Page 1

INSTALLATION, OPERATING AND

SUPPLY VOLTAGE

REQUIRED

26

COVER

FM 720

ISO 9001

Series 8000 Pressure Transmitters

employ a piezo-resistive sensor operated

from a flush diaphragm specially

designed for paper, food and drugs

industries where viscous and/or

biologically active fluids are encountered.

A monolithic amplifier provides a 4-20 mA

current output capable of being used in

control and indicating loops without

further application.

The instruments are adjustable for zero

and span: the span adjustment having

sufficient turn down to enable all

intermediate ranges to be

accommodated.

INSTALLATION

Ensure that the pressure range and

maximum working pressures selected are

compatible with the expected pressures in

the system. While the instruments are fully

calibrated in the works, it is advisable to

check zero and span before installation, if

possible with the instruments in the attitude

in which they are to be mounted.

As these instruments are designed for direct

contact with the process medium their

sophisticated temperature compensation

enables accurate operation over a wide

range of temperatures. Care should be

taken however during cleaning processes.

Processes, that the maximum permissible

temperatures are not exceeded. An

addendum to these instructions gives hints

for installation and cleaning-in-situ.

The instrument may be mounted in any

position and is normally self supporting by

the pipework.

While the instruments have high resistance

to EM and RF interference, it is strongly

recommended that for long cable runs, the

instrument leads be screened.

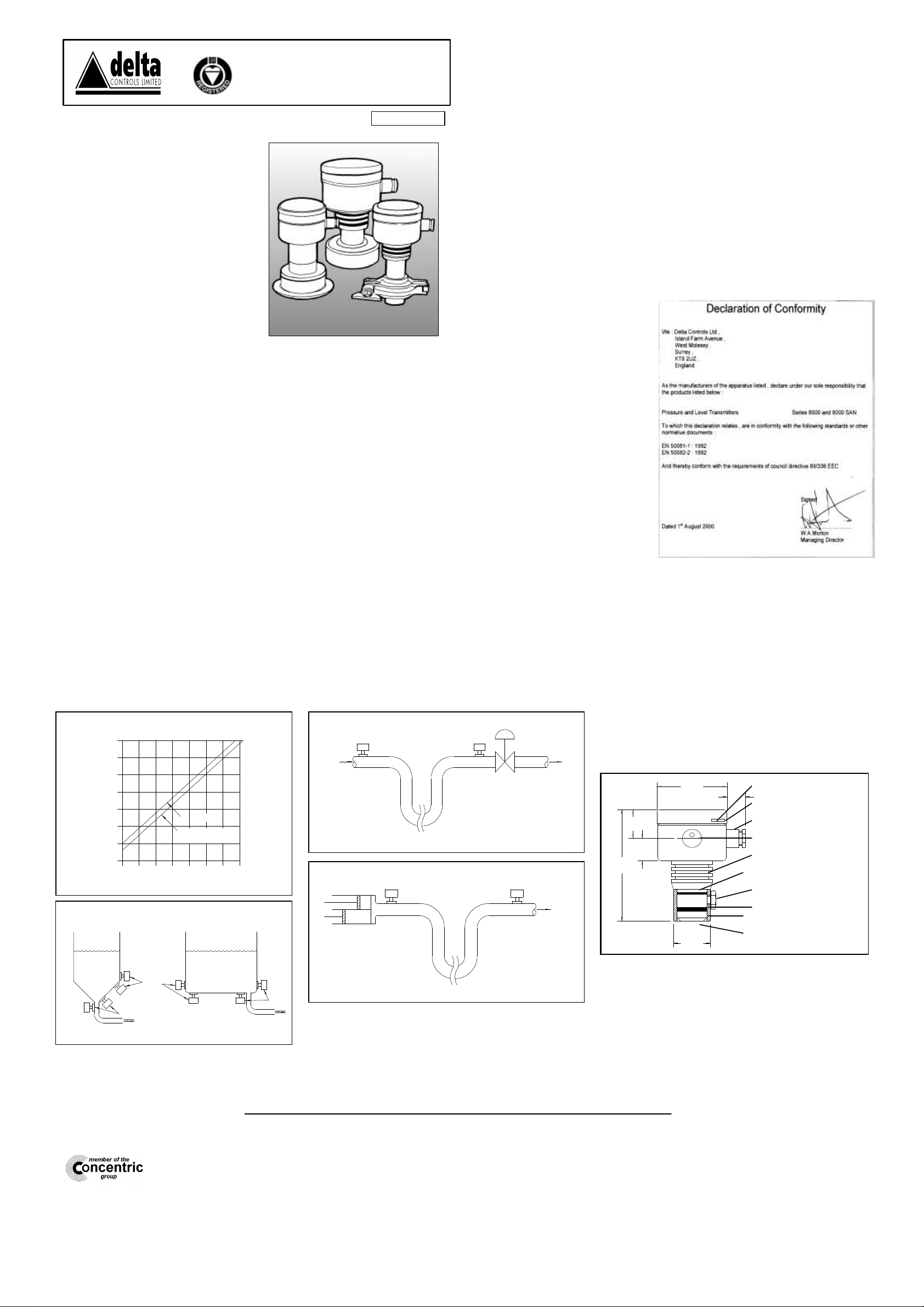

VOLTAGE v LOAD

Voltage must be within triangular area

45

40

35

30

25

20

15

10

2000 400 600 800 1000 1200 1400

As supplied

Without 100 ohm

internal resistor

EXTERNAL LOAD OHM

RIGHT

WRONG

In the interest of development and improvement Delta Controls Ltd, reserve the right to amend without notice, details contained in this publication.

DELTA CONTROLS LIMITED, ISLAND FARM AVENUE, WEST MOLESEY, SURREY KT8 2UZ

TEL. +44 (020) 8939 3500 FAX. +44 (020) 8783 1163 E-MAIL:sales@delta-controls.com

Registered Office Registered in England No 486464

MAINTENANCE INSTRUCTIONS

FOR SERIES 8000 AND 8000SAN

FLOW TRANSMITTERS

ISSUE B 04/00

OUPUT SIGNAL

The transmitters use the standard 4 to 20

mA two wire system in which the power

supply, transmitter and load are in series.

This means therefore, that for a constant

voltage at the power supply, as the signal

level rises, the drop across the load reduces

the voltage available at the transmitter. This

voltage should at all times be within the

range 13 to 40 V and the attached load /

voltage diagram shows the permitted range

of supply voltage for the satisfactory

operation of the instrument.

ADJUSTMENT

Zero and span controls are accessible by

removal of the threaded lid. Disconnection

of the electrical wiring is not necessary for

the functioning of the instrument, but proper

site practices should be followed when

working on the instrument which is ‘live’ with

respect to power or process.

MAINTENANCE

No maintenance is normally necessary or

required on these instruments.

Should the cover be removed for adjustment,

ensure that the O-ring seal is not damaged.

Light greasing is recommended.

Fig 1

WRONG

Fig 2

No legal liability will be accepted by Delta Controls Ltd, for any errors, omissions or amendments.

RIGHT

WRONG

INSTRUMENTATION SOLUTIONS FOR INDUSTRY

HINTS ON INSTALLATION

The mounting position of the level transmitter

in a tank is important; incorrect positioning

may lead to inaccuracies, particularly during

filling or discharging.

In general, the unit should avoid inlets and

outlets, and be protected against direct

impact from cleaning jets.

The installer should also avoid mounting

directly upstream or rapidly closing valves,

which may create shock waves in excess of

the instrument’s over-range capability.

Piston pumps and homogenizers also create

pressure fluctuations which may damage or

shorten the life of the units.

WELDING INSTRUCTIONS

The fitting of Delta type 8000 level/pressure

transmitters with mounting ‘W’, requires that

the mating part be welded to the tank or pipe

of the process plant.

NB These instructions also apply for the

fitting of 1:1 repeaters which use the same

fittings.

The units may have, according to the model,

a push-in nipple secured by a side bolt, or, in

the case of the hygiene units, a fine thread

and lockring.

It is very important that during the welding

operation, no deformation of the push-fit

boss or the M56 x 1.25 thread should take

place. The following procedure minimises

this possibility.

1. Cut a close fitting hole for the nipple in the

pipe or tank. Bevel the inside of that hole.

2. Attach copper/aluminium mandrel to the

weld nipple with the bolt or lockring provided.

3. Using MIG techniques and a fine

electrode, weld the nipple in place.

DO NOT ATTEMPT THE COMPLETED

WELD IN A SINGLE OPERATION.

First weld two spots opposite to each other

and allow to cool. Next weld two more spots

at right angles to the first and allow to cool.

Complete the weld, welding opposite

quadrants.

WRONG

Fig 3

103

RIGHT

Fig 4

WARRANTY

We guarantee this instrument against faulty

workmanship and material for a period of

one year from the date of delivery. The

company undertakes to repair, free of

charge, ex-works any instrument found to be

defective within the specified period provided

the instrument has been used within the

specification in accordance with these

instructions and has not been misused in

any way. Detailed notice of such defects

and satisfactory proof thereof must be given

to the company immediately after the

discovery and the goods have to be returned

free of charge to the company, carefully

packed and accompanied by a detailed

failure report.

To comply with health and safety

requirements, the instrument must be clean

and safe to handle and accompanied by a

formal statement

ł

65

22

ł

33

16

O-RING

PG9 CABLE GLAND

VENT

COOLING FINS

SECONDARY O –RING

M8 SCREW

O-RING SEAL

WELD NIPPLE

DIAPHRAGM

Stock No: 002522/8000

Fig 5

Loading...

Loading...