Page 1

E5

Operation and Installation Manual

Hybrid Inverter

The power behind competitiveness

www.deltaww.com

Page 2

Page 3

09

09

09

09

10

10

10

12

13

14

18

18

20

20

20

21

23

24

25

26

28

28

29

29

30

32

32

33

34

34

35

35

36

36

37

38

39

Table of Contents

1 General Information

1.1 About this Manual

1.2 Product Description

1.3 Additional Information

2 Product Overview

2.1 Unpack the Inverter

2.2 Checking Unit and Accessories

2.3 Product Label

2.4 Exterior Objects

3 Installation

4 Wiring

4.1 Preparation Before Wiring

4.2 AC Connection

4.2.1 Required Protective Devices and Cable Cross-sections

4.2.2 AC Connection

4.2.3 AC Plug Assembly

4.2.4 AC Plug Shield Assembly

4.3 DC Connection (from PV Array)

4.4 Battery Connection

4.5 CAN Connection

4.6 Communication Module Connections

4.7 RS-485 Connection

4.8 Digital Input / DRM & EPO Functions

4.9 Dry Contact Connection

4.10 Multiple inverter combinations

5 Turning On the Hybrid Inverter

5.1 LCD Flow Chart

5.2 First startup

5.3 Home Page

5.3.1 Meter

5.3.2 Energy Log

5.3.3 Event Log

5.3.4 Inverter Information

5.3.5 General Settings

5.3.6 Operation Mode

5.3.6.1 Self-consumption mode

5.3.6.2 Peak cut mode

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

Page 4

5.3.6.3 Selling first mode

5.3.6.4 Charge first mode

5.3.6.5 Discharge first mode

5.3.6.6 Without battery mode

5.3.6.7 Special Modes

5.3.7 Function Setting

5.3.8 Install Settings

6 Maintenance

7 Error message and Trouble Shooting

8 De-Commissioning

9 Technical Data

40

41

43

44

45

47

48

50

51

55

56

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4

Page 5

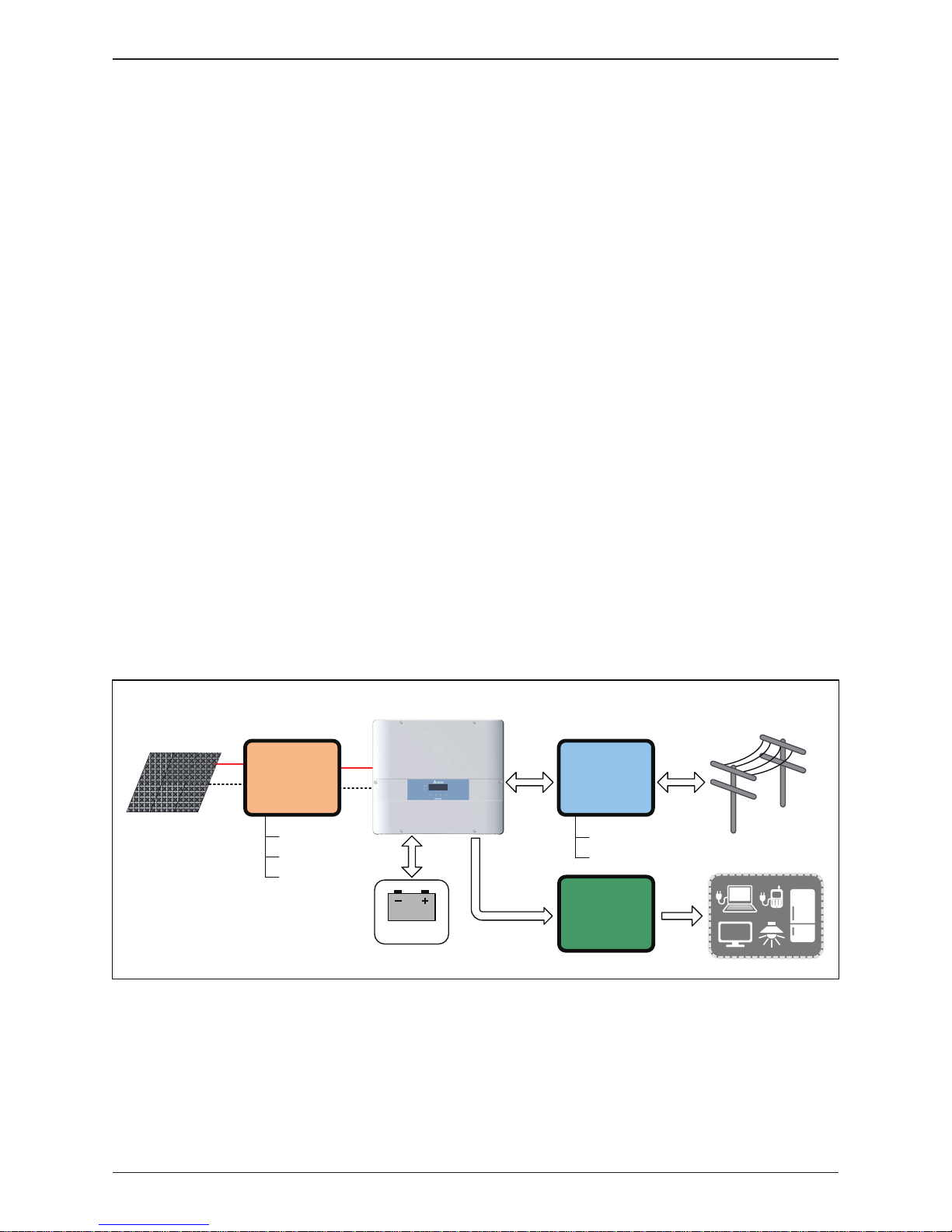

Figure 1-1 : Storage system operation illustration

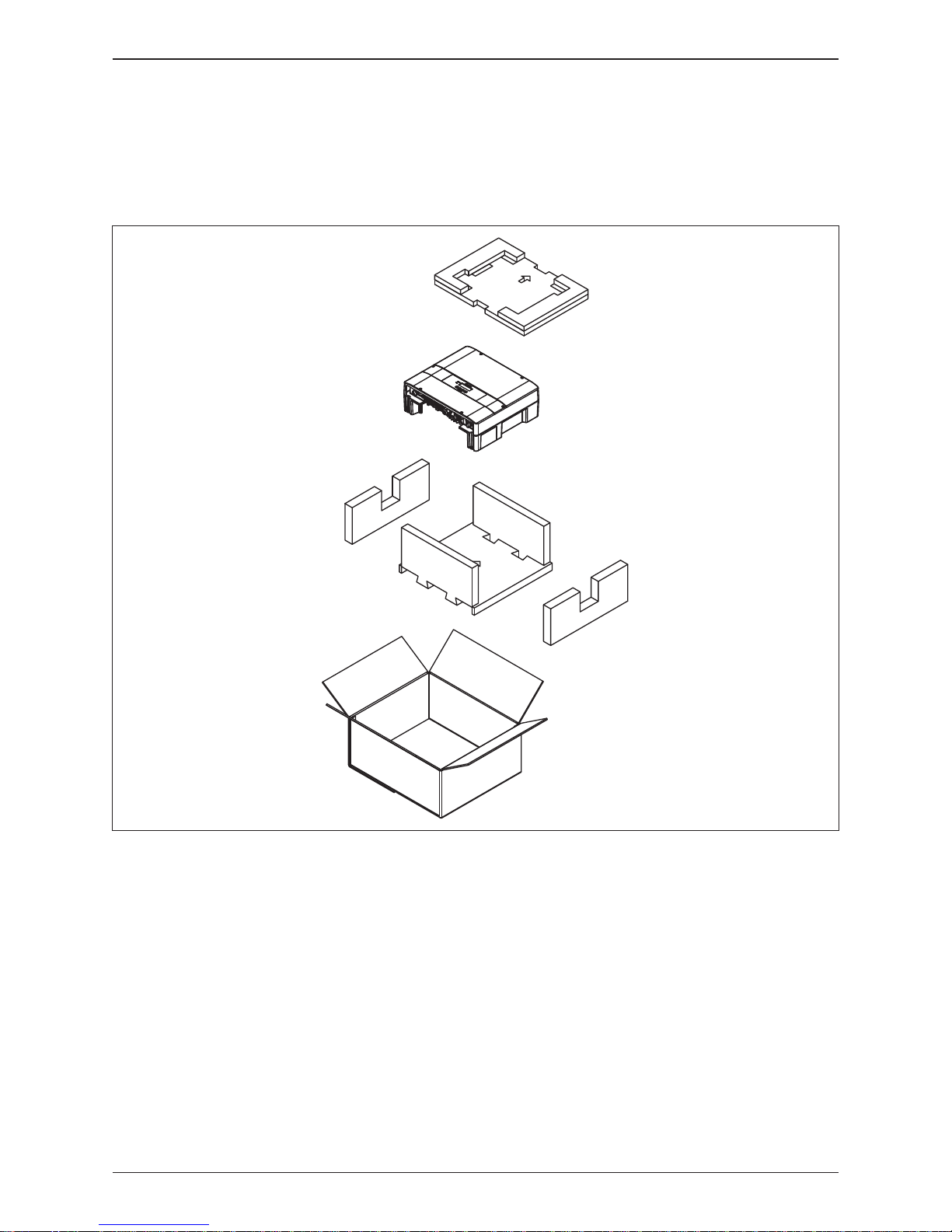

Figure 2-1 : Unpack the inverter

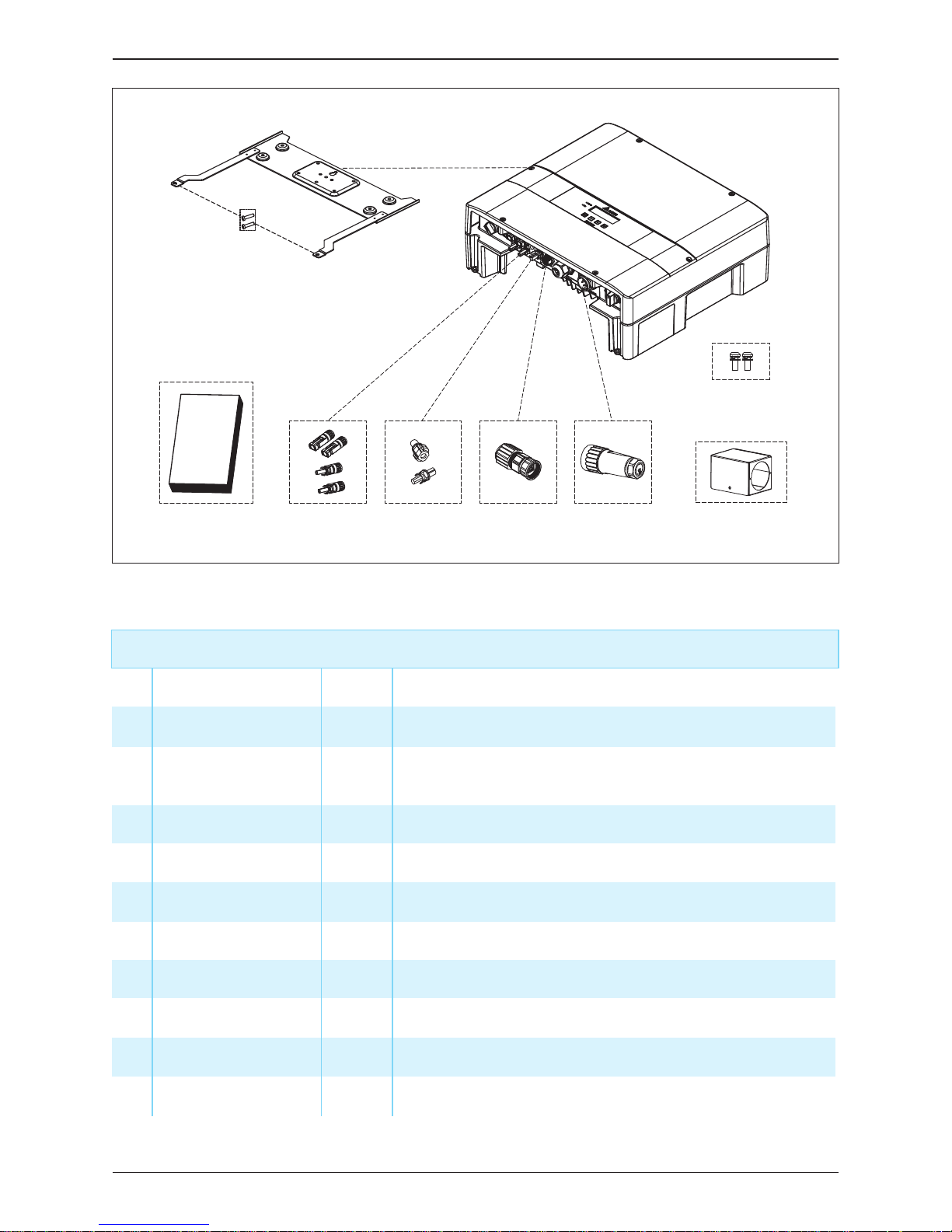

Figure 2-2 : Packing list

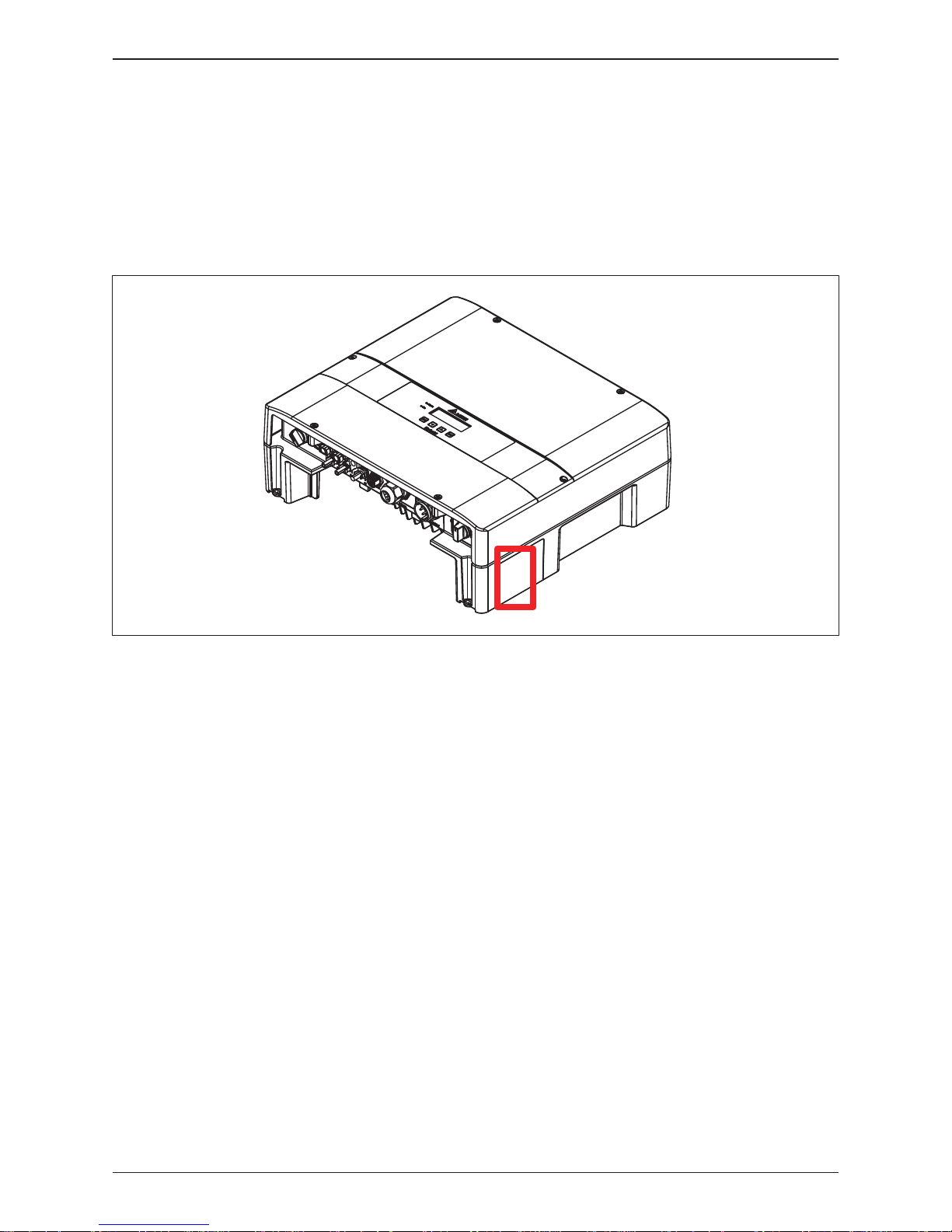

Figure 2-3 : Product label

Figure 2-4 : Inverter’s exterior objects

Figure 2-5 : Input / output interface

Figure 3-1 : Mounting bracket dimension

Figure 3-2 : Recommended installation

Figure 3-3 : Screw the mounting bracket

Figure 3-4 : Attach to the bracket and fasten with screws

Figure 3-5 : Proper installation gaps

Figure 4-1 : Connection of system for floating solar array and battery

Figure 4-2 : AC connection

Figure 4-3 : Terminal for wire crimping

Figure 4-4 : Striping the wires

Figure 4-5 : AC plug illustration for E5

Figure 4-6 : AC Plug Shield Assembly

Figure 4-7 : DC plug wiring illustration

Figure 4-8 : Assemble the Battery Connector

Figure 4-9 : Overview of RJ45 Connectors

Figure 4-10 : Assembling Procedure of RJ45 Connectors

Figure 4-11 : Suitable cables for RJ45 connector

Figure 4-12 : Communication module

Figure 4-13 : Single-phase parallel combinations

Figure 4-14 : Multiple inverters RS-485 connection

Figure 4-15 : EPO & Digital input & DRMs parallel connection

Figure 5-1 : Menu page

Figure 5-2 : User Interface

Figure 5-3 : Country and language settings for first startup

Figure 5-4 : Home page

Figure 5-5 : Power meter page

Figure 5-6 : Energy log flow chart

Figure 5-7 : Event log flow chart

Figure 5-8 : Inverter information page

Figure 5-9 : General settings page

Figure 5-10 : Operation mode page

Figure 5-11 : Self-consumption mode current flows

Figure 5-12 : Self-consumption mode behavior

Figure

09

10

11

12

13

13

15

15

16

16

17

19

20

21

21

22

23

24

25

26

26

27

28

30

30

31

32

32

33

34

34

35

35

36

36

37

38

38

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

5

Page 6

Figure 5-13 : Peak cut mode current flows

Figure 5-14 : Peak cut mode behavior

Figure 5-15 : Selling first mode current flows

Figure 5-16 : Selling first mode behavior

Figure 5-17 : Charge first mode current flows

Figure 5-18 : Charge first mode behavior

Figure 5-19 : Charge first mode behavior (for AU & NZ)

Figure 5-20 : Discharge first mode current flows

Figure 5-21 : Discharge first mode behavior

Figure 5-22 : Without battery mode current flows

Figure 5-23 : Without battery mode behavior

Figure 5-24 : Standalone mode current flows

Figure 5-25 : Standalone mode behavior

Figure 5-26 : Forced charge mode current flows

Figure 5-27 : Forced charge mode behavior

Figure 5-28 : Function Settings page

Figure 5-29 : Install Settings page

39

39

40

40

41

41

42

43

43

44

44

45

45

46

46

47

49

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

6

Page 7

Table

Table 2-1 : Packing list

Table 4-1 : AC input cable requirement

Table 4-2 : Maximum rating of input power

Table 4-3 : Cable size

Table 4-4 : Battery cable size

Table 4-5 : RJ45 socket pin assignment of CAN

Table 4-6 : Pin definition and data format of RS-485

Table 4-7 : Definition of digital input & EPO functions

Table 4-8 : Definition of DRMs for Australia and New Zealand

Table 5-1 : LED indicator

Table 5-2 : Dry contact trigger condition

Table 7-1 : Error Message

Table 7-2 : Fault Message

Table 9-1 : Specifications for E5

11

20

24

24

25

27

28

29

29

33

48

51

53

56

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7

Page 8

Safety Instructions

This manual uses the following instructions for conveying important safety related

information.

DANGER!

- The inverter is not allowed to remove the covers during installation and

maintenance when inverter energized. Death and serious injury will occur

if this hazardous situation is not avoided.

WARNING:BURN HAZARD!

- The unit may reach very high temperatures and the device surface can become

quite hot. Sufficient cooling time is necessary for optimal yield.

- Avoid contact with the unit to minimize the risk of being burnt.

- Machine and equipment damage may occur if this hazardous situation is not

avoided.

CAUTION !

WARNING !

- Death and serious injury may occur if this hazardous situation is not avoided.

- Repair work on the device should ONLY be carried out by the manufacturer.

No user serviceable parts inside.

- Installation and maintenance work shall be performed by qualified electrician

and shall comply with local Regulations.

8

Page 9

This manual is to provide the explanation and procedures for installing, operating,

maintaining, and troubleshooting of E5 hybrid inverter.

This device is a hybrid inverter with following features:

• Integrated energy management system

• Integrated charger controller and inverter

• Transformerless

• Single phase hybrid system

- Solar / Battery to Grid

- Solar / Battery / Grid to Load

- Solar / Grid to Battery

The operation of hybrid inverter is shown as Figure 1-1. Inverter convert the

DC input power supplied from the PV Array and Battery into single phase AC

output power to Grid and Load.

Figure 1-1 : Storage system operation illustration

For more detailed or other related product information, please visit

http://www.deltaww.com

1 General Information

1.1 About this Manual

1.2 Product Description

1.3 Additional Information

PV Array

Electrical Grid

Hybrid Inverter

DC Distribution

box

AC Distribution

box

Surge arrestor

Fuse

DC switch

Surge arrestor

AC breaker

L , N , PE

Install if necessary

AC Distribution

box

Home Load

Battery

General Information

9

Page 10

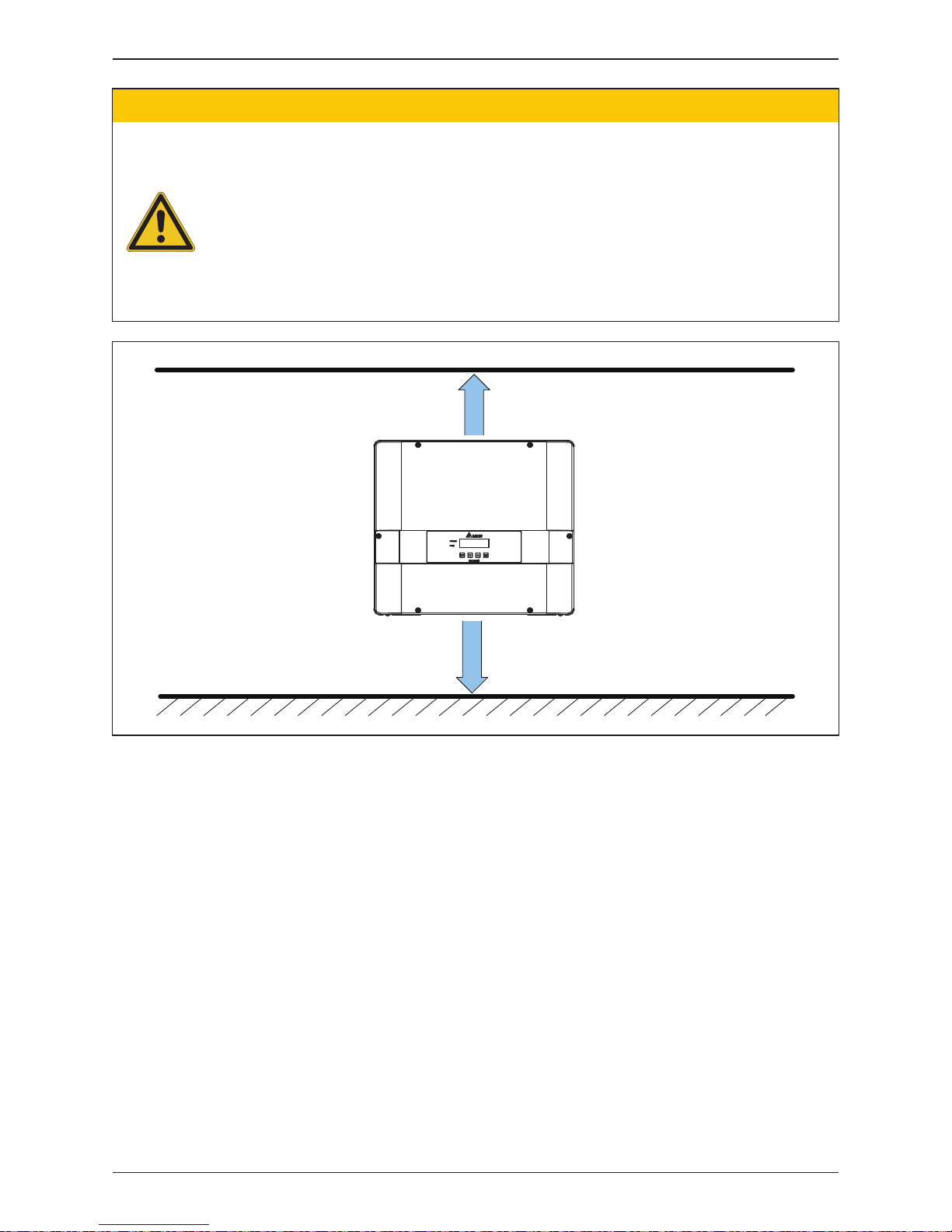

Figure 2-1 : Unpack the inverter

The unpacking procedure of E5 inverter is shown as Figure 2-1.

Unforeseeable events causing damage or movement may occur during shipment.

Please check following items upon receiving your inverter.

• Check the damage on the packaging.

• Check if all the accessories are in the package.

The standard accessories are shown in Figure 2-2 and Table 2-1.

• Check the model number and the serial number on the packaging is identical

with the model number and serial number on the unit itself.

If there is any visible damage to the inverter / accessories or packaging, please

contact your inverter supplier.

2 Product Overview

2.1 Unpack the Inverter

2.2 Checking Unit and Accessories

10

Product Overview

Page 11

Figure 2-2 : Packing list

E5 Hybrid inverter

Object Qty Description

1 Hybrid Inverter 1 pc

1 pc

E5 hybrid inverter

2 User Manual

The Instruction to provide the information of safety,

Installation, specification, etc.

3

4

5

Table 2-1 : Packing list

①

② ⑥⑤ ③ ④

⑩

⑧

⑨

⑦

6

7

8

9

10 #6-32 Screw 2 pcs To fix the AC plug shield.

1 set

1 set

AC Plug Shield

BT Connector

Exterior cover for AC Plug

1 pcAC Plug Connector for AC connection

Connector for Battery connection

DC Connector 2 sets Connector for PV array connection

RJ45 Connector 1 pc Connector for Battery communication

Mounting Bracket 1 pc To mount the hybrid inverter on the wall.

M4 Screw 2 pcs To fix the hybrid inverter on the wall.

11

Product Overview

Page 12

Please refer to Figure 2-3 for the location of product label. You can identify the

model number and the specifications by the information on the product label.

In Australia and New Zealand, users can also identify the supported Demand

Response Modes (DRMs) of E5 here.

Figure 2-3 : Product label

2.3 Product Label

12

Product Overview

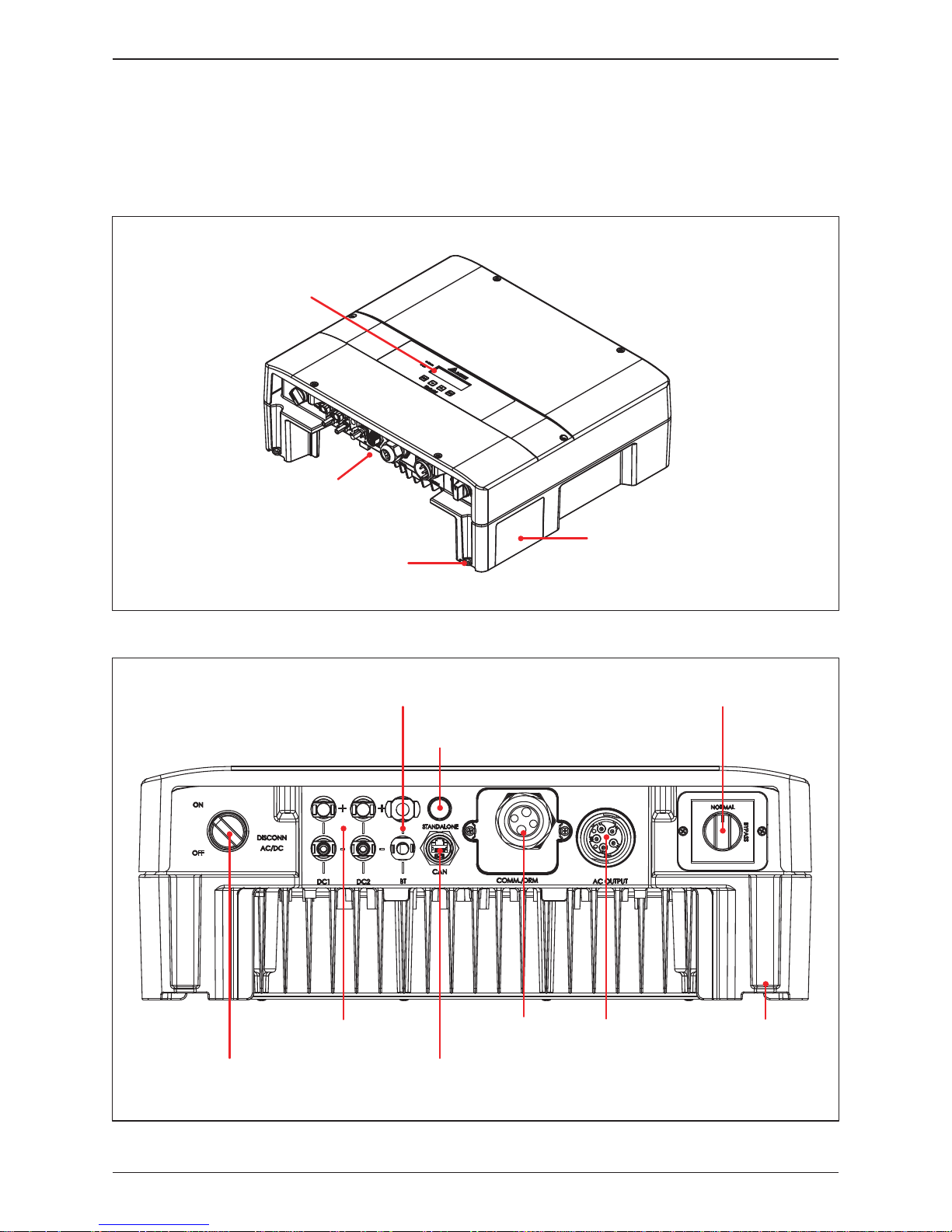

Page 13

LCD / LED Display

and Buttons

Label

Grounding Hole

Input /

Output

Interfaces

The Inverter’s exterior objects are shown in Figure 2-4. The detailed input /

output interfaces illustration is shown in Figure 2-5.

Figure 2-4 : Inverter’s exterior objects

2.4 Exterior Objects

Figure 2-5 : Input / output interface

Manual bypass switch

Standalone Button

AC Connector

4 port + PE

RS-485 * 2

EPO

Dry Contact

Digital Input/ DRMs

PV Connector

(2 string)

AC / DC Switch

Grounding Hole

BT Connector

CAN (RJ45)

13

Product Overview

Page 14

This unit is designed to be wall-mounted. Please ensure the installation is

perpendicular to the floor and the AC plug at the bottom. Do not install the

device on a slanting wall.

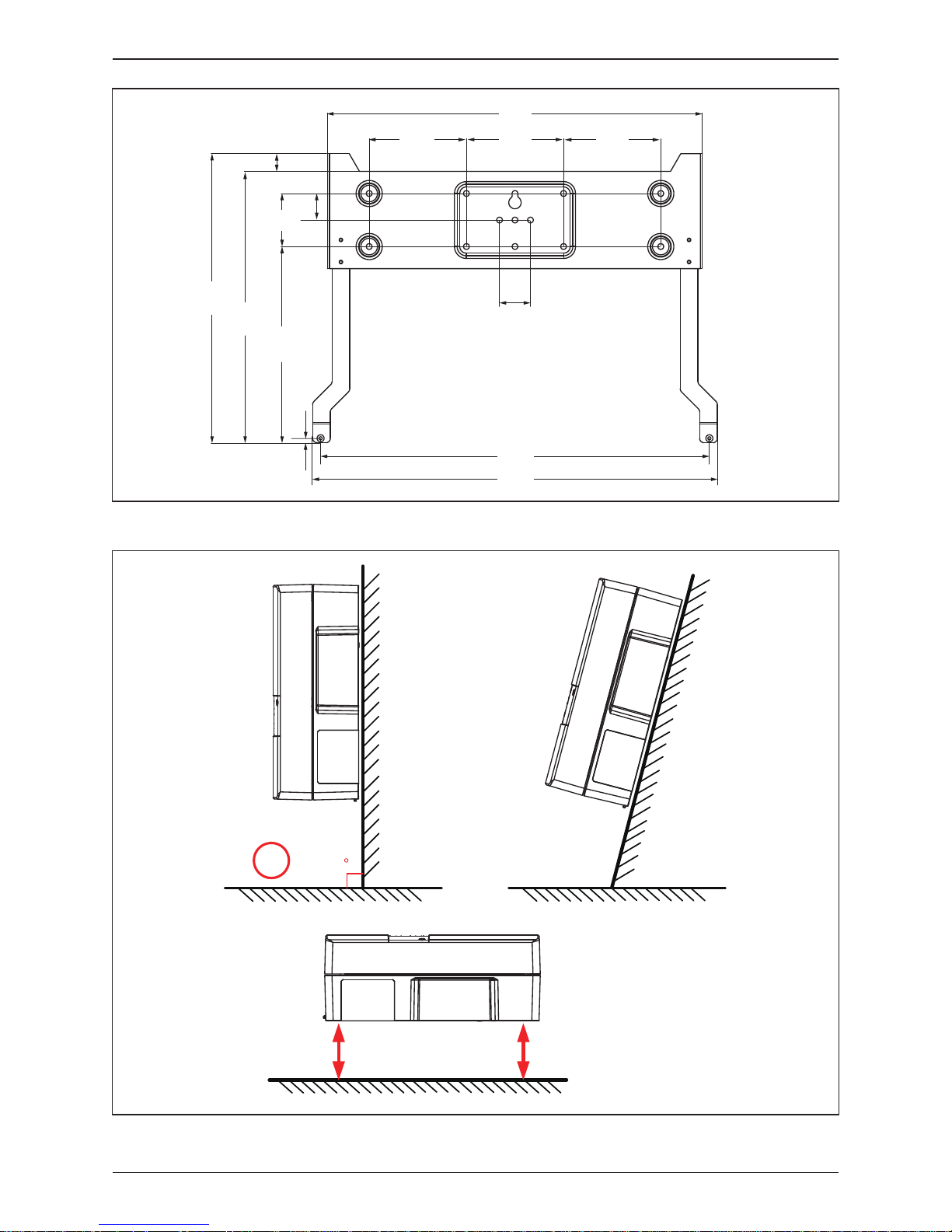

To mount the inverter on the wall, please follow the procedure below:

1. Screw the mounting bracket on the wall with 8 M6 Phillips head screws.

Please refer to Figure 3-3.

2. Attach the inverter to the mounting bracket.

3. Use Hex Wrench fixing the inverter with 2 M4 Hexagon Socket screws.

Please refer to Figure 3-4.

3 Installation

- The unit should not be installed in a direct sunlight.

- Servicing of batteries should be performed or supervised by personnel

knowledgeable about batteries and the required precautions.

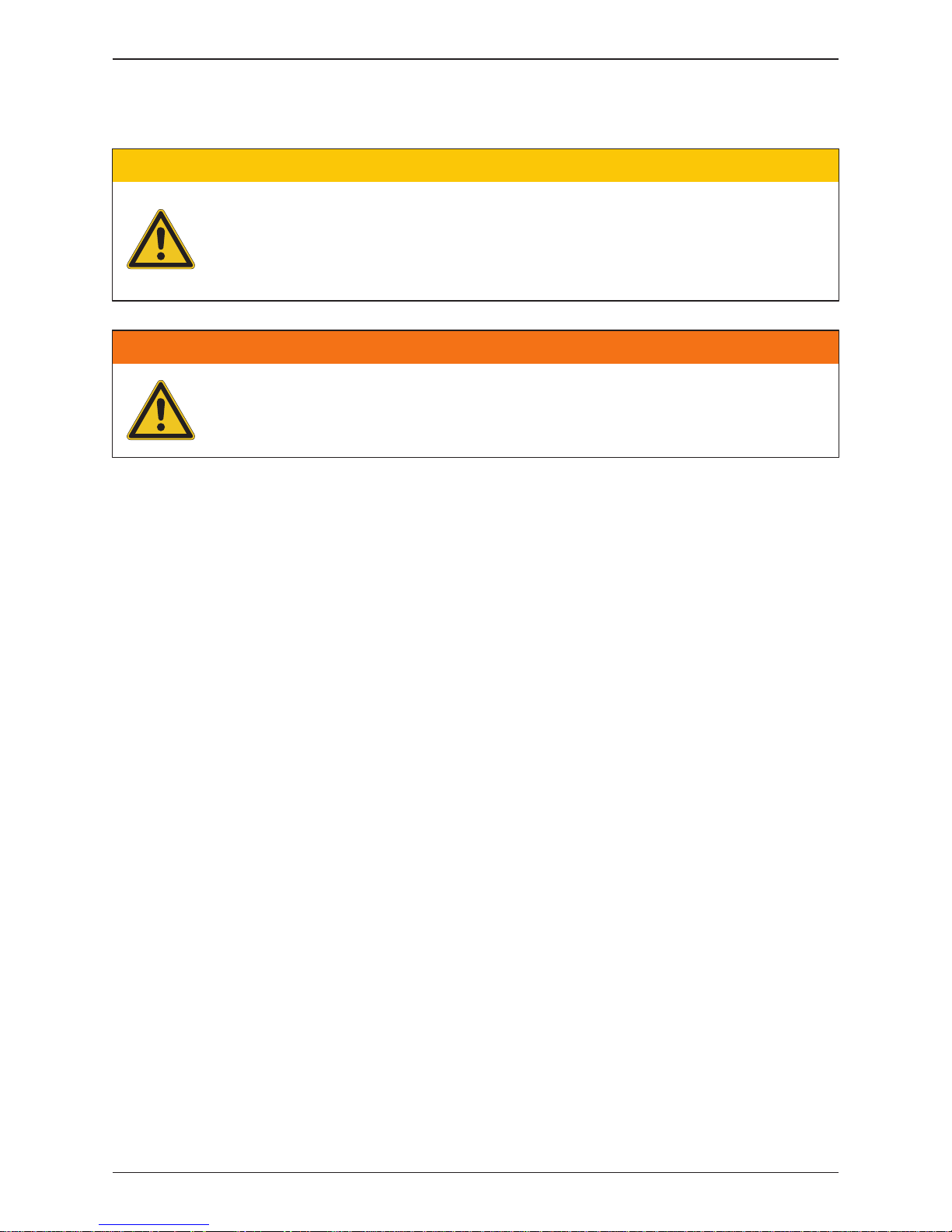

CAUTION !

WARNING !

- Do not install the unit near or on flammable surfaces.

- Please mount the unit tightly on a solid / smooth surface.

14

Installation

Page 15

Figure 3-1 : Mounting bracket dimension

Figure 3-2 : Recommended installation

90

Not

Recommended

Not

Recommended

Keep >30 cm from floor and

water if installed this way

424

110

110

110

35

440

327

30

60222

20

5

302

458

15

Installation

Page 16

Figure 3-4 : Attach to the bracket and fasten with screws

Figure 3-3 : Screw the mounting bracket

M4 Screw M4 Screw

16

Installation

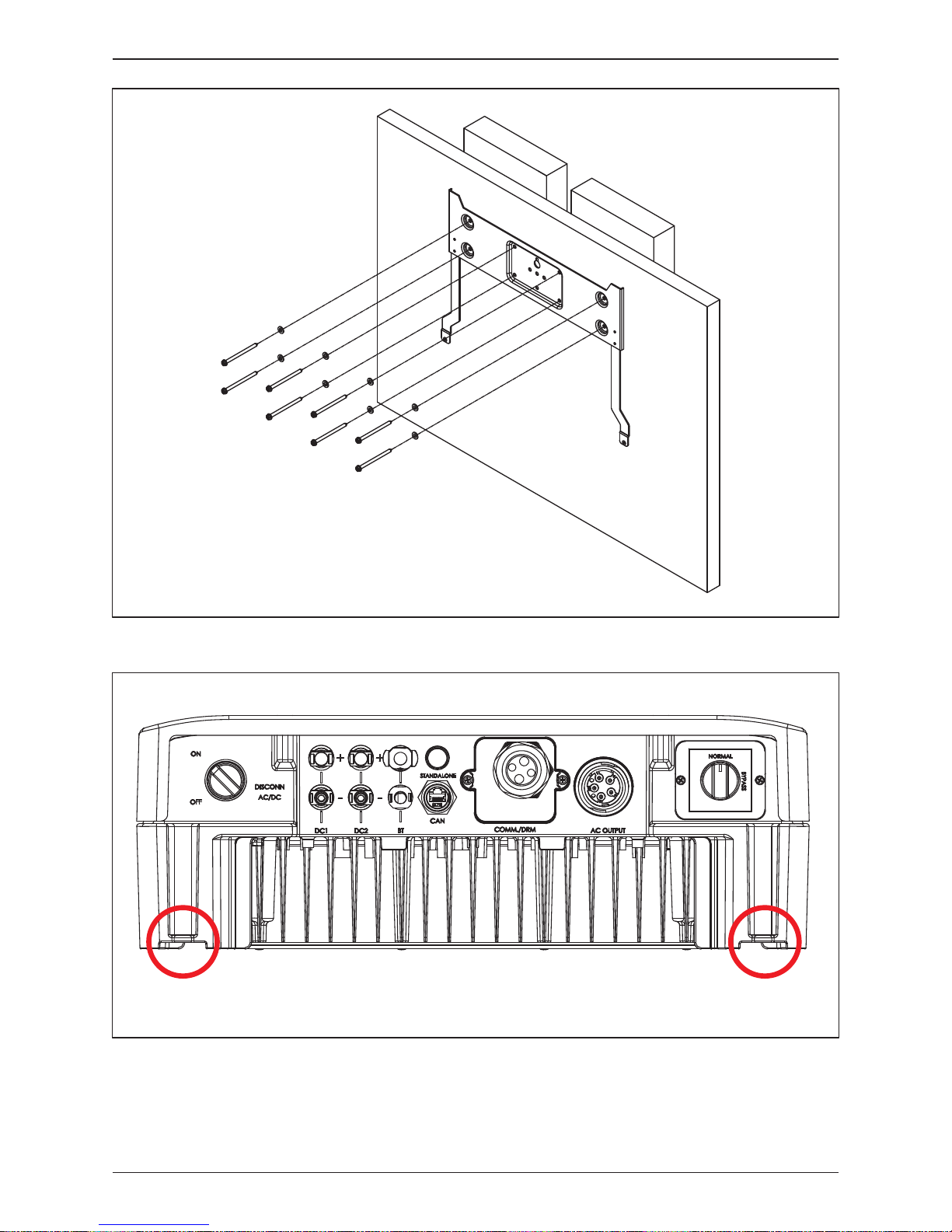

Page 17

> 20 cm

> 20 cm

Figure 3-5 : Proper installation gaps

- The bracket supplied with the unit is specially designed and should be the only

mounting device used for the unit.

- It is recommended to install the inverter in a suitable location which offers

non-obscured and safe access, in turn ensuring easy access for service and

maintenance.

- Please install hybrid inverter at an eye level to allow easy observation for operation

and parameter setting.

- Ambient temperature -25° C~60° C. (power de-rating above 40° C)

CAUTION !

17

Installation

Page 18

• Please use PVC insulated outdoor power cables and connected to the inverter

through a specific certified connector.

• Please use ungrounded PV power system due to E5 does not have galvanic

isolation between the DC-input, Battery and AC-output.

• E5 has array insulation resistance measuring function. Please ensure the

insulation resistance of array is over 550k ohm.

• There are two earth bonding methods for E5.

You can ground the inverter by enclosure grounding hole that shown in Figure 2-4

or by PE terminal of AC plug. Please use at least one grounding method to

avoid electric shock.

• Inverter can support DC inputs in parallel connection (1 MPP tracker) or

separate connection (2 MPP trackers).

• The overview of wiring please refers to Figure 4-1.

4 Wiring

4.1 Preparation Before Wiring

WARNING:SHOCK HAZARD!

- Whenever a PV array is exposed to sunlight, a shock hazard may exist due to

output wires or exposed terminals. To reduce the risk of shock during installation,

cover the array with an opaque (dark) material and ensure that the AC/DC

disconnect switch in the inverter is set to OFF before commencing any wiring.

18

Wiring

Page 19

Communication

Wiring CAN and RS-485

2

4

PV Wiring

Parallel or

Separate

+

-

+

-

+

-

3

BT Wiring

1

AC Wiring

L(Grid)

PE

L(Load)

N(Grid)

N(Load)

Figure 4-1 : Connection of system for floating solar array and battery

19

Wiring

Page 20

It is recommended to install a 30A or 32A upstream circuit breaker between AC

side and inverter side for over current protection. The AC cable must be jacked

and meet the specifications in Table 4-1.

Model Current Rating Recommended TorqueWire Size

25 AE5

0.7 N・m

Table 4-1 : AC input cable requirement

5 - 8mm

2

4.2

AC Connection

WARNING !

- Before commencing AC wiring, please ensure AC breaker is switched off.

4.2.1

Required Protective Devices and Cable Cross-sections

The AC wiring system diagram is shown in Figure 4-2. It recommended users

follow the diagram connecting the AC wiring. The connection between Grid N

and Load N is used to eliminate the floating voltage between Load N and PE.

E5 can still works without the Grid N and Load N connection.

4.2.2 AC Connection

PE

PE

L

N

N L N L

RCD

Backup Power

loads

AC load

P1

Distribution PanelDelta E5

Grid

Load

L

N

PE

L

N

Figure 4-2 : AC connection

20

Wiring

Page 21

- Make sure to use the proper size of AC cable.

- Please choose the terminals as shown in Figure 4-3 for wires crimping.

- Failed to follow these instructions may cause AC plug damage.

CAUTION!Machine and equipment damage may occur.

Figure 4-3 : Terminal for wire crimping

The AC wiring system diagram is shown in Figure 4-3. It recommended users

follow the diagram connecting the AC wiring. The connection between Grid N

and Load N is used to eliminate the floating voltage between Load N and PE.

E5 can still works without the Grid N and Load N connection.

4.2.3 AC Plug Assembly

Follow the steps below to strip the wires before assembling the AC plug as

shown in Figure 4-4 :

• Remove 55 mm (2.2 inch) of AC cable outer jacket.

• Trim the L-N(Grid), L-N(Load) wire to 52.5 mm (2.0 inch).

• Strip 10 mm (0.5 inch) of insulation from all wires ends.

• Crimp terminals for all wires.

Figure 4-4 : Striping the wires

outer jacket

12mm

[0.5in.]

52.5 mm

[2.0 in.]

55mm[2.2in.](PE)

21

Wiring

Page 22

Assemble the AC plug and wires as the procedures shown in Figure 4-5.

The sequence of L(Grid), N(Grid), L(Load), N(Load) and PE must be connected

correctly. The AC voltage should be L-N 230 Vac ± 10%.

1. Fixed this part

2. Rotate to loosen

the AC plug

3. Depart the AC plug.

4. Insert the wires

5. Tighten the screws to

fixed the wires..

5. Reassemble the AC plug

Inverter

7. Rotate to tighten the plug

6. Connect the AC plug

to inverter

8. Rotate the gland to

fix wires

Figure 4-5 : AC plug illustration for E5

L(Grid)

PE

L(Load)

N(Grid)

N(Load)

Cable

Cable

Align the biggest latch of the AC plug and socket

Socket AC plug

Cable

22

Wiring

Page 23

AC plug shield is a cover to prevent users loosens the AC plug easily and cause

electrical shock. To assemble the AC plug shield, please follow the instruction

below.

1. There has a slot at well installed AC plug's upper side. Please refer to the

dotted line in Figure 4-6. Assemble 2 metal parts of AC plug shield at this slot.

2. Use 2 #6-32 screws to fix the metal parts.

(The torque of the screw: 8±1 Kgf-cm)

4.2.4 AC Plug Shield Assembly

Figure 4-6 : AC Plug Shield Assembly

23

Wiring

Page 24

Type of limit E5

Total input power 5.5 kW

DC1 / DC2 2.75 kW / 2.75 kW

Table 4-2 : Maximum rating of input power

- The maximum open circuit voltage of PV array should not exceed 600Vdc.

- It is recommended to install an over current protection device between PV

array side and inverter side.

- Any device installed between PV array and inverter must have capability to

withstand the open-circuit voltage and short-circuit current of PV array.

- The input power to the inverter should not higher than the rated power shown

in Table 4-2.

CAUTION !

WARNING !

- When undertaking DC wiring, please ensure the correct polarities are connected.

- When undertaking DC wiring please ensures that the power switch on the PV

array is OFF.

Model Current Rating Wire size

E5 DC 12A 2 - 3mm

2

/ 14 AWG

Table 4-3 : Cable size

4.3 DC Connection (from PV Array)

Figure 4-7 : DC plug wiring illustration

DC wiring polarities are divided into positive and negative, which is shown in

Figure 4-7. The connection shall be coherent with the indication marked on

inverter.

PV-KST 4/6 ⅡPV-KBT 4/6 Ⅱ

24

Wiring

Page 25

Battery wiring uses 1 pair of Phoenix connector. Please follow the instructions

below to assemble the connector.

1. Put the stripped wire into the cable adapter

2. Lock it.

3.

Attach the bottom part of the cable adapter to the upper part of the cable adapter.

4. Rotate and tighten them.

Figure 4-8 depicts the procedure listed above.

The connection shall be coherent with the indication marked on inverter.

Battery box’s assembly please refers to battery box quick install guide.

4.4 Battery Connection

WARNING !

-

When undertaking battery wiring, please ensure the correct polarities are connected.

-

When undertaking battery wiring, please ensures that the power switch on the battery

side is OFF.

-

There is an internal disconnection device and a battery management system (BMS)

in the battery box. It's not necessary to install another disconnection device

between inverter and battery box.

-

Servicing of batteries should be performed or supervised by personnel knowledgeable

about batteries and the required precautions.

Model Current Rating Wire size

E5 DC 40A 8 - 9mm

2

/ 8 AWG

Table 4-4 : Battery cable size

Figure 4-8 : Assemble the Battery Connector

18mm

25

Wiring

Page 26

The communication interface between E5 and battery is CAN bus. The physical

connection type is RJ45 socket. To meet the IP65 class, please use the RJ45

connector of E5 accessory. Figure 4-9 describes the parts of RJ45 connectors.

To assemble the connector, please follow the procedure below:

1. Insert the sealing nut, seals, and support into the cable assembly.

(Cable OD range: 5.0 ~ 6.5 mm.)

2. Connect the sealing nut on the half-finished goods and screw tightly.

(Sealing nut torsion value range: 5~15 kgf-cm)

4.5 CAN Connection

Figure 4-9 : Overview of RJ45 Connectors

Figure 4-10 : Assembling Procedure of RJ45 Connectors

26

Wiring

Page 27

RJ-45 cable without cable connector boots plug cover (soft plastic) is

recommended as indicated in Figure 4-11.

The terminal configuration of CAN connection as specified in Table 4-5.

Figure 4-11 : Suitable cables for RJ45 connector

Pin Assignment

1 VCC (+24V)

2 GND

3 Battery Fault Sensor

4 CANH

5 CANL

6 N/A

7 N/A

8 N/A

Table 4-5 : RJ45 socket pin assignment of CAN

27

Wiring

Page 28

Figure 4-12 : Communication module

Please refer to Figure 4-12 for the Communication Module illustration.

The module provides VCC, RS-485, dry contact, and EPO terminals for

different use.

EPO & Digital Inputs & DRMs

Dry Contact

RS

VCC

GND

-485

Terminal

Resistor

4.6 Communication Module Connections

+

+

-

-

+

+

-

-

The pin definition and data format of RS-485 is shown in Table 4-6.

Installers should switch ON the terminal resistor when single inverter is installed.

Pin Function Data Format

1 VCC (+24V)

Baud rate: 19200

Data bits: 8

Stop bit: 1

Parity: N/A

2 GND

3 DATA+

4 DATA5 DATA+

6 DATA-

Table 4-6 : Pin definition and data format of RS-485

4.7 RS-485 Connection

1

2

3

4

5

6

28

Wiring

Page 29

Communication Module has 1 set of emergency power off function (EPO).

When the VCC and INV OFF pins are short-circuited, inverter will shut down

immediately. The module also provides 6 sets of digital input function (K1~K6).

Please refer to Table 4-7 for the digital input definition. The suitable electric wire

is 30-16AWG.

In Australia and New Zealand, the Demand Response Modes (DRMs) are

also use digital input function to assert. The definition is different from normal

digital input function; please refer to Table 4-8 for the DRMs pin definitions.

4.8 Digital Input / DRM & EPO Functions

Short Inverter’s action

VCC & INV OFF Emergency power off (EPO)

VCC & K1 0% active power

VCC & K2 Maximum 30% active power

VCC & K3 Maximum 60% active power

VCC & K4 Maximum 100% active power

VCC & K5 Reserved

VCC & K6 Reserved

Table 4-7 : Definition of digital input & EPO functions

Short Inverter’s action

VCC & INV OFF DRM 0 (Disconnect from grid)

VCC & K1 DRM 5 (0% generate power)

VCC & K2 DRM 6 (50% generate power)

VCC & K3 DRM 7 (75% generate power and sink reactive power)

VCC & K4 DRM 8 (100% generate power)

VCC & K5 Reserved

VCC & K6 Reserved

Table 4-8 : Definition of DRMs for Australia and New Zealand

Communication Module has 1 set of Dry Contact. The trigger condition of this

function can be customized by Installer. When the function is triggered, the output

two ports will be short-circuited. Please refer to section 5.3.8 Install Settings for

more details about trigger condition assignation.

4.9 Dry Contact Connection

29

Wiring

Page 30

E5 can be used in single-phase parallel combination system. In this application,

inverter may be parallel connected to a same AC grid. It recommended connecting

the RS-485, EPO, and digital input together of all E5s for an easily and immediately

remote control. Please refer to Figure 4-13, Figure 4-14 and Figure 4-15 for the

illustration of multiple inverters combination.

In Australia and New Zealand, the max valid combinations number of E5s is 3.

Please do not install more than 3 E5s at same point of common coupling.

4.10 Multiple inverter combinations

Figure 4-13 : Single-phase parallel combinations

Figure 4-14 : Multiple inverters RS-485 connection

L (Grid)

ID: 1 ID: 2 ID: N

N (Grid)

Data Format:

Baud rate: 9600, 19200 , or 38400

Data bits: 8

Stop bit: 1

Parity: N/A

RS485/USB

or

RS485/RS232

Terminal Resistor

120Ω(1/2W)

DATA+ to DATA-

Terminal Resistor

120Ω(1/2W)

DATA+ to DATA-

30

Wiring

Page 31

SW

INV_1

(VCC)V1

K0 (EPO)

K1 (0% Power)

K2 (30% Power)

K3 (60% Power)

K4 (100% Power)

K5

K6

INV_2

(VCC)V1

K0 (EPO)

K1 (0% Power)

K2 (30% Power)

K3 (60% Power)

K4 (100% Power)

K5

K6

INV_N

(VCC)V1

K0 (EPO)

K1 (0% Power)

K2 (30% Power)

K3 (60% Power)

K4 (100% Power)

K5

K6

EPO Button

Figure 4-15 : EPO & Digital input & DRMs parallel connection

31

Wiring

Page 32

5 Turning On the Hybrid Inverter

WARNING:BURN HAZARD!

- The enclosure temperature may exceed 70°C while inverter is operation.

A dangerous burn hazard is present in this situation.

5.1 LCD Flow Chart

E5 includes a 4x20 character type LCD display and 2 LED to indicate inverter’s

status. Table 5-1 reveals more information about inverter status and LED

indicator.

The following section will introduce the functions that can be adjusted by users

through the LCD panel. When you are adjusting settings, LCD panel will change

the display cursor from “►” to “ ”.

Meter

Energy Log

Event Log

Inverter Information

General Setting

Operation Mode

Function Setting

Install Setting

5.3.1

5.3.2

5.3.3

5.3.4

5.3.5

5.3.6

5.3.7

5.3.8

Meter

Energy Log

Event Log

Information

►

General Settings

Operation Mode

Function Settings

Install Settings

ESC : Exit Menu

UP : Move Up

Down : Move Down

ENT: Enter or Confirm

LED Indicator (GRN)

LED Indicator (RED)

Figure 5-2 : User Interface

Figure 5-1 : Menu page

32

Turning On the Hybrid Inverter

Page 33

Condition Green LED

Countdown or Standalone FLASH

Power ON ON

Error or Fault OFF

AC/DC switch off OFF

Bootloader mode FLASH

Red LED

OFF

OFF

ON

OFF

Table 5-1 : LED indicator

5.2 First Startup

At first startup, you have to supply AC power and turn on the AC/DC switch.

After a while, LCD display will come live and ask you to set language, country

(electricity regulation), and operation mode.

When all the settings are done, you can see Home Page showing on display.

Now you can supply DC power and wait inverter doing self-test and starting

operation.

In the case of no AC power, you can turn on DC power first then switch on

the AC/DC switch and press the standalone button about 1 second. If DC side

has enough voltage and power, inverter will turn on after a while. In this condition,

inverter is forced operating in standalone mode.

You can also turn on E5 by using battery power. Switch on AC/DC switch and

wake up the battery, waiting about 30 seconds you will see inverter starting

to work in standalone mode. The method of wake up battery will be described

in battery box’s manual.

Figure 5-3 : Country and language settings for first startup

First Startup

Select Country,

AU/NZ

Germany LV

NL

►

Select Language,

English

Deutsch

Nederlands

►

Set Operation Mode,

Self consump.

Peak cut

Selling first

►

Country:

Mode:

YesNo

Germany LV

Self-consump.

ENT

ESC

ENT

ESC

ENT

ESC

33

Turning On the Hybrid Inverter

Page 34

Figure 5-4 : Home page

When inverter is operating normally, the LCD display will show home page on

screen. In this page, you can get the information about inverter operation

status, PV power, BT power (charge/ discharge), load power, and grid power

(purchase/ selling).

Pressing any key in home page can you enter menu page. There are 8 branches

in the menu. The following chapters will introduce you these subpages.

5.3 Home Page

In meter page, you can get more detail information about PV, BT, Load, and

Grid power.

5.3.1 Meter

Figure 5-5 : Power meter page

2014.12.13 13:50

Status: On Grid

PV►1022W Load►1695W

BT◄1100W Grid►1573W

PV power

BT power

Load power

Grid Power

Inverter Status

Day-Time

BT►: Discharge

BT◄: Charge

Grid►: Purchase

Grid◄: Selling

Load Power:

Load Voltage:

Load Current:

Frequency:

3000

230

13.0

50.00

W

V

A

Hz

BT SOC:

BT Charge:

BT Voltage:

BT Current:

100

+/- 3000

200

39.5

%

W

V

A

250

10.0

2500

DC1 DC2PV

V

I

P

250

10.0

2500

V

A

W

Grid Power:

Grid Voltage:

Grid current:

Frequency:

+/- 3000

230

12.0

50.00

W

V

A

Hz

ENT

Meter

Energy Log

Event Log

Inverter Info.

►

34

Turning On the Hybrid Inverter

Page 35

Energy log can be separate into load power log and PV power log; each log

can record its own day / month / year power.

5.3.2 Energy Log

This page can records the last 30 events of error and fault. The latest event

will be revealed on the top.

5.3.3 Event Log

Figure 5-6 : Energy log flow chart

Figure 5-7 : Event log flow chart

Meter

Energy Log

Event Log

Inverter Info.

►

Load Power

PV Power

►

L-Day

2013.02.23

2013.02.22

2013.02.21

12

11

15

kWh

kWh

kWh

L-Month

2013.11

2013.10

2013.09

300

360

333

kWh

kWh

kWh

L-Year

2013

2012

2011

3650

3325

3360

kWh

kWh

kWh

Load Power

PV-Day

2013.02.23

2013.02.22

2013.02.21

12

11

15

kWh

kWh

kWh

PV-Month

2013.11

2013.10

2013.09

300

360

333

kWh

kWh

kWh

PV-Year

2013

2012

2011

3650

3325

3360

kWh

kWh

kWh

PV Power

ENT

ENT

1. 2013.02.20 15:30

AC Freq High

2. 2013.02.19 09:30

AC Volt Low

Meter

Energy Log

Event Log

Inverter Info.

►

ENT

35

Turning On the Hybrid Inverter

Page 36

This page can helps you to recognize your inverter. There are serial number,

installation date, firmware version, setting country, inverter operation mode,

BT SOH, and BT Capacity information in this page.

Please be noticed that inverter operation mode shown in this page is not the

same as the operation mode set by user. Please refer to 5.3.6 Operation Mode

chapter for more detail information.

5.3.4 Inverter Information

Figure 5-8 : Inverter information page

S/N:

Install:

DSP 1.80

Comm. 1.65

RN11179CB0

2014.10.13

Red. 1.65

ID: 002

Country:

Mode:

BT SOH:

BT Capacity

Germany LV

Self-consump.

100%

6.0kWh

Meter

Energy Log

Event Log

Inverter Info.

►

ENT

In this page you can change display language, time, and RS-485 communication

baud rate.

5.3.5 General Settings

Figure 5-9 : General settings page

General Settings

Operation Mode

Function Settings

Install Settings

►

Language

Date & Time

Baud Rate

►

English

Deutsch

Nederlands

►

2013.10.04 13:50

9600

19200

38400

►

Language Date & Time Baud Rate

ENT

ENT

36

Turning On the Hybrid Inverter

Page 37

Hybrid inverter has 6 normal operation modes for users to choose.

Each mode has different behavior between PV, battery, grid, and home load.

The following are the description of these modes.

In some area, the detail behavior of each operation mode may be different due

to the local electricity regulations.

5.3.6 Operation Mode

Figure 5-10 : Operation mode page

General Settings

Operation Mode

Function Settings

Install Settings

►

Self consump.

Peak cut

Selling first

Charge first

►

Current Setting:

Self consumption

Exit Change

Discharge first

Without BT

►

ENT

ENT

37

Turning On the Hybrid Inverter

Page 38

Self-consumption mode is standard hybrid inverter mode.

In this mode, PV power is supplied in following priority :

1. Supply for home load.

2. Charge the battery until it is full.

3. Feed-in the remaining power to grid.

When there is no PV power, battery starts to discharge and supply home load

until it’s empty.

If you had set the time settings, the behavior of hybrid inverter will change.

We will explain it in 5.3.7 Function Setting chapter.

5.3.6.1 Self-consumption mode

Figure 5-11 : Self-consumption mode current flows

Figure 5-12 : Self-consumption mode behavior

Electrical Grid

Hybrid Inverter

Battery

Input or

output

Charge or

discharge

Input

Output

Home Load

PV Array

19:0012:0007:0000:00 24:00

PV power

PV power used

for home load consumption

Excess PV power

Battery discharges

Home load power usage

38

Turning On the Hybrid Inverter

Page 39

When home load consumption exceeds the Peak Cut Power you set in Function

Setting page, battery will discharge to assist the power usage.

5.3.6.2 Peak cut mode

Figure 5-13 : Peak cut mode current flows

Figure 5-14 : Peak cut mode behavior

Electrical Grid

Hybrid Inverter

Battery

Input or

output

Charge or

discharge

Input

Output

Home Load

PV Array

19:0012:0007:0000:00 24:00

PV power

PV power used

for home load consumption

Excess PV power

Home load power usage

Battery discharges

39

Turning On the Hybrid Inverter

Page 40

Selling first mode is a standard PV inverter mode combining with 6 time settings.

In normal operation, power generated by PV array will all feed-in to home load

and grid. If users have set the time settings, inverter will change behavior in

these time intervals. Please refer to 5.3.7 Function Setting chapter for more

detail about time settings.

5.3.6.3 Selling first mode

Figure 5-15 : Selling first mode current flows

Figure 5-16 : Selling first mode behavior

Electrical Grid

Hybrid Inverter

Battery

Input or

output

Charge or

discharge

Input

Output

Home Load

PV Array

19:0012:0007:0000:00 24:00

PV power

PV power used

for home load consumption

Excess PV power

Home load power usage

40

Turning On the Hybrid Inverter

Page 41

Figure 5-17 : Charge first mode current flows

Figure 5-18 : Charge first mode behavior (general)

Electrical Grid

Hybrid Inverter

Battery

Input or

output

Charge or

standby

Input

Output

Home Load

PV Array

19:0012:0007:0000:00 24:00

PV power

PV power used

for home load consumption

Excess PV power

Home load power usage

In this mode, PV power is supplied for battery charging first. After battery is

fully charged, the remaining PV power then feed-in to home load and grid.

Battery will not discharge in this mode even if there is no PV power.

Users in Australia and New Zealand can charge the battery from grid power by

using this mode due to the permission of electricity regulations. Battery will be

charged by PV or grid with the maximum charge current.

5.3.6.4 Charge first mode

41

Turning On the Hybrid Inverter

Page 42

Figure 5-19 : Charge first mode behavior (for AU & NZ)

19:0012:0007:0000:00 24:00

PV power

PV power used

for home load consumption

Excess PV power

Home load power usage

42

Turning On the Hybrid Inverter

Page 43

In this mode, battery will not be charged any more.

All the PV power is feed-in to home load and grid. Battery keeps discharging

when there is no PV power until it is empty.

5.3.6.5 Discharge first mode

Figure 5-20 : Discharge first mode current flows

Figure 5-21 : Discharge first mode behavior

Electrical Grid

Hybrid Inverter

Battery

Input or

output

Discharge

or standby

Input

Output

Home Load

PV Array

19:0012:0007:0000:00 24:00

PV power

PV power used

for home load consumption

Excess PV power

Battery discharges

Home load power usage

43

Turning On the Hybrid Inverter

Page 44

If your battery was damaged for some reason, you can disconnect the battery

wiring and choose without BT mode. In this mode, hybrid inverter acts like a

basic grid-tie PV inverter.

5.3.6.6 Without battery mode

Figure 5-22 : Without battery mode current flows

Figure 5-23 : Without battery mode behavior

Electrical Grid

Hybrid Inverter

Input or

output

Input

Output

Home Load

PV Array

19:0012:0007:0000:00 24:00

PV power

PV power used

for home load consumption

Excess PV power

Home load power usage

44

Turning On the Hybrid Inverter

Page 45

In addition to the 5 modes above, hybrid inverter still have 3 special modes.

These modes cannot be enabled by user but will be enabled automatically by

inverter in some special condition.

Hybrid inverter changes to standalone mode automatically during a power

outage occur. At this time, grid side is disconnected by inverter and home load

are supported by PV and battery power as much as possible.If the battery is

not connected, only when there has sufficient PV power can inverter enter

standalone mode.

• Standalone mode

5.3.6.7 Special Modes

Figure 5-24 : Standalone mode current flows

Figure 5-25 : Standalone mode behavior

Hybrid Inverter

Battery

Charge or

discharge

Input

Output

Home Load

PV Array

19:0012:0007:0000:00 24:00

PV power

PV power used

for home load consumption

Excess PV power

Battery discharges

Home load power usage

45

Turning On the Hybrid Inverter

Page 46

Although battery stops any action when SOC (state of charge) reach 0%,

the self-discharge phenomenon may still causing SOC lower than 0%.

At this time, hybrid inverter will force battery charging from PV power and grid

power until the battery SOC reaching 30%.

• Forced charge mode

Figure 5-26 : Forced charge mode current flows

Electrical Grid

Hybrid Inverter

Battery

Input or

output

Forced

Charge

Input

Output

Home Load

PV Array

Figure 5-27 : Forced charge mode behavior

19:0012:0007:0000:00 24:00

PV power

PV power used

for home load consumption

Excess PV power

Home load power usage

46

Turning On the Hybrid Inverter

Page 47

In function settings page, you can assign SOC limit, peak cut power, and

BT charge / discharge time interval.

5.3.7 Function Setting

Figure 5-28 : Function Settings page

You can assign the lower limit of battery SOC. Battery will stop discharging

when its SOC reach this limit.

• SOC Limit

Peak cut power is used in peak cut mode. You can assign the peak power of

home load usage from grid. When the home load consumption exceeds this

value, battery will discharge to supply remaining power.

• Peak Cut Power

Time settings can be separated into BT charge time and BT discharge time.

Each setting can set 3 time intervals. These 6 time intervals cannot overlap

with each other.

When the inverter operation mode set to self-consumption or selling first mode,

time settings is enabled. Hybrid inverter will automatically change the mode

to charge first / discharge first in the time intervals you set and return to

self-consumption / selling first mode outside the intervals.

• Time Settings

General Settings

Operation Mode

Function Settings

Install Settings

►

SOC Limit

Peak Cut PWR

Time Settings

►

30%

3kW

BT Charge Time

BT Discharge Time

►

BT Charge Time:

00:00 – 00:00

00:00 – 00:00

00:00 – 00:00

►

BT Charge Time

BT Discharge Time

►

BT Discharge Time:

00:00 – 00:00

00:00 – 00:00

00:00 – 00:00

►

BT Charge Time

BT Discharge Time

ENT

ENT

47

Turning On the Hybrid Inverter

Page 48

- The settings in Install Settings page can only be adjusted by qualified installers or

engineers. Changing these settings may result in damage to the inverter and other

equipment.

CAUTION !

5.3.8 Install Settings

Install Settings page is for installer only.

To enter this page, installer has to key in installer password.

The page includes following functions :

Inverter ID is used to recognized the inverter when you communicating with

it via RS-485.

• Inverter ID

Inverter will measure the impedance between PV array and PE before

connecting to grid. To avoid risk of electrical shock, it’s not recommending to

disable this function.

• Insulation

Each country has its own electricity regulations. The hybrid inverter can meets

more than one electricity regulations. Installer must select the country correctly.

• Country

Installer can choose the trigger condition of dry contact. The explanations of

these conditions are shown in following table.

• Dry Contact

This option is used to clear the battery power fault message. Before clearing

the fault message, please make sure the battery has been repaired.

• Clear BT PF

Setting Dry Contact Trigger Timing

Disable No action.

On Grid Inverter is connecting to grid.

Insulation Insulation test fail.

Alarm Any error or fault occurs.

Any fault occurs.

Table 5-2 : Dry contact trigger condition

Error Any error occurs.

Fault

This function is currently used in Germany only. Installer in Germany should

set the PV array capacity and enable this function. The maximum feed-in power

to grid will be limited at a percentage of PV array capacity. Installers can set

the various limit percentage to meet the local electricity regulation.

• Subsidy Function

48

Turning On the Hybrid Inverter

Page 49

If you connect the inverter to a remote controller via Wi-Fi interface, you may

use these functions to reset the Wi-Fi module settings.

• Wi-Fi Settings

This option is used to return factory settings. The entire energy log will be

cleared. Please use it with caution.

• Return to Factory

Figure 5-29 : Install Settings page

General Settings

Operation Mode

Function Settings

Install Settings

►

Password

****

Setting ID:

ID = 0

02

Inverter ID:

Insulation:

Country:

Dry Cont.

►

002

ON

Germany LV

Insulat.

Inverter ID:

Insulation:

Country:

Dry Cont.

►

AU/NZ

AU/NZ 2005

Germany LV

NL

►

002

ON

Germany LV

Insulat.

Inverter ID:

Insulation:

Country:

Dry Cont.

►

002

ON

Germany LV

Insulat.

Clear BT PF

Subsidy Function

Wi-Fi Settings

Return to Factory

►

BT Power Fault

has been cleared!

Clear BT PF

Subsidy Function

Wi-Fi Settings

Return to Factory

►

Mode:

PV capacity:

►

ON

Feed-in %: 100%

5.0 kW

Clear BT PF

Subsidy Function

Wi-Fi Settings

Return to Factory

►

Inverter ID

Country

Dry Contact

Clear BT PF

Subsidy Function

Wi-Fi Settings

Disable

On Grid

Insulat.

Alarm

►

Return to Factory ?

Yes / ►No

Clear BT PF

Subsidy Function

Wi-Fi Settings

Return to Factory

►

Return to Factory

Reset IP Address

Reset Password

Reboot Wi-Fi

Reset User Settings

►

ENT

ENT

49

Turning On the Hybrid Inverter

Page 50

In order to ensure the normal operation of inverter, please check and clean the

unit regularly. Once there are any impaired or loose parts, please contact your

inverter installer.

If the hybrid inverter was damaged and cannot supply the power to home load,

please turn off the AC/DC switch at bottom left and turn on the manual bypass

switch at bottom right to keep the power supply to home load via grid.

Please be noticed that when you turn on the manual bypass switch, grid and

home load are forced connected together. In this case, if grid fault occurred,

inverter will stop supplying any power to grid and home load for avoid electrical

shock of maintainer.

6 Maintenance

Warning!Electric Shock

- Before any maintenance, please make sure you are well insulated to avoid

risk of electric shock.

50

Maintenance

Page 51

ERROR

MessageCode Cause Action

7 Error message and Trouble Shooting

AC Freq High

Grid frequency over the limit of

electricity regulation.

Check the grid frequency.

If grid frequency is not in acceptable range,

contact the utility operator to modify it.

If grid frequency lies in acceptable range

but the error still exist, please contact your

inverter supplier.

E01

AC Freq Low

Grid frequency under the limit

of electricity regulation.

Check the grid frequency.

If grid frequency is not in acceptable range,

ask the utility operator to modify it.

If grid frequency lies in acceptable range

but the error still exist, please contact your

inverter supplier.

E02

Grid Quality

Grid harmonic distortion

>8.5% and >2.2s

Check AC wiring; keep the wire short and

straight.

Contact the utility operator to improve the

grid quality.

If the grid quality is good but the error still

exist, please contact your inverter supplier.

E07

No Grid

Grid voltage <20V or voltage

half-cycle > 50ms

Check the triggering of upstream circuit

breaker.

Check the wire connection between inverter

side and grid side.

Contact the utility operator for the information

about power failure.

E09

AC Volt Low

Grid voltage under the limit of

electricity regulation.

Check the grid voltage.

If grid voltage is not in acceptable range,

ask the utility operator to modify it.

If grid voltage lies in acceptable range but

the error still exist, please contact your

inverter supplier.

E10

AC Volt High

Grid voltage over the limit of

electricity regulation.

Check the grid voltage.

If grid voltage is not in acceptable range,

ask the utility operator to modify it.

If grid voltage lies in acceptable range but

the error still exist, please contact your

inverter supplier.

E11

AC Volt High

Grid voltage over the limit of

electricity regulation.

Check the grid voltage.

If grid voltage is not in acceptable range,

ask the utility operator to modify it.

If grid voltage lies in acceptable range but

the error still exist, please contact your

inverter supplier.

E12

51

Error message and Trouble Shooting

Page 52

ERROR

MessageCode Cause Action

AC Volt High

Grid voltage over the limit of

electricity regulation.

Check the grid voltage.

If grid voltage is not in acceptable range,

ask the utility operator to modify it.

If grid voltage lies in acceptable range but

the error still exist, please contact your

inverter supplier.

E13

Solar1 High

DC1 voltage > 600V

(more than 0.1s)

Disconnect the DC1 input and check the

PV array voltage.

If the PV array voltage still over 600V,

please contact the PV array supplier.

If the PV array voltage is fine but the error still

exist, please contact your inverter supplier.

E30

Solar2 High

DC2 voltage > 600V

(more than 0.1s)

Disconnect the DC2 input and check the

PV array voltage.

If the PV array voltage still over 600V,

please contact the PV array supplier.

If the PV array voltage is fine but the error still

exist, please contact your inverter supplier.

E31

Insulation

PV array impedance in either

input < 550 kohm

Check the insulation of DC input wiring.

Check the string for ground faults.

If the insulation of DC wiring is fine but the

error still exist, please contact your inverter

supplier.

E34

Table 7-1 : Error Message

52

Error message and Trouble Shooting

Page 53

Fault

MessageCode Cause Action

DC Injection

DC component in grid current

over the limit

Check the power supply line for direct

current.

Contact the utility operator to improve the

grid quality.

F01

Temp High

Internal temperature too high

to cause power output < 5%

Check the temperature of installation

environment.

Contact your inverter supplier.

F05

HW NTC1 Fail

Internal fault Contact your inverter supplier.F06

Temp Low

Internal temperature < -25℃

Check the temperature of installation

environment.

Contact your inverter supplier.

F07

HW NTC2 Fail

Internal fault Contact your inverter supplier.F08

HW NTC3 Fail

Internal fault Contact your inverter supplier.F09

HW NTC4 Fail

Internal fault Contact your inverter supplier.F10

DC RLY Fail Internal device fault Contact your inverter supplier.F13

HW DSP ADC1

Internal fault Contact your inverter supplier.F15

HW DSP ADC2

Internal fault Contact your inverter supplier.F16

HW DSP ADC3

Internal fault Contact your inverter supplier.F17

HW Red ADC1

Internal fault Contact your inverter supplier.F18

HW Red ADC2

Internal fault Contact your inverter supplier.F19

HW COMM2 Internal fault Contact your inverter supplier.F22

HW COMM1 Internal fault Contact your inverter supplier.F23

Ground Cur. Residual current over the limit

Check the insulation of DC input wiring.

Check the string for ground faults.

F24

RCMU Fail Internal device fault Contact your inverter supplier.F27

RLY Short Internal device fault Contact your inverter supplier.F28

RLY Open Internal device fault Contact your inverter supplier.F29

Bus Unbal. Internal fault Contact your inverter supplier.F30

HW Bus OVR Internal fault Contact your inverter supplier.F31

HW Eff.

Inverter efficiency < 70% or

> 130%

Contact your inverter supplier.F20

53

Error message and Trouble Shooting

Page 54

Fault

Message Cause Action

HW Bus OVR Internal fault Contact your inverter supplier.

HW Bus OVR Internal fault Contact your inverter supplier.

AC Cur. High

Grid current >135% rated and

keep over 50ms

Contact your inverter supplier.

AC Cur. High

Grid current >125% rated and

keep over 5s

Contact your inverter supplier.

HW CT A Fail Internal device fault Contact your inverter supplier.

HW AC OCR

AC current over the limit

20 times within 2s

Check AC and DC wiring for ground faults.

Inverter may be struck by the lighting.

Check the whole wiring of hybrid system.

If this fault occurs often, please contact

your inverter supplier.

SA OPP System overload

In standalone mode, PV and BT power is

insufficient to supply the home load.

Please reduce the load.

HW ZC Fail Internal fault Contact your inverter supplier.

Solar 1 OCR

DC1 current > 135% rated and

keep over 0.2s

Contact your inverter supplier.

BT OVP

BT UVP

Battery system internal fault Contact your inverter supplier.

Battery system internal fault Contact your inverter supplier.

BT OTP

BT UTP

Battery system internal fault Contact your inverter supplier.

Battery system internal fault Contact your inverter supplier.

BT OCP Battery system internal fault Contact your inverter supplier.

Battery system internal fault Contact your inverter supplier.BT CVI

BT TF Battery system internal fault Contact your inverter supplier.

Battery system internal fault Contact your inverter supplier.

Loss communication between

inverter and battery over 10

seconds.

Check CAN connection between inverter

and battery.

Solar 2 OCR

DC2 current > 135% rated and

keep over 0.2s

Contact your inverter supplier.

Solar 1 OCR

DC1 current > 140% rated and

keep over 0.1s

Contact your inverter supplier.

Solar 2 OCR

DC2 current > 140% rated and

keep over 0.1s

Contact your inverter supplier.

Table 7-2 : Fault Message

BT PF

HW COMM BT

Code

F33

F35

F36

F37

F42

F45

F48

F50

F60

F97

F98

F99

F100

F101

F102

F103

F61

F70

F71

F104

F112

54

Error message and Trouble Shooting

Page 55

If it is necessary to put the device out of operation for maintenance or storage,

please follow the procedures below:

At inverter side:

1. Switch off the AC/DC switch and wait for display turning off.

2. Switch the manual bypass switch to normal.

3. Wait for E5’s display panel and battery box’s LED indicator light off.

At wiring side:

4. Switch off AC power line breaker to disconnect from grid.

5. Switch off DC power line breaker to disconnect from PV array.

6.

Use proper voltmeter to check that the AC and DC power are truly disconnected.

7. Remove the AC, DC, and battery wiring.

8. Remove the communication module RS-485 connection from the computer

connection.

Now you may unload the inverter.

8 De-Commissioning

WARNING !

-

To avoid injuries, please follow the procedures to unload the inverter.

55

De-Commissioning

Page 56

Model

GENERAL

Enclosure

Operating temperature

Relative humidity

Galvanic isolation

Safety class

Maximum input power

Recommended PV power range

Nominal voltage

Operating voltage

Startup voltage

Startup power

MPP tracker

Absolute maximum voltage

Full power range

E5

Mounting bracket

Aluminum with powder coating

-25℃~60℃ full power up to 40℃

0% – 100% non-condensing.

Operating Altitude 0 to 2000m (0 to 6666 ft.)

NO

Environmental category Outdoor, wet locations

Protection degree IP65 (Electronics)

Pollution degree Internal : II, External : III

Overvoltage category AC output :III, DC Input :II

Maximum backfeed

current to the array

0

Class I metal enclosure with protective earth

Weight

Dimensions(W*H*D) 510 × 445 × 177mm

Connectors Weather resistant connectors

Audible noise < 40dB

5.5kW

5kW‒6kW

370Vdc

100Vdc – 550Vdc

> 125Vdc

30W

220Vdc‒450Vdc

1 MPP tracker (Parallel connection)

2 MPP trackers (Separate connection)

600Vdc

DC INPUT (Solar side)

9 Technical Data

27kg

Technical Data

56

Page 57

Model

DC INPUT (Solar side)

Number of inputs

Rated current

Maximum short circuit

current per MPPT (Isc)

Nominal charge/discharge current

Battery type

Voltage

Nominal current

Maximum current

Inrush current

Maximum output fault current (rms)

Maximum overcurrent protection

Tare loss

Frequency

Total harmonic distortion

Power factor

2 pairs MC4

12Adc x 2

15A / 15A

According to the battery specification

Operating voltage 40Vdc – 450Vdc

Maximum allowed charge /

discharge current

40A

Refer to battery box user manual

Number of inputs 1 pair Phoenix connectors

Nominal power

5000VA

Maximum power 5250VA*

3600VA

3600VA

21.7A

24A

15.7A

15.7A

According to country setting

(Programmable 230Vac ± 20%)

16A / 100us

28A

28A

> 0.99 @ full power

Output adjustable: 0.80 leading – 0.80 lagging

Rated 50/60 Hz (Programmable 45-65 Hz)

< 3 %

Active anti-islanding method Reactive power injection

BT INPUT

E5

Output current DC component < 0.5% rated current

< 25W

Maximum efficiency 97.2%

EU efficiency 96.5%

AC connector

* Charging power will be limited at 3200W when charging BX_6.0 battery box.

Line + Neutral + PE; AC plug meets IP67

Grid StandaloneAC INPUT / OUTPUT

Technical Data

57

Page 58

Table 9-1 : Specifications for E5

Model

SYSTEM INFORMATION / COMMUNICATION

User interface

External communication

Variations and flicker

Immunity

Electrical safety

Black-on-white character type LCD display

365 days data logger and real time clock

30 events record

2 RS-485 connections

EN 61000-3-3

CE conformity Yes

Grid interface VDE-AR-N 4105, AS4777, G59/3, EN 50438

Emission EN 61000-6-3

Harmonics EN 61000-3-2

EN 61000-6-2

CS

Immunity

PFMF

IEC 61000-4-2

IEC 61000-4-3

IEC 61000-4-4

IEC 61000-4-5

ESD

RS

EFT

Surge

IEC 61000-4-6

IEC 61000-4-8

IEC 62109-1/ -2, IEC 62040

REGULATIONS & DIRECTIVES

E5

Technical Data

58

Page 59

Page 60

Version 05170803

5013241204

Loading...

Loading...