Page 1

WORKSHOP MANUAL

DPS FUEL INJECTION PUMP

2008

DDNX117A(EN)

Page 2

(D) Kommen Sie nicht mit dem Hochdruckstrahl in Verbindung! Besonders nicht, wenn

Druckrohrleitung oder Dichtung geprüft werden! Hochdruckflüssigkeiten können tödliche

Verletzungen verursachen! Im Falle einer Berührung mit der Haut, kontaktieren Sie

sofort einen Arzt. Bitte beachten Sie die Gesundheits-/und Sicherheitsunterlagen.

(E) Mantenga las manos y el cuerpo lejos del rociado del líquido, especialmente inyectores,

tuberías y juntas de alta presión con fugas. La inyección de alta presión puede perforar

la piel humana y producir una lesión fatal. En caso de que la inyección atraviese la piel,

consiga atención médica inmediatamente. Vea la hoja de Datos de Sanidad y

Seguridad.

(EN) Do not put your skin into the fuel jets under pressure, especially those due to pressure

pipe or seal leaks. High pressure liquids can cause deadly injuries. In case of an

injection under the skin, contact a doctor immediately. Please refer to the health and

security fuel documents.

(F) Ne pas approcher les mains ni le corps des jets de liquides, particulièrement ceux

provenant des fuites de tuyaux et des joint soumis a la haute pression. Le liquide sous

haute pression injecté sous la peau peut causer des blessures mortelles. En cas

d’injection sous la peau, consulter immédiatement un médecin. Se reporter a la fiche de

santé et de sécurité du gazole.

(IT) Non esporre le mani o altre parti del corpo a getti di gasolio ad alta pressione,

specialmente a quelli provenienti da tubi o paraolii. I getti di liquidi ad alta pressione

possono causare ferite anche mortali. In caso di iniezione sotto pelle contattare

immediatamente un medico. Fare riferimento alle schede di sicurezza del gasolio.

(NL) Zorg dat uw handen of andere lichaamsdelen niet in contact komen met vloeistofstralen

onder hoge druk, met name bij een lek aan een leiding of dichting. Als de vloeistof onder

hoge druk onder de huid terechtkomt, kan dit zelfs tot dodelijke verwondingen leiden. Als

de vloeistof onder de huid terechtkomt, onmiddellijk een arts raadplegen. Lees de

gezondheids- en veiligheidsfiche met betrekking tot de brandstof.

(P) Não exponha a pele a jactos de combustível sob pressão, especialmente os devidos a

fugas de tubos de pressão ou vedantes. Líquidos a alta pressão podem causar

ferimentos mortais. No caso de injecção subcutânea, consulte imediatamente um

médico. Consulte por favor a documentação respeitante a saúde e segurança de

combustíveis.

(D) Schutzbrille/Gesichtsschutz tragen.

(E) Úsese protección para los ojos/la cara.

(EN) Wear eye/face protection.

(F) Porter un appareil de protection des yeux / du visage.

(IT) Proteggersi gli occhi/la faccia.

(NL) Veiligheidsbril/-masker gebruiken.

(P) Use protecção da face/olhos.

(D) Von Zündquellen fernhalten - Nicht rauchen.

(E) Conservar alejado de toda llama o fuente de chispas -No fumar.

(EN) Keep away from sources of ignition - No smoking.

(F) Conserver à l'écart de toute flamme ou source d'étincelles - Ne pas fumer.

(IT) Conservare lontano da fiamme e scintille - Non fumare.

(NL) Ver van open vuur en ontstekingsbronnen houden – Niet roken.

(P) Mantenha afastado de fontes de ignição – Proibido fumar.

(D) Geeignete Schutzhandschuhe tragen.

(E) Usen guantes adecuados.

(EN) Wear suitable gloves.

(F) Porter des gants appropriés.

(IT) Usare guanti adatti.

(NL) Aangepaste veiligheidshandschoenen dragen.

(P) Use luvas apropriadas.

Page 3

INTRODUCTION I

DISMANTLING II

COMPONENT INSPECTION AND RENEWAL III

REASSEMBLY IV

TESTING V

TABLE OF CONTENTS

DDNX117A(EN) - Issue 1 of 08/2008

i

© Delphi

Page 4

APPENDIX VI

Produced and published by:

Delphi Diesel Systems Ltd.

Spartan Close

Warwick CV34 6AG Tel: +44 (0) 1926 472 900

England Fax: +44 (0) 1926 472 901

TABLE OF CONTENTS

ii

DDNX117A(EN) - Issue 1 of 08/2008

© Delphi

Page 5

1.

INTRODUCTION

1.1 The Pump.......................................................................................................................................................................1-1

1.2 General...........................................................................................................................................................................1-2

1.3 This Manual...................................................................................................................................................................1-2

1.4 Equipment......................................................................................................................................................................1-2

1.5 Pump Name Plate..........................................................................................................................................................1-3

1.6 Replacement Of Parts...................................................................................................................................................1-4

INTRODUCTION I

TABLE OF CONTENTS

DDNX117A(EN) - Issue 1 of 08/2008

iii

© Delphi

Page 6

2.

DISMANTLING

2.1 Preparation....................................................................................................................................................................2-5

2.1.1 Cleaning and draining..................................................................................................................................2-5

2.1.2 Mounting the pump and initial inspection.................................................................................................2-5

2.1.3 General..........................................................................................................................................................2-5

2.1.4 Measuring drive shaft end float..................................................................................................................2-6

2.1.5 Measuring drive shaft radial play...............................................................................................................2-6

2.1.6 Removing sealing caps and locking wire...................................................................................................2-7

2.2 Governor Cover, Link Assembly & Control Levers.....................................................................................................2-7

2.2.1 Backleak connection, throttle lever stop screws and maximum fuel screw...........................................2-7

2.2.2 Cold idle advance (CIA) linkage..................................................................................................................2-8

2.2.3 Light load advance (LLA) linkage................................................................................................................2-8

2.2.4 Throttle lever................................................................................................................................................2-9

2.2.5 Torque trimmer..........................................................................................................................................2-10

2.2.6 Boost control device..................................................................................................................................2-11

2.2.7 Governor cover removal............................................................................................................................2-13

2.2.8 Dismantling the governor cover assembly..............................................................................................2-15

2.2.9 Throttle shaft and governor spring...........................................................................................................2-17

2.2.10 Control bracket and governor assembly..................................................................................................2-18

2.2.11 Governor control arm assembly and idle actuator.................................................................................2-20

2.3 High Pressure Outlets, End Plate Assembly, Shut-Off Solenoid & Transfer Pump...............................................2-21

2.3.1 High pressure outlets.................................................................................................................................2-21

2.3.2 End plate assembly....................................................................................................................................2-22

2.3.3 Shut-off solenoid........................................................................................................................................2-23

2.3.4 Transfer pump............................................................................................................................................2-23

2.4 Advance Device, Latch Valve And Rotor Vent Switch Valve...................................................................................2-24

2.4.1 Dismantling the advance device...............................................................................................................2-24

2.4.2 Advance housing........................................................................................................................................2-26

2.4.3 Latch valve..................................................................................................................................................2-27

2.4.4 Rotor vent switch valve.............................................................................................................................2-28

2.5 Hydraulic Head And Drive Shaft Assembly..............................................................................................................2-28

2.5.1 Releasing the hydraulic head....................................................................................................................2-28

2.5.2 Removing the drive shaft nut, key and thrust washer............................................................................2-29

2.5.3 Dismantling the shaft assembly................................................................................................................2-31

2.5.4 Pump housing............................................................................................................................................2-32

2.6 Removal Of The Head And Rotor Only......................................................................................................................2-33

2.6.1 Preparation.................................................................................................................................................2-33

2.6.2 Transfer pump and head fittings..............................................................................................................2-33

2.6.3 Releasing the hydraulic head....................................................................................................................2-34

II DISMANTLING

TABLE OF CONTENTS

iv

DDNX117A(EN) - Issue 1 of 08/2008

© Delphi

Page 7

3.

COMPONENT INSPECTION AND RENEWAL

3.1 Cleaning.......................................................................................................................................................................3-35

3.2 General.........................................................................................................................................................................3-35

3.2.1 Mated and matched assemblies...............................................................................................................3-35

3.2.2 Examination and replacement..................................................................................................................3-35

3.2.3 Seals............................................................................................................................................................3-35

3.3 Details...........................................................................................................................................................................3-36

3.3.1 Hydraulic head rotor..................................................................................................................................3-36

3.3.2 Hydraulic head plungers............................................................................................................................3-36

3.3.3 Cam ring and scroll plates.........................................................................................................................3-36

3.3.4 Rollers and shoes.......................................................................................................................................3-36

3.3.5 Transfer pump............................................................................................................................................3-36

3.3.6 End plate and transfer pump liner............................................................................................................3-36

3.3.7 Control valves.............................................................................................................................................3-36

3.3.8 Delivery valves and cambox pressurising valves....................................................................................3-37

3.3.9 High pressure outlet pressurising valves.................................................................................................3-37

3.3.10 Springs........................................................................................................................................................3-37

3.3.11 Fittings and threads...................................................................................................................................3-37

3.3.12 Linkages......................................................................................................................................................3-37

3.3.13 Control shafts.............................................................................................................................................3-37

3.3.14 Drive shaft and associated component....................................................................................................3-38

3.3.15 Advance device..........................................................................................................................................3-38

3.3.16 Levers and external controls.....................................................................................................................3-38

3.3.17 Pump housing............................................................................................................................................3-38

3.3.18 Orifices........................................................................................................................................................3-38

3.3.19 Electrical connections................................................................................................................................3-38

3.3.20 Oversize metering valves..........................................................................................................................3-38

COMPONENT INSPECTION AND RENEWAL III

TABLE OF CONTENTS

DDNX117A(EN) - Issue 1 of 08/2008

v

© Delphi

Page 8

4.

REASSEMBLY

4.1 Preparation..................................................................................................................................................................4-39

4.2 Drive Shaft Assembly, Governor Weight Cage, Pump Housing, Head And Rotor................................................4-39

4.2.1 Drive shaft assembly..................................................................................................................................4-39

4.2.2 Governor weight cage and drive shaft assembly....................................................................................4-40

4.2.3 Inner bearing, scroll plates, and cam ring................................................................................................4-41

4.2.4 Hydraulic head rotor plug..........................................................................................................................4-43

4.2.5 Assembly of the drive shaft to the hydraulic head..................................................................................4-43

4.2.6 Housing.......................................................................................................................................................4-44

4.2.7 Fitting the pump housing to the drive shaft and hydraulic head...........................................................4-44

4.2.8 Transfer pump rotor...................................................................................................................................4-45

4.2.9 Drive shaft oil seals....................................................................................................................................4-46

4.2.10 Checking end-float and radial play...........................................................................................................4-47

4.2.11 Fitting the drive shaft key or pin...............................................................................................................4-48

4.3 Hydraulic Head And Rotor..........................................................................................................................................4-48

4.3.1 Rotor plug...................................................................................................................................................4-48

4.3.2 Preparation of the hydraulic head............................................................................................................4-49

4.3.3 Fitting the hydraulic head to the pump housing.....................................................................................4-49

4.3.4 Final location of the hydraulic head.........................................................................................................4-49

4.3.5 Checking drive shaft end-float..................................................................................................................4-49

4.4 Cam Screw, Servo Piston, Adv. Housing, Latch Valve, Rotor Vent Switch Valve, Head Locking Screw.............4-50

4.4.1 Cam screw..................................................................................................................................................4-50

4.4.2 Servo piston................................................................................................................................................4-50

4.4.3 Fitting the advance housing......................................................................................................................4-51

4.4.4 Hydraulic head fixings...............................................................................................................................4-51

4.4.5 Advance device fittings (pressure end)....................................................................................................4-54

4.4.6 Advance device fittings (spring end)........................................................................................................4-55

4.5 Transfer Pump, End Plate Assembly, Stop Solenoid, High Pressure Outlets........................................................4-58

4.5.1 Transfer pump............................................................................................................................................4-58

4.5.2 End plate.....................................................................................................................................................4-58

4.5.3 Stop solenoid or blanking plug.................................................................................................................4-60

4.5.4 High pressure outlets.................................................................................................................................4-60

4.6 Governor Linkage, Idle Actuator, Support Plate, Cover...........................................................................................4-62

4.6.1 Governor linkage........................................................................................................................................4-62

4.6.2 Idle actuator................................................................................................................................................4-63

4.6.3 Fitting the support plate............................................................................................................................4-63

4.6.4 Assembling the governor cover................................................................................................................4-66

4.6.5 Fitting the governor cover.........................................................................................................................4-71

4.6.6 Aligning / fitting external levers................................................................................................................4-75

4.6.7 Control stop screws...................................................................................................................................4-78

4.6.8 Boost control device..................................................................................................................................4-80

4.6.9 Fuel connections, timing cover or plug, light load advance lever, cold idle advance linkage............4-85

4.6.10 External brackets, drive hub and timing adaptor....................................................................................4-88

IV REASSEMBLY

TABLE OF CONTENTS

vi

DDNX117A(EN) - Issue 1 of 08/2008

© Delphi

Page 9

5.

TESTING

5.1 Preparation..................................................................................................................................................................5-89

5.1.1 Leak testing.................................................................................................................................................5-89

5.1.2 Test machine..............................................................................................................................................5-89

5.1.3 Test machine drive.....................................................................................................................................5-90

5.1.4 Test conditions...........................................................................................................................................5-90

5.1.5 Connecting fuel lines.................................................................................................................................5-90

5.1.6 Machine test procedure.............................................................................................................................5-91

5.1.7 Transfer pressure measurement and initial setting................................................................................5-91

5.1.8 Cambox pressure measurement...............................................................................................................5-92

5.1.9 Adjustments to be pre-set.........................................................................................................................5-92

5.2 Test Procedure.............................................................................................................................................................5-97

5.2.1 Priming........................................................................................................................................................5-97

5.2.2 Checking and setting transfer pressure....................................................................................................5-97

5.2.3 Cambox pressure and backleakage checks..............................................................................................5-98

5.2.4 Speed advance setting...............................................................................................................................5-98

5.2.5 Light load advance (HSDI).........................................................................................................................5-99

5.2.6 Cold idle advance (HSDI).........................................................................................................................5-100

5.2.7 Latch valve setting...................................................................................................................................5-101

5.2.8 Rotor vent switch valve...........................................................................................................................5-102

5.2.9 Excess fuel................................................................................................................................................5-102

5.2.10 Maximum fuel delivery setting...............................................................................................................5-102

5.2.11 Governor setting and testing..................................................................................................................5-106

5.2.12 Anti-stall screw and idling control setting.............................................................................................5-108

5.2.13 Stop control check....................................................................................................................................5-110

5.3 Timing........................................................................................................................................................................5-110

5.3.1 General......................................................................................................................................................5-110

5.3.2 Preparation...............................................................................................................................................5-111

5.3.3 Flange marking method...........................................................................................................................5-112

5.3.4 Peg-timing method..................................................................................................................................5-113

5.4 Leakage Testing.........................................................................................................................................................5-117

TESTING V

TABLE OF CONTENTS

DDNX117A(EN) - Issue 1 of 08/2008

vii

© Delphi

Page 10

6.

APPENDIX

6.1 Torque Values............................................................................................................................................................6-119

6.1.1 End plate, brackets, hydraulic head and rotor.......................................................................................6-119

6.1.2 Governor and housing assemblies.........................................................................................................6-120

6.1.3 Auto advance arrangement.....................................................................................................................6-121

6.1.4 Pump body, drive shaft and throttle bracket.........................................................................................6-122

6.2 Special Tools And Fittings (Repair).........................................................................................................................6-122

6.3 Materials....................................................................................................................................................................6-124

6.4 Special Tools And Materials (Test)..........................................................................................................................6-125

6.5 Abbreviations Used In This Manual........................................................................................................................6-127

VI APPENDIX

TABLE OF CONTENTS

viii

DDNX117A(EN) - Issue 1 of 08/2008

© Delphi

Page 11

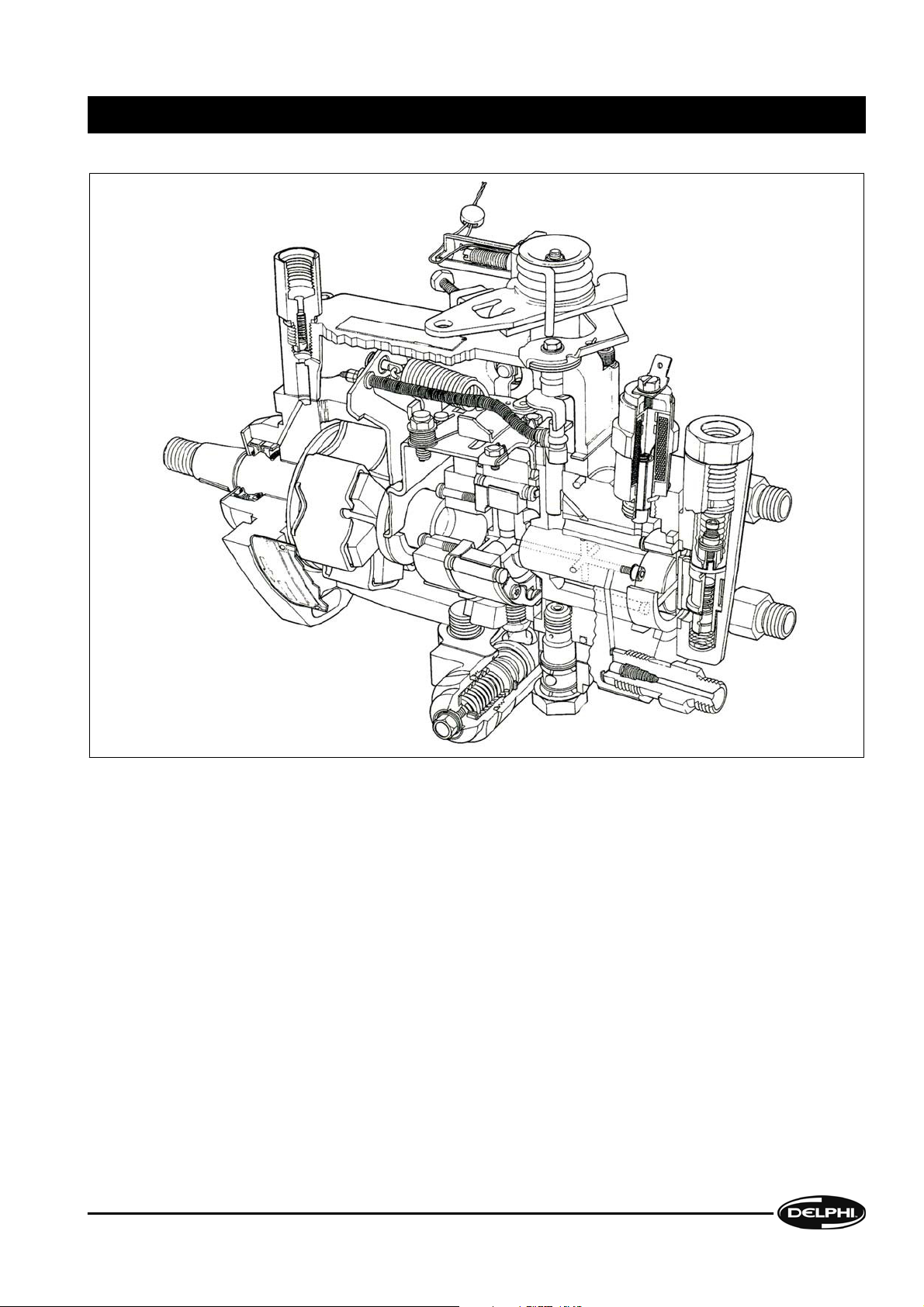

1.1 The Pump

The DPS distributor-type fuel injection pump is a compact self-contained unit which is suitable for highspeed diesel

engines of up to two litres swept volume per cylinder and two, three, four or six cylinders. All internal working parts are

lubricated by fuel oil and the pump housing is maintained at a pressure which prevents the ingress a[ external dirt or

other foreign matter.

It can be specified for direct or indirect injection engines and can be fitted with a range of options to produce performance

curves to match a wide variety of engine requirements, including boost-pressure control of delivery level for

turbocharged engines.

Due to the complexity of this product, the need for highly-trained personnel, a high level of investment in equipment

and workshop resources, together with the need for continual up-dating of technical data such as Test Plans and Service

Information, it can only be tested or serviced by Delphi Authorised Distributors.

The expression "HSDI" is used to describe a particular pump specification. It is the abbreviation of "High Speed Direct

Injection" and it refers to pumps which cater for the particular requirements of engines of this type.

INTRODUCTION I

INTRODUCTION

DDNX117A(EN) - Issue 1 of 08/2008

1-1

© Delphi

Page 12

1.2 General

Fuel pumps may require off-engine workshop attention for two main reasons:

a. Investigation of a specific fault in engine performance which may only require partial dismantling.

b. A complete overhaul e.g. at the same time as a major high-mileage engine overhaul. A full performance test is

recommended, both before and after any level of attention, as many aspects of performance are inter-related.

1.3 This Manual

This Workshop Manual is divided into the following sections:

1. Section 1 - Introduction

2. Section 2 - Dismantling

3. Section 3 - Component inspection

4. Section 4 - Reassembly

5. Section 5 - Testing

6. Section 6 - Appendix (Technical Information, Tools etc.).

Each section is laid out on a step-by-step basis, with each action accompanied by an illustration showing the component

(s) involved and, where applicable, its/their position(s) on the pump. The Manual is not based on any one particular

pump specification, but covers pump features which have been included up to the time of publication. For the purposes

of illustration, several pump specifications have been used.

The pumps illustrated are for clockwise rotation (when viewed from the drive end); anticlockwise pumps will have items

such as the maximum fuel screw, hydraulic excess fuel control, latch valve and boost control fitted on the side opposite

to that shown.

Instructions for both full and partial dismantling of the pump are included e.g. total dismantling and examination of all

components other than those which are factory-sealed units, and removal of the hydraulic head and rotor only.

All the necessary tools are listed in

Section 6. Special tools are identified by part number and standard tools by type and

size.

1.4 Equipment

Any tools, both standard and special-purpose, used for the servicing or repair of fuel injection equipment (FIE) must be

reserved solely for use on FIE. Worn or damaged tools can cause damage to critical components, as well as being a

safety hazard.

The working area must be scrupulously clean and should be in a room separated from any other activity; the ingress of

dust and dirt, airborne or otherwise, should be prevented.

The minimum facilities required are:

1. A bench covered in non-rusting metal or industrial-grade linoleum and fitted with an engineer's vice with a jaw

size of 100mm (4 in.). The vice jaws must be faced with either soft metal or fibre pads.

2. An adjustable pump-mounting device such as the Hartridge "Hydraclamp", fitted with an appropriate adaptor plate.

3. Easily-cleaned compartmented trays for separate storage of dismantled components.

4. All the necessary tools as listed in

Section 6 of this Manual.

5. A low-pressure washing facility using a suitable, approved, cleaning fluid (not water or water-based) to clean pumps

externally prior to dismantling. Cleaning must be carried out in a place separated from the "clean area".

6. A tank large enough to accommodate a complete pump and filled with clean test oil, near to a source of clean, dry,

variable pressure compressed air for carrying out leakage tests.

7. A supply of clean, lint-free (non-fluffy) cloths for cleaning and drying components. Cotton waste must never be

used.

8. A pump test machine which conforms to ISO 4008.

I INTRODUCTION

INTRODUCTION

1-2

DDNX117A(EN) - Issue 1 of 08/2008

© Delphi

Page 13

9. Adequate storage facilities for pumps, tools and test equipment, with separate areas for pumps before and after

repair.

Note: All cleaning tanks, workshop and test facilities and fluids must conform to any Fire Prevention or Health and

Safety Regulations in force at the time of use.

1.5 Pump Name Plate

The number stamped on the name plate attached to the pump housing identifies the type and model of the pump. Pumps

which are of identical build, but with modified settings for different applications, are further identified by the Setting

Code stamped beneath the Despatch Number.

A typical Despatch Number could be as shown below:

Marketing Code: (See Note)

R = France

C= Spain

G = India

M = Mefin, Romania

P = WSK Poznan, Poland

V=Brazil

U = Greenville, USA

J = Kk, Japan

No prefix letter = UK

Note: This letter will not be used in

future Service documentation.

This character indicates whether or not an

ESOS is fitted to the pump and, if so, its

type. (For more details, see SIN DT294).

Changes to the individual specification

affecting parts interchangeability, but not

fit or function of the pump.

Individual features number.

Design change letter.

(No significance at present).

Product type (DPS)

Design Source Code

0 = USA 1 = Korea 2 & 3 = UK

4 = France 5 = Spain 6 = Brazil

7 = India 8 = Poland 9 = Japan

Number of delivery ports

0 = 4 1 = 6 2 = 3 cylinders

3 = 4 4 = 6 cylinders

5-9 to be allocated

C

85 2 0 A 06 0 A

Note: If the name plate has been painted over, special care is needed when removing the paint to avoid erasure of the

information. Use a small quantity of proprietary paint stripper, carefully observing the manufacturer's instructions.

INTRODUCTION I

INTRODUCTION

DDNX117A(EN) - Issue 1 of 08/2008

1-3

© Delphi

Page 14

1.6 Replacement Of Parts

All gaskets and seals must be replaced during reassembly. However, in the event of partial dismantling, only those seals

which have been disturbed need replacement, unless leaks from elsewhere are detected during testing prior to

dismantling.

If any part of a "mated" assembly is worn or damaged, the whole assembly must be replaced. Any component showing

signs of corrosion or water ingress, cracks or distortion must be replaced.

It is imperative that only service parts supplied by Delphi Aftermarket Operations are used as replacements. Parts

supplied from alternative sources may appear to be externally similar and may carry the same part numbers as the

genuine item but may be inferior in material specification or finish and lead to malfunction or premature failure.

I INTRODUCTION

INTRODUCTION

1-4

DDNX117A(EN) - Issue 1 of 08/2008

© Delphi

Page 15

2.1 Preparation

Note: A list of all tools required, together with toque values for all fixings, is contained in Section 6.

2.1.1 Cleaning and draining

Externally clean the pump. Remove the drain plug

or inspection cover on the side of the pump and

drain any fuel oil remaining in the housing. In the

case of HSDI pumps slacken, but do not remove, the

cover plate. If the pump is to have a possible defect

rectified or is subject to a warranty assessment, a

preliminary test on the test machine may be

required. In this case externally clean the pump as

above but drain the fuel oil into a clean container

for possible subsequent analysis.

Note: Before disturbing any component which is

required to indicate timing, e.g. the cover plate,

check that It is not necessary to confirm the

accuracy of the timing position in response to, say,

a warranty claim.

2.1.2 Mounting the pump and initial inspection

Mount the pump on a Hydraclamp using a Hartridge

mounting plate (1) and, depending on the pump

spigot diameter, either a 46mm or 50mm bore

adaptor ring (2). Remove the drive flange, hub, gear

or pulley and the timing adaptor, if fitted. In the case

of HSDI pumps, no adaptor is required until the

drive and timing components have been removed.

If the pump has not seized, and it requires a machine

test prior to dismantling, further examination will

first be necessary to determine if dirt or water

ingress has occurred, so as to avoid damage to the

test equipment. In most cases viewing of the

internal components through the inspection

aperture may be adequate, but if any doubt exists

remove the advance device and closely examine the

components for signs of wear, corrosion or metal

particles.

2.1.3 General

Remove any external brackets, such as those used for mounting control cable ends, noting their positions and

components.

Inspect all components as they are removed and put those considered unfit for further service to one side for

replacement. A guide to areas of possible wear or damage appears in

Section 3 (Component Inspection &

Renewal).

DISMANTLING II

DISMANTLING

DDNX117A(EN) - Issue 1 of 08/2008

2-5

© Delphi

Page 16

2.1.4 Measuring drive shaft end float

Note: The pump and gauge must be clamped to

an assembly plate mounted in a vice or on a

Hydraclamp.

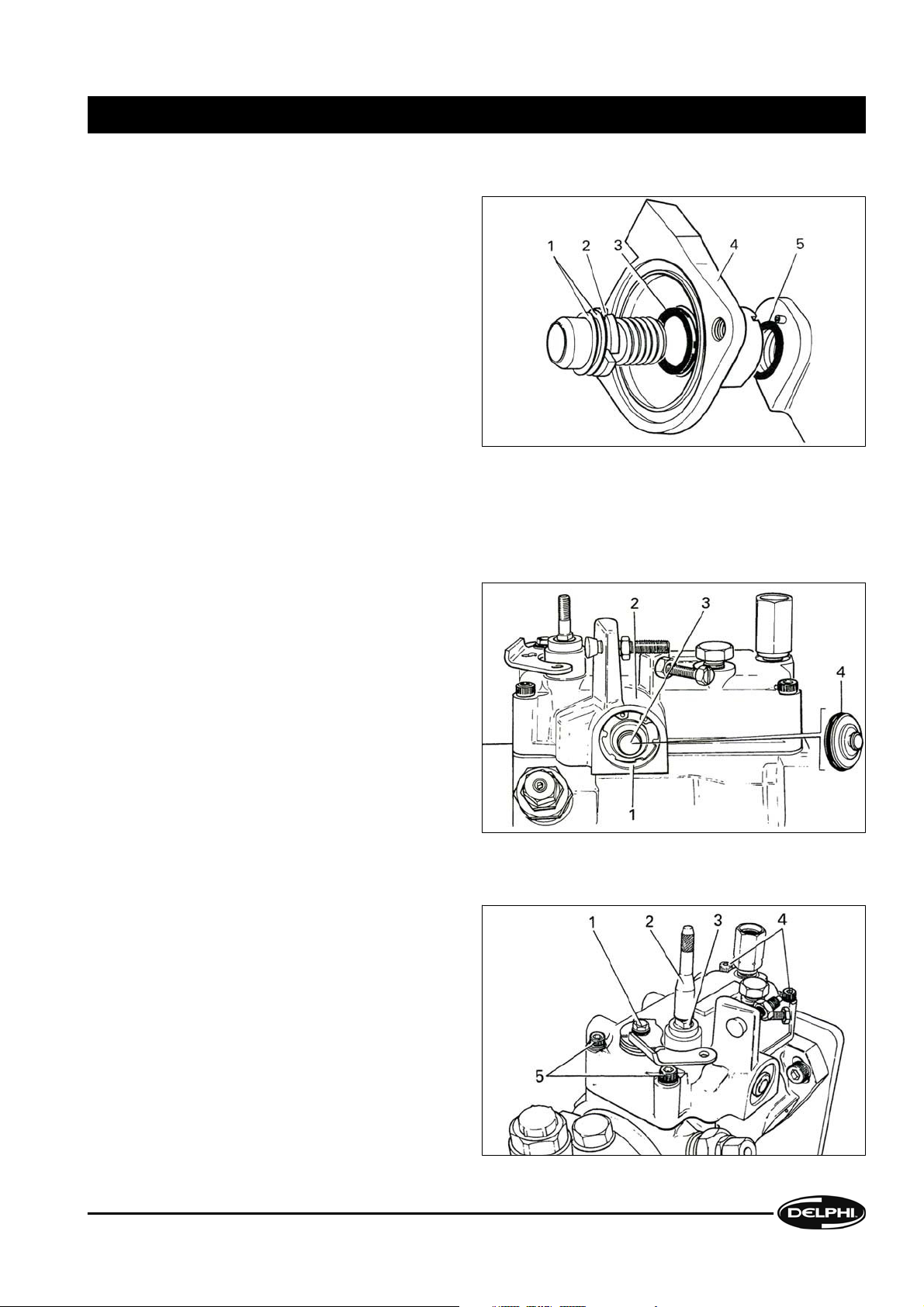

Fit the appropriate adaptor (1) to the drive shaft

thread. Screw in the dial gauge holder (2), and fit

the gauge (4). Adjust the gauge pin to contact the

pump housing at (3). Push the drive shaft inwards

and set the dial gauge to zero. Pull the drive shaft

outwards and note the maximum gauge reading.

End-float should be 0.05mm to 0.2mm. If the

maximum is exceeded, examine the housing thrustfaces during dismantling. If no significant wear or

damage is apparent, requiring replacement of the

pump housing, correct the end-float by the use of

alternative shims during reassembly.

2.1.5 Measuring drive shaft radial play

With the pump and gauge (1) mounted rigidly

relative to each other adjust the gauge pin to bear

against the drive shaft (2). Push the shaft radially

towards the gauge and set the gauge to zero. Pull

the shaft radially to the opposite extreme and

record the gauge movement. Repeat the readings

with the gauge repositioned as shown at (3) and (4).

Do not rotate the drive shaft. Reject the housing if

the max, play or the difference between the

measurements exceed the figures in the table

below.

Drive type Max. play Max. difference

Belt 0.22mm 0.1mm

Gear or hub 0.27mm 0.2mm

II DISMANTLING

DISMANTLING

2-6

DDNX117A(EN) - Issue 1 of 08/2008

© Delphi

Page 17

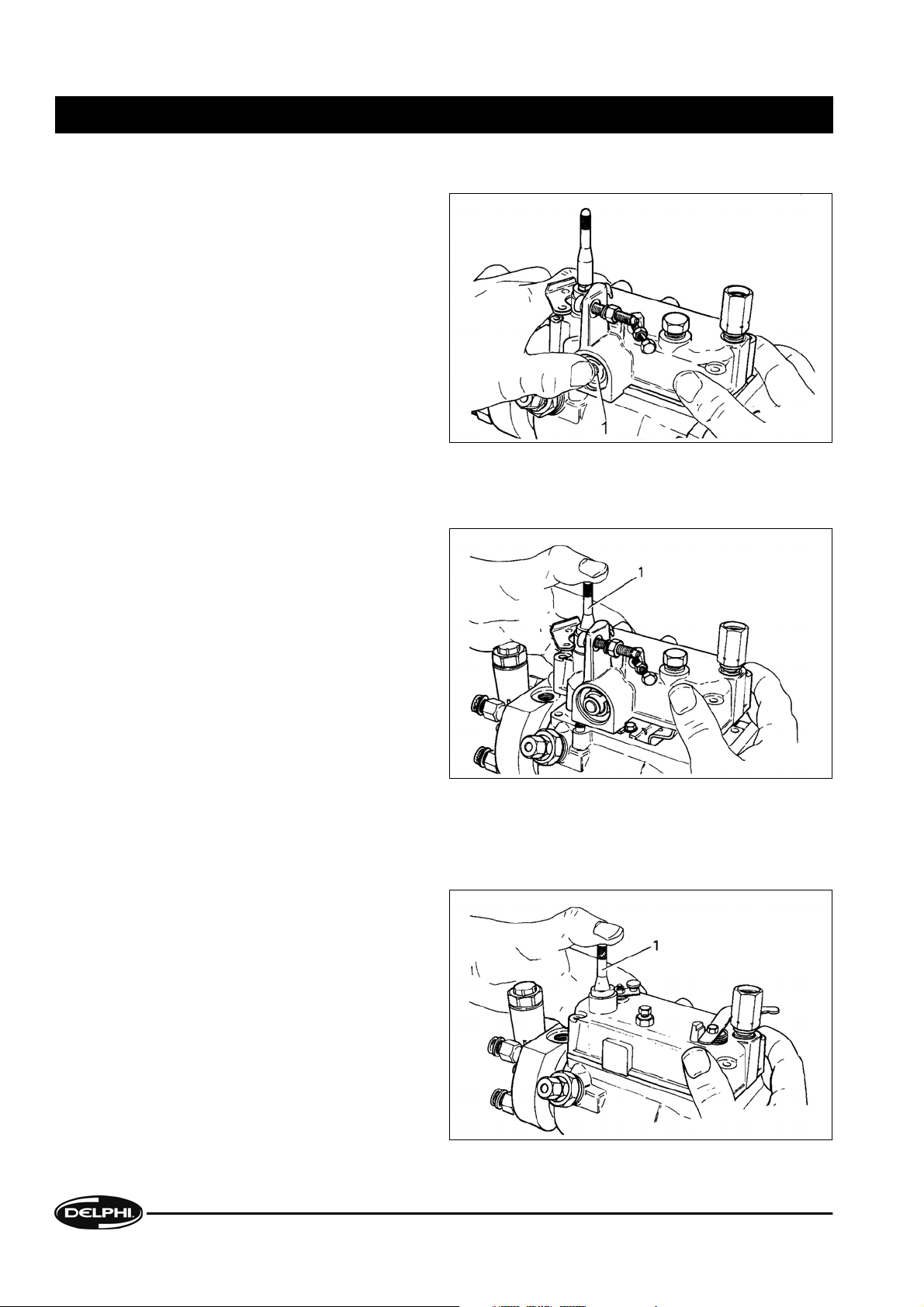

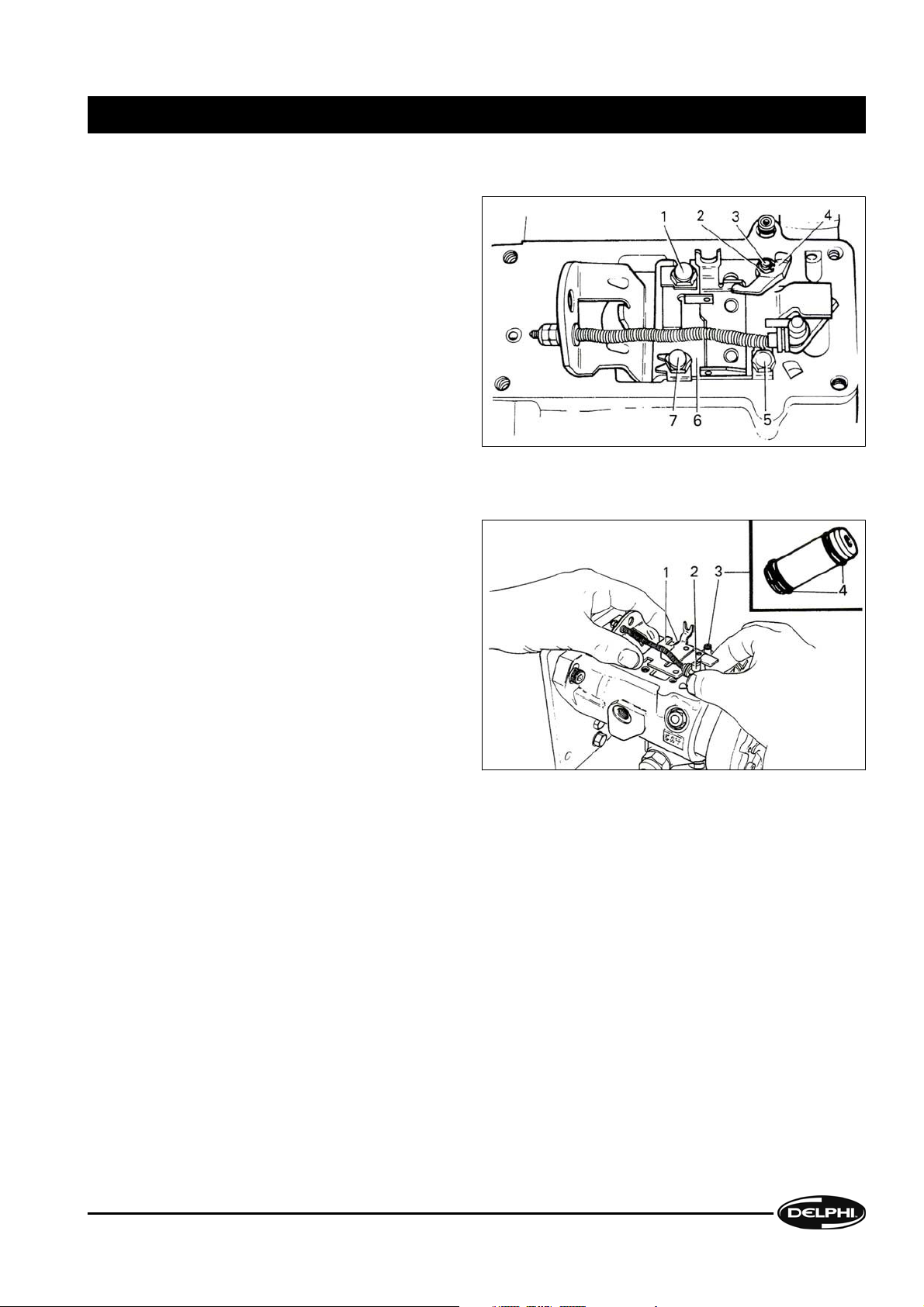

2.1.6 Removing sealing caps and locking wire

Remove any shrink-sleeving, sealing caps or

locking wire from adjustment screws. In the

illustration the maximum speed adjusting screw (1),

latch valve (2) and the maximum fuel screw (3) are

shown sealed.

2.2 Governor Cover, Link Assembly & Control Levers

2.2.1 Backleak connection, throttle lever stop screws and maximum fuel screw

Loosen, but do not remove, the backleak connection

(1) or the pressurising valve, if fitted.

Loosen the governor cover plug (2) or vent screw,

whichever is fitted. Loosen the lock-nuts (3), (4), (5)

and remove their respective control screws.

Note: The position of the maximum fuel screw on

the governor cover may differ from one type of

pump to another, depending on the application. For

pumps fitted with boost control, maximum fuel

adjustment is incorporated within the boost control

device. On HSDI pumps, maximum fuel is set with

the torque trimmer.

DISMANTLING II

DISMANTLING

DDNX117A(EN) - Issue 1 of 08/2008

2-7

© Delphi

Page 18

2.2.2 Cold idle advance (CIA) linkage

Remove and discard the plastic protection cap (1).

Using a suitable lever with no sharp edges, remove

the CIA link (3) and the fast idle link (5). Both of these

parts are plastic and particular care must be taken

when dismantling.

Remove the C-clip (11) from the lever pivot on the

cover plate (7). Unscrew and remove the cover plate

screws (2) and (10), discard the star washers (9) and

(12) and detach the cover plate (7). Remove and

discard the O-ring (6).

Slide the lever (4) off the pivot and unhook the

spring (8) .

2.2.3 Light load advance (LLA) linkage

Unscrew and remove the LLA cam follower locknut

(1) and the washer (2). Slacken and remove the grub

screw (3), if fitted.

Remove the cap (6) from the rocker arm pivot (12).

Detach the circlip (7) followed by the thin and thick

washers (8) and (9).

Slide the rocker arm (10) on its pivot towards the

rear of the pump. Unscrew the pivot and remove

the rocker arm, dust cap (11) and pivot from the

pump housing. Remove the flexible dust cover (13)

and the cam follower (5) from the rocker arm and

unscrew the lock-nut (4).

Note: The cam follower may be in the form of

either a roller or, on later pumps, a captive ball.

II DISMANTLING

DISMANTLING

2-8

DDNX117A(EN) - Issue 1 of 08/2008

© Delphi

Page 19

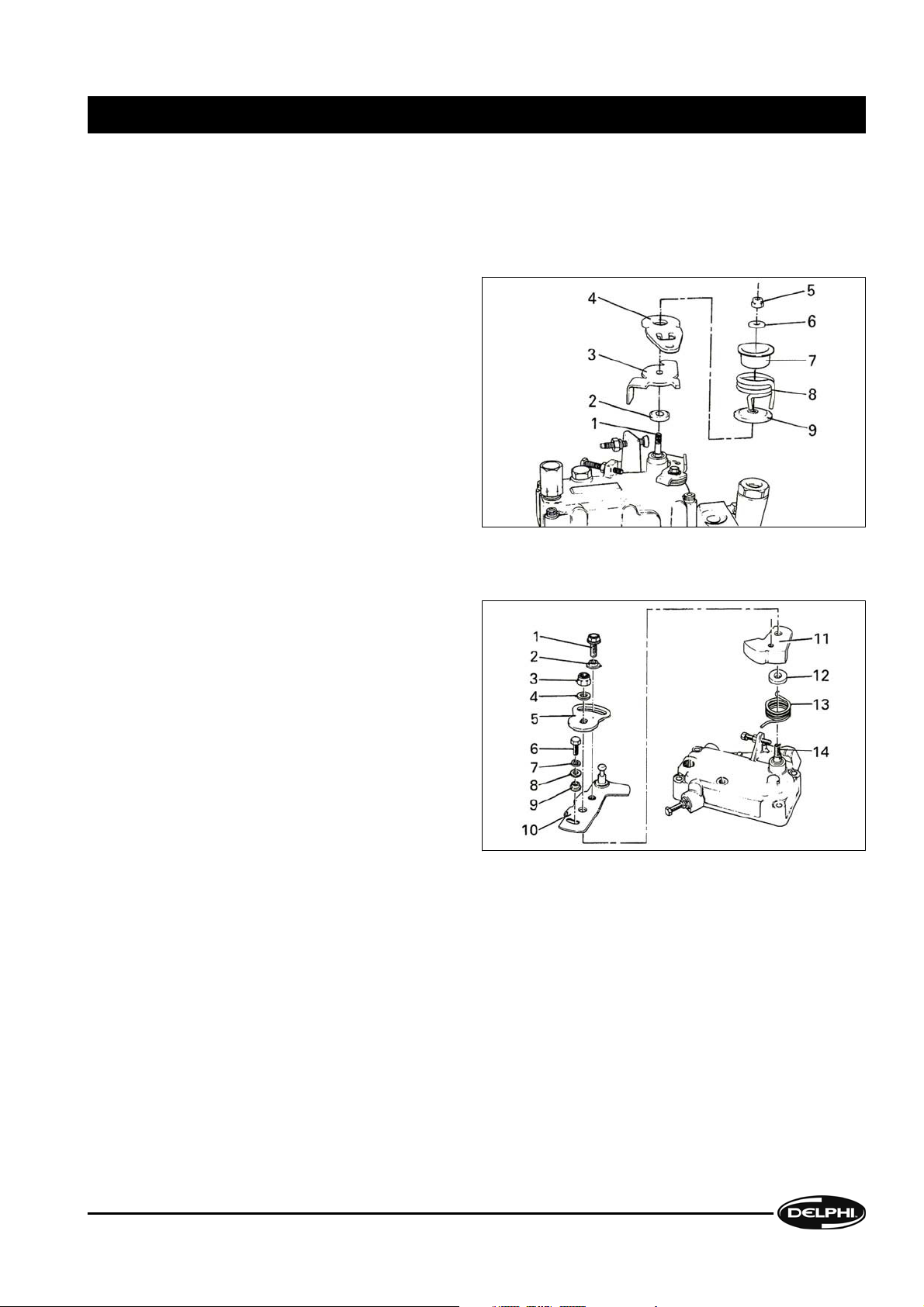

2.2.4 Throttle lever

Make a note of how the individual components of the throttle lever assembly are fitted together. The throttle lever

arrangement will differ according to the specification of the pump; the principle types are covered below.

A) Throttle lever without vernier plate

Remove the following from the throttle shaft (1); nut

(9, washer (6), spring guide (7), spring (8), lower

spring seat (9), throttle lever (4), break-back lever (3)

and dust cover (2).

B) Throttle lever with vernier plate

Slacken and remove the vernier plate securing bolt

(1) and collar (2). Remove the LLA cam vernier

locking bolt (6), spring washer (7), flat washer (8)

and collar (9), if fitted.

Remove the nut (3) and washer (4) from the throttle

shaft (14). Note which way up the vernier plate (5)

is fitted before removing it (the shaft hole may not

be centrally placed relative to the curved slot).

Remove the throttle lever assembly (10), LLA cam

(11), dust cover (12), and throttle lever return spring

(13).

DISMANTLING II

DISMANTLING

DDNX117A(EN) - Issue 1 of 08/2008

2-9

© Delphi

Page 20

C) Throttle lever with vernier plate (pumps with mechanical excess fuel)

Place a suitable socket over the governor cover vent

screw to act as a temporary stop for the throttle

lever. Remove the external bracket, slacken the

excess fuel linkage spring peg nut (1) and the

throttle shaft nut (4). Remove the vernier plate bolt

(6), together with the spring and flat washers.

Unhook the excess fuel linkage springs (12) and (13)

from the plate (11).

Hold the throttle lever (14) and remove the governor

cover vent screw assembly. Allow the throttle lever

to rotate clockwise and lift it over the idling shaft.

Remove the linkage spring, nut (1), washer and peg

(2). Remove nut (9), washer, plate, and washer from

the excess fuel shaft (10).

Remove throttle shaft nut (4), washer (5), and vernier plate (7) from the throttle shaft (3). Unhook the return spring

(8) and remove it with the throttle lever. Remove the cap washer which is beneath the lever. Remove the tension

spring (13) from the throttle lever.

D) Single-piece throttle lever

Remove the retaining nut and washers and lift the lever and return spring off the throttle shaft.

2.2.5 Torque trimmer

A) Removing

(i) Early type [A]

Cut a slot in the tamperproof screw head (1) with a

hacksaw and remove it, together with the socket

headed screw (7) and the cover (2).

Slacken the pre-load adjuster (4) and stroke adjuster

(5). Use the locking plate (3) to remove the torque

trimmer (6) from the governor cover.

(ii) Later type [B]

Cut a slot in the tamperproof screw head (8) with a hacksaw; it will be necessary to cut into the plastic cap (9).

Remove the screw and discard the plastic cap. Slacken the pre-load and stroke adjusters (10) and (11), then locknut

(12). Remove the torque trimmer (13) from the governor cover.

II DISMANTLING

DISMANTLING

2-10

DDNX117A(EN) - Issue 1 of 08/2008

© Delphi

Page 21

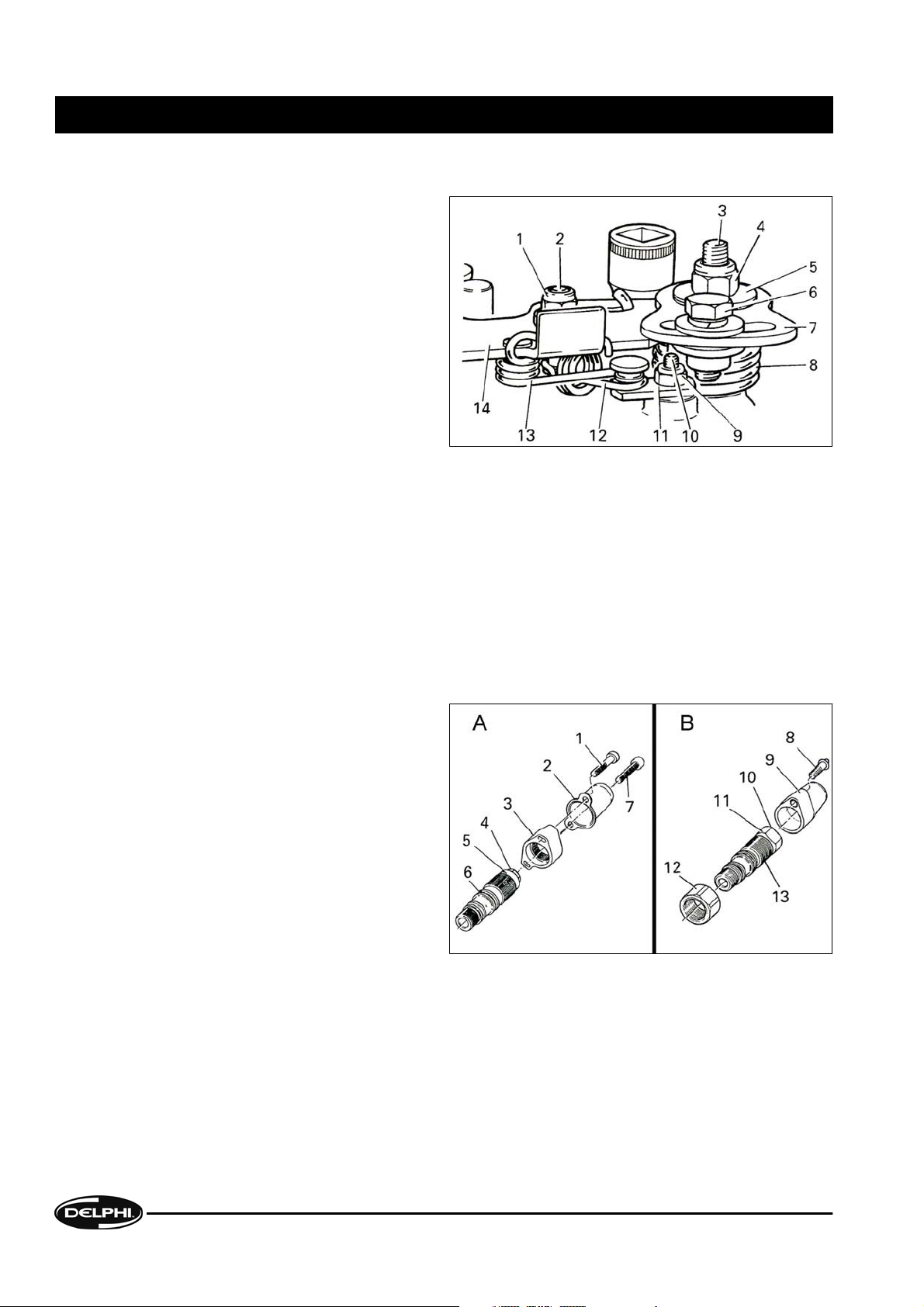

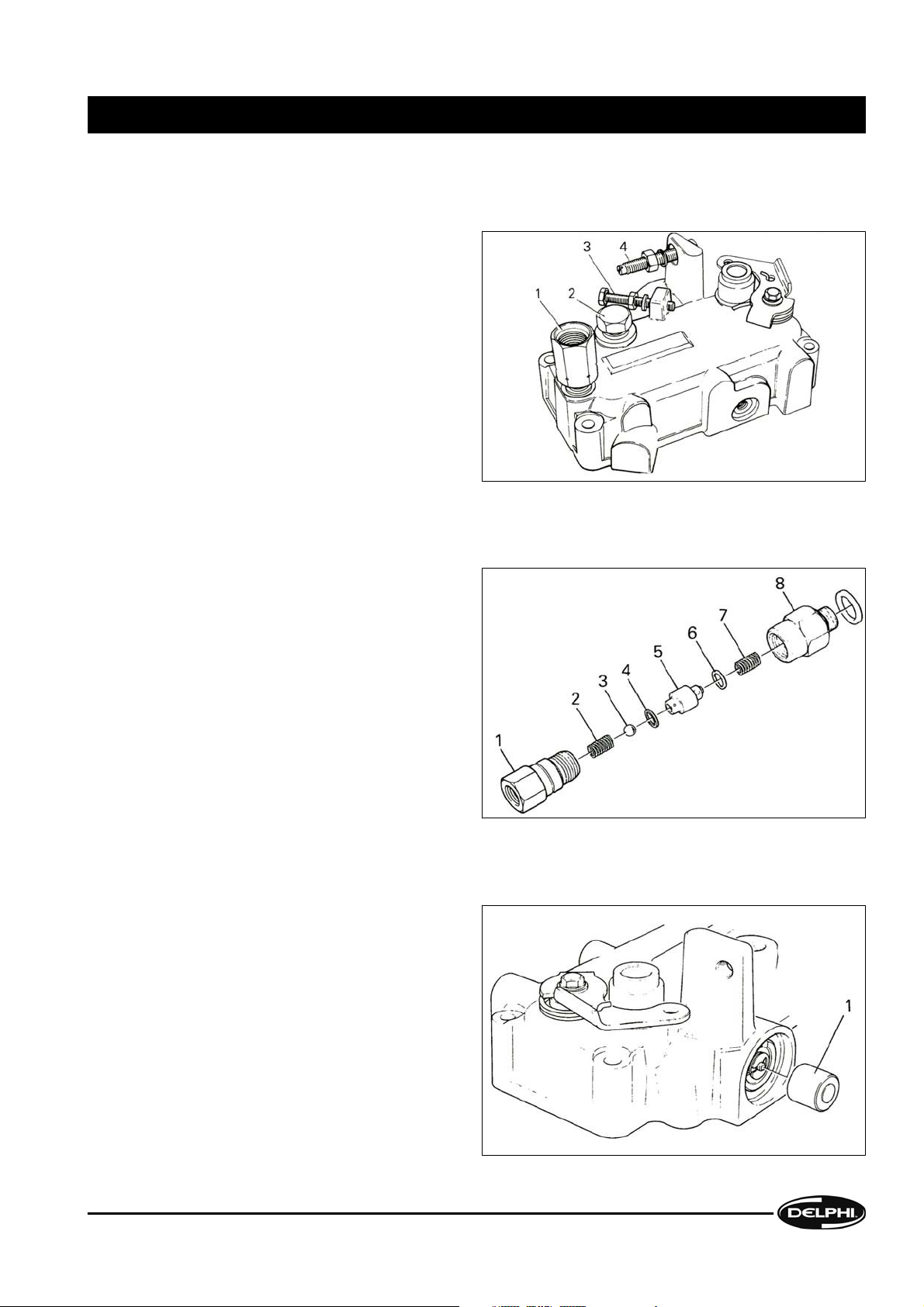

B) Dismantling

Remove the pre-load adjuster (1), together with the

pre-load spring (4); remove and discard the O-ring

(2). Unscrew the stroke adjuster (3) and discard the

O-ring (5).

Tip out the plunger (6) and springs from the body

(12) and discard the two O-rings (13) & (14) from the

body. Slide the following components off the

plunger: small spring (11), shim (10) (if fitted), guide

(9), shim(s) (8) and large spring (7).

2.2.6 Boost control device

A) Removing the pipe connectors & spring adjuster

Note the positions of the two external pipe

connections (1) & (2), if fitted, then unscrew and

remove them. Unscrew and remove the locking ring

(3) and spring adjuster (4), using the special tool.

Note: On some units the locking ring and spring

adjuster are replaced by a plug and shims; in this

case the special tool will not be required.

B) Removing the cover

Remove the pre-load spring (1) , if fitted, from the

housing (2).

Unscrew and remove the two securing screws (3)

and (4) and remove the cover.

Note: Take care when releasing the cover as it is

under pressure from the internal spring.

DISMANTLING II

DISMANTLING

DDNX117A(EN) - Issue 1 of 08/2008

2-11

© Delphi

Page 22

C) Removing the diaphragm

Remove the diaphragm assembly (1); lift out the

spring plate (2), control spring (3), shim (4) and fuel

control rod (5).

Note: Early boost controls were fitted with

diaphragm assemblies which could be dismantled.

Current replacement diaphragms are supplied preassembled to the adjustment screw body.

D) Removing the fuel adjustment screw

Hold the nut (2) with a suitable spanner; using a

suitable hexagon key, unscrew and remove the fuel

adjustment screw (1) from the adjustment screw

body. Carefully lever out and discard the O-ring (3)

from its recess in the rear of the diaphragm

assembly.

E) Removing the diaphragm stroke adjustment

Unscrew and remove the diaphragm stroke

adjustment screw (1) from the screw body (2).

Remove and discard the O-ring from the adjustment

screw.

II DISMANTLING

DISMANTLING

2-12

DDNX117A(EN) - Issue 1 of 08/2008

© Delphi

Page 23

F) Removing the boost control housing

Remove the shim(s) (1). Use the special tool to

unscrew and remove the stroke adjustment screw

body (2); remove the shim(s) (3). Detach the

housing (4); carefully remove and discard the O-ring

(5).

2.2.7 Governor cover removal

A) Pumps with hydraulic excess fuel

(i) Removing the closing plug

Using suitable circlip pliers, remove the internal

circlip (1) , from the governor cover (2). Lever out

the closing plug (3) and remove and discard the Oring (4).

(ii) Removing the governor cover securing screws and slackening the stop lever

Fit the appropriate protection sleeve (2) to the

throttle shaft (3) and remove the four governor

cover securing screws (4) and (5) and plain washers.

Depending upon the type of securing screw used,

either the special Torx tool or a hexagon key will be

required.

Slacken the stop lever bolt (1) or shaft nut,

whichever is fitted.

Note: The stop lever can be in several forms and

may be positioned at either end or on the side of the

governor cover.

DISMANTLING II

DISMANTLING

DDNX117A(EN) - Issue 1 of 08/2008

2-13

© Delphi

Page 24

(iii) Disengaging the hydraulic excess fuel device

Position the pump so that the drive end is to the

right. Grip the governor cover firmly as shown;

depress and hold in the hydraulic excess fuel piston

(1) with the thumb, so as to disengage the fork in

the control bracket from the excess fuel pin. Lift the

governor cover sufficiently to release the excess

fuel pin from the fork and then release the excess

fuel piston.

(iv) Removing the governor cover

Pressing firmly on the protection sleeve (1) push the

throttle shaft down through the governor cover and

lift the complete cover assembly clear. Remove the

protection sleeve.

Remove and discard the O-ring and nylon ring, if

fitted, from the recess in the throttle shaft spigot.

B) Pumps with mechanical excess fuel

(i) Removing the governor cover

Fit a protection sleeve (1) to the throttle shaft.

Remove the four governor cover securing screws

and plain washers (as shown in

Section 2.2.7 (ii)).

Pressing firmly on the protection sleeve as shown.

push the throttle shaft down through the governor

cover and lift the complete cover assembly clear.

Remove the protection sleeve.

Note: When removing the governor cover, ensure

that the excess fuel lever does not damage the

governor link.

II DISMANTLING

DISMANTLING

2-14

DDNX117A(EN) - Issue 1 of 08/2008

© Delphi

Page 25

2.2.8 Dismantling the governor cover assembly

A) Removing the backleak connection or pressurising valve, vent screw and stop screws

Unscrew and remove the backleak connection (1) or

pressurising valve and the governor cover plug (2)

or vent screw; remove and discard the sealing

washer(s). Slacken and remove the idling stop

screw (3) and the throttle stop screw (4).

B) Dismantling the cambox pressurising valve

Clamp the pressurising valve body (8) in a softjawed vice. Unscrew the fuel connection (1). Tip out

the following components: spring (2), ball (3),

sealing washer (4), valve body (5), sealing washer

(6) and filter spring (7).

C) Dismantling the hydraulic excess fuel device

Remove the hydraulic excess fuel piston (1)

DISMANTLING II

DISMANTLING

DDNX117A(EN) - Issue 1 of 08/2008

2-15

© Delphi

Page 26

From inside the governor cover, use the excess fuel

piston (1) to push out the excess fuel assembly.

Separate the sleeve (2) and discard the O-ring (3).

Remove the external E-clip (4), spring (5) and pin

guide (6) from the excess fuel pin (7).

D) Removing the stop lever

Remove the bolt (2) or nut, whichever is fitted, and

the "star" and plain washers (3). Carefully lift off the

lever (4) and release the tension on the spring (1).

Remove the dust cover (5).

E) Removing the stop shaft

Push the stop shaft (1) down through the governor

cover. Remove and discard the O-rings.

Note: Some pumps may have additional levers,

e.g. idling. Slacken and remove the fixing nut or

bolt, washers, return spring and dust cap. Push the

shaft through the bore in the governor cover, and

discard the O-rings or seal. In the case of the sidemounted idling lever and shaft, remove the E-clip

and operating fork from the shaft and push the shaft

outwards through the governor cover.

II DISMANTLING

DISMANTLING

2-16

DDNX117A(EN) - Issue 1 of 08/2008

© Delphi

Page 27

2.2.9 Throttle shaft and governor spring

A) Dismantling the variable speed governor

Remove and discard the governor cover gasket (1).

Detach the main governor spring (5) from the

throttle shaft link (6) and the idling spring peg (2).

Remove the peg, idling spring (3) and ball seat (4)

from the governor control arm (8).

Note how many O-rings (7) are fitted !o the throttle

shaft; remove and discard them.

B) Dismantling the two-speed governor

Remove and discard the governor cover gasket (1).

Restrain the end plug (6) and remove the selflocking nut (2), spring guide (3), spring (4) and pivot

ball washer (5) from the spring pack (7). Detach the

spring pack from the control arm (9).

Note: Do not dismantle the spring pack and throttle

shaft or disturb the end plug relative to the spring

tube as these are factory preset; also, there is a fixed

idling spring on the governor arm.

Note how many O-rings (8) are fitted to the throttle

shaft; remove and discard them.

DISMANTLING II

DISMANTLING

DDNX117A(EN) - Issue 1 of 08/2008

2-17

© Delphi

Page 28

2.2.10 Control bracket and governor assembly

A) Disengaging the scroll link plate return spring

The return spring can be either a "coil" type or a coiled "hairpin" type.

(i) Coil-type spring

Very carefully grip the shoulder on the central pin

(1) with thin-nosed pliers and pull it away from the

spring stop (2) in the direction of the arrow,

compressing the spring. Carefully release the

spring tension and remove the spring and pin. If it

is difficult to grip the pin, carefully slacken the

spring stop screw and allow the stop to swing clear

of the pin.

CAUTION

The spring is under sufficient pressure to cause it to

fly away if it is not restrained.

(ii) Hairpin-type spring

Release the spring (1) from the peg (2) on the control

bracket (3). Remove the governor bracket screw (4),

which retains the link plate return spring assembly,

and remove the upper thrust washer (5), return

spring (6), spring collar (7), lower thrust washer (8)

and spacer (9).

II DISMANTLING

DISMANTLING

2-18

DDNX117A(EN) - Issue 1 of 08/2008

© Delphi

Page 29

B) Bell crank lever and locking tabs

Remove external circlip (2) and lift off the bell crank

lever (4).

With a suitable screwdriver, bend down the tabs on

the tab washers securing the three control bracket

screws (1), (5) and (7) and the bell crank post (3).

Unscrew and remove the screws from the governor

bracket (6) and discard the tab washers.

C) Governor control bracket, metering valve and transfer tube

Lift out the bracket (1), together with the control arm

assembly and the metering valve (2) from the pump

housing. Separate the bracket assembly from the

governor control arm.

Carefully remove the transfer tube (3) either from

the governor cover or the housing. Remove and

discard the O-rings (4). If the transfer tube is a

hollow pin pressed into the pump housing leave it

in situ, unless it is damaged, and discard the O-ring.

DISMANTLING II

DISMANTLING

DDNX117A(EN) - Issue 1 of 08/2008

2-19

© Delphi

Page 30

2.2.11 Governor control arm assembly and idle actuator

A) Dismantling the governor link assembly

(i) Single-spring link assembly

Unscrew and remove the governor linkage locknut

(1) and adjusting nut (2). Detach the washer (3) and

pivot ball washer (4). Withdraw the spring linkage

from the governor control arm (5) and remove the

washer (6), spring (7) and spring retainer (8) from

the link hook (9). Release the metering valve (10).

(ii) Three-spring link assembly

Hold the assembly in compression and unscrew the

locknut (1) and the linkage nut (2); remove the

washer (3) and pivot ball washer (4), from the

linkage hook (14).

Slowly release the compression of the springs and

disengage the hook from the governor control arm

(5). Remove the washer (6), spring (7), spacer (8),

washer (9) spring (10), spring retainer (11), spring

(12) and guide (13) from the hook. Release the

metering valve (15).

B) Removing the idle actuator

Use the special tool or a hexagon key to remove the

two socket-headed screws (1); remove the guide

bracket (2) and the idle actuator (3) from the pump

housing.

Note: Idle actuators operated by a lever mounted

in the top of the governor cover are slotted to

receive the eccentric pin on the idling shaft.

II DISMANTLING

DISMANTLING

2-20

DDNX117A(EN) - Issue 1 of 08/2008

© Delphi

Page 31

2.3 High Pressure Outlets, End Plate Assembly, Shut-Off Solenoid & Transfer Pump

2.3.1 High pressure outlets

A) Axial

Unscrew and remove each high pressure outlet (1).

Remove and discard the seating washer from the

bottom of each outlet bore. The pressurising valves,

if fitted, are factory-sealed units and cannot be

serviced. Delivery valves, if fitted, must be retained

in their matched pairs.

B) Radial with delivery valves

Remove all the nuts (2) securing the outlet

connections to the clamping plate (12), if fitted, and

remove the plate. Remove the banjo bolts (1) and

discard the washers (3). Place each outlet assembly

(4) in a soft-jawed vice, clamping at the banjo bolt

end (but

not across the sealing faces). Unscrew

and remove the delivery valve holder (11). Remove

the peg (10), spring (9), upper washer (8), valve (7),

body (6) and lower washer (5). Discard both sealing

washers.

DISMANTLING II

DISMANTLING

DDNX117A(EN) - Issue 1 of 08/2008

2-21

© Delphi

Page 32

C) Radial without delivery valves

Slacken and remove the connector clamping nuts

(2) and clamping plate (4), if fitted. Slacken and

remove the pressurising valves (1) or, alternatively,

the banjo bolts and discard the washers (3).

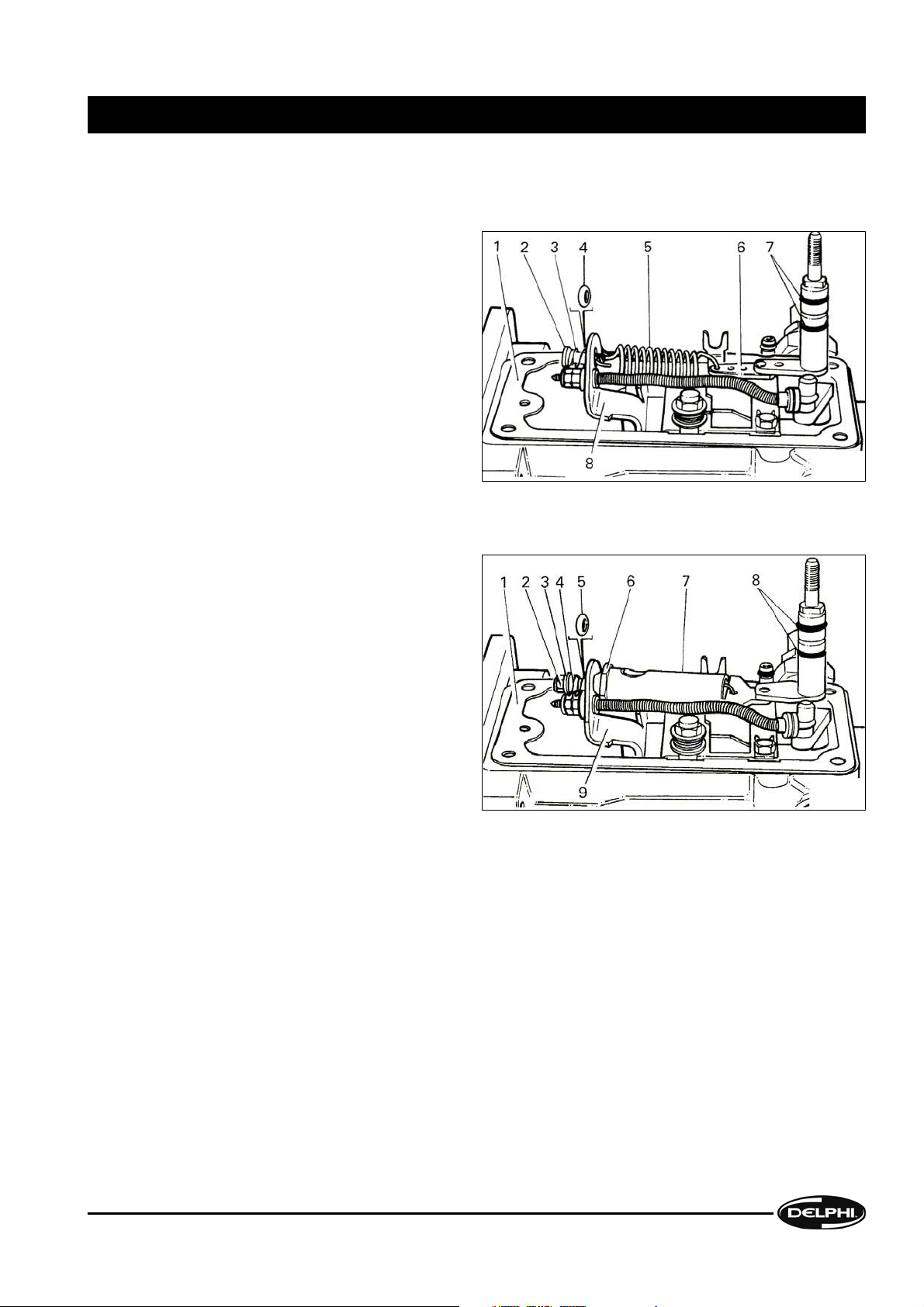

2.3.2 End plate assembly

A) Removing the end plate assembly

If fitted, slacken and remove the transfer pressure

relief valve (3). Discard the O-rings (1) and (2).

Slacken, but do not remove, the fuel inlet adaptor

(4).

Remove the four end plate screws (5) and the four

support bracket screws (8), if fitted.

Remove the end plate assembly (7) and pump

support bracket (6), if fitted.

B) Dismantling the end plate assembly

Remove the fuel inlet adaptor (1), followed by the

fuel inlet filter (3), spring (4), transfer pressure

adjuster (5), peg (6) and regulating spring (7),

regulating sleeve (8), piston (10), sealing washer (9)

and priming spring (11).

Discard the O-ring (2) or the copper washer, if fitted,

inlet filter and sealing washer.

Remove the sandwich plate (12), if of the "loose"

type. Some plates are bonded to the end plate and

are not removable.

Note: In later pumps the peg and spring are

combined into one assembly.

II DISMANTLING

DISMANTLING

2-22

DDNX117A(EN) - Issue 1 of 08/2008

© Delphi

Page 33

2.3.3 Shut-off solenoid

Unscrew and remove the shut-off solenoid

assembly (1). Tip out the plunger (2) and spring (3):

remove and discard the O-ring (4) from the solenoid

body and remove the terminal nut (6) and washer

(5). Some pumps may have the solenoid replaced

by a plug (7). If so, remove the plug and discard the

O-ring.

2.3.4 Transfer pump

A) Removing the transfer pump components

Remove the transfer pump sealing ring (1).

Carefully lift out the liner (2) together with the

transfer pump blades (3) (and springs, if steel

blades are fitted).

Note: Incorrect reassembly of the liner could

seriously affect transfer pump performance and

may damage the blades.

B) Slackening the transfer pump rotor

Hold the drive shaft using a suitable tommy-bar (2)

inserted through the governor arm aperture and

into the hole in the drive shaft. Use the special tool

(1) to slacken the transfer pump rotor in the

direction of rotation shown by the arrow (3)

on the nameplate. Do not remove the transfer

rotor at this stage.

Note: Left-handed transfer rotors are marked with

an arrow on the end face showing the direction in

which to unscrew the rotor.

DISMANTLING II

DISMANTLING

DDNX117A(EN) - Issue 1 of 08/2008

2-23

© Delphi

Page 34

2.4 Advance Device, Latch Valve And Rotor Vent Switch Valve

2.4.1 Dismantling the advance device

A) Speed advance (plus start retard, if fitted)

Invert the pump so that the advance device is

uppermost.

Remove the spring cap advance gauge access

screw (1) and discard the sealing washer (2).

Unscrew the advance piston spring cap (3), shim(s)

(5) and main advance spring(s) (6) & (7). Unscrew

the piston plug (9); remove and discard the O-rings

(4) and (8).

If fitted, remove the spring plate (12), circlip (11),

and retard spring (10).

B) Speed advance, start retard & manual idle advance (spring end)

Note: This particular type of advance device must

be removed from the pump prior to dismantling,

therefore it will be necessary to refer to

Section

2.4.2

. However, slacken the plug (1) and cap (16)

before removing the advance assembly.

Remove the piston plug (1), discard its O-ring (2)

and remove the advance piston (3).

Hold nut (12) with a suitable thin spanner and

slacken the locknut (11). From the pressure side of

the advance piston bore, insert a screwdriver into

the slot in the inner end of the spindle (5); unscrew

and remove the nut and locknut.

Holding both components firmly together, remove the manual idling advance lever (13) and detent plate (15).

Separate the detent plate from the lever; take care not to lose the three steel balls (14). Push the spindle through

the cap.

Clamp the advance housing in a soft-jawed vice; remove the cap (16) and anchor plate (17). Remove the phasing

shim (18) and anchor plate from the cap. Remove the shims (20) from the cap and discard the cap O-ring (19).

Remove the spindle and advance spring assembly. Detach the following from the spindle: advance spring (10),

spring (8), O-rings (9) (which must be discarded), washer (7), spring plunger (6) and retard spring (4).

II DISMANTLING

DISMANTLING

2-24

DDNX117A(EN) - Issue 1 of 08/2008

© Delphi

Page 35

C) Start retard, speed advance & manual cold idle advance (pressure end)

Unscrew and remove the advance gauge access

screw (1) from the advance spring cap (3) and

discard the seal (2). Unscrew the following: spring

cap, shim(s) (5), main advance springs (6), spring

plate (7), circlip (8) and retard spring (9).

Remove and discard the O-ring (4).

Remove and discard the E-clip (18) from the

housing; remove the washer (17) and splined lever

(16) from the shaft (12).

Unscrew and remove the housing assembly (15).

The cam (11) may be retained in the advance

housing. If so, remove it and the internal circlip (10).

Remove the shaft from its housing; remove and

discard both O-rings (13) and (14) from the shaft.

D) Servo-controlled advance piston with mechanical light load advance, cold idle advance and speed advance

(i) Light load advance

Remove the operating plunger (2) and the servo

spring (4). Tip out the shim(s) (3) from the plunger

and remove the circlip (1). Using an appropriate

lever, remove and discard the oil seal (5) from the

spring cap (6). Unscrew the spring cap and discard

the O-ring (7).

(ii) Cold idle advance

Whilst holding the lever (9), slacken and remove the

self-locking nut (8). Remove the lever from the

splined shaft.

Remove the plug assembly (10). Push the shaft and

piston assembly (12) through the plug. Remove and

discard the O-rings (11) from the shaft, the two Orings (13) and (15) and two split nylon rings (14) and

(16) from the plug.

Note: On later pumps the shaft, piston and pin are

a loose assembly and should be dismantled for

examination.

DISMANTLING II

DISMANTLING

DDNX117A(EN) - Issue 1 of 08/2008

2-25

© Delphi

Page 36

2.4.2 Advance housing

A) Removing the advance housing

Remove the advance housing cap-nut (1); remove

and discard the sealing washer (2).

Slacken the head locating fitting (9) or transfer

pressure damper (7), whichever is fitted, no more

than three turns. Tap the advance housing (4) with

a soft-faced mallet to free it from the gasket (3).

Remove the head locating fitting and the advance

housing together, taking care not to lose the lockoff bail (6), if fitted.

Note: In the case of a head locating fitting with a

captive lock-off ball do not disturb the slotted screw

in the head of the fitting.

Remove and discard the O-rings (5) or (8), and the nylon ring, if fitted, from the head locating fitting or the damper;

discard the gasket.

B) Removing the advance piston

Remove the advance piston (1). in the case of the

servo advance device, remove the circlip (5) and

washer (4) retaining the spring pin (3). Remove the

servo valve (2). Do not disturb the lock-off ball

retaining-screw in the head of the advance piston;

this is a factory sealed assembly.

Note: The advance housing, advance piston and

servo valve are a mated assembly and cannot be

replaced individually.

II DISMANTLING

DISMANTLING

2-26

DDNX117A(EN) - Issue 1 of 08/2008

© Delphi

Page 37

C) Removing the cam screw

Fit the correct adaptor (1) to the cam screw (2).

Using a suitable socket and tommy-bar or torque

wrench, slacken the cam screw one complete turn.

The cam ring will almost certainly become stuck in

the pump housing. To free the cam ring remove the

tommy-bar and socket from the adaptor and,

ensuring that the adaptor remains in place on the

cam screw, tap the adaptor sideways with a softfaced mallet; remove the cam screw.

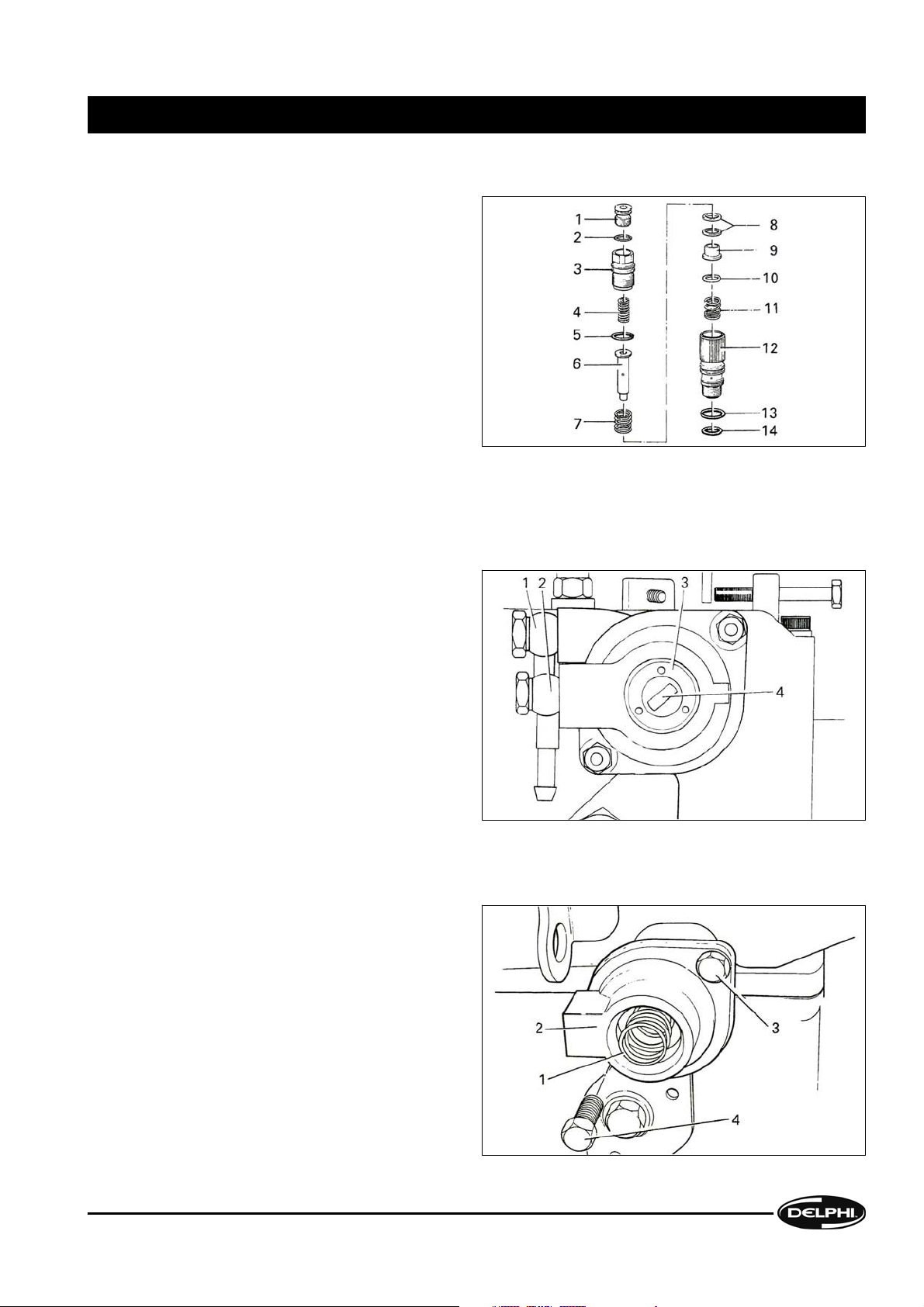

2.4.3 Latch valve

A) Removing the latch valve

Slacken, in turn, the locknut (1), sleeve nut (2) and

body screw (3). Hold the locknut and slacken the

adjuster (4). Note the position of the latch valve in

the hydraulic head; remove the complete valve

assembly and discard the sealing washer (5).

B) Dismantling the latch valve

Remove the adjuster (1) and locknut (2) from the

sleeve nut (4). Separate the adjuster from the locknut; remove and discard the square-section rubber

washer (3). Tip out the spring (6) and remove the

sleeve nut from the body screw (8); remove and

discard the sleeve nut O-ring (5).

Tip out the valve (7) from the body screw. Remove

and discard the two O-rings (9) from the body

screw. If the filter (10) is damaged or blocked, use a

suitable piece of rod to push it out from within the

valve body.

Note: Some pumps have "differential" latch valves.

These valves are hollow and have a control orifice

in the side of the valve stem.

DISMANTLING II

DISMANTLING

DDNX117A(EN) - Issue 1 of 08/2008

2-27

© Delphi

Page 38

2.4.4 Rotor vent switch valve

While the valve assembly (1) is still secure in the

hydraulic head, slacken the spring plug (2) in the

body (6). Unscrew and remove the valve assembly

from the hydraulic head. Discard the two backing

washers (7) and (9), the two O-rings (8) and the seal

(10). Remove the plug, discard its O-ring (3), and

remove the spring (4) and valve (5).

Note the position of the switch valve assembly in

the hydraulic head.

Note: (1) If both valves are specified, take care not

to mix the valve pins as they are the same nominal

diameter.

Note: (2) The valves are matched to their bodies and must be kept assembled.

Note: (3) If a head locking screw is specified in place of the rotor vent switch valve, remove the screw and discard

the sealing washer.

2.5 Hydraulic Head And Drive Shaft Assembly

2.5.1 Releasing the hydraulic head

Grip the hydraulic head as shown and, whilst

keeping it straight, pull and twist it out of the pump

housing just far enough to expose the large O-ring

(1). Leave the head in this position.

II DISMANTLING

DISMANTLING

2-28

DDNX117A(EN) - Issue 1 of 08/2008

© Delphi

Page 39

2.5.2 Removing the drive shaft nut, key and thrust washer

A) Removing the drive shaft nut and key

If still fitted, remove the hub securing nut and

washer. Using either a suitable pair of side cutters

or a small screwdriver carefully lever out the

Woodruff key (1). If the alternative pin is fitted it

must be removed. If fitted, remove the circlip (2) and

the thrust washer (3).

B) Removing the outer oil seal, drive shaft circlip and thrust washer (if fitted)

Lever out the outer seal, avoiding damage to the

seal bore in the pump housing. Remove the circlip

(4) and thrust washer (3) and then ball (2) from the

indent (1) in the shaft. The inner seal will be

removed after withdrawal of the drive shaft.

C) Removing the pump housing from the head and drive shaft assembly

Remove the pump from the Hydraclamp and place

it on the bench with the hydraulic head downwards.

Press down on the end of the drive shaft and then

lift the housing off the head and drive shaft

assembly.

DISMANTLING II

DISMANTLING

DDNX117A(EN) - Issue 1 of 08/2008

2-29

© Delphi

Page 40

D) Removing the drive shaft assembly

Set the Hydraclamp plate horizontal. Grasp the cam

ring in one hand and the drive shaft in the other. Lift

the assembly off the hydraulic head, invert it, and

place it upright into the Hydraclamp plate as shown.

If the outer scroll plate (1) has adhered to the head,

remove it and place it with the other loose

components.

Place a plunger retaining cap (2) over the hydraulic

head rotor and discard the large O-ring (3).

E) Removing the cam ring, scroll plate, rollers and shoes

Lift off the cam ring (2), scroll plate (3) and rollers

and shoes (1) and (5) (ensuring that they remain in

their matched pairs) and the inner bearing (4).

F) Removing the drive shaft and governor weights

Lift out the drive shaft. Lift out the thrust sleeve (1),

weights (3) and the thrust washer (2) from the

weight cage (4).

II DISMANTLING

DISMANTLING

2-30

DDNX117A(EN) - Issue 1 of 08/2008

© Delphi

Page 41

2.5.3 Dismantling the shaft assembly

A) Remove the roller cage

Grip the drive shaft lightly in a soft-jawed vice taking

care to avoid any damage to the surface of the

shaft. Do not over-tighten the vice. Use a

suitable Torx screw bit and adaptor (1) to remove

the four catch plate screws (2). Remove the catch

plate (3) and shoe plate (4).

B) Slackening the support block screws

Invert the drive shaft and clamp it (across the gaps

in the large diameter, as shown) in the vice

fitted with soft jaws.

Note: Before slackening the support block screws

of drive shafts with internal timing discs, mark the

position of the disc (1) in relation to the drive shaft

using an indelible felt-tip marker or a suitable

electric etching tool as shown at (3). This will ensure

that the disc is correctly aligned during reassembly.

Using an extended Torx screw adaptor (2) , slacken

ail the support block screws (4).

C) Removing the support blocks and timing disc

Remove the drive shaft from the vice and remove

the support block screws (1), washers, timing disc,

if fitted (see previous illustration), and support

blocks (2).

Note: In the case of two-plunger pumps, mark the

position of the shorter support block with a felt-tip

pen or etcher; this controls the position of the offset

tang on the hydraulic head rotor and hence the

position of the delivery port in relation to the drive

shaft keyway.

DISMANTLING II

DISMANTLING

DDNX117A(EN) - Issue 1 of 08/2008

2-31

© Delphi

Page 42

2.5.4 Pump housing

A) Removing the oil seal

Note the direction of the seal lip (i.e. facing inwards

or outwards). Use the specified tool (1) to lever out

the seal, which must be discarded, taking care to

avoid damage to the seal bore in the housing.

In the case of twin seals, the outer seal, circlip,

spacer and ball were removed prior to removal of

the housing from the shaft . The inner seal must

now be removed, again avoiding damage to the

seal bore in the housing.

B) Removing the advance housing stud

Examine the advance housing stud (1). There are

two methods for fixing the stud in the pump

housing: one stud type has a threaded section, the

end of which will be visible inside the pump

housing; the other has a splined section and a large

diameter head, which can also be seen inside the

pump housing.

If the stud is damaged, the threaded type may be

removed with the use of a suitable stud extraction

tool If the stud is of the splined type the complete

pump housing must be replaced.

II DISMANTLING

DISMANTLING

2-32

DDNX117A(EN) - Issue 1 of 08/2008

© Delphi

Page 43

2.6 Removal Of The Head And Rotor Only

2.6.1 Preparation

Mount the pump in a Hydraclamp with its axis

horizontal. Remove all of the high pressure outlets

(1) whether axial, as shown, or radial (as described

in

Section 2.3.1). Remove the end plate assembly

(2) (as described in

Section 2.3.2) and blanking plug

(3) or stop solenoid. Discard all disturbed sealing

washers.

Remove the governor cover (4) (as described in

Section 2.2.7); disconnect the throttle spindle from

the governor spring assembly. Remove all the

governor control bracket screws, lift the control

bracket assembly and withdraw the metering valve

from the hydraulic head.

2.6.2 Transfer pump and head fittings

Remove and discard the end plate seal. Note the

position of the fuel outlet slot in the end face of the

liner. Remove the liner, blades and springs, if fitted.

Hold the drive shaft with a suitable tommy-bar (3)

through the transverse hole in the shaft and use the

special adaptor tool (4) to slacken, but not remove,

the transfer pump rotor. The rotor must be

unscrewed in the direction of pump rotation

as shown on the pump name plate.

Note: Left-handed transfer rotors are marked with