Page 1

INSTRUCTION MANUAL

10" Compound

Power Miter Saw

(Model SM100M)

Part No. 90513776 1-07

Copyright © 2007 Delta Machinery

ESPAÑOL: PÁGINA 23

To learn more about DELTA MACHINERY

visit our website at: www.deltamachinery.com.

For Parts, Service, Warranty or other Assistance,

please call

1-800-223-7278 (In Canada call 1-800-463-3582).

FRANÇAIS: PAGE 38

Page 2

2

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

SAFETY GUIDELINES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

GENERAL SAFETY RULES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

ADDITIONAL SPECIFIC SAFETY RULES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

FUNCTIONAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

CARTON CONTENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

ESPAÑOL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

FRENCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

SERVICE CENTER LOCATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .back cover

Read and understand all warnings and operating instructions before using any tool or equipment. When

using tools or equipment, basic safety precautions should always be followed to reduce the risk of personal injury.

Improper operation, maintenance or modification of tools or equipment could result in serious injury and property

damage. There are certain applications for which tools and equipment are designed. Delta Machinery strongly

recommends that this product NOT be modified and/or used for any application other than for which it was designed.

If you have any questions relative to its application DO NOT use the product until you have written Delta Machinery

and we have advised you.

Online contact form at www.deltamachinery.com

Postal Mail: Technical Service Manager

Delta Machinery

4825 Highway 45 North

Jackson, TN 38305

(IN CANADA: 125 Mural St. Suite 300, Richmond Hill, ON, L4B 1M4)

Information regarding the safe and proper operation of this tool is available from the following sources:

Power Tool Institute

1300 Sumner Avenue, Cleveland, OH 44115-2851

www.powertoolinstitute.org

National Safety Council

1121 Spring Lake Drive, Itasca, IL 60143-3201

American National Standards Institute, 25 West 43rd Street, 4 floor, New York, NY 10036 www.ansi.org

ANSI 01.1Safety Requirements for Woodworking Machines, and

the U.S. Department of Labor regulations www.osha.gov

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS!

Page 3

3

Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

Used without the safety alert symbol indicates potentially hazardous situation which, if not avoided, may result

in property damage.

It is important for you to read and understand this manual. The information it contains relates to protecting

YOUR SAFETY and PREVENTING PROBLEMS. The symbols below are used to help you recognize this

information.

SAFETY GUIDELINES - DEFINITIONS

Some dust created by power sanding, sawing, grinding, drilling, and other construction activities

contains chemicals known to cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to

these chemicals: work in a well ventilated area, and work with approved safety equipment, such as those dust masks

that are specially designed to filter out microscopic particles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling, and other construction activities. Wear

protective clothing and wash exposed areas with soap and water. Allowing dust to get into your mouth, eyes, or lay on

the skin may promote absorption of harmful chemicals.

Use of this tool can generate and/or disperse dust, which may cause serious and permanent respiratory or other

injury. Always use NIOSH/OSHAapproved respiratory protection appropriate for the dust exposure. Direct particles away

from face and body.

Wear appropriate hearing protection during use. Under some conditions and duration of use, noise from this product

may contribute to hearing loss.

CALIFORNIA PROPOSITION 65

For your convenience and safety, the following warning labels are on your miter saw.

ON MOTOR HOUSING:

WARNING: FOR YOUR OWN SAFETY, READ INSTRUCTION MANUAL BEFORE OPERATING SAW. WHEN SERVICING, USE

ONLY IDENTICAL REPLACEMENT PARTS. ALWAYS WEAR EYE PROTECTION.

ON FENCE:

CLAMP SMALL PIECES BEFORE CUTTING. SEE MANUAL

ON GUARD:

DANGER – KEEP AWAY FROM BLADE.

ON GUARD RET

AINER PLA

TE:

TO REDUCE THE RISK OF INJURY, READ INSTRUCTION MANUAL BEFORE OPERATING

MITER SAW. WHEN SERVICING, USE ONLY IDENTICAL REPLACEMENT PARTS. DO NOT EXPOSE TO RAIN OR USE IN

DAMP LOCATIONS. ALWAYS USE PROPER EYE AND RESPIRATORY PROTECTION. USE ONLY 10" (254MM) SAW BLADES

RECOMMENDED FOR 5200RPM OR HIGHER WITH 5/8" ARBOR." KEEP HANDS OUT OF PATH OF SAW BLADE. DO NOT

OPERATE SAW WITHOUT GUARDS IN PLACE. CHECK LOWER GUARD FOR PROPER CLOSING BEFORE EACH USE.

ALWAYS TIGHTEN ADJUSTMENT KNOBS BEFORE USE. DO NOT PERFORM ANY OPERATION FREEHAND. NEVER REACH

IN BACK OF SAW BLADE. NEVER CROSS ARMS IN FRONT OF BLADE. TURN OFF TOOL AND WAIT FOR SAW BLADE TO

STOP BEFORE MOVING WORKPIECE, CHANGING SETTINGS OR MOVING HANDS. DISCONNECT POWER BEFORE

CHANGING BLADE OR SERVICING. TO REDUCE THE RISK OF INJURY, RETURN CARRIAGE TO THE FULL REAR POSITION

AFTER EACH CROSSCUT OPERATION. THINK! YOU CAN PREVENT ACCIDENTS.

CLAMP SMALL PIECES

BEFORE CUTTING. SEE MANUAL.

DANGER

KEEP AWAY

FROM BLADE

ON TABLE: (2 PLACES)

DO NOT EXPOSE TO RAIN OR USE IN DAMP LOCATIONS.

Page 4

4

GENERAL SAFETY RULES

READ AND UNDERSTAND ALL WARNINGS AND OPERATING INSTRUCTIONS BEFORE

USING THIS EQUIPMENT. Failure to follow all instructions listed below, may result in

electric shock, fire, and/or serious personal injury or property damage.

IMPORTANT SAFETY INSTRUCTIONS

1. FOR YOUR OWN SAFETY, READ AND

UNDERSTAND THE INSTRUCTION MANUAL

BEFORE OPERATING THE MACHINE. Learning the

machine’s application, limitations, and specific

hazards will greatly minimize the possibility of

accidents and injury.

2. USE CERTIFIED SAFETY EQUIPMENT. Eye

protection equipment should comply with ANSI

Z87.1 standards, hearing equipment should

comply with ANSI S3.19 standards, and dust

mask protection should comply with

MSHA/NIOSH certified respirator standards.

Splinters, air-borne debris, and dust can cause

irritation, injury, and/or illness.

3. DRESS PROPERLY. Do not wear tie, gloves, or

loose clothing. Remove watch, rings, and other

jewelry. Roll up your sleeves. Clothing or jewelry

caught in moving parts can cause injury.

4. DO NOT USE THE MACHINE IN A

DANGEROUS ENVIRONMENT. The use of power

tools in damp or wet locations or in rain can cause

shock or electrocution. Keep your work area welllit to prevent tripping or placing arms, hands, and

fingers in danger.

5. MAINTAIN ALL TOOLS AND MACHINES IN PEAK

CONDITION. Keep tools sharp and clean for best and

safest performance. Follow instructions for lubricating

and changing accessories. Poorly maintained tools and

machines can further damage the tool or machine and/or

cause injury.

6. CHECK FOR DAMAGED PARTS. Before using the

machine, check for any damaged parts. Check for

alignment of moving parts, binding of moving

parts, breakage of parts, and any other conditions

that may affect its operation. A guard or any other

part that is damaged should be properly

repaired or replaced. Damaged parts can cause

further damage to the machine and/or injury.

7. KEEP THE WORK AREA CLEAN. Cluttered areas and

benches invite accidents.

8. KEEP CHILDREN AND VISITORS AWAY. Your shop is

a potentially dangerous environment. Children and

visitors can be injured.

9. REDUCE THE RISK OF UNINTENTIONAL

STARTING. Make sure that the switch is in the

“OFF” position before plugging in the power cord.

In the event of a power failure, move the switch to

the “OFF” position. An accidental start-up can

cause injury.

10. USE THE GUARDS. Check to see that all guards

are in place, secured, and working correctly to

prevent injury.

11. REMOVE ADJUSTING KEYS AND WRENCHES

BEFORE STARTING THE MACHINE. Tools,

scrap pieces, and other debris can be thrown at

high speed, causing injury.

12. USE THE RIGHT MACHINE. Don’t force a

machine or an attachment to do a job for which it

was not designed. Damage to the machine and/or

injury may result.

13. USE RECOMMENDED ACCESSORIES. The use

of accessories and attachments not

recommended by Delta may cause damage to the

machine or injury to the user.

14. USE THE PROPER EXTENSION CORD. Make

sure your extension cord is in good condition.

When using an extension cord, be sure to use

one heavy enough to carry the current your

product will draw. An undersized cord will cause a

drop in line voltage, resulting in loss of power and

overheating. See the Extension Cord Chart for the

correct size depending on the cord length and

nameplate ampere rating. If in doubt, use the next

heavier gauge. The smaller the gauge number,

the heavier the cord.

15. SECURE THE WORKPIECE. Use clamps or a vise

to hold the workpiece when practical. Loss of

control of a workpiece can cause injury.

16. FEED THE WORKPIECE AGAINST THE DIRECTION

OF THE ROTATION OF THE BLADE, CUTTER, OR

ABRASIVE SURFACE. Feeding it from the other

direction will cause the workpiece to be thrown out

at a high speed.

17. DON’T FORCE THE WORKPIECE ON THE

MACHINE. Damage to the machine and/or injury

may result.

18. DON’T OVERREACH. Loss of balance can make

you fall into a working machine, causing injury.

19. NEVER STAND ON THE MACHINE. Injury could occur

if the tool tips, or if you accidentally contact the cutting

tool.

20. NEVER LEAVE THE MACHINE RUNNING

UNATTENDED. TURN THE POWER OFF. Don’t leave

the machine until it comes to a complete stop. Achild or

visitor could be injured.

21. TURN THE MACHINE “OFF”, AND DISCONNECT

THE MACHINE FROM THE POWER SOURCE before

installing or removing accessories, before

adjusting or changing set-ups, or when making

repairs. An accidental start-up can cause injury.

22. MAKE YOUR WORKSHOP CHILDPROOF WITH

PADLOCKS, MASTER SWITCHES, OR BY

REMOVING STARTER KEYS. The accidental

start-up of a machine by a child or visitor could

cause injury.

23. STAY ALERT, WATCH WHAT YOU ARE DOING,

AND USE COMMON SENSE. DO NOT USE THE

MACHINE WHEN YOU ARE TIRED OR UNDER

THE INFLUENCE OF DRUGS, ALCOHOL, OR

MEDICATION. A moment of inattention while

operating power tools may result in injury.

24. THE DUST GENERATED by certain woods and

wood products can be injurious to your health.

Always operate machinery in well-ventilated areas,

and provide for proper dust removal. Use wood

dust collection systems whenever possible.

Page 5

ADDITIONAL SPECIFIC SAFETY RULES

SAVE THESE INSTRUCTIONS.

Refer to them often and use them to instruct others.

1. DO NOT OPERATE THIS MACHINE until it is

completely assembled and installed according to

the instructions. A machine incorrectly assembled can

cause serious injury.

2. OBTAIN ADVICE from your supervisor, instructor,

or another qualified person if you are not thoroughly

familiar with the operation of this machine.

Knowledge is safety.

3. FOLLOW ALL WIRING CODES and recommended

electrical connections to prevent shock or electrocution.

4. SECURE THE MACHINE TO A SUPPORTING

SURFACE. Vibration can possibly cause the machine to

slide, walk, or tip over, causing serious injury.

5. USE ONLY CROSSCUT SAW BLADES. Use only

zero-degree or negative hook angles when using

carbide-tipped blades. Do not use blades with deep

gullets. These can deflect and contact the guard,

and can cause damage to the machine and/or

serious injury.

6. USE ONLY BLADES OF THE CORRECT SIZE

AND TYPE specified for this tool to prevent damage to

the machine and/or serious injury.

7. USE A SHARP BLADE. Check the blade to see if it runs

true and is free from vibration. A dull blade or a vibrating

blade can cause damage to the machine and/or serious

injury.

8. INSPECT BLADE FOR CRACKS or other damage prior

to operation. A cracked or damaged blade can come

apart and pieces can be thrown at high

speeds, causing serious injury. Replace cracked or

damaged blades immediately.

9. CLEAN THE BLADE AND BLADE FLANGES prior to

operation. Cleaning the blade and flanges allows you to

check for any damage to the blade or flanges. A cracked

or damaged blade or flange can come apart and pieces

can be thrown at high speeds, causing serious injury.

10. USE ONLY BLADE FLANGES specified for this tool to

prevent damage to the machine and/or serious injury.

11. CLEAR THE AREA OF FLAMMABLE LIQUIDS and/or

gas prior to operation. Sparks can occur that would

ignite the liquids and cause a fire or an explosion.

12. CLEAN THE MOTOR AIR SLOTS of chips and

sawdust. Clogged motor air slots can cause the machine

to overheat, damaging the machine and possibly

causing a short which could cause serious injury.

13. TIGHTEN THE TABLE CLAMP HANDLE and any other

clamps prior to operation. Loose clamps can cause

parts or the workpiece to be thrown at high speeds.

14. NEVER START THE TOOL with the blade against

the workpiece. The workpiece can be thrown,

causing serious injury.

15. KEEP ARMS, HANDS, AND FINGERS away from the

blade to prevent severe cuts. Clamp all workpieces that

would cause your hand to be in the “Table Hazard Zone”

(within the red lines).

16. ALLOW THE MOTOR TO COME TO FULL SPEED

prior to starting cut. Starting the cut too soon can cause

damage to the machine or blade and/or serious injury.

17. WHEN USING A SLIDING MITER SAW AS A

REGULAR MITER SAW, LOCK THE SLIDE

MECHANISM IN PLACE. If the slide mechanism is not

locked, the saw can kick back toward you.

18. NEVER REACH AROUND or behind the saw blade. A

moving blade can cause serious injury.

19. NEVER CUT FERROUS METALS or masonry. Either of

these can cause the carbide tips to fly off the blade at

high speeds causing serious injury.

20. NEVER CUT SMALL PIECES. Cutting small pieces

(where your hand would be within 6” of the saw blade)

can cause your hand to move into the blade, resulting in

serious injury.

21. NEVER LOCK THE SWITCH in the “ON” position.

Setting up the next cut could cause your hand to move

into the blade, resulting in severe injury.

22. NEVER APPLY LUBRICANT to a running blade.

Applying lubricant could cause your hand to move into

the blade, resulting in serious injury.

23. DO NOT PERFORM FREE-HAND OPERATIONS

(wood that is not held firmly against the fence and

table). Hold the work firmly against the fence and table.

Free-hand operations on a miter saw could cause the

workpiece to be thrown at high speeds, causing serious

injury. Use clamps to hold the work when possible.

24. PROPERLY SUPPORT LONG OR WIDE WORK-

PIECES. Loss of control of the workpiece can cause

serious injury.

25. AFTER COMPLETING CUT,

release power switch and

wait for coasting blade to come to a complete stop

before returning saw to raised position. A moving blade

can cause serious injury.

26. TURN OFF THE MACHINE and allow the blade to

come to a complete stop prior to cleaning the blade

area or removing debris in the path of the blade. A

moving blade can cause serious injury.

27. TURN OFF MACHINE and allow the blade to come to a

complete stop before removing or securing workpiece,

changing workpiece angle, or changing the angle of the

blade. A moving blade can cause serious injury.

28. PROPERLY SUPPORT LONG OR WIDE WORK-

PIECES. Loss of control of the workpiece can cause

injury.

29. NEVER PERFORM LAYOUT, ASSEMBLY, OR SET-UP

WORK on the table/work area when the machine is

running. A sudden slip could cause a hand to move into

the blade. Severe injury can result.

30. TURN THE MACHINE “OFF”, disconnect the machine

from the power source, and clean the table/work area

before leaving the machine. LOCK THE SWITCH IN

THE “OFF” POSITION to prevent unauthorized use.

Someone else might accidentally start the machine and

cause injury to themselves.

31. BEFORE OPERATING THE SAW, check and securely

lock the bevel, miter, and sliding fence adjustments.

32. THE CUTTING HEAD MUST RETURN QUICKLY TO

THE FULL UP POSITION. Failure to do so will not allow

the lower guard to operate properly and may result in

personal injury. See manual section on “Adjusting the

Cuttinghead Return”.

33. ADDITIONAL INFORMATION regarding the safe and

proper operation of power tools (i.e. a safety video) is

available from the Power Tool Institute, 1300 Sumner

Avenue, Cleveland, OH 44115-2851 (www.powertool

institute.com). Information is also available from the

National Safety Council, 1121 Spring Lake Drive, Itasca,

IL 60143-3201. Please refer to the American National

Standards Institute ANSI 01.1 Safety Requirements for

Woodworking Machines and the

U.S. Department of

Labor regulations.

5

READ AND UNDERSTAND ALL WARNINGS AND OPERATING INSTRUCTIONS BEFORE USING

THIS EQUIPMENT. Failure to follow all instructions listed below, may result in electric shock,

fire, and/or serious personal injury or property damage.

Page 6

6

A separate electrical circuit should be used for your machines. This circuit should not be less than #12 wire and should

be protected with a 20 Amp time lag fuse. If an extension cord is used, use only 3-wire extension cords which have 3prong grounding type plugs and matching receptacle which will accept the machine’s plug. Before connecting the

machine to the power line, make sure the switch (s) is in the “OFF” position and be sure that the electric current is of the

same characteristics as indicated on the machine. All line connections should make good contact. Running on low

voltage will damage the machine.

SHOCK HAZARD. DO NOT EXPOSE THE MACHINE TO RAIN OR OPERATE THE MACHINE IN DAMP

LOCATIONS.

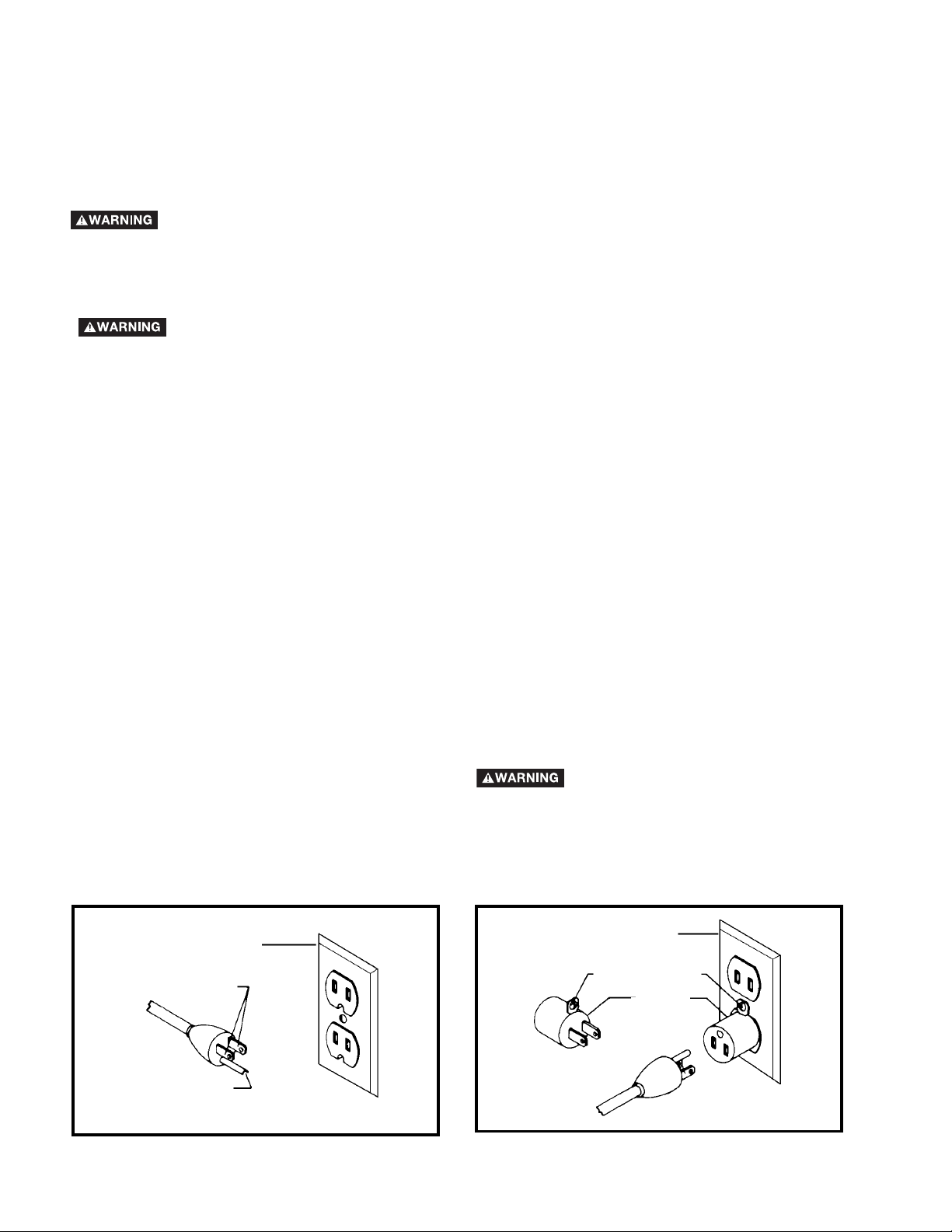

Fig. A Fig. B

GROUNDED OUTLET BOX

CURRENT

CARRYING

PRONGS

GROUNDING BLADE

IS LONGEST OF THE 3 BLADES

GROUNDED OUTLET BOX

GROUNDING

MEANS

ADAPTER

2. Grounded, cord-connected machines intended for

use on a supply circuit having a nominal rating less

than 150 volts:

If the machine is intended for use on a circuit that has an

outlet that looks like the one illustrated in Fig. A, the

machine will have a grounding plug that looks like the plug

illustrated in Fig. A. A temporary adapter, which looks like

the adapter illustrated in Fig. B, may be used to connect

this plug to a matching 2-conductor receptacle as shown in

Fig. B if a properly grounded outlet is not available. The

temporary adapter should be used only until a properly

grounded outlet can be installed by a qualified electrician.

The green-colored rigid ear, lug, and the like, extending

from the adapter must be connected to a permanent

ground such as a properly grounded outlet box. Whenever

the adapter is used, it must be held in place with a metal

screw.

NOTE: In Canada, the use of a temporary adapter is not

permitted by the Canadian Electric Code.

SHOCK HAZARD. IN ALL CASES, MAKE

CERTAIN THE RECEPTACLE IN

QUESTION IS PROPERLY GROUNDED.

IF YOU ARE NOT SURE HAVE A

QUALIFIED ELECTRICIAN CHECK THE

RECEPTACLE.

1. All grounded, cord-connected machines:

In the event of a malfunction or breakdown, grounding

provides a path of least resistance for electric current to

reduce the risk of electric shock. This machine is equipped

with an electric cord having an equipment-grounding

conductor and a grounding plug. The plug must be plugged

into a matching outlet that is properly installed and

grounded in accordance with all local codes and

ordinances.

Do not modify the plug provided - if it will not fit the outlet,

have the proper outlet installed by a qualified electrician.

Improper connection of the equipment-grounding

conductor can result in risk of electric shock. The

conductor with insulation having an outer surface that is

green with or without yellow stripes is the equipmentgrounding conductor. If repair or replacement of the

electric cord or plug is necessary, do not connect the

equipment-grounding conductor to a live terminal.

Check with a qualified electrician or service personnel if the

grounding instructions are not completely understood, or if

in doubt as to whether the machine is properly grounded.

Use only 3-wire extension cords that have 3-prong

grounding type plugs and matching 3-conductor

receptacles that accept the machine’s plug, as shown in

Fig. A.

Repair or replace damaged or worn cord immediately.

POWER CONNECTIONS

Your machine is wired for 120 Volt, 60 HZ alternating current. Before connecting the machine to the power source,

make sure the switch is in the “OFF” position.

GROUNDING INSTRUCTIONS

SHOCK HAZARD. THIS MACHINE MUST BE GROUNDED WHILE IN USE TO PROTECT THE

OPERATOR FROM ELECTRIC SHOCK.

Page 7

7

FOREWORD

ShopMaster Model SM100M is a 10" Compound Power Miter Saw designed to cut wood, plastic, and aluminum.

Compound angle and bevel cutting are easy and accurate. It can crosscut up to 5-3/4" x 2-3/8", miter at 45° both left and

right up to 4-1/8" x 2-3/8", bevel at 45° left up to 5-7/8" x 1-9/16", and compound 45° x 45°,4-1/8" x 1-9/16". It has positive

miter stops at 0°, 22.5°, 31.62°, and 45° both left and right, and bevel stops at 0° and 45° adjustable. Adust bag is included

to catch fine dust and wood chips.

FUNCTIONAL DESCRIPTION

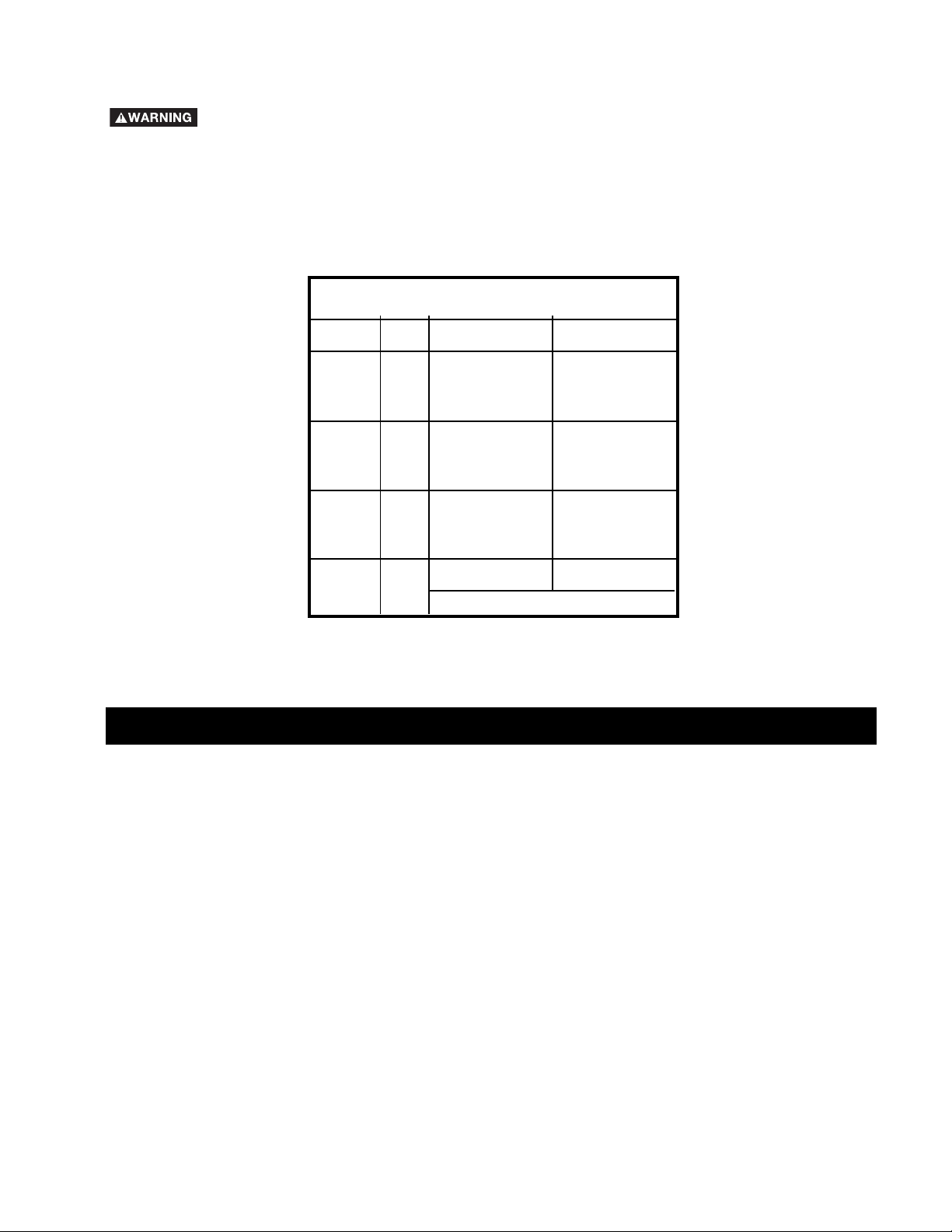

EXTENSION CORDS

Use proper extension cords. Make sure your extension cord is in good condition and is a 3-wire

extension cord which has a 3-prong grounding type plug and matching receptacle which will accept the machine’s plug.

When using an extension cord, be sure to use one heavy enough to carry the current of the machine. An undersized

cord will cause a drop in line voltage, resulting in loss of power and overheating. Fig. C, shows the correct gauge to use

depending on the cord length. If in doubt, use the next heavier gauge. The smaller the gauge number, the heavier the

cord.

MINIMUM GAUGE EXTENSION CORD

RECOMMENDED SIZES FOR USE WITH STATIONARY ELECTRIC MACHINES

Ampere Total Length Gauge of

Rating Volts of Cord in Feet Extension Cord

0-6 120

up to

25 18 AWG

0-6 120 25-50 16 AWG

0-6 120 50-100 16 AWG

0-6 120 100-150 14 AWG

6-10 120

up to

25 18 AWG

6-10 120 25-50 16 AWG

6-10 120 50-100 14 AWG

6-10 120 100-150 12 AWG

10-12 120

up to

25 16 AWG

10-12 120 25-50 16 AWG

10-12 120 50-100 14 AWG

10-12 120 100-150 12 AWG

12-16 120

up to

25 14 AWG

12-16 120 25-50 12 AWG

12-16 120

GREATER THAN 50 FEET NOT RECOMMENDED

NOTICE: The photo on the manual cover illustrates the current production model. All other illustrations contained in the

manual are representative only and may not depict the actual color, labeling, or accessories, and are intended to

illustrate technique only.

Fig. C

Page 8

8

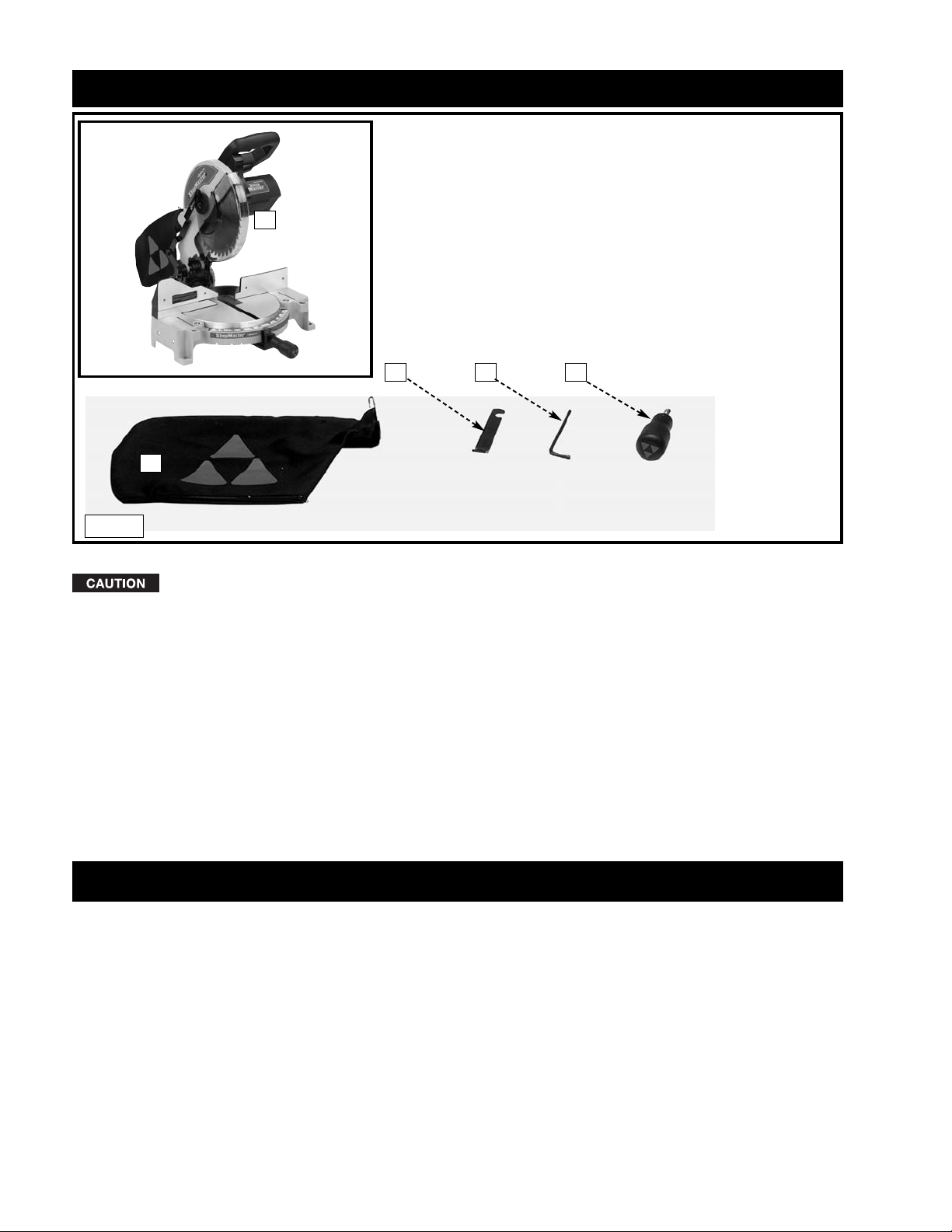

ASSEMBLY

ASSEMBLY TOOLS REQUIRED

(Supplied)

* 5mm hex wrench

* 1/2” Blade wrench

(Not supplied)

* Phillips head screw driver

* A square to make adjustments

UNPACKING AND CLEANING

Carefully unpack the machine and all loose items from the shipping container(s). Remove the protective coating from all unpainted

surfaces. This coating may be removed with a soft cloth moistened with kerosene (do not use acetone, gasoline or lacquer thinner for this

purpose). After cleaning, cover the unpainted surfaces with a good quality household floor paste wax.

Fig. 1

Remove the miter saw and all loose items from the carton.

Do not lift the miter saw by the switch handle. This action can cause misalignment. Always lift the machine

by the base or the carrying handle.

1. Miter Saw

2. Dust Bag

3. 1/2" Blade Wrench

4. 5mm Hex Wrench

5. Table Lock Handle

CARTON CONTENTS

2

3

4 5

1

Page 9

9

For your own safety, do not connect the machine to the power source until the machine is

completely assembled and you read and understand the entire instruction manual.

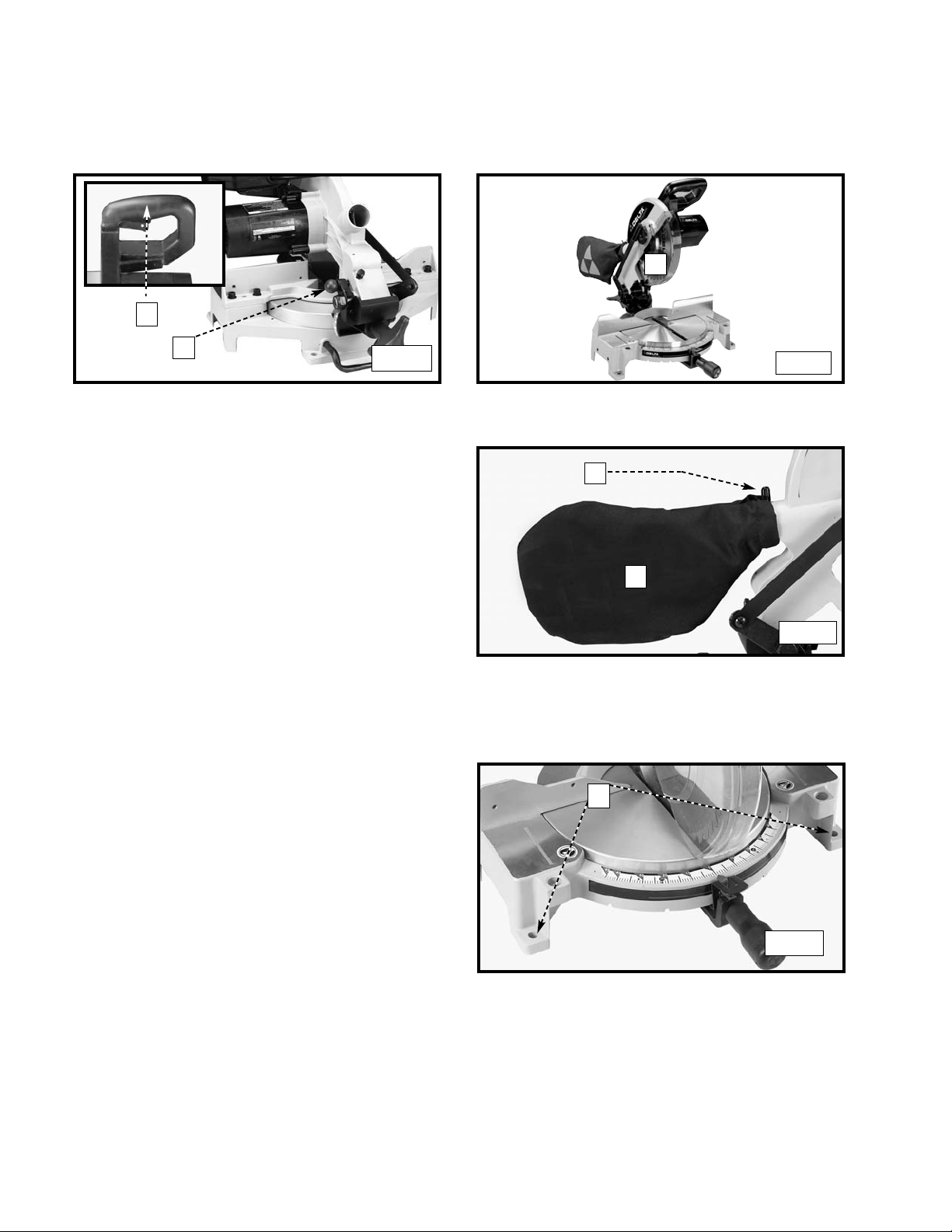

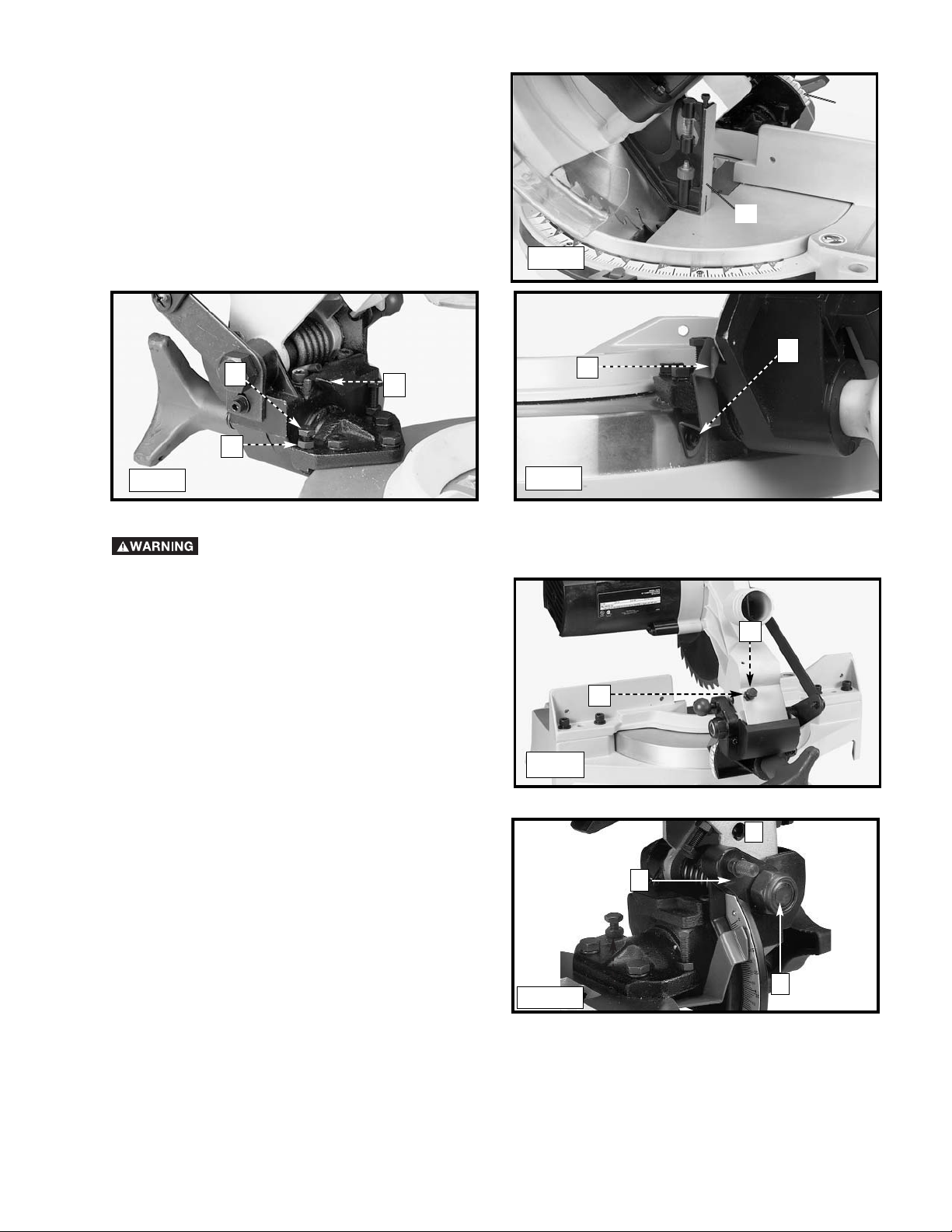

Thread the table lock handle (A) Fig. 2 into the threaded hole (B)

of the arm bracket.

1. Turn the table lock handle (A) Fig. 3 counter-clockwise one

or two turns, and depress the index lever (B) to release the

45° positive stop.

DISCONNECT MACHINE FROM POWER SOURCE!

B

A

Fig. 2

ATTACHING THE TABLE LOCK HANDLE

ROTATING THE TABLE TO THE 90° DEGREE POSITION

Fig. 3

A

B

2. Rotate the table to the left until the index stop engages with

the 90° positive stop (Fig. 4). Tighten the table lock handle

(A).

Fig. 4

A

Page 10

10

FASTENING THE MACHINE TO A SUPPORTING SURFACE

Before operating your compound miter saw, make sure that it is

firmly mounted to a sturdy workbench or other supporting

surface. Four holes are provided, two of which are shown at (A)

Fig. 8.

When frequently moving the saw from place to place, mount

the saw on a 3/4" piece of plywood, and clamp the plywood to

a supporting surface with “C” clamps.

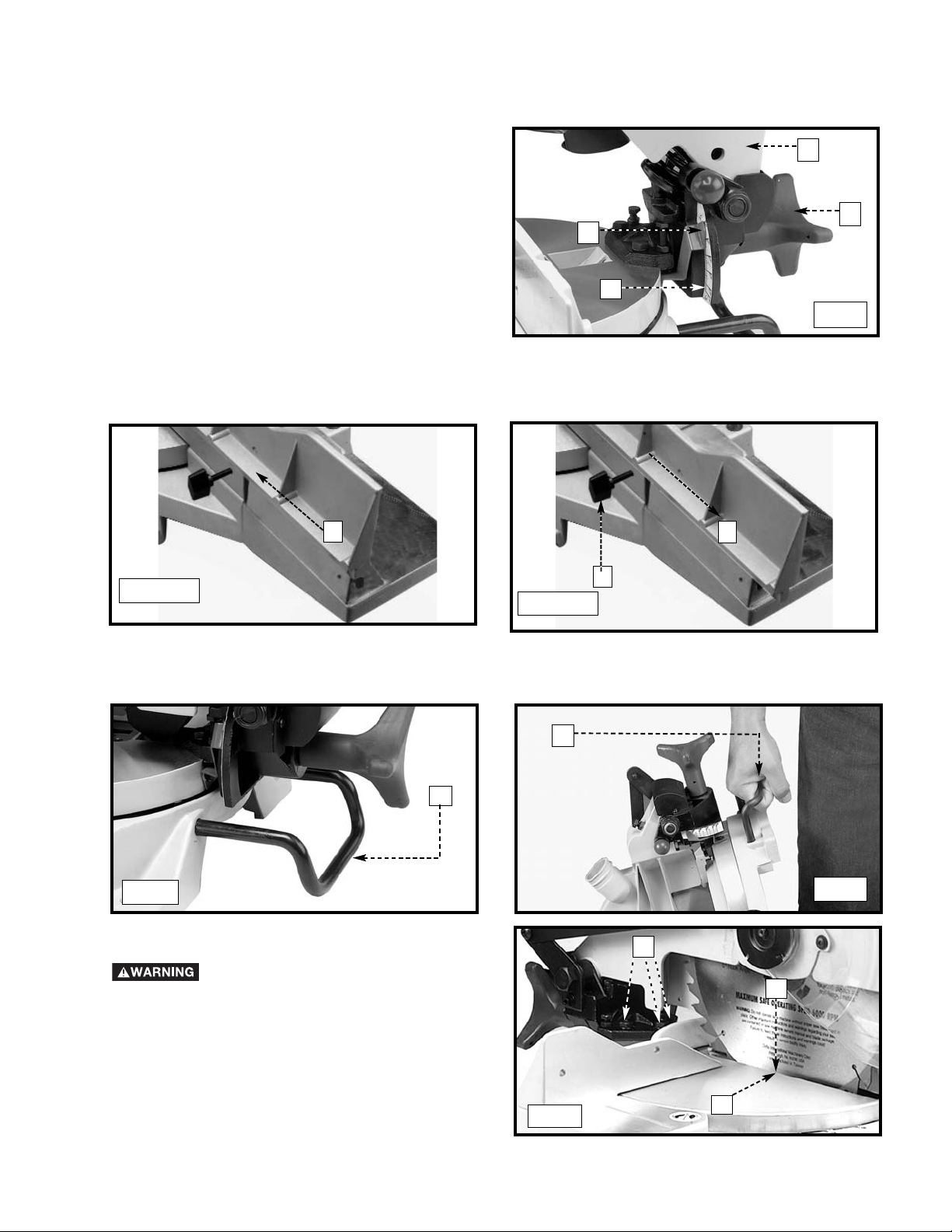

1. Push down on handle (A), Inset, Fig. 5. Pull out the cuttinghead lock knob (B).

2. Move the cuttinghead (C) to the up position (Fig. 6).

ATTACHING THE DUST BAG

Squeeze the spring clips (A) Fig. 7 of the dust bag (B) and clip

the dust bag (B) over the ribs of the dust chute.

MOVING CUTTINGHEAD TO THE UP POSITION

Fig. 5

Fig. 6

A

B

C

Fig. 7

A

B

A

Fig. 8

Page 11

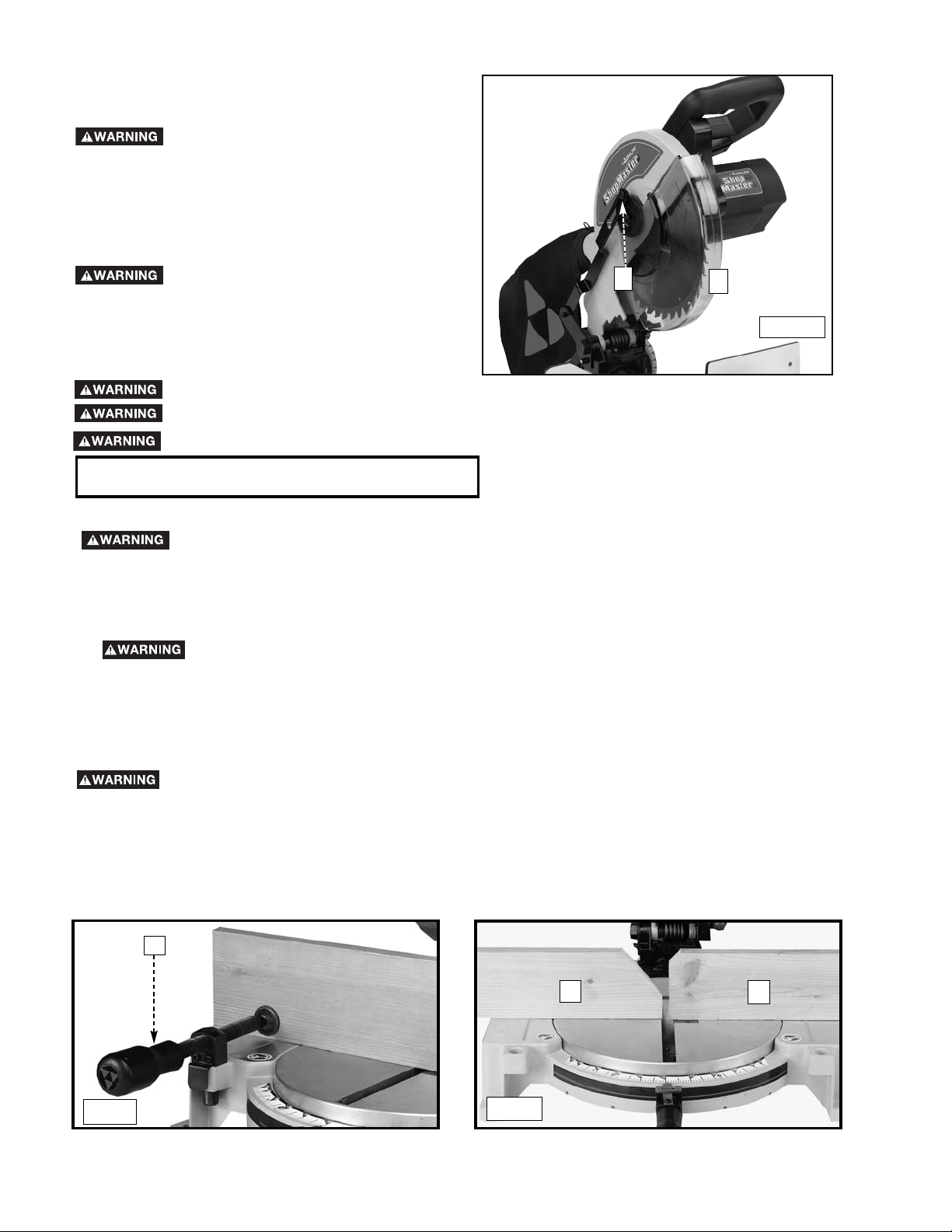

A turning saw blade can be dangerous. After completing cut, release switch trigger (A) Fig. 11, to activate

blade brake. Keep cuttinghead down until blade has come to a complete stop.

The torque developed during braking may loosen the arbor screw (E) Fig. 45. The arbor screw should be checked

periodically and tightened if necessary.

11

OPERATION

TABLE HAZARD AREA

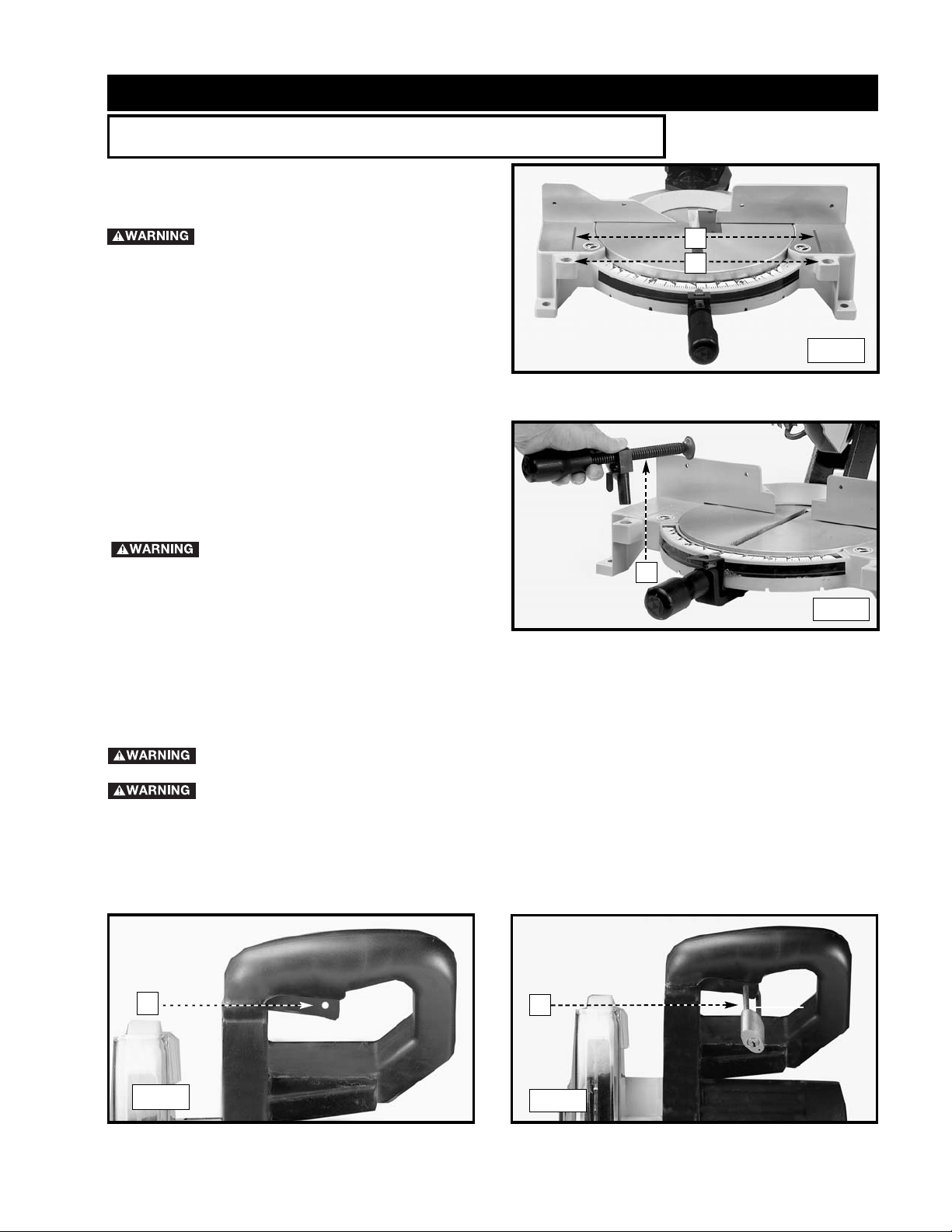

The area inside the two red lines on

the table (A) Fig. 9 is designated as a

"HAZARD ZONE". Never place your

hands inside this area while the

machine is running. Maintain hands

6” from blade.

1. An optional work clamp (A) Fig. 10 is available. Use this

accessory clamp, especially with short workpieces. Never

allow your hands to be in the “Hazard Zone”.

2. Two holes (B) Fig. 9 are provided in the base of the miter

saw, enabling you to use the clamp (A) Fig.10 on either the

right or left hand side of the saw blade.

Keep your hands out of path of saw blade.

If necessary, clamp the workpiece in place before making

the cut if hands would be within 6” of the blade.

STARTING AND STOPPING THE MITER SAW

To start the miter saw, depress the switch trigger (A) Fig. 11 To stop the miter saw, release the switch trigger.

This saw is equipped with an automatic electric blade brake. As soon as the switch trigger (A) Fig. 11, is released, the electric brake

is activated and stops the blade in seconds.

OPERATIONAL CONTROLS AND ADJUSTMENTS

USING THE OPTIONAL WORK CLAMP

Fig. 9

A

B

A

LOCKING THE SWITCH IN THE “OFF” POSITION

IMPORTANT: When the miter saw is not in use, the switch should be locked in the "OFF" position using a padlock (B)

Fig. 12, with a 3/16" diameter shackle to prevent unauthorized use of the saw.

Fig. 10

Fig. 11

Fig. 12

A

B

Page 12

12

ADJUSTING THE POINTER

To transport the saw, always lock the cuttinghead in the down

position. Lower the cuttinghead (A) Fig.17, and push the

cuttinghead lock knob (B) into the hole in the cutting arm until it

locks the cuttinghead.

IMPORTANT: Carrying the machine by the switch handle will

cause misalignment. Always lift the machine by the base or

by the carrying handle (See Fig. 20).

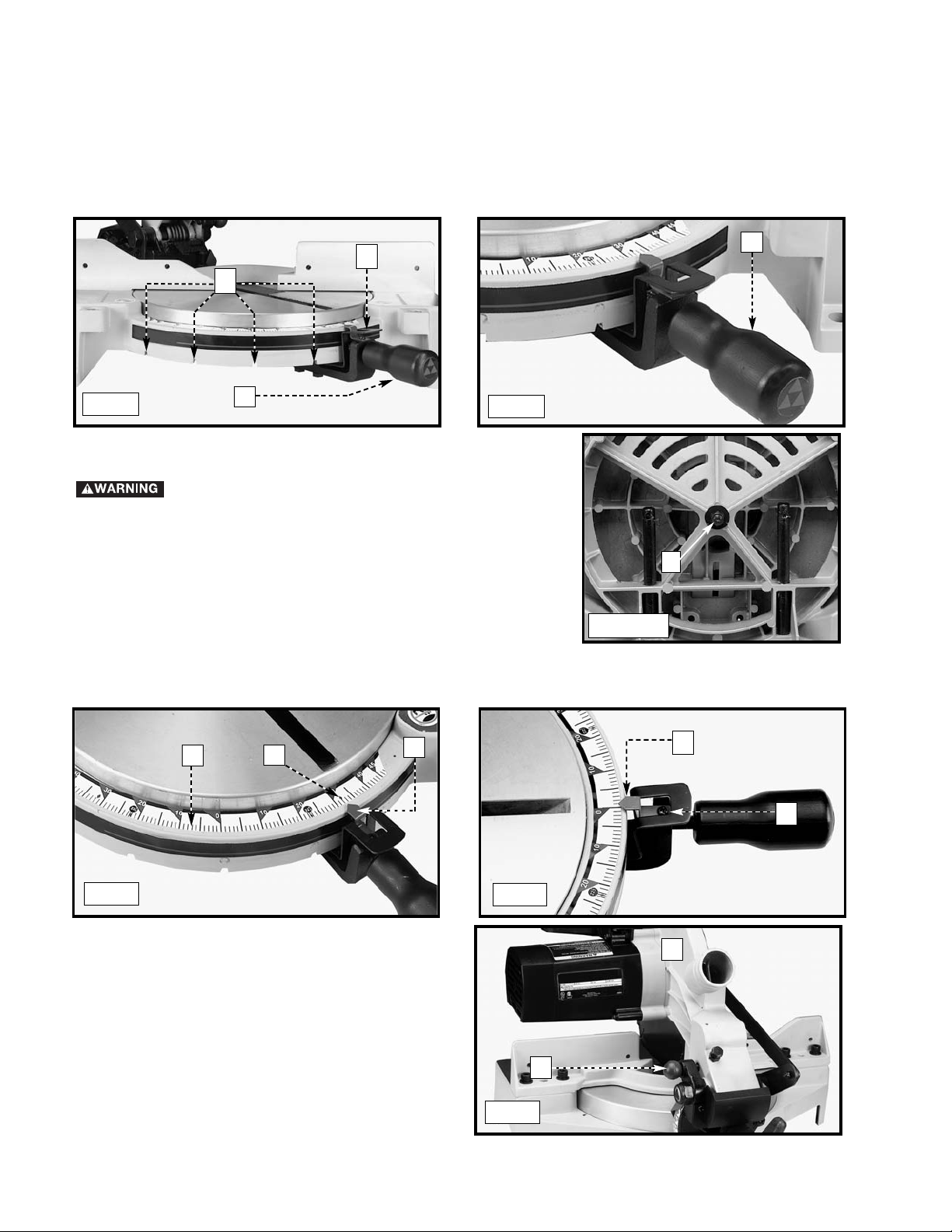

Your miter saw will cut any angle from a straight 90° cut to 47° right and left. Turn the lock handle (A) Fig. 13 counter-clockwise

one or two turns, depress the index lever (B), and move the control arm to the desired angle. Tighten the lock handle (A).

The miter saw is equipped with positive stops at the 0°, 22.5°, 31.62°, and 45° right and left positions. Loosen the lock handle (A)

Fig. 14 and move the control arm until the bottom of the index lever (B) engages into one of the positive stops, four of which are

shown at (C). Tighten the lock handle (A). To disengage the positive stop, depress the index lever (B).

A triangle indicator (D) Fig. 15 is provided on the miter scale at the 31.62° right and left miter positions for cutting crown moulding.

(Refer to the “CUTTING CROWN MOULDING” section of this manual).

IMPORTANT: Always tighten the lock handle (A) Fig. 14 before cutting.

POINTER AND SCALE

The pointer (E) Fig. 15 indicates the angle of cut. Each line on the scale (F)

represents 1 degree. When you move the pointer from one line to the next on the

scale, you change the angle of cut by 1 degree.

ROTATING THE TABLE FOR MITER CUTTING

Fig. 13

Fig. 14

C

B

A

A

Fig. 15

F

D

E

To adjust the pointer (E) Fig. 16, loosen the screw (G), adjust the pointer (E), and tighten the screw.

E

G

Fig. 16

LOCKING THE CUTTINGHEAD IN

THE DOWN POSITION

A

B

Fig. 17

ADJUSTING THE SLIDING FIT BETWEEN THE

MOVABLE TABLE AND THE BASE

DISCONNECT THE MACHINE FROM THE POWER

SOURCE .

To adjust the sliding fit between the movable table and the base, turn the

nut (A) Fig. 14A clockwise to increase the sliding fit (opposite to decrease

the fit). This adjustment should not be so tight that it restricts the rotating

movement of the table, or so loose that it affects the accuracy of the saw.

A

Fig. 14A

Page 13

13

You can tilt the cuttinghead of your compound miter saw to cut

any bevel angle from a 90° straight cut off to a 45° left bevel

angle. Loosen the bevel lock handle (A) Fig. 18, tilt the cutting

arm (B) to the desired angle, and tighten the lock handle (A).

Positive stops are provided to rapidly position the saw blade at

90° and 45° to the table. Refer to the section of this manual

titled “ADJUSTING 90° AND 45° BEVEL STOPS.” The bevel

angle of the cuttinghead is determined by the position of the

pointer (C) Fig.18 on the scale (D).

A triangle indicator is provided on the bevel scale at the 33.86°

bevel angle for cutting crown moulding. Refer to the “CUTTING

CROWN MOULDING” section of this manual.

A rear support bar (A) Fig. 19 is provided to prevent the machine from tipping to the rear when the cuttinghead returns to the up

position. For maximum support, pull the bar (A) out as far as possible.

You can also use the support bar (A) Fig. 20 to carry the machine.

TILTING THE CUTTINGHEAD FOR BEVEL CUTTING

C

B

A

D

Fig. 18

REAR SUPPORT/CARRYING HANDLE

A

Fig. 19

Fig. 20

A

ADJUSTING THE BLADE PARALLEL TO

THE TABLE SLOT

1. Lower the cutting arm. The saw blade (A) Fig. 21 should be

parallel to the left edge (B) of the table opening.

2. To adjust, loosen the three bolts (C) Fig. 21 and move the

cutting arm until the blade is parallel with the left edge (B)

of the table opening and centered in the slot. Tighten the

three bolts (C).

DISCONNECT MACHINE FROM POWER

SOURCE!

Fig. 21

C

B

A

IMPORTANT: Move the sliding fence to provide clearance for the blade and guard. The degree of tilt determines

how far to move the sliding fence. Refer to the section “Adjusting Sliding Fence”.

The sliding fence (A) Fig. 18A provides support for extra large workpieces used with your saw. Set it as close as

possible to the saw blade. When miter cutting (blade 90° to the table and at an angle to the right or left), set the

fence all the way toward the blade (Fig. 18B). When bevel cutting, however (blade tilted at an angle to the table),

move the fence (A) far enough away from the blade to allow for proper clearance. To reposition the fence, loosen the

lock handle (B), and slide the fence (A) to the desired location. Tighten the lock handle (B).

ADJUSTING SLIDING FENCE

Fig. 18A

A

A

B

Fig. 18B

Page 14

14

1. Loosen the bevel lock handle (A) Fig. 18 and move the cutting arm (B) Fig. 19 all the way to the right. Tighten the bevel lock

handle.

2. Place one end of a square (A) Fig. 24 on the table and the other end against the blade. Check to see if the blade is 90° to the

table (Fig. 24).

3. To adjust, loosen the locknut (B) Fig. 25, and turn the screw (C) until the head of the screw (C) contacts the casting (D) when

blade is 90° degrees to the table. Tighten the locknut (B).

1. You can limit the downward travel of the saw blade to

prevent it from contacting any metal surfaces of the

machine. Make this adjustment by loosening the locknut

(A) Fig. 23 and turning the adjusting screw (B) in or out.

2. Lower the blade as far as possible. Rotate the blade by

hand to make certain the teeth do not contact any metal

surfaces.

3. Tighten the locknut (A)

ADJUSTING THE DOWNWARD TRAVEL OF THE SAW BLADE

DISCONNECT MACHINE FROM POWER SOURCE!

Fig. 23

ADJUSTING 90° AND 45° BEVEL STOPS

DISCONNECT MACHINE FROM POWER SOURCE!

A

B

Fig. 24

Fig. 25

A

D

C

B

Fig. 22

In order that the saw can bevel to a full 47 degrees left, the left side of the fence can be adjusted to the left to provide clearance. To

adjust the fence, loosen the plastic knob shown in Figure 22 and slide the fence to the left. Make a dry run with the saw turned off and

check for clearance. Adjust the fence to be as close to the blade as practical to provide maximum workpiece support, without interfering

with arm up & down movement. Tighten knob securely. When the bevel operations are complete, don’t forget to relocate the fence to

the right. NOTE: The guide groove in the left side fence can become clogged with sawdust. If you notice that it is becoming clogged,

use a stick or some low pressure air to clear the guide groove.

FENCE ADJUSTMENT

DISCONNECT MACHINE FROM POWER SOURCE!

Page 15

15

4. Loosen the bevel lock handle. Move the cutting arm all the

way to the left bevel position and tighten the bevel lock

handle.

5. Use a combination square (A) Fig. 26 to see if the blade is

at 45° to the table.

6. To adjust, loosen the locknut (E) Fig. 27, and turn the screw (F)

until it contacts the casting (G). Tighten the locknut (E).

7. Check to see that the bevel pointer (P) Fig. 28 is pointing to the

45° mark on the bevel scale (S) Fig. 26. To adjust the bevel

pointer (P) Fig. 28, loosen the screw (H) and adjust pointer (P).

Tighten the screw (H) securely.

8. These positive stops enable you to rapidly position the blade at

the 90° and 45° bevel angle to the table.

A

S

Fig. 26

Fig. 27

Fig. 28

E

G

F

P

H

The tension of the cuttinghead return spring was adjusted

at the factory so that the cuttinghead returns to the "up"

position after cutting.

To adjust the spring tension, loosen the locknut (A) Fig.

29 and turn the screw (B) (clockwise to increase or

counterclockwise to decrease the spring tension). After

adjustment, tighten the locknut (A).

ADJUSTING THE TENSION OF THE CUTTINGHEAD RETURN SPRING

CUTTING HEAD MUST RETURN QUICKLY TO THE UP POSITION. DISCONNECT MACHINE

FROM POWER SOURCE.

B

A

Fig. 29

After a long period of time, an adjustment of the sliding fit

between the cuttinghead arm (B) Fig. 29A, and the

trunnion (C) may be necessary. To adjust, tighten the nut

(D). This adjustment should not be so tight that it restricts

the sliding movement of the cuttinghead arm (B) or so

loose that it affects the accuracy of the saw cut.

ADJUSTING SLIDING FIT BETWEEN

CUTTINGHEAD ARM AND TRUNNION

C

D

Fig. 29A

B

Page 16

16

TYPICAL OPERATIONS AND HELPFUL HINTS

1. Before cutting, make certain that the cutting arm and table are at their correct settings and firmly locked in place.

2. Place the workpiece on the table and hold or clamp it firmly against the fence. The optional clamp (A) Fig. 30 can also be used

on the right side of the machine.

3. If the position or size of the workpiece causes your hand to be in the “Hazard Zone”, use the work clamp

to secure the workpiece. Keep your hands out of the “Hazard Zone”.

4. For best results, cut at a slow, even cutting rate.

5. Never attempt freehand cutting (wood that is not held firmly against the fence and table).

Holes are provided in the fence to attach an auxiliary fence (A) Fig. 31. This auxiliary fence is constructed of straight wood

approximately 1/2" thick by 3" high by 20" long.

MACHINE USE

AUXILIARY WOOD FENCE

When performing multiple or repetitive operations that result in small cut-off pieces (one inch or less), the saw

blade can catch the cut-off pieces and project them out of the machine or into the blade guard and housing,

causing damage or injury. To limit the risk, mount an auxiliary wood fence on your saw (Fig. 31).

NOTE: The auxiliary fence (A) is used ONLY with the saw blade in the 0° bevel position (90° to the table). When you bevel cut (blade

tilted), remove the auxiliary fence.

A

A

A

Fig. 30

Fig. 31

Cuttinghead must return quickly to the full up position. Sluggish or incomplete return of the

cuttinghead will effect lower guard operation possibly resulting in personal injury.

DO NOT REMOVE ANY OF THE BLADE GUARDS.

Make sure that all guards are in place and functioning properly before operating the saw.

Make sure that the fences are clear of the guard and blade before operating the saw.

ADJUSTING THE LOWER BLADE

GUARD

DISCONNECT THE MACHINE FROM

POWER SOURCE.

This machine incorporates a blade guard (A) Fig. 29B to

cover the rear section of the blade. After an extended

period of use, the movable lower blade guard may not

operate smoothly when the cuttinghead is lowered. This

can be corrected by adjusting nut (B) until the lower blade

guard moves freely.

Overtightening the nut could impair

guard movement.

NOTE: This unit has been designed with an articulating

rear guard. Before contacting the workpiece, the rear

guard will rotate upward to expose more of the blade as

the cuttinghead is lowered.

Fig. 29B

B

A

Page 17

17

GENERAL CUTTING OPERATIONS

1. Your machine has the capacity to cut standard 2 x 4’s, lying flat or on edge, at the 45° right and left miter angles (Fig. A1 & A2).

2. A standard 2 x 6 can be cut in the 90° straight cut-off position in one pass (Fig. A3).

3. Cutting a standard 4 x 4 can be accomplished with one pass (Fig. A4).

4. This machine has the capacity to accurately cut crown mouldings and other bevel-type cuts (Fig. A5).

5. Cutting various sizes of plastic pipe is an easy job with this machine (Fig. A6). Material must be CLAMPED OR HELD FIRMLY

TO THE FENCE TO KEEP IT FROM ROLLING.

This is extremely important when making angle cuts.

A1 A2

A3

A4

A5

A6

Page 18

18

CUTTING BOWED MATERIAL

Check to see if your workpiece is bowed. If it is, make sure the material is positioned on the table as shown in Fig. 34.

If the material is positioned the wrong way, as shown in Fig. 35, the workpiece will pinch the blade near the completion of the cut.

RIGHT

WRONG

C

B

A

C

WORK SUPPORT EXTENSIONS

For support when cutting long pieces, a work support extension

can be constructed. Fig. 36 illustrates the miter saw mounted to

two standard 2 x 4’s (A). Fasten the four mounting legs (two of

which are shown at (B) Fig. 36 to the 2 x 4’s, using four screws

(not supplied) through the four holes in the mounting legs. The

length of the 2 x 4’s (A) can vary, depending on the kind of work

that will need to be cut.

NOTE: Ensure that the top of the support 2 x 4’s (C) are

level with the miter saw table.

This is critical because the distance from the top of the

2 x 4’s (A) to the miter saw table varies from saw to saw. In

most cases, standard 2 x 4’s (C) can used. If these are too high,

cut the 2 x 4s (C) to provide this height or use other

properly-sized wood.

CUTTING ALUMINUM

Aluminum extrusions such as used for making aluminum screens and storm windows can easily be cut with your compound miter saw.

When cutting aluminum extrusions, or other sections that can be cut with a saw blade and are within the capacity of the machine,

position the material so the blade is cutting through the smallest cross-section (Fig. 32). The wrong way to cut

aluminum angles is illustrated in Fig. 33. Be sure to apply a stick wax to the blade before cutting aluminum stock. This stick wax is

available at most industrial mill supply houses. The wax provides proper lubrication and keeps chips from adhering to the blade.

NEVER APPLY LUBRICANT TO THE BLADE WHILE THE MACHINE IS RUNNING.

FENCE

BLADE

WRONG

FENCE

BLADE

RIGHT

Fig. 33

Fig. 32

Fig. 34

Fig. 35

Fig. 36

Page 19

19

CUTTING CROWN MOULDING

One of the many features of the saw is the ease of cutting crown moulding. The following is an example of cutting both inside and

outside corners on 52°/38° wall angle crown moulding.

1. Move the table to the 31.62° right miter position and lock the table in position. NOTE: A positive stop is provided to find this angle

quickly.

2. Tilt the saw blade to the 33.86° left bevel position and tighten bevel lock handle. NOTE: A triangle indicator is provided on the bevel

scale to find this angle quickly.

3. Place the crown moulding on the table with the CEILING EDGE of the moulding against the fence, and make the cut, as shown in

Fig. 37.

NOTE: The piece of crown moulding used for the outside corner will always be on the right hand side of the blade, as shown at (A)

Fig. 37. The piece of crown moulding used for the inside corner will always be on the left hand side of the blade, as shown at (B)

Fig. 37.

4. To make the matching halves of the inside and outside corners, rotate the table to the 31.62° left miter position.

NOTE: A positive stop is provided to find this angle quickly. The saw blade is already tilted to the 33.86° left bevel position from the

previous cut.

5. Place the crown moulding on the table with the WALL EDGE of the crown moulding against the fence and make the cut. Again, the

piece of crown moulding used for the outside corner will always be on the right side of the blade, as shown at (C) Fig. 38. The piece

of crown moulding used for the inside corner will always be on the left side of the blade, as shown at (D) Fig. 38.

6. Fig. 39 illustrates the two outside corner pieces; (A) being the piece cut at (A) Fig. 37 and (C) being the piece cut at (C) Fig. 38.

7. Fig. 40 illustrates the two inside corner pieces; (B) being the piece cut at (B) Fig. 37, and (D) being the piece cut at (D) Fig. 38.

45-45 CROWN MOULDING

NOTE: If you are cutting crown moulding that is 45°-45°, follow the same procedure above, with the exception that the bevel position

will always be at 30° and the miter position will be 35-1/4° to the right or left.

OTHER ANGLES

NOTE: The above instructions are assuming the angle between the walls is 90°. If you need help cutting crown moulding set at angles

other than 90°, see the instruction sheet “CUTTING CROWN MOULDING” on the Delta Machinery web site at

www.deltamachinery.com.

Fig. 38

Fig. 37

Fig. 39

Fig. 40

D

C

B

A

C

A

B

D

WALL

EDGE

CEILING

EDGE

Page 20

20

Brush life varies. It depends on the load on the motor. Check the brushes after the first 50 hours of use for a new machine or after

a new set of brushes has been installed. After the first check, examine them after about 10 hours of use until a replacement is

necessary. To inspect the brushes:

MAINTENANCE

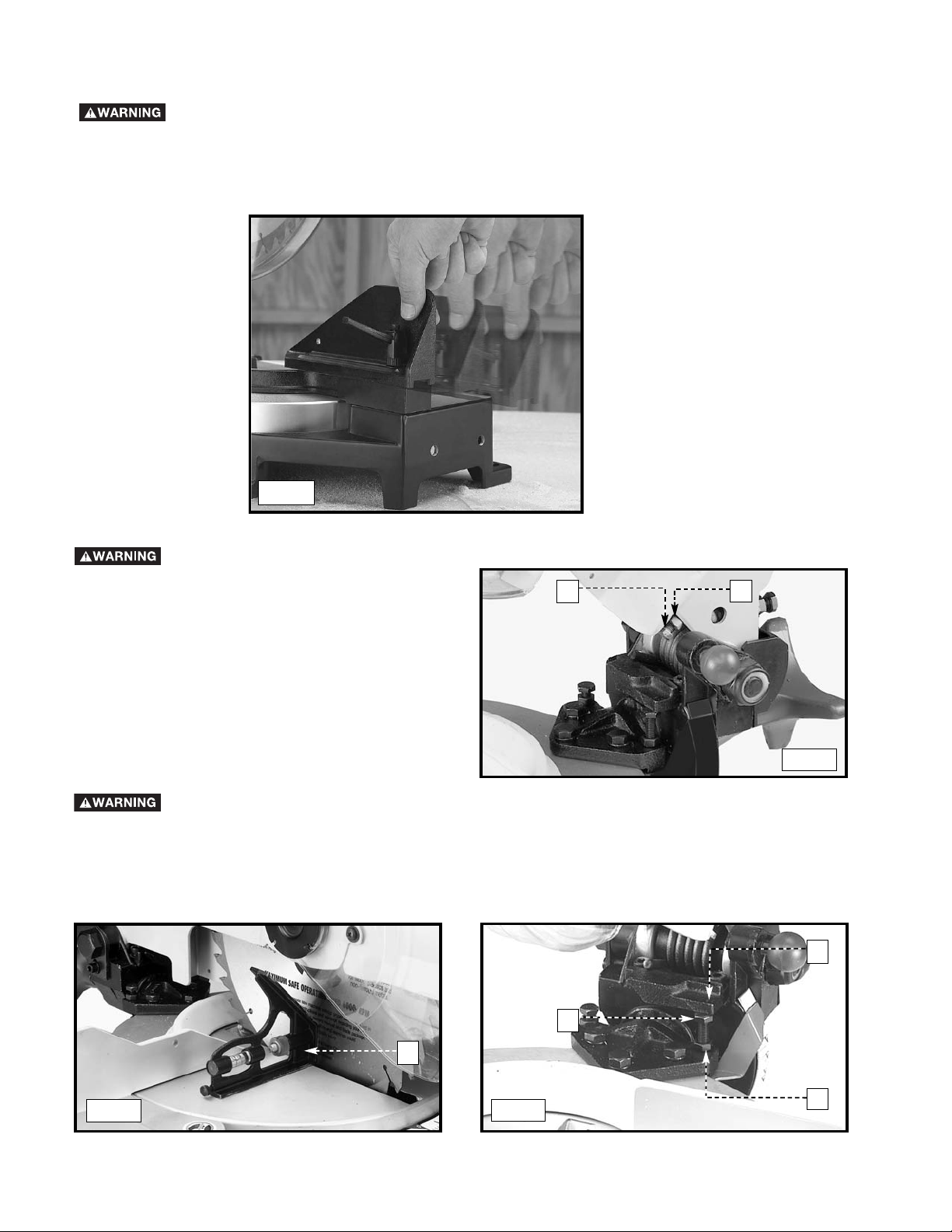

CHANGING THE BLADE

Use only cross-cutting saw blades.

When using carbide-tipped blades, do not

use blades with deep gullets as they can

deflect and contact the guard.

Use only 10" diameter saw blades which are

rated for 5200 rpm or higher and have 5/8"

diameter arbor holes.

1. Remove screw (A) Fig. 41 and rotate cover (B) to the rear

(Fig. 42).

2. To remove the saw blade, insert the hex wrench (C)

Fig. 43 into the hex hole located on the rear end of the

motor shaft to keep the shaft from turning.

3. Use a wrench (D) Fig. 44 to loosen the arbor screw (E) by

turning it clockwise.

4. Remove the arbor screw (E) Fig. 44, the outside blade

flange (B), and the saw blade from the saw arbor.

5. Attach the new saw blade

making certain that the teeth of

the saw blade are pointing down (Fig. 44). Place the

outside blade flange (F) on the arbor, and attach the arbor

screw (E) by turning it counter-clockwise using the wrench

(D). At the same time, use the hex wrench (C) Fig. 43 to

keep the arbor from turning.

6. Rotate the cover back to the front and replace the screw

that was removed in STEP 1.

DISCONNECT MACHINE FROM POWER SOURCE!

Remove wrenches (C) Fig. 43 and (D) Fig. 44

before starting machine.

The cover must be returned to its original

position and the screw tightened before

activating the saw. Failure to do so may

allow the guard to contact the spinning saw

blade resulting in damage to the saw and

severe personal injury.

Fig. 41

Fig. 42

Fig. 43

Fig. 44

A

B

B

C

E

F

D

T

E

E

T

H

BRUSH INSPECTION AND REPLACEMENT

DISCONNECT MACHINE FROM POWER SOURCE!

Page 21

1. Remove three screws (A) Fig. 45 and remove the motor

cover (B).

2. The brushes are located in the two holders (C) Fig. 46.

Remove spade type terminal connector (D) and pull out

brush holders (C).

3. Fig. 47 illustrates one of the brushes (E) removed from the

holder (C). When the carbon on either brush (E) is worn to

3/16" in length or if either spring (F) or shunt wire is burned

or damaged in any way, replace both brushes. If the

brushes are found to be serviceable after re-moving,

reinstall them in the same position.

21

TROUBLESHOOTING

BE SURE TO FOLLOW SAFETY RULES AND INSTRUCTIONS

TROUBLE! SAW WILL NOT START

WHAT’S WRONG? WHAT TO DO…

1.Saw not plugged in. 1.Plug in saw.

2.Fuse blown or circuit breaker tripped. 2.Replace fuse or reset

circuit breaker.

3.Cord damaged. 3.Have cord replaced by

authorized service center.

4.Brushes worn out. 4.Have brushes replaced

by authorized service center.

TROUBLE! SAW MAKES UNSATISFACTORY CUTS

WHAT’S WRONG? WHAT TO DO…

1.Dull blade. 1.Replace blade.

2.Blade mounted backwards. 2.Turn blade around.

3.Gum or pitch on blade. 3.Remove blade and

clean with turpentine.

4.Incorrect blade for work being done. 4.Change the blade.

TROUBLE! BLADE DOES NOT COME UP TO SPEED

WHAT’S WRONG? WHAT TO DO…

1.Extension cord too light or too long. 1.Replace with adequate

size cord.

2.Low house current. 2.Contact your electric

company.

KEEP THE MACHINE CLEAN

Periodically blow out all air passages with dry compressed air. All plastic parts should be cleaned with a soft damp cloth.

NEVER use solvents to clean plastic parts. They could possibly dissolve or otherwise damage the material.

Wear ANSI Z87.1 safety glasses while using compressed air.

FAILURE TO START

Should your machine fail to start, check to make sure the prongs on the cord plug are making good contact in the outlet. Also, check

for blown fuses or open circuit breakers in the line.

B

A

Fig. 45

Fig. 46

Fig. 47

D

C

C

E

F

Page 22

22

PARTS, SERVICE OR WARRANTY ASSISTANCE

All Delta Machines and accessories are manufactured to high quality standards and are serviced by a network of PorterCable · Delta Factory Service Centers and Delta Authorized Service Stations. To obtain additional information regarding

your Delta quality product or to obtain parts, service, warranty assistance, or the location of the nearest service outlet,

please call 1-800-223-7278 (In Canada call 1-800-463-3582).

A complete line of accessories is available from your Delta Supplier, Porter-Cable · Delta Factory Service Centers,

and Delta Authorized Service Stations. Please visit our Web Site www.deltamachinery

.com

for a catalog or for

the name of your nearest supplier.

Since accessories other than those offered by Delta have not been tested

with this product, use of such accessories could be hazardous. For safest operation, only

Delta recommended accessories should be used with this product.

ACCESSORIES

Two Year Limited New Product Warranty

Delta will repair or replace, at its expense and at its option, any new Delta machine, machine part, or machine accessory

which in normal use has proven to be defective in workmanship or material, provided that the customer returns the product

prepaid to a Delta factory service center or authorized service station with proof of purchase of the product within two

years and provides Delta with reasonable opportunity to verify the alleged defect by inspection. For all refurbished Delta

product, the warranty period is 180 days. Delta may require that electric motors be returned prepaid to a motor

manufacturer’s authorized station for inspection and repair or replacement. Delta will not be responsible for any asserted

defect which has resulted from normal wear, misuse, abuse or repair or alteration made or specifically authorized by

anyone other than an authorized Delta service facility or representative. Under no circumstances will Delta be liable for

incidental or consequential damages resulting from defective products. This warranty is Delta’s sole warranty and sets

forth the customer’s exclusive remedy, with respect to defective products; all other warranties, express or implied, whether

of merchantability, fitness for purpose, or otherwise, are expressly disclaimed by Delta.

SERVICE

WARRANTY

TROUBLE! MACHINE VIBRATES EXCESSIVELY

WHAT’S WRONG? WHAT TO DO…

1.Saw not mounted securely. 1.Tighten all mounting

hardware.

2.Stand or bench on uneven floor. 2.Reposition on flat level

surface.

3.Damaged saw blade. 3.Replace blade.

TROUBLE! DOES NOT MAKE ACCURATE MITER CUTS

WHAT’S WRONG? WHAT TO DO…

1.Miter scale not adjusted correctly. 1.Check and adjust.

2.Blade is not square to fence. 2.Check and adjust.

3.Blade is not perpendicular to table. 3.Check and adjust fence.

4.Workpiece moving. 4.Clamp workpiece to

fence or glue 120 grit

sandpaper to fence with

rubber cement.

TROUBLE! MATERIAL PINCHES BLADE

WHAT’S WRONG? WHAT TO DO…

1.Cutting bowed material. 1.Position bowed material

as shown in Figure 36.

Page 23

23

23

Para obtener más información sobre Delta Machinery,

visite nuestro sitio web en: www.deltamachinery.com

Para las piezas, el servicio, la garantía o la otra ayuda llaman por favor

1-800-223-7278

(

en la llamada 1-800-463-3582 de Canada).

MANUAL DE INSTRUCCIONES

Sierra de Ingletes Compuesta

Motorizada de 254 mm

(Modelo SM100M)

90513776 1-07

Copyright © 2007 Delta Machinery

Page 24

2424

Lea y entienda todas advertencias y las instrucciones operadoras antes de utilizar cualquier instrumento o el equipo.

Cuando se usa instrumentos o equipo, las precauciones básicas de la seguridad siempre se deben seguir para reducir el riesgo de la herida

personal. La operación impropia, la conservación o la modificación de instrumentos o equipo podrían tener como resultado el daño grave

de la herida y la propiedad. Hay ciertas aplicaciones para que equipaas con herramienta y el equipo se diseña. La Delta Machinery

recomienda totalmente que este producto no sea modificado y/o utilizado para ninguna aplicación de otra manera que para que se diseñó.

Si usted tiene cualquiera pregunta el pariente a su aplicación no utiliza el producto hasta que usted haya escrito Delta Machinery y nosotros

lo hemos aconsejado.

La forma en línea del contacto en www. deltamachinery. com

El Correo Postal: Technical Service Manager

Delta Machinery

4825 Highway 45 North

Jackson, TN 38305

(IN CANADA: 125 Mural St. Suite 300, Richmond Hill, ON, L4B 1M4)

Información con respecto a la operación segura y apropiada de este instrumento está disponible de las fuentes siguientes:

Power Tool Institute (Instituto de Herramientas Eléctricas)

1300 Sumner Avenue, Cleveland, OH 44115-2851

www.powertoolinstitute.org

Consejo Nacional de Seguridad (National Safety Council)

1121 Spring Lake Drive, Itasca, IL 60143-3201

American National Standards Institute, 25 West 43rd Street, 4 floor, New York, NY 10036 www.ansi.org

Requisitos de Seguridad ANSI 01.1 para las máquinas de carpintería y

normas del Departamento del Trabajo de los Estados Unidos www.osha.gov

INSTRUCCIONES DE SEGURIDAD IMPORTANTES

GUARDE ESTAS INSTRUCCIONES!

Page 25

25

indica una situación de peligro inminente que, si no se evita, provocará la muerte o lesiones graves.

indica una situación de peligro potencial que, si no se evita, provocará la muerte o lesiones graves.

indica una situación de peligro potencial que, si no se evita, provocará lesiones leves o moderadas.

utilizado sin el símbolo de alerta de seguridad indica una situación de peligro potencial que, si no se evita,

puede provocar daños en la propiedad.

Es importante que lea y comprenda este manual. La información que contiene se relaciona con la

protección de SU SEGURIDAD y la PREVENCIÓN DE PROBLEMAS. Los símbolos que siguen se utilizan

para ayudarlo a reconocer esta información.

PAUTAS DE SEGURIDAD/DEFINICIONES

LA PROPUESTA 65 DE CALIFORNIA

Algunas partículas originadas al lijar, aserrar, amolar, taladrar y realizar otras actividades de construcción

contienen productos químicos que producen cáncer, defectos de nacimiento y otros problemas

reproductivos. Algunos ejemplos de estos productos químicos son:

• el plomo de las pinturas a base de plomo;

• la sílice cristalina de ladrillos, el cemento y otros productos de mampostería; y

• el arsénico y el cromo de la madera con tratamiento químico (CCA).

El riesgo derivado de estas exposiciones varía según la frecuencia con la que se realice este tipo de trabajo. Para reducir la

exposición a estos productos químicos: se recomienda trabajar en áreas bien ventiladas y usar equipos de seguridad aprobados,

como las máscaras para polvo especialmente diseñadas para filtrar las partículas microscópicas.

• Evite el contacto prolongado con las partículas de polvo originadas al lijar, aserrar, esmerilar, taladrar y realizar demás actividades de

la construcción. Use indumentaria protectora y lave las áreas expuestas con agua y jabón. Evite que el polvo entre en la boca y en los

ojos o se deposite en la piel, para impedir la absorción de productos químicos nocivos.

El uso de esta herramienta puede generar o dispersar partículas de polvo, que pueden causar lesiones respiratorias

permanentes y graves u otras lesiones. Use siempre protección respiratoria aprobada por NIOSH/OSHA (Instituto Nacional de

Salud y Seguridad Ocupacional de los EE.UU./Administración de la Salud y Seguridad Ocupacional de los EE.UU.) apropiada para la

exposición al polvo. Aleje la cara y el cuerpo del contacto con las partículas.

Utilice la protección auditiva apropiada durante el uso. En determinadas condiciones y según el período de uso, el ruido

provocado por este producto puede originar pérdida de audición.

Para su comodidad y seguridad, la herramienta incluye las siguientes etiquetas de advertencia.

EN LA

CAJA

DEL MOT

OR:

ADVERTENCIA: POR SU PROPIA SEGURIDAD, LEA EL MANUAL DE INSTRUCCIONES ANTES DE OPERAR LA SIERRA. AL

REPARAR, SÓLO UTILICE PIEZAS DE REPUESTO IDÉNTICAS. SIEMPRE UTILICE PROTECCIÓN PARA LOS OJOS.

EN LA

GUÍA:

AJUSTE LAS PIEZAS PEQUEÑAS ANTES DE CORTAR.

CONSULTE EL MANUAL.

EN LA

GUARDA: PELIGRO – MANTÉNGASE ALEJADO DE LA HOJA.

EN LA

PLACA DE RETENCIÓN DE LA GUARDA: “SUJETE EL SOPORTE CORRECTAMENTE CON

AMBOS TORNILLOS ANTES DE USAR”

CLAMP SMALL PIECES

BEFORE CUTTING. SEE MANUAL.

DANGER

KEEP AWAY

FROM BLADE

EN LA TABLA (2 LUGARES)

EN LA PLACA DE RETENCIÓN DEL PROTECTOR: PARA REDUCIR EL RIESGO DE LESIONES, LEA EL MANUAL DE

INSTRUCCIONES ANTES DE OPERAR LA SIERRA INGLETADORA. AL REALIZAR EL MANTENIMIENTO, SÓLO UTILICE

PIEZAS DE REPUESTO IDÉNTICAS. NO EXPONGA A LA LLUVIA NI UTILICE EN LUGARES HÚMEDOS. SIEMPRE UTILICE

PROTECCIÓN ADECUADA PARA LOS OJOS Y VÍAS RESPIRATORIAS. UTILICE ÚNICAMENTE HOJAS DE SIERRA DE 10”

RECOMENDADAS PARA 5.200 RPM O MÁS, CON EJE DE 5/8”. MANTENGA LAS MANOS ALEJADAS DEL TRAYECTO DE LA

HOJA DE LA SIERRA. NO OPERE LA SIERRA SI LOS PROTECTORES NO ESTÁN ADECUADAMENTE INSTALADOS.

VERIFIQUE QUE EL PROTECTOR INFERIOR CIERRE CORRECTAMENTE ANTES DE CADA USO. AJUSTE SIEMPRE LAS

PERILLAS DE REGULACIÓN ANTES DE UTILIZAR LA HERRAMIENTA. NO REALICE NINGUNA OPERACIÓN SIN MANOS.

NUNCA SE ESTIRE PARA ALCANZAR ALGO DETRÁS DE LA HOJA DE LA SIERRA. NUNCA CRUCE LOS BRAZOS FRENTE A

LA HOJA. APAGUE LA HERRAMIENTA Y AGUARDE HASTA QUE LA HOJA DE LA SIERRA SE DETENGA ANTES DE MOVER

LA PIEZA DE TRABAJO, CAMBIAR LOS AJUSTES O MOVER LAS MANOS. DESCONECTE LA ENERGÍAANTES DE CAMBIAR

LA HOJA O REALIZAR EL MANTENIMIENTO. PARA REDUCIR EL RIESGO DE LESIONES, REGRESE EL MECANISMO DE

TRANSPORTE A LA POSICIÓN POSTERIOR DESPUÉS DE CADA CORTE TRANSVERSAL. ¡PRESTE ATENCIÓN! PUEDE

EVITAR ACCIDENTES.

NO EXPONGA A LA LLUVIA NI LA UTILICE EN LUGARES HÚMEDOS.

Page 26

26

NORMAS GENERALES DE SEGURIDAD

1. PARA SU PROPIA SEGURIDAD, LEA EL MANUAL DE

INSTRUCCIONES ANTES DE UTILIZAR LA MÁQUINA.

Al aprender la aplicación, las limitaciones y los peligros

específicos de la máquina, se minimizará enormemente

la posibilidad de accidentes y lesiones.

2. USE PROTECCIÓN DE LOS OJOS Y DE LA

AUDICIÓN. USE SIEMPRE ANTEOJOS DE

SEGURIDAD. Los lentes de uso diario NO son anteojos

de seguridad. USE EQUIPO DE SEGURIDAD

CERTIFICADO. El equipo de protección de los ojos debe

cumplir con las normas ANSI Z87.1. El equipo de

protección de la audición debe cumplir con las normas

ANSI S3.19.

3. USE INDUMENTARIA ADECUADA. No use ropa

holgada, guantes, corbatas, anillos, pulseras u otras

joyas que podrían engancharse en las piezas móviles. Se

recomienda usar calzado antideslizante. Use una

cubierta protectora del pelo para sujetar el pelo largo.

4. NO UTILICE LA MÁQUINA EN UN ENTORNO

PELIGROSO. La utilización de herramientas mecánicas

en lugares húmedos o mojados, o en la lluvia, puede

causar descargas eléctricas o electrocución. Mantenga

bien iluminada el área de trabajo para evitar tropezar o

poner en peligro los brazos, las manos y los dedos.

5. MANTENGA TODAS LAS HERRAMIENTAS Y

MÁQUINAS EN CONDICIONES ÓPTIMAS. Mantenga

las herramientas afiladas y limpias para lograr el mejor y

más seguro rendimiento. Siga las instrucciones de

lubricación y cambio de accesorios. Las herramientas y

las máquinas mal mantenidas pueden dañar más la

herramienta o la máquina y/o causar lesiones.

6. COMPRUEBE SI HAY PIEZAS DAÑADAS. Antes de

utilizar la máquina, compruebe si hay piezas dañadas.

Compruebe la alineación de las piezas móviles, si las

piezas móviles se atascan, si hay piezas rotas y toda

otra situación que podría afectar su funcionamiento. Un

protector o cualquier otra pieza que presente daños

debe repararse o reemplazarse apropiadamente. Las

piezas dañadas pueden causar daños adicionales a la

máquina y/o lesiones.

7. MANTENGA LIMPIA EL ÁREA DE TRABAJO. Las

áreas y los bancos desordenados invitan a que se

produzcan accidentes.

8. MANTENGA ALEJADOS A LOS NIÑOS Y A LOS

VISITANTES. El taller es un entorno potencialmente

peligroso. Los niños y los visitantes pueden sufrir

lesiones.

9. REDUZCA EL RIESGO DE UN ARRANQUE NO

INTENCIONADO. Asegúrese de que el interruptor esté

en la posición de apagado antes de enchufar el cable de

alimentación. En caso de un apagón, mueva el

interruptor a la posición de apagado. Un arranque

accidental podría causar lesiones.

10.UTILICE LOS PROTECTORES. Asegúrese de que todos

los protectores estén colocados en su sitio, sujetos

firmemente y funcionando correctamente para prevenir

lesiones.

11.QUITE LAS LLAVES DE AJUSTE Y DE TUERCA

ANTES DE ARRANCAR LA MÁQUINA. Las

herramientas, los pedazos de desecho y otros residuos

pueden salir despedidos a alta velocidad, causando

lesiones.

12.UTILICE LA MÁQUINA ADECUADA. No fuerce una

máquina o un aditamento a hacer un trabajo para el que

no se diseñó. El resultado podría ser daños a la máquina

y/o lesiones.

13.UTILICE ACCESORIOS RECOMENDADOS. La

utilización de accesorios y aditamentos no

recomendados por Delta podría causar daños a la

máquina o lesiones al usuario.

14.UTILICE EL CORDÓN DE EXTENSIÓN ADECUADO.

Asegúrese de que el cordón de extensión esté en

buenas condiciones. Cuando utilice un cordón de

extensión, asegúrese de utilizar un cordón que sea lo

suficientemente pesado como para llevar la corriente

que su producto tome. Un cordón de tamaño

insuficiente causará una caída de la tensión de la línea,

lo cual producirá una pérdida de potencia y

recalentamiento. Consulte el Cuadro de cordones de

extensión para obtener el tamaño correcto dependiendo

de la longitud del cordón y la capacidad nominal en

amperios indicada en la placa de especificaciones. En

caso de duda, utilice el próximo calibre más grueso.

Cuanto más pequeño sea el número de calibre, más

pesado será el cordón.

15.SUJETE FIRMEMENTE LA PIEZA DE TRABAJO.

Utilice abrazaderas o un tornillo de carpintero para

sujetar la pieza de trabajo cuando resulte práctico. La

pérdida de control de una pieza de trabajo puede causar

lesiones.

16.HAGA AVANZAR LA PIEZA DE TRABAJO CONTRA

EL SENTIDO DE ROTACIÓN DE LA HOJA, EL

CORTADOR O LA SUPERFICIE ABRASIVA. Si la hace

avanzar desde el otro sentido, el resultado será que la

pieza de trabajo salga despedida a alta velocidad.

17.NO FUERCE LA PIEZA DE TRABAJO SOBRE LA

MÁQUINA. El resultado podría ser daños a la máquina

y/o lesiones.

18.NO INTENTE ALCANZAR DEMASIADO LEJOS. Una

pérdida del equilibrio puede hacerle caer en una

máquina en funcionamiento, causándole lesiones.

19.NO SE SUBA NUNCA A LA MÁQUINA. Se podrían

producir lesiones si la herramienta se inclina o si usted

hace contacto accidentalmente con la herramienta de

corte.

20.NO DEJE NUNCA DESATENDIDA LA MÁQUINA

CUANDO ESTÉ EN MARCHA. APÁGUELA. No deje la

máquina hasta que ésta se detenga por completo. Un

niño o un visitante podría resultar lesionado.

21.APAGUE LA MÁQUINA Y DESCONÉCTELA DE LA

FUENTE DE ALIMENTACIÓN antes de instalar o quitar

accesorios, antes de ajustar o cambiar configuraciones

o al realizar reparaciones. Un arranque accidental puede

causar lesiones.

22.HAGA SU TALLER A PRUEBA DE NIÑOS CON

CANDADOS E INTERRUPTORES MAESTROS O

QUITANDO LAS LLAVES DE ARRANQUE. El arranque

accidental de una máquina por un niño o un visitante

podría causar lesiones.

23.MANTÉNGASE ALERTA, FÍJESE EN LO QUE ESTÁ

HACIENDO Y USE EL SENTIDO COMÚN. NO UTILICE

LA MÁQUINA CUANDO ESTÉ CANSADO O BAJO LA

INFLUENCIA DE DROGAS, ALCOHOL O MEDICAMENTOS. Un momento de distracción mientras se

estén utilizando herramientas mecánicas podría causar

lesiones.

24. EL POLVO GENERADO por determinadas maderas y

productos para madera puede ser perjudicial para su

salud. Siempre opere la máquina en áreas con buena

ventilación y encárguese de eliminar el polvo

adecuadamente. Utilice un sistema de recolección de

polvo, cuando esto sea posible.

LEA Y COMPRENDA TODAS LAS ADVERTENCIAS Y LAS INSTRUCCIONES DE

OPERACIÓN ANTES DE UTILIZAR ESTE EQUIPO. El incumplimiento de cualquiera de las

instrucciones enumeradas abajo puede provocar descarga eléctrica, incendio o lesiones

personales graves o daños a la propiedad.

INSTRUCCIONES IMPORTANTES SOBRE SEGURIDAD

Page 27

27

1. NO UTILICE ESTA MÁQUINA HASTA QUE esté

montada e instalada de acuerdo con las

instrucciones.

2. OBTENGA ASESORAMIENTO de su supervisor,

instructor u otra persona calificada si no está

familiarizado con la utilización de esta máquina.

3. SIGA TODOS LOS CÓDIGOS DE CABLEADO y

las conexiones eléctricas recomendadas.

4. MONTE LA HERRAMIENTA FIRMEMENTE en una

superficie de soporte estable antes de utilizarla.

5. UTILICE LOS PROTECTORES SIEMPRE QUE

SEA POSIBLE. Asegúrese de que estén colocados

en su sitio, sujetos firmemente y funcionando

correctamente.

6. UTILICE ÚNICAMENTE HOJAS DE SIERRA DE

CORTE TRANSVERSAL. Utilice únicamente

ángulos de gancho de cero grados o negativos

cuando emplee hojas con puntas de carburo. No

utilice hojas que tengan gargantas profundas. Estas

hojas pueden doblarse y entrar en contacto con el

protector.

7. USE SÓLO HOJAS DEL TAMAÑO Y TIPO

CORRECTO especificadas para esta herramienta.

8. USE UNA HOJA AFILADA. Compruebe la hoja

para ver si funciona libremente y si está libre de

vibraciones.

9. INSPECCIONE LA HOJA PARA VER SI TIENE

GRIETAS u otros daños antes de utilizarla.

Reemplace inmediatamente la hoja agrietada o

dañada.

10.LIMPIE LA HOJA Y LAS PESTAÑAS DE LA HOJA

antes de utilizarla. Compruebe si la hoja tiene daños

y apriete firmemente la tuerca del eje

portaherramienta.

11.USE SÓLO LAS PESTAÑAS DE HOJA

especificadas para esta herramienta.

12.DESPEJE EL ÁREA DE LÍQUIDOS INFLAMABLES

y/o gases inflamables antes de utilizar la máquina.

13.LIMPIE LAS RANURAS DE VENTILACIÓN DEL

MOTOR para quitar las virutas y el serrín.

14. APRIETE EL MANGO DE LA ABRAZADERA DE

LA MESA y cualquier otra abrazadera antes de

utilizar la máquina.

15.NUNCA ARRANQUE LA HERRAMIENTA con la

pieza de trabajo contra la hoja.

16.MANTENGA LAS MANOS alejadas de la

trayectoria de la hoja de sierra. Sujete con

abrazaderas todas las piezas de trabajo que

requerirían que la mano esté en la "Zona de peligro

de la mesa" (dentro de las líneas rojas).

17.DEJE QUE EL MOTOR alcance su velocidad

máxima antes de comenzar el corte.

18. NUNCA PONGA LAS MANOS ALREDEDOR ni

detrás de la hoja de sierra.

19.NUNCA CORTE METALES FERROSOS ni

mampostería.

20.NUNCA CORTE DE NUEVO PEDAZOS

PEQUEÑOS.

21.NUNCA BLOQUEE EL INTERRUPTOR en la

posición de encendido.

21.NO APLIQUE LUBRICANTE a una hoja que esté

en marcha.

GUARDE ESTAS INSTRUCCIONES.

Refiérase a ellas con frecuencia y utilícelas para adiestrar a otros.

22. NO REALICE OPERACIONES A PULSO. Sujete

firmemente la pieza de trabajo contra el tope-guía y

la mesa. Use abrazaderas para sujetar la pieza de

trabajo cuando sea posible.

23. SOPORTE APROPIADAMENTE las piezas de

trabajo LARGAS o anchas.

24.DESPUÉS DE COMPLETAR EL CORTE, suelte el

interruptor de alimentación y espere a que la hoja

que gira por inercia se detenga por completo antes

de regresar la sierra a la posición subida.

25.APAGUE LA HERRAMIENTA Y DEJE QUE LA

HOJA SE DETENGA POR COMPLETO antes de

limpiar el área de la hoja o quitar los residuos que

estén en la trayectoria de la hoja. Una hoja que gira

por inercia hasta detenerse es peligrosa.

26.APAGUE LA HERRAMIENTA Y DEJE QUE LA

HOJA SE DETENGA POR COMPLETO antes de

retirar o sujetar la pieza de trabajo, cambiar el

ángulo de la pieza de trabajo o cambiar el ángulo

de la hoja.

27.NUNCA REALICE TRABAJO DE INSTALACIÓN,

MONTAJE o preparación en el área de la mesa o de

trabajo cuando la máquina esté en marcha.

28.APAGUE LA MAQUINA Y DESCONÉCTELA de la

fuente de alimentación antes de instalar o quitar

accesorios, antes de ajustar o cambiar

preparaciones o al hacer reparaciones.

29.APAGUE LA MÁQUINA, desconéctela de la fuente

de alimentación y limpie el área de la mesa y de

trabajo antes de dejar la máquina. BLOQUEE EL

INTERRUPTOR EN LA POSICIÓN DE APAGADO

para impedir el uso no autorizado.

30.NO TIRE DE ESTA UNIDAD POR EL CABLE DE

ALIMENTACIÓN. No deje que el cable de

alimentación entre en contacto con instrumentos o

bordes afilados, superficies calientes, aceite o

grasa. No ponga ningún peso sobre el cable de

alimentación. Un cable de alimentación dañado

puede causar descargas eléctricas o electrocución.

31.ANTES OPERAR EL VIO. El cheque y cierra

seguramente el bisel, mitra, y los ajustes de la cerca

de sliding.

32. EL CABEZAL DE CORTE DEBE VOLVER

RÁPIDAMENTE A LA POSICIÓN MÁS ALTA. De lo

contrario, el protector inferior no funcionará

adecuadamente y eso puede ocasionar lesiones

personales. Consulte la sección del manual referida al

“Ajuste del retorno del cabezal de corte”.

33.HAY INFORMACIÓN ADICIONAL disponible

relacio-nada con la utilización segura y apropiada

de herrami-entas mecánicas (por ejemplo, un video

sobre seguridad) a través del Instituto de

Herramientas Mecánicas, Power Tool Institute, 1300

Sumner Avenue, Cleveland, OH 44115-2851

(www.powertool-institute.com). También hay

información disponible a través del Consejo

Nacional de Seguridad, National Safety Council,

1121 Spring Lake Drive, Itasca, IL 60143-3201.

Sírvase consultar también los Requisitos de

Seguridad para Máquinas de Elaboración de la

Madera ANSI 01.1 del Instituto Nacional Americano

de Normas (American National Standards Institute)

y las normas OSHA 1910.213 del Departamento de

Trabajo de los EE.UU.

NORMAS ESPECÍFICAS ADICIONALES DE SEGURIDAD

LEA Y COMPRENDA TODAS LAS ADVERTENCIAS Y LAS INSTRUCCIONES DE

OPERACIÓN ANTES DE UTILIZAR ESTE EQUIPO. El incumplimiento de cualquiera de las

instrucciones enumeradas abajo puede provocar descarga eléctrica, incendio o lesiones

personales graves o daños a la propiedad.

Page 28

28

Debe utilizarse un circuito eléctrico independiente para las máquinas. Este circuito debe tener alambre de no menos del No. 12 y

debe estar protegido con un fusible de acción retardada de 20 A. Si se utiliza un cordón de extensión, utilice únicamente cordones

de extensión de tres alambres que tengan enchufes de tipo de conexión a tierra con tres terminales y un receptáculo coincidente

que acepte el enchufe de la máquina. Antes de conectar el máquina a la línea de alimentación, asegúrese de que el interruptor(s)

esté en la posición de apagado y cerciórese de que la corriente eléctrica tenga las mismas características que las que estén

indicadas en la máquina. Todas las conexiones a la línea de alimentación deben hacer buen contacto. El funcionamiento a bajo

voltaje dañará el máquina.