Dell EMC Unity™ All Flash and Unity Hybrid

Dell EMC Unity 480/F, Unity 680/F, Unity

880/F

Installation and Service Guide

302-005-519

REV 01

Copyright © 2019 Dell Inc. or its subsidiaries. All rights reserved.

Published June 2019

Dell believes the information in this publication is accurate as of its publication date. The information is subject to change without notice.

THE INFORMATION IN THIS PUBLICATION IS PROVIDED “AS-IS.“ DELL MAKES NO REPRESENTATIONS OR WARRANTIES OF ANY KIND

WITH RESPECT TO THE INFORMATION IN THIS PUBLICATION, AND SPECIFICALLY DISCLAIMS IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. USE, COPYING, AND DISTRIBUTION OF ANY DELL SOFTWARE DESCRIBED

IN THIS PUBLICATION REQUIRES AN APPLICABLE SOFTWARE LICENSE.

Dell, EMC, and other trademarks are trademarks of Dell Inc. or its subsidiaries. Other trademarks may be the property of their respective owners.

Published in the USA.

Dell EMC

Hopkinton, Massachusetts 01748-9103

1-508-435-1000 In North America 1-866-464-7381

www.DellEMC.com

2 Unity 480/F, Unity 680/F, Unity 880/F Installation and Service Guide

CONTENTS

Additional resources 7

Chapter 1

Installation Procedures 9

Hardware terms.......................................................................................... 10

Release information.................................................................................... 10

Before you begin.........................................................................................10

Installation workflow including optional DAEs............................................. 10

Site and equipment preparation................................................................... 11

Unpack the DPE..........................................................................................12

Record the product serial number from the DPE.........................................13

Install the rails in the cabinet.......................................................................13

Install the DPE on the rails.......................................................................... 15

Secure the system in the cabinet................................................................ 16

Attach the storage processors to the network............................................16

Install optional DAEs....................................................................................17

Connect power to the DPE..........................................................................17

Power up optional DAEs................................................................. 18

Verify status LEDs...................................................................................... 18

Installing the front bezel.............................................................................20

Connect a Windows-based computer to your storage system.....................21

Automatically assigning a dynamic storage system management port IP

address.......................................................................................................22

Manually assigning a static storage system management port IP address....

23

Download and install the Connection Utility software.................... 23

Run the Connection Utility.............................................................24

Unpack the (optional) disk-array enclosures.............................................. 25

15-drive DAE container contents................................................... 25

25-drive DAE container contents...................................................27

Install the disk array enclosure....................................................................28

Install 15-drive DAE........................................................................28

Install 25-drive DAE........................................................................31

Cabling the DPE to a DAE...........................................................................35

Cabling the first optional DAE to create back-end bus 1............................. 36

Cabling the second optional DAE to create back-end bus 0........................ 37

Cabling an expansion DAE to an existing DAE to extend a back-end bus.... 37

Connecting power to the DAE.................................................................... 38

Chapter 2

Service Procedures 41

Replace a faulted disk in the DPE............................................................... 42

Identifying and locating the faulted part in Unisphere....................42

Remove a faulted 2.5" disk............................................................ 42

Install a 2.5" disk........................................................................... 42

Verifying the operation of the new part in Unisphere.....................43

Returning a faulted part.................................................................43

Add a new disk in the DPE.......................................................................... 44

Removing the front bezel.............................................................. 44

Remove a disk filler module........................................................... 44

Install a 2.5" disk........................................................................... 45

Unity 480/F, Unity 680/F, Unity 880/F Installation and Service Guide 3

CONTENTS

Verifying the operation of the new part in Unisphere.....................45

Replace a power supply.............................................................................. 46

Identifying and locating the faulted part in Unisphere....................46

DPE power supply LEDs................................................................ 46

Remove a power supply.................................................................46

Install a power supply.....................................................................47

Verifying the operation of the new part in Unisphere.....................48

Returning a faulted part.................................................................48

Replace an embedded module.................................................................... 49

Identifying and locating the faulted part in Unisphere....................49

Preparing the SP assembly for service.......................................... 49

Embedded module LEDs................................................................ 50

Remove a faulted embedded module..............................................51

Transfer the 4-port card................................................................53

Install an embedded module...........................................................55

Rebooting a SP assembly into Normal Mode................................. 55

Verifying the operation of the new part in Unisphere.....................56

Add a 4-port card....................................................................................... 56

Preparing the SP assembly for service.......................................... 56

Remove an embedded module....................................................... 57

Identify the location for the new 4-port card.................................58

Install a 4-port card....................................................................... 58

Install an embedded module...........................................................59

Adding the 4-port card to SP B..................................................... 60

Rebooting a SP assembly into Normal Mode................................. 60

Committing the new I/O ports....................................................... 61

Verifying the operation of the new part in Unisphere..................... 61

Replace a 4-port card................................................................................. 61

Identifying and locating the faulted part in Unisphere.................... 61

Preparing the SP assembly for service.......................................... 62

Embedded module LEDs................................................................ 62

Remove an embedded module....................................................... 64

Remove a 4-port card....................................................................65

Install a 4-port card....................................................................... 66

Install an embedded module...........................................................67

Rebooting a SP assembly into Normal Mode................................. 68

Verifying the operation of the new part in Unisphere.....................68

Add an SFP................................................................................................ 69

Install an SFP module.................................................................... 69

Committing the new I/O ports.......................................................69

Verifying the operation of the new part in Unisphere.....................70

Replace a faulted SFP................................................................................ 70

Identifying and locating the faulted part in Unisphere....................70

Remove an SFP module................................................................. 70

Install an SFP module..................................................................... 71

Verifying the operation of the new part in Unisphere..................... 71

Returning a faulted part.................................................................72

Replace an I/O module............................................................................... 72

Identifying and locating the faulted part in Unisphere.................... 72

Preparing the SP assembly for service.......................................... 72

DPE I/O module LEDs....................................................................73

Remove a faulted I/O module........................................................ 73

Install a new I/O module................................................................ 74

Rebooting a SP assembly into Normal Mode................................. 75

Verifying the operation of the new part in Unisphere.....................75

Returning a faulted part.................................................................75

4 Unity 480/F, Unity 680/F, Unity 880/F Installation and Service Guide

CONTENTS

Add an I/O module......................................................................................76

Locating a slot for a new I/O module............................................. 76

Remove a filler I/O module............................................................ 76

Install a new I/O module................................................................ 76

Verifying that the new I/O ports are recognized............................ 77

Adding the I/O module to SP B......................................................78

Committing the new I/O ports.......................................................78

Replace a fan module..................................................................................78

Identifying and locating the faulted part in Unisphere....................78

Preparing the storage processor (SP) for service..........................79

Remove the SP assembly.............................................................. 80

Remove the top cover from the SP assembly................................ 82

Remove the faulted fan module..................................................... 83

Install a new fan module.................................................................84

Install the top cover on the SP assembly....................................... 84

Install the SP assembly..................................................................85

Rebooting an SP assembly into Normal Mode............................... 86

Verifying the operation of the new part in Unisphere.....................87

Returning a faulted part.................................................................87

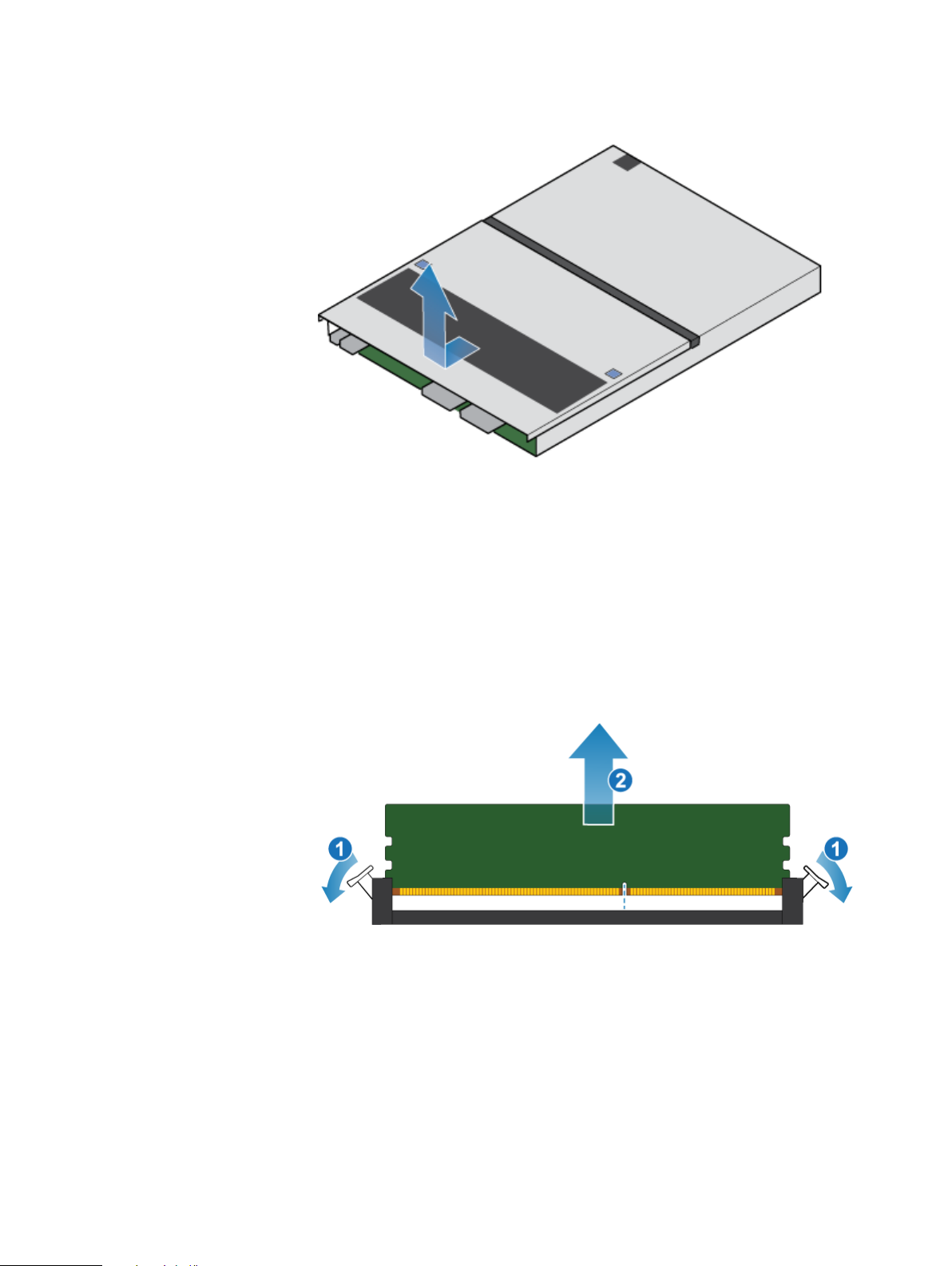

Replace a dual inline memory module (DIMM)............................................88

Identifying and locating the faulted part in Unisphere....................88

Preparing the storage processor (SP) for service......................... 88

Remove the SP assembly.............................................................. 89

Remove the top cover from the SP assembly.................................91

Remove the faulted dual inline memory module............................. 92

Install the dual inline memory module............................................ 92

Install the top cover on the SP assembly....................................... 93

Install the SP assembly..................................................................94

Rebooting an SP assembly into Normal Mode............................... 95

Verifying the operation of the new part in Unisphere.....................96

Returning a faulted part.................................................................96

Replace an M.2 SSD...................................................................................96

Identifying and locating the faulted part in Unisphere....................96

Preparing the storage processor (SP) for service..........................97

Remove the SP assembly.............................................................. 98

Remove the top cover from the SP assembly.............................. 100

Remove the faulted M.2 SSD........................................................101

Install the M.2 SSD...................................................................... 102

Install the top cover on the SP assembly......................................103

Install the SP assembly................................................................ 104

Rebooting an SP assembly into Normal Mode.............................. 105

Verifying the operation of the new part in Unisphere................... 106

Returning a faulted part............................................................... 106

Replace an SP assembly........................................................................... 106

Identifying and locating the faulted part in Unisphere.................. 106

Preparing the storage processor (SP) for service........................ 106

Remove the SP assembly............................................................. 108

Remove the top cover from the SP assembly............................... 110

Transfer parts from the faulted SP assembly to the replacement SP

assembly........................................................................................111

Install the top cover on the SP assembly...................................... 114

Install the SP assembly................................................................. 114

Rebooting an SP assembly into Normal Mode...............................115

Verifying the operation of the new part in Unisphere.................... 116

Returning a faulted part................................................................116

Unity 480/F, Unity 680/F, Unity 880/F Installation and Service Guide 5

CONTENTS

Appendix A

Appendix B

Configuration Worksheet 117

Configuration worksheet........................................................................... 118

Safety precautions for handling replaceable units 121

Handling replaceable units.........................................................................122

Avoiding electrostatic discharge (ESD) damage ..........................122

Emergency procedures (without an ESD kit)............................... 122

Hardware acclimation times......................................................... 123

Removing, installing, or storing replaceable units......................... 124

Unpacking a part.......................................................................... 125

Standard touch point colors...................................................................... 125

6 Unity 480/F, Unity 680/F, Unity 880/F Installation and Service Guide

Additional resources

DANGER

WARNING

CAUTION

NOTICE

Note

As part of an improvement effort, revisions of the software and hardware are

periodically released. Therefore, some functions described in this document might not

be supported by all versions of the software or hardware currently in use. The product

release notes provide the most up-to-date information on product features. Contact

your technical support professional if a product does not function properly or does not

function as described in this document.

Where to get help

Support, product, and licensing information can be obtained as follows:

Product information

For product and feature documentation or release notes, go to Unity Technical

Documentation at: www.emc.com/en-us/documentation/unity-family.htm.

Troubleshooting

For information about products, software updates, licensing, and service, go to Online

Support (registration required) at: https://Support.EMC.com. After logging in, locate

the appropriate Support by Product page.

Technical support

For technical support and service requests, go to Online Support at: https://

Support.EMC.com. After logging in, locate Create a service request. To open a

service request, you must have a valid support agreement. Contact your Sales

Representative for details about obtaining a valid support agreement or to answer any

questions about your account.

Special notice conventions used in this document

Indicates a hazardous situation which, if not avoided, will result in death or

serious injury.

Indicates a hazardous situation which, if not avoided, could result in death or

serious injury.

Indicates a hazardous situation which, if not avoided, could result in minor or

moderate injury.

Addresses practices not related to personal injury.

Presents information that is important, but not hazard-related.

Additional resources 7

Additional resources

8 Unity 480/F, Unity 680/F, Unity 880/F Installation and Service Guide

CHAPTER 1

Note

Installation Procedures

This chapter describes how to install the system.

Review the information in Safety precautions for handling replaceable units on page

121 before handling replaceable parts.

l

Hardware terms..................................................................................................10

l

Release information............................................................................................10

l

Before you begin................................................................................................ 10

l

Installation workflow including optional DAEs..................................................... 10

l

Site and equipment preparation...........................................................................11

l

Unpack the DPE................................................................................................. 12

l

Record the product serial number from the DPE................................................ 13

l

Install the rails in the cabinet.............................................................................. 13

l

Install the DPE on the rails..................................................................................15

l

Secure the system in the cabinet........................................................................16

l

Attach the storage processors to the network................................................... 16

l

Install optional DAEs........................................................................................... 17

l

Connect power to the DPE................................................................................. 17

l

Verify status LEDs.............................................................................................. 18

l

Installing the front bezel.................................................................................... 20

l

Connect a Windows-based computer to your storage system............................ 21

l

Automatically assigning a dynamic storage system management port IP address

...........................................................................................................................22

l

Manually assigning a static storage system management port IP address..........23

l

Unpack the (optional) disk-array enclosures......................................................25

l

Install the disk array enclosure........................................................................... 28

l

Cabling the DPE to a DAE.................................................................................. 35

l

Cabling the first optional DAE to create back-end bus 1.....................................36

l

Cabling the second optional DAE to create back-end bus 0................................37

l

Cabling an expansion DAE to an existing DAE to extend a back-end bus............37

l

Connecting power to the DAE............................................................................38

Installation Procedures

9

Installation Procedures

Hardware terms

Release information

Before you begin

Procedure

1. Set up a product support account.

If you do not already have a product support account, go to https://

support.emc.com/products/39949 to set one up. You will need a support

account to access the latest troubleshooting information, online chat,

installation and maintenance videos, utilities and wizards.

2. Complete the

The

Configuration Worksheet

support.emc.com/products/39949. Configuration worksheet information is also

included in Configuration Worksheet on page 117.

Configuration Worksheet

is available for download from https://

.

Installation workflow including optional DAEs

Use the following documents and software and sequence of actions as a guide to

install the storage system:

1. Use the

to:

a. Prepare the site for installation.

b. Unpack the storage system.

c. Rack and install the storage system.

d. Cable the system components.

e. Power up the system components.

f. Use the Connection Utility (CU) to discover and configure the system

g. Launch a browser, log in to the system, and follow the Unisphere Initial

2. Use Unisphere to:

Quick Start Guide

management IP address for network management.

Configuration Wizard tasks to complete the initial system configuration.

or this guide and the

Unity Hardware Information Guide

a. Complete the Initial Configuration Wizard tasks:

l

Accept License Agreement and Configure User Credentials

l

Install License File

l

Configure Network Services (DNS/NTP)

l

Configure FAST Cache and Pools (optional)

l

Configure Alerts (optional)

10 Unity 480/F, Unity 680/F, Unity 880/F Installation and Service Guide

l

Note

Configure Support Credentials, Customer Contact Information, and EMC

Secure Remote Services (recommended)

l

Configure iSCSI Interfaces (optional)

l

Set up a NAS Server (optional)

b. Enable SSH under Service > Service Tasks (recommended for remote

support)

c. Update system software under Settings > Software and Licenses (as

required)

d. Configure Block and File resources, and Hosts (as required)

3. Use this guide and the

Hardware Information Guide

a. Rack and install optional DAEs

b. Cable the optional DAEs

c. Power up the optional DAEs

d. Configure extra Block and File resources, and Hosts (as required)

Site and equipment preparation

Installation Procedures

to:

The following items are required for installation.

Tools: ESD protection kit, slotted or Phillips screwdriver (optional), and a mechanical

lift (optional).

Management console: A Windows-based computer to run the initialization,

maintenance, and management tools with:

l

At least 100 MB of free space

l

Connection on same LAN subnet as your storage system (recommended)

l

Web browser (Internet Explorer, Mozilla Firefox, Google Chrome)

Refer to the Unity Support Matrix on the support website for compatibility and

interoperability information related to the Web browsers.

Space: Cabinet vertical space of 2U (3.5 inches, 8.9 cm) for the disk processor

enclosure (DPE), and if applicable, the following cabinet space for each DAE:

l

2U, 25-drive DAE (3.4 inches, 8.63 cm)

l

3U, 15-drive DAE (5.75 inches, 14.6 cm)

Network connections: The following I/O modules and embedded modules are available

for network connectivity.

l

4-port 16Gb Fibre Channel I/O module

l

4-port 25GbE Optical I/O module

l

4-port 10GbE BaseT I/O module

l

4-port 12Gb SAS backend I/O module

l

10GbE BaseT 4-port card

l

25GbE 4-port card

Network information:

Site and equipment preparation 11

Installation Procedures

l

l

l

l

l

Unpack the DPE

DNS and NTP servers accessible from the storage system (recommended)

Windows Domain Controller (recommended)

SMTP server network connection to the storage system and the management

host (optional)

If you are using the Connection Utility, the management port and login information

required includes:

n

A static IP address for the system

n

The subnet mask of the LAN to which the system is connected

n

The default gateway address of the LAN to which the system is connected

n

Passwords for system users admin and service

If you are setting up the system on a network with DHCP servers, DNS servers,

and Dynamic DNS services, you need:

n

The system serial number

n

Domain information

Component

2U, 25-drive disk processor

enclosure (DPE)

Tool-less rails

The disk processor enclosure (DPE) is a 2U component with 25 2.5" drive slots. Verify

that you have received all of the DPE components, including cables, bezel, and rail kit.

Image

12 Unity 480/F, Unity 680/F, Unity 880/F Installation and Service Guide

Component Image

Power cords

Bezel for disk processor

enclosure (1)

Record the product serial number from the DPE

The PSNT for the 25-slot DPE is a black pull-out tag that is located between the

drives in slots 16 and 17.

Figure 1 Location of the product serial number tag

Installation Procedures

Pull the tag out and record the product serial number from the tag on the

Configuration Worksheet. The product serial number is three letters followed by 11

numbers. After recording the information, return the tag to its inserted position.

Install the rails in the cabinet

This task describes the procedure to install one rail. After installing one rail, repeat the

procedure for the other rail. The procedure is the same for both the left and right rail.

You can install the rails into either a square or round hole rack.

Procedure

1. Position the rail end piece so the label FRONT is located at the front of the rack

and facing towards the inside of the rack, while orienting the rear of the rail to

align level with the holes on the rear of the rack.

2. From the rear of the rack, pull the rail straight back until the latch is locked.

3. To install the front end piece of the rail, press the blue latch release button until

the latch rotates open.

Record the product serial number from the DPE 13

Installation Procedures

4. Pull the rail forward until the pins slide into the holes on the front of the rack,

then release the latch to secure the rail in place.

Figure 2 Installing the rails

5. Repeat for the other rail.

14 Unity 480/F, Unity 680/F, Unity 880/F Installation and Service Guide

Install the DPE on the rails

CAUTION

The enclosure is heavy and should be installed into or removed from a rack by

two people. To avoid personal injury and/or damage to the equipment, do not

attempt to lift and install the enclosure into a rack without a mechanical lift

and/or help from another person.

L'enclosure étant lourde, sa mise en place dans l'armoire nécessite deux

personnes. Afin de ne pas vous blesser et/ou endommager le matériel, n’essayez

pas de soulever et d’installer l’armoire sur une rampe sans avoir recours à un

relevage mécanique et/ou à l’aide d’une autre personne.

Das Gehäuse ist schwer und sollte nur von zwei Personen in einem Rack

installiert werden. Zur Vermeidung von körperlichen Verletzungen und/oder der

Beschädigung des Gerätes, bitte das Gehäuse nicht ohne die Hilfe einer zweiten

Person anheben und einbauen.

Il contenitore è pesante e dev'essere installato nel rack da due persone. Per

evitare danni personali e/o all’apparecchiatura, non tentare di sollevare ed

installare in un rack il contenitore senza un sollevatore meccanico e/o l’aiuto di

un’altra persona.

Debido a su considerable peso, la instalación del compartimento en el bastidor

deben realizarla siempre dos personas. Para evitar daños personales o en el

equipo, el compartimento no debe levantarse ni instalarse en el bastidor sin la

ayuda de un elevador mecánico o de otra persona.

Installation Procedures

Procedure

1. Lift the enclosure and slide it onto the rails from the front of the cabinet.

2. Push the system into the rack until the slam latches engage and lock the system

into the rack.

Ensure that the enclosure is flush with the front of the rack, fully seated in the

cabinet, and does not slide out.

Install the DPE on the rails 15

Installation Procedures

Figure 3 Installing the system in the enclosure

Secure the system in the cabinet

Procedure

1. If securing the system for shipment in the cabinet or in other unstable

environments, locate the hard mount captive screw under each latch and

tighten using a #1 Phillips screwdriver.

Figure 4

Securing the system in the cabinet

Attach the storage processors to the network

Procedure

1. Locate two bulk Category (CAT) 5, 5e, 6, 6a or better Ethernet cables.

2. Connect two Ethernet cables from the LAN to the 1 Gb RJ45 management

ports from which you will configure the system. This will be one port on each

storage processor.

16 Unity 480/F, Unity 680/F, Unity 880/F Installation and Service Guide

Note

Note

Note

Note

Installation Procedures

The SP A and SP B network management ports must be connected on the same

subnet. In general, both SPs should have mirrored configurations in order to

provide failover.

Figure 5 Cabling the storage processors to the network

Additional information about the ports and cabling is in the

Guide

, available on the Unity Info Hub at http://bit.ly/unityinfohub or on Online

Support (https://support.emc.com/products/39949).

Install optional DAEs

If you are installing one or more optional DAEs, see Unpack the (optional) disk-array

enclosures on page 25 for installation instructions.

If you are not installing an optional DAE, continue to the next section.

Connect power to the DPE

Before you begin

All components must be racked and the network cabling completed before connecting

the storage system to power and booting the system.

Procedure

1. Verify that the cabinet circuit breakers are in the On position and that power is

connected to the cabinet.

Hardware Information

No power cables should be connected to the PDUs at this time.

2. Attach a double-sided Shut Down Procedure cable label to each power cable

using the tie wraps included in the Accessory Kit.

Attach each label close to the end of the power cable where it plugs into the

DPE.

Install optional DAEs 17

Note

Installation Procedures

3. Plug each DPE power cable into each SP assembly's power supply unit.

The power cable to SP assembly A is gray. The power cable to SP assembly B is

black.

4. Secure each power cable to the system component with the cable retention bail

on the power supply unit.

5. Connect the DPE to the power distribution unit as follows:

a. Connect the power supply for SP assembly A, shown in gray, to PDU A .

b. Connect the power supply for SP assembly B, shown in black, to PDU B.

Figure 6 Cabling the DPE to the PDU

6. Bundle and secure the cables as necessary with tie wraps.

7. If your storage system has been installed in a cabinet, place the single-sided

8. Monitor the system as it powers up. It takes approximately 10-15 minutes for

Power up optional DAEs

If you installed one or more optional DAEs, attach the power cables. See Connecting

power to the DAE on page 38 for instructions on powering up a DAE.

If you are not installing an optional DAE, continue to the next section.

Verify status LEDs

The system should be available in approximately 15 minutes.

This section calls out only the LEDs that you need to verify to ensure that the system

powered up correctly.

adhesive backed Shut Down Procedure label included in the Accessory Kit on

the back of the cabinet door. Otherwise, place this label in a location that is

visible while viewing the storage system from the rear.

the system to power up. The LEDs show the progress of system activation.

Green, blue, and amber activity lights blink during the startup sequence. Review

the next section for information on the power up states.

The

Unity Hardware Information Guide

The array is powered up and ready to run the Connection Utility when the SP Fault

LED shows intervals of amber for one second and blue for three seconds. If the

system is on a network with a DNS server and DHCP, the management IP address can

be assigned automatically. When it is assigned, the SP Fault LED is solid blue. Ensure

that the power-up is complete and that the system is ready before you continue.

18 Unity 480/F, Unity 680/F, Unity 880/F Installation and Service Guide

provides more details on all system LEDs.

DPE rear status LEDs

Figure 7 Storage processor assembly LEDs

Table 1 Storage processor assembly LEDs

LED Location State Description

Installation Procedures

Storage processor assembly

fault

Storage processor assembly

power

Amber Fault has occurred.

Blue A management IP address has

been assigned.

Amber or blue

blinking

Blue and

amber

alternating

(blue for 3

seconds)

Blue and

amber

alternating at

one second

intervals

Off No fault has occurred, normal

Green Storage processor assembly

Green blinking Storage processor assembly

System is booting.

System not initialized. A

management IP address has

not been assigned.

Storage processor assembly

in Service Mode.

operation.

is on (main power).

is initializing a serial over LAN

session (Standby Mode).

Off Storage processor assembly

is off.

Verify status LEDs 19

CAUTION

Installation Procedures

DPE front status LEDs

Figure 8 DPE and disk drive LEDs

Table 2 DPE and disk drive LEDs

LED Location State Description

Disk drive fault Amber Fault has occurred.

Off No fault has occurred, normal

operation.

Disk drive active Blue Disk drive activity.

DPE fault/power Blue Power is on. No fault has

Installing the front bezel

Remove the plastic protective strip from the front of the bezel prior to placing

the system into operation. Failure to do so will cause the system to overheat.

Procedure

1. If present, remove the plastic protective strip from the front of the bezel.

2. Align the bezel with the enclosure.

3. Gently push the bezel into place on the cabinet until it latches.

4. If the bezel has a lock, insert the key that shipped with your enclosure into the

lock, and turn the key to lock the bezel.

Off Disk drive is powered off.

occurred, normal operation.

Amber Power is on. Fault has occurred

within the enclosure.

Off Power is off.

20 Unity 480/F, Unity 680/F, Unity 880/F Installation and Service Guide

Note

NOTICE

Installation Procedures

Figure 9 Installing the front bezel

Connect a Windows-based computer to your storage system

At the end of the power-up process, the SP Fault LED blinks in intervals of amber for

one second and then blue for three seconds, indicating that the system is ready to run

the Connection Utility.

You must connect a Windows-based computer to your system directly or remotely

over a subnetwork. This computer will be used to continue setting up your system and

must be on the same subnet as the storage system to complete the initialization.

Check to see if there is security software running on your workstation/laptop such as

Cisco Security Agent or McAfee Host Intrusion Prevention Service that may prevent

the initialized system from being detected. If there is, disable it (Windows Services)

before running the initialization.

The system management ports support both IPv4 and IPv6. You can assign an IP

address to a system in the following ways:

l

If you are running the storage system on a dynamic network that includes a DHCP

server and a DNS server, the management IP address can be assigned

automatically.

l

If you are not running the storage system in a network that supports DHCP or you

would rather manually assign a static IP address, you must install and run the

Connection Utility on the Windows-based computer.

Dynamic IP addresses (DHCP) should not be used for any components of the EMC

Secure Remote Services Virtual Edition (ESRS VE) servers, Policy Manager servers,

or managed devices.

Connect a Windows-based computer to your storage system 21

NOTICE

Installation Procedures

If you use DHCP to assign IP addresses to any EMC Secure Remote Services (ESRS)

components (ESRS Virtual Edition servers, Policy Manager, or managed devices),

they must have static IP addresses. Leases for the IP addresses that Dell EMC devices

use cannot be set to expire. It is recommended that you assign static IP addresses to

those devices you plan to have managed by ESRS.

Automatically assigning a dynamic storage system management port IP address

Assigning an IP address to a storage system management port dynamically requires

the following:

l

Network DNS server (with dynamic DNS services enabled)

l

Network DHCPv4 server and/or a DHCPv6 server and/or a router advertising

DNS servers

l

Connectivity between the storage system, the DHCP server, and the DNS server

The DHCP server must be configured to automatically register DHCP clients with

Dynamic DNS services. By default, storage systems are configured to use DHCP for IP

assignment and will accept an IP address offered by a network DHCP server.

Perform the following steps to automatically assign an IP address to your storage

system management port:

Procedure

1. After you power up the storage system, check the SP Fault LED.

l

If the SP Fault LED is solid blue, a management IP address has been

assigned.

l

If the SP Fault LED is solid blue for three seconds and then flashes amber

for one second intervals, no management IP address has been assigned.

Check the connectivity between the system, the DNS server, and the DHCP

server.

2. Open a web browser and access the Unisphere management interface

specifying the following as a URL in the browser's address bar:

serial_number.dns_zone

where

URL string

serial_number Serial number of your storage system. You

dns_zone Network DNS zone on which the storage

Description

can find this in the packing materials that

came with your system (for example,

FNM00131800283). It is also on the PSNT tag

on the front of the DPE.

system is located (for example,

mylab.emc.com).

Based on the examples provided in this table, the URL to the storage system

would be FNM00131800283.mylab.emc.com.

22 Unity 480/F, Unity 680/F, Unity 880/F Installation and Service Guide

Note

Note

Installation Procedures

If a certificate error appears, follow the instructions in your browser either to

bypass the error or to install the self-signed storage system certificate. For

more detail about your storage system certificate, refer to the

Security Configuration Guide

3. Log in with the default username and password.

l

Username: admin

l

Password: Password123#

The Unisphere Initial Configuration wizard launches.

4. Continue with the steps in the Unisphere Initial Configuration wizard to accept

the license agreement, configure, and update the software on your system.

The Unisphere Initial Configuration wizard online help provides information

about the steps remaining to accept the license agreement, configure, and

update the software on your system.

5. Confirm that the SP Fault LED is now out.

.

EMC Unity

This provides an indication that all operating system software has booted and

SP is ready for I/O.

Manually assigning a static storage system management port IP address

To manually assign a static IP address for the storage system management port, you

must install and run the Connection Utility on a Windows-based computer. The

Connection Utility assigns a network address to the storage system.

Download and install the Connection Utility software

Procedure

1. Download the Connection Utility installation program from the Dell EMC Online

Support website (https://support.emc.com/products/39949), under the

Downloads selection on the menu bar of the product page for your storage

system.

2. Install the Connection Utility software on a Windows computer.

To use the Auto Discover method, install the Connection Utility on a computer

in the same subnet as the storage system's management port.

3. Launch the Connection Utility.

In Windows: C:\Program Files\DELL EMC\Unity\ConnectionUtility

The Connection Utility automatically sets the displayed language based on the

settings of the computer. To change the language displayed in the Connection

Utility, select the language from the list under Change language:.

Manually assigning a static storage system management port IP address 23

Installation Procedures

Run the Connection Utility

Before you begin

Obtain the following information:

l

Serial Number: Unique identifier associated with the storage system (printed on a

tag located on the system). This identifies your system when you use the

Connection Utility to discover storage systems on a subnet. When you register

your system online, this value is the Product ID.

l

System name: Name that you will be assigning to the storage system.

l

IP address: Management IPv4 or IPv6 address through which Unisphere connects

to the storage system.

l

Subnet mask: For IPv4 management addresses, the subnet mask is an IP address

mask that identifies the range of IP addresses in the subnet where the storage

system is connected.

l

Subnet prefix length: For IPv6 management addresses, the subnet prefix length

is the number of significant bits in the address that will be used for routing

purposes.

l

Gateway address: IP address of the default gateway for the management

interface. The gateway is the IP address of the router or node used to

communicate outside the local subnet.

Run the Connection Utility from a host attached to the same subnet as your storage

system. Doing so lets the Connection Utility automatically detect the new storage

system. If you are unable to run the Connection Utility from the same subnet, you can

still manually configure the connection.

Procedure

1. On the Welcome screen, select one of the following methods to configure your

system, and then click Next:

l

Auto Discover - Use this method if you are running the Connection Utility

from a host on the same subnet as your storage system. This method

automatically discovers unconfigured storage systems on your local network

and sends the configuration file directly to the storage system.

l

Manual Configuration - Use this method if you are running the Connection

Utility from a host that is not on the same subnet as your storage system.

This method enables you to create a configuration file that you can save to a

USB flash drive. You then insert the flash drive into the USB port on the

storage system, and the storage system automatically reads the

configuration from the USB drive.

2. [Applies to Auto Discover mode only] From the list of automatically discovered

systems, select the system you want to configure, and then click Next. Note: If

you do not see the system listed on the screen, try clicking Discover to restart

the discovery process. If the problem persists, refer to troubleshooting

instructions.

3. On the Configure screen, specify the following:

l

Name - A meaningful name for this system. You can specify a name up to 32

characters. It can only contain alpha-numeric characters and a dash. It

cannot contain any space characters, underscores, or begin and end with a

dash.

24 Unity 480/F, Unity 680/F, Unity 880/F Installation and Service Guide

Note

Installation Procedures

l

In the Management IPv4 Address and Management IPv6 Address

sections, select the options you want, specify relevant information, and then

click Next.

4. Review the configuration information, and then do the following based on the

mode you selected:

l

For Auto Discover mode, click Start to apply the configuration on the

storage system.

l

For Manual Configuration mode:

a. Click Save to USB drive. Ensure that you save the configuration file to

the root directory level of the USB drive.

b. Click Next to identify the location of the port on your storage system.

c. Insert the USB drive into one of the available USB ports on either SP.

The storage system will automatically detect the USB drive and apply the

network connection information. This process may take up to 10 minutes.

When successfully completed, a response file (iw_resp.txt) is written back

to the USB drive.

5. Click Finish.

6. Confirm that the SP Fault LED is solid blue, which indicates that the system's IP

address has been set.

After you finish

In a web browser, access Unisphere by specifying the URL: http://<ip_address>/.

Where, <ip_address> is the IP address you set for the storage system.

Refer to the

Configuration Worksheet

for information on the user credentials you must

use the first time you log on.

The Initial Configuration Wizard launches the first time you access Unisphere. Refer to

the

Configuration Worksheet

and

Unisphere Online Help

configuring and start using your system.

Unpack the (optional) disk-array enclosures

Disk-array enclosures (DAEs) provide additional storage. The types of DAEs available

are:

l

3U 15 disk 3.5" drive DAE

l

2U 25 disk 2.5" drive DAE

DAEs are optional. If you have one or more DAEs in the system, verify that you have

received all of the DAE components, including cables, bezel, rail kit, and mounting

screws.

for more information on

15-drive DAE container contents

Verifying shipping package contents

Confirm that you received all necessary equipment needed to install the new 15-drive

DAE.

Verify that you received the following:

Unpack the (optional) disk-array enclosures 25

CL4139

CL5665

CL5766

Installation Procedures

Component Quantity

Disk-array enclosure (DAE) Front view

Rear view

Snap in rail kit

1

1 (includes 2

rails and 6

screws)

Power cords (AC or DC) AC power cords

DC power cords

Bezel for disk-array

enclosure (with key)

SAS cables (either 1 meter or

2 meter copper) that

connect disk-array

enclosures to each other (1

meter cables) or to DPE (2

meter cables)

2

1

2

26 Unity 480/F, Unity 680/F, Unity 880/F Installation and Service Guide

CL5583

Installation Procedures

25-drive DAE container contents

Verifying shipping package contents

Confirm that you received all necessary equipment needed to install the new 25-drive

DAE.

Verify that you received the following:

Component Quantity

Disk-array enclosure (25drive DAE)

Rail kit, including

Snap-in rails (2)

Screws (3 per rail)

Front view

Rear view

1

1

Power cords 2

Bezel for disk-array

enclosure (with key)

mini-SAS HD cables (either 1

meter or 2 meter copper)

that connect disk-array

enclosures to each other (1

meter cables) or to DPE (2

meter cables)

25-drive DAE container contents 27

1

2

Note

Right Rear

Left Rear

Key Tabs

CL5866

Note

Installation Procedures

Install the disk array enclosure

There are two types of DAEs. One is a 3U 15 disk 3.5" drive DAE. The other is a 2U 25

disk 2.5" drive DAE. DAEs are optional. The installation procedures are slightly

different for each.

Install 15-drive DAE

Installing snap-in rails in the cabinet

The snap-in rails are dedicated left and right, and cannot be interchanged. The front

edge of each rail is stamped L or R for left or right side when the rail faces the cabinet

front.

The snap-in rails have two key tabs at the top and bottom edge on the rear of each

rail. The key tabs ensure that the rails are installed in the appropriate 2U space.

Procedure

1. From the rear of the cabinet, insert the two key tabs into the holes of the 2Uspace on the rear cabinet channel.

Figure 10

Key tabs at rear rail top and bottom edge

As the key tabs and adaptors are pushed into the rear mounting holes, the

spring clips will ride over the cabinet channel and snap into place.

2. Holding the rail extended, push the key tabs and the adaptors into the rear

mounting holes until the spring clips snap into place on the outside of the rear

cabinet channel.

28 Unity 480/F, Unity 680/F, Unity 880/F Installation and Service Guide

CL5867

CAUTION

CL5868

Front

Installation Procedures

Figure 11 Aligning the rear adaptors (left rear of cabinet shown)

3. At the front of the cabinet, making sure the rail is level, pull it forward and align

the rail adaptor with the mounting hole in the channel. Push in on the spring clip

while pulling forward on the rail. When the spring clip is forward of the front

cabinet channel, and the adaptor is in the mounting holes, release the spring clip

so it holds the rail in place.

Ensure the spring clip is securely attached to the channel. It may be

necessary to push in on the clip to assist in snapping it into place.

Figure 12 Securing the Spring Clips

4. From the rear of the cabinet, secure the rail in place using one M5 screw on

each rail.

Install 15-drive DAE 29

CL5869

Right RearLeft Rear

WARNING

CL5845

Installation Procedures

Installing the DAE on the rails

Figure 13 Installing the M5 Screw

The enclosure is heavy and should be installed into or removed from a rack by

two people. To avoid personal injury and/or damage to the equipment, do not

attempt to lift and install the enclosure into a rack without a mechanical lift

and/or help from another person.

Procedure

1. With help from another person, lift the enclosure and, from the front of the

cabinet/rack, slide the enclosure onto the rails.

Figure 14

Sliding the enclosure onto the rails

30 Unity 480/F, Unity 680/F, Unity 880/F Installation and Service Guide

2. Once the enclosure is completely seated into the rear tabs, secure the front of

the enclosure to the front vertical channels with four screws (two per side), but

do not tighten the screws until they are all in place.

Figure 15 Securing the front of the enclosure

CL5846

Screws (2)

Screws (2)

Front

Rear

Note

CAUTION

Installation Procedures

Install 25-drive DAE

Installing the rails in the cabinet

The snap-in rails are dedicated left and right, and cannot be interchanged.

Procedure

1. Orient the rails. Face the front of the cabinet when orienting the left and right

rail placement. The front edge of each rail is stamped L or R.

2. From the rear of the cabinet, insert the adapters into the holes on the rear rack

channel with the rail extended as shown in Figure 16 on page 32.

3. Push the rail into the rear mounting holes until the spring clips snap into place

on the outside of the rear channel.

Ensure the holes on the rail line up with the holes on the cabinet. This will

ensure proper alignment of the rails. Also, check that the rails are level and

using the same cabinet Unit markers from front to rear. Ensure you are

using the same unit markers from the front of the cabinet to the rear of the

cabinet.

Install 25-drive DAE 31

CAUTION

CAUTION

Installation Procedures

Figure 16 Push rail into rear channel mounting holes

4. From the rear of the cabinet, secure the rails in place using one M5 screw on

each rail.

Figure 17 Installing the M5 Screw

5. Working from the front of the cabinet, align the adaptor with the mounting hole

on the front of the rack as shown in Figure 18 on page 33.

Ensure the holes on the rail line up with the holes on the cabinet. This will

ensure proper alignment of the rails. Also, check that the rails are level

from front-to-back and left-to-right. Ensure you are using the same unit

markers from the front of the cabinet to the rear of the cabinet.

6. Push in on the spring clip while pulling the rail forward. When the spring clip is

forward of the front rack channel, and the adaptor is in the mounting holes,

release the spring clip so it holds the rail in place.

Ensure the spring clip is securely attached to the channel. It may be

necessary to push in on the clip to assist in snapping it into place.

32 Unity 480/F, Unity 680/F, Unity 880/F Installation and Service Guide

Installing the DAE on the rails

CAUTION

Installation Procedures

Figure 18 Securing rail to front channel

The enclosure is heavy and should be installed into or removed from a rack by

two people. To avoid personal injury and/or damage to the equipment, do not

attempt to lift and install the enclosure into a rack without a mechanical lift

and/or help from another person.

L'enclosure étant lourde, sa mise en place dans l'armoire nécessite deux

personnes. Afin de ne pas vous blesser et/ou endommager le matériel, n’essayez

pas de soulever et d’installer l’armoire sur une rampe sans avoir recours à un

relevage mécanique et/ou à l’aide d’une autre personne.

Das Gehäuse ist schwer und sollte nur von zwei Personen in einem Rack

installiert werden. Zur Vermeidung von körperlichen Verletzungen und/oder der

Beschädigung des Gerätes, bitte das Gehäuse nicht ohne die Hilfe einer zweiten

Person anheben und einbauen.

Il contenitore è pesante e dev'essere installato nel rack da due persone. Per

evitare danni personali e/o all’apparecchiatura, non tentare di sollevare ed

installare in un rack il contenitore senza un sollevatore meccanico e/o l’aiuto di

un’altra persona.

Debido a su considerable peso, la instalación del compartimento en el bastidor

deben realizarla siempre dos personas. Para evitar daños personales o en el

equipo, el compartimento no debe levantarse ni instalarse en el bastidor sin la

ayuda de un elevador mecánico o de otra persona.

Install 25-drive DAE 33

CAUTION

CL5994

Installation Procedures

Do not install the enclosure without the rear rail screws installed and fully

tightened. If the screws are not installed and tightened, the rails could rotate out

of position, possibly causing the enclosure to fall, causing damage to the DAE

and causing personnel injury.

Procedure

1. With help from another person, lift the enclosure and, from the front of the

cabinet/rack, slide the enclosure onto the rails.

Figure 19 Sliding the enclosure onto the rails

When the enclosure slides to the back of the cabinet, the rear tabs on the rails

insert into the notches in the rear of the enclosure. The tabs secure and support

the rear of the enclosure.

Figure 20

Rail tabs securing the rear of the enclosure

34 Unity 480/F, Unity 680/F, Unity 880/F Installation and Service Guide

2. Secure the front of the enclosure to the front vertical channels with four

screws (two per side), but do not tighten the screws until they are all in place.

Figure 21 Securing the front of the enclosure

Note

Cabling the DPE to a DAE

If you have one or more DAEs, cable the DAEs to the DPE back-end ports so that the

storage is available in the system.

Ensure that the DAE is located close enough to route and connect to the DPE using

the two-meter DPE-to-DAE interconnect cables. Five-meter and ten-meter

interconnect cables are available when connecting enclosures across multiple racks.

Installation Procedures

General DAE back-end bus configuration rules:

1. Maximum number of enclosures per bus is 10.

2. Maximum number of drive slots per bus is 250, up to specific system limitations

for drive slots.

3. For best performance, it is recommended that you evenly distribute DAEs across

the available back-end buses.

Consider the maximum number of drives that can be installed in the storage system

model. DAEs can be added to the system while the operating system is active, and up

to the DAE and drive slot limit for the storage system. DAEs or drive slots that are

over the system limit cannot operate in the system.

The storage processors connect to the DAEs with mini-SAS HD cables. The cables

connect LCCs in the DAEs of a storage platform in a daisy-chain topology. The miniSAS HD ports on the storage processors in the DPE are labeled 0 and 1. Mini-SAS HD

port 0 is connected internally to the SAS expander that connects the drives on the

front of the DPE.

Each DAE supports two redundant connections to the DPE: LCC A and LCC B.

It is recommended that you connect the first optional DAE to the mini-SAS HD output

port 1 of each storage processor. This connection creates back-end bus 1 (BE1) and

designates this DAE as enclosure 0 of this bus. The address of this enclosure is BE1

Enclosure 0. In a two back-end bus system, it is recommended that you connect the

second optional DAE to the mini-SAS HD port 0 of each storage processor.

DAE load balancing

If your system has several optional DAEs, you can daisy-chain them within that bus.

However, it is recommended that you balance each bus. In other words, optimize your

environment by using every available bus, and spread the number of enclosures and

Cabling the DPE to a DAE 35

B A

A B

0 1

1 0

Installation Procedures

drives as evenly as possible across the buses. The rule of load or bus balancing is

applied to all DAEs.

Cabling the first optional DAE to create back-end bus 1

Connect the first optional expansion DAE to port 1 of the DPE to create back-end bus

1 (BE1) and designate this DAE as enclosure 0 of this bus. We refer to the address of

this enclosure as BE1 Enclosure 0 (1_0).

To prepare for this cabling task:

l

Locate the mini-SAS HD cables to be used to connect to the newly installed

expansion DAE. Typically these cables are two-meters long. You use longer cables,

typically five-meters or eight-meters, to connect enclosures located in different

racks. Cables are shipped without labels attached. The cables and ports are not

colored.

l

Locate the sheet of cable labels provided.

Orient the cable connectors as described in the procedure that follows, making sure

that you do NOT connect:

l

A DPE expansion port 0 to another DPE expansion port 0

l

Any A-side ports to B-side ports

Procedure

1. Label a pair of mini-SAS HD cables.

2. Connect port 1 on SP A in the bottom slot of the DPE to port A on the link

control card (LCC A) in the bottom of the DAE.

3. Connect port 1 on SP B in the top slot of the DPE to port A on the link control

card (LCC B) in the top of the DAE.

Figure 22

Cabling one DPE to one 25-drive DAE

36 Unity 480/F, Unity 680/F, Unity 880/F Installation and Service Guide

Note

B A

A B

1 0

0 1

Note

Installation Procedures

Cabling the second optional DAE to create back-end bus 0

Connect the second optional expansion DAE to the DPE expansion port 0 to extend

back-end bus 0 (BE0) and designate this DAE as enclosure 0 of this bus. We refer to

the address of this enclosure as BE0 Enclosure 0 (0_0).

When cabling the 15-drive DAE LCC SAS ports, ensure that the cables do not overlap

behind the DAE.

Procedure

1. Label a pair of mini-SAS HD cables.

2. Connect port 0 on SP A in the bottom slot of the DPE to port A on the link

control card (LCC A) in the bottom of the DAE.

3. Connect port 0 on SP B in the top slot of the DPE to port A on the link control

card (LCC B) in the top of the DAE.

Figure 23 Cabling a DPE to a second 25-drive DAE

After you finish

If you need to cable more than two optional DAEs, refer to the

Unity Installation Guide

Cabling an expansion DAE to an existing DAE to extend a back-end bus

Connect the optional expansion DAE to the last installed DAE in the back-end bus to

extend to the new DAE.

When cabling the 15-drive DAE LCC SAS ports, ensure that the cables do not overlap

behind the DAE.

Procedure

1. Label a pair of mini-SAS HD cables.

Cabling the second optional DAE to create back-end bus 0 37

.

B

A

x4

x4

A

B

#

0

1

1

1

0

0

0 1

0

1

x4x4

x4

x4

x4 x4

A

B

AB

A

B

A

B

x4

x4

1

2

CL5765

21

Installation Procedures

2. Connect port B on the link control card (LCC A) of the lower-numbered DAE to

port A on the link control card (LCC A) of the higher-numbered DAE.

LCC A is on the lower portion of the DAE.

3. Connect port B on the link control card (LCC B) of the lower-numbered DAE to

port A on the link control card (LCC B) of the higher-numbered DAE.

LCC B is on the upper portion of the DAE.

Example 1 Connect the DAE to another DAE

Figure 24 25-drive DAE extended to a 15-drive DAE

Connecting power to the DAE

Procedure

1. Verify that the cabinet circuit breakers are in the On position and that power is

connected to the cabinet.

2. Connect the power cables to the optional DAEs.

Figure 25

38 Unity 480/F, Unity 680/F, Unity 880/F Installation and Service Guide

Connecting power cables to the 3U, 15-drive DAE

Installation Procedures

Figure 26 Connecting power cables to the 2U, 25-drive DAE

3. Secure each power cable to the power supply with the cable retention bail.

4. Connect the power to the each DAE as follows:

a. Connect the power cable for LCC A to PDU A.

b. Connect the power cable for LCC B to PDU B.

The enclosures power up immediately once the cable is connected.

5. Bundle and secure the cables as necessary with tie wraps.

Connecting power to the DAE 39

Installation Procedures

40 Unity 480/F, Unity 680/F, Unity 880/F Installation and Service Guide

CHAPTER 2

Note

Service Procedures

This document describes how to replace parts or add new parts to a system.

Before you service the system, ensure that you have received the new part and have

correctly identified its intended location in the system. Go to the Unisphere Service

section for instructions on how to identify failures, order new parts and safely handle

hardware components.

When servicing the system, only add or replace one component at a time. New

hardware added while simultaneously servicing other components may not be

recognized by the system and can cause errors.

Review the information in Safety precautions for handling replaceable units on page

121 before handling replaceable parts.

l

Replace a faulted disk in the DPE.......................................................................42

l

Add a new disk in the DPE..................................................................................44

l

Replace a power supply......................................................................................46

l

Replace an embedded module............................................................................49

l

Add a 4-port card...............................................................................................56

l

Replace a 4-port card......................................................................................... 61

l

Add an SFP........................................................................................................ 69

l

Replace a faulted SFP........................................................................................70

l

Replace an I/O module.......................................................................................72

l

Add an I/O module............................................................................................. 76

l

Replace a fan module......................................................................................... 78

l

Replace a dual inline memory module (DIMM)................................................... 88

l

Replace an M.2 SSD.......................................................................................... 96

l

Replace an SP assembly................................................................................... 106

Service Procedures

41

Note

Service Procedures

Replace a faulted disk in the DPE

Take the following actions to remove a faulted disk and install the replacement disk

into the DPE.

Identifying and locating the faulted part in Unisphere

Before you replace a faulted part, locate its placement within the storage system.

Procedure

1. In Unisphere, select System View.

2. Select the Enclosures page.

3. Locate the faulted part marked orange, and displayed in the Enclosures view.

Remove a faulted 2.5" disk

Procedure

1. Push down on the orange button to release the latch.

2. Remove the disk from the slot.

Install a 2.5" disk

Figure 27

3. Place the disk on a static-free surface.

If you are installing multiple disks in a system that is powered up, wait at least 10

seconds before sliding the next disk into position.

Removing a 2.5" disk

Procedure

1. Align the disk with the guides in the slot.

2. With the latch fully opened, gently push the disk into the slot.

The latch begins to rotate downward when it meets the enclosure.

3. Push the orange button until the disk is fully seated in the slot.

42 Unity 480/F, Unity 680/F, Unity 880/F Installation and Service Guide

4. Push the latch down until it locks into place

The activity light flashes to indicate that the spin-up sequence has begun.

Figure 28 Installing a 2.5" disk

Verifying the operation of the new part in Unisphere

Service Procedures

Verify that the new part is recognized by your system, and operating correctly.

Procedure

1. In Unisphere, select System View.

2. On the Summary page, confirm that the system status is OK.

3. Select the Enclosures page.

4. Verify that the part appears with the OK status in the enclosure view. You may

Returning a faulted part

We appreciate the return of defective material within 5 business days (for US

returns). For International customers, please return defective material within 5-10

business days. All instructions and material required to return your defective part were

supplied with your good part shipment.

Procedure

1. Package the faulted part in the shipping box that contained the replacement

2. Ship the failed part to your service provider as described in the instructions that

3. (Optional) For more information about returning customer-replaceable parts,

need to refresh Unisphere by clicking on the refresh icon next to the

Enclosures view.

If the system health monitor shows the part as faulted, contact your service

provider.

part, and seal the box.

were included with the replacement part.

from Unisphere, click Support > Replace Disk Drives, Power Supplies, and

Other Parts > Return a Part to display the part return instructions.

If your screen does not show the Return a Part option, contact your service

provider for instructions on what to do next.

Verifying the operation of the new part in Unisphere 43

Service Procedures

Add a new disk in the DPE

Take the following actions to add a new disk in the DPE.

Removing the front bezel

Procedure

1. If the bezel has a lock, insert the key that shipped with your enclosure into the

lock, and turn the key to unlock the bezel.

2. Press the two latch buttons on the bezel surface to release the bezel from the

cabinet.

3. Pull the bezel off the cabinet and put it on a clean, static-free surface.

Remove a disk filler module

Procedure

1. Insert your finger into the cutout on the disk filler module.

2. Pull the filler module out of the slot.

Figure 29 Removing a disk filler module

44 Unity 480/F, Unity 680/F, Unity 880/F Installation and Service Guide

Install a 2.5" disk

Note

Service Procedures

If you are installing multiple disks in a system that is powered up, wait at least 10

seconds before sliding the next disk into position.

Procedure

1. Align the disk with the guides in the slot.

2. With the latch fully opened, gently push the disk into the slot.

The latch begins to rotate downward when it meets the enclosure.

3. Push the orange button until the disk is fully seated in the slot.

4. Push the latch down until it locks into place

The activity light flashes to indicate that the spin-up sequence has begun.

Figure 30 Installing a 2.5" disk

Verifying the operation of the new part in Unisphere

Verify that the new part is recognized by your system, and operating correctly.

Procedure

1. In Unisphere, select System View.

2. On the Summary page, confirm that the system status is OK.

3. Select the Enclosures page.

4. Verify that the part appears with the OK status in the enclosure view. You may

need to refresh Unisphere by clicking on the refresh icon next to the

Enclosures view.

If the system health monitor shows the part as faulted, contact your service

provider.

Install a 2.5" disk 45

Service Procedures

Replace a power supply

Take the following actions to remove the faulted power supply and install the

replacement power supply into the system.

Identifying and locating the faulted part in Unisphere

Before you replace a faulted part, locate its placement within the storage system.

Procedure

1. In Unisphere, select System View.

2. Select the Enclosures page.

3. Locate the faulted part marked orange, and displayed in the Enclosures view.

DPE power supply LEDs

Use the fault LEDs to identify the faulted part.

Figure 31 DPE power supply LEDs

Table 3 DPE power supply LEDs

LED Location State Description

AC power (input) Green AC power is on.

DC power (output) Green DC power is on.

Fault Solid amber Power supply or backup fault.

Remove a power supply

There are two power supplies. The power supplies are installed in the top and bottom

SP assembly, and the top power supply is installed upside-down. This procedure works

for removing either power supply, however, the direction in which the release handle

Off AC power is off. Verify source

power

Off DC power is off. Verify source

power.

Check cable connection.

Blinking

amber

Off No fault.

BIOS, POST, and OS starting

up or system overheating.

46 Unity 480/F, Unity 680/F, Unity 880/F Installation and Service Guide

Note

Service Procedures

is pressed is to the left for the bottom power supply, and to the right for the top

power supply.

You do not need to power down the system to remove a power supply.

Procedure

1. Rotate the power cable retention bail to the left (to the right for the bottom

power supply). Remove the power cable from the power supply.

Figure 32 Removing the power cable

Install a power supply

The power supplies are installed in the top and bottom SP assemblys, meaning that

the top power supply is installed upside-down. This procedure works for installing

either power supply.

2. Push and hold the orange release tab to the left (to the right for the bottom

power supply) and grasp the power supply by its handle. Remove the power

supply by pulling it from the SP assembly.

Figure 33

Removing a power supply

Procedure

1. Align the power supply with the slot in the SP assembly. The power cable

retention bail will be on the right for the bottom power supply and on the left

for the top power supply.

Install a power supply 47

0 1 2 3

XXX XXX XXXX XX

REV:XXX

1

Service Procedures

2. Push the power supply into the SP assembly until it clicks into place.

Figure 34 Installing a power supply

3. Connect the power cable to the power supply and secure the cord with the

retention bail at the connector.

Figure 35 Inserting the power cable

Verifying the operation of the new part in Unisphere

Verify that the new part is recognized by your system, and operating correctly.

Procedure

1. In Unisphere, select System View.

2. On the Summary page, confirm that the system status is OK.

3. Select the Enclosures page.

4. Verify that the part appears with the OK status in the enclosure view. You may

need to refresh Unisphere by clicking on the refresh icon next to the

Enclosures view.

If the system health monitor shows the part as faulted, contact your service

provider.

Returning a faulted part