Page 1

1

OPERATING MANUAL

FULLY AUTOMATIC BREADMAKER FOR

ALL KINDS OF BREAD DOUGHS,

BB 1350

Please read the instructions carefully before using the machine. You will find a range of

important and useful hints. Please keep the operating manual in a safe place and pass it on

with the machine to other users.

Page 2

2

For technical reasons this page is empty

Page 3

3

TABLE OF CONTENTS Page

CE Declaration of Conformity ................................................................................................4

General notes on safety ........................................................................................................5

Special notes on safety .........................................................................................................6

Areas of use ...........................................................................................................................7

Technical data .......................................................................................................................7

Items supplied .......................................................................................................................8

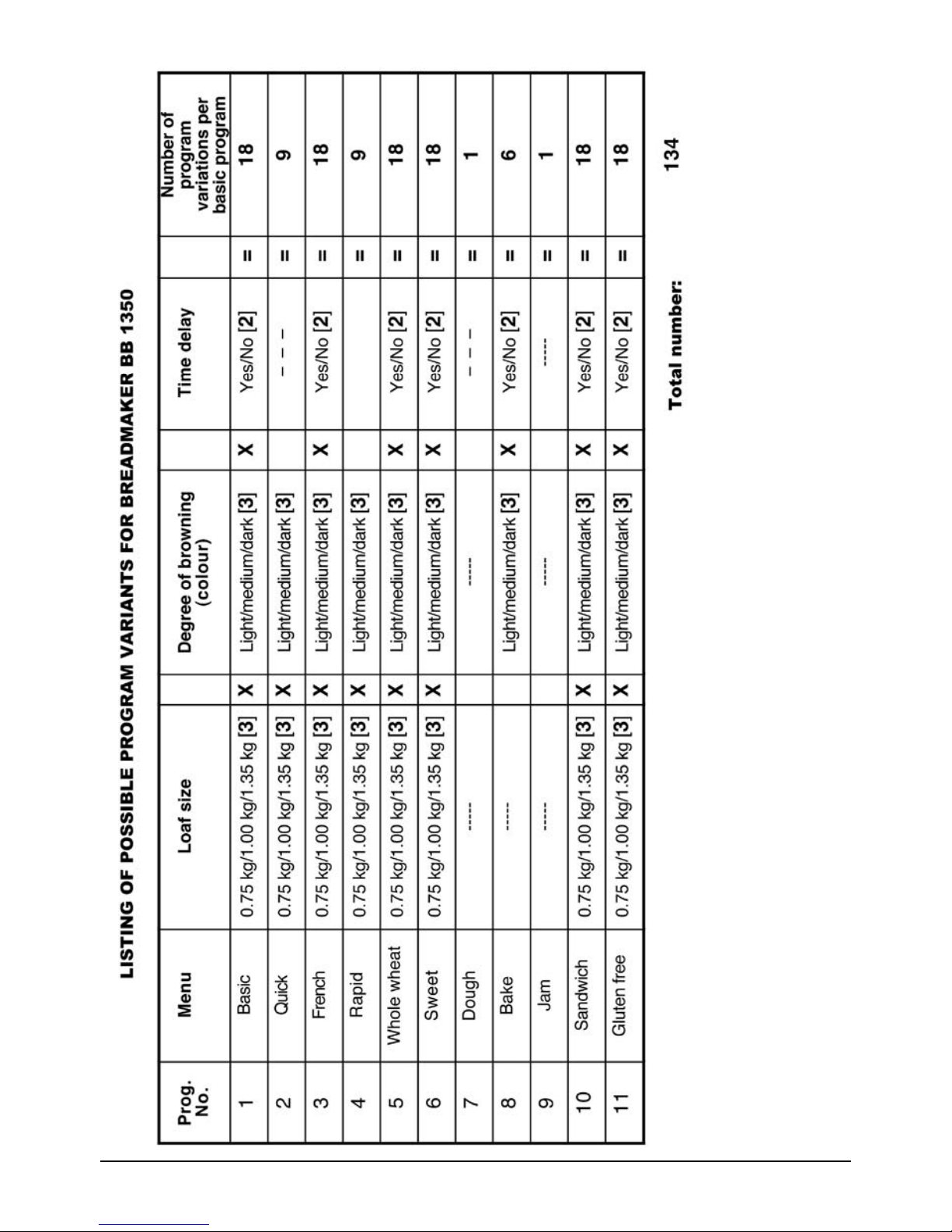

List of possible program variations .......................................................................................9

Preparation times (including preheating times where available) .........................................10

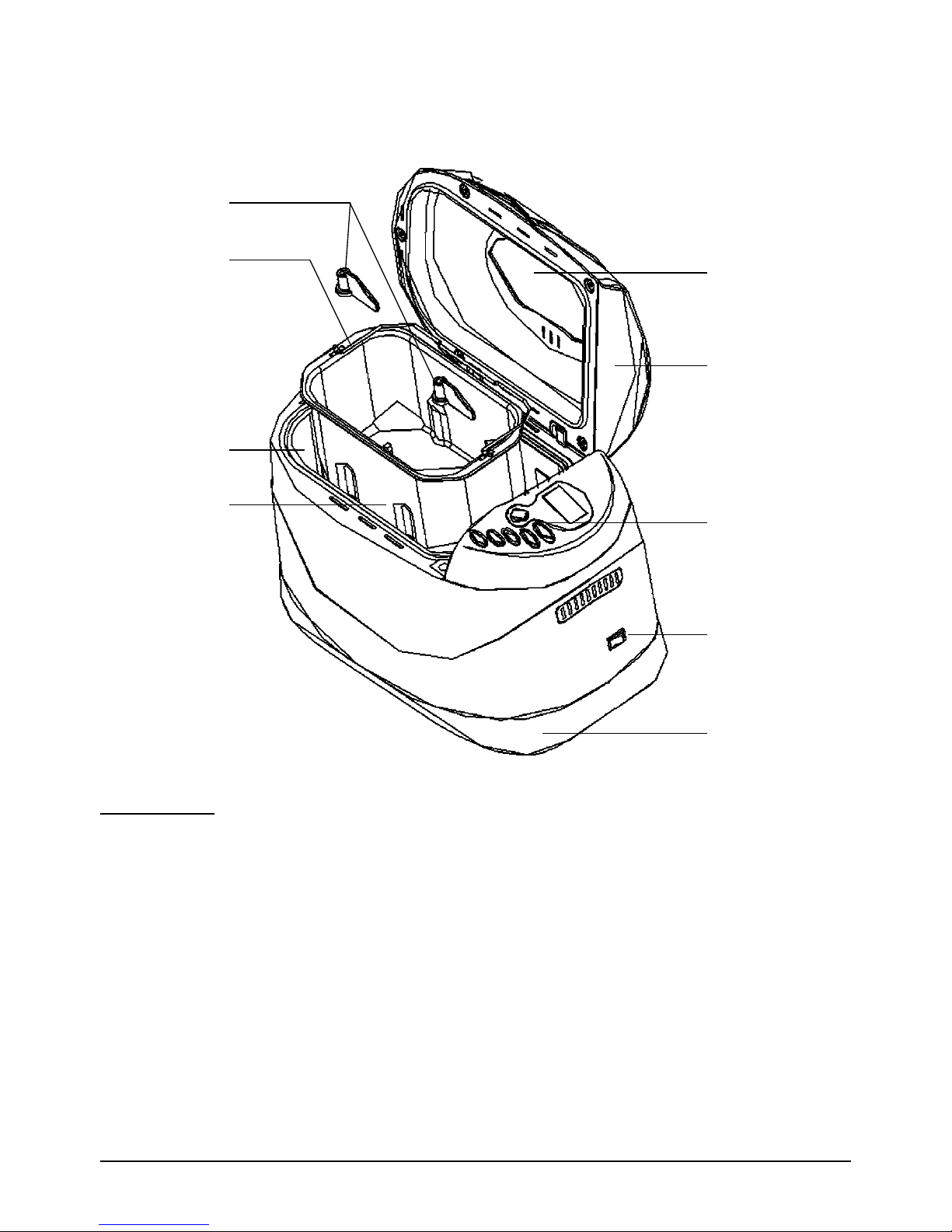

Description of equipment .............................................................................................. 11-12

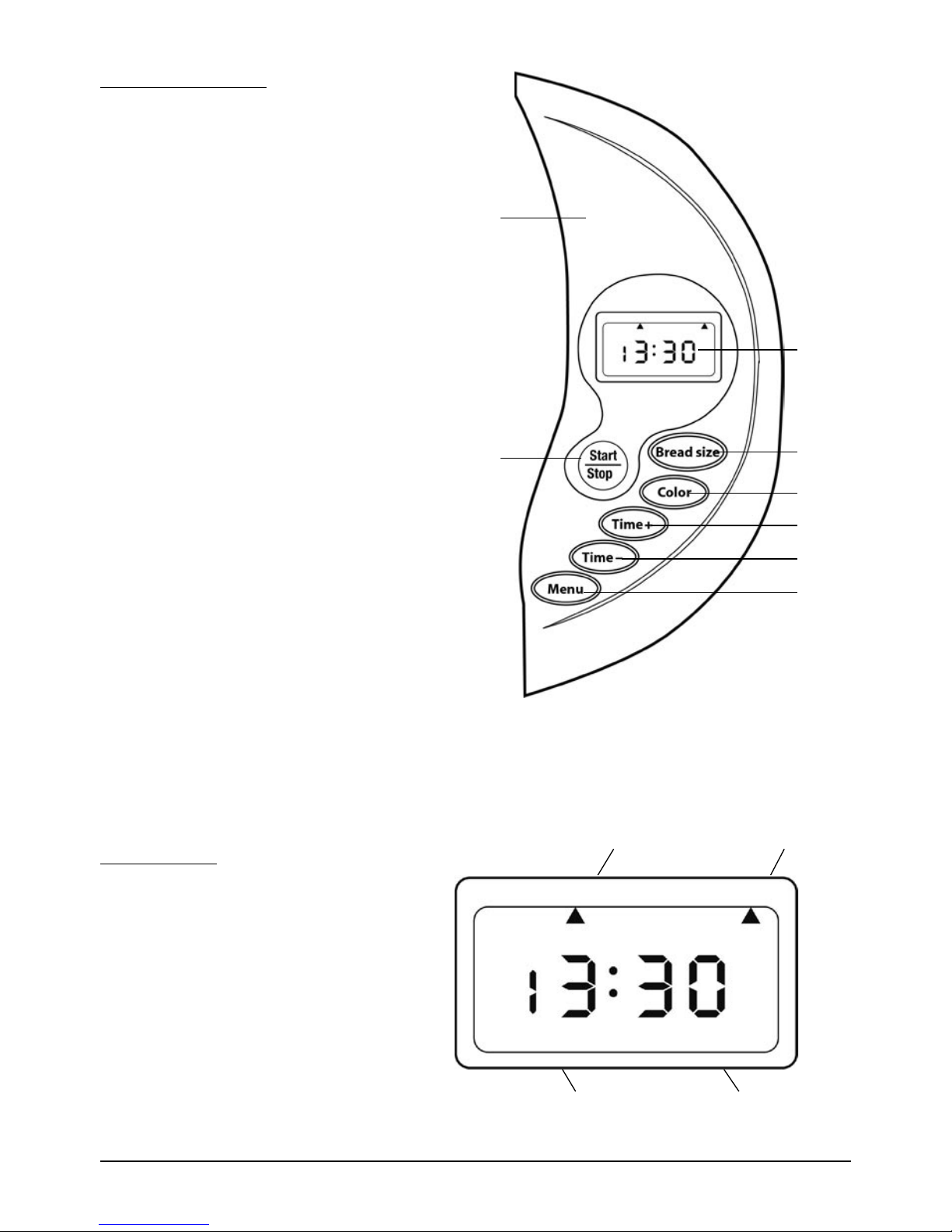

Description of the display and operational controls ...................................................... 13-16

Heat retention function ........................................................................................................16

Memory in event of power failure ........................................................................................16

Ambient conditions .............................................................................................................17

Error messages on the LCD display ....................................................................................17

Before using for the first time ..............................................................................................18

Use of the breadmaker .................................................................................................. 18-20

Helpful hints .................................................................................................................. 21-22

Tips regarding recipes .........................................................................................................23

Recipes .......................................................................................................................... 24-29

Own recipes .................................................................................................................. 30-31

Cleaning ..............................................................................................................................32

Undesirable baking results – causes and solutions ............................................................33

Troubleshooting ............................................................................................................. 34-37

Warranty conditions ............................................................................................................38

Disposal ...............................................................................................................................39

Page 4

4

CE DECLARATION OF CONFORMITY

Hans-Ulrich Petermann GmbH & Co. KG hereby declares that this product complies with the following EU Directives: 73/23/EC, 89/336/EC and

89/109/EC and that this is confirmed by the CE marking.

The equipment meets the requirements of German Law on equipment

safety. This is shown by the GS symbol from an independent testing

institution:

Page 5

5

GENERAL SAFETY ADVICE

This appliance may only be connected to a properly installed and protected

power outlet with supply voltage in accordance with the identification label.

Always unplug the appliance in case of malfunction, before cleaning and when

the appliance is not in use! Never pull by the power cable!

Never submerge the appliance in water and do not expose to rain or othermoisture!

If the appliance should fall into water, only remove it from the water when theplug is removed from the socket! Do not use again until it has been inspected by

an authorised servicing centre. This also applies if the power cable or appliance is

damaged or when the appliance has been dropped.

Ensure that the power cable and appliance is never placed on hot surfaces or near

heat sources. Ensure that the power cable can not come into contact with hot or

sharp-edged objects.

Never use the appliance when standing on a wet floor or when your hands or

the appliance are wet.

Do not kink the power cable or wind it around the appliance.

Do not leave the appliance unsupervised during operation!

Repairs must only be performed by authorised customer service centres. Never

attempt to open the appliance or insert metallic objects etc. inside.

If the appliance is not used as intended or operated incorrectly, we accept no

liability for any resulting damage!

Never use the appliance outdoors, as it may be exposed to rain or other water!

Electrical appliances are not toys! Use and store the appliance out of reach of

children. Do not leave the connection cable hanging down.

Do not allow children to operate this appliance.

If the power cable is damaged it must, for safety reasons, be replaced by an authorized servicing centre.

This appliance is not designed for commercial use, but exclusively for use in

the domestic household!

Page 6

6

SPECIAL NOTES ON SAFETY

WHEN USING BREADMAKERS

Do not stand the equipment on hot surfaces or near sources of heat. It should

not be placed beneath wall cupboards or too near the wall, to avoid a build-up

of heat.

Bread can burn! Never stand your breadmaker near highly flammable materials,

such as near or beneath net curtains!

Only stand the breadmaker on a heat resistant, level, non-slip area of your

kitchen worktop.

Never place anything on the machine or cover the vents. Heat and steam must

be able to escape freely, otherwise heat will build up and may damage the

equipment. Covering the vents also constitutes a fire hazard.

Use the equipment only for making bread or preparing doughs and jams, and

not for any other purpose!

Do not insert bulky foodstuffs, metal foil or the like into the machine to avoid

damaging it.

Use only the accessories provided. If you use parts made by other manufacturers

you will forfeit your entitlement to cover under the warranty.

Never use more than the quantities given in the recipes provided in the operating manual.

Never try to remove ingredients or dough from the breadmaker when it is

switched on!

Never remove the baking pan while the machine is in operation! Never touch a

rotating kneading hook – risk of injury!

Do not touch the baking pan or kneading hook with pointed or sharp objects.

If the non-stick coating of the baking pan or of a kneading hook is damaged

by improper use please refrain from using the part concerned. You can obtain

kneading hooks and baking pans from the customer service address at reasonable cost.

Use the baking pan with the utmost care. Always remove the baking pan from

the machine when adding ingredients, to avoid spillage on the baking chamber.

Burning dough is a fire risk!

Pull out the plug immediately if you notice unusual smoke, steam or smells. The

dough may have overflowed onto the heating element. Ensure that the outside

of the baking pan and the baking chamber are always clean.

Page 7

7

The surface of the equipment lid may become hot to the touch. Proceed with

care. To remove the dough container always use an oven cloth or glove.

Do not relocate the equipment when the dough container is full of hot liquid

(jam).

THE EQUIPMENT CAN BE USED FOR:

1) Kneading dough, e.g. for rolls or cakes and pastries.

2) Making bread according to the attached recipes or according to recipe books on

the market.

3) Processing baking mixes.

4) Making jam.

TECHNICAL DATA

Rated voltage: 230 V

Rated frequency: 50 Hz

Rated burden: 850 W

Level of protection: I

Basic program: 11

Program variations: 134

Timer: up to 13 hours’ baking delay

Heat retention function: 1 hour

Memory in the event of power failure: 15 minutes

Loaf sizes: 0.75 kg, 1.00 kg, 1.35 kg

Kneading hook and baking pan: non-stick coating

Page 8

8

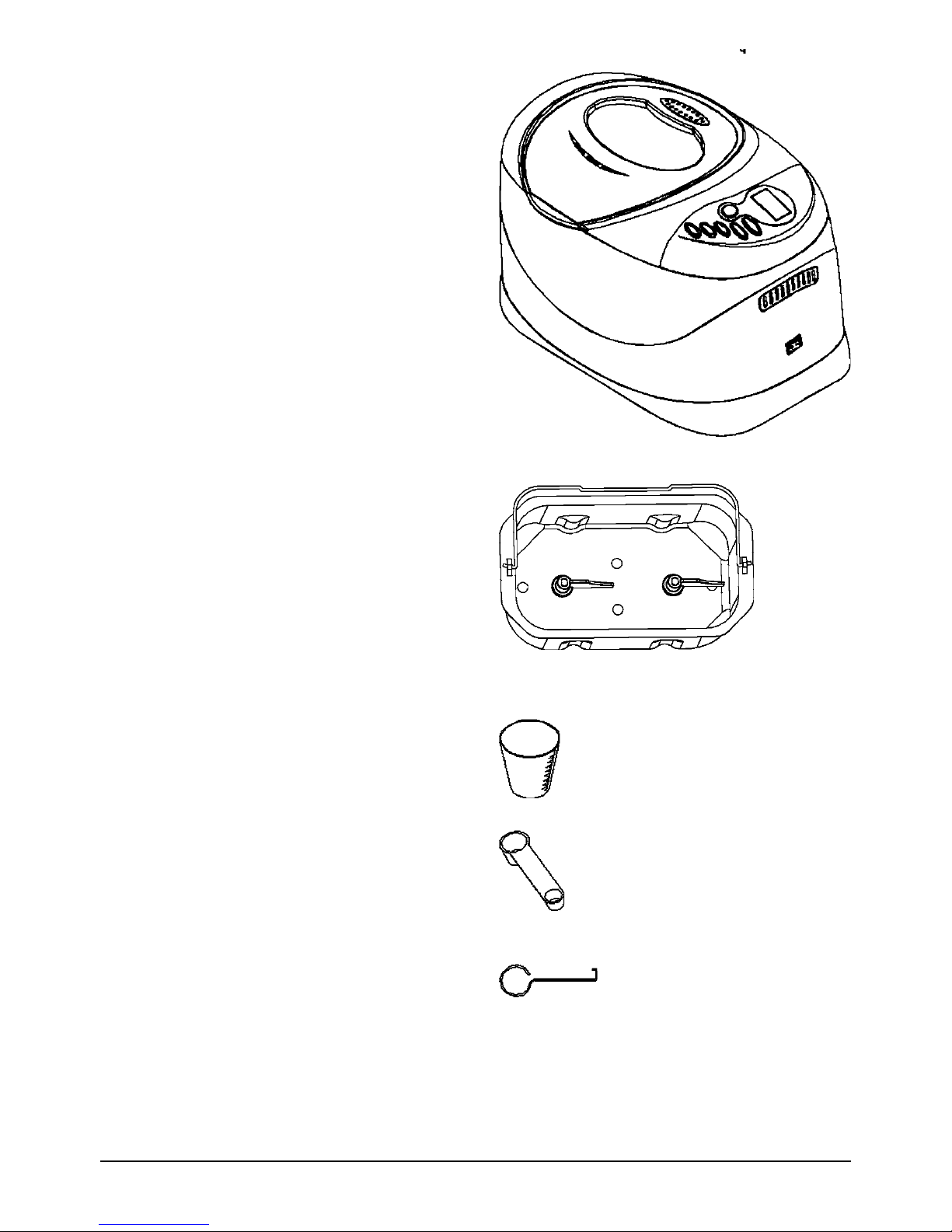

ITEMS SUPPLIED

1 Breadmaker

2 Kneading hooks and 1 baking pan

1 Measuring beaker

1 Measuring scoop (teaspoon/tab-

lespoon)

1 Tool to remove baked-in kneading

hooks

1 Operating manual without illustra-

tions

Page 9

9

Page 10

10

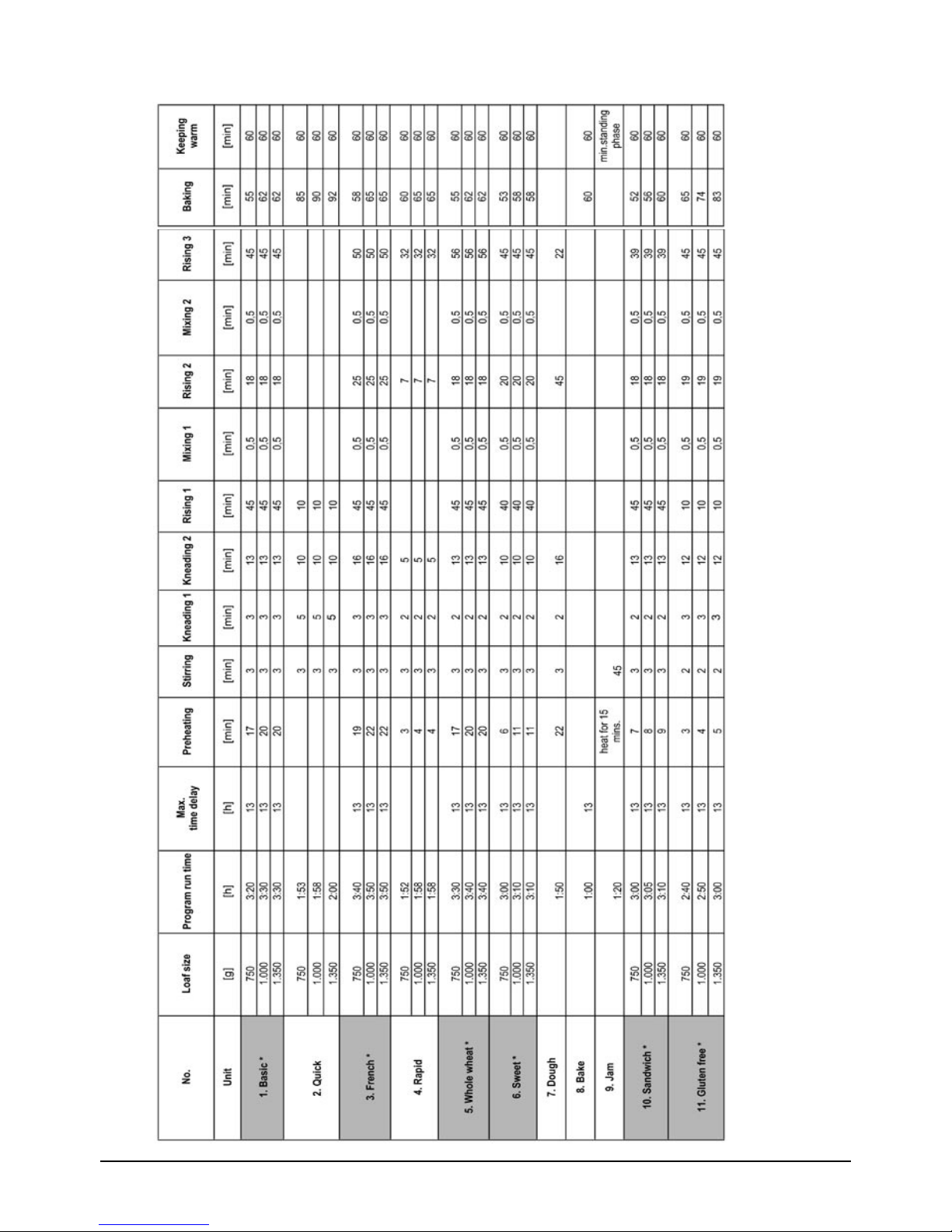

Preparation times

Program Total time ** Program sequence

*Adding of ingredients at point ** possible only with these programs

Program run time calculated without heat retention time

Page 11

11

DESCRIPTION OF

EQUIPMENT

I

A

B

C

D

E

F

G

H

Breadmaker:

A) Casing lid

B) Control panel

C) ON/OFF switch

D) “COOL TOUCH” casing

E) Baking pan, non-stick coated

F) Baking chamber

G) Handle for removing baking pan

H) Kneading hook, non-stick coated

I) Viewing window

Page 12

12

Operating buttons:

J) LCD display

K) Select button [“Bread size”]

L) Select button for degree of browning [“Colour”]

M) Select button [“Time +”]

N) Select button [“Time –”]

O) Select button [“Menu”]

1 = Basic

2 = Quick

3 = French

4 = Rapid

5 = Whole wheat

6 = Sweet

7 = Dough

8 = Bake

9 = Jam

10 = Sandwich

11= Gluten free

P) Select button [“Start/Stop”]

Q) List of basic programs 1 – 11

LCD-Display:

R) Display symbol for selected degree

of browning

S) Display symbol for selected loaf size

T) Display of operating time, dependent

on program selected

U) Display of basic program selected

O

U

T

R S

N

M

L

K

J

Q

P

light medium dark 0.75 kg 1.00 kg 1.35 kg

1 = Basic

2 = Quick

3 = French 4 = Rapid

5 = Whole wheat 6 = Sweet

7 = Dough 8 = Bake

9 = Jam 10 = Sandwich

11= Gluten free

light medium dark 0.75kg 1.00kg 1.35kg

Page 13

13

The relatively long time of 2-3 seconds prevents you from ending the program prematurely by touching the “Start/Stop” button inadvertently.

Select button

Please note that for programs marked with a star (*) the stirrer has a built-in

delay (preheating function). You will find details of the appropriate preheating

time in the table on Page 10 in the “preheating” column.

This button is used to select the desired programs (1-11). Each time a button is

pressed you will hear a bleep, and the place in the program will be moved forward

by one point. Note the explanation of the various basic programs below:

1 = Basic*:

This program is used to process (knead, allow to stand, bake) mixed and white

breads, consisting of wheat flour and/or rye flour.

2 = Quick:

“Quick” breads are baked with baking powder or bicarbonate of soda, which is activated by humidity and heat. We recommend that you firstly add all liquid ingredients

and then the dry ingredients to the baking pan. Lumps could form in the corners of

the baking pan because of the shorter program time. We therefore recommend that

you break down the lumps of flour using a suitable baking spatula, if necessary. The

bread is made in a decidedly shorter time; we therefore recommend that you only use

recipes with basic bread ingredients (water, milk, eggs, possibly butter or margarine,

flour, salt, sugar). The program is not suitable for breads with special ingredients.

Please consider that bread on this setting is generally somewhat smaller and not

as light.

DESCRIPTION OF THE DISPLAY AND OPERATIONAL

CONTROLS

Select button

You may start or interrupt the selected program using this button. To start, press the

button once. You will hear a short bleep, both dots on the digital display will start to

flash and the program will begin.

Menü

All other buttons, with the exception of

the “Start/Stop” button, are deactivated

after the program has started, i.e. not

functional for safety reasons.

To stop the program, hold the button down

for about 2-3 seconds until a short whistling sound informs you that the program

has ended.

light medium dark 0.75 kg 1.00 kg 1.35 kg

Menu

Page 14

14

3 = French*:

This program is used to process doughs with longer standing phases. For light,

crustier breads made of white, heavily ground flour (mostly Type 405).

4 = Rapid*:

This program is used for making breads quickly. This program has no facility for

baking the bread later; see list of possible program variations on Page 9.

5 = Whole wheat*:

This program is used to make breads with a high proportion of rye and wheat wholegrain flour, oats or bran. On this setting the longer preheating phase is used to allow

the “grains” to absorb water more easily and to open up (sunflower seeds, sesame

seeds, linseed, etc.).

The bread is therefore smaller, denser and heavier than comparable light breads. We

do not recommend baking on a timer with this program as the quality of the bread

could be adversely affected.

6 = Sweet*:

This program is used to make sweet bread, e.g. with fruit juice, sugar, coconut flakes,

raisins, dried fruits or chocolate.

7 = Dough*:

This program is used to make dough (kneading and allowing to stand) but without

the bake function. The dough can, for example, be used to make pizzas, plaits and

rolls.

8 = Bake:

This program is only for baking doughs, without kneading or allowing them to rise

(e.g. doughs which you have previously mixed or whose preparation has been interrupted by a lengthy power cut).

This program can also be used to rebake a bread which is too light or possibly not

baked thoroughly enough.

Note: the preset time cannot be changed on this program. Press the “Start/Stop”

button on the equipment if you wish to end the baking process prematurely.

9 = Jam*:

This program is used to make home-made jam.

10 = Sandwich*:

This program is used to make sandwich bread and to bake light bread with thinner

crusts.

11 = Gluten free*:

This baking program is particularly suited to the baking properties of gluten-free

flour mixes or types.

Page 15

15

Select button

for degree of browning

This button is used to select the desired

crust colour: light, medium or dark. Every

time the button is pressed the arrow in

the LCD display moves up one browning

level.

Select button

This button is used to select the desired

bread weight. Press the button until the

arrow in the digital display appears beneath the desired weight (0.75 kg, 1.00

kg, 1.35 kg).

Farbe

Brotgröße

Zeit +

Zeit –

Please note that the breadmaker has been preset as standard to the 1 kg size.

By pressing the “Loaf size” button you can change the current programming

time in the LCD display, depending on the weight of bread selected. See the

list of individual preparation times on Page 10.

Because of loss of liquid during baking, the weight of the ingredients is usually greater

than that of the finished bread.

Select buttons

If you do not wish the breadmaker to begin immediately you may set the desired

total delay time by pressing the above buttons. The maximum delay time which can

be set is 13 hours. This function is used to ensure that freshly baked bread is ready

at the desired time (e.g. for breakfast).

Note: The delay time includes the relevant baking time, irrespective of the

program selected.

Before setting the time delay you must first of all choose the desired program

and the degree of browning (“colour”).

Every time the “Time +” button is pressed the delay time is increased by 10 minutes,

and when the “Time –” button is pressed it is reduced by 10 minutes. The fixed baking times for the different programs are neither increased nor shortened by these

settings.

light medium dark 0.75 kg 1.00 kg 1.35 kg

light medium dark 0.75 kg 1.00 kg 1.35 kg

Color

Bread size

Time Time

Page 16

16

Example:

It is now 20:30 and you would like the bread to be ready for the next morning at 7:00,

i.e. in 10 hours and 30 minutes’ time. First of all select the desired program, the degree of browning and the desired loaf size. Then press the “Time +” button or “Time

–” button until “10:30” appears in the digital display. Now press the “Start/Stop”

button to start the time delay program. The colon in “10:30” begins to flash and the

remaining time is counted down in the LCD display.

If, for example, you have chosen the wholegrain bread program “5” and a loaf size

of 0.75 kg (program run time: 3 hours 40 minutes) the breadmaker will be in ready

mode for 7 hours and will begin the program during the night at 3:20.

Next morning at 7:00 you will have fresh bread. If you do not wish to remove the

bread from the baking pan immediately at the end of the program, the bread will be

kept warm for 1 hour using the built-in heat retention function.

Do not use any easily perishable ingredients for baking on time delay, e.g. eggs,

fresh milk, fruit, onions, etc.

HEAT RETENTION FUNCTION

When the baking process has ended, the bread will be kept warm automatically

for 1 hour. This prevents the inside of the bread becoming “soggy”. If you do not

wish to use this additional function please press the “Start/Stop” button to end the

program manually.

MEMORY IN THE EVENT OF POWER FAILURE

If there is a short power cut during the program the selected settings will automatically

be stored for about 15 minutes. If the mains power returns within 15 minutes the program will continue automatically without the “Start/Stop” button having to be pressed

again. If the power cut lasts longer than 15 minutes the contents of the memory will

be lost and the breadmaker will have to be restarted (from the beginning).

If the longer power cut has occurred during the kneading/standing phase the program may be started again (from the beginning) by simply pressing the “Start/Stop”

button.

If a longer power cut has occurred during baking the baking process may be completed by using Program 8 (bake only).

Page 17

17

AMBIENT CONDITIONS

The breadmaker will function WITHOUT any problems within a wide range of temperatures but there may be differences in the size of the loaf if the room is very hot

or very cold. The best results will be obtained at room temperatures between 15

and 34oC.

ERROR MESSAGES ON THE LCD DISPLAY

If the message shown appears after the

machine has started, the temperature in

the baking chamber of the equipment is

too high. In this case stop the program,

open the lid and allow the breadmaker to

cool down for about 20-30 minutes. After

that the equipment may be restarted.

If the following message appears after

the machine has started, the temperature

sensor has malfunctioned. In this case do

not continue to use the machine but send

the machine to the authorised customer

service address for servicing.

The display shown here will appear if the

machine is operated in an environment

that is too cold. After it has appeared you

will hear 5 bleeps at intervals.

Then the machine will switch to the normal

display for setting the desired program and

loaf size. However, it will not be possible

to start a program.

This is a safety function because the yeast

in the bread dough does not rise at an

ambient temperature that is too low.

light medium dark 0.75 kg 1.00 kg 1.35 kg

light medium dark 0.75 kg 1.00 kg 1.35 kg

light medium dark 0.75 kg 1.00 kg 1.35 kg

Page 18

18

BEFORE USING FOR THE FIRST TIME

Carefully remove the breadmaker from its packaging and clean the baking pan, the

kneading hooks, the measuring beaker, the measuring scoop and the removal tool

in hot water using washing-up liquid or alternatively in a dishwasher (see also notes

in the CLEANING section). Then rinse well and dry.

Place the machine near a power socket. Take care that you have a level, dry, nonslip and heat-resistant surface on which to stand it. Then plug the machine in and

activate the ON/OFF switch on the side beneath the operating buttons, bringing it

to position “I”.

Before using for the first time please carry out a 10 minute test bake, using the baking

pan and kneading hooks (without ingredients) with the lid down. To do this activate

the “Menu” button until the program place “8” appears in the LCD display. Then press

the “Start/Stop “ button briefly. You will hear a short bleep, and the breadmaker will

begin to heat up. To switch off the heating process press the “Start/Stop” button

again for about 3 seconds. The switching off of the heating element will again be

signalled by a short whistle. Then please switch the machine off by returning the

ON/OFF switch to the “O” position.

It is quite normal for a slight smell and a little smoke to be produced at this point

(sealing of heating element during manufacture) and is not a problem. Despite this

ensure there is sufficient ventilation and clean the baking pan and the kneading hooks

once again in hot water with a little washing-up liquid. Then rinse well and dry.

USE OF THE BREADMAKER

1) First insert the two kneading hooks into the driving axles in the dough container

and turn the kneading hooks in a clockwise direction until they click into the

axles.

We recommend smearing the bare ends of the driving axles with a small amount

of margarine suitable for baking so that the dough does not stick to the axles

and the kneading hooks can be released from the bread more easily later on.

2) A long bleep will sound during the program for the programs listed below:

> Basic < after about 25 minutes (*)

> French < after about 25 minutes (*)

> Whole wheat < after about 25 minutes (*)

> Sweet < after about 15 minutes (*)

> Sandwich < after about 13 minutes (*)

A bleep while the program is running (see Point 2) means that more ingredients (e.g.

nuts, raisins, linseeds, caraway seeds, dried fruit, etc.) may now be added.

(*) the exact times

can be seen in the

list of preparation

times on Page 10.

Page 19

19

3) Now place the chosen ingredients into the dough container.

Take the greatest possible care when using the baking pan. When adding the

ingredients always take the baking pan out of the machine, to avoid spilling

onto the baking chamber. Risk of fire from burning dough!

Keep to the order given in the relevant recipe:

a) First of all the liquid ingredients are placed in the baking pan, e.g. milk, water,

oil, eggs, soft butter or margarine.

b) The dry ingredients are firstly mixed together, e.g. flour, salt, sugar. Then the

mixture of dry ingredients should be added to the liquid in the baking pan.

c) Always make the yeast or baking powder the last ingredient to go into the

container.

Use only dried yeast! Never add this to liquid but always to dry ingredients,

in a small hollow made in the centre of the dry ingredients. (The yeast might

otherwise be prevented from rising, particularly if the baking process is delayed

using the timer).

4) Now place the baking pan in the breadmaker in the centre of the baking cham-

ber and press downwards gently until you hear it click into place. Fold down the

handle of the dough container.

5) Now carefully close the lid of the machine and connect the mains cable to an

earthed socket installed in accordance with the regulations.

6) Now switch the machine on using the ON/OFF switch located on the side of the

machine (under the operating buttons). Switch to “I”.

7) Now press the “Menu” button to select the desired program.

8) To select the desired degree of browning press the “Colour” button.

9) To select the desired loaf size (0.75 kg, 1.00 kg. 1.35 kg) press the “Loaf size”

button.

10) If necessary, now set the desired time delay by pressing the “Time +” or “Time

–” buttons.

11) Finally press the “Start/Stop” button to start the program.

12) A bleep during the program – see Point 2 – means that more ingredients (e.g.

nuts, raisins, linseed, caraway seed, dry fruit, etc.) may now be added.

Open the lid of the machine only to add ingredients. If you open the lid too often

the bread may collapse.

During the baking process there may be steam coming from the ventilation

openings on the machine lid. This process is normal and is not a cause for

complaint.

Page 20

20

13) At the end of the program you will hear about 8 – 10 bleeps. This signals the end

of the program and the machine has now switched to heat retention mode. If

you would like to take the bread out immediately press the “Start/Stop” button

for about 2-3 seconds to end the program manually.

The equipment, the baking pan and the bread are – when removed immediately

– very hot. Always use oven cloths or gloves. Do not grasp the machine, the

baking pan (including handle) or the bread with bare hands!

14) Open the lid and pull up the baking pan from the baking chamber using the

handle. Tilt the baking pan and shake it carefully so that the bread falls out. If

possible allow the bread to cool on a cooling tray. Generally the bread can be

removed easily because of the non-stick coating on the baking pan. If the bread

is stuck fast loosen the bread from the edges of the dough container using a

baking spatula made of plastic or wood.

15) Switch the machine off (ON/OFF switch in “O” position)

Never use a knife or other metal objects to loosen the bread. This may damage

the non-stick coating.

After removing the bread check immediately whether the kneading hooks have remained in the bread. The kneading hooks are baked in and may remain in the loaf

when it is removed.

16) Never forget to remove the kneading hooks before the bread is sliced. Otherwise

the hooks could be damaged. Baked-in kneading hooks can be pulled from the

bread using the removal tool provided.

If the bread is still hot the removal of the kneading hooks is simple. However,

the hole which appears is somewhat bigger than with cool bread.

Leave the breadmaker to cool for about _ hour with the lid open and switched off

(ON/OFF switch on side to “O” position) before you bake more bread.

If you do not wish to bake any more bread always return the ON/OFF switch on the

side to the “OFF” position (“O” setting) and also pull the plug from the socket.

Page 21

21

HELPFUL HINTS

➤ Ensure that all ingredients are at about the same temperature. Room temperature to

lukewarm (18oC to 23oC) is best.

➤ When using very soft water the fermenting process of the yeast is heightened, i.e. the

dough rises further. To prevent the dough from rising too much we recommend reducing

the yeast quantity given by about 25%.

➤ The fermenting process of the yeast is also dependent on the prevailing air pressure, i.e.

in high regions about 900 m/NN the fermenting process is stronger. Here too we would

recommend reducing the quantity of yeast by 25%.

➤ Baking mixes can be processed to make bread using the machine. However, it is impor-

tant to check the total weight of all ingredients and ensure that 1,350 g is not exceeded.

The dough may overflow and reach the heating element.

➤ The viewing window may, in some circumstances, be misted up by the release of con-

densation at the beginning of the baking process; this process is normal and is not a

cause for complaint.

➤ When baking using your own recipes ensure that the total weight of the ingredients is

monitored so that you can a) program the machine correctly and b) ensure that no dough

overflows.

➤ The more sugar you use, the darker the bread crust will be.

➤ Note that the baking result will change if you change the individual ingredients.

➤ If you use, for example, dried fruit instead of nuts, the liquid content of the dough is

increased. This may mean that less water is needed.

➤ Do not restrict the circulation of air during use, i.e. do not cover up the ventilation slots

of the drive motor and the exhaust apertures.

➤ If you are not satisfied with the baking results, begin by changing the recipe slightly. Try

it once more.

➤ Rye flour does not contain vegetable gluten, i.e. the bread does not rise very much. That

is why the rye flour used should consist of 30% wheat flour.

Page 22

22

➤ Under no circumstances use too much yeast or baking powder. The dough might overflow.

Also the bread could push against the lid if it rises too much.

➤ The use of fresh yeast may have a negative effect on the desired baking result. Therefore

use only dried yeast to produce the dough.

➤ Different types of flour and other ingredients from various manufacturers might lead to

different results.

➤ Always add the liquid ingredients to the baking pan first, then the dry ingredients mixed

together.

➤ Under no circumstances increase the quantities for the 1,350 g recipes because the

dough would overflow and could reach the heating element – fire risk!

➤ If dough reaches the heating element, smoke will come from the baking chamber. In this

case keep the lid of the breadmaker closed, switch the machine off using the ON/OFF

switch and also pull out the plug from the socket. Leave the machine to cool sufficiently

and then clean the baking chamber and the heating element as described in the section

on “CLEANING”.

➤ To achieve a satisfactory result we recommend that you keep exact records of recipes

and ingredients used.

If you require more kneading hooks or a new baking pan you can order them at reasonable cost from our service address (see page 38).

Page 23

23

TIPS REGARDING RECIPES

Pleas use the measuring scoops included in the following way:

The small measuring scoop (teaspoon) is equivalent to a level teaspoon

The large measuring scoop (tablespoon) is equivalent to a level tablespoon

Even slight deviations when adding ingredients may have a considerable effect

on baking results. Therefore be especially accurate when weighing out the

liquid and dry ingredients.

1) Adding and weighing liquid ingredients:

With most of the recipes described below we recommend that you add only water or

milk which is lukewarm. Butter or margarine should likewise always be soft or liquid

when added. The required quantity of water, fresh milk, etc. must be determined using

a measuring beaker.

2) Measuring powdered ingredients:

Always keep to the details in the relevant recipe. Use either the measuring scoop or

kitchen scales to determine the quantity required.

3) Adding of ingredients:

Keep to the following order: liquid ingredients, eggs, salt, powdered ingredients. Add the

yeast only to dry flour (into a hollow). Ensure that the yeast does not come into direct

contact with salt.

When the dough has been kneaded for between about 13 – 25 minutes, depending on

the program selected, you will hear a whistle which indicates that you may now add more

ingredients (nuts, fruit, etc.). Do not add the other ingredients to the dough too soon,

or some of the taste may be sacrificed during the ongoing kneading process. If you are

baking using the timer do not add any easily perishable ingredients to the dough (e.g.

eggs or fruit).

4) Types of flour:

Most of the types of flour obtainable in the market place are suitable for making bread

such as: > wheat flour Type 405 for light wheat bread

> rye flour Type 1800 for almost all wholegrain breads

> rye flour Type 1370 for dark, mixed bread

> rye flour Type 1150 for bread made with rye and wheat

flour

> rye flour Type 997 for light rye bread

> rye flour Type 815 for light cakes and biscuits

Ready-mixed bread packs are also suitable.

The baking properties of a grain-based flour depend on the gluten part of the type

of flour used. In this context bakers talk of “strong” or “soft” flours. Strong flours

have a high proportion of gluten. Wheat flour has the best baking properties of all

grain flour types.

Page 24

24

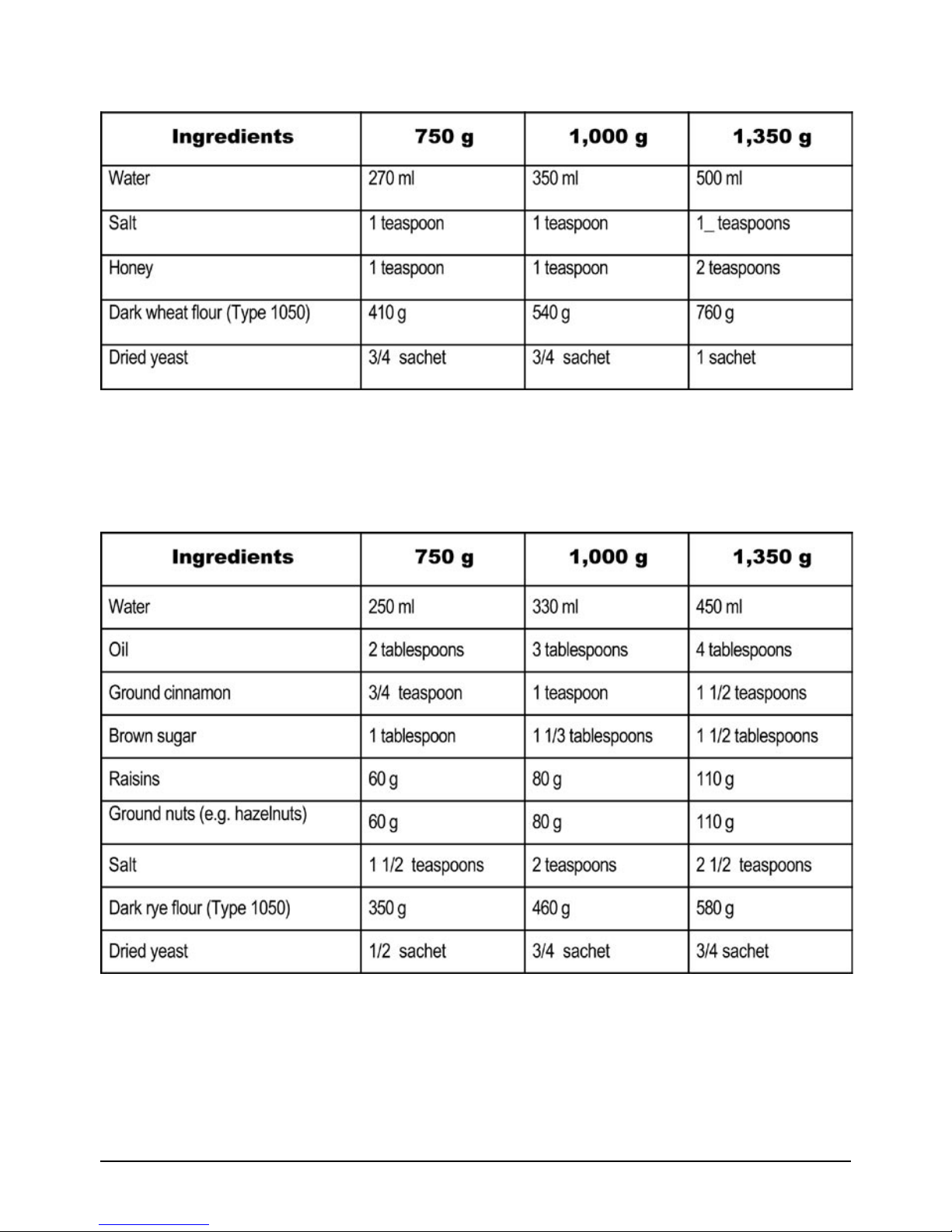

Recipes:

Here are some recipe suggestions for your breadmaker.

Please always add the ingredients in the order given. Ensure that the dried yeast does not

come into contact with liquid. The recipes in this instruction manual assume that the content

of a sachet of dried yeast is 7 g.

Basic (Program 1 “Basic”)

Banana nut bread

(Program 2 “Quick”)

Page 25

25

White bread (Program 3: “French”)

Potato bread (Program 4 “Rapid”)

Page 26

26

French herb bread (Program 4: “Rapid”)

Pizza dough (Program 4: “Rapid”)

Page 27

27

Wholegrain bread (Program 5: “Whole wheat”)

Cinnamon raisin nut bread (Program 6: “Sweet”)

Page 28

28

Christmas bread (Program 6: “Sweet”)

Sandwich bread (Program 10: “Sandwich”)

Page 29

29

Jam (Program 9: “Jam”)

Good luck!

Gluten free bread (Program 11: “Gluten free”)

Page 30

30

Own recipes

Page 31

31

Own recipes

Page 32

32

CLEANING

Before cleaning always pull out the plug and allow the machine to cool down!

Wipe the outside of the machine with a damp well-wrung cloth and then rub dry. Do

not use sharp or chafing cleaning agents.

Never put water in the machine!

Do not use metallic objects or sharp or chafing cleaning agents to clean the baking

chamber, the baking pan, the kneading hooks or the heating element. Use a soft

damp sponge or a soft cloth. Wipe dry. Leave the lid of the machine open to allow

the inside to dry thoroughly.

The non-stick coating of the baking pan and kneading hooks should under no

circumstances be damaged using hard or chafing objects.

If the kneading hooks remain in the baking pan (and are not stuck in the bread),

remove them from the axles first if you have already removed the baking pan from

the machine.

The kneading hooks are still very hot shortly after baking! Do not touch with

unprotected fingers!

If the kneading hooks are firmly seated on the axles, fill the baking pan with hot water

and allow to stand for about 1/2 hour. You will then be able to remove the kneading

hooks easily.

If there is baked-on dough residue, wash or soak the kneading hooks with soap suds

and ensure that the hole on the underside is cleaned of all dough residue.

All accessories (baking pan, kneading hooks, measuring beaker, measuring scoop,

removal tool) may alternatively be cleaned in the dishwasher.

Page 33

33

Table of faults

Page 34

34

TROUBLESHOOTING

- The breadmaker is not

heating up property.

> The lid is not closed cor-

rectly.

>> Close the lid correctly

so that the heat cannot

escape.

- It is very difficult to remove

bread from the baking

pan.

> The axles of the kneading

hook drive were not greased before use with margarine suitable for baking.

The bread has stuck to the

driving axles.

>> Carefully loosen the

bread from the baking

pan using a suitable aid,

e.g. plastic scraper).

Pour hot water into the

dough container and

allow the driving axles

to soak for about 10

minutes. Then clean thoroughly.

- The equipment is not

working.

> Equipment not connected

to socket.

>> Insert plug into socket.

Correction:

Cause:Fault:

> The ON/OFF switch has

not been activated.

> Fault in the socket. >> Check the plug with

another suitable machine

and have the electrical

installation checked if

necessary by an electrician.

- During baking there is

smoke coming from the

ventilation apertures.

> The heating element is

still unused and is lightly

greased for manufacturing

reasons.

>> As described in the ope-

rating manual, allow the

machine to heat up for

about 10 minutes. The

slight release of smoke

will cease by itself after a

short time.

> The dough has overflo-

wed and has reached the

heating element.

>> Switch the equipment off

and pull out the plug. Remove the hot baking pan

and carefully clean the

hot heating element. Use

suitable aids (e.g. oven

glove, to avoid burns).

>> Move ON/OFF switch to

position “I”.

Page 35

35

- The LCD display shows

“ ” after switching on

and the equipment gives 5

bleeps. “

>The ambient temperature

is too cold for the yeast in

the bread dough.

>> Switch the equipment

off. Set up again in a

warmer place. After

about 1 hour allow the

equipment to operate

again.

Correction:

Cause:Fault:

- The ingredients were not

stirred evenly.

> The program was interrup-

ted inadvertently.

>> Stir the ingredients and

start the program once

again.

> The lid was raised several

times during the last rising

phase.

>> Do not open the lid while

the last rising phase is

running.

> Ingredients possibly not

added in the correct order.

>> Add ingredients only ac-

cording to the details in

the operating manual.

> Liquid used was too cold. >> Keep to the details in the

operating manual.

> Margarine or butter used

was too hard.

>>Ensure the ingredients

are of the correct temperature.

- The LCD display shows

only “

” after pressing

the “Start/Stop” button.“

> The temperature in the

baking chamber is still too

high following a previous

baking process.

>> Switch the equipment off

and open the lid. Allow

the breadmaker to cool

down sufficiently before

using again.

- The LCD display shows

only “ ” after the

“Start/Stop” button is

pressed.“

> The temperature sensor

has malfunctioned.

>> Have the equipment

checked at the service

address given.

- The motor runs but the

kneading hooks are not

turning.

> The baking pan is not

correctly inserted into the

baking chamber.

>> Position the baking pan

in the centre of the baking chamber and press

it down lightly until you

hear it click into place.

> Kneading hooks were not

fitted correctly.

>> Ensure that the kneading

hooks are correctly fitted.

> The kneading hooks are

not fitted correctly.

>> Ensure that the kneading

hooks are fitted correctly.

Page 36

36

- The bread is not fully baked.

> Possibly the incorrect

program was chosen.

>> Place the bread back

in the pan and rebake

using Program “8”.

- After cutting, the bread is

hollow inside.

> Too much water used. >> Put in less water.

>> Check the adding of salt.

> Water temperature too

high.

>> Ensure that the water is

of the correct temperature.

> No salt added.

- The bread is too small or

has not risen.

> The lid was opened during

the baking phase.

>> Keep lid closed during

baking phase.

> Proportion of wholegrain

flour or grains too high.

>> Reduce the appropriate

proportions.

> The yeast was mixed with

salt.

>> Do not mix the yeast

with salt.

- The dough has overflowed.

> Proportion of liquid too

high.

>> Reduce the proportion of

liquid and check consistency of dough.

- After baking, the bread is

“soggy”.

> The bread was left in the

dough container too long,

the humidity it contained

could not escape from the

hot bread and has softened the bread inside.

>>Remove the bread from

the dough container in

good time.

- The kneading hooks have

been baked in.

> This is normal procedure. >> Remove the kneading

hooks using the instructions in the operating

manual.

Correction:

Cause:Fault:

- The bread has risen so

much that the dough is

touching the lid.

> Fresh yeast used. >> Use only dried yeast.

> Ambient temperature too

high.

>> Use the equipment

under the ambient conditions described in the

operating manual.

> The dough is so heavy

that the drive mechanism

cannot function.

>> Follow the recipe in-

structions closely and

measure out the ingredients accurately.

Page 37

37

- The crust is too thick and

the degree of browning

is too dark when making

cakes or foods with heavy

sugar content.

> Different recipes or ingre-

dients have a major effect

on results.

Too much sugar used.

>> If the degree of browning

is too dark for the recipe

used, press the “Start/

Stop” button about 5

-10 minutes before the

baking program ends,

to interrupt the baking

process early. Then allow

the bread to stand in the

baking pan for about 20

minutes before you open

the lid.

If we are unable to help you in this way please send the defective machine in its original

packaging, with proof of purchase (date, stamp and signature of your dealer or purchase

receipt), to our customer service office.

If you no longer have the original packaging, please pack the machine well with

sufficient insulating material to avoid damage in transit. We will not be liable for

transport damage caused by improper or insufficient packaging.

If you experience faults which are not listed here please ask our customer service. Our

customer service personnel will be pleased to help you.

Correcting:

Cause:Fault:

Page 38

38

GUARANTEE CONDITIONS

Your appliance is covered by guarantee for a period of 3 years. This guarantee does

not cover defects caused by incorrect connection, the use of attachments supplied

by other manufactures, normal wear and tear, the use of force, your own attempts

at repairs, or damage caused by improper use. This Guarantee does not affect your

statutory rights.

Save your sales receipt. Return the faulty appliance to the ALDI shop where you bought

it. Leave your name, address and telephone number there and let them know whether you

either wish a new item (only if still available) or if you wish your money back.

Subject to technical alterations!

JTM CONTRACTS UK LIMITED

SUITE 3 HALLAM HOUSE

WATERSIDE BUSINESS PARK

DINNINGTON

S25 8QU

TELEPHONE 01909 517672

Page 39

39

If you require more kneading hooks or a new baking pan you can order these

at a reasonable cost from our service address (see page 38).

DISPOSAL

When the machine is no longer serviceable unplug it and take all parts and packaging

materials to be disposed of in an environmentally friendly way – according to the

currently valid regulations. The pertinent local administration authority will provide

more information on this.

Page 40

40

© HUP GmbH & Co. KG BB 1350.06-E 07/06

Loading...

Loading...