Page 1

3 Speed digital ambient

air Cleaner

Système numérique de filtration

de l’air ambiant à 3 vitesses

Purificador digital de aire ambiental

de 3 velocidades

Français (12)

Español (22)

www.DeltaMachinery.com

Instruction manual

Manuel d’utilisation

Manual de instrucciones

INSTRUCTIVO DE OPERACIÓN, CENTROS

DE SERVICIO Y PÓLIZA DE GARANTÍA.

LÉASE ESTE INSTRUCTIVO

ANTES DE USAR EL PRODUCTO.

50-871

Page 2

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS .................................. 2

SAFETY GUIDELINES - DEFINITIONS ................................... 2

GENERAL SAFETY RULES ..................................................... 3

FUNCTIONAL DESCRIPTION ................................................. 5

POWER CONNECTIONS ......................................................... 4

MOTOR SPECIFICATIONS ...................................................... 4

GROUNDING INSTRUCTIONS ................................................ 4

EXTENSION CORDS ................................................................ 5

CARTON CONTENTS ............................................................... 5

UNPACKING AND CLEANING ................................................6

INSTALLATION OPTIONS ........................................................ 6

OPERATION .............................................................................. 8

TROUBLESHOOTING .............................................................. 8

MAINTENANCE ........................................................................ 9

ACCESSORIES ........................................................................ 10

WARRANTY ............................................................................. 10

FRANÇAIS ................................................................................ 12

ESPAÑOL .................................................................................22

IMPORTANT SAFETY INSTRUCTIONS

READ AND UNDERSTAND ALL WARNINGS AND OPERATING INSTRUCTIONS BEFORE

USING THIS EQUIPMENT. Failure to follow all instructions listed below, may result in

electric shock, fire, and/or serious personal injury or property damage.

Woodworking can be dangerous if safe and proper operating procedures are not followed. As with all machinery,

there are certain hazards involved with the operation of the product. Using the machine with respect and caution

will considerably lessen the possibility of personal injury. However, if normal safety precautions are overlooked or

ignored, personal injury to the operator may result. Safety equipment such as guards, push sticks, hold-downs,

featherboards, goggles, dust masks and hearing protection can reduce your potential for injury. But even the best

guard won’t make up for poor judgment, carelessness or inattention. Always use common sense and exercise

caution in the workshop. If a procedure feels dangerous, don’t try it. Figure out an alternative procedure that feels

safer. REMEMBER: Your personal safety is your responsibility. For additional information please visit our website

www.DeltaMachinery.com.

This machine was designed for certain applications only. DELTA

strongly recommends that this machine not be modified and/or used for any application other than

that for which it was designed. If you have any questions relative to a particular application, DO NOT use the

machine until you have first contacted DELTA® to determine if it can or should be performed on the product.

If you have any questions relative to its application DO NOT use the product until you have written DELTA

Equipment Corporation and we have advised you. Contact us online at www.DeltaMachinery.com or by mail at

Technical Service Manager, DELTA® Power Equipment Corporation, 4825 Highway 45 North, Jackson, TN 38305.

Information regarding the safe and proper operation of this tool is available from the following sources:

®

Power Equipment Corporation

®

Power

• Power Tool Institute, 1300 Sumner Avenue, Cleveland, OH 44115-2851or online at www.powertoolinstitute.com

• National Safety Council, 1121 Spring Lake Drive, Itasca, IL 60143-3201

• American National Standards Institute, 25 West 43rd Street, 4 floor, New York, NY 10036 www.ansi.org - ANSI 01.1

Safety Requirements for Woodworking Machines

• U.S. Department of Labor regulations www.osha.gov

SAFETY GUIDELINES - DEFINITIONS

This manual contains information that is important for you to know and understand. This information relates to

protecting YOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we

use the symbols below. Please read the manual and pay attention to these sections.

Indicates an imminently hazardous situation which, if not avoided, will result in death or serious

injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious

injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate

injury.

Used without the safety alert symbol indicates potentially hazardous situation which, if not avoided,

may result in property damage.

2

Page 3

GENERAL SAFETY RULES

FAILURE TO FOLLOW THESE RULES MAY RESULT IN SERIOUS PERSONAL INJURY.

FOR YOUR OWN SAFETY, READ AND UNDERSTAND THE INSTRUCTION MANUAL BEFORE OPERATING THE

•

UNIT.

Learn the unit’s application and limitations as well as the specific hazards peculiar to it.

KEEP WORK AREA CLEAN.

•

DON’T USE IN DANGEROUS ENVIRONMENT.

•

Keep work area well-lighted.

KEEP CHILDREN AND VISITORS AWAY.

•

DISCONNECT UNIT

•

CHECK DAMAGED PARTS.

•

before servicing.

Cluttered areas and benches invite accidents.

Don’t use this unit in damp or wet locations, or expose it to rain.

All children and visitors should be kept a safe distance from work area.

Before further use of the unit, properly repair or replace any part that is damaged.

FAILURE TO FOLLOW THESE RULES MAY RESULT IN SERIOUS INJURY.

DO NOT USE THIS UNIT TO FILTER

METAL DUST. Combining wood and

metal dust can create an explosion or fire hazard. This

unit is intended to filter non-explosive atmospheres

only.

DO NOT USE THIS UNIT TO

DISSIPATE FUMES OR SMOKE.

Explosions or fire can result. This air cleaner is

intended for use where only dry airborne dust is

present. Its use should be limited to non-explosive,

non-metallic atmospheres.

1. DO NOT operate this UNIT until it is completely

assembled and installed according to the

instructions. A unit incorrectly assembled can cause

injury.

2. OBTAIN ADVICE from your supervisor, instructor, or

another qualified person if you are not thoroughly

familiar with the operation of this unit. Knowledge is

safety.

3. FOLLOW ALL WIRING CODES and recommended

electrical connections to prevent electrical shock or

electrocution.

4. DO NOT LIFT THIS UNIT BY THE POWER CORD.

Do not use the power cord as a hanging device. A

damaged power cord can cause electrical shock or

electrocution.

5. SECURELY ANCHOR THIS UNIT to a permanent or

fixed supporting structure when suspending it from

the ceiling. A falling unit can cause serious injury.

Always keep a minimum of 7 feet between the bottom

of the unit and the floor surface to allow for sufficient

head clearance. Use only a chain rated for a minimum

of 150 lb. working load to adequately hold the unit.

Use steel S-Hooks that are at least 1/4" in diameter to

suspend the unit from the ceiling. Lag-type bolts used

to suspend the unit from the ceiling must be threaded

at least 1-1/2" into supporting structural members.

6. SUPPORT THIS UNIT or securely clamp it to the work

surface when it is used in a portable application to

eliminate potential injury and/or damage to the unit.

7. ENSURE THAT THE INTAKE AND EXHAUST AREAS

ARE CLEAR prior to starting the unit. Clogged intakes

or exhausts can cause an explosion and/or fire.

8. KEEP ARMS, HANDS, and fingers AWAY FROM THE

FAN. Avoid all exposure to rotating parts to prevent

injury.

9. DO NOT OPERATE THIS UNIT WITHOUT THE FILTERS

IN PLACE. Dust and other small debris will go directly

to the motor, causing over-heating and the potential for

fire and/or explosion.

10. DO NOT ATTEMPT to remove or replace the filter(s)

while the unit is running. Exposed fan blades can

cause severe cuts. Make certain that the unit is

disconnected from the power source.

11. MAINTAIN THE UNIT in top condition. Clogged filters

can increase the potential for fire or explosion. Follow

all instructions for changing and cleaning filters.

12. STORE THE UNIT in a location that eliminates the

potential for damage to the power cord. A damaged

power cord can cause shock or electrocution. Safely

store power cord on the unit to eliminate tripping

hazards.

13. TURN THE UNIT “OFF” and disconnect the unit

from the power source before installing or removing

accessories, before adjusting or changing set-ups, or

when making repairs. An accidental start-up can cause

serious injury.

14. UNPLUG machine from power source before

servicing, changing filter, unclogging or cleaning unit.

15. REPLACE or repair damaged or worn cord

immediately.

16. DO NOT operate any fan with a damage cord or plug.

Discard fan or return to an authorized service facility for

examination and/or repair.

17. DO NOT run cord under carpeting. DO NOT cover with

throw rugs, runners, or similar coverings. Arrange cord

away from traffic area and where it will not be tripped

over.

SAVE THESE INSTRUCTIONS.

Refer to them often and use them to instruct others.

3

Page 4

POWER CONNECTIONS

A separate electrical circuit should be used for your machines. This circuit should not be less than #12 wire and

should be protected with a 20 Amp time lag fuse. If an extension cord is used, use only 3-wire extension cords

which have 3-prong grounding type plugs and matching receptacle which will accept the machine’s plug. Before

connecting the machine to the power line, make sure the switch (s) is in the “OFF” position and be sure that the

electric current is of the same characteristics as indicated on the machine. All line connections should make good

contact. Running on low voltage will damage the machine.

DO NOT EXPOSE THE MACHINE TO RAIN OR OPERATE THE MACHINE IN DAMP LOCATIONS.

MOTOR SPECIFICATIONS

Your machine is wired for 120 volts, 60 HZ alternating current. Before connecting the machine to the power source,

make sure the switch is in the “OFF” position.

GROUNDING INSTRUCTIONS

THIS MACHINE MUST BE GROUNDED WHILE IN USE TO PROTECT THE OPERATOR FROM

ELECTRIC SHOCK.

1. All grounded, cord-connected machines:

In the event of a malfunction or breakdown, grounding provides a path of least resistance for electric current to

reduce the risk of electric shock. This machine is equipped with an electric cord having an equipment-grounding

conductor and a grounding plug. The plug must be plugged into a matching outlet that is properly installed and

grounded in accordance with all local codes and ordinances.

Do not modify the plug provided - if it will not fit the outlet, have the proper outlet installed by a qualified electrician.

Improper connection of the equipment-grounding conductor can result in risk of electric shock. The conductor with

insulation having an outer surface that is green with or without yellow stripes is the equipment-grounding conductor.

If repair or replacement of the electric cord or plug is necessary, do not connect the equipment-grounding conductor

to a live terminal.

Check with a qualified electrician or service personnel if the grounding instructions are not completely understood,

or if in doubt as to whether the machine is properly grounded.

Use only 3-wire extension cords that have 3-prong grounding type plugs and matching 3-conductor receptacles that

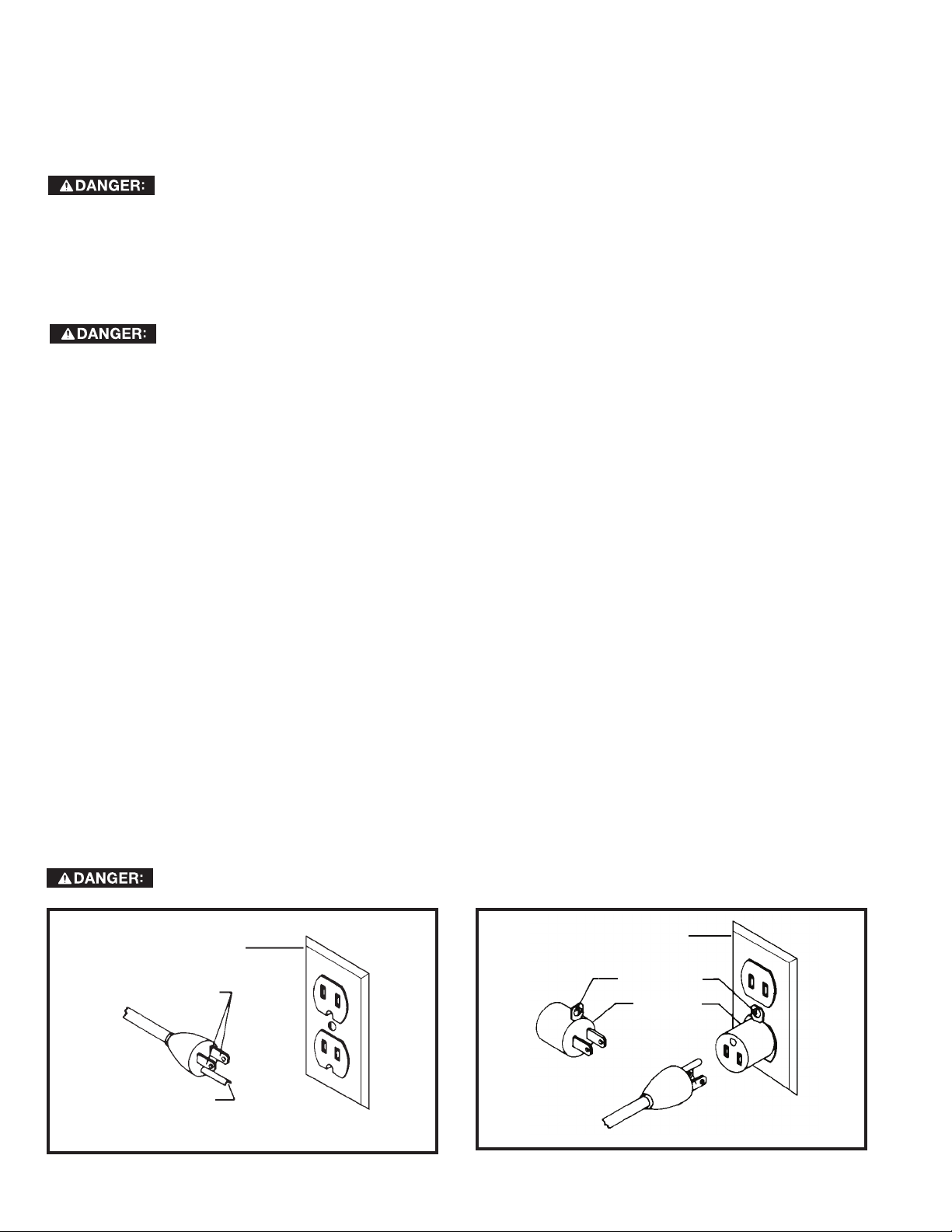

accept the machine’s plug, as shown in Fig. A.

Repair or replace damaged or worn cord immediately.

2. Grounded, cord-connected machines intended for use on a supply circuit having a nominal rating less than

150 volts:

If the machine is intended for use on a circuit that has an outlet that looks like the one illustrated in Fig. A, the

machine will have a grounding plug that looks like the plug illustrated in Fig. A. A temporary adapter, which looks like

the adapter illustrated in Fig. B, may be used to connect this plug to a matching 2-conductor receptacle as shown

in Fig. B if a properly grounded outlet is not available. The temporary adapter should be used only until a properly

grounded outlet can be installed by a qualified electrician. The green-colored rigid ear, lug, and the like, extending

from the adapter must be connected to a permanent ground such as a properly grounded outlet box. Whenever the

adapter is used, it must be held in place with a metal screw.

NOTE: In Canada, the use of a temporary adapter is not permitted by the Canadian Electric Code.

IN ALL CASES, MAKE CERTAIN THE RECEPTACLE IN QUESTION IS PROPERLY GROUNDED.

IF YOU ARE NOT SURE, HAVE A QUALIFIED ELECTRICIAN CHECK THE RECEPTACLE.

GROUNDED

OUTLET BOX

CURRENT

CARRYING

PRONGS

GROUNDING BLADE

IS LONGEST OF THE 3 BLADES

FIG. A FIG. B

4

GROUNDED OUTLET BOX

GROUNDING

MEANS

ADAPTER

Page 5

EXTENSION CORDS

Use proper extension cords. Make

sure your extension cord is in good

condition and is a 3-wire extension cord which has a

3-prong grounding type plug and matching

receptacle which will accept the machine’s plug.

When using an extension cord, be sure to use one

heavy enough to carry the current of the machine.

An undersized cord will cause a drop in line voltage,

resulting in loss of power and overheating. Fig. C

shows the correct gauge to use depending on the

cord length. If in doubt, use the next heavier gauge.

The smaller the gauge number, the heavier the cord.

MINIMUM GAUGE EXTENSION CORD

RECOMMENDED SIZES FOR USE WITH STATIONARY ELECTRIC MACHINES

Ampere

Rating

0-6

0-6

0-6

0-6

6-10

6-10

6-10

6-10

10-12

10-12

10-12

10-12

12-16

12-16

12-16

Volts Total Length

120

120

120

120

120

120

120

120

120

120

120

120

120

120

120

of Cord in

Feet

up to 25

25-50

50-100

100-150

up to 25

25-50

50-100

100-150

up to 25

25-50

50-100

100-150

up to 25

25-50

GREATER THAN 50 FEET NOT RECOMMENDED

FIG. C

Gauge of Extension

Cord

18 AWG

16 AWG

16 AWG

14 AWG

18 AWG

16 AWG

14 AWG

12 AWG

16 AWG

16 AWG

14 AWG

12 AWG

14 AWG

12 AWG

FUNCTIONAL DESCRIPTION

FOREWORD

Model 50-871 3 Speed Digital Ambient Air Cleaner is specifically designed to quietly circulate and filter nonmetallic dust which is generated throughout the work area. The Air Cleaner is furnished with two filters: an outer

filter which filters particles that are five microns and larger, and a secondary disposable filter that captures 91%

of the dust particles that are one micron and larger (one micron = one millionth of a meter). Because breathing

microscopic particles can be a potential health hazard, filtering microscopic dust particles offers a cleaner and

safer environment. This Air Cleaner will filter the air in a room measuring 20’ x 20’ x 8’ either 13, 16, or 18 times an

hour, depending on the setting. If desired, multiple units can be used to filter larger areas. An occasional cleaning

and/or replacement of filters is the only required maintenance.

CARTON CONTENTS

1. Air cleaner

FIG. 1A

FIG. 1B

2. Remote Control Unit

(Batteries not included)

3. 1" Eye-Bolts (4)

4. Rubber Feet (4)

5. 5/16" Flange nuts (4)

5

Page 6

UNPACKING AND CLEANING

The Air Cleaner is shipped complete in one shipping container. Carefully unpack the Air Cleaner and all loose items

from the shipping container.

Styrofoam blocks have been packed inside the unit for protection. REMOVE THESE BLOCKS (A) Fig. 2 prior to use.

To Remove:

1. Disconnect unit from power source.

2. Remove outer filter by lifting up on the bottom and pulling out (Fig. 2A).

3. Remove inner filter by lifting up on the bottom and pulling out (Fig. 2B).

4. Remove styrofoam blocks (A) Fig. 2C and replace filters.

DO NOT LIFT THE AIR CLEANER BY POWER CORD.

FIG. 2A FIG. 2B FIG. 2C

INSTALLATION OPTIONS

Determine whether the Air Cleaner will be used on the floor, on a bench, or hanging from an overhead support.

If the Air Cleaner will be used as a mobile unit, proceed to “USING THE AIR CLEANER ON A BENCH OR FLOOR

SURFACE” section. If the unit will be ceiling-mounted, proceed to section “MOUNTING THE AIR CLEANER TO A

CEILING OR OVERHEAD SUPPORT.”

IMPORTANT: When determining where to mount the air cleaner, always select a location where the air flow is

unrestricted. Do not locate the unit in a corner or near any heating or cooling vents.

USING THE AIR CLEANER ON A BENCH OR FLOOR SURFACE

Locate (4) self-adhesive rubber feet (A) Fig. 3 supplied with the unit. Carefully place the Air Cleaner on a firm

supporting surface with access to the bottom of the cabinet. Apply a self-adhesive rubber foot (A) Fig. 3 to the

bottom at each corner of the air cleaner cabinet. The rubber feet will help eliminate vibration and will prevent the

possibility of the air cleaner “walking” across the floor or work surface.

For operator safety, clamp the unit to a work bench or position it securely on sawhorses.

The air cleaner cabinet has convenient lifting handles located on either side (one of which is shown at (A) Fig. 4). To

avoid damage to the air filters, carry the air cleaner with the filters positioned away from your body.

FIG. 3 FIG.4

6

Page 7

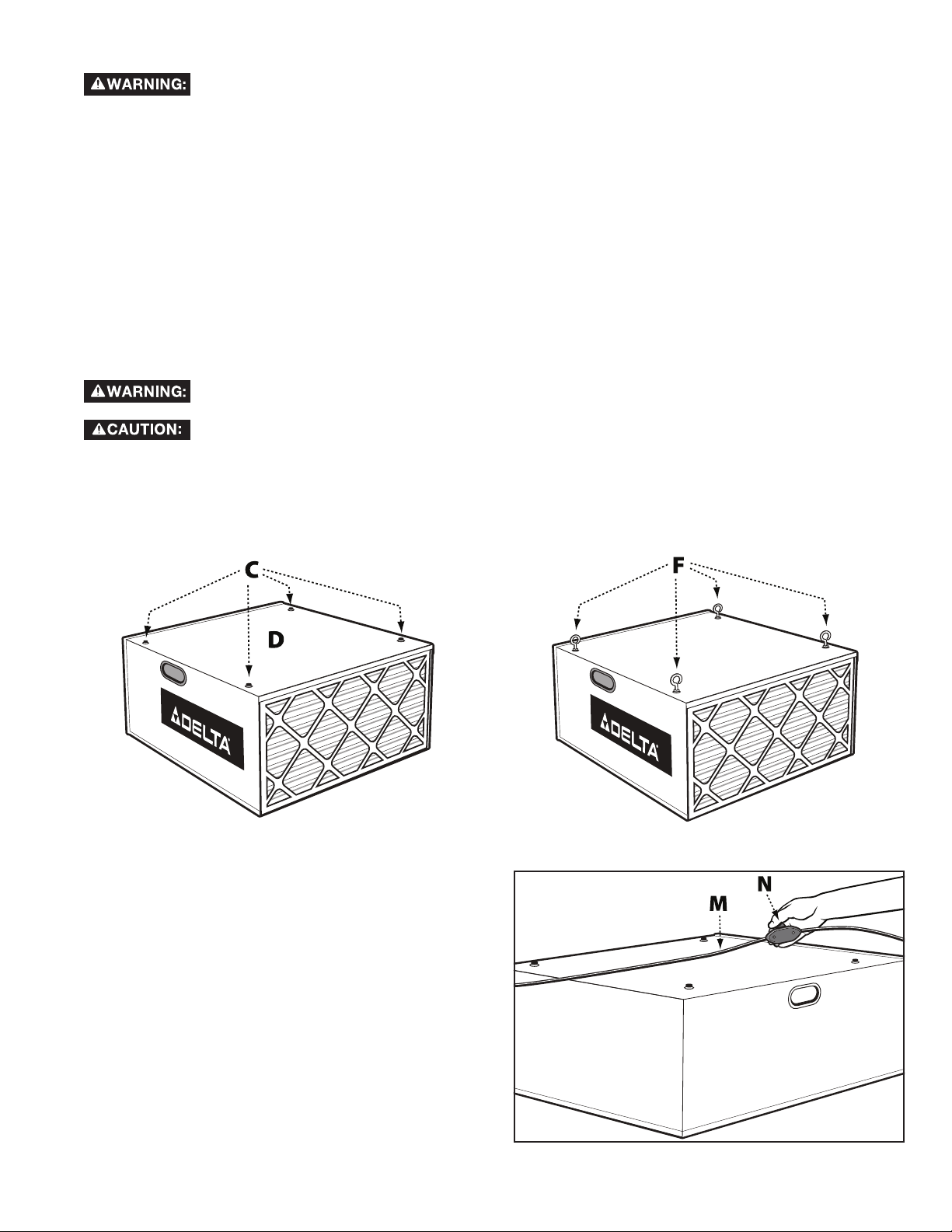

MOUNTING THE AIR CLEANER TO THE CEILING OR OVERHEAD SUPPORT

This unit weighs approximately 60 pounds. When mounting overhead, be certain that the unit is

securely fastened and supported.

1. Locate the four 1" eye bolts and the four 5/16" Flange nuts supplied with the unit.

2. Use a flat blade screwdriver (not supplied) to remove the four screws (C) Fig. 5 from the top of air cleaner (D).

3. Thread one flange nut on each bolt approximately 5/16".

4. Thread the eye-bolts (F) Fig. 6 into the four holes where the screws were removed in STEP 2.

NOTE: Be certain that the flange nuts are tightened against the surface of the air cleaner.

NOTE: When suspending the air cleaner from the ceiling or other overhead support, use steel s-hooks that are a

minimum of 5/16".

NOTE: Thread all lag hooks at least 1-1/2" into the supporting structural members.

Never secure the air cleaner hardware to drywall, drop ceiling tile/frame, or other non-structural members.

Keep a minimum of seven feet between bottom of air cleaner and the floor surface.

Do not use rope, cable, or power cord to suspend the unit from the ceiling. Use chain rated

for a minimum of a 150 lb. working load.

IMPORTANT: When determining a location to mount the unit, the air cleaner will operate more efficiently when the air

flow is unrestricted. Do not locate the unit in a corner or near any heating or cooling vents.

FIG. 5 FIG. 6

ON/OFF SWITCH

The Air Cleaner is equipped with an in-line rocker

switch (M) Fig.7, located on the power cord (N). To

start or stop the motor, press downward on the rocker

switch, according to the markings on the side. When

you are finished with the air cleaner, turn the switch off

rather than unplug the unit.

NOTE: The ON-OFF Switch must be turned “ON”

before using the remote control feature.

FIG. 7

7

Page 8

USING THE REMOTE CONTROL

To reduce the risk of fire or electric

shock, do not use this unit with any

solid-state speed control device.

The remote control provided with this unit is not

considered a solid-state device.

The Air Cleaner is equipped with a REMOTE CONTROL

(A) Fig.8A.

NOTE: The remote requires two (2) AAA batteries (not

supplied). The Battery housing is located underneath

the back cover.

Notice that the remote control has three control buttons

(Fig. 8A): TIME (B), ON/OFF (C), and SPEED (D). These

buttons correspond to the LED sensor panel on the

rear of the machine (K) Fig. 8B.

NOTE: When the machine is connected to the power

source, a green light (E) will be activated on the panel.

To activate the blower unit, press the "ON/OFF" button

(C) Fig. 8A. The machine will begin in the default speed

of HIGH on the sensor panel. Press the SPEED button

once, and the machine will run at the MEDIUM level.

Press the SPEED button again, and the machine will

run at the LOW level. Press the SPEED button a third

time, and the machine will return to HIGH speed mode.

To turn the machine off, press the “ON/OFF” button (C)

Fig. 8A.

This unit has a timer that can be set by remote control.

FIG. 8A FIG. 8B

When the machine is ON in the speed setting desired,

pressing the "TIME" button (B) Fig. 8A on the remote

control will set the machine to run for one hour.

Pressing the "TIME" button again will set the machine

to run for two hours. Notice that the light on the sensor

panel has now moved to the 2HR location (G) Fig. 8B.

When the "TIME" button is pressed a third time, the

machine will run for three hours. At this point the red

light will show up under the 1HR and 2HR locations.

When you press the "TIME" button a fourth time, the

unit will run for four hours. Notice that the indicator

light glows at the 4HR location. Pressing the "TIME"

button further will increase the time settings in one

hour increments to a maximum of fifteen hours.

All functions can be manually controlled by using the

two buttons on the sensor panel (K) Fig. 8B.

OPERATION

NOTE: The air cleaner may produce a slight odor for the first few hours of operation due to the protective coating

which is applied to internal components. This odor will dissipate and should be disregarded.

IMPORTANT: Never operate the air cleaner without air filters in place.

1. Make SURE that the filter material is correctly installed in place.

2. Plug in the power cord.

3. Press the ON/OFF button, START operation. (The RUN light will light up in the color of the relevant speed, and

the POWER light will stop flashing.)

4. Press the TIMER button to set the time, the MAX time setting is 15 hours.

The DELTA® 50-871 3 Speed Air Cleaner can be used in

a. bench-top sanding applications.

b. circular saw applications.

c. dry wall applications.

d. shop cleaning applications.

e. floor sanding applications.

f. any other application where non-metallic dust is a factor.

TROUBLESHOOTING

For assistance with your machine, visit our website at www.DeltaMachinery.com for a list of service centers or

call the DELTA® Power Equipment Corporation help line at 1-800-223-7278.

8

Page 9

MAINTENANCE

FILTER EXCHANGE

1. When CLEAN FILTER light illuminates, this means that the filter material needs to be changed.

2. After installing the new clean filter, make SURE to press CLEAN FILTER for 5 seconds, at which the POWER light

will begin to flash; PRESS the ON/OFF button to start operation.

3. Remove the outer first stage filter (A) Fig. 9A by lifting and pulling out on the bottom of the filter. Replace the

first stage filter depending on its condition. When you replace the outer filter, check to see if the filter has an

air flow arrow (A) Fig 9C. If so, point the arrow inward. If the filter does not have an air flow arrow, install the

filter either way.

When CLEAN FILTER light illuminates, this means that the filter material needs to be changed.

After installing the new clean filter, make SURE to press CLEAN FILTER for 5 seconds, at which the POWER light will

begin to flash; PRESS the ON/OFF button to start operation.

Compressed air can be dangerous. For operator safety, do not exceed an air pressure of 30 psi.

Do not point the air nozzle toward yourself or anyone else. Always wear safety glasses and a dust

mask when using compressed air.

4. Replace the filter, turn the unit "ON" and reset the digital indicator as below:

a) To reset the machine, press the RESET (Fig. 8B) button for about 5 seconds and wait for the CLEAN FILTER

signal to fade out. The PWR signal will start to flash; then press the ON/OFF button to run the machine.

RECOMMENDATIONS

If the pleated pre-filter has been changed 3 times, you MUST change the INNER filter once.

FIG. 9A

FIG. 9B

AIR FLOW

FIG. 9C

9

Page 10

ACCESSORIES

A complete line of accessories is available from your DELTA® Supplier, DELTA® Factory Service Centers, and DELTA®

Authorized Service Centers. Please visit our Web Site www.DeltaMachinery.com for an online catalog or for the

name or your nearest supplier.

Since accessories other than those offered by DELTA® have not been tested with this product,

use of such accessories could be hazardous. For safest operation, only DELTA® recommended

accessories should be used with this product.

PARTS, SERVICE OR WARRANTY ASSISTANCE

All DELTA® machines and accessories are manufactured to high quality standards and are serviced by a network of

DELTA® Factory Service Centers and DELTA® Authorized Service Centers. To obtain additional information regarding

your DELTA® quality product or to obtain parts, service, warranty assistance, or the location of the nearest service

center, please call 1-800-223-7278.

WARRANTY

To register your tool for warranty service visit our website at www.DeltaMachinery.com.

Five Year Limited New Product Warranty

DELTA® will repair or replace, at its expense and at its option, any new DELTA® machine, machine part, or machine accessory which in normal

use has proven to be defective in workmanship or material, provided that the customer returns the product prepaid to a DELTA

center or authorized service station with proof of purchase of the product within five years and provides DELTA

to verify the alleged defect by inspection. For all refurbished DELTA

for any asserted defect which has resulted from normal wear, misuse, abuse or repair or alteration made or specifically authorized by anyone

other than an authorized DELTA

damages resulting from defective products. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the

above limitation or exclusion may not apply to you. This warranty is DELTA

with respect to defective products; all other warranties, express or implied, whether of merchantability, fitness for purpose, or otherwise, are

expressly disclaimed by DELTA

1-800-223-7278. This warranty gives you specific legal rights and you may have other rights which vary in certain states or provinces.

LATIN AMERICA: This warranty does not apply to products sold in Latin America. For products sold in Latin America,

see country specific warranty information contained in the packaging, call the local company or see website for warranty

information.

®

service facility or representative. Under no circumstances will DELTA® be liable for incidental or consequential

®

. For further detail of warranty coverage and warranty repair information, visit www.DeltaMachinery.com or call

®

product, the warranty period is 180 days. DELTA® will not be responsible

®

’s sole warranty and sets forth the customer’s exclusive remedy,

®

with reasonable opportunity

®

factory service

10

Page 11

REPLACEMENT PARTS

Use only identical replacement parts. For a parts list or to order parts, visit our website at www.DeltaMachinery.com/service. You

can also order parts from your nearest factory-owned branch, Authorized Warranty Service Center or by calling Technical

Service Manager at 1-800-223-7278 to receive personalized support from one of our highly-trained representatives.

FREE WARNING LABEL REPLACEMENT

If your warning labels become illegible or are missing, call

1-800-223-7278

for a free replacement.

FOR YOUR OWN SAFETY

1. READ AND UNDERSTAND

INSTRUCTION MANUAL

BEFORE OPERATING AIR

CLEANER.

2. To reduce the risk of injury,

disconnect from power supply

before servicing or changing

filters.

3. When ceiling mounted,

install Air Cleaner at least 7

feet above floor.

4. If used, ceiling mounts must

be anchored to building

structure. Never secure

mounts to dry wall, drop

ceiling tile/frame or other

non-structural members.

5. To reduce the risk of electrical

shock, do not expose to water

or rain.

6. Use only for the collection of

dry airborne dust. Never duct

the Air Cleaner directly to a

machine. Never use the Air

Cleaner to dissipate fumes

or smoke.

PARA SU PROPIA SEGURIDAD

1. LEA Y ENTIENDA EL MANUAL DE

INSTRUCCIONES ANTES DE

OPERAR EL LIMPIADOR DE AIRE.

2. Desconecte la unidad de la fuente

de energía antes de renidar

servicio o cambiar filtros para

reducir el riesgo de lesionamiento.

3. Instale el Limpiador de Aire por lo

menos 213 cm sobre el nievel del

piso cuando se trate de una

instalación de techno.

4. De utilizarse, los montajes de

techno deben anclarse a la

estructura del edificio. Jamás

afiance los mentajes al muro en

seco, lozas o marcos de platones

u otros miembros no estructurales.

5. No exponga la unidad al agua ni

la lluvia para reducir el riesgo de

choques eléctricos.

6. Utilice la unidad soló para la

recolección de polvo aéreo seco.

Jamás conduzca el Limpiador de

Aire directamente a una máquina.

Jamás utilice el Limplador de Aire

para disipar emanaciones o humo.

410-09-752-0017

To reduce risk of injury from moving parts, unplug before

servicing. Keep hands away from moving parts. Only

operate with air filters installed.

Desenchute la máquina antes de rendir servicio para

reducir el riesgo de lesionamientos ocasionados por

piezas en movimiento. Aleje las manos de las piezas

en movimiento. Opere solo con los filtros de aire

instalados.

410-09-752-0018

SERVICE AND REPAIRS

All quality tools will eventually require servicing and/or replacement of parts. For information

about DELTA® Power Equipment Corporation, its factory-owned branches, or to locate an

Authorized Warranty Service Center, visit our website at www.DeltaMachinery.com/service

or call our Customer Care Center at 1-800-223-7278. All repairs made by our service centers are fully

guaranteed against defective material and workmanship. We cannot guarantee repairs made or attempted by

others. By calling this number you can also find answers to most frequently asked questions 24 hours/day.

You can also write to us for information at DELTA® Power Equipment Corporation, 4825 Highway 45 North,

Jackson, TN 38305 - Attention: Technical Service Manager. Be sure to include all of the information shown

on the nameplate of your tool (model number, type, serial number, date code, etc.)

11

Page 12

IMPORTANTES CONSIGNES DE SÉCURITÉ

ASSUREZ-VOUS D’AVOIR BIEN LU ET COMPRIS TOUTES LES MISES EN

GARDE ET LES CONSIGNES D’UTILISATION AVANT D’UTILISER CET

ÉQUIPEMENT. Le fait de ne pas respecter toutes les instructions ci-dessous,

peut avoir pour conséquence : choc électrique, incendie et/ou blessures graves ou dégâts matériels.

Le travail du bois peut être dangereux si des procédures d’utilisation sécuritaires et adéquates ne sont pas

respectées. Comme c’est le cas pour toute pièce de machinerie, certains dangers sont assortis à l’utilisation de

ce produit. En utilisant cet appareil selon les directives et avec prudence, vous réduirez grandement la possibilité

de blessures. Cependant, si les précautions normales de sécurité sont négligées ou ignorées, la personne utilisant

l’appareil pourra être blessée. L’équipement de sécurité comme les dispositifs de protection, bâtons poussoir,

dispositif de retenue à ressort, cales-guide, lunettes, masques anti-poussière et protecteurs d’oreilles peut réduire

les risques de blessures. Mais même les dispositifs de protection les plus efficaces ne pourront vous protéger

contre un manque de jugement, de soin ou d’attention. Utilisez toujours votre bon sens et faites preuve de prudence

dans l’atelier. Si une manœuvre vous semble dangereuse, ne la tentez pas. Essayez plutôt de trouver une autre

solution qui vous paraît plus sûre. RAPPELEZ-VOUS : Vous êtes responsable de votre propre sécurité. Pour des

renseignements complémentaires, rendez-vous sur notre site web à l’adresse www.DeltaMachinery.com.

Cet appareil a été conçu seulement pour certains types d’utilisation. DELTA® Power

Equipment Corporation recommande fortement que cet appareil ne soit ni modifié ni utilisé à

toute autre fin que celles pour lesquelles il a été conçu. Si vous avez des questions sur un type d’utilisation en

particulier, N’UTILISEZ PAS l’appareil avant d’avoir d’abord contacté DELTA® pour déterminer si elle peut ou si elle

devrait être réalisée avec ce produit.

Si vous avez des questions sur son utilisation, N’UTILISEZ PAS le produit tant que vous n’avez pas écrit à

DELTA® Power Equipment Corporation et obtenu une réponse de leur part. Contactez-nous en ligne sur www.

DeltaMachinery.com ou par courrier à l’adresse suivante : responsable du service technique, DELTA® Power

Equipment Corporation, 4825 Highway 45 North, Jackson, TN 38305.

• Les informations concernant l’utilisation sûre et correcte de cet outil sont disponibles auprès des sources suivantes :

• Power Tool Institute, 1300 Sumner Avenue, Cleveland, OH 44115-2851 ou en ligne sur HYPERLINK http://www.

powertoolinstitute.com/ www.powertoolinstitute.com

• National Safety Council, 1121 Spring Lake Drive, Itasca, IL 60143-3201

• American National Standards Institute, 25 West 43rd Street, 4 floor, New York, NY 10036 HYPERLINK http://www.

ansi.org/ www.ansi.org - ANSI 01.1 Exigences de sécurité pour machines à bois

• U.S. Department of Labor regulations www.osha.gov

CONSIGNES DE SÉCURITÉ - DÉFINITIONS

Ce manuel contient des informations qu’il est important de connaître et de comprendre. Ces informations ont pour

but d’assurer VOTRE SÉCURITÉ et de PRÉVENIR LES PROBLÈMES D’ÉQUIPEMENT. Pour vous aider à reconnaître

ces informations, nous utilisons les symboles ci-dessous. Veuillez lire le manuel et prêter attention à ces sections-là.

indique une situation dangereuse imminente qui, si elle n’est pas évitée, provoquera la mort ou une

blessure grave.

indique une situation dangereuse potentielle qui, si elle n’est pas évitée, provoquera la mort

ou une blessure grave.

indique une situation dangereuse potentielle qui, si elle n’est pas évitée, peut provoquer une

blessure mineure ou modérée.

utilisé sans le symbole d’alerte de sécurité indique une situation potentiellement dangereuse qui,

si elle n’est pas évitée, peut entraîner des dommages matériels.

12

FRANÇAIS

Page 13

RÈGLES DE SÉCURITÉ GÉNÉRALES

LE NON-RESPECT DE CES RÈGLES PEUT PROVOQUER DES BLESSURES GRAVES.

POUR VOTRE PROPRE SÉCURITÉ, LISEZ ET COMPRENEZ LE MANUEL D’UTILISATION AVANT DE METTRE EN ROUTE

•

L’APPAREIL.

MAINTENIR L’AIRE DE TRAVAIL PROPRE.

•

NE PAS UTILISER DANS UN ENVIRONNEMENT DANGEREUX.

•

et ne l’exposez pas à la pluie.Gardez votre aire de travail bien éclairée.

ÉLOIGNER LES ENFANTS ET LES VISITEURS.

•

de travail.

DÉBRANCHER L’APPAREIL

•

VÉRIFIER LES PIÈCES ENDOMMAGÉES.

•

Apprenez l’utilisation de l’unité et ses limites ainsi que les risques spécifiques qui lui sont propres.

Les aires et bancs de travail encombrés attirent les accidents.

N’utilisez pas cet appareil dans un endroit humide ou mouillé,

Tous les enfants et visiteurs doivent demeurer à une distance sécuritaire de l’aire

avant toute opération d’entretien.

Avant d’utiliser l’appareil, bien réparer ou remplacer toute pièce endommagée.

LE NON-RESPECT DE CES RÈGLES PEUT PROVOQUER DES BLESSURES GRAVES.

NE PAS UTILISER CET APPAREIL POUR

FILTRER DE LA POUSSIÈRE DE MÉTAL.

Le fait de combiner de la poussière de bois et de métal peut

générer un danger d’explosion ou d’incendie. Cet appareil

est conçu pour filtrer uniquement des atmosphères non

explosives.

NE PAS UTILISER CET APPAREIL POUR

DISSIPER DES VAPEURS OU DES

FUMÉES. Des explosions ou incendies peuvent en

résulter. Ce système de filtration de l’air est conçu pour

une utilisation où seule une poussière sèche est présente

dans l’air. Son utilisation devrait être limitée aux

atmosphères non explosives et non métalliques.

1. NE PAS faire fonctionner cet appareil tant qu’il n’est

pas complètement monté et installé en respectant

les instructions. Un appareil qui n’est pas monté

correctement peut provoquer des blessures.

2. DEMANDEZ CONSEIL à votre supérieur, instructeur

ou à une autre personne qualifiée, si vous n’êtes pas

familier avec le fonctionnement de cet appareil. Vos

connaissances sont garantes de votre sécurité.

3. RESPECTER TOUS LES CODES DE CÂBLAGE et

connexions électriques recommandés pour éviter un

choc électrique ou une électrocution.

4. NE PAS SOULEVER CET APPAREIL PAR LE

CORDON D’ALIMENTATION. Ne pas utiliser le cordon

d’alimentation comme un dispositif d’accrochage. Un

cordon d’alimentation endommagé peut provoquer un

choc électrique ou une électrocution.

5. BIEN FIXER CET APPAREIL à une structure de

support permanente ou fixe quand il est suspendu

au plafond. La chute d’un appareil peut provoquer

de graves blessures. Toujours garder un minimum de

2,15 m (7 pieds) entre le fond de l’appareil et la surface

du plancher pour garantir une distance suffisante

au-dessus de la tête. Utilisez uniquement une chaîne

capable de soutenir une charge de travail minimum de

68,2 kg (150 livres) de façon à bien maintenir l’appareil.

Utilisez des crochets d’acier en S d’un diamètre d’au

moins 6,4 mm (1/4 po) pour suspendre l’appareil au

plafond. Les tire-fonds utilisés pour suspendre

l’appareil au plafond doivent être filetés sur au moins

38 mm (1 1/2 po) dans la charpente.

6. SOUTENIR cet appareil ou le fixer solidement

à la surface de travail quand il est utilisé de façon

portable pour éviter les blessures potentielles et/ou

d’endommager l’appareil.

7. S’ASSURER QUE LES ZONES D’ENTRÉE ET

DE SORTIE SONT DÉGAGÉES avant de démarrer

l’appareil. Des zones d’entrée ou de sortie bouchées

peuvent provoquer une explosion et/ou un incendie.

8. GARDER SES BRAS, MAINS et doigts LOIN DES

PALES DU VENTILATEUR. Évitez tout contact avec les

pièces rotatives pour prévenir les blessures.

9. NE PAS UTILISER CET APPAREIL SANS LES

FILTRES EN PLACE. La poussière et autres petits

débris iront directement au moteur, ce qui provoquera

une surchauffe et un incendie et/ou une explosion

potentiels.

10. NE PAS TENTER d’enlever ou de remplacer le ou

les filtres lorsque l’appareil est en marche. Les pales

apparentes du ventilateur peuvent provoquer de graves

coupures. Assurez-vous que l’appareil est débranché

de la source d’alimentation.

11. MAINTENIR L’APPAREIL en excellent état. Des filtres

bouchés peuvent augmenter le risque d’incendie ou

d’explosion. Suivez les consignes pour changer et

nettoyer les filtres.

12. GARDER L’APPAREIL dans un endroit où le cordon

d’alimentation ne peut pas être endommagé. Un

cordon d’alimentation abîmé peut provoquer un choc

électrique ou une électrocution. Bien ranger le cordon

d’alimentation sur l’appareil pour éviter que quelqu’un

ne trébuche dessus.

13. ÉTEINDRE L’APPAREIL et le débrancher de la

source d’alimentation avant d’installer ou d’enlever

des accessoires, avant d’ajuster ou de modifier des

réglages ou avant de faire des réparations. Une mise en

route accidentelle peut provoquer de graves blessures.

14. DÉBRANCHEZ l’appareil de la source d’alimentation

avant de procéder à l’entretien ou au changement du

filtre, de déboucher ou de nettoyer l’unité.

15. REMPLACEZ ou réparez immédiatement tout cordon

d’alimentation endommagé ou usé.

16. NE faites PAS fonctionner un ventilateur dont

le cordon ou la fiche est endommagé. Éliminez le

ventilateur ou retournez-le auprès d’un centre de

réparation autorisé afin qu’il soit examiné et/ou réparé.

17. NE faites PAS passer le cordon sous un tapis ou une

moquette. NE couvrez PAS le cordon avec une moquette,

un tapis de passage ou autre. Disposez le cordon en dehors

des zones de passage, là où il ne fera pas trébucher.

CONSERVER CES CONSIGNES.

Consultez-les souvent et utilisez-les pour enseigner aux autres.

13

Page 14

BRANCHEMENTS

Un circuit électrique séparé doit être utilisé pour vos appareils. Ce circuit ne doit pas comporter de fils de calibre de moins de 12 et

doit être protégé par un fusible à action différée de 20 ampères. Si vous utilisez une rallonge, ne prenez que des rallonges à 3 fils avec

fiche de mise à la terre à 3 branches et un réceptacle correspondant qui acceptera la prise de l’appareil. Avant de brancher l’appareil

sur l’alimentation, assurez-vous que l’interrupteur est en position « OFF » et que le courant électrique que vous allez utiliser possède

les mêmes caractéristiques que celui indiqué sur l’appareil. Toutes les connexions électriques doivent établir un bon contact. Une

utilisation en basse tension endommagera l’appareil.

NE PAS UTILISER L’APPAREIL DANS UN ENDROIT HUMIDE OU MOUILLÉ, ET NE PAS L’EXPOSER

À LA PLUIE.

SPÉCIFICATIONS DU MOTEUR

Votre appareil est câblé pour un courant alternatif de 120 V, 60 Hz. Avant de brancher l’appareil sur la source d’alimentation, assurezvous que l’interrupteur est en position « OFF ».

DIRECTIVES DE MISE À LA TERRE

CET APPAREIL DOIT ÊTRE MIS À LA TERRE LORSQU’IL EST EN MARCHE POUR PROTÉGER

CELUI QUI LE MANIPULE D’UN CHOC ÉLECTRIQUE.

1. Pour tous les appareils branchés par un cordon d’alimentation et mis à la terre :

Dans le cas d’un dysfonctionnement ou d’une panne, la mise à la terre fournit un chemin de moindre résistance au courant électrique

pour réduire le risque de choc électrique. Cet appareil est équipé d’un cordon électrique possédant un conducteur de terre et une

fiche de terre. La fiche doit être branchée sur une prise correctement installée et mise à la terre conformément à tous les codes et

règlements locaux.

Ne pas modifier la fiche fournie - si elle n’entre pas dans la prise, faites installer une prise adéquate par un électricien qualifié. Un

branchement incorrect du conducteur de terre peut entraîner un risque de choc électrique. Le conducteur avec

un isolant comportant une surface extérieure verte, avec ou sans rayures jaunes, est le conducteur de terre.

Si la réparation ou le remplacement du cordon électrique ou de la fiche est nécessaire, ne pas brancher le conducteur de terre à une

borne sous tension.

Si les instructions de mise à la terre ne sont pas complètement comprises, ou si vous doutez que l’appareil soit correctement relié à la

terre, vérifiez avec un électricien qualifié ou le personnel de service.

Utilisez uniquement des rallonges à 3 fils avec fiche de mise à la terre à 3 branches et des réceptacles adaptés acceptant la prise de

l’appareil, tels que sur la Fig. A.

Réparez ou remplacez immédiatement un cordon abîmé ou usé.

2. Appareils reliés à la terre et branchés par l’intermédiaire d’un cordon d’alimentation destinés à une utilisation

sur un circuit d’alimentation ayant une puissance nominale de moins de 150 volts :

Si l’appareil est destiné à être utilisé sur un circuit possédant une sortie qui ressemble à celle dessinée sur la Fig. A, l’appareil aura

une prise de terre ressemblant à celle dessinée sur la Fig. A. Un adaptateur temporaire ressemblant à celui dessiné sur la Fig. B, peut

être utilisé pour connecter cette fiche à un réceptacle à 2 conducteurs comme dans la Fig. B si une prise de terre appropriée n’est pas

disponible. L’adaptateur temporaire doit être utilisé uniquement jusqu’à ce qu’une prise de terre appropriée puisse être installée par

un électricien qualifié. La cosse rigide de couleur verte, la patte, l’ergot, etc. sortant de l’adaptateur doivent être branchés à la terre

de façon permanente par l’intermédiaire d’une boîte de prise de terre. Chaque fois que l’adaptateur est utilisé, il doit être maintenu en

place avec une vis en métal.

REMARQUE : Au Canada, l’utilisation d’un adaptateur temporaire n’est pas autorisée par le Code canadien de l’électricité.

DANS TOUS LES CAS, ASSUREZ-VOUS QUE LE RÉCEPTACLE EN QUESTION EST BIEN RELIÉ

À LA TERRE. SI VOUS N’ÊTES PAS SÛR, FAITES VÉRIFIER LE RÉCEPTACLE PAR UN

ÉLECTRICIEN QUALIFIÉ.

PRISE DE

TERRE

FICHES

CONDUCTRICES DE

COURANT

FICHE DE MISE À

LA TERRE EST LA PLUS LONGUE DES 3 FICHES

FIG. A FIG. B

14

BOÎTE DE PRISE DE TERRE

BORNIERS

MOYENS

ADAPTATEUR

Page 15

RALLONGES

Utilisez des rallonges

adéquates. Assurez-vous

que votre rallonge est en bon état et que

c’est bien une rallonge 3 fils avec une fiche

de mise à la terre à 3 branches et un

réceptacle correspondant qui acceptera la

prise de l’appareil. Lorsque vous utilisez une

rallonge, assurez-vous qu’elle soit capable de

supporter le courant de l’appareil. Un cordon

de trop faible capacité provoquera une chute

de tension sur la ligne, entraînant une perte

de puissance et de la surchauffe. La Fig. C

montre la jauge appropriée du cordon de

prolongation à utiliser en fonction de sa

longueur. Si vous avez un doute, utilisez le

cordon de prolongation de jauge

immédiatement supérieur. Plus le numéro est

petit, plus la jauge est grosse.

AUGE MINIMUM POUR CORDON PROLONGATEUR

CALIBRES RECOMMANDÉS POUR UNE UTILISATION AVEC DES APPAREILS ÉLECTRIQUES STATIONNAIRES

Ampérage

Service

Nominal

0 À 6

0 À 6

0 À 6

0 À 6

6 À 10

6 À 10

6 À 10

6 À 10

10 À 12

10 À 12

10 À 12

10 À 12

12 À 16

12 À 16

12 À 16

Volts

120

120

120

120

120

120

120

120

120

120

120

120

120

120

120

Longueur Totale Du Cordon

25 À 50 (7,62 À 15,24 M)

50 À 100 (15,24 À 30,48 M)

100 À 150 (30,48 À 45,72 M)

25 À 50 (7,62 À 15,24 M)

50 À 100 (15,24 À 30,48 M)

100 À 150 (30,48 À 45,72 M)

25 À 50 (7,62 À 15,24 M)

50 À 100 (15,24 À 30,48 M)

100 À 150 (30,48 À 45,72 M)

25 À 50 (7,62 À 15,24 M)

En Pieds

JUSQU’À 25 (7,62 M)

JUSQU’À 25 (7,62 M)

JUSQU’À 25 (7,62 M)

JUSQU’À 25 (7,62 M)

LES RALLONGES DE PLUS DE 50 PIEDS (15,24 M) NE SONT PAS

FIG. C

RECOMMANDÉES

Jauge Des Fils

Électriques De La

Rallonge

18 AWG

16 AWG

16 AWG

14 AWG

18 AWG

16 AWG

14 AWG

12 AWG

16 AWG

16 AWG

14 AWG

12 AWG

14 AWG

12 AWG

DESCRIPTION DU FONCTIONNEMENT

AVANT-PROPOS

Le système de filtration de l’air DELTA® modèle 50-871 est spécifiquement conçu pour faire circuler et filtrer

silencieusement la poussière non métallique générée au sein de l’aire de travail. Le système de filtration de l’air

est fourni avec deux filtres : un filtre externe filtrant les particules de cinq microns et plus, et un filtre secondaire

jetable qui capte 91 % des particules de poussière d’un micron et plus (un micron = un millionième de mètre).

Étant donné qu’inhaler des particules microscopiques peut être un danger pour la santé, la filtration des particules

microscopiques de poussière offre un environnement plus propre et plus sûr. Ce système de filtration de l’air sera

en mesure de filtrer l’air d’une pièce mesurant 6 x 6 x 2,45 m (20 pi x 20 pi x 8 pi), 13, 16 ou 18 fois par heure, selon

le réglage. Si vous le souhaitez, plusieurs appareils peuvent être utilisés pour filtrer des zones plus vastes. Un

nettoyage et/ou le remplacement occasionnel des filtres est le seul entretien nécessaire.

CONTENU DU CARTON

FIG. 1A

1. Système de filtration de l’air

FIG. 1B

2. Télécommande

(Piles non comprises)

3. Boulons à œil (4) de 2,54 cm (1 po)

4. Supports en caoutchouc (4)

5. Écrous à bride de 5/16-20 (4)

15

Page 16

DÉBALLAGE ET NETTOYAGE

Le système de filtration de l’air est expédié complet dans une caisse d’expédition. Déballez minutieusement le

système de filtration de l’air et toutes les pièces détachées se trouvant dans la caisse d’expédition.

Des blocs de styromousse ont été emballés avec l’appareil pour le protéger. ENLEVER CES BLOCS (A) Fig. 2 avant

l’utilisation. Pour enlever :

1. Débrancher l’appareil de la source d’alimentation.

2. Retirer le filtre externe en soulevant le bas et en tirant vers l’extérieur (Fig. 2A).

3. Retirer le filtre interne en soulevant le bas et en tirant vers l’extérieur (Fig. 2B).

4. Retirer les blocs de styromousse (A) Fig. 2C et remplacer les filtres.

NE PAS SOULEVER LE SYSTÈME DE FILTRATION DE L’AIR PAR LE CORDON D’ALIMENTATION.

FIG. 2A FIG. 2B FIG. 2C

MONTAGE

Déterminez si le système de filtration de l’air sera utilisé sur le plancher, sur un établi ou s’il sera suspendu d’un support

en hauteur. Si le système de filtration de l’air est utilisé en tant qu’appareil mobile, allez à la section « UTILISER LE

SYSTÈME DE FILTRATION DE L’AIR SUR UN ÉTABLI OU SUR LE PLANCHER ». Si l’appareil est fixé au plafond, allez à

la section « FIXER LE SYSTÈME DE FILTRATION DE L’AIR AU PLAFOND OU À UN SUPPORT EN HAUTEUR. »

IMPORTANT : Au moment de décider de l’emplacement du système de filtration de l’air, toujours choisir un endroit où l’air

circule librement. Ne pas placer l’appareil dans un coin ou près de bouches de chauffage ou de refroidissement.

UTILISER LE SYSTÈME DE FILTRATION DE L’AIR SUR UN ÉTABLI OU

SUR LA SURFACE DU PLANCHER

Localiser (4) pieds en caoutchouc auto-adhésif (A) Fig. 3 fournis avec l’appareil. Placer avec précaution le système

de filtration de l’air sur une surface ferme où vous pourrez avoir accès à la partie inférieure de l’appareil. Placer

un pied en caoutchouc auto-adhésif (A) Fig. 3 sur la partie inférieure de l’appareil, à chaque coin. Les pieds en

caoutchouc aideront à supprimer la vibration et éviteront que le système de filtration de l’air se déplace à travers la

pièce ou l’aire de travail.

Pour la sécurité de celui qui le manipule, fixez l’appareil à un établi ou positionnez-le solidement sur des chevalets.

Le coffre du système de filtration de l’air est pourvu de poignées pratiques de chaque côté pour le soulèvement (une

d’entre elles est visible sur (A) la Fig. 4). Pour éviter d’endommager les filtres à air, assurez-vous que ces derniers ne

sont pas en contact avec votre corps lorsque vous transportez l’appareil.

FIG. 3 FIG.4

16

Page 17

FIXER LE SYSTÈME DE FILTRATION DE L’AIR AU PLAFOND OU À UN

SUPPORT EN HAUTEUR

Cet appareil pèse environ 27,22 kg (60 livres). Lorsque vous le fixez en hauteur, assurezvous que l’appareil est bien attaché et soutenu.

1. Prenez les 4 boulons à œil de 2,54 cm (1 po) et les 4 écrous à bride de 5/16 fournis avec l’appareil.

2. Utilisez un tournevis plat (non fourni) pour enlever les 4 vis (C) Fig. 5 sur le dessus du système de filtration de l’air (D).

3. Vissez un écrou à bride sur chaque boulon d’environ 19,1 mm (5/16" po).

4. Placez les boulons à œil (F) Fig. 6 dans les 4 trous d’où les vis ont été retirées à l’ÉTAPE 2.

REMARQUE : Assurez-vous que les écrous à bride sont bien serrés à la surface du système de filtration de l’air.

REMARQUE : Pour fixer l’appareil au plafond ou sur un support en hauteur, utilisez des crochets d’acier en S d’un

diamètre d’au moins 6,4 mm (5/16 po).

REMARQUE : Placez tous les tire-fonds à au moins 38 mm (1 1/2 po) dans la charpente.

Ne jamais fixer le système de filtration de l’air sur de la cloison sèche, sur des carreaux

de faux-plafond ou d’autres éléments qui ne font pas partie de la charpente.

Garder un minimum de 2,14 m (7 pieds) entre la partie inférieure du système de filtration de l’air

et la surface du plancher.

Ne pas utiliser une corde, un câble, ou un cordon d’alimentation pour suspendre l’appareil au plafond.

Utilisez une chaîne adaptée à une charge de travail de 68 kg minimum (150 livres).

IMPORTANT : Au moment de décider de l’emplacement du système de filtration de l’air, pensez que l’appareil

fonctionnera plus efficacement dans un endroit où l’air circule librement. Ne pas placer l’appareil dans un coin ou

près de bouches de chauffage ou de refroidissement.

FIG. 5 FIG. 6

INTERRUPTEUR MARCHE/

ARRÊT (ON/OFF)

Le système de filtration de l’air est équipé d’un

interrupteur à bascule en ligne (M) Fig.7, situé sur le

cordon d’alimentation (N). Pour mettre en route ou

arrêter le moteur, appuyez vers le bas sur l’interrupteur

à bascule, en suivant les instructions sur le côté.

Lorsque vous avez fini d’utiliser le système de filtration

de l’air, éteignez-le en appuyant sur l’interrupteur plutôt

que de le débrancher.

REMARQUE : L’interrupteur MARCHE/ARRÊT

(ON-OFF) doit être mis sur « ON » avant d’utiliser la

télécommande.

17

FIG. 7

Page 18

UTILISER LA TÉLÉCOMMANDE

Pour réduire le risque

d’incendie ou de choc

électrique, ne pas utiliser cet appareil avec tout

dispositif de contrôle de vitesse à semi-conducteur.

La télécommande fournie avec cet appareil n’est

pas considérée comme un dispositif de contrôle de

vitesse à semi-conducteur.

Le système de filtration de l’air est équipé d’une

TÉLÉCOMMANDE (A) Fig.8A.

REMARQUE : La télécommande nécessite deux (2)

piles AAA (non fournies). Le compartiment à piles est

situé sous le couvercle arrière.

Notez que la télécommande possède trois boutons de

commande

REMARQUE : Quand l’appareil est branché à la

source d’alimentation, un voyant vert (E) s’allume sur

le panneau.

Pour activer le ventilateur, enfoncez le bouton « ON/

OFF » (MARCHE/ARRÊT) (C) Fig. 8A. L’appareil

démarrera à la vitesse ÉLEVÉE par défaut sur le

panneau des capteurs. Enfoncez une fois le bouton

« SPEED » (VITESSE), l’appareil fonctionnera à une

vitesse MOYENNE. Enfoncez le bouton « SPEED » à

nouveau, l’appareil fonctionnera à FAIBLE vitesse.

Enfoncez le bouton « SPEED » une troisième fois,

l’appareil reviendra au mode de vitesse ÉLEVÉE.

Pour éteindre l’appareil, appuyez sur le bouton

MARCHE/ARRÊT (ON/OFF) (C) Fig. 8A.

Lorsque l’appareil est en MARCHE au réglage de

vitesse désiré, l’enfoncement du bouton « TIME »

(HEURE) (B) Fig. 8A de la télécommande réglera

FIG. 8A

l’appareil pour un fonctionnement d’une durée d’une

heure. Appuyer une deuxième fois sur le bouton

« TIME » permettra à l’appareil de fonctionner

pendant deux heures. Veuillez prendre note que le

voyant apparaissant sur le panneau de capteurs

est maintenant à l’emplacement « 2HR » (G) Fig.

8B. Lorsque vous appuyez une troisième fois sur le

bouton « TIME », l’appareil fonctionnera pendant trois

heures. À ce moment, le voyant rouge s’allumera

sous l’emplacement « 1HR » et « 2HR ». Lorsque vous

appuyez sur « TIME » pour la quatrième fois, l’appareil

fonctionnera pendant quatre heures. Veuillez prendre

note que le voyant luit à l’emplacement de « 4HR ».

En appuyant de nouveau sur le bouton « TIME », la

durée des réglages augmentera par tranches d’une

heure pour un maximum de quinze heures. .

Toutes ces fonctions peuvent être contrôlées

manuellement en utilisant les deux boutons du

panneau capteur (K) Fig. 8B.

FIG. 8B

OPÉRATIONS

REMARQUE : Le nettoyeur à air peut produire une légère odeur pendant les premières heures d’utilisation en raison

du revêtement protecteur appliqué sur les composants internes. Cette odeur se dissipera et ne devrait pas être prise

en compte.

IMPORTANT : Ne jamais utiliser le nettoyeur à air si les filtres à air ne sont pas en place.

1. S’ASSURER que le matériel du filtre est bien installé.

2. Brancher le cordon d’alimentation; mettre en fonction l’interrupteur du cordon en ligne à ON (MARCHE). (Le

voyant POWER (d’ALIMENTATION) clignotera de manière constante).

3. Appuyer sur la touche ON/OFF (MARCHE/ARRÊT), DÉBUTER l’utilisation. (Le voyant RUN (EN MARCHE)

s’allumera selon la couleur de la vitesse pertinente, et le voyant POWER (ALIMENTATION) cessera de clignoter).

4. Appuyer sur la touche TIMER (MINUTERIE), le réglage MAX de l’heure est de 15 heures.

Le système de nettoyage de l’air DELTA® 50-871 3 vitesses peut être utilisé pour :

a. applications de ponçage sur table.

b. applications sur scie circulaire.

c. applications sur cloisons sèches.

d. applications de nettoyage d’usine.

e. applications pour sabler le plancher.

f. toute autre application où la poussière non métallique est un facteur.

DIAGNOSTIC DES ANOMALIES

Pour une assistance sur votre appareil, rendez-vous sur notre site à l’adresse www.DeltaMachinery.com pour

obtenir la liste des centres de service ou appelez l’assistance de DELTA® Power Equipment Corporation au

1 800 223-7278.

18

Page 19

ENTRETIEN

CHANGER ET NETTOYER LES FILTRES

1. Lorsque le voyant CLEAN FILTER (NETTOYER FILTRE) s’allume, cela signifie que le matériel du filtre doit être

changé.

2. Après l’installation du nouveau filtre propre, S’ASSURER d’appuyer sur la touche CLEAN FILTER (NETTOYER

FILTRE) pendant 5 secondes. À ce moment, le voyant POWER (ALIMENTATION) commencera à clignoter;

APPUYER sur la touche ON/OFF (MARCHE/ARRÊT) pour débuter l’opération.

3. Retirer le filtre primaire extérieur (D) Fig. 9B en soulevant et tirant la partie inférieure du filtre. Replacer le filtre

primaire selon sa condition. Lors du remplacement du filtre extérieur, vérifier si le filtre est muni d’une flèche de

circulation d’air (A) Fig. 9D. Si tel est le cas, pointer la flèche vers l’intérieur. Si le filtre n’est pas muni d’une flèche

de circulation d’air, installer le filtre d’une façon ou d’une autre.

Lorsque le voyant CLEAN FILTER (NETTOYER FILTRE) s’allume, cela signifie que le matériel du filtre doit être

changé.

Après l’installation du nouveau filtre propre, S’ASSURER d’appuyer sur la touche CLEAN FILTER (NETTOYER

FILTRE) pendant 5 secondes. À ce moment, le voyant POWER (ALIMENTATION) commencera à clignoter; APPUYER

sur la touche ON/OFF (MARCHE/ARRÊT) pour débuter l’opération.

L’air comprimé peut s’avérer dangereux. Pour la sécurité de l’opérateur, ne pas dépasser

une pression d’air de 8,97 kg/cm2 (30 psi). Ne pas pointer la buse à air vers vous ou une

autre personne. Toujours porter des lunettes de sécurité et un masque antipoussière au moment d’utiliser de l’air

comprimé.

4. Remplacez le filtre, mettez l’appareil en marche (« ON ») et réinitialiser l’indicateur numérique comme ci-dessous :

a) Pour réinitialiser l’appareil, appuyez sur le bouton « RESET » (RÉINITIALISER) (Fig. 8B) pendant environ 5

secondes et attendez que le signal « CLEAN FILTER » (NETTOYER LE FILTRE) s’estompe. Le signal « PWR »

(ALIMENTATION) commencera à clignoter; appuyez ensuite sur le bouton « ON/OFF » (MARCHE/ARRÊT) pour

mettre l’appareil en marche.

RECOMMENDATIONS

Si le préfiltre plissé a été changé trois fois, vous DEVEZ changer le filtre interieur une fois.

FIG. 9A

FIG. 9B

FIG. 9C

19

AIR FLOW

Page 20

ACCESSOIRES

La gamme complète des accessoires peut être obtenue auprès de votre fournisseur DELTA®, des centres de

service du fabricant et des centres de service DELTA® autorisés. Rendez-vous sur notre site à l’adresse www.

DeltaMachinery.com pour obtenir un catalogue, ou pour connaître le nom de votre fournisseur le plus proche.

Étant donné que les accessoires autres que ceux offerts par DELTA® n’ont pas été testés

avec ce produit, leur utilisation pourrait être dangereuse. Pour une utilisation en toute

sécurité, seuls les accessoires recommandés par DE LTA® doivent être utilisés avec ce produit.

ASSISTANCE PIÈCES, SERVICE ET GARANTIE

Tous les appareils et tous les accessoires DELTA® sont fabriqués selon des normes de qualité exigeantes et sont

soutenus par un réseau de centres de service du fabricant et de centres de service DE LTA® autorisés. Pour en

savoir plus sur votre produit de qualité DE LTA®, obtenir des pièces, du service, une assistance quant à la garantie ou

l’emplacement du centre de service le plus proche de chez vous, veuillez composer le 1 800 223-7278.

GARANTIE

Pour l’enregistrement de votre appareil auprès du service de la garantie, rendez-vous sur notre site à l’adresse

www.DeltaMachinery.com.

Garantie limitée de cinq ans pour les produits neufs

DELTA® réparera ou remplacera, à ses frais et à sa discrétion, tout nouvel appareil, pièce ou accessoire de l’appareil de DELTA® qui, pour une

usure normale, est jugé défectueux en raison d’un défaut de fabrication ou de matériau, à condition que le client retourne le produit prépayé

à un centre de service du fabricant ou à un centre de service autorisé DELTA

l’achat et offre à DELTA

reconditionnés, la durée de garantie est de 180 jours. DELTA

d’une mauvaise utilisation, d’abus ou de réparations ou d’altérations faites ou expressément autorisées par quiconque autre qu’un centre

de service ou un représentant de DELTA

indirects résultant de produits défectueux. Certains États ne permettant pas l’exclusion ou la limitation des dommages directs ou indirects, la

limitation ou exclusion peut ne pas s’appliquer à votre cas. Cette garantie est la seule garantie de DELTA

client en ce qui concerne les produits défectueux; toute autre garantie, expresse ou implicite, que ce soit de la valeur marchande, de la capacité

de remplir une fonction ou autre, est expressément exclue par DELTA

informations sur les réparations sous garantie, rendez-vous sur notre site à l’adresse www.DeltaMachinery.com ou appelez le 1 800 223-7278.

Cette garantie vous donne des droits légaux spécifiques et vous pouvez avoir d’autres droits qui sont différents selon les États ou provinces.

AMÉRIQUE LATINE : Cette garantie ne s’applique pas aux produits vendus en Amérique latine. Pour les produits vendus

en Amérique latine, voir les informations de garantie relatives au pays en question contenues dans le carton, appeler la

société locale ou consulter la section garantie sur le site Web.

®

une occasion raisonnable de vérifier le défaut allégué au moyen d’une inspection. Pour tous les produits DELTA®

®

autorisé. En aucun cas, DELTA® ne pourra être tenu pour responsable des dommages directs ou

®

ne peut être tenu responsable de tout défaut confirmé issu de l’usure normale,

®

avec une preuve d’achat du produit dans les cinq ans après

®

, et elle devient le recours exclusif du

®

. Pour plus de renseignements sur la couverture de la garantie et des

20

Page 21

PIÈCES DE RECHANGE

Utilisez uniquement des pièces de rechange identiques. Pour obtenir la liste des pièces ou commander des pièces, rendezvous sur notre site à l’adresse www.DeltaMachinery.com/service. Vous pouvez aussi commander des pièces auprès de votre

représentant local, centre de service garantie autorisé ou en appelant le responsable du service technique au 1 800 223-7278 pour

recevoir une assistance personnalisée de la part d’un de nos représentants hautement qualifiés.

REMPLACEMENT GRATUIT DES ÉTIQUETTES DE MISE EN GARDE

Si vos étiquettes de mise en garde sont devenues illisibles ou si vous les avez perdues, appelez le 1 800 223-7278 pour

qu’on vous les remplace gratuitement.

FOR YOUR OWN SAFETY

1. READ AND UNDERSTAND

INSTRUCTION MANUAL

BEFORE OPERATING AIR

CLEANER.

2. To reduce the risk of injury,

disconnect from power supply

before servicing or changing

filters.

3. When ceiling mounted,

install Air Cleaner at least 7

feet above floor.

4. If used, ceiling mounts must

be anchored to building

structure. Never secure

mounts to dry wall, drop

ceiling tile/frame or other

non-structural members.

5. To reduce the risk of electrical

shock, do not expose to water

or rain.

6. Use only for the collection of

dry airborne dust. Never duct

the Air Cleaner directly to a

machine. Never use the Air

Cleaner to dissipate fumes

or smoke.

PARA SU PROPIA SEGURIDAD

1. LEA Y ENTIENDA EL MANUAL DE

INSTRUCCIONES ANTES DE

OPERAR EL LIMPIADOR DE AIRE.

2. Desconecte la unidad de la fuente

de energía antes de renidar

servicio o cambiar filtros para

reducir el riesgo de lesionamiento.

3. Instale el Limpiador de Aire por lo

menos 213 cm sobre el nievel del

piso cuando se trate de una

instalación de techno.

4. De utilizarse, los montajes de

techno deben anclarse a la

estructura del edificio. Jamás

afiance los mentajes al muro en

seco, lozas o marcos de platones

u otros miembros no estructurales.

5. No exponga la unidad al agua ni

la lluvia para reducir el riesgo de

choques eléctricos.

6. Utilice la unidad soló para la

recolección de polvo aéreo seco.

Jamás conduzca el Limpiador de

Aire directamente a una máquina.

Jamás utilice el Limplador de Aire

para disipar emanaciones o humo.

410-09-752-0017

To reduce risk of injury from moving parts, unplug before

servicing. Keep hands away from moving parts. Only

operate with air filters installed.

Desenchute la máquina antes de rendir servicio para

reducir el riesgo de lesionamientos ocasionados por

piezas en movimiento. Aleje las manos de las piezas

en movimiento. Opere solo con los filtros de aire

instalados.

410-09-752-0018

SERVICE ET RÉPARATIONS

Tous les outils de qualité auront éventuellement besoin d’entretien et/ou de remplacement des pièces. Pour

des informations au sujet de DELTA® Power Equipment Corporation, ses filiales ou pour trouver un centre

de service de garantie autorisé, rendez-vous sur notre site à l’adresse www.DeltaMachinery.com/service ou

appelez notre service à la clientèle au 1 800 223-7278. Toutes les réparations réalisées par nos centres de

service sont entièrement garanties contre les défauts de matériau et de fabrication. Nous ne pouvons garantir

les réparations réalisées ou tentées par d’autres. En appelant ce numéro, vous pouvez également obtenir 24

h/24 des réponses aux questions les plus fréquemment posées.

Vous pouvez aussi nous écrire à l’adresse suivante : DELTA® Power Equipment Corporation, 4825 Highway

45 North, Jackson, TN 38305 — Attention: Technical Service Manager. Assurez-vous de fournir toutes les

informations présentes sur la plaque de votre outil (numéro de modèle, type, numéro de série, code date, etc.)

21

Page 22

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

LEA Y COMPRENDA TODAS LAS ADVERTENCIAS E INSTRUCCIONES DE

OPERACIÓN ANTES DE UTILIZAR ESTA MÁQUINA. No seguir todas las

instrucciones que se indican a continuación, puede dar lugar a descarga

eléctrica, incendio y/o lesiones personales graves o daños a la propiedad..

El trabajo de carpintería puede ser peligroso si no se siguen los procedimientos operativos y de seguridad

adecuados. Como ocurre con toda maquinaria, existen ciertos riesgos involucrados con el funcionamiento del

producto. El uso de la máquina con respeto y cautela reducirá considerablemente la posibilidad de lesiones

personales. No obstante, el operador puede sufrir lesiones si se pasan por alto o se ignoran las precauciones de

seguridad correspondientes. Los equipos de seguridad tales como protecciones, varillas de empuje, anclajes,

peines de sujeción, gafas, máscaras anti polvo y protección auditiva pueden reducir la posibilidad de sufrir lesiones.

Pero ni el mejor protector de seguridad será suficiente para compensar la poca capacidad de discernimiento,

el descuido o la falta de atención. Utilice siempre el sentido común y tenga cuidado en el taller. Si cree

que un procedimiento es peligroso, no lo intente. Busque un procedimiento alternativo que sea más seguro.

RECUERDE: Su seguridad personal es su responsabilidad. Para obtener más información visite nuestro sitio

web www.DeltaMachinery.com.

Esta máquina fue diseñada únicamente para ciertos usos. DELTA® Power Equipment

Corporation recomienda encarecidamente que esta máquina no sea modificada y/o

utilizada para cualquier uso distinto a los fines para los que fue diseñada. Si tiene alguna

pregunta relacionada a algún uso en particular, NO utilice la máquina antes de haberse comunicado con DELTA®

para determinar si tal uso es posible o si debería realizarse con el producto.

Si tiene alguna pregunta relacionada a su uso, NO utilice el producto hasta que haya escrito a DELTA® Power

Equipment Corporation y que le hayamos dado la asesoría adecuada. Comuníquese con nosotros en línea en

www.DeltaMachinery.com o por correo postal con la Dirección de Servicio Técnico (Technical Service Manager) a la

siguiente dirección: DELTA® Power Equipment Corporation, 4825 Highway 45 North, Jackson, TN 38305.

La información sobre el funcionamiento seguro y apropiado de esta herramienta está disponible en las siguientes

fuentes:

• Power Tool Institute, 1300 Sumner Avenue, Cleveland, OH 44115-2851 o en línea en www.powertoolinstitute.com

• National Safety Council, 1121 Spring Lake Drive, Itasca, IL 60143-3201

• American National Standards Institute, 25 West 43rd Street, 4 floor, New York, NY 10036 www.ansi.org - ANSI 01.1

• Requisitos de seguridad para máquinas de carpintería

• Reglamentaciones del Departamento de Trabajo de EE. UU. www.osha.gov

PAUTAS DE SEGURIDAD, DEFINICIONES

Este manual contiene información que es importante que usted conozca y comprenda. Esta información se refiere

a la protección de SU SEGURIDAD y la PREVENCIÓN DE PROBLEMAS CON LOS EQUIPOS. Para ayudarle a

reconocer dicha información, utilizamos los símbolos que se muestran a continuación. Lea el manual y preste

atención a estas secciones

Indica una situación de peligro inminente que, en caso de no evitarse, puede ocasionar la muerte o

lesiones graves.

Indica una situación posiblemente peligrosa que, en caso de no evitarse, podría ocasionar la

muerte o lesiones graves.

Indica una situación posiblemente peligrosa que, en caso de no evitarse, podría ocasionar

lesiones menores a moderadas.

Cuando se utiliza sin el símbolo de alerta de seguridad indica una situación posiblemente

peligrosa que, de no evitarse, podría provocar daños materiales.

22

ESPAÑOL

Page 23

NORMAS GENERALES DE SEGURIDAD

NO SEGUIR LAS ADVERTENCIAS DE ESTAS NORMAS PUEDE PROVOCAR LESIONES GRAVES.

POR SU PROPIA SEGURIDAD, LEA Y COMPRENDA EL MANUAL DE INSTRUCCIONES ANTES DE UTILIZAR LA UNIDAD.

•

Conozca el uso y las limitaciones de la unidad, así como los riesgos específicos y peculiares de la misma.

MANTENGA LIMPIA EL ÁREA DE TRABAJO.

•

NO LA UTILICE EN UN ENTORNO PELIGROSO.

•

Mantenga el área de trabajo bien iluminada.

MANTENGA ALEJADOS A LOS NIÑOS Y VISITANTES.

•

área de trabajo.

DESCONECTE LA UNIDAD

•

REVISE LAS PARTES DAÑADAS.

•

antes de darle mantenimiento.

Antes de seguir utilizando, repare o reemplace adecuadamente cualquier parte que esté dañada.

NO SEGUIR ESTAS NORMAS PODRÍA PROVOCAR LESIONES GRAVES.

Las áreas y bancos atestados de objetos dan pie a posibles accidentes.

No utilice esta unidad en lugares húmedos o mojados, ni la exponga a la lluvia

Todos los niños y visitantes deben mantenerse a una distancia segura del

NO UTILICE ESTA UNIDAD PARA

FILTRAR POLVO DE METALES. La

combinación de polvo de madera y de metales puede

generar riesgo de explosión o incendio. Esta unidad está

diseñada para filtrar solamente atmósferas no explosivas.

NO UTILICE ESTA UNIDAD PARA DISIPAR

GASES O HUMO. Pueden provocar

explosiones o incendios. Este purificador de aire está

diseñado para utilizarse solo donde haya polvo seco

emitido en el aire. Su uso debe limitarse a atmósferas no

explosivas y no metálicas.

1. NO opere esta unidad hasta que esté completamente

montada e instalada de acuerdo con las

instrucciones. Una unidad montada incorrectamente

puede causar lesiones.

2. OBTENGA ASESORÍA de su supervisor, instructor

u otra persona calificada si no está completamente

familiarizado con el funcionamiento de esta unidad. El

conocimiento implica seguridad.

3. SIGA TODOS LOS CÓDIGOS DE CABLEADO y las

conexiones eléctricas recomendadas para prevenir

una descarga eléctrica o electrocución.

4. NO LEVANTE ESTA UNIDAD UTILIZANDO EL CABLE

DE ALIMENTACIÓN. No utilice el cable de alimentación

como un dispositivo para colgar artículos. Un cable de

alimentación dañado puede provocar una descarga

eléctrica o electrocución.

5. SUJETE FIRMEMENTE ESTA UNIDAD en una

estructura de soporte permanente o fija al

suspenderla desde el techo. Si la unidad se cae puede

causar lesiones graves. Siempre mantenga un mínimo

de 2 metros (7 pies) entre la parte inferior de la unidad

y la superficie del piso para permitir una altura mínima

suficiente. Utilice solamente una cadena calificada

para levantar un mínimo de 68 kilos (150 libras) de

carga para sostener la unidad de forma adecuada.

Utilice ganchos de acero en “S” que midan al menos

de 0.6 cm (1/4") de diámetro para colgar la unidad

desde el techo. Los pernos tirafondo (tipo “lag”) que

se utilizan para suspender la unidad en el techo deben

pasarse al menos a 1.27 cm (1-1/2") dentro de los

elementos estructurales de soporte.

6. APOYE ESTA UNIDAD o sujétela firmemente a la

superficie de trabajo cuando se la utilice en forma

portátil para eliminar posibles lesiones y/o daños a la

unidad.

7. ASEGÚRESE DE QUE LAS ÁREAS DE ADMISIÓN

Y ESCAPE ESTÉN LIMPIAS antes de encender la

unidad. Los tubos de admisión o de escape que

estén obstruidos pueden causar una explosión y/o un

incendio.

8. MANTENGA LOS BRAZOS, MANOS y dedos LEJOS