Page 1

®

T-SQUARE® MITER SAW TABLES AND CUT-OFF STOPS

Miter Tables for 10” Saws (Models 78-802, 78-804, 78-806, 78-808)

Miter Tables for 12” and Slide Saws (Models 79-803, 79-804, 79-806, and 79-808)

Cut-Off Saw Stops ( Model 78-989, 78-990, 78-992, and 78-994)

Part No. 1351767

Dated 5-1-2001

INSTRUCTION MANUAL

Page 2

INTRODUCTION

Biesemeyer® T-Square® Miter Tables and Saw Stops are designed to fit all miter saws and used in conjunction with the

adhesive backed measuring tapes that read right-to-left (left hand) and left-to-right (right-hand). Tapes are available in

English or Metric/English combination. The use of the stops along with the accessory tables and measuring tapes eliminate the need for cumbersome C-clamps and hand-held measuring tapes, and will make any motorized miter saw more

accurate, more productive and more economical to use. The following instructions explain the assembly procedure when

using the table system with a Delta miter or slide saw and these instructions are the same for other brands and models of

miter and slide saws.

SEPATGNIRUSAEMDEKCAB-EVISEHDA

.oNledoMhtgneLhtdiWepyT

*650-97toof21hcni2/1hsilgnE/cirteM,dnahthgiR

*750-97toof21hcni2/1hsilgnE/cirteM,dnaHtfeL

160-97toof21hcni2/1hsilgnE,dnaHthgiR

260-97toof21hcni2/1hsilgnE,dnaHtfeL

*460-97toof21hcni4/3hsilgnE/cirteM,dnaHthgiR

560-97toof21hcni4/3hsilgnE,dnaHthgiR

*760-97toof6hcni4/3hsilgnE/cirteM,dnaHthgiR

660-97toof21hcni4/3hsilgnE,dnaHtfeL

860-97toof6hcni4/3hsilgnE,dnaHthgiR

960-97toof6hcni2/1hsilgnE,dnaHthgiR

070-97toof6hcni2/1hsilgnE,dnaHtfeL

*170-97toof6hcni2/1cirteM/hsilgnE,dnaHtfeL

* Metric/English tapes are not compatible with the Inside Miter Cutoff Saw Stop or the Inside Miter Cutoff Stop.

ASSEMBLY INSTRUCTIONS

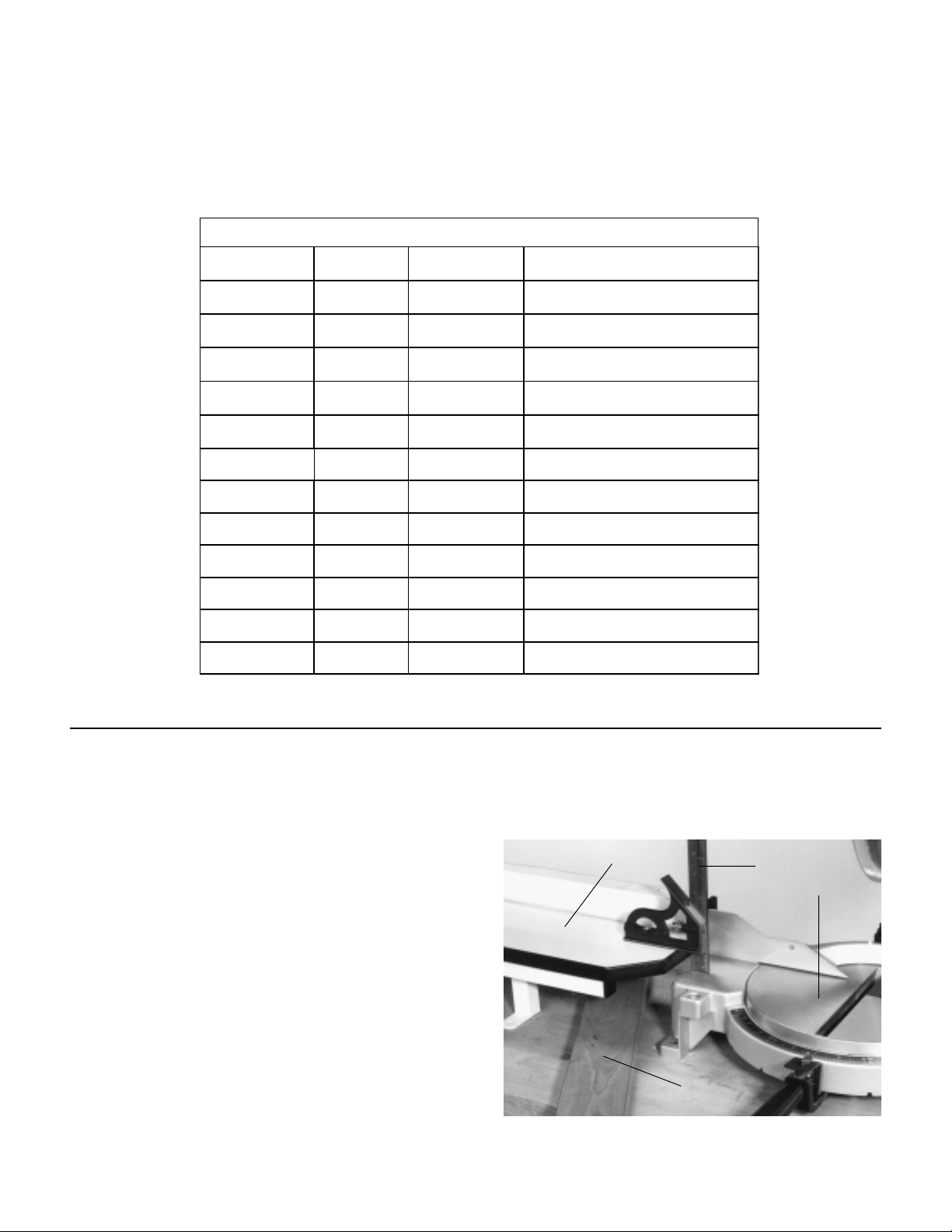

1. Place the saw tables, one of which is shown at (A) Fig. 2,

on a workbench or other suitable flat surface.

2. Position the miter saw (B) Fig. 2, next to the miter table as

shown, and using a combination square (C), measure the

distance the saw table is below the surface of the miter table.

NOTE: If the saw table is higher than the surface of the miter

table, the miter tables will have to be raised to the same level

as the saw table in the same manner.

A

C

B

3. Plane a piece or pieces of hardwood stock (D) Fig. 2, to

the same thickness that the saw is below the miter table surface. This is the distance which was determined in STEP 2.

D

Fig. 2

2

Page 3

4. Mount the miter saw to the planned stock (D) Fig. 3, and

using a straight edge (E), make certain the saw table surface is level with the miter table surface, as shown in Fig. 3,

and that the saw fence (F) is in line with the fence (A) of the

miter tables, as shown in fig. 4

5. IMPORTANT: If you are attaching a scale to the top

of the miter table fence, it is important to determine if

the miter saw is a center pivot saw in order to accurately use the scale. This can be done as follows

E

D

Fig. 3

A

F

E

A

F

6. Cut a piece of stock (G) Fig. 5, at the 45 degree left miter

angle and without moving the work piece, make a mark on

the miter table fence at the end of the work piece, as shown.

7. Move the miter arm (P) to the 90 degree straight cut-off

position, as shown in Fig. 6, and slide the workpiece (G)

until it contacts the saw blade teeth. If the stock does not

change position, you have a center pivot saw which can be

fastened to the top of the workbench with the saw fence in

line with the miter table fence. If the workpiece did move,

make a second mark on the miter table fence at the end of

the workpiece at its new position, as shown.

D

Fig. 4

G

Fig. 5

G

3

P

Fig. 6

Page 4

8. Measure the distance between the two marks (H) Fig. 7,

and plane a piece of stock to this dimension. The height and

length of the stock should be the same size as the miter saw

fence.

9. Fig. 7 illustrates the piece of stock (J) which will be fastened to the left miter fence.

10. Fig. 8 illustrates both the left and right fence halves (J)

fastened to the saw fence. These fence halves were fabricated in STEP 8.

11. Fasten the miter saw (K) and miter tables (L) Fig. 8, to

the workbench or other suitable flat surface, making certain

that the saw table surface (K) is level with the miter table

surface (L), and that the saw fence (J) is in line with the miter

table fence.

J

H

H

Fig. 7

M

J

L

12. IMPORTANT: If the miter saw you are using is

equipped with a sliding fence, the sliding fence (N) Fig.

9, must either be removed or modified so that it will slide

over the top of the miter table fence (M).

T APE INSTALLATION

1. Make a 90 Degree straight cut-off on a workpiece (H) Fig.

10, as shown. Make certain that the workpiece (H) extends

over onto the miter table (J). Without moving the workpiece

(H), make a mark (K) on the miter table fence at the end of

the workpiece. Extend the mark (K) to the top of the miter

table fence as shown.

2. Measure the length of the cut-off workpiece (H) Fig. 10.

Line up the mark on the measuring tape with the mark (K)

Fig.1 1 on the miter table fence that corresponds to the length

of the cut-off workpiece. In this case, the length is 14 inches.

3. Trim the ends of the tape to the desired length and remove the backing from the tape. Carefully install tape (L)

Fig. 11, to the top center of the miter table fence, lining up

the marks determined in STEP 2.

M

L

M

J

K

Fig. 8

N

4. Use a roller to press the tape securely to the surface.

J

H

K

Fig. 10 Fig. 1 1

Fig. 9

K

L

4

Page 5

78-989 DUAL POINTER

CUT-OFF STOP

The 78-989 Dual Pointer Cut-Off Stop, shown in Fig. 12,

gives precise settings to 1/64th of an inch. An adjustable

stop screw (C) positively limits the workpiece (D), as shown,

and should be adjusted to the scale and cursor (A). The

dual pointer cut-off stop can be used on the right hand side

of the saw blade by using the cursor (E) and stop screw

(F).

78-990 DUAL POINTER OUT-

SIDE/CUT-OFF MITER STOP

The 78-990 Dual Pointer Outside/Cut-Off Miter Stop is designed to act as a positive stop for 90 degree cut-off

workpieces, as shown in Fig. 13, or 45 degree outside

workpieces, as shown in Fig. 14. The stop (B) is adjustable by loosening locknut (A) Figs. 13 and 14, adjusting

the stop (B), and tightening locknut (A). Cursor (C) Figs.

13 and 14, is provided for 90 degree square cuts and cursor (D) is used for 45 degree miter cuts. The cursors (C)

and (D) are adjustable by loosening screws (E), adjusting

the cursor and tightening the screws. This stop is designed

to be used on either side of the saw blade, as an extra set

of cursors and stop are provided on the opposite end of

the miter stop.

78-992 DUAL POINTER FLIP

A

E

C

F

Fig. 12

E

D

E

A

B

Fig. 13

D

C

STOP

The 78-992 Dual Pointer Flip-Stop is used mainly when

making repetitive cutting operations, as shown in Fig. 15,

and then flipped up out of the way with lever (A) when not

in use. For more convenience, the Flip-Stop can be used

with two or more stops as shown at (B) and (E) Fig. 16,

and positioned as close as 4-1/2 inches apart anywhere

along the fence for making multiple, often used repetitive

cuts without having to remeasure. Fig. 16 illustrates lever

(A) flipped up out of the way and stop (B) used to position

the workpiece. An adjustable stop screw (D) Fig. 15, positively limits the workpiece, as shown, and should be adjusted to the scale and cursor (C). The cursor (C) Fig. 15,

is supplied on each side of the stop, enabling you to use

the stop on either side of the saw blade.

C

C

D

E

D

C

E

A

B

Fig. 14

E

B

A

Fig. 15

A

Fig. 16

5

Page 6

78-994 DUAL POINTER IN-

SIDE/CUT-OFF MITER STOP

F

E

The 78-994 Dual Pointer Inside/Cut-off Miter Stop is designed to act as a positive stop for 90 degree cut-off

workpieces, as shown in Fig. 17, or 45 degree inside miter

angles, as shown in Fig. 18. The outside edge of the 45

degree miter angle is suppported by the adjustable stop

block (C), as shown in Fig. 18. The stop can be used on

either the right or left side of the saw blade as the stop bar

(B) can be removed and inserted into the other end of the

bracket by loosening the two screws (A) Figs. 17 and 18,

Removing stop bar (B) and inserting stop bar into opposite

end of bracket, making sure indent in stop bar is engaged

with end of screw (A). Cursor (D) Figs. 17 and 18, is used

for straight 90 degree cuts and cursor (E) is used when

cutting 45 degree miter angles. The cursors (D) and (E)

are adjustable by loosening screws (F), adjusting cursors

(D) and (E) , and tightening screws (F).

B

A

F

D

Fig. 17

F

E

B

A

F

D

C

Fig. 18

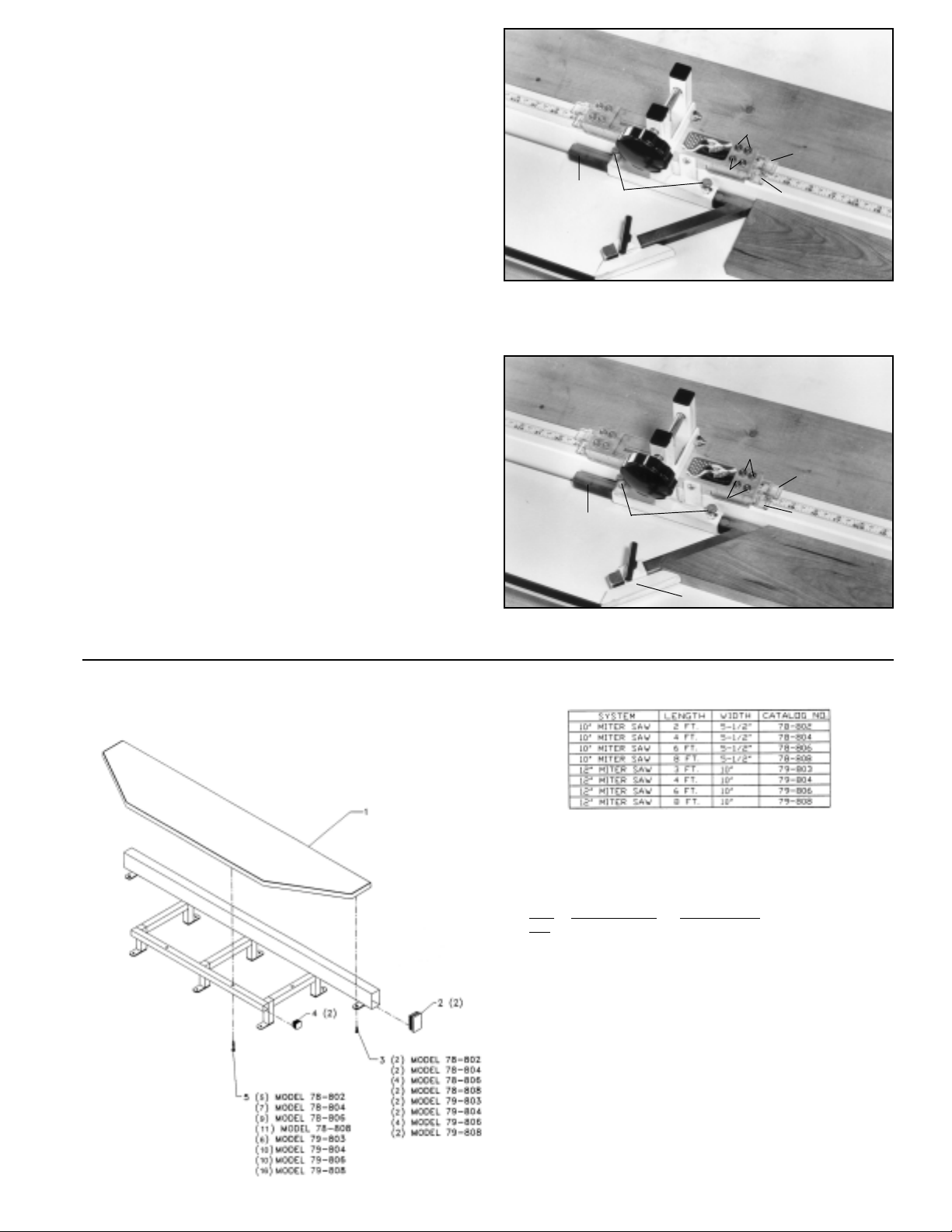

REPLACEMENT PARTS

MITER SA W TABLE

78-802, 78-804, 78-806, 78-808

79-803, 79-804, 79-806, 79-808

REF. PART NUMBER DESCRIPTION

NO.

* OPTIONAL MITER SAW TABLE ASSY,

1 1351825 TABLE (5-1/2” x 2’)

1 1351826 TABLE (5-1/2” x 4’)

1 1351827 TABLE (5-1/2” x 6’)

1 1351828 TABLE (5-1/2” x 8’)

1 1351861 TABLE (10” x 3’)

1 1351862 TABLE (10” x 4’)

1 1351863 TABLE (10” x 6’)

1 1351864 TABLE (10” x 8’)

2 1351823 END CAP

3 1350441 #10 X 5/8” PH PN HD SCREW

4 1351824 END CAP

5 1351911 #10 X 1-1/2” PAN HD SCREW

* NOT SHOWN ASSEMBLED

INCL:

6

Page 7

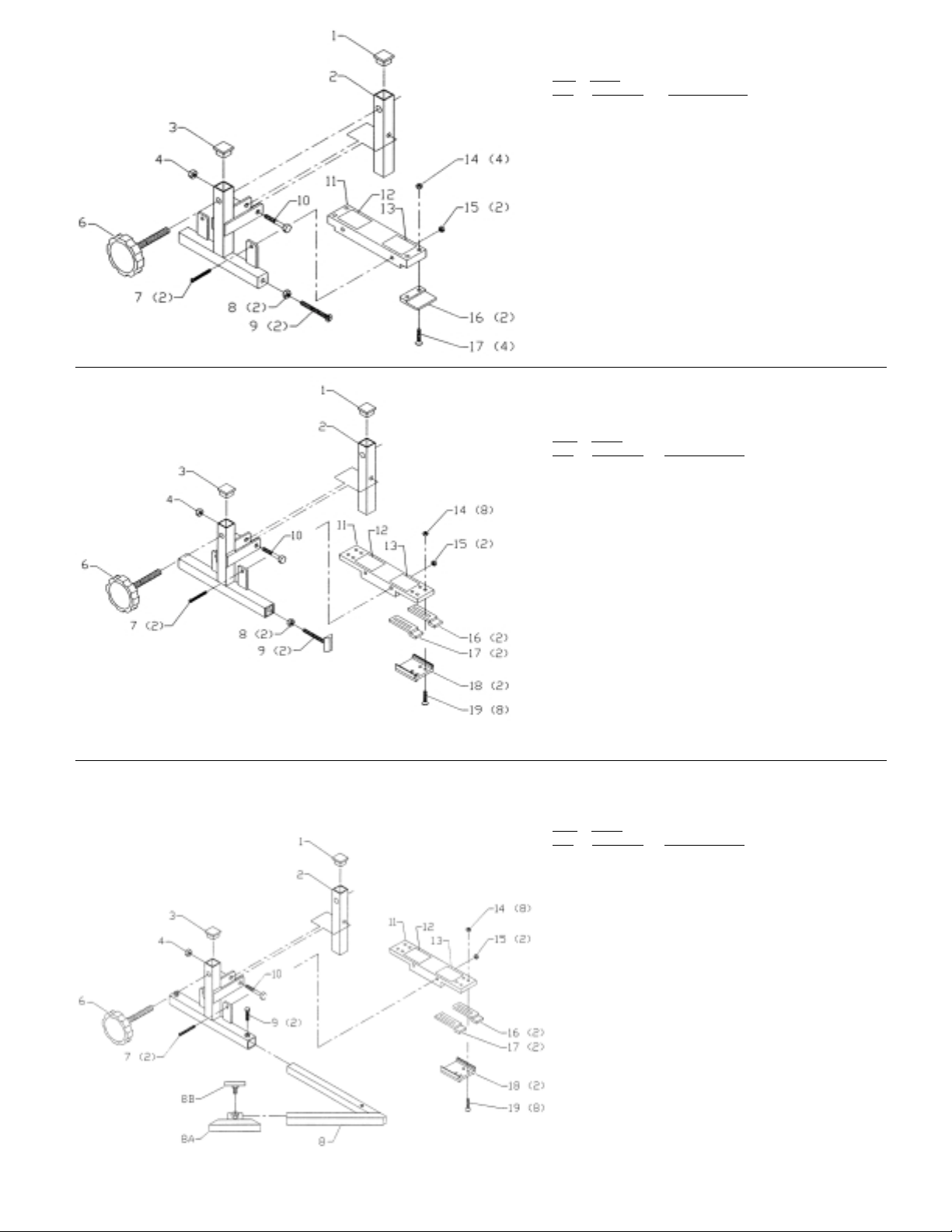

78-989

DUAL POINTER CUTOFF SA W STOP

REF PART

NO. NUMBER DESCRIPTION

* 78-989 DUAL POINTER CUTOFF SAW STOP,

1 1350191 END CAP

2 1350192 CLAMP BAR

3 1350191 END CAP

4 1350280 1/4-20 LOCK NUT

6 1350188 KNOB

7 1350408 #10-32 X 1-3/4" PAN HD SCR

8 1350409 5/16-18 HEX NUT

9 1350410 5/16-18 X 2” FLAT HD SCR

10 1350303 1/4-20 X 1-1/2” HEX HD SCR

11 1351312 SLIDE BLOCK

12 1350207 NAMEPLATE

13 1350077 FLAG DECAL

14 1350315 #10-32 HEX NUT

15 1350315 #10-32 HEX NUT

16 1350189 CURSOR

17 1350411 #10-32 X 7/8” FLAT HD SCR

* NOT SHOWN ASSEMBLED

INCL:

78-990

DUAL POINTER OUTSIDE MITER

CUTOFF SA W STOP

REF. PART

NO. NUMBER DESCRIPTION

* 78-990 DUAL POINTER OUTSIDE MITER

CUTOFFSAW STOP

1 1350191 END CAP

2 1350192 CLAMP BAR

3 1350191 END CAP

4 1350280 1/4-20 LOCK NUT

6 1350188 KNOB ASSY

7 1350408 #10-32 X 1-3/4” PAN HD SCREW

8 1350409 5/16-18 HEX NUT

9 1350980 FOOT ASSY

10 1350303 1/4-20 X 1-1/2” HEX HD SCREW

11 1351315 SLIDE BLOCK

12 1350207 NAMEPLATE

13 1350077 FLAG DECAL

14 1350698 #08-32 HEX NUT

15 1350315 #10-32 HEX NUT

16 1350694 CURSOR (RED)

17 1350696 CURSOR (BLACK)

18 1350693 CURSOR CLAMP

19 1350697 #08-32 X 7/8" FLAT HD SCREW

* NOT SHOWN ASSEMBLED

, INCL:

78-994

DUAL POINTER INSIDE MITER

CUTOFF SAW STOP

REF. PART

NO. NUMBER DESCRIPTION

* 78-994 DUAL POINTER INSIDE MITER CUTOFF

1 1350191 END CAP

2 1350192 CLAMP BAR

3 1350191 END CAP

4 1350280 1/4-20 LOCK NUT

6 1350188 KNOB ASSY

7 1350408 #10-32 X 1-3/4” PAN HD SCREW

8 1352139 SLIDE BAR

8A 1350975 INSIDE MITER STOP

8B 1350809 WING SCREW

9 1350295 1/4-20 X 1/2” HEX HD SCREW

10 1350303 1/4-20 X 1-1/2” HEX HD SCREW

11 1351315 SLIDE BLOCK

12 1350207 NAMEPLATE

13 1350077 FLAG DECAL

14 1350698 #08-32 HEX NUT

15 1350315 #10-32 HEX NUT

16 1350694 CURSOR (RED)

17 1350696 CURSOR (BLACK)

18 1350693 CURSOR CLAMP

19 1350697 #08-32 X 7/8” FLAT HD SCREW

* NOT SHOWN ASSEMBLED

SAW STOP

, INCL:

7

Page 8

78-992

DUAL POINTER FLIP-STOP

REF. PART

NO. NUMBER DESCRIPTION

* 78-992 DUAL POINTER FLIP-STOP,

1 1350191 END CAP

2 1350280 1/4-20 LOCK NUT

3 1350413 #10-32 X 1-1/4" HEX SOC SET SCREW

4 1350408 #10-32 X 1-3/4” PAN HD SCREW

5 1350212 FLIP ASSY

6 1350203 KNOB

7 1350409 5/16-18 HEX NUT

8 1360412 5/16-18 X 1-1/2” FLAT HD SCREW

9 1350414 5/16-18 X 1-1/4” HEX HD SCREW

10 1350308 5/16" FLATWASHER

11 1350411 #10-32 X 7/8” FLAT HD SCREW

12 1350189 CURSOR

13 1350315 #10-32 HEX NUT

14 1350315 #10-32 HEX NUT

15 1350206 NAMEPLATE

16 1351318 SLIDEBLOCK

17 1350303 1/4-20 X 1-1/2” HEX HD SCREW

18 1350202 CLAMP ASSY

19 1350066 KNOB ASSY

* NOT SHOWN ASSEMBLED

INCL:

PARTS, SERVICE OR WARRANTY ASSISTANCE

This product is manufactured to high quality standards and is serviced by a network of

Factory Service centers and Authorized Service Stations.

To obtain additional information regarding this product, or to obtain parts, service or

warranty assistance, please call our toll-free numbers. Highly qualified and experienced

Customer Service Representatives are standing by to assist you.

PORTER CABLE/DELTA

4825 HWY 45 N

Jackson, TN 38302

Toll Free:

(800) 223-7278

Hours:

BIESEMEYER

216 South Alma School Rd.

Suite 3

Mesa, AZ 85210

Toll Free:

(800) 782-1831

®

Weekdays

7:00 AM to 5:00 PM

Central Standard Time

E-Mail:

mail@biesemeyer.com

Hours:

Weekdays

7:30 AM to 4:00 PM

Mountain Standard Time

Loading...

Loading...