Page 1

Industrial Automation Headquarters

Delta Electronics, Inc.

Taoyuan Technology Center

No.18, Xinglong Rd., Taoyuan City,

Taoyuan County 33068, Taiwan

TEL: 886-3-362-6301 / FAX: 886-3-371-6301

Asia

Delta Electronics (Jiangsu) Ltd.

Wujiang Plant 3

1688 Jiangxing East Road,

Wujiang Economic Development Zone

Wujiang City, Jiang Su Province, P.R.C. 215200

TEL: 86-512-6340-3008 / FAX: 86-769-6340-7290

Delta Greentech (China) Co., Ltd.

238 Min-Xia Road, Pudong District,

ShangHai, P.R.C. 201209

TEL: 86-21-58635678 / FAX: 86-21-58630003

AH Motion Controller - Hardware Manual

Delta Electronics (Japan), Inc.

Tokyo Ofce

2-1-14 Minato-ku Shibadaimon,

Tokyo 105-0012, Japan

TEL: 81-3-5733-11

Delta Electronics (Korea), Inc.

1511, Byucksan Digital Valley 6-cha, Gasan-dong,

Geumcheon-gu, Seoul, Korea, 153-704

TEL: 82-2-515-5303 / FAX: 82-2-515-5302

Delta Electronics Int’l (S) Pte Ltd.

4 Kaki Bukit Ave 1, #05-05, Singapore 417939

TEL: 65-6747-5155 / FAX: 65-6744-9228

Delta Electronics (India) Pvt. Ltd.

Plot No 43 Sector 35, HSIIDC

Gurgaon, PIN 122001, Haryana, India

TEL : 91-124-4874900 / FAX : 91-124-4874945

11 / FAX: 81-3-5733-1211

Americas

Delta Products Corporation (USA)

Raleigh Ofce

P.O. Box 12173,5101 Davis Drive,

Research Triangle Park, NC 27709, U.S.A.

TEL: 1-919-767-3800 / FAX: 1-919-767-8080

Delta Greentech (Brasil) S.A.

Sao Paulo Ofce

Rua Itapeva, 26 - 3° andar Edicio Itapeva One-Bela Vista

01332-000-São Paulo-SP-Brazil

TEL: 55 11 3568-3855 / FAX: 55 11 3568-3865

AH Motion Controller Hardware Manual

Europe

Delta Electronics (Netherlands) B.V.

Eindhoven Ofce

De Witbogt 20, 5652 AG Eindhoven, The Netherlands

TEL : +31 (0)40-8003800 / FAX : +31 (0)40-8003898

AH-0259520-02

*We reserve the right to change the information in this manual without prior notice.

2018-08-31

www.deltaww.com

Page 2

AH Motion Controller Hardware Manual

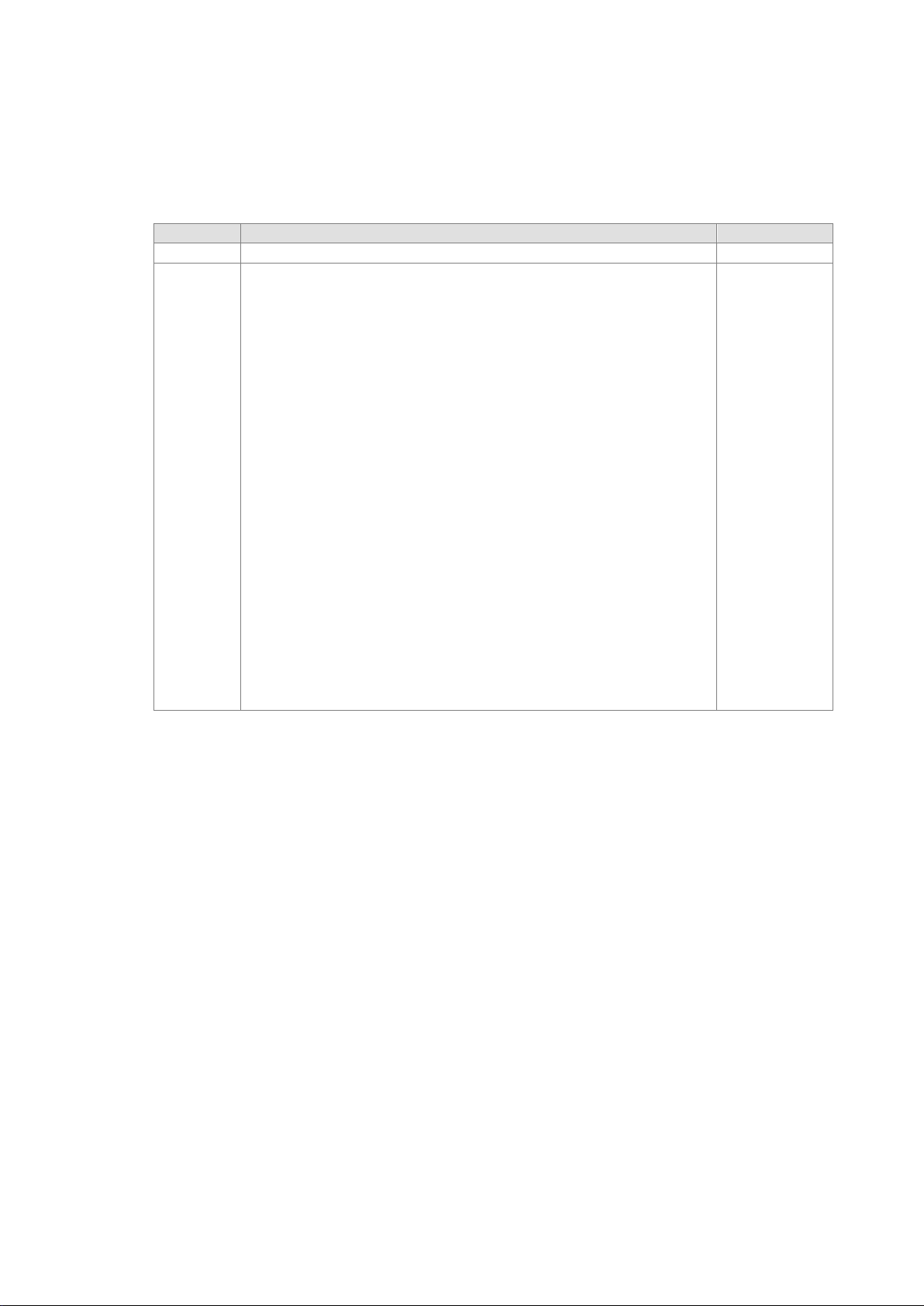

Version

Revision

Date

1st

The first version was published.

2017/09/20

1. Modules including AH10EN-5A, AH15EN-5A,

circuit diagrams of a transistor to COM

Revision History

AH10SCM-5A, AH15SCM-5A, AH10DNET-5A,

H10PFBS-5A, AH10PFBM-5A, AHRTU-DNET-5A

2nd

A

A

HRTU-PFBS-5A, AHRTU-ETHN-5A

HBP03M2-5A (AH motion backplane) wer

A

added i

2. The information on modules including

n Chapter 1.

AH10EN-5A, AH15EN-5A, AH10SCM-5A

A

H15SCM-5A, AH10DNET-5A, AH10PFBS-5A

H10PFBM-5A, AHRTU-DNET-5A

A

A

HRTU-PFBS-5A, AHRTU-ETHN-5A

and

e

,

,

,

AHBP03M2-5A (AH motion backplane) as well as

updates on I/O network and module configurati

w

ere added in Chapter 2.

3. The reference information on modules in Chapter

3 has changed to AH500 Series Hardwar

M

anual.

4. The reference information on modules in Chapter

4 has changed to AH500 Series Hardwar

M

anual.

5. Section 3.2.7: Update information concer ning

ontact 5 and contact 29.

c

6. Chapter 4: Change C0,C1, C2, C 3 in output

e

e

,

,

on

2018/08/31

Page 3

AH Motion Controller - Hardware Manual

Contents

Preface

P.1 Introduction ..................................................................................... II

P.1.1 Applicable Products ......................................................................... II

P.1.2 Related Manuals ............................................................................. II

P.2 Navigation between Manuals ........................................................... III

Chapter 1 Product Introduction

1.1 The AH Series Motion Controller ..................................................... 1-2

1.1.1. Product Features ........................................................................... 1-3

1.1.2. Overview of the System Configurations ............................................ 1-6

1.2 AH Motion CPU Specifications ......................................................... 1-8

1.2.1 Environmental Specif ications .......................................................... 1-8

1.2.2 General Specifications .................................................................... 1-8

Cha

pter 2 System Configuration

2.1 Basic System Configuration ............................................................ 2-2

2.1.1. AH Motion CPU Network Configuration .............................................. 2-3

2.1.2. AH500 Series Module Configuration ................................................. 2-4

2.2 Software Connection .................................................................... 2-10

2.3 Overall Network Configuration ..................................................... 2-11

2.3.1 EtherNet/IP ..................................................................................... 2-12

Chapter 3 Product Specifications

3.1 Environmental Specifications .......................................................... 3-2

3.2 AH Motion CPU ................................................................................ 3-2

3.2.1 General Specifications .................................................................... 3-2

3.2.2 Motion Control Function Specifications .............................................. 3-5

3.2.3 Communication Ports ..................................................................... 3-6

3.2.4 I/O Addressing of AH Motion CPU .................................................... 3-7

3.2.5 Profiles ...................................................................................... 3-14

i

Page 4

3.2.6 Dimensions ................................................................................. 3-15

3.2.7 Arrangement of Terminals ............................................................. 3-16

3.2.8 Memory Card Slot ........................................................................ 3-16

3.3 I/O Modules ................................................................................. 3-17

Chapter 4 Installation and Wiring

4.1 Quick Review before Installation .................................................... 4-2

4.1.1 AH Motion Hardware Components ................................................... 4-2

4.2 Points to Note on Installation ......................................................... 4-6

4.3 Installation ..................................................................................... 4-7

4.3.1 CPU Rack Installation in a Control Panel ........................................... 4-7

4.3.2 Mounting a Backplane ................................................................... 4-7

4.3.3 Installing a Module ........................................................................ 4-9

4.3.4 Installing a Removable Terminal Block ............................................ 4-10

4.3.5 Installing an External Terminal Module ............................................ 4-14

4.3.6 Connecting Communicati o n Cabl es ................................................. 4-15

4.3.7 Installing and Removing a Memory Card ......................................... 4-15

4.4 Points to Note about Wiring ......................................................... 4-16

4.5 Wiring Power Supply Modules ...................................................... 4-18

4.5.1 Precautions ................................................................................. 4-18

4.5.2 Ground ....................................................................................... 4-19

4.5.3 Wiring Power Supply Module s ........................................................ 4-20

4.5.4 Power Consumption ..................................................................... 4-23

4.6 Wiring AH Motion CPU Modules .................................................... 4-24

4.6.1 Specifications of Inputs and Outputs ............................................... 4-24

4.6.2 Wiring AHxxEMC-5A ..................................................................... 4-27

4.7 Wiring I/O Modules ...................................................................... 4-31

Chapter 5 Maintenance and Inspection

5.1 Cautions ......................................................................................... 5-2

5.2 Daily Maintenance .......................................................................... 5-2

5.2.1 Tools Required for Inspection .......................................................... 5-3

ii

Page 5

5.2.2 Daily Inspection ............................................................................ 5-3

5.3 Periodic Maintenance ...................................................................... 5-4

5.3.1 Tools Required for Inspection .......................................................... 5-4

5.3.2 Periodic Inspection ........................................................................ 5-4

Appendices

A.1 EMC Standards for an AH Motion System ........................................... A-2

A.1.1 EMC Standards Applicable to an AH Motion System ............................ A-2

A.1.2 Installation Instructions for the EMC Standards ................................. A-3

A.1.3 Cables ......................................................................................... A-4

iii

Page 6

P

Preface

Table of Contents

P.1 Introduction .................................................................................................... II

P.1.1 Applicable Products ..................................................................................... II

P.1.2 Related Manuals ......................................................................................... II

P.2 Navigation between Manuals ......................................................................... III

I

Page 7

AH Motion Controller – Hardware Manual

_P

P.1 Introduction

Thank you for purchasing the AH series Motion Co ntroller CPU with our advanced motion control system.

This manual introduces the hardware structures, specifications, and the installation of AH motion controller system

products based on AH motion controller CPUs. Please ensure that you understand the configuration and operations of the

AH series motion control system, and us e the AH series Motion Controller CPU correctly.

To obtain required informatio n for different system configurations, you can navigate bet ween different manuals of AH

Motion Controller series manuals and other relat ed manuals.

P.1.1 Applicable Products

This manual relates to the following products

- AHxxEMC-5A (AH08EMC-5A/AH10EMC-5A/AH20EMC-5A)

- AH500 series modules

P.1.2 Related Manuals

The related manuals of the AH Motion Controller series motion controllers are composed of the following.

1. AH Motion Controller - Hardware Manual

It introduces function specific ations, electrical specifications, appearances, dimensions, and etc.

2. ISPSoft User Manual

It introduces the use of ISPSoft, the progr amming languages (ladder diagrams, i nstruction lists, sequential function

charts, function block diagrams, and structured texts), the concept of POUs, the concept of tasks, and the operation of

motion control programming.

3. AH Motion Controller - Standard Instructions Manual

It introduces the elements for standard programming including devices, symbols and standard instructions.

4. AH Motion Controller - Operation Manual

It introduces basic knowledge of motion control structure, software/hardware setup, quick start of Software operations,

devices to be used, motion control operations and troubleshooting.

5. AH Motion Controller - Motion Control Instructions Manual

It introduces the elements for motion control programming including axis parameters, symbols and single

axis/multi-axes motion instructions.

6. AH500 Motion Control Module Manual

It introduces the specifications for the AH500 series motion control modules, the wiring, the instructions, and the

functions.

7. AH500 Module Manual

It introduces the use of special I/O modules of AH500 series PLCs. For example, network modules, analog I/O

modules, temperature measurement modules, and etc.

II

Page 8

Preface

P_

AH500 Motion Control Module Manual

AH500 Module Manual

AH Motion

AH Motion Control

AH Motion

AH Motion

Instructions Manual

modules

3. Getting started with the software

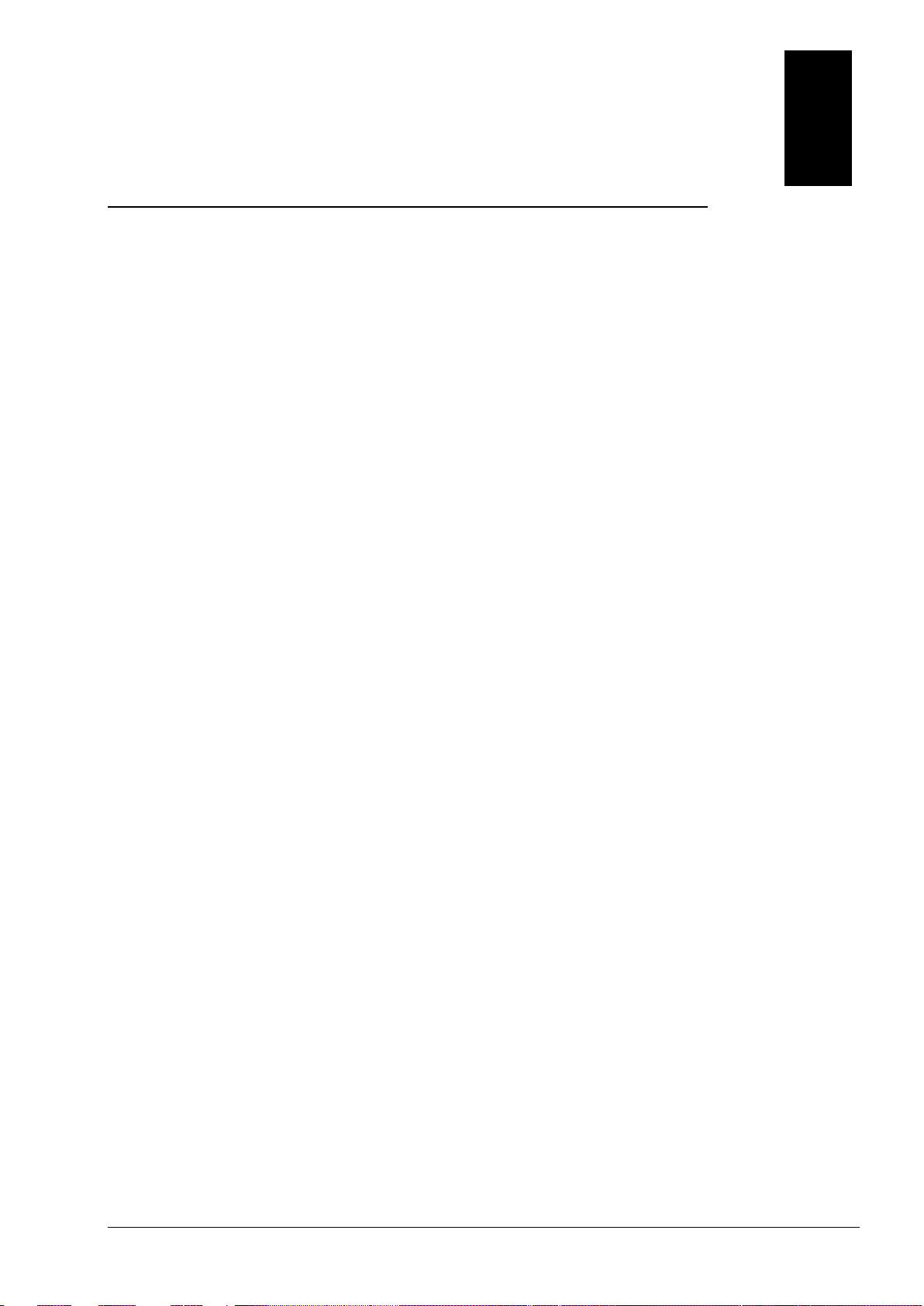

P.2 Navigation between Manuals

Before using the products, there are three manuals that should be utilized as fundamental information: AH Motion

Controller - Hardware Manual, ISPSoft User Manual, and AH Motio n Controller - Standard Instructions Manual.

With the fundamental manuals, you can understand the basic information of hardware configuration, operation procedures

of the software, and the basic instructions for using the system.

To obtain required information for di fferent system configurat ions and applic ations, refer t o other manual s as indicated i n

the table below. Reading all manual s related to your s ystem configur ation hel ps you mak e the most us e of the AH s eries

motion control system.

Related manuals

General operation procedures

1. Overview of AH Motion Controller series

products

2. Setting up hardware configurati on for the

system

for motion control applications V

AH Motion series manuals

Fundamental

ler - Instructions Manual

Controller – Standard

Controller – Hardware Manual

V

ISPSoft User Manual

Controller – Operation Manual

for communication (e.g. EtherCAT)

for motion control applications V

for communication (e.g. EtherCAT)

for additional motion control m odules V

4. Programming

for motion control applications V V

for additional motion control m odules V

for I/O extension using AH500 series

for I/O extension using AH500 series

modules

V

V

V

V

V

V

III

Page 9

AH Motion Controller – Hardware Manual

_P

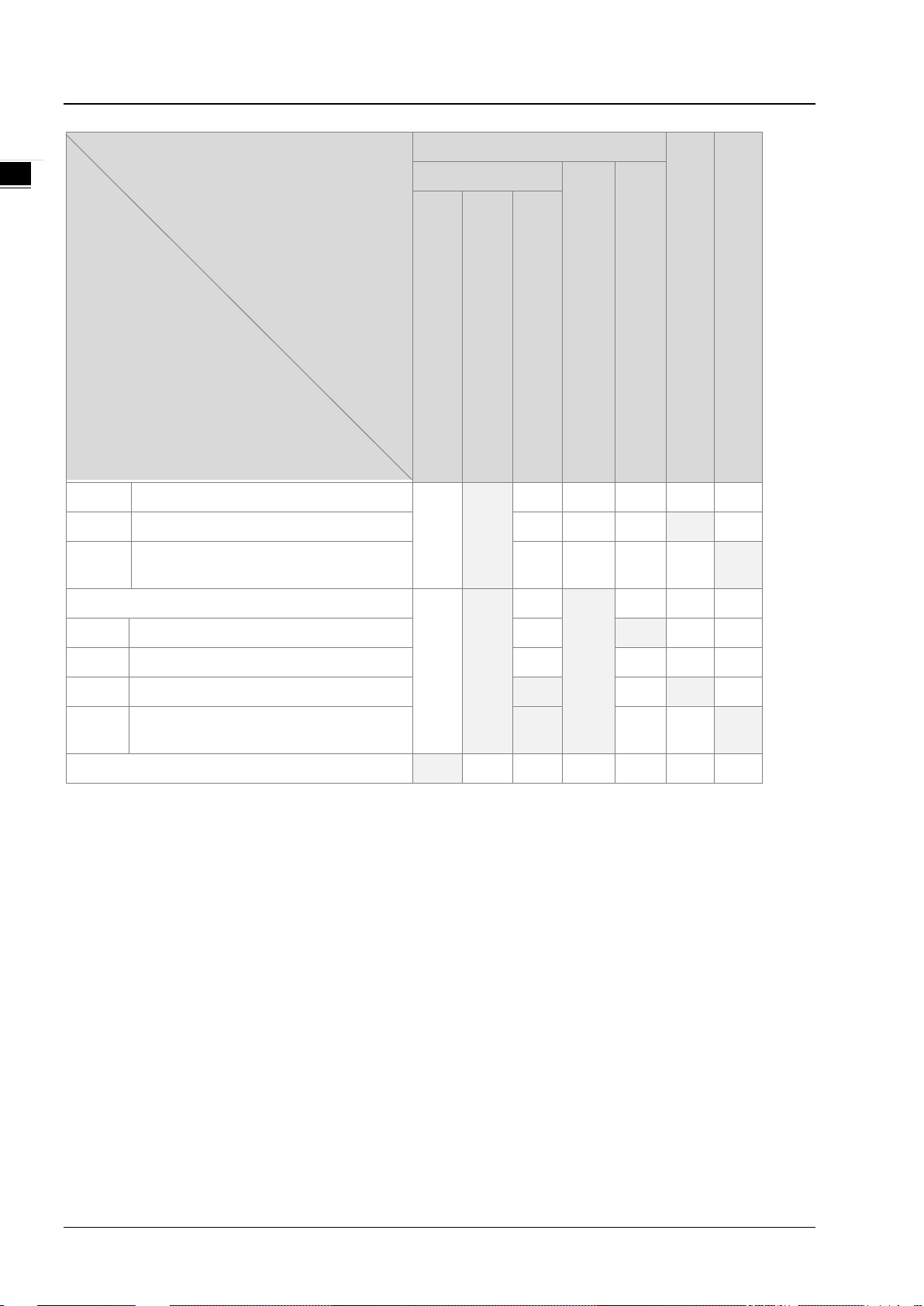

AH500 Motion Control Module Manual

AH500 Module Manual

AH Motion

AH Motion Control

AH Motion

AH Motion

Instructions Manual

for communication (e.g. EtherCAT)

for additional motion control modules

V* V

Related manuals

General operation procedures

for communication (e.g. EtherCAT)

for additional motion control modules V

for I/O extension using AH500 series

modules

AH Motion series manuals

Fundamental

Controller – Standard

Controller – Hardware Manual

ISPSoft User Manual

V

ler - Instructions Manual

Controller – Operation Manual

5. Testing and troubleshooting

for motion control applications V*

V

6. Maintenance and Inspection V

*Note: Information regarding Error codes and Indi cators and the associated troubleshooting information are attached as

Appendices for a quick reference. For the complete troubleshooting of the system, refer to AH Motion Controller –

Operation Manual.

for I/O extension using AH500 series

modules

V

V* V

IV

Page 10

1

Chapter 1 Product Introduction

Table of Contents

1.1 The AH Series Motion Controller ................................................................. 1-2

1.1.1. Product Features ....................................................................................... 1-3

1.1.2. Overview of the System Configurations ........................................................ 1-6

1.2 AH Motion CPU Specifications ..................................................................... 1-8

1.2.1 Environmental Specifications ..................................................................... 1-8

1.2.2 General Specifications ................................................................................ 1-8

1-1

Page 11

AH Motion Controller – Hardware Ma nual

_

n

verter

s

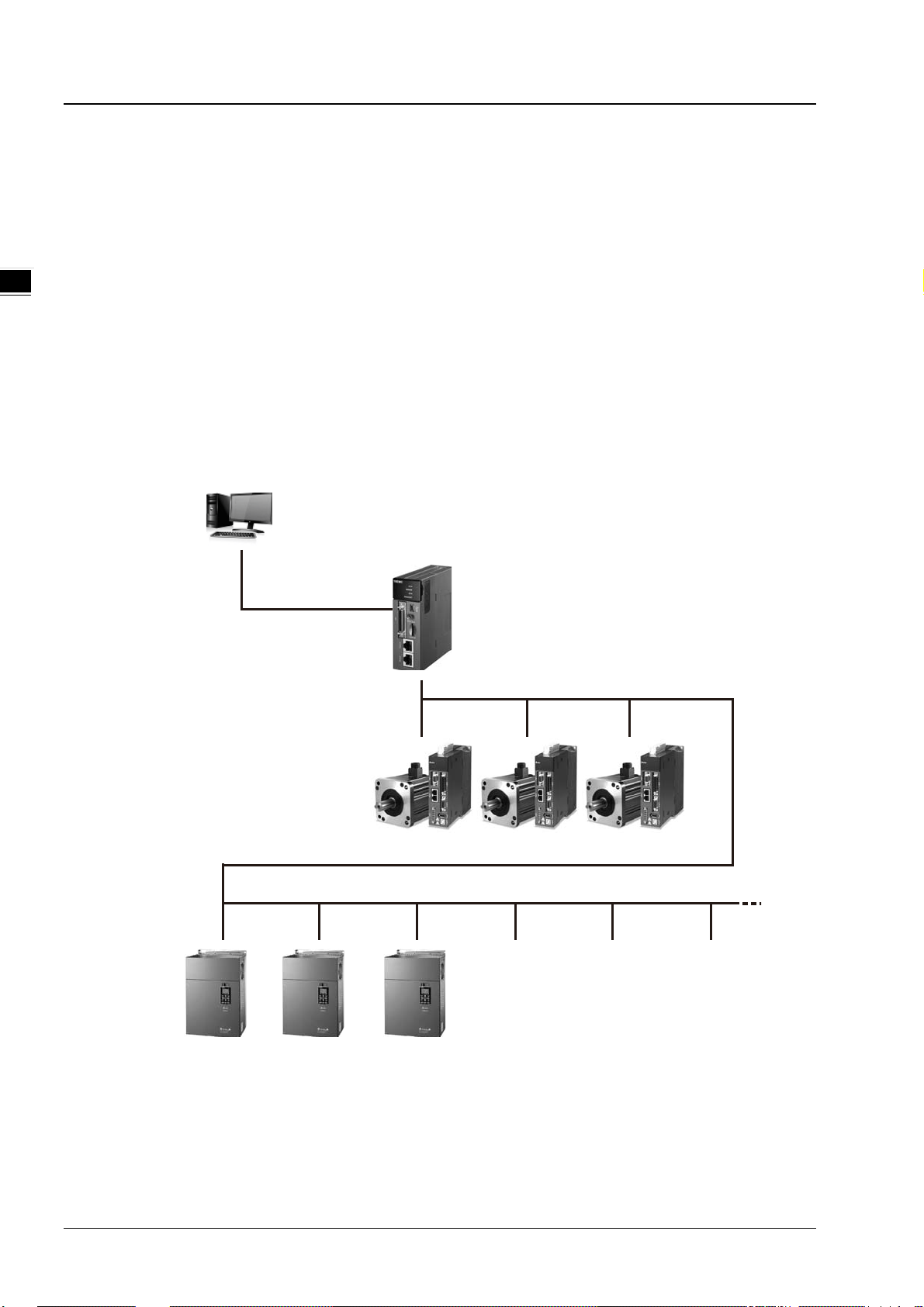

1.1 The AH Series Motion Controller

The AH series motion controllers are the new generation motion controllers that provide high-speed performanc e throug h

high speed interface, e.g. EtherCAT, and abundant functionality by the various functional modules. In machine automation

applications, they provide accessibility, maintainability and reliability which are demanded in machine automation

controllers.

1

The AH series motion controllers support the functionality of AH500 series PLCs, and are fully comply with PLCopen

motion control function blocks that are required for motion control. T he built-in high-speed motion network interface is

capable of synchronizing I/O devices quickly and can be used in motion control devices, machine vision equipment, I/O

devices, and more. With these products, you can build up a machine automation system easily throu gh ISPSoft software

to achieve maximum functionality and user-friendly operation.

With the machine automation system that is built from Delta products, you can connect devices easily and apply the

system as a complete solution with functionality and usability.

PLC

Software

ISPSoft

AH series motion controller

1-2

Servo driv es

I

General-purpose slaves

Page 12

Chapter 1 Product Introduction

_

1.1.1. Product Features

Hardware Features

1. High performance motion control

AHxxEMC-5A features EtherCAT motion control interface and is capable of controlling up to 32 axes. Maximum 6

axes synchronous linear interpolation and 3 axes synchronous circu lar interpolation.

Supports PLCopen motion control standard function blocks.

2. High efficiency

The AH Motion CPU adopts a 32-bit high-speed processor. The instructions are executed at a speed of 0.3

milliseconds per 1k steps. (50% of the instructions are ladder instructions, and 50% of the instructions are other

standard instructions.)

3. Multiple I/O modules

The I/O modules supported by the AH Motion CPU are digital input/output modules, analog input/output modules,

temperature measurement modules, network modules, motion control modules and remote I/O modules.

1

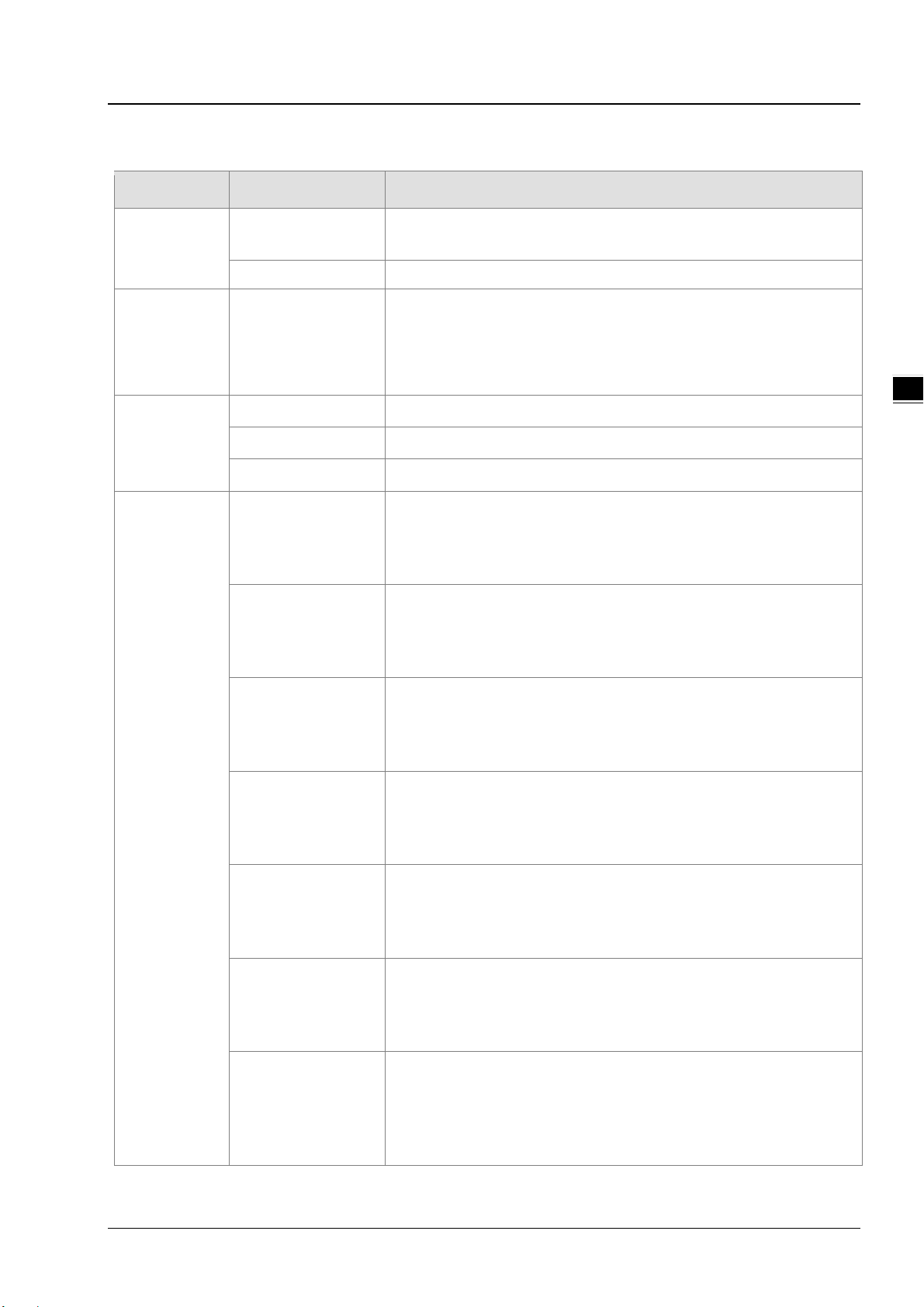

Module Description

Digital input/output

Digital

input/output

module

Analog

input/output

module

Temperature

measurement

module

Motion control

module

Network

module

Remote I/O

Module

AH16AM10N-5A, AH16AM30N-5A, AH16AN01P-5A, AH16AN01R-5A, AH16AN01S-5A,

AH16AN01T-5A, AH16AP1 1P-5A, AH16AP1 1R-5A, AH16AP11T-5A, AH32AM10N-5A,

AH32AM10N-5B, AH32AM10N-5C, AH32AN02P-5A, AH32AN02P-5B, AH32AN02P-5C,

AH32AN02T-5A, AH32AN02T -5B, AH32AN02T-5C, AH64AM10N-5C, AH64AN02P-5C and

AH64AN02T-5C

Analog input/output

AH04AD-5A, AH04DA-5A, AH06XA-5A, AH08AD-5A, AH08AD-5B, AH08AD-5C,

AH08DA-5A, AH08DA-5B, and AH08DA-5C

Measuring the temperature

AH04PT-5A, AH04TC-5A, AH08TC-5A, and AH08PTG-5A

Controlling the motion

AH02HC-5A, AH04HC-5A, AH05PM-5A, AH10PM-5A, AH15PM-5A, AH20MC-5A

Additional communication interface

AH10SCM-5A, AH10COPM-5A, AH10EN-5A, AH15EN-5A, AH10SCM-5A, AH15SCM-5A,

AH10DNET-5A, AH10PFBS-5A, AH10PFBM-5A

It can be installed on the main backplane to work as a RTU workstation. (it supports multiple

communication ports) AHRTU-DNET-5A, AHRTU-PFBS-5A and AHRTU-ETHN-5A.

4. Larger program capacity and memory

The program capacity of the AH Motion CP U can be up to 256k steps. Users do not need to change to a more

advanced CPU if the user program grows bigger.

The AH Motion CPU offers 128k words of data registers; 64k words of D devices and 64k words of L devices.

1-3

Page 13

_

1

AH Motion Controller – Hardware Ma nual

5. Serial control interface with multiple functions

AHxxEMC-5A provides one serial interface throu gh USB: COM1.

AHBP03M2-5A/AHBP05M2-5A (AH motion backplane) provides one serial interface through terminal block:

COM2.

You can use the USB serial interface (COM1) as RS-232 and terminal block serial interface (COM2) as RS-485

according to the application. The data transfer rate can be increased from 9600 bps to 115200bps.

ISPSoft,can perform automatic data exchange simply by filling the data exchange form in the software. Users do

not need to write any program for this purpose and can save time and efforts. For details of data exchange

between devices, refer to ISPSoft User Manual.

6. Memory card

The memory card has the following functions.

System backup: for user program, CPU parameters, module tables, and setting values in devices.

System recovery: for user program, CPU parameters, module tables, and setting values in devices.

Parameter storage: The values in the devices

Log storage: The system error log and the system status log

7. Hot swap

The AH motion series I/O modules support the on-line uninterruptible hot swapping. W hen the s ystem runs, users

can replace the module with error without stopping the system or setting the module t o offline state. After the

module is replaced, the new module will resume normal operation automatically.

1-4

Page 14

Chapter 1 Product Introduction

_

Software Features

1. Complying with IEC 61131-3

The AH Motion CPU complies with IEC 61131-3 editing environment which supports various programming

languages, multiple function blocks, tasks, and symbol tables.

The programming l anguages which are supported are, structured texts (ST), ladder diagrams (LD), sequential

function charts (SFC), and Continuous Function Chart (CFC).

1

You can select a programming language according to your preference and the convenience. The programming

languages support one another so that the programs written by different users are related.

2. Various function blocks*

In addition to standard IEC61131-3 function blocks (including PLCopen motion control function blocks), we also

offer various convenient function blocks (DFB). You can write the program frequently executed in a function block

so that the program becomes more structured and can be executed more conveniently.

The encryption function supported by ISPSoft provides the secrecy of function blocks for special businesses. The

program inside a function block cannot be learned, and the patent of a business will not be infringed.

*Note: A function block is a program element equipped with the operation function. It is similar to a subroutine, and is

a type of POU (Program Organization Unit). It cannot operate by itself, and has to be called through the program POU.

After the related parameters are transmitted, the function defined by a function block is executed. Besides, the fina l

operation result can be sent to the device or variable used in the superior POU after the execution of the function

block is complete.

3. Task

The user program supports 283 tasks at most: 32 cyclic tasks, 32 I/O interrupt tasks, 212 external interrupt tasks, 1

24V LV detection, 4 timed interrupt tasks, and 2 communication interrupt tasks.

Users can enable and disable a task during the execution of a program by means of TKON and TKOFF.

4. On-line debugging mode

After a single instruction step has been complete, or after a breakpoint is specified, users can easily find the bug in

the program by means of the on-line debugging mode supported by the AH Motion CPU.

Note: Structured Text (ST) do not support on-line debugging mode, and sequential function charts (SFC)

programming support the debugging mode during the action and the transition.

1-5

Page 15

AH Motion Controller – Hardware Ma nual

_

5. On-line editing mode

When the system runs, users can make use of the on-line editing mode to update the program without affecting

the operation of the system.

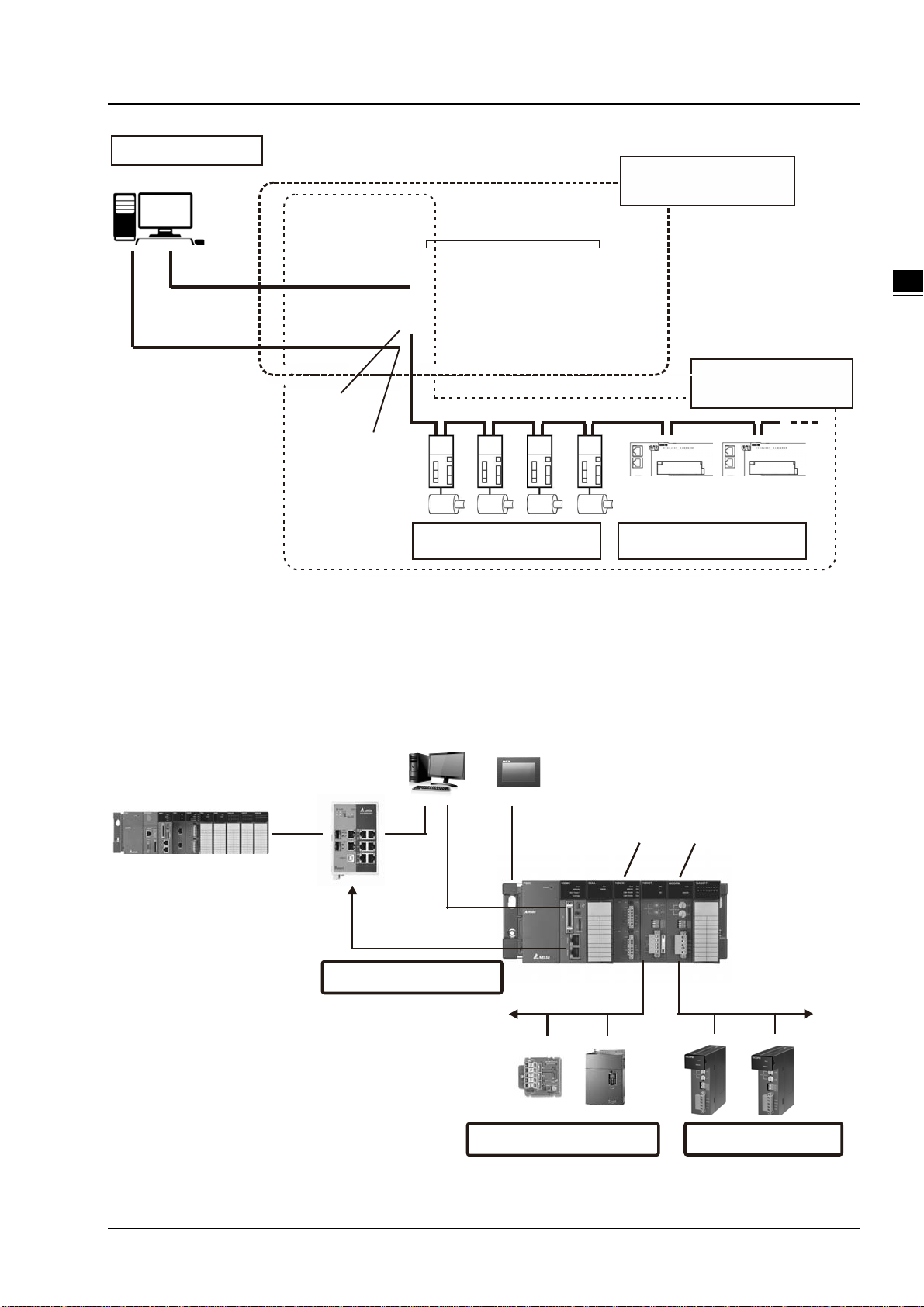

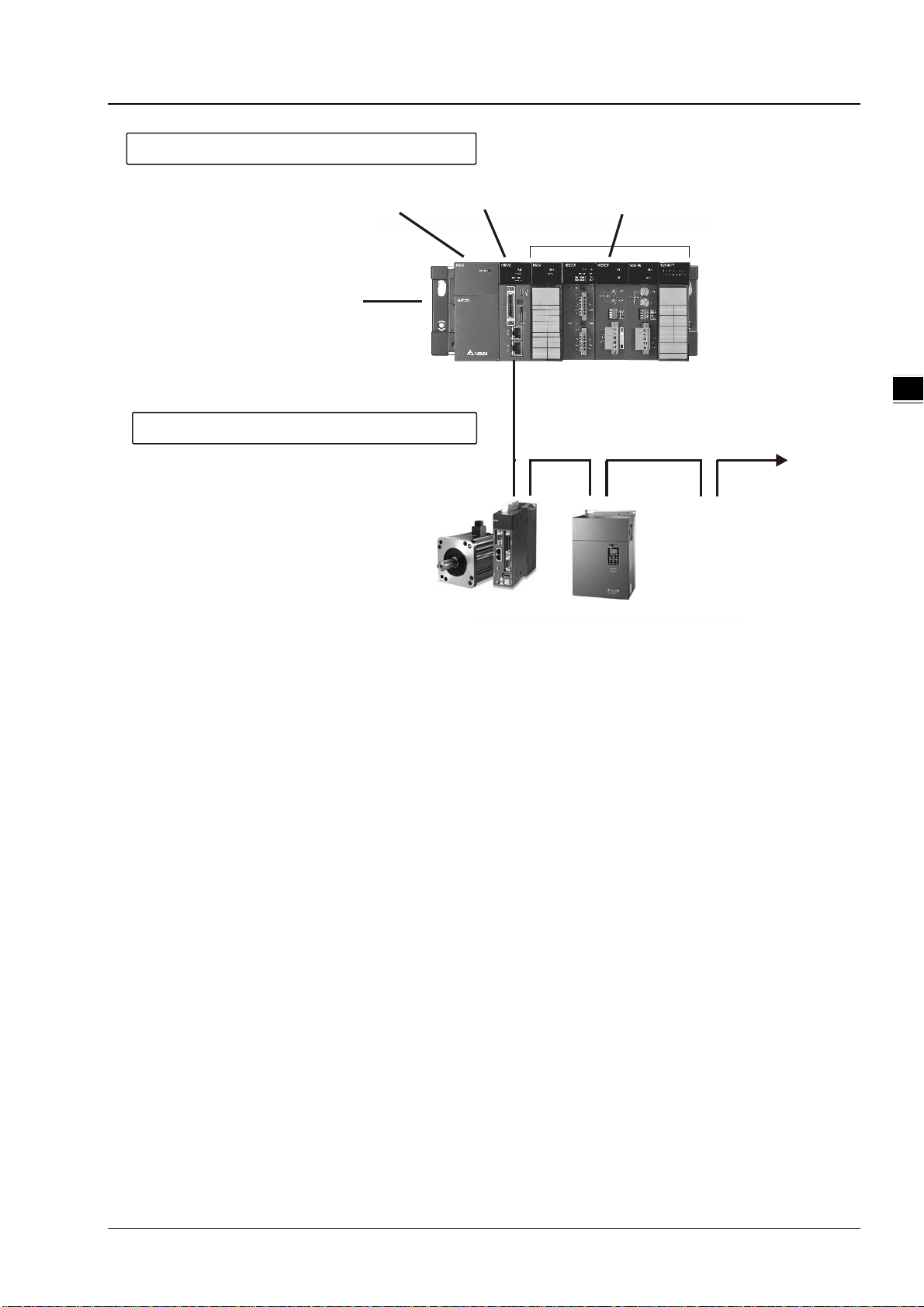

1.1.2. Overview of the System Configurations

1

The two categories of system configurations of AH Motion series motion control CPU are as follows.

Basic System Configurations

The AH Motion series CPU basic configurations include the AH Motion CPU Network Configuration, AH500 Series

Module Configuration, and Supported Software.

AH Motion Network Configuration

- AHxxEMC-5A

You can use the EtherCAT master port built in on the CPU interface to connect to slave devices such as analog and digital

I/O, servo drives, AC motor drives and encoder input devices. With EtherCAT network configuration, you can design a

system capable of performing very accurate sequence and motion control in a fixed cycle.

AH500 Series Module Configuration

With the motion backplane, you can also add AH500 series I/O modules* in addition to the EtherCAT network. AH500

series modules can be installed directly to the motion backplane where the CPU module is mounted.

*Note: a few of AH500 series I/O modules are not supported by the motion backplane. Refer to Ch2 System

Configuration for the list of supported products.

Supported Software

ISPSoft is the major programming software that you use for an AH Motion series motion controller. You can connect the

software on the computer to the USB interface on the CPU module through a commercially available USB cable. You can

also connect ISPSoft to the Ethernet port on the CPU module with an Ethernet cable or to the built-in RS-485 port on the

Motion backplane with a RS-485 cable and a converting device, e.g. IFD6500 USB/RS-485 converter. In addition to

ISPSoft, you can also use other software for configuring various applications based on different networks.

1-6

Page 16

_

Support Software

ISPSoft

AH Motion CPU

Power

Supply

CPU

Chapter 1 Product Introduction

AH500 Series Module

Configuration

AH I/O modules

USB(RS- 232)

LAN or EtherNet/IP

CPU

Rack

AH MotionNetwork

Bullt-In EtherCAT port

Bullt- In Ether Net/IP port

EtherCAT

Servo drives/encoder

input slaves

General-purpose slaves

Configuration

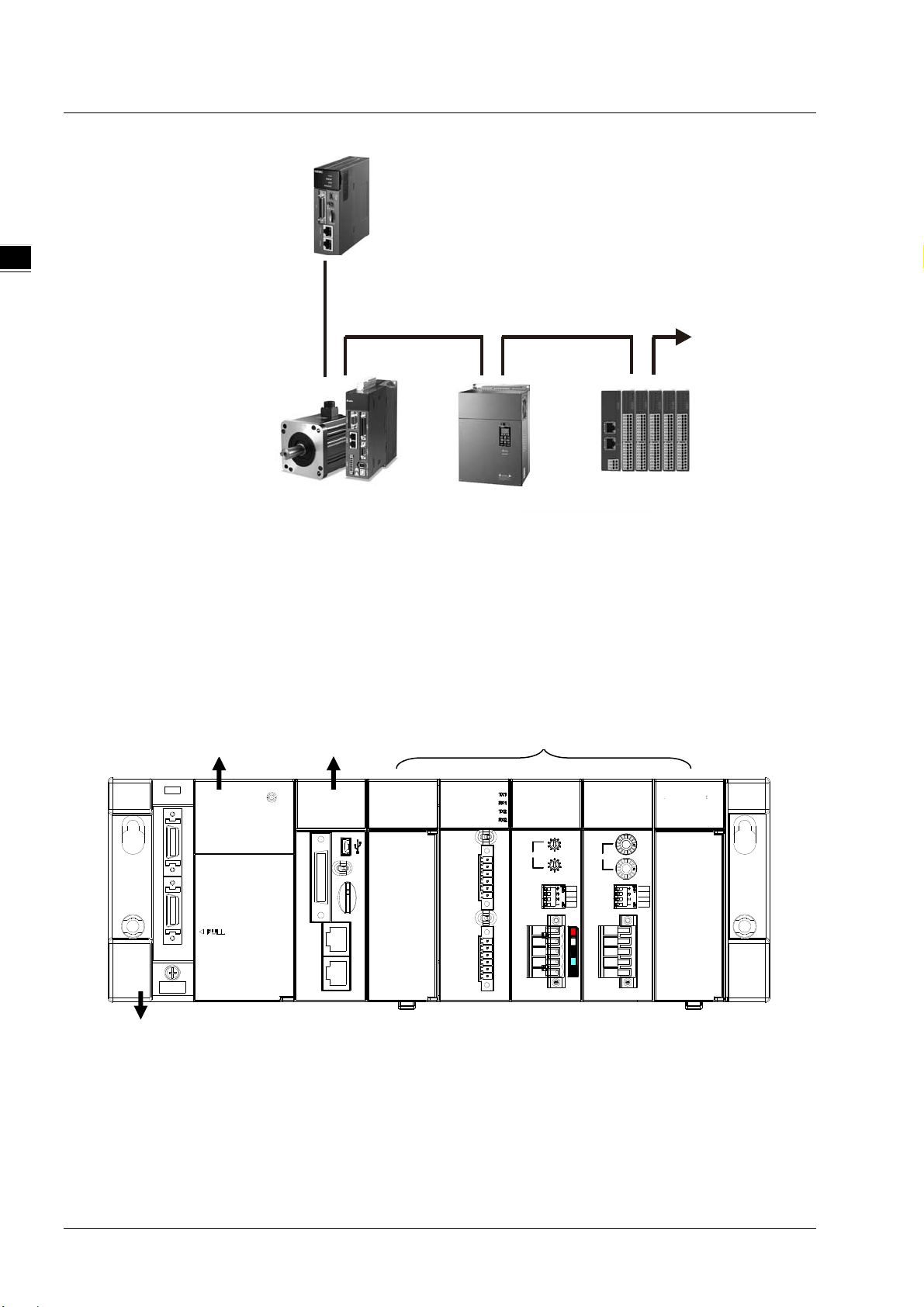

Other Network Configurations

Through the network interfaces on the AH motion CPU and the m otion backplane, you can connect host computers,

Human Machine Interfaces (HMI) and other AH series PLCs with RS-232(USB), RS-485, and EtherNet/IP networks. In

addition, you can also create CANopen network and additional serial communication network (RS-485) by mounting

AH500 series network modules on the motion backplane.

PC HMI

1

Et herNet/IP Scanner

( A H 500 Se r i es PLC )

DVS Series

Et h er n et Sw i tch

EtherNet/IP (Adapter)

USB RS-485

Power CPU

Serial Comm.

Module

CANopen

Module

CANo penSerial communications

1-7

Page 17

AH Motion Controller – Hardware Ma nual

_

Supported Software

ISPSoft is the major programming software that you use for an AH Motion series motion controller. You can use ISPSoft to

set up the controller configurations, parameters, and to develop the program. Debugging and simulate operation.

Required software

1

- ISPSoft: Programming and hardware configuration

- COMMGR: Communication management

- EtherCAT Builder: EtherCAT network configurator (for AHxxEMC-5A)

Optional software

- EtherNet/IP Builder: EtherNet/IP network configurator

- CANopen Builder: CANopen network configurator

1.2 AH Motion CPU Specifications

1.2.1 Environmental Specifications

Environmental Specifications

Operating temperature

Storage temperature

Operating humidity

-20~60°C

-40~70°C

5~95%

No condensation

Storage humidity

Vibration/Shock

resistance

Operating environment

Installation location

Pollution degree

5~95%

No condensation

International standards IEC 61131-2, IEC 68-2-6 (TEST Fc)/

IEC 61131-2 & IEC 68-2-27 (TEST Ea)

No corrosive gas exists.

In a control box

2

1.2.2 General Specifications

General Specifications

AHxxEMC-5A Remark

Execution

Input/Output control

Programming language

The program is executed cyclically.

Cyclically refreshed inputs/outputs

Direct inputs/outputs

IEC 61131-3

The inputs and outputs can be

controlled through the direct

inputs (DX device) and direct

outputs (DY device).

1-8

Page 18

Chapter 1 Product Introduction

_

General Specifications

AHxxEMC-5A Remark

Ladder diagram (LD), continuous function

chart (CFC), structured text (ST), and

sequential function chart (SFC).

Instruction execution speed

Constant scan cycle (ms)

Program capacity (step)

Installation

Installation of modules

Number of modules

Number of tasks

Number of input/output

devices

Number of inputs/outputs

0.3 ms/K steps

1-32000

(The scan cycle can be increased by one

millisecond.)

256K steps

DIN rails or screws

Modules are installed directly on a backplane.

Five input/output modules at most can be

installed on a motion backplane.

283 tasks (32 cyclic tasks, 32 I/O interrupt

tasks, 212 external interrupt tasks, 1 24V LV

detection, 4 timed interrupt tasks, and 2

communication interrupt tasks).

X/Y devices (bit): 8192

(X0.0~X511.15/Y0.0~Y511.15)

X/Y devices (word): 512

(X0~X511/Y0~Y511)

338 inputs/ 324 outputs (AHBP05M2-5A)

1

The scan cycle time can be

specified by parameters.

Number of devices which can be

used in a program

Number of inputs/outputs

accessible to an CPU

Input relay [X]

Output relay [Y]

Auxiliary relay [M]

Timer [T]

Counter [C]

32-bit counter [HC/AC]

Data register [D]

Stepping relay [S]

Index register [E]

Special auxiliary relay [SM]

Special data register [SR]

Serial communication port

Ethernet port

8192 (X0.0~X511.15)

8192 (Y0.0~Y511.15)

8192 (M0~M8191)

2048 (T0~T2047)

2048 (C0~C2047)

HC: 64 (HC0~HC63)

AC: 56 (AC0~ AC55)

D device (bit): 1048576 (D0.0~D65535.15)

D device (word): 65536 (D0~D65535)

2048 (bit) (S0~S2047)

32 (word) (E0~E31)

SM(bit): 2048 (SM0~SM2047)

SR(word): 2048 (SR0~SR2047)

One RS-232(USB), One RS-485

communication port

10/100 M

1-9

Page 19

AH Motion Controller – Hardware Ma nual

_

General Specifications

AHxxEMC-5A Remark

1

USB port

Memory card slot

Real-time clock

Mini USB

Supports Micro SD card (SD 2.0)

Years, months, days, hours, minutes,

seconds, and weeks

The function is available when the

CPU is used together with the

motion backplane

1-10

Page 20

2

Chapter 2 System Configuration

Table of Contents

2.1 Basic System Configuration ........................................................................ 2-2

2.1.1. AH Motion CPU Network Configuration ......................................................... 2-3

2.1.2. AH500 Series Module Configuration ............................................................. 2-4

2.2 Software Connection ................................................................................ 2-10

2.3 Overall Network Configuration ................................................................. 2-11

2.3.1 EtherNet/IP ................................................................................................. 2-12

Page 21

AH Motion Controller – Hardware Ma nual

_2

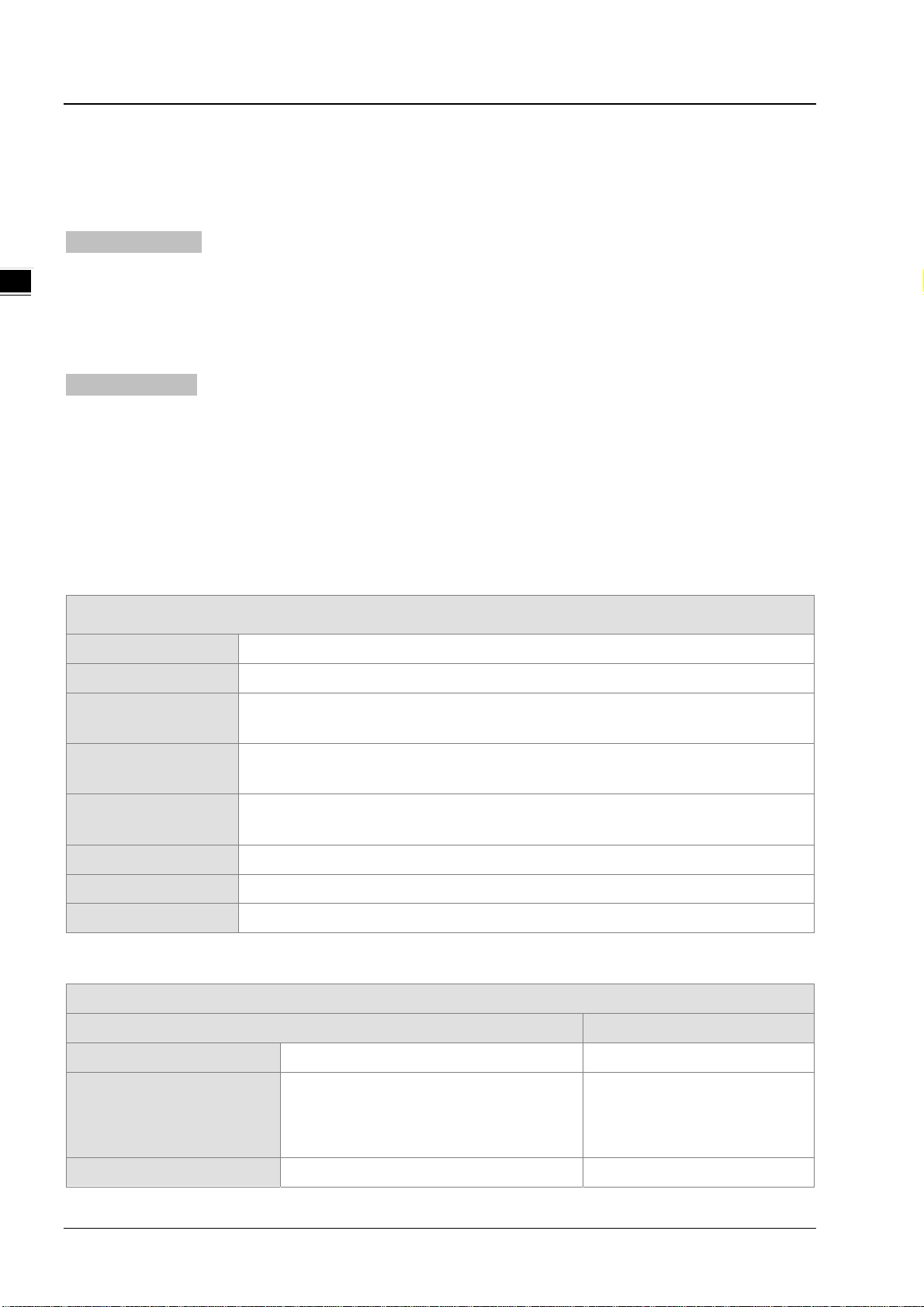

2.1 Basic System Configuration

An AH Motion series CPU provides two types of configurations as follows.

1. Basic Configurations

The basic configurations explained in this section include the CPU network configuration and the configuration of the I/O

modules which are controlled by the CPU.

- AH Motion CPU network configuration

- AH500 Series Module Configuration

2. Other Network Configurations

In addition to the main CPU network configuration, you can also set up other network configurations which are connecte d

to the CPU’s built-in EtherNet/IP port and other network modules.

AH Motion CPU Network Configuration

- AHxxEMC

The AH Motion CPU provides EtherCAT network as a basic motion system.

With the EtherCAT network system, you can obtain execution results of both sequence and motion control operation in the

high speed communications period of EtherCAT network. This feature enables precise sequence control and motion

control with a constant cycle time and steady operational results.

AH500 Series Module Configuration

CPU Rack

The CPU Rack consists of products as follows.

- AH Motion series CPU

- AH Motion series backplane

- AH500 series power supply module

- AH500 series motion control modules

- AH500 series network modules*

- AH500 series digital I/O modules and special I/O modules.

*Note: Some AH500 series network modules are not supported by AH Motion CPU. Refer to 2.1.2 AH500 Series Module

Configuration for the supported models.

Page 22

_

AH500 Series Module Configuration

C

Chapter 2 System Configuration

Power supply module

Motion backplane

AH Motion CPU Network Configuration

EtherCAT slaves

AH Motion CPU

EtherCAT network

configuration(AH10EMC)

Servo Drives

2.1.1. AH Motion CPU Network Configuration

Digital I/O, Special I/O

Inverters General-prupose slave s

2

AHxxEMC – EtherCAT

The EtherCAT network configuration includes AHxxEMC which is the core motion CPU, an AH motion backplane*, and an

AH500 series power supply module. You can connect the built-in EtherCAT master port to the EtherCAT slave devces.

The AHxxEMC can also be used as a motion control module in an AH500 series PLC configuration. You can install it onto

the AH500 series main backplane to perform motion control function.

For more information about this application, refer to AH500 Motion Control Module Manual.

*Note: The AH motion backplane must be used together with AHxxEMC when you use AHxxEMC as a motion CPU.

2-3

Page 23

AH Motion Controller – Hardware Manual

_2

A

HMotionCPU

EtherCAT

1

EtherCAT sla ves

Servo drives General-purpose slaves

Inverters

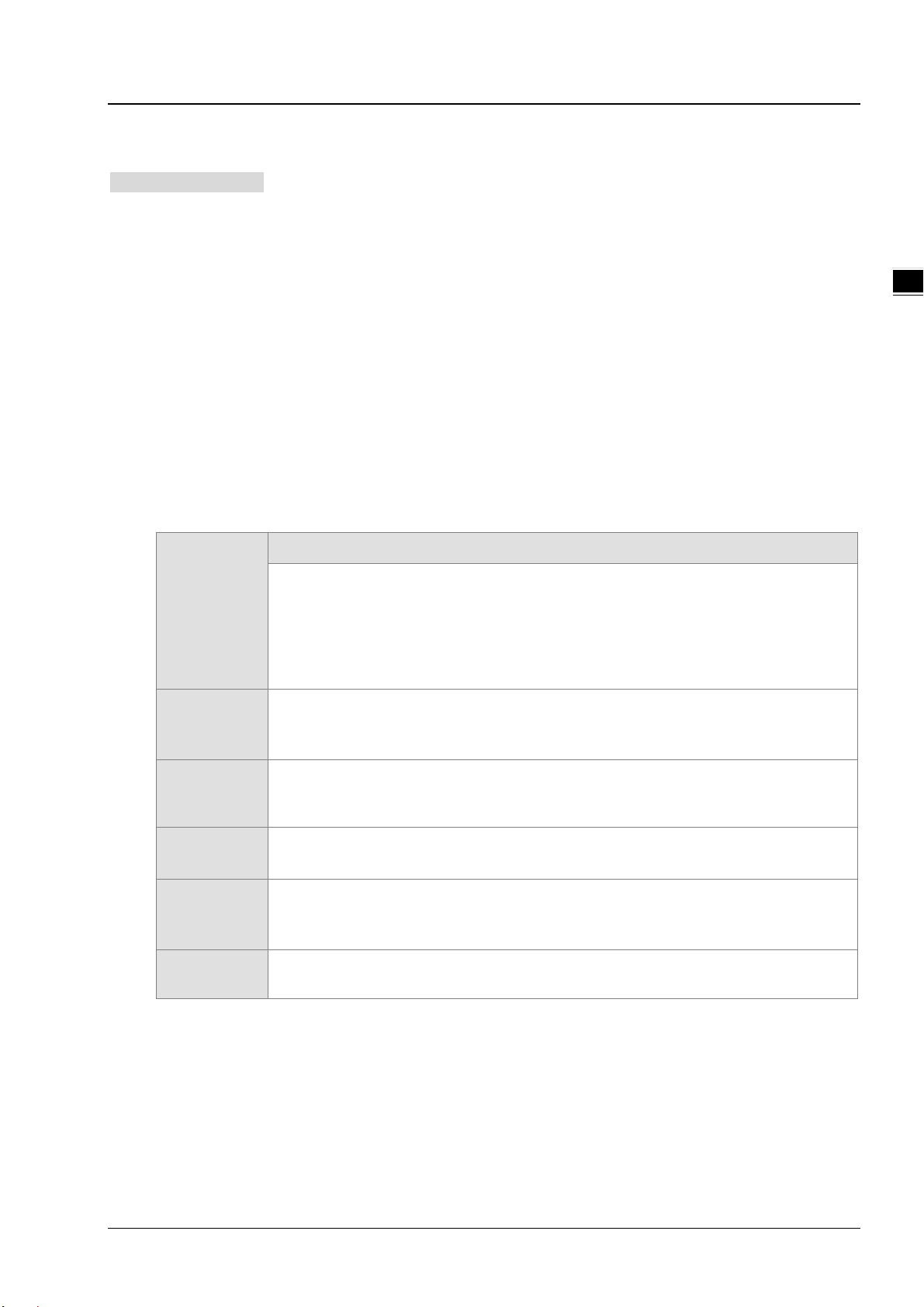

2.1.2. AH500 Series Module Configuration

The AH Motion CPU rack consists of a motion backplane with a power supply module and a motion CPU. You can mount

additional AH500 series moudles to the right for different applications. T he available modules include d igital input/output

modules, analog input/output modules, network modules, and motion control modules.

AH Motion CPU Rack

A CPU module, a power supply module, and I/O modules are installed on a motion backplane.

Powre supply module

AH Motion CPU

10EMC

BUS FAULT

CN1

Ethernet EtherCAT

ERROR

SYSTEM

RUN

RUNSTOP

Micro SD

06XA 10SCM

ERROR

RUN

AH500 series modules

10DNET

RUN

ERROR

COM1 RS485

COM2 RS485

TR1

TR2

OFF

ON

COM1

TX+

TXRX+

RX-

FG

ON

COM2

TX+

TXRX+

RXGND

FG

Node Address

D+

DGNDGND

FG

OFF

D+

DGND

FG

10COPM

MS

NS

5

6

4

7

1

3

x10

8

2

9

1

0

5

Node Address

6

4

7

0

3

x10

8

2

9

1

0

DR 1

DR 0

IN 1

IN 0

ERROR

16AN01T

RUN

312

0

5

124910

118

15147613

1

x16

0

x16

DR 2

DR 1

DR 0

IN 0

CAN+

SHLD

CAN-

GND

AH Motion backplane

2-4

Page 24

Chapter 2 System Configuration

_

Components

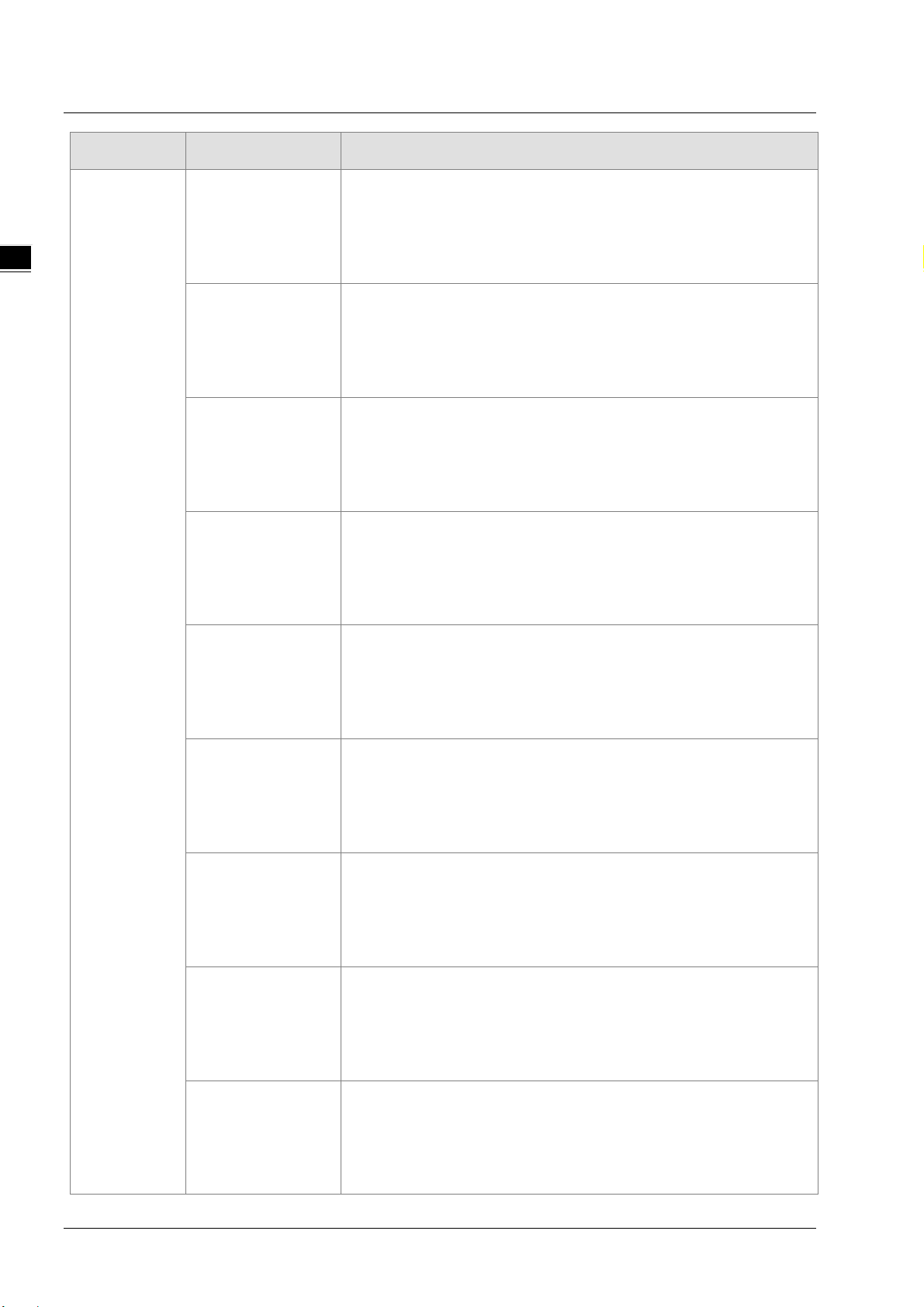

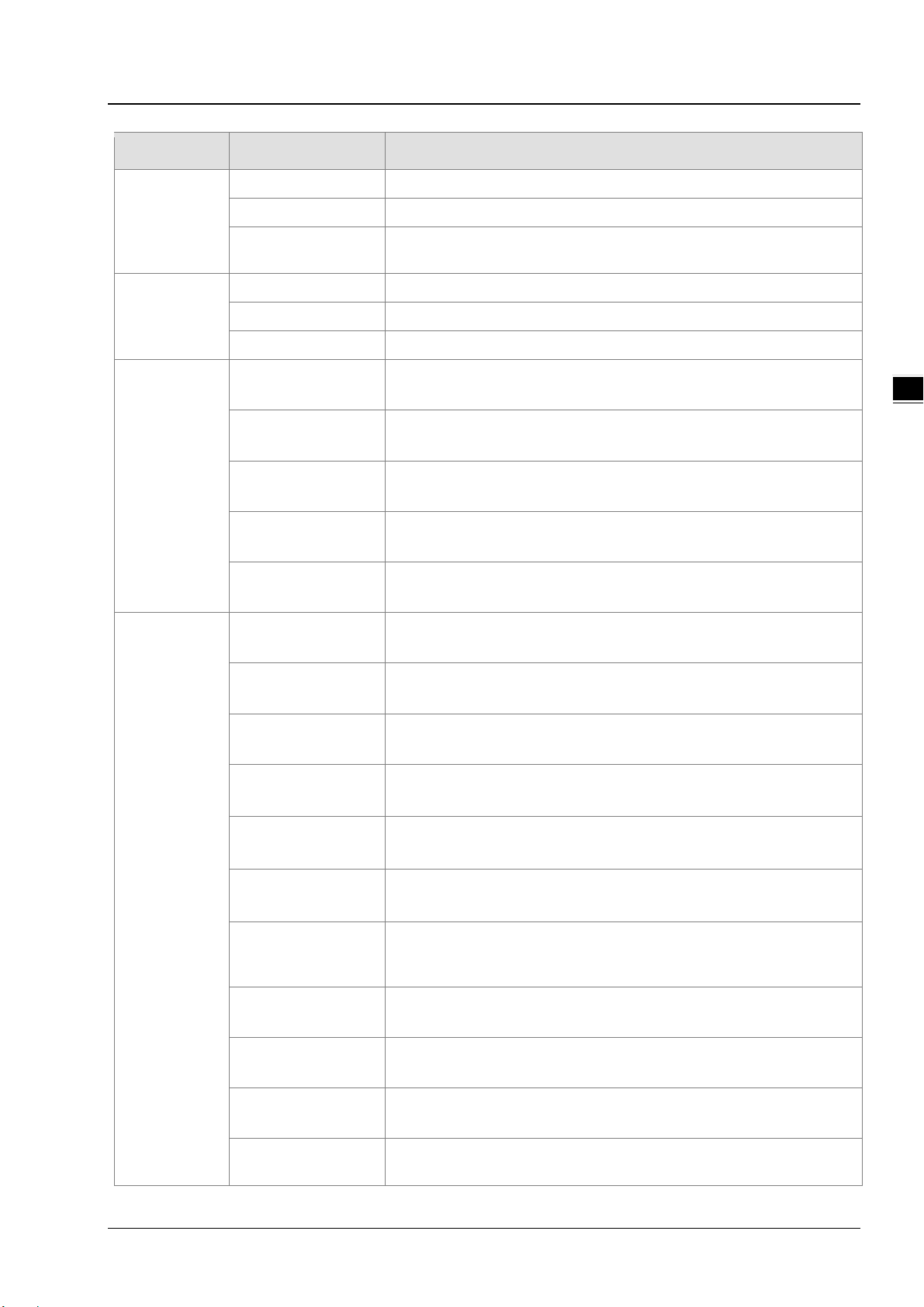

Component Model Name Description

Power supply

module

AH Motion

CPU

Motion

backplane

AHPS05-5A

AHPS15-5A 24 VDC

AHxxEMC-5A

AHBP03M2-5A Three slots available for additional AH500 series modules.

AHBP05M2-5A Five slots available for additional AH500 series modules.

AHBP07M2-5A Seven slots available for additional AH500 series modules.

AH16AM10N-5A

AH32AM10N-5A

100~240 VAC

50/60 Hz

AH08EMC-5A: 8 axes; AH10EMC-5A: 16 axes; AH20EMC-5A: 32 axes

One EtherCAT port

One EtherNet/IP port (adapter)

One built-in USB port (RS-232)

One built-in micro SD interface

24 VDC

5 mA

16 inputs

Terminal block

24 VDC

5 mA

32 inputs

Terminal block

2

Digital

input/output

module

AH32AM10N-5B

AH32AM10N-5C

AH64AM10N-5C

AH16AM30N-5A

AH16AN01R-5A

24 VDC

5 mA

32 inputs

DB37 connector

24 VDC

5 mA

32 inputs

MIL connector

24 VDC

3.2 mA

64 inputs

MIL connector

100~240 VAC

4.5 mA~9 mA (100 V, 50 Hz)

16 inputs

Terminal block

240 VAC/24 VDC

2 A

16 outputs

Relay

Terminal block

2-5

Page 25

AH Motion Controller – Hardware Manual

_2

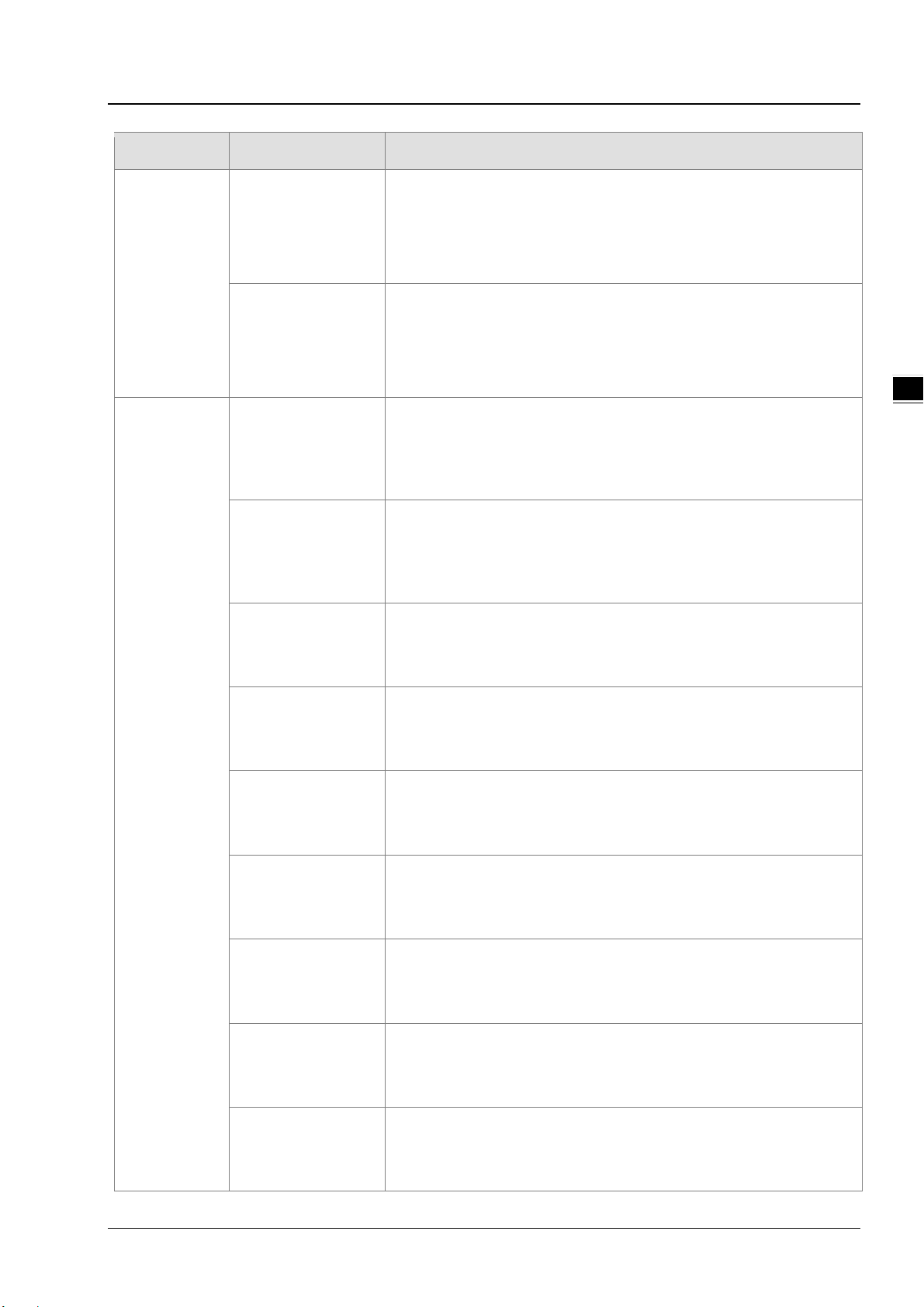

Component Model Name Description

12~24 VDC

0.5 A

AH16AN01T-5A

AH16AN01P-5A

AH32AN02T-5A

AH32AN02T-5B

16 outputs

Sinking output

Terminal block

12~24 VDC

0.5 A

16 outputs

Sourcing output

Terminal block

12~24 VDC

0.1 A

32 outputs

Sinking output

Terminal block

12~24 VDC

0.1 A

32 outputs

Sinking output

DB37 connector

AH32AN02T-5C

AH32AN02P-5A

AH32AN02P-5B

AH32AN02P-5C

12~24 VDC

0.1 A

32 outputs

Sinking output

MIL connector

12~24 VDC

0.1 A

32 outputs

Sourcing output

Terminal block

12~24 VDC

0.1 A

32 outputs

Sourcing output

DB37 connector

12~24 VDC

0.1 A

32 outputs

Sourcing output

MIL connector

12~24 VDC

0.1 A

AH64AN02T-5C

2-6

64 outputs

Sinking output

MIL connector

Page 26

Chapter 2 System Configuration

_

Component Model Name Description

12~24 VDC

0.1 A

AH64AN02P-5C

AH16AN01S-5A

AH04AD-5A

AH08AD-5A

64 outputs

Sourcing output

MIL connector

100~240 VAC

0.5 A

16 outputs

TRIAC

Terminal block

Four-channel analog input module

Hardware resolution: 16 bits

0/1 V~5 V, -5 V~5 V, 0 V~10 V, -10 V~10 V, 0/4 mA~20 mA, and -20

mA~20 mA

Conversion time: 150 us/channel

Eight-channel analog input module

Hardware resolution: 16 bits

0/1 V~5 V, -5 V~5 V, 0 V~10 V, -10 V~10 V, 0/4 mA~20 mA, and -20

mA~20 mA

Conversion time: 150 us/channel

2

Analog

input/output

module

AH08AD-5B

AH08AD-5C

AH04DA-5A

AH08DA-5A

AH08DA-5B

AH08DA-5C

Eight-channel analog input module

Hardware resolution: 16 bits

0/1 V~5 V, -5 V~5 V, 0 V~10 V, and -10 V~10 V

Conversion time: 150 us/channel

Eight-channel analog input module

Hardware resolution: 16 bits

0/4 mA~20 mA, and -20 mA~20 mA

Conversion time: 150 us/channel

Four-channel analog output module

Hardware resolution: 16 bits

0/1 V~5 V, -5 V~5 V, 0 V~10 V, -10 V~10 V, and 0/4 mA~20 mA

Conversion time: 150 us/channel

Eight -channel analog output module

Hardware resolution: 16 bits

0/1 V~5 V, -5 V~5 V, 0 V~10 V, -10 V~10 V, and 0/4 mA~20 mA

Conversion time: 150 us/channel

Eight-channel analog output module

Hardware resolution: 16 bits

0/1 V~5 V, -5 V~5 V, 0 V~10 V, and -10 V~10 V

Conversion time: 150 us/channel

Eight-channel analog output module

Hardware resolution: 16 bits

0/4 mA~20 mA

Conversion time: 150 us/channel

AH06XA-5A

Four-channel analog input module

Hardware resolution: 16 bits

0/1 V~5 V, -5 V~5 V, 0 V~10 V, -10 V~10 V, 0/4 mA~20 mA, and -20

mA~20 mA

2-7

Page 27

AH Motion Controller – Hardware Manual

_2

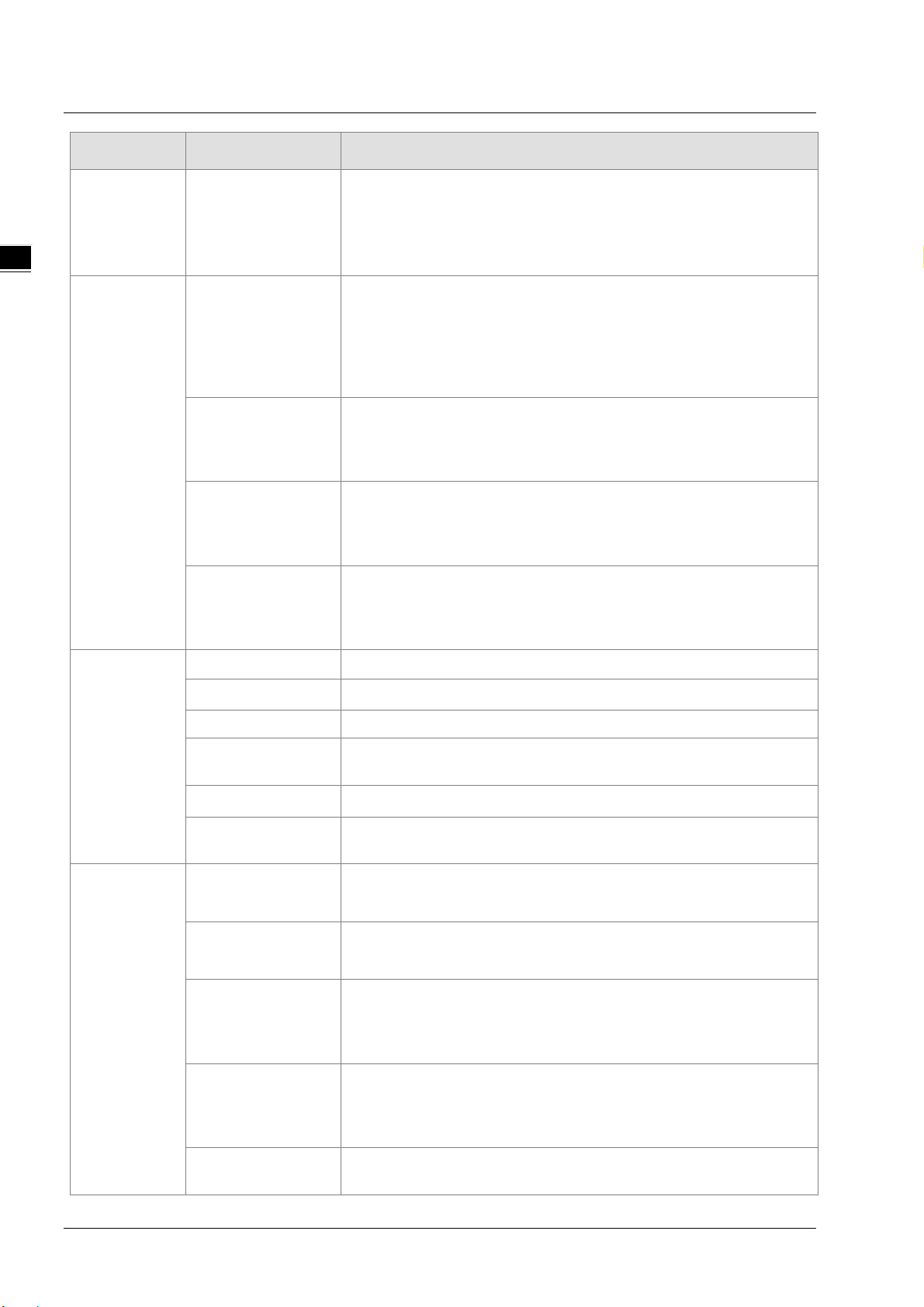

Component Model Name Description

Conversion time: 150 us/channel

Two-channel analog output module

Hardware resolution: 16 bits

0/1 V~5 V, -5 V~5 V, 0 V~10 V, -10 V~10 V, and 0/4 mA~20 mA

Conversion time: 150 us/channel

Four-channel four-wire/three-wire RTD

Sensor type: Pt100/Pt1000/Ni100/Ni1000 sensor, and 0~300 Ω input

impedance

Temperature

measurement

module

AH04PT-5A

AH08PTG-5A

AH04TC-5A

Resolution: 0.1°C/0.1°F (16 bits)

Four-wire conversion time: 150 ms/channel

Three-wire conversion time: 300 ms/channel

Eight-channel four-wire/three-wire/two-wire RTD

Sensor type: Pt100/Pt1000/Ni100/Ni1000, and 0~300 Ω input impedance

Resolution: 0.1°C/0.1°F (16 bits)

Conversion time: 20 ms/4 channels and 200 ms/8 channels

Four-channel thermocouple

Sensor type: J, K, R, S, T, E, N, and -150~+150 mV

Resolution: 0.1°C/0.1°F

Conversion time: 200 ms/channel

Motion control

module

Network

module

Eight-channel thermocouple

AH08TC-5A

AH02HC-5A Two-channel high-speed counter module (200 kHz)

AH04HC-5A Four-channel high-speed counter module (200 kHz)

AH05PM-5A Two-axis pulse train motion control module (1 MHz)

AH10PM-5A

AH15PM-5A Four-axis pulse train motion control module (1 MHz )

AH20MC-5A

AH10EN-5A

AH15EN-5A

AH10SCM-5A

Sensor type: J, K, R, S, T, E, N, and -150~+150 mV

Resolution: 0.1°C/0.1°F

Conversion time: 200 ms/channel

Six-axis pulse train motion control module

(Four axes: 1 MHz; Two axes: 200 kHz)

Twelve-axis DMCNET (Delta Motion Control Network) motion control

module (10 Mbps)

It is an Ethernet communication module with two Ethernet ports, and

supports Modbus TCP protocols, and EtherNet/IP software (V2.0). It can

function as a master or a slave.

It is an Ethernet communication module with two Ethernet ports, and

supports Modbus TCP protocols, and IEC60870-5-104. It can function as a

master or a slave.

It is a serial communication module with two RS-485/RS-422 ports, and

supports Modbus and UD Link protocols. One part of communication is

isolated from the other part of the communication, and one part of power

is isolated from the other part of the power.

It is a serial communication module with two RS-232 ports, and supports

AH15SCM-5A

AH10DNET-5A

2-8

Modbus and UD Link protocols. One part of communication is isolated

from the other part of the communication, and one part of power is

isolated from the other part of the power.

It is a DeviceNet communication module. It can function as a master or

slave. A maximum of 1Mbps per second can be transferred.

Page 28

Chapter 2 System Configuration

_

Component Model Name Description

AH10PFBM-5A It is a PROFIBUS communication module. It can function as a master.

AH10PFBS-5A It is a PROFIBUS communication module. It can function as a slave.

Remote I/O

module

I/O extension

cable

AH10COPM-5A

AHRTU-DNET-5A It is a DeviceNet remote I/O communication module.

AHRTU-PFBS-5A It is a PROFIBUS remote I/O communication module.

AHRTU-ETHN-5A It is an Ethernet remote I/O communication module.

UC-ET010-24A or

DVPACAB7A10

UC-ET010-24C or

DVPACAB7B10

UC-ET010-33B or

DVPACAB7C10

UC-ET010-13B or

DVPACAB7D10

UC-ET010-15B or

DVPACAB7E10

UB-10-ID32A or

DVPAETB-ID32A

UB-10-OR16A or

DVPAETB-OR16A

It is a CANopen communication module. It can function as a master or a

slave.

1.0 meter I/O extension cable (MIL connector) for AH32AM10N-5C and

AH64AM10N-5C

1.0 meter I/O extension cable (MIL connector) for AH32AN02T-5C,

AH32AN02P-5C, AH64AN02T-5C and AH64AN02P-5C

1.0 meter I/O extension cable (DB37 connector) for AH32AM10N-5B,

AH32AN02T-5B, and AH32AN02P-5B

1.0 meter I/O extension cable for AH04HC-5A and AH20MC-5A

1.0 meter I/O extension cable for AH10PM-5A and AH15PM-5A

I/O external terminal module for AH32AM10N-5C and AH64AM10N-5C

32 inputs

I/O external terminal module for AH32AN02T-5C and AH64AN02T-5C

16 relay outputs

2

External

terminal

module

UB-10-OR16B or

DVPAETB-OR16B

UB-10-ID32B or

DVPAETB-ID32B

UB-10-OR32A or

DVPAETB-OR32A

UB-10-OR32B or

DVPAETB-OR32B

UB-10-OT32A or

DVPAETB-OT32A

UB-10-OT32B or

DVPAETB-OT32B

UB-10-IO16C or

DVPAETB-IO16C

UB-10-IO24C or

DVPAETB-IO24C

UB-10-IO34C or

DVPAETB-IO34C

I/O external terminal module for AH32AN02P-5C and AH64AN02P-5C

16 relay outputs

I/O external terminal module for AH32AM10N-5B

32 inputs

I/O external terminal module for AH32AN02T-5B

32 relay outputs

I/O external terminal module for AH32AN02P-5B

32 relay outputs

I/O external terminal module for AH32AN02T-5C, AH32AN02P-5C,

AH64AN02T-5C, and AH64AN02P-5C

32 transistor outputs

I/O external terminal module for AH32AN02T-5B and AH32AN02P-5B

32 transistor outputs

I/O external terminal module for AH04HC-5A and AH20MC-5A

I/O external terminal module for AH10PM-5A

I/O external terminal module for AH10PM-5A

2-9

Page 29

AH Motion Controller – Hardware Manual

_2

LCSof

Component Model Name Description

Dummy

module

AHASP01-5A Dummy module used for an empty I/O slot

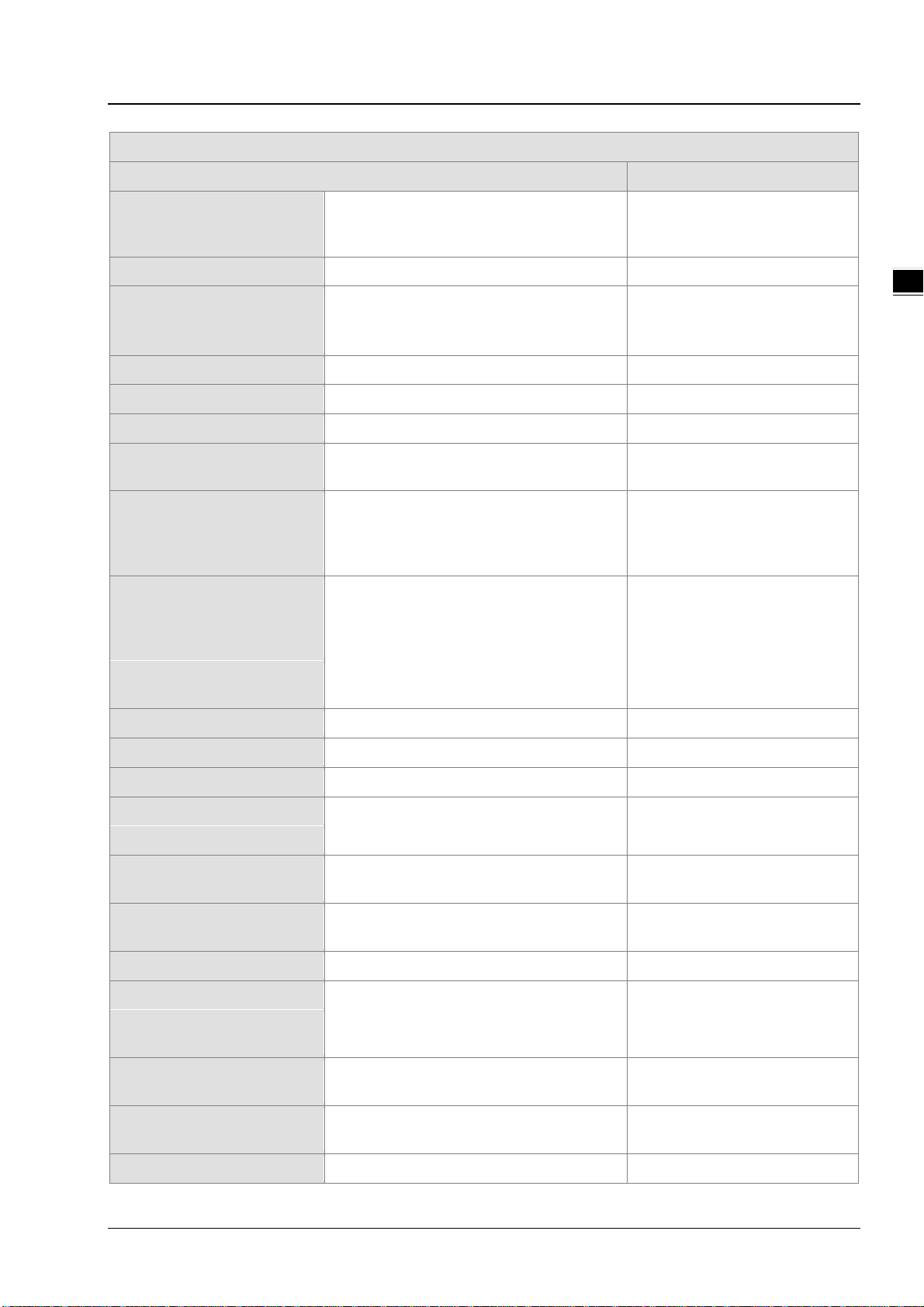

2.2 Software Connection

Through the network interfaces on the AH motion CPU and the motion backplane, you can connect the CPU to the host

computer with RS-232(USB), RS-485, and Ethernet networks. In this configuration, you can also connect ISPSoft with

AH500 series PLCs. Refer to

Motion system and the ISPSoft.

ISPSoft User Manual

for information on the procedures of the connections between the AH

P

tware

ISPSoft

EtherNet/I P Ne twork

therNet/IP Scanner

RS-232

RS-485

AH500 AH Motion/

series PLCs

AH Motion CPU

2-10

Page 30

Chapter 2 System Configuration

_

I

nform

ati

o

a

yer

2.3 Overall Network Configuration

- AHxxEMC

In addition to the AH Motion CPU network, e.g. EtherCAT, you can expand AH Motion system with additional networks

such as CANopen network and serial communication networks. The diagram below shows the overall network

configuration of different layers.

For operation procedures on connecting different communication networks, refer to ISPSoft User Manual.

n L

EtherNet/IP

Control Layer

EtherNet/IP

AH Motion CPU

Serial

communication

module

CANopen module

PC

AH500 series CPU

Bu ilt-in

EtherNet/IP port

CANopen

EtherNet/IP module port

Built-in EtherNet/IP port

AH Motion CPU

HMI

Buil t-in

EtherNet/IP port

Built-in

EtherCAT port

EtherCAT

2

Robot

Device Layer

Servo Drives

Serial communications

RS-422/R S- 485 seri al-com m uni cat ons devices

Servo Drives

EtherCAT slaves

2-11

Page 31

AH Motion Controller – Hardware Manual

_2

Layer Function Network type Protocols Devices

Message communications

Information Layer

Control Layer

Device Layer -

field networks

(CIP) with host personal

computer

Automatic data exchange

between controllers (no

programming required)

Communication between

PLC and devices with

serial interface.

High-speed, high accuracy

communications with servo

drives and slaves(32 axes)

High-speed, high accuracy

communications with servo

drives and slaves (16

axes)

EtherNet/IP

EtherNet/IP

MODBUS TCP

Serial communications

Serial communications

EtherCAT EtherCAT protocol

CANopen CANopen protocol CANopen module

2.3.1 EtherNet/IP

Please refer to EtherNet/IP operation manual for more details.

CIP message

communications

EtherNet/IP

MODBUS TCP

MODBUS

RS-422/RS-485

MODBUS

RS-422/RS-485

Built-in EtherNet/IP

port

Delta controllers

Serial communication

module

Built-in EtherCAT

port

2-12

Page 32

3

Chapter 3 Product Specifications

Table of Contents

3.1 Environmental Specificatio ns ..................................................................... 3-2

3.2 AH Motion CPU ........................................................................................... 3-2

3.2.1 General Specifications ............................................................................... 3-2

3.2.2 Motion Control Function Specifications ......................................................... 3-5

3.2.3 Communication Ports ................................................................................ 3-6

3.2.4 I/O Addressing of AH Motion CPU ................................................................ 3-7

3.2.5 Profiles ................................................................................................ 3-14

3.2.6 Dimensions ............................................................................................ 3-15

3.2.7 Arrangement of Terminals ........................................................................ 3-16

3.2.8 Memory Card Slot ................................................................................... 3-16

3.3 I/O Modules ............................................................................................. 3-17

3-1

Page 33

AH Motion Controller – Hardware Manual

_3

Environmental Specifications

Operating temperature

Storage temperature

-40~70°C

No condensation

No condensation

resistance

IEC 61131-2 & IEC 68-2-27 (TEST Ea)

Operating environment

Installation location

In a control box

Pollution degree

2

General Specifications

AHxxEMC-5A

Remark

Execution

The program is executed cyclical ly.

device).

sequential function chart (SFC ) .

Instruction execution speed

Program capacity (step)

256K steps

Installation

DIN rails or screws

installed on a motion backplane.

communication interrupt tasks).

3.1 Environmental Specifications

-20~60°C

Operating humidity

Storage humidity

Vibration/Shock

5~95%

5~95%

International standards IEC 61131-2, IEC 68-2-6 (TEST Fc)/

No corrosive gas exists.

3.2 AH Motion CPU

3.2.1 General Specifications

AHxxEMC-5A

Input/Output control

Cyclically refreshed inputs/outputs

Direct inputs/outputs

The inputs and outputs can be

controlled through the direct inputs

(DX device) and direct outputs (DY

Programming language

Constant scan cycle (ms)

Installation of modules

Number of modules

Number of tasks

IEC 61131-3

Ladder diagram (LD), continuous f unction

chart (CFC), structured text (ST), and

0.3 ms/K steps

1-32000

(The scan cycle can be increased by one

millisecond.)

Modules are installed directly on a

backplane.

Five input/output modules at most c an be

283 tasks (32 cyclic tasks, 32 I/O interrupt

tasks, 212 external interrupt tasks, 1 24V LV

detection, 4 timed interrupt tasks, and 2

The scan cycle time can be

specified by parameters.

3-2

Page 34

3_

General Specifications

AHxxEMC-5A

Remark

Number of input/output

(X0~X511/Y0~Y511)

accessible to an CPU

Input relay [X]

Output relay [Y]

8192 (Y0.0~Y511.15)

Auxiliary relay [M]

8192 (M0~M8191)

Timer [T]

2048 (T0~T2047)

Counter [C]

2048 (C0~C2047)

AC: 56 (AC0~ AC55) (AHxxEMC)

D device (word): 65536 (D0~D65535)

Stepping relay [S]

Index register [E]

32 (E0~E31)

Special auxiliary relay [SM]

SM: 2048 (SM0~SM2047)

Special data register [SR]

communication port

Ethernet port

10/100 M

USB port

Mini USB

Memory card slot

Supports Micro SD card (SD 2.0)

motion backplane

Weight

230g

Rated input

Current

Voltage

1. Differential input terminals.

captures.

devices

X/Y devices (bit): 8192

(X0.0~X511.15/Y0.0~Y511.15)

X/Y devices (word): 512

Chapter 3 Product Specifications

Number of devices which can be

used in a program

Number of inputs/outputs

32-bit counter [HC/AC]

Data register [D]

Serial communication port

328 inputs/ 324 outputs (AHxxEMC)

8192 (X0.0~X511.15)

HC: 64 (HC0~HC63)

D device (bit): 1048576 (D0.0~D65535.15)

2048 (S0~S2047)

SR: 2048 (SR0~SR2047)

One RS-232(USB), One RS-485

Number of inputs/outputs

Real-time clock

Description of the terminals

Terminal Description

X0.0+, X0.0-,

X0.1+, X0.1(*2)

Years, months, days, hours, minutes,

seconds, and weeks

2. The functions of the terminals:

High-speed count:

The terminals are the RESET input

terminals for counter 0~counter 1.

X0.0+ and X0.0- are for counter 0.

X0.1+ and X0.1- are for count er 1.

High-speed capture: The terminals can

function as trigger signals for hig h-speed

The function is available when the

CPU is used together with the

Response

characteristic

1MHz +/-5mA +/-5V

3-3

Page 35

AH Motion Controller – Hardware Manual

_3

Rated input

Current

Voltage

Interrupt inputs

1. Differential input terminals.

Interrupt inputs

interrupt inputs.

Y0.8,

Y0.11

function as high-speed comparison outputs.

Terminal Description

1. Common input terminals.

2. The functions of the terminals:

High-speed count:

The terminals are the RESET input

X0.2, X0.3,

X1.4, X1.5

(*2)

X0.8+, X0.8-,

X0.9+, X0.9(*2)

High-speed capture: X0.2 and X0.3 can function

1. Differential input terminals.

2. The functions of the terminals:

Motion control: The terminals are for a manual

High-speed count:

High-speed capture: The terminals can function

terminals for counter 2~counter 5.

X0.2 is for counter 2.

X0.3 is for counter 3.

X1.4 is for counter 4

X1.5 is for counter 5

as trigger signals for high-speed captures.

pulse generator.

The terminals are for counter 0.

X0.8+ and X0.8- are the A-phase inputs for

counter 0. X0.9+ and X0.9- are the

B-phase inputs for counter 0.

as trigger signals for high-speed captures.

Response

characteristic

100kHz(*1) 5mA 24V

1MHz +/-5mA +/-5V

2. The functions of the terminals:

X0.10+, X0.10-,

X0.11+, X0.11(*2)

1. Common input terminals.

2. The functions of the terminals:

X0.12,

X0.13,

X0.14,

X0.15,

X1.0,

X1.1,

X1.2,

X1.3

(*2)

1. Pulse output temrinals (ope n c ol lector).

Y0.9,

Y0.10,

2. The function of the terminals:

High-speed count:

The terminals are for counter 1.

X0.10+ and X0.10- are the A-phase inputs

for counter 1. X0.11+ and X0.11- are the

B-phase inputs for counter 1.

High-speed capture: The terminals can function

as trigger signals for high-speed captures.

High-speed count:

The terminals are for counter 2~counter 5.

X0.12 and X0.13 are for counter 2.

X0.14 and X0.15 are for coun ter 3.

X1.0 and X1.1 are for counter 4.

X1.2 and X1.3 are for counter 5.

High-speed capture: The terminals can function

as trigger signals for high-speed captures.

Interrupt inputs:

X0.12, X0.13, X0.14 and X0.15 can function as

High-speed comparison: The terminals can

1MHz +/-5mA +/-5V

100 kHz(*1) 5mA 24 V

200 kHz 15 mA 24 V

3-4

Page 36

Chapter 3 Product Specifications

3_

Specifications

AHxxEMC-5A

supported

(Axis 1~axis 32)

Storage

The capacity of the built-in storage is 256K steps.

Unit

Open collector output:200KHz

Specifications

AHxxEMC-5A

Operating switch

RUN-STOP switch

Output terminal

Y0.8, Y0.9, Y0.10, and Y0.11

EtherCAT port

The maximum capacity is 32 GB.

You can use them freely.

Number of counters

6

capture/comparison

*1. If the frequency of input signals received by an input terminal must be 200 kHz, the input termi nal must be connected

to a 1 kΩ (2 W) resistor in parallel

*2. From HWCONFIG of the ISPSoft, two different filter settings for IO inputs can be set, X Input Sing le Filter Time and X

Input Single Frequency Filter Fac tor. For details, please refer to section 4.4.4.1 in the AH Motion Controller Operation

Manual.

3.2.2 Motion Control Function Specifications

AHxxEMC-5A

Number of substantial axes

Motor control

Maximum speed

Input

signal

Input terminal

AH08EMC-5A: 8 axes; AH10EMC-5A: 16 axes; AH20EMC-5A: 32 axes

Motor unit, mechanical unit

High-speed motion control system EtherCAT

The response time is 100Mbps.

EtherCAT: 100M bps

Diffrential input: 1MHz

Open collector input : 200KHz

X0.0+, X0.0-,

X0.1+, X0.1-,

X0.8+, X0.8-,

X0.9+, X0.9-, X0.10+, X0.10-, X0.11+, X0. 11-, X0.2, X0.3, X0.12,

X0.13, X0.14, X0.15,

X1.0,X1.1, X1.2, X1.3, X1.4, X1.5,

Output

signal

Memory card slot

M-code

G-code

Number of high-speed

External

communication port

Mini USB port

Ethernet port

Supports Micro SD card

M00~M01, M03~M101, and M103~M6553 5: The execution of a program pauses.

(WAIT)

G0 (rapid positioning), G1 (linear i nterpolation), G2 (circular interpolation,

clockwise), G3 (circular interp ol ation, counterclockwise), G4 (dwell), G17 (XY

plane selection), G18 (ZX plane selection), G19 (YZ plane selection), G90

(absolute programming), and G 91 ( i nc remental programming)

6

3-5

Page 37

AH Motion Controller – Hardware Manual

_3

Specifications

AHxxEMC-5A

Number of interrupt devices

Specifications

Electrical isolation

500 VDC

Connector

RJ45

Transmission cable

CAT-5, CAT-5e, CAT-6

Specifications

Electrical isolation

500 VDC

Connector

RJ45

UC-EMC200-02 (20M)

216

3.2.3 Communication Ports

AHxxEMC-5A

AHxxEMC is equipped with a mini USB port and an Ethernet port and an EtherCAT port.

Mini USB: A mini USB port can function as a slave statio n. You can download or upload a pr ogram throug h a mini USB

port. The communication protoc ols supported by the mini USB port are MODBUS ASCII and MODBUS RTU

(RS-232).

Ethernet: The Ethernet port supp orts communication protocol MODBUS TCP and EtherNet/IP adapter.

MODBUS TCP

The Ethernet port on AH Motion CPU c an exchange data with a device with Ethern et interface, e.g. AH500

series PLCs, through a common Ethernet cable.

- Can be c onnected to ISPSoft. A program can be uploaded/downloa ded and monitored.

- Can also function as a standard MODBUS TCP slave.

EtherNet/IP adapter

The Ethernet port on AH Motion CPU can be connected by an EtherNet/IP scanner and perform data exchange

through a common Ethernet cable.

- Can b e connected to EtherNet/IP scanner through I/O connection.

- Can be connected to EtherNet/IP scanner through CIP Message.

EtherCAT: An EtherCAT port can be used to perform motion control function based on EtherCAT communications .

Delta Cable

Transmission cable

UC-EMC003-02 (0.3M), UC-EMC005-02 (0.5M), UC-EMC010-02 (1M),

UC-EMC020-02 (2M), UC-EMC050-02 (5M), UC-EMC100-02 (10M),

3-6

Page 38

3_

Communication specifications:

Specifications

Serial transmission rate

9,600~57,600 bps

Number of data bits

7 bits~8 bits

Parity bit

Even parity bit/Odd parity bit/None

Number of stop bits

1 data bit~2 data bits

ASCII mode

Slave stations are supported.

RTU mode

Slave stations are supported.

Number of data read/written (ASCII mode)

100 registers

Number of data read/written (RTU mode)

100 registers

Ethernet

MODBUS TCP

EtherNet/IP

Transmission rate

Communication protocol

Number of data read/written

Maximum transmission distance

Specifications

Serial transmission rate

Communication protocol

Chapter 3 Product Specifications

Specifications

Interface

Interface

Interface

Mini USB

10/100 Mbps 10/100 Mbps

MODBUS TCP EtherNet/IP

100 registers 250 registers

100 meters 100 meters

EtherCAT

100 Mbps

EtherCAT packet format

Number of axes supported

AH08EMC-5A: 8 axes; AH10EMC-5A: 16 axes;

AH20EMC-5A: 32 axes

3.2.4 I/O Addressing of AH Motion CPU

The I/O addressing bet ween A H Motion CP Us and AH500 I/O modules installed on the motion backplane is a part of the

CPU specifications. The range of I/O addressing of AH Motion CPUs is explained in this section.

Software-defined address

Every AH motion CPU supports software-defined addresses between AH Motion CPU and its I/O modules. As a

default setting, a starting address is given by the soft ware and I /O addres ses are autom atic ally alloc ated according to

the starting address. For example, AH16AM10N-5A, digital input module with 16 inputs, takes the input device range

of 16 bits, starting from Xn.0 (Xn.0~Xn.15).

User-defined address

If you want to define the I/O addresses according to actual needs, you can assign a starting address to an input/output

module by software. You can benefit from the user-defined addresses that allow you to obtain a flexible and

customized program. The available user-defined addresses for each I/O module will be listed later.

3-7

Page 39

AH Motion Controller – Hardware Manual

_3

16AM

16 inputs. The input device range occupies 16 bits. (Xn.0~Xn.15)

16AN

16 outputs. The output device range occupies 16 bits. (Yn.0~Yn.15)

n

32AM

32 inputs. The input device range occupies 32 bits. (Xn.0~Xn+1.15)

64AM

64 inputs. The input device range occupies 64 bits. (Xn.0~Xn+3.15)

64AN

64 inputs. The output device range occupies 64 bits. (Yn.0~Yn+3.15)

Software-defined Addresses

Digital Input/Output Modules

Input/Output devices are automatically assigned to a digital input/output module through HWCONFIG in ISPSoft

according to the number of inputs/outputs which the digital input/output module has. The default start addresses are

shown below.

Note:

1. The below diagram only shows the lis t of the modules and is not an actual configuration.

2. AH16AR10N-5A(16AR) is not supported.

16AP

32AN 32 outputs. The output device range occupies 32 bits. (Yn.0~Yn+1.15)

8 inputs and 8 outputs. The input device range occupies 16 bits, and the output device range

occupies 16 bits. (X

.0~Xn.15, and Yn.0~Yn.15)

Analog Input/Output Modules

Input/Output data registers are automatically assigned to an analog input/output module through HWCONFIG in

ISPSoft according to the number of registers which is defin ed for t he analog in put/out put module. A channel occupies

two words.

Note: The below diagram only sho ws the list of the modules and is not an actual configuration.

3-8

Page 40

Chapter 3 Product Specifications

3_

04AD

08AD

output device range occupies 4 data registers.

04DA

08DA

04PT

08PTG

04TC

08TC

4 input channels. The input device range occupies 8 data registers.

06XA

Temperature Measurement Modules

Input data registers are automatically assigned to a temperature measurement module through HWCONFIG in

ISPSoft according to the number of register s which is defined for the temperatur e measurement module. A channel

occupies two words.

8 input channels. The input device range occupies 16 data registers

4 input channels, and 2 output channels. The input device range occupies 8 data registers, and the

4 output channels. The output device range occupies 8 data registers

8 output channels. The output device range occupies 16 data registers.

Note: The below diagram only sho ws the list of the modules and is not an actual configuration.

4 input channels. The input device range occupies 8 data registers.

8 input channels. The input device range occupies 16 data registers

4 input channels. The input device range occupies 8 data registers.

8 input channels. The input device range occupies 16 data registers

3-9

Page 41

AH Motion Controller – Hardware Manual

_3

occupies 2 data registers.

occupies 4 data registers.

Module Manual for more information about the parameter setting.

Module Manual for more information about the parameter setting.

Motion Control Modules

Input/Output data registers are aut omatically assigned to a motion control modul e through HWCONFIG in ISPSoft

according to the number of registers which is defined for the motion control module.

Note: The below diagram only sho ws the list of the modules and is not an actual configuration.

02HC

04HC

05PM

10PM

15PM

20MC

2 input channels. The input device range occupies 14 data registers, and the output device range

4 input channels. The input device range occupies 28 data registers, and the output device range

No input registers and no output regist ers are assigned to it. Please refer to AH500 Motion Control

Module Manual for more information about the parameter setting.

No input registers and no output regist ers are assigned to it. Please refer to AH500 Motion Control

No input registers and no output regist ers are assigned to it. Please refer to AH500 Motion Control

No input registers and no output regist ers are assigned to it. Please refer to AH500 Motion Control

Module Manual for more information about the parameter setting.

Network Modules

Input/Output data registers are automatically assigned to a network module through HWCONFIG in ISPSoft according

to the number of registers which is def ined for the network module.

Note: The below diagram only sho ws the list of the modules and is not an actual configuration.

3-10

Page 42

Chapter 3 Product Specifications

3_

registers.

10SCM

10DNET

No input device and output device will be occupied.

10PFBS

No input device and output device will be occupied.

10PFBM

10COPM

The input device range occupies 2 data registers.

15SCM

The input device range occupies 18 data registers.

10EN/15EN

The input device range occupies 20 dat a r egisters and output device range 20 data

The input device range occupies 18 data registers.

The input device range occupies 15 data registers.

User-defined Addresses

Digital Input/Output Modules

You can assign input devices and output devices to a digital input/output module through HWCONFIG in ISPSoft. The

input devices should be within the range between X0.0 and X511.15, and the output devices should be within the

range between Y0.0 and Y511.15. Take AH16AP11R-5A for example. The default input dev ices are X0.0~X0.15, and

the default output devices are Y0.0~Y0.15. You can change the input device range from X0.0~X0.15 to X10.0~X10.15,

and change the output device range from Y 0.0~Y0.15 to Y20.0~Y20.15.

The default input/output device range: X0.0~X0.15, and Y0.0~Y0.15

The user-defined input/output device range: X10.0~X10.15, and Y20.0~Y20.15

3-11

Page 43

AH Motion Controller – Hardware Manual

_3

Analog Input/Output Modules

You can assign input registers and outp ut re gist ers t o an a nal og in put/ out put modu le thr oug h HWCONFIG in ISPSoft.

The input registers and the output registers should be within the range between D0 and D65535. Take AH06XA-5A

for example. The original input registers are D0~D7, and the original output registers are D8~D11. You can change the

input device range from D0~D7 to D50~D57, and change the output device range from D8~D11 to D100~D103.

The default input/output device range: D0~D7, and D8~D11

The user-defined input/output device range: D50~D57, and D100~D103

Temperature Measurement Modules

You can assign input registers to a t emperature measurement module through HWCONFIG in ISPSoft . The input

registers should be within the range between D0 and D65535. Take AH08T C-5A for example. The original input

registers are D0~D15. You can change the input device range from D0~D15 to D60~D75.

The default input device range: D0~D151

3-12

Page 44

Chapter 3 Product Specifications

3_

The user-defined input device range: D60~D75

Motion Control Modules

You can assign input registers and output registers to a motion control modu le through HWCONFIG in ISPSoft. The

input registers should be within the range between D0 and D65535, and the output registers should be within the

range between D0 and D65535. Take AH04HC -5A for example. The original input regis ters are D0~D27. You can

change the input device range from D0~D27 to D200~D227.

The default input device range: D0~D27

The user-defined input device range: D200~D227

Network Modules

You can ass ign input registers and output registers to a n etwork module through HWCONFIG in ISPSoft. The input

registers shou ld be within the r ange between D0 and D65535, and the output registers should be within the range

between D0 and D65535. Take AH1 0EN-5A* for example. The original input registers are D0~D19. You can change

the input device range from D0~D19 to D150~D169.

*Note: The diagram below is only a demonstration on changing input device range.

3-13

Page 45

AH Motion Controller – Hardware Manual

_3

RUN

ETH

ERRO R

RUN

Ethe rnet Eth erCAT

CN 1

R UN

S TO P

Mi cro S D

Et herC AT

10EMC

ETH

ERRO R

1

4

5

2

3

6

8

7

9

10....

11

Number

Name

Description

1

Model name

Model name of the CPU module

Blink: The user program is in a debugging mode.

The default input device range: D0~D19

The user-defined input device range: D150~D169

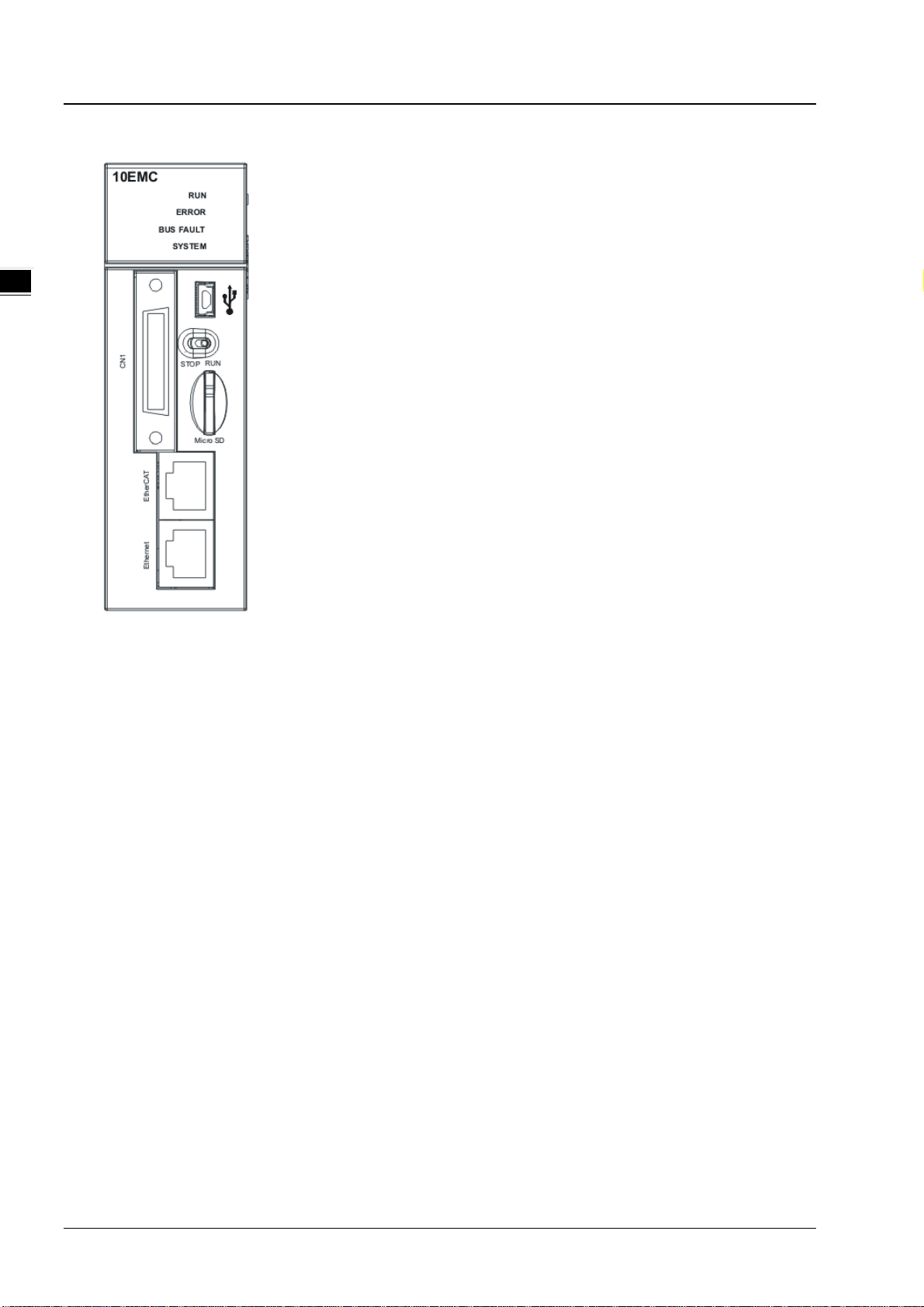

3.2.5 Profiles

AHxxEMC-5A

2

RUN LED

indicator

3-14

Operating status of the CPU module

ON: The user program is being executed.

OFF: The execution of the user program s tops.

Page 46

3_

Number

Name

Description

ERROR LED

Blink: A slight error occurs in the system.

Blink: A slight error occurs in the I/O bus.

Blink: The CPU module is being reset / The value in the device is being cleared.

3

Mini USB port

Providing the RS-232 communicat ion interface

STOP: The execution of the user program st ops .

5

SD slot

Micro SD interface

6

Connector

Connecting the module and an I/O extension cable.

7

EtherCAT port

Providing the EtherCAT communication i nterface

8

Ethernet port

Providing the Ethernet communication interface

9

Set screw

Fixing the module

11

Hook

Connecting the module and a backplan e.

RUN

ETH

ERROR

RUN

Ethernet

EtherCAT

CN1

RUN

STOP

Micro SD

EtherCAT

10EMC

ETH

ERROR

indicator

BUS FAULT LED

indicator

SYSTEM LED

indicator

Chapter 3 Product Specifications

Error status of the CPU module

ON: A serious error occurs in the system.

OFF: The system is normal.

Error status of the I/O bus

ON: A serious error occurs in the I/O bus.

OFF: The I/O bus is normal.

System status of the CPU module

ON: The external input/output is forced ON/OFF.

OFF: The system is in a default status.

4 RUN/STOP switch

10 Label Nameplate

3.2.6 Dimensions

RUN: The user program is executed.

Dimensions are in mm.

3-15

Page 47

AH Motion Controller – Hardware Manual

_3

Function

Function

Pulse

Count

Pulse

Count

1

COM COM

19

Y0.11 Out3

3

COM COM

21

Y0.9 Out1

4

COM COM

22

Y0.8 Out0

6

X1.5 Rst5

24

X1.2 CntA5

7

S/S S/S

25

X1.1 CntA4

8

X1.4 Rst4

26

X1.0 CntA4

9

S/S S/S

27

X0.15

CntA3

10

X0.3 Rst3

28

X0.14

CntA3

11

S/S S/S

29

X0.13

CntA2

13

X0.1- Rst1-

31

X0.1+

Rst1+

14

X0.11-

CntB1-

32

X0.11+

CntB1+

16

X0.0- Rst0-

34

X0.0+ Rst0+

17

X0.9-

MPGB-

CntB0-

35

X0.9+

MPGA-

CntB0+

SD

MiniSD

MicroS

3.2.7 Arrangement of Terminals

AHxxEMC-5A

Pin Terminal

2 COM COM 20 Y0.10 Out2

5 S/S S/S 23 X1.3 CntA5

12 X0.2 Rst2 30 X0.12

DOG5-

15 X0.10-

DOG4-

CntA1- 33 X0.10+

Pin Terminal

DOG3

DOG2

DOG1

DOG0

DOG5+

DOG4+

CntA2

CntA1+

18 X0.8- MPGB+ CntA0- 36 X0.8+ MPGA+ CntA0+

3.2.8 Memory Card Slot

AHxxEMC-5A

The AH Motion seri es CPU modules support micro SD cards. You can purchase products which meet the specifications

supported by the memory card slot on the AH Motion CPU.

SD Cards

SD cards have three size types: SD cards, miniSD cards, and microSD cards. The AH Motion CPU supports Micro SDHC

cards.

3-16

Page 48

Chapter 3 Product Specifications

3_

Type

SD

SDHC

SDXC

Capacity

32 GB max.

system

2

Size

SD

SDHC

MiniSDHC

MicroSDHC

SDXC

MicroSDXC

Class 10 (Min. 10 MB/sec.)

Specifications for Memory Cards