Page 1

10"BandSaw

Scie_rubande

254mm(10po)

Sierradebanda

54mm(10po)

A15113-01-13-06Rev.A

Copyright© 2006DeltaMachinery

InstructionManual

Manueld'Utilisation

ManualdeInstrucciones

www.deltamachinery.com

(800)223-7278- US

(800)463-3582- CANADA

Page 2

IMPORTANT SAFETY INSTRUCTIONS ........................................................... 2

SAFETY GUIDELINES = DEFiNITiONS ........................................................... 3

GENERAL SAFETY RULES .................................................................... 4

ADDITIONAL SPECIFIC SAFETY RULES ......................................................... 5

FUNCTIONAL DESCRIPTION .................................................................. 7

CARTON CONTENTS ......................................................................... 7

ASSEMBLY ................................................................................. 8

OPERATION ............................................................................... 12

TROUBLESHOOTING GUIDE .................................................................. 20

TROUBLESHOOTING ........................................................................ 22

MAINTENANCE ............................................................................. 23

SERVICE .................................................................................. 23

ACCESSORIES ............................................................................. 23

WARRANTY ................................................................................ 24

FRAN_AIS ................................................................................. 25

ESPA_IOL .................................................................................. 47

Read and understand all warnings and operating instructions before using any tool or equipment.

When using tools or equipment, basic safety precautions should always be followed to reduce the risk of

personal injury. Improper operation, maintenance or modification of tools or equipment could result in serious

injury and property damage. There are certain applications for which tools and equipment are designed. Delta

Machinery strongly recommends that this product NOT be modified and/or used for any application other than

for which it was designed.

if you have any questions relative to its application DO NOT use the product until you have written Delta Machinery

and we have advised you.

Online contact form at www.deltamachinery.com

Postal Mail: Technical Service Manager

Delta Machinery

4825 Highway 45 North

Jackson, TN 38305

(IN CANADA: 125 Mural St. Suite 300, Richmond Hill, ON, L4B 1M4)

Information regarding the safe and proper operation of this tool isavailable from the following sources:

Power Tool Institute

1300 Sumner Avenue, Cleveland, OH 44115-2851

www.powertoolinstitute.org

National Safety Council

1121 Spring Lake Drive, Itasca, IL60143-3201

American National Standards Institute, 25 West 43rd Street, 4 floor, New York, NY 10036 www.ansi.org

ANSi 01.1Safety Requirements for Woodworking Machines, and the U.S. Department of Labor regulations www.osha.g£y

SAVE THESE INSTRUCTIONS!

Page 3

it is important for you to read and understand this manual. The information it contains relates to

protecting YOUR SAFETY and PREVENTING PROBLEMS. The symbols below are used to help you _Q_

recognize this information.

indicates an imminently hazardous situation which, if not avoided, will result in death or

_ serious injury.

__,dL

-- injury.

-- injury.

-- avoided, may result inproperty damage.

CALiFORNiA PROPOSiTiON 65

SOME DUST CREATED BY POWER SANDING, SAWING, GRINDING, DRILLING, AND OTHER CONSTRUCTION

ACTIVITIES contains chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of

these chemicals are:

• lead from lead-based paints,

•crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber•

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to

these chemicals: work in a well ventilated area, and work with approved safety equipment, always wear NIOSH/OSHA

approved, properly fitting face mask or respirator when using such tools.

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious

indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate

Used without the safety alert symbol indicates potentially hazardous situation which, if not

Page 4

Failure to follow these rules may result in serious personal injury.

1. FOR YOUR OWN SAFETY, READ THE INSTRUCTION

MANUAL BEFORE OPERATING THE MACHINE. Learning

the machine's application, limitations, and specific hazards

will greatly minimize the possibility of accidents and injury.

2. WEAR EYE AND HEARING PROTECTION. ALWAYS

USE SAFETY GLASSES. Everyday eyeglasses are NOT

safety glasses. USE CERTIFIED SAFETY EQUIPMENT.

Eye protection equipment should comply with ANSI Z87.1

standards. Hearing equipment should comply with ANSI

$3.19 standards.

3. WEAR PROPER APPAREL, Do not wear loose clothing,

gloves, neckties, rings, bracelets, or other jewelry which may

get caught in moving parts. Nonslip protective footwear is

recommended. Wear protective hair covering to contain long

hair.

4. DO NOT USE THE MACHINE IN A DANGEROUS

ENVIRONMENT. The use of power tools in damp or wet

locations or in rain can cause shock or electrocution. Keep

your work area well-lit to prevent tripping or placing arms,

hands, and fingers in danger.

5. MAINTAIN ALL TOOLS AND MACHINES IN PEAK

CONDiTiON, Keep tools sharp and clean for best and safest

performance. Follow instructions for lubricating and changing

accessories. Poorly maintained tools and machines can further

damage the tool or machine and/or cause injury.

6. CHECK FOR DAMAGED PARTS. Before using the machine,

check for any damaged parts. Check for alignment of moving

parts, binding of moving parts, breakage of parts, and any

other conditions that may affect its operation. A guard or any

other part that is damaged should be properly repaired or

replaced with Delta or factory authorized replacement

parts. Damaged parts can cause further damage to the

machine and/or injury.

7. KEEP THE WORK AREA CLEAN. Cluttered areas and benches

inviteaccidents.

8. KEEP CHILDREN AND VISITORS AWAY. Your shop is a

potentially dangerous environment. Children and visitors can be

injured.

9. REDUCE THE RISK OF UNINTENTIONAL STARTING. Make

sure that the switch is in the "OFF" position before plugging

in the power cord. In the event of a power failure, move the

switch to the "OFF" position. An accidental start-up can cause

injury. Do not touch the plug's metal prongs when unplugging

or plugging in the cord.

10. USE THE GUARDS. Check to see that all guards are in place,

secured, and working correctly to prevent injury.

11. REMOVE ADJUSTING KEYS AND WRENCHES BEFORE

STARTING THE MACHINE. Tools, scrap pieces, and other

debris can be thrown at high speed, causing injury.

12. USE THE RIGHT MACHINE. Don't force a machine or an

attachment to do a job for which it was not designed. Damage

to the machine and/or injury may result.

13. USE RECOMMENDED ACCESSORIES. The use of

accessories and attachments not recommended by Delta

may cause damage to the machine or injury to the user.

14. USE THE PROPER EXTENSION CORD. Make sure your

extension cord is in good condition. When using an extension

cord, be sure to use one heaw enough to carry the current

your product will draw. An undersized cord will cause a drop

in line voltage, resulting in loss of power and overheating. See

the Extension Cord Chart for the correct size depending on

the cord length and nameplate ampere rating. If in doubt, use

the next heavier gauge. The smaller the gauge number, the

heavier the cord.

15. SECURE THE WORKPIECE. Use clamps or a vise to hold the

workpiece when practical. Loss of control of aworkpiece can

cause injury.

16. FEED THE WORKPIECE AGAINST THE DiRECTiON OF

THE ROTATION OF THE BLADE, CUTTER, OR ABRASIVE

SURFACE. Feeding it from the other direction will cause the

workpiece to be thrown out at high speed.

17. DON'T FORCE THE WORKPIECE ON THE MACHINE.

Damage to the machine and/or injury may result.

18. DON'T OVERREACH. Loss of balance can make you fall into

a working machine, causing injury.

19. NEVER STAND ON THE MACHINE. Injurycould occur ifthe tool

tips,or ifyou accidentally contact the cuttingtool.

20. NEVER LEAVE THE MACHINE RUNNING UNATTENDED.

TURN THE POWER OFE Don't leavethe machine until it comes

to acomplete stop. A child or visitor couldbe injured.

21. TURN THE MACHINE "OFF", AND DISCONNECT THE

MACHINE FROM THE POWER SOURCE before installing or

removing accessories, changing cutters, adjusting or changing

set-ups. When making repairs, be sure to lock the start switch

in the "OFF" position. An accidental start-up can cause injury.

22. MAKE YOUR WORKSHOP CHILDPROOF WiTH

PADLOCKS, MASTER SWITCHES, OR BY REMOVING

STARTER KEYS. The accidental start-up of a machine by a

child or visitor could cause injury.

23. STAY ALERT, WATCH WHAT YOU ARE DOING, AND USE

COMMON SENSE. DO NOT USE THE MACHINE WHEN

YOU ARE TIRED OR UNDER THE iNFLUENCE OF DRUGS,

ALCOHOL, OR MEDICATION. A moment of inattention while

operating power tools may result in injury.

24. _ USE OF THIS TOOL CAN GENERATE AND

DISBURSE DUST OR OTHER AIRBORNE PARTICLES,

iNCLUDiNG WOOD DUST, CRYSTALLINE SiLiCA DUST

AND ASBESTOS DUST. Direct particles away from face

and body. Always operate tool in well ventilated area and

provide for proper dust removal. Use dust collection system

wherever possible. Exposure to the dust may cause serious

and permanent respiratory or other injury, including silicosis (a

serious lung disease), cancer, and death. Avoid breathing the

dust, and avoid prolonged contact with dust. Allowing dust to

get into your mouth or eyes, or lay on your skin may promote

absorption of harmful material. Always use properly fitting

NIOSH/OSHA approved respiratory protection appropriate for

the dust exposure, and wash exposed areas with soap and

water.

Page 5

Failure to follow these rules may result in serious personal injury.

1. DO NOT OPERATE THiS MACHINE UNTIL it is

assembled and installed according to the instruc-

tions.

2. OBTAIN ADVICE from your supervisor, instructor,

or another qualified person if you are not familiar

with the operation of this tool.

3. FOLLOW ALL WiRiNG CODES and recommended

electrical connections.

4. USETHE GUARDSWHENEVER POSSIBLE. Checkto

see that they are in place, properly adjusted, secured,

and working correctly.

5. USE PROPER BLADE SiZE and type.

6. ADJUST THE UPPER BLADE GUIDE so that it is

about 1/8" above the workpiece.

7. PROPERLY ADJUST the blade tension, tracking,

blade guides, and blade support bearings.

8. KEEP ARMS, HANDS, AND FINGERS away from

the blade.

9. AVOID AWKWARD OPERATIONS and hand po-

sitions where a sudden slip could cause a hand to

move into the blade.

10. NEVER START THE MACHINE before clearing the

table of all objects (tools, scrap pieces, etc.).

11. NEVER START THE MACHINE with the workpiece

against the blade.

12. HOLD WORKPIECE FIRMLY against the table. DO

NOT attempt to saw a workpiece that does not have

a flat surface against the table.

13. HOLD WORKPIECE FIRMLY and feed into blade at

a moderate speed.

14. NEVER REACH UNDER THE TABLE while the ma-

chine is running.

15. TURN THE MACHINE "OFF" to back out of an un-

completed or jammed cut.

16. MAKE "RELIEF" CUTS prior to cutting long curves.

17. TURN THE MACHINE "OFF" and wait for the blade

to stop prior to cleaning the blade area, removing

debris near the blade, removing or securing work-

piece, or changing the angle of the table. A coasting

blade can be dangerous.

18. NEVER PERFORM LAYOUT, ASSEMBLY, or set-

up work on the table/work area when the machine is

running.

19. TURN THE MACHINE "OFF" AND DISCONNECT

THE MACHINE from the power source before in-

stalling or removing accessories, before adjusting or

changing set-ups, or when making repairs.

20. TURN THE MACHINE "OFF", disconnect the ma-

chine from the power source, and clean the table/

work area before leaving the machine. LOCK THE

SWITCH iN THE "OFF" POSiTiON to prevent unau-

thorized use.

21.

ADDITIONAL INFORMATION regarding the safe

and proper operation of power tools (i.e. a safety

video) isavailable from the Power Tool Institute, 1300

Sumner Avenue, Cleveland, OH 44115-2851 (www.

powertoolinstitute.com). Information is also avail-

able from the National Safety Council, 1121 Spring

Lake Drive, Itasca, IL 60143-3201. Please refer to

the American National Standards Institute ANSI 01.1

Safety Requirements for Woodworking Machines

and the U.S. Department of Labor OSHA 1910.213

Regulations.

THESE iNSTRUCTiONS.

Refer to them often and use them to instruct others.

POWER CONNECTIONS

A separate electrical circuit should be used for your machines. This circuit should not be less than #12 wire and should

be protected with a 20 Amp time lag fuse. If an extension cord is used, use only 3-wire extension cords which have

3-prong grounding type plugs and matching receptacle which will accept the machine's plug. Before connecting the

machine to the power line, make sure the switch (s) is in the "OFF" position and be sure that the electric current is of

the same characteristics as indicated on the machine. All line connections should make good contact. Running on low

voltage will damage the machine.

DO NOT EXPOSE THE MACHINE TO RAIN OR OPERATE THE MACHINE IN DAMP LOCATIONS.

MOTOR SPECiFiCATiONS

Your machine is wired for 120 volt, 60 HZ alternating current. Before connecting the machine to the power source,

make sure the switch is inthe "OFF" position.

Page 6

GROUNDING iNSTRUCTiONS

This machine must be grounded while in use to protect the operator from electric shock.

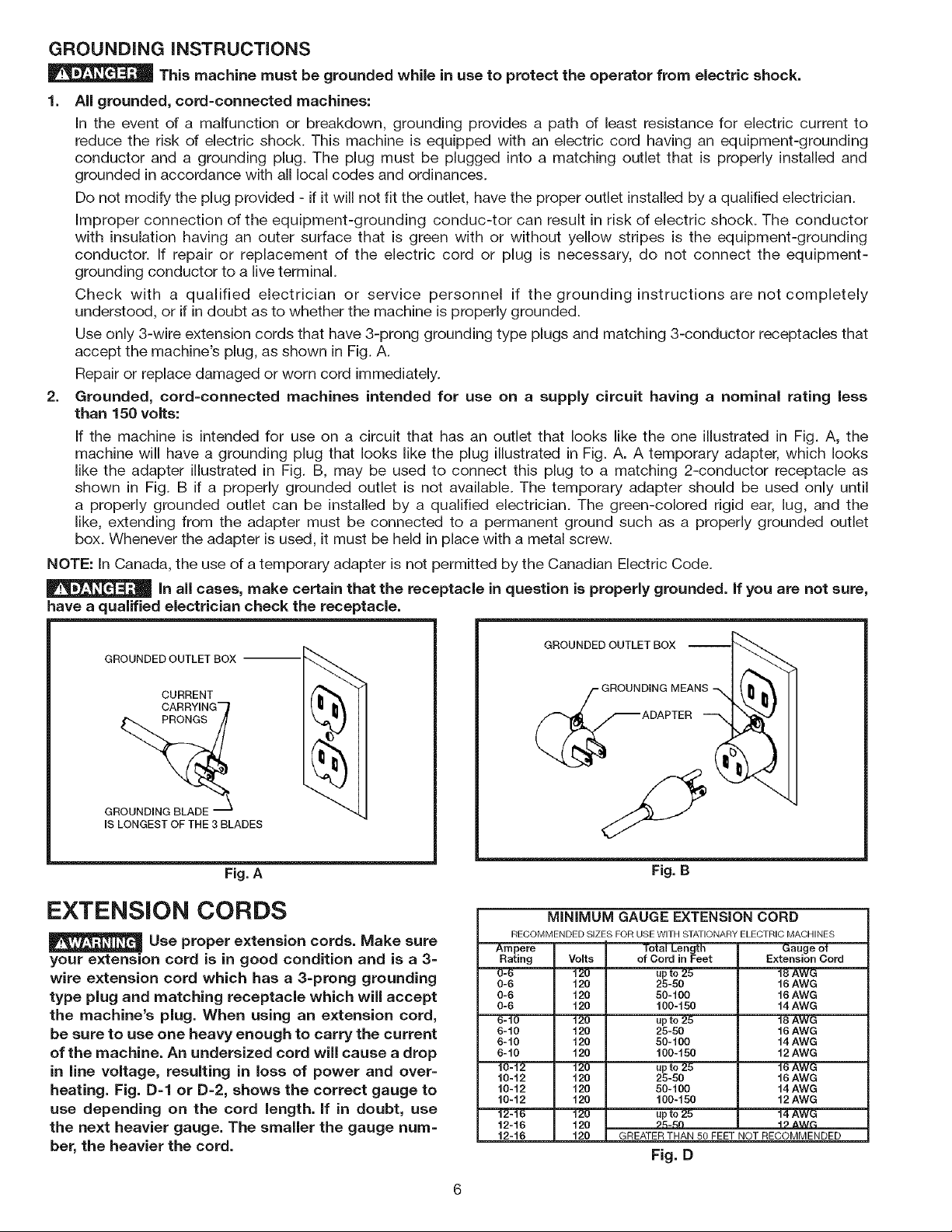

1. All grounded, cord-connected machines:

In the event of a malfunction or breakdown, grounding provides a path of least resistance for electric current to

reduce the risk of electric shock. This machine is equipped with an electric cord having an equipment-grounding

conductor and a grounding plug. The plug must be plugged into a matching outlet that is properly installed and

grounded in accordance with all local codes and ordinances.

Do not modify the plug provided - if it will not fit the outlet, have the proper outlet installed by a qualified electrician.

Improper connection of the equipment-grounding conduc-tor can result in risk of electric shock. The conductor

with insulation having an outer surface that is green with or without yellow stripes is the equipment-grounding

conductor. If repair or replacement of the electric cord or plug is necessary, do not connect the equipment-

grounding conductor to a live terminal.

Check with a qualified electrician or service personnel if the grounding instructions are not completely

understood, or if in doubt as to whether the machine is properly grounded.

Use only 3-wire extension cords that have 3-prong grounding type plugs and matching 3-conductor receptacles that

accept the machine's plug, as shown in Fig. A.

Repair or replace damaged or worn cord immediately.

2. Grounded, cord-connected machines intended for use on a supply circuit having a nominal rating less

than 150 volts:

If the machine is intended for use on a circuit that has an outlet that looks like the one illustrated in Fig. A, the

machine will have a grounding plug that looks like the plug illustrated in Fig. A. A temporary adapter, which looks

like the adapter illustrated in Fig. B, may be used to connect this plug to a matching 2-conductor receptacle as

shown in Fig. B if a properly grounded outlet is not available. The temporary adapter should be used only until

a properly grounded outlet can be installed by a qualified electrician. The green-colored rigid ear, lug, and the

like, extending from the adapter must be connected to a permanent ground such as a properly grounded outlet

box. Whenever the adapter is used, it must be held in place with a metal screw.

NOTE: In Canada, the use of a temporary adapter is not permitted by the Canadian Electric Code.

In all cases, make certain that the receptacle in question is properly grounded. If you are not sure,

have a qualified electrician check the receptacle.

GROUNDED OUTLET BOX

CURRENT

CAR RYIN G"-_

GROUNDING BLADE

IS LONGEST OF THE 3 BLADES

Fig. A

EXTENSION CORDS

Use proper extension cords. Make sure

your extension cord is in good condition and is a 3=

wire extension cord which has a 3=prong grounding

type plug and matching receptacle which will accept

the machine's plug. When using an extension cord,

be sure to use one heavy enough to carry the current

of the machine. An undersized cord will cause a drop

in line voltage, resulting in loss of power and over=

heating. Fig. D=I or D=2, shows the correct gauge to

use depending on the cord length, if in doubt, use

the next heavier gauge. The smaller the gauge num-

ber, the heavier the cord.

GROUNDED OUTLET BOX

MEAN

Fig. B

MiNiMUM GAUGE EXTENSION CORD

RECOMMENDED SIZES FOR USE WITH STATIONARY ELECTRIC MACHINES

Ampere Total Length

Rating Volts of Cord JnFeet

0-6 120 up to 25

0-6 120 25-50

0-6 120 50-100

0-6 120 100-150

6-10 120 up to 25

6-10 120 25-50

6-10 120 50-100

6-10 120 100-150

10-12 120 up to 25

10-12 120 25-50

10-12 120 50-100

10-12 120 100-150

12-16 120 up to 25

12-16 120 _._n

12-16 120

GREATER THAN 50 FEET NOT RECOMMENDED

Gauge of

Extension Cord

18 AWG

16 AWG

16 AWG

14 AWG

18 AWG

16 AWG

14 AWG

12 AWG

16 AWG

16 AWG

14 AWG

12 AWG

14 AWG

4_ AW_

Fig. D

Page 7

FOREWORD

The Delta Model BS150LS 10" Band Saw has a powerful 1/2 HE ball-bearing motor for smooth performance and long

life. The saw has a 7 inch depth of cut capacity. The BS150LS is supplied with a cast iron table and sturdy steel stand

which provides heavy-duty support and a comfortable work height.

NOTICE: The photo on the manual cover illustrates the current production model. All other illustrations contained in the

manual are representative only and may not depict the actual labeling or accessories included. These are intended to

illustrate technique only.

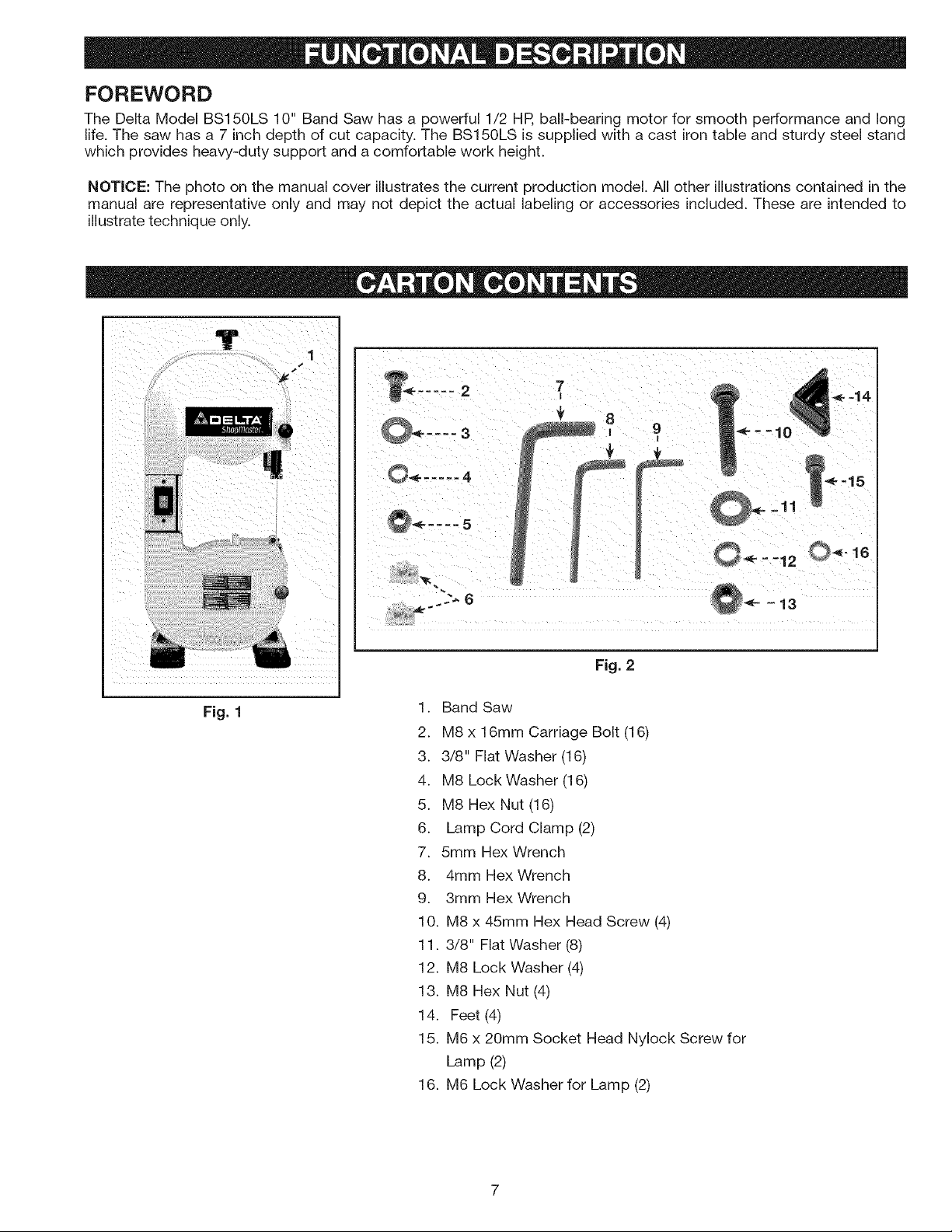

Fig. 1

....

7

I

Fig. 2

1. Band Saw

2. M8 x 16mm Carriage Bolt (16)

3. 3/8" Flat Washer (16)

4. M8 Lock Washer (16)

5. M8 Hex Nut (16)

6. Lamp Cord Clamp (2)

7. 5mm Hex Wrench

8. 4mm Hex Wrench

9. 3mm Hex Wrench

10. M8 x 45mm Hex Head Screw (4)

11. 3/8" Flat Washer (8)

12. M8 Lock Washer (4)

13. M8 Hex Nut (4)

14. Feet (4)

15. M6 x 20mm Socket Head Nylock Screw for

Lamp (2)

16. M6 Lock Washer for Lamp (2)

Page 8

UNPACKING AND CLEANING

Carefully unpack the machine and all loose items from the shipping container(s). Remove the rust-preventative oil from

unpainted surfaces using a soft cloth moistened with mineral spirits, paint thinner or denatured alcohol.

Do not use highly volatile solventssuch as gasoline, naphtha, acetone or lacquer thinner for cleaning your

machine.

After cleaning, cover the unpainted surfaces with a good quality household floor paste wax.

For your own safety, do not connect the machine to the power source until the machine is

completely assembled and you read and understand the entire instruction manual

ASSEMBLY TOOLS REQUIRED

1. 3mm Hex Wrench - provided

2. 4mm Hex Wrench - provided

3. 5mm Hex Wrench - provided

4. M8 Socket - not provided

5. M8 Wrench - not provided

ASSEMBLY TIME ESTIMATE

Assembly for this machine takes approximately 2 to 3 hours.

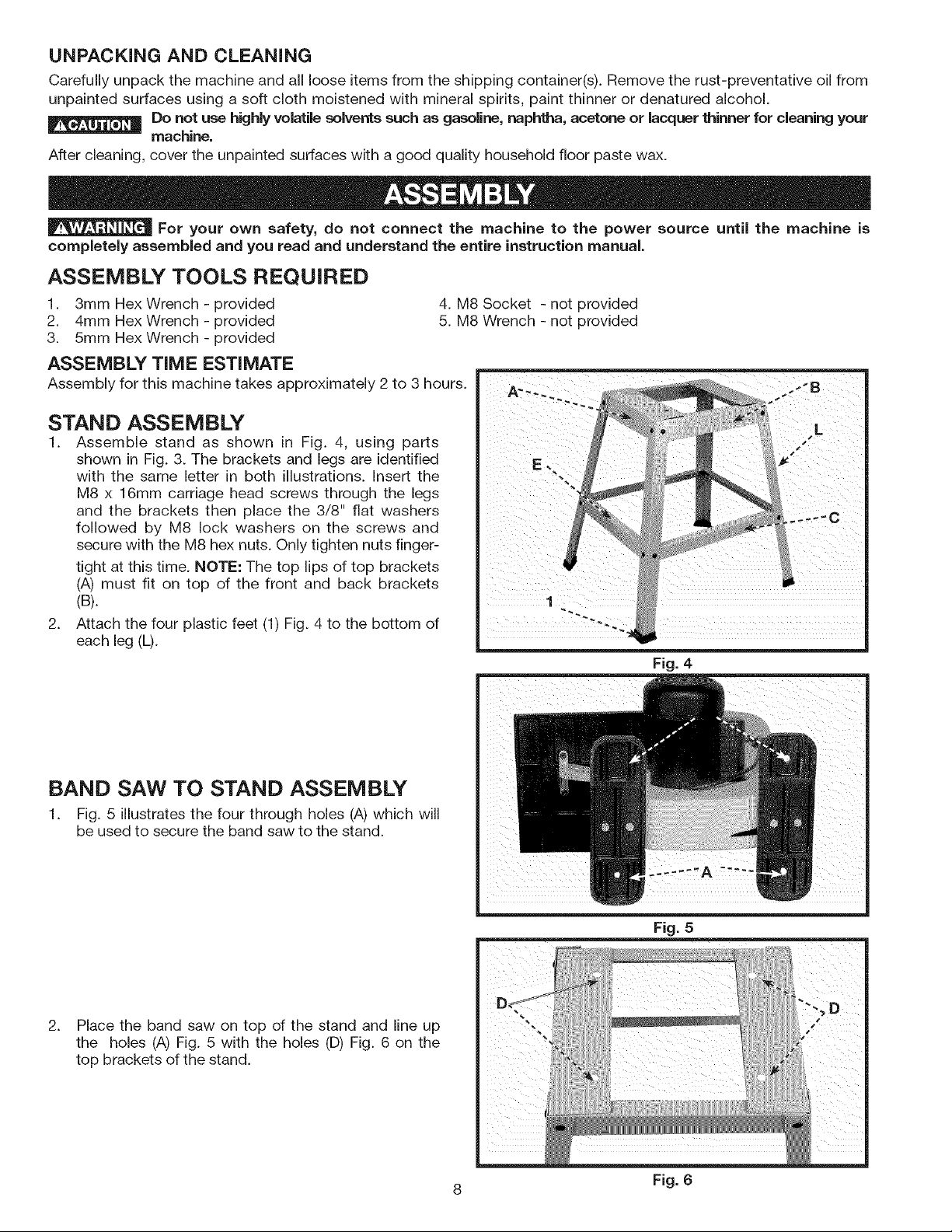

STAND ASSEMBLY

1. Assemble stand as shown in Fig. 4, using parts

shown in Fig. 3. The brackets and legs are identified

with the same letter in both illustrations. Insert the

M8 x 16mm carriage head screws through the legs

and the brackets then place the 3/8" flat washers

followed by M8 lock washers on the screws and

secure with the M8 hex nuts. Only tighten nuts finger-

tight at this time. NOTE: The top lips of top brackets

(A) must fit on top of the front and back brackets

(B).

2. Attach the four plastic feet (1) Fig. 4 to the bottom of

each leg (L).

Fig. 4

BAND SAW TO STAND ASSEMBLY

1. Fig. 5 illustrates the four through holes (A) which will

be used to secure the band saw to the stand.

2_

Place the band saw on top of the stand and line up

topthebracketsh°les(A)ofFig.the5stand.withthe holes (D)Fig. 6 on the

Fig. 5

8 Fig. 6

Page 9

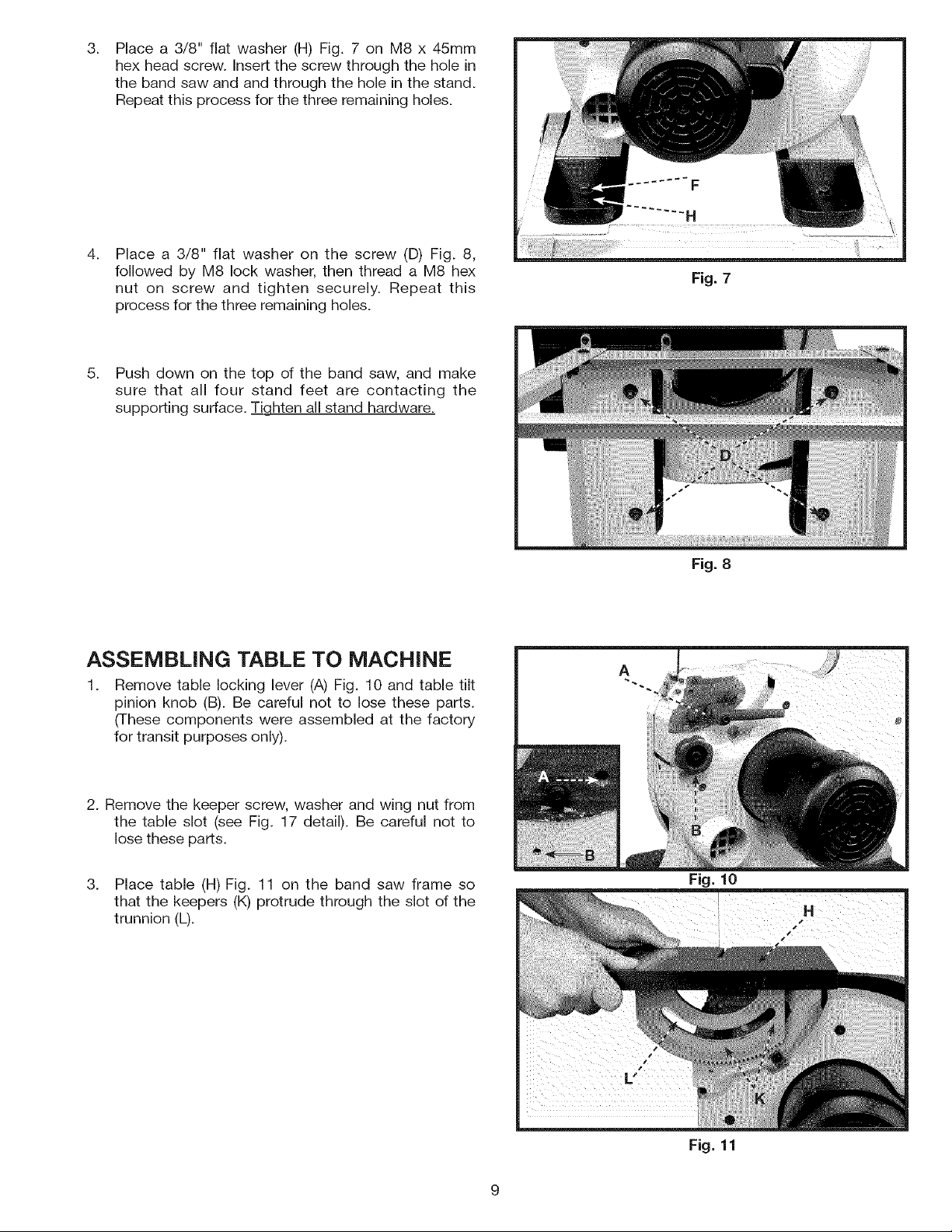

3.

Place a 3/8" flat washer (H) Fig, 7 on M8 x 45mm

hex head screw. Insert the screw through the hole in

the band saw and and through the hole in the stand.

Repeat this process for the three remaining holes.

.

Place a 3/8" flat washer on the screw (D) Fig. 8,

followed by M8 lock washer, then thread a M8 hex

nut on screw and tighten securely. Repeat this

process for the three remaining holes.

5. Push down on the top of the band saw, and make

sure that all four stand feet are contacting the

supporting surface. Tighten all stand hardware.

Fig. 7

ASSEMBLING TABLE TO MACHINE

1.

Remove table locking lever (A) Fig. 10 and table tilt

pinion knob (B). Be careful not to lose these parts.

(These components were assembled at the factory

for transit purposes only).

2. Remove the keeper screw, washer and wing nut from

the table slot (see Fig. 17 detail). Be careful not to

lose these parts.

3. Place table (H) Fig. 11 on the band saw frame so

that the keepers (K) protrude through the slot of the

trunnion (L).

Fig. 8

Fig. 10

Fig. 11

Page 10

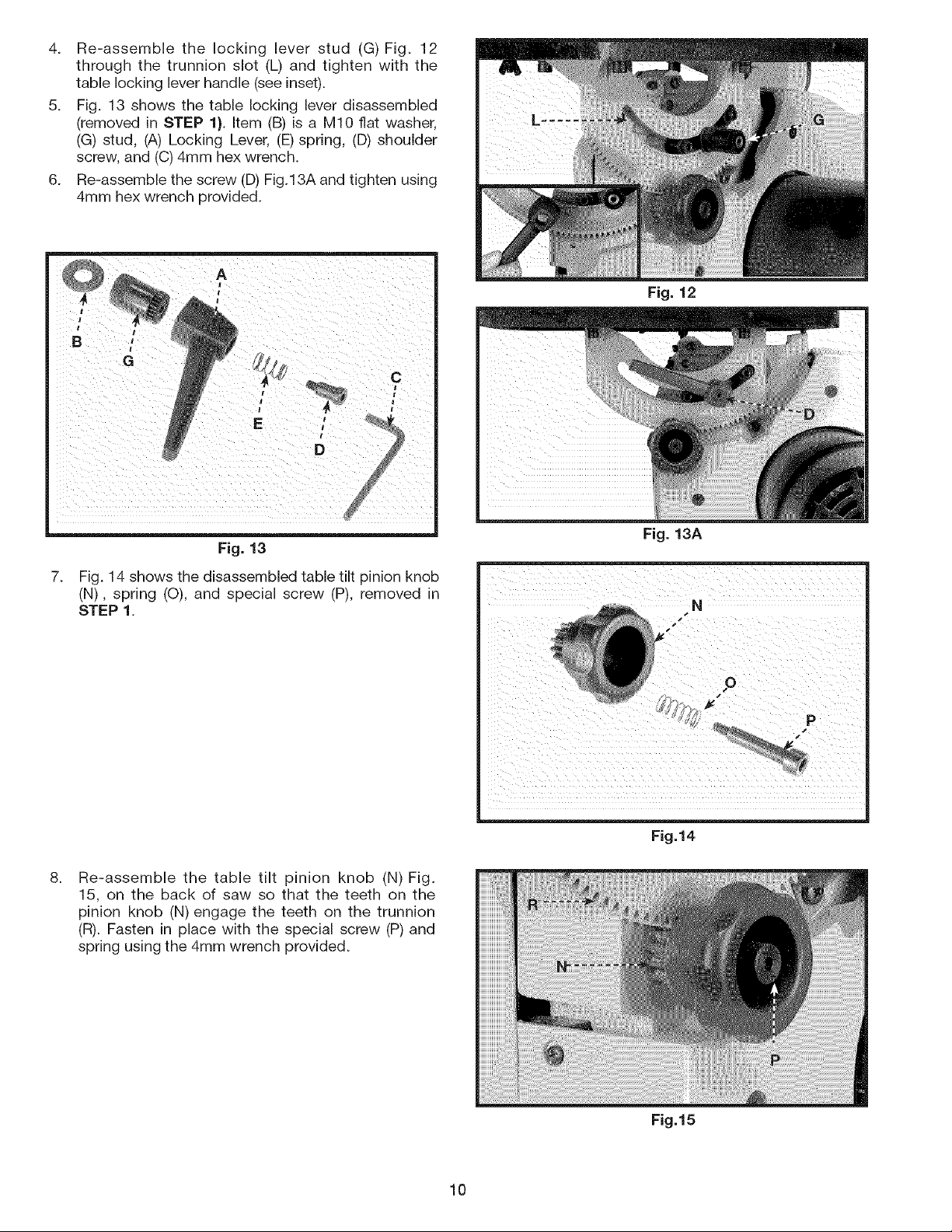

4. Re-assemblethe lockingleverstud (G)Fig. 12

throughthe trunnionslot (L)andtightenwiththe

tablelockingleverhandle(seeinset).

5. Fig.13showsthetablelockingleverdisassembled

(removedinSTEP1).Item(B)isa M10flatwasher,

(G)stud,(A)LockingLever,(E)spring,(D)shoulder

screw,and(C)4mmhexwrench.

6. Re-assemblethescrew(D)Fig.13Aandtightenusing

4mmhexwrenchprovided.

Fig. 12

Fig. 13

7.

Fig. 14 shows the disassembled table tilt pinion knob

(N), spring (O), and special screw (P), removed in

STEP 1.

8.

Re-assemble the table tilt pinion knob (N) Fig.

15, on the back of saw so that the teeth on the

pinion knob (N) engage the teeth on the trunnion

(R). Fasten in place with the special screw (P) and

spring using the 4mm wrench provided.

Fig. 13A

N

Fig.14

10

Fig.15

Page 11

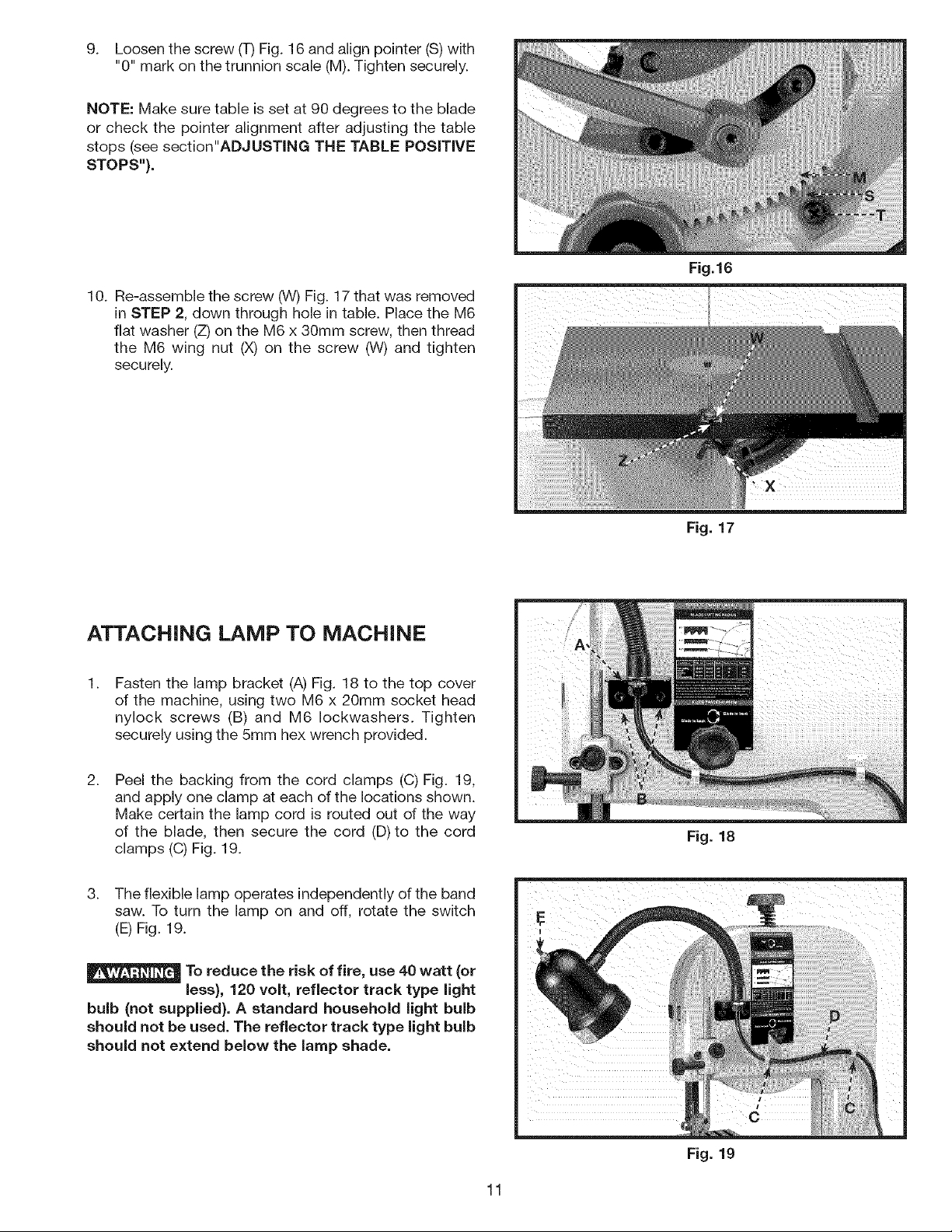

9. Loosenthescrew(T)Fig.16andalignpointer(S)with

"0"markonthetrunnionscale(M).Tightensecurely.

NOTE:Makesuretableissetat90degreestotheblade

orcheckthepointeralignmentafteradjustingthetable

stops(seesection"ADJUSTINGTHE TABLE POSiTiVE

STOPS").

10. Re-assemble the screw (W) Fig. 17 that was removed

in STEP 2, down through hole in table. Place the M6

flat washer (Z) on the M6 x 30mm screw, then thread

the M6 wing nut (X) on the screw (W) and tighten

securely.

Fig.16

ATTACHING LAMP TO MACHINE

1.

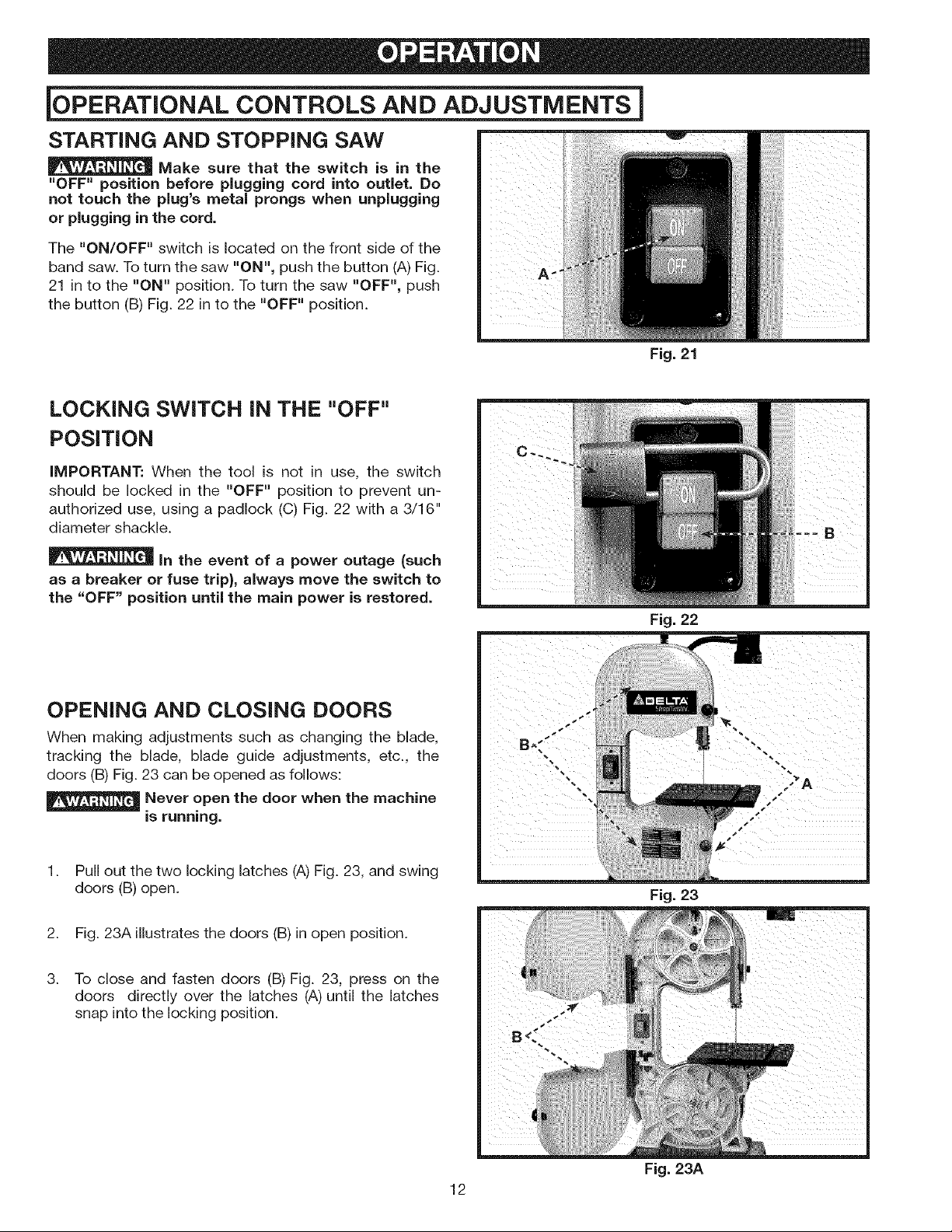

Fasten the lamp bracket (A) Fig. 18 to the top cover

of the machine, using two M6 x 20mm socket head

nylock screws (B) and M6 Iockwashers. Tighten

securely using the 5mm hex wrench provided.

2.

Peel the backing from the cord clamps (C) Fig. 19,

and apply one clamp at each of the locations shown.

Make certain the lamp cord is routed out of the way

of the blade, then secure the cord (D)to the cord

clamps (C) Fig. 19.

3. The flexible lamp operates independently of the band

saw. To turn the lamp on and off, rotate the switch

(E) Fig. 19.

To reduce the risk of fire, use 40 watt (or

less), 120 volt, reflector track type light

bulb (not supplied). A standard household light bulb

should not be used. The reflector track type light bulb

should not extend below the lamp shade.

Fig. 17

Fig. 18

11

Fig. 19

Page 12

IOPERATIONAL CONTROLS AND ADJUSTMENTS I

STARTING AND STOPPING SAW

Make sure that the switch is in the

"OFF" position before plugging cord into outlet. Do

nottouchtheplug'smetalprongswhenunplugging

or plugging in the cord.

The "ON/OFF" switch is located on the front side of the

band saw. To turn the saw "ON", push the button (A) Fig.

21 in to the "ON" position. To turn the saw "OFF", push

the button (B) Fig. 22 in to the "OFF" position.

LOCKING SWITCH IN THE "OFF"

POSITION

IMPORTANT: When the tool is not in use, the switch

should be locked in the "OFF" position to prevent un-

authorized use, using a padlock (C) Fig. 22 with a 3/16"

diameter shackle.

Fig. 21

in the event of a power outage (such

as a breaker or fuse trip}, always move the switch to

the "OFF" position until the main power is restored.

OPENING AND CLOSING DOORS

When making adjustments such as changing the blade,

tracking the blade, blade guide adjustments, etc., the

doors (B) Fig. 23 can be opened as follows:

_ .Never open the door when the machine

is running.

Pull out the two locking latches (A) Fig. 23, and swing

doors (B) open.

2. Fig. 23A illustrates the doors (B) in open position.

3. To close and fasten doors (B) Fig. 23, press on the

doors directly over the latches (A) until the latches

snap into the locking position.

Fig. 22

Fig. 23

12

Fig. 23A

Page 13

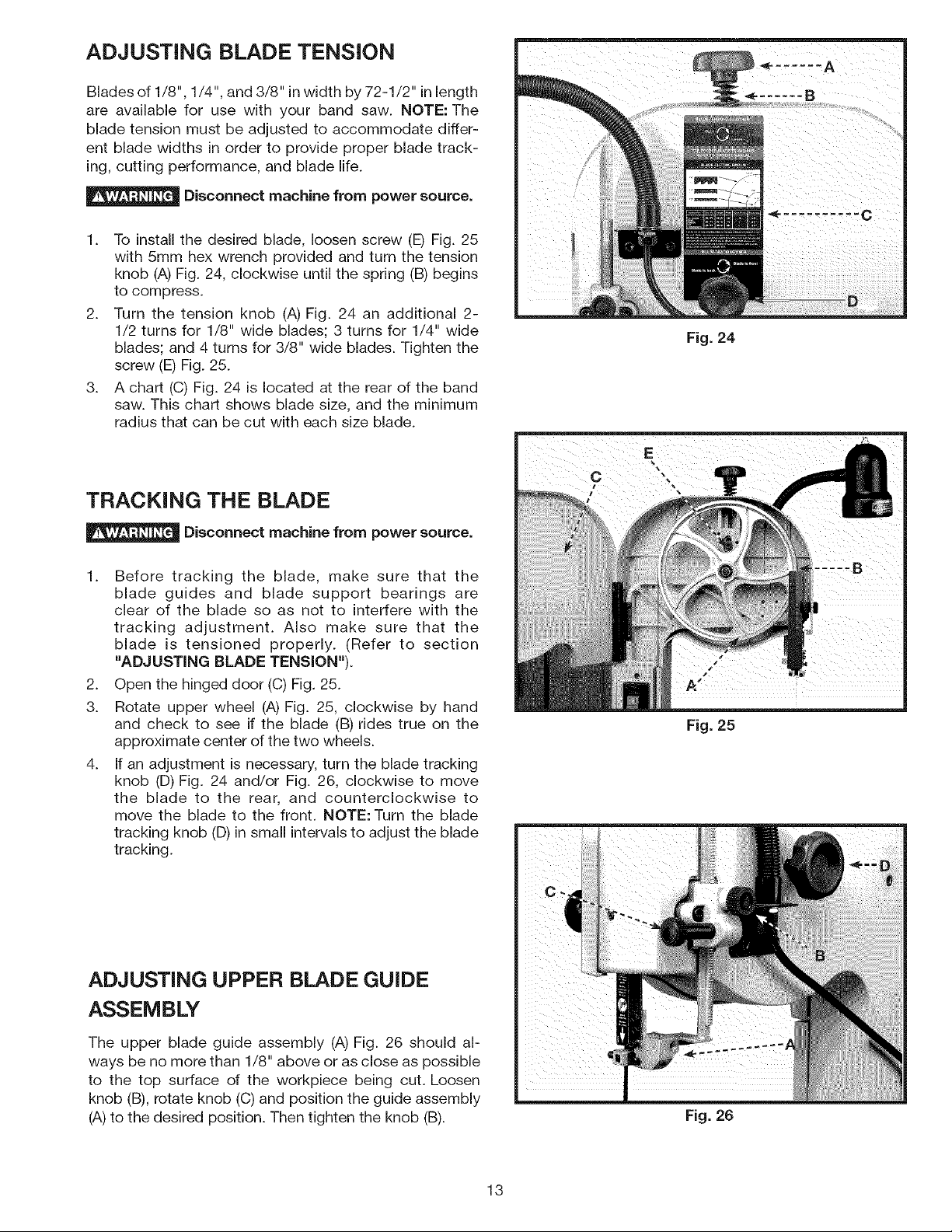

ADJUSTING BLADE TENSION

Blades of 1/8", 1/4", and 3/8" in width by 72-1/2" inlength

are available for use with your band saw. NOTE: The

blade tension must be adjusted to accommodate differ-

ent blade widths in order to provide proper blade track-

ing, cutting performance, and blade life.

Disconnect machine from power source.

1. To install the desired blade, loosen screw (E) Fig. 25

with 5mm hex wrench provided and turn the tension

knob (A) Fig. 24, clockwise until the spring (B) begins

to compress.

2. Turn the tension knob (A)Fig. 24 an additional 2-

1/2 turns for 1/8" wide blades; 3 turns for 1/4" wide

blades; and 4 turns for 3/8" wide blades. Tighten the

screw (E) Fig. 25.

3. A chart (C) Fig. 24 is located at the rear of the band

saw. This chart shows blade size, and the minimum

radius that can be cut with each size blade.

TRACKING THE BLADE

Fig. 24

Disconnect machine from power source.

1. Before tracking the blade, make sure that the

blade guides and blade support bearings are

clear of the blade so as not to interfere with the

tracking adjustment. Also make sure that the

blade is tensioned properly. (Refer to section

"ADJUSTING BLADE TENSION").

2. Open the hinged door (C) Fig. 25.

3. Rotate upper wheel (A) Fig. 25, clockwise by hand

and check to see if the blade (B) rides true on the

approximate center of the two wheels.

4. If an adjustment is necessary, turn the blade tracking

knob (D) Fig. 24 and/or Fig. 26, clockwise to move

the blade to the rear, and counterclockwise to

move the blade to the front. NOTE: Turn the blade

tracking knob (D) insmall intervalsto adjust the blade

tracking.

ADJUSTING UPPER BLADE GUIDE

Fig. 25

ASSEMBLY

The upper blade guide assembly (A) Fig. 26 should al-

ways be no more than 1/8" above or as close as possible

to the top surface of the workpiece being cut. Loosen

knob (B), rotate knob (C) and position the guide assembly

(A)to the desired position. Then tighten the knob (B).

Fig. 26

13

Page 14

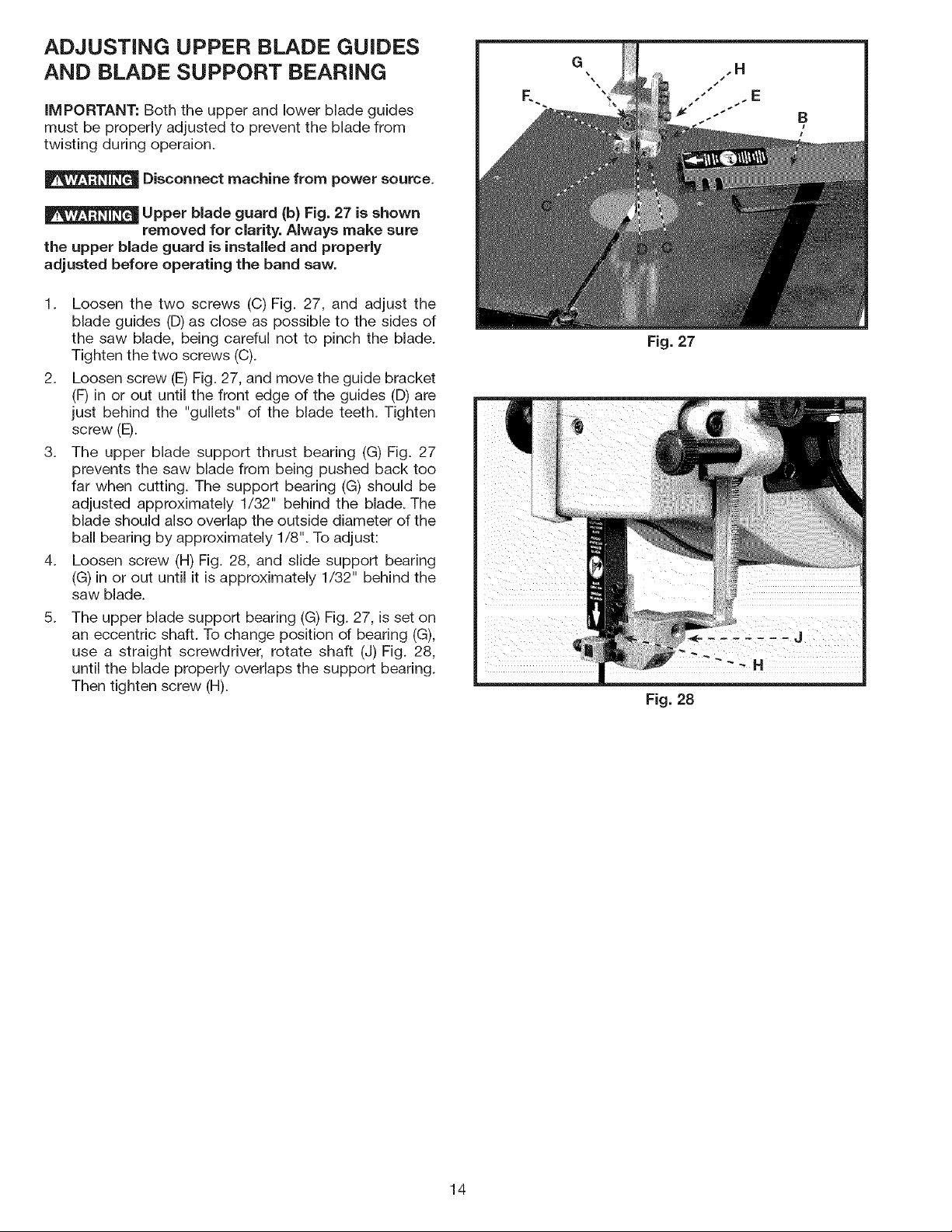

ADJUSTING UPPER BLADE GUIDES

AND BLADE SUPPORT BEARING

IMPORTANT." Both the upper and lower blade guides

must be properly adjusted to prevent the blade from

twisting during operaion.

Disconnect machine from power source.

Upper blade guard (b) Fig. 27 is shown

removed for clarity. Always make sure

the upper blade guard is installed and properly

adjusted before operating the band saw.

1. Loosen the two screws (C) Fig. 27, and adjust the

blade guides (D) as close as possible to the sides of

the saw blade, being careful not to pinch the blade.

Tighten the two screws (C).

2. Loosen screw (E) Fig. 27, and move the guide bracket

(F) in or out until the front edge of the guides (D) are

just behind the "gullets" of the blade teeth. Tighten

screw(E).

3. The upper blade support thrust bearing (G) Fig. 27

prevents the saw blade from being pushed back too

far when cutting. The support bearing (G) should be

adjusted approximately 1/32" behind the blade. The

blade should also overlap the outside diameter of the

ball bearing by approximately 1/8". To adjust:

4. Loosen screw (H) Fig. 28, and slide support bearing

(G) in or out until it is approximately 1/32" behind the

saw blade.

8.

The upper blade support bearing (G) Fig. 27, is set on

an eccentric shaft. To change position of bearing (G),

use a straight screwdriver, rotate shaft (J) Fig. 28,

until the blade properly overlaps the support bearing.

Then tighten screw (H).

Fig. 27

Fig. 28

14

Page 15

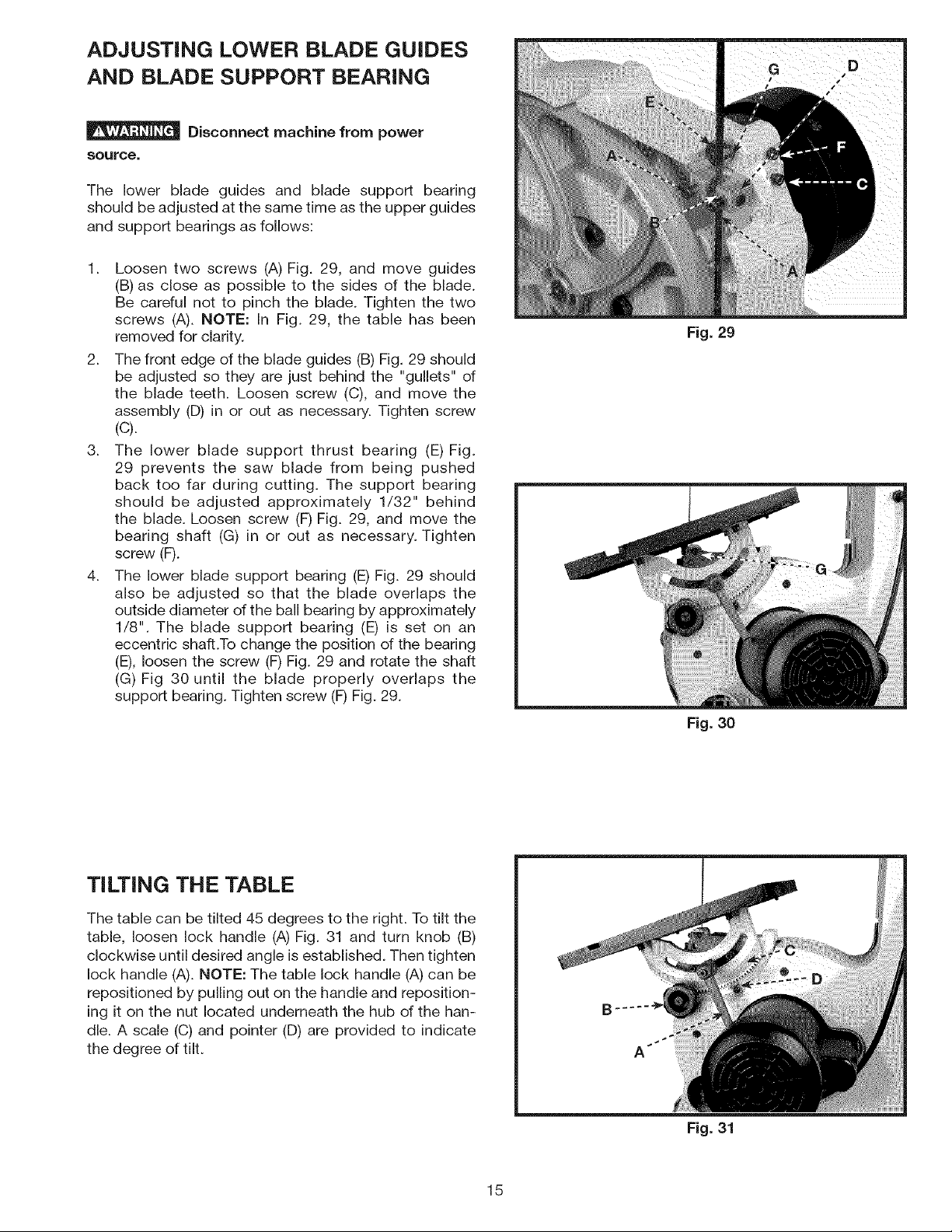

ADJUSTING LOWER BLADE GUIDES

AND BLADE SUPPORT BEARING

Disconnect machine from power

Source.

The lower blade guides and blade support bearing

should be adjusted at the same time as the upper guides

and support bearings as follows:

1. Loosen two screws (A) Fig. 29, and move guides

(B) as close as possible to the sides of the blade.

Be careful not to pinch the blade. Tighten the two

screws (A). NOTE: In Fig. 29, the table has been

removed for clarity.

2. The front edge of the blade guides (B) Fig. 29 should

be adjusted so they are just behind the "gullets" of

the blade teeth. Loosen screw (C), and move the

assembly (D) in or out as necessary. Tighten screw

(C).

3. The lower blade support thrust bearing (E) Fig.

29 prevents the saw blade from being pushed

back too far during cutting. The support bearing

should be adjusted approximately 1/32" behind

the blade. Loosen screw (F) Fig. 29, and move the

bearing shaft (G) in or out as necessary. Tighten

screw (F).

4. The lower blade support bearing (E) Fig. 29 should

also be adjusted so that the blade overlaps the

outside diameter of the ball bearing by approximately

1/8". The blade support bearing (E) is set on an

eccentric shaft.To change the position of the bearing

(E), loosen the screw (F)Fig. 29 and rotate the shaft

(G) Fig 30 until the blade properly overlaps the

support bearing. Tighten screw (F)Fig. 29.

Fig. 29

Fig. 30

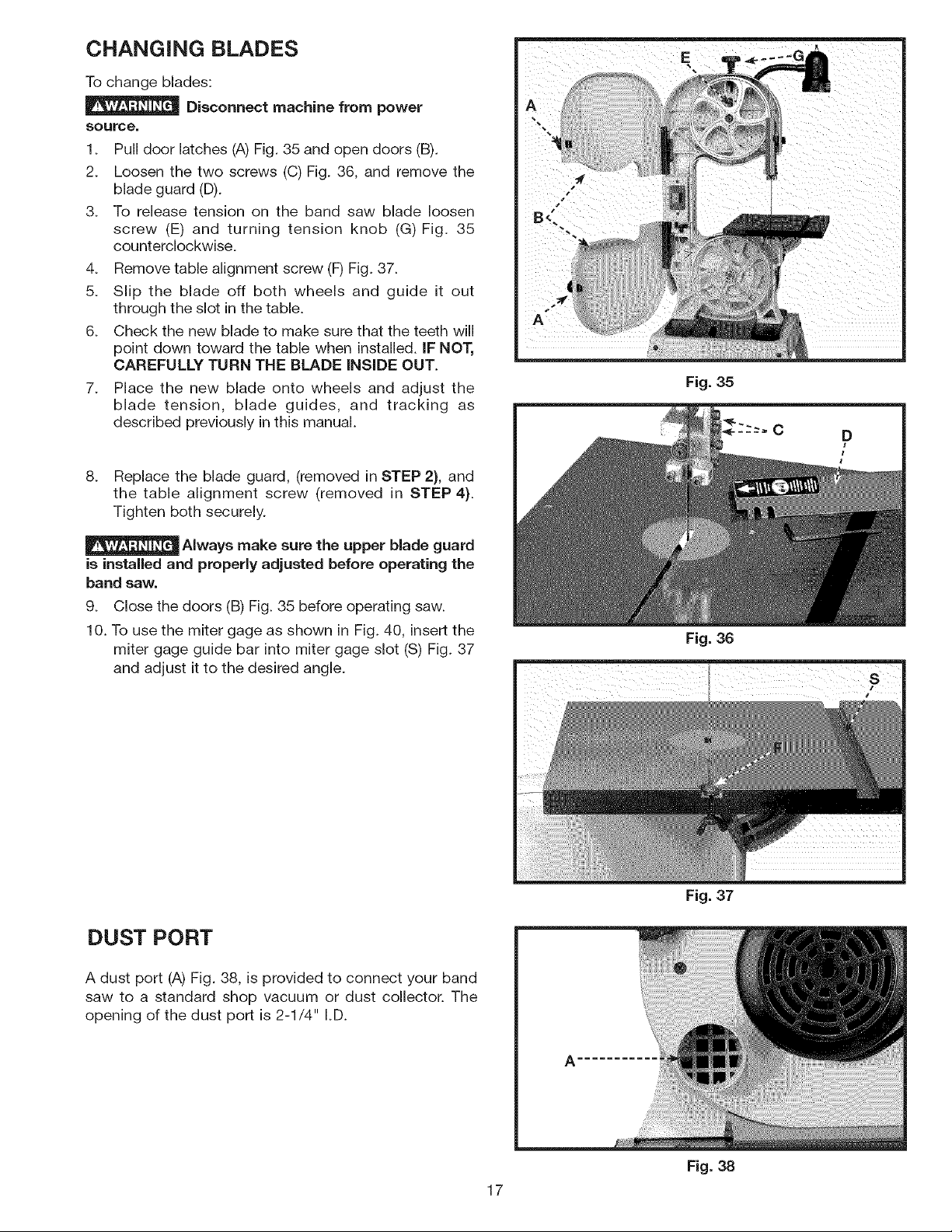

TILTING THE TABLE

The table can be tilted 45 degrees to the right. To tilt the

table, loosen lock handle (A) Fig. 31 and turn knob (B)

clockwise until desired angle is established. Then tighten

lock handle (A). NOTE: The table lock handle (A) can be

repositioned by pulling out on the handle and reposition-

ing it on the nut located underneath the hub of the han-

dle. A scale (C) and pointer (D) are provided to indicate

the degree of tilt.

Fig. 31

15

Page 16

ADJUSTING THE TABLE

POSiTiVE STOPS

Positive stops are provided for the table at the 90 and

45 degree angle to the blade. To check and adjust the

positive stops:

Disconnect machine from power

source.

1.

Tilt the table to the 90 degree position as shown in

Fig. 32 and tighten lock handle (A). Place a square

(H) on the table and against the blade and check to

see ifthe blade is 90 degrees to the table surface. If

an adjustment is necessary:

2.

Tilt the table to expose the lock nut (E) Fig. 33.

Loosen lock nut (E) and return table to the 90°

position. With the lock handle (A) Fig. 32 loose, turn

the adjusting screw (F) Fig. 34, using the 3mm hex

wrench provided until the blade is 90 degrees to the

table. Then tighten lock handle (A) and lock nut (E) on

the adjustment screw (F).

Fig. 32

3.

Tilt the table to the 45 degree position as shown

in Fig. 34. Place a square (H) Fig. 34 on the table

and against the blade and check to see if the blade

is 45 degrees to the table surface. If an adjustment

is necessary.

.

Loosen the lock nut (N) Fig. 33 on the adjustment

screw (J) located on the underside of the table. With

the lock handle (A) Fig. 34 loose, turn adjustment

screw (J) using 3mm hex wrench provided until

the blade is 45 degrees to the table. Tighten lock

handle (A) and lock nut (N) on the adjustment screw

(d).

Fig. 33

Fig. 34

16

Page 17

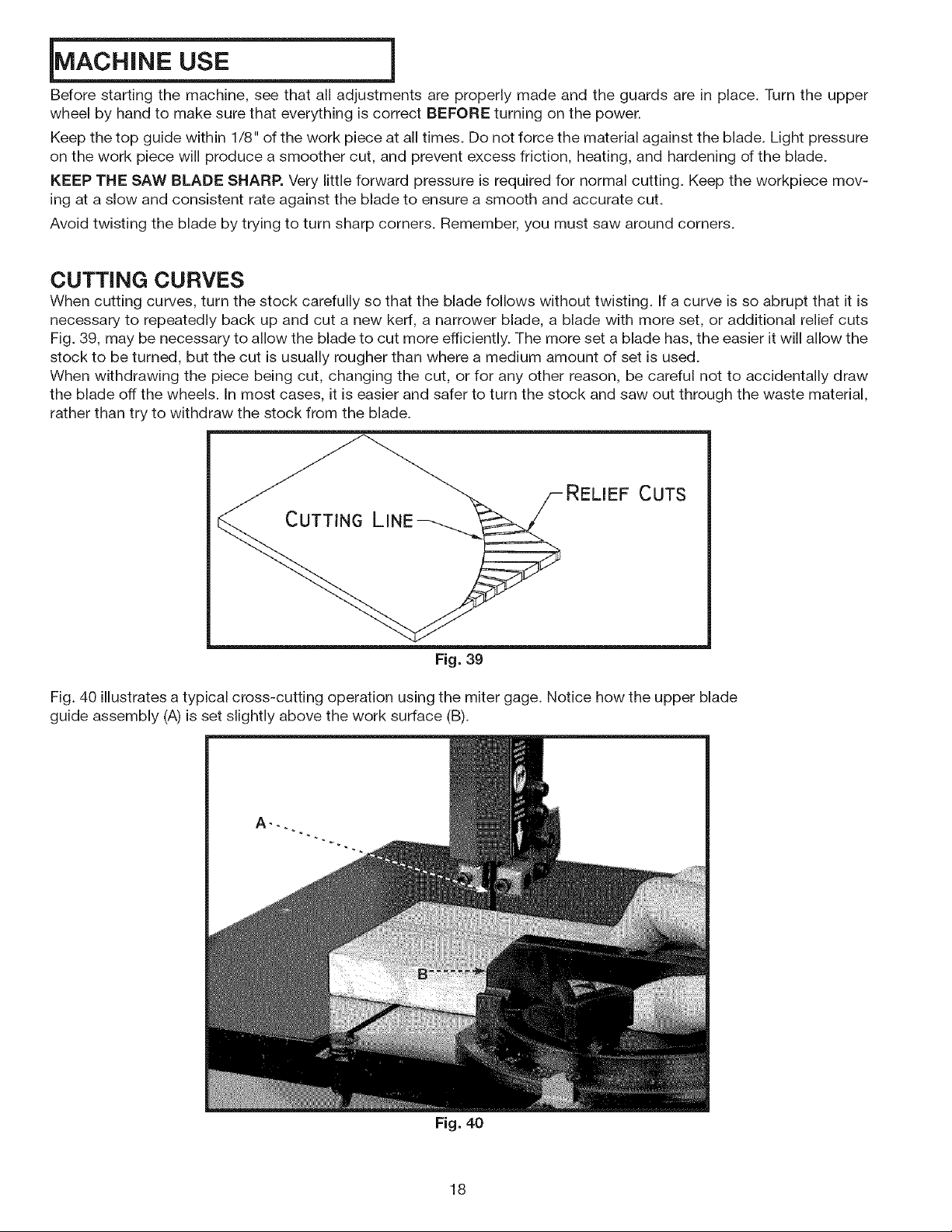

CHANGING BLADES

To change blades:

Disconnect machine from power

source.

1. Pull door latches (A) Fig. 35 and open doors (B).

2. Loosen the two screws (C) Fig. 36, and remove the

blade guard (D).

3. To release tension on the band saw blade loosen

screw (E) and turning tension knob (G)Fig. 35

counterclockwise.

4. Remove table alignment screw (F) Fig. 37.

5. Slip the blade off both wheels and guide it out

through the slot in the table.

6. Check the new blade to make sure that the teeth will

point down toward the table when installed, iF NOT,

CAREFULLY TURN THE BLADE iNSiDE OUT.

7. Place the new blade onto wheels and adjust the

blade tension, blade guides, and tracking as

described previously in this manual.

8. Replace the blade guard, removed in STEP 2), and

the table alignment screw (removed in STEP 4).

Tighten both securely.

Fig. 35

Always make sure the upper blade guard

is installed and properly adjusted before operating the

band saw.

9. Close the doors (B) Fig. 35 before operating saw.

10. To use the miter gage as shown in Fig. 40, insertthe

miter gage guide bar into miter gage slot (S) Fig. 37

and adjust it to the desired angle.

DUST PORT

A dust port (A) Fig. 38, is provided to connect your band

saw to a standard shop vacuum or dust collector. The

opening of the dust port is 2-1/4" I.D.

Fig. 36

Fig. 37

17

Fig. 38

Page 18

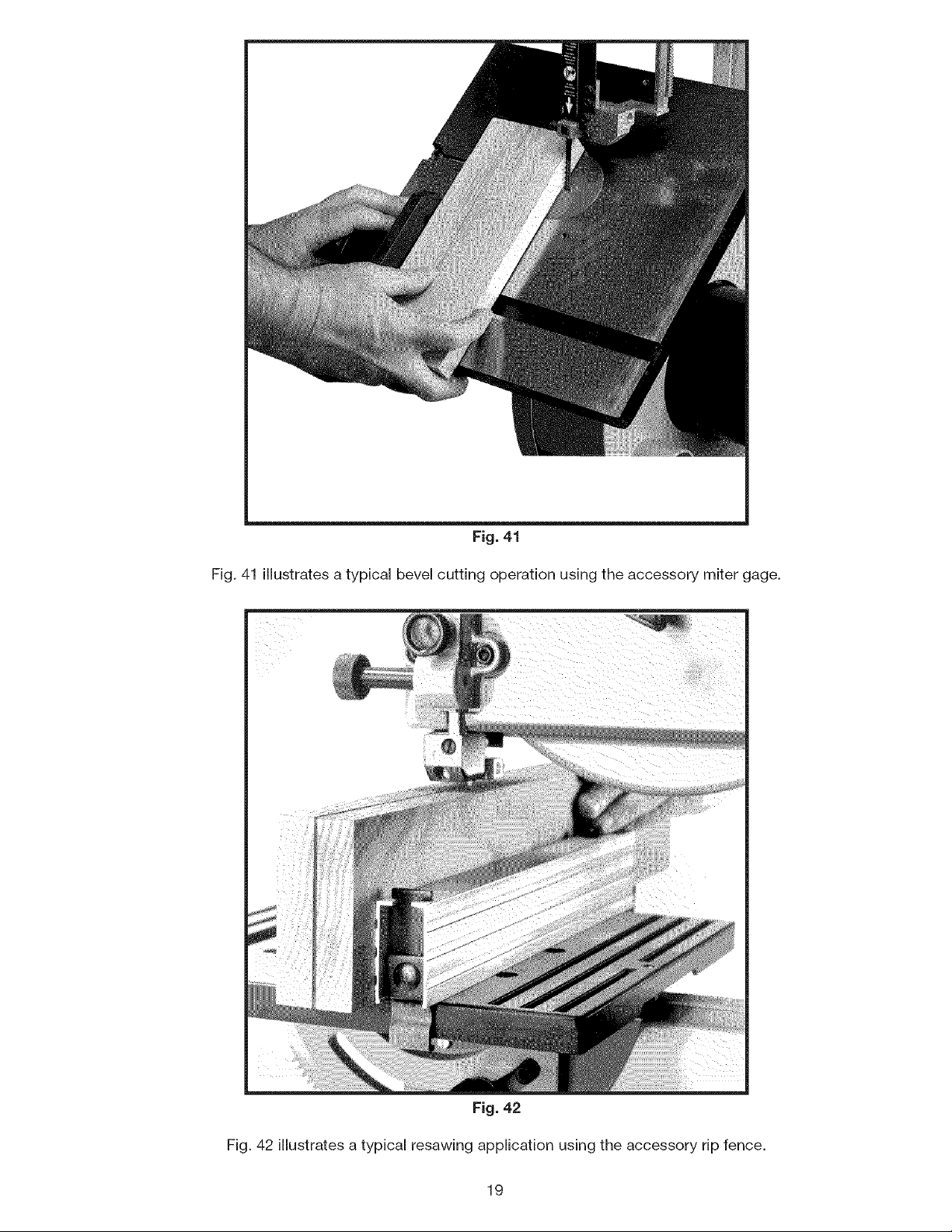

Before starting the machine, see that all adjustments are properly made and the guards are in place. Turn the upper

wheel by hand to make sure that everything is correct BEFORE turning on the power.

Keep the top guide within 1/8" of the work piece at all times. Do not force the material against the blade. Light pressure

on the work piece will produce a smoother cut, and prevent excess friction, heating, and hardening of the blade.

KEEP THE SAW BLADE SHARP. Very little forward pressure is required for normal cutting. Keep the workpiece mov-

ing at a slow and consistent rate against the blade to ensure a smooth and accurate cut.

Avoid twisting the blade by trying to turn sharp corners. Remember, you must saw around corners.

CUTTING CURVES

When cutting curves, turn the stock carefully so that the blade follows without twisting. If a curve is so abrupt that it is

necessary to repeatedly back up and cut a new kerf, a narrower blade, a blade with more set, or additional relief cuts

Fig. 39, may be necessary to allow the blade to cut more efficiently. The more set a blade has, the easier it will allow the

stock to be turned, but the cut is usually rougher than where a medium amount of set is used.

When withdrawing the piece being cut, changing the cut, or for any other reason, be careful not to accidentally draw

the blade off the wheels. In most cases, it is easier and safer to turn the stock and saw out through the waste material,

rather than try to withdraw the stock from the blade.

RELIEF CUTS

CUTTING LINE

Fig. 39

Fig. 40 illustratesa typical cross-cutting operation using the miter gage. Notice how the upper blade

guide assembly (A) is set slightly above the work surface (B).

Fig. 40

18

Page 19

Fig.41

Fig.41illustratesatypicalbevelcuttingoperationusingtheaccessorymitergage.

Fig.42

Fig.42illustratesatypicalresawingapplicationusingtheaccessoryripfence.

19

Page 20

Forassistancewithyourmachine,visitourwebsiteatwww.deltamachinery.com for a list of service centers or call

the DELTA Machinery help line at 1-800-223-7278 (In Canada call 1-800-463-3582).

In spite of how well a band saw is maintained, problems can occur. The following troubleshooting guide will help you

solve the more common problems:

Trouble: SAW WILL NOT START.

Probable Cause

1. Saw not plugged in.

2. Fuse blown or circuit breaker tripped.

3. Cord damaged.

Trouble: BREAKER KICKS OUT FREQUENTLY.

Probable Cause

1. Extension cord too light or too long.

2. Feeding stock too fast.

3. Blade in poor condition (dull, warped, gummed).

4. Low voltage supply.

Trouble: BAND SAW VIBRATES EXCESSIVELY.

Probable Cause

1. Machine not mounted securely to stand.

2. Stand on uneven surface.

3. Worn belt.

4. Pulley not aligned.

5. Motor not fastened securely.

Remedy

1. Plug insaw.

2. Replace fuse or reset circuit breaker.

3. Have cord replaced.

Remedy

1. Replace with adequate size cord.

2. Feed stock more slowly.

3. Clean or replace blade.

4. Contact an electrician.

Remedy

1. Tighten all mounting hardware.

2. Reposition on flat level surface.

3. Replace belt.

4. Adjust pulleys.

5. Tighten all mounting hardware.

Trouble: BAND SAW DOES NOT COME UP TO SPEED.

Probable Cause

1. Low voltage due to improper extension cord size.

2. Low voltage.

Trouble: BLADES BREAK.

Probable Cause

1. Blade not tensioned properly.

2. Blade guides improperly adjusted.

3. Blade support bearing improperly adjusted.

4. Blade wheel tracking adjustment improperly set.

5. Bad weld on blade.

6. Worn tires.

7. Forcing wide blade around short radius.

8. Dull blade or insufficient set.

9. Upper blade guide set too high.

10. Continuous running of machine when not actually

cutting.

Remedy

1. Replace with adecjuate size cord.

2. Contact an electrician.

Remedy

1. Adjust blade tension.

2. Check and adjust blade guides.

3. Adjust blade support bearing.

4. Check and adjust blade tracking.

5. Replace the blade.

6. Replace tires.

7. Change to a narrower blade.

8. Replace blade.

9. Set upper blade guide within 1/8" of workpiece.

10. Turn off machine when not performing cutting

operation.

(continued on next page)

2O

Page 21

Trouble:BLADE WILL NOT TRACK.

Probable Cause

1. Blade too loose

2. Upper wheel not properly adjusted.

3. Improperly adjusted blade support bearing.

Trouble: CUT DOES NOT AGREE WITH SETTING ON THE TILT SCALE.

Probable Cause Remedy

1. Pointer out of adjustment 1. Adjust pointer.

Trouble: BLADE WILL NOT STAY ON WHEEL.

Probable Cause

1. Blade not tensioned properly.

2. Blade guides improperly adjusted.

3. Blade support bearing improperly adjusted.

4. Blade wheel not tracking properly.

5. Bad weld on blade.

6. Worn tires.

Remedy

1. Adjust tension

2. Adjust upper wheel.

3. Adjust blade support bearing.

Remedy

1. Adjust blade tension.

2. Check and adjust blade guides.

3. Adjust blade support bearing.

4. Check and adjust blade tracking.

5. Replace the blade.

6. Replace tires.

Trouble: BAND SAW MAKES UNSATISFACTORY CUTS.

Probable Cause

1. Blade not tensioned properly.

2. Blade guides improperly adjusted.

3. Blade support bearing improperly set.

4. Blade wheel not tracking properly.

5. Bad weld on blade.

6. Worn tires.

7. Incorrect blade for work being done.

8. Dull blade or insufficient set.

9. Upper blade guide set too high.

Remedy

1. Adjust blade tension.

2. Check and adjust blade guides.

3. Adjust blade support bearing.

4. Check and adjust blade tracking.

5. Replace the blade.

6. Replace tires.

7. Change the blade.

8. Replace blade.

9. Set upper blade guide within 1/8" of work piece.

21

Page 22

BAND SAW BLADES

A band saw blade is a delicate piece of steel that is subjected to tremendous strain. You can ob-

tain long use from a band saw blade if you use it properly. Use blades of proper thickness, width

and temper for the various types of material and cuts.

Always use the widest blade possible. Use narrow blades only for sawing small, abrupt curves

and for fine, delicate work. This will save blades and will produce better cuts. For cutting wood

and similar materials, Delta offers blades in widths of 1/8", 1/4", and 3/8".

Any one of a number of conditions may cause a band saw blade to break. Blade breakage is, in

some cases, unavoidable, being the natural result of the peculiar stresses to which blades are

subjected. Blades will break often due to avoidable causes, such as the lack of care to the blade

or the blade not being properly adjusted to the band saw. The most common causes of blade

breakage are:

(1) faulty alignments and adjustments of the guides.

(2) forcing or twisting a wide blade around a curve of short radius.

(3) feeding the work piece too fast into the blade.

(4) dullness of the teeth, or absence of sufficient set.

(5) improperly tensioned blade.

(6) top guide set too high above the work piece being cut.

(7) using a blade with a lumpy or improperly finished braze or weld.

(8) continuous running of the saw blade when not cutting.

Use blades that are 721/2'' in length on this machine.

Always use a sharp blade. Keep it free from gum and pitch. Clean frequently with a stiff fiber

brush.

Narrow blades are used for cutting small circles or curves while the wider blades are best suited

for straight cutting such as ripping.

A new blade, in most cases, will perform better and last longer than a re-sharpened blade.

Insure that the blade guides are adjusted properly.

Do not force or twist the blade around a curve or a very short radius.

Feed the workpiece through the blade at a consistent rate, allow the blade to do the cutting - do

not feed the work piece too fast.

Do not apply excessive tension to the blade. The tension is only necessary to drive the blade

without slipping on the wheels. Narrow blades require less tension than wider blades.

For assistance with your machine, visit our website at www.deltamachinerv.com for a list of service centers or call the

DELTA Machinery help line at 1-800-223-7278 (In Canada call 1-800-463-3582).

22

Page 23

KEEP MACHINE CLEAN

Periodically blow out all air passages with dry compressed

air. All plastic parts should be cleaned with a soft damp

cloth. NEVER use solvents to clean plastic parts. They

could possibly dissolve or otherwise damage the material.

Wear certified safety equipment for

eye, hearing and respiratory protection while using

compressed air.

FAILURE TO START

Should your machine fail to start, check to make sure

the prongs on the cord plug are making good contact

in the outlet. Also, check for blown fuses or open circuit

breakers in the line.

LUBRICATION & RUST PROTECTION

Apply household floor paste wax to the machine table,

extension table or other work surface weekly. Or use a

commercially available protective product designed for

this purpose. Follow the manufacturer's instructions for

use and safety.

To clean cast iron tables of rust, you will need the

following materials: a sheet of mediurr_Scotch-Brite TM

Blending Hand Pad, a can of WD-40 and a can of

degreaser. Apply the WD-40 and polish the table surface

with the Scotch-Brite pad. Degrease the table, then apply

the protective product as described above.

REPLACEMENT PARTS

Use only identical replacement parts. For a parts list or to

order parts, visit our website at servicenet.deltamachiner3&,

corn. You can also order parts from your nearest factory-

owned branch, or by calling our Customer Care Center at

1-800-223-7278 to receive personalized support from highly-

trained technicians.

SERVICE AND REPAIRS

All quality tools will eventually require servicing and/or

replacement of parts. For information about Delta Machinery,

its factory-owned branches, or an Authorized Warranty

A complete line of accessories is available from your Delta Supplier, Porter-Cable • Delta Factory Service Centers, and

Delta Authorized Service Stations. Please visit our Web Site www.deltamachinery.com for a catalog or for the name of

your nearest supplier.

Since accessories other than those offered by Delta have not been tested with this product, use

of such accessories could be hazardous. For safest operation, only Delta recommended accessories should be

used with this product.

Service Center, visit our website at www.deltamachinery_,

corn or call our Customer Care Center at 1-800-223-7278.

All repairs made by our service centers are fully guaranteed

against defective material and workmanship. We cannot

guarantee repairs made or attempted by others.

You can also write to us for information at Delta Machinery,

4825 Highway 45 North, Jackson, Tennessee 38305 -

Attention: Product Service. Be sure to include all of the

information shown on the nameplate of your tool (model

number, type, serial number, etc.)

23

Page 24

Toregisteryourtoolforwarrantyservicevisitourwebsiteatwww.deltamachinery.com.

Two Year Limited New Product Warranty

Delta will repair or replace, at its expense and at its option, any new Delta machine, machine part, or machine accessory which in normal

use has proven to be defective in workmanship or material, provided that the customer returns the product prepaid to a Delta factory service

center or authorized service station with proof of purchase of the product within two years and provides Delta with reasonable opportunity

to verify the alleged defect by inspection. For all refurbished Delta product, the warranty period is 180 days. Delta may require that electric

motors be returned prepaid to a motor manufacturer's authorized station for inspection and repair or replacement. Delta will not be responsible

for any asserted defect which has resulted from normal wear, misuse, abuse or repair or alteration made or specifically authorized by anyone

other than an authorized Delta service facility or representative. Under no circumstances will Delta be liable for incidental or consequential

damages resulting from defective products. This warranty isDelta's sole warranty and sets forth the customer's exclusive remedy, with respect

to defective products; all other warranties, express or implied, whether of merchantability, fitness for purpose, or otherwise, are expressly

disclaimed by Delta.

24

Page 25

r w w

FRAN(_AIS

25

Page 26

_: 'vH - ' ' Life et comprendre toutes instructions d'avertissements et operation avant d'utiliser

n'importe queJ outJJ ou n'importe quel _quipement. En utiJisant les outils ou I'_quJpement, les precautions de s_ret_

fondamentales toujours devraient _tre suivies pour r_duire le risque de blessure personnelJe. L'op_ration d_plac_e,

I'entretien ou la modification d'outils ou d'_quipement ont pour r_sultat la blessure s_rieu× et les dommages

de proprietY. IJ y a de certaines appJicatJons pour Jequel outils et I'_quipement sont con_us. La Delta Machinery

recommande avec force que ce produit n'ait pas modifi_ et/ou utJJis_ pour I'application autrement que pour lequel iJ

a _t_ con_u.

Si vous avez n'importe quelles questions relatives & son application n'utilisent pas le produit jusqu'& ce que vous avez ecrit

Delta Machinery et nous vous avons conseille.

La forme en ligne de contact & www.deltamachinery.com

Courrier Postal: Technical Service Manager

Delta Machinery

4825 Highway 45 North

Jackson, TN 38305

Information en ce qui concerne I'op_ration sore et correcte de cet outil est disponible des sources suivantes:

Power Tool Institute

1300 Sumner Avenue, Cleveland, OH 44115-2851

www.powertoolinstJtute.org.

National Safety Council

1121 Spring Lake Drive, Itasca, IL 60143-3201

American National Standards Institute, 25 West 43rd Street, 4 floor, New York, NY 10036 www.ansi.org. ANSI 01.1 Safety

Requirements for Woodworking Machines, and the U.S. Department of Labor regulations www.osha.q_O_

Ce guide contient des renseignements importants gue vous deviez bien saisin Cette information porte sur VOTRE

SECLIRITE et sur LA PREVENTION BE PROBLEMES D'EQUIPEMENT. Afin de vous aider & identifier cette

information, nous avons utilise les symboles ci-dessous. Veuillez life attentivement ce guide en portant une attention

particuli@e a ces sections.

Indique un danger imminent qui, s'iJ n'est pas _vit_, causera de graves blessures ou la mort.

Indique la possibiJit_ d'un danger qui, s'iJ n'est pas _vit_, pourrait causer de graves blessures

ou la mort.

Indique la possibilit_ d'un danger qui, s'iJ n'est pas _vit_, peut causer des dommages a la proprietY.

Sans le symbole d'alerte.lndique la possibiJit_ d'un danger qui, s'il n'est pas _vit_, peut causer des

dommages; mineures ou moyennes.

LA PROPOSiTiON DE CAUFORNIE 65

La poussi_re produite par Je port,age _Jectrique le sciage, le meulage, le pergage et autres

activJt_s de construction peut contenir des produits chimiques qui sont reconnus, par I'_tat de la CaJifomie, de causer

le cancer, les anomalies cong_nitales ou autres mau× de reproduction. Ces produits chJmiques comprennent, entre

autres :

,, le plomb provenant des peintures & base de plomb;

o la silice cristalline provenant de briques, de beton ou d'autres produits de magonnerie

• I'arsenic et le chrome provenant du bois de charpente trait_ chimiquement

Le risque d'exposition & ces produits depend de la fr_quence d'execution de ce genre de travaux. Afin de reduire I'exposition

& ces produits chimiques, travaillez darts un endroit bien a@6 et utilisez de I'equipement de securit_ approuv_, portez toujours

un masque facial ou respirateur homologue MSHA/NIOSH bien ajuste Iorsque vous utilisez de tels outils.

CONSERVEZ CES INSTRUCTIONS!

26

Page 27

L'inobservation de ces r_gles peut conduire b des blessures graves.

1. POUR SA S¢:CURIT_: PERSONNELLE, LIRE LA NOTICE

D'UTILISATION, AVANT DE METTRE LA MACHINE EN

MARCHE, et pour aussi apprendre I'applicationet les limitesde

la machine ainsi que les risques qui lui sont particuliers ainsi, les

possibilit6s d'accident et de blessures seront beaucoup reduites.

2. PORTEZ DES DISPOSITIFS DE PROTECTION DES YEUX

ET DE L'OUi'E. UTILISEZ TOUJOURS DES LUNETTES DE

S#:CURITE. Des lunettes ordinaires ne constituent PAS des

lunettes de securit& UTILISEZ DES }_QUIPEMENTS DE

SURETE HOMOLOGU}_S. Lesdispositifs de protection des yeux

doivent _tre conformes aux normes ANSI Z87.1. Les dispositifs

de protection de I'ouTedoivent _tre conformes aux normes ANSI

$3.19.

3. PORTER UNE TENUE APPROPRIEE. Pas de cravates, de

gants, ni de v_tements amples. Enlever montre, bagues et autres

bijoux. Rouler les manches. Les v_tements ou les bijoux qui

se trouvent pris dans les pieces mobiles peuvent entrainer des

blessures.

4. NE PASUTILISER LA MACHINE DANS UN ENVIRONNEMENT

DANGEREUX. L'utilisation d'outils electriques dans des

endroits humides ou sous la pluie peut entrafner des decharges

electriques ou une electrocution. Garder la zone de travail bien

6clairee pour &viter de tr6bucher ou d'exposer les doigts, les

mains ou les bras & une situation dangereuse.

5. GARDER LES OUTILS ET LES MACHINES EN PARFAIT

_:TAT.Garder les outils aff[_t6set propres afin d'obtenir le meilleur

et le plus sOr rendement. Suivre les instructions pour lubrifier

et changer les accessoires. Les outils et les machines mal

entretenus peuvent se degrader davantage, eVou entrainer des

blessures.

6. INSPECTER LES PI#CES POUR DECELER TOUT DOMMAGE.

Avant d'utiliser la machine, la verifier pour voir s'il n'y a pas de

pi_ces endommagees. Wrifier I'alignement des pieces mobiles

et si ces pieces nese coincent pas, la rupture de pieces, ou toute

autre condition pouvant en affecter le fonctionnement. Toute

piece ou protecteur endommage dolt _tre repar6 ou remplac&

Les pieces endommagees peuvent degrader davantage la

machine et/ou entrafnerdes blessures.

7. GARDER L'AIRE DE TRAVAIL PROPRE. Les zones et etablis

encombres favorisent les accidents.

8. GARDER LES ENFANTS ET LES VlSITEURS A DISTANCE.

L'atelier est un lieu potentiellement dangereux. Les enfants et les

visiteurs peuvent se blesser.

9. _:VITER LE DEMARRAGE ACCIDENTEL. S'assurer que

I'interrupteur est sur <<OFF ,, (ARRCT) avant de brancher le

cordon. En cas de coupure de courant, placer I'interrupteur

& la position <<OFF ,, (ARRE_). Un d6marrage accidentel peut

entrainer des blessures.

10. UTILISER LES DISPOSITIFS PROTECTEURS. Wrifier que tous

les dispositifs protecteurs sont bien en place, bien fixes et en bon

&tat de marche pour eviter les blessures.

11. ENLEVER LES CLES DE REGLAGE ET CELLES DE SERRAGE

AVANT DE METTRE LA MACHINE EN MARCHE. Les outils,

les chutes et les autres debris peuvent _tre projetes violemment

et blesser.

12. UTILISER LA BONNE MACHINE. Ne pas forcer la machine ou

I'accessoire & faire un travail pour lequel il n'a pas et6 con;u.

Des dommages & la machine et/ou des blessures pourraient

s'ensuJvre.

13. UTILISER LES ACCESSOIRES RECOMMAND¢:S. L'utilisation

d'accessoires non recommandes par Delta peut endommager la

machine et blesser I'utilisateur.

14. UTILISER LE CORDON PROLONGATEUR APPROPRIE.

S'assurer que le cordon prolongateur est en bon etat. Lorsqu'un

cordon prolongateur est utilis&, s'assurer que celui-ci est d'un

calibre suffisant pour I'alimentation necessaire & la machine. Un

cordon d'un calibre insuffisant entra_nera une perte de tension

d'o[_ une perte de puissance et surchauffe. Voir le tableau sur

les cordons prolongateurs pour obtenir le calibre approprie selon

la Iongueur du cordon et I'amp&rage de la machine. S'il y a un

doute, utiliser un cordon d'un calibre sup&rieur. Plus le chiffre est

petit, plus lefil est gros.

15. FIXER LA PI#CE. Utilisez les brides ou I'etau quand vous ne

pouvez pas fixer I'objet sur la table et contre la barriere &la main

ou quand votre main sera dangereusement pres de la lame (&

moins de 6").

16. AVANCER LA PI#CE DANS LE SENS CONTRAIRE A LA

ROTATION DE LA LAME, DE LA FRAISE OU DE LA SURFACE

ABRASIVE. L'alimentation dans I'autre sens peut entrainer une

projection violente de lapiece.

17. NE PAS FORCER LA MACHINE EN AVAN(_ANT LA PI#CE

TROP VlTE. Des dommages et/ou des blessures peuvent

s'ensuivre.

18. NE PAS SE PENCHER AU-DESSUS DE LA MACHINE. Une

perte de I'equilibre peut entrafner une chute sur la machine en

marche et causer des blessures.

19. NE JAMAIS MONTER SUR LA MACHINE. On peut se

blesser gravement si la machine bascule ou si I'on touche

accidentellement son outil tranchant.

20. NE JAMAIS LAISSER LA MACHINE EN MARCHE SANS

SURVEILLANCE. COUPER LE COURANT. Ne pas quitter la

machine tant qu'elle n'est pas compl_tement arr_tee. Un enfant

ou un visiteur pourrait se blesseE

21. METTRE LA MACHINE A L'ARR_:T ,, OFF ,, ET LA

Di_BRANCHER avant d'installer ou d'enlever des accessoires,

d'ajuster ou de changer des montages, ou lots des r_parations.

Un demarrage accidentel peut entra_nerdes blessures.

22. METTRE L'ATELIER A L'ABRI DES ENFANTS AU MOYEN

DE CADENAS, D'INTERRUPTEURS PRINClPAUX OU EN

ENLEVANT LES BOUTONS DES DISPOSITIFS DE MISE EN

MARCHE. Le d&marrage accidentel de la machine par un enfant

ou un visiteur peut entrafner des blessures.

23. RESTER ViGiLANT, ATTENTIF, ET FAIRE PREUVE DE BON

SENS. NE PAS UTILISER LA MACHINE LORSQUE L'ON EST

FATIGUe:OU SOUS L'INFLUENCE DE DROGUES, D'ALCOOL

OU DE Mi_DICAMENTS. Un instant d'inattention Iors de

I'utilisation d'outils electriques peut entrainer des blessures

graves.

24. _ L'UTILISATION DE CET OUTIL

PEUT PRODUIRE ET DISPERSER DE LA POUSSI_:RE OU

D'AUTRES PARTICULES EN SUSPENSION DANS L'AIR,

TELLES QUE LA SClURE DE BOIS, LA POUSSI#RE DE

SILIClUM CRISTALLIN ET LA POUSSI#:RE D'AMIANTE.

Dirigez les particules loin du visage et du corps. Faites

toujours fonctionner I'outil dans un espace bien ventile et

prevoyez I'evacuation de la poussiere. Utilisez un systeme

de depoussierage chaque fois que possible. L'exposition

la poussi_re peut causer des problemes de sant_ graves et

permanents, respiratoires ou autres, tels que la silicose (une

maladie pulmonaire grave) et le cancer, et m_me le d_c_s de

la personne affect_e. Evitez de respirer de la poussi_re et de

rester en contact prolonge avec celle-ci. En laissant la poussiere

pen_trer dans vos yeux ou votre bouche, ou en la laissant

reposer sur votre peau, vous risquez de promouvoir I'absorption

de substances toxiques. Portez toujours des dispositifs de

protection respiratoire homologues par NIOSH/OSHA, appropries

&I'exposition & lapoussiere et detaille appropriee, et lavez & I'eau

et au savon les surfaces de votre corps qui ont et_ exposees.

27

Page 28

L'inobservation de ces r_gles peut conduire b des blessures graves.

1. NE PAS FAIRE FONCTIONNER CET APPAREIL

avant qu'il ne soit assembl_ et install_ conform_ment

aux directives.

2. CONSULTER le superviseur, instructeur, ou autre

personne qualifi_e si vous n'_tes pas familiaris6 avec

le fonctionnement de cet outil.

3. SUIVRE TOUSLES CODES DE CABLAGE et les

connexions 61ectriques recommand6es.

4. UTILISER LES DISPOSITIFS DE PROTECTION

CHAQUE FOIS QUE POSSIBLE. V@ifier qu'ils

sont bien en place, correctement r_gl6s, fix6s et

fonctionnent correctement.

5. UTILISER LA BONNE TAILLE DE LAME et le bon

type.

6. AJUSTER LE GUIDE SUPF:RIEUR DE LA LAME

pour qu'il soit environ & 3,2 mm (1/8 po) au-dessus de

la piece.

7. AJUSTER CORRECTEMENT la tension de la lame,

I'alignement, les guides de lame et les roulements

d'appui de la lame.

8. ELOIGNER LES BRAS, MAINS, ET LES DOIGTS de

la lame.

9. EVITER LES OPERATIONS MALADROITES et 6viter

de placer les mains & un endroit ou un glissement

soudain pourrait amener la main sur la lame.

10. NE JAMAIS DF:MARRER L'APPAREIL avant d'avoir

d_barrass6 la table de tousles objets (outils, d6chets

de d_coupe, etc.).

11. NE JAMAIS DI_MARRER UAPPAREIL avec la piece

contre la lame.

12. TENJR FERMEMENT LA PI#CE contre la table. NE

PAS essayer de scier une piece qui ne comporte pas

un c6t_ plat contre la table.

13. TENJR FERMEMENT LA PI#CE et I'acheminer sous

la lame & une vitesse mod@_e.

14. NE JAMAIS SE PENCHER SOUS LA TABLE alors

que I'appareil est en marche.

15. ETEINDRE UAPPAREIL pour reculer Iors d'une coupe

incomplete ou d'une lame coinc_e.

16. FAIRE DES COUPES DE _ REDRESSEMENT ,9avant

de couper de Iongues courbes.

17. F:TEINDRE L'APPAREIL et attendre que la lame

s'immobilise avant de nettoyer la section de la lame,

de retirer les d6bris pros de la lame, de retirer et de

fixer la piece ou de modifier I'angle de la table. Une

lame d_bray6e peut _tre dangereuse.

18. NE JAMAIS EFFECTUER D'OPERATIONS DE

TRA(_AGE, D'ASSEMBLAGE, ou de r6glage sur

la table/l'espace de travail Iorsque I'appareil est en

marche.

19. ETEINDRE UAPPAREIL ET COUPER LE COURANT

avant d'installer ou de retirer des accessoires, avant

tout r_glage ou modifications de ceux-ci ou Iors de

r_parations.

20. F:TEINDRE L'APPAREIL, couper le courant, et

nettoyer la table/l'espace de travail avant de quitter

I'appareil. VERROUILLER L'INTERRUPTEUR EN

POSITION _ D'ARR#T,9 pour 6viter toute utilisation

non autoris6e.

21. DES JNFORMATIONS SUPPLEMENTAIRES (c.-

&-d., une vid6o sur la s_curit_), indiquant comment

utiliser des outils 61ectriques correctement et en toute

s6curit6, sont disponibles aupr_s du Power Tool

Institute, 1300 Sumner Avenue, Cleveland, OH 44115-

2851, Etats-Unis (www.powertoolinstitute.com). Des

renseignements sont _galement disponibles aupr_s

du National Safety Council, 1121 Spring Lake Drive,

Itasca, IL 60143-3201 E.-U. Se reporter & la norme

ANSI 01.1 de I'American National Standards Institute

concernant les machines de travail du bois, ainsi

qu'& la r_glementation OSHA 1910.213. du minist@e

am@icaJn du travail.

CONSERVER CES INSTRUCTIONS.

Consultez les souvent et utilisez les pour enseigner de

nouveaux op rateurs.

RACCORDEMENTS leLECTRIQUES

Un circuit 61ectrique s6par6 dolt _tre utilis6 pour les machines. Les ills de ce circuit doivent _tre au moins de calibre 12.

Ce circuitdoit _tre prot_g_ par un fusible temporis_ de 20 A. Si on utilise un cordon prolongateur, ce cordon dolt _tre

trois ills, avoir unefiche & trois broches et une prise de courant & trois cavit_s, mise & la terre qui correspond & la fiche

de la machine. Avant debrancher la machine, s'assurer que I'interrupteur (les interrupteurs) se trouve(nt) en position

,_OFF >_(ARRIt:T) et que le courant_lectrique pr_sente les m_mes caract@istiques que celles qui sont inscrites sur la

machine. Toutes les connexions _lectriquesdoivent _tablir un bon contact. Le fonctionnement sur une basse tension

endommagera la machine.

Ne pas exposer la machine a la pluie, et ne pas I'utiliser darts des endroits humides.

SPC:CIFICATIONS DU MOTEUR

Cette machine est c&bl_e pour un fonctionnement sur un courant alternatif de 120 volts 60 Hz. Avant de brancher la machine,

s'assurer que I'interrupteur setrouve & la position ,, OFF _(ARRET).

28

Page 29

iNSTRUCTiONS DE MISE A LA TERRE

Cette machine dolt _tre raise a la terre pendant son emploi, afin de prot_gerl'utilisateur des d_charges

_lectriques

1. Toutes les machines avec cordon misa la terre: Dans I'eventualite d'un mauvais fonctionnement ou d'unepanne, la

mise & la terre fournit un trajet de moindre r6sistancepermettant de reduire le risque de decharge _lectrique. Cettemachine

est dot6e d'un cordon electrique poss6dant unconducteur de mise & la terre de I'equipement ainsi que d'unefiche mise

& la terre. La fiche dolt _tre branchee dans une prisede courant correspondante, installee de fagon adequate etmise & la

terre conform_ment &tousles codes et reglementslocaux.

Ne pas modifier la fiche fournie - si elle ne s'adapte pas & laprise de courant, il faut faire installer une prise de

courantconvenable par un electricien competent.

Un mauvais raccordement du conducteur de mise & la terrede I'equipement peut entrafner un risque de

decharge61ectrique. Le conducteur poss6dant un isolant avec surfaceext_rieure de couleur verte, avec ou sans rayures

jaunes, estle conducteur de mise b, la terre de I'equipement. Si unereparation ou un remplacement du cordon _lectrique

s'averen_cessaire, ne pas brancher le conducteur de mise & la terrede I'equipement & une borne sous tension.

Consulter un electricien competent ou le personnel de serviceapres-vente si on ne comprend pas entierement

lesinstructions de mise &la terre, ou si I'on doute que la machinesoit correctement mise & la terre.

Utiliser seulement des cordons prolongateurs & trois ills dot_sd'une fiche mise & la terre, & trois broches, et de prises &

troiscavit_s convenant & la fiche de la machine, comme I'illustre lafigure A.

Reparer ou remplacer sans d_lai tout cordon endommage ouus6.

2. Machines avec cordon misa la terre pr_vues pour uneutilisation sur une alimentation nominale inf_rieure

&150volts :Si cette machine est pr_vue pour _tre utilis6e sur un circuit quicomporte une prise semblable & celle illustree

& la figure A, lamachine devra comporter une fiche raise & la terre semblable& celle illustree & la figureA. Un adaptateur

temporairesemblable & celui illustr6 & la figureB, peut _tre utilise pourraccorder cette fiche & une prise & deux cavit6s

comme celleillustree & la figure B, si une prise correctement miss & la terren'est pas disponible. L'adaptateur temporaire ne

dolt _treutilis6 que jusqu'au moment o0 une prise correctement raise& la terre est install6e par un 61ectricien competent.

L'oreillerigide ou autre dispositif semblable de couleur verte, sur ledessus de I'adaptateur, doit _tre connect_ sur une

raise & laterre permanente comme, par exemple une botte & prisescorrectement raise & la terre. Quand un adaptateur est

utilise,celui-ci dolt 6tre retenu en place par une visen metal.

REMARQUE: Au Canada, le Code canadien de I'_lectricit_ne permet pas I'emploi d'un adaptateur temporaire.

Darts tousles cas, s'assurer quela prise en question est bien raise & la terre. Darts le doute, demander

un p_tentde v_rifier la prise.

Bofte & prises raise a la terre

Broches

Lla broche de__

plus Ionguedes trois

Fig. A

CORDON DE RALLONGE

EmpIoyez les cordes

appropri_es de prolongation, s'assurent votre corde

de prolongation est en bon _tat. en utilisant une corde

de prolongation, soyez s_r d'empIoyer un assez Iourd

pour porter le courant de la machine, une corde trop

petite causera une baisse darts la tension secteur, ayant

pour r_sultat la perte de puissance et de surchauffe, fig.

d-1 or d-2, expositions la mesure correcte & employer

selon la Iongueur de corde, en cas de doute, utilisez

la prochaine mesure plus Iourde. plus le hombre de

mesure est petit, plus la corde est Iourde.

Fig. B

MESUR MiNiMUM DE CORDE D'EXTENSION

TAILLES RECOMMANDEES POUR L'CUSAGE AVEC STATIONNAIRES ELECTRIQUES LES OUTILS

Longueur

Estimation

pere

0-6

0-6

0-6

0-5

6-10

6-10

6-10

6-10

10-12

10-12

10-t2

10-12

12-16

12-t6

12-t6

Volts

120

120

120

120

120

120

120

120

120

120

120

120

120

120

120

Totale De

Corde En Mesure De Corde D'Am

Pieds D'E×tension

up to 25 t8 AWG

25-50 t 6 AWG

50-100 t6 AWG

t00-150 t4 AWG

up to 25 t8 AWG

25-50 t6 AWG

50-t00 t4 AWG

t00-150 t2 AWG

up to 25 t6 AWG

25-50 t 6 AWG

50-100 t 4 AWG

t00-150 t2 AWG

up to 25 t4 AWG

25-50 t2 AWG

50 PI PLUS GRANDS QUE NON RECQMMANDES

Fig. D

29

Page 30

AVANT=PROPOS

La scie &ruban Delta module BS150LS de 254 mm (10 po) est dot_e d'un puissant moteur de 1/2 HP mont_ sur rou-

lement & billes pour une performance 61ev_ et une Iongue dur_e. La profondeur de coupe maximale de la scie est de

17,7 cm (7 po). Le module BS150LS est livr_ avec une table en fonte et un robuste socle en acier qui fournit un appui

solide et une hauteur de travail confortable.

REMARQUE : La photo de la couverture du mode d'emploi illustre le mod&le de production actuel. Les autres illustra-

tions de ce mode d'emploi ne sont pr_sentes qu'& titre indicatif et il est possible que les 6tiquettes et accessoires actuels

different des caract_ristiques r_elles de ce module. Ces illustrations ont uniquement pour but d'illustrer latechnique.

7

I

Fig. 1

Fig. 2

1. Scie& ruban

2. (16) ecrous hexagonaux M8

3. (16) rondelles plates de 9,5 mm (3/8 po)

4. 16) rondelles de blocage M8

5. 16) ecrous hexagonaux M8

6. (2) colliers du cordon d'alimentation de la lampe

7. Cle hexagonale de 5 mm

8. CI_ hexagonale de 4 mm

9. Cl_ hexagonale de 3 mm

10. (4) visa t_te hexagonale M8 x 45 mm)

11. (8) rondelles plates de 9,5 mm (3/8 po)

12. (4) rondelles de blocage M8

13. (4) ecrous hexagonaux M8

14. (4) pattes du socle

15. (2) visa pans creux & filetage autofreinant (Nylock)

M6 x 20 mm pour la lampe

16. (2) rondelles de blocage M6 pour la lampe

3O

Page 31

DI'=SEMBALLAGE ET NETTOYAGE

D6semballer soigneusement la machine et toutes les pi_ces de ou des emballage(s) d'exp6dition. Retirer I'huile anti-

corrosion des surfaces non peintes & I'aide d'un chiffon doux humidifi6 avec de I'alcool, du diluant & peinture ou de

I'alcool d6natur6.

N'utiliser pas de solvants hautement volatils tel I'essence, le naphte, I'ac6tone ou du diluant

a laque pour nettoyer.

Apr_s nettoyage, couvrir les surfaces non peintes d'une cire & parquets d'usage domestique de bonne qualit6.

Pour sa propre s_curit_, ne pas brancher I'appareil a une source d'alimentation jusqu'a ce

qu'il soit enti_rement assembl6, ni avant d'avoir lu et compris I'int_gralit_ de ce mode d'emploi.

OUTILS Ni_CESSAIRES POUR L'ASSEME}LAGE

1. Cle hexagonale de 3 mm - fournie

2. Cle hexagonale de 4 mm - fournie

3. Cle hexagonale de 5 mm - fournie

4. Douille M8 - non fournie

5. Cle M8 - non fournie

DURI_E ESTIMi'=E POUR L'ASSEME}LAGE :

env. 2 & 3 heures.

ASSEMBLAGE DU SOCLE

1. Assembler le socle comme I'illustre la fig. 4, & I'aide

des pi_ces pr6sent6es & la fig. 3. Les traverses et

les pattes sont identifi6es par les m6mes lettres

sur les deux photos. Ins6rer les vis de carrosserie

M8x16 mm dans les pattes et les traverses puis

enfiler les rondelles plates de 9,5 mm (3/8 pc), suivies

des rondelles de blocage M8 et fixer solidement avec

les 6crous hexagonaux M8. Pour le moment, serrer

les 6crous &la main seulement.

REIVIARQUE : positionner les bords sup6rieurs des

traverses sup6rieures (A) par-dessus les traverses avant

et arri@e (B).

2. Ins6rer les quatre pieds de plastique (1) fig. 4, au bas

de chaque patte (L).

Fig. 4

ASSEMBLAGE DE LA SClE/_ RUE}AN AU

SOCLE

1. La fig. 5 illustre les quatre trous d6bouchants (A) qui

fixeront la scie & ruban au socle.

2. Installer la scie & ruban sur le dessus du socle et

aligner les trous (A) fig. 5, avec ceux (D) fig. 6, des

traverses sup6rieures du socle.

Fig. 5

31 Fig. 6

Page 32

3_

Enfiler une rondelle plate de 9,5 mm (3/8 po) (H) fig.

7, sur la vis & t6te hexagonale M8 x 45 mm. Ins@er

la vis dans le trou de la scie & ruban et dans le trou

du socle. R6p6ter I'assemblage pour les trois autres

trous.

4_

Enfiler une rondelle plate de 9,5 mm (3/8 po) sur

la vis (D) fig. 8, suivi d'une rondelle de blocage M8

puis visser un _crou hexagonal et serrer solidement.

R6p6ter I'assemblage pour les trois autres trous.

5_ Pousser sur le dessus de la scie & ruban et s'assurer

que les quatre pattes du socle s'appuient sur la

surface portante. Serrer toute la quincaillerie du

socle.

Fig. 7

ASSEMBLAGE DE LA TABLE SUR

L'APPAREIL

Retirer le levier de verrouillage de la table (A) fig. 1O,

et le bouton d'inclinaison de la table (B). Veuillez

prendre soin de ne pas perdre ces pi_ces. (Ces

composants ont _t6 assembl6s & I'usine & des fins

de transport seulement.)

2_

Retirer la vis d'arr_t, la rondelle et 1'6crou papillon

de la rainure de la table (consulter la fig. 17 pour les

d6tails). Veuillez prendre soin de ne pas perdre ces

pi_ces.

3_

Installer la table (H) fig. 11, sur le b&ti de la scie

ruban de sorte que les vis d'arr_t (K) d6passent par

la rainure du tourillon (L).

Fig. 8

Fig. 10

32

Fig. 11

Page 33

4. Remonterlegoujondu levierdeverrouillage(G)fig.

12,parlarainuredutourillon(L)puisleserreravecla

poign6edulevierdeverrouillage(consulterI'encart).

5. Lafig. 13illustrele levierdeverrouillaged_mont6

(retir6&I' F:TAPE 1). L'article (B) est une rondelle

plate M10, (G) un goujon, (A) un levier de verrouillage,

(E)un ressort, (D)une vis & 6paulement et (C) une cl6

hexagonale de 4 mm.

6. Remonter la vis (D) fig. 13A et la serrer avec la cl_

hexagonale de 4 mm fournie.

Fig. 12

Fig. 13

7_

La fig. 14 illustre le bouton d'inclinaison de la table

(N), le ressort (O) et la vis sp_ciale (P), retires &

I'ETAPE 1.

8_

Remonter le bouton d'inclinaison de la table (N)

fig. 15, au dos de la scie de sorte que les dents du

pignon du bouton (N) s'engagent dans les dents du

tourillon (R). Le fixer & I'aide de la vis sp_ciale (P) et

du ressort avec la cl6 hexagonale de 4 mm fournie.

Fig. 13A

Fig.14

33

Fig.15

Page 34

9. Desserrerlavis(1-)fig.16,etalignerlepointeur(S)

avecle rep@ez@ode 1'6chelledu tourillon(M).

Serrersolidement.

REMARQUE:s'assurerquelatableestperpendicu-

laire&lalameouv@ifierI'alignementdupointeurune

loisquelesbuttesdelatableont6t6r6gl6es(consulter

larubrique<<RI_GLAGE DES BUTI_ES POSiTiVES DE

LA TABLE ,,).

10. Remettre la vis (W) fig. 17, qui a _t_ retiree

I'IeTAPE 2, dans le trou de la table. Enfiler une

rondelle plate M6 (Z) sur la vis M6 x 30 mm puis

visser I'_crou papillon M6 (X) sur la vis (W) et serrer

solidement.

Fig.16

FIXATION DE LA LAMPE SUR L'APPAREIL

1. Fixer le support de la lampe (A) fig. 18, sur le

couvercle sup@ieur de I'appareil & I'aide de deux

vis & pans creux _ filetage autofreinant (Nylock)

M6 x 20 mm (B) et de rondelles de blocage M6.

Serrer solidement avec la cl_ hexagonale de 5 mm

fournie.

2. D_coller I'endos des colliers de la lampe (C) fig.

19, et installer un collier _ chaque endroit illustr_.

S'assurer que le cordon de la lampe soit achemin6

loin de la lame, puis fixer le cordon d'alimentation (D)

aux colliers de cordon (C) fig. 19.

3. La lampe flexible fonctionne ind_pendamment de

la scie & ruban. Pour allumer ou 6teindre la lampe,

tourner I'interrupteur (E)fig. 19.

Fig. 17

Fig. 18