

Waesdonckstraat 1

2640 Mortsel

Tel: +32(0)32195070

Fax: +32(0)32899320

BTW: BE 863.958.709

info@deltawatersystems.com

sales@deltawatersystems.com

Loading...

Loading...