Page 1

Page 2

Preface

Thank you for choosing DELTA’s multi-function BLD-E1 Series. The BLD-E1 Series is manufactured

with high-quality components and materials and incorporate the latest microprocessor technology

available.

This manual is to be used for the installation, parameter setting, troubleshooting, and daily

maintenance of the brushless DC motor drive. To guarantee safe operation of the equipment, read

the following safety guidelines before connecting power to the brushless DC motor drive. Keep this

operating manual at hand and distribute to all users for reference.+

To ensure the safety of operators and equipment, only qualified personnel familiar with brushless DC

motor drive are to do installation, trial run and parameter setting. Always read this manual thoroughly

before using BLD-E1 series, especially the WARNING, DANGER and CAUTION notes. Failure to

comply may result in personal injury and equipment damage. If you have any question, please

contact your dealer.

PLEASE READ PRIOR TO INSTALLATION FOR SAFETY.

DANGER!

1. DC input power must be disconnected before any wiring to the brushless DC motor drive is

made.

2. There are highly sensitive MOS components on the printed circuit boards. These components

are especially sensitive to static electricity. To prevent damage to these components, do not

touch these components or the circuit boards with metal objects or your bare hands.

3. Never reassemble internal components or wiring.

4. Ground the BLD-E1 using the ground terminal. The grounding method must comply with the

laws of the country where the brushless DC motor drive is to be installed. Refer to the Basic

Wiring Diagram.

5. BLD-E1 series is used only to control variable speed of 3-phase induction motors, NOT for 1-

phase motors or other purpose.

6. BLD-E1 series shall NOT be used for life support equipment or any life safety situation.

7. To prevent personal injury, please keep children and unqualified people away from the

equipment.

Page 3

WARNING!

Never connect the output terminals U/T1, V/T2, and W/T3 of

brushless DC motor drive directly to the AC mains circuit power

supply.

DO NOT use Hi-pot test for internal components. The semi-

conductor used in brushless DC motor drive easily damage by

high-voltage.

A charge may still remain in the DC-link capacitors with hazardous

voltages, even if the power has been turned off. To prevent

personal injury, please ensure that power has turned off before

opening the brushless DC motor drive and wait for the capacitors

to discharge to safe voltage levels.

Only qualified persons are allowed to install, wire and maintain

brushless DC motor drives.

Some parameters settings can cause the motor to run

immediately after applying power.

CAUTION!

DO NOT install the brushless DC motor drive in a place subjected to high temperature, direct

sunlight, high humidity or liquids.

Only use brushless DC motor drives within specification. Failure to comply may result in fire,

explosion or electric shock.

When the motor cable between brushless DC motor drive and motor is too long, the layer

insulation of the motor may be damaged. Please use a specific brushless DC motor for the

brushless DC motor drive or add a reactor to prevent damage to the motor. Refer to appendix

B Reactor for details.

The rated voltage for brushless DC motor drive must be ≤ 240V (≤ 120V for 115V models and ≤

480V for 460V models).

Page 4

Table of Contents

Preface .............................................................................................................i

Table of Contents..........................................................................................iii

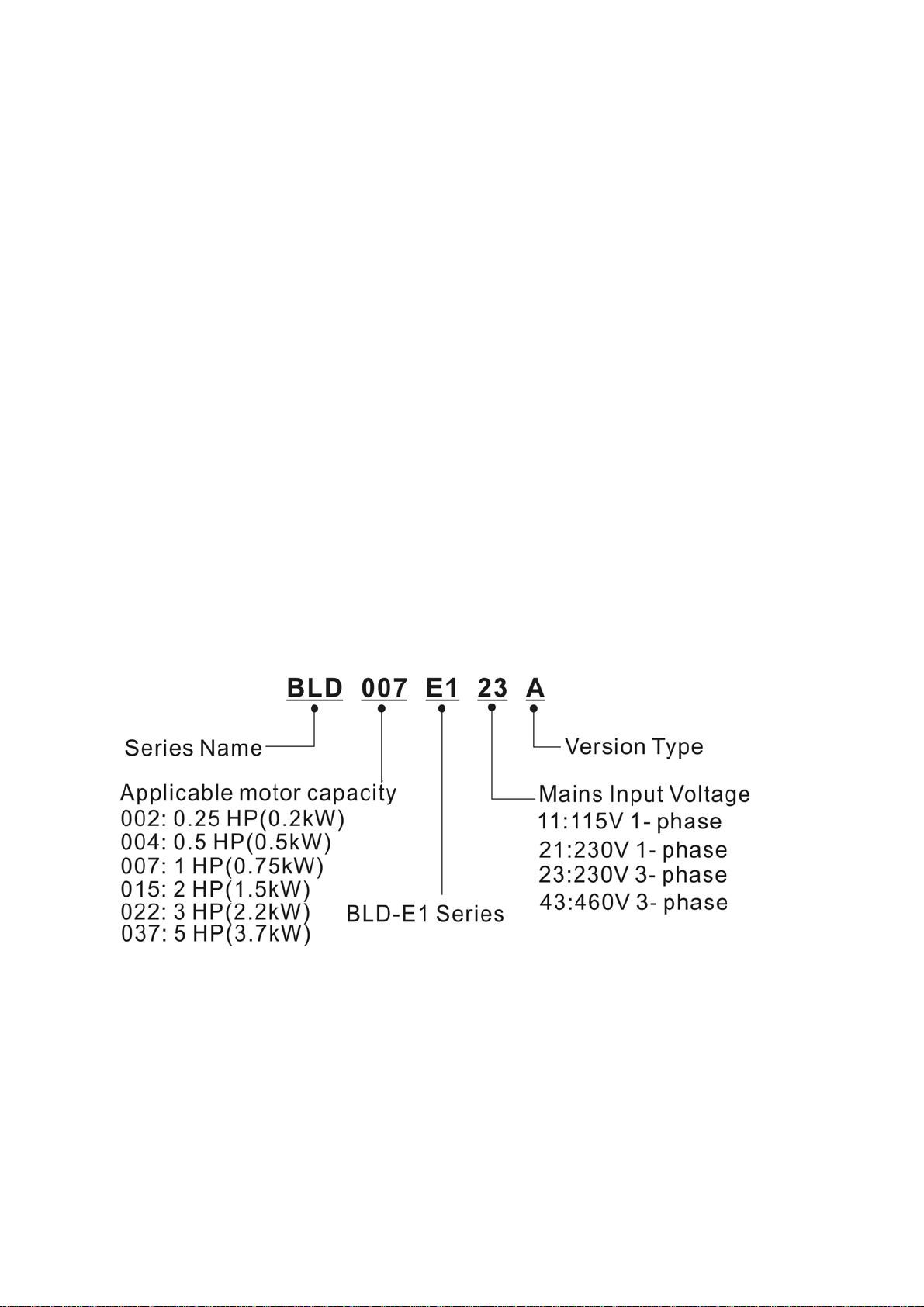

Chapter 1 Introduction................................................................................1-1

1.1 Receiving and Inspection..................................................................... 1-2

1.1.1 Nameplate Information................................................................ 1-2

1.1.2 Model Explanation ...................................................................... 1-2

1.1.3 Series Number Explanation ........................................................ 1-3

1.1.4 Drive Frames and Appearances ................................................. 1-3

1.1.5 Remove Instructions ................................................................... 1-8

1.2 Preparation for Installation and Wiring ................................................. 1-8

1.2.1 Ambient Conditions..................................................................... 1-8

1.2.2 DC-bus Sharing: Connecting the DC-bus of the Brushless DC

motor drive in Parallel ........................................................................ 1-10

1.3 Dimensions........................................................................................ 1-12

Chapter 2 Installation and Wiring ..............................................................2-1

2.1 Wiring .................................................................................................. 2-2

2.2 External Wiring .................................................................................... 2-6

2.3 Main Circuit.......................................................................................... 2-7

2.3.1 Main Circuit Connection.............................................................. 2-7

2.3.2 Main Circuit Terminals ................................................................ 2-9

2.4 Control Terminals .............................................................................. 2-10

Page 5

Chapter 3 Keypad and Start Up..................................................................3-1

3.1 Keypad.................................................................................................3-2

3.2 Operation Method ................................................................................3-6

3.3 Trial Run ..............................................................................................3-8

Chapter 4 Parameters..................................................................................4-1

4.1 Summary of Parameter Settings ..........................................................4-2

4.2 Description for Parameter Settings ....................................................4-33

Chapter 5 Troubleshooting.........................................................................5-1

5.1 Over Current (OC)................................................................................5-1

5.2 Ground Fault ........................................................................................5-2

5.3 Over Voltage (OV)................................................................................5-2

5.4 Low Voltage (Lv) ..................................................................................5-3

5.5 Over Heat (OH)....................................................................................5-4

5.6 Overload ..............................................................................................5-4

5.7 Keypad Display is Abnormal ................................................................5-5

5.8 Phase Loss (PHL) ................................................................................5-5

5.9 Motor cannot Run.................................................................................5-6

5.10 Motor Speed cannot be Changed ......................................................5-7

5.11 Motor Stalls during Acceleration.........................................................5-8

5.12 Electromagnetic/Induction Noise........................................................5-9

5.13 Environmental Condition ....................................................................5-9

5.14 Affecting Other Machines.................................................................5-10

Chapter 6 Fault Code Information and Maintenance................................6-1

6.1 Fault Code Information.........................................................................6-1

6.1.1 Common Problems and Solutions ...............................................6-2

Page 6

Chapter 1 Introduction| BLD-E1 Series

6.1.2 Reset .......................................................................................... 6-7

6.2 Maintenance and Inspections .............................................................. 6-7

Appendix A Specifications........................................................................ A-1

Appendix B Accessories ........................................................................... B-1

B.1 All Brake Resistors & Brake Units Used in the Brushless DC Motor Drive

............................................................................................................B-1

B.1.1 Dimensions and Weights for Brake Resistors ............................ B-3

B.2 No-fuse Circuit Breaker Chart .............................................................B-6

B.3 Fuse Specification Chart .....................................................................B-7

B.4 AC Reactor..........................................................................................B-8

B.4.1 AC Input Reactor Recommended Value.....................................B-8

B.4.2 AC Output Reactor Recommended Value.................................. B-8

B.4.3 Applications ................................................................................ B-9

B.5 Zero Phase Reactor (RF220X00A) ...................................................B-11

B.6 DIN Rail.............................................................................................B-12

Page 7

This page intentionally left blank

Page 8

Chapter 1 Introduction

The brushless DC motor drive should be kept in the shipping carton or crate before installation. In

order to retain the warranty coverage, the brushless DC motor drive should be stored properly when it

is not to be used for an extended period of time. Storage conditions are:

CAUTION!

1. Store in a clean and dry location free from direct sunlight or corrosive fumes.

°

2. Store within an ambient temperature range of -20

C to +60 °C.

3. Store within a relative humidity range of 0% to 90% and non-condensing environment.

4. DO NOT place on the ground directly. It should be stored properly. Moreover, if the surrounding

environment is humid, you should put exsiccator in the package.

5. DO NOT store in an area with rapid changes in temperature. It may cause condensation and

frost.

6. If the brushless DC motor drive is stored for more than 3 months, the temperature should not be

higher than 30 °C. Storage longer than one year is not recommended, it could result in the

degradation of the electrolytic capacitors.

7. When the brushless DC motor drive is not used for longer time after installation on building sites

or places with humidity and dust, it’s best to move the brushless DC motor drive to an

environment as stated above.

Revision May 2009, 00DE, V0.50 1-1

Page 9

Chapter 1 Introduction|BLD-E1 Series

1.1 Receiving and Inspection

This BLD-E1 brushless DC motor drive has gone through rigorous quality control tests at the factory

before shipment. After receiving the brushless DC motor drive, please check for the following:

Inspect the unit to assure it was not damaged during shipment.

Make sure that the part number indicated on the nameplate corresponds with the part

number of your order.

1.1.1 Nameplate Information

Example for 1HP/0.75kW 3-phase 230V brushless DC motor drive

1.1.2 Model Explanation

1-2 Revision May 2009, 00DE, V0.50

Page 10

Chapter 1 Introduction| BLD-E1 Series

1

4

T

A

1.1.3 Series Num b er Explanation

9

007E 123

230V 3-phase 1HP(0.75kW)

If the nameplate information does not correspond to your purchase order or if there are

any problems, please contact your distributor.

0

1

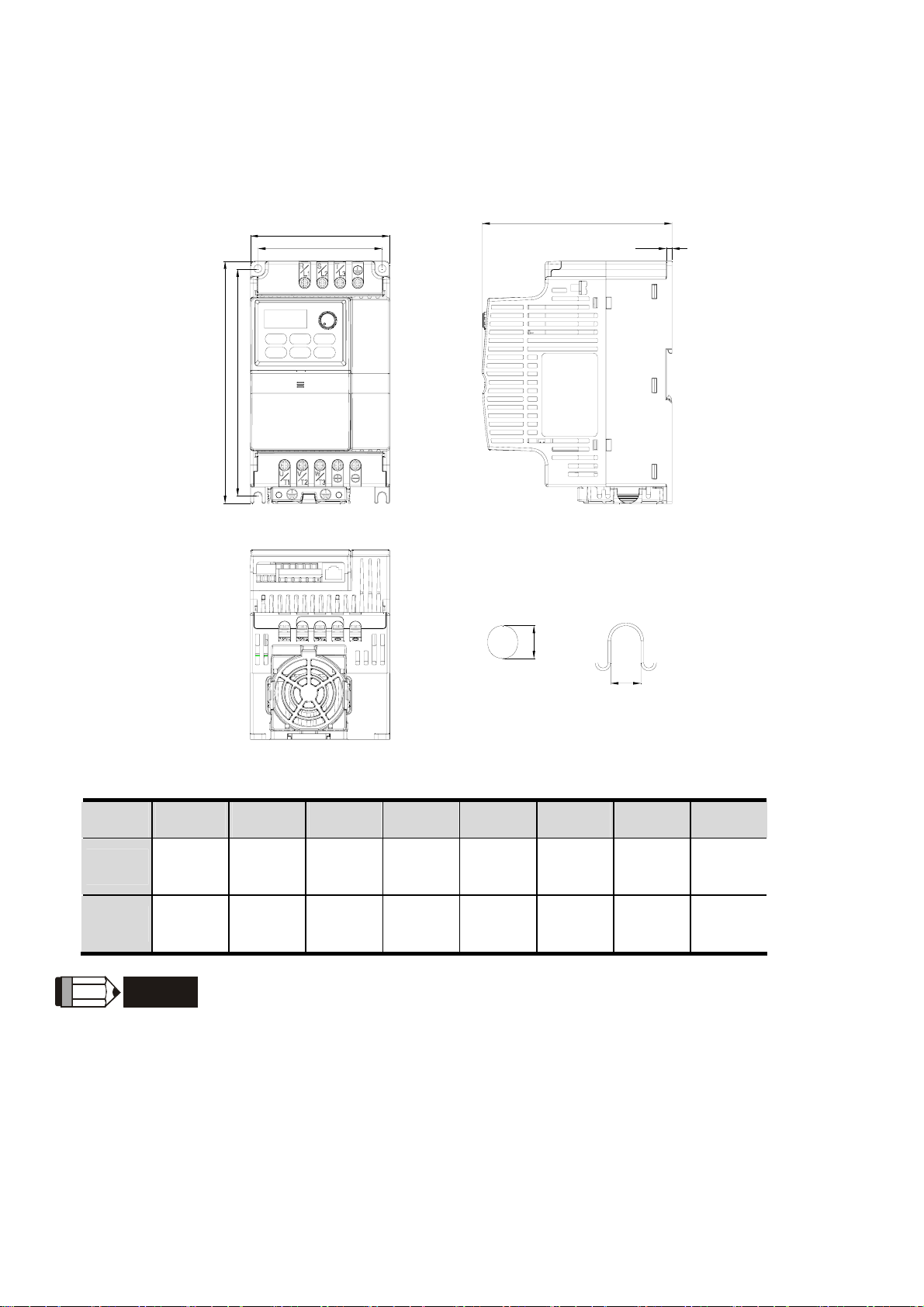

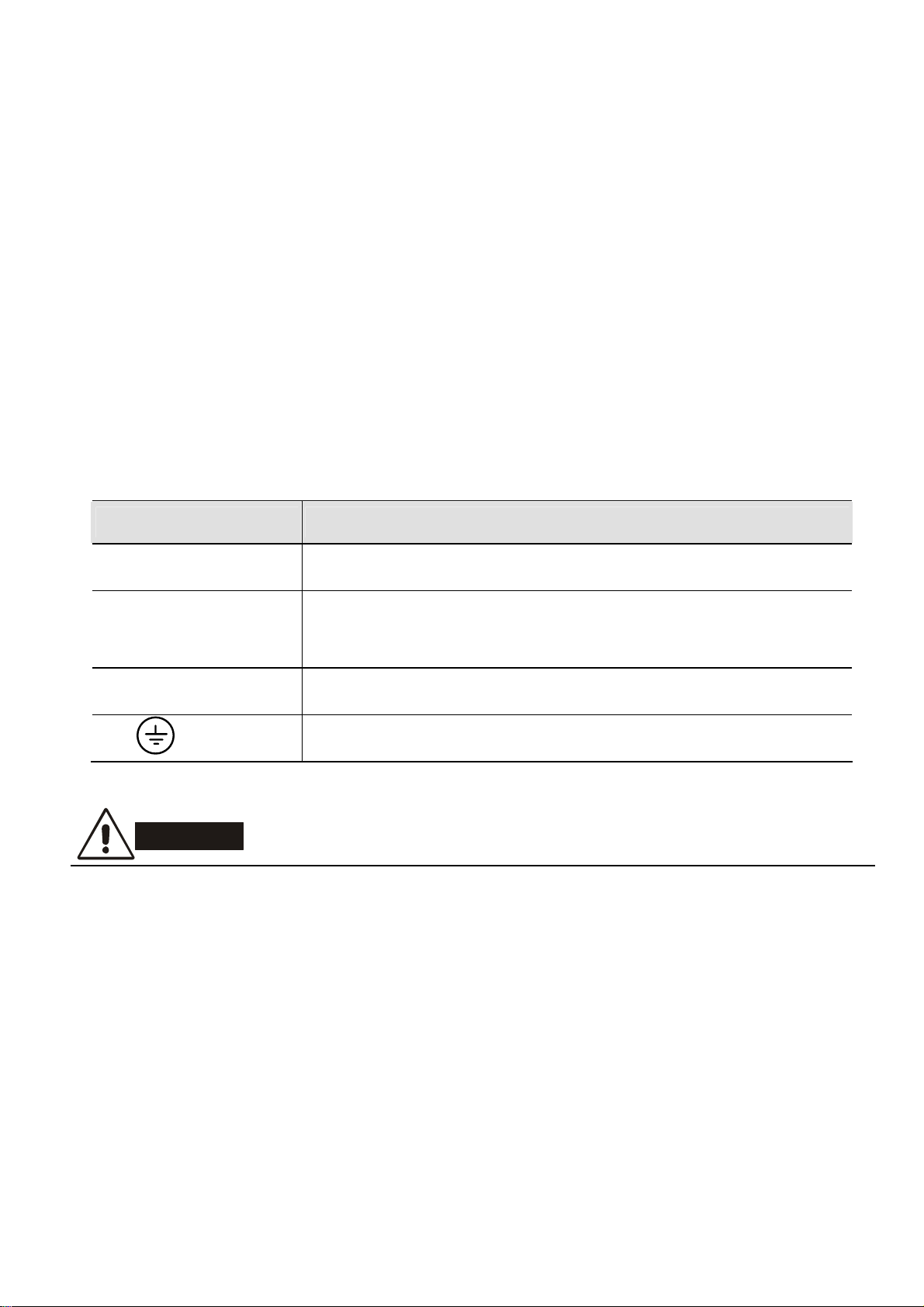

1.1.4 Drive Frames and Appearances

0.25-2HP/0.2-1.5kW (Frame A)

000

Production number

Production week

Production year 2009

Prod uction factory

T: Taoyuan, W: Wujiang

Model

Input terminals

(R/L1, S/L2, T/L3 )

1-5HP/0.75-3.7kW (Frame B)

Dig ital keypa d

Cont rol board cover

Output terminals

(U/T1, V/T2, W/T3)

Input terminals

(R/L1, S/L2, T/L3)

Digital keypad

Case body

Control board cover

Output terminals

(U/T1, V/T2, W/T3)

Revision May 2009, 00DE, V0.50 1-3

Page 11

Chapter 1 Introduction|BLD-E1 Series

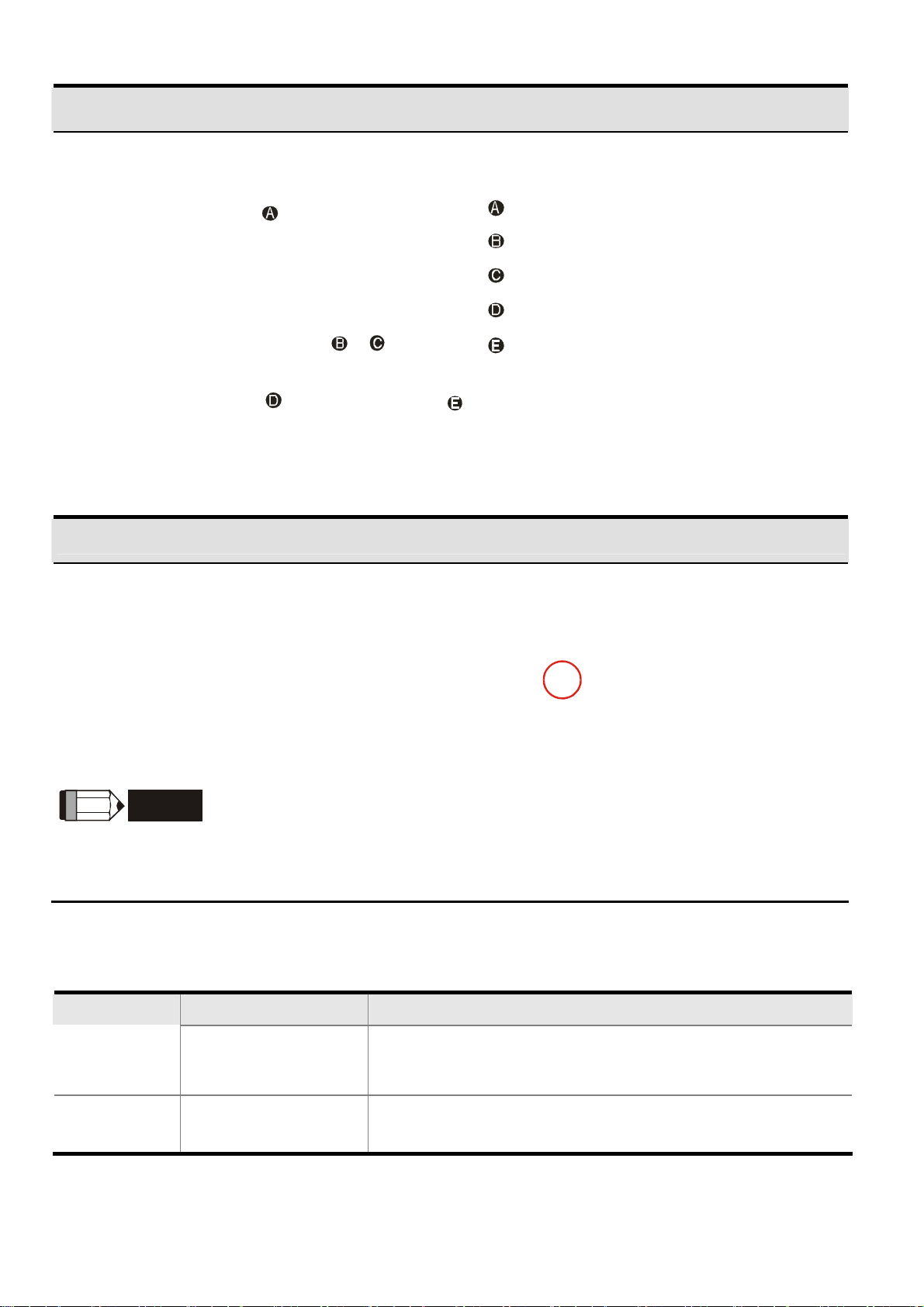

Internal Structure

Digital keypad

NPN/PNP

ACI/AVI

External terminals

RS485 port (RJ-45)

RFI Jumper Location

NOTE

The RFI jumper of frame A and frame B is beside the input terminals (R/L1, S/L2, T/L3) as circled in

above picture and can be removed by loosening the screws.

Frame Power range Models

BLD002E111A/121A/123A, BLD004E111A/121A/123A/

A

B

0.25-2hp (0.2-1.5kW)

1-5hp (0.75-3.7kW)

143 A, BLD007E121A/123A/143A, BLD015E123A/143A

BLD007E111A , BLD015E121A, BLD022E121A /123A/

143A, BLD037E123A/143A

1-4 Revision May 2009, 00DE, V0.50

Page 12

Chapter 1 Introduction| BLD-E1 Series

RFI Jumper

RFI Jumper: The brushless DC motor drive may emit the electrical noise. The EMI(electromagnetic

interference with standard Y capacity) is used to suppress the interference (Radio Frequency

Interference) on the power line. As the leakage current will be increased after using with EMI, user

can cut off the RFI when reducing the leakage current is required.

Main power isolated from earth:

If the brushless DC motor drive is supplied from an isolated power (IT power), the RFI jumper must

be cut off. Then the RFI capacities (filter capacitors) will be disconnected from ground to prevent

circuit damage (according to IEC 61800-3) and reduce earth leakage current.

CAUTION!

1. After applying power to the brushless DC motor drive, do not cut off the RFI jumper. Therefore,

please make sure that main power has been switched off before cutting the RFI jumper.

2. The gap discharge may occur when the transient voltage is higher than 1,000V. Besides,

electro-magnetic compatibility of the brushless DC motor drives will be lower after cutting the

RFI jumper.

3. Do NOT cut the RFI jumper when main power is connected to earth.

4. The RFI jumper cannot be cut when Hi-pot tests are performed. The mains power and motor

must be separated if high voltage test is performed and the leakage currents are too high.

5. To prevent drive damage, the RFI jumper connected to ground shall be cut off if the brushless

DC motor drive is installed on an ungrounded power system or a high impedance grounding

(over 30 ohms) power system or a corner grounded TN system.

About Grounding System

According to international standard IEC60364, the grounding system can be divided as follows:

1. The first letter: the connection between grounded point and power equipment (generator or

transformer)

T: connect to the same grounded point directly, I: NOT connect to the grounded point

(insulation) or grounded via high-resistance equipment.

2. The second letter: connection method between grounded point and the electrical device being

supplied

T: connect to grounded point, independent of other power supplied grounded point, N:

grounded via the power supply system

3. The third and forth letter: position of grounded conductor

S: neutral and grounded point are disconnection, C: neutral is connected to grounded point in

parallel

Revision May 2009, 00DE, V0.50 1-5

Page 13

Chapter 1 Introduction|BLD-E1 Series

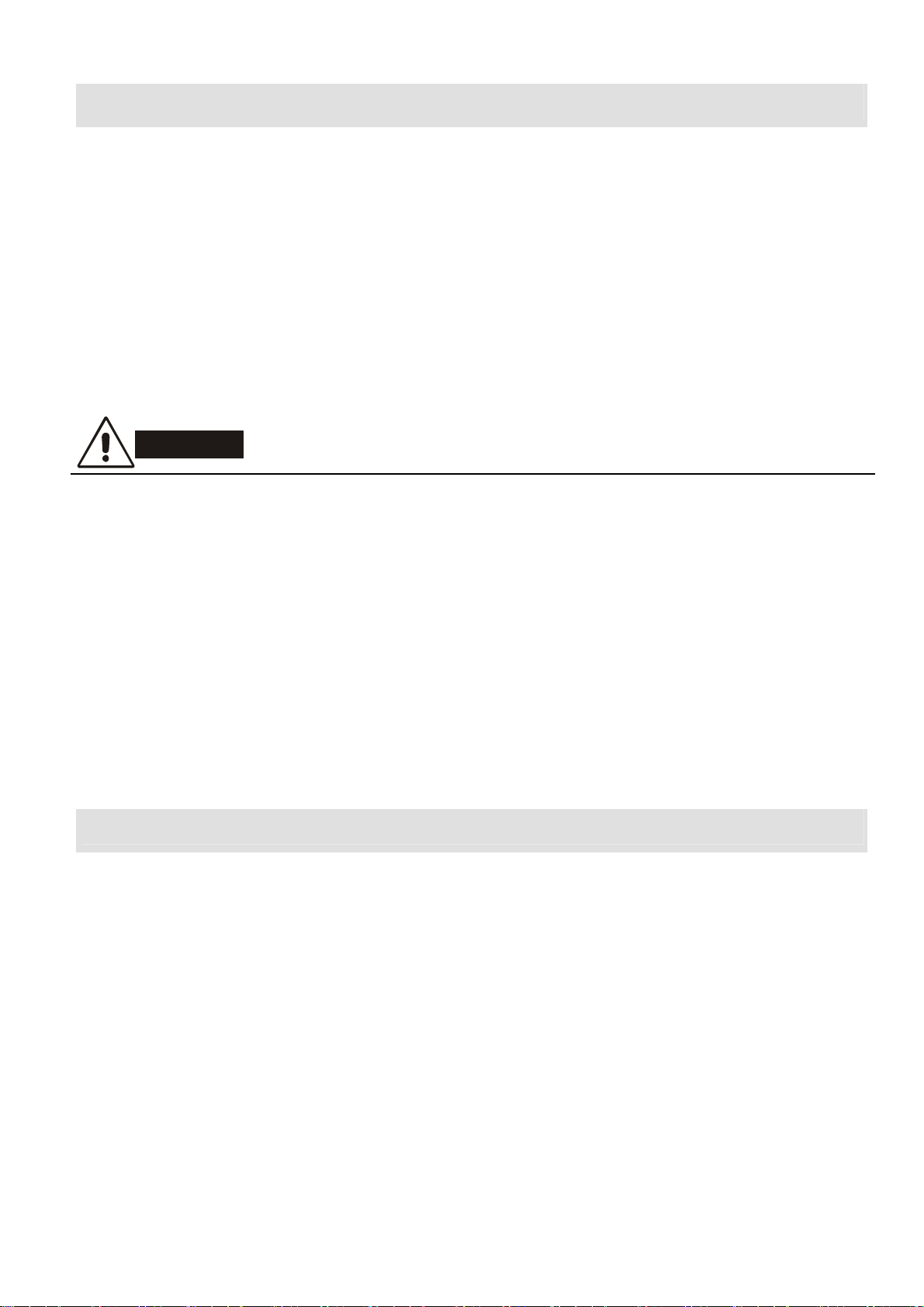

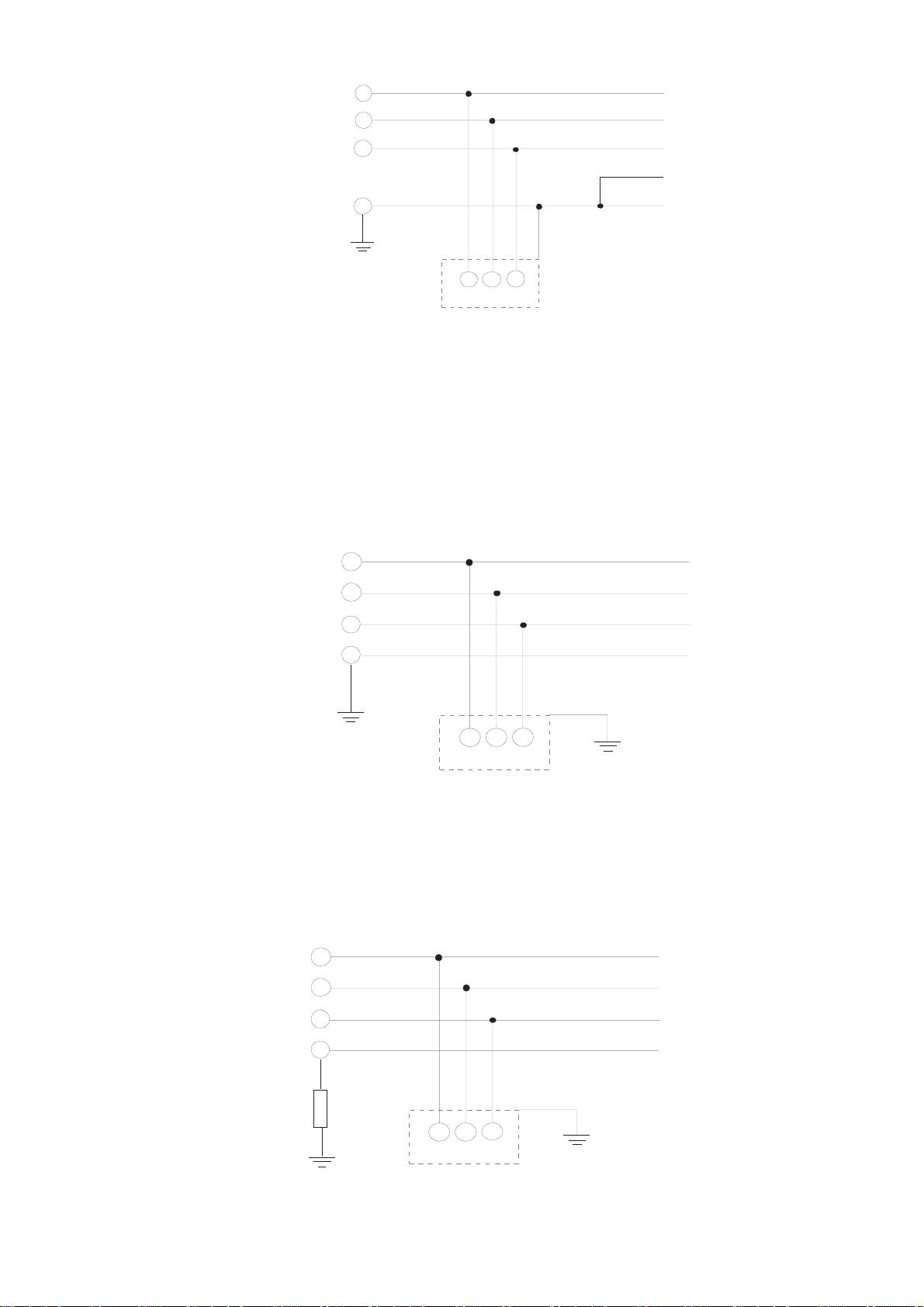

TN-S grounding system:

TN-S is a grounding system with 3-phase, 4-line and PE line. The feature of TN-S system is the

neutral line and protective earth(PE) line have an only common grounding at the neutral point of

transformer. The neutral line (N) is live part and PE line is NOT live part. This grounding system

equips safe and reliable basic potential.

L1

L2

L3

N

PE

L1 L2

TN-S grounding system

L3

TN-C grounding system:

TN-C grounding system is called 3-phase and 4-line system. This system combines the neutral

line with protective earthing(PE) and is called PEN line. This grounding system is sensitive to

the grounding malfunction with simple wiring but it is only suitable for the occasions with

balanced 3-phase overload. If the high harmonic current caused by the unbalanced current of

PEN line and other power electronic equipment superposes on the neutral line in the normal

situation and makes the neutral line to be live part with unstable current, it will cause unstable

neutral grounding potential. Moreover, it will also make the equipment case connected with

PEN line be live part to result in personal injury and incorrect accurate electronic equipment

operation (can’t get a suitable potential base point).

L1

L2

L3

PEN

L1 L2

TN-C grounding system

L3

TN-C-S grounding system:

TN-C-S grounding system is made up of two grounding systems, including TN-C system and

TN-S system. The connection point of these two systems is at the connection point of N line

and PE line.

1-6 Revision May 2009, 00DE, V0.50

Page 14

Chapter 1 Introduction| BLD-E1 Series

L1

L2

L3

N

PEN

L3

L1 L2

TN-C-S grounding system

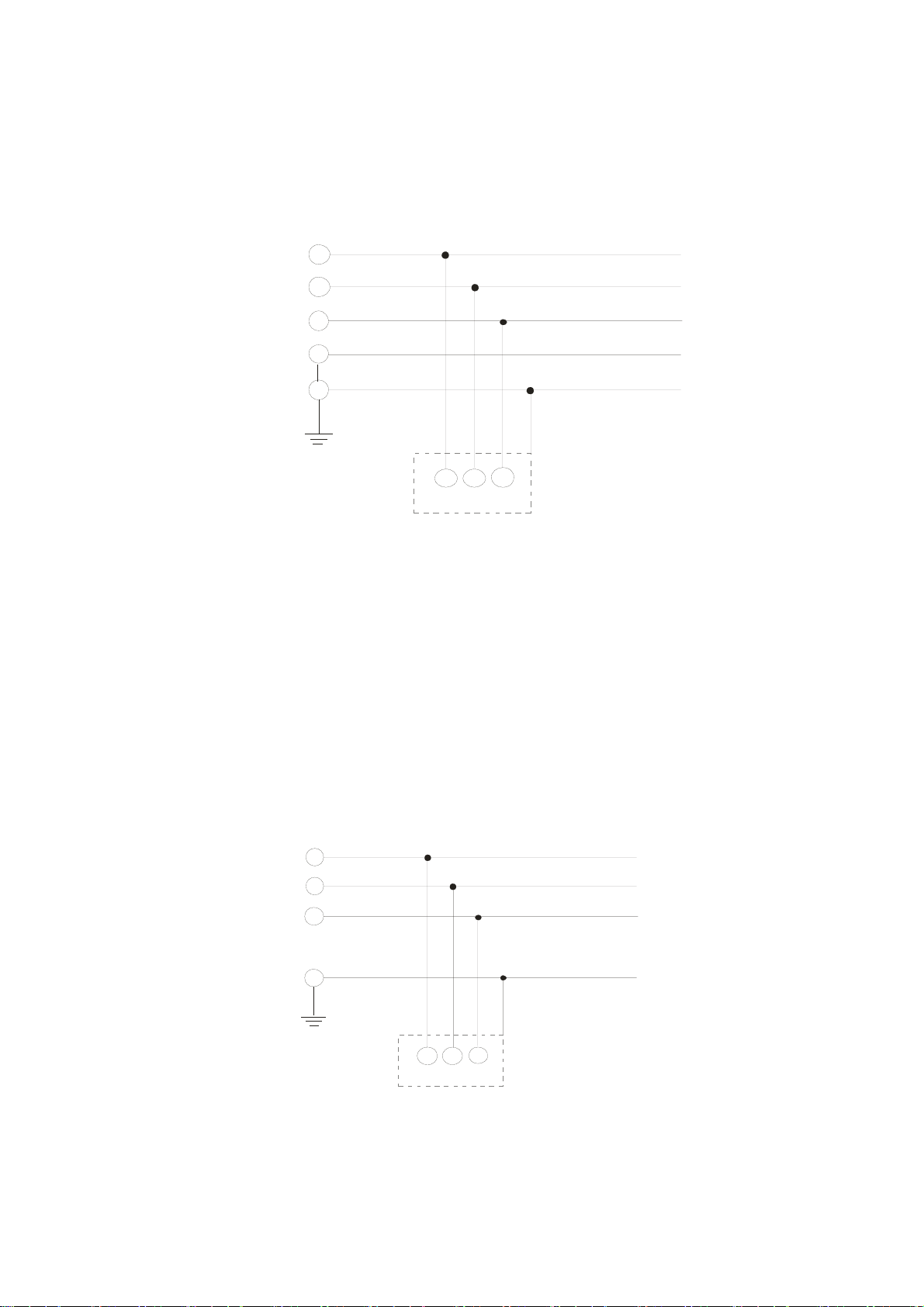

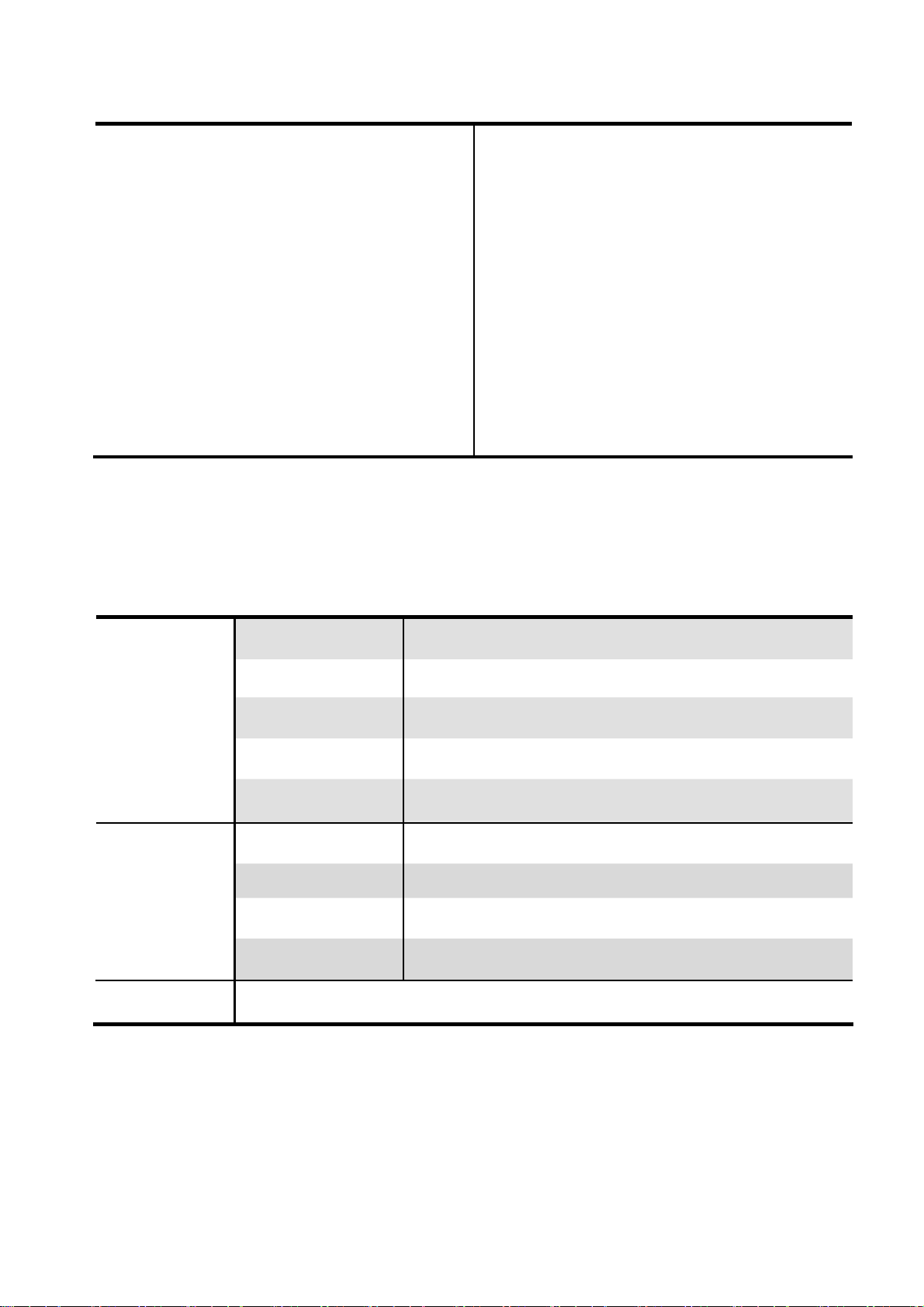

TT grounding system:

TT grounding system is usually called 3-phase 4-line grounding system. The feature of TT

grounding system is no electrical connection between the neutral line and protective earthing,

i.e. the grounding of the neutral and PE line is separated. No matter 3-phase load is balanced

or not, the PE line won’t be live part as the neutral line is live part when this system is in normal

operation. When only 1-phase grounding is fault, the fault can’t be stopped immediately due to

the low sensitive of protective earthing and only equipment case may be live part.

PE

L1

L2

L3

N

PE

L1 L2

TT grounding system

IT grounding system:

IT grounding system is a 3-phase 3-line grounding system. The neutral of the system

transformer is not grounded or grounded by the impedance, no neutral line N and protective

earthing is grounded separately. The advantage of this system is that when only one phase is

grounded, it won’t cause greater current in the case and the system will operate normally.

L3

L1

L2

L3

N

PE

L1 L2

IT grounding system

L3

Revision May 2009, 00DE, V0.50 1-7

Page 15

Chapter 1 Introduction|BLD-E1 Series

1.1.5 Remove Instructio n s

Remove Front Cover

Remove Fan

For Frame A and Frame B,

press and hold in the tabs on each side of the

fan and pull the fan up to release.

Step 1 Step 2

1.2 Preparation for Installation and Wiring

1.2.1 Ambient Conditions

Install the brushless DC motor drive in an environment with the following conditions:

-10 ~ +40°C (14~104°F) for UL & cUL

-10 ~ +30 °C (14~86°F)for side-by-side mounting

86 ~ 106 kPa

<1000m

<20Hz: 9.80 m/s2 (1G) max

20 ~ 50Hz: 5.88 m/s2 (0.6G) max

86 ~ 106 kPa

<20Hz: 9.80 m/s2 (1G) max

20 ~ 50Hz: 5.88 m/s2 (0.6G) max

Operation

Storage

Transportation

Pollution

Degree

Air Temperature

Relative Humidity <90%, no condensation allowed

Atmosphere

pressure

Installation Site

Altitude

Vibration

Temperature -20°C ~ +60°C (-4°F ~ 140°F)

Relative Humidity <90%, no condensation allowed

Atmosphere

pressure

Vibration

2: good for a factory type environment.

1-8 Revision May 2009, 00DE, V0.50

Page 16

Chapter 1 Introduction| BLD-E1 Series

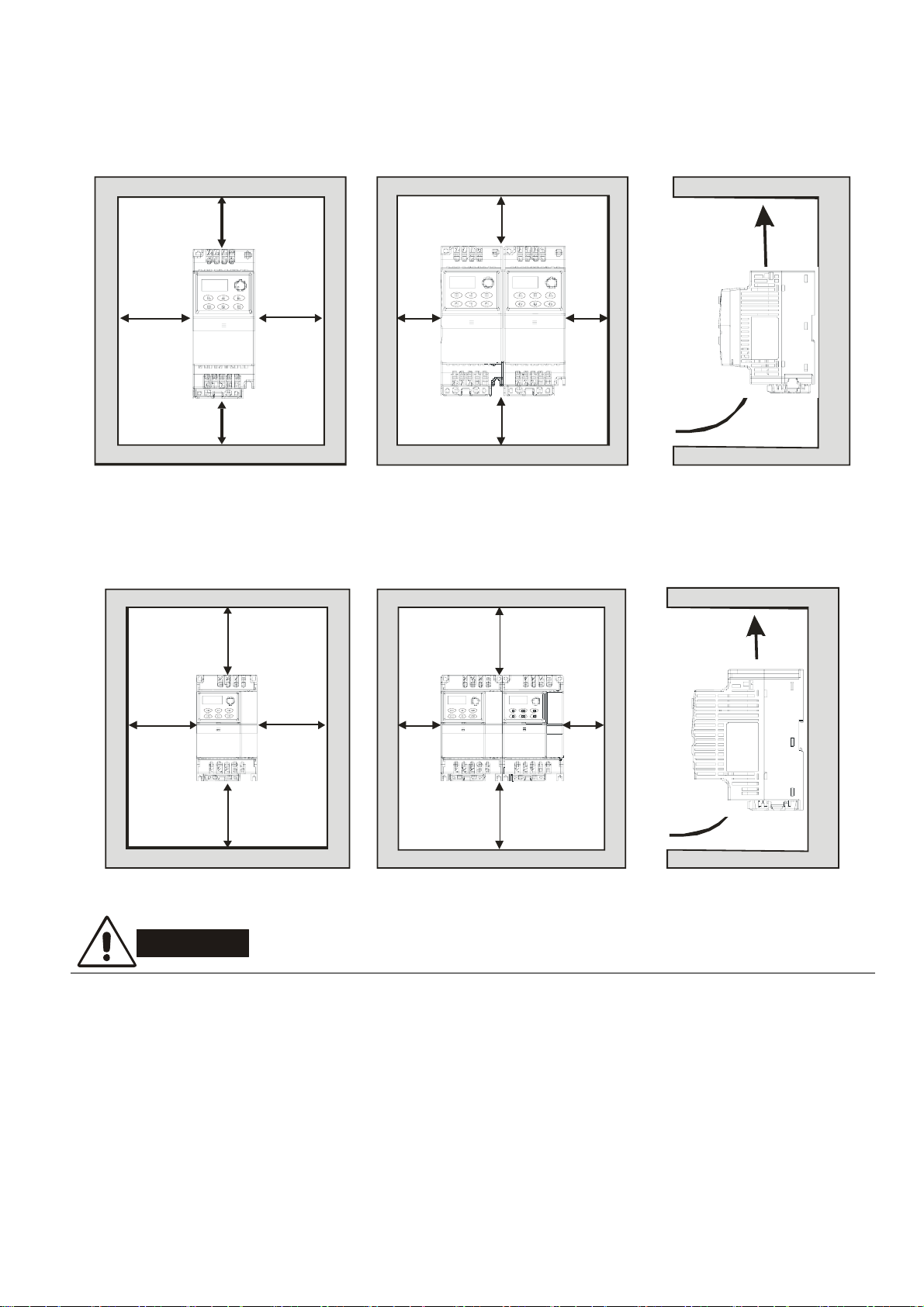

Minimum Mounting Clearances

Frame A Mounting Clearances

120mm

50mm

50mm

120mm

sing le dr ive

Frame B Mounting Clearances

120mm

Air Flow

50mm

50mm

120mm

side-by-side installation

air flow

150mm

50mm

50mm

150mm

single drive

150mm

50mm

50mm

150mm

side-by-side installation air flow

Air Flow

CAUTION!

1. Operating, storing or transporting the brushless DC motor drive outside these conditions may

cause damage to the brushless DC motor drive.

2. Failure to observe these precautions may void the warranty!

3. Mount the brushless DC motor drive vertically on a flat vertical surface object by screws. Other

directions are not allowed.

4. The brushless DC motor drive will generate heat during operation. Allow sufficient space

around the unit for heat dissipation.

Revision May 2009, 00DE, V0.50 1-9

Page 17

Chapter 1 Introduction|BLD-E1 Series

A

5. The heat sink temperature may rise to 90°C when running. The material on which the brushless

DC motor drive is mounted must be noncombustible and be able to withstand this high

temperature.

6. When brushless DC motor drive is installed in a confined space (e.g. cabinet), the surrounding

temperature must be within 10 ~ 40°C with good ventilation. DO NOT install the brushless DC

motor drive in a space with bad ventilation.

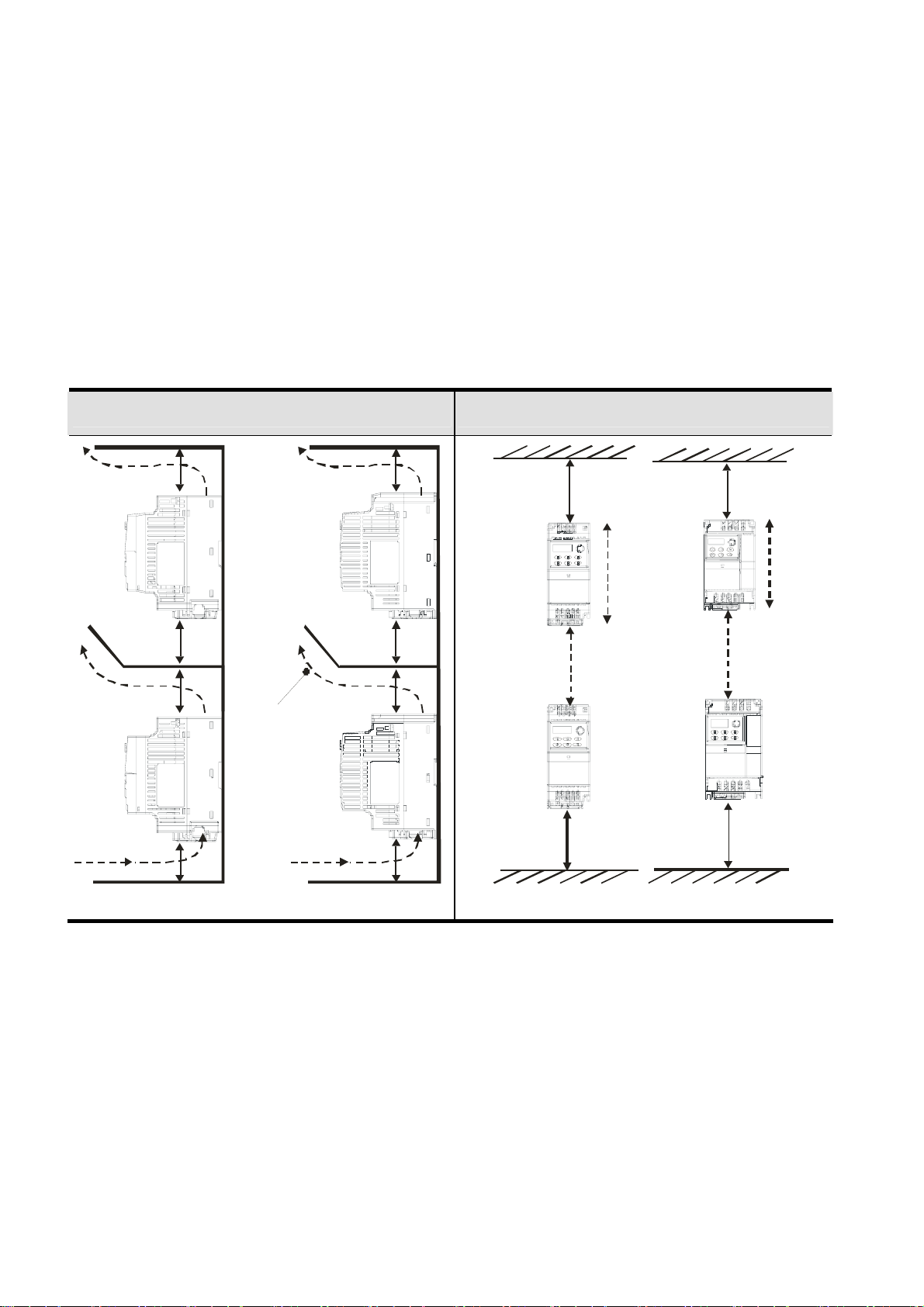

7. When installing multiple brushless DC motor drives in the same cabinet, they should be

adjacent in a row with enough space in-between. When installing one brushless DC motor drive

below another one, use a metal separation between the brushless DC motor drives to prevent

mutual heating.

Installation with Metal Separation Installation without Metal Separation

120mm

120mm

120mm

120mm

Frame

air flow

150mm

150mm

150mm

150mm

Frame B

120mm

A

120mm

Frame A

150mm

A

Frame B

B

B

150mm

1.2.2 DC-bus Sharing: Connecting the DC-bus of the Brushless DC motor

drive in Parallel

1. The brushless DC motor drives can absorb mutual voltage that generated to DC bus when

deceleration.

2. Enhance brake function and stabilize the voltage of the DC bus.

3. Only the same capacity and same power system can be connected in parallel.

4. The 5 drives should be in same power system, e.g. if the input voltage is 220V, the 5 brushless

DC motor drives connected in parallel must also be 220V.

1-10 Revision May 2009, 00DE, V0.50

Page 18

Chapter 1 Introduction| BLD-E1 Series

NOTE

Prevent fiber particles, scraps of paper, dust, metal particles from adhering to the heatsink.

The material on which the brushless DC motor is mounted must be noncombustible and be able to

withstand the high temperature to prevent fire accidents.

The parallel connection of multiple drives is NOT for 115V models.

Revision May 2009, 00DE, V0.50 1-11

Page 19

Chapter 1 Introduction|BLD-E1 Series

1.3 Dimensions

(Dimensions are in millimeter and [inch])

Frame A

W

W1

H

H1

D

D1

S1

S2

Frame W W1 H H1 D D1 S1 S2

A

B

Frame A:

72.0

[2.83]

100.0

[3.94]

NOTE

BLD002E111A/121A/123A, BLD004E111A/121A/123A/143A, BLD007E121A/123A/143A,

59.0

[2.32]

89.0

[3.50]

174.0

[6.86]

174.0

[6.85]

151.6

[5.97]

162.9

[6.42]

136.1

[5.36]

136.0

[5.36]

4.0

[0.16]

4.0

[0.16]

5.4

[0.21]

5.9

[0.23]

BLD015E123A/143A

5.4

[0.21]

5.4

[0.21]

Frame B:

BLD007E111A , BLD015E121A, BLD022E121A /123A/143A, BLD037E123A/143A

1-12 Revision May 2009, 00DE, V0.50

Page 20

Chapter 2 Installation and Wiring

After removing the cover of input/output terminals and control terminals, check if terminals are clear.

Be sure to observe the following precautions when wiring.

CAUTION!

1. Make sure that power is only applied to the R/L1, S/L2, T/L3 terminals. Failure to comply

may result in damage to the equipment. The voltage and current should lie within the

range as indicated on the nameplate.

2. All the units must be grounded directly to a common ground terminal to prevent lightning

strike or electric shock and also for decreasing the noise interference.

3. Please make sure to fasten the screw of the main circuit terminals to prevent sparks

which is made by the loose screws due to vibration.

DANGER!

1. A charge may still remain in the DC bus capacitors with hazardous voltages even if the power

has been turned off. To prevent personal injury, please ensure that the power is turned off and

wait ten minutes for the capacitors to discharge to safe voltage levels before opening the

brushless DC motor drive.

2. Only qualified personnel familiar with brushless DC motor drives is allowed to perform

installation, wiring and commissioning.

3. Make sure that the power is off before doing any wiring to prevent electric shock.

CAUTION!

1. Use wire gauges that comply with the local regulations during wiring.

2. Check following items after finishing the wiring:

A. Are all connections correct?

B. No loose wires?

C. No short-circuits between terminals or to ground?

Revision May 2009, 00DE, V0.50 2-1

Page 21

Chapter 2 Installation and Wiring| BLD-E1 Series

2.1 Wiring

There are main circuit and control circuit for the wiring of the brushless DC motor. Users must

connect wires according to the circuit diagrams on the following pages.

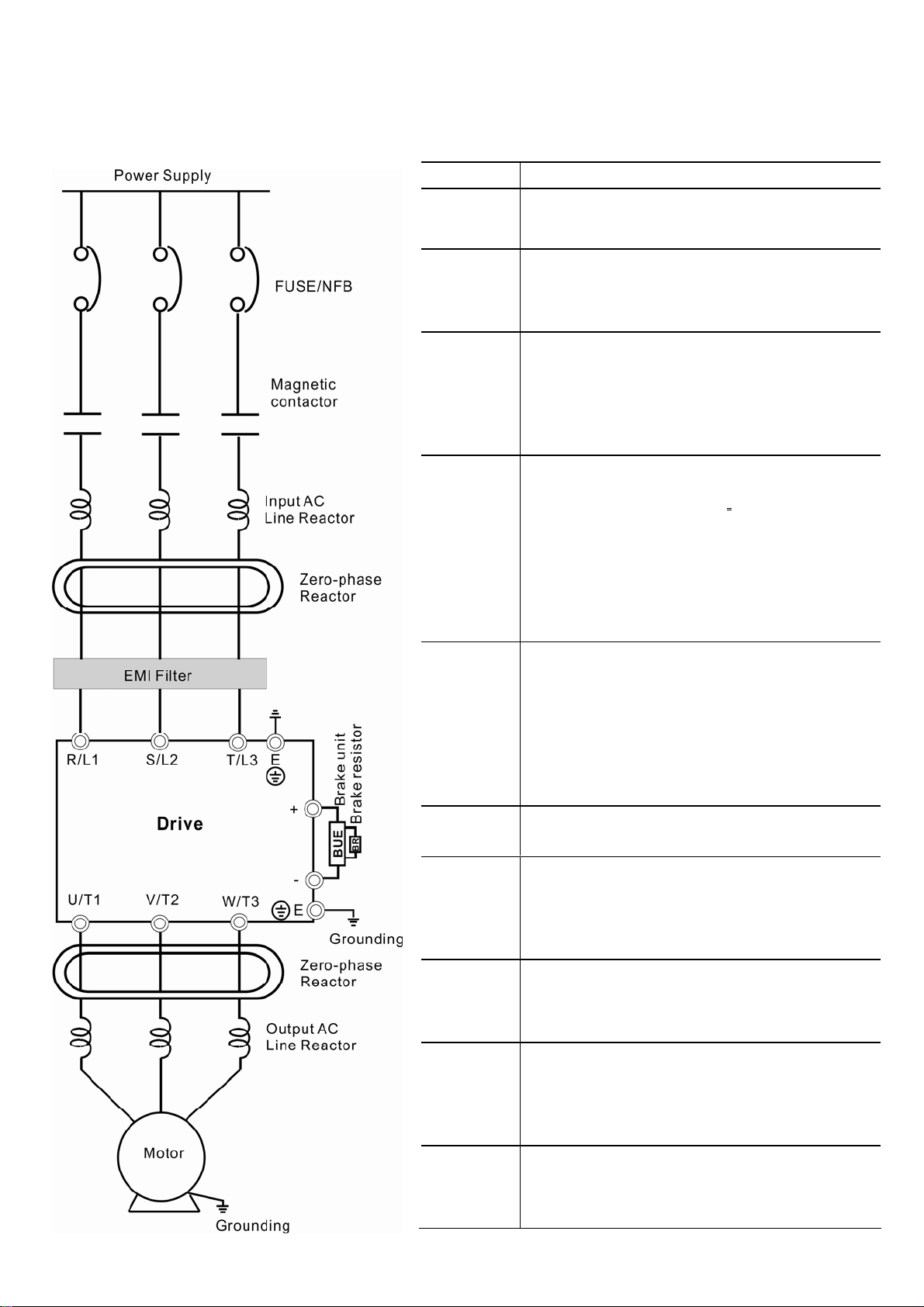

Figure 1 for models of BLD-E1 Series

BLD002E111A/121A, BLD004E111A/121A, BLD007E111A/121A, BLD015E121A, BLD022E121A

2-2 Revision May 2009, 00DE, V0.50

Page 22

Chapter 2 Installation and Wiring| BLD-E1 Series

Figure 2 for models of BLD-E1 Series

BLD002E123A, BLD004E123A/143A, BLD007E123A/143A, BLD015E123A/143A,

BLD022E123A/143A, BLD037E123A/143A

Revision May 2009, 00DE, V0.50 2-3

Page 23

Chapter 2 Installation and Wiring| BLD-E1 Series

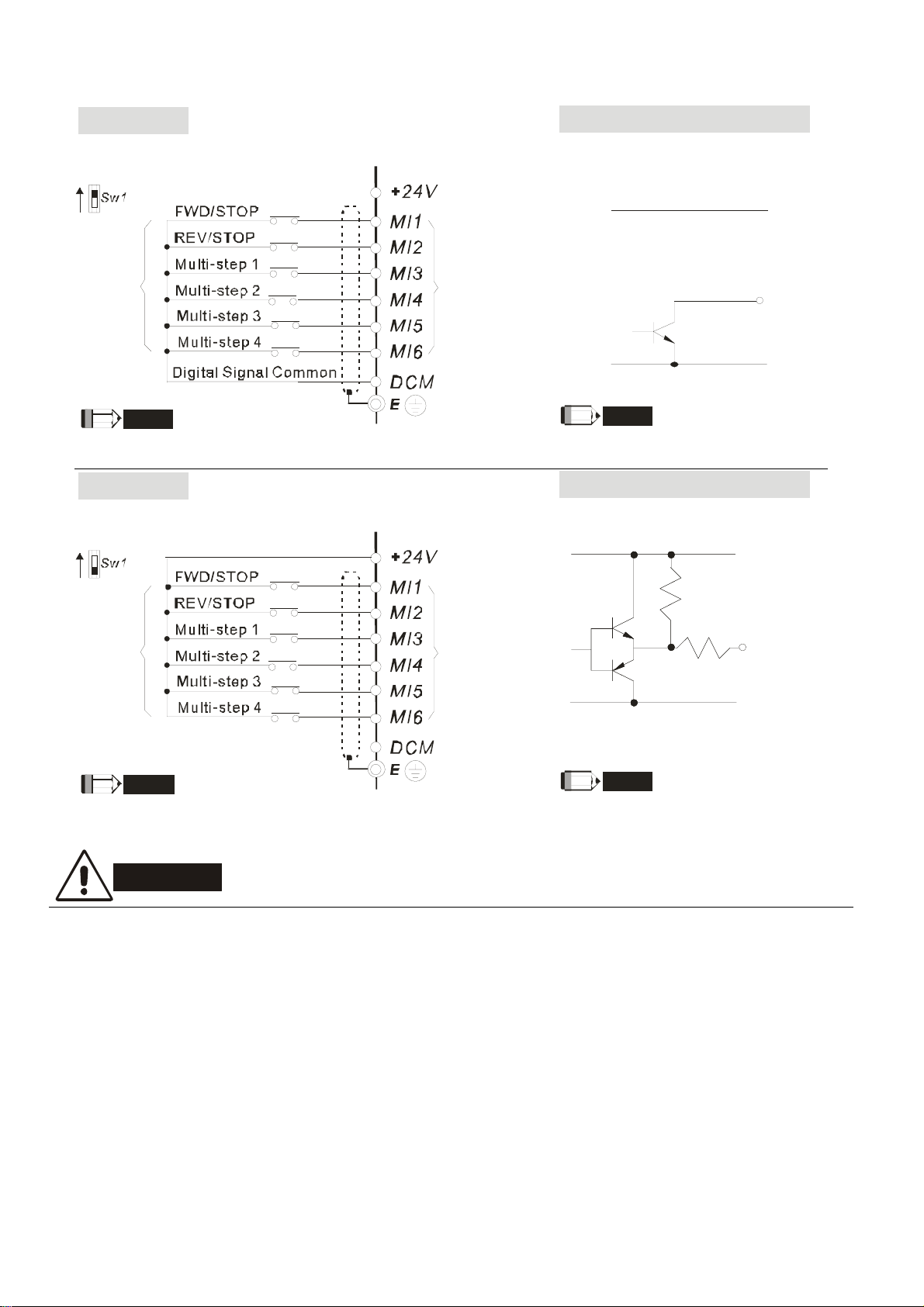

Figure 3 Wiring for NPN mode and PNP mode

NPN M o d e

Applicable Output Signal

Factory setting is NPN

NPN

PNP

Factory

setting

NOTE

Don't ap ply mains voltage into ab ove terminals.

PNP Mod e

Factory setting is PNP

NPN

PNP

Multi-function

input terminals

Open collector output

VCC

O/P

0V

NOTE

It needs to connect O/P to multi-function

input termi nals for norma l operation.

Applicable Output Signal

Complementary outp ut

VCC

Factory

setting

NOTE

Don't ap ply mains voltage into ab ove terminals.

Multi-function

input terminals

NOTE

It needs to connect O/P to multi-function

input termi nals for norma l operation.

O/P

0V

CAUTION!

1. The wiring of main circuit and control circuit should be separated to prevent erroneous actions.

2. Please use shield wire for the control wiring and not to expose the peeled-off net in front of the

terminal.

3. Please use the shield wire or tube for the power wiring and ground the two ends of the shield

wire or tube.

4. Damaged insulation of wiring may cause personal injury or damage to circuits/equipment if it

comes in contact with high voltage.

5. The brushless DC motor drive, motor and wiring may cause interference. To prevent the

equipment damage, please take care of the erroneous actions of the surrounding sensors and

the equipment.

2-4 Revision May 2009, 00DE, V0.50

Page 24

Chapter 2 Installation and Wiring| BLD-E1 Series

6. With long motor cables between the brushless DC motor drive and motor, high capacitive

switching current peaks can cause over-current, high leakage current or lower current readout

accuracy. To prevent this, the motor cable should be less than 20m for 3.7kW models and

below. And the cable should be less than 50m for 5.5kW models and above. For longer motor

cables use an AC output reactor.

7. The brushless DC motor drive, electric welding machine and the greater horsepower motor

should be grounded separately.

8. Use ground leads that comply with local regulations.

9. No brake resistor is built in the BLD-E1 series, it can install brake resistor for those occasions

that use higher load inertia or frequent start/stop. Refer to Appendix B for details.

10. To prevent the lightening strike and electric shock, the metal grounding wire of electric

equipment should be thick, short and connect to the specific ground terminal of the variable

frequency system.

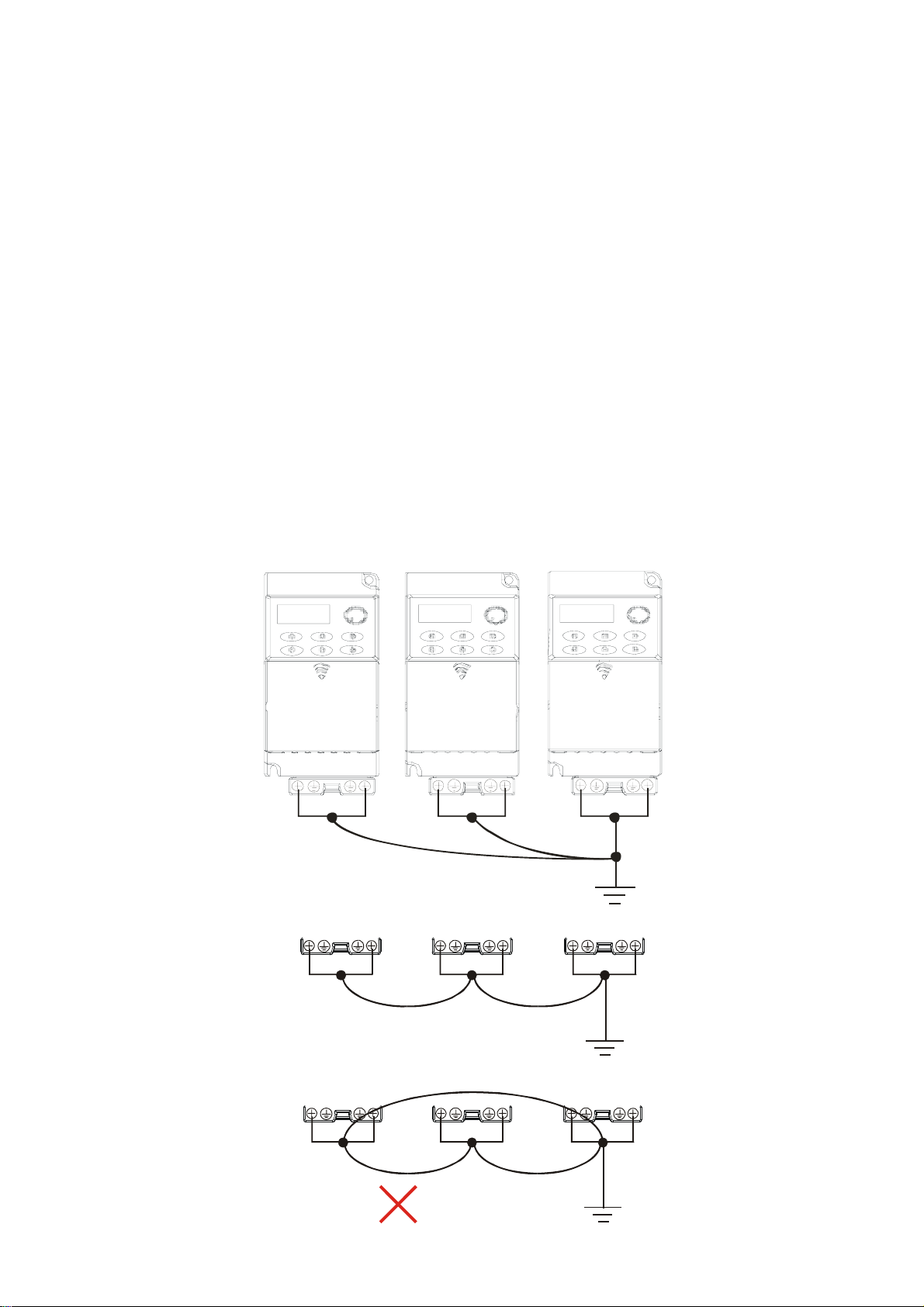

11. Multiple BLD-E1 units can be installed in one location. All the units should be grounded directly

to a common ground terminal, as shown in the figure below. Ensure there are no ground

loops.

Excellent

Good

Not allowed

Revision May 2009, 00DE, V0.50 2-5

Page 25

Chapter 2 Installation and Wiring| BLD-E1 Series

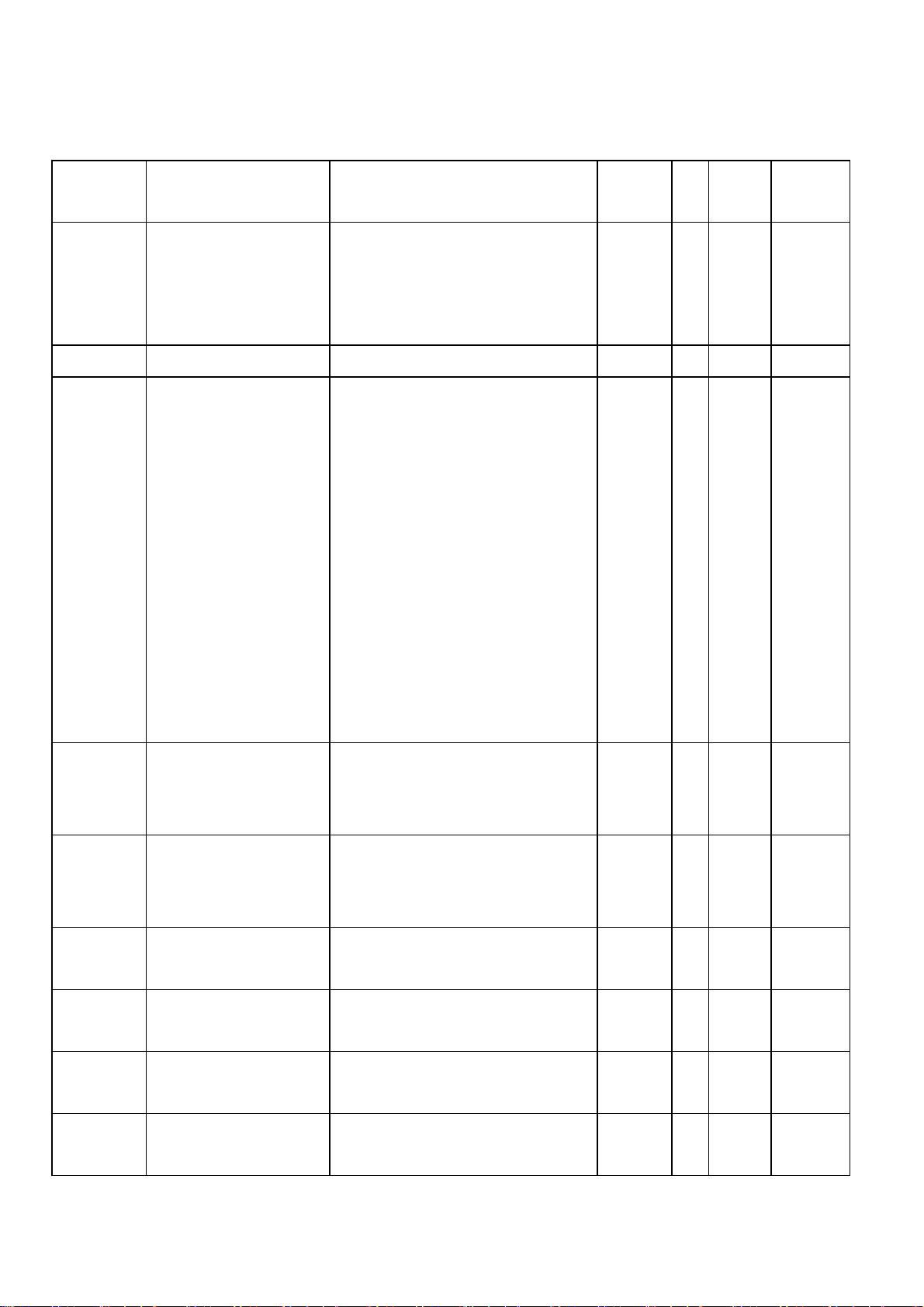

2.2 External Wiring

Items Explanations

Power

supply

Fuse/NFB

(Optional)

Magnetic

contactor

(Optional)

Input AC

Line

Reactor

(Optional)

Zero-phase

Reactor

(Ferrite

Core

Common

Choke)

(Optional)

EMI filter

Driver

Brake

resistor

and Brake

unit

Output AC

Line

Reactor

Grounding

Please follow the specific power supply

requirements shown in Appendix A.

There may be an inrush current during

power up. Please check the chart of

Appendix B and select the correct fuse with

rated current. Use of an NFB is optional.

Do NOT run/stop brushless DC motor drives

by turning the magnetic contactor ON/OFF,

as it will reduce the usage life of drive. If you

still need to run/stop drives by turning the

magnetic contactor ON/OFF, it is

recommended to do so only ONCE per hour.

Used to improve the input power factor, to

reduce harmonics and provide protection

from AC line disturbances.

switching spikes and short interruptions). AC

line reactor should be installed when the

power supply capacity is 500kVA or more or

advanced capacity is activated .The wiring

distance should be

appendix B for details.

Zero phase reactors are used to reduce

radio noise especially when audio equipment

is installed near the brushless DC motor

drive. Effective for noise reduction on both

the input and output sides. Attenuation

quality is good for a wide range from AM

band to 10MHz. Appendix B specifies the

zero phase reactor. (RF220X00A)

To reduce electromagnetic interference. It is

built in 230V 1-phase and 460V models.

The surrounding temperature should be

within the specification (refer to chapter 1) to

prevent from reducing the drive’s usage life.

Please wire according to chapter 2 wiring,

wrong wire may cause damage.

Used to reduce the deceleration time of the

motor. Please refer to the chart in Appendix

B for specific Brake resistors.

Motor surge voltage amplitude depends on

motor cable length. For applications with

long motor cable (>20m), it is necessary to

install a reactor at the drive output side.

Please refer to the chart in appendix B.

To prevent electric shock due to leakage

current of the drive, the drive and motor

should be grounded. Please refer to

specification of main circuit terminal.

≤

(surges,

10m. Refer to

2-6 Revision May 2009, 00DE, V0.50

Page 26

Chapter 2 Installation and Wiring| BLD-E1 Series

2.3 Main Circuit

2.3.1 Main Circuit Connection

Terminal Symbol Explanat ion of Terminal Function

R/L1, S/L2, T/L3

U/T1, V/T2, W/T3

+, -

E

Input terminals of commercial power (1-phase/3-phase)

Output terminals of brushless DC motor drive for connecting

brushless DC motor. Wire: U/T1 (Red); V/T2 (White); W/T3 (Black)

Connections for External Brake unit (BUE series)

Earth connection, please comply with local regulations.

CAUTION!

Mains power terminals (R/L1, S/L2, T/L3)

DO NOT apply 1-phase power to 3-phase models. It is unnecessary to consider phase-

sequence of these mains power terminals (R/L1, S/L2, T/L3).

To connect a no fuse switch between 3-phase AC input power and main circuit terminals

(R/L1, S/L2, T/L3) is necessary. It is recommended to add a magnetic contactor (MC) in the

power input wiring to cut off power quickly and reduce malfunction when activating the

protection function of brushless DC motor drives. Both ends of the MC should have an R-C

surge absorber.

Please make sure to fasten the screw of the main circuit terminals to prevent sparks which is

made by the loose screws due to vibration.

Please use voltage and current within the regulation shown in Appendix A.

Revision May 2009, 00DE, V0.50 2-7

Page 27

Chapter 2 Installation and Wiring| BLD-E1 Series

When using a general GFCI (Ground Fault Circuit Interrupter), select a current sensor

with sensitivity of 200mA or above, and not less than 0.1-second operation time to avoid

nuisance tripping. For the specific GFCI of the brushless DC motor drive, please select a

current sensor with sensitivity of 30mA or above.

Output terminals for main circuit (U, V, W)

The factory setting of the operation direction is forward running.

When it needs to install the filter at the output side of terminals U/T1, V/T2, W/T3 on the

brushless DC motor drive. Please use inductance filter. Do not use advanced capacitors

or L-C (Inductance-Capacitance) or R-C (Resistance-Capacitance), unless approved by

Delta.

DO NOT connect advanced capacitors or surge absorbers at the output terminals of

brushless DC motor drives.

Use well-insulated motor, suitable for drive operation.

When using a general GFCI (Ground Fault Circuit Interrupter), select a current sensor

with sensitivity of 200mA or above, and not less than 0.1-second operation time to avoid

nuisance tripping. For the specific GFCI of the brushless DC motor drive, please select a

current sensor with sensitivity of 30mA or above.

Terminals [+, -] for connecting brake resistor

Connect a brake resistor or brake unit in applications with frequent decelerations, short

deceleration time, insufficient brake torque or requiring increased brake torque.

When using external brake unit, please connect it to the terminals [+, -]. Please do NOT

connect brake resistors to terminals [+, -] directly, as it may cause damage.

All BLD-E1 series don’t have a built-in brake chopper. Please connect an external

optional brake unit (BUE-series) and brake resistor.

When not used, please leave the terminals [+, -] open.

2-8 Revision May 2009, 00DE, V0.50

Page 28

Chapter 2 Installation and Wiring| BLD-E1 Series

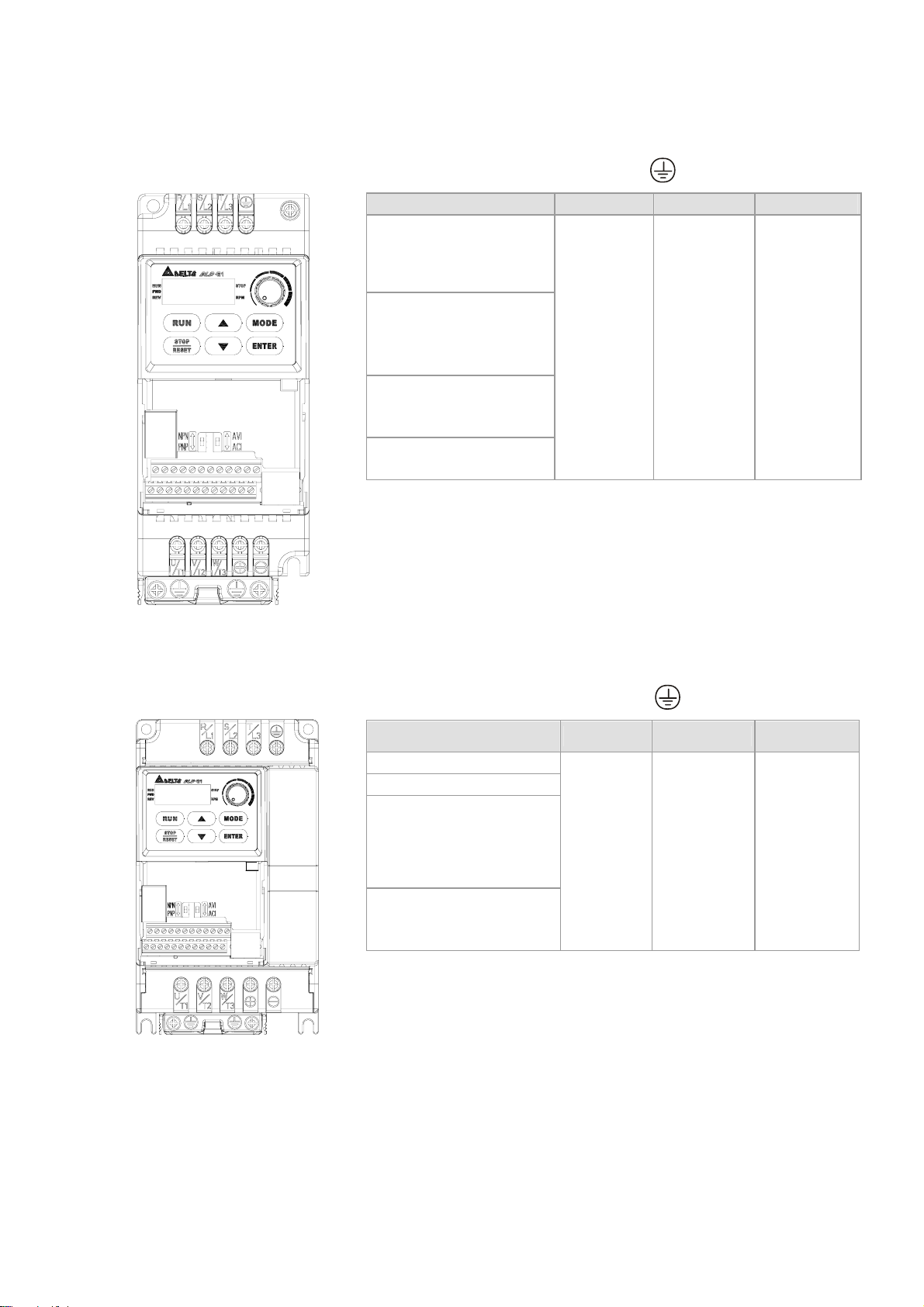

2.3.2 Main Circuit Terminals

Frame A

Main circuit terminals:

R/L1, S/L2, T/L3, U/T1, V/T2, W/T3,

Models Wire Torque Wire type

BLD002E111A

BLD002E121A

BLD002E123A

BLD004E111A

BLD004E121A

BLD004E123A

BLD004E143A

BLD007E121A

BLD007E123A

BLD007E143A

BLD015E123A

BLD015E143A

12-18

AWG (3.3-

0.8mm

2

)

, +, -

14-16

kgf-cm

(12-14

in-lbf)

Stranded

copper

Only,

75℃

Frame B

Main circuit terminals:

R/L1, S/L2, T/L3, U/T1, V/T2, W/T3,

Models Wire Torque Wire type

BLD007E111A

BLD015E121A

BLD022E121A

BLD022E123A

BLD022E143A

BLD037E123A

BLD037E143A

8-18

AWG.

(8.3-

0.8mm

2

)

, +/B1, B2, -

16-19

kgf-cm

(14-17

in-lbf)

Stranded

copper

Only,

75℃

Revision May 2009, 00DE, V0.50 2-9

Page 29

Chapter 2 Installation and Wiring| BLD-E1 Series

2.4 Control Terminals

Specification Torque Wire

Terminal A, B 2 kgf-cm (2 in-lbf) 16-24 AWG (1.3-0.2mm2)

Terminal symbols and functions

Terminal

Terminal Function

Symbol

MI1 Forward-Stop command

Factory Settings (NPN mode)

ON: Connect to DCM

ON: forward running

OFF: Ramp to stop

MI2 Reverse-Stop command

MI3 Multi-function Input 3

MI4 Multi-function Input 4

MI5 Multi-function Input 5

MI6 Multi-function Input 6

2-10 Revision May 2009, 00DE, V0.50

ON: reverse running

OFF: Ramp to stop

Refer to Pr.04-05 to Pr.04-08 for programming the

Multi-function Inputs.

ON: the activation current is 16mA.

OFF: leakage current tolerance is 10μA.

Page 30

Chapter 2 Installation and Wiring| BLD-E1 Series

Terminal

Factory Settings (NPN mode)

Terminal Function

Symbol

ON: Connect to DCM

+24V DC Voltage Source +24VDC, 20mA

DCM Digital Signal Common Common for digital inputs

HU/U Reserved

HV/V Reserved

HW/W Reserved

Sending PG signals to the drive, e.g. activation,

A PG feedback signal contact 1

operation, speed control etc.

Sending PG signals to the drive, e.g. activation,

B PG feedback signal contact 2

operation, speed control etc.

PG feedback signal contact

Sending PMW signals to the drive to activate at

Z/PWM

PWM

the origin position.

SPO Reserved

+5V Encoder Power Supply

GND Feedback Signal Common

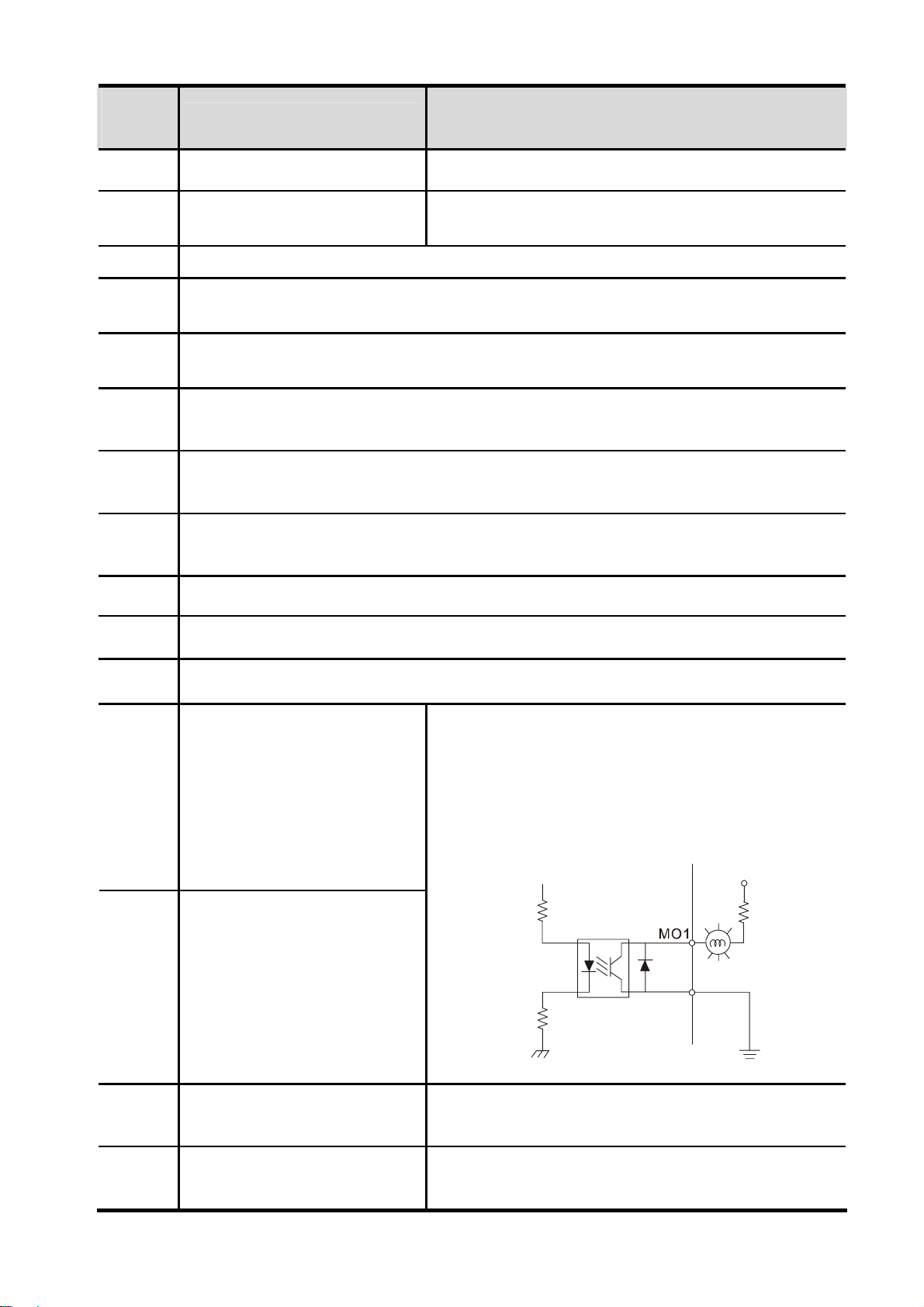

Multi-function Output 1

(Photocoupler)

The brushless DC motor monitors all kinds of

signal, such as during operation, speed attained

and overload indication, by the open collector

MO1

output. Please refer to Pr.02-13, Pr.02-14 for more

details.

Multi-function Output 2

(Photocoupler)

MO2

Max:

+5V

MCM

internal circuit

48VDC/50mA

MCM

Max 48Vdc 50mA

(Photocoupler)

Power supply for analog frequency setting +10VDC

+10V Potentiometer power supply

3mA (variable resistor 3~5kΩ)

Revision May 2009, 00DE, V0.50 2-11

Multi-function output common

Page 31

Chapter 2 Installation and Wiring| BLD-E1 Series

A

A

ACMA

Terminal

Symbol

AVI

ACI

Terminal Function

Analog voltage Input

+10V

VI

CM

internal circuit

Analog current Input

CI

DC

Factory Settings (NPN mode)

ON: Connect to DCM

Impedance: 20kΩ

Resolution: 10 bits

Range: 0 ~ 10VDC =

0 ~ Max. Output Speed (Pr.01-00)

Impedance: 250Ω/100kΩ

Resolution: 10 bits

Range: 4 ~ 20mA =

0 ~ Max. Output Speed(Pr.01-00)

internal circuit

Analog control signal

ACM

Common for AVI and ACI

(common)

NOTE: Control signal wiring size: 18 AWG (0.75 mm

2

) with shielded wire

Analog inputs (AVI, ACI, ACM)

Analog input signals are easily affected by external noise. Use shielded wiring and keep it

as short as possible (<20m) with proper grounding. If the noise is inductive, connecting

the shield to terminal ACM can bring improvement.

If the analog input signals are affected by noise from the brushless DC motor drive,

please connect a capacitor and ferrite core as indicated in the following diagrams:

AVI/ACI

C

ACM

ferrite core

wind each wires 3 times or more around the core

2-12 Revision May 2009, 00DE, V0.50

Page 32

Chapter 2 Installation and Wiring| BLD-E1 Series

Digital inputs (MI1~MI6, DCM)

When using contacts to control the digital inputs, please use high quality components to

avoid contact bounce.

Digital outputs (MO1, MO2, MCM)

Make sure to connect the digital outputs to the right polarity, see wiring diagrams.

When connecting a relay to the digital outputs, connect a surge absorber or fly-back diode

across the coil and check the polarity.

Revision May 2009, 00DE, V0.50 2-13

Page 33

Chapter 2 Installation and Wiring| BLD-E1 Series

This page intentionally left blank

2-14 Revision May 2009, 00DE, V0.50

Page 34

Chapter 3 Keypad and Start Up

3.1 Keypad

3.2 Operation Method

3.3 Trial Run

Make sure that the wiring is correct. In particular, check that the

output terminals U/T1, V/T2, W/T3 are NOT connected to power

Verify that no other equipment is connected to the motor.

Do NOT operate the brushless DC motor drive with humid hands.

Check if it displays 2000.0 on the digital keypad after power is

It should be stopped when fault occurs during running and refer to

and that the drive is well grounded.

applied.

“Fault Code Information and Maintenance” for solution. Please do

NOT touch output terminals U, V, W when power is still applied to

L1/R, L2/S, L3/T even when the brushless DC motor drive has

stopped. It may cause electric shock if touching the output

terminals U, V, W.

Revision May 2009, 00DE, V0.50 3-1

Page 35

Chapter 3 Keypad and Start Up| BLD-E1 Series

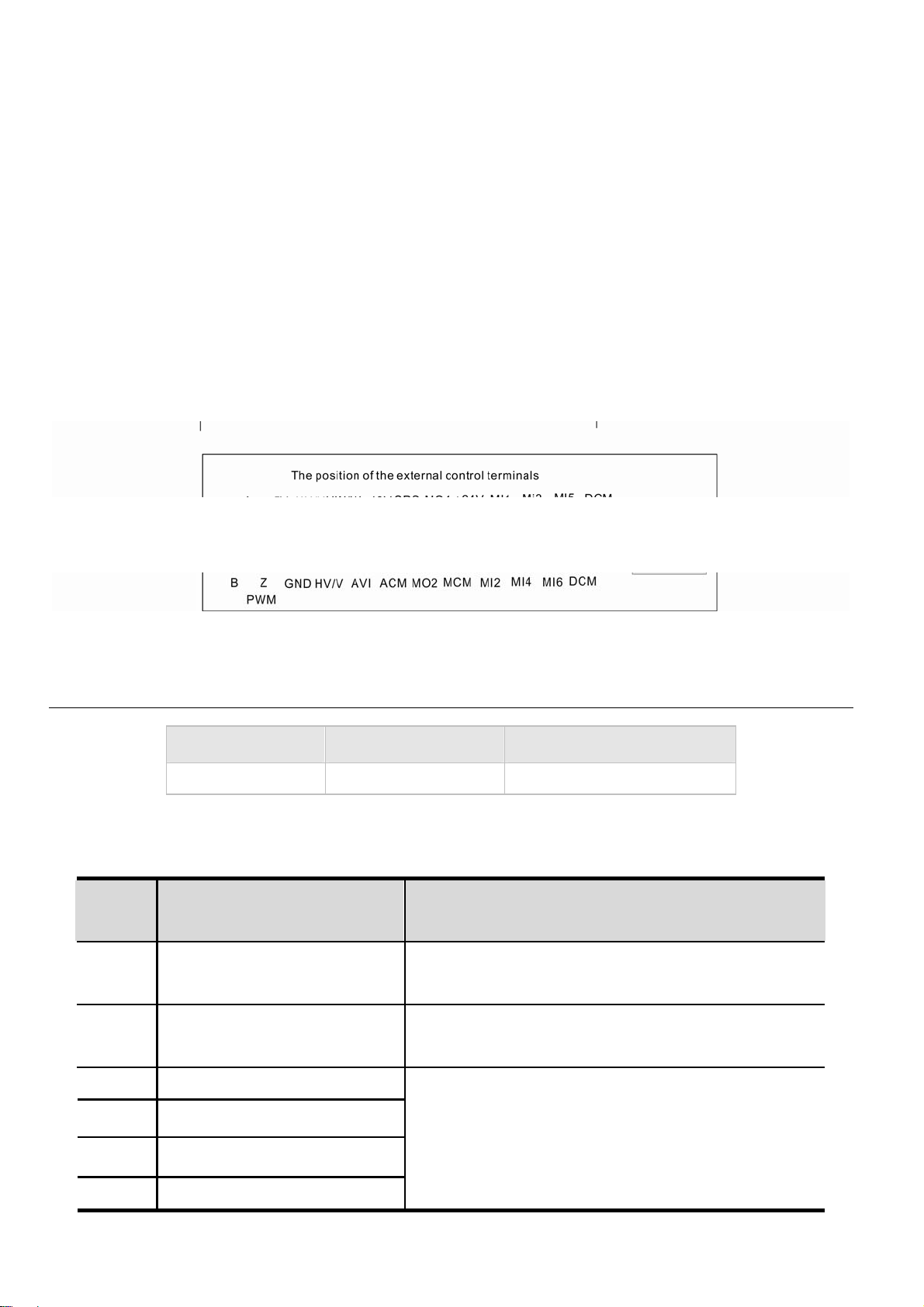

3.1 Keypad

1

3

2

4

7

Status Display

1

Display t he driver's operation status.

2

LED Display

In dicat e spee d, volta ge, cu rre nt and

user defined units.

Potentiometer

3

For maste r sp eed set ti ng

4

RUN Key

Start operation

.

5

6

8

5

UP and DOWN Key

Set the parameter number and change the

numerical data, su ch as master speed.

6

MODE

Chan ge between di ff erent disp la y mode.

STOP/RESET

7

Stop operation and reset the drive

af ter fault occurred .

There are five indications on the keypad:

STOP Stop indicator: it will light up when the motor is stop

RUN RUN indicator: it will light up when the motor is running

FWD Forward indicator: it will light up when the motor runs in forward direction

REV Reverse indicator: it will light up when the motor runs in reverse direction

RPM Speed indicator: it will light up when the speed is setting or outputting

3-2 Revision May 2009, 00DE, V0.50

Page 36

Chapter 3 Keypad and Start Up| BLD-E1 Series

Display Message Descriptions

Displays the master speed of the drive and RPM signal blinking.

Displays the actual output speed at terminals U/T1, V/T2, and W/T3.

User defined unit

Displays the output current at terminals U/T1, V/T2, and W/T3.

Displays the brushless DC motor drive forward run status.

Displays the brushless DC motor drive reverse run status.

The counter value (C).

Speed is controlled by current setting.

Speed is controlled by potentiometer and operation is controlled by the

digital keypad.

Displays the selected parameter.

Displays the actual stored value of the selected parameter.

External Fault.

Display “End” for approximately 1 second if input has been accepted and

automatically stored in memory.

Display “Err”, if the input is invalid.

Revision May 2009, 00DE, V0.50 3-3

Page 37

Chapter 3 Keypad and Start Up| BLD-E1 Series

3.1.1 How to Operate the Digital Keypad

The setting values in the following diagram are only example. Please regards the setting value

according to BLD-E1 Series.

3-4 Revision May 2009, 00DE, V0.50

Page 38

Chapter 3 Keypad and Start Up| BLD-E1 Series

Reference Table for the 7-segment LED Display of the Digital Keypad

Digit 0 1 2 3 4 5 6 7 8 9

LED

Display

ASCII 0x30 0x31 0x32 0x33 0x34 0x35 0x36 0x37 0x38 0x39

Digit A b Cc d E F G Hh i Jj

LED

Display

ASCII 0x41 0x62 0x43,0x63 0x64 0x45 0x46 0x47 0x48,0x68 0x69 0x4a,0x6a

Digit K L n o P q r S t Uu

LED

Display

ASCII 0x4b 0x4c 0x6e 0x6f 0x50 0x71 0x72 0x53 0x74 0x55,0x75

Digit v Y Z

LED

Display

ASCII 0x76 0x59 0x5a

Digit

LED

Display

ASCII 0xb0 0xb1 0xb2,0xb3 0xb4 0xb5 0xb6 0xb7 0xb8,0xb9 0xba 0xbb,0xbc

Digit

LED

Display

ASCII 0xbd 0xbe 0xbf 0xc0 0xc1 0xc2 0xc3 0xc4 0xc5 0xc6,0xc7

Digit

LED

Display

ASCII 0xc8 0xc9 0xca

A﹒ b﹒C﹒c﹒ d﹒E

K﹒ L﹒n﹒ o﹒P

v﹒ Y﹒Z﹒

﹒

﹒

F﹒ G

q﹒ r

﹒

H

﹒

S

﹒h﹒

i

﹒

t

﹒

J

﹒

U

﹒j﹒

﹒u﹒

Revision May 2009, 00DE, V0.50 3-5

Page 39

Chapter 3 Keypad and Start Up| BLD-E1 Series

3.2 Operation Method

The operation method can be set via communication and control terminals.

Operation

Method

Operate from the

communication

Operate from the

digital keypad

Frequency Source

When setting communication by the PC, it needs to use VFD-USB01 or

IFD8500 converter to connect to the PC.

Refer to the communication address 2000H and 2101H setting for details.

Operation Command

Source

Figure 3-1

Potentiometer RUN, STOP/RESET

3-6 Revision May 2009, 00DE, V0.50

Page 40

Chapter 3 Keypad and Start Up| BLD-E1 Series

Operation

Method

Operate from

external signal

Frequency Source

FWD/Stop

Factory setting:

NPN Mode

NPN

PNP

* Don't apply the mains voltage directly

to abo v e term in a ls.

Factory setting:

AC I Mode

AVI

ACI

ACI/AVI switch

Factory setting is ACI

Factory

setting

REV/Stop

Multi-step 1

Multi-step 3

Multi-step 4

Digital Signal Common

5K

Analog Signal Common

Multi-step 2

3

2

1

Operation Command

Source

+24V

MI1

MI2

MI3

MI4

Multi-function

input

terminals

MI5

MI6

DCM

E

+10V

Power supply

+10V 20mA

AVI

Master Frequency

0 to 10V 47K

ACI/AVI

4-20mA/0-10V

ACM

E

Figure 3-1

MI3-DCM (Set Pr.04-05=d10)

MI4-DCM (Set Pr.04-06=d11)

MI1-DCM (FWD/STOP)

MI2-DCM(REV/STOP)

Revision May 2009, 00DE, V0.50 3-7

Page 41

Chapter 3 Keypad and Start Up| BLD-E1 Series

3.3 Trial Run

The factory setting of trial run is by the potentiometer, please operate by the following steps.

1. After applying the power, setting the parameter according to the motor type in

parameter group 08. (For Delta’s ECMD-E9 Series of motor, the drive will atuo set the

motor parameter to the default value)

2. Please execute angle detection for the first time operation of Delta ECMD-E9 Motor

and drive. First set 08-00=1 and press RUN, the keypad will show “tun” during the

angle detection. The keypad will return to the main menu after the auto-detection is

finished.

3. Verify that LED display shows 0~3000RPM (depends on the potentiometer position)

with RPM signal blinking and FWD indicator lighted on.

4. Please set potentiometer to a low running speed around 100RPM.

5. Press RUN key for forward running. For ramp to stop, please press STOP/RESET key.

6. To switch to reverse running, press the MODE key and look for FWD page, then press

UP/DOWN key to REV page to finish setting.

7. Check following items:

Check if the direction of motor rotation is correct.

Check if the motor runs steadily without abnormal noise and vibration.

Check if acceleration and deceleration are smooth.

If the results of trial run are normal, please start the formal run.

3-8 Revision May 2009, 00DE, V0.50

Page 42

Chapter 4 Parameters

The BLD-E1 parameters are divided into 14 groups by property for easy setting. In most applications,

the user can finish all parameter settings before start-up without the need for re-adjustment during

operation.

4.1 Summary of Parameter Setting

00:System Parameter

01:Basic Parameters

02:Digital Input/Output Parameters

03:Analog Input/Output Parameter

04:Multi-Step Speed Parameters

05:IM Parameters

06:Protection Parameters

07:Special Parameters

08:PM Parameters

4.2 Description of Parameter Setting

00:System Parameter

01:Basic Parameters

02:Digital Input/Output Parameters

03:Analog Input/Output Parameter

04:Multi-Step Speed Parameters

05:IM Parameters

06:Protection Parameters

07:Special Parameters

08:PM Parameters

09:Communication Parameters

10:Speed Feedback Control Parameters

11 : Advanced Parameters

12:User-defined Parameters

13:View User-defined Parameters

09:Communication Parameters

10:Speed Feedback Control Parameters

11 : Advanced Parameters

12:User-defined Parameters

13:View User-defined Parameters

Revision May 2009, 06EE, V0.50 4-1

Page 43

Chapter 4 ParametersAT |Troubleshooting}| BLD-E1 Series

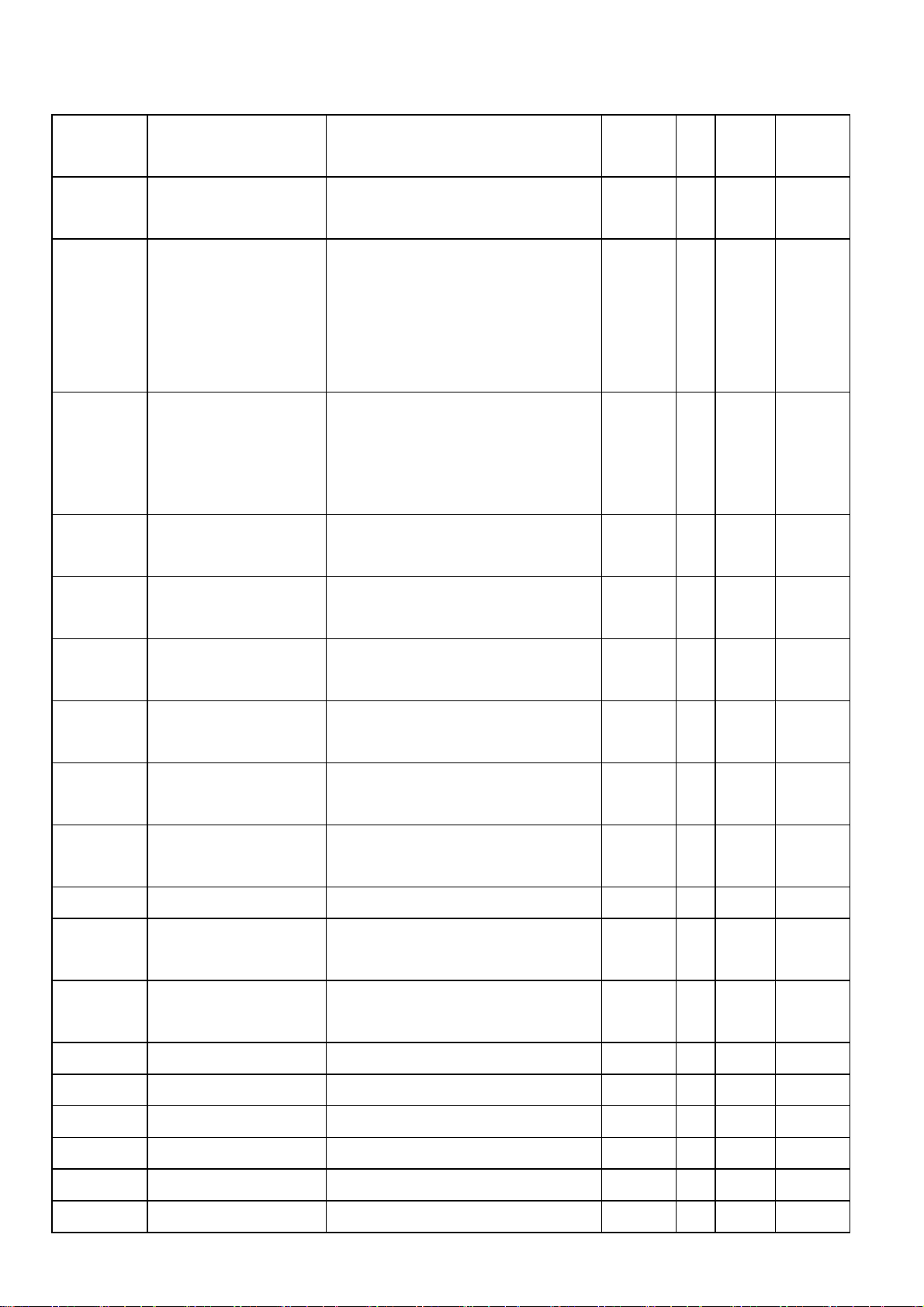

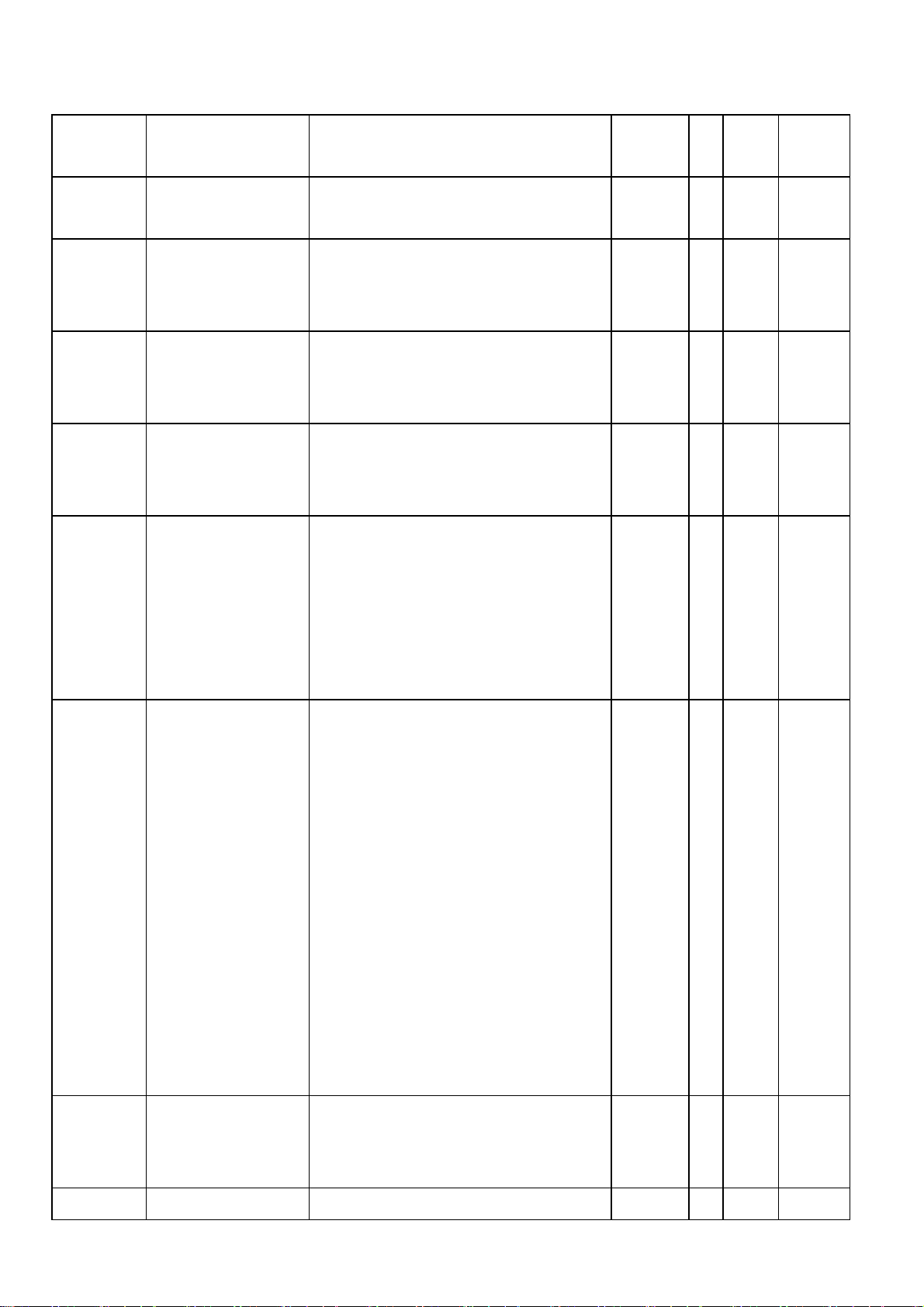

4.1 Summary of Parameter Settings

Group 00 System Parameters

Parameter Explanation Settings

00.00 Identity Code of

the Brushless DC

Motor Drive

0:115V,1PH,0.2KW,1/4HP

2:115V,1PH,0.4KW,1/2HP

4:115V,1PH,0.7KW,1HP

0:230V,1PH,0.2KW,1/4HP

2:230V,1PH,0.4KW,1/2HP

4:230V,1PH,0.7KW,1HP

6:230V,1PH,1.5KW,2HP

8:230V,1PH,2.2KW,3HP

0:230V,3PH,0.2KW,1/4HP

2:230V,3PH,0.4KW,1/2HP

4:230V,3PH,0.7KW,1HP

6:230V,3PH,1.5KW,2HP

: The parameter can be set during operation.

Factory

Setting

Read-

only

VF VFPG FOCPM

○ ○ ○

8:230V,3PH,2.2KW,3HP

10:230V,3PH,3.7KW,5HP

3:460V,3PH,0.4KW,1/2HP

5:460V,3PH,0.7KW,1HP

7:460V,3PH,1.5KW,2HP

9:460V,3PH,2.2KW,3HP

11:460V,3PH,3.7KW,5HP

00.01 Rated Current

Display of the

Brushless DC

Motor Drive

00.02 Parameter Reset 0:No function

00.03 Start-up Display

Display according to the model

series

10:All parameters are reset to

factory settings

0:Frequency command

Read-

only

0 ○ ○ ○

0 ○ ○ ○

○ ○ ○

Selection

4-2

Revision May 2009, 00DE, V0.50

1:Out put frequency

2:DC BUS voltage

3:Output current

4:output voltage

Page 44

Chapter 4 Parameters| BLD-E1 Series

Parameter Explanation Settings

5:defined by user (Pr.00-04)

00.04 Content of Multi-

function Display

0:Display the output current from

drive to motor

1:Reserved

2:Display actual output frequency

3:Display DC-Bus voltage (U)

4:Display output voltage of U, V,

W (E)

5:Display output power factor

angle (n.)

6:Display output power (kW)

7:Display actual motor speed in

rpm (HU)

Factory

VF VFPG FOCPM

Setting

0 ○ ○ ○

8:Display estimate output torque

(%)

9:Display PG feedback

10:Display the electrical angle of

drive output 11:Display the signal

value % of VR analog input

terminal

12:Display the signal value % of

ACI analog input terminal

13:Display the signal value % of

AVI analog input terminal

14:Reserved

15:Display IGBT temperature ℃

16:Digital input status ON/OFF

17:Digital output status ON/OFF

18:Multi-step speed (S)

19:The corresponding CPU pin

status of digital input

20:The corresponding CPU pin

status of digital output

21~23:Reserved

24:Output AC voltage when

Revision May 2009, 00DE, V0.50 4-3

Page 45

Chapter 4 ParametersAT |Troubleshooting}| BLD-E1 Series

Parameter Explanation Settings

malfunction

25:Output DC voltage when

malfunction

26:Motor frequency when

malfunction

27:Output current when

malfunction

28:Output frequency when

malfunction

29:Frequency command when

malfunction

30:Output power when

malfunction

Factory

VF VFPG FOCPM

Setting

31:Output torque when

malfunction

32:Input terminal status when

malfunction

33:Output terminal status when

malfunction

34:Drive status when malfunction

00.05 Reserved

00.06 Software Version Read-only #.# ○ ○ ○

00.07 Selection of motor

stop method

00.08 Setting of Motor

Running Direction

00.09 Control Method 0:V/Fcontrol

0:decelerate braking to stop

1:coast to stop

0:reverse running allowed

1:reverse running not allowed

2:forward running not allowed

0 ○ ○ ○

0 ○ ○ ○

8 ○ ○ ○

1:V/Fcontrol + Encoder (VFPG)

8:FOC PM Control (FOCPM)

00.10 Speed Unit 0:Hz

3:RPM

00.11 Reserved

00.12 Carrier Frequency 2~15KHz 8 ○ ○ ○

00.13 Auto voltage 0:Enable AVR 0 ○ ○ ○

4-4

Revision May 2009, 00DE, V0.50

3 ○ ○ ○

Page 46

Chapter 4 Parameters| BLD-E1 Series

Parameter Explanation Settings

Regulation (AVR) 1:Disable AVR

2:Disable AVR when deceleration

stop

00.14 Source of

Frequency

Command

00.15 Source of

Operation

Command

0:Digital keypad input

1:RS-485 serial communication

input

2:External analog input

(Pr.03-00~03-02)

3:Digital terminals input

(Pr.04-00~04-15)

0:Digital keypad input

1:External terminal operation

2: RS-485 serial communication

Factory

VF VFPG FOCPM

Setting

2 ○ ○ ○

0 ○ ○ ○

input

Revision May 2009, 00DE, V0.50 4-5

Page 47

Chapter 4 ParametersAT |Troubleshooting}| BLD-E1 Series

r

Group 01 Basic Parameters : The parameter can be set during operation.

Paramete

01.00 Maximum Operation

01.01 1st Output

01.02 1st Output Voltage

01.03 2nd Output

Explanation Settings

120~4000RPM (10~400Hz) 3000

Frequency

0~400.00Hz 60.00 ○ ○ ○

Frequency Setting 1

(Base Frequency/

Rated Motor

Frequency)

230V Series:0.0V~255.0V

Setting 1

(Base Voltage/ Rated

Motor Voltage)

Frequency Setting 1

460V Series:0.0V~510.0V

0~400.00Hz 0.50 ○ ○

Factory

Setting

(250)

220.0

440.0

VF VFPG FOCPM

○ ○ ○

○ ○ ○

01.04 2nd Output Voltage

Setting 1

01.05 3rd Output

Frequency Setting 1

01.06 3rd Output Voltage

Setting 1

01.07 4th Output

Frequency Setting 1

01.08 4th Output Voltage

Setting 1

01.09 Start Frequency 0~4000rpm (0~400.00Hz) 6 (0.5) ○ ○

01.10 Output Frequency

Upper Limit

01.11 Output Frequency

Lower Limit

230V Series:0.0V~255.0V

460V Series:0.0V~510.0V

0~400.00Hz 0.50 ○ ○

230V Series:0.0V~255.0V

460V Series:0.0V~510.0V

0~400.00Hz 0.00 ○ ○

230V Series:0.0V~255.0V

460V Series:0.0V~510.0V

0~4000rpm (0~400.00Hz) 3000

0~4000rpm (0~400.00Hz) 0 (0.00) ○ ○ ○

5.0

10.0

5.0

10.0

0.0

0.0

(250)

○ ○

○ ○

○ ○

○ ○ ○

01.12 Accel Time 1 0.00~600.00 sec 3.00 ○ ○ ○

01.13 Decel Time 1 0.00~600.00 sec 2.00 ○ ○ ○

01.14 Accel Time 2 0.00~600.00 sec 3.00 ○ ○ ○

01.15 Decel Time 2 0.00~600.00 sec 2.00 ○ ○ ○

01.16 Accel Time 3 0.00~600.00 sec 3.00 ○ ○ ○

01.17 Decel Time 3 0.00~600.00 sec 2.00 ○ ○ ○

4-6

Revision May 2009, 00DE, V0.50

Page 48

Chapter 4 Parameters| BLD-E1 Series

Parameter Explanation Settings

VF VFPG FOCPM

Setting

01.18 Accel Time 4 0.00~600.00 sec 3.00 ○ ○ ○

01.19 Decel Time 4 0.00~600.00 sec 2.00 ○ ○ ○

01.20 Reserved

01.21 Reserved

01.22 Reserved

Factory

01.23 Switch Frequency

0~4000rpm (0~400.00Hz) 0 (0.00) ○ ○ ○

between 1st/4th

Accel/decel

01.24 S-curve for

0.0~25.0 sec 0.0 ○ ○ ○

Acceleration

Departure Time S1

01.25 S-curve for

0.0~25.0 sec 0.0 ○ ○ ○

Acceleration Arrival

Time S2

01.26 S-curve for

Deceleration

Departure Time S3

01.27 S-curve for

Deceleration Arrival

Time S4

01.28 Mode Selection when

Frequency < Fmin

01.29 Switch Frequency

form S to S5

01.30 S-curve for

Deceleration Arrival

0.0~25.0 sec 0.0 ○ ○ ○

0.0~25.0 sec 0.0 ○ ○ ○

0:Output waiting

0 ○ ○

1:Zero-speed operation

th

2 : Fmin (4

output frequency

setting)

0~4000rpm (0~400.00Hz) 0 (0.00) ○ ○ ○

0.0~25.0 sec 0.0 ○ ○ ○

Time S5

01.31 Time required for

0.00~600.00 sec 2.00 ○ ○ ○

deceleration to stop

NOTE: With Delta ECMD-E9 Series motor, rated frequency is 2000rpm and maximum frequency is

3000rmp.

Revision May 2009, 00DE, V0.50 4-7

Page 49

Chapter 4 ParametersAT |Troubleshooting}| BLD-E1 Series

r

Group 02 Digital : The parameter can be set during operation.

Paramete

Explanation Settings

02.00 2-wire/3-wire

Operation Control

02.01 Multi-Function

Command Input

(MI3)

Factory

VF VFPG FOCPM

Setting

0:2-wire operation mode1,

FWD/STOP, REV/STOP

0 ○ ○ ○

1:2 –wire mode1, FWD/STOP,

REV/STOP (Line Start Lockout)

2:2-wire mode2, RUN/STOP,

REV/FWD

3:2-wire mode2, RUN/STOP,

REV/FWD (Line Start Lockout)

4:3-wire,

5:3-wire (Line Start Lockout).

0:no function 1 ○ ○ ○

02.02 Multi-Function

Input (MI4)

02.03 Multi-Function

Command Input

(MI5)

02.04 Multi-Function

Command Input

(MI6)

1:Multi-step command 1 2 ○ ○ ○

2:Multi-step command 2 3 ○ ○ ○

3:Multi-step command 3 4 ○ ○ ○

4:Multi-step command 4 ○ ○ ○

5:Reset ○ ○ ○

6:Reserved ○ ○ ○

7:acceleration/deceleration speed

○ ○ ○

inhibit

8:the 1st, 2nd

○ ○ ○

acceleration/deceleration time

selection

9:the 3rd, 4th

○ ○ ○

acceleration/deceleration time

selection

10: EF input (Pr.07-28) ○ ○ ○

11: Reserved ○ ○ ○

4-8

Revision May 2009, 00DE, V0.50

12: Stop output ○ ○ ○

Page 50

Chapter 4 Parameters| BLD-E1 Series

Parameter Explanation Settings Factory

Setting

13~14: Reserved ○ ○ ○

15:Running speed

○ ○ ○

command from VR

16:Running speed

○ ○ ○

command from ACI

17:Running speed

○ ○ ○

command from AVI

18:Emergency Stop

○ ○ ○

(Pr.07-28)

19~26:Reserved ○ ○ ○

27:ASR1/ASR2 Selection ○ ○ ○

28:Emergency stop (EF1)

○ ○ ○

(Motor coasts to stop)

VF VFPG FOCPM

02.05 ~

02.08

Reserved

29~30:Reserved ○ ○ ○

31: High torque bias (by

○ ○ ○

Pr.07-21)

32: Middle torque bias (by

○ ○ ○

Pr.07-22)

33: Low torque bias (by

○ ○ ○

Pr.07-23)

34-37: Reserved ○ ○ ○

38: Disable EEPROM write

○ ○ ○

function

39:Reserved ○ ○ ○

40:Enable drive to

○ ○ ○

function

02.09 Digital Input

0.001~ 30.000 Sec 0.005 ○ ○ ○

Response Time

02.10 Digital Input

0~65535 0 ○ ○ ○

Operation

Direction

02.11 Reserved

Revision May 2009, 00DE, V0.50 4-9

Page 51

Chapter 4 ParametersAT |Troubleshooting}| BLD-E1 Series

Parameter Explanation Settings Factory

Setting

02.12 Reserved

02.13 Multi-function

Output (MO1)

02.14 Multi-function

Output (MO2)

0:No function 41 ○ ○ ○

1: Operation indication 41 ○ ○ ○

2: Operation speed attained ○ ○ ○

3:Desired frequency

attained 1 (Pr. 02-25, 02-

26)

4:Desired frequency

attained 2 (Pr. 02-27, 02-

28)

5: Zero speed (frequency

command)

○ ○ ○

○ ○ ○

○ ○ ○

VF VFPG FOCPM

6: Zero speed with stop

(frequency command)

7: Over torque (OT1) (Pr.

06-05~06-07)

8: Over torque (OT2) (Pr.

06-08~06-10)

9: Drive ready ○ ○ ○

10:Low-voltage Detection

(LV)

11:Malfunction indication ○ ○ ○

12:Reserved ○ ○ ○

13:Overheat warning (Pr.

06-14)

21:Ove voltage warning ○ ○ ○

22:Over-current stall

○ ○ ○

○ ○ ○

○ ○ ○

○ ○ ○

○ ○ ○

○ ○ ○

prevention warning

23:Over-voltage stall

prevention warning

24:Drive operation mode

(Parameter: 00.21=0)

4-10

Revision May 2009, 00DE, V0.50

○ ○ ○

○ ○ ○

Page 52

Chapter 4 Parameters| BLD-E1 Series

Parameter Explanation Settings Factory

Setting

25: Forward running

command

26: Reverse running

command

27~30:Reserved ○ ○ ○

31:Forward running input ○ ○ ○

32:Reverse running input ○ ○ ○

33:Zero-speed (Actual

output frequency)

34:Zero speed with Stop

(actual output frequency)

35~39:Reserved ○ ○ ○

40:Speed attained

○ ○ ○

○ ○ ○

○ ○ ○

○ ○ ○

VF VFPG FOCPM

○ ○ ○

02.23 Multi-output

Direction

02.24 Reserved

02.25 Desired

Frequency

Attained 1

02.26 Width of Desired

Frequency

Attained 1

02.27 Desired

Frequency

Attained 2

02.28 Width of Desired

Frequency

(including zero speed)

0~65535 0 ○ ○ ○

0~4000RPM

(0.00~400.0Hz)

0~4000RPM

(0.00~400.0Hz)

0~4000RPM

(0.00~400.0Hz)

0~4000RPM

(0.00~400.0Hz)

0 (0.00) ○ ○ ○

24 (2.00) ○ ○ ○

0 (0.00) ○ ○ ○

24 (2.00) ○ ○ ○

Attained 2

Revision May 2009, 00DE, V0.50 4-11

Page 53

Chapter 4 ParametersAT |Troubleshooting}| BLD-E1 Series

r

r

r

Group 03: Time Parameters : The parameter can be set during operation.

Paramete

03.00 Analog Input (VR) 0:No function 1 ○ ○ ○

03.01 Analog Input (ACI) 1:Frequency command (torque limit

03.02 Analog Input 3 2:Reserved 0

(AVI) 3: Preload input ○ ○ ○

4~6:Reserved

7: Positive torque limit ○

8: Negative torque limit ○

9: Regenerative torque limit ○

10: Positive/negative torque limit ○

03.03 Analog Input Bias

03.04 Analog Input Bias

Explanation Settings

under TQR control mode)

-100.0~100.0% 0.0 ○ ○ ○

VR

-100.0~100.0% 0.0 ○ ○ ○

Factory

VF VFPG FOCPM

Setting

0 ○ ○ ○

ACI

03.05 Analog Input Bias

AVI

03.06 Positive/negative

Bias Mode VR

03.07 Positive/negative

Bias Mode ACI

(can be set to 0 or

1 only)

03.08 Positive/negative

Bias Mode AVI

03.09 Analog Input Gain

VR

-100.0~100.0% 0.0 ○ ○ ○

0: Zero bias

1: Serve bias as the center, lowe

than bias=bias

2: Serve bias as the center, greate

than bias=bias

3: The absolute value of the bias

voltage while serving as the center

(single polar)

4: Serve bias as the center (single

polar)

0.0~500.0% 100.0 ○ ○ ○

0 ○ ○ ○

0 ○ ○ ○

0 ○ ○ ○

03.10 Analog Input Gain

ACI

03.11 Analog Input Gain

AVI

03.12 Analog Input Delay

Time VR

4-12

Revision May 2009, 00DE, V0.50

0.0~500.0% 100.0 ○ ○ ○

0.0~500.0% 100.0 ○ ○ ○

0.00~2.00 sec 0.05 ○ ○ ○

Page 54

Chapter 4 Parameters| BLD-E1 Series

r

Paramete

03.13 Analog Input Delay

Explanation Settings

0.00~2.00 sec 0.05 ○ ○ ○

Time ACI

03.14 Analog Input Delay

0.00~2.00 sec 0.05 ○ ○ ○

Time AVI

03.15 Loss of the ACI

Signal

0: Disable

1: Continue operation at the last

frequency

2: Decelerate to 0Hz

3: Stop immediately and display E.F.

Factory

VF VFPG FOCPM

Setting

0 ○ ○ ○

Revision May 2009, 00DE, V0.50 4-13

Page 55

Chapter 4 ParametersAT |Troubleshooting}| BLD-E1 Series

Group 04: Multi-Step Speed Parameters

: The parameter can be set during operation.

Parameter Explanation Settings

04.00 Zero Step Speed

Frequency

04.01 1st Step Speed

Frequency

04.02 2nd Step Speed

Frequency

04.03 3rd Step Speed

Frequency

04.04 4th Step Speed

Frequency

04.05 5th Step Speed

Frequency

04.06 6th Step Speed

0~4000RPM (0.00~400.0Hz) 0.00 ○ ○ ○

0~4000RPM (0.00~400.0Hz) 0.00 ○ ○ ○

0~4000RPM (0.00~400.0Hz) 0.00 ○ ○ ○

0~4000RPM (0.00~400.0Hz) 0.00 ○ ○ ○

0~4000RPM (0.00~400.0Hz) 0.00 ○ ○ ○

0~4000RPM (0.00~400.0Hz) 0.00 ○ ○ ○

0~4000RPM (0.00~400.0Hz) 0.00 ○ ○ ○

Factory

VF VFPG FOCPM

Setting

Frequency

04.07 7th Step Speed

Frequency

04.08 8th Step Speed

Frequency

04.09 9th Step Speed

Frequency

04.10 10th Step Speed

Frequency

04.11 11th Step Speed

Frequency

04.12 12th Step Speed

Frequency

04.13 13th Step Speed

Frequency

0~4000RPM (0.00~400.0Hz) 0.00 ○ ○ ○

0~4000RPM (0.00~400.0Hz) 0.00 ○ ○ ○

0~4000RPM (0.00~400.0Hz) 0.00 ○ ○ ○

0~4000RPM (0.00~400.0Hz) 0.00 ○ ○ ○

0~4000RPM (0.00~400.0Hz) 0.00 ○ ○ ○

0~4000RPM (0.00~400.0Hz) 0.00 ○ ○ ○

0~4000RPM (0.00~400.0Hz) 0.00 ○ ○ ○

04.14 14th Step Speed

Frequency

04.15 15th Step Speed

Frequency

0~4000RPM (0.00~400.0Hz) 0.00 ○ ○ ○

0~4000RPM (0.00~400.0Hz) 0.00 ○ ○ ○

4-14

Revision May 2009, 00DE, V0.50

Page 56

Chapter 4 Parameters| BLD-E1 Series

Group 05: IM Parameters : The parameter can be set during operation.

Parameter Explanation Settings

05.18 Accumulative

Motor Operation

Time (min.)

05.19 Accumulative

Motor Operation

Time (day)

05.21 Accumulative

Drive Power-on

Time (min.)

05.22 Accumulative

Drive Power-on

Time (day)

00~1439 0 ○ ○ ○

00~65535 0 ○ ○ ○

00~1439 0 ○ ○ ○

00~65535 0 ○ ○ ○

Factory

VF VFPG FOCPM

Setting

Revision May 2009, 00DE, V0.50 4-15

Page 57

Chapter 4 ParametersAT |Troubleshooting}| BLD-E1 Series

r

Group 6: Protection Parameters

Paramete

06.00 Low Voltage Level 160.0~220.0Vdc

06.01 Phase-loss

06.02 Over-current Stall

06.03 Over-current Stall

06.04 Accel./Decel. Time

Explanation Settings

320.0~440.0Vdc

0: Warn and keep operation

Protection

Prevention during

Acceleration

Prevention during

Operation

1: Warn and ramp to stop

2: Warn and coast to stop

00: disable

00~250%

00: disable

00~250%

0: by current accel/decel time

: The parameter can be set during operation.

Factory

Setting

180.0

360.0

2 ○ ○ ○

00 ○ ○

00 ○ ○

0 ○ ○

VF VFPG FOCPM

○ ○ ○

Selection of Stall

Prevention at

constant speed

06.05 Over-torque

Detection Selection

(OT1)

1: by the 1st accel/decel time

2: by the 2nd accel/decel time

3: by the 3rd accel/decel time

4: by the 4th accel/decel time

5: by auto accel/decel time

0: disable

1: over-torque detection during

constant speed operation, continue

to operate after detection

2: over-torque detection during

constant speed operation, stop

operation after detection

3: over-torque detection during

operation, continue to operate after

detection

0 ○ ○ ○

4: over-torque detection during

operation, stop operation after

detection

06.06 Over-torque

Detection Level

(OT1)

06.07 Over-torque 0.0~60.0 sec 0.1 ○ ○ ○

4-16

Revision May 2009, 00DE, V0.50

10~250% 150 ○ ○ ○

Page 58

Chapter 4 Parameters| BLD-E1 Series

r

Paramete

Explanation Settings

Detection Time

(OT1)

06.08 Over-torque

Detection Selection

(OT2)

0: disable

1: over-torque detection during

constant speed operation, continue

to operate after detection

2: over-torque detection during

constant speed operation, stop

operation after detection

3: over-torque detection during

operation, continue to operate after

detection

4: over-torque detection during

Factory

VF VFPG FOCPM

Setting

0 ○ ○ ○

operation, stop operation after

detection

06.09 Over-torque

10~250% 150 ○ ○ ○

Detection Level

(OT2)

06.10 Over-torque

0.0~60.0 sec 0.1 ○ ○ ○

Detection Time

(OT2)

06.11 Current Limit 0~250% 200 ○ ○ ○

06.12 Electronic Thermal

Relay Selection

0: Inverter motor

1: Standard motor

2 ○ ○ ○

2: Disable

06.13 Electronic Thermal

30.0~600.0 sec 60.0 ○ ○ ○

Characteristic

06.14 Heat Sink Over-

0.0~110.0℃ 85.0 ○ ○ ○

heat (OH) Warning

06.15 Stall Prevention

0~100% (refers to Pr. 06-02, 06-03) 50 ○ ○ ○

Limit Level

06.16 Present Fault

Record

0: No fault

0 ○ ○ ○

06.17 Second Most 1: Over-current during acceleration 0 ○ ○ ○

Revision May 2009, 00DE, V0.50 4-17

Page 59

Chapter 4 ParametersAT |Troubleshooting}| BLD-E1 Series

r

Paramete

06.18 Third Most Recent

06.19 Fourth Most Recent

06.20 Fifth Most Recent

06.21 Sixth Most Recent

Explanation Settings

Recent Fault

Record

Fault Record

Fault Record

Fault Record

Fault Record

(ocA)

2: Over-current during deceleration

(ocd)

3: Over-current during constant

speed (ocn)

4: Ground fault (GFF)

5:Reserved

6: Over-current at stop (ocS)

7: Over-voltage during acceleration

(ovA)

8: Over-voltage during deceleration

Factory

VF VFPG FOCPM

Setting

0 ○ ○ ○

0 ○ ○ ○

0 ○ ○ ○

0 ○ ○ ○

(ovd)

9: Over-voltage during constant

speed (ovn)

10: Over-voltage at stop (ovS)

11: Low-voltage during acceleration

(LvA)

12: Low-voltage during deceleration

(Lvd)

13: Low-voltage during constant

speed (Lvn)

14: Low-voltage at stop (LvS)

15: Phase loss protection (PHL)

16: IGBT heat sink over-heat (oH1)

17:Reserved

18:18: TH1 open loop error (tH1o)

19~20:Reserved

21: over-load (oL) (150% 1Min)

22: Motor over-load (EoL1)

23~25:Reserved

26: over-torque 1 (ot1)

27: over-torque 1 (ot2)

28: Reserved

4-18

Revision May 2009, 00DE, V0.50

Page 60

Chapter 4 Parameters| BLD-E1 Series

r

Paramete

Explanation Settings

Factory

Setting

29: Reserved

30: Memory write-in error (cF1)

31: Memory read-out error (cF2)

32: Isum current detection error (cd0)

33: U-phase current detection error

(cd1)

34: V-phase current detection error

(cd2)

35: W-phase current detection error

(cd3)

36:current detection error (Hd0)

37:current detection error (Hd1)

38:Over-voltage detection error

VF VFPG FOCPM

(Hd2)

39: Ground current detection error

(Hd3)

40: Auto tuning error (AuE)

41:Reserved

42: PG feedback error (PGF1)

43: PG feedback loss (PGF2)

44: PG feedback stall (PGF3)

45: PG slip error (PGF4)

46~47:Reserved

48: Analog current input error (ACE)

49: External fault input (EF)

50: Emergency stop (EF1)

51:B.B. (Base Block)

52~53:Reserved

54: Communication error (cE1)

55: Communication error (cE2)

56: Communication error (cE3)

57: Communication error (cE4)

58: Communication Time-out (cE10)

59: PU time-out (cP10)

Revision May 2009, 00DE, V0.50 4-19

Page 61

Chapter 4 ParametersAT |Troubleshooting}| BLD-E1 Series

r

Group 07 Protection Parameters : The parameter can be set during operation.

Paramete

07.00 Reserved

07.01 Reserved

07.02 DC Brake

07.03 DC Brake Time

07.04 DC Brake Time

07.05 DC Brake

07.06 DC Brake

Explanation Settings

Current Level

during Start-up

during Stopping

Starting

Frequency

Proportional Gain

Factory

VF VFPG FOCPM

Setting

0~100% 0 ○ ○

0.0~60.0 sec 0.0 ○ ○ ○

0.0~60.0 sec 0.0 ○ ○ ○

0~4000rpm (0.00~400.0Hz) 0.00 ○ ○

1~500 50 ○ ○

07.07 ~

07.10

07.11 Fan Control 0: Fan always ON

07.12 Reserved

07.13 Reserved

07.14 Maximum Torque

Reserved

1: 1 minute after brushless DC motor

drive stops, fan will be OFF

2: Brushless DC motor drive runs

and fan ON, brushless DC motor

drive stops and fan OFF

3: Fan ON to run when preliminary

heat sink temperature attained

4: Fan OFF

0~300% 100 ○

Command

1 ○ ○ ○

07.15 ~

07.18

Reserved

4-20

Revision May 2009, 00DE, V0.50

Page 62

Chapter 4 Parameters| BLD-E1 Series

Parameter Explanation Settings Factory

Setting

07.19 Source of

Torque Offset

0: Disable

1: Analog input (Pr.03-

00)

0 ○

2: Torque offset setting

(Pr.07-20)

3: Control by external

terminal ( Pr.07-21 to 07-

23)

07.20 Torque Offset

0.0~100.0% 0.0 ○

Setting

07.21 High Torque

0.0~100.0% 30.0 ○

Offset

07.22 Mid Torque

0.0~100.0% 20.0 ○

VF VFPG FOCPM

Offset

07.23 Low Torque

0.0~100.0% 10.0 ○

Offset

07.24 Forward Motor

0~300% 200 ○

Torque Limit

07.25 Forward

0~300% 200 ○

Regenerative

Torque Limit

07.26 Reverse Motor

0~300% 200 ○

Torque Limit

07.27 Reverse

0~300% 200 ○

Regenerative

Torque Limit

07.28 Emergency

Stop (EF) &

0: Coast to stop

1: By deceleration Time 1

0 ○ ○ ○

Forced Stop

Selection

2: By deceleration Time 2

3: By deceleration Time 3

4: By deceleration Time 4

5: By Pr.01-31

07.29 Time Required

0.000~1.000 sec 0.000 ○

for Decreasing

Torque at Stop

Revision May 2009, 00DE, V0.50 4-21

Page 63

Chapter 4 ParametersAT |Troubleshooting}| BLD-E1 Series

r

Group 08 PM Parameters : The parameter can be set during operation.

Paramete

08.00 Motor Auto

08.01 Full-load Current

08.02 Rated power of

Explanation Settings

0: No function

Tuning

of Motor

Motor

1: Only for the unloaded motor, auto

measure the angle between

magnetic pole and PG origin (Pr.

08.09)

2: For PM parameters

3: Auto measure the angle between

magnetic pole and PG origin

(Pr.08-09)

40~120%)*00.01 Amps #.## ○

0.00~655.35kW #.## ○

Factory

VF VFPG FOCPM

Setting

0 ○

08.03 Rated speed of

Motor (rpm)

08.04 Number of Motor

Poles

08.05 Rs of Motor 0.000~65.535Ω # ○

08.06 Reserved

08.07 Lq of Motor 0.0~6553.5mH # ○

08.08 Back