Del Morino Rotex 90, Rotex 150, Rotex 110, Rotex 130, Rotex 170 Manual Of Use And Maintenance

...Page 1

Rotex-e-06 Manual of use and maintenance : Rotex

Del Morino srl , v.Caroni di Sotto 19,

I-52033 Caprese Michelangelo AR Italy

Ph: +39-575-791059 Fax: +39-575-791210

E.mail: export@del-morino.it

http://www.del-morino.it

MANUAL OF USE AND MAINTENANCE

ROTARY HARROW ROTEX

Page 2

2

PREFACE

This manual is an integral p art of the machine.

It must always accompany the machine and be kept within reach of the operator.

The enclosures mentioned are on integral part of this manual.

The purpose of this manual.

This manual gives information for the correct and safe use of the machine.

The owner must read this manual carefully before work with the machine.

Responsibility of the o wner

The owner is responsible for acc idents or dam ages c aused to people or things due to negligence in following

the instructions in this manual.

Assistance in using this manual

Explanations: contact the dealer.

Request for additional copies of the manual: in case of loss or wear and tear, or in case one wants the

manual in a different language, the customer should ask the dealer or manufacturer.

Pay attention to the warning signals

<Danger>: indicates a situation that is potentially dangerous which, if not avoided, will cause death or

serious

damage.

<Warning>: indicates a situation that is potentially dangerous which, if not avoided, will cause death or

serious damage.

<Caution>: indicates a situation that is potentially dangerous which, if not avoided, can cause minor to

moderate damage or it indicates to be careful about an unsafe procedure.

<Important>: indicates instructions that must be followed precisely in order to avoid damage to the product,

process

or environment.

<Note>: indicates supplementary information.

Page 3

3

DESCRIPTION

FUNCTION OF USE

The machine, thanks to the large r ange of types m odels and vers ions all c onf igurable through many available

variants according to specific requirement, carries out all the func tion related with tools rotation in various

work environment (open field, vineyards, orchards, flower gardens, parks, vegetable gardens) , in all type of

ground whatever its composition (sandy soil, medium mixture, clay) and consistency (crumbly, hard, semiplastic) may be.

The use of a technical constr uctive conc ept tr ended to the s earc h of high perf ormances, reduction of troubles

and durability, improves the power/consumption ratio of the tractor thanks to the elasticity of the machine

frame, to the tools shape and to many original technical solutions.

PERFORMANCES

The machine is connected to the tr actor by a 3° point hitch which gives a movement of translation and a

cardan shaft connected to the PTO which gives a movement of translation to the tools carrier.

The working width is fix and it is determined by the choice of the machine type.

The working depth is adjustable by a rear roller.

The working area is fix.

PERFORMANCE LIMITS

Maximum forwarding speed: 5 km/h.

Speeds higher than the m aximum can comprom ise the condition of the m achine, the quality of the work

and the safety of the operator.

Maximum power applicable to the gear box: from 13 to 59 kW ± 5% at 540 g/m in depending from the

models.

Higher power than one indicated, can damage irreparably the transmiss ion gear box; especially during

heavy works.

Maximum working depth: from 180 to 210 mm depending from the model.

STANDARD FEATURES

- Shear bolt cardan shaft.

VARIANTS & ACCESSORIES

- Wire roller.

- Cage roller.

- Spiked roller.

- Levelling blade.

- Seeder (110÷250).

Page 4

4

TECHINICAL SPECIFICATIONS

CHARACTERISTICS FOR MODEL

Model

Type

Power

Working width

Weight Maximum working

depth

Total width

N° of tools

HP KW cm. inch Kg. lbs. cm. inch cm. inch n°

rotors

n°

teeth

ROTEX

90

18-35

13-26

90

35

198

455

18 7 95

37,5 4 8

110

20-40

15-30

110

43

211

465

18 7 115

45,3 5 10

130

25-45

18-33

130

52

226

498

18 7 135

53,1 6 12

150

30-50

22-38

150

60

248

546

18 7 155

60,9 7 14

170 30-80 22-59 170 67 295 650 21 9 175 68,7 8 16

190

40-80

30-59

190

75

320

705

21 9 195

76,5 9 18

230

50-80

38-59

230

90

415

914

21 9 235

92,1

11

22

250

60-80

44-59

250

99

440

970

21 9 255

100

12

24

Page 5

5

SAFETY INFORMATION

GENERAL REGULATIONS

Only work in daylight.

To prevent damage due to lunch of objects or parts of blades, before to start job be sure that any

persons or animals should be in the radius of 50 meters from the machine.

Wear long pants and heavy shoes.

The protections are integral part of the machine: always work with the protections.

Make sure that the 4 wheels of all components be adjusted to the same cutting height.

Pay attention to the soil: make sure that are not stones, sticks, iron wires, etc…

Pay attention using the machine on slopes: proceed to the maxim um slope and never work in slanting

direction.

Before leaving the driver's seat, turn off the engine and disengage the transmission engine-shaft.

Check immediately the machine if it touches foreign objects.

Check immediately the machine if there are unusual strong vibrations.

Change quickly defective parts.

SAFETY RESTRICTIONS

Children and people who are not familiar with these instructions must not be permitted to use the machine.

Local regulations can restrict the use of the machine in accordance to the age.

Page 6

6

SAFETY SIGNS ON THE MACHINE

In this section, the safety signs on the machine are reproduced and explained.

1 2 3 4 5 6

1. Read the operator manual.

2. Disconnect the tractor key before maintenance and repair operations.

3. Stay at safety distance from blades when machine is moving.

1. Danger of flying objects. Stay at safety distance.

4. Stay at safety distance from blades when machine is moving.

5. Stay at safety distance from blades when machine is moving.

The safety signs on the machine must always be legible.

In case of damage, the labels of the signs must be replaced.

In the case of machine replacement parts that have safety signs, the signs must be replaced.

Supplying of new safety labels and the applica tion procedure

Contact your dealer to receive new safety labels with instructions for application.

Page 7

7

INSTRUCTIONS FOR USE

BEFORE BEGINNING WORK

a) Connect the machine to the tractor as follows :

1. Insert the lifting arms of the tractor in the lower attachment points of the machine, lock by safety pin.

2. Connect the tractor linkage to the 3° point hitch of the m achine (triangle vertex), insert the pin and

lock with safety pin.

b) Check the gearbox and transmission oil level.

c) With the machine raised, go to the working area.

d) Connect the tractor PTO to the machine PTO.

e) Check that PTO chain is locked to prevent the protection sheet of PTO rotating.

BEGINNING WORK

a) Keep people and animals at least 65 feet radius all around the machine.

b) Pull down the machine until the hoes touch the ground.

c) Connect PTO power and gradually bring it to 540 r.p.m...

d) Pull down completely the machine and start to work.

AT THE END OF WORK

a) Stop the tractor.

b) Raise the machine until the hoes goes out from ground.

c) Disconnect PTO power.

d) Disconnect tractor PTO from machine PTO.

e) Raise completely the machine

Page 8

8

SEEDER

1. SEEDER SET UP

To empty the hopper, m ove lever “4” f rom pos ition “C” to position “A” . After dis charge of all seed m ove again

lever “4” to position “C”.

Fill the hopper with seed, now it is necessary to make set up of the mac hine considering how many Kg of

seed you want to sow each hectare. Refer to the below table operate as follow:

Seed type

Set up

Lever 1

Set up

Lever 2

Set up

Sluice gate 3

Wheat

10

2

Totally open

Corn - Pea 8 3

Totally open

Hemp - Sorghum

6

2

Totally open

Alfalfa 3 1

Half open

Onion 3 1

Half open

Depending on the type of seed, operate as follow:

1. Unscrew locking knob then adjust Lever “1” in correct position, screw docking knob.

2. Unscrew locking knob then adjust Lever “2” in correct position, screw docking knob...

3. Adjust position of Sluice gate “3” pulling in direction “A” to open or pushing in direction “C” to close.

Repeat adjustment on all Sluice gates.

Page 9

9

To verify weight in Kg that will be sow (generally the weight in Kg per hectare related to each type of seed is

showed on technical sheet of the seed) operate as follow:

Model

Wheel turns

Factor K

110

34

400

130

29

400

150

25

400

170

22

400

190

20

400

230

17

400

250

15

400

Lift the seeder till the two wheels “W” and “W1” can turn free (picture 1).

Place a towel under the seeder spreader to collect the seed.

Turn the drive wheel “W” clock wise as showed by the arrow (picture 2) many times as showed on the above

table (choice your model).

Collect and weight the seed in the towel.

The seed weight multiplied per Factor “K” will be the total weight sowed per hectare.

In case of discrepancy respect to the desired weight, change position of Lever “1” and repeat weight

verification.

Picture 2

Picture 1

Page 10

10

MAINTENANCE INSTRUCTIONS

On diagram "A" the maintenances are indicated with their terms to effect on the machine.

Not follow the scheduled terms can compromise the functionality of the machine and in this case the warranty

is not applicable.

DIAGRAM "A" SCHEDULED MAINTENANCE

FIRST

START

AFTER

10 HOURS

WORK

EVERY

30 H.

EVERY

500 H.

END OF

SEASON

BEGIN

WROK

END

WORK

MACHINE Greasing Greasing Greasing

Cleaning

Greasing

Cleaning

GEARBOX Oil level Fill oil Fill oil

Oil

replacement

TRANSMISSION Oil level Fill oil Oil level

Oil

replacemnet

SCREWS

Locking

Locking

TOOLS

Check

Check

Check

Check

Page 11

11

1.

GREASING

At the scheduled time on diagram “A”, grease point “B”.

Greasing point is equipped with greaser HYDRAULIC TYPE MODEL "A" UNI 7663.

To greasing use only MULTIFUNCTIONAL GREASE LITHIUM BASED Type NLGI 2.

2.

OIL LEVEL – OIL REPLACEMENT IN GEARBOX

At the scheduled time on diagram “A” verify the level and replace oil in the gearbox.

To fill oil use only OIL SAE 140 EP.

Gearbox capacity: 1,1 L (Rotex 90-110-130-150), 2,5 L (Rotex 170-190-230-250).

a) To check the oil level in gear box, operate as follows :

1. With the machine on level unscrew the level plug "B" and check that oil touches lower hole rim.

2. If the level it's ok screw and lock plug "B".

3. If the level it's low, unscrew plug "A" and fill oil.

4. When the level it's ok screw and lock plugs "A" and "B".

b) To replace oil in the gearbox, operate as follows:

1. With the machine on level unscrew the level plugs “C”, "D" and “E” and drain completely oil.

2. Screw the plug “E”.

3. Fill new oil through the hole “D” up to oil touches lower hole rim “C”.

4. When the level is ok, screw the plugs “C” and “D”.

3. OIL LEVEL – OIL TRANSMISSION REPLACEMENT

At the scheduled time on diagram "A" check the level or replace oil in the transmission.

To fill oil use only OIL SAE 140 EP.

Tank capacity: from 3,6 L to 12,5 L depending from the model.

Page 12

12

c) To check the oil in the transmission, operate as follows:

1. With the machine on level unscrew the plug "B" and check that oil touches lower hole rim.

2. If the level is ok, lock the plug "B".

3. If the level is low, fill oil.

4. When the level is ok, lock the plug “B”.

d) To replace oil in the transmission, operate as follows:

1. Unscrew the plug “B”, turn backward the machine and drain completely oil.

2. Introduce the new oil through the hole “B” up to oil touches lower hole rim.

3. When level is ok, lock the plug “B”.

4. TOOLS REPLACEMENT

a) To replace the tools, operate as follows:

1. Unscrews the two screws "A" which lock the tools to replace.

2. Take out the two screws and remove the tool “B”.

3. Place the new tool and the two screws “A”.

4. Lock the screws "A" with pneumatic wrench.

5. Repeat this operation for all the tools to replace.

ATTENTION: each rotor is equipped with a couple of right and left tools according to the position,

don’t invert the right tools with the left one s.

Page 13

13

PROBLEMS SOLVING

TROUBLES CAUSES AND SOLUTIONS

Insufficient working depth

-Decrease the forwarding speed

-Tools are not sharpened or damaged

Tools don’t penetrate

Rotary harrow bounces on the round and vibrates

-Broken or damaged tools

-Check the tools assembling

-Foreign objects between hoes - clean

-Decrease the forwarding speed

-Soil too dry and hard

Rotor compactness, obstruction

-Soil too wet

-Reduce working depth

-Increase number of revolutions of the rotor

Excessive tilling of the soil

-Increase forwarding speed

- Decrease number of revolutions of the rotor

Poor tilling of the soil

- Decrease the forwarding speed

-Increase number of revolutions of the rotor

Page 14

14

TRANSPORT

Except when working, moving the machine takes place when the machine is standing still and the

transmission is disconnected.

<Important>: keep speed low avoiding holes and ground roughness.

<Note> when on the road, obey existing traff ic laws. Exhibit the signal signs on the rear ends. Respect

any local laws there may be.

<Note> Lock the lifting bars of the tractor with the chain and tightners. They must be parallel to the bars.

STORAGE

Store the machine in a dry place that isn't dusty.

INFORMATION ON DEMOLITION

At the end of its working life, the machine m ust be sent to be demolished and that can only be

done by an authorized authority, in accordance with the national laws in force for the environment.

Therefore it is necessar y to get information f rom the qualified local author ities on the procedur e to follow.

The machine is mainly composed of: iron materials and paints.

WARRANTY

The machine is covered by the manufacturer warranty for a period of 24 months.

The warranty is not applicable when:

a) The maintenance work has not been done correctly.

b) The machine has been used out of its own service.

c) The machine has been transformed or modified without the manufacturer's written authorization.

Page 15

15

WORK AND MAINTENANCE SHEET

Every user should register on this sheet the facts about the life of the m achine (both work and m aintenance) ,

so as to attest its conditions.

DATE

WORKING

HOURS

MAITENANCE

NOTE

USER

Page 16

16

SPARE PART AND ACCESSORIES

Page 17

17

ROTEX MECHANISMS 90-110-130-150

Page 18

18

ROTEX MECHANISMS 170-190

Page 19

19

ROTEX MECHANISMS 230-250

Page 20

20

ROTEX SHEET 90-110-130-150

Page 21

21

ROTEX SHEETS 170-190

Page 22

22

ROTEX SHEETS 230-250

Page 23

23

LEVELLING BLADE ROTEX 90-110-130

LEVELLING BLADE ROTEX 150

LEVELLING BLADE ROTEX 170-190-230-250

Page 24

24

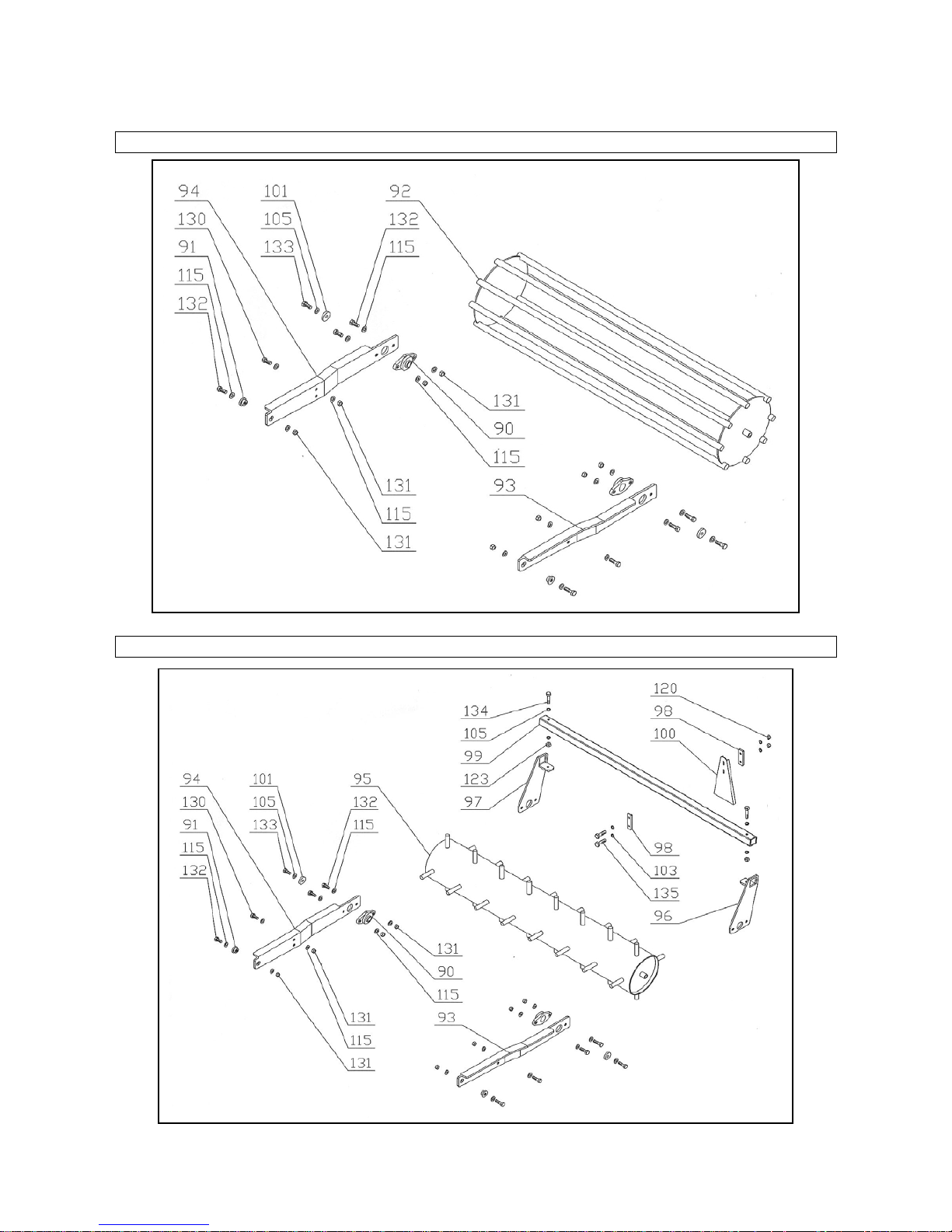

ROTEX ROLLER LIFTING 110-130-150-170-190-230-250

ROTEX WIRE ROLLER

Page 25

25

ROTEX CAGE ROLLER

ROTEX SPIKED ROLLER

Page 26

26

SEEDER HOLDER

Page 27

27

SPARE PARTS LIST ROTEX

Pos Code Description

Quantity

90

110

130

150

170

190

230

250

1

42000002

GEARBOX

1 1 1 1 1 1 2

42000027

GEARBOX

1 1 3

42400008

UCFC 206 SUPPORT

3 4 5 6 7 8 10

11 4 42400009

UCFC 208 SUPPORT

1 1 1 1 1 1 5

42400010

UCFC 209 SUPPORT

1 1 6

41000038

BEARING 6307

1 1 1 1 1 1 7

41000039

BEARING 6208

3 4 5 6 7 8 11

12 8 41100013

OIL SEAL 80x45x10

8

10

12

14

16

18

20

22 9 41100014

OIL SEAL 80x55x10

2 2 10

41200008

ORING 330

3 4 5 6 7 8 10

11

11

ERP165D

SEAL

4 5 6 7 12

ERP449D

SEAL 8 9

11

12

13

ERP166D

SEAL

3 4 5 6 7 8 10

11

14

ERP164D

SEAL

1 1 1 1 1 1 15

ERP450D

SEAL 1 1

16

40400003

SEEGER Ø80 UNI 7437

4 5 6 7 8 9 11

12

17

41900005

SAFETY PROTECTION

1 1 1 1 1 1 1 1 18

ERP062VD

SIDE BLADE HOLDER

3 4 5 6 7 8 10

11

19

ERP403VD

CENTRAL BLADE HOLDER

1 1 1 1 1 1 20

ERP446VD

CENTRAL BLADE HOLDER

1 1 21

ERP153VD

SIDE HUB

3 4 5 6 22

ERP152VD

CENTRAL HUB

1 1 1 1 23

ERP451VD

SIDE HUB

7 8 11

12

24

ERP452VD

CENTRAL HUB

1 1 25

ERP157D

SAFETY WASHER

3 4 5 6 7 8 10

11

26

ERP156D

CENTRAL SHAFT

1 1 1 1 1 1 27

ERP410D

CENTRAL SHAFT

1 1 28

ERP301D

GEAR H 25

4 5 6 7 8 9 29

ERP406D

SIDE GEAR H 30

10

11

30

ERP405D

CENTRAL GEAR H 30

1 1 31

ERP302D

GEAR BUSH H 25

4 5 6 7 8 9 32

ERP154D

GEAR BUSH H 30

11

12

33

ERP326ZD

SUPPORT CAP UCFC 206

3 4 5 6 7 8 10

11

34

ERP360ZD

SUPPORT CAP UCFC 208

1 1 1 1 1 1 35

ERP411ZD

SUPPORT CAP UCFC 209

1 1 36

ERP303D

RIGHT TOOTH L=180

4 4 6 8 37

ERP304D

LEFT TOOTH L=180

4 6 6 6 38

ERP162D

RIGHT TOOTH L=220

8 8 39

ERP163D

LEFT TOOTH L=220

8

10

40

ERP447D

RIGHT/LEFT TOOTH L=280

12

12

41

ERP447D

RIGHT LEFT/TOOTH L=280

10

12

42

ERP051AVD

MAIN FRAME 90

1 42

ERP051BVD

MAIN FRAME 110

1 42

ERP051CVD

MAIN FRAME 130

1 42

ERP051DVD

MAIN FRAME 150

1 42

ERP051EVD

MAIN FRAME 170

1 42

ERP051FVD

MAIN FRAME 190

1 42

ERP051GVD

MAIN FRAME 230

1 42

ERP051HVD

MAIN FRAME 250

1 43

ERP052AVD

COVER 90

1 43

ERP052BVD

COVER 110

1 43

ERP052CVD

COVER 130

1

Page 28

28

Pos Code Description

Quantity

90

110

130

150

170

190

230

250

43

ERP052DVD

COVER 150

1 43

ERP052EVD

COVER 170

1 43

ERP052FVD

COVER 190

1 43

ERP052GVD

COVER 230

1 43

ERP052HVD

COVER 250

1 44

ERP436VD

LEFT TAIL BOARD

1 1 1 1 1 1 1 1 45

ERP417VD

RIGHT TAIL BOARD

1 1 1 1 1 1 1 1 46

ERP056VD

SUPPORT

1 1 1 1 47

ERP322VD

LOWER HITCH

2 2 2 2 48

ERP055VD

GEARBOX SUPPORT

1 1 1 1 1 1 49

ERP341VD

GEARBOX COVER

1 1 1 1 1 1 50

ERP053VD

III POINT HITCH

1 1 1 1 50

ERP054VD

III POINT HITCH

1 1 51

ERP057AVD

FRONT PIPE 170

1 51

ERP057BVD

FRONT PIPE 190

1 53

ERP349VD

LOWER HITCH HOLDFAST

2 2 54

ERP058VD

LOWER HITCH

2 2 55

42500024

COVER SEAL 90

1 55

42500025

COVER SEAL 110

1 55

42500026

COVER SEAL 130

1 55

42500027

COVER SEAL 150

1 55

42500028

COVER SEAL 170

1 55

42500029

COVER SEAL 190

1 55

42500034

COVER SEAL 230

1 55

42500035

COVER SEAL 250

1 56

ERP063AVD

FRONT PIPE 230

1 56

ERP063BVD

FRONT PIPE 250

1 57

ERP064VD

III POINT LEFT SUPPORT

1 1 58

ERP065VD

III POINT RIGHT SUPPORT

1 1 59

ERP066VD

GEARBOX SUPPORT

1 1 60

ERP424VD

GEARBOX SUPPORT

1 1 61

ERP426VD

LEFT SIDE III POINT

1 1 62

ERP427VD

RIGHT SIDE III POINT

1 1 63

ERP067VD

III POINT BEAM

1 1 64

ERP068VD

LEFT REIFORCEMENT

1 1 65

ERP069VD

RIGHT REINFORCEMENT

1 1 66

ERP366VD

SUPPORT HOLDFAST

2 2 2 2 67

ERP073VD

LOWER HITCH

2 2 68

43700012

III POINT PIN

1 1 1 1 1 1 69

SRM220D

COMPLETE PIN I CATEGORY

2 2 2 2 70

43700010

I CATEGORY PIN

2 2 71

ERP082ZD

III POINT PIN

1 1 72

ERP083ZD

PIN II CATEGORY

2 2 73

SRM233ZD

BUSH

4 4 4 4 4 4 4 4 74

ERP330AVD

LEVELLING BLADE 90

1 74

ERP330BVD

LEVELLING BLADE 110

1 74

ERP330CVD

LEVELLING BLADE 130

1 74

ERP330DVD

LEVELLING BLADE 150

1 74

ERP330EVD

LEVELLING BLADE170

1 74

ERP330FVD

LEVELLING BLADE 190

1 74

ERP330GVD

LEVELLING BLADE 230

1 74

ERP330HVD

LEVELLING BLADE 250

1 75

ERP331VD

BLADE SUPPORT

2

76

URC181ZD

LIFTING BRACKET

1 1 77

ERP060VD

BLADE ARM

2 2 2 2 2 2 2

2

Page 29

29

Pos Code Description

Quantity

90

110

130

150

170

190

230

250

78

ERP333VD

BLADE ARM HOLDFAST

2 2 2 2 2 2 2 2 79

ERP363VD

BLADE LEFT SUPPORT

1 1 79

ERP465VD

BLADE LEFT SUPPORT

1 1 80

ERP364VD

BLADE RIGHT SUPPORT

1 1 80

ERP466VD

BLADE RIGHT SUPPORT

1 1 81

ERP061VD

BLADE ARM HITCH

2 2 2 2 82

ERP442VD

REAR TIR ROD HITCH

2 2 2 2 2 2 2 83

ERP086VD

LEFT TIE ROD FRONT HITCH

1 1 1 83

ERP074VD

LEFT TIE ROD FRONT HITCH

1 1 1 1 84

ERP087VD

RIGHT TIE ROD FRONT HITCH

1 1 1 84

ERP075VD

RIGHT TIE ROD FRONT HITCH

1 1 1 1 85

41800010

TIE ROD

2 2 2 2 2 2 2 86

ERP336AVD

SCRAPER 90

1 86

ERP336BVD

SCRAPER 110

1 86

ERP336CVD

SCRAPER 130

1 86

ERP336DVD

SCRAPER 150

1 86

ERP336EVD

SCRAPER 170

1 86

ERP336FVD

SCRAPER 190

1 86

ERP336GVD

SCRAPER 230

1 86

ERP336HVD

SCRAPER 250

1 87

ERP070AVD

WIRE ROLLER 90

1 87

ERP070BVD

WIRE ROLLER 110

1 87

ERP070CVD

WIRE ROLLER 130

1 87

ERP070DVD

WIRE ROLLER 150

1 87

ERP070EVD

WIRE ROLLER 170

1 87

ERP070FVD

WIRE ROLLER 190

1 87

ERP070GVD

WIRE ROLLER 230

1 87

ERP070HVD

WIRE ROLLER 250

1 88

ERP076VD

WIRE ROLLER LEFT ARM

1 1 1 1 1 1 1 1 89

ERP077VD

WIRE ROLLER RIGHT ARM

1 1 1 1 1 1 1 1 90

42400006

SUPPORT UCFL 205

2 2 2 2 2 2 2 2 91

ERP328ZD

BUSH

2 2 2 2 2 2 2 2 92

ERP071AVD

CAGE ROLLER 90

1 92

ERP071BVD

CAGE ROLLER 110

1 92

ERP071CVD

CAGE ROLLER 130

1 92

ERP071DVD

CAGE ROLLER 150

1 92

ERP071EVD

CAGE ROLLER 170

1 92

ERP071FVD

CAGE ROLLER 190

1 92

ERP071GVD

CAGE ROLLER 230

1 92

ERP071HVD

CAGE ROLLER 250

1 93

ERP078VD

LEFT ARM CAGE+SPIKED ROLLER

1 1 1 1 1 1 1 1 94

ERP079VD

RIGHT ARM CAGE+SPIKED ROLLER

1 1 1 1 1 1 1 1 95

ERP072AVD

SPIKED ROLLER 90

1 95

ERP072BVD

SPIKED ROLLER 110

1 95

ERP072CVD

SPIKED ROLLER 130

1 95

ERP072DVD

SPIKED ROLLER 150

1 95

ERP072EVD

SPIKED ROLLER 170

1 95

ERP072FVD

SPIKED ROLLER 190

1 95

ERP072GVD

SPIKED ROLLER 230

1 95

ERP072HVD

SPIKED ROLLER 250

1 96

ERP080VD

LEFT SUPPORT SCRAPERS

1 1 1 1 1 1 1 1 97

ERP081VD

RIGHT SUPPORT SCRAPERS

1 1 1 1 1 1 1 1 98

ERP433VD

SCRAPERS PLATE

8

10

12

14

16

18

22

24

99

ERP434AVD

SCRAPERS BEAM 90

1 99

ERP434BVD

SCRAPERS BEAM 100

1

Page 30

30

Pos Code Description

Quantity

90

110

130

150

170

190

230

250

99

ERP434CVD

SCRAPERS BEAM 130

1 99

ERP434DVD

SCRAPERS BEAM 150

1 99

ERP434EVD

SCRAPERS BEAM 170

1 99

ERP434FVD

SCRAPERS BEAM 190

1 99

ERP434GVD

SCRAPERS BEAM 230

1 99

ERP434HVD

SCRAPERS BEAM 250

1 100

ERP431ZD

SCRAPER

4 5 6 7 8 9 11

12

101

HOL214D

ROLL STOPPER

2 2 2 2 2 2 2 2 102

40100197

SCREW M10x45 UNI5739

12

16

20

24

28

32

40

44

103

40300003

WASHER Ø10 UNI 6592

56

68

80

92

96

108

140

152

104

40100102

SCREW M12x50 UNI 5737

4

10

10

10

10

10 6 6

105

40300004

WASHER Ø12 UNI 6592

52

66

66

66

116

116

116

116

106

40100229

SCREW M14x45 PF UNI 5739

16

20

24

28

32

36

107

40300064

WASHER CONTACT Ø14 UNI 7604

16

20

24

28

32

36

44

48

108

40200155

NUT CONELOCK M14 PF DIN 980

16

20

24

28

32

36

44

48

109

40200153

NUT M30x2 DIN 985

1 1 1 1 1 1 1 1 110

40300016

WASHER Ø30 UNI 6592

1 1 1 1 1 1 1 1 111

40200154

NUT M36x3 UNI 5589

3 4 5 6 7 8 10

11

112

40100042

SCREW M8x16 UNI 5739

7 8 9

10

11

12

14

15

113

40300002

WASHER Ø8 UNI 6592

7

22

23

24

25

26

28

29

114

40100145

SCREW M14x55 UNI 5739

4 4 115

40300009

WASHER Ø14 UNI 6592

14

29

29

29

29

29

57

57

116

40100061

SCREW M12x45 UNI 5739

8 8 8 8 4 4 4 4 117

40300007

WASHER Ø20 UNI 6592

4 4 4 4 4 4 4 4 118

40100012

SCREW M10x30 UNI 5739

18

22

26

30

34

38

46

50

119

40100030

SCREW M10x20 UNI 5739

8 8 8 8 8 8 8 8 120

40200003

NUT CONELOCK M10 DIN 980

26

32

38

44

50

56

68

74

121

40100014

SCREW M12X30 UNI 5739

16

16

16

16

48

52

54

58

122

40100015

SCREW M12x35 UNI 5739

6 6 6 6 6 6 123

40200006

NUT CONELOCK M12 DIN 980

16

23

23

23

51

51

57

57

124

ERP368VD

LEFT BLADE SUPPORT

1 1 1 125

40300065

WASHER CONTACT Ø12 UNI 7604

32

36

44

48

126

ERP369VD

RIGHT BLADE SUPPORT

1 1 1 127

40100023

SCREW M12x40 UNI 5739

4 4 4 4 36

36

36

36

128

40100080

SCREW M16x35 UNI 5739

8 8 129

40300006

WASHER Ø16 UNI 6592

8 8 8 8 8 16

16

130

40100018

SCREW M14x40 UNI 5739

2 2 2 2 2 2 16

16

131

40200011

NUT CONELOCK M14 DIN 980

6

10

10

10

10

10

24

24

132

40100158

SCREW M14x45 UNI 5739

6 6 6 6 6 6 6 6 133

40100013

SCREW M12x25 UNI 5739

2 2 2 2 2 2 2 2 134

40100064

SCREW M12x80 UNI 5737

2 2 2 2 2 2 2 2 135

40100045

SCREW M10x80 UNI 5737

8

10

12

14

16

18

22

24

136

41300001

SAFETY PIN Ø10

2 2 2 2 2 2 3 3 137

40100230

SCREW M10x30-10,9 UNI 5739

16

20

24

28

32

36

44

48

138

40300066

WASHER CONTACT Ø10 UNI 7604

16

20

24

28

32

36

44

48

139

ERP084VD

III POINT LEFT SUPPORT

1 1 140

ERP085VD

III POINT RIGHT SUPPORT

1 1 141

ERP458VD

TOOTH SPACER

22

24

142

40100245

SCREW M14x55 PF UNI 5738

44

48

143

40100118

SCREW M18x1500 UNI 5737

2 2 2 143

40100103

SCREW M18x90 UNI 5737

2 2 2 2 144

40200028

NUT M18 DIN 980

2 2 2 2 2 2 2 145

40300020

WASHER Ø18 UNI 6592

2 2 2 4 4 4

4

146 ERP459VD

REAR RIGHT TIE ROD HITCH WIRE

ROLER

1 1 1 1

Page 31

31

Pos Code Description

Quantity

90

110

130

150

170

190

230

250

147

ERP460VD

REAR LEFT TIE ROD HITCH WIRE

ROLER

1 1 1

1

150

INT060BVD

SEEDER FRAME

1 150

INT060CVD

SEEDER FRAME

1 150

INT060DVD

SEEDER FRAME

1 150

INT060EVD

SEEDER FRAME

1 1 1 1 151

ERP091BVD

FRAME 110

1 151

ERP091CVD

FRAME 130

1 151

ERP091DVD

FRAME 150

1 151

ERP091EVD

FRAME 170

1 151

ERP091FVD

FRAME 190

1 151

ERP091GVD

FRAME 230

1 151

ERP091HVD

FRAME 250

1 152

ERP090BVD

SEEDER 110 SPRAYER

1 152

ERP090CVD

SEEDER 130 SPRAYER

1 152

ERP090DVD

SEEDER 150 SPRAYER

1 152

ERP090EVD

SEEDER 170 SPRAYER

1 152

ERP090FVD

SEEDER 190 SPRAYER

1 152

ERP090GVD

SEEDER 230 SPRAYER

1 152

ERP090HVD

SEEDER 250 SPRAYER

1 153

ERP089VD

REAR ROLL RIGHT BRACKET

1 1 1 1 1 1 1 154

ERP088VD

REAR ROLL LEFT BRACKET

1 1 1 1 1 1 1 155

INT062VD

SAFETY PROTECTION

1 1 1 1 1 1 1 156

INT189VD

SAFETY PROTECT. LOWER SIDE

1 1 1 1 1 1 1 157

ERP397VD

SPACER

2 158

INT268D

RIGHT WHEEL BUSH

1 1 1 1 1 1 1 159

INT260D

LEFT WHEEL AXLE

1 1 1 1 1 1 1 160

INT063VD

PIGNONE

1 1 1 1 1 1 1 161

INT264ZD

PINION SPACER

5 5 5 5 5 5 5 162

INT064VD

DOUBLE CROWN

1 1 1 1 1 1 1 163

SRM205ZD

SPACER ≠ 13x25x35

3 3 3 3 3 3 3 164

SRM204ZD

SPACER ≠ 6x25x35

3 3 3 3 3 3 3 165

SRM203ZD

SPACER

2 2 2 2 2 2 2 166

PLASTIC PIPE

11

13

13

15

15

15

15

167

43000018

HOSE CLAMP 32-50

11

13

13

15

15

15

15

168

42500030

PLUG 50x50

2 2 2 2 2 2 2 169

42900001

RUBBER WHEEL Ø210x80

2 2 2 2 2 2 2 170

40800011

CHAIN ASA 41S ½” 67 LINK + JOINT

1 1 1 1 1 1 1 171

42300007

ELASTIC PIN 6x40 UNI 6873

1 1 1 1 1 1 1 172

40200002

NUT CONELOCK M8 DIN 980

7 7 7 7 7 7 7 173

40200059

NUT M14 DIN 982

3 3 3 3 3 3 3 174

40100001

SCREW M8x20 UNI 5739

7 7 7 7 7 7 7 175

40100251

SCREW M12x20 UNI 5931

1 1 1 1 1 1 1 176

40100095

SCREW M12x130 UNI 5737

1 1 1 1 1 1 1 177

40100025

SCREW M14x50 UNI 5739

4 4 4 4 4 4 4 178

40100227

SCREW M8x60 UNI 5737

5 5 5 5 5 5 5 179

40100109

SCREW M14x60 UNI 5737

4 4 4 4 4 4 4 180

40100034

SCREW M16x40 UNI 5739

4 181

40100130

SCREW M 16x60 UNI 5739

4 4 4 4 4 4 182

40200040

NUT M8 DIN 982

5 5 5 5 5 5 5 183

40200008

NUT CONELOCK M16 DIN 980

4 4 4 4 4 4 4 184

42600019

PTO SHAFT IV° CAT. BOLT L=700

1 1 1 1 184

42600110

PTO SHAFT V° CAT. BOLT L=700

1 1 184

42600111

PTO SHAFT VI° CAT. BOLT L=700

1

1

Page 32

32

SEEDER FRAME

Page 33

33

SEEDER MECHANISM

Page 34

34

INDEX

PREFACE

...........................................................................................................................................................2

DESCRIPTION

...................................................................................................................................................3

FUNCTION

OF USE ........................................................................................................................................3

PERFORMANCES

..........................................................................................................................................3

PERFORMANCE

LIMITS ................................................................................................................................3

STANDARD

FEATURES ....................................................................................................................................3

VARIANT

S & ACCESSORIES ..........................................................................................................................3

TECHINICAL SPECIFICATIONS

.......................................................................................................................4

SAFETY INFORMATION

...................................................................................................................................5

GENERAL

REGULATIONS ............................................................................................................................5

SAFETY

RESTRICTIONS ...............................................................................................................................5

SAFETY SIGNS ON THE MACHINE

.................................................................................................................6

INSTRUCTIONS FOR USE

................................................................................................................................7

BEFORE

BEGINNING WORK ........................................................................................................................7

BEGINNING

WORK ........................................................................................................................................7

AT

THE END OF WORK .................................................................................................................................7

SEEDER

.............................................................................................................................................................8

1.

SEEDER SET UP .....................................................................................................................................8

MAINTENANCE INSTRUCTIONS

...................................................................................................................10

DIAGRAM

"A" SCHEDULED MAINTENANCE ..............................................................................................10

1.

GREASING ............................................................................................................................................11

2.

OIL LEVEL – OIL REPLACEMENT IN GEARBOX ...............................................................................................11

3. OIL LEVEL – OIL TRANSMISSION REPLACEMENT ............................................................................11

4.

TOOLS REPLACEMENT ..............................................................................................................................12

PROBLEMS SOLVING

....................................................................................................................................13

TRANSPORT

....................................................................................................................................................14

STORAGE

........................................................................................................................................................14

INFORMATION ON DEMOLITION

..................................................................................................................14

WARRANTY

.....................................................................................................................................................14

WORK AND MAINTENANCE SHEET

.............................................................................................................15

ROTEX MECHANISMS 90-110-130-150

.........................................................................................................17

ROTEX MECHANISMS 170-190

......................................................................................................................18

ROTEX MECHANISMS 230-250

......................................................................................................................19

ROTEX SHEET 90-110-130-150

.....................................................................................................................20

ROTEX SHEETS 170-190

................................................................................................................................21

Page 35

35

ROTEX SHEETS 230-250

................................................................................................................................22

LEVELLING BLADE ROTEX 90-110-130

.......................................................................................................23

LEVELLING BLADE ROTEX 150

....................................................................................................................23

LEVELLING BLADE ROTEX 170-190-230-250

..............................................................................................23

ROTEX ROLLER LIFTING 110-130-150-170-190-230-250

............................................................................24

ROTEX WIRE ROLLER

...................................................................................................................................24

ROTEX CAGE ROLLER

..................................................................................................................................25

ROTEX SPIKED ROLLER

...............................................................................................................................25

SEEDER HOLDER

...........................................................................................................................................26

SPARE PARTS LIST ROTEX

..........................................................................................................................27

SEEDER FRAME

.............................................................................................................................................32

SEEDER MECHANISM

....................................................................................................................................33

Loading...

Loading...