Page 1

Delta Fan/Pump Vector

Control Drive

CP2000 Series

Quick Start Guide

www.deltaww.com

Page 2

Warning! T

his is a short guide, and does not give all necessary safety information.

Refer to the CP2000 Series User Manual for all safety information to avoid

damage to the drive, motor or personal injury.

Document Version 1.0

Published August 25, 2017

Page 3

Table of Contents

CHAPTER 1 INTRODUCTION .................................................................................................. 3

1-1 Before You St art ............................................................................................................... 3

CHAPTER 2 CONTROL WIRING .............................................................................................. 4

2-1 Cabling ............................................................................................................................. 4

CHAPTER 3 SET UP THE VFD P ARAMETERS ....................................................................... 5

3-1 About Parameters ............................................................................................................ 5

3-2 VFD Digital Keypad .......................................................................................................... 5

3-3 Digital Keypad Keys ......................................................................................................... 6

3-4 Display Workflow .............................................................................................................. 7

3-5 Setting Up Parameters for the First Time.......................................................................... 7

Changes to System Parameters (00) group ........................................................................ 8

Changes to Basic Parameters (01) group ........................................................................... 9

Digital Input / Output Parameters (02) group ......................................................................10

Motor Parameters (05) group .............................................................................................10

Special Parameters (07) group ..........................................................................................11

Communication Parameters (09) group .............................................................................12

CHAPTER 4 START UP TEST .................................................................................................14

APPENDIX A PUBLICATION HISTORY ..................................................................................15

Page 4

Chapter 1 Introduction

Chapter 1 Introduction

This Quick Start Guide shows you how to configure the CP2000 Series drive settings to work

with your Delta Controls controllers. The guide assumes the drive has already been installed onsite by a qualified technician.

Refer to the CP2000 Series User Manual for more information about how to

unpack (Chapter 3), install (Chapter 2) and wire the drive (Chapter 4 and 5) to its

power supply.

1-1 Before You Start

Verify the following wiring setup before you turn on the VFD for the fi rst time.

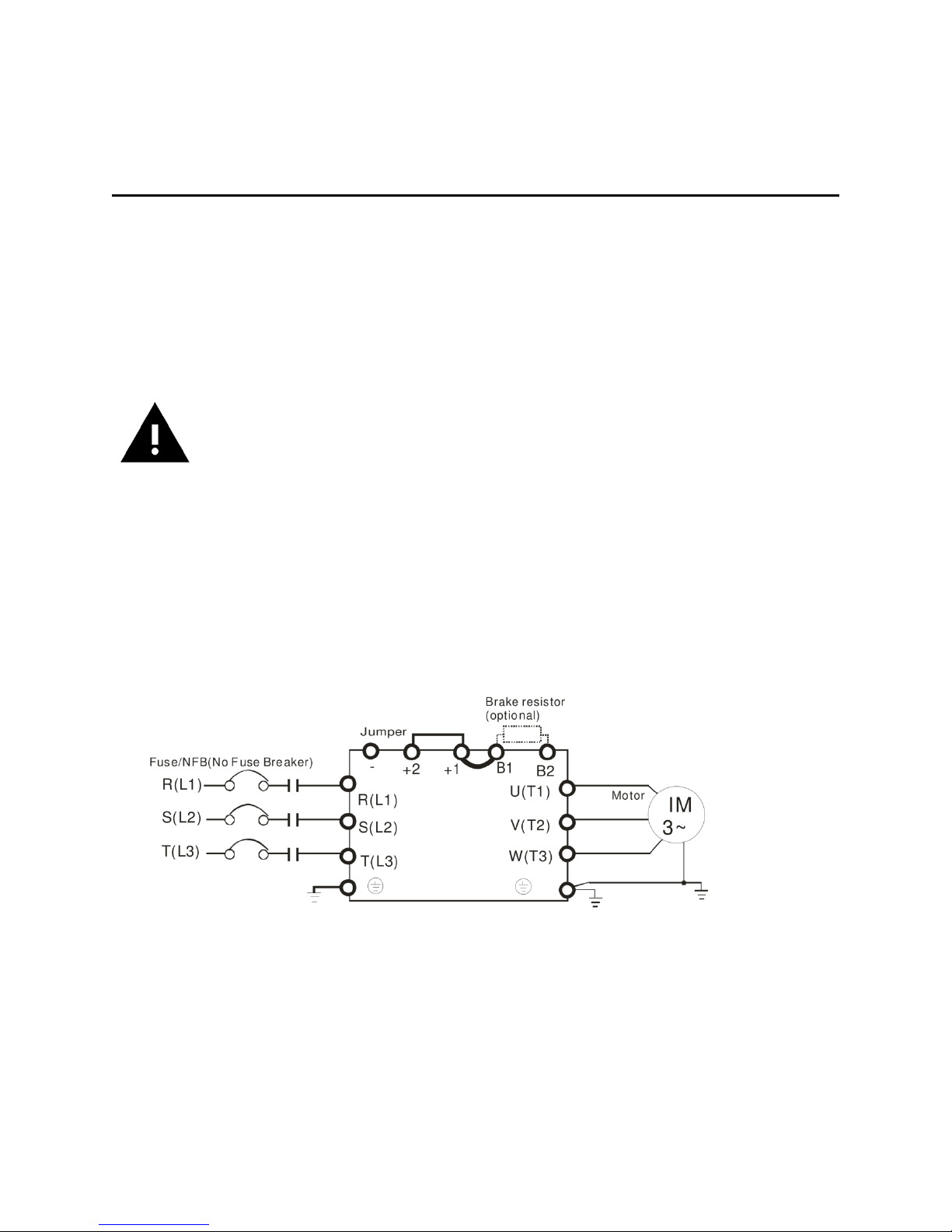

• Make sure the line voltage (L1/L2/L3) is not connected to the output terminals (U/V/W) of

the VFD.

• Ensure the motor is connected to the drive before applying power to the VFD.

3

Page 5

Do not remove the factory jumpers between STO1/STO2/+24V and

Chapter 2 Control Wiring

Chapter 2 Control Wiring

SCM1/SCM2/DCM.

Make sure the AFM1 and AVI1 switches are in the 0-10V position.

Make sure the Start Relay shown is not in a closed state when the drive is initially

powered up.

For the conventional start/stop, speed control and speed feedback via hard-wired I/O, the

following wiring terminations are required:

• Start/Stop: Control relay contacts wired between FWD and DCM.

• Speed Control: 0-10V speed control is connected to AVI1 (+) and ACM (-).

• Speed Feedback: 0-10V speed status is connected to AFM (+) and ACM (-).

2-1 Cabling

The analog speed signals should be using shielded cable.

4

Page 6

Chapter 3 Set Up the

VFD Parameters

Chapter 3 Set Up the V FD Parameters

This section describes how to set up the VFD parameters when you turn on the drive for the first

time, and how to use the digital keypad on the VFD to access these parameter settings.

3-1 About Parameters

The VFD parameters are organized in groups which are numbered from 00 to 13. Members in

the same group share a common prefix (00 to 13) and each parameter member is identified by

a unique number. The parameters and their settings are accessible on the keypad main menu

by selecting Parameter Setup.

For example, the group Basic Parameters share the prefix “01” and “01-00” is the maximum

operation frequency parameter.

See Chapter 11 and 12 in the VFD-CP2000 User Manual for more details about

the parameters and their factory settings.

3-2 VFD Digital Keypad

The digital keypad consists of keys and a display screen. This section only applies to the KPC

CC01 keypad.

See Chapter 10 in the VFD-CP2000 User Manual for more information.

5

Page 7

Chapter 3 Set Up the VFD Parameters | CP2000

Key

Description of Function

RUN

When the VFD is in HAND mode, pressing RUN starts the motor.

STOP/RESET

This key has the highest processing priority in any situation.

will clear an outstanding Fault.

FWD/REV

Used to reverse the rotation direction of the motor. Not used in

HVAC applications.

HAND

Pressing HAND puts the VFD into local control mode, where remote

control the speed using the keypad.

AUTO

Pressing AUTO puts the VFD into remote control mode, which can

in AUTO.

MENU

Press MENU to open or return to the main menu that lists 13

options, including Parameter (Pr) Setup and Display Setup.

ESC

Press ESC to leave the current menu and go back up one level in

any change to the value.

ENTER

Press ENTER to go to the next level in the menu. It will also apply a

change to a parameter whose value has been altered.

These keys perform two functions, depending on the state of the

these keys can be used to adjust the running speed of the drive.

F1, F2, F3, F4

These keys are not used by default, but can be customized to

perform application specific functions.

3-3 Digital Keypad Keys

Pressing STOP stops the VFD whether the VFD is in HAND mode or

AUTO mode. Once the drive has stopped, pressing STOP/RESET

signals are ignored. "HAND" displays on the keypad screen.

While in this mode, it is possible to start the VFD and to manually

be either hardwired I/O or BACnet control. "AUTO" displays on the

keypad screen. The local RUN and speed control is displayed while

the menu. It will also leave any parameter viewed without making

display. When in the menu, and scroll through the different

menu levels and parameters. When a single parameter is being

adjusted, and determine which digit of the setting will be

adjusted when you use and . On the display’s main page,

6

Page 8

3-4 Display Workflow

3-4 Display Workflow | CP2000

3-5 Setting Up Parameters for the First Time

This section describes how to configure the drive correctly after turning it on for the first time.

To access the VFD parameters on the keypad display,

1. Push the MENU button on the keypad.

2. Scroll through the menu using and to select 1. Pr Setup and press ENTER.

Parameter (Pr) Setup is a menu option that allows you to change the drive’s setup

parameters. The parameters are organized as groups under Parameter Setup, from

System or Drive Parameters (00) to Industry Application Parameters (13).

3. Scroll through the list using and to select the parameter group you want to

modify. Press ENTER to view the parameters in the selected group.

4. Use and to select the parameter you want to modify. Press ENTER to go to the

parameter’s option menu.

5. To select a number that represents the option you want to set, use and .

7

Page 9

Chapter 3 Set Up the VFD Parameters | CP2000

Parameter

Display Text

Description of Parameter

Default

Value

Preferred

Value

00-20 Source of

Source of

The source of frequency

hardwired I/O control)

0

2

00-21 Source of

Source of

This determines which

5 - not used

0

1

00-22 Stop

Stop Methods

This determines what the

for HVAC)

0

1

To enter a value, use and to increase or decrease the number displayed. In

some cases when you are presented with a string of numbers, decimal places, dates or

times, you may need to use and to move the cursor’s position to make a specific

change.

6. Press ENTER to save the option or changes you’ve made. Use ESC button to go back

up one level in the menu, or push MENU to return to the main menu.

7. Use steps 3 to 6 to make the required changes to the parameters listed below.

The following tables list the parameters that you need to set up and their recommended values.

Changes to System Parameters (00) group

frequency

operation

FREQ

OPER

parameter determines which

control signal controls the

drive's frequency in AUTO

mode.

Parameter options:

0 - Keypad (not

recommended)

1 - RS-485 BACnet

2 - Analog Input (used for

control signal starts or stops

the drive in AUTO mode.

Parameter options:

0 - Keypad (not

recommended)

1 - Hardwired I/O Terminals

2 - RS-485 BACnet

3 - not used

4 - not used

method

drive does when

commanded to stop.

Parameter options:

0 – Ramp to stop

1 – Coast to stop (preferred

8

Page 10

3-5 Setting Up Parameters for the First Time | CP2000

Parameter

Display Text

Description of Parameter

Default

Value

Preferred

Value

00-32 Keypad

KPD STOP

This determines whether the

(preferred for safety)

0

1

Parameter

Display Text

Description of Parameter

Default

Value

Preferred

Value

01-11 Output

Lower Bound

This determines the

prevent motor overheating.

0.00 Hz

10-15 Hz

01-12

1st ACC Time

This is the time, in seconds,

too low.

10 secs

60 secs

01-13

1st DEC Time

This is the time, in seconds,

centrifugal fans.

10 secs

60 secs

stop function

ENABLE

STOP key on the keypad is

active when the drive is

running in AUTO mode.

Parameter options:

0 – STOP key disabled.

1 – STOP key enabled

Changes to Basic Parameters (01) group

frequency lower

limit

Acceleration time

1

FREQ

minimum speed of the drive

motor. It is important that

this speed is not too low to

for the drive to ramp up from

0 Hz to 60 Hz. It's important

that this time is not too fast,

or an overload fault will trip.

The factory default time is

Deceleration time

1

for the drive to ramp down

from 60 Hz to 0 Hz. If this

time is set too low, an OVN

fault will occur. The factory

default time is too low for

large inertia loads like

9

Page 11

Chapter 3 Set Up the VFD Parameters | CP2000

Parameter

Display Text

Description of Parameter

Default

Value

Preferred

Value

02-35 External

Fault Reset OP

When s et to 1, th e drive

recommended).

0

1

Parameter

Display Text

Description of Parameter

Default

Value

Preferred

Value

05-01 Full load

Motor 1 Rated

This determines the full load

None

As stated

nameplate.

05-02 Rated

Motor 1 Rated

This determines the motor

None

As stated

0.746

05-03 RPM of

Motor 1 Rated

This determines the motor’s

1710 RPM.

motors.

As stated

nameplate.

05-04 Number of

Motor 1 Poles

This determines the motor’s

8 – 900 RPM

4, which is

RPM value

Digital Input / Output Parameters (02) group

operation after

reset and activate

Motor Parameters (05) group

current of motor

power of motor

A

P

automatically restarts after a

power failure, assuming the

FWD terminal is still closed.

When s et to 0, th e drive

powers up again and stops,

requiring a cycle of the Start

signal (turn off and then turn

on again) to resume normal

operation (Value 0 is not

rating of the motor in amps.

power in kW.

on the

motor

on the

motor

nameplate.

Note: kW

= HP *

motor

poles in motor

60Hz RPM.

number of poles.

Parameter options:

2 – 3600 RPM

4 – 1800 RPM

6 – 1200 RPM

10

This is fine

for 4 pole

correct for

~1800 RPM

motors.

on the

motor

as stated

on the

motor

nameplate.

Page 12

3-5 Setting Up Parameters for the First Time | CP2000

Parameter

Display Text

Description of Parameter

Default

Value

Preferred

Value

07-06 Restart

Momentary

The operation mode when

minimum frequency

0

1

07-07 Maximum

Power Loss

The duration of the period of

seconds.

2 secs

20 secs

07-10 Restart

Fault Re-RUN

This determines what the

minimum frequency

0

1

07-11 Number of

Auto Restart

The number of times the

Range is 0 to 10 times.

0

1 or more

Special Parameters (07) group

Setting up these parameters is optional but useful to minimize efforts to correct drive faults.

after momentary

power down

power loss

duration

after fault

Power

Time

Way

the AC motor drive restarts

from a

momentary power loss.

Parameter options:

0 – Stop operation

1 – Speed search start, at

the current speed

2 – Speed search start, at

power loss in seconds

before the drive will stop

operation.

Range is between 2 to 20

drive does after a fault

occurs.

Parameter options:

0 – Stop operation

1 – Restarts automatically,

speed search starts with

current speed

2- Restarts automatically,

speed search starts with

auto restarts

drive can restart

automatically after a fault.

11

Page 13

Chapter 3 Set Up the VFD Parameters | CP2000

Parameter

Display Text

Description of Parameter

Default

Value

Preferred

Value

07-12 Speed

Restart Method

This determines how the

from minimum frequency.

0

3

07-33 Auto

Reset

When a r estart occurs after

intervention.

60 secs

60 secs

Parameter

Display Text

Description of Parameter

Default

Value

Preferred

Value

09-31 Internal

COM1 Protocol

Set up the protocol

1 – BACnet MS/TP

0

1

search on startup

restart internal of

fault (Internal

time counter for

faults)

RestartCNT

drive starts the motor. This is

a useful setting if the drive

occasionally starts when the

motor is already spinning.

Parameter options:

0 – Disable. Wait for the

motor to stop spinning

before next start.

1 – Speed search, starting

from maximum frequency

(normally 60Hz).

2 – Speed search, starting

from motor start frequency

(normally 0.5Hz).

3 – Speed search, starting

a fault, the drive starts this

internal time clock and

counts the number of faults

that occur within this time

period. If the number of

faults do not exceed the

number recorded in the 0711 parameter, the time clock

and fault are reset back to

zero.

When the number of faults

exceed the 07-11 parameter

value, the drive faults and

stops, requiring user

Communication Parameters (09) group

These parameters are only necessary if you are planning to communicate to the built-in BACnet

interface in the drive.

communication

protocol

communication used.

Parameter options:

0 – Modbus

12

Page 14

3-5 Setting Up Parameters for the First Time | CP2000

Parameter

Display Text

Description of Parameter

Default

Value

Preferred

Value

09-50 BACnet

BACnet

MS/TP MAC address, range

10

To avoid

not use 0.

09-51 BACnet

Baud Rate

BACnet

BaudRate

MS/TP Baud rate 9.6, 19.2,

38.4, 76.8 kbps

38.4

76.8

09-52 BACnet

BACnet

BACnet device address, low

65536.

10

Site

09-53 BACnet

BACnet

BACnet device address,

parameter value 9-52.

0

Site

09-55 BACnet

BACnet Poll

MS/TP Max Master. This

of 127.

127

127

Dnet

Address

of 0 127.

conflict

with Delta

NET2

port, do

Device ID L ‡

DeviceIDL

word, range 0 to 6553.

specific

This value is added to the

value of parameter 9-53 *

Device ID H ‡

DeviceIDH

high word, range 0 to 63.

specific

This value is multiplied by

65536 and added to

max address

Max

should be left at the default

‡ The device address requires a bit of explanation. Let's say we wanted to address the drive to

99701. In this case, the value is above 65535, so the value of parameter 9-53 can't be 0. Take

the address you want (99701) and divide it by 65536, then truncate that value (which gives us

1). This is the value to use in parameter 9-53. Next, take the value of parameter 9-53 (in this

case, it’s 1) and multiply it by 65536 (65536). Take that value and subtract it from the address

you actually want. (99701 - 65536 = 34165) This is the value to use in parameter 9-52.

13

Page 15

Chapter 4 Start Up Test

Chapter 4 Start Up Test

1. After the drive has been installed and configured correctly, complete this start up test.

2. Cycle power to the drive, as some of the parameters require a drive restart to take effect.

3. Push the HAND button on the keypad so that the drive is running under local control.

4. Use the keypad to set a safe running speed command for the motor. This is value F on

the display. A speed of 20 Hz should be safe.

5. Push the START button. The drive should start and the motor spin up to 20 Hz, as

indicated by the H value on the display.

6. If the motor is running okay, use the keypad to run the motor through its entire speed

range (minimum speed to 60 Hz). Assuming the motor and load responds well to all

speeds, move on.

7. Push the STOP button to stop the drive.

8. Once the motor comes to a stop, push the AUTO button to put the drive into automatic

(non-local) control.

9. On the Delta controller, set the AO for speed to a safe speed.

10. On the Delta controller command the BO to start the drive.

The drive should now be starting, and running up to the commanded speed.

11. Adjust the Delta controller's AO value across its range to ensure that the full speed

range can be commanded, and that the minimum speed of the drive is being enforced.

12. Verify that the feedback speed (AI) is reading properly.

13. Stop the drive by commanding the BO to stop.

14

Page 16

Document

Version

Date Published

Change Description

1.0

August 2017

First release.

Appendix A P ublication History

Appendix A Publication History

15

Loading...

Loading...