Page 1

CS2 Color Scanner

A Self-Contained, Easy-To-Use Scanning/Lighting System in a

Compact Package For Production Line Automation Applications

The CS2 Color Scanner analyzes

reflected light captured by a silicon

cell.

It determines color by turning on only

the desired color at a given time using

its patented, solid-state lighting

system.

The CS2 then activates data outputs

based on the relative magnitude of the

Base color and the ratio of the Base

color and the Sense color.

Primary features

•

Fast response rate: 500

microseconds, 50 uS optional.

•

100,000 hour life LED lighting

system

•

Automatic adjustment to changing

ambient

•

Optically isolated outputs for Base

limit and Ratio limit. Analog

outputs for Base and Sense colors

•

Easy set-up using integrated bar

graph display

•

Compact size: 6 x 6.4 x 1.25"

•

Low power requirements: 24Vdc @

250 mA maximum

•

Color range options: blue to nearinfrared

•

Versatility: Other options include

optimizing computer interface. Use

with rotary pulse generator to check

product or defect length, too.

Use the CS2 Color Scanner to:

•

Sort objects and compare

peeled vs. unpeeled

organic vs. non-organic

ripe vs. green

over-ripe/ro tten vs. normal

•

Detect product defects such as

stains

spills

knots

over or undercooked product

•

Align

materials

labels

packages

•

Read paint markings

where bar coding or inkjet

printing is impractical or

impossible

The CS2 detects deviations from

normal or average color, based on the

Sense/Base ratio.

It can be configured to detect either a

high or low ratio. whether that's a

feature needed to be recognized or a

product defect.

Using the narrow-line scanning area

option, a wide area up to 1.25" can be

scanned for defects or features.

Detecting green areas on carrots, knots

on wood, and burned cookies are

applications that typically use the Low

Ratio setting. Detecting white ends on

asparagus is an example of a High

Ratio setting.

Setup is a simple, three-step

process

1. Mount scanner(s)

2. Wire power & outputs

3. Adjust gains & thresholds and

you're your way to the benefits of

improved product quality. Fast!

Where to find more information

Free Sample Testing 2

How The CS2 Works 2

Using the Displays 3

Bar Graph Display 3

Status Indicators 3

Inputs and Outputs 3

Scan Cycle 3

Base & Sense Limit Outputs 4

Data Ready Output 4

External Trigger Input 4

Threshold Analog Inputs 4

Analog Outputs 4

Mounting the CS2 5

Wiring 6

Configuration 8

Adjustments 9

Color Tolerances 10

Pencil Sorting Example 10

Putting It To Work 11

Comparing Colors 11

Application Guidelines 12

Power Supplies 12

Electrical noise 1 2

Data Skew 12

Color Errors 12

Background Errors 12

Reflections 12

Intensity Variations 12

Using Multiple CS2s 12

Technical Information 14

Ordering Information 14

Company Profile 14

General Application Information 15

:

11719 NE 95th Street, Vancouver, Washington 98682-2444 (360) 254-8688 Fax (360)254-5435

email@deltacompsys.com http://www.deltacompsys.com

Page 2

CS2 Color Scanner

Free Sample Testing

Delta will test your samples and tell you if your application

is a candidate for the CS2 color scanner (or another Delta

color scanning product).

This service is available to anyone with a potential

application. Simply send the samples, along with a business

card (se we can call and get a brief description of the

application) to:

Delta Computer Systems, Inc.

11719 NE 95th Streed, Suite D

Vancouver, WA 98682

Attn: Steve Nylund

If this brochure is more than a year old, please call and

cornfirm our address before sending. Please call (360)254-

8688.

After receiving your samples and discussing the application,

we will test your samples using a CS2 scanner and/or a

spectrometer. Will will then recommend a praticular

configuration for online testing.

Take advantage of the offer today. It's easy!

How The CS2 Works

The CS2 measures the difference in reflected light between

two light sources. In its standard configuration, the

reference color is 880-940nm (near-infrared) which is

referred to as the Base color. The second light source is

660nm (red) which is referred to as the Sense color. The

reflected color is measured by turning on the Base and Sense

high intensity LEDs, one color at a time, and reading a

silicon photocell. The amplified information is stored so

that the measured color information will still be present

when the LEDs are off. The LEDs are on for only about 20

microseconds out of the 500 microsecond cycle in order to

reduce power and maximize life.

Once the reflected Base and Sense color amplitudes are

stored, the current or real time-time values are subtracted

from the running averages ( running averages are derived

from the minimum color amplitudes) for each color. The

running averages change ove r time, allowing the CS2 to

automatically adjust to changes in temperature, ambient

lighting, etc., and making periodic recalibration to

compensate for these changes unnecessary.

By comparing the ratio of the Base and Sense colors, a

determination can be made as to when and where a color

deviation occurs. The CS2 can be configured to detect either

a Low or High Ratio deviation. Example applications where

the Low Ratio setting is used include detecting green areas

on carrots, knots on wood and burned cookies, while the

High Ratio setting would be used to detect white ends on

asparagus, some paint applications, eand so on. The default

setting is Low Ratio.

Delta Computer Systems, Inc.

email@deltacompsys.com http://www.deltacompsys.com

When more sophisticated filtering, thresholds, or limit

algorithms are needed, the CS2 provides an easy interface to

an optimizing computer. In addition to analog inputs to

permit control of the Base and Sense Thresholds, analog

outputs are provided for Base and Sense colors. The outputs

do not provide absolute color information, but provide

relative values that can be processed by an optimizing

computer.

, 11719 NE 95th Street, Vancouver, Washington 98682-2444 (360) 254-8688 2

Page 3

CS2 Color Scanner

y

g

y

y

y

y

g

(

)

(

)

(

)

Using the Displays

LED's

LED's

Bar Graph Display

In order to make adjustment easy, the CS2 contains its own

voltmeter with a bar graph display which is visible through

the top. This display uses a "moving dot" technique where

the segment position represents the amplitude of the

reflected light.

Output Bar Graph Displa

ht bar indicates Sense Color

Bri

Green

Yellow

Less intense bar indicates Base Color

Red

The lowest voltage segments are yellow, the center green,

and the highest are red. Usually, once the Gains are

adjusted, the background intensity will be no higher than the

yellow segments and normal objects will be in the green

range. The 10th (red) segment indicates an overrange

condition; at this point the readings are invalid. The Gains

need to be set such that the highest intensity is not higher

than the 9th segment.

Both the Base color and the Sense color are simultaneously

displayed using a different intensity for each color. The

brighter LED represents the Sense color.

Status Indicators

Four indicators provide status of the digital inputs and

outputs. Indicators are lit when the condition they represent

is true (Output NPN transistor ON).

Bar Graph

TB2

TB1

Status

Indicators

Trig In

Data Read

Trig In

Base Limit

Sense Limit

Inputs and Outputs

The CS2 provides two analog and three digital outputs and

two analog inputs. The digital outputs are: Data Ready,

Base Limit and Sense Limit. All three are optically isolated

uncommitted NPN open-collector outputs.

The two analog outputs provide voltages proportional to the

real time Base color and Sense color. Updated every scan

cycle, the outputs range from 0-10V and will drive high

impedance inputs (2 kohms or higher). These outp uts are

not temperature compensated and must be used with the

appropriate software algorithms.

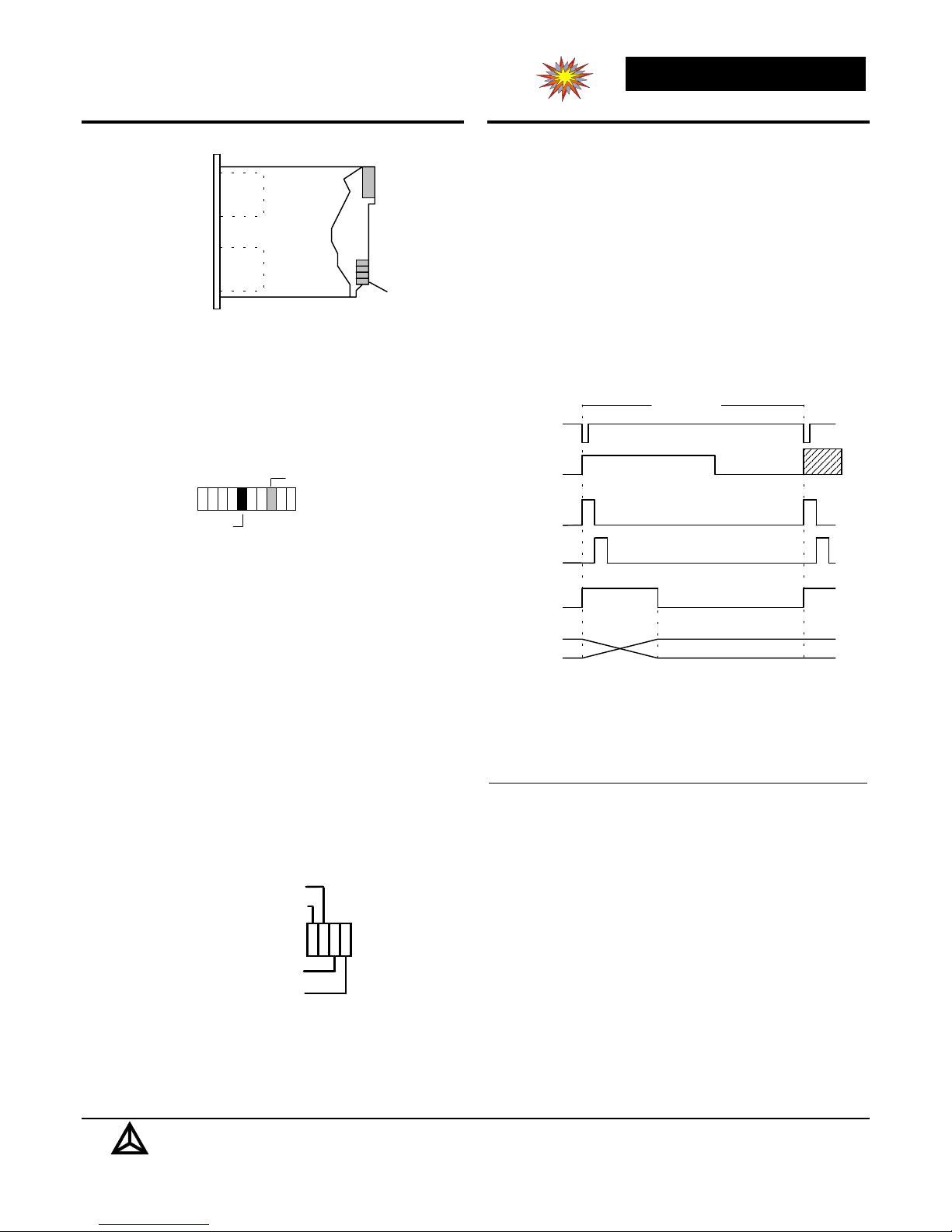

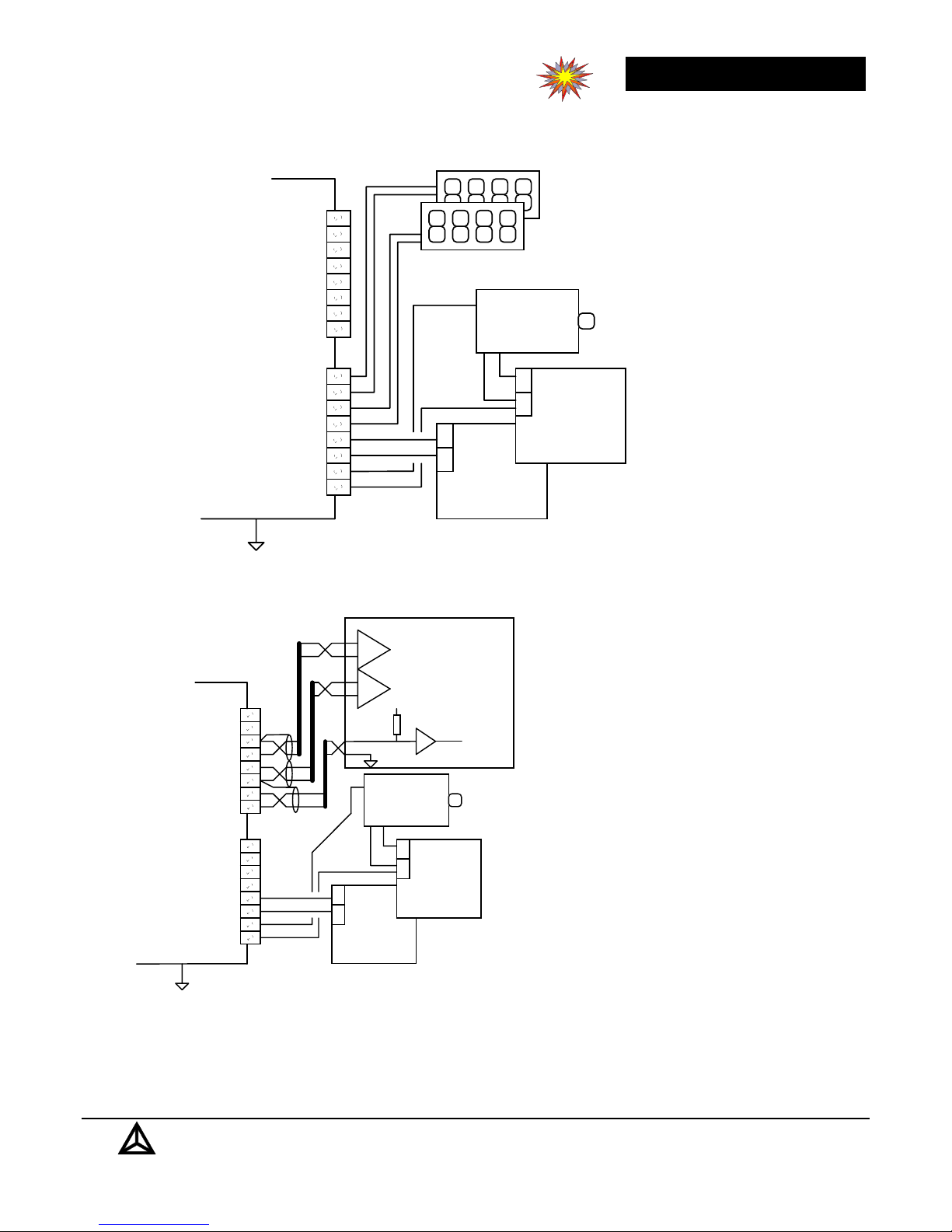

Scan Cycle

RPG Phase

NPN output ON

Bus

Scan Cycle

Trigger Delay Time

Data Read

Outputs Stable

Limits NPN output ON when

limits exceed setpoint

See

Note 1

Jumpers

Internal

Trigger

OR

External

Trigger

Input

Measure

Sense

Measure

Base

Data

Read

Output

Limit &

Analo

Outputs

Trigger Delay Time

(Determines Scan

Cycle Time when

using internal Data B & S Auto Restart

trigger) Ready 2 4 8

(default) 500us 110us 22us

*Special order, must

be set by factory

Note 1. When using an external trigger, the Scan Cycle Tim e i s

determined by the tim e between RPG transitions ( RPG NPN output

changes from OFF to ON). I f the time between transitions i s less

than the Trigger Delay Time, scan data will be lost.

S

B

NPN output ON

435us 110us 22us Yes

380us 110us 22us Yes

330us 110us 22us Yes Yes

275us 110us 22us Yes

220us 110us 22us Yes Yes

164us 110us 22us Yes Yes

110us 55us 22us Yes Yes Yes

*50us 25us 12us Yes Yes Yes

Delta Computer Systems, Inc.

email@deltacompsys.com http://www.deltacompsys.com

, 11719 NE 95th Street, Vancouver, Washington 98682-2444 (360) 254-8688 3

Page 4

CS2 Color Scanner

Base & Sense Limit Outputs

Limit outputs provide the means to control an external

device when the setpoints are exceeded. Each is an isolated

open collector NPN output. When the limit setpoint is met

(Base color above setpoint and Sense limit below setpoint),

the NPN output is turned ON. ON current is 1.6 mA

minimum, 8 mA typical. The maximum open collector

voltage is 30VDC.

Note: If the limit outputs are connected to a high speed

input, they may need to be qualified with the Data Ready

output.

Data Ready Output

The Data Ready output should be used when the CS2 is

connected to a fast Analog-to-Digital converter. Inaccurate

readings can result if the A-D tries to read the analog color

voltages at the same time that the CS2 is updating them. By

synchronizing the external A-D converter to the CS2's

scanning cycle, this problem is eliminated.

The Data Ready output varies with the scan time. When

scanning with the internal trigger, Data is valid (Data Ready

line OFF) for approximately 110 microseconds each scan.

For high scan rates, the Data Ready NPN open collector

load resistor may need to be lowered (below 2.7k). It is a

good idea to allow 20-50% margin for gain degradation of

the opto-coupler. The ON current is 1.6 mA minimum, 8

mA typical. The maximum open collector voltage is 30Vdc.

External Trigger Input

This input allows a scanning cycle to be started by an

external signal. It is particularly useful when the scanner is

connected up to an optimizing computer. When the

scanning cycle is initiated by a signal from a rotary pulse

generator (RPG) connected to a belt or other co nveying

system, the length of objects and features detected can be

determined by counting the number o f RPG counts that

occur while the object or feature is within view of the

scanner. In this way, dimensional information can be

obtained.

To use this option, jumper the scanner for external triggered

operation, and wire the output of the RPG (or other trigger

source) to the Trig In terminals. The trigger input of the

CS2 requires 5 mA and will work with signal sources

between 3.5 and 24V, ensuring compatibility with most TTL

and open-collector encoders.

Threshold Analog Inputs

The CS2 provides two analog inputs to control the Base and

Sense limit setpoints. For applications using these inputs,

please contact Delta for assistance.

Analog Outputs

The CS2 provides two analog outputs proportional to the

real time Base color and Sense color. These outputs are

updated every scan cycle. The outputs are 0-10V and will

drive high impedance inputs ( 2 kohms or higher).

When using the analog outjputs with a PLC or other

computer, the Sense reading is divided by the Base reading

to get the Sense/Base ratio. This ratio is then compared with

a threshold value as is done within the CS2.

However, using the analog outputs allows additional

flexibility, such as multiple thresholds, thresholds that can

be stored and set remotely.

Note that is is often advantageous to subtract the

background readings before calculating ratios in cases where

the object being viewed does not completely fill the viewing

area.

Contact Delta for help with specific applications.

Delta Computer Systems, Inc.

email@deltacompsys.com http://www.deltacompsys.com

, 11719 NE 95th Street, Vancouver, Washington 98682-2444 (360) 254-8688 4

Page 5

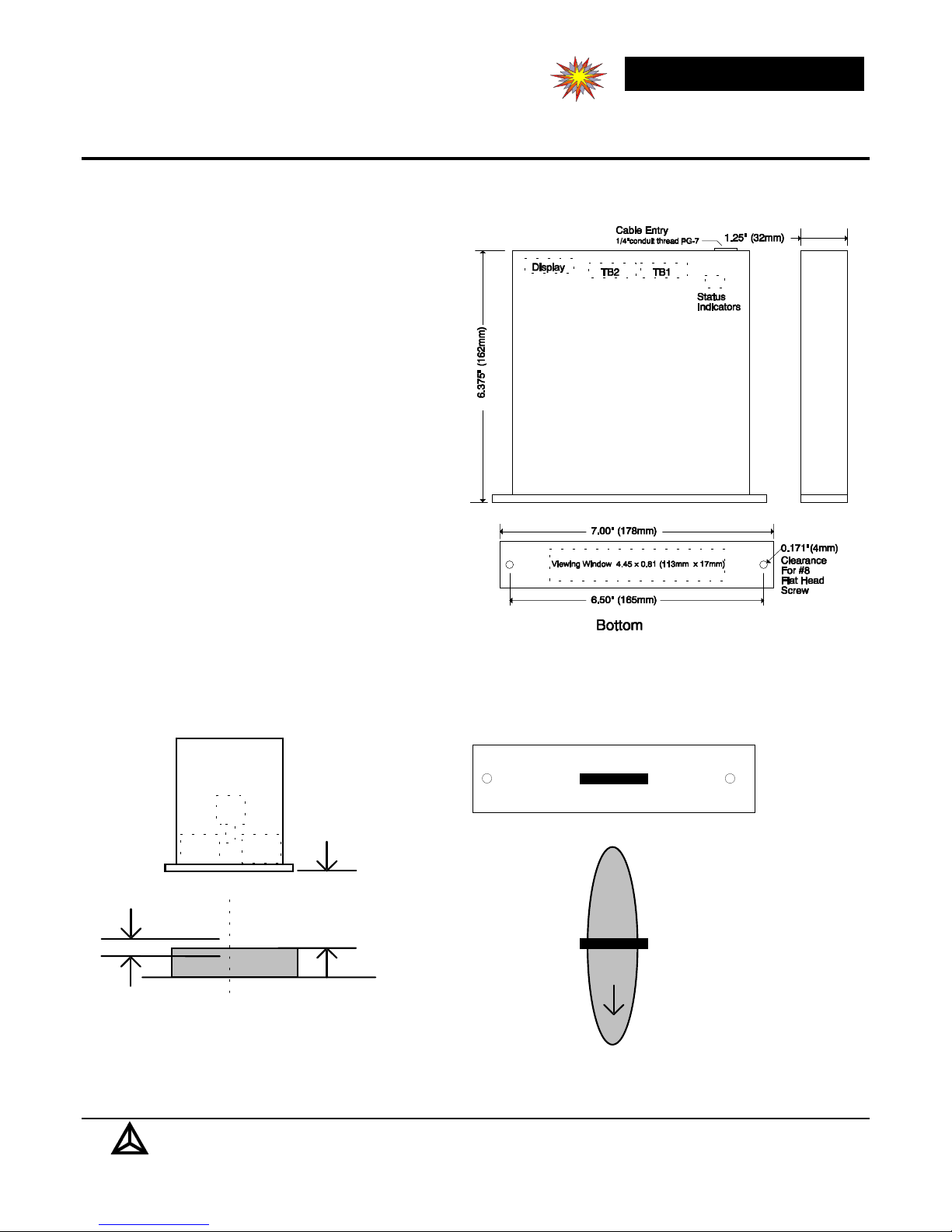

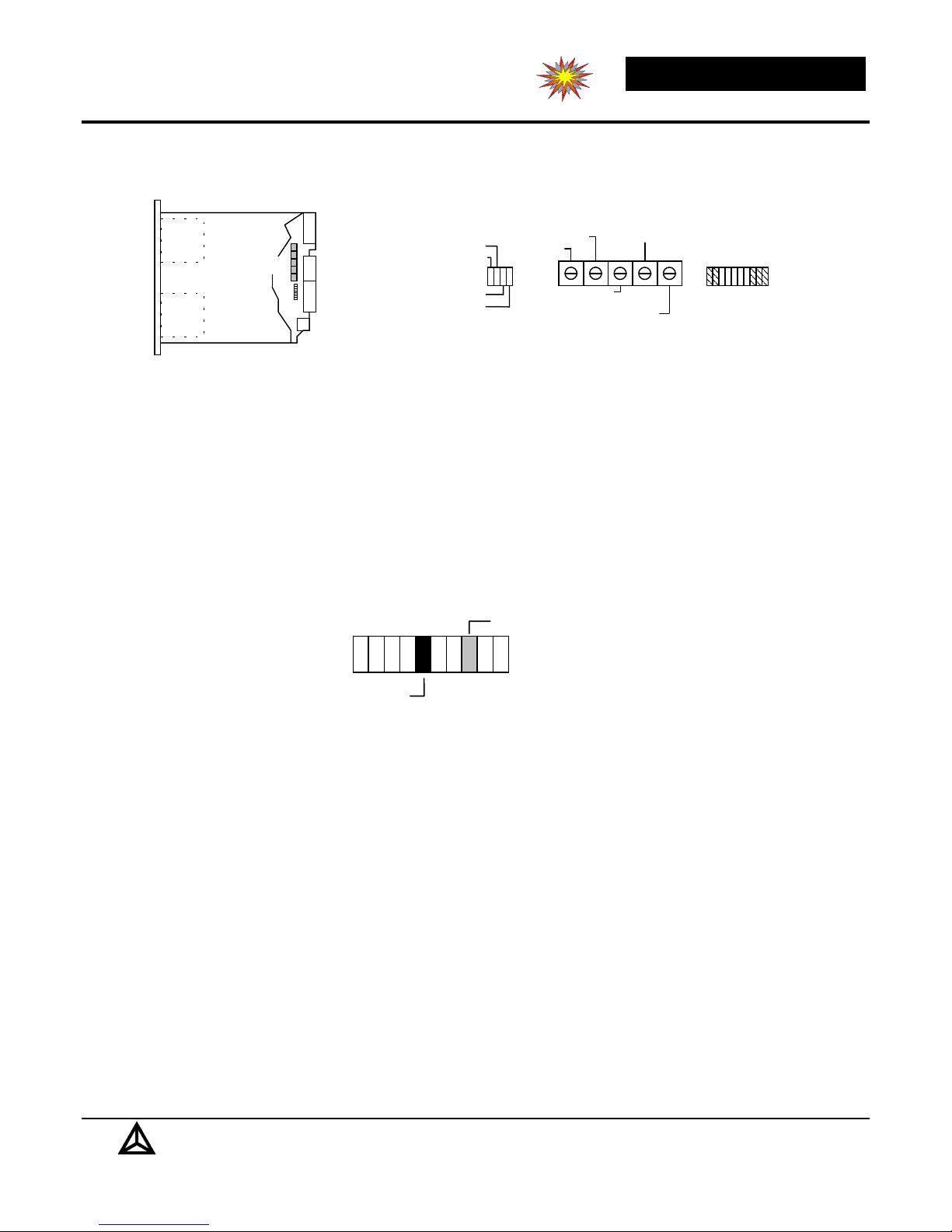

Mounting the CS2

j

The CS2 scanner is contained in a enclosure which has

mounting tabs on the bottom. The lighting LEDs shine

through the clear bottom and the optics pick up the

reflected light through the bottom also. The bar graph

display and status indicators can be viewed through the

clear top.

Mount the CS2 so that the object to be scanned is within

the scanning area. In the default configuration, the center

of the scanning range is 1.75" from the bottom of the

scanner. Although the CS2 can see to some extent from

about 1" to about 4", best performance is from 1.5 to 2".

The CS2 will operate in any position. However, in dirty

environments, it is best to have the CS2 lo oking straight

down, and worst to be loo king straight up. If the scanner

must be placed such that it is looking up, a stream of air

may be adequate to keep the window clean.

CS2 Color Scanner

It is also advantageous to be able to see the indicators

through the clear top of the unit when it is in operation.

CS2

Viewer

LEDs

Scanning Range

LEDs

Nominal Distance

from Scanner to

ob

ect

Object

Background

Scanning Area Line Orientation

P/N CS2-NR-A1X8-00

Bottom View of CS2

Object

Scanning Area

Various scanning areas and shapes are possible.

Please contact Delta for further information.

Delta Computer Systems, Inc.

email@deltacompsys.com http://www.deltacompsys.com

Top View of Scanned Area

, 11719 NE 95th Street, Vancouver, Washington 98682-2444 (360) 254-8688 5

Page 6

CS2 Color Scanner

y

y

gg

gg

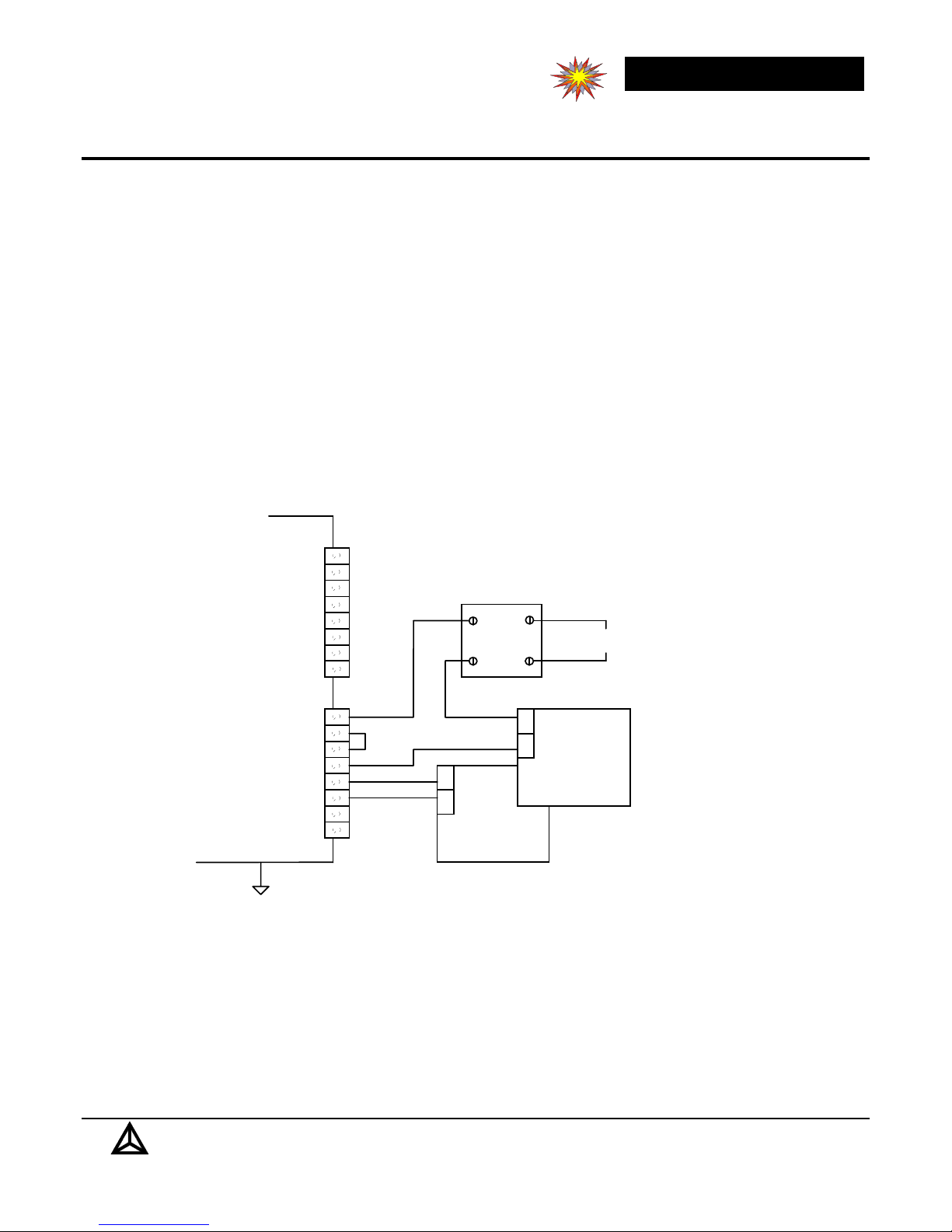

Wiring

The CS2 is designed to be wired using watertight flexible plastic conduit. In applications where sealed operation is

unnecessary, the wires can be run out through a strain relief connector. The conduit can also be used to pressurize the CS2

with low pressure, dry air for additional protection.

The number and type of wires required depend on the mode of operation. Only two wires, for 24Vdc power, are required to

operate the device. In simple applications, two more wires are used for the output. A four wire cable with an overall shield is

fine.

If analog threshold inputs or color outputs are used they need to be run through individually twisted, shielded pairs.

General Wiring Guidelines

1. The CS2 has sensitive circuitry which can be affected by electrical noise generated by loads. Its power supply should not

be used to power other loads.

2. The output of the 24Vdc sensor power supply must be isolated from earth ground. The CS2's common is connected to

earth ground through its case.

Application using Sense and Base Limits Outputs for Sorting or Rejecting Objects

CS2

Sense Threshold

Base Threshold

Common

Sense Color

Base Color

Common

Data Read

Data Read

Sense Limit Sense Limit +

Base Limit Base Limit +

Common

24V +

External Tri

External Tri

er er +

Case

In this application, the

CS2 is used in its

default configuration

(internal trigger, darker

+

SSR Load

-

-

+

areas to be sorted or

rejected, object scanned

every 500uS). In order

to activate the solidstate-relay (SSR), the

object in the scanning

- Output

+

Phoenix

- Sensor

Power

+

24Vdc

Phoenix

CM 90-PS-110 AC/24

Order No. 2943408

or equiv.

CM 90-PS-110 AC/24

Order No. 2943408

or equiv.

Power

24Vdc

area must cause the

Base color to exceed

the Base Threshold

(object present)

and

the

Sense color must be

below the Sense

Threshold (Low Ratio).

Delta Computer Systems, Inc.

email@deltacompsys.com http://www.deltacompsys.com

, 11719 NE 95th Street, Vancouver, Washington 98682-2444 (360) 254-8688 6

Page 7

CS2 Color Scanner

y

y

gg

gg

y

y

gg

gg

q

q

g

Using the CS2 With a Rotary-Pulse-Encoder (RPG) for Counting Objects and Defects

Defect Counter

To synchronize CS2's

scan with an external

event, use the external

trigger input. In this

example, a new scan is

started every time a

pulse is received from

the RPG. The Sense

Limit output is used to

count the number of

dark areas (defects)

seen, while the Base

Limit output is used to

count the number of

objects.

CS2

Sense Threshold

Base Threshold

Common

Sense Color

Base Color

Common

Data Read

Data Read

Sense Limit -

Sense Limit +

Base Limit Base Limit +

Common

24V +

External Tri

External Tri

er er +

Case

Object Counter

Phase A

+

Open Collector

NPN

RPG

+

-

-

+

Phoenix

- Sensor

Power

+

24Vdc

Phoenix

CM 90-PS-110 AC/24

Order No. 2943408

or equiv.

CM 90-PS-110 AC/24

Order No. 2943408

or equiv.

Output

Power

24Vdc

Sense Threshold

CS2

External Tri

External Tri

Base Threshold

Common

Sense Color

Base Color

Common

Data Read

Data Read

Sense Limit Sense Limit +

Base Limit Base Limit +

Common

24V +

er er +

Case

Example Using the CS2 with an Optimizing Computer

Optimizing Computer

+

-

Isolated Differential

Analo

5V

2.7K

Phase A

Open Collector

NPN

RPG

-

+

-

+

Phoenix

CM 90-PS-110 AC/24

Order No. 2943408

or e

Inputs 0-10Vdc

A/D

Trigger

TTL or CMOS

Output

Power

24Vdc

uiv.

+

-

+

+

-

-

+

+

+

-

- Sensor

Power

+

24Vdc

Phoenix

CM 90-PS-110 AC/24

Order No. 2943408

uiv.

or e

In applications that require more sophisticated

filtering, thresholds, or limit algorithms, CS2's

analog outputs and inputs provide an easy interface

to an optimizing computer. As shown, the analog

outputs are read each time the Data Ready isolated

NPN output goes from ON to OFF. The

optimizing computer then processes the analog

information. Remember, the analog data provided

by the CS2 is not absolute color information, but

relative values.

In this example the Base and Sense Threshold

analog inputs are not used. If desired, these can be

used to control of the Base and Sense Limits

setpoints. By controlling the se tpoints, the

optimizing computer can use the CS2's two

isolated NPN outputs for control. Contact Delta

for additional information.

Delta Computer Systems, Inc.

email@deltacompsys.com http://www.deltacompsys.com

, 11719 NE 95th Street, Vancouver, Washington 98682-2444 (360) 254-8688 7

Page 8

Configuration

gg

gg

g

gg

gg

g

2

4

8

Internal Tri

External Tri

Hi

h Ratio

Low Ratio

er

er

LED's

LED's

Internal Tri

External Tri

Hi

Low Ratio

Configuration

Jumpers

Default Jumper Configuration

2

4

8

er

er

h Ratio

Bar Graph

TB2

TB1

Status

Indicators

CS2 Color Scanner

Sense Low/High Ratio

The Sense Limit is jumper configurable to respond to

either Sense/Base ratios that are lower than normal (Low)

or Sense/Base ratios that are higher than normal (High).

Example applications where the Dark setting (default) is

used including detecting green areas on carrots, knots on

wood and burnt cookies, while the High setting would be

used to detect white ends on asparagus, some paint

applications, etc.

External and Internal Triggers

When using the Internal trigger (default), every 500

microseconds the CS2 automatically takes new Sense and

Base color readings, calculates averages and Sense/Base

ratio and updates the outputs and indicators.

If an external trigger is desired, move the jumper from the

internal trigger position to the external trigger position and

wire the output of the RPG (or other trigger source) to the

Trig In terminals located on TB1.

Delta Computer Systems, Inc.

email@deltacompsys.com http://www.deltacompsys.com

, 11719 NE 95th Street, Vancouver, Washington 98682-2444 (360) 254-8688 8

Page 9

CS2 Color Scanner

y

y

y

g

Adjustments

The CS2 has five potentiometers (pots): LED Time, Overall Gain, Sense Match, Base Threshold, and Sense Threshold. The

LED time adjustment is not used for basic operation; contact Delta for more information

LED's

LED's

Trim Pots

Output

Bar Graph

TB2

TB1

Status

Indicators

Data Read

Trig In

Base Limit

Sense Limit

Status Indicators

Overall Gain

Led Time

Sense Match

Sense Limit Threshold

Base Limit Threshold

Yellow

Output Bar Graph

Red

Green

Displa

The procedure below is for applications where the background (with no object present) is dark compared to the objects to be

viewed and the features to be identified are relatively dark (in the Sense color spectrum) compared to the object. Examples

include green areas on carrots, knots on wood and burned cookies.

Gains and Thresholds

1. Mount and wire the unit and connect power. The lighting LEDs on the bottom of the CS2 and the Data Ready indicator

should come on when power is applied. The output bar graph display may or may not be lit.

2. Find a sample object with the greatest reflectance (biggest and lightest). Put it in the viewing area and adjust the Overall

Gain until the less intense bar graph indicator is in the 8th or 9th p osition (red).

Output Bar Graph Displa

Green

Less intense bar indicates Base Color

ht bar indicates Sense Color

Bri

Yellow

Red

3. Adjust the Sense Match pot until the bright bar graph indicator is on to p of the less intense bar graph indicator (8th or 9th

position).

4. Put an average object in the viewing area. Both base color and sense color bar graph indicators should be within the

center of the display (green).

5. Remove all objects. Reflected light from background should display no higher tha n the second bar graph indicator

(yellow).

6. Place an average size and color object in the viewing area for about ten seconds. Remove all objects and then

immediately put a minimum size, normal color object in the viewing area. Adjust the Base Threshold pot such that the

Base Limit indicator is just activated.

7. Put a marginally nominal object in the viewing area (make sure the low/high ratio limit configuration jumper setting is

correct). Adjust the Sense Threshold pot such that the sense limit indicator is just activated.

8. Fine tune both threshold adjustments while observing on-line operations.

Delta Computer Systems, Inc.

email@deltacompsys.com http://www.deltacompsys.com

, 11719 NE 95th Street, Vancouver, Washington 98682-2444 (360) 254-8688 9

Page 10

CS2 Color Scanner

Color Tolerances

You want a bunch of paperweights in the shape of our logo.

You sketch the thing, add dimensions, and send it off to a

turn-key manufacturing shop with these instructions:

Dimensions: ±0.035"

Weight 1 LB, ±1 oz.

Color: Red; just like the sample.

To keep costs down, you've given generous to lerances on

dimensions and weights, but what is your color tolerance?

The manufacturer might think he's got an exc ellent match,

and you might think it clashes terribly. It ge ts worse. If you

are matching items that are not colored the same way, such

as plastic and metal, you have to take into account the

lighting as well.

Most colors are made up of a mixture of pigments and can

look very different under varied lighting. Different

pigments are used for paints, plastics, inks, dyes, etc.

Perfect matches of diffe rent materials under varie d lighting

conditions is virtually impossible.

So how do you express color tolerances? Color can be

expressed in mathematical terms; intensity, hue, etc., and

can have mathematical tolerances, but this will seldom

produce optimum results.

Why is that? In order to keep manufacturing costs d own,

tolerances should be as wide as possible. But color

tolerances are based on perception, and are not evenly

distributed. In most cases, larger variations in intensity are

permissible than in hue.

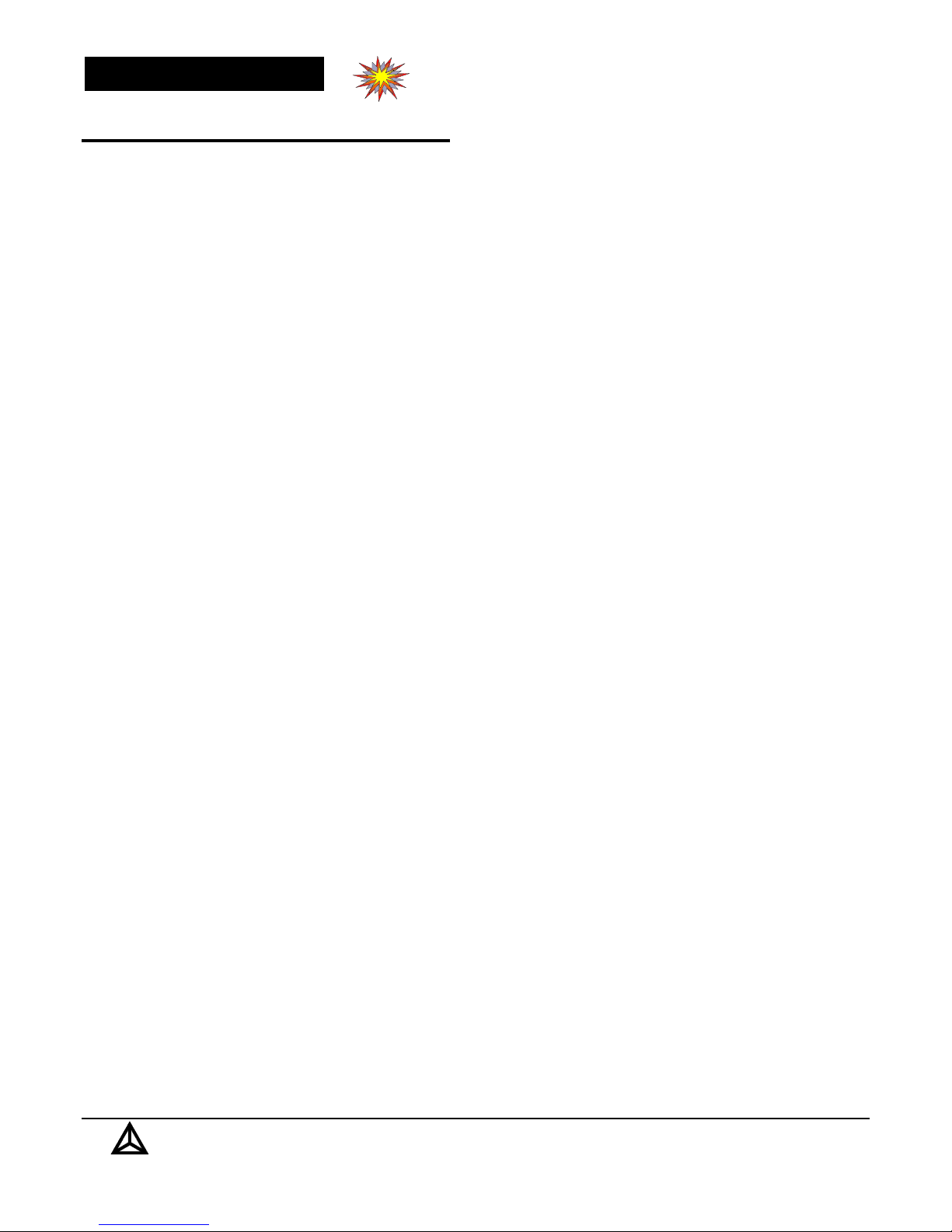

The pencils travel lengthwise, erasers first, under the CS2

which is configured for a viewing area of 1/32" by 1/2". A

rotary pulse generator (RPG) provides a pulse for every

1/32" of pencil travel so that the entire top side of pencil is

examined. The CS2 is triggered from this RPG.

The optimizing computer reads the raw analog color

information, subtracts the average background intensity, and

determines when a pencil is in the viewing area -- Base color

amplitude 15% or more than average Base amplitude, pencil

length -- counts RPG pulses while Base amplitude is high,

eraser present -- counts RPG pulses while Sense/Base ratio

is 110% or more than average Sense/Base ratio at the

beginning of the pencil, paint present -- checks that

Sense/Base ratio does not go high again during remainder of

the pencil length.

The system was set up, adjusted and it ran great. Except,

after maintenance shutdowns. Sometimes it would just

ignore the pencils.

A little troubleshooting pinpointed the prob lem. During

maintenance, the machine was cleaned using air nozzles.

The fine sawdust settled everywhere, including on the pencil

conveying belt. The sawdust was light colored and highly

reflective, making the background intensity readings as high

as the pencils!

A simple continuous belt cleaning system took care of the

problem.

Tolerances in hue are often not even. Butter, for example

can be quite orange without cause for concern, but even

slightly green butter is likely to be repulsive.

Creating a multidimensional tolerance color model is

possible, but would take a lot of time. Even if you went to

this expense, on line, high speed testing against this model

would be very expensive.

In short, color is a perception issue, and is still more of an

art than a science. Fortunately, in many real-world

situations, a one dimension test for color is all that is

required; green areas on carrots, white ends on asparagus,

dark knots on wood, paint either there or not there, etc.

These types of applications are suited to the CS2 scanner.

Pencil Sorting Example

In this hypothetical application, red pencils are being

examined for missing erasers and missing paint. The CS2 is

used with an optimizing computer in order to make length as

well as color decisions on the product.

Delta Computer Systems, Inc.

, 11719 NE 95th Street, Vancouver, Washington 98682-2444 (360) 254-8688 10

email@deltacompsys.com http://www.deltacompsys.com

Page 11

CS2 Color Scanner

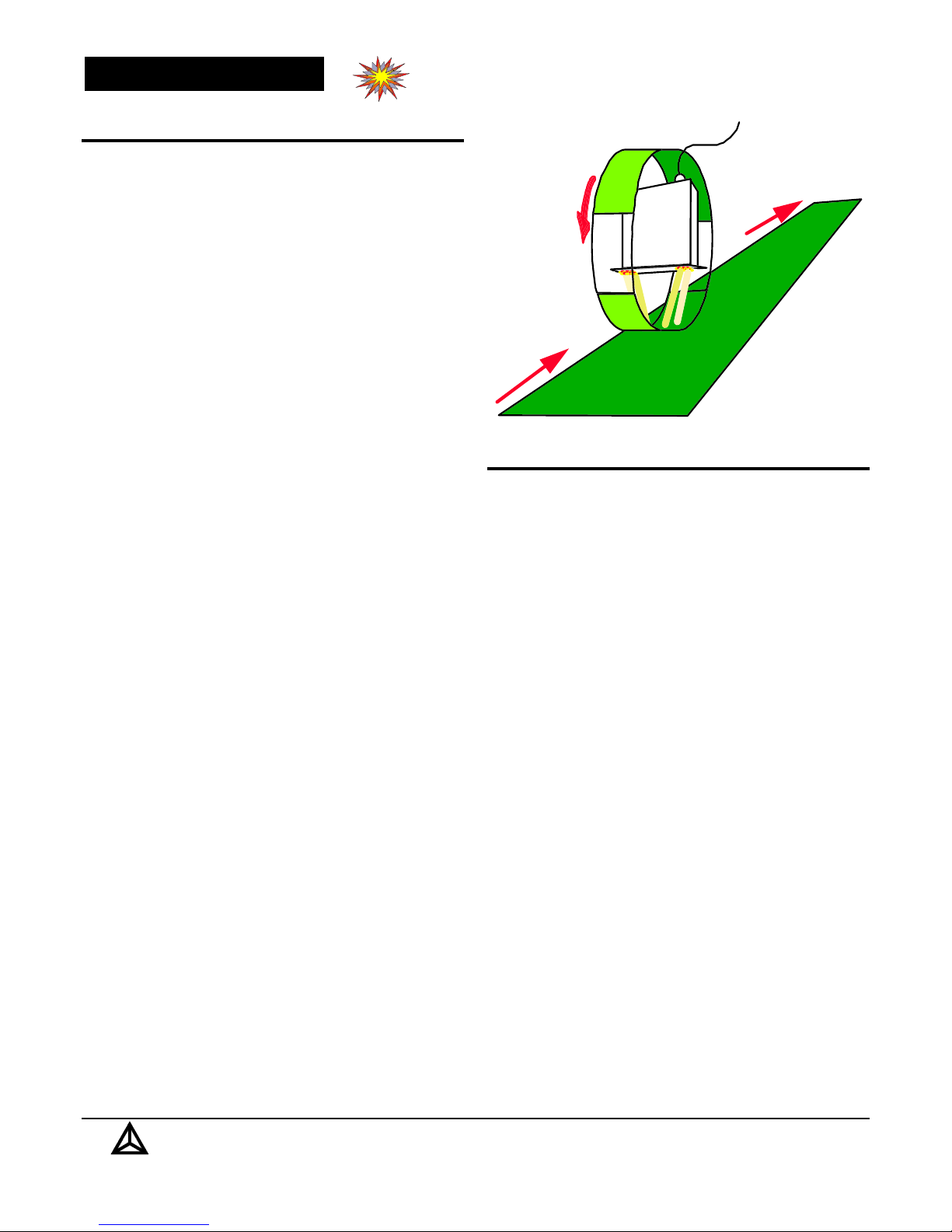

Putting It To Work

Comparing Colors

The CS2 is primarily intended for use in applications where

objects are 100% scanned for a deviation in average or

normal color, whether the deviation is a defect or a feature

that needs to be recognized.

It is possible to compare against a sample and activate the

limit outputs based on deviation from a sample.

Consider the hypothetical case where paper is being

manufactured for manila envelopes.

Currently, samples are taken to the lab on a regular basis and

tests are conducted to determine if the paper has the proper

beige color. The problems with the current system is that

the paper machines run continuously and at a rate that makes

it unfeasible to take samples often. On the other hand, if the

paper color goes out of spec., a tremendous amount of waste

can be created before the problem is identified and

corrected.

A CS2 was mounted above the flow of paper (web) inside of

a special wheel. One-half of the area of the wheel was

removed and the inside of the other half covered with a labtested sample of the paper. The wheel is mounted just above

the web and rotated at the same speed as the web. The CS2

alternately looks at the web and the sample paper.

In this special case the concepts of Base color and Sense

color do not apply. Instead the CS2 colors were chosen to

correspond to the colors of the various dyes used in the

paper, and the outputs analyzed for differences between the

sample and the web.

Traversing Heads

In the case of slow moving lineflow (baked goods, for

example), a 100% inspection can be done using a CS2 and a

traversing mechanism.

The outputs of the CS2 are connected to a controlling

computer which also reads the position of the CS2 as it is

moved back and forth across the lineflow.

A traversing head can also extend beyond the lineflow to

check against a reference color, as in the previous manila

envelope example.

The paper is still lab tested, but now, with the on-line

inspection, out-of-spec. color conditions can be found and

corrected immediately.

Delta Computer Systems, Inc.

, 11719 NE 95th Street, Vancouver, Washington 98682-2444 (360) 254-8688 11

email@deltacompsys.com http://deltacompsys.com

Page 12

CS2 Color Scanner

Application Guidelines

Power Supplies

The silicon cell used in the CS2 is electrically connected to

its metal package which is connected to the CS2's metal

enclosure. Therefore the CS2 must be connected to a good

ground, preferably the same ground as the machinery around

it, and the signals from the CS2 isolated. The CS2 must be

powered by a dedicated power supply, and the optional

analog inputs and outputs must be isolated if they are used.

The Limit outputs are isolated in the CS2.

Electrical noise

The signal level from the silicon cell is low and is amplified

by high speed circuitry. This circuitry is sensitive to

electrical noise from intense electrical fields. The CS2's

metal enclosure is an adequate shield against most electrical

interference. Use high quality shielded cable to reduce

electrical noise. If analog inputs or outputs are used, they

should be wired using individually shielded, twisted pairs.

Data Skew

The CS2 reads colors one at a time, in sequence. The Base

color is captured 22 microseconds after the Sense color. If

an object is moving while it is scanned, the information from

the two colors will be skewed slightly. If an abrupt change

in data occurs, the Sense/Base ratio will be momentarily

incorrect. Usually this will not cause any problems. If it is a

problem, it can be filtered out, either electronically in standalone applications or with a software filter when used with a

computer. The data skew can also be reduced by decreasing

the LED time (contact Delta for more information).

Color Errors

The CS2 uses an unfiltered silicon cell which captures all

reflected light. It determines color by turning on only the

desired color at a given time. The wavelength of the LED

lighting is a function of the LEDs. This wavelength varies

slightly with temperature.

Ambient light, or any other extraneous light, is an error

source. The CS2's LEDs are very bright, so reasonable

amounts of ambient light can be tolerated. (Don't be fooled

by the apearance of the CS lighting. The LEDs are only on

about 5% of the time. Your eyes average this light, making

it appear 20 times less intense.)

Background Errors

In order to see o bjects, it is necessary to distinguish the m

from the background. To maintain a good contrast, the

background should be black in the color spectrum of

interest. If the background is paintable, a flat black paint

such as Krylon 1602 can be used. Most black belting is also

acceptable. Wet or otherwise reflective surfaces actually

produce low backgr ound readings as long as light cannot

reflect directly back into the viewer.

Because the light from the CS2 tends to dissipate in all

directions, increasing the distance from the CS2 to the

background will reduce the background readings. If this is

done, be sure the increased distance does not allow ambient

light to become a problem.

Usable results can sometimes be obtained even if the

background cannot be made totally black. Ho wever, the

object signal should be at least twice as strong as the

background signal. The background will also contribute

more errors if the Sense/Base ratio of the background is very

different from the Sense/Base ratio of the objects. If this is

the case the background signal must be reduced to an

insignificant level.

Reflections

When either the CS2 lighting or ambient light is allowed to

reflect directly into the scanner it will overdrive the circuitry

and cause meaningless outputs. Usually this condition can

be avoided by controlling the relative angle of the scanner to

the objects and background.

In some applications it is impossible to avoid an occasional

reflection. In these cases, an external optimizing computer

can be used to "trap" the overdrive readings and ignore

them. This technique avoids making decisions on bad data,

but the overdriven data are still lost.

Intensity Variations

The CS2 lighting pattern is made up of multiple LEDs; some

variation in intensity is to be expected. The larger the

viewing area, (length, width, and depth), the more intensity

variation will occur. The LEDs used in the CS2 are

specially selected and the light pattern is optimized at the

factory. The default configuration pattern is optimized for

low ratio limit operation. The light pattern is adjusted such

that objects outside the specified viewing area but still

within the lighting area will not be read as having low

Sense/Base ratios, thus eliminating false limits. If needed,

other light pattern optimization techniques can be used.

Using Multiple CS2s

The scanning area of the CS2 is limited to about 1.25" by

the lighting. However, multiple CS2s can be used to cover a

wide area. Care must be taken to avoid interference between

the units. This is easily accomplished by either physical

Delta Computer Systems, Inc.

email@deltacompsys.com http://www.deltacompsys.com

, 11719 NE 95th Street, Vancouver, Washington 98682-2444 (360) 254-8688 12

Page 13

spacing or controlling the scans. If CS2s are mounted such

that the light from one does not extend into the other's

viewing area, then they will not interfere with each other.

In multiple unit applications, it is often advantageous to

have the units next to each other so that they take up as little

space as possible. The light from each unit will extend into

the adjoining unit's viewing area. In this case, interference

can be avoided by using the External Trigger mode and

triggering adjacent units at different times. A separation of

50 microseconds is sufficient. In applications which use a

quadrature output rotary pulse generator, this can be done by

connecting ajacent units to the other output phase, i.e.

scanners 1, 3, 5, etc. to phase A and scanners 2, 4, 6, etc. to

phase B.

If large numbers of units are requir e d, you may want to

consider a custom scanner. Multiple units can be packaged

into a single enclosure, resulting in a cleaner package. Units

can also be packaged around a tube, etc. Contact Delta for

details.

CS2 Color Scanner

Delta Computer Systems, Inc.

email@deltacompsys.com http://www.deltacompsys.com

, 11719 NE 95th Street, Vancouver, Washington 98682-2444 (360) 254-8688 13

Page 14

CS2 Color Scanner

Technical Information

Base and Sense Color

Light Source Options

Stand Off Distance

Scanning Range

Scanning Area

Response Time

Operating Modes

Two Analog Outputs

(Base and Sense)

Two Analog Inputs

(Base and Sense Threshold)

One Digital Input

(External Trigger)

Three Digital Outputs

(Data Ready, Sense

and Base Limit)

Supply Voltage

Blue, green, yellow, orange, red, and

near-infrared (450nm to 950nm)

1.75 inches (44.5mm); configurable to six inches

±0.25 inches (6.4mm); configurable to ±2 inches

0.04 x 0.33 inches (1mm x 8mm); configurable

to 2 inches. Various shapes and sizes available

50us

Continuous or External Trigger

0-10 volts at 5 mA maximum

0-10 volts, input impedance minimum of 50k

Optically isolated, 3.5 - 24 volts, 5 mA minimum

Optically isolated, TTL/CMOS compatible;

1.6 mA minimum, 8 mA typical; 30 volt

maxi mum

24 VDC (±5%)

Ω

Current Consumption

Enclosure

250 mA maximum

Extruded aluminum, optional NEMA 4X

Ordering Information

License agreements provide Delta with the exclusive rights to use the CS2 technology in all applications outside of frozen

potato processing. If you have any questions, please ask a Delta representative.

Company Profile

Delta Computer Systems, Inc. manufactures color scanners, motion controllers a nd other industrial controls providing high

performance automation solutions to a wide range of industries.

Delta Computer Systems, Inc.

, 11719 NE 95th Street, Vancouver, Washington 98682-2444 (360) 254-8688 14

email@deltacompsys.com http://deltacompsys.com

Page 15

CS2 Color Scanner

General Application Information

The term "color" actually inplies visable light -wavelengths from about 400 nm (violet) to about 750 nm

(deep red), although in this document any color that can

be seen by the CS2 is refered to as a color.

With high intensity LEDs available at 450nm (blue) and at

a variety of wavelengths up to 700nm, the CS2 can see all

of athese colors. But the CS2's capability does not stop

there; the precision silicon photodiodes in the CS2 can see

into the near-infrared (NIR) up to about 1,000nm, and

LEDs are readily available in this region as well.

NIR LEDs are used in the CS2 and similar scanners for

several different functions. One involves using the NIR

reading to establish a baseline value that is constant (or

nearly constant) regardless of the visible color of the

product.

For example, to detect "browness" on cookies, any one of

several visable colors can be used. But using one color

(monochromatic) and looking for changes in amplitude

will not produce good results, since other factors, such as

dirty optics, temperature changes, etc., can produce

signals that are indistinguishable from "browness"

changes.

However, using the ratio of a visable color to an NIR

color will give the desired result: the ratio will only

change with product color, not with ambient conditions.

Here are some examples of items and applications that

Delta has successfully tested:

•

Detecting the presence or absence of brown glue on

brown wood

•

Detecting "browness" of crackers, etc.

•

Detecting green ends on carrots

•

Detecting white ends on asparagus

•

Detecting various defects on potatoes

•

Differentiating between tomatoes and MOT (material

other than tomatoes)

•

Using a modified CS2, differentiating between

several different colors of cloth

•

Using a modified CS2, ide ntifing several different

colors on a cardboard box

•

Some of these applications are in use, and some

remain in testing. More tests are done on a regular

basis.

Other uses of the NIR spectrum include sorting items that

can be differentiated in the NIR spectrum. Delta's CSplus-T50 tomato sorters, for example, uses two different

NIR colors to differentiate tomatoes and virtually any

other item.

Delta's LGM length graders use monochromatic NIR light

to detect product presence only. They function as

reflective light curtains and detect products regardless of

visable color. The viewing area is very long and narrow

allowing the LGM to cover an area approximately two

inches in diameter at about six inches from the scanner.

The LGM measures product length at 1/32 inch resolution

at speeds of 550 ft/min.

Delta Computer Systems, Inc.

, 11719 NE 95th Street, Vancouver, Washington 98682-2444 (360) 254-8688 15

email@deltacompsys.com http://deltacompsys.com

Loading...

Loading...