Dell EMC Unity 480, Unity 680F, Unity 480F, Unity 680, Unity 880 Hardware Information Manual

...

Dell EMC Unity™ All Flash and Unity Hybrid

Unity 480/F, Unity 680/F, Unity 880/F

Hardware Information Guide

302-005-520

REV 01

Copyright © 2019 Dell Inc. or its subsidiaries. All rights reserved.

Published June 2019

Dell believes the information in this publication is accurate as of its publication date. The information is subject to change without notice.

THE INFORMATION IN THIS PUBLICATION IS PROVIDED “AS-IS.“ DELL MAKES NO REPRESENTATIONS OR WARRANTIES OF ANY KIND

WITH RESPECT TO THE INFORMATION IN THIS PUBLICATION, AND SPECIFICALLY DISCLAIMS IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. USE, COPYING, AND DISTRIBUTION OF ANY DELL SOFTWARE DESCRIBED

IN THIS PUBLICATION REQUIRES AN APPLICABLE SOFTWARE LICENSE.

Dell, EMC, and other trademarks are trademarks of Dell Inc. or its subsidiaries. Other trademarks may be the property of their respective owners.

Published in the USA.

Dell EMC

Hopkinton, Massachusetts 01748-9103

1-508-435-1000 In North America 1-866-464-7381

www.DellEMC.com

2 Unity 480/F, Unity 680/F, Unity 880/F Hardware Information Guide

CONTENTS

Additional resources 5

Chapter 1

Chapter 2

DPE component descriptions 7

2U, 25-drive DPE component overview........................................................8

DPE front view............................................................................................. 9

System identification tags..............................................................10

DPE rear view.............................................................................................. 11

DPE embedded modules and 4-port cards...................................... 11

DPE I/O module types....................................................................14

DPE power supply.......................................................................... 16

Storage processor assembly internal components.......................................17

Technical specifications 19

Technical specifications............................................................................. 20

Dimensions and weight................................................................................21

Power requirements....................................................................................21

Operating environment requirements......................................................... 22

DPE airflow....................................................................................23

Environmental recovery.................................................................24

Shipping and storage requirements............................................... 24

Shock and Vibration.......................................................................24

Fire suppressant disclaimer........................................................... 25

Air quality requirements.................................................................25

Unity 480/F, Unity 680/F, Unity 880/F Hardware Information Guide 3

CONTENTS

4 Unity 480/F, Unity 680/F, Unity 880/F Hardware Information Guide

Additional resources

DANGER

WARNING

CAUTION

NOTICE

Note

As part of an improvement effort, revisions of the software and hardware are

periodically released. Therefore, some functions described in this document might not

be supported by all versions of the software or hardware currently in use. The product

release notes provide the most up-to-date information on product features. Contact

your technical support professional if a product does not function properly or does not

function as described in this document.

Where to get help

Support, product, and licensing information can be obtained as follows:

Product information

For product and feature documentation or release notes, go to Unity Technical

Documentation at: www.emc.com/en-us/documentation/unity-family.htm.

Troubleshooting

For information about products, software updates, licensing, and service, go to Online

Support (registration required) at: https://Support.EMC.com. After logging in, locate

the appropriate Support by Product page.

Technical support

For technical support and service requests, go to Online Support at: https://

Support.EMC.com. After logging in, locate Create a service request. To open a

service request, you must have a valid support agreement. Contact your Sales

Representative for details about obtaining a valid support agreement or to answer any

questions about your account.

Special notice conventions used in this document

Indicates a hazardous situation which, if not avoided, will result in death or

serious injury.

Indicates a hazardous situation which, if not avoided, could result in death or

serious injury.

Indicates a hazardous situation which, if not avoided, could result in minor or

moderate injury.

Addresses practices not related to personal injury.

Presents information that is important, but not hazard-related.

Additional resources 5

Additional resources

6 Unity 480/F, Unity 680/F, Unity 880/F Hardware Information Guide

CHAPTER 1

DPE component descriptions

l

2U, 25-drive DPE component overview............................................................... 8

l

DPE front view.....................................................................................................9

l

DPE rear view......................................................................................................11

l

Storage processor assembly internal components.............................................. 17

DPE component descriptions 7

Note

DPE component descriptions

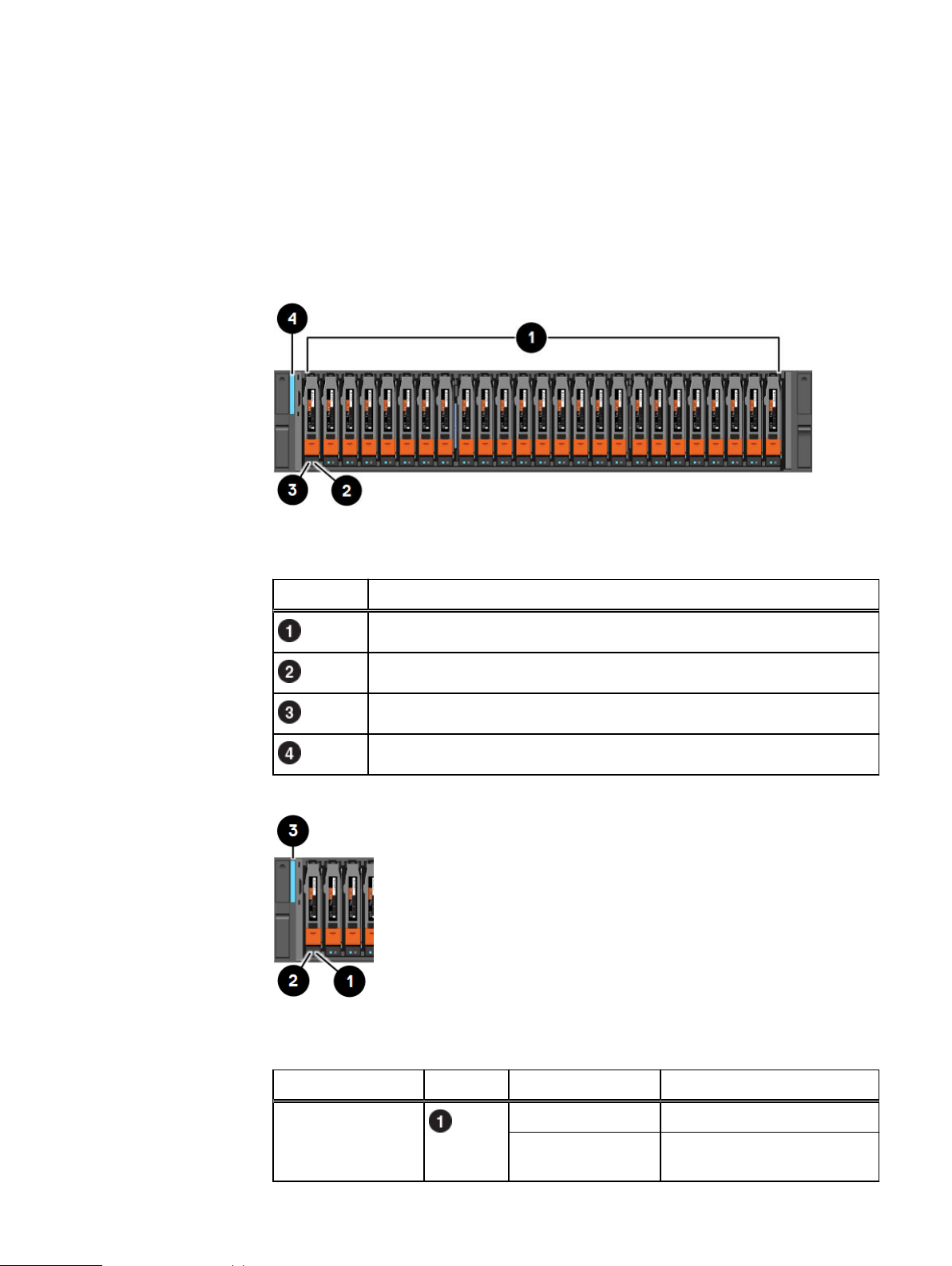

2U, 25-drive DPE component overview

The 25-drive DPE is two rack units (U), 8.9 cm (3.5 in.) high, 79.2 cm (31.2 in.) deep,

and includes slots for twenty-five 2.5-in. drives.

The DPE consists of the following components:

l

Drives

l

Midplane

l

Storage processor assembly

l

Power supply module

l

EMI shielding

Drives

Each drive consists of one drive in a carrier. The drive carriers are metal and plastic

assemblies that provide smooth, reliable contact with the enclosure slot guides and

midplane connectors. Each carrier has a handle with a latch and spring clips. The latch

holds the drive in place to ensure proper connection with the midplane. Drive activity

and fault LEDs are located on the front of the enclosure.

SAS and SAS flash drives are supported. The drives are populated in the system from

left to right.

The first four drive slots are reserved for system drives, and should not be removed.

You can visually distinguish between drive types by their different latch and handle

mechanisms and by type, capacity, and speed labels on each drive. You can add or

remove a drive while the DPE is powered on, but you should exercise special care

when removing modules while they are in use. Drives are sensitive electronic

components.

Midplane

The midplane separates the front-facing drives from the rear-facing SP assemblies. It

distributes power and signals to all components in the enclosure. The SP assemblies

and drives plug directly into the midplane.

Storage processor assembly

Each DPE contains two SP assemblies. The SP assembly is the intelligent component

providing the compute capability of the DPE. Acting as the control center, each SP

assembly includes status LEDs.

Storage processor assembly power supply module

Each SP assembly contains a power supply module that connects the system to an

exterior power source. Redundant power supplies can keep the entire DPE running if

one power supply fails. The power supplies include LEDs to indicate component status.

A latch on the module locks it into place to ensure proper connection.

EMI shielding

EMI compliance requires a properly installed electromagnetic interference (EMI)

shield in front of the DPE drives. When installed in cabinets that include a front door,

the DPE includes a simple EMI shield. Other installations require a front bezel that has

a locking latch and integrated EMI shield. Remove the bezel or shield to remove and

install the drives.

8 Unity 480/F, Unity 680/F, Unity 880/F Hardware Information Guide

DPE front view

On the front, the DPE contains the following elements:

l

Drives in 2.5 in. carriers

l

Status LEDs

Figure 1 DPE front view

DPE component descriptions

Table 1 DPE component locations

Location Description

SAS or SAS Flash drives

Drive fault LED

Drive ready/activity LED

DPE power on LED

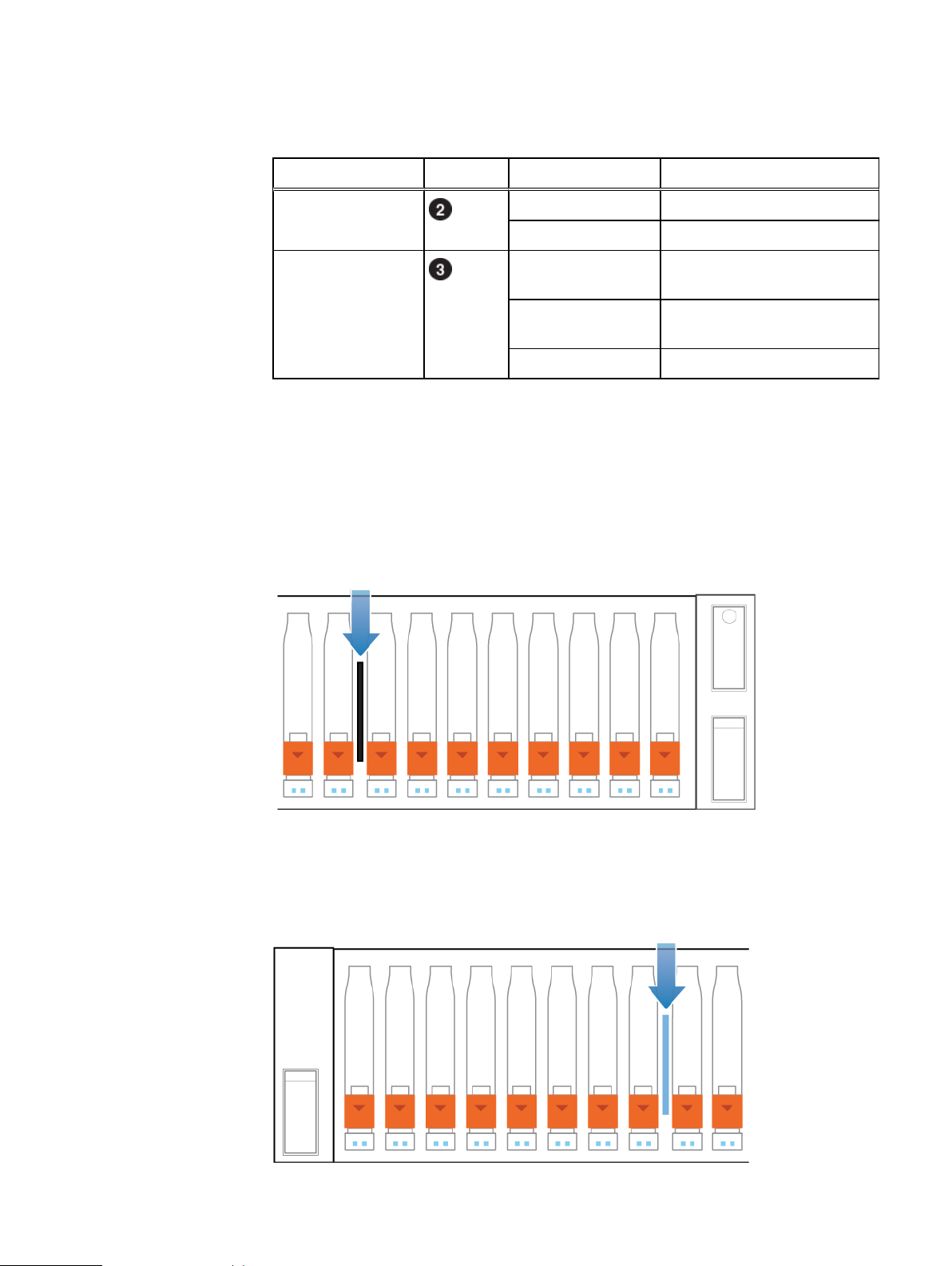

Figure 2 DPE and disk drive LEDs

Table 2 DPE and disk drive LEDs

LED Location State Description

Disk drive fault Amber Fault has occurred.

Off No fault has occurred, normal

operation.

DPE front view 9

DPE component descriptions

Table 2 DPE and disk drive LEDs (continued)

LED Location State Description

Disk drive active Blue Disk drive activity.

DPE fault/power Blue Power is on. No fault has

System identification tags

The Product Serial Number Tag (PSNT) and World Wide Name Seed are serialized

labels that allow customer support to track nested hardware material in the field.

Product Serial Number Tag

The PSNT for the 25-slot DPE is a black pull-out tag that is located between the

drives in slots 16 and 17.

Figure 3

PSNT location

Off Disk drive is powered off.

occurred, normal operation.

Amber Power is on. Fault has occurred

within the enclosure.

Off Power is off.

World Wide Name (WWN) Seed Tag

The World Wide Name (WWN) Seed tag is a blue pull-out tag that is located between

the drives in slot 7 and 8.

Figure 4

10 Unity 480/F, Unity 680/F, Unity 880/F Hardware Information Guide

WWN Seed tag location

DPE rear view

5

Note

DPE component descriptions

On the rear of the DPE are two SP assemblies: SP assembly A and SP assembly B.

Each SP assembly contains the following hardware components:

l

One embedded module

l

Two optional I/O modules

l

One power supply module

Figure 5 DPE rear view with hardware component locations

Table 3 DPE hardware component locations

Location Description

Storage processor assembly B

Storage processor assembly A

Power supply module

I/O module, slots 0 and 1

Embedded module

DPE embedded modules and 4-port cards

About embedded modules

Each SP assembly contains one embedded module that can hold one 4-port card for

connectivity.

Both SP assemblies must have the same type of embedded modules in the same slots.

The embedded module contains the following components:

l

One 4-port card

l

One non-maskable interrupt (NMI) button

l

Two mini-SAS HD back-end ports

l

Two RJ-45 LAN connectors

DPE rear view 11

Note

5

6

7

8

DPE component descriptions

n

System management port ( )

n

Service port ( )

l

One USB 3.0 port

l

One mini-USB port (unused)

l

One DB9 serial port (service access)

The following figure shows the location of these components on the embedded

module in SP assembly A. The location of the components in SP assembly B is

mirrored.

Figure 6 Embedded module rear view with component locations

Table 4 Embedded module component locations

Location Description

4-port card

Mini serial port (unused)

Mini-SAS HD back-end ports

DB9 serial port (unused)

RJ-45 LAN connector - service port

RJ 45 LAN connector - system management port

Non-maskable interrupt (NMI) button

USB 3.0 port

About 4-port cards

The 4-port card is an optional component located within the embedded module. There

are two supported 4-port cards: the 25GbE 4-port card and the 10GbE BaseT 4-port

card.

The 25GbE 4-port card supports 1GbE SFP to RJ45, 10GbE or 25GbE SFP28, 25GbE

passive TwinAx, and 10GbE active or passive TwinAx. Depending on the installed SFP

or TwinAx cable, the following speeds are supported: 1GbE, 10GbE, and 25GbE. The

ports may be configured individually with TwinAx or any of the supported SFPs.

12 Unity 480/F, Unity 680/F, Unity 880/F Hardware Information Guide

DPE component descriptions

The 10GbE BaseT 4-port card serves Ethernet traffic and iSCSI block protocol. The

following speeds are supported: 1GbE and 10 GbE.

Embedded module and 4-port card LED status

Figure 7 Embedded module LEDs

Table 5 Embedded module LEDs

LED Location State Description

Embedded module power Amber Embedded module has faulted

Off No fault has occurred, normal

operation.

Ethernet port link Green Link established.

Off No link established.

Ethernet port activity Amber Port activity.

Off No port activity.

SAS port/activity Link Blue SAS port link is up.

Off No link established.

Port link Green Link up with high speed.

Amber Link up with degraded speed.

Off Link down.

Storage processor assembly

fault

Amber Fault has occurred.

Blue Storage processor assembly

in Degraded Mode.

Amber or blue

blinking

Blue and

amber

alternating

(green for 3

seconds)

System is booting.

System not initialized. A

management IP address has

not been assigned.

Blue and

amber

alternating at

one second

intervals

DPE embedded modules and 4-port cards 13

Storage processor assembly

in Service Mode.

DPE component descriptions

Table 5 Embedded module LEDs (continued)

LED Location State Description

Off No fault has occurred, normal

operation.

Storage processor assembly

power

Unsafe to remove White Do not remove the embedded

Nonmaskable interrupt (NMI) button

The nonmaskable interrupt (NMI) button is a recessed button located on the

embedded module, which is used to reset the system password or force a system

reboot.

Use a bent paper clip or pen to press the recessed button. Press the button for

approximately 2 seconds to reset the password. The SP assembly fault LED blinks blue

when the password has been successfully reset.

Press the button for 10 or more seconds to force a system reboot.

Figure 8

Location of the NMI button on the embedded module

Green Storage processor assembly

is on (main power).

Green blinking Storage processor assembly

is initializing a serial over LAN

session (Standby Mode).

Off Storage processor assembly

is off.

module. Improper removal

could cause data loss.

Off Safe to remove the embedded

module when the embedded

module has been properly

prepared.

DPE I/O module types

I/O module installation priority

There are two I/O module slots per SP assembly: slot 0 and slot 1. Slot 0 has a 16 lane

PCIe channel, and slot 1 has an 8 lane PCIe channel.

Populate new I/O modules in the following order to take advantage of the increased

speed on slot 0. If two I/O modules are ordered, use the same installation priority for

both I/O modules.

14 Unity 480/F, Unity 680/F, Unity 880/F Hardware Information Guide

DPE component descriptions

1. 4-port 25GbE Optical I/O module

2. 4-port 16Gb Fibre Channel I/O module

3. 4-port 10GbE BaseT I/O module

4. 4-port 12Gb SAS backend I/O module

When adding new I/O modules, always install I/O modules in pairs: one module in SP

assembly A and one module in SP assembly B. Both SP assemblies must have the

same type of I/O modules in the same slots.

I/O module LED status

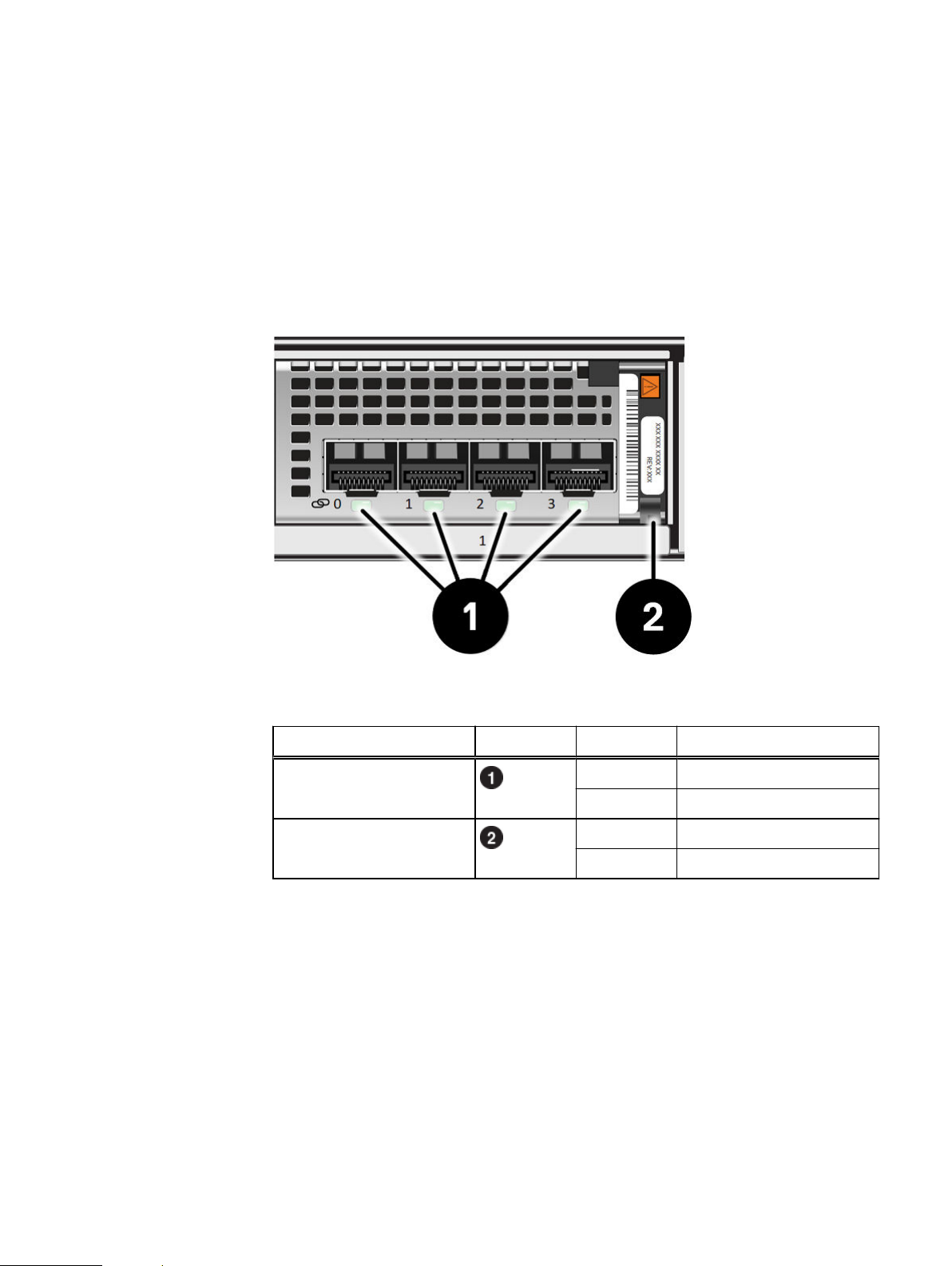

Figure 9 DPE I/O module LEDs

Table 6 DPE I/O module LEDs

LED Location State Description

Port link Green or blue Link up

Off Link down

Power fault Green Power

Amber Power fault

4-port 25GbE Optical I/O module

The 4-port 25GbE Optical I/O module is an Ethernet I/O module that is used to serve

Ethernet network traffic and iSCSI block protocol to hosts for the platform. The I/O

module uses an optical 10G or 25G capable SFP+ connection to a host or switch port.

4-port 16Gb Fibre Channel I/O module

The 4-port 16Gb Fibre Channel I/O module comes with four optical ports, one power

and fault LED, and a combination link and activity LED for each optical port. This I/O

module can interface at speeds of 4, 8, and 16 Gb/s FC for host or initiator layered

connections.

4-port 10GbE BaseT I/O module

The 4-port 10GbE BaseT I/O module can interface at speeds of 1 Gb/s and 10 Gb/s

and supports both IP(file) and iSCSI (Block) on the same SP assembly. Ports can be

configured as both IP and iSCSI simultaneously. The I/O module comes with four 10Gb/s RJ-45 ports, one power/fault LED, activity LED, and link LED for each port.

DPE I/O module types 15

Note

Note

NOTICE

DPE component descriptions

4-port 12Gb SAS backend I/O module

Where supported, the 4-port 12Gb SAS backend I/O module comes with four x4 lane

mini-SAS high density (HD) ports, one power and fault LED, and a combination link

and activity LED for each port. Install thisI/O module into the SP assembly to provide

additional SAS buses. Labeled 12Gb SAS v1.

The optional back-end 12-Gb/s SAS module is only supported on Unity 480F, Unity

680F, and Unity 880F systems.

The 4-port 12Gb SAS backend I/O module can also be configured to support x8 lane

cabling for the 80-drive DAE by combining ports 0 and 1 as back-end 2, or ports 2 and

3 to create back-end 4. The I/O module can also be configured to support both x4 lane

and x8 lane back-ends simultaneously.

If the 4-port 12Gb SAS backend I/O module is to be configured for x8 lane cabling, the

x8 lane cable must be inserted into the I/O module before persisting it. If the x8 lane

cables are not inserted into the I/O module first, all four ports default to x4 lane ports.

DPE power supply

The power supply used in your system must meet the system power requirements and

must be the same type of power supply to be used in both nodes. Do not mix power

supply types.

Figure 10 DPE power supply LEDs

Table 7 DPE power supply LEDs

LED Location State Description

AC power (input) Green AC power is on.

Off AC power is off. Verify source

power

DC power (output) Green DC power is on.

Off DC power is off. Verify source

power.

Fault Solid amber Power supply or backup fault.

Check cable connection.

16 Unity 480/F, Unity 680/F, Unity 880/F Hardware Information Guide

Note

DPE component descriptions

Table 7 DPE power supply LEDs (continued)

LED Location State Description

Blinking

amber

Off No fault.

BIOS, POST, and OS starting

up or system overheating.

Storage processor assembly internal components

Included within the SP assembly are the following components:

l

Dual inline memory modules (DIMM)

l

M.2 SSDs

l

Internal battery backup module

l

Fan module

Dual inline memory modules

Twenty-four, 288-pin DIMM sockets support up to 12 DDR4 DIMMs, capable of up to

96 GB, 192 GB, or 384 GB of memory, depending on the model.

Internal battery backup module

The SP assembly includes a Lithium-ion (Li-ion) internal battery that powers the

associated SP assembly during a power event.

M.2 SSD

Each SP assembly has two slots for M.2 SSD on a M.2 SSD adaptor located between

DIMM slots 5/17 and 6/18. One M.2 SSD is used for general system operations, while

the other M.2 SSD is used for vaulting.

Fan module

Six redundant fan modules connect to the motherboard within the SP assembly to

provide continuous airflow through the front drives and through the rear of the SP

assembly to keep the components at optimal operating temperatures.

The SP assembly performs a protective thermal shutdown if two cooling modules fault

within the same SP assembly.

Storage processor assembly internal components 17

DPE component descriptions

18 Unity 480/F, Unity 680/F, Unity 880/F Hardware Information Guide

CHAPTER 2

Technical specifications

l

Technical specifications..................................................................................... 20

l

Dimensions and weight....................................................................................... 21

l

Power requirements........................................................................................... 21

l

Operating environment requirements.................................................................22

Technical specifications 19

Technical specifications

Technical specifications

Storage processor assembly specifications

Parameter (per SP

assembly)

Unity 480/480F Unity 680/680F Unity 880/880F

CPU Two, 8-core 1.8 GHz

Intel Skylake

processors

Memory 96 GB (12 x 8 GB) 192 GB (12 x 16 GB) 384 GB (12 x 32 GB)

Embedded SAS ports Two, 4-lane 12 GB

SAS

Optional SAS ports Four, 4-lane or two,

8-lane 12 Gb/s SAS

I/O module

Two, 12-core 2.1 GHz

Intel Skylake

processors

Two, 4-lane 12 GB

SAS

Four, 4-lane or two,

8-lane 12 Gb/s SAS

I/O module

Two, 16-core 2.1 GHz

Intel Skylake

processors

Two, 4-lane 12 GB

SAS

Four, 4-lane or two,

8-lane 12 Gb/s SAS

I/O module

DAE and drive specifications

Supported DAEs:

l

2U, 25-drive disk-array enclosure

l

3U, 15-drive disk-array enclosure

l

3U, 80-drive disk-array enclosure

Table 8

Drive and DAE support

Parameter Unity 480/480F Unity 680/680F Unity 880/880F

Maximum drives 750 1000 1500

Minimum drives 4 4 4

Maximum DAEs 48 60 60

Maximum 25-drive

DAE

Maximum 15-drive

DAE

Maximum 80-drive

DAE

29 (750) 39 (1000) 59 (1500)

48 (745) 60 (925) 60 (925)

9 (745) 12 (985) 18 (1465)

Drive counts listed in parentheses next to the maximum amount of DAEs represent the

maximum achievable drive count when using the maximum of each DAE, plus the 25

drives on the DPE.

Embedded module specifications

Supported optional 4-port cards:

l

10GbE BaseT 4-port card

l

25GbE 4-port card

The 4-port card can also be left unpopulated.

I/O module specifications

Supported I/O modules:

20 Unity 480/F, Unity 680/F, Unity 880/F Hardware Information Guide

Note

Technical specifications

l

4-port 16Gb Fibre Channel I/O module

l

4-port 25GbE Optical I/O module

l

4-port 10GbE BaseT I/O module

l

4-port 12Gb SAS backend I/O module

Power supply unit specifications

You can use high line power, such as in a rack, or low line power, such as from a wall

power outlet, to supply power to the DPE. All Unity models support both high line and

low line power. A step-up transformer, not included, is required to use high line power

with Unity 880/880F systems.

Table 9 Power specifications per Unity model

Model High line Low line

Unity 480/480F 1800 W 1450 W

Unity 680/680F 1800 W 1450 W

Unity 880/880F 1800 W 1800 W (Step-up

transformer required)

Dimensions and weight

Table 10

Dimension Value

Weight (unpopulated) 25.9 kg (54.11 lbs)

Vertical size 2 NEMA units

Height 8.72 cm (3.43 in.)

Width 44.72 cm (17.61 in.)

Depth 79.55 cm (31.32 in.)

The weight does not include mounting rails. Allow approximately 2.3-4.5 kg (5-10 lb)

for a rail set.

2U, 25-drive DPE, dimensions and weight

Power requirements

Power consumption values are based on enclosures with all power supplies, drives,

embedded modules and I/O modules populated.

To estimate power consumption values for your specific environment, go to https://

powercalculator.emc.com/.

Dimensions and weight 21

Technical specifications

Table 11 DPE power requirements, per model

Specification Unity 480/480F Unity 680/680F Unity880/880F

AC line voltage 100 to 240 VAC

± 10%, single phase,

47 to 63 Hz

AC line current

(operating maximum)

Power consumption

(operating maximum)

Power factor 0.95 minimum at full

Heat dissipation

(operating maximum)

In-rush current 45 Apk cold per line

Startup surge current 120 Apk hot per line

10.6 A max at 100

VAC; 5.3 A max at

200VAC

1060 VA (1050W)

max at 100 VAC; 1060

VA (1050 W) max at

200 VAC

load, @ 100/ 200 VAC

3.78 x 106 J/hr,

(3,581 Btu/hr) max at

100 VAC; 3.78 x 10

J/hr, (3,581 Btu/hr)

max 200VAC

cord, at any line

voltage

cord, at any line

voltage

100 to 240 VAC

± 10%, single phase,

47 to 63 Hz

11.72 A max at 100

VAC; 5.86 A max at

200VAC

1172 VA (1161 W) max

at 100 VAC; 1172 VA

(1161 W) max at 200

VAC

0.95 minimum at full

load, @ 100/ 200 VAC

4.18 x 106 J/hr,

(3,960 Btu/hr) max

6

at 100 VAC; 4.18 x 10

J/hr, (3,960 Btu/hr)

max 200VAC

45 Apk cold per line

cord, at any line

voltage

120 Apk hot per line

cord, at any line

voltage

100 to 240 VAC

± 10%, single phase,

47 to 63 Hz

14.41 A max at 100

VAC; 7.2 A max at

200VAC

1440.77 VA (1411.96)

max at 100 VAC;

1440.77 VA (1411.96

W) max at 200 VAC

0.95 minimum at full

load, @ 100/ 200 VAC

5.08 x 106 J/hr,

(4,818 Btu/hr) max at

6

100 VAC; 5.08 x 10

J/hr, (4,818 Btu/hr)

max 200VAC

45 Apk cold per line

cord, at any line

voltage

120 Apk hot per line

cord, at any line

voltage

6

AC protection 20 A fuse on each

power supply, single

line

AC inlet type (high

line power)

AC inlet type (low line

power)

Ride-through sharing 10 ms min 10 ms min 10 ms min

Current sharing ± 5 percent of full

IEC320-C14 appliance

coupler, per power

zone

IEC320-C20

appliance coupler, per

power zone

load, between power

supplies

Operating environment requirements

Temperature gradient and altitude requirements

Systems and components must not experience changes in temperature and humidity

that are likely to cause condensation to form on or in that system or component. Do

not exceed the temperature gradient of 20°C/hr (36°F/hr), or the altitude

requirement of 3050 m (10,0000 ft).

20 A fuse on each

power supply, single

line

IEC320-C14 appliance

coupler, per power

zone

IEC320-C20

appliance coupler, per

power zone

± 5 percent of full

load, between power

supplies

20 A fuse on each

power supply, single

line

IEC320-C14 appliance

coupler, per power

zone

IEC320-C20

appliance coupler, per

power zone

± 5 percent of full

load, between power

supplies

22 Unity 480/F, Unity 680/F, Unity 880/F Hardware Information Guide

Technical specifications

Recommended range of operation

The recommended range of operation is the limit under which equipment operates the

most reliably while still achieving reasonably energy-efficient data center operation.

The recommended range of operation is 18°C–27°C (64.4°F to 80.6°F) at 5.5°C

(41.9°F) dew point to 60% relative humidity and 15°C (59°F) dew point.

Continuous allowable range of operation

Data center economization techniques such as free cooling can be employed to

improve overall data center efficiency. These techniques can cause equipment inlet

conditions to fall outside the recommended range, but still within the continuously

allowable range. Equipment can be operated without any hourly limitations in this

range.

The continuous allowable range of operation is 10°C–35°C (50°F–95°F) at 20% to

80% relative humidity with 21°C (69.8°F) maximum dew point (maximum wet bulb

temperature). De-rate the maximum allowable dry bulb temperature by 1°C per 300 m

above 950 m (1°F per 547 ft above 3117 ft).

Expanded allowable range of operation

During certain times of the day or year, equipment inlet conditions can fall outside the

continuously allowable range but still within the expanded improbable range.

Equipment operation is limited to ≤ 10% of annual operating hours in this range.

The expanded allowable range of operation is 5°C–10°C and 35°C–40°C (with no

direct sunlight on the equipment) at -12°C dew point and 8% to 85% relative humidity

with 24°C dew point (maximum wet bulb temperature). Outside the continuously

allowable range (10°C–35°C), the system can operate down to 5°C or up to 40°C for

a maximum of 10% of its annual operating hours. For temperatures 35 °C–40°C

(95°F–104°F), de-rate the maximum allowable dry bulb temperature by 1°C per 175 m

above 950 m (1°F per 319 ft above 3117 ft).

DPE airflow

Exceptions to the expanded allowable range of operation

During certain times of the day or year, equipment inlet conditions can fall outside the

continuously allowable range but still within the expanded exceptional range.

Equipment operation is limited to ≤ 1% of annual operating hours in this range.

Exceptions to the expanded allowable range of operation are 5°C–10°C and 35°C–

40°C (with no direct sunlight on the equipment) at -12°C dew point and 8% to 85%

relative humidity with 24°C dew point (maximum wet bulb temperature). Outside the

continuously allowable range (10°C–35°C), the system can operate down to 5°C or

up to 45°C for a maximum of 1% of its annual operating hours. For temperatures

between 35°C and 45°C (95°F–104°F), de-rate the maximum allowable dry bulb

temperature by 1°C per 125 m above 950 m (1°F per 228 ft above 3117 ft).

The DPE uses an adaptive cooling algorithm that increases or decreases fan speed as

the unit senses changes to the external ambient temperature. Exhaust increases with

ambient temperature and fan speed, and is roughly linear within recommended

operating parameters. Note that the information in the table below is typical, and was

measured without cabinet front/rear doors that would potentially reduce front-toback air flow.

DPE airflow 23

NOTICE

Technical specifications

Table 12 DPE airflow

Max Airflow CFM Min Airflow CFM Max Power

106 CFM 40 CFM 850 W

Environmental recovery

If the system exceeds the maximum ambient temperature by approximately 10°C

(18°F), the SP assemblies in the system begin an orderly shutdown that saves cached

data, and then shut themselves down. Link control cards (LCCs) in each DAE in the

system power down disks but remain powered on.

If the system detects that the temperature has dropped to an acceptable level, it

restores power to the DPEs and the LCCs restore power to their disks.

Shipping and storage requirements

Usage (Watts)

Shock and Vibration

Systems and components must not experience changes in temperature and humidity

that are likely to cause condensation to form on or in that system or component. Do

not exceed the shipping and storage temperature gradient of 45°F/hr (25°C/hr).

Table 13 Shipping and storage requirements

Requirement Description

Ambient temperature -40° F to 149°F (-40°C to 65°C)

Temperature gradient 45°F/hr (25°C/hr)

Relative humidity 10% to 90% noncondensing

Elevation -50 to 35,000 ft (-16 to 10,600 m)

Storage time (unpowered) Recommendation Do not exceed 6 consecutive months of

unpowered storage.

Products have been tested to withstand the shock and random vibration levels. The

levels apply to all three axes and should be measured with an accelerometer on the

equipment enclosures within the cabinet and shall not exceed:

Platform condition

Response measurement level

Non operational shock 10 G’s, 7 ms duration

Operational shock 3 G’s, 11 ms duration

Non operational random vibration 0.40 Grms, 5–500 Hz, 30 minutes

Operational random vibration 0.21 Grms, 5–500 Hz, 10 minutes

24 Unity 480/F, Unity 680/F, Unity 880/F Hardware Information Guide

Note

Technical specifications

Systems that are mounted on an approved package have completed transportation

testing to withstand the following shock and vibrations in the vertical direction only

and shall not exceed:

Packaged system condition Response measurement level

Transportation shock 10 G’s, 12ms duration

Transportation random vibration

Fire suppressant disclaimer

Fire prevention equipment in the computer room should always be installed as an

added safety measure. A fire suppression system is the responsibility of the customer.

When selecting appropriate fire suppression equipment and agents for the data

center, choose carefully. An insurance underwriter, local fire marshal, and local

building inspector are all parties that you should consult during the selection of a fire

suppression system that provides the correct level of coverage and protection.

Equipment is designed and manufactured to internal and external standards that

require certain environments for reliable operation. We do not make compatibility

claims of any kind nor do we provide recommendations on fire suppression systems. It

is not recommended to position storage equipment directly in the path of high

pressure gas discharge streams or loud fire sirens so as to minimize the forces and

vibration adverse to system integrity.

The previous information is provided on an “as is” basis and provides no

representations, warranties, guarantees or obligations on the part of our company.

This information does not modify the scope of any warranty set forth in the terms and

conditions of the basic purchasing agreement between the customer and the

manufacturer.

l

1.15 Grms

l

1 hour Frequency range 1–200 Hz

Air quality requirements

The products are designed to be consistent with the requirements of the American

Society of Heating, Refrigeration and Air Conditioning Engineers (ASHRAE)

Environmental Standard Handbook and the most current revision of Thermal

Guidelines for Data Processing Environments, Second Edition, ASHRAE 2009b.

Cabinets are best suited for Class 1 datacom environments, which consist of tightly

controlled environmental parameters, including temperature, dew point, relative

humidity and air quality. These facilities house mission-critical equipment and are

typically fault-tolerant, including the air conditioners.

The data center should maintain a cleanliness level as identified in ISO 14664-1, class 8

for particulate dust and pollution control. The air entering the data center should be

filtered with a MERV 11 filter or better. The air within the data center should be

continuously filtered with a MERV 8 or better filtration system. In addition, efforts

should be maintained to prevent conductive particles, such as zinc whiskers, from

entering the facility.

The allowable relative humidity level is 20 to 80% non condensing, however, the

recommended operating environment range is 40 to 55%. For data centers with

gaseous contamination, such as high sulfur content, lower temperatures and humidity

Fire suppressant disclaimer 25

Technical specifications

are recommended to minimize the risk of hardware corrosion and degradation. In

general, the humidity fluctuations within the data center should be minimized. It is also

recommended that the data center be positively pressured and have air curtains on

entry ways to prevent outside air contaminants and humidity from entering the

facility.

For facilities below 40% relative humidity, it is recommended to use grounding straps

when contacting the equipment to avoid the risk of Electrostatic discharge (ESD),

which can harm electronic equipment.

As part of an ongoing monitoring process for the corrosiveness of the environment, it

is recommended to place copper and silver coupons (per ISA 71.04-1985, Section 6.1

Reactivity), in airstreams representative of those in the data center. The monthly

reactivity rate of the coupons should be less than 300 Angstroms. When monitored

reactivity rate is exceeded, the coupon should be analyzed for material species and a

corrective mitigation process put in place.

Storage time (unpowered) recommendation: do not exceed 6 consecutive months of

unpowered storage.

26 Unity 480/F, Unity 680/F, Unity 880/F Hardware Information Guide

Loading...

Loading...