Page 1

Multec 3.5 Top Feed Fuel Injector

Application Manual

Fuel Systems Applications Engineering

Delphi Energy & Chassis Systems

5500 W. Henrietta Rd.

P.O. Box 20366

Rochester, New York 14602 USA

Delphi Energy and Chassis Systems 2005

Page 2

Page 3

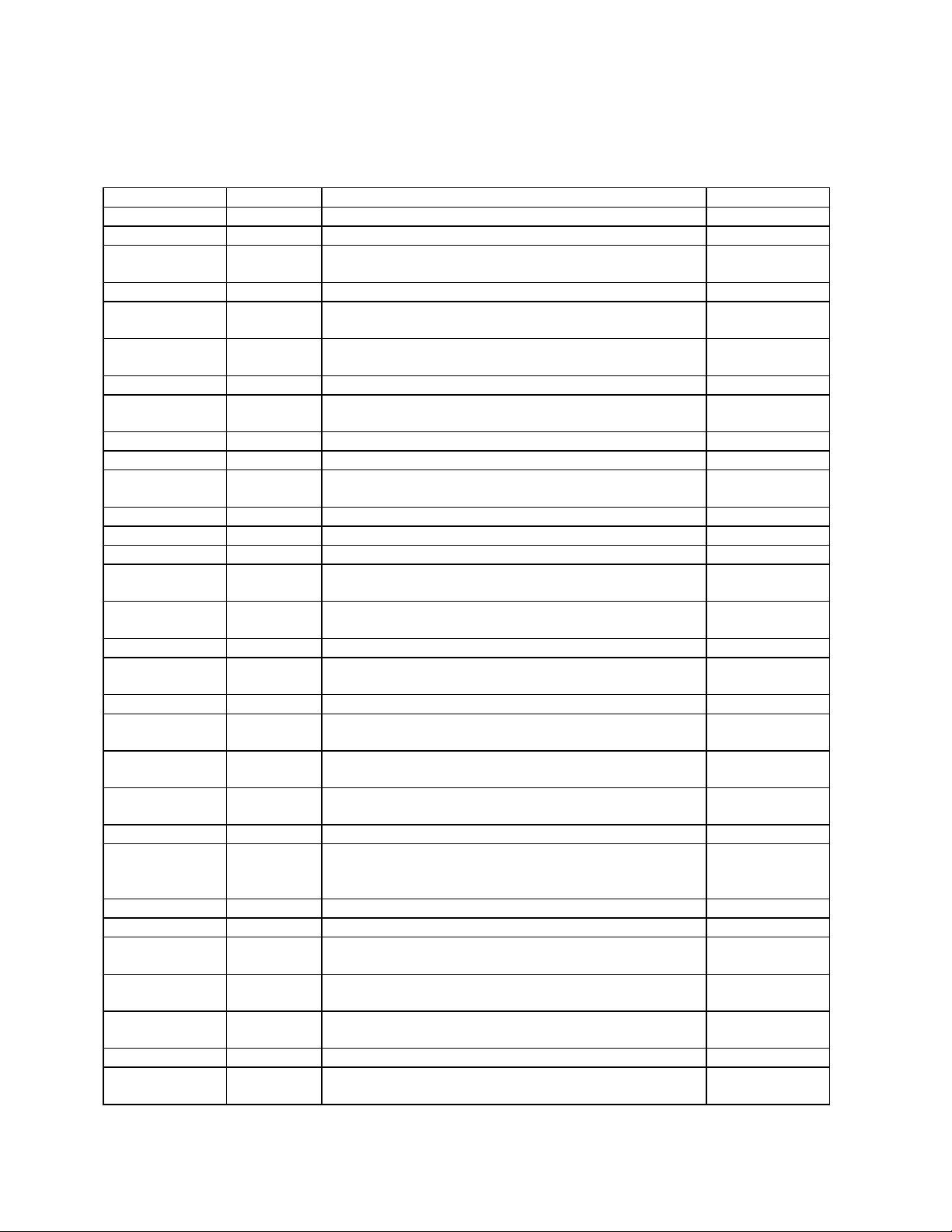

Multec 3.5 Fuel Injector Application Manual Revision Summary

Multec 3.5 Top Feed Fuel Injector Application Manual

Release/Revision Summary Sheet

CHANGE NO. DATE REASON FOR CHANGE PAGE(S)

Issued April 2004 N/A N/A

1 July 2005 Replaced “J-spray…” with “J-2715 (Draft)” in section

1.9.4.2

1 Nov. 05 Added shutdown throttle closure note to section 8.4.4 8-4

1 Changed ‘and applicable’ to ‘any applicable’ in

section 1.9.1

1 Nov 05 Added reference to Worldwide Emissions Standards

booklet to section 2.2.3 and 1.9.3

1 Nov 05 Updated MTBE phase out plans in section 2.2.6.2 2-10

1 Nov 05 Updated gasoline sulfur requirements in section

2.2.6.3.4

1 Nov 05 Re-worded section 2.2.7.3 for clarity 2-18

1 Nov 05 Corrected return and inlet locations in Figure 2-5 2-23

1 Nov 05 Added extended tip description to section 3.2.2 and

view to Figure 3-2

1 Nov 05 Changed “core” to “valve” in section 3.2 3-1

1 Nov 05 Added rotational orientation note to section 3.3.5 3-6

1 Nov 05 Reworded section 3.5.1 for clarity 3-11

1 Nov 05 Added Zener diode voltage range and injector flow

test for vehicle calibration note to section 3.6.3

1 Nov 05 Revised calculation example from max flow to min

flow in section 3.7

1 Nov 05 Added J-2715 to section 3.8 3-21

1 Nov 05 Revised 96% spray volume for dual spray to 90% in

section 3.8.2

1 Nov 05 Updated Figure 3-12 to current data format 3-26

1 Nov 05 Removed word “serviceable” from filter requirements

in section 3.12

1 Nov 05 Changed “Component Technical Specification” to

“Engineering Product Specification” in section 3.16

1 Nov 05 Added “absolute” to manifold air pressure in Table

3-2

1 Nov 05 Revised Figure 6-1 to include o-ring installation tool 6-3

1 Nov 05 Added section 6.4 and Figure 6-2 – injector

installation into fuel rail and renumbered remaining

sections

1 Nov 05 Added reference to Figure 6-1 in section 4.3 4-8

1 Nov 05 Added “total” to A/F variation” in section 3.10.2 3-33

1 Nov 05 Added section 5.2.3.3 “Variable Fuel Pressure

Compensation”. Renumbered remaining sections.

1 Nov 05 Added reference to terminal lubricant (section 7.5) in

Table 6-1

1 Nov 05 Added reference to terminal lubricant (section 7.5) in

section 4.4.4

1 Nov 05 Added reference to Figure 6-1 in section 6.5 6-6

1 Nov 05 Added metal fuel line recommendation to section

7.3.5

1-7

1-5

1-6, 2-8

2-12

3-3, 3-4

3-13

3-19

3-22

3-36

3-39

3-40

6-4

5-10

6-2

4-14

7-5

Delphi Energy and Chassis Systems

Revision: 11/05-1

Page 4

Multec 3.5 Fuel Injector Application Manual Revision Summary

1 Nov 05 Renumbered pages in section 4 starting at 1 4-1

1 Nov 05 Changed dwell time from 1 hr to 0.5 hr and duration

9-3

from 240 hours to 120 hours in section 9.3.2.1

Delphi Energy and Chassis Systems

Revision: 11/05-01

Page 5

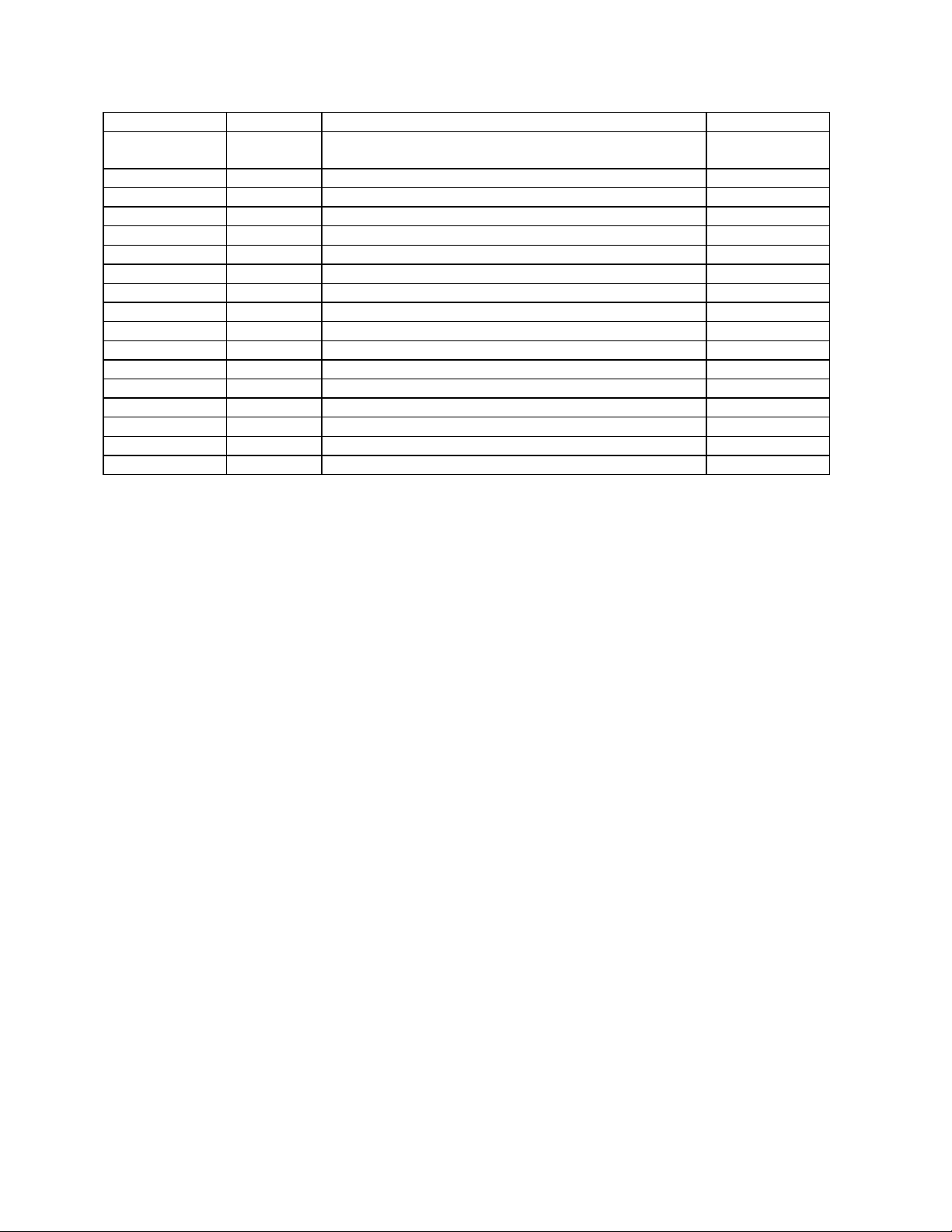

Multec 3.5 Fuel Injector Application Manual Table of Contents

Table of Contents

1. 0 INTRODUCTION ................................................................................1-1

1.1 SCOPE OF DOCUMENT .....................................................................................................................1-1

1.2 CLASSIFICATION .............................................................................................................................. 1-1

1.3 DOCUMENT MANAGEMENT ............................................................................................................... 1-1

1.3.1 Document Release and Updates .........................................................................................1-1

1.4 COMMERCIAL CONSIDERATIONS .......................................................................................................1-1

1.5 OBJECTIVES OF THIS MANUAL .......................................................................................................... 1-1

1.6 HOW THIS MANUAL IS ARRANGED..................................................................................................... 1-2

1.7 CONVENTIONS USED IN THIS MANUAL............................................................................................... 1-4

1.8 HYPERLINKS....................................................................................................................................1-5

1.9 APPLICABLE DOCUMENTS ................................................................................................................1-5

1.9.1 Order of Precedence ............................................................................................................ 1-5

1.9.2 Government Documents ......................................................................................................1-5

1.9.3 Other Delphi Reference Documents ....................................................................................1-5

1.9.4 Industry Documents .............................................................................................................1-6

1.9.5 Useful Web Sites..................................................................................................................1-6

2. 0 FUNDAMENTALS .............................................................................. 2-1

2.1 GENERAL ........................................................................................................................................2-1

2.2 ENGINE COMBUSTION FUNDAMENTALS ............................................................................................. 2-2

2.2.1 Air/Fuel Ratio Effects on Combustion ..................................................................................2-3

2.2.2 Fuel Atomization................................................................................................................... 2-7

2.2.3 Fuel Spray Characteristics and Injection Timing.................................................................. 2-8

2.2.4 Benefits of Electronic Fuel Injection Over Other Types of Fuel Systems ............................2-9

2.2.5 Impact of Transient Conditions on Combustion ................................................................... 2-9

2.2.6 Impact of Fuel Composition................................................................................................2-10

2.2.7 Engine-Vehicle Environment..............................................................................................2-14

2.2.8 Maximum Power Fueling Requirements ............................................................................2-19

2.2.9 Injector Flow Tolerances ....................................................................................................2-20

2.3 FUEL FLOW CONSIDERATIONS........................................................................................................2-20

2.3.1 Minimum Fuel Pump Flow Output......................................................................................2-21

2.3.2 Nominal Fuel Pump Output ................................................................................................ 2-21

2.3.3 Fuel Pump Check Valve Requirements .............................................................................2-22

2.3.4 Pressure Regulator Gain/Considerations (Vacuum Biased).............................................. 2-22

2.4 IMPACT OF EMISSIONS REQUIREMENTS .......................................................................................... 2-23

2.4.1 The Impact of Emission Requirements on Fuel Control Systems .....................................2-23

2.4.2 Fuel Injector Design Effects on Evaporative Emissions.....................................................2-25

2.4.3 Impact of Canister Purge on Engine Fueling .....................................................................2-26

2.4.4 Impact of EGR and PCV on engine fueling........................................................................ 2-27

2.4.5 Injector Flow Characterization............................................................................................ 2-27

3. 0 PRODUCT DESCRIPTION.................................................................3-1

3.1 SCOPE............................................................................................................................................3-1

3.2 GENERAL DESCRIPTION ...................................................................................................................3-1

3.2.1 Appearance .......................................................................................................................... 3-3

3.2.2 Exterior Outline..................................................................................................................... 3-3

Delphi Energy and Chassis Systems

Revision: 11/05-1 i

Page 6

Table of Contents Multec 3.5 Fuel Injector Application Manual

3.2.3

Usage Definition ................................................................................................................... 3-3

3.2.4 Failure Diagnostics...............................................................................................................3-3

3.3 PHYSICAL SPECIFICATIONS ..............................................................................................................3-3

3.3.1 Dimensions........................................................................................................................... 3-3

3.3.2 Mass ..................................................................................................................................... 3-5

3.3.3 Identification and Markings ..................................................................................................3-5

3.3.4 Internal Components ............................................................................................................ 3-5

3.3.5 Injector Retaining Clip ..........................................................................................................3-6

3.3.6 Seal rings..............................................................................................................................3-7

3.4 CUSHION SEAL INJECTOR DESIGN ....................................................................................................3-8

3.5 INJECTOR DESIGN ...........................................................................................................................3-8

3.5.1 Dual Spray Fuel Injector.....................................................................................................3-11

3.6 INJECTOR CONTROLS – CONTROLLER DRIVE CIRCUIT ..................................................................... 3-12

3.6.1 Minimum Operating Voltage (MOV) ................................................................................... 3-12

3.6.2 Driver Considerations.........................................................................................................3-12

3.6.3 Driver Circuit Clamping Voltage ......................................................................................... 3-13

3.6.4 Injector Polarity................................................................................................................... 3-13

3.7 INJECTOR FLOW RATE SIZING ........................................................................................................3-13

3.8 INJECTOR TARGETING, PLACEMENT AND CONE ANGLE....................................................................3-21

3.8.1 Targeting ............................................................................................................................3-21

3.8.2 Cone Angle......................................................................................................................... 3-22

3.8.3 Spray Atomization ..............................................................................................................3-23

3.9 PULSE-WIDTH LIMITS .................................................................................................................... 3-27

3.9.1 Minimum Pulse-Width (MPW) ............................................................................................ 3-28

3.9.2 Tailbiting .............................................................................................................................3-30

3.10 LINEAR AND WORKING FLOW RANGE ..................................................................................... 3-31

3.10.1 Linear Range......................................................................................................................3-31

3.10.2 Working Flow Range .......................................................................................................... 3-33

3.11 TIP LEAKAGE ........................................................................................................................3-34

3.11.1 Total Fuel System Tip Leakage Monte Carlo Analysis ......................................................3-35

3.12 CONTAMINATION RESISTANCE ............................................................................................... 3-36

3.13 DYNAMIC AND STATIC FUEL FLOW SPECIFICATIONS................................................................ 3-36

3.13.1 Flow Test Fluid Specification .............................................................................................3-37

3.14 NOISE ..................................................................................................................................3-38

3.15 ELECTRICAL SPECIFICATIONS ................................................................................................3-38

3.15.1 Solenoid Coil Specifications...............................................................................................3-38

3.15.2 Avalanche Energy ..............................................................................................................3-38

3.16 ENVIRONMENTAL CONDITIONS...............................................................................................3-39

3.16.1 Hot Fuel Handling...............................................................................................................3-39

3.16.2 Environmental Exposure ....................................................................................................3-40

4. 0 SYSTEM INTERFACE........................................................................4-1

4.1 GENERAL ........................................................................................................................................4-1

4.1.1 Interface Control Document .................................................................................................4-2

4.2 MECHANICAL INTERFACES ............................................................................................................... 4-3

4.2.1 Locating the Fuel Injector .....................................................................................................4-3

4.2.2 Orienting the Injector ............................................................................................................ 4-4

4.2.3 Vibration Levels....................................................................................................................4-5

4.2.4 Fuel Supply System Interface ..............................................................................................4-7

ii Delphi Energy and Chassis Systems

Revision: 11/05-01

Page 7

Multec 3.5 Fuel Injector Application Manual Table of Contents

4.3 SEAL RINGS.....................................................................................................................................4-8

4.4 ELECTRICAL INTERFACE................................................................................................................... 4-9

4.4.1 Electromagnetic Compatibility..............................................................................................4-9

4.4.2 Wire Routing......................................................................................................................... 4-9

4.4.3 Fuel Injector Polarity........................................................................................................... 4-10

4.4.4 Fuel Injector Connector ...................................................................................................... 4-11

4.4.5 Controller............................................................................................................................4-14

5. 0 SOFTWARE .......................................................................................5-1

5.1 GENERAL ........................................................................................................................................5-1

5.2 CONTROL ALGORITHMS ................................................................................................................... 5-2

5.2.1 Injection Methods .................................................................................................................5-2

5.2.2 Open Loop Injector and Fuel Rail Characterization ............................................................. 5-4

5.2.3 Open-Loop Characterization ................................................................................................ 5-9

5.2.4 Closed-Loop Corrections ...................................................................................................5-14

5.2.5 Fuel Injection Timing ..........................................................................................................5-15

5.3 DIAGNOSTICS ................................................................................................................................5-17

5.3.1 Fuel Trim Diagnostics......................................................................................................... 5-17

5.3.2 Oxygen Sensor Diagnostics...............................................................................................5-18

5.3.3 Catalytic Converter Diagnostics ......................................................................................... 5-18

5.3.4 Injector Driver Diagnostics .................................................................................................5-18

5.3.5 Engine Misfire Diagnostics.................................................................................................5-18

5.3.6 Factors Affecting Engine Diagnostics ................................................................................5-19

6. 0 PRODUCT HANDLING ......................................................................6-1

6.1 PACKING PROCEDURES ...................................................................................................................6-3

6.2 RECEIVING AND STORAGE................................................................................................................ 6-4

6.3 MOVEMENT WITHIN THE PLANT ........................................................................................................ 6-4

6.4 INSTALLATION IN FUEL RAIL ............................................................................................................. 6-4

6.5 INSTALLATION ON THE ENGINE..........................................................................................................6-5

6.6 COMPONENT ASSEMBLY BEST PRACTICES ....................................................................................... 6-8

6.7 MAINTENANCE, SERVICE AND REPAIR .............................................................................................. 6-9

6.7.1 Diagnosing Malfunction Codes ............................................................................................6-9

6.7.2 Replacement Techniques ....................................................................................................6-9

6.7.3 Adjustments........................................................................................................................ 6-11

6.7.4 Interchangeability ...............................................................................................................6-11

6.8 SUPPORT OF COMPONENT AFTER SALE..........................................................................................6-11

7. 0 RECOMMENDATIONS AND PRECAUTIONS...................................7-1

7.1 TEMPERATURE ................................................................................................................................7-1

7.2 DURABILITY.....................................................................................................................................7-2

7.2.1 Injector Characteristics.........................................................................................................7-3

7.3 WEAR AND CONTAMINATION ............................................................................................................ 7-3

7.3.1 Internal Corrosion.................................................................................................................7-3

7.3.2 External Exposure ................................................................................................................ 7-3

7.3.3 Plugging................................................................................................................................7-4

7.3.4 Contamination Resistance ...................................................................................................7-4

7.3.5 Fuel System Generated Contamination ............................................................................... 7-5

7.3.6 Maximum Fuel Pressure ......................................................................................................7-5

Delphi Energy and Chassis Systems

Revision: 11/05-1 iii

Page 8

Table of Contents Multec 3.5 Fuel Injector Application Manual

7.3.7

Injector Storage .................................................................................................................... 7-5

7.4 PREVENTING ENGINE HYDRO-LOCK ..................................................................................................7-6

7.4.1 Engine Prime Pulse at Start .................................................................................................7-6

7.4.2 Vehicle Assembly Fuel System Prime .................................................................................7-7

7.5 INJECTOR HARNESS CONNECTOR – CORROSION ..............................................................................7-7

8. 0 TESTING RECOMMENDATIONS AND PRECAUTIONS ..................8-1

8.1 DYNAMOMETER TESTING .................................................................................................................8-1

8.1.1 Cylinder-to-Cylinder Distribution ..........................................................................................8-1

8.2 DURABILITY TESTING ....................................................................................................................... 8-1

8.3 DYNAMIC VEHICLE TESTING ............................................................................................................. 8-2

8.4 STANDARD VEHICLE DEVELOPMENT TESTS.......................................................................................8-2

8.4.1 Hot Fuel Handling................................................................................................................. 8-2

8.4.2 Spray Effect on Emissions ...................................................................................................8-3

8.4.3 Cold Driveability and Startability ..........................................................................................8-3

8.4.4 Crank vs. Leak .....................................................................................................................8-4

8.4.5 Altitude Driveability and Emissions ...................................................................................... 8-4

8.4.6 Low Pulse-Width Fueling Accuracy...................................................................................... 8-4

8.4.7 Driveability Index Fuel Sensitivity......................................................................................... 8-4

8.4.8 Spark Plug Fouling Tests .....................................................................................................8-5

8.4.9 Voltage Sensitivity ................................................................................................................ 8-5

8.4.10 Manifold Pressure Sensitivity ............................................................................................... 8-5

8.4.11 Standard Durability Tests .....................................................................................................8-5

8.4.12 Icing Tests ............................................................................................................................ 8-5

8.4.13 Production Limit Verification Tests....................................................................................... 8-5

9. 0 VALIDATION REQUIREMENTS ........................................................9-1

9.1 GENERAL ........................................................................................................................................9-1

9.2 VALIDATION TESTS ..........................................................................................................................9-1

9.2.1 Preliminary Physical Analysis .............................................................................................. 9-2

9.3 ENVIRONMENTAL EXPOSURE............................................................................................................ 9-2

9.3.1 External Corrosion................................................................................................................9-2

9.3.2 Temperature.........................................................................................................................9-3

9.3.3 Life Cycling ...........................................................................................................................9-3

9.3.4 Mechanical Integrity .............................................................................................................9-4

9.3.5 Overpressurization ...............................................................................................................9-5

9.3.6 Over-voltage.........................................................................................................................9-5

9.3.7 Injector Noise .......................................................................................................................9-6

9.3.8 Note on Additional Exposures..............................................................................................9-6

9.4 VERIFICATION................................................................................................................................. 9-6

10. 0 APPENDIX......................................................................................10-1

10.1 INTRODUCTION. ....................................................................................................................10-1

10.2 MULTEC 3.5 FUEL INJECTOR SYSTEM CUSTOMER COMPONENT CHECKLIST ............................ 10-2

10.3 COMPONENT APPLICATION CHECKLIST ..................................................................................10-8

10.4 COMPONENT ASSEMBLY BEST PRACTICES........................................................................... 10-12

10.5 GLOSSARY OF TERMS AND ABBREVIATIONS..........................................................................10-17

11. 0 INDEX.............................................................................................11-3

iv Delphi Energy and Chassis Systems

Revision: 11/05-01

Page 9

Multec 3.5 Fuel Injector Application Manual Table of Contents

Tables

Table 2-1 - Stoichiometry of Alternate Fuel Blends .................................................................................2-4

Table 3-1 Solenoid Electrical Properties................................................................................................ 3-39

Table 3-2 - Injector Environmental Operating Conditions...................................................................... 3-39

Table 6-1 – Multec 3.5 Injector Handling ................................................................................................. 6-2

Table 6-2 - Recommended seal ring lubricants.......................................................................................6-8

Table 8-1 - Injector tip soak temperature vs required fuel pressure........................................................8-3

Table 9-1 - Potential Injector Test Fuels..................................................................................................9-4

Table 9-2 - Injector Verification Matrix Template ..................................................................................... 9-7

Figures

Figure 2-1- Engine Fuel System (shown is a demand fuel rail for a V6 application)............................... 2-2

Figure 2-2 - Air Fuel Ratio Effect on Catalytic Converter Efficiency ........................................................ 2-6

Figure 2-3 - Fuel Distillation Curve vs Temperature..............................................................................2-13

Figure 2-4 - 50% Vapor / Liquid Ratio vs RVP, Fuel and Pressure.......................................................2-17

Figure 2-5 - Fuel Pressure Regulator and Gain Calculation.................................................................. 2-23

Figure 2-6 - Engine Management System Open Loop vs Closed Loop System Architecture............... 2-24

Figure 2-7 - Catalytic Converter Efficiency vs Air/Fuel Ratio................................................................. 2-24

Figure 2-8 California Tailpipe Emissions Limits.....................................................................................2-25

Figure 2-9 - Evaporative Emissions Regulations..................................................................................2-26

Figure 3-1 - Top Feed Port Fuel Injection................................................................................................3-2

Figure 3-2 - Multec 3.5 Fuel Injector Dimensions – Seal ring design. (For exact dimensions, refer to

Delphi Injector Outline Drawing).......................................................................................................3-4

Figure 3-3 – Multec 3.5 Fuel Injector Dimensions – Cushion seal / Face seal design (For exact

dimensions, refer to Delphi Injector Outline Drawing. ...................................................................... 3-4

Figure 3-4 - Injector Identification and Markings......................................................................................3-5

Figure 3-5 Multec 3.5 Internal Components ............................................................................................3-6

Figure 3-6 -Injector Retaining Clip Designs ............................................................................................. 3-7

Figure 3-7 - Multec 3.5 Magnetic Circuit................................................................................................3-10

Figure 3-8 - Multec 3.5 Fuel Flow Path.................................................................................................. 3-10

Figure 3-9 - Dual Spray Injector.............................................................................................................3-11

Figure 3-10 - Injector Targeting .............................................................................................................3-21

Figure 3-11 - Dual Spray Injector Separation and Orientation Angle .................................................... 3-25

Figure 3-12 - Sample Single and Dual Spray Injector Patternator Results ........................................... 3-26

Figure 3-13 Injector Opening and Closing Response............................................................................ 3-27

Figure 3-14 - High Pulse-Width Flow Effects. Static Occurs at 10 msec (rep. rate = 10 msec)...........3-29

Figure 3-15 - Low Pulse-Width Flow Effects. (Rep. rate = 10msec) ...................................................3-29

Figure 3-16 - Injector Flow Curve Tailbiting...........................................................................................3-31

Figure 3-17 - Linear Range....................................................................................................................3-32

Figure 3-18 - Injector Working Flow Range ........................................................................................... 3-34

Figure 3-19 Fuel Rail Total Tip Leak Monte Carlo Simulation Example (4 cylinder)............................3-36

Figure 4-1 - Block Diagram ...................................................................................................................... 4-1

Figure 4-2 - Example of Recommended Mounting Feature Dimensions ................................................4-4

Figure 4-3 - Example of data presentation for steady state rpm. ............................................................4-7

Figure 4-4 - Typical Spectral Map............................................................................................................4-7

Figure 4-5 Injector Connector Polarity '+'..............................................................................................4-10

Figure 4-6 - Injector Electrical Connectors ............................................................................................4-11

Figure 4-7 - Metri-Pack Harness Connector ..........................................................................................4-12

Figure 4-8 - USCAR Harness Connector...............................................................................................4-13

Figure 4-9 - Electrical schematic of saturated switch injector driver circuit ........................................... 4-15

Figure 4-10 - Oscilloscope trace of injector avalanche energy measurement ......................................4-16

Figure 5-1 - Injector Firing Schemes (red bar = injection event) .............................................................5-4

Figure 5-2 - Slope and intercept graph (Flow vs. Pulse Width) ............................................................... 5-5

Figure 5-3 - Sequential injection timing considerations (4500 rpm) ......................................................5-16

Figure 6-1 Injector Seal Ring Installation Precaution .............................................................................6-3

Delphi Energy and Chassis Systems

Revision: 11/05-1 v

Page 10

Table of Contents Multec 3.5 Fuel Injector Application Manual

Figure 6-2 Injector Installation Surface .................................................................................................... 6-5

Figure 7-1 - Thermocoupled injector........................................................................................................ 7-2

vi Delphi Energy and Chassis Systems

Revision: 11/05-01

Page 11

Multec 3.5 Fuel Injector Application Manual Introduction

1.0 Introduction

1.1 Scope of Document

This Application Manual communicates Multec 3.5 Top Feed Port Fuel

Injector application guidelines for spark ignition engines.

1.2 Classification

The information and specifications in this manual covers Multec 3.5

gasoline fuel injectors.

1.3 Document Management

This document shall be maintained by Delphi. Express written consent of

Delphi must be obtained before any use or modification of this document

is permitted.

1.3.1 Document Release and Updates

The information contained in this manual is accurate and current as of the

date of publication. As changes occur that update the content of the

manual a new manual revision shall be released. All updates shall be

issued and distributed by Delphi-E&C electronically. The latest revision

shall be uploaded to an Applications Engineering website for access

throughout Delphi. http://hal.roc.acr.gmeds.com/applications/

1.4 Commercial Considerations

All commercial considerations/cost and scheduling requirements shall be

handled by the Delphi Sales and Marketing Group.

1.5 Objectives of this Manual

Delphi provides advanced fuel systems technology for both automotive

and non-automotive applications. The Multec 3.5 Fuel Injector is an

example of Delphi leadership and its commitment to continuous

improvement and world-class quality.

This Multec 3.5 Fuel Injector Application Manual has been developed to

support the efforts to integrate the Multec 3.5 Fuel Injector into a specific

fuel system or engine management system.

Delphi Energy Chassis Systems Revision: 11/05-1 1-1

Page 12

Introduction Multec 3.5 Fuel Injector Application Manual

The objectives of this document are to help:

• Obtain maximum value and optimum performance from the Multec

3.5 Fuel Injector

• Integrate the Multec 3.5 Fuel Injector within the engine control system

(hardware and software)

• Protect the Multec 3.5 Fuel Injector from damage caused by improper

usage, mounting, handling, or installation

• Prevent testing errors that might result in an inaccurate evaluation of

Multec 3.5 Fuel Injector performance

• Prevent calibration errors that may interfere with the proper operation

of the Multec 3.5 Fuel Injector

To accomplish these objectives, this manual provides the following:

• A description of the components and features of the Multec 3.5 Fuel

Injector

• A description of the process used to determine the requirements

needed to achieve the following objectives:

− Accurate fuel flow requirements

− Proper injector spray

− Proper injector spray targeting

• A description of the options for packaging and mounting, as well as the

optional features available to meet underhood packaging, serviceability

and diagnostic requirements

• Calibration and testing guidelines

• A checklist of interface details required for Delphi to ensure that the

proper fuel injector selection is made to meet customer requirements.

The fuel injector should be specified based upon the constraints/

demands of the engine control module (engine controller and software)

and the chassis fuel supply subsystem (fuel rail, fuel pressure regulator,

fuel pump, fuel filter and supply lines).

1.6 How this Manual is Arranged

An overview of each section in this manual is provided below.

1-2 Delphi Energy and Chassis Systems

Revision: 11/05-01

Page 13

Multec 3.5 Fuel Injector Application Manual Introduction

Section 1.0 — Introduction

Section 1.0 provides an overview of the scope, objectives, and format of

this manual and lists documents on which it is based. The documents

listed in section 1.9 can be referred to for additional detail to aid in

understanding the requirements set forth in this manual.

Section 2.0 — Injector Fundamentals

Section 2.0 describes the characteristics and requirements of the Multec

3.5 Fuel Injector and its related components. Also discussed is an

overview of combustion fundamentals with a detailed description of how

the fuel system works together with the air/fuel delivery system and

exhaust gas treatment to meet vehicle emissions requirements.

Section 3.0 — Product Description

Section 3.0 provides an overview of fuel injector construction, materials,

performance and cost drivers. Physical and electrical specifications for

standard assemblies are defined and flow and performance specifications

for commonly available fuel injectors are provided. Also discussed is the

process Delphi uses to provide custom products.

Section 4.0 — System Interface – Hardware & Electrical

Section 4.0 describes and illustrates the mechanical and electrical

interfaces required to obtain optimum performance from the fuel injector.

The electrical interface, chassis fuel supply and fuel filtration interface are

also described.

Section 5.0 — System Interface – Software Controls

Section 5.0 provides both an overview and specific detail on the software

requirements to operate the fuel injector. Various control algorithms

commonly used to achieve optimum performance under varying engine

conditions are described, and additional algorithms, which are based on

emissions and driveability requirements, are recommended. Calibration

and diagnostics are also discussed. Understanding this section is critical

to achieving optimum performance from the Multec 3.5 Fuel Injector.

Section 6.0 — Product Handling

Section 6.0 presents Delphi recommendations for the handling, storage,

installation, and servicing of the fuel injector. Proper handling of the

product, from the time it arrives on the receiving dock until it is installed

in the vehicle, reduces the risk of accidental damage and helps ensure that

the fuel injector will function as intended.

Delphi Energy Chassis Systems Revision: 11/05-1 1-3

Page 14

Introduction Multec 3.5 Fuel Injector Application Manual

Section 7.0 — Recommendations and Precautions

Section 7.0 provides a summary of Delphi recommendations and

precautions for proper fuel injector use. Common misuses are identified

and alternate solutions presented.

Section 8.0 — Testing Procedures

Section 8.0 discusses testing procedures that are based on the experience

of Delphi and its customers. Adhering to the recommendations contained

in this section will ensure that the fuel injector is evaluated correctly under

conditions that parallel normal use and operation.

Section 9.0 — Validation Requirements

Section 9.0 outlines the process for validating the fuel injector, i.e.,

ensuring that it meets specified quality, reliability, and durability goals

and conforms to governmental standards/regulations.

Section 10 - Appendix

10.1— Introduction

10.2— Injector/ System Component Checklist

10.3— Multec 3.5 Injector Application Guideline Checklist

10.4— Component Assembly Best Practices

10.5— Glossary of Terms and Abbreviations

Section 11.0 — Index

1.7 Conventions Used in this Manual

The pages in this manual are formatted with a wide left margin. The

purpose of this format is to help locate important topics throughout the

document. The left margin contains additional information:

• key words and information to which special attention must be paid.

Other important information is shown in italic type and is preceded with

the boldface word NOTE, CAUTION, or WARNING.

•

Note—Indicates important technical detail that is relevant to the topic

being discussed.

•

Caution —Indicates information about a condition or an activity that

must be performed to prevent damage to the Multec 3.5 Fuel Injector,

fuel system, electronic control system, engine or the vehicle.

•

Warning —Indicates a condition that might pose a risk to personal

safety.

1-4 Delphi Energy and Chassis Systems

Revision: 11/05-01

Page 15

Multec 3.5 Fuel Injector Application Manual Introduction

Note: Unless otherwise noted, the numbered figures displayed in this

manual are illustrations, not technical drawings. As such, these

illustrations may not reflect actual dimensions. All final critical

dimensions should be confirmed on part prints.

1.8 Hyperlinks

All references to section numbers, figures and tables are hyperlinks that

will jump to the section of the document containing the reference when

the mouse is left clicked over the reference number. (Applies only to

WORD version of the applications manual.)

1.9 Applicable Documents

1.9.1 Order of Precedence

When there appears to be a contradiction between this application manual

and an outline drawing or other document, the conflict must be formally

resolved through the Delphi application engineer. Until the contradiction

can be resolved, the part outline drawing will always take precedence.

Nothing in this document shall be considered to supersede any applicable

law or regulation unless a specific exemption has been obtained.

1.9.2 Government Documents

To be supplied by customer for specific country.

1.9.3 Other Delphi Reference Documents

1.9.3.1 Multec 3.5 Fuel Injector specific Part Number and associated outline drawing

1.9.3.2 Multec 3.5 Fuel Injector Component Technical Specification (or equivalent document) if

available

1.9.3.3 Delphi Fuel Rail Applications Manual

1.9.3.4 Delphi Catalytic Converter Applications Manual

1.9.3.5 Delphi Fuel Pump Applications Manual

1.9.3.6 Delphi EGR Applications Manual

1.9.3.7 SFMEA

1.9.3.8 OBD-II Diagnostic Procedures

1.9.3.9 Delphi Worldwide Emissions Standards summary booklet

Delphi Energy Chassis Systems Revision: 11/05-1 1-5

Page 16

Introduction Multec 3.5 Fuel Injector Application Manual

1.9.4 Industry Documents

1.9.4.1 SAE Standard Procedure J1832

1.9.4.2 SAE J-2715 (Draft) Gasoline Fuel Injector Spray Measurements and Characterizations

1.9.4.3 ASTM D86, “Standard Test Method for Distillation of Petroleum Products at Atmospheric

Pressure”

1.9.4.4 ASTM D2533, “Standard Test Method for Vapor-Liquid Ratio of Spark-Ignition Engine

Fuels”

1.9.4.5 ASTM D4814, “Standard Specification for Automotive Spark-Ignition Engine Fuel”

1.9.4.6 ASTM D5191, “Standard Test Method for Vapor Pressure of Petroleum Products (Mini

Method)”

1.9.4.7 World Wide Fuel Charter

1.9.4.8 Internal Combustion Engine Fundamentals. John B. Heywood, McGraw-Hill Publishing,

1988.

1.9.5 Useful Web Sites

1.9.5.1 EPA Vehicle Emissions Information:

http://www.epa.gov/ebtpages/airmobilevehicleemissions.html

1.9.5.2 CARB Web Site: http://www.arb.ca.gov/

1.9.5.3 Delphi Corp Web Site:

http://www.delphi.com/

1-6 Delphi Energy and Chassis Systems

Revision: 11/05-01

Page 17

Multec 3.5 Fuel Injector Application Manual Fundamentals

2.0 Fundamentals

2.1 General

The Multec 3.5 Fuel Injector is a component of the Air/Fuel Subsystem.

The function of the fuel injector is to provide the required fuel quantity

and spray geometry to the each engine cylinder to meet vehicle

performance and emissions requirements over a wide range of operating

conditions. The Multec 3.5 Fuel Injector is designed for electronic port

fuel injection systems, which maintain an individual fuel injector for each

engine cylinder and operate the individual injectors via an electrical

signal. The control logic for each injector is typically governed through an

electrical control module that is provided by the customer. The customer

develops the logic with input from Delphi.

The fuel injector supply system typically consists of the fuel injectors, a

fuel rail or conduit, a fuel pressure regulator and connections to fuel

supply and return lines. This portion of the fuel system is installed directly

to the intake system of the engine. On some applications, especially

returnless fuel systems, a mechanical device for damping fuel pressure

pulsations may be incorporated to reduce fuel line "hammer". Returnless

fuel systems do not have a return line connection and typically incorporate

the pressure regulator either closer to or within the fuel supply tank. (See

Fuel Rail Applications Manual for more details.)

The vehicle fuel system includes the above mentioned injector supply

system as well as fuel supply and return (optional) lines, fuel filter, fuel

pump and fuel tank. The evaporative emissions system, while not directly

linked to the fuel injector supply system, must be considered, as vapor

purge from this system into the engine intake system will directly impact

how the fuel injector is controlled under certain conditions.

Delphi Energy and Chassis Systems

Revision: 11/05-1 2-1

Page 18

Fundamentals Multec 3.5 Fuel Injector Application Manual

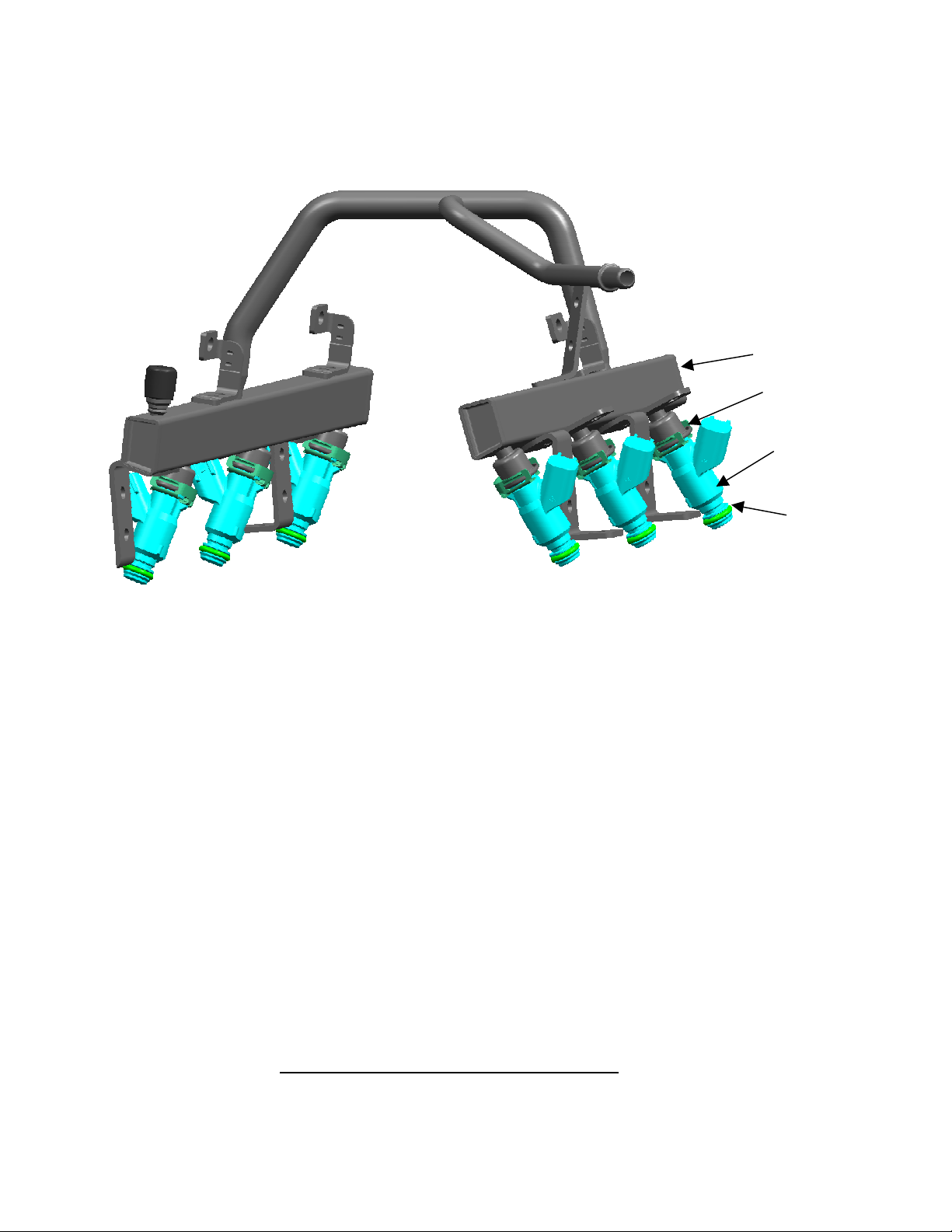

Fuel Rail

Injector Clip

Multec 3.5

Fuel Injector

Figure 2-1- Engine Fuel System (shown is a demand fuel rail for a V6 application)

2.2 Engine Combustion Fundamentals

Internal combustion is a complex process involving interactions of many

engine subsystems over widely changing conditions. A complete

explanation of these interactions and requirements and the theory of

combustion are outside the scope of this manual. The following subsections summarize the major considerations involved with the fuel

injector’s impact on combustion. If a more detailed explanation is

required on any of these topics, please contact Delphi Energy and Chassis

Systems.

Manifold Seal

The following text is suggested for those who would like a more

comprehensive understanding of internal combustion engine operation and

theory:

Internal Combustion Engine Fundamentals. John B. Heywood,

McGraw-Hill Publishing, 1988.

2-2 Delphi Energy and Chassis Systems

Revision: 11/05-1

Page 19

Multec 3.5 Fuel Injector Application Manual Fundamentals

2.2.1 Air/Fuel Ratio Effects on Combustion

The goal of the Multec 3.5 Fuel Injector is to supply the correct fuel mass

to achieve the correct air/fuel ratio (A/F). Complete combustion will

depend, in general, on the following:

• The air and fuel must be in the proper portions (referred to as the

stoichiometric mixture or ratio); this proportion will depend upon the

chemistry of the fuel.

Ref. Sec 2.2.1.1

Ref Sec. 2.2.7.2 & 8.4.1

Note

Note: Stoichiometric A/F refers to the quantitatively derived ratio of air

to fuel that will allow the chemical process of combustion to be delivered

to ideal equilibrium. In this manual, A/F is stated in terms of their

molecular weights – that is, molecular weight of air over molecular

weight of fuel.

• The mixture must be in vapor state, as liquid fuel is not combustible.

Note: In order to eliminate any confusion, it is important to note that for

the fuel injection process fuel must be in a liquid state in order to be

properly metered by the fuel injector. Vapor formation before the

injection process is highly undesirable and can cause a host of

driveability problems (See Sec. 2.2.7.2 and 8.4.1). However, it is

important for the actual combustion process that fuel is in the vapor

state. This is typically achieved through the fuel spray and particle size

characteristics of the liquid fuel after it is injected. Other factors, such as

injection time, fuel spray targeting, residence time and the air induction

characteristics all play a role in this process.

Throughout this manual, it should be assumed that when A/F ratios are

stated as being stoichiometric, it is in reference to standard nonoxygenated fuels unless specifically stated otherwise. It should be noted

that oxygenates (MTBE, ethanol) have a higher (lower numerically)

stoichiometric air/fuel ratio than standard gasoline. This effectively

means that more fuel is needed for the same intake airflow to obtain

complete combustion.

2.2.1.1 Stoichiometric Mixtures, Definitions

As noted in the last section, stoichiometric A/F refers to the quantitatively

derived ratio of air to fuel that will allow the chemical process of

combustion to be delivered to ideal equilibrium. Typical values for this

are 14.7:1 for standard, non-oxygenated gasoline. Stoichiometry values

for alternate fuel blends are shown in Table 2-1.

Delphi Energy and Chassis Systems

Revision: 11/05-1 2-3

Page 20

Fundamentals Multec 3.5 Fuel Injector Application Manual

Since the A/F will vary depending on the makeup of hydrocarbons in the

gasoline, a more appropriate method for referencing A/F is to use a

normalized value. In this way, we can refer to stoichiometric A/F as equal

to 1, regardless of the makeup of the gasoline. Two such terms are

commonly used:

• Lambda (λ), where λ= (A/F actual) / (A/F stoichiometric). This is also

referred to as the excess air ratio.

• λ > 1.00 for lean mixtures

• λ < 1.00 for rich mixtures

• Equivalence Ratio (φ), where φ= (F/A actual) / (F/A stoichiometric)

• φ < 1.00 for lean mixtures

• φ > 1.00 for rich mixtures

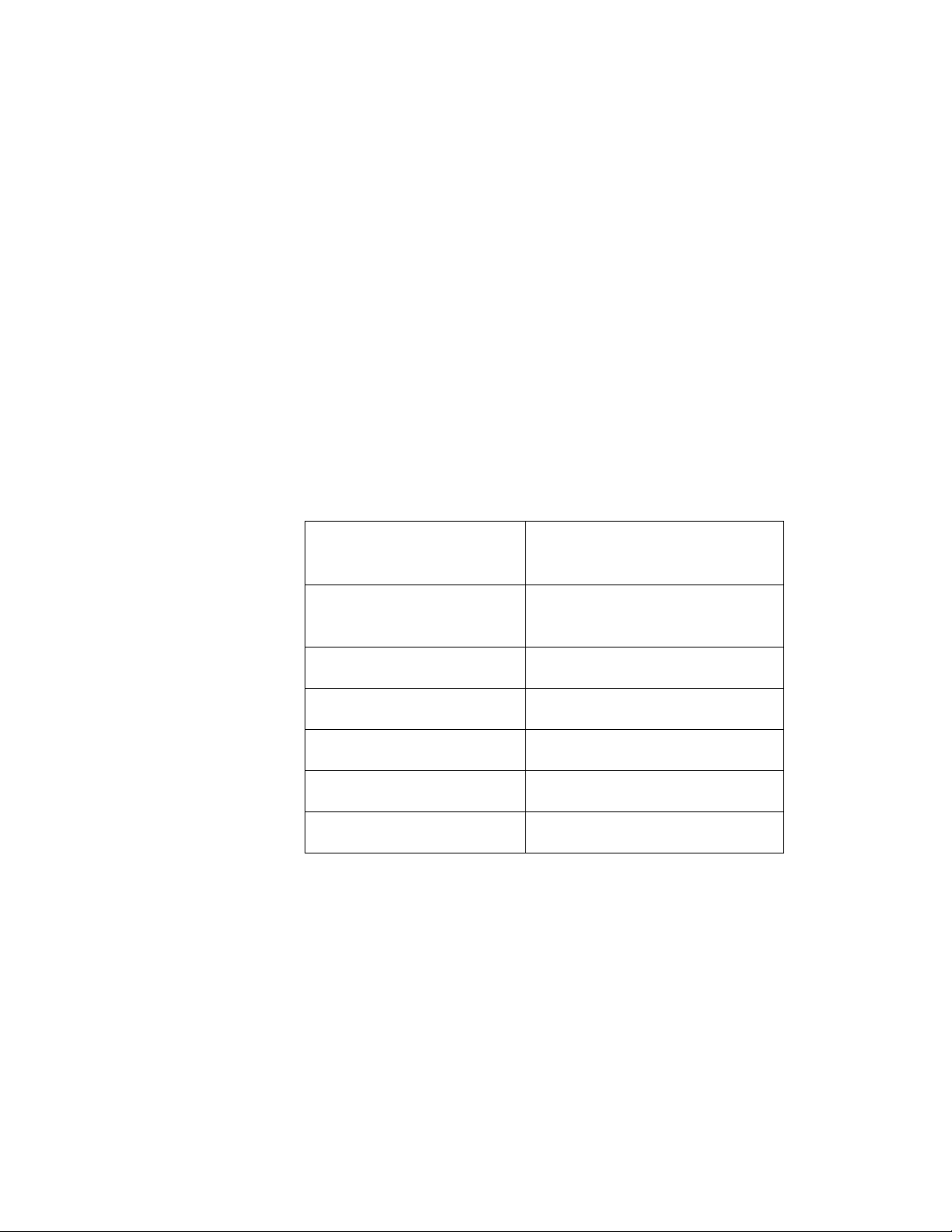

Fuel Type Stoichiometric Air /Fuel

Typical Unleaded

Gasoline

10% Ethanol Blend 13.9

24% Ethanol Blend 13.3

85% Ethanol Blend* 9.95

15% MTBE Blend 14.1

100% Ethanol* 9.0

*Non-standard fuels requiring special fuel rail and injector

components.

Table 2-1 - Stoichiometry of Alternate Fuel Blends

2.2.1.2 Stoichiometric “Ideal” Combustion Mixtures

Ratio

14.5 (Range 14.2 – 14.8)

Complete or “ideal” combustion produces by-products of carbon dioxide

(CO2), nitrogen (N2) and water (H2O). However, ideal combustion does

not occur in an actual engine. The chemical equilibrium required is often

difficult to achieve. Transient operating conditions, combustion chamber

2-4 Delphi Energy and Chassis Systems

Revision: 11/05-1

Page 21

Multec 3.5 Fuel Injector Application Manual Fundamentals

design, fuel quality (contaminants and other non-combustibles) and the

limited time available to complete the process (especially at high engine

rpm.) all contribute to less than ideal combustion.

A catalytic converter is usually used in the exhaust system to transform

the harmful by-products of combustion to less harmful gases:

HC, CO, NOx Three-way catalyst H2O, CO2, N2

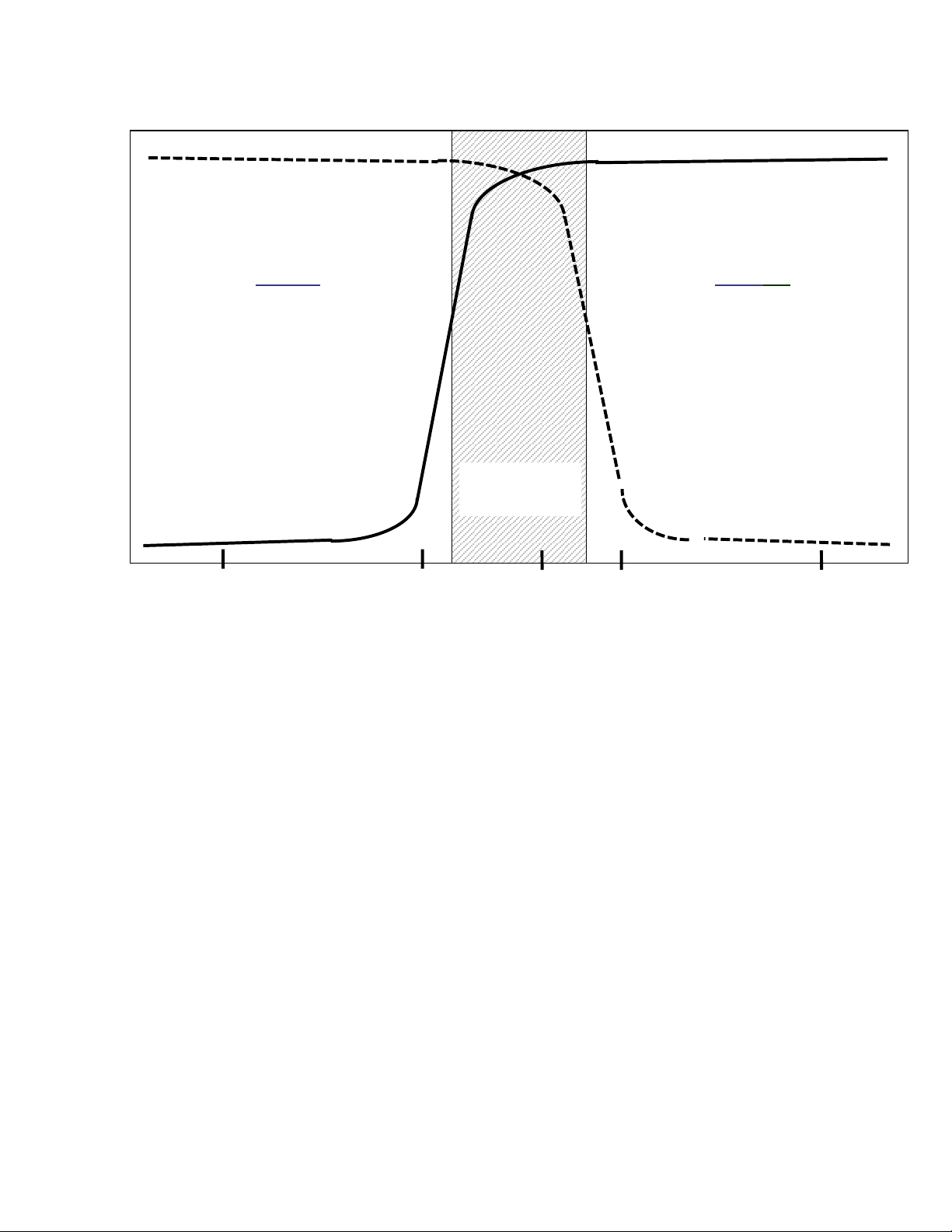

Figure 2-2 illustrates the relationship between the air/fuel ratio and

catalytic converter efficiency. Optimum converter efficiency is achieved

at 14.5 +/- 0.3 A/F.

2.2.1.3 Rich Mixtures

• A mixture with "excess fuel"; also described by a Lambda < 1.00 or an

equivalence ratio >1.00

Rich mixtures have a larger proportion of fuel relative to the

stoichiometric ratio, which typically results in increased fuel consumption

and hydrocarbon emissions. As the amount of fuel in the ratio increases, it

displaces intake air, and thus oxygen, in the mixture. This lack of oxygen

results in some portion of the fuel to be incompletely combusted, thus

increasing hydrocarbon emissions. If excessively rich, the lack of oxygen

can also result in a large increase in carbon monoxide emissions (CO).

Controlled rich mixtures are regularly used at vehicle start-up when the

engine is cold. This is done to help ensure vehicle start and performance

quality, as it is more difficult for fuel to vaporize under these conditions.

Rich mixtures may also be used under conditions where maximum engine

power is required, or to help protect the catalytic converter under high

load conditions.

Delphi Energy and Chassis Systems

Revision: 11/05-1 2-5

Page 22

Fundamentals Multec 3.5 Fuel Injector Application Manual

Converter Efficiency (%)

100

80

60

40

Conversion Efficiency for a Typical Three-Way Catalyst

Rich Region: where little O

available, so reduction can easily

be done to NO

means stripping away oxygen)

. (Reduction

X

2

is

Lean Region: where excess O2 is

available to oxidize HC & CO.

(Oxidizing means adding oxygen)

Window

CO

+/- 0.3

NO

13.0 14.0 14.6 15.0 16.0

Figure 2-2 - Air Fuel Ratio Effect on Catalytic Converter Efficiency

2.2.1.4 Lean Mixtures

Air/Fuel Ratio

• A mixture with "excess air"; also described by a Lambda >1.00 or an

equivalence ratio <1.00

Lean mixtures have excess oxygen and higher combustion temperatures

resulting in increased oxides of nitrogen (NO

) emissions. Nitric oxide

x

(NO) is the primary oxide created. It forms at a significant rate when

combustion chamber temperatures are above 1200 oF (650oC.) The rate

of NOx formation increases with excess oxygen concentration,

temperature and time at temperature. NOx is typically highest just lean of

stoichiometry. Lean mixtures above a 16 – 17 to 1 air/fuel ratio decrease

NOx production due to the lowering of combustion temperatures.

While NOx production is an undesirable product of running slightly lean,

there are several benefits that can be realized by running lean of

stoichiometry. A controlled lean combustion process can reduce the

output of hydrocarbon (HC) and carbon monoxide (CO) emissions, as well

as reducing fuel consumption. Diluting the intake charge with a non-

2-6 Delphi Energy and Chassis Systems

Revision: 11/05-1

Page 23

Multec 3.5 Fuel Injector Application Manual Fundamentals

L

combustible dilutant can reduce NOx. One of the most common of these

is exhaust gas, recirculated into the mixture via an EGR system. (Ref.

Delphi EGR Applications Manual for more information on this process).

2.2.1.5 Non-Combustible Mixtures

Air/fuel ratios outside the combustible mixture limits (too rich or too lean)

cause engine misfire, reduced power, a significant increase in emissions

(primarily HC from unburned fuel) and poor overall engine performance.

Combustible mixture limits are dependent on many factors, some of which

are combustion chamber design, ignition system energy, fuel composition,

amount of EGR, etc.

2.2.2 Fuel Atomization

Fuel atomization is the transformation of bulk fuel into spray. Fuel enters

the intake port as an atomized stream. The fuel droplets evaporate when

they mix with the air and also when they contact a hot surface. When the

intake valve opens, the air/fuel mixture passes into the cylinder where it

mixes with residual exhaust gases. Combustion is initiated near the end of

the compression stroke when the spark plug fires.

The optimum fuel spray characteristics for a particular application are

dependent upon the following:

• Intake manifold design

• Mixture motion control device

• Combustion chamber characteristics

• Spark plug configuration

• Injector spray targeting

• Injection timing

• The temperature of the target area

These criteria must be validated.

Combustion requires vaporized fuel. One of the functions of the fuel

injector is to atomize the fuel. Smaller fuel particles are both easier to mix

uniformly with air and require less heat to vaporize. Fuel particle size is

dependent on system fuel pressure, spray pattern, and injector spray

orifice design.

Note

imits to these characteristics must be totally understood. Combustion

efficiency and rate are dependent on specific application and fundamental

engine design.

Delphi Energy and Chassis Systems

Revision: 11/05-1 2-7

Page 24

Fundamentals Multec 3.5 Fuel Injector Application Manual

f

2.2.3 Fuel Spray Characteristics and Injection Timing

For maximum vaporization, fuel is typically targeted at the intake valve,

as it is typically the hottest surface in the combustion chamber induction

path. Fuel is typically injected before the intake valve opens and is

allowed some residence time to allow the fuel to vaporize. Fuel

vaporization also occurs as the air/fuel mixture passes the valve on its way

toward the combustion chamber. As the time between valve events

decreases (as engine rpm increases), the time for vaporization is also

reduced.

PZEV (partial zero emission vehicle) exhaust emission regulations have

placed additional emphasis on fuel delivery (atomization and timing.) The

majority of the tailpipe emissions measured during a Federal Emissions

Test Procedure (FTP) are generated during the time period between engine

start and catalytic converter warm-up (reference section 2.2.7.3.)

Alternate fuel delivery schemes may be employed during this time period

to minimize emissions. Consult with your Delphi Applications Engineer

for more information.

Note

See Section 5 for

calibrating optimum

injection timing

Note

Reference Worldwide Emissions Standards booklet available from Delphi

or emissions regulations and test profiles.

Spray not targeted at the intake valve can be stored as liquid on the intake

port walls. The conditions when this collected fuel enters the combustion

chamber may be difficult to predict, affecting engine emissions and

driveability.

Typically, open intake valve fuel injection timing is not recommended for

conventional fuel injection systems with Multec 3.5 injectors because the

fuel bypasses the heating effects of the intake valve. If injection takes

place as the intake valve first opens, the reversion pulse at the end of the

exhaust stroke can divert the spray, greatly affecting both the targeting of

the spray and the particle size. If injection occurs just as the intake valve

closes, the fuel spray may be affected by a back flow of air caused by the

pressure wave generated by the valve’s closure.

Direct injection schemes that utilize open valve injection require specific

hardware. Please consult a Delphi representative for more information on

Delphi direct injection (DI) fuel systems.

This manual covers only the basics of spray particle size, targeting and

injector timing. Consult a Delphi Applications Engineer for more

information.

2-8 Delphi Energy and Chassis Systems

Revision: 11/05-1

Page 25

Multec 3.5 Fuel Injector Application Manual Fundamentals

2.2.4 Benefits of Electronic Fuel Injection Over Other Types of Fuel Systems

Electronic fuel injection has enabled engines to meet tighter exhaust

emissions standards through improved fuel control. Engine calibration

software can be programmed to deliver the precise amount of fuel required

by the engine under all operating conditions. Typical A/F ratio

distribution requirements are +/- 1.0 cylinder to cylinder

In addition, evaporative emissions standards require closed fuel systems

using seal rings and minimal tip leakage. The Multec 3.5 injector is a dry

coil design. There are no internal seal rings, eliminating possible sources

of evaporative emissions.

Purging the evaporative canister during engine operation requires better

control of lower fuel rates, placing greater demands on the low pulse

width capability of the injector (see section 2.4.3).

2.2.5 Impact of Transient Conditions on Combustion

See Section 3.9.1

The term "transient conditions" is used to describe a change in engine load

and/or operating conditions. The primary focus is in response to drivercommanded vehicle acceleration or deceleration maneuvers, but other

changes in state, such as transmission gear changes, torque converter lock

condition (automatic transmissions) and air conditioning compressor

engagement can impact fueling requirements. The impact of transient

conditions on combustion and emissions are typically magnified during

cold engine operating conditions.

During these transient conditions, the amount of fuel required and the

amount of fuel delivered may be different as there is likely to be some

"lag" between the actual change in state and the response of the fuel

injection system to these changes. In addition, fuel that builds up on

manifold walls or in crevices during steady state engine conditions may be

suddenly forced into the engine due to rapid changes in engine pressure

and airflow. This can be detrimental to driveability and emissions. These

differences in fuel delivery can be accounted for by software corrections

such as wall wetting compensations, deceleration enleanment and

acceleration enrichment.

When the vehicle is in a coasting (overrun) condition with the throttle

closed, the fuel supply to the cylinder can be stopped by shutting off the

injectors. This aids in further reducing the power output of the engine and

conserves fuel. Transitions into and out of this mode often require very

small amounts of fuel delivered in rapid fashion to minimize the impact on

vehicle performance and stability.

Delphi Energy and Chassis Systems

Revision: 11/05-1 2-9

Page 26

Fundamentals Multec 3.5 Fuel Injector Application Manual

p

Caution

Extreme transient conditions can require low pulse-widths. Commanded

ulse-widths must not fall below the application’s minimum specifications.

Inconsistencies in injector flow, pulse-to-pulse and part-to-part result

when operated below minimum recommended ranges.

2.2.6 Impact of Fuel Composition

2.2.6.1 Overview

Gasoline is a complex variable mixture of hydrocarbons, and can include

oxygenates such as ethanol, MTBE, etc. The net overall effect on

combustion depends on both the average properties of the fuel, e.g.,

average hydrogen-to-carbon ratio (H/C) and the molar percent or

molecular weight of each of the hydrocarbon species present. The lower

molecular weight hydrocarbon constituents, which are easier to burn, tend

to increase fuel volatility, making it easier to vaporize the fuel. The

higher molecular weight constituents, which are harder to burn, tend to

reduce fuel volatility. The presence of these higher molecular weight

constituents may increase the potential for engine deposits. Reference

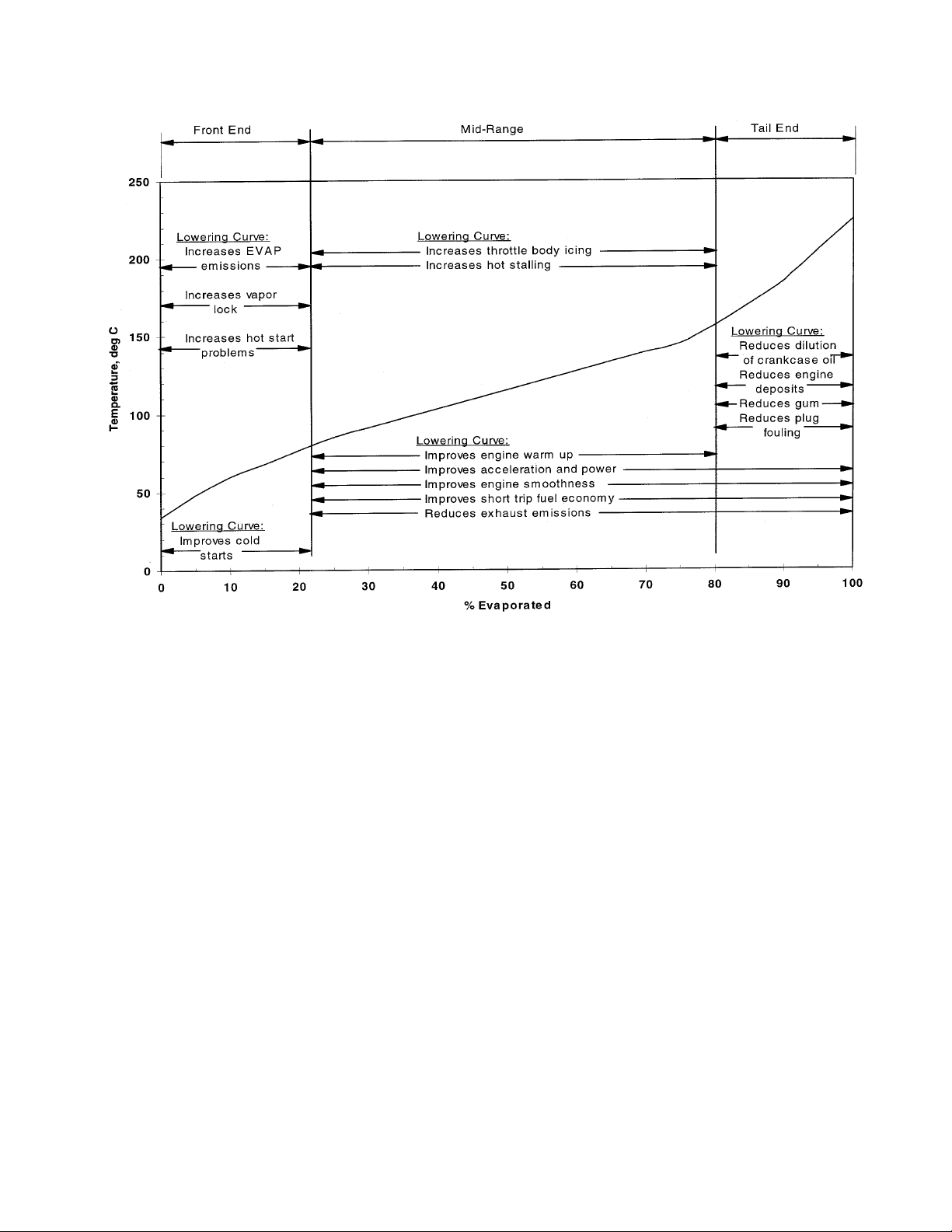

Figure 2-3 for fuel distillation curve vs temperature properties, and the

effects of changing distillation properties on vehicle and fuel system

performance.

Fuel composition is adjusted by the fuel supply companies throughout the

year to best match the volatility of the fuel to the climate in which the fuel

is used. Reference World Wide Fuel Charter or ASTM D4814, “Standard

Specification for Automotive Spark-Ignition Engine Fuel”. Fuels outside

these specifications can compromise fuel injector performance.

2.2.6.2 Gasoline Composition – Oxygenates – Reformulated Gasoline (RFG)

As part of the U.S. Clean Air Act of 1990, oxygenated fuels are required

in ozone non-attainment areas to help reduce CO emissions. Oxygenates

help reduce the reactivity of the exhaust gas, and thus help reduce smog

formation. The California Air Resource Board (CARB) has phased out

the use of MTBE as an oxygenate. CARB Phase III fuel was introduced

during 2003 and uses ethanol as the oxygenate. In addition, many states

in the US have or are planning to phase out MTBE.

MTBE and Ethanol are common oxygenates used to provide the additional

oxygen in the combustion process to reduce CO emissions. Oxygenates

have higher stoichiometric air fuel ratios (rich relative to standard

gasolines) for optimum combustion, due to a reduction in the energy

2-10 Delphi Energy and Chassis Systems

Revision: 11/05-1

Page 27

Multec 3.5 Fuel Injector Application Manual Fundamentals

p

content of the fuel (see Table 2-1.) This must be considered in the flow

sizing of the injector and fuel supply system, as a given application will

have slightly higher fuel consumption depending on the percentage of

oxygenate in the fuel.

Ref. Sec. 2.2.7.2 & 8.4.1

Note:

In addition, small additions of these oxygenated fuels can greatly increase

the volatility of the fuel. Since this may require the fuel system

calibration to be adjusted to accommodate these types of fuels, vehicle

development testing at both hot and cold temperature extremes with these

fuels is recommended.

In general, increasing oxygenate concentrations tend to increase

deterioration of plastics and swell in elastomers. Because oxygenates

increase the solubility of water in the fuel, use of these types of fuels can

accelerate wear and corrosion in fuel system components.

For high ethanol concentration fuels, deviations from regulated or typical

levels of pHe and corrosives could compromise fuel injector performance.

Delphi tests most fuel system components to be robust to typically

available U.S. oxygenated fuel blends (maximum 2.7 mass% oxygen,

which is roughly 15% MTBE or 10% denatured ethanol). Higher

ercentages of alcohols will shorten the operating life of the injector.

Please consult a Delphi representative to obtain a current list of all fuels

the Multec 3.5 Fuel Injector has been validated in.

Specific injector models are available from Delphi with enhancements to

operate with higher oxygenated blends.

2.2.6.3 Gasoline Composition

The following provides an overview of how other constituents in gasoline

can impact both performance and emissions.

2.2.6.3.1 Paraffins (approx. 54 %mass)

As paraffin concentration increases:

• Soot formation reduced

• Resistance to surface ignition increased

• Reduced heating value (thus lower energy content and increased fuel

consumption)

• Effects octane rating

Delphi Energy and Chassis Systems

Revision: 11/05-1 2-11

Page 28

Fundamentals Multec 3.5 Fuel Injector Application Manual

2.2.6.3.2 Aromatics (approx. 35 %mass)

As aromatic concentration increases:

• Increases octane rating

• Increases energy content (increases fuel economy)

• Makes fuel more difficult to burn

• Reduces fuel volatility

• Increases self ignition temperature

• Increases soot formation

• Increases deterioration of fuel system plastics and elastomer (swell)

• Increases solubility of water

• Reactivity of exhaust gas (smog formation)

2.2.6.3.3 Olefins (approx 10%)

2.2.6.3.4 Others

Olefins are unsaturated hydrocarbons that can lead to deposit formation on

intake valves and injector tips. Olefins are created in the refining process.

Gasolines with high levels of olefins require additional detergent chemical

additives to prevent deposit formation on the injector director plate.

Silicon and lead content in gasoline can be detrimental to oxygen sensors;

lead content can lead to products of combustion that can potentially cause

injector plugging and have been shown to be detrimental to both catalysts

and exhaust gas recirculation devices.

Sulfur in gasoline has been shown to reduce catalytic converter efficiency.

CARB regulations reduced sulfur to 30 ppm average 80 ppm max for Tier

2 emissions. The EPA will complete the phase in of these regulations in

2006.

2-12 Delphi Energy and Chassis Systems

Revision: 11/05-1

Page 29

Multec 3.5 Fuel Injector Application Manual Fundamentals

Figure 2-3 - Fuel Distillation Curve vs Temperature

2.2.6.4 Driveability Index

A more complete understanding of the impact of fuel volatility on fuel

system performance can be obtained by measuring the fuel’s distillation

curve and computing the driveability index (DI). Figure 2-3 shows a fuel

distillation curve and which aspects of engine performance are impacted

for a typical gasoline.

DI = 1.5T

evaporated temperatures measured by ASTM D86. Temperatures are

specified in °F.

AAMA and ASTM proposed limits for DI are 1200 to 1290 max. DI

values exceeding these limits have been documented to produce customer

dissatisfaction due to reduced driveability.

+ 3T50 +T90 where T10, T50, T90 are the 10%, 50% and 90 %

10

Delphi Energy and Chassis Systems

Revision: 11/05-1 2-13

Page 30

Fundamentals Multec 3.5 Fuel Injector Application Manual

N

f

2.2.7 Engine-Vehicle Environment

2.2.7.1 Impact of High Engine Temperatures on Combustion

As the engine and engine compartment temperatures increase, several

factors must be considered to obtain optimum combustion. Hot air

entering the induction system is lower in density and results in a reduced

mass air flow rate. To maintain the optimum air/fuel ratio, the engine

controller must reduce the amount of metered fuel. Speed density

systems, which do not have the ability to directly measure intake airflow,

utilize an inlet air temperature sensor to estimate the reduction in mass

airflow at elevated temperatures. Mass airflow systems are capable of

reading reduced airflow rates directly from the calibrated air flow meter

Refer to Section 5

ote: Low pulse-widths, such as at idle or during overrun conditions,

could fall below the injector minimum working flow range under elevated

temperature conditions. This could cause pulse-to-pulse variations that

directly affect idle quality. The impact on idle quality depends on the

injector firing scheme. Typically the minimum commanded pulse width is

limited in the engine control software.

It is important to consider these operating conditions when determining

the proper flow size for the injector.

2.2.7.2 High Ambient Temperature Startability

Reference section 8.4.1

or Hot Fuel Handling

Tests.

While high ambient temperature conditions must be evaluated for most

engine components, several conditions in combination can cause specific

problems for the fuel system.

In general, fuel system components reach their peak temperatures after the

vehicle has been shut down. This period is usually referred to as the soak

period. It is during this soak period that problems may occur if the vehicle

is re-started.

During normal operation, the fuel injector does not typically see extreme

temperatures because the fuel flowing through the tip helps dissipate heat

energy. When the vehicle is shut down, fuel is no longer flowing through

the injector. Injector tip temperatures rise and can eventually reach an

equilibrium temperature with their surrounding environment in the intake

manifold or cylinder head.

The problems typically encountered are due to the premature vaporization

of fuel, either upstream of the metering orifice in the injector or as liquid

fuel passes through the metering orifice and "flashes" to vapor. Although

the fuel system is under pressure, the temperature can rise to the point that

this pressure is no longer able to suppress formation of vapor.

The likelihood that a particular fuel will vaporize is characterized by its

2-14 Delphi Energy and Chassis Systems

Revision: 11/05-1

Page 31

Multec 3.5 Fuel Injector Application Manual Fundamentals

volatility. The volatility of gasoline is measured by the RVP (Reid Vapor

Note

Pressure). Typically, RVP is stated as the pressure required to suppress

the formation of vapor at 100° F (38° C.) Fuel in the vapor state

contains less heating energy by volume than fuel in the liquid state

causing a lean air fuel ratio.

Figure 2-4 shows the relationship between fuel vapor formation and fuel

type, RVP, and pressure. For equivalent RVP levels, E10 fuels form

vapor at lower temperatures than E0 (straight gasoline). Higher system

pressures suppress vapor formation.

The fuel vapor causes two problems:

• Vapor "bubbles" above the metering orifice restrict the flow of liquid

fuel through the metering orifice.

• Vapor "bubbles" do not deliver the same energy content as liquid fuel.

These two problems cause a lean shift, as the volume passed through the

metering orifice contains some percentage of vapor rather than 100%