Page 1

Automation for a Changing World

Delta Vector Control Drive

C2000 Series

www.deltaww.com

Page 2

Powerful Features.

High Efficiency.

The C2000 Series AC motor drive provides the most efcient solution for all

types of drive applications. It features precise speed, torque and position

control functions that are suitable for both sensor and sensorless types

of synchronous and asynchronous motors. The C2000 Series is also equipped

with built-in PLC functions and supports the CANopen Master/Slave extension

for the ultimate in system exibility and fast data exchange.

1

Page 3

Table of Contents

Standard Models

Advanced Drive Controls

Modular Design

Certications

LCD Keypad

Features and Applications

High-speed networks

Convenient operation platform

High performance eld oriented control

Fast response to impact load

Auto energy saving operation

DEB function

Permanent magnet motors (SPM, IPM)

REG2000 Series

AFE2000 Series

3

3

5

6

7

8

Active Front End

11

AFE2000 Series

Operation Temperature and

12

Protection Level

Environment for Operation,

13

Storage and Transportation

Specications

Wiring

Dimensions

Option cards

Ordering information

2

13

Page 4

Standard Models (IP20/NEMA1)

Power range

230 V (kW) 0.75 1.5 2.2 3.7 5.5 7.5 11 15 18.5 22 30 37 45 55 75 90

230 V (HP) 1 2 3 5 7.5 10 15 20 25 30 40 50 60 75 100 125

Frame Size A B C D E F

Power range

460 V (kW) 0.75 1.5 2.2 3.7 4.0 5.5 7.5 11 15 18.5 22 30 37 45 55 75 90 110 132 160 185 220 280 315 355 450

460 V (HP) 1 2 3 5 5 7.5 10 15 20 25 30 40 50 60 75 100 125 150 175 215 250 300 375 425 475 600

Frame Size A B C D0 D E F G

Power range

575 V (kW)

575 V (HP)

Frame Size

Power range

690 V (kW)

690 V (HP)

Frame Size

:230 V 0.75 ~ 90 kW

:460 V 0.75 ~ 450 kW

: 575 V 1.5 ~ 15 kW

1.5 2.2 3.7 5.5 7.5 11 15

2 3 5 7.5 10 15 20

A B

: 690 V 18.5 ~ 630 kW

18.5 22 30 37 45 55 75 90 110 132 160 200

25 30 40 50 60 75 100 125 150 175 215 270 335 425 530 600 745 840

C D E F G H

315 400 450 560 630

250

Advanced Drive Controls

▪

High Performance

1. High bandwidth control

2. Speed / torque / position control mode

3. Dual rating design

(normal duty / heavy duty)

4. 4-quadrant torque control and limit

5. For both synchronous and

asynchronous motors

▪

Environmental Adaptability

1. 50℃ operating temperature

2. Built-in DC reactor

3. Coated circuit boards

4. Built-in EMC lter

5. International safety standard

(CE/UL/cUL)

*Note: Please refer to the Product Specication

3

Page 5

H

▪

Versatile Drive Controls

1. Built-in safe stop function

2. Built-in PLC function

3. Built-in brake unit

4. Supports various network

protocols

5. Position control

▪

Modular Design

1. Hot pluggable LCD keypad

2. I/O extension cards

3. Various PG (encoder) feedback cards

4. Network cards for eldbus modules

5. Removable fan

4

Page 6

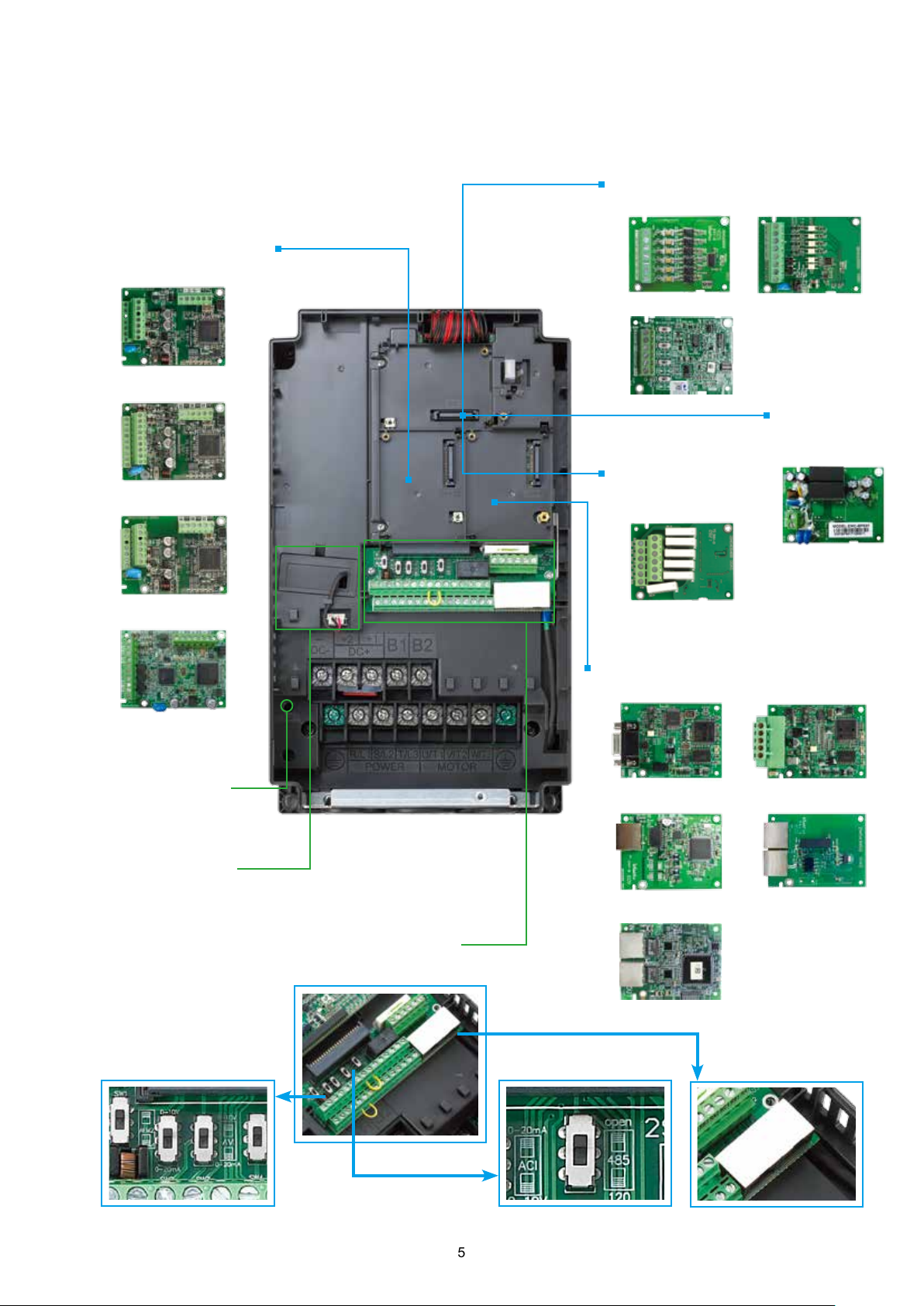

Modular Design

Various accessories options, such as I/O extension cards, encoder feedback cards, communication cards,

hot pluggable LCD keypad, removable terminals and removable fans.

►

I/O extension cards

EMC-D42AEMC-D611A

►

PG (Encoder) cards

EMC-PG01O / EMC-PG02O

EMC-A22A

EMC-PG01U / EMC-PG02U

►

24V Power

Shift Card

EMC-BPS01

►

Relay Extension

EMC-PG01L / EMC-PG02L

Card

EMC-R6AA

EMC-PG01R

■Removable fan

To ensure personal safety,

do not begin wiring before

the indicator light is off.

*NOTE: "u" are optional accessories.

■Power indicator

To prevent personal injury, please do not

perform wiring before power indicator is off.

■Removable terminals

Convenient wiring and safety equipment.

Analog I/O switch Termination resistor

►

Communication cards

CMC-PD01

CMC-MOD01 / CMC-EIP01 EMC-COP01

CMC-EC01

Dual RJ45

communication ports

CMC-DN01

5

Page 7

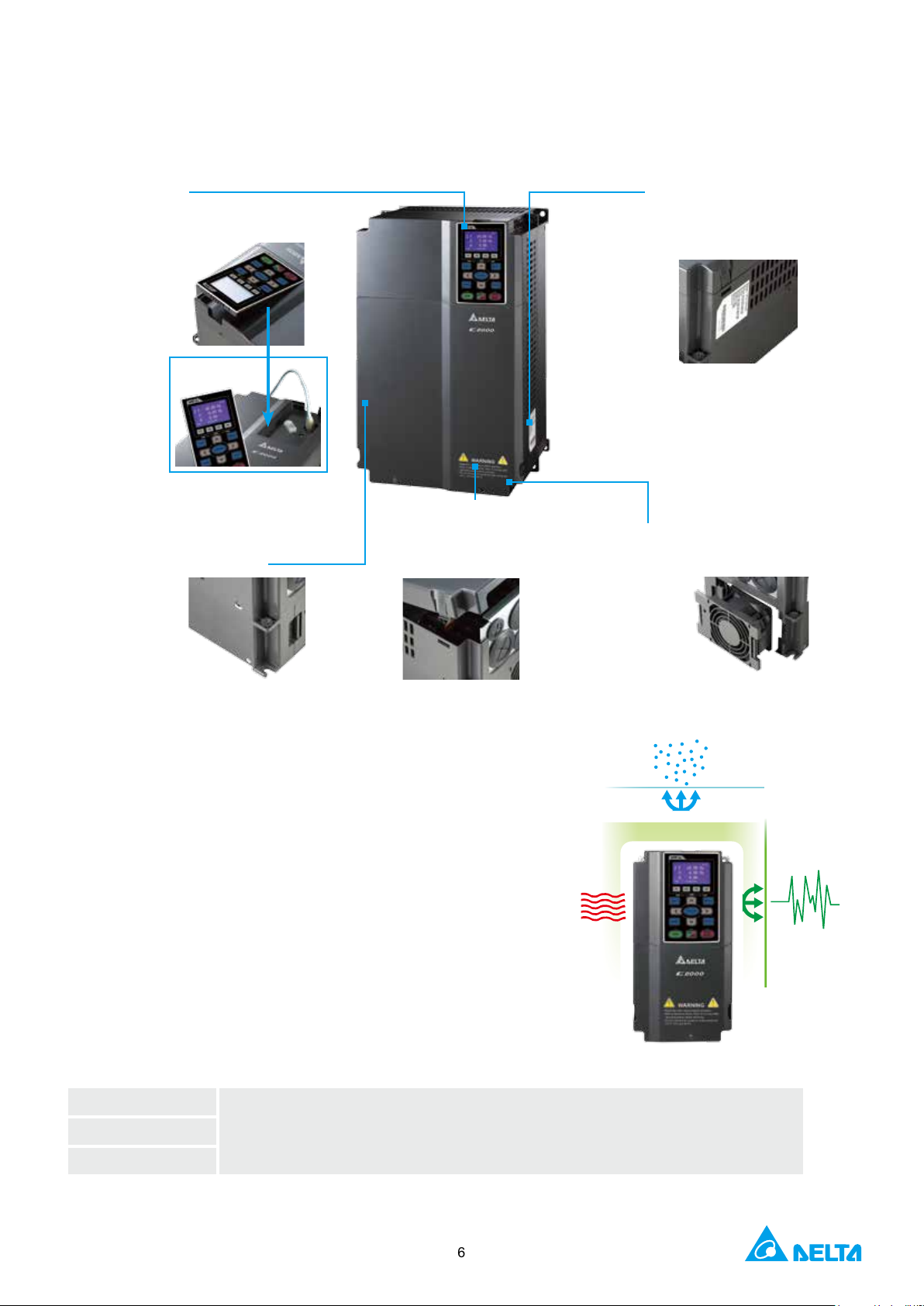

The modular design fullls the needs of system applications and equipment maintenance.

■

KPC-CC01 keypad

■

Standard RJ45 network cable for remote operation.

■

Easy to remove with one press.

■

RFI Jumper

■

Remove the safety screws and

press on both side tabs to remove

the cover.

■

The product nameplate shows

the input / output voltage,

input / output current, the

frequency range, and more.

■

Modular fan design, easy to

replace and clean, extending

product service life.

Excellent Environment Adaptability

►

Built-in DC choke to surpress harmonics*

►

Built-in EMC lter to lter noise*

►

Conformal coating (Class 3C3 of IEC60721-3-3 standard)

ensures drive operation stability and safety in critical environments.

►

The electronic components of the drive are isolated from the

cooling system to reduce heat interference. Dissipated heat can be

Heat

dissipation

discharged by ange-mounting installation, and forced fan cooling

can import cold air into the heat sink. The heat dissipation

performance is optimized by these two cooling methods.

*Note: Please refer to the Product Specication

Certifications

UL, cUL

C-Tick

ROHS

CE

Low Voltage: EN61800-5-1

EMC: EN61000-3-12, EN61800-3, IEC61000-6-2, IEC61000-6-4, IEC61000-4-2,

IEC61000-4-3, IEC61000-4-4, IEC61000-4-5, IEC61000-4-6, IEC61000-4-8

Dust-proof

Interference

immunity

6

Page 8

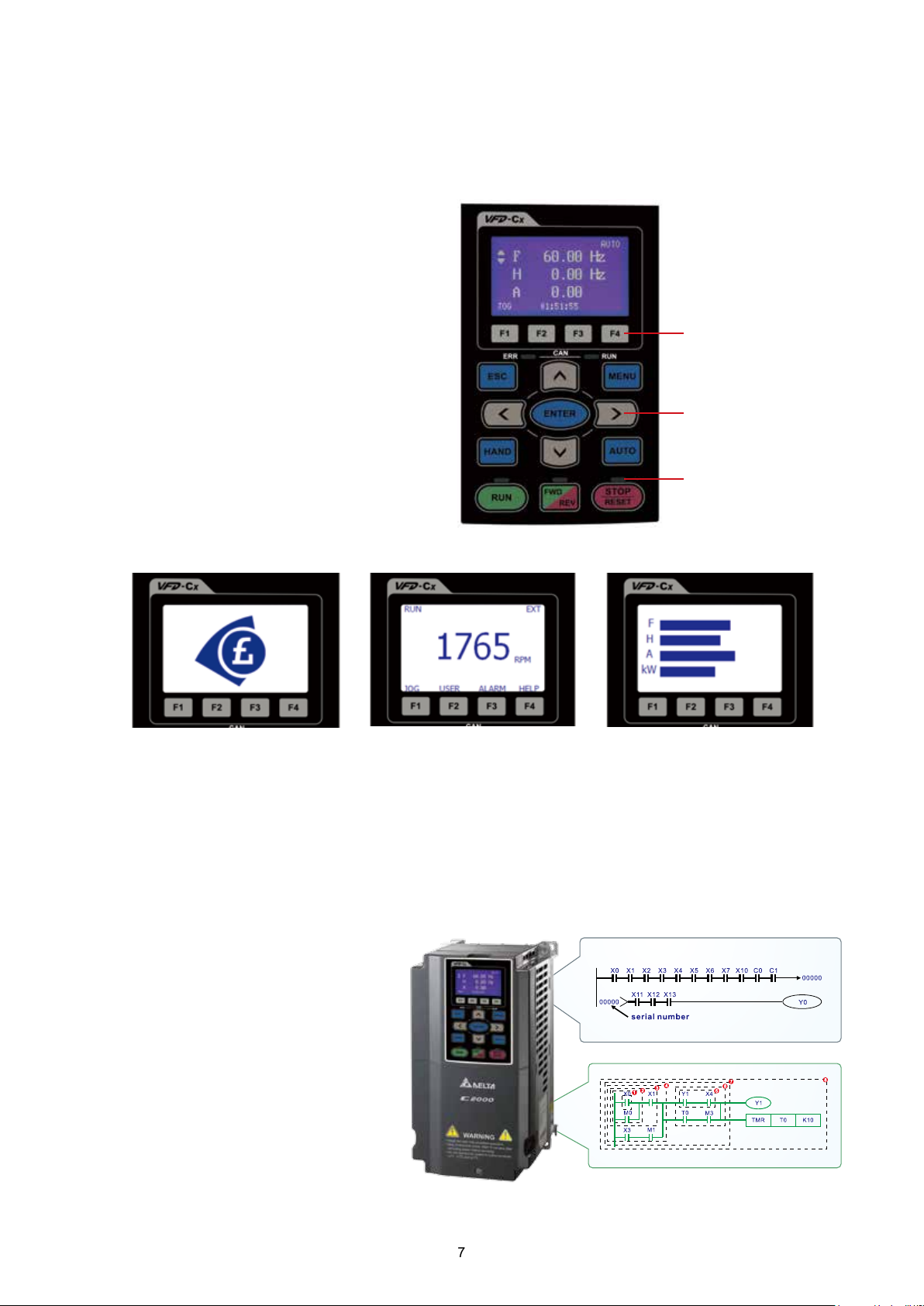

Quick and Easy Parameters Setting via the

LCD Keypad

■

Multi-column display for the drive status

■

Simple and intuitive operation

■

User-dened parameter groups

■

Real Time Clock and calendar function

■

Language selection for display

■

Copy function saves parameters and PLC

programs to the keypad memory for later

transfer to another drive

■

IP66 protection level

F1 to F4: User-dened

function keys

Selection keys

LED displays the

current drive status

Create homepage logo Editable message display Editable chart display

Intelligent PLC Functions

■

Built-in 10 K steps capacity of PLC

functions. Distributed control and

independent operation are easily

achieved via network connection.

■

CANopen Master protocol and PLC

functions provide synchronous control

and fast data exchange.

7

Page 9

High-Speed Network

►

Provides optional MODBUS RTU and various

eldbus cards for exible applications

■

■

CANopen

(DS402)

►

Advanced network functions

►

Built-in MODBUS communication

Ability to control up to 8 Slave drives via the CANopen Master function

•

Supports all Delta industrial automation products

(Built-in EDS les for all Delta industrial automation products)

•

I/O data congurations for each device on the CANopen network

•

Motion control planning function

•

WPL Soft

CANopen

■

DeviceNet

Through the Delta specially designed DeviceNet

Builder software, users can easily establish

a standard DeviceNet control network by the

parameter pre-assignment function for each

equipment and remote I/O.

•

Supports all Delta industrial automation products

(Built-in EDS les for all Delta industrial automation

products)

•

I/O data congurations

for each device on the

DeviceNet network

•

DeviceNet layout software

1 Mbps 25 m

500 kbps 100 m

CANopen

■ EtherNet/IP

■

MODBUS TCP

Delta provides communication integrator software

that offers graphic module settings and a user friendly

interface to support all Ethernet products settings and

online monitoring.

•

Delta software for Ethernet/MODBUS TCP products

•

Graphic module settings and a user friendly interface

•

Auto search function

•

Supports Virtual

COM settings

•

TAP-CN03 distribution

box for long distances

•

RJ45 cable

Convenient Drive System Management Platform

■

Provides a complete operation platform for users' easy control and monitoring via PC, including parameters

save/setting, real-time wave monitor, quick setup, for multiple languages and with multi-language operation systems.

Start-up display

Displays horsepower, rated voltage and current of the drive in use.

Parameter management

Provides parameter setting/save/copy/comparison for

convenient parameter management.

Trend records

Monitors the drive operation form via network and

displays I/O terminal status. Useful for tasks such as

"trial run monitoring".

Quick setup

Guides the user step-by-step through the drive

settings according to quick setup wizard.

*NOTE: These software programs are available for download on Delta's website

8

Page 10

High-Performance Field Oriented Control

The FOC+PG mode of C2000 Series can output 150%

of starting torque at extremely low speeds for precise

and stable speed control.

Example for 3.7kW model

300

250

200

150

Torque(%)

100

50

0

-1 1 3 5 7 9 11

Frequency(Hz)

C type

0Hz

0.1Hz

0.5Hz

1Hz

2Hz

3Hz

5Hz

10Hz

Fast Response to

Impact Load

During load changes, the C2000 Series calculates the

required torque response and minimizes the vibration

caused by load impact using FOC.

100

80

60

40

20

0

-20

-40

Speed (RPM)

-60

-80

-100

150 200 250

100

300 350

Time

400 450 500

Precise position and speed control ideal for printing

machine applications.

Auto Energy-Saving

Operation

Auto-calculates the optimal voltage for the load

output using load power when under constant speed

operation.

Frequency Command = Frequency Output

Output Voltage

Output Current

Current < Rated Current * 0.35

5sec

Deceleration Energy Backup (DEB)

This function controls the motor deceleration to stop when power blinks off to prevent mechanical damage and

then accelerates to its original operation speed when power resumes.

Input Voltage

Motor Speed

Power Blink Off

DEB

Decelerate to Stop

Motor Flying Start

DEB Return Time

Time

9

Input Voltage

Motor Speed

Unexpected Power Shut Down

Safe Motor Stop

DEB

Decelerate to Stop

DEB Return Time

Time

Page 11

A Drive for Permanent Magnet

(PM) Motors

The C2000 is a dual mode drive to control

both an induction motor and permanent

magnet motor. The dynamic response

of a PM motor provides precise

control of position, speed

and torque.

Permanent magnet motor

Servo motor

Encoder

AC motor drive

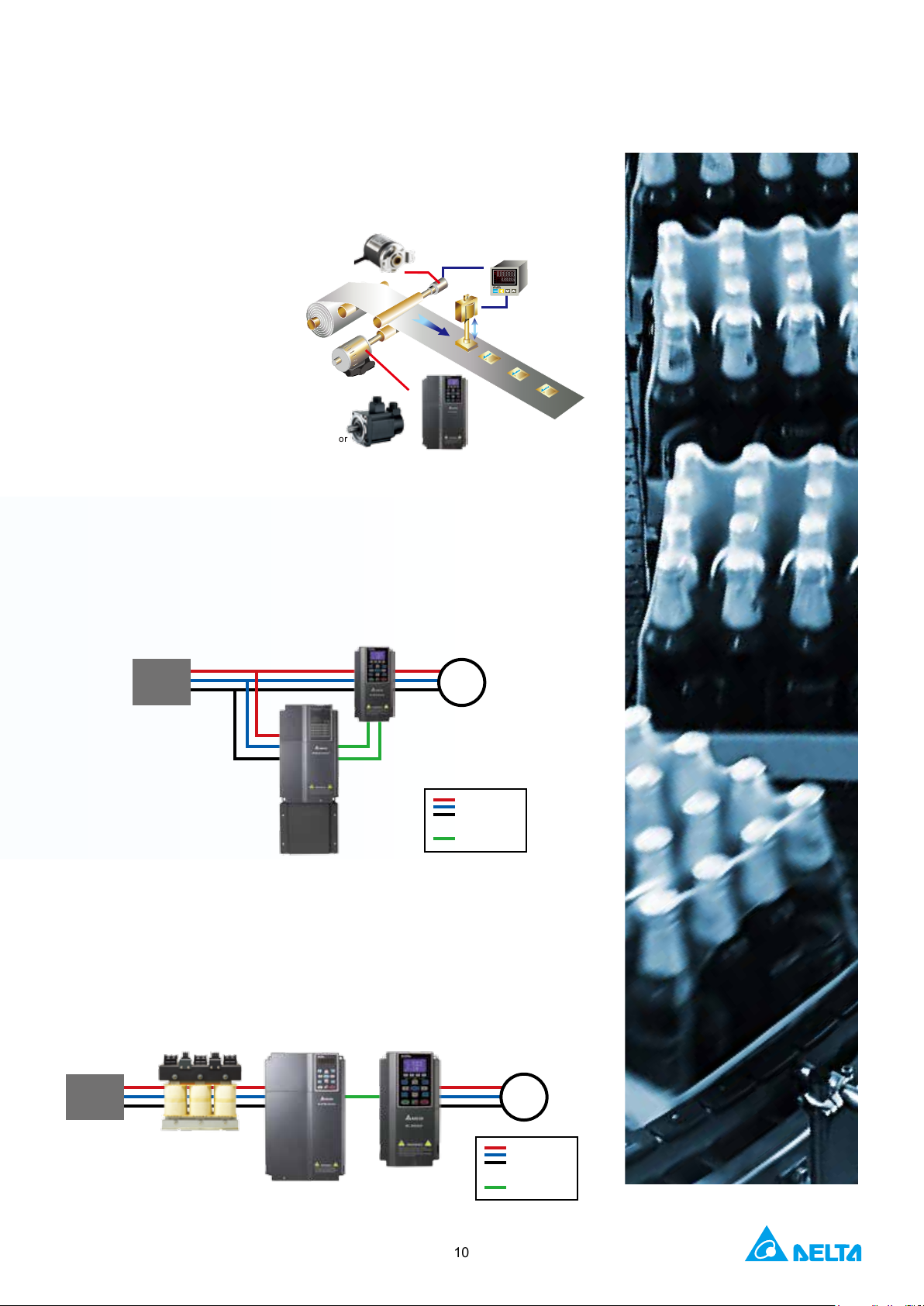

Delta REG2000 Series for

Power Regeneration

Using the REG2000 with the C2000 in a crane and hoist application

provides the user with a four-quadrant operation and energy saving

results.

Mains

Power

M

Counter

AC Voltage

DC Voltage

Delta AFE2000 Series for

Power Regeneration and

Power Quality Improvement

The Active Front End Unit (AFE2000) helps to reduce torque ripple and

harmonics with a higher power factor to provide excellent production

quality and outstanding energy saving results.

Mains

Power

10

M

AC Voltage

DC Voltage

Page 12

Delta Active Front End AFE2000 Series

Tr ad it io na l AC m ot o r d r iv e

Tr a d it i on al AC mo t or d r iv e

Features

■

Replaces traditional brake resistor to reduce heat generation.

■

Clear energy savings: more than 95% of the

regenerative energy is converted into electricity

and supplied back to the mains.

■

Full-load operation: input-side current THD lower than

5% and improves power factor up to 99%.

■

AC motor drives with AFE2000:

supports 4-quadrant operation with variable

frequencies and adjustable system.

■

Constant DC bus voltage: unaffected

by mains voltage uctuations.

Improves power factor and decreases harmonic distortion.

THD<=5%, power factor > 99%

60%

99%

80%

AF E 2 000

Improves power factor by 20%

Power

Foctor (%)

Decreases harmonic

distortion by 55%

5%

THD (%)

AF E 2000

Applications

■

Large-inertia loads, such as centrifuge equipment, dewatering machines and roving machines

■

4-quadrant loads including elevators, cranes and pumpjacks (oil extraction machines)

■

Quick braking, such as machine tools, bag making machines, auto storage and retrieval systems, and lathes

■

Long-term energy feedback, such as wind power, water power, steel printing and paper making machinery (winding

equipment)

■

Improves power quality for industries such as semiconductor and panel industries

11

Page 13

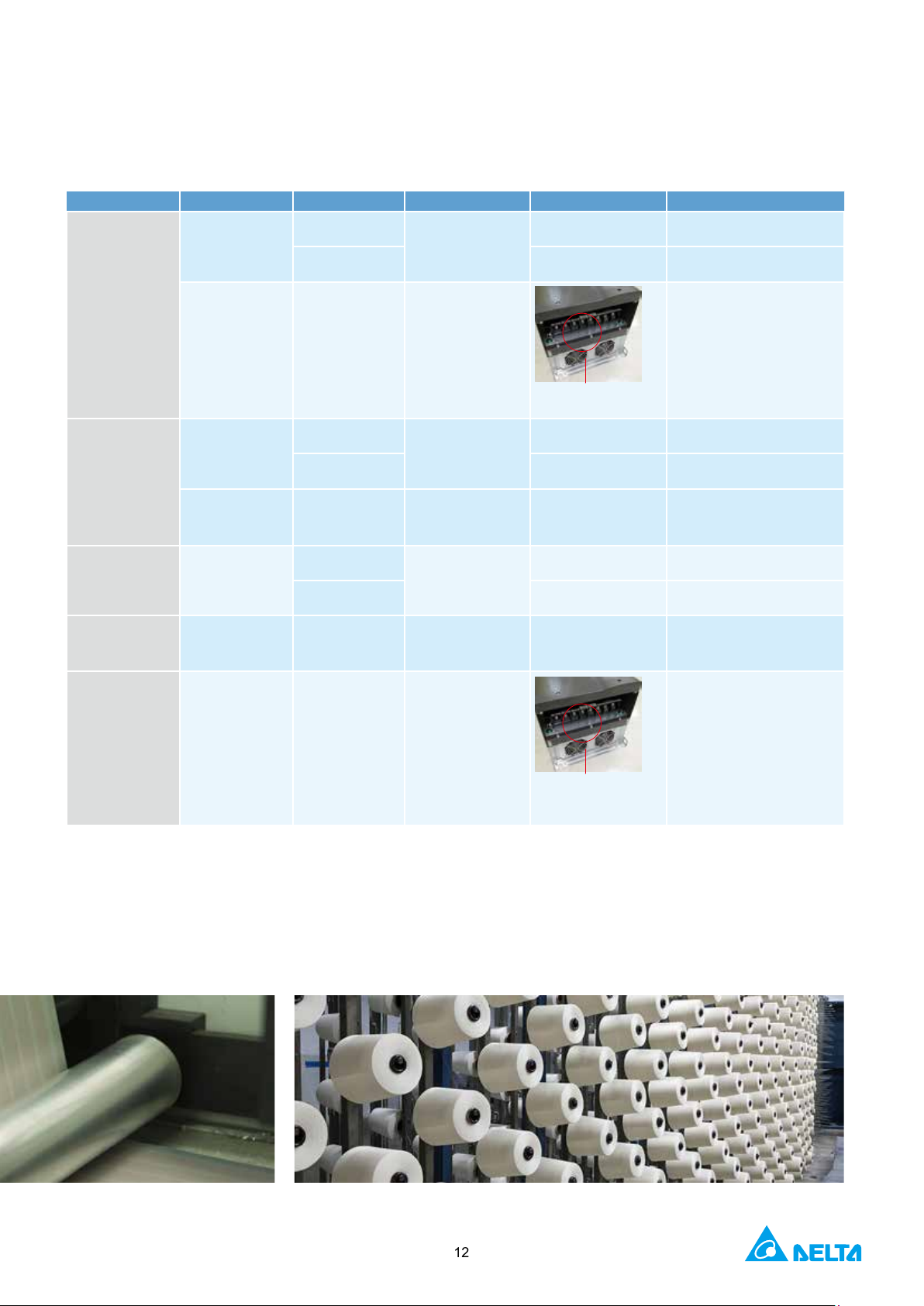

Operation Temperature and Protection Level

Model Frame Top Cover Conduit Box Protection Level OperationTemperature

VFDxxxCxxA

VFDxxxCxxS

VFDxxxCxxE

VFDxxxCxxU

VFDxxxC53A-21

VFDxxxC63B-21

VFDxxxC63B-21

Frame

A ~ C

230 V: 0.75 ~ 22 kW

460 V: 0.75 ~ 30 kW

Frame

D ~ H

230 V: > 22 kW

460 V: > 30 kW

Frame

A ~ C

460 V: 0.75 ~ 30 kW

Frame

D ~ H

230 V: > 22 kW

460 V: > 30 kW

Frame

A ~ C

1.5 ~ 37 kW

Frame

D ~ H

> 45 kW

Remove top cover

Standard with top

cover

N / A

Remove top cover

Standard with top

cover

N / A Standard conduit box IP20 / UL Type1 / NEMA1 -10 ºC ~ 40 ºC

Remove top cover

Standard with top

cover

N / A Standard conduit box IP20 / UL Type1 / NEMA1 -10 ºC ~ 40 ºC

Standard conduit plate

No conduit box

Standard conduit plate

Standard conduit plate

IP20 / UL Open Type -10 ºC ~ 50 ºC

IP20 / UL Type1 / NEMA1 -10 ºC ~ 40 ºC

IP00

IP20 / UL Open Type

Protection degree for

the circled area is IP00,

other areas are IP20

IP20 / UL Open Type -10 ºC ~ 50 ºC

IP20 / UL Type1 / NEMA1 -10 ºC ~ 40 ºC

IP20 / UL Open Type -10 ºC ~ 50 ºC

IP20 / UL Type1 / NEMA1 -10 ºC ~ 40 ºC

-10 ºC ~ 50 ºC

VFDxxxC63B-00

Frame

> 45 kW

D ~ H

N / A

No conduit box

IP00

IP20 / UL Open Type

Protection degree for

the circled area is IP00,

other areas are IP20

-10 ºC ~ 50 ºC

12

Page 14

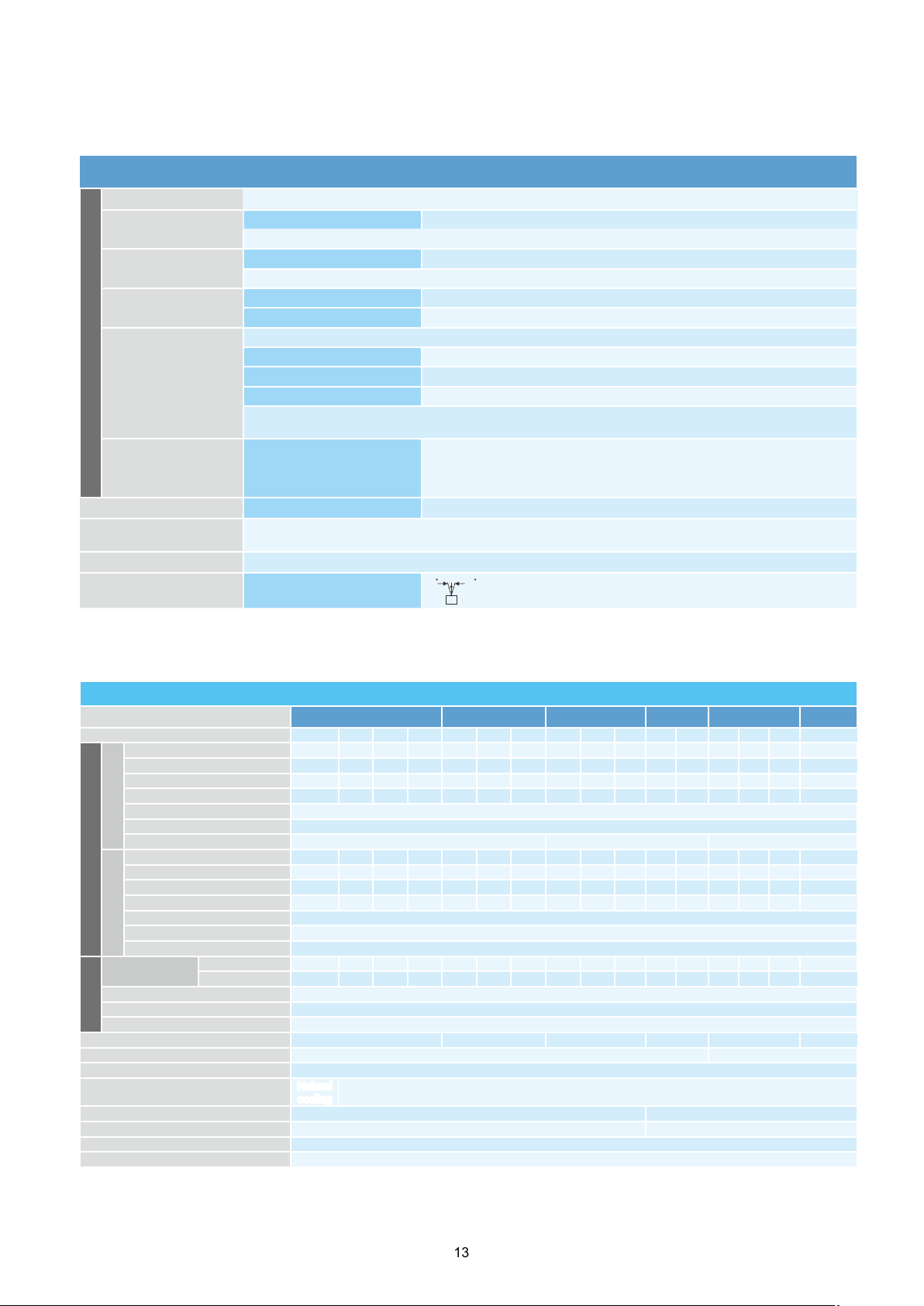

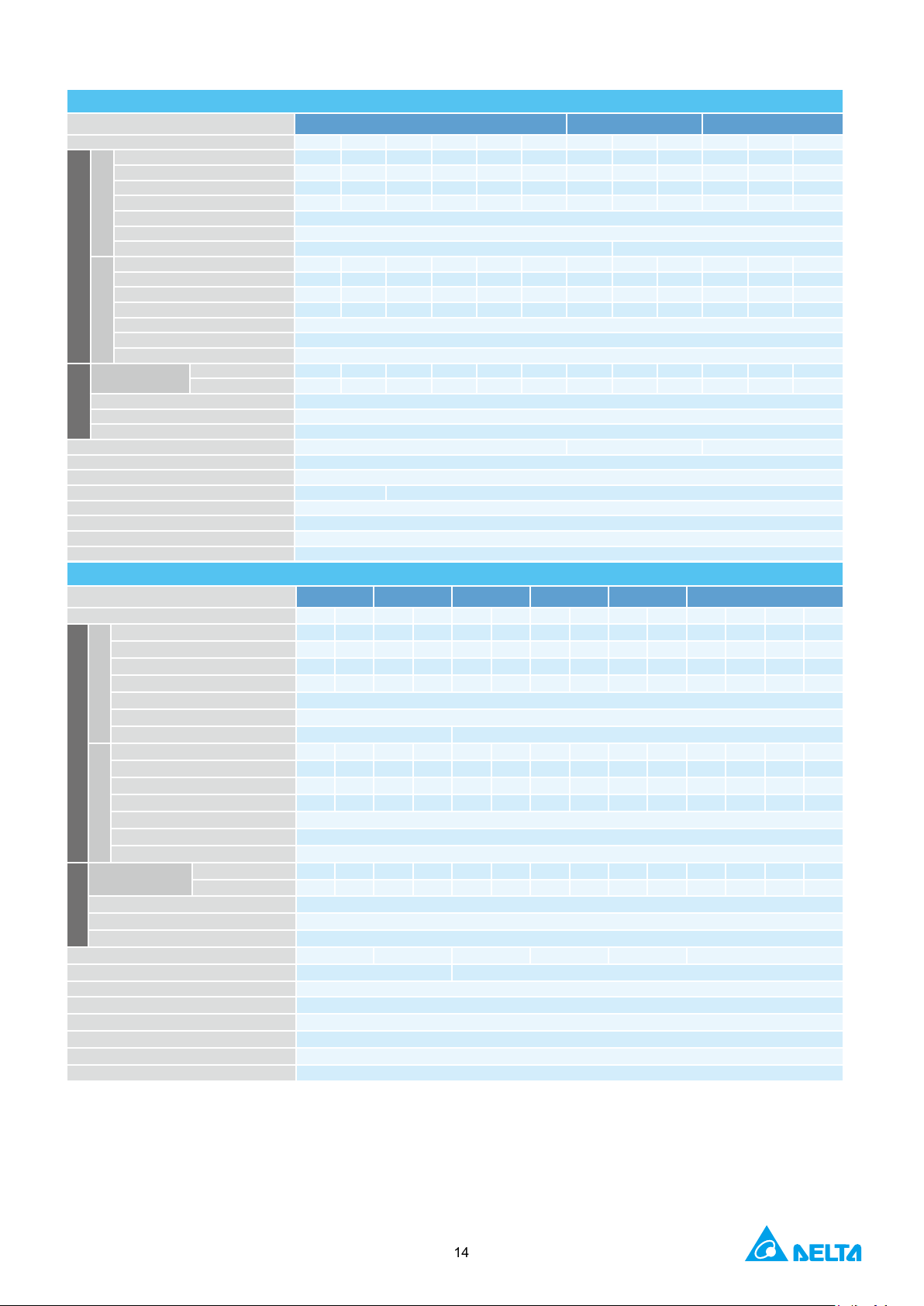

230 V

A

BCDEF

Model VFD- ���C��

007

015

022

Rated Output Capacity (kVA)

Rated Output Current (A)

Applicable Motor Output (kW)

Applicable Motor Output (HP)

Overload Capacity

Max. Output Frequency (Hz)

Carrier Frequency (kHz)

Rated Output Capacity (kVA)

1.9

2.8

4.0

6.4

9.612192528344555688196

131

Rated Output Current (A)

4.8

Applicable Motor Output (kW)

Applicable Motor Output (HP)

Overload Capacity

Max. Output Frequency (Hz)

Carrier Frequency (kHz)

Input Rating

Normal Duty

Heavy Duty

Rated Voltage / Frequency

Operating Voltage Range

Frequency Tolerance

Drive Weight (Kg)

Efciency (%)

Power Factor

Natural

cooling

Braking Chopper

Frame A, B, C: built-in

Frame D and above: optional

DC Choke

Frame A, B, C: optional

Frame D and above: built-in

EMC Filter

Optional

EMC-COP01

Optional

Environment for Operation, Storage and

DO NOT expose the AC motor drive to harsh environments, such as dust, direct sunlight, corrosive / ammable gasses, humidity, liquid or vibrations.

10 1 0

Transportation

The salts in the air must be less than 0.01 mg / cm2 per year.

Installation Location

Surrounding

Temperature (°C)

Rated Humidity

Air Pressure

Environment

Pollution Level

Altitude

Package Drop

Vibration

Impact

Operation Position

(kPa)

IEC60364-1 / IEC60664-1 Pollution degree 2, indoor use only

Storage / Transportation

Only allowed in non-condensation, non-frost, non-conductive environment.

Operation/Storage / Transportation Max. 95%

Only allowed in non-condensation, non-frost, non-conductive environment.

Operation / Storage 86

Transportation 70

I

EC60721-3-3

Operation

Storage

Transportation

If the AC motor drive is to be used under harsh environment with high level of contamination (e.g. dew, water, dust), make

sure it is installed in an environment qualied for IP54 such as in a cabinet.

Operation

Storage / Transportation ISTA procedure 1 A (according to weight) IEC60068-2-31

1.0 mm, peak to peak value range from 2 Hz to 13.2 Hz; 0.7 G ~ 1.0 G range from 13.2 Hz to 55 Hz;

1.0 G range from 55 Hz to 512 Hz. Comply with IEC 60068-2-6.

IEC / EN 60068-2-27

Max. allowed offset angle ±10 °

(under normal installation position)

-25 ~ 70

106

~

106

~

Class 3C3; Class 3S2

Class 1C2; Class 1S2

Class 2C2; Class 2S2

If the AC motor drive is installed at an altitude 0 ~ 1000 m, follow normal operation

restriction. If it is installed at altitude 1000 ~ 2000 m, decrease 1% of rated current or lower 0.5 °C

of temperature for every 100 m increase in altitude. Maximum altitude for Corner Grounded TN

system is 2000m, for application over 2000m please contact Delta for more details.

Specifications

Frame Size

*

NORMAL DUTY

Output Rating

HEAVY DUTY

Input Current (A)

Cooling Method

2.0 3.2 4.4 6.8 10 13 20 26 30 36 48 58 72 86 102 138

5 8 11 17 25 33 49 65 75 90 120 146 180 215 255 346

0.75 1.5 2.2 3.7 5.5 7.5 11 15 18.5 22 30 37 45 55 75 90

1 2 3 5 7.5 10 15 20 25 30 40 50 60 75 100 120

120% of rated current: 1 minute for every 5 minutes; 160% of rated current: 3 seconds for every 30 seconds

2 ~ 15 (default setting 8) 2 ~ 10 (default setting 6) 2 ~ 9 (default setting 4)

7.1 10 16 24 31 47 62 71 86 114 139 171 204 242 329

0.4 0.75 1.5 2.2 3.7 5.5 7.5 11 15 19 22 30 37 45 55 75

0.5 1 2 3 5 7.5 10 15 20 25 30 40 50 60 75 100

150% of rated current: 1 minute for every 5 minutes; 180% of rated current: 3 seconds for every 30 seconds

6.4 12 16 20 28 36 52 72 83 99 124 143 171 206 245 331

6.1 11 15 18.5 26 34 50 68 78 95 118 136 162 196 233 315

2.6 ± 0.3 5.4 ± 1 9.8 ± 1.5 38.5 ± 1.5 64.8 ± 1.5 86.5± 1.5

037 055 075 110 150 185 220 300 370 450 550 750 900

0.00 ~ 599.00

0.00 ~ 300.00

2 ~ 6 (default setting 2)

3-phase AC 200 V ~ 240 V (-15% ~ +10%), 50 / 60 Hz

97.8 98.2

170 ~ 264V

47 ~ 63 Hz

> 0.98

Fan cooling

ac

* The factory setting is Normal Duty mode

13

Page 15

460 V

Frame Size

Model VFD-���C��

007

015

022

Rated Output Capacity (kVA)

Rated Output Current (A)

Applicable Motor Output (kW)

Applicable Motor Output (HP)

Overload Capacity

Max. Output Frequency (Hz)

Carrier Frequency (kHz)

Rated Output Capacity (kVA)

2.3

3.0

4.5

6.5

7.6

9.6141824293445

Rated Output Current (A)

2.9

Applicable Motor Output (kW)

Applicable Motor Output (HP)

Overload Capacity

Max. Output Frequency (Hz)

Carrier Frequency (kHz)

Input Rating

Normal Duty

Heavy Duty

Rated Voltage / Frequency

Operating Voltage Range

Frequency Tolerance

Drive Weight (Kg)

Efciency (%)

Power Factor

Cooling Method

Natural cooling

Fan cooling

Braking Chopper

Frame A, B, C: built-in; Frame D and above: optional

DC Choke

Frame A, B, C: optional; Frame D and above: built-in

EMC Filter

VFDXXXC43A: Optional; Frame A~C VFDXXXC43E: Built-in

EMC-COP01

VFDXXXC43A: optional; VFDXXC43E: built-in

460 V

Model VFD-���C��

370

450

550

*

Rated Output Capacity (kVA)

Rated Output Current (A)

Applicable Motor Output (kW)

Applicable Motor Output (HP)

Overload Capacity

Max. Output Frequency (Hz)

Carrier Frequency (kHz)

Rated Output Capacity (kVA)

556984

114

136

167

197

235

280

348

417

466

517

677

Rated Output Current (A)

69

Applicable Motor Output (kW)

Applicable Motor Output (HP)

Overload Capacity

Max. Output Frequency (Hz)

Carrier Frequency (kHz)

Normal Duty

Heavy Duty

Rated Voltage / Frequency

Operating Voltage Range

Frequency Tolerance

Drive Weight (Kg)

Efciency (%)

Power Factor

> 0.98

Cooling Method

Fan cooling

Braking Chopper

Frame A, B, C: built-in; Frame D and above: optional

DC Choke

Frame A, B, C: optional; Frame D and above: built-in

EMC Filter

Frame D0~H: Optional

EMC-COP01

VFDXXXC43A: optional; VFDXXC43E: built-in

*

NORMAL DUTY

Output Rating

HEAVY DUTY

Input Current (A)

A B C

2.4 3.2 4.8 7.2 8.4 10 14 19 25 30 36 48

3.0 4.0 6.0 9.0 10.5 12 18 24 32 38 45 60

0.75 1.5 2.2 3.7 4.0 5.5 7.5 11 15 18.5 22 30

1 2 3 5 5 7.5 10 15 20 25 30 40

120% of rated current: 1 minute for every 5 minutes; 160% of rated current: 3 seconds for every 30 seconds

2 ~ 15 (default setting 8) 2 ~ 10 (default setting 6)

3.8 5.7 8.1 9.5 11 17 23 30 36 43 57

0.4 0.75 1.5 2.2 3.7 4.0 5.5 7.5 11 15 18.5 22

0.5 1 2 3 5 5 7.5 10 15 20 25 30

150% of rated current: 1 minute for every 5 minutes; 180% of rated current: 3 seconds for every 30 seconds

4.3 5.9 8.7 14 15.5 17 20 26 35 40 47 63

4.1 5.6 8.3 13 14.5 16 19 25 33 38 45 60

037 040 055 075 11 0 150 185 220 300

0.00 ~ 599.00

0.00 ~ 300.00

2 ~ 6 (default setting 2)

3-phase AC 380 V ~ 480 V ( -15% ~ +10%), 50 / 60 Hz

323 ~ 528 V

AC

47 ~ 63 Hz

2.6 ± 0.3 5.4 ± 1 9.8 ± 1.5

97.8

> 0.98

Frame Size

NORMAL DUTY

Output Rating

HEAVY DUTY

Input Current (A)

Input Rating

D0 D E F G H

750 900 1100 1320 1600 1850 2200 2800 3150 3550 4500

58 73 88 120 143 175 207 247 295 367 438 491 544 720

73 91 11 0 150 180 220 260 310 370 460 550 616 683 866

37 45 55 75 90 11 0 132 160 185 220 280 315 355 450

50 60 75 100 125 150 175 215 250 300 375 420 475 600

120% of rated current: 1 minute for every 5 minutes; 160% of rated current: 3 seconds for every 30 seconds

0.00 ~ 599.00

2 ~ 10 (default setting 6) 2 ~ 9 (default setting 4)

86 105 143 171 209 247 295 352 437 523 585 649 815

30 37 45 55 75 90 11 0 132 160 185 220 280 315 355

40 53 60 75 100 125 150 175 215 250 300 375 425 475

150% of rated current: 1 minute for every 5 minutes; 180% of rated current: 3 seconds for every 30 seconds

0.00 ~ 300.00

2 ~ 6 (default setting 2)

74 101 114 157 167 207 240 300 380 400 494 555 625 866

70 96 108 149 159 197 228 285 361 380 469 527 594 815

3 - phase AC 380 V ~ 480 V (-15% ~ +10% ), 50 / 60 Hz

323 ~ 528 V

47 ~ 63 Hz

27 ± 1.5 38.5 ± 1.5 64.8 ± 1.5 86.5 ± 1.5 134 ± 4 228

97.8 98.2

AC

* The factory setting is Normal Duty mode

NOTES

1) The carrier frequency is default. Increasing the carrier frequency requires a reduction in current. please refer to Pr. 06-55 Derating Protection drawing.

2) The AC motor drive should operate in derating current when its control method is set to FOC Sensorless, TQC+PG, TQC sensorless. PM+PG, PM sensorless. Please refer to Pr. 06-55 for more information.

3) Select the AC motor drive with capacity one grade larger for the impact load application.

4) The rated input current will be affected not only by Power Transformer and the connection of the reactors on input side, but also fluctuates with the impedance of power side.

5) For Frame A, B and C, Model VFDXXXC43A is under IP20 / NEMA1 / UL TYPE1 protection level.

6) For Frame D and above, if the last character of the model is A then it is under IP20 protection level but the wiring terminal is under IP00 protection level;

7) if the last character of the model is E, it is under IP20 / NEMA1 / UL TYPE1 protection level.

14

Page 16

Frame Size

Model VFD-���C53A-21

Light Duty

Rated Output Capacity (kVA)

Rated Output Current (A)

Applicable Motor Output (kW)

Applicable Motor Output (HP)

Rated Output Capacity (kVA)

Applicable Motor Output (kW)

0.75

1.5

2.2

3.7

5.5

7.5

11

Rated Output Capacity (kVA)

Rated Output Current (A)

Applicable Motor Output (kW)

Applicable Motor Output (HP)

Carrier Frequency (kHz)

Light Duty

Normal Duty

Heavy Duty

Rated Voltage / Frequency

Operating Voltage Range

446 ~ 660 VAC

Frequency Tolerance

47 ~ 63 Hz

Efciency (%)

97

98

Power Factor

> 0.98

AC Drive Weight (Kg)

3 ± 0.3

4.8 ± 1

Braking Chopper

Built-in

DC Choke

Optional

EMC Filter

Optional

Model VFD-���C63B-00 / -21

Rated Output Capacity (kVA)

Applicable Motor Output ( 690V, kW)

Applicable Motor Output ( 690V, HP)

Applicable Motor Output (575V, HP)

Rated Output Current (A)

Rated Output Capacity (kVA)

Applicable Motor Output ( 690V, kW)

15

18.522303745557590110

Applicable Motor Output ( 690V, HP)

Applicable Motor Output (575V, HP)

1520253040506075100

125

Rated Output Current (A)

Rated Output Capacity (kVA)

Applicable Motor Output ( 690V, kW)

Applicable Motor Output ( 690V, HP)

1520253040506075100

125

Applicable Motor Output (575V, HP)

Rated Output Current (A)

Carrier Frequency (kHz)

Light Duty

Normal Duty

Heavy Duty

Rated Voltage / Frequency

Operating Voltage Range

446 ~ 759 VAC

Frequency Tolerance

47 ~ 63 Hz

Efciency (%)

97

Power Factor

> 0.98

AC Drive Weight (Kg)

10 ± 1.5

39 ± 1.5

61 ± 1.5

Cooling Method

Fan cooling

Braking Chopper

Frame C (built-in)

Frame D and above (optional)

DC Choke

Frame C (optional)

Frame D and above (built-in)

EMC Filter

Optional

*

Rated Output Current (A)

575 V

A B

015 022 037 055 075 110 150

3 4.3 6.7 9.9 12.1 18.7 24.1

3 4.3 6.7 9.9 12.1 18.7 24.2

1.5 2.2 3.7 5.5 7.5 11 15

2 3 5 7.5 10 15 20

2.5 3.6 5.5 8.2 10 15.4 19.9

2.5 3.6 5.5 8.2 10 15.5 20

Applicable Motor Output (HP)

Normal Duty

Output

Heavy Duty

Input Current (A)

Input

Cooling Method Natural cooling Fan cooling

1 2 3 5 7.5 10 15

2.1 3 4.6 6.9 8.3 12.9 16.7

2.1 3 4.6 6.9 8.3 13 16.8

0.75 1.5 2.2 3.7 3.7 7.5 7.5

1 2 3 5 5 10 10

3.8 5.4 10.4 14.9 16.9 21.3 26.3

3.1 4.5 7.2 12.3 15 18 22.8

2.6 3.8 5.8 10.7 12.5 16.9 19.7

-Phase

3

2 ~15 (default setting 4)

525 VAC ~ 600 V

( -15% ~ +10%), 50 / 60 Hz

AC

690 V

Frame Size

Light Duty

*

185 220 300 370 450 550 750 900 1100 1320

29 36 43 54 65 80 103 124 149 179

18.5 22 30 37 45 55 75 90 11 0 132

25 30 40 50 60 75 100 125 150 175

20 25 30 40 50 60 75 100 125 150

24 30 36 45 54 67 86 104 125 150

24 29 36 43 54 65 80 103 124 149

20 25 30 40 50 60 75 100 125 150

C D E

Output

Normal Duty

Heavy Duty

Input Current (A)

Input

* Parameter 00-16; available load modes: Light Duty (LD), Normal Duty (ND) and Heavy Duty (HD); default setting is LD mode

20 24 30 36 45 54 67 86 104 125

17 24 29 36 43 54 65 80 103 124

11 15 18.5 22 30 37 45 55 75 90

10 15 20 25 30 40 50 60 75 100

14 20 24 30 36 45 54 67 86 104

29 36 43 54 65 81 84 102 122 147

24 29 36 43 54 65 66 84 102 122

20 24 29 36 43 54 53 66 84 102

3-Phase 525 VAC ~ 690 V

2 ~ 9 (default setting 4)

( -15% ~ +10%), 50 / 60 Hz

AC

15

Page 17

Frame Size

Model VFD-���C63B-00 / -21

*

Light Duty

Rated Output Capacity (kVA)

Applicable Motor Output ( 690V, kW)

Applicable Motor Output ( 690V, HP)

Applicable Motor Output (575V, HP)

Rated Output Current (A)

Normal Duty

Rated Output Capacity (kVA)

Applicable Motor Output ( 690V, kW)

132

160

200

250

315

355

450

630

Applicable Motor Output ( 690V, HP)

Applicable Motor Output (575V, HP)

150

175

200

250

350

400

450

745

Rated Output Current (A)

Heavy Duty

Rated Output Capacity (kVA)

Applicable Motor Output ( 690V, kW)

Applicable Motor Output ( 690V, HP)

Applicable Motor Output (575V, HP)

Rated Output Current (A)

Light Duty

Normal Duty

Heavy Duty

Rated Voltage / Frequency

Operating Voltage Range

446 ~ 759 VAC

Frequency Tolerance

47 ~ 63 Hz

Efciency (%)

97

98

Power Factor

> 0.98

AC Drive Weight (Kg)

88 ± 1.5

135 ± 4

243 ± 5

Cooling Method

Fan cooling

Braking Chopper

Frame D and above (optional)

DC Choke

Frame D and above (built-in)

EMC Filter

Optional

690 V

F G H

1600 2000 2500 3150 4000 4500 5600 6300

215 263 347 418 494.5 534.7 678.5 776

160 200 250 315 400 450 560 630

215 270 335 425 530 600 745 850

175 200 250 350 400 450 500 745

180 220 290 350 430 465 590 675

179 215 239 347 402.5 442.7 534.7 776

175 215 270 335 425 475 600 850

Output

Carrier Frequency (kHz)

Input Current (A)

Input

* Parameter 00-16; available load modes: Light Duty (LD), Normal Duty (ND) and Heavy Duty (HD); default setting is LD mode

150 180 220 290 350 385 465 675

149 179 215 263 333.5 356.5 483 776

110 132 160 200 250 280 400 630

150 175 215 270 335 375 530 850

125 150 175 200 250 335 450 745

125 150 180 220 290 310 420 675

2 ~ 9 (default setting 4) 2 ~ 9 (default setting 3)

178 217 292 353 454 469 595 681

148 178 222 292 353 388 504 681

123 148 181 222 292 313 423 681

-Phase

3

525 VAC ~ 690 V

( -15% ~ +10%), 50 / 60 Hz

AC

16

Page 18

General Specifications

Control Method

Starting Torque

V / F Curve

Speed Response Ability

Max. Output Frequency (Hz)

Frequency Output Accuracy

Frequency Setting Signal

Accel. / decel. Time

Over-Temperature Protection

Stall Prevention

Restart after Instantaneous

Power Failure

Grounding Leakage Current

Protection

Pulse Width Modulated (PWM)

model:

model

:

model: Normal duty 160%, heavy duty 180% of torque current

model

: Maximum 200% of torque current

Normal duty:

±0.01%, -10 ° C ~ +40 ° C,

model

:

model

:

model

: PWM

model: Over-current protection for

model

: Over-current protection for 225% rated current (Normal duty)

(

Heavy duty: around 202% ~ 210%

Control Mode

Torque Limit

Torque Accuracy at TQC Mode

Output Frequency Resolution

Overload Capacity

Control Characteristics

Main Control Function

Fan Control

Motor Protection

Over-current Protection

Over-Voltage Protection

Protection Characteristics

Short-circuit Current Rating (SCCR)

230 V / 460 V

1: V / F,2: SVC,3: VF+PG,4: FOC+PG,5: TQC+PG,6: PM+PG,7: FOC sensorless,8: TQC sensorless,

9: PM sensorless

575 V / 690 V

1: V / F,2: V / F+PG,3: SVC

Reach up to 150% or above at 0.5 Hz. Under FOC+PG mode, starting torque can reach 150% at 0 Hz

4-point adjustable V / F curve and square curve

5 Hz (vector control can reach up to 40 Hz)

230 V / 460 V

575 V / 690 V

TQC + PG:±5%

TQC Sensorless:±15%

Light Duty /

Digital command:

Digital command: 0.01 Hz, Analog command: 0.03 * max. output frequency / 60 Hz (±11 bit)

230 V / 460 V

Normal duty: 120% of rated current can endure for 1 minute during every 5 minutes ;

160% of rated current can endure for 3 seconds during every 30 seconds

Heav y duty: 150% of rated current can endure for 1 minute during every 5 minutes ;

180% of rated current can endure for 3 seconds during every 30 seconds

575 V / 690 V

Light duty: 120% of rated current can endure for 1 minute

Normal duty: 120% of rated current can endure for 1 minute, 150% can endure for 3 seconds

Heavy duty: 150% of rated current can endure for 1 minute, 180% can endure for 3 seconds

+10 V ~ -10V, 0 ~ +10 V, 4 ~ 20 mA, 0 ~ 20 mA,

0.00 ~ 600.00 / 0.0 ~ 6000.0

Torque control, Speed / torque control switching, Feed forward control, Zero-servo control,

Momentary power loss ride thru, Speed search, Over-torque detection, Torque Limit, 16-step speed (Max.),

Accel / decel time switch, S-curve accel / decel, 3-wire sequence, Auto-Tuning (rotational, stationary), Dwell,

Slip compensation, Torque compensation, JOG frequency, Fault restart,

Frequency upper / lower limit settings, DC injection braking at start / stop, High slip braking, Parameter copy

PID control (with sleep function), Energy saving control, MODOBUS communication (RS-485 RJ45, Max.

115.2 kbps)

230 V model:

VFD150C23A (include) and series above: PMW control; VFD110C23A and below: on / off switch control

460 V model:

VFD185C43A (include) and series above: PMW control; VFD150C43A and below: on / off switch control

575 V / 690 V

Electronic thermal relay protection

230 V / 460 V

Current clamp (Normal duty: around 170 ~ 175%); (Heavy duty: around 180 ~ 185%)

575 V / 690 V

Current clamp (Light duty: around 128 ~ 141%

The C2000 Series will shut down under below conditions:

230 V: DC bus over 410 V; 460 V: DC bus over 820 V; 575 V / 690 V: DC bus over 1189 V

Built-in temperature sensor

Stall prevention during acceleration, deceleration and running independently

Parameter setting up to 20 seconds

Leakage current is higher than 50% of rated current of the AC motor drive

Per UL508C, the drive is suitable for use on a circuit capable of delivering not more than 100kA symmetrical

amperes (rms) when protected by fuses given in the fuse table

0.01 ~ 599.00 Hz;

Seconds

control

Heavy duty:

Analog command:

pulse input

); (

0.00 ~ 300.00 Hz

±0.1%, 25 ±10 ° C

240% of rated current (Normal duty)

Normal duty: around 170 ~ 175%);

)

;

International Certications

Note: EAC Certification is for 230V and 460V models only

17

Page 19

Wiring

Wiring Diagram for Frame A ~ C

*Input: 3-phase power

NOTE

It is not recommended to use a power capacitor or automatic power factor regulator (APFR) at the power input side. If the system requires such a device, please

make sure a reactor is installed between the drive and the power capacitor or APFR.

18

Page 20

Wiring Diagram for Frame D ~ F

*Input: 3-phase power

19

Page 21

Wiring Diagram for Frame G ~ H

*Input: 3-phase power

NOTE

It is not recommended to use a power capacitor or automatic power factor regulator (APFR) at the power input side. If the system requires such a device, please

make sure a reactor is installed between the drive and the power capacitor or APFR.

20

Page 22

MODEL

FRAME_A

Dimensions

FrameWHDW1

H1

D1*

ØØ1Ø2

Ø3

Digital Keypad

Frame A

Unit: mm [inch]

VFD007C23A

VFD015C23A

VFD022C23A

VFD037C23A

VFD007C43A / 43E

VFD015C43A / 43E

VFD022C43A / 43E

VFD037C43A / 43E

VFD040C43A / 43E

VFD055C43A / 43E

VFD015C53A-21

VFD022C53A-21

VFD037C53A-21

mm 130.0 250.0 170.0 116.0 236.0 45.8 6.2 22.2 34.0 28.0

A1

inch 5.12 9.84 6.69 4.57 9.29 1.80 0.24 0.87 1.34 1.10

*D1: Flange mount.

21

Page 23

Frame B

Frame

WHDW1H1

D1*S1Ø1Ø2Ø3

MODEL

mm

MODEL

VFD055C23A

VFD075C23A

VFD110C23A

VFD075C43A / 43E

VFD110C43A / 43E

VFD150C43A / 43E

VFD055C53A-21

VFD075C53A-21

VFD110C53A-21

VFD150C53A-21

mm 190.0 320.0 190.0 173.0 303.0 77.9 8.5 22.2 34.0 28.0

B1

inch 7.48 12.60 7.48 6.81 11.93 3.07 0.33 0.87 1.34 1.10

See Detail A

See Detail B

Detail A (Mounting Hole)

Detail B (Mounting Hole)

*D1: Flange mount.

Frame C

VFD150C23A

See Detail A

See Detail B

VFD185C23A

VFD220C23A

VFD185C43A / 43E

VFD220C43A / 43E

VFD300C43A / 43E

Detail A (Mounting Hole)

VFD185C63B-21

VFD220C63B-21

VFD300C63B-21

VFD370C63B-21

Detail B (Mounting Hole)

Frame W H D W1 H1 D1* S1 Ø1 Ø2 Ø3

C1

inch 9.84 15.75 8.27 9.09 15.00 3.66 0.33 0.87 1.34 1.97

250.0 400.0 210.0 231.0 381.0 92.9 8.5 22.2 34.0 50.0

*D1: Flange mount.

22

Page 24

Frame D

mm

mm

MODEL

FRAME_D1

FRAME_D0-1

W

W1

SEE DETAIL A

D

D1

D2

SEE DETAIL B

S1S1

DETAIL A

(MOUNTING HOLE)

VFD300C23A

VFD370C23A

VFD550C43A

VFD750C43A

VFD450C63B-00

VFD550C63B-00

Frame W H D W1 H1 H2 H3 D1* D2 S1 S2 Ø1 Ø2 Ø3

D1

inch 12.99 - 10.83 11.22 21.65 20.67 19.37 4.22 0.63 0.43 0.71 - - -

Frame W H D W1 H1 H2 H3 D1* D2 S1 S2

D0-1

inch 11.02 - 10.04 9.25 19.69 18.70 17.40 3.71 0.63 0.43 0.71

VFD370C43S

VFD450C43S

330.0 - 275.0 285.0 550.0 525.0 492.0 107.2 16.0 11.0 18.0 - - -

280.0 - 255.0 235.0 500.0 475.0 442.0 94.2 16.0 11.0 18.0

DETAIL B

(MOUNTING HOLE)

*D1: Flange mount.

S2

23

Page 25

mm

inch

Frame D

MODEL

FRAME_D2

FRAME_D0-2

W

W1

SEE DETAIL A

D

D1

D2

VFD300C23E

VFD370C23E

VFD550C43E

VFD750C43E

VFD450C63B-21

VFD550C63B-21

3

2

VFD370C43U

VFD450C43U

SEE DETAIL B

1

1

3

2

S1S1

DETAIL A

(MOUNTING HOLE)

DETAIL B

(MOUNTING HOLE)

S2

Frame W H D W1 H1 H2 H3 D1* D2 S1 S2 Ø1 Ø2 Ø3

D2

330.0 688.3 275.0 285.0 550.0 525.0 492.0 107.2 16.0 11.0 18.0 76.2 34.0 22.0

12.99 27.10 10.83 11.22 21.65 20.67 19.37 4.22 0.63 0.43 0.71 3.00 1.34 0.87

Frame W H D W1 H1 H2 H3 D1* D2 S1 S2 Ø1 Ø2 Ø3

D0-2

mm 280.0 614.4 255.0 235.0 500.0 475.0 442.0 94.2 16.0 11.0 18.0 62.7 34.0 22.0

inch 11.02 21.19 10.04 9.25 19.69 18.70 17.40 3.71 0.63 0.43 0.71 2.47 1.34 0.87

*D1: Flange mount.

24

Page 26

mm

Frame E

MODEL

FRAME_E1

W

W1

SEE DETAIL A

D

D1

SEE DETAIL B

VFD450C23A

VFD550C23A

VFD750C23A

VFD900C43A

VFD1100C43A

Frame W H D W1 H1 H2 H3 D1* D2 S1 S2 S3 Ø1 Ø2 Ø3

E1

inch 14.57 - 11.81 13.19 23.19 22.05 20.80 5.63 0.71 0.51 0.51 0.71 - - -

VFD750C63B-00

VFD900C63B-00

VFD1100C63B-00

VFD1320C63B-00

370.0 - 300.0 335.0 589 560.0 528.0 143.0 18.0 13.0 13.0 18.0 - - -

S3

D2

Unit:mm[inch]

*D1: Flange mount.

25

Page 27

Frame E

mm

MODEL

FRAME_E2

W

W1

SEE DETAIL A

SEE DETAIL B

D

D1

S3 D2

VFD450C23E

VFD550C23E

VFD750C23E

VFD900C43E

VFD1100C43E

Frame W H D W1 H1 H2 H3 D1* D2 S1 S2 S3 Ø1 Ø2 Ø3

E2

inch 14.57 28.18 11.81 13.19 23.19 22.05 20.80 5.63 0.71 0.51 0.51 0.71 0.87 1.34 3.62

VFD750C63B-21

VFD900C63B-21

VFD1100C63B-21

VFD1320C63B-21

370.0 715.8 300.0 335.0 589.0 560.0 528.0 143.0 18.0 13.0 13.0 18.0 22.0 34.0 92.0

*D1: Flange mount.

26

Page 28

Frame

WHDW1H1H2H3

D1*D2S1S2S3Ø1Ø2

Ø3

Frame F

MODEL

FRAME_F1

W

W1

D

D1

See Detail A

VFD900C23A

VFD1320C43A

VFD1600C43A

VFD1600C63B-00

VFD2000C63B-00

mm 420.0 - 300.0 380.0 800.0 770.0 717.0 124.0 18.0 13.0 25.0 18.0 92.0 35.0 22.0

F1

inch 16.54 - 11.81 14.96 31.50 30.32 28.23 4.88 0.71 0.51 0.98 0.71 3.62 1.38 0.87

See Detail B

S3

D2

S1

S2

Detail A (Mounting Hole)

S1

Detail B (Mounting Hole)

*D1: Flange mount.

27

Page 29

Frame

WHDW1H1H2H3

D1*D2S1S2S3Ø1Ø2

Ø3

Frame F

MODEL

FRAME_F2

W

W1

D

D1

See Detail A

VFD900C23E

VFD1320C43E

VFD1600C43E

VFD1600C63B-21

VFD2000C63B-21

mm 420.0 940.0 300.0 380.0 800.0 770.0 717.0 124.0 18.0 13.0 25.0 18.0 92.0 35.0 22.0

F2

inch 16.54 37.00 11.81 14.96 31.50 30.32 28.23 4.88 0.71 0.51 0.98 0.71 3.62 1.38 0.87

See Detail B

S3

D2

S1

S2

Detail A (Mounting Hole)

S1

Detail B (Mounting Hole)

*D1: Flange mount.

28

Page 30

mm

inch

Frame G

MODEL

FRAME_G1

W

W1

D

S3

VFD1850C43A

VFD2200C43A

VFD2500C63B-00

VFD3150C63B-00

Frame W H D W1 H1 H2 H3 S1 S2 S3 Ø1 Ø2 Ø3

G1

500.0 - 397.0 440.0 1000.0 963.0 913.6 13.0 26.5 27.0 - - -

19.69 - 15.63 217.32 39.37 37.91 35.97 0.51 1.04 1.06 - - -

29

Page 31

Frame G

mm

inch

MODEL

FRAME_G2

W1

W

D

VFD1850C43E

VFD2200C43E

VFD2500C63B-21

VFD3150C63B-21

S3

Frame W H D W1 H1 H2 H3 S1 S2 S3 Ø1 Ø2 Ø3

G2

500.0 1240.2 397.0 440.0 1000.0 963.0 913.6 13.0 26.5 27.0 22.0 34.0 117.5

19.69 48.83 15.63 217.32 39.37 37.91 35.97 0.51 1.04 1.06 0.87 1.34 4.63

30

Page 32

mm

inch

mm

Frame H1

MODEL

FRAME_H1

VFD2800C43A

VFD3150C43A

VFD3550C43A

VFD4500C43A

Frame W H D W1 W2 W3 W4 W5 W6 H1 H2 H3 H4

H1

Frame H5 D1 D2 D3 D4 D5 D6 S1 S2 S3 Ø1 Ø2 Ø3

H1

700.0 1435.0 398.0 630.0 290.0 - - - - 1403.0 1346.6 - -

27.56 56.50 15.67 24.80 11.42 - - - - 55.24 53.02 - -

- 45.0 - - - - - 13.0 26.5 25.0 - - -

inch - 1.77 - - - - - 0.51 1.04 0.98 - - -

31

Page 33

inch

27.56

68.70

15.9

24.80

19.69

24.80

29.92

31.50

-

68.07

66.99--

Frame

H5D1D2D3D4D5D6S1S2S3Ø1Ø2Ø3

MODEL

FRAME_H2

Frame H2

VFD2800C43E-1

VFD3150C43E-1

VFD3550C43E-1

VFD4500C43E-1

Frame W H D W1 W2 W3 W4 W5 W6 H1 H2 H3 H4

H2

H2

mm 700.0 1745.0 404.0 630.0 500.0 630.0 760.0 800.0 - 1729.0 1701.6 - -

mm - 51.0 38.0 65.0 204.0 68.0 137.0 13.0 26.5 25.0 - - -

inch - 2.0 1.50 2.56 8.03 2.68 5.4 0.51 1.04 0.98 - - -

32

Page 34

mm

inch

mm

Frame H3

MODEL

FRAME_H3

Side fasteners

VFD2800C43E

VFD3150C43E

VFD3550C43E

VFD4500C43E

Frame W H D W1 W2 W3 W4 W5 W6 H1 H2 H3 H4

H3

Frame H5 D1 D2 D3 D4 D5 D6 S1 S2 S3 Ø1 Ø2 Ø3

H3

700.0 1745.0 404.0 630.0 500.0 630.0 760.0 800.0 - 1729.0 1701.6 - -

27.56 68.70 15.9 24.80 19.69 24.80 29.92 31.50 - 68.07 66.99 - -

- 51.0 38.0 65.0 204.0 68.0 137.0 13.0 26.5 25.0 22.0 34.0 117.5

inch - 2.0 1.50 2.56 8.03 2.68 5.4 0.51 1.04 0.98 0.87 1.34 4.63

Side fasteners

33

Page 35

690 V Frame H1

MODEL

690V

Frame

WHDW1W2W3W4W5W6H1H2H3H4

Frame

H5D1D2D3D4D5D6S1S2S3Ø1Ø2Ø3

FRAME_H1

VFD4000C63B-00

VFD4500C63B-00

VFD5600C63B-00

VFD6300C63B-00

H1

H1

mm 700.0 - 398.0 - 630.0 290.0 - - - - 1435.0 1403.0 -

inch 27.56 - 15.67 - 24.80 11.42 - - - - 56.50 55.24 -

mm 1346.6 45.0 - - - - - 13.0 26.5 25.0 - - -

inch 53.02 1.77 - - - - - 0.51 1.04 0.98 - - -

34

Page 36

690 V Frame H2

MODEL

690V

Frame

WHDW1W2W3W4W5W6H1H2H3H4

mm

Frame

H5D1D2D3D4D5D6S1S2S3Ø1Ø2Ø3

mm

FRAME_H2

VFD4000C63B-21

VFD4500C63B-21

VFD5600C63B-21

VFD6300C63B-21

H2

H2

inch 27.56 68.70 15.91 31.50 24.80 - 19.69 24.80 29.92 68.07 - - 66.99

inch 53.02 2.01 1.50 2.56 8.03 2.68 5.39 0.51 1.04 0.98 0.87 1.34 4.63

Side Fasteners

700.0 1745.0 404.0 800.0 630.0 - 500.0 630.0 760.0 1729.0 - - 1701.6

1346.6 51.0 38.0 65.0 204.0 68.0 137.0 13.0 26.5 25.0 22.0 34.0 117.5

35

Page 37

▪

Accessories

▪

EMC-PG01L / EMC-PG02L

Terminals Description

VP

PG1

PG2

Set by

Pr.10-00 ~ 10-02

PG OUT

▪

EMC-PG01O / EMC-PG02O

PG1

PG2

Set by

Pr.10-00 ~ 10-02

PG OUT

DCM Common for power and signal

A1, / A1,

B1, / B1, Z1, / Z1

A2, / A2,

B2, / B2

AO, / AO,

BO, / BO,

ZO, / ZO, SG

Terminals Description

VP

DCM Common for power and signal

A1, / A1 ,B1, / B1,

Z1, / Z1

A2, / A2,

B2, / B2

V+, / V-

V- Negative power supply input

A / O, B / O, Z / O

Output voltage for power: +5 V / +12 V ± 5% (use FSW3 to switch +5 V / +12 V)

Max. output current: 200 mA

Encoder input signal (Line Driver)

Open collector input: +5 V / +24 V (Note1)

1-phase or 2-phase input

Max. input frequency: EMC-PG01L: 300KHz; EMC-PG02L: 30KHz

Pulse input signal (Line Driver or Open Collector)

Open collector input: +5 V / +24 V (Note1)

1-phase or 2-phase input

Max. input frequency: EMC-PG01L: 300KHz; EMC-PG02L: 30KHz

PG card output signals.

Max. output voltage for Line driver: 5 V

Max. output current: 50 mA

Max. output frequency: EMC-PG01L: 300KHz; EMC-PG02L: 30KHz

SG: The GND of PG card is the same as the host controller or PLC, so a common

output signal is attained.

Output voltage for power: +5 V / +12 V ± 5% (use FSW3 to switch +5 V / +12 V)

Max. output current: 200 mA

Encoder input signal (Line Driver or Open Collector)

Open collector input: +5 V / +24 V (Note1)

1-phase or 2-phase input

Max. input frequency: EMC-PG01O: 300KHz; EMC-PG02O: 30KHz

Pulse input signal (Line Driver or Open Collector)

Open collector input: +5 V / +24 V (Note1)

1-phase or 2-phase input

Max. input frequency: EMC-PG01O: 300KHz; EMC-PG02O: 30KHz

Needs external power source for PG OUT circuit.

Input voltage of power:+12 V ~ +24 V

PG card output signals. Division frequency function: 1 ~ 255 times

Add a pull-up resistor to the open collector output signals to avoid signal

interferences.

[Three pull-up resistors are included in the package (1.8 KΩ / 1 W)]

Max. Output current: 20 mA

Max output frequency: EMC-PG01O: 300KHz; EMC-PG02O: 30KHz

frequency function: 1 ~ 255 times

Division

DC

EMC-PG01R

Terminals Description

R1- R2 Resolver output power 7 Vrms, 10 kHz

S1,S2, S3, S4 Resolver input signal 3.5 ± 0.175 Vrms, 10 kHz

Pulse input signal (Line Driver or Open Collector)

Open collector input: +5 V / +24 V (Note1)

1-phase or 2-phase input; Max. input frequency: 300 KHz

PG card output signals. Division frequency function: 1 ~ 255 times

AO, / AO,

BO, / BO,

ZO, / ZO, SG

Max. output voltage for Line driver: 5 V

Max. output current: 50 mA

Max. output frequency: 300 KHz

SG: The GND of PG card is the same as the host controller or PLC, so a common

output signal is attained.

DC

Set by

Pr.10-00 ~ 10-02

PG1

PG2 A2, / A2, B2, / B2

PG OUT

36

Page 38

▪

▪

EMC-D611A

▪

EMC-D42A

EMC-PG01U / EMC-PG02U

FJMP1

S

: Standard UVW Output Encoder; D: Delta Encoder

Terminals Description

Output voltage for power: +5 V / +12 V ± 5% (use FSW3 to switch +5 V / +12 V)

Max. output current: 200 mA

Common for power and signal

Encoder input signal (Line Driver)

1-phase or 2-phase input.

Max. input frequency: 300 KHz

Encoder input signal

PG1

VP

DCM

A1, / A1 ,B1, / B1,

Z1, / Z1

U1, / U1, V1, / V1,

W1, / W1

Pulse input signal

Set by

Pr.10-00 ~ 10-02

PG2

A2, / A2, B2, / B2

Open collector input: +5 V / +24 V (Note1)

1-phase or 2-phase input; Max. input frequency: 300KHZ

PG card output signals.

Division frequency function: 1 ~ 255 times

PG OUT

AO, / AO,

BO, / BO,

ZO, / ZO, SG

Max. output voltage for Line driver: 5 VDC

Max. output current: 50 mA

Max. output frequency: 300 KHz

SG: The GND of PG card is the same as the host controller or PLC, so a common

output signal is attained.

Note 1: For the Open Collector, set input voltage to 5 ~ 15 mA and install a pull-up resistor

[5

V] Recommend pull-up resistor: 100 ~ 220 Ω, 1 / 2 W and above

[12

V] Recommend pull-up resistor: 510 ~ 1.35 KΩ, 1 / 2 W and above

[24

V] Recommend pull-up resistor: 1.8K ~ 3.3 KΩ, 1 / 2 W and above

I/O Extension Card

I/O Extension Card

Terminals Description

COM

MI10 ~ MI13

MO10 ~ MO11

MXM

Common for multi-function input terminals

Select SINK (NPN) / SOURCE (PNP) in J1 jumper / external power supply

Refer to Pr. 02-26 ~ Pr. 02-29 to program the multi-function inputs MI10 ~ MI13.

Internal power is applied from terminal E24: +24 V

External power +24 VDC: max. voltage 30 VDC, min. voltage 19 VDC, 30 W

ON: the activation current is 6.5 mA; OFF: leakage current tolerance is 10 μA

Multi-function output terminals (photocoupler)

Duty-cycle: 50%; Max. output frequency: 100 Hz

Max. current: 50 mA; Max. voltage: 48 V

Common for multi-function output terminals MO10, MO11 (photocoupler)

Max 48 V

50 mA

DC

DC

± 5% 200 mA, 5 W

DC

Terminals Description

AC AC power common for multi-function input terminal (Neutral)

Refer to Pr. 02-26 ~ Pr. 02-31 for multi-function input selection

MI10 ~ MI15

Input voltage: 100 ~ 130 V

Input impedance: 27 KΩ

Terminal response time: ON: 10 ms; OFF: 20 ms

; Input frequency: 57 ~ 63 Hz

AC

37

Page 39

▪

EMC-R6AA

Relay

▪

EMC-BPS01

▪

EMC-A22A

Extension Card

Analog I/O

extension card

Terminals Description

Refer to Pr. 02-36 ~ Pr. 02-41 for multi-function output selection

Resistive load:

RA10 ~ RA15

RC10 ~ RC15

3 A (N.O.) / 250 V

5 A (N.O.) / 30 VDC

Inductive load (COS 0.4)

2.0 A (N.O.) / 250 VAC

2.0 A (N.O.) / 30 VDC

It is used to output each monitor signal, such as for drive in operation, frequency attained or overload

indication.

AC

Terminals Description

Refer to Pr. 14-00 ~ Pr. 14-01 for function selection (input), and Pr. 14-18 ~ Pr. 14-19 for mode selection.

AVI10

AVI11

AFM10

AFM11

There are two sets of AVI port, SSW3(AVI10) and SSW4(AVI11), which can be switched to AVI or ACI.

AVI: Input 0 ~ 10V

ACI: Input 0 ~ 20mA / 4 ~ 20mA

Refer to Pr. 14-12 ~ Pr. 14-13 for function selection (output), and Pr. 14-36 ~ Pr. 14-37 for mode selection.

There are two sets of AFM port, SSW1(AFM10) and SSW2(AFM11), which can be switched to AVO or ACO.

AVO: Output 0 ~ 10.00V

ACO: Output 0 ~ 20.0mA / 4.0 ~ 20.0mA

24V Power

Shift Card

ACM

Analog signal common terminal

Terminals Description

When the AC motor drive power is off, the external power supply card provides external power to the network

system, PLC function, and other functions to allow continued operations.

24 V GND

Input power: 24 V

Maximum input current: 0.5 A

Note:

Do not connect the control terminal +24 V (Digital control signal common: SOURCE) directly to the EMC-BPS01 input terminal 24 V.

Do not connect control terminal GND directly to the EMC-BPS01 input terminal GND.

±5%

DC

38

Page 40

▪

CMC-EIP01

Network Interface

Network Interface

Interface

Transmission cable

Network Interface

Transmission method

▪

CMC-PN01

Network Interface

Features

►

Support EtherNet/IP and MODBUS TCP protocol

►

User-dened parameter mapping

►

IP Filter, basic rewall function

RJ-45 with Auto MDI / MDIX

Number of ports 1 Port

Transmission method IEEE 802.3, IEEE 802.3u

Category 5e shielding 100 M

▪

CMC-EC01

Features

►

Supports Ethernet CAT protocol

►

Supports standard CiA402 speed mode

►

Supports SDO (Service Data Objects) function:

- To write motor drive parameters

- To read motor drive information

►

Auto shutdown function for interruptions during data transmission

Interface RJ-45

Number of ports 2 Ports

IEEE 802.3, IEEE 802.3u

Transmission cable Category 5e shielding 100 M

Transmission speed 10 / 100 Mbps Auto-Detect

Network protocol

Transmission speed 100 Mbps

Network protocol EtherCAT

ICMP, IP, TCP, UDP, DHCP, BOOTP, SMTP,

EtherNet/IP, Modbus TCP

Interface

Number of Ports

Transmission Method

Features

►

Supports PROFINET IO device

►

Supports synchronous data transmission and synchronous parameter access

►

Provides GSDML file for PROFINET communication

RJ-45

2 Ports

IEEE 802.3

Transmission Cable

Transmission Speed

Network Protocol

39

Category 5e shielding 100M

10/100 Mbps auto-negotiate

PROFINET

Page 41

PROFIBUS DP Connector

Transmission cable

Communication

GSD document

▪

DeviceNet Connector

Interface

DeviceNet Connector

Interface

1

CAN_H

6

CAN_GND

CMC-PD01

Features

►

Supports PROFIBUS DP protocol

►

Supports PZD control data exchange

►

Supports PKW polling AC motor drive parameters

►

Supports user diagnosis function

►

Auto-detects baud rates; supports Max. 12 Mbps

Interface DB9 connector

Transmission method High-speed RS-485

Shielded twisted pair cable

Electrical isolation 500 V

▪

CMC-DN01 Features

CMC-DN01

DC

►

Supports all baud rates on DeviceNet bus: 125 kbps, 250 kbps, 500 kbps and extendable

serial transmission speed mode

►

Based on the high-speed communication interface of Delta HSSP protocol, able to

conduct immediate control of an AC motor drive

►

Supports Group 2 only connection and polling I/O data exchange

►

For I/O mapping, supports Max. 32 words of input and 32 words of output

►

Supports EDS le conguration in DeviceNet conguration software

►

Node address and serial transmission speed can be set up on AC motor drive

►

Power supplied from AC motor drive

5-Pin 5.08mm pluggable connector

Transmission method CAN

Transmission cable

Transmission speed

Network protocol DeviceNet protocol

Shielded twisted pair cable

(with 2 power cables)

125 kbps, 250 kbps, 500 kbps and

extendable serial transmission

speed mode

Message type Cyclic data exchange

Module name CMC-PD01

DELA08DB.GSD

Company ID 08DB (HEX)

Serial transmission

speed supported

(auto-detection)

Transmission method SPI communication

Terminal function

Communication protocol Delta HSSP protocol

9.6 kbps; 19.2 kbps; 93.75 kbps; 187.5 kbps; 125 kbps;

250 kbps; 500 kbps; 1.5 Mbps;

3 Mbps; 6 Mbps; 12 Mbps (bits per second)

50 PIN communication terminal

1. Communicating with AC motor drive

2. Transmitting power supply from AC motor drive

▪

EMC-COP01

Built-in EMC-COP01 card are available for VFDXXXC23E and VFDXXXC43E

RJ-45 Pin denition

8~1

Male

8~1

Female

Pin Pin name Denition

CAN_H bus line (dominant high)

2 CAN_L CAN_L bus line (dominant low)

3 CAN_GND Ground / 0 V / V-

Ground / 0 V / V-

40

Page 42

Accessories

▪

Delta Standard Fieldbus Cables

Delta Cables Part Number Description Length

UC-CMC003-01A CANopen cable, RJ45 connector 0.3 m

UC-CMC005-01A CANopen cable, RJ45 connector 0.5 m

UC-CMC010-01A CANopen cable, RJ45 connector 1 m

UC-CMC015-01A CANopen cable, RJ45 connector 1.5 m

CANopen Cable

DeviceNet Cable

EtherNet Cable

CANopen / DeviceNet TAP

PROFIBUS Cable UC-PF01Z-01A PROFIBUS DP cable 305 m

UC-CMC020-01A CANopen cable, RJ45 connector 2 m

UC-CMC030-01A CANopen cable, RJ45 connector 3 m

UC-CMC050-01A CANopen cable, RJ45 connector 5 m

UC-CMC100-01A CANopen cable, RJ45 connector 10 m

UC-CMC200-01A CANopen cable, RJ45 connector 20 m

UC-DN01Z-01A DeviceNet cable 305 m

UC-DN01Z-02A DeviceNet cable 305 m

UC-EMC003-02A EtherNet / EtherCAT cable, Shielding 0.3 m

UC-EMC005-02A EtherNet / EtherCAT cable, Shielding 0.5 m

UC-EMC010-02A EtherNet / EtherCAT cable, Shielding 1 m

UC-EMC020-02A EtherNet / EtherCAT cable, Shielding 2 m

UC-EMC050-02A EtherNet / EtherCAT cable, Shielding 5 m

UC-EMC100-02A EtherNet / EtherCAT cable, Shielding 10 m

UC-EMC200-02A EtherNet / EtherCAT cable, Shielding 20 m

TAP-CN01 1 in 2 out, built-in 121Ω terminal resistor 1 in 2 out

TAP-CN02 1 in 4 out, built-in 121Ω terminal resistor 1 in 4 out

TAP-CN03 1 in 4 out, RJ45 connector, built-in 121Ω terminal resistor 1 in 4 out

Unit: mm

▪ CANopen Breakout Box

Model: TAP-CN03

Unit: mm [inch]

L ± 10

66.50 [2.62]

41

Page 43

Model Name

▪

230 V / 460 V:

VFD 007 C 43 A

Input voltage

23 230 V 3-Phase

43 460 V 3-Phase

Product Series

C C2000

Applicable Motor Capacity

007: 1 HP (0.75 kW) ~ 4500: 600 HP (450 kW)

* Refer to product specification for detailed information

Series Name

Variable Frequency Drive

Version

A Wall mount

S Smaller size

U Smaller size with junction box

Built-in EMC lter (Frame A~C),

E

Built-in conduit box (Frame D and above)

▪

575 V / 690 V:

VFD 007 C 43 A - 2 1

Version

A Wall mount

B Wall mount with 690V rated current

Applicable Motor Capacity

015: 2 HP (1.5 kW) ~ 6300: 675 HP (630 kW)

* Refer to product specification for detailed information

NEMA Protection Level

0 UL Open Type

1 NEMA 1

IP Protection Level

0 IP00 2 IP20

Input Voltage

53 575 V 3-Phase

63 690 V 3-Phase

Product Series

C C2000

Series Name

Variable Frequency Drive

42

Page 44

Ordering Information

Frame Size

Power Range

Models

Frame A

Frame B

Frame C

230 V:

0.75 ~ 3.7 kW

460 V:

0.75 ~ 5.5 kW

575 V:

1.5 ~ 3.7 kW

230 V:

5.5 ~ 11 kW

460 V:

7.5 ~ 15 kW

575 V:

5.5 ~ 15 kW

230 V:

15 ~ 22 kW

460 V:

18.5 ~ 30 kW

690 V:

18.5 ~ 37 kW

VFD007C23A

VFD015C23A

VFD022C23A

VFD037C23A

VFD055C23A

VFD075C23A

VFD110C23A

VFD150C23A

VFD185C23A

VFD220C23A

VFD007C43A

VFD015C43A

VFD022C43A

VFD037C43A

VFD040C43A

VFD055C43A

VFD075C43A

VFD110C43A

VFD150C43A

VFD185C43A

VFD220C43A

VFD300C43A

VFD007C43E

VFD015C43E

VFD022C43E

VFD037C43E

VFD040C43E

VFD055C43E

VFD075C43E

VFD110C43E

VFD150C43E

VFD185C43E

VFD220C43E

VFD300C43E

VFD015C53A-21

VFD022C53A-21

VFD037C53A-21

VFD055C53A-21

VFD075C53A-21

VFD110C53A-21

VFD150C53A-21

VFD185C63B-21

VFD220C63B-21

VFD300C63B-21

VFD370C63B-21

Frame D

Frame E

Frame F

230 V:

30 ~ 37 kW

460 V:

37 ~ 75 kW

690 V:

55 ~ 75 kW

230 V:

45 ~ 75 kW

460 V:

90 ~ 110 kW

690 V:

75 ~ 132 kW

230 V:

90 kW

460 V:

132 ~ 160 kW

690 V:

160 ~ 200 kW

Frame

_D1

VFD300C23A

VFD370C23A

VFD550C43A

VFD750C43A

VFD450C63B-00

VFD550C63B-00

Frame

_E1

VFD450C23A

VFD550C23A

VFD750C23A

VFD900C43A

VFD1100C43A

VFD750C63B-00

VFD900C63B-00

VFD1100C63B-00

VFD1320C63B-00

Frame

_F1

VFD900C 23A

VFD1320C 43A

VFD1600C 43A

VFD1600C63B-00

VFD2000C63B-00

Frame

_D0-1

VFD370C43S

VFD450C43S

Frame

_E2

VFD450C23E

VFD550C23E

VFD750C23E

VFD900C43E

VFD1100C43E

VFD750C63B-21

VFD900C63B-21

VFD1100C63B-21

VFD1320C63B-21

Frame

_F2

VFD900C 23E

VFD1320C 43E

VFD1600C 43E

VFD1600C63B-21

VFD2000C63B-21

Frame

_D2

VFD300C23E

VFD370C23E

VFD550C43E

VFD750C43E

VFD450C63B-21

VFD550C63B-21

Frame

_D0-2

VFD370C43U

VFD450C43U

43

Page 45

Frame G

Frame Size Power Range Models

460 V:

185 ~ 220 kW

690 V:

250 ~ 315 kW

Frame

_G1

VFD1850C43A

VFD2200C43A

VFD2500C63B-00

VFD3150C63B-00

Frame

_G2

VFD1850C43E

VFD2200C43E

VFD2500C63B-21

VFD3150C63B-21

Frame H

Frame H

(690 V Model)

460 V:

280 ~ 450 kW

690 V:

400 ~ 630 kW

Frame

_H1

VFD2800C43A

VFD3150C43A

VFD3550C43A

VFD4500C43A

Frame

_H1

VFD4000C63B-00

VFD4500C63B-00

VFD5600C63B-00

VFD6300C63B-00

Frame

_H2

VFD2800C43E-1

VFD3150C43E-1

VFD3550C43E-1

VFD4500C43E-1

Frame

_H2

VFD4000C63B-21

VFD4500C63B-21

VFD5600C63B-21

VFD6300C63B-21

Frame

_H3

VFD2800C43E

VFD3150C43E

VFD3550C43E

VFD4500C43E

44

Page 46

Global Operations

India

Chandigarh

Gurgaon

Kolkata

Ahmedabad

Mumbai

Pune

Hyderabad

Bangalore

Chennai

Coimbatore

Visakhapatnam

Chhattisgarh

Uzbekistan

Sri Lanka

Kazakhstan

Tadzhikistan

Mexico

Sonoma

Fremont

Los Angeles

San Diego

Jalisco

Edmonton

Mexico City

Guatemala

Taoyuan Plant 1

Canada

USA

Plano

Nuevo Leon

Queretaro

Puebla

El Salvador

Nicaragua

Costa Rica

Panama

Ecuador

Zurich

Chicago

Kitchener

Boston

Raleigh

R. Dominicana

Brit.Virgin Is.

Colombia

Peru

Bolivia

Paraguay

Chile

Tainan Plant

(Diamond-rated Green Building)

Netherlands

Amsterdam

Eindhoven

France

Paris

Spain

Barcelona

Madrid

Italy

Milan

Rome

Central Europe

H

Netherlands

I

Germany

J

Czech

K

Austria

L

Slovenia

M

Croatia

N

Poland

O

Hungary

P

Switzerland

Brasil

Sao Paulo

Bela Vista

Paraná

Santa Catarina

Ireland

Belgium

Senegal

Togo

United

Kingdom

France

Spain

Morocco

Nigeria

Benin

Germany

Sust

E

F

H I

P

JKL

M

Italy

Albania

Congo

A

N

O

Kosovo

Malta

Tunisia

Libya

B

C

D

Belarus

Cyprus

Northern Europe

A

B

C

D

E

F

G

Moldavia

Romania

Serbia

Bulgaria

Greece

Israel

Egypt

Cairo

Zambia

South Africa

Shanghai Office

Finland

Estonia

Latvia

Lithuania

Sweden

Denmark

Iceland

Russia

Moscow

Tashkent

Georgia

Turkey

Istanbul

Armenia

Lebanon

Jordan

Iraq

Qatar

Saudi

Arabia

Ethiopia

Kenya

Tanzania

UAE

Dubai

Oman

Uruguay

Argentina

45

Page 47

Tadzhikistan

India

Chandigarh

Gurgaon

Kolkata

Ahmedabad

Mumbai

Pune

Hyderabad

Bangalore

Chennai

Coimbatore

Visakhapatnam

Chhattisgarh

Sri Lanka

Amsterdam, the Netherlands Research Triangle Park, U.S.A.

6 Factories 117 Branch Offices 13 R&D Centers 915 Distributors

Korea

Seoul

Daegu

Japan

Tokyo

1

2

5

7

11 12

22

24

3

Korea

8

6

9

27

10

Taiwan

1314

151617

23

26

4

25

19

20

21

18

Osaka

Japan

Thailand

Dalian

Shanghai

Wujiang (Wujiang Plant 3 & Wujiang Motor Plant )

Dongguan

Taoyuan

(Technology Center & Plant 1)

Zhong li

Taichung

Tainan

Vietnam

Malaysia

Singapore

Indonesia

Malaga

Philippines

Australia

Melbourne

China

1

Heilongjiang

Harbin

2

Jilin

Changchun

3

Liaoning

Shenyang

Dalian

4

Shanxi

Taiyuan

5

Beijing

6

Tianjin

7

Hebei

Shijiazhuang

Qinhuangdao

Tangshan

8

Shandong

Qingdao

Jinan

Yantai

Jiangsu

9

Yangzhou

Nanjing

Nantong

Changzhou

Wuxi

Suzhou

Kunshan

Xuzhou

10

Shanghai

Jiading

Songjiang

11

Anhui

Hefei

12

Zhejiang

Hangzhou

Ninggbo

Wenzhou

Jiaxing

Shaoxing

13

Fujian

Xiamen

Fuzhou

Quanzhou

14

Jiangxi

Nanchang

15

Guangdong

Shenzhen

Guangzhou

Foshan

16

Guangxi

Nanning

Guilin

Liuzhou

17

Yunnan

Kunming

18

Sichuan

Chengdu

19

Shaanxi

Xian

20

Henan

Zhengzhou

Luoyang

Changyuan

21

Hubei

Wuhan

Xiangfan

22

Hunan

Changsha

Hengyang

23

Inner Mongolia

Baotou

24

Guizhou

Guiyang

25

Gansu

Lanzhou

26

Xinjiang

Urumqi

27

Anhui

Wuhu

46

Page 48

Industrial Automation Headquarters

Delta Electronics, Inc.

Taoyuan Technology Center

No.18, Xinglong Rd., Taoyuan District,

Taoyuan City 33068, Taiwan

TEL: 886-3-362-6301 / FAX: 886-3-371-6301

Asia

Delta Electronics (Shanghai) Co., Ltd.

No.182 Minyu Rd., Pudong Shanghai, P.R.C.

Post code : 201209

TEL: 86-21-6872-3988 / FAX: 86-21-6872-3996

Customer Service: 400-820-9595

Delta Electronics (Japan), Inc.

Tokyo Ofce

Industrial Automation Sales Department

2-1-14 Shibadaimon, Minato-ku

Tokyo, Japan 105-0012

TEL: 81-3-5733-1155 / FAX: 81-3-5733-1255

Delta Electronics (Korea), Inc.

Seoul Ofce

1511, 219, Gasan Digital 1-Ro., Geumcheon-gu,

Seoul, 08501 South Korea

TEL: 82-2-515-5305 / FAX: 82-2-515-5302

Delta Energy Systems (Singapore) Pte Ltd.

4 Kaki Bukit Avenue 1, #05-04, Singapore 417939

TEL: 65-6747-5155 / FAX: 65-6744-9228

Delta Electronics (India) Pvt. Ltd.

Plot No.43, Sector 35, HSIIDC Gurgaon,

PIN 122001, Haryana, India

TEL: 91-124-4874900 / FAX : 91-124-4874945

Delta Electronics (Thailand) PCL.

909 Soi 9, Moo 4, Bangpoo Industrial Estate (E.P.Z),

Pattana 1 Rd., T.Phraksa, A.Muang,

Samutprakarn 10280, Thailand

TEL: 66-2709-2800 / FAX : 662-709-2827

Delta Electronics (Australia) Pty Ltd.

Unit 20-21/45 Normanby Rd., Notting Hill Vic 3168, Australia

TEL: 61-3-9543-3720

Americas

Delta Electronics (Americas) Ltd.

Raleigh Ofce

P.O. Box 12173, 5101 Davis Drive,

Research Triangle Park, NC 27709, U.S.A.

TEL: 1-919-767-3813 / FAX: 1-919-767-3969

Delta Electronics Brazil

São Paulo Sales Ofce

Rua Itapeva, 26 - 3°, andar Edicio Itapeva,

One - Bela Vista 01332-000 - São Paulo - SP - Brazil

TEL: 55-12-3932-2300 / FAX: 55-12-3932-237

Delta Electronics International Mexico S.A. de C.V.

Mexico Ofce

Gustavo Baz No. 309 Edicio E PB 103

Colonia La Loma, CP 54060

Tlalnepantla, Estado de México

TEL: 52-55-3603-9200

EMEA

Headquarters: Delta Electronics (Netherlands) B.V.

Sales: Sales.IA.EMEA@deltaww.com

Marketing: Marketing.IA.EMEA@deltaww.com

Technical Support: iatechnicalsupport@deltaww.com

Customer Support: Customer-Support@deltaww.com

Service: Service.IA.emea@deltaww.com

TEL: +31(0)40 800 3900

BENELUX: Delta Electronics (Netherlands) B.V.

De Witbogt 20, 5652 AG Eindhoven, The Netherlands

Mail: Sales.IA.Benelux@deltaww.com

TEL: +31(0)40 800 3900

DACH: Delta Electronics (Netherlands) B.V.

Coesterweg 45, D-59494 Soest, Germany

Mail: Sales.IA.DACH@deltaww.com

TEL: +49(0)2921 987 0

France: Delta Electronics (France) S.A.

ZI du bois Challand 2, 15 rue des Pyrénées,

Lisses, 91090 Evry Cedex, France

Mail: Sales.IA.FR@deltaww.com

TEL: +33(0)1 69 77 82 60

Iberia: Delta Electronics Solutions (Spain) S.L.U

Ctra. De Villaverde a Vallecas, 265 1º Dcha Ed.

Hormigueras – P.I. de Vallecas 28031 Madrid

TEL: +34(0)91 223 74 20

Carrer Llacuna 166, 08018 Barcelona, Spain

Mail: Sales.IA.Iberia@deltaww.com

Italy: Delta Electronics (Italy) S.r.l.

Via Meda 2–22060 Novedrate(CO)

Piazza Grazioli 18 00186 Roma Italy

Mail: Sales.IA.Italy@deltaww.com

TEL: +39 039 8900365

Russia: Delta Energy System LLC

Vereyskaya Plaza II, ofce 112 Vereyskaya str.

17 121357 Moscow Russia

Mail: Sales.IA.RU@deltaww.com

TEL: +7 495 644 3240

Turkey: Delta Greentech Elektronik San. Ltd. Sti. (Turkey)

Şerifali Mah. Hendem Cad. Kule Sok. No:16-A

34775 Ümraniye – İstanbul

Mail: Sales.IA.Turkey@deltaww.com

TEL: + 90 216 499 9910

GCC: Delta Energy Systems AG (Dubai BR)

P.O. Box 185668, Gate 7, 3rd Floor, Hamarain Centre

Dubai, United Arab Emirates

Mail: Sales.IA.MEA@deltaww.com

TEL: +971(0)4 2690148

Egypt + North Africa: Delta Electronics

Unit 318, 3rd Floor, Trivium Business Complex, North 90 street,

New Cairo, Cairo, Egypt

Mail: Sales.IA.MEA@deltaww.com

*We reserve the right to change the information in this catalogue without prior notice.

DELTA_IA-MDS_C2000_C_EN_20200818

Loading...

Loading...