Page 1

Part No. 1341095

Dated 4-30-99

BIESEMEYER® MODEL NO. 78-939 CUT-OFF FENCE

For use with Biesemeyer® commercial and home shop fences, and other makes of

Biesemeyer-style fences 3-1/2” or 4” wide

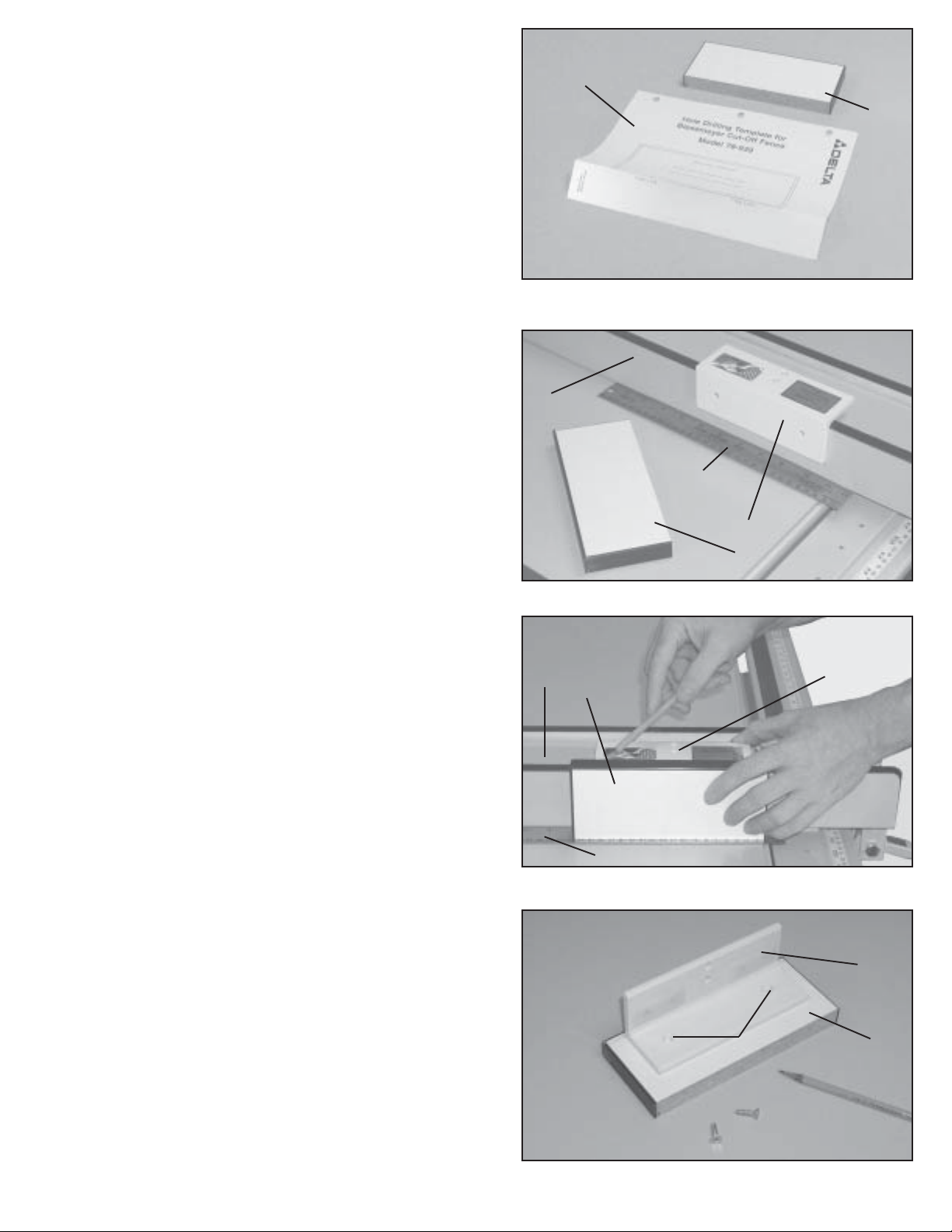

The cut-off fence is shipped complete in one container. Fig 1, illustrates all components shipped.

1

2

3

9

COMPONENTS

1. Drilling template (for Biesemeyer® fences only)

2. Clamp and bracket assembly

3. Knob assembly

4. 1/4-20 x 1” hex head bolt

5. 1/4” flat washer

SAFETY RULES

6

7

8

Fig. 1

6. 1/4-20 locknut

7. #10x 3/4” flat head self-tapping screw

8. 6” cut-off fence support

9. Cut-off fence board

5

4

1. DO NOT use cut-off fence in ripping applications; it is

only to be used with the miter gage to perform cut-offs.

2. ALWAYS make certain saw fence and cut-off fence are

securely fastened before use.

3. ALWAYS turn the saw off and allow the saw blade to

come to a complete stop before attempting to remove

cut-off pieces.

4. AVOID trapping the workpiece between the fence and

saw blade. The piece of wood being cut must be past the

cut-off fence before contacting the saw blade.

Page 2

ASSEMBLY

DISCONNECT SAW FROM POWER SOURCE UNTIL

ALL ASSEMBLY AND SET-UP PROCEDURES HAVE

BEEN COMPLETED.

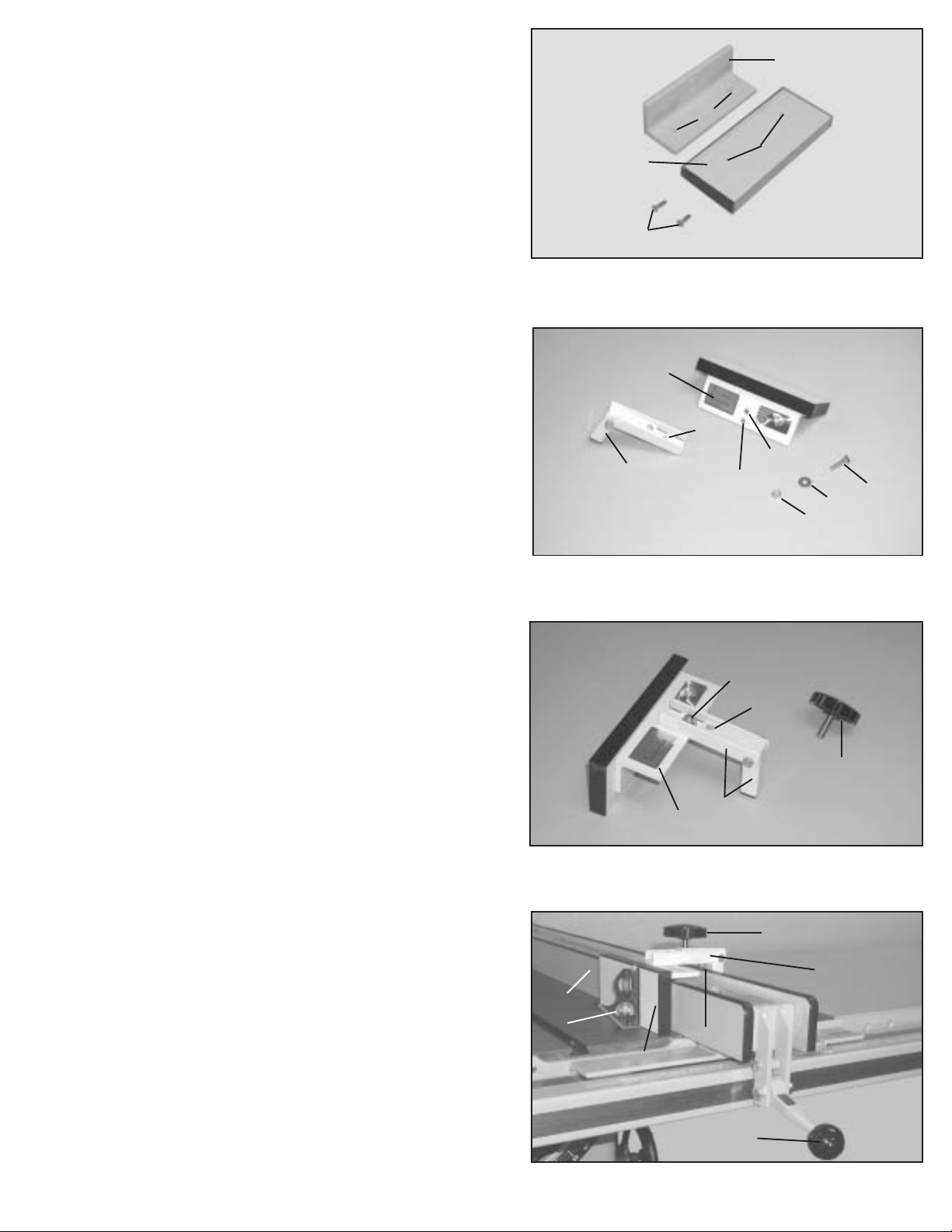

FOR BIESEMEYER

FENCES ONLY.

1. Fold template (A) Fig. 2, on fold line and align the

template with the bottom of fence board (B). Using a punch,

mark the fence board (B) as indicated on the template (A)

for Commercial or Home Shop installation. Then proceed

to section “FOR ALL FENCES” STEP 8.

FOR BRANDS OTHER THAN BIESEMEYER

2. Place cut-off support (C) Fig. 3, onto saw fence (D) as

shown.

3. Place a straight edge (E) Fig. 3, approximately

1/16”- 1/8” thick, onto saw table as shown. Then, place

cut-off fence board (F) Figs. 3 and 4, vertically onto straight

edge (E) and against saw fence (D) with the unfinished

edge down as shown in fig. 4.

4. Hold cut-off fence board (F) Fig. 4, Firmly against

cut-off fence support (C), and draw a line across the rear

of cut-off fence board (F) as shown.

®

COMMERCIAL OR HOME SHOP

A

B

Fig. 2

D

E

C

F

Fig. 3

5. Remove cut-off fence board (F) Fig. 4, and cut-off fence

support (C) from saw fence (D), and place cut-off fence

board onto a flat, supporting surface with pencil marks

facing up as shown in Fig. 5.

6. Align the top of cut-of f fence support (C) Fig. 5, with the

pencil line on cut-off fence board (F) and center cut-off

fence support (C) onto board.

7. Using a pencil, mark the back of cut-off fence board (F)

Fig. 5, through the two holes (G) in cut-off fence support

(C).

D

F

C

E

Fig. 4

C

FG

Fig. 5

2

Page 3

FOR ALL FENCES

8. Using a 1/8” drill bit, drill two 1/8” pilot holes 1/2” deep at

the two marked locations on the back of cut-off fence board

(F) Figs. 5 and 6. NOTE: Mark the drill bit with masking

tape to act as a depth gage to prevent drilling through

fence board.

9. Align two holes (G) Fig. 6, with drilled holes (H) and

fasten cut-off fence support (C) to cut-off fence board (F)

using two #10 x 3/4” flat head screws (J).

10. Align hole (K) Fig. 7, in clamp and bracket assembly

(L) with the appropriate thru-hole (M) or (N) in cut-off fence

support (C) and fasten using the 1” long hex head bolt (P),

flat washer (R) and lockwasher (S). NOTE: Thru-hole (M)

Fig. 7, is used for Biesemeyer

fences which are approximately 4” wide, and thru-hole

(N) is used for Biesemeyer®home shop fences, or

fences that are approximately 3-1/2” wide. Also, bolt

(P) Fig. 7, is to be inserted from the bottom with the

flat washer (R) and lock nut (S) located on top.

CAUTION: Do not tighten lock nut (S) Fig. 7,

completely , for clamp and bracket assembly (L) Fig. 8,

needs to move freely.

®

commercial fences, or

C

G

F

H

J

Fig. 6

C

K

N

L

M

P

R

S

Fig. 7

11. Fig. 8 illustrates clamp and bracket assembly (L)

properly fastened to cut-off fence support (C), for use with

a Biesemeyer

®

commercial fence. Assembly to

Biesemeyer® home shop-style fences is similar.

12. Thread knob (T) into threaded hole (W) of clamp and

bracket assembly (L) approximately four complete turns.

13. Place entire cut-off fence assembly (X) Fig. 9, so it

straddles the saw fence (D) as shown, and tighten knob

(T) until cut-off fence assembly (X) is firmly clamped to

the saw fence (D). Then secure saw fence (D) in place by

pushing down on handle (H).

14. Using a square (Y) Fig. 9, determine if cut-off fence

board is 90 degrees to saw table. If an adjustment is

necessary, loosen knob (T) slightly and turn adjustment

screw (Z) accordingly. Then tighten knob (T) and recheck

squareness. Repeat adjustment if necessary.

S

W

T

L

C

Fig. 8

T

X

D

Y

Z

F

H

Fig. 9

3

Page 4

T

X

A

B

D

Fig. 10

SET -UP AND USE

DISCONNECT SAW FROM POWER SOURCE

1. Place entire cut-off fence (X) Fig. 10, so it straddles saw fence (D), and is positioned close to the front

edge of saw table as shown. Then tighten knob (T).

WARNING: ALWAYS POSITION CUT-OFF FENCE (X) FIG. 10, IN FRONT OF THE SAW BLADE SO

THE WORKPIECE CANNOT BE TRAPPED BETWEEN SAW FENCE AND SAW BLADE TO AVOID

KICKBACK. THE PIECE OF MATERIAL BEING CUT MUST BE PAST THE CUT-OFF FENCE (X)

BEFORE CONTACTING THE SAW BLADE.

2. Adjust and lock saw fence (D) Fig. 10, to the desired setting. NOTE: Cut-off fence assembly (X) is 1”

thick; therefore, you must add 1” when setting the saw fence to the desired cut.

3. Place edge of material to be cut (A) Fig. 10, against face of miter gage (B) and slide material until the

edge contacts cut-off fence (X) as shown.

4. Apply power to the saw.

Warning: ALWAYS turn the saw off and allow the saw blade to come to a complete stop before

attempting to remove cut-off pieces.

4

Page 5

REPLACEMENT P ARTS

78-939

CUT-OFF FENCE

REF.

NO. PART NUMBER DESCRIPTION

* 78-939 CUT-OFF FENCE, CONST OF:

1 1350066 KNOB ASSEMBLY

2 1352363 CLAMP

3 1350191 END CAP

4 1350303 1/4-20 X 1-1/2” HEX HD SCREW

5 1350295 1/4-20 X 1/2” HEX HD SCREW

6 1350077 FLAG DECAL

7 1350300 #10 X 4/4” FLAT HD SCREW

8 1350302 1/4-20 X 1” HEX HD SCREW

9 1350019 GLIDE PAD

10 1352361 SUPPORT

11 1352370 NAMEPLATE

12 1350280 1/4-20 LOCKNUT

13 1352364 BRACKET ASSEMBLY

14 1350312 1/4” FLAT WASHER

15 1350280 1/4-20 LOCKNUT

16 1352360 BOARD

* NOT SHOWN ASSEMBLED

5

Page 6

PARTS, SERVICE OR WARRANTY ASSISTANCE

To obtain additional information regarding this product or to obtain parts, service or warranty

assistance, please call or fax the following toll free number. Highly qualified and experienced

Customer Service Representatives are standing by to assist you.

Biesemeyer® Manufacturing

4825 Highway 45 North

Jackson, TN

38305

Phone Toll Free

(731) 660-5986 (800) 782-1831

Two Year Limited Warranty

Delta will repair or replace, at its expense and at its option, any Delta machine, machine part, or machine

accessory which in normal use has proven to be defective in workmanship or material, provided that the customer notifies his supplying distributor of the alleged defect within two years from the date of delivery to him, of

the product and provides Delta Machinery with reasonable opportunity to verify the defect by inspection. Delta

Machinery may require that electric motors be returned prepaid to the supplying ddistributoror authorized service center for inspection and repair or replacement. Delta Machinery will not be respponsible for any asserted

defect which has resulted from misuse, abuse or repair or alteration made or specificallyauthorized by anyone

other than an authorized Delta service facility, or representative. Under no circumstances will Delta Machinery

be liable for incidental or consequential damages resulting from defective products. This warranty is Delta

Machinery’s sole warrantyand sets forth the customers exclusive remedy to defective products;all other warranties, express or implied, whether of merchantability, fitness for purpose, or otherwise, are expressly disclaimed

by Delta.

6

Page 7

Cut Here

Model 78-939

Center marks for commercial fence holes

Biesemeyer Cut-Off Fence

Hole Drilling Template for

Center marks for home shop fence holes

Page 8

THIS PAGE INTENTIONALL Y LEFT BLANK\

Loading...

Loading...