Page 1

CS64A

Color Sensors

010627a

(Address updated)

Page 2

Contents

1. Specifications ............................................................................... 4

2. Introduction ................................................................................. 5

3. Mounting the CS64A................................................................... 7

4. Wiring the CS64A ..................................................................... 10

5. Adjustment................................................................................. 11

6. Sample Quick Test..................................................................... 12

7. Threshold Setting ...................................................................... 13

8. Characteristics ........................................................................... 13

1.1 Ordering Information................................................................. 4

2.1 Primary Features........................................................................ 6

3.1 Moving Line Applications......................................................... 8

3.2 Fixed Applications..................................................................... 8

8.1 Temperature............................................................................. 13

8.2 Edge Effects............................................................................. 14

8.3 Angle of CS64A to Material.................................................... 14

8.4 Distance Performance.............................................................. 14

8.5 General Information ................................................................ 14

9. Recalibration.............................................................................. 15

10. Maintenance............................................................................... 15

11. Frequently Asked Questions..................................................... 16

12. Troubleshooting......................................................................... 20

13. Support....................................................................................... 20

14. Repairs........................................................................................ 20

15. Warranty.................................................................................... 21

Although great effort has been taken to ensure the accuracy of the information in

this document, Delta Computer Systems, Inc. cannot accept responsibility for

problems resulting from errors or omissions in this document. The information

in this document is subject to change without notice.

Neither Delta Computer Systems, Inc. nor anyone else involved in the creation,

production, delivery, or support of this product shall be liable for any direct,

indirect, or consequential injuries or damages arising out of the use, the results of

use, or inability to use this product.

Copyright (c) 1996, 1997, 1998, 1999, 2000, 2001 Delta Computer Systems, Inc.

Printed in USA

2

Page 3

3

Page 4

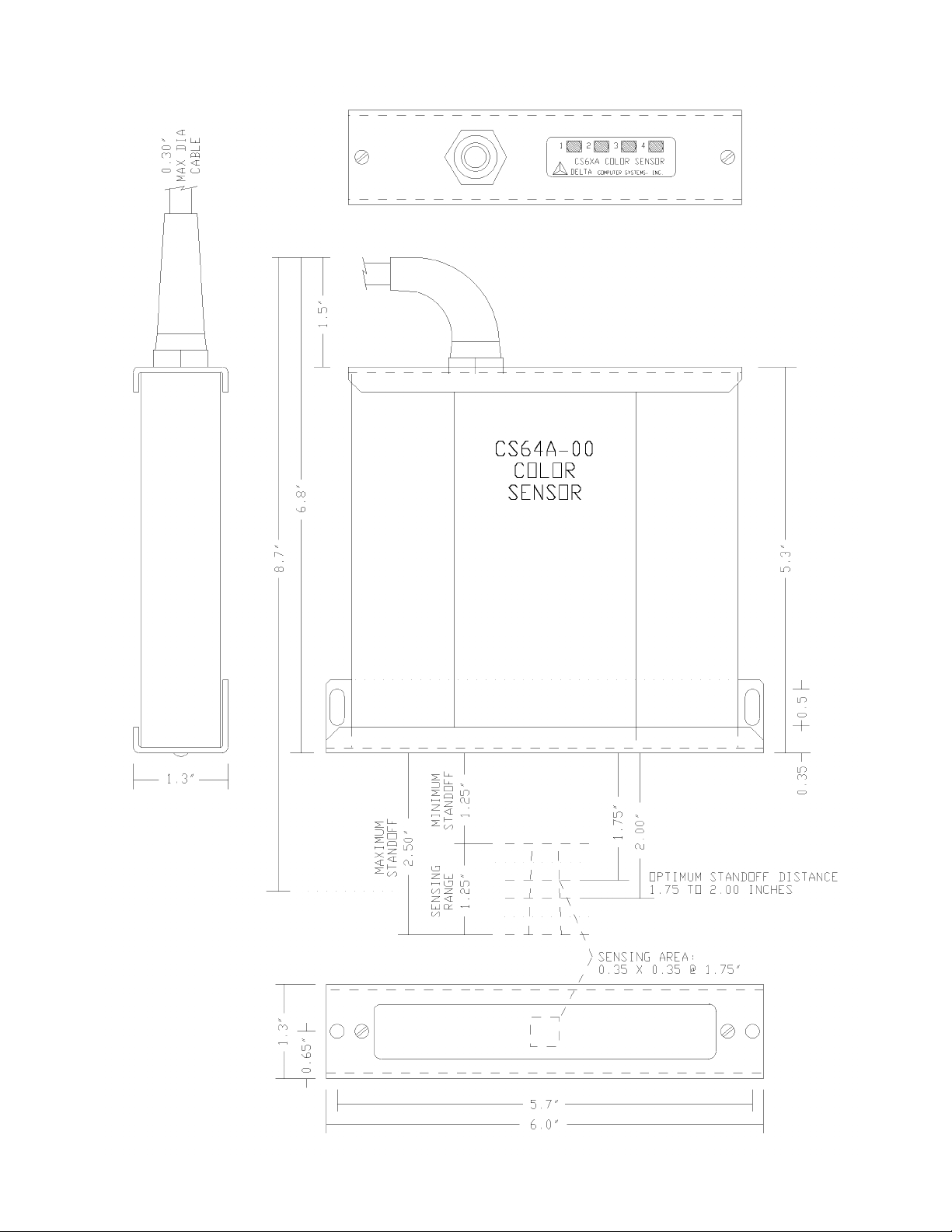

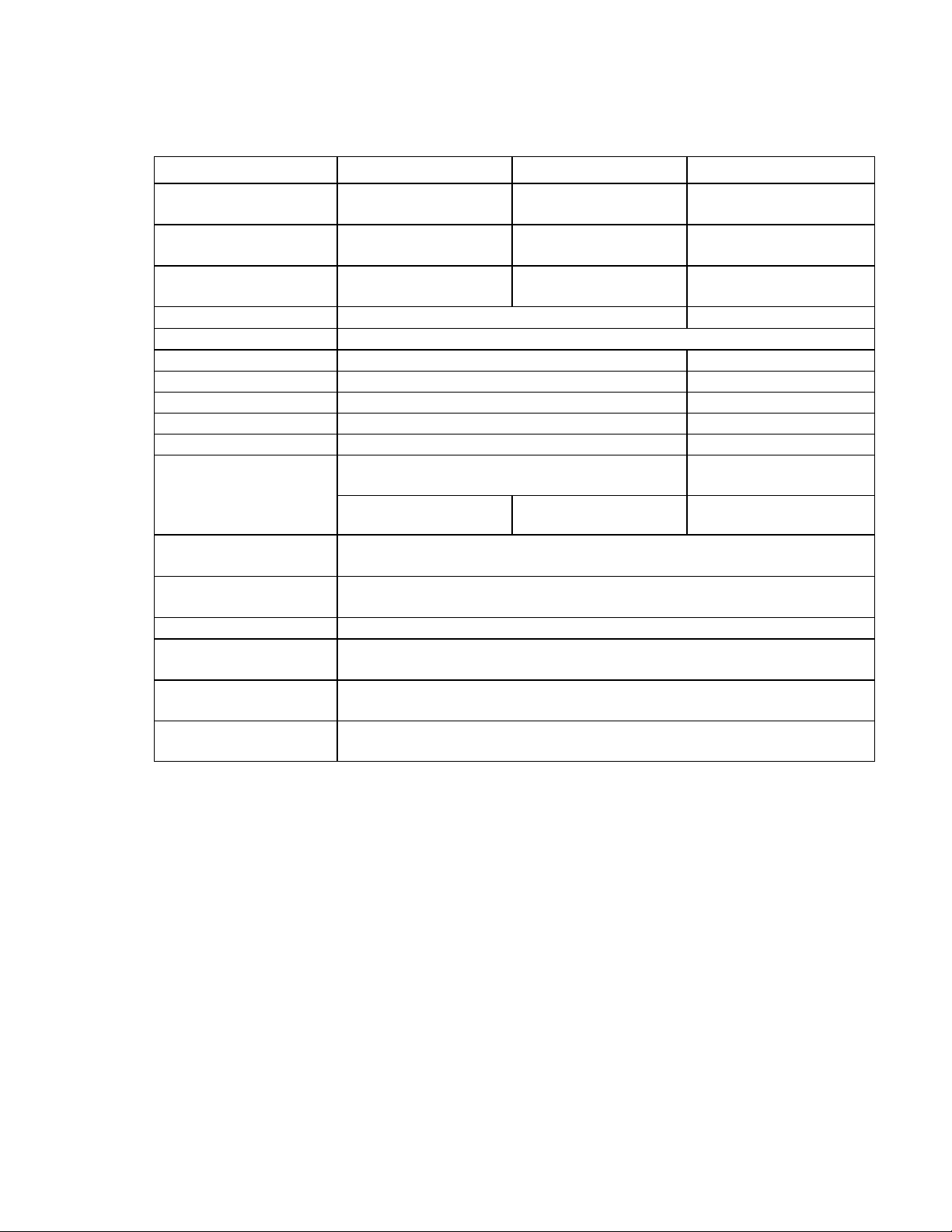

1. Specifications

Model

Sensor-to-Object

Standoff Distance

Sensor-to-Object

Sensing Range

Sensing Area

Response Time

Output Update Rate

Analog Outputs

Color 1

Color 2

Color 3

Color 4

Calibration

At Standoff

Distance

Ratio Variation with

Sensing Distance

Temperature

Stability

Supply Voltage

Current

Consumption

Enclosure

Environment

CS64A-00

1.75 to 2.0” (4550mm) optimum

1.25” (32mm): 1.25 to

2.5” sensor-to-object

0.35” (9mm) square @

1.75” (45mm)

CS64A-02

4.75 to 5.0” (120125mm) optimum

1.25” (32mm): 4.25 to

5.0 sensor-to-object

0.7” (18mm) square @

4.75” (120mm)

CS64A-04-BNR

3.75 to 4.0” (95-100mm)

optimum

2.75” (70mm): 3.0 to

5.75 sensor-to-object

0.48” (12mm) square @

3.75” (95mm)

62us to read all 4 colors 47us to read all 3 colors

< 1 millisecond

Four, 0 to 10V at 5mA max Three, 0-10V, 5mA max

470nm Blue 470nm Blue

880nm Near-Infrared 880nm Near-Infrared

660nm Red 660nm Red

570nm Green N/A

9.5V and 100% ratios (Red/NIR, Blue/NIR, and

Green/NIR) with >99% diffuse reflection

9.5V and 100% ratios

(Red/NIR, Blue/NIR)

1.75” (45mm) 4.75” (120mm) 3.75” (95mm)

0.6% max per 0.25” (6mm) change in sensor-to-object distance (<2% max

over sensing range)

Ratios 0.1%/C typical

+24VDC ±5%

100mA maximum

Dust tight; 6.0 x 5.3 x 1.3” (153 x 135 x 33mm) excluding strain relief;1.25

lb (2.75 kg)

+10 to +40C operating; -25 to +85C storage; 0 to 90% humidity, noncondensing

1.1 Ordering Information

CS64A-00 1.75 to 2.0 inch (45 to 50mm) nominal standoff distance

CS64A-02 4.75 to 5.0 inch (120 to 125mm) nominal standoff distance

CS64A-04-BNR 3.00 to 5.75 inch (75 to 145mm) working distance, Blue, NIR, and Red

Other color sensors are available with standoff distances to 6", update rates to 50

microseconds as well as other color combinations and options. Contact Delta or your

local Delta color sensor distributor for more information, or visit our web page at

www.deltacompsys.com.

6/27/2001 DELTA Computer Systems, Inc. (360) 254-8688

4

Page 5

Introduction

The CS64A color sensor contains a light generation system to illuminate the object to be

sensed, and a light receiving system to read the diffuse reflected light from the object.

The light generation system consists of four sets of light emitting diode (LED) light

sources—a total of 28 LEDs. The CS64A determines color by turning on just one set of

LEDs (one color) at a time and analyzing the light captured by it’s precision silicon

photodiode.

The CS64A color sensor reads four different wavelengths--Blue, Near-infrared (NIR),

Red, and Green. Reflected energy in each of the color ranges appears as a 0-10V signal

on the corresponding four analog outputs, making the CS64A compatible with any PLC,

PC, or system having 0-10V analog inputs.

Using the ratios of Red/NIR, Blue/NIR and Green/NIR, it is possible to distinguish

between a wide range of colors. Very similar colors typically have a 10% difference in at

least one ratio, while some colors may have ratio differences 70% or more.

The CS64A was developed specifically for on-line color sensing applications, including:

• Distinguish between objects to ensure the correct color object is being processed on

your automated production line, such as vehicle headliners, door and body panels,

and seats

• Sort objects by color

• Monitor color variations of materials during manufacture such as carpets and ceramic

tile

• Detect presence of metal coatings or wood varnish

• Monitor color quality of granular foods such as sugar

• Detect paint marks where bar coding is impractical

• Detect over- or under-cooked baked goods

The diffuse LED lighting and large sensing area make the CS64A relatively immune to

material grain direction and similar variations. The CS64A-00's long standoff distance of

1.75 to 2" and sensor-to-target distance variation tolerance of 1.25 to 2.5" are important

benefits in many applications as well. The CS64A-02 has an extended standoff distance

of 4.75-5.00” while the CS64A-04-BNR has a very wide working range of 2.75” (3.00 to

5.75” sensor-to-object).

Each of the CS64A’s four 0-10V analog outputs has an adjustment potentiometer and an

indicator LED. The indicator LEDs come on when the output reaches about 2 volts and

the indicator LED intensity increase with amplitude.

The high-intensity LEDs in the CS64A’s lighting system have a typical life of 100,000

hours. (Actual intensity is 64 times higher than it appears since the LEDs are pulsed at a

low duty cycle).

The intensity of all LEDs varies with temperature due to the properties of the

semiconductor materials used. The CS64A sensors use feedback circuitry to maintain

amplitudes over a wide range of temperature and to compensate for light loss due to

normal LED aging. This feedback along with the long life of the LEDs, greatly reduces

the need for recalibration.

5

Page 6

1.2 Primary Features

• Superior color detection on a wide range

of materials

• Versatile analog outputs allow unlimited

sorting and show data trends

• Long sensing range and standoff distance

• Four color ranges are sensed—from blue

to near-infrared

• Near-infrared differentiates between

materials such as leather, vinyl, and cloth

• Robust LED lighting system—no light

bulbs to burn out

• Feedback compensation for LED aging

• Fast, one millisecond update rate

For more information on Delta’s growing lines of color sensors, motion controllers, and

other industrial products, visit our web site at:

www.deltacompsys.com

6

Page 7

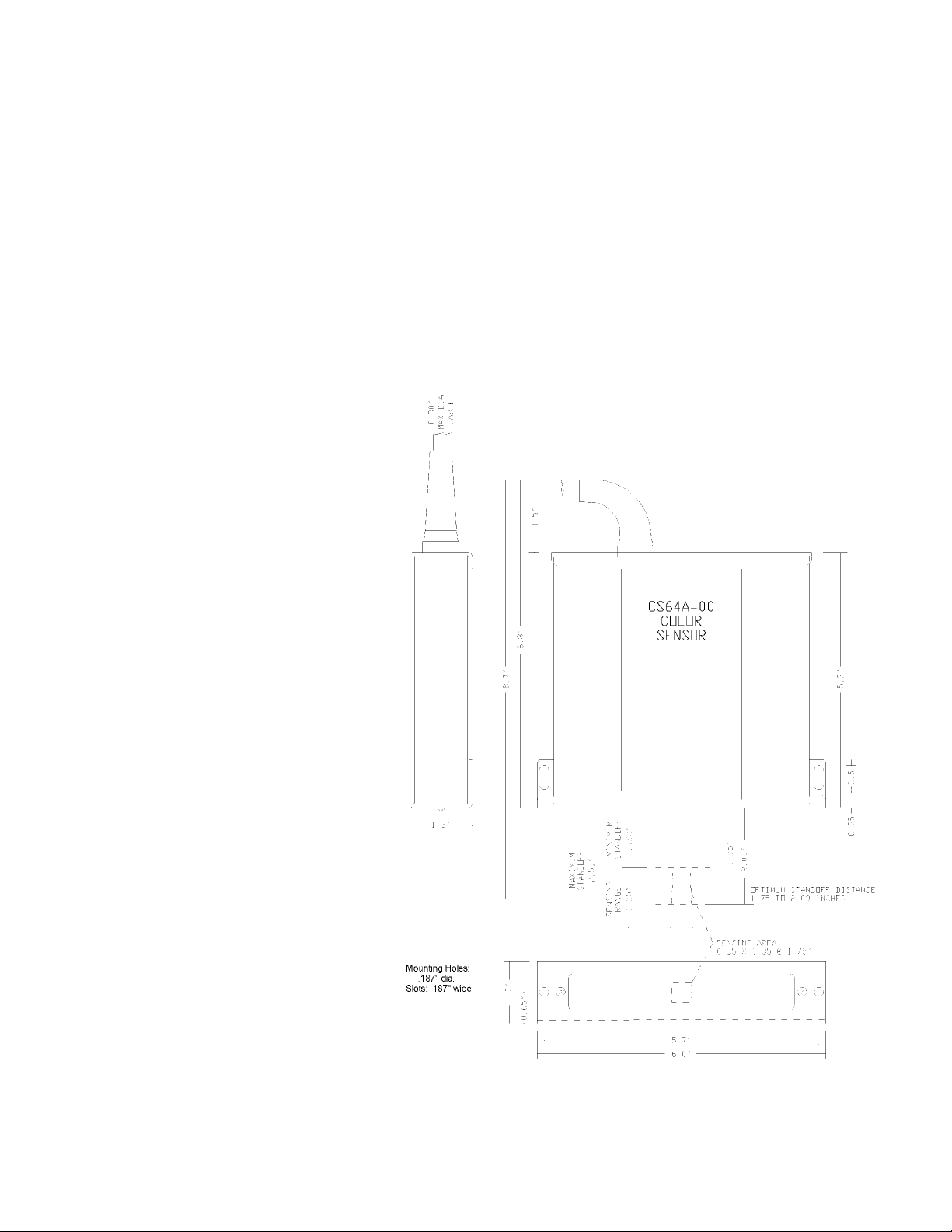

2. Mounting the CS64A

In general, the sensing area should be as dark as possible (especially if small differences

in color are to be detected). Any light that is in the sensing area that is not generated by

the CS64A is a source of error. The Blue and Green colors are more sensitive to

extraneous light than are the Red and NIR colors since these LEDs are less intense.

Small amounts of constant light can sometimes be tolerated, but bright pulsing lights

(such as fluorescent) and sunlight should never be allowed to shine into the sensing area.

Direct sunlight can also cause overheating (or damage if it shines through the lens).

The CS64A-00 should be mounted such that the bottom is 1.75 to 2 inches from the

average target object position. The sensing range will be +-1/2 inch allowing for sensor

to object movement. (See

Specifications for standoff

and range for other models).

The CS64A’s lighting system

is much more intense than it

appears because of the low

duty cycle of its light emitting

diodes (LEDs). However, in

most applications it is

desirable to keep extraneous

light out of the sensing area.

This area includes not only

the area that is directly read

by the sensor (0.35” square

for the CS64A-00), but also

the immediate surrounding

surfaces since light will

reflect into the direct sensing

area. The optimum type of

light block depends on the

application and the

environment.

If it is possible that the

CS64A could be bumped hard

enough to cause damage, it

should be mounted such that

it is protected. To minimize

electrical noise, the CS64A

enclosure should be

grounded.

If the sensor is used in a wet

or corrosive area, order the

OEM package. This package

allows the CS64A to be

mounted inside a NEMA 4X

enclosure. For convenience, a window kit is also available.

7

Page 8

2.1 Moving Line Applications

t

r

q

In cases where the product moves under the sensor as on an assembly line, it is usually

important not to overly restrict headroom (distance from sensor to the target object).

2.1.1 Adequate space and moderate light levels (normal factory lighting, no direct

sunlight)

It is usually adequate to use a plate mounted above the line at a distance approximately

equal to the sensor standoff distance (~2” for the CS64A-00). This plate should be 12”

square or more with the CS64A mounted in the center. The bottom side of the plate

should be painted with a good quality optically flat black paint such as Krylon 1602 Ultra

Flat Black. This plate will prevent extraneous light from being reflected into the sensing

area.

Top View: CS64A with Light Block Plate

CS64A-00

Color Senso

Side View: CS64A with Light Block Plate

Color Sensor Light

Block

Plate

Optional curtain

or brush

2.1.2 Limited space and high or varying light levels

If there is not enough room for a large flat plate, or if a usable size plate is inadequate, a

curtain or brush can be used to block additional light. Ideally, a plate of the largest

practical dimensions would still be used, with the curtains or brushes mounted on the

edges. The bottom edge should just clear the normal travel of the objects. The curtains

and brushes should be of dark materials. If the curtain or brush is close to the direct

sensing area (within 2”), it should be tested to make sure that it does not reflect in the

visible or near-infrared regions (see manual for information on how to test with the

CS64A).

Objects travel

underneath

Light Blocking Plate

– 12” s

uare or more

Bottom of plate and other

inside surfaces flat black

Target Object

Bel

2.2 Fixed Applications

In cases where the product is clamped into a fixture, sensor-to-target distance restrictions

are usually less important.

2.2.1 Fixed applications with very tight control of sensor-to-target distances

In these applications, a rectangular tube of an inflexible material such as sheet metal can

be used between the sensor and object. If necessary, weather-stripping can be used on

the bottom edge to completely block out light without marring the objects. Again, it is

preferable that the tube be as large as practical (ID: 4” x 6” or more) to minimize internal

reflections and that the interior painted optically flat black. If space is very limited, the

8

Page 9

inside dimensions of the rectangular could be a small as 3/4” by 4”, although 1” x 4 ½”

r

g

ject

r

ject

would be preferable. Flat black surfaces are especially important with these smaller

inside dimensions.

Top View: CS64A with Light Block Tube

Side View: CS64A with Light Block Tube

CS64A-00

Color Senso

Light Blocking Tube

– 4” x 6” inside

Light

Block

Tube

Inside of tube

to be flat black

Color Sensor

Optional seal or

weathe

-strippin

Target

Ob

2.2.2 Fixed applications where it is necessary to accommodate variations

in sensor-to-target distances

In some applications, the standoff distance will vary, if not during the normal sensing

time, then during loading or unloading of the objects. In these applications the tube must

be of a very flexible material. A brush can be used, as can deep weather-stripping or a

bellows for maximum accommodation.

Side View: CS64A with Bellows

Color Sensor

Bellows

Target

Ob

Inside of bellows

to be flat black

As with rigid tubes, it is preferable that the bellows be as large as practical (ID: 4” x 6”)

to minimize internal reflections. The inside of the bellows should be optically flat black.

It is not always practical to paint flexible devices, so it is important to ensure that the

material itself is black. Flat or matte finishes are preferable over gloss finishes,

especially in bellows with small inside dimensions.

If space allows, flexible polyurethane bellows are available from McMaster-Carr with

inside dimensions of 6 5/8” square or 4” square. (Outside dimensions are 8 5/8” and 6”,

respectively). McMaster-Carr also carries a wide variety of brushes and vinyl weatherstripping, door gaskets, and rubber wear strips.

9

Page 10

3. Wiring the CS64A

The CS64A requires a 24Vdc power source capable of supplying 100mA. It should be a

linear power supply and not be used to supply other loads. A 250mA fast blow fuse

should be used between the power supply and the sensor.

The power supply voltage must be maintained within 5% (22.8 to 25.2V) at the sensor.

A P6KE30A Transzorb protects against overvoltage and reverse voltage. This device

limits the working voltage to a maximum of 25.6 volts. On the other hand, voltages

below 5% may cause the light intensity to be reduced and calibration to be lost.

Delta recommends connecting the CS64A's 24V power supply common to the CS64A's

enclosure (as shipped), so the power supply should be isolated and not connected to

ground at any other point.

A five pair, shielded, 0.3" max OD cable, (Alpha 5475C or Consolidated 5775) will fit

the CS64A strain relief and will be adequate for most environments up to about 20 feet.

For longer distances or noisy environments, heavier gauge wire and better shielding may

be required.

The analog output wire pairs should be connected to differential inputs for best noise

performance.

The CS64A uses 45 degree terminal blocks that are accessed by removing the top cover.

Insert the cable through the strain relief before connecting to the terminal blocks.

Block Terminal Signal

TB1 +24 Power Supply Positive

TB1 CMN Circuit Common (PS and Outputs)

TB1 CMN Circuit Common (PS and Outputs)

TB1 GND Enclosure Ground*

TB2 1 Blue: Color 1 Output

TB2 2 NIR: Color 2 Output

TB2 3 Red: Color 3 Output

TB2 4 Green: Color 4 Output

*The CS64A is shipped with a jumper wire between the GND and CMN terminals,

connecting the circuit common to enclosure ground. This is the recommended grounding

for lowest electrical noise. To isolate the circuit common from ground, remove this

jumper.

10

Page 11

4. Adjustment

The CS64A-00 is factory calibrated to read Spectralon as 9.50V on all four colors (100%

ratios) at 1.75” standoff. (Refer to specification table for standoff distance for other

models). Spectralon has >99% reflectance over the visible/NIR spectrum. (The 9.50V

setting ensures that the outputs do not exceed 10V over the full sensing range). You can

either maintain this calibration or match the calibration to your application.

In any case, you should define a calibration standard using either a white calibration

standard material or the lightest material that the sensor will see. Make the calibration

piece large (preferably about 4” square) for ease of alignment. The calibration material

must be opaque in the visible and NIR ranges. If this is not possible, bond a piece of

opaque material (e.g. flat black aluminum plate) to the reverse side of the calibration

piece.

Either adjust to specified values using the standard or record the factory values for future

reference. Refer to Section 7 for recalibration period recommendations.

Tip: If you decide to establish your own calibration standard, you should do so before

setting up ratio thresholds for your application. Otherwise, if you change the relative

amplitudes of the CS64A color outputs, you will need to change your ratio thresholds as

well.

For best results, adjust the gain with the CS64A at normal operating temperature and in a

normal mounting position, etc. Let it warm up for 15 minutes or more.

To calibrate the CS64A, place your calibration material under the sensor at the normal

standoff distance (1.75" for CS64A-00) and adjust for each output to read 8.5 volts (9.0

volts for very white material).

If possible, for maximum convenience, adjust the gains in software, or in the analog

circuitry to which the CS64A is connected, rather than using the pots inside the CS64A.

If you choose to use the pots in the CS64A, they are located as shown below.

Color 1 Color 2 Color 3 Color 4

Blue NIR Red Green

11

Page 12

5. Sample Quick Test

You can do a quick test using the CS64A simply by wiring the +24V power, placing the

samples one at a time at the standoff distance (1.75 to 2 inches from the bottom of the

CS64A-00), recording the analog readings, and calculating the ratios on a calculator:

1

2

3

4

5

6

7

8

9

10

11

12

Measure Calculate

Sample NIR Red Green Blue Red/NIR Grn/NIR Blu/NIR

Differences in the Red/NIR, Green/NIR and Blue/NIR ratios are used to

differentiate between colors.

Usually, the amplitudes cannot be used directly since they vary with distance, dirt, etc.

Occasionally, it is necessary to use the NIR amplitude to differentiate between shades of

the same color (light and dark gray, for example). If the NIR amplitude is used, be sure

that:

1. The sensor to target distance is tightly controlled,

2. The sensor window is kept clean and/or

3. There is sufficient variation in the NIR amplitude—10% is usually adequate for very

clean and controlled conditions, while more difference will allow for more distance

variation.

12

Page 13

6. Threshold Setting

To differentiate between colors, set up thresholds on the Red/NIR, Green/NIR, and

Blue/NIR ratios.

If a sample is different from every other sample in one of the ratios, a set of thresholds

(upper and lower) on that ratio can sort that color from all of the others.

Since the Red and NIR colors are the strongest, it is often advantageous to use the

Red/NIR to sort as many of the samples as possible, setting secondary thresholds on the

Blue/NIR and Green/NIR ratios as needed to sort the remaining samples. You may not

need to use all of the ratios, often one or two will be enough for a given set of samples.

The larger the ratio difference between samples, the better the system will work. The

minimum difference required for reliable operation depends on the variability of the

colors, the presentation, and the ambient conditions. The presentation of the samples

includes variations in the distance from the CS64A to the samples, the angle of the

samples, etc. Ambient conditions include extraneous light, temperature, etc.

Generally a ratio difference of 10% or more will provide good result. If there is a ratio

difference in more than one ratio, the differences can be combined before checking

against thresholds.

As explained in the previous section, the amplitudes typically cannot be used directly

since they vary with distance, dirt, etc.

Sometimes, however, it is necessary to use thresholds on the NIR amplitude to

differentiate between shades of the same color. If the NIR amplitude is used:

1. The sensor to target distance must be constant,

2. The sensor window must be kept clean and/or

3. There must be sufficient variation in the NIR amplitude.

For very clean and controlled conditions, a 10% difference in the NIR amplitude may be

adequate, while more difference will allow for more distance variation and more dirt

buildup on the sensor window.

Of course, in your program, you will want to make the thresholds variables so they can

be adjusted if required.

7. Characteristics

7.1 Temperature

The feedback circuitry automatically compensates for the normal LED intensity variation

with temperature yielding a typical stability of 0.1%/C for the Red/NIR, Blue/NIR, and

Green/NIR ratios (0.3%/C maximum). In the most critical applications, the CS64A

should be maintained at a constant temperature since the LED color varies slightly with

temperature.

13

Page 14

7.2 Edge Effects

The CS64A-00 sees an area of about 0.35 x 0.35 inches. When material is entering or

leaving the sensing area, the color can appear wrong for a variety of static and dynamic

conditions. For best results, read the analog outputs and compute the color only when the

CS64A sees the intended material over the entire viewing area.

7.3 Angle of CS64A to Material

The most consistent readings are obtained if the material is perpendicular to the CS64A

in both planes. If angle differences cannot be avoided, it is preferable to have the angle

the narrow way and the standoff at the longer end of the recommended range (2 inches

for CS64A-00). In some cases when dealing with shiny materials, angling the sensor

slightly with respect to the target may produce more consistent readings. Concave

surfaces should be avoided if possible.

7.4 Distance Performance

The amplitudes of the signals reach the maximum value close to the CS64A (about 1.5"

for CS64A-00) and then decrease with distance. The ratios of Red/NIR, Green/NIR and

Blue/NIR are adjusted to be constant within the specified tolerance over the specified

working range of the sensor. As the sample is moved further from the CS64A, the ratios

will gradually become less consistent. This effect, along with the decrease in signal

amplitude, limits the usable range of the CS64A. In applications where the differences in

samples are large, the CS64A-00 may work well out to 3" or more.

7.5 General Information

The term "color" actually implies visible light--wavelengths from about 400nm (violet) to

about 750nm (deep red), although in this document any wavelength that can be seen by

the CS64A is referred to as a color.

With high intensity blue LEDs (450nm) and several visible wavelengths up to 700nm

available, DELTA's sensors can be made to see practically the entire visible color

spectrum. But the capability does not stop there; the precision photodiode in the sensors

can see into the near infrared up to about 1,000nm, and LEDs are readily available in this

region as well.

NIR LEDs are used in the CS64A-00 and similar general purpose color sensors to

provide a baseline value that is relatively constant for a given type of material regardless

of color. This "divisor color" compensates for distance variations.

The NIR spectrum can be valuable in special applications. For example, the ratio of two

different NIR colors can be used to detect certain types of glue, while ignoring visible

color variations. Contact Delta for more information on these applications.

14

Page 15

8. Recalibration

The LEDs have a typical operating life of 100,000 hours or about 10 years of continuous

operation.

The intensity of LEDs varies with temperature and aging due to the properties of the

semiconductor materials used. The CS64A sensors use feedback circuitry to maintain

amplitudes over a wide range of temperature and to compensate for LED aging.

The automatic compensation will not eliminate 100% of the variation, so calibration

should be checked regularly. The recalibration period depends on the application. In

many cases, every three to six months or more may suffice, while in very critical

applications, it may be necessary to check every week or every shift.

To check, place the calibration material in the sensing area at the typical sensing distance

and monitor the outputs with a voltmeter or your data acquisition system.

Typically, if any change is needed, you will only need to change one or two gains

slightly. (See Adjustments section for details). If other adjustments seem to be needed,

make certain that you have the proper calibration material and the sensor window and

sensing area are clean before adjusting.

Unless you are using narrow thresholds on the NIR amplitudes, we do not recommend

readjusting all outputs to compensate for small variations in amplitude. Calculate the

ratios, and adjust only to compensate for intensity degradations that affect the ratios.

If practical, we recommend that either a provision be made for adjusting the gains in

software, or that gain adjustment capabilities be built into the analog circuitry to which

the CS64A is connected. The gain adjust pots on the CS64A can be used if no other

adjustment point is available.

9. Maintenance

Cleaning: Under normal conditions, the CS64A requires little or no maintenance other

than keeping the window and sensing area clean. Use only water and cleaning materials

compatible with polycarbonate, such as isopropyl alcohol.

In dusty conditions, an automated air nozzle can be used to help keep the window clean.

The ratio calculations will compensate for signal strength degradation down to about 75%

of normal signal. Beyond that, performance will start to suffer. Once the window and

viewing area are cleaned, the ratio calculations will automatically readjust to the clean

conditions.

If the window becomes scratched or damaged, it should be replaced. Order from Delta:

Part No: CS64A-Window.

15

Page 16

10. Frequently Asked Questions

Q. How many different colors can the CS64A detect?

A. Unlike many color sensors, the CS64A does not limit the number of sorting outputs.

The CS64A, when used with a host PLC or computer with math capabilities, can sort into

virtually unlimited categories.

Q. What if my materials are textured?

A. The CS64A has been very successful in handling a variety of textured, grainy, and

other difficult surfaces where other color sensors give inconsistent readings.

Q. Can the CS64A work with patterned materials?

A. The CS64A-00 reads the average color within its sensing area of approximately 9mm

(0.35”) square. If the pattern is smaller than this area, the CS64A-00 will provide

consistent readings from the sample. For larger patterns, contact Delta for special CS64A

versions with larger sensing areas.

Q. Can the CS64A distinguish between hues of the same color (e.g. light red and dark

red)?

A. Yes, in most cases. If the colors are exactly the same hue, then all of the ratios

(Red/NIR, Blue/NIR, and Green/NIR) will be the same, however the amplitude of the

signals will vary. Generally it is best to use the NIR amplitude to differentiate between

lighter and darker versions of the same colors sine the NIR is the strongest light and less

susceptible to electrical and optical noise. The use of small differences in amplitudes

requires consistent sensor-to-target distance and a reasonably clean environment.

Q. Is it true that the CS64A can distinguish between different materials of the same

color?

A. It depends on the materials. For example, with carpet, vinyl and leather, the CS64A

was able to separate all three colors in each material type, and also all of the material

types from each other for a total of nine unique categories.

Q. What if I can’t position the sensor close to the sample?

A. The CS64A-02 handles a sensor-to-object range of 110-125mm (4.25-5”) standoff

distance as compared to the 35-60mm (1.25-2.5”) of the CS64A-00. If a wide variation

in sensor-to-object distance is needed, the CS64A-04-BNR operates from 75-145mm (3-

5.75”).

Q. How can I verify that the CS64A will work with my samples?

A. Delta will test your samples for you and send a report showing the performance of the

CS64A on your samples and recommendations for your application. There is no charge

for this testing on new applications. Demonstration units are also available to qualified

customers.

Q. What outputs are available from the CS64A?

A. The CS64A outputs four 0-10V analog voltages proportional to the diffuse reflected

light in four color ranges: Red, Blue, Green, and Near-infrared (NIR). Special versions

may have less than four outputs, and/or different color combinations. A 12-bit A-D

converter has adequate resolution to handle these signals. In additional to allowing

almost unlimited sorting, the analog outputs also allow color variation trends to be seen.

Q. How is sorting typically done?

16

Page 17

A. In PLC sorting applications, the host system typically reads the four 0-10V signals

and sets thresholds on the Red/NIR, Blue/NIR, Green/NIR ratios and NIR amplitude

readings as needed. (Usually not all four are required in a given application). Using

ratios compensates for most variations caused by sensor-to-target distance changes and

dust on the sensor window.

Q. Does the CS64A require special lighting?

A. No additional lighting is required. The CS64A is completely self-contained with its

own lighting system using high intensity light-emitting diodes (LEDs). No external light

is needed and for maximum consistency, ambient light should be blocked from the

sensing area.

Q. What are the power requirements for the CS64A?

A. The CS64A is rated for 24Vdc ±5% and 100mA maximum. Typical current draw is

about 40mA. Although the power supply is not critical, for best noise performance a

dedicated, linear supply is recommended. A dedicated supply also allows the circuit

common and case ground to be connected inside the sensor, which often results in lowest

electrical noise.

Q. Does the CS64A require any other inputs?

A. No. The CS64A "free-runs" and outputs are updated at a 1ms rate. Filtering

minimizes glitches, so it is not necessary to synchronize the A-D to the sensor.

Q. Can I use the CS64A in a washdown environment?

A. The standard enclosure for the CS64A is dust-tight. For wet environments, any

model of the CS64A can be ordered with a special package that allows it to be mounted

into a sealed enclosure of your choice (specify –OEM at the end of the part number). An

optional window kit is available as well.

Q. Does the CS64A have a color sensitivity specification (e.g. delta E (with CIELAB or

CIEXYZ coordinates) that is common with spectrophotometers)?

A. Since on-line applications vary so widely, this specification would be of limited

value. Instead, Delta will test your samples for you and send a report showing the

performance of the CS64A on your samples and recommendations for your application.

(No charge on new applications). Demo units are also available to qualified customers.

Q. How sensitive is the CS64A to changes in angle of the object?

A. The sensitivity to angles varies from very insensitive on matte surfaces to quite

sensitive on gloss surfaces. This effect can be minimized with proper orientation of the

sensor to the object. If possible, the varying angle should be oriented with the small

dimension of the CS64A.

Q. How about curved surfaces?

A. Again, this is more critical on glossy surfaces and, if possible, the curve should be

oriented with the small dimension of the CS64A. Concave, glossy surfaces should be

avoided if possible as they can cause direct reflections.

Q. I would like to have the sensor “look” through a slot. What materials/paints would be

good to look through?

A. Ideally, the inside surface of the slot should be optically flat black. In most cases, this

can be easily achieved by painting with a high quality, flat black paint such as Krylon

17

Page 18

1602 Ultra-flat black. Some materials and finishes may provide acceptable performance

without painting. They may not be obvious, however black anodized aluminum reflects

in the near-infrared spectrum, for example, and should not be used without painting. The

CS64A can be used to test materials—look for very low readings on all four outputs. A

slot is a good way to eliminate ambient light, and soft weather-stripping or brush can be

used to seal the bottom if required.

Q. What is the minimum size that I can make the slot that the CS64A looks through?

A. If space is tight, you can reduce the slot to about 5/8 x 3 inches providing the sensor

is centered well. A better solution might be to angle the sides of the hole so the dimension

closest to the sensor is 3/4 by 3 1/2 inches and tapers down to about 1/2 x 2 inches.

Q. Can I use the CS64A pointing up?

A. The CS64A can be mounted in any orientation. With the sensor pointing up, it is

important to watch dust build-up on the sensing window. Using ratios dramatically

reduces the sensitivity to dust and other environmental factors.

Q. How often should the calibration be checked?

A. As with all similar instruments, the calibration of the CS64A should be checked

periodically. The CS64A uses special compensation circuitry to greatly reduce the time

and temperature drift inherent with the LEDs. The required frequency of recalibration

depends on the required precision, and could be as often as once a week, or as infrequent

as once a quarter or more. It is generally most convenient to do the calibration in

software in the host system, in which case it can be highly automated if desired.

Q. Is it necessary to use a special material to verify calibration of the CS64A?

A. No. As explained in the CS64A manual, the user can use virtually any stable material

as a calibration standard. The CS64A is factory calibrated to read Spectralon (>99%

diffuse reflective over the visible and NIR range) as 9.50V volts at 1.75" standoff

distance. If you wish to maintain the factory calibration, Spectralon is available from

Labsphere (www.labshpere.com). They sell this material in a convenient 2" diameter

disk: SRS-99-020 99% 2.38D x 0.60H. If you place this disk 1.75" from the bottom of

the sensor, block out all ambient light, and adjust all four outputs to 9.5V, you will

duplicate factory calibration. (You can adjust either at the sensor or through software).

Q. If a color sensor is disconnected and not used for a several months and then

reconnected and powered will it require calibration?

A. It should not change significantly over time just sitting on the shelf if it is protected

from dirt, etc. However, we would recommend recalibrating until it can be verified that it

is not necessary in your application. Thanks to the feedback compensation, the CS64A

stabilizes within a few minutes of powering on.

Q. I left a demo unit running overnight and am getting slightly different readings. Why

is this?

A. Our demo units probably do not meet the specifications for temperature and time

drift. On demo units, we verify basic functionality and recalibrate before shipping, but we

do not check drift. Production units have low temperature and time drift. Although all

LEDs experience intensity changes with both temperature and time, the CS64A uses

special circuitry to dramatically reduce this variation. If all readings are going down, this

could also be due to dust on the sensing window or an increase in distance from sensor to

target material. Using ratios automatically compensate for these changes. Although any

18

Page 19

color sensor will require periodic calibration checks, this can typically be done at widely

spaced intervals with the CS64A. The drift of demo units is not representative of the

performance of production units.

Q. What are the limitations to the detection of colors?

A. The measurement consistency varies from application to application. Here are the

various error sources associated with any color sensor, including the CS64A.

Sample color variations: Often colors vary from sample to sample. Dark objects tend to

display the largest amount of variations. If possible, check multiple samples over time to

verify consistency before setting up the thresholds.

Presentation variations: The largest variation in multiple readings of the same object is

typically differences in the orientation of the object to the sensor. Not only does the

distance from the object to the sensor effect the readings, but so does the angle of the

object. The least sensitive objects are those with a matte or other non-glossy finish and

with a flat to slightly convex surface. The most difficult objects have a gloss finish and a

concave surface. The CS64A-00 handles these types of variation better than most color

sensors, in fact spectrophotometers often require contact measurements which eliminate

distance variations but also make them unsuitable for most on-line applications. Small

sensor-to-object variations (~1/4") typically only cause a few tenths of a percent variation

in ratios of the CS64A's readings--see spec sheet for worst case specs. Angle variations

are not specified and are dependent on glossiness of the object.

Environment: Dust collecting on the CS64A's window reduces signal strength. Use of

ratios eliminates errors from uniformly distributed dust, but eventually the loss of signal

strength will impact performance.

Noise: Electrical and optical noise is typically the next largest variation from reading-toreading of the same object. Noise is greater for green and blue since the green and blue

LEDs are less intense, and less for NIR and red. Optical noise is primarily caused by

changing ambient light conditions. Extraneous light in the sensing area is an error signal

and should be eliminated as much as possible. Low levels of constant light may be

tolerable, while sunlight is almost never tolerable. For lowest electrical noise, we

recommend connecting the CS64A analog outputs to differential inputs using shielded

twisted pair wires and a dedicated power supply, which allows the circuit common, and

case ground to be connected inside the sensor. This noise can also be effectively

eliminated in many applications simply by averaging multiple readings.

Temperature: Output voltage variation with temperature is specified and 100% tested.

The LED color also drifts slightly with temperature, but this is insignificant in most

applications.

Time: There is a certain amount of reading variation over time, typically a few tenths of

a percent per week or less. This can be dealt with by recalibrating more often in critical

applications.

19

Page 20

11. Troubleshooting

The CS64A's output indicator LEDs provide helpful troubleshooting information.

The green LEDs come on when the output voltage reaches approximately 2 volts and

gradually increase in intensity as the output voltage increases, so they should be at least

slightly on for all but very dark objects.

If the green indicator LEDs are off (or very dim), when light colored material is in the

normal sensing area, check for:

1. Dirt buildup on the window

2. Incorrect sensor to target distance

3. Problems with power supply or wiring

12. Support

Delta offers extensive telephone support on all of its products, both before and after the

sale. Delta offers testing of samples using color sensors or spectrometer. To have

samples tested, send them to:

On new applications, this testing is typically done at no charge. If required, training and

field support can be provided on a time and expense basis.

Delta Computer Systems, Inc.

1818 SE 17

Battle Ground, WA 98604

Attn: Color Sample Testing

(360) 254-8688

FAX (360) 254-5435

th

Street

13. Repairs

If a CS64A needs repair, call Delta to receive an RMA number before returning unit.

Including a brief description of the problem will help to speed the repair time.

20

Page 21

14. Warranty

The Products shall be free from defects in materials and workmanship under normal and

proper use and service for a period of one (1) year from the date of shipment by DELTA.

The obligation of DELTA under this warranty shall be limited to repairing or replacing

the Product or any part thereof, which, in the opinion of DELTA, shall be proved

defective in materials or workmanship under normal use and service during the warranty

period.

Defective Products shall be returned, postage prepaid, to DELTA at the address set forth

in Section 12.

DISCLAIMER OF OTHER WARRANTIES. EXCEPT FOR THE SPECIFIC

EXPRESS WARRANTY CONTAINED IN THIS SECTION, THERE ARE NO

OTHER REPRESENTATIONS OR WARRANTIES MADE BY DELTA,

EXPRESS OR IMPLIED. DELTA EXPRESSLY DISCLAIMS ANY AND ALL

IMPLIED WARRANTIES, INCLUDING ANY WARRANTIES OF

MERCHANTABILITY AND ANY WARRANTIES OF FITNESS FOR A

PARTICULAR PURPOSE. FURTHER, DELTA DISCLAIMS ANY LIABILITY

FOR SPECIAL, CONSEQUENTIAL OR INCIDENTAL DAMAGES RESULTING

FROM ANY BREACH OF WARRANTY BY DELTA.

21

Page 22

Index

Analog output, 5, 6, 10

Angle, 13, 14

Applications, 5, 14

Fixed, 8

Moving Line, 8

Black, flat, 8, 9, 11

Calibration, 4, 10, 11, 15

Material, 11, 15

Re-, 5, 11, 15, 18

Spectralon, 11, 18

Cleaning, 15

LEDs, 5, 6, 7, 13, 14, 15, 20

Aging, 5, 15

Operating life, 15

Light, extraneous, 7, 8

Mounting, 7, 8

Bellows, 9

Brushes, 8, 9

Curtain, 8

Light block plate, 8

Light block tube, 9

Near-infrared (NIR), 14

Amplitude, 12, 13

Purpose, 14

NEMA, 7

OEM package, 7

Orientation, 18

Power supply, 10

Ratios, 5, 13, 14

Threshold, 11, 13

Sorting, 17

Standoff distance, 4, 9, 16

Target object, 7, 8, 14

Temperature, 5, 13

Update rate, 6

Wiring, 10

22

Loading...

Loading...