Page 1

INSTRUCTION MANUAL

D AT E D 3-5-96 PA RT NO. 1349984

'Delta International Machinery Corp. 1996

Biesemeyer

fi

T-SquarefiCommercial Fence Systems

50 C a pacity (Model 78-904)

30 C a pacity (Model 78-907)

Page 2

INTRODUCTION

The 50 capacity (model 78-904) and 30 cap acity (model 78-907) BiesemeyerfiT-Square

fi

Commercial fence systems are specially designed to be used with:

Delt a 10 T ilting Arbor Unisaws

fi

Delt a 10 T ilting Arbor Saws

Delt a 10 Contractor sfiSaws

Delt a 10 Contractor sfiSaws II

The T-SquarefiCommercial Fence Systems include the fence assembly, front rail, rear rail and

front guide tube. The accessory right extension t able (78-925 for 50 cap acity model and 78-927

for 30 c a p acity model) must be ordered separately or a similar extension t able must be con structed by following instructions in this manual. The accessory leg kit (model 78-952), used

to support the extension t able, must also be ordered separately . IMPORTANT:The T-Square

fi

Fence System is designed to be used O N LY with a supporting extension t able.

The following instructions illustrate assembling the T-SquarefiCommercial Fence System to a

Delt a 10 T ilting Arbor Unisawfi. Instructions for assembling the fence system to Delt a 10 Tilting

Arbor Saws and 10 Contractor sfiSaws are identical unless otherwise noted.

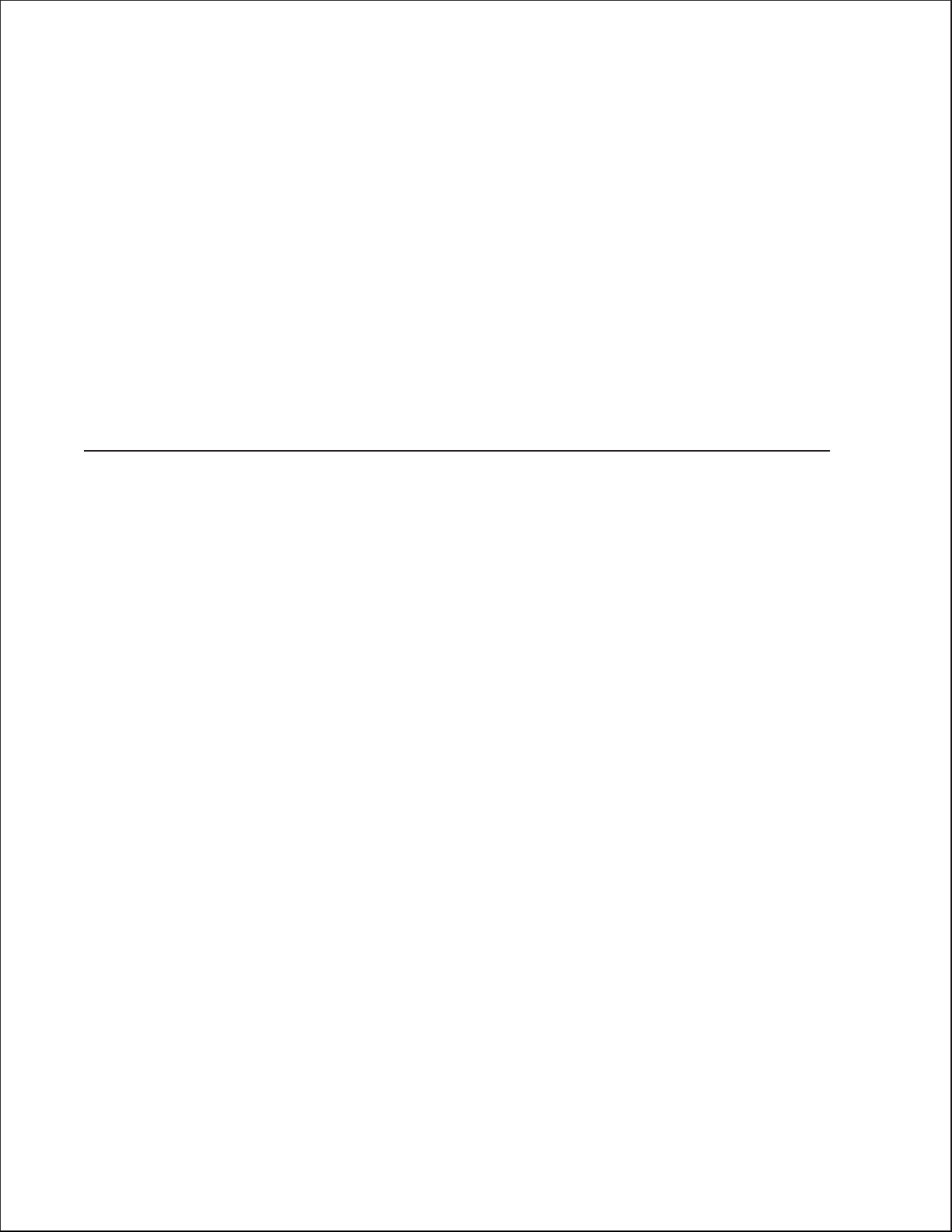

UNPACKING

Carefully unp ack the T -Squarefifence system from the shipping carton(s). Figure 2 illustrates all

the items supplied with the 78-904 and 78-907 fence system.

1 - Rear Rail

2 - Front Rail

3 - Guide T ube

4 - T-Square

fi

Fence Assembly

5 - Switch Adapter for Unisaws

fi

6 - Switch Adapter for Contractor sfiSaws

7 - Cable Strap

8 - T emplate for aligning front rail to saw t able

for fastening front and rear rails to

right extension t able

9 - 1-1/2 long flat head Phillip s screws (14)

10 - 1-1/4 O.D. Flat W ashers (14)

11 - 1/4-20 hex nut s (14)

for fastening rear rail to saw t able and sheet met al

extension wing if applicable

12 - 3/8-24 x 1-1/4 long hex head cap screws (3)

13 - 7/8 O.D. flat washers (3)

14 - Lock washers (3)

15 - 3/8-24 hex nut s (3)

for fastening front rail to saw t able and sheet metal

extension wing if applicable

16 - 3/8-16 x 1-1/4 long flat head Phillip s screws (3)

17 - 7/8 O.D. flat washers (3)

18 - Lock washers (3)

19 - 3/8-16 hex nut s (3)

for fastening guide tube to front rail

20 - 1/2 long hex screws (7)

21 - Lock washers (7)

for fastening on-off switch adapter to guide tube where

applicable on Unisawsfior ContractorsfiSaws

22 - 3/4 long hex head screws (2)

23 - Lock washers (2)

for fastening on-off switch to switch adapter where

applicable on Contractor sfiSaws

24 - 3/8-16 x 1 long hex head screw (1)

25 - 7/8 O.D. Flat washer (1)

27 - Hex nut (1)

Page 3

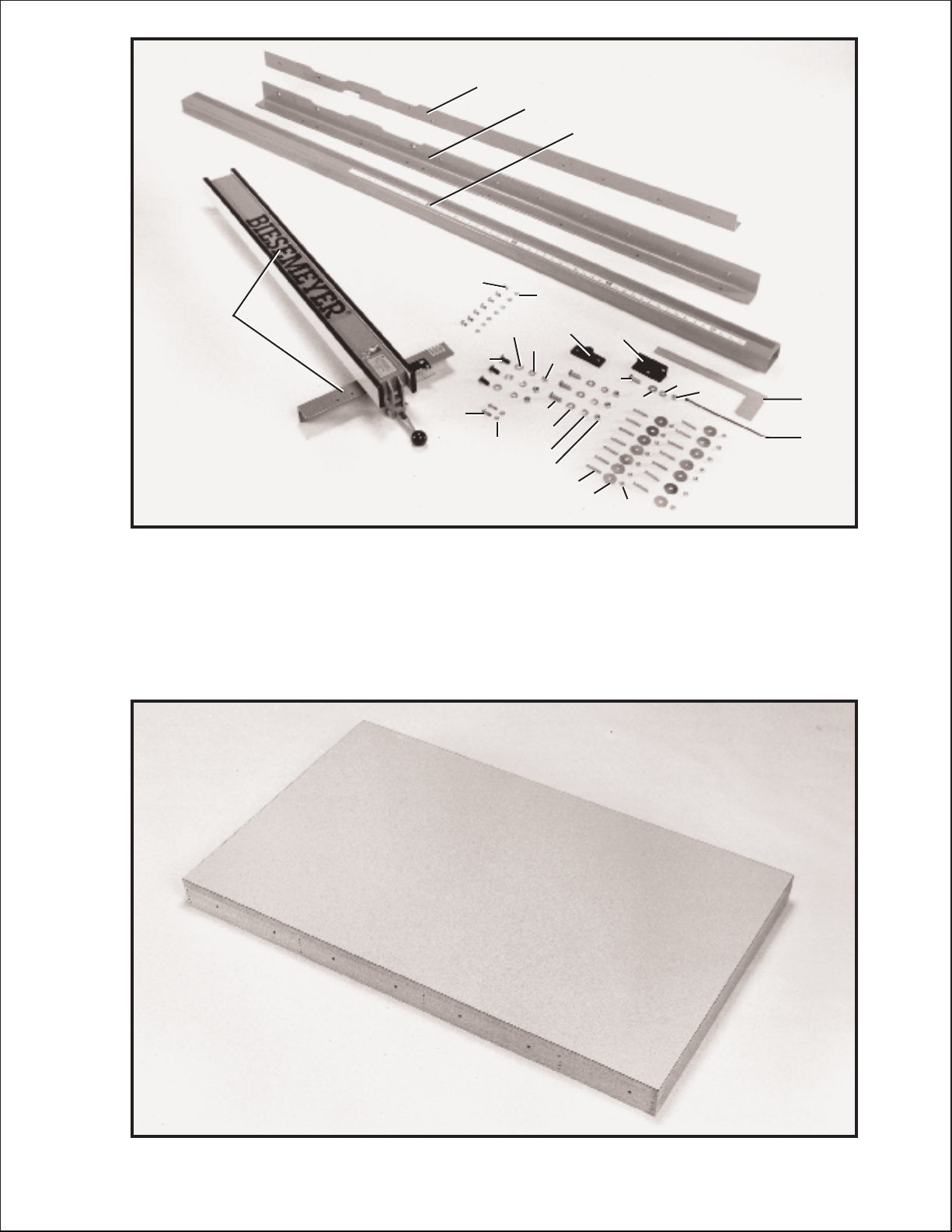

If you purchased the accessory right extension t able (model 78-925 for 50 cap acity fence or model

78-927 for 30 cap acity fence) carefully unp ack the extension t able from the shipping cont ainer . Figure

3 illustrates the right extension t able removed from the cont ainer . NOTE: If you did not purchase the

accessory right extension t able for use with your T -Squarefifence, refer to the ASSEMBLY INSTRUCTION section of this manual for information on constructing a right extension t able.

Fig. 2

Fig. 3

7

1

8

2

27

3

6

5

11

10

26

9

20

21

24

25

16

17

22

23

18

19

12

13

14

15

4

Page 4

Fig. 4

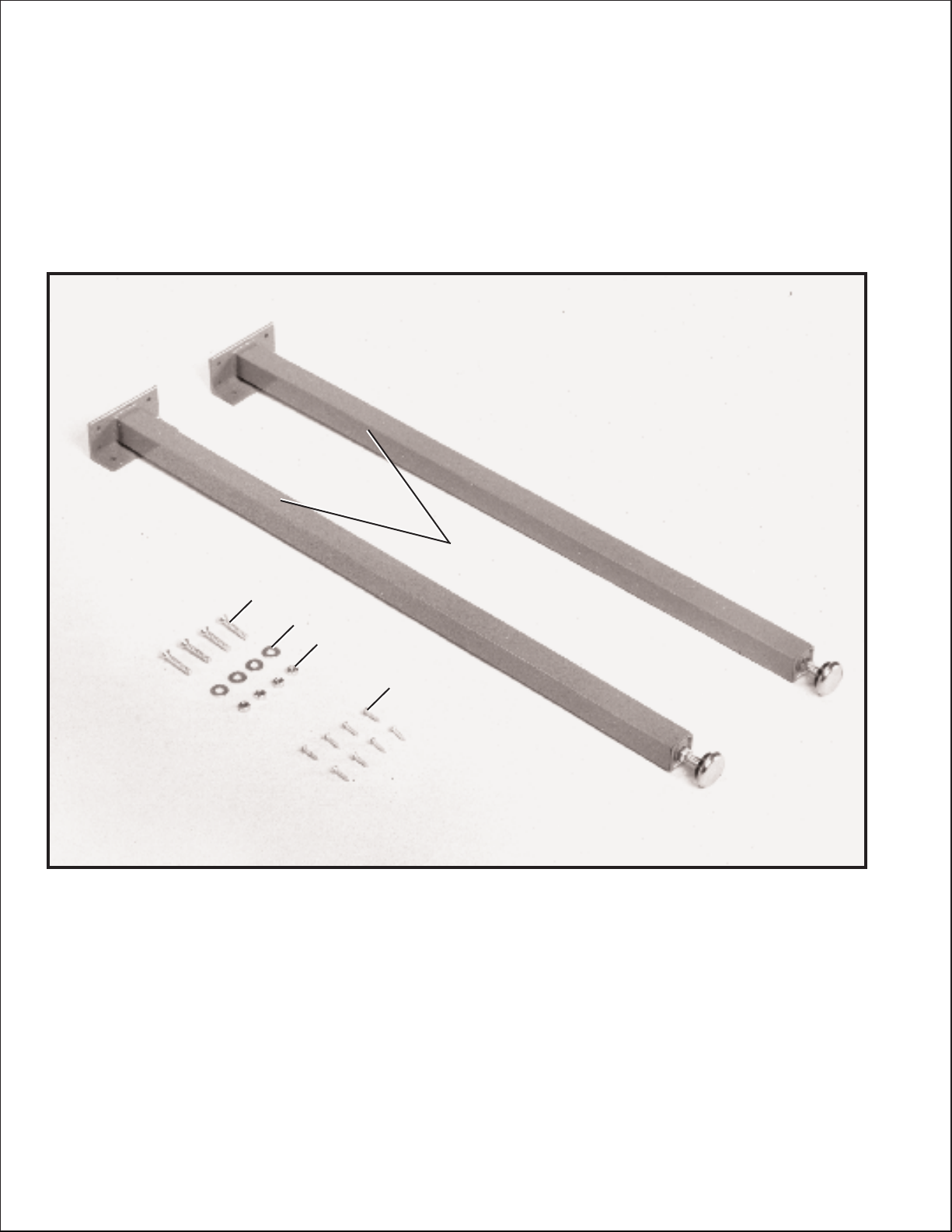

If you purchased the accessory leg kit (model 78-952) for use with the right

extension t able, Figure 4 illustrates the legs and loose items supplied with

this accessory.

1 - Legs (2)

2 - 5/8 long wood screws #8 (8)

3 - 1/4-20 x 1-1/2 long flat head Phillip s screws (4)

4 - 1/4 flat washers (4)

5 - 1/4-20 hex nut s (4)

ASSEMBLY INSTRUCTIONS

When retrofitting the T -SquarefiFence System to t able saws that have been

equipped with original equipment fence, guide rails and extension wings, remove

the fence, front and rear guide rails and right hand extension wing from the saw.

If you purchased the saw and T -Squarefifence system as a promotional item,

assemble the saw as explained in the machine instruction manual and proceed to

assemble the T -Squarefifence to the saw as follows:

1. DISCONNECT THE S AW FROMTHEPOWER SOURCE.

3

4

5

2

1

Page 5

Fig. 5

Fig. 6

Fig. 7

Fig. 8

2. Assemble the front rail (A) Fig. 5, to front of saw t able

using the two 3/8-16 x 1-1/4 long flat head Phillip s

screws (B), 7/8 flat washers, lock washers and 3/8-16

hex nut s supplied. Screws (B) are inserted through the

two holes in the front rail, as shown and through the two

through holes in the front of the saw t able and fastened

to the t able with the flat washers, lockwashers and hex

nut s. IMPORTANT:Do not completely tighten front

rail mounting hardware at this time.

3. Using the template (D) Figures 6 and 7, check and

adjust front rail at both ends of the saw t able as shown,

to make sure rail (A) is level with t able surface and

tighten rail mounting hardware (B). IMPORTANT:

Template (D) must be on saw table when checking,

not on extension wing.

4. Assemble rear rail (E) Fig. 8, to rear of saw t able

using the two 3/8-24 x 1-1/4 long hex head screws (F),

7/8 flat washers and lockwashers as shown. NOTE:

When mounting fence to Unisaws, the two screws (F) are

threaded into the threaded holes in the saw t able, as

shown. When mounting fence to 10 Tilting Arbor Saws

or 10 Contractor s Saws, through holes are provided

instead of threaded holes on the rear edge of the saw

table. In this case the rear rail (E) is fastened to the t able

with the two hex head screws (F) and the flat washers,

lockwashers and hex nut s will be inside the rear ledge of

the saw t able.

5 Make certain top edge of rail (E) Fig. 8 is below t able

surface and that top edge of cut-out s (G) are below miter

gage slot s before tightening screws (F).

6.If the t able saw is equipped with a lef t hand sheet

metal extension wing, fasten the front rail (A) Fig. 7, to

the sheet met al extension wing with the 1-1/4 long flat

head Phillip s screw through hole (C) Fig. 7, in the front

rail and through the slot in the sheet metal extension

wing. Fasten the rear rail (E) Fig. 8, to the sheet metal

extension wing with the 1-1/4 long hex head screw

through hole (H) Fig. 8, in the rear rail and through the

slot in the sheet metal extension wing. Fasten both the

front and rear rails in place using the flat washers, lock

washers and hex nuts supplied.

A

B

A

B

D

C

A

B

D

E

F

G

G

F

H

Page 6

6

Fig. 9

Fig. 10

Fig. 1 1

8. Position the two legs (H) Fig. 10, at the two far corners

of the inside of one end of the extension t able, as shown,

and mark the position of the eight holes to be drilled into

the bottom of the t able. IMPORTA N T:If your saw and

fence system will be used with a mobile base under neath the saw base and table legs, the position of the

legs may have to be changed to fit onto the mobile

base. Remove the two legs (H) and using a 1/16 drill

bit, drill the eight holes 1/2 deep. Replace the two legs

and fasten to the bottom of the t able using the eight 3/4

long wood screws ( I) supplied.

9. Figure 11 illustrates one of the legs (H) fastened to

the bottom of the extension t able with the four wood

screws ( I). Using a 1/4 drill bit, drill two through holes

through the end piece (J) of the t able using the two holes

(K) as a template.

7. If you did not purchase the accessory right extension t able for use with your

T-Squarefifence, construct an extension t able by following the dimensions shown

in Fig. 9.

H

H

I

I

H

K

K

I

M

J

Page 7

Fig. 12

Fig. 13

Fig. 14

Fig. 15

10. Fasten the leg bracket (L) Fig. 12, to the end piece

(J) of the t able using the two 1-1/2 long flat head

Phillip s screws, flat washers and hex nuts (M) Figs. 1 1

and 12. Fasten the remaining leg to the extension t able

in the same manner.

11. Figure 13 illustrates the two legs (H) assembled to

the bottom of the t able.

12. Place t able assembly (N) Fig. 14, in position

between the two rails, as shown. Make sure end of t able

(O) is flush against saw t able (P) and using a bar clamp

(Q) snug up end of rails to hold t able in position. Using a

straight edge make sure t able (O) is in the same plane

and level with saw t able (P). Lightly t ap t able up or down

and adjust leveling screws (R) Fig. 15, in bottom of

legs to accomplish this. When you are cert ain t able (O)

Fig. 14, is level and in the same plane with saw t able (P),

tighten bar clamp (Q) to hold everything in position. Then

drill 1/4 through holes through the front and rear of the

extension t able using the holes (S) provided in rails as

template. NOTE: Number of holes (S) in the front and

rear rails will vary depending on the length of the rails

you purchased.

J

L

M

M

H

P

O

N

S

Q

R

Page 8

Fig. 17

Fig. 18 Fig. 19

16. Figure 19 illustrates the switch and nipple (W)

assembled to the switch adapter (X). The switch adapter

will be fastened to the front rail (A) and guide tube

through holes (Y) in the front rail af ter the guide tube is

fastened to the front rail (A).

15. Assemble the switch and nipple (W) Fig. 18, to switch

adapter for Unisaws (X) supplied with your T-Square fence.

14. If you are assembling the T-Squarefifence to a Delt a

Unisawfithat has the on-of f switch (W) Fig. 17, suspended

from the bottom of the saw t able, as shown, remove the

switch and nipple (W) from the bottom of the saw t able.

13. Af ter the holes have been drilled in the edge of the front and rear extension

table board, fasten both front and rear rail to t able using the 1-1/2 flat head

Phillip s screws (T) Fig. 16, 1-1/4 O.D. flat washers (U) and hex nuts (V).

Fig. 16

T

T

U

V

W

Z

X

W

Y

X

A

W

Page 9

Fig. 20

Fig. 21

Fig. 22

Fig. 23

17. Lay the guide tube (B) Fig. 20, on the saw t able as

shown, and line up the threaded holes (C) on bottom of

guide tube (B) with the through holes (D) on the front rail

(A). IMPORTAN T:If a switch adapter is being used for

Unisaws or 10 Contractor s Saws to mount the

switch to the rail and guide tube, holes (E) are used

to mount the Unisaw switch adapter and holes (F)

will be used for the Contractor s Saw switch adapter .

22. On the Contractor s S a w , att ach the switch (M)

Fig. 23, to the switch adapter (K) using the 1 long hex

screw (N), flat washer , lockwasher and hex nut supplied.

18. Position the guide tube (B) Figs. 21 and 22, on the

front rail and fasten the guide tube to the rail using the

1/2 long hex screws (G) and lockwashers in all of the

holes except the ones used to fasten the switch adapter

if applicable.

19. Figure 21 illustrates the Unisaw switch adapter (H)

mounted to the front rail and guide tube using two 3/4

long hex screws (J) and lockwashers.

20. Figure 22 illustrates the Contractor s Saw switch

adapter (K) mounted to the front rail guide tube using two

3/4 long hex screws (J) and lockwashers.

21. NOTE: If there is not enough cord (L) Figs. 21 and

22, available to pull out and reposition the switch, simply

cut the cable strap holding the cord to the inside of the

saw cabinet. After switch is repositioned, make cert ain

that the cord does not come into cont act with the saw

blade and use the cable clamp supplied with the fence to

hold the cord in position.

A

B

C

D

F

F

E

E

B

G

G

J

J

H

L

G

L

K

B

J

N

K

M

Page 10

Fig. 24

Fig. 25

Fig. 26

FENCE OPERATION

IMPORTANT: Before operating fence, make sure the fence is adjusted parallel to

the miter gage slot, as explained later on in this manua l.

1. To move the fence along the guide rail, simply lif t

up clamp lever (A) as shown in Fig. 24, slide fence to

desired position on rail, and push down on clamp lever

(A) as shown in Fig. 25, to lock fence in position. NOTE:

A magnet (E) Fig. 25, is provided to hold clamp handle

(A) Figs. 24 and 25, in the up position when moving the

fence.

2. The dist ance the fence is positioned away from the

blade is indicated by the witness line (B) Fig. 26, located

on the cursor (C). If it is necessary to adjust the cursor

(C), make a test cut with the fence locked in position.

Measure the width of the finished cut and adjust the

cursor (C) by loosening the two screws (D), adjusting the

cursor (C) until the witness line (B) is aligned with the

same marking on the scale as the finished cut. Then

tighten the two screws (D).

A

A

B

C

D

E

Page 11

Fig. 27

Fig. 28

Fig. 29

Fig. 30

ADJUSTING FENCE

PARALLEL TO

MITER GAGE SLOTS

NOTE: Delt a t able saws have been aligned at the factory

so that the miter gage slot s in the t able are p arallel with

the saw blade. It is recommended, however, to check

and make certain this alignment is correct before adjust ing the fence p arallel to the miter gage slot as follows:

The fence (A) Fig. 27, must be adjusted so it is p arallel to

the miter gage slot s (B). To check and adjust, move

fence (A) until the bottom edge of the fence is in line with

the edge of one of the miter gage slot s as shown, and

push down on the fence clamping lever (C). Check to see

if the fence (A) is p arallel to the miter gage slot the entire

length of the t able. If an adjustment must be made, lif t up

fence locking lever (C) and raise fence up of f the guide

tube, as shown in Fig. 28. Slightly tighten or loosen one

of the two adjusting screws (D) or (E) Fig. 28, using a

3/16 allen wrench (F), not supplied. Replace the fence

on the guide tube and check again to see if the edge of

the fence is p arallel with the miter gage slot the entire

length of the slot. Repeat this adjustment until you are

sure the fence is p arallel with the miter gage slot.

IMPORTANT:VERY LITTLE MOVEMENT OF SCREWS

(D) A N D (E) IS NECESSARY TO ADJUST THE

FENCE PARALLEL WITH THE MITER GAGESLOT.

ADJUSTING CLAMPING

ACTION O F FENCE

LOCKING HANDLE

When the fence locking handle (A) is pushed to the down

position, as shown in Fig. 29, the fence assembly (B)

should be completely clamped to the guide tube (C). If

the fence assembly (B) is not completely clamped to the

guide tube (C) when the handle (A) is pushed down, as

shown in Fig. 29, lif t up handle (A) and raise fence

assembly (B) up of f the guide tube (C). Slightly tighten

the two adjusting screws (D) and (E) Fig. 30, using the

3/16 allen wrench (F) not supplied. Adjusting screws

(D) and (E) Fig. 30, should be tightened an equal

amount. Replace fence onto the guide tube and recheck to see if the fence assembly (B) Fig. 29, is com pletely tightened to the guide tube (C) with the locking

handle (A) pushed down. Adjust further if necessary.

IMPORTANT:AFTER ADJUSTING THE CLAMPING

ACTION O F TH E FENCE LOCKING HANDLE, CHECK

TO SEE IF THE FENCE IS PARALLEL TO THE MITER

GAGESLOT AN D ADJUST IF NECESSARY.

A

C

B

E

F

D

A

C

B

F

D

E

Page 12

LUBRICATION

1. Apply paste wax to fence and guide tube sliding sur faces weekly. Also, saw t able and extension t able surface

should be waxed of ten.

2. Apply grease to cam lock (A) Fig. 31, and cam foot (B)

occasionally to prevent wear.

Fig. 31

Delt a will rep air or replace, at it s expense and at it s option, any Delt a machine, machine part, or machine

accessory which in normal use has proven to be defective in workmanship or material, provided that the

customer notifies his supplying distributor of the alleged defect within two years from the date of delivery

to him, of the product and provides Delt a Machinery with reasonable opportunity to verify the defect by

inspection. Delt a Machinery may require that electric motors be returned prep aid to the supplying dis tributor or authorized service center for inspection and rep air or replacement. Delta Machinery will not be

responsible for any asserted defect which has resulted from misuse, abuse or rep air or alteration made

or specifically authorized by anyone other than an authorized Delt a service facility or represent ative.

Under no circumst ances will Delta Machinery be liable for incident al or consequential damages resulting

from defective product s. This warranty is Delt a Machinery s sole warranty and set s forth the custome rs

exclusive remedy, with respect to defective products; all other warranties, express or implied, whether of

merchantability , fitness for purpose, or otherwise, are expressly disclaimed by Delt a.

Two Y ear Limited Warranty

Delt a Machinery

Printed in U.S.A.

PARTS, SERVICE OR WARRANTY ASSISTANCE

To obt ain additional information regarding this product or to obt ain p art s, service or warranty

assist ance, please call or fax the following toll free Hotline number . Highly qualified and

experienced Customer Service Representatives are st anding by to assist you on weekdays

from 7:00 A M to 5:00 PM Mountain S tandard T ime.

Biesemeyer

fi

a subsidiary of Delt a W oodworking Machinery

216 South Alma School Rd., Suite 3

Mesa, AZ 85210

Phone: Hotline: Fax:

(602) 835-9300 (800) 782-1831 (602) 834-8515

A

B

Loading...

Loading...