Page 1

Dell Latitude 7390

Owner's Manual

Regulatory Model: P28S

Regulatory Type: P28S002

Page 2

Notes, cautions, and warnings

NOTE: A NOTE indicates important information that helps you make better use of your product.

CAUTION: A CAUTION indicates either potential damage to hardware or loss of data and tells you how to avoid the problem.

WARNING: A WARNING indicates a potential for property damage, personal injury, or death.

© 2018 Dell Inc. or its subsidiaries. All rights reserved. Dell, EMC, and other trademarks are trademarks of Dell Inc. or its subsidiaries. Other trademarks

may be trademarks of their respective owners.

2018 - 01

Rev. A00

Page 3

Working on your computer

Safety precautions

The safety precautions chapter details the primary steps to be taken before performing any disassembly instructions.

Observe the following safety precautions before you perform any installation or break/x procedures involving disassembly or reassembly:

• Turn o the system and all attached peripherals.

• Disconnect the system and all attached peripherals from AC power.

• Disconnect all network cables, telephone, and telecommunications lines from the system.

• Use an ESD eld service kit when working inside any notebook to avoid electrostatic discharge (ESD) damage.

• After removing any system component, carefully place the removed component on an anti-static mat.

• Wear shoes with non-conductive rubber soles to reduce the chance of getting electrocuted.

Standby power

Dell products with standby power must be unplugged before you open the case. Systems that incorporate standby power are essentially

powered while turned o. The internal power enables the system to be remotely turned on (wake on LAN) and suspended into a sleep

mode and has other advanced power management features.

1

Unplugging, pressing and holding the power button for 15 seconds should discharge residual power in the system board, notebooks

Bonding

Bonding is a method for connecting two or more grounding conductors to the same electrical potential. This is done through the use of a

eld service electrostatic discharge (ESD) kit. When connecting a bonding wire, ensure that it is connected to bare metal and never to a

painted or non-metal surface. The wrist strap should be secure and in full contact with your skin, and ensure that you remove all jewelry

such as watches, bracelets, or rings prior to bonding yourself and the equipment.

Electrostatic discharge — ESD protection

ESD is a major concern when you handle electronic components, especially sensitive components such as expansion cards, processors,

memory DIMMs, and system boards. Very slight charges can damage circuits in ways that may not be obvious, such as intermittent

problems or a shortened product life span. As the industry pushes for lower power requirements and increased density, ESD protection is an

increasing concern.

Due to the increased density of semiconductors used in recent Dell products, the sensitivity to static damage is now higher than in previous

Dell products. For this reason, some previously approved methods of handling parts are no longer applicable.

Two recognized types of ESD damage are catastrophic and intermittent failures.

• Catastrophic – Catastrophic failures represent approximately 20 percent of ESD-related failures. The damage causes an immediate and

complete loss of device functionality. An example of catastrophic failure is a memory DIMM that has received a static shock and

immediately generates a "No POST/No Video" symptom with a beep code emitted for missing or nonfunctional memory.

• Intermittent – Intermittent failures represent approximately 80 percent of ESD-related failures. The high rate of intermittent failures

means that most of the time when damage occurs, it is not immediately recognizable. The DIMM receives a static shock, but the

Working on your computer 3

Page 4

tracing is merely weakened and does not immediately produce outward symptoms related to the damage. The weakened trace may

take weeks or months to melt, and in the meantime may cause degradation of memory integrity, intermittent memory errors, etc.

The more dicult type of damage to recognize and troubleshoot is the intermittent (also called latent or "walking wounded") failure.

Perform the following steps to prevent ESD damage:

• Use a wired ESD wrist strap that is properly grounded. The use of wireless anti-static straps is no longer allowed; they do not provide

adequate protection. Touching the chassis before handling parts does not ensure adequate ESD protection on parts with increased

sensitivity to ESD damage.

• Handle all static-sensitive components in a static-safe area. If possible, use anti-static oor pads and workbench pads.

• When unpacking a static-sensitive component from its shipping carton, do not remove the component from the anti-static packing

material until you are ready to install the component. Before unwrapping the anti-static packaging, ensure that you discharge static

electricity from your body.

• Before transporting a static-sensitive component, place it in an anti-static container or packaging.

ESD eld service kit

The unmonitored Field Service kit is the most commonly used service kit. Each Field Service kit includes three main components: anti-static

mat, wrist strap, and bonding wire.

Components of an ESD eld service kit

The components of an ESD eld service kit are:

• Anti-Static Mat – The anti-static mat is dissipative and parts can be placed on it during service procedures. When using an anti-static

mat, your wrist strap should be snug and the bonding wire should be connected to the mat and to any bare metal on the system being

worked on. Once deployed properly, service parts can be removed from the ESD bag and placed directly on the mat. ESD-sensitive

items are safe in your hand, on the ESD mat, in the system, or inside a bag.

• Wrist Strap and Bonding Wire – The wrist strap and bonding wire can be either directly connected between your wrist and bare metal

on the hardware if the ESD mat is not required, or connected to the anti-static mat to protect hardware that is temporarily placed on

the mat. The physical connection of the wrist strap and bonding wire between your skin, the ESD mat, and the hardware is known as

bonding. Use only Field Service kits with a wrist strap, mat, and bonding wire. Never use wireless wrist straps. Always be aware that the

internal wires of a wrist strap are prone to damage from normal wear and tear, and must be checked regularly with a wrist strap tester

in order to avoid accidental ESD hardware damage. It is recommended to test the wrist strap and bonding wire at least once per week.

• ESD Wrist Strap Tester – The wires inside of an ESD strap are prone to damage over time. When using an unmonitored kit, it is a best

practice to regularly test the strap prior to each service call, and at a minimum, test once per week. A wrist strap tester is the best

method for doing this test. If you do not have your own wrist strap tester, check with your regional oce to nd out if they have one.

To perform the test, plug the wrist-strap's bonding-wire into the tester while it is strapped to your wrist and push the button to test. A

green LED is lit if the test is successful; a red LED is lit and an alarm sounds if the test fails.

• Insulator Elements – It is critical to keep ESD sensitive devices, such as plastic heat sink casings, away from internal parts that are

insulators and often highly charged.

• Working Environment – Before deploying the ESD Field Service kit, assess the situation at the customer location. For example,

deploying the kit for a server environment is dierent than for a desktop or portable environment. Servers are typically installed in a rack

within a data center; desktops or portables are typically placed on oce desks or cubicles. Always look for a large open at work area

that is free of clutter and large enough to deploy the ESD kit with additional space to accommodate the type of system that is being

repaired. The workspace should also be free of insulators that can cause an ESD event. On the work area, insulators such as Styrofoam

and other plastics should always be moved at least 12 inches or 30 centimeters away from sensitive parts before physically handling any

hardware components

• ESD Packaging – All ESD-sensitive devices must be shipped and received in static-safe packaging. Metal, static-shielded bags are

preferred. However, you should always return the damaged part using the same ESD bag and packaging that the new part arrived in.

The ESD bag should be folded over and taped shut and all the same foam packing material should be used in the original box that the

new part arrived in. ESD-sensitive devices should be removed from packaging only at an ESD-protected work surface, and parts should

never be placed on top of the ESD bag because only the inside of the bag is shielded. Always place parts in your hand, on the ESD mat,

in the system, or inside an anti-static bag.

• Transporting Sensitive Components – When transporting ESD sensitive components such as replacement parts or parts to be

returned to Dell, it is critical to place these parts in anti-static bags for safe transport.

Working on your computer

4

Page 5

ESD protection summary

It is recommended that all eld service technicians use the traditional wired ESD grounding wrist strap and protective anti-static mat at all

times when servicing Dell products. In addition, it is critical that technicians keep sensitive parts separate from all insulator parts while

performing service and that they use anti-static bags for transporting sensitive components.

Electrostatic discharge — ESD protection

ESD is a major concern when you handle electronic components, especially sensitive components such as expansion cards, processors,

memory DIMMs, and system boards. Very slight charges can damage circuits in ways that may not be obvious, such as intermittent

problems or a shortened product life span. As the industry pushes for lower power requirements and increased density, ESD protection is an

increasing concern.

Due to the increased density of semiconductors used in recent Dell products, the sensitivity to static damage is now higher than in previous

Dell products. For this reason, some previously approved methods of handling parts are no longer applicable.

Two recognized types of ESD damage are catastrophic and intermittent failures.

• Catastrophic – Catastrophic failures represent approximately 20 percent of ESD-related failures. The damage causes an immediate and

complete loss of device functionality. An example of catastrophic failure is a memory DIMM that has received a static shock and

immediately generates a "No POST/No Video" symptom with a beep code emitted for missing or nonfunctional memory.

• Intermittent – Intermittent failures represent approximately 80 percent of ESD-related failures. The high rate of intermittent failures

means that most of the time when damage occurs, it is not immediately recognizable. The DIMM receives a static shock, but the

tracing is merely weakened and does not immediately produce outward symptoms related to the damage. The weakened trace may

take weeks or months to melt, and in the meantime may cause degradation of memory integrity, intermittent memory errors, etc.

The more dicult type of damage to recognize and troubleshoot is the intermittent (also called latent or "walking wounded") failure.

Perform the following steps to prevent ESD damage:

• Use a wired ESD wrist strap that is properly grounded. The use of wireless anti-static straps is no longer allowed; they do not provide

adequate protection. Touching the chassis before handling parts does not ensure adequate ESD protection on parts with increased

sensitivity to ESD damage.

• Handle all static-sensitive components in a static-safe area. If possible, use anti-static oor pads and workbench pads.

• When unpacking a static-sensitive component from its shipping carton, do not remove the component from the anti-static packing

material until you are ready to install the component. Before unwrapping the anti-static packaging, ensure that you discharge static

electricity from your body.

• Before transporting a static-sensitive component, place it in an anti-static container or packaging.

Before working inside your computer

1 Ensure that your work surface is at and clean to prevent the computer cover from being scratched.

2 Turn o your computer.

3 If the computer is connected to a docking device (docked), undock it.

4 Disconnect all network cables from the computer (if available).

CAUTION

computer.

5 Disconnect your computer and all attached devices from their electrical outlets.

6 Open the display.

7 Press and hold the power button for few seconds, to ground the system board.

: If your computer has an RJ45 port, disconnect the network cable by rst unplugging the cable from your

CAUTION

CAUTION: To avoid electrostatic discharge, ground yourself by using a wrist grounding strap or by periodically touching an

unpainted metal surface at the same time as touching a connector on the back of the computer.

: To guard against electrical shock unplug your computer from the electrical outlet before performing Step # 8.

Working on your computer 5

Page 6

8 Remove any installed ExpressCards or Smart Cards from the appropriate slots.

After working inside your computer

After you complete any replacement procedure, ensure that you connect external devices, cards, and cables before turning on your

computer.

CAUTION: To avoid damage to the computer, use only the battery designed for this particular Dell computer. Do not use batteries

designed for other Dell computers.

1 Connect any external devices, such as a port replicator or media base, and replace any cards, such as an ExpressCard.

2 Connect any telephone or network cables to your computer.

CAUTION: To connect a network cable, rst plug the cable into the network device and then plug it into the

computer.

3 Connect your computer and all attached devices to their electrical outlets.

4 Turn on your computer.

6 Working on your computer

Page 7

Removing and installing components

This section provides detailed information on how to remove or install the components from your computer.

Recommended tools

The procedures in this document require the following tools:

• Phillips #0 screwdriver

• Phillips #1 screwdriver

• Small plastic scribe

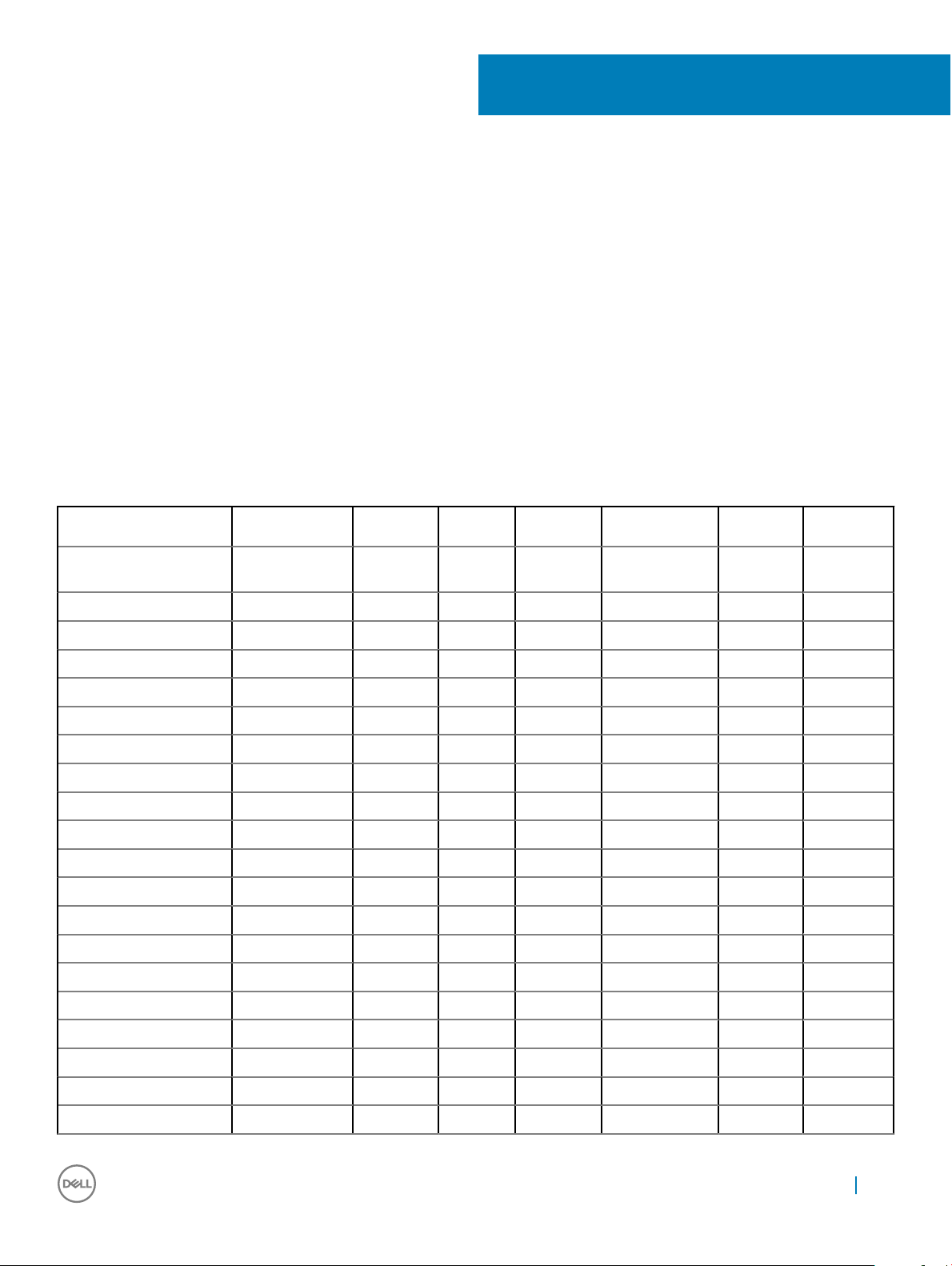

Screw size list

Table 1. Latitude 7390 - screw size list

2

Component M2.5x 6.0 M2.0 x 5.0

Back cover 8 (captive

screws)

Battery—3-cell 1

Battery—4-cell 2

SSD module 1

Heat sink module 4

System fan 2

Speaker 4

WWAN card 1

WLAN card 1

Power connector port 1

ESD bracket 1

EDP bracket 2

Touchpad buttons 2

Fingerprint reader 1

LED board 1

M2.5 x

3.5

M2.0x3.0 M2.5x4.0 M2.0 x 2.5 M2.0 x 2.0

Smart card reader cage 2

Keyboard Lock bracket 1

Display hinge 6

Display panel 2

Antenna—Innity displays 2

Removing and installing components 7

Page 8

Component M2.5x 6.0 M2.0 x 5.0

Keyboard support plate 19

Keyboard 5

System board 8

Memory module bracket 1

M2.5 x

3.5

M2.0x3.0 M2.5x4.0 M2.0 x 2.5 M2.0 x 2.0

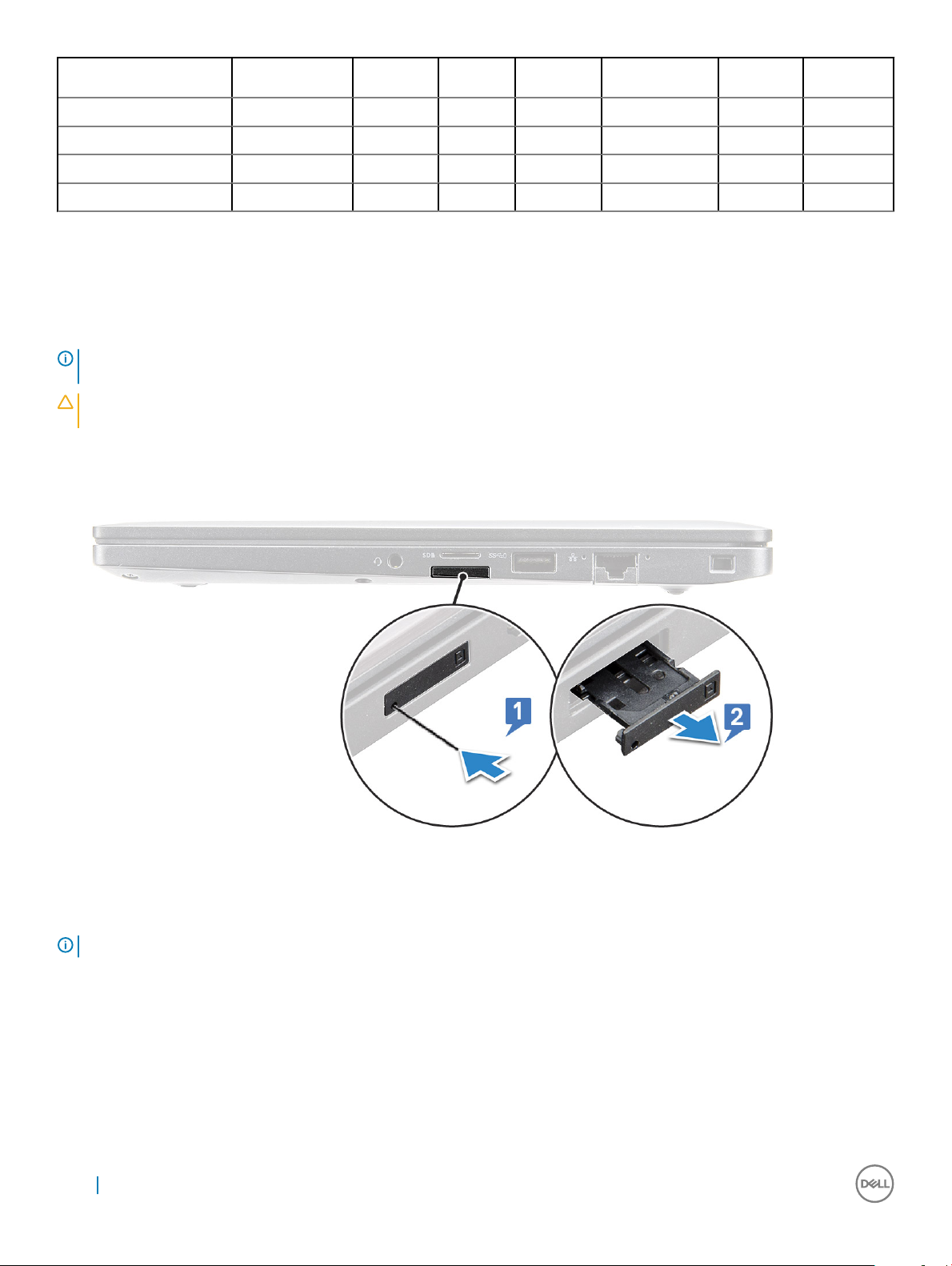

Subscriber Identication Module (SIM) card

Removing SIM card or SIM card tray

NOTE: SIM card or SIM card tray removal is only available on systems that are shipped with WWAN module. Hence, removing

procedure is only applicable for systems that are shipped with WWAN module.

CAUTION: Removing the SIM card when the computer is On, may cause data loss or damage the card. Ensure that your

computer is turned o or the network connections are disabled.

1 Insert a paperclip or a SIM card removal tool into the pinhole on the SIM card tray [1].

2 Use a scribe to pull the SIM card tray [2].

3 Remove the SIM card, if a SIM card is available from the SIM card tray.

Replacing SIM card

NOTE

: You can replace a SIM card only for those systems that are shipped with WWAN module.

1 Insert a paperclip or a SIM card removal tool into the pinhole on the SIM card tray.

2 Use a scribe to pull the SIM card tray.

3 Place on the SIM card on the tray.

4 Insert the SIM card tray into the slot.

Removing and installing components

8

Page 9

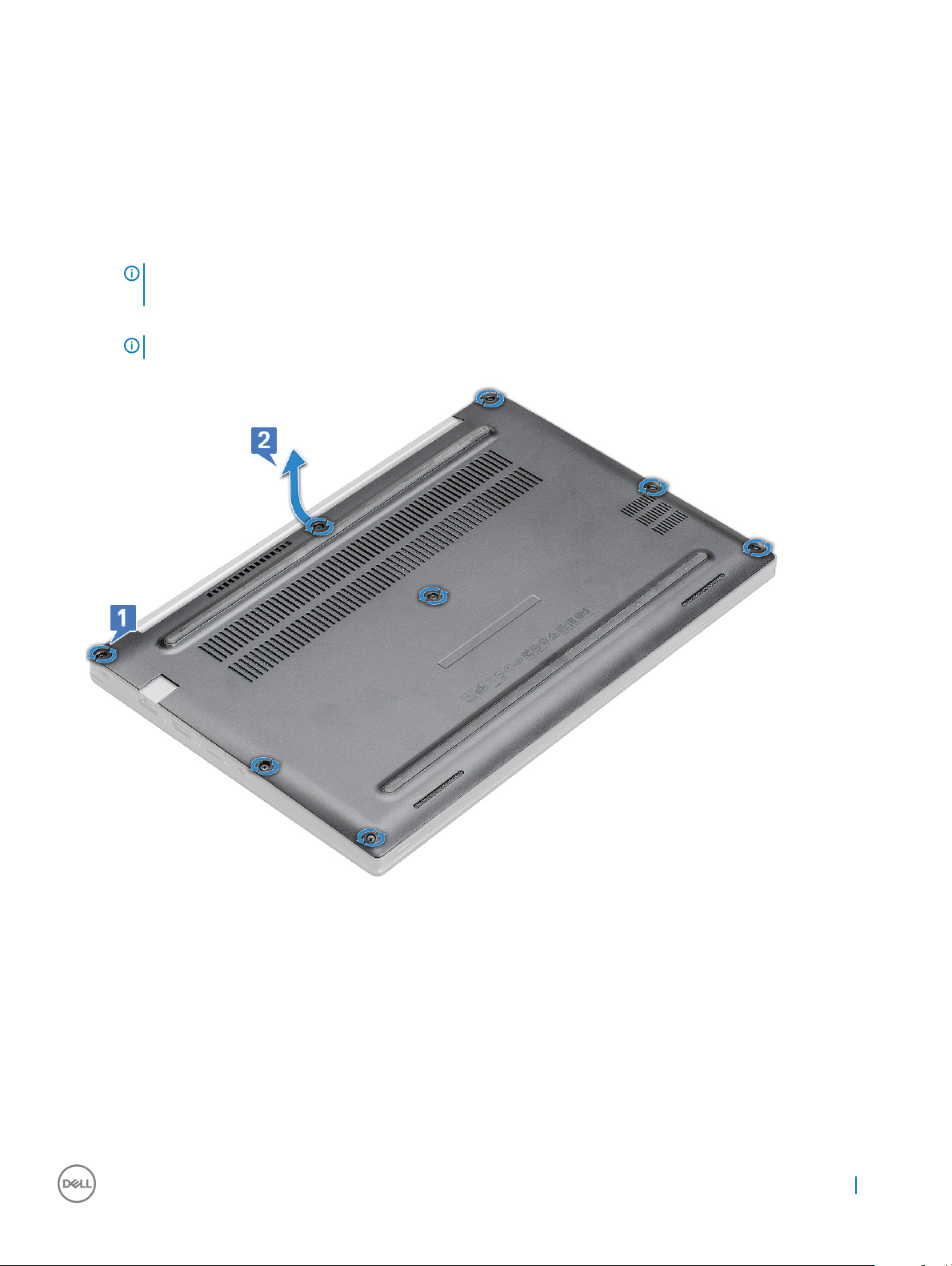

Base cover

Removing base cover

1 Follow the procedure in Before working inside your computer.

2 To release the base cover:

a Loosen the M2.5 x 6.0 captive screws (8) that secure the base cover to the computer [1].

Remember: Exercise caution when loosening the screws. Angle the screw driver to match the head of the screw to

avoid a possible stripped screw head.

b Use a plastic scribe to release the base cover from the edge and lift it from the computer [2].

NOTE: Pry the edges starting from SIM card tray button clockwise.

3 Lift the base cover from the computer.

Removing and installing components

9

Page 10

Installing base cover

1 Align the base cover tabs to the slots on the edges of the computer.

2 Press the edges of the cover until it clicks into place.

3 Tighten the M2.5 x 6.0 captive screws to secure the base cover to the computer.

Remember

possible stripped screw head.

4 Follow the procedure in After working inside your computer.

: Exercise caution when tightening the screws. Angle the screw driver to match the head of the screw to avoid a

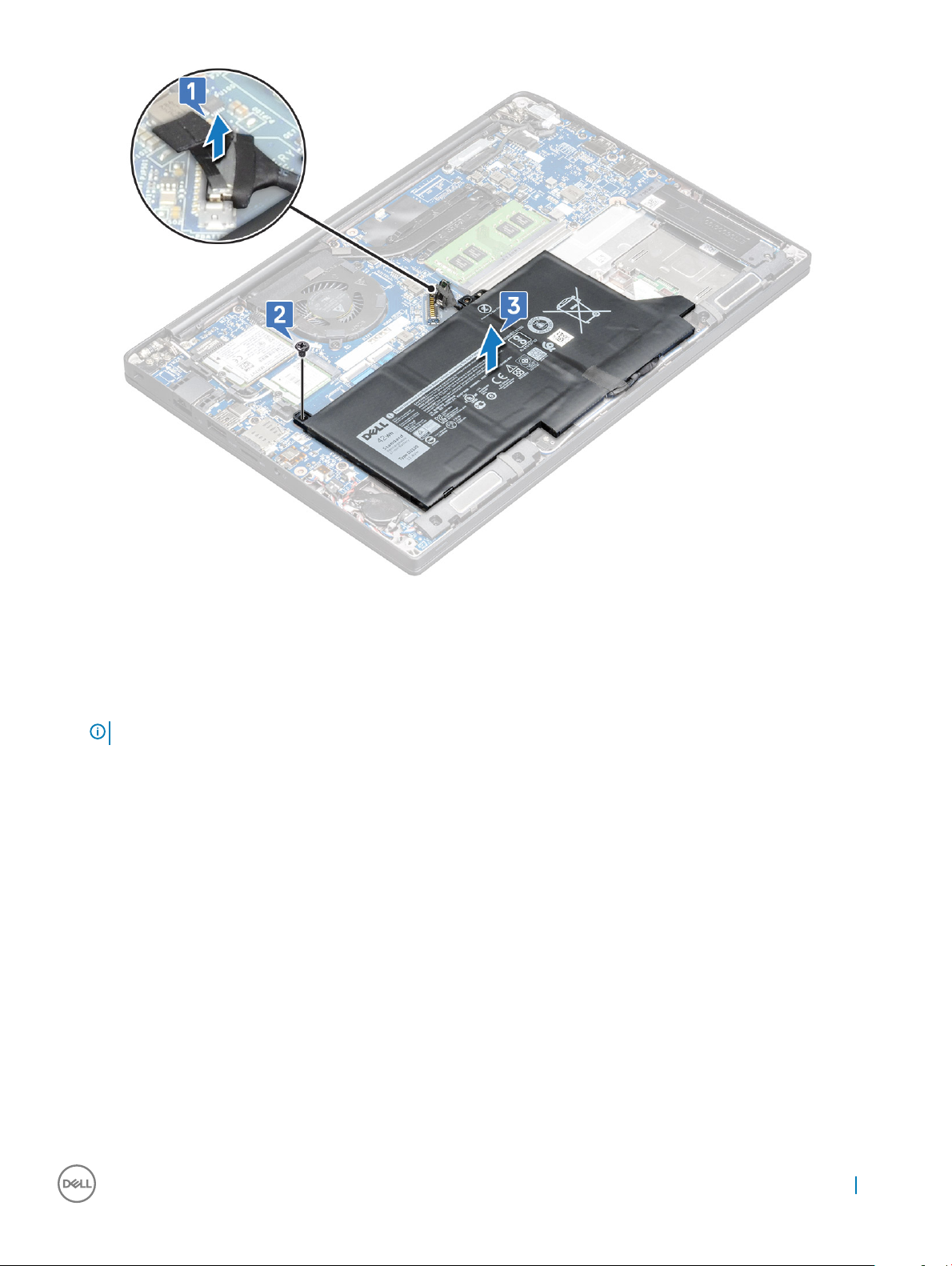

Battery

Removing 3-cell battery

1 Follow the procedure in Before working inside your computer.

2 Remove the base cover.

3 To remove the battery:

a Disconnect the battery cable from the connector on the system board [1].

: Pull the connector by the lever attached to the connector. Ensure to pull gently.

NOTE

b Remove the M2.0 x 5.0 screw that secures (2) the battery to the computer [2].

c Lift the battery from the computer [3].

10

Removing and installing components

Page 11

Installing 3-cell battery

1 Insert the battery into the slot on the computer.

2 Route the battery cable through the routing clip and connect the battery cable to the connector on the system board.

NOTE

: Route the battery cable, if the cable at the base of the battery is un-routed.

3 Replace the M2.0 x 5.0 screw to secure the battery to the computer.

4 Install the base cover

5 Follow the procedure in After working inside your computer.

Removing 4-cell battery

1 Follow the procedure in Before working inside your computer.

2 Remove the base cover.

3 To remove the battery:

a Disconnect the battery cable from the connector on the system board [1].

b Remove the two M2.0 x 5.0 screw that secure the battery to the computer[2].

c Lift the battery from the computer [3].

Removing and installing components

11

Page 12

Installing 4-cell battery

1 Insert the battery into the slot on the computer.

2 Route the battery cable through the routing clip and connect the battery cable to the connector on the system board.

NOTE

: Route the battery cable, if the cable at the base of the battery is un routed.

3 Replace the two M2.0 x 5.0 screws to secure the battery to the computer.

4 Install the base cover

5 Follow the procedure in After working inside your computer.

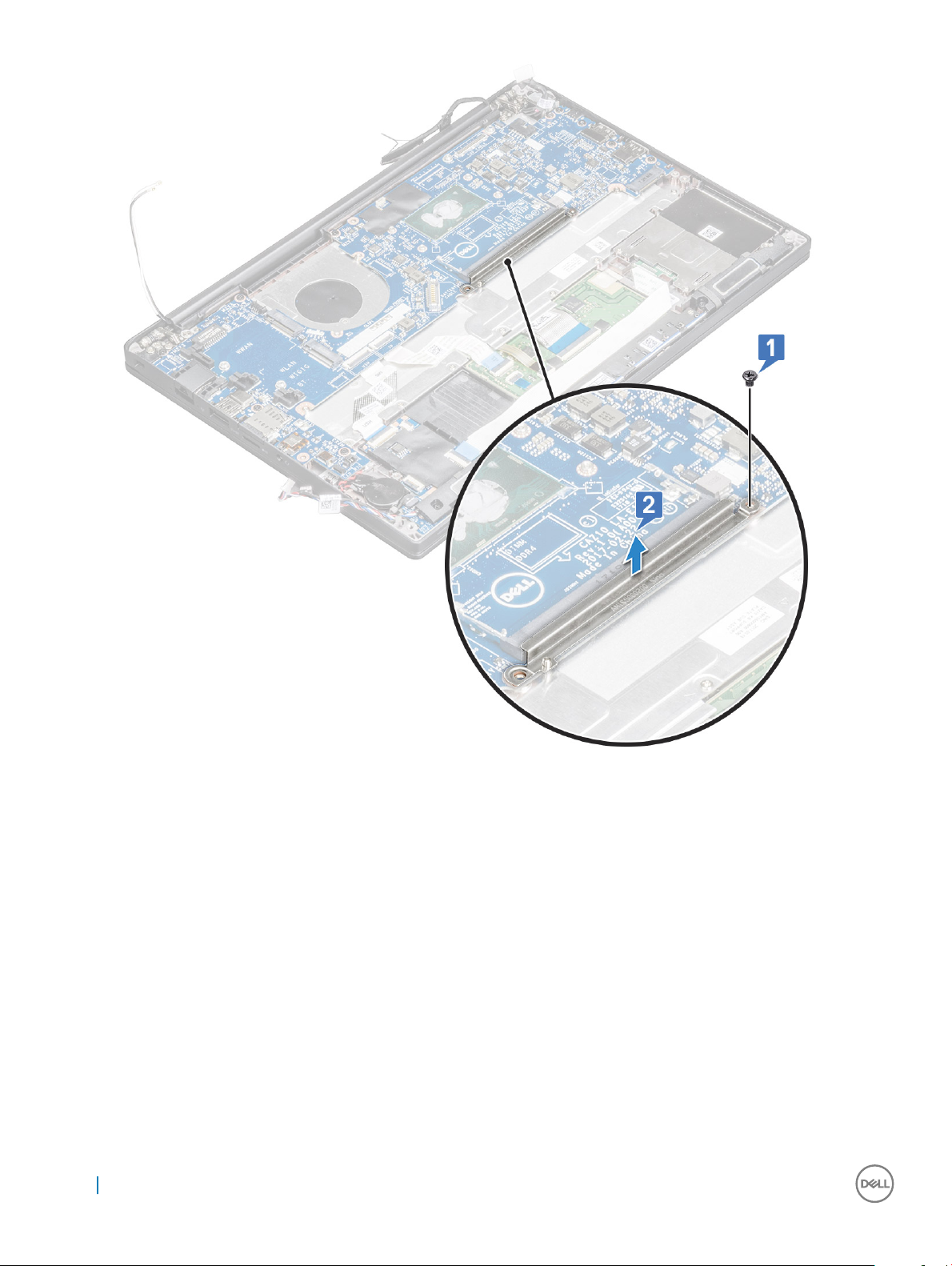

PCIe Solid State Drive (SSD)

Removing PCIe SSD

1 Follow the procedure in Before working inside your computer.

2 Remove the :

a base cover

b battery

3 To remove the PCIe SSD:

a Loosen the M2.0x3.0 captive screw that secure the SSD bracket [1].

b Remove the SSD bracket [2].

: Ensure to remove the SSD bracket, if the system is shipped with bracket.

NOTE

c Remove the PCIe SSD from the connector on the system board [3].

12

Removing and installing components

Page 13

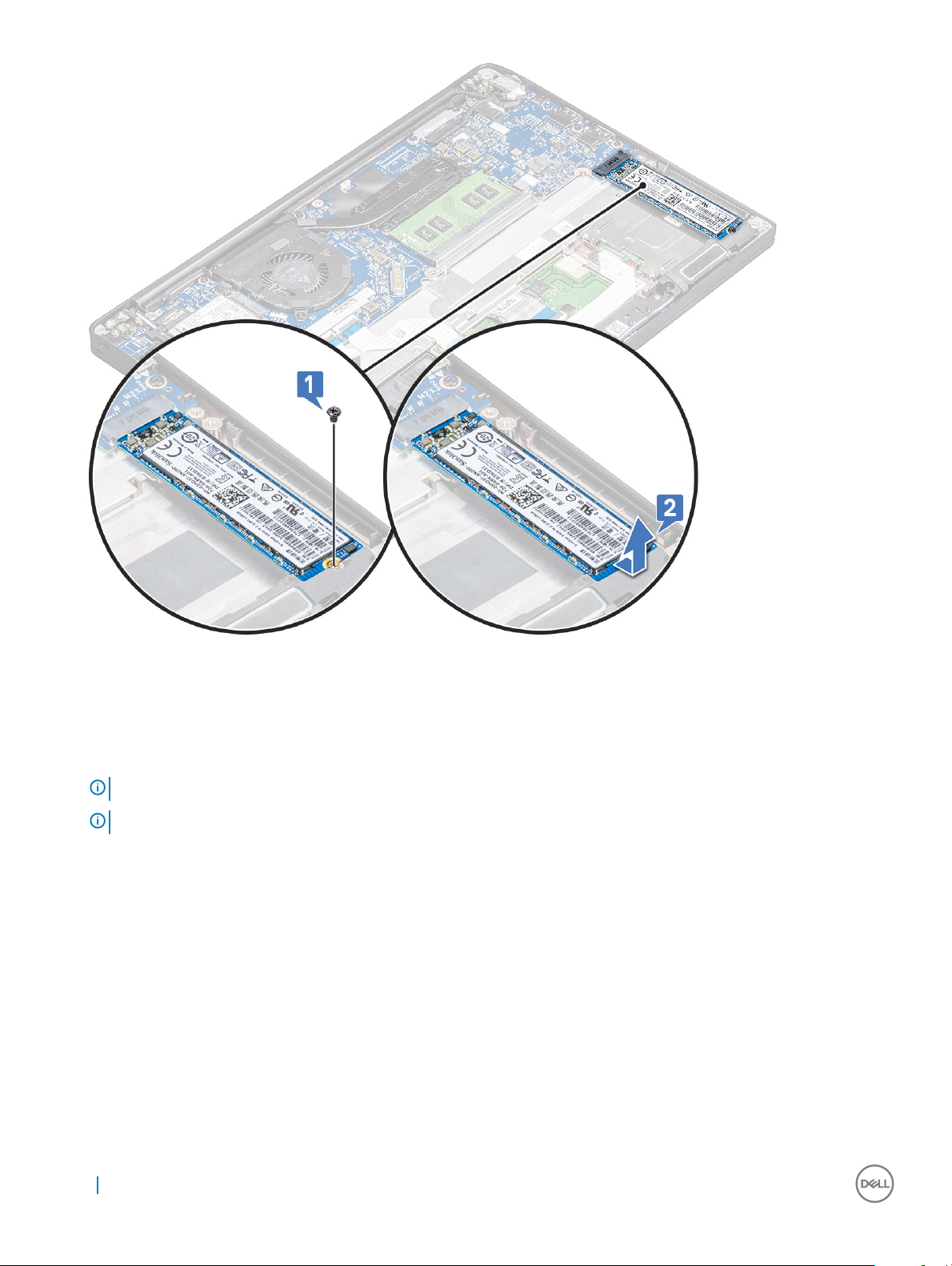

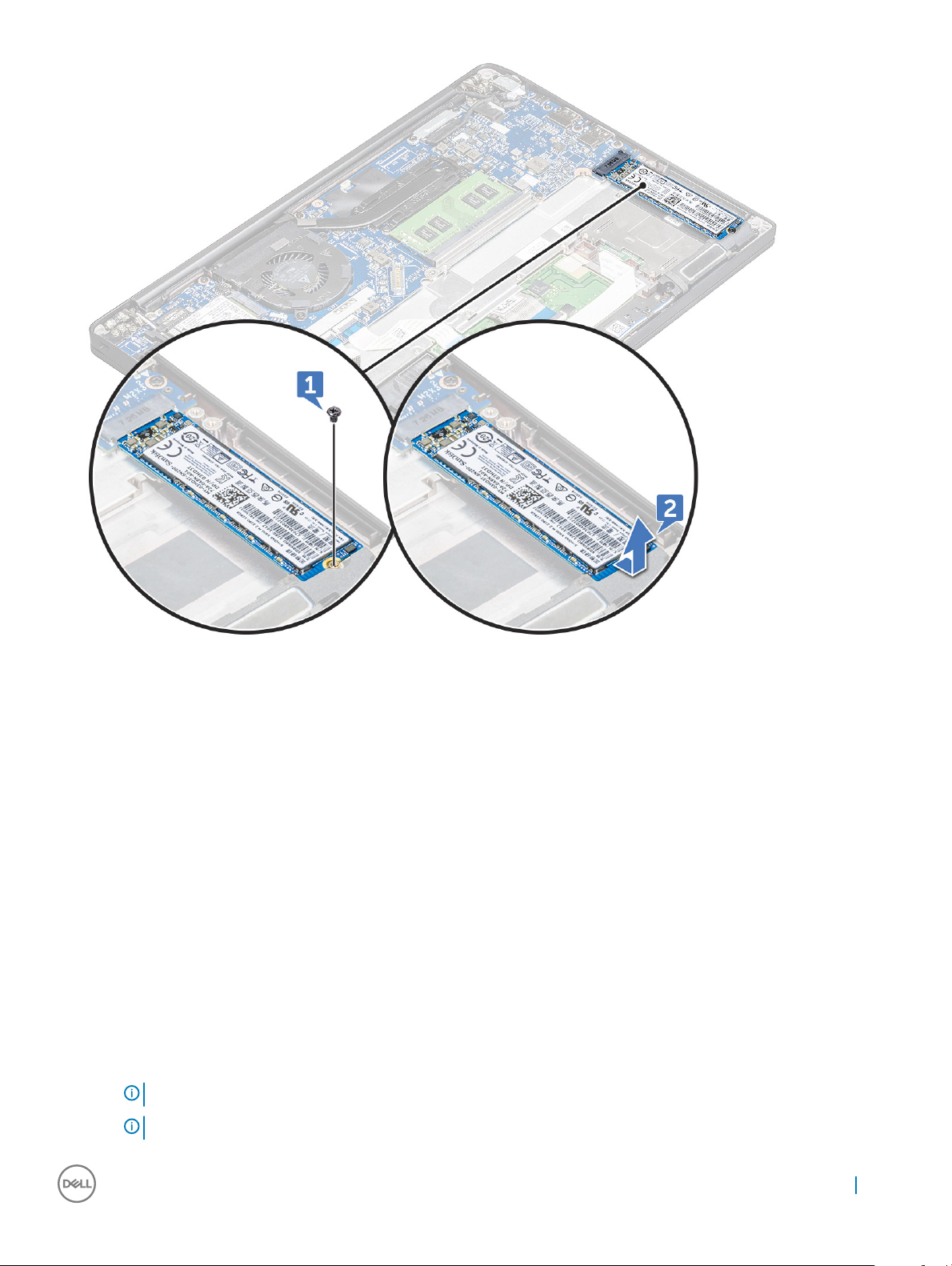

Removing PCIe SSD without bracket

1 Follow the procedure in Before working inside your computer.

2 Remove the :

a base cover

b battery

3 To remove the PCIe SSD:

a Loosen the M2.0x3.0 captive screw that secure the SSD bracket [1].

b Slightly lift the SSD and pull out from its connector [2].

: Ensure to lift the PCle SSD card by an angle NOT more than 30°.

NOTE

Removing and installing components 13

Page 14

Installing PCIe SSD

1 Insert the PCIe SSD card into the connector.

2 Install the SSD bracket over the PCIe SSD card.

NOTE

: When installing the SSD bracket, ensure that the tab on the bracket is held securely with the tab on the palm rest.

NOTE: Ensure to install the bracket is the system is shipped with bracket.

3 Tighten the M2.0x3.0 screws to secure it the SSD bracket.

4 Install the base cover.

5 Follow the procedure in After working iinside your computer.

SATA Solid State Drive (SSD)

Removing SATA SSD

1 Follow the procedure in Before working inside your computer.

2 Remove the base cover.

3 To remove the SATA SSD:

a Remove the M2.0x3.0 screw that secures the SSD [1].

b Slide and lift the SSD to disconnect it from the connector [2]. .

14

Removing and installing components

Page 15

Installing SATA SSD

1 Insert the SATA SSD card into the connector.

2 Tighten the screw to secure the SATA SSD to the system board.

3 Install the base cover.

4 Follow the procedure in After working inside your computer.

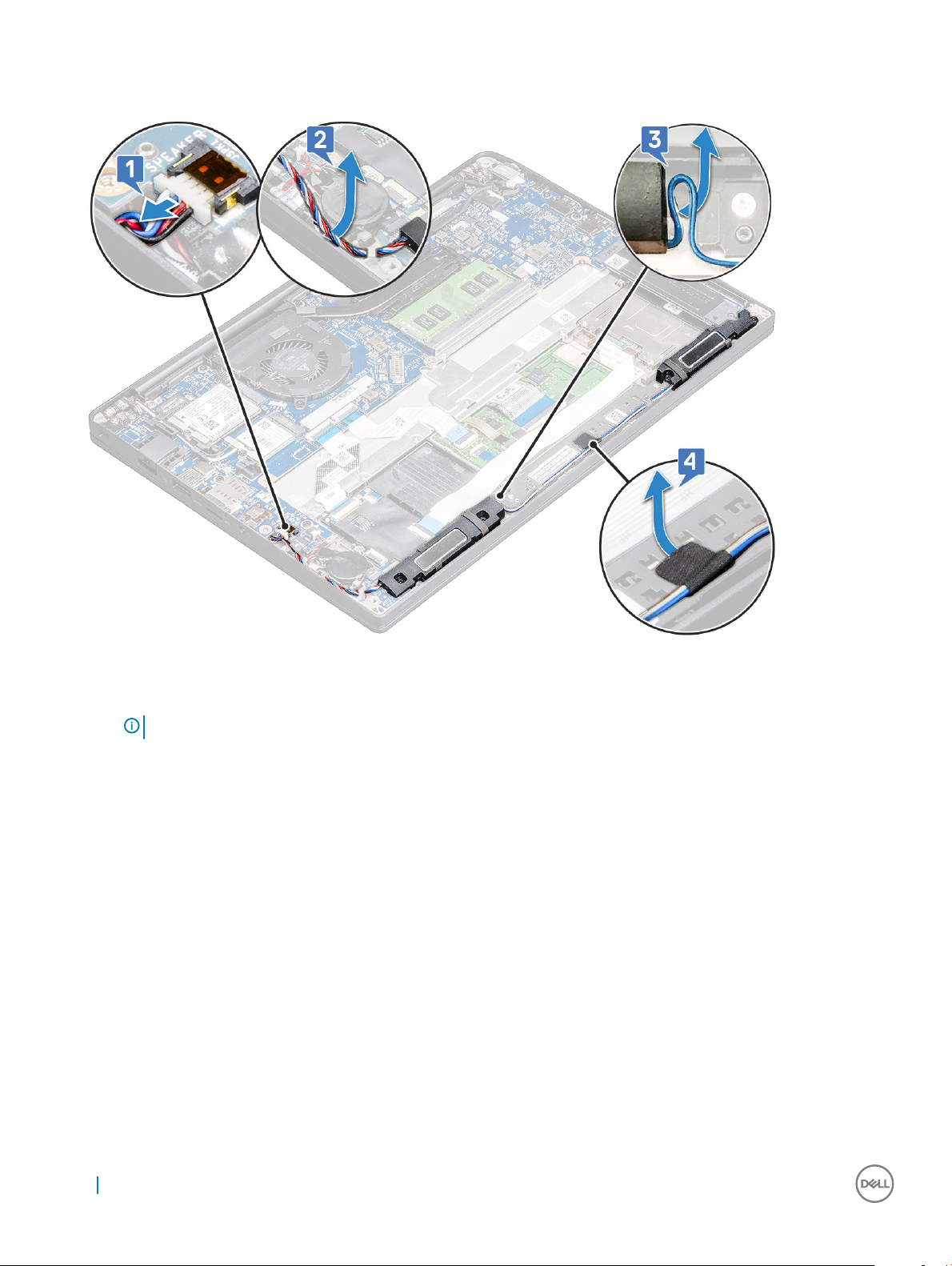

Speaker

Removing speaker module

1 Follow the procedure in Before working inside your computer.

2 Remove the:

a base cover

b battery

3 To release the speaker module:

a Push the pin to disconnect the speaker cable from the connector on the system board [1].

: Ensure to unroute the speaker cable from the routing clip.

NOTE

NOTE: Use a plastic scribe to release the cable from the connector. Do not pull the cable as it may result in breakage.

Removing and installing components 15

Page 16

b Un-route the speaker cable from the routing clips [2,3].

c Remove the tape that secures the speaker cables to the touchpad board [4].

4 To remove the speaker module:

a Remove the M2.0x3.0 screws (4) that secure the speaker module to the computer [1].

b Lift the speaker module from the computer [2].

NOTE

: Ensure to un-route the speaker cable from the routing clips.

16 Removing and installing components

Page 17

Installing speaker module

1 Place the speaker module into the slots on the computer.

2 Route the speaker cable through the retention clips on the computer.

3 Connect the speaker cable to the connector on the system board.

4 Install the:

a battery

b base cover

5 Follow the procedure in After working inside your computer.

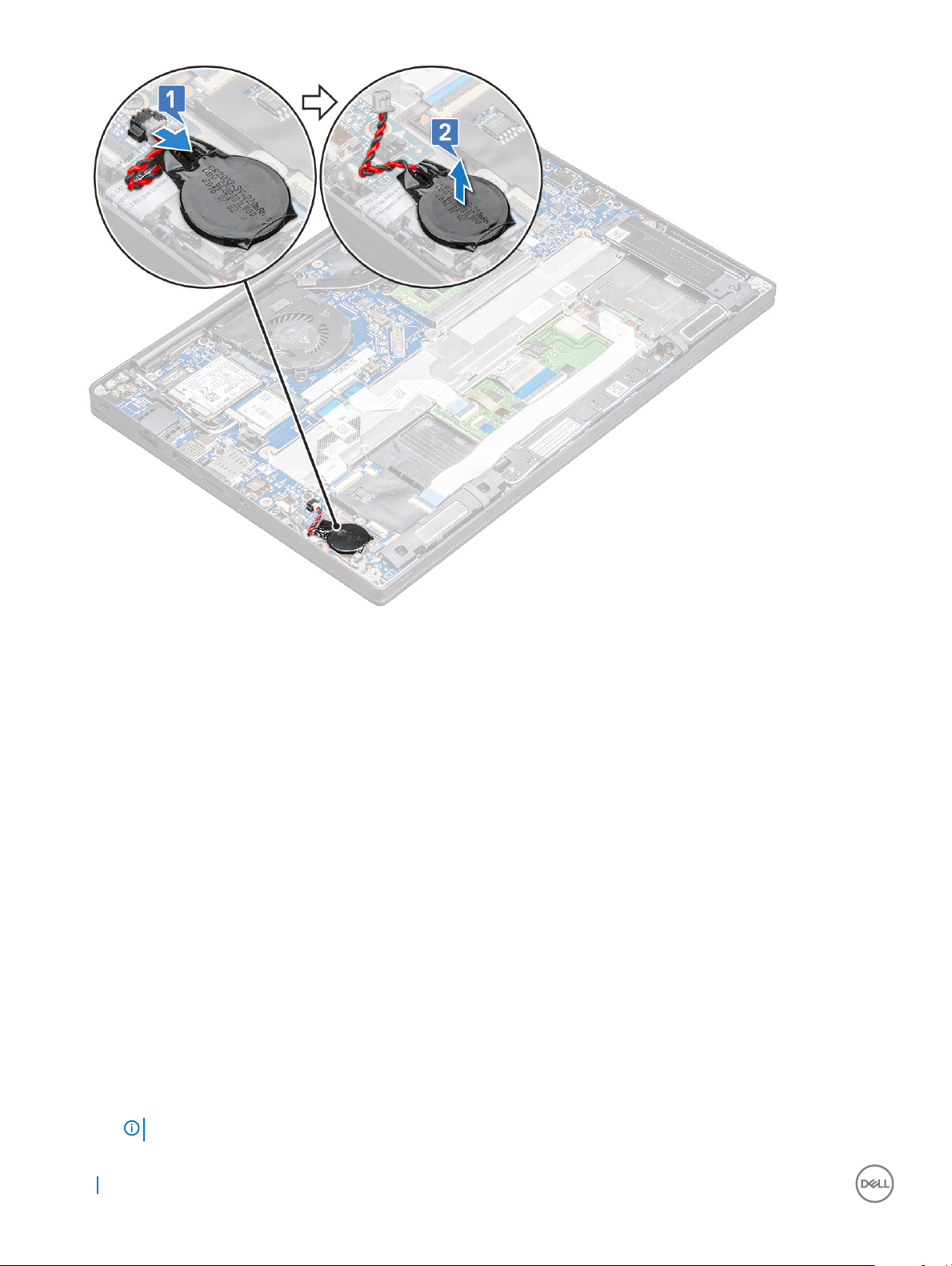

Coin cell battery

Removing the coin cell battery

1 Follow the procedure in Before working inside your computer.

2 Remove the :

a base cover

b battery

3 To remove the coin cell battery:

a Disconnect the coin cell battery cable from the connector on the system board [1].

b Lift the coin cell battery to release it from the adhesive [2].

Removing and installing components

17

Page 18

Installing coin cell battery

1 Ax the coin cell battery on the slot inside the computer.

2 Route the coin cell battery cable through the routing channel before connecting the cable.

3 Connect the coin cell battery cable to the connector on the system board.

4 Install the :

a battery

b base cover

5 Follow the procedure in After working inside your computer.

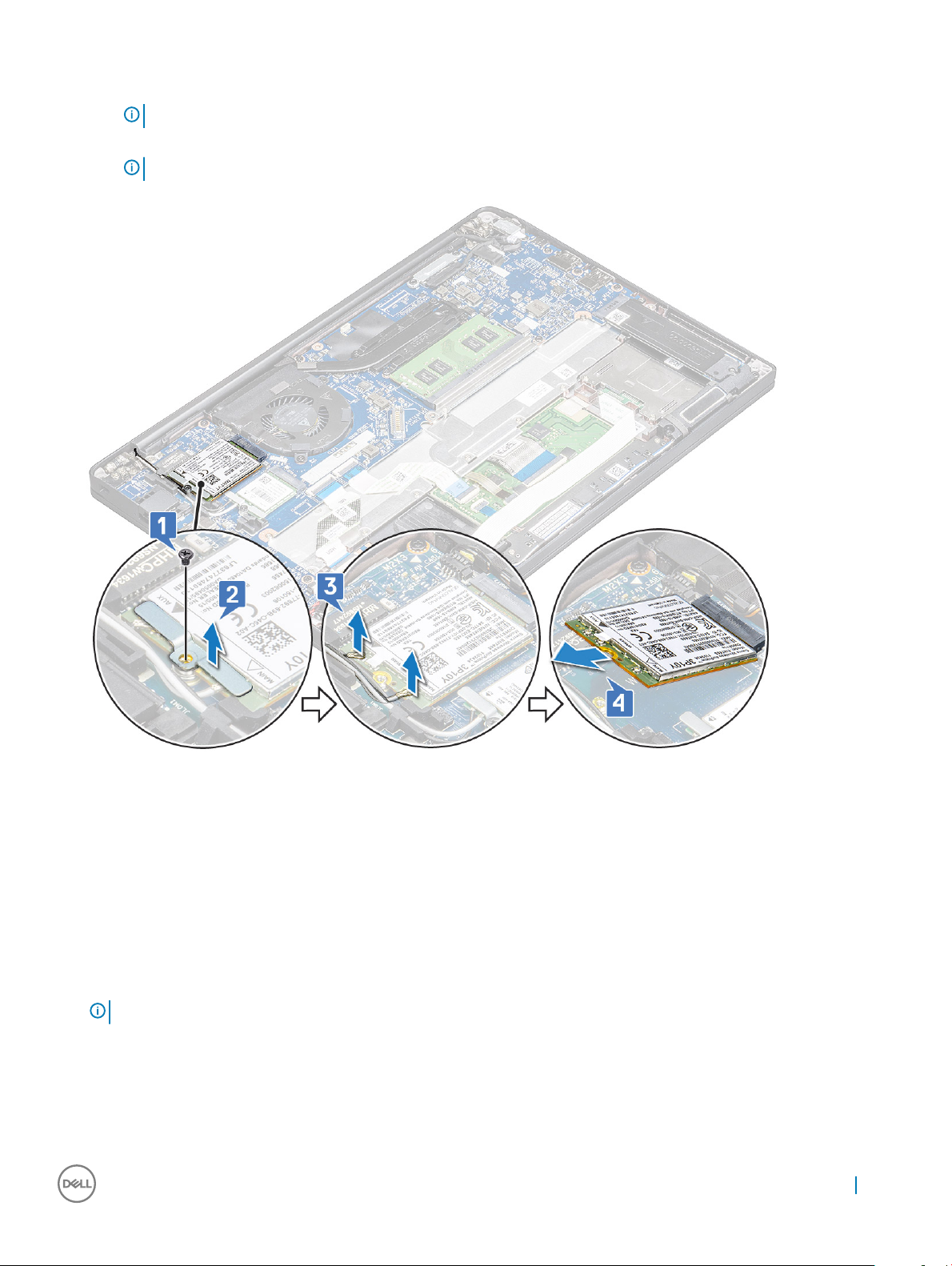

WWAN card

Removing WWAN card

1 Follow the procedure in Before working inside your computer.

2 Remove the :

a base cover

b battery

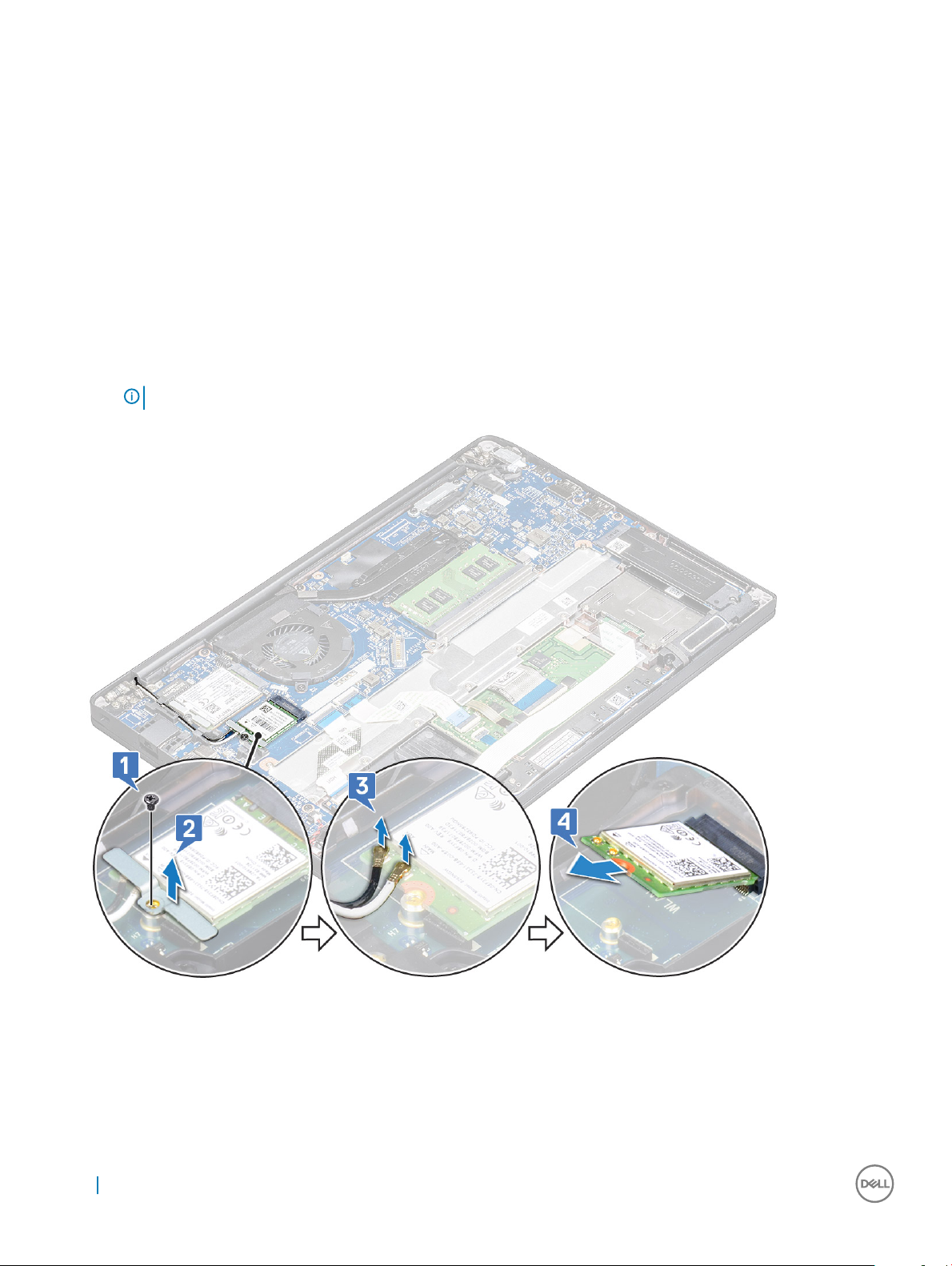

3 To remove the WWAN card:

a Remove the M2.0 x 3.0 screw that secures the metal bracket to the WWAN card [1].

: The WWAN card pops out by an angle 15°.

NOTE

18 Removing and installing components

Page 19

b Lift the metal bracket that secures the WWAN card [2].

c Disconnect the WWAN cables from the connectors on the WWAN card with a plastic scribe.[3].

NOTE: Ensure to press the WWAN card, and then release the cables from the connectors.

d Slide and lift the WWAN card from the connector on the system board [4].Lift the WWAN card from the computer .

NOTE: Ensure to lift the WWAN card by an angle NOT more than 35°.

Installing WWAN card

1 Insert the WWAN card into the connector on the system board.

2 Connect the WWAN cables to the connectors on the WWAN card.

3 Place the metal bracket and tighten the M2.0 x 3.0 screw to secure it to the computer.

4 Install the :

a battery

b base cover

5 Follow the procedure in After working inside your computer.

: The IMEI number can also be found on the WWAN card.

NOTE

Removing and installing components 19

Page 20

WLAN card

Removing WLAN card

1 Follow the procedure in Before working inside your computer.

2 Remove the :

a base cover

b battery

3 To remove the WLAN card:

a Remove the M2.0 x 3.0 screw that secures the metal bracket to the WLAN card [1].

b Lift the metal bracket [2].

c Disconnect the WLAN cables from the connectors on the WLAN card [3].

d Remove the WLAN card from the computer [4].

NOTE: Ensure NOT to pull the WLAN card more than 35°, to avoid damage to pin.

Installing WLAN card

1 Insert the WLAN card into the connector on the system board.

2 Connect the WLAN cables to the connectors on the WLAN card.

3 Place the metal bracket and tighten the M2.0 x 3.0 screw to secure it to the computer.

20

Removing and installing components

Page 21

4 Install the .:

a battery

b base cover

5 Follow the procedure in After working inside your computer.

Memory modules

Removing memory module

1 Follow the procedure in Before working inside your computer.

2 Remove the :

a base cover

b battery

3 To remove the memory module:

a Pull the clips securing the memory module until the module snaps-out [1].

b Remove the memory module from the connector on the system board [2].

NOTE: Ensure to lift the memory module card by an angle NOT more than 35°.

Removing and installing components 21

Page 22

Installing memory module

1 Insert the memory module into the connector until snaps in.

2 Install the :

a battery

b base cover

3 Follow the procedures in After working inside your computer.

Heat sink

Removing heat sink assembly

Heat sink assembly comprises of heat sink and the system fan.

1 Follow the procedure in Before working inside your computer.

2 Remove the :

a base cover

b battery

3 To remove the heat sink assembly:

NOTE

: To identify the number of screws, see screw list

a Disconnect the fan cable from the system board [1].

b Remove the M2.0 x 5.0 screws (6) that secure the heat sink assembly to the system board [2].

NOTE

: Perform the order of the callout numbers [1, 2, 3] as indicated on the heat sink.

c Lift the heat sink assembly from the system board [3].

22

Removing and installing components

Page 23

Installing heat sink assembly

Heat sink assembly comprises of heat sink and the system fan.

1 Align the heat sink assembly with screw holders on the system board and tighten the screws (4) to the system board.

2 Tighten the M2.0 x 5.0 screws to secure the fan to the system board

3 Connect the fan cable to the connector on the system board.

4 Install the :

a battery

b base cover

5 Follow the procedure in After working inside your computer.

Power connector port

Removing power connector port

1 Follow the procedure in Before working inside your computer.

2 Remove the :

a base cover

b battery

3 To remove the power connector port:

a Disconnect the power connector port cable from the system board [1].

: Ensure to remove the adhesive tape that covers the connector.

NOTE

NOTE: Use a plastic scribe to release the cable from the connector. Do not pull the cable as it may result in breakage

Removing and installing components 23

Page 24

b Remove the M2.0x3.0 screw (1) to release the metal bracket on the power connector port [2].

c Lift the metal bracket from the computer [3].

d Remove the power connector port from the computer [4].

Installing power connector port

1 Install the power connector port into the slot on the computer.

2 Place the metal bracket on the power connector port.

3 Tighten the M2.0x3.0 screw to secure the power connector port to the computer.

4 Connect the power connector port cable to the connector on the system board.

5 Install the :

a battery

b base cover

6 Follow the procedure in After working inside your computer.

LED board

Removing LED board

1 Follow the procedure in Before working inside your computer.

2 Remove the :

a base cover

b battery

24

Removing and installing components

Page 25

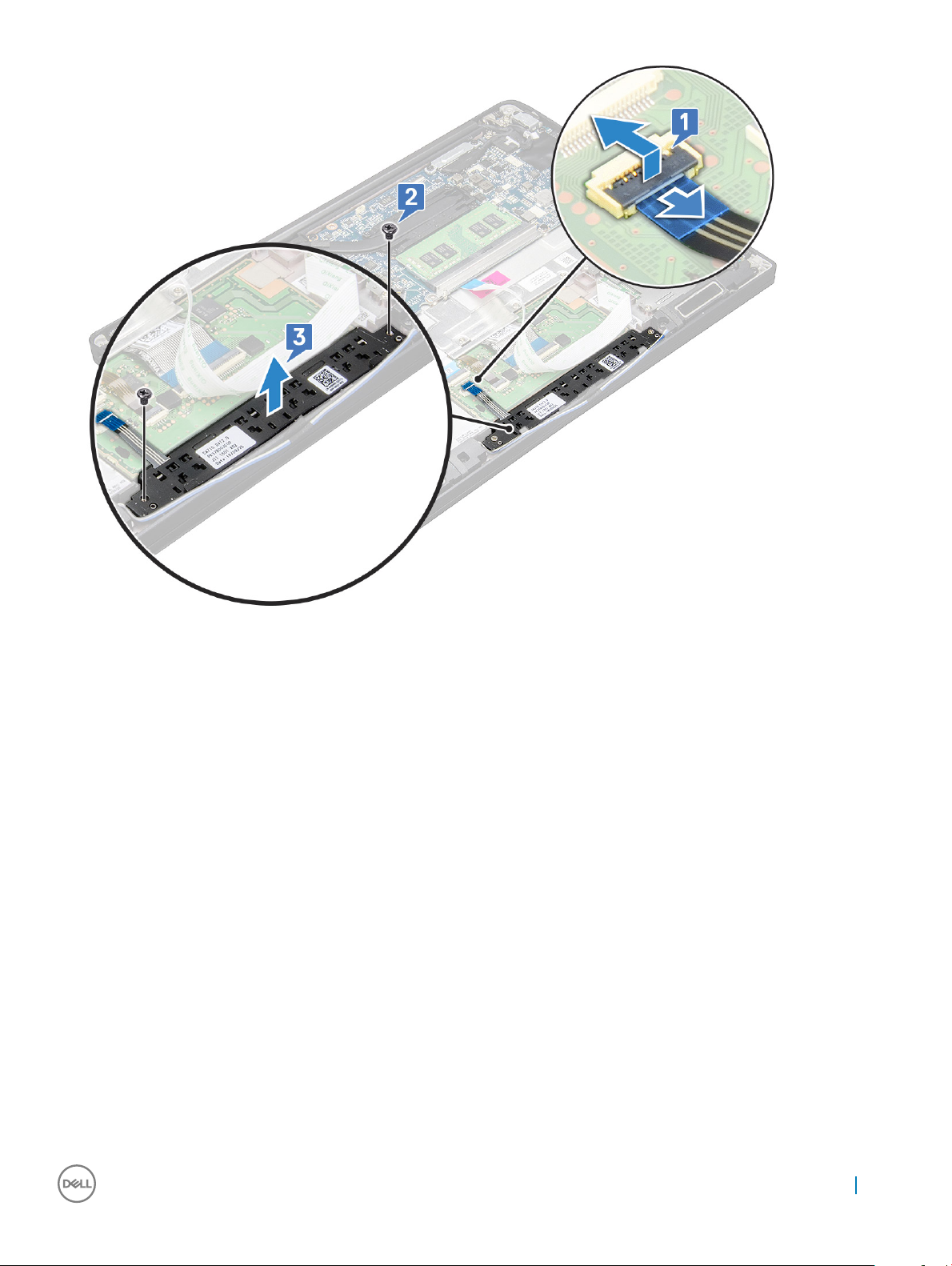

3 To remove the LED board:

a Disconnect the LED cable from the LED board [1].

CAUTION: Avoid pulling the cable as it would result in breaking the cable connector. Instead, use a scribe to release

the LED cable from its connector.

b Unroute the LED cable from the routing channel [2].

c Remove the M2.0 x 2.5 (1) screw that secures the LED board to the computer [3]

d Lift the LED board from the computer [4].

Installing LED board

1 Insert the LED board into the slot on the computer.

2 Tighten the screw to secure the LED board.

3 Connect the LED cable to the LED board.

4 Install the :

a battery

b base cover

5 Follow the procedure in After working inside your computer.

Removing and installing components

25

Page 26

Smart card module

Removing smart card cage

1 Follow the procedure in Before working inside your computer.

2 Remove the:

a base cover

b battery

c PCIe SSD card

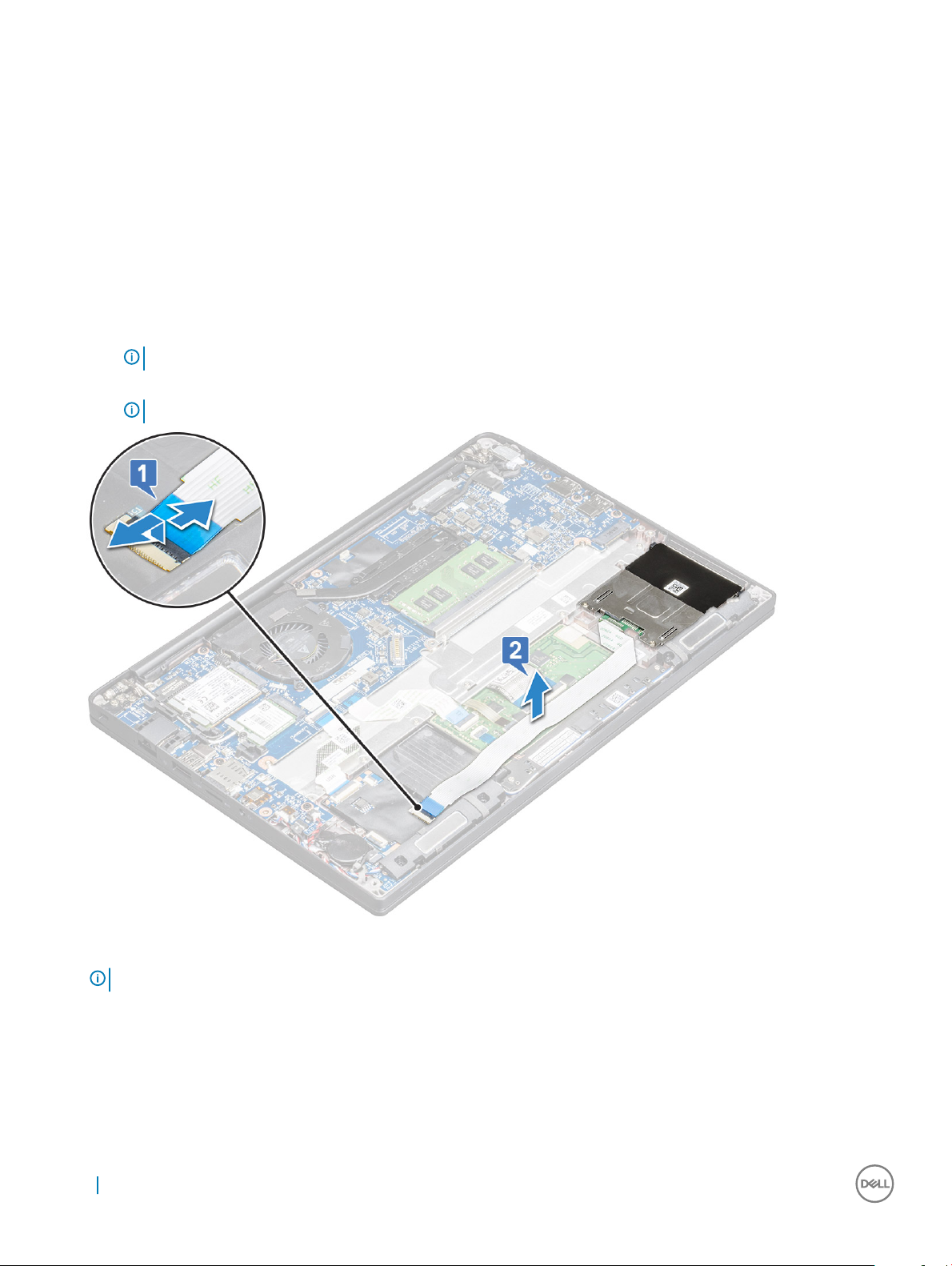

3 To disconnect the smart card cable:

a Disconnect the smart card cable [1].

NOTE: Ensure to gently push the connector, to avoid damage to the smart card head.

b Lift the smart card cable that is axed to the touchpad module [2].

NOTE: Ensure to pull gently to release it with adhesive tape.

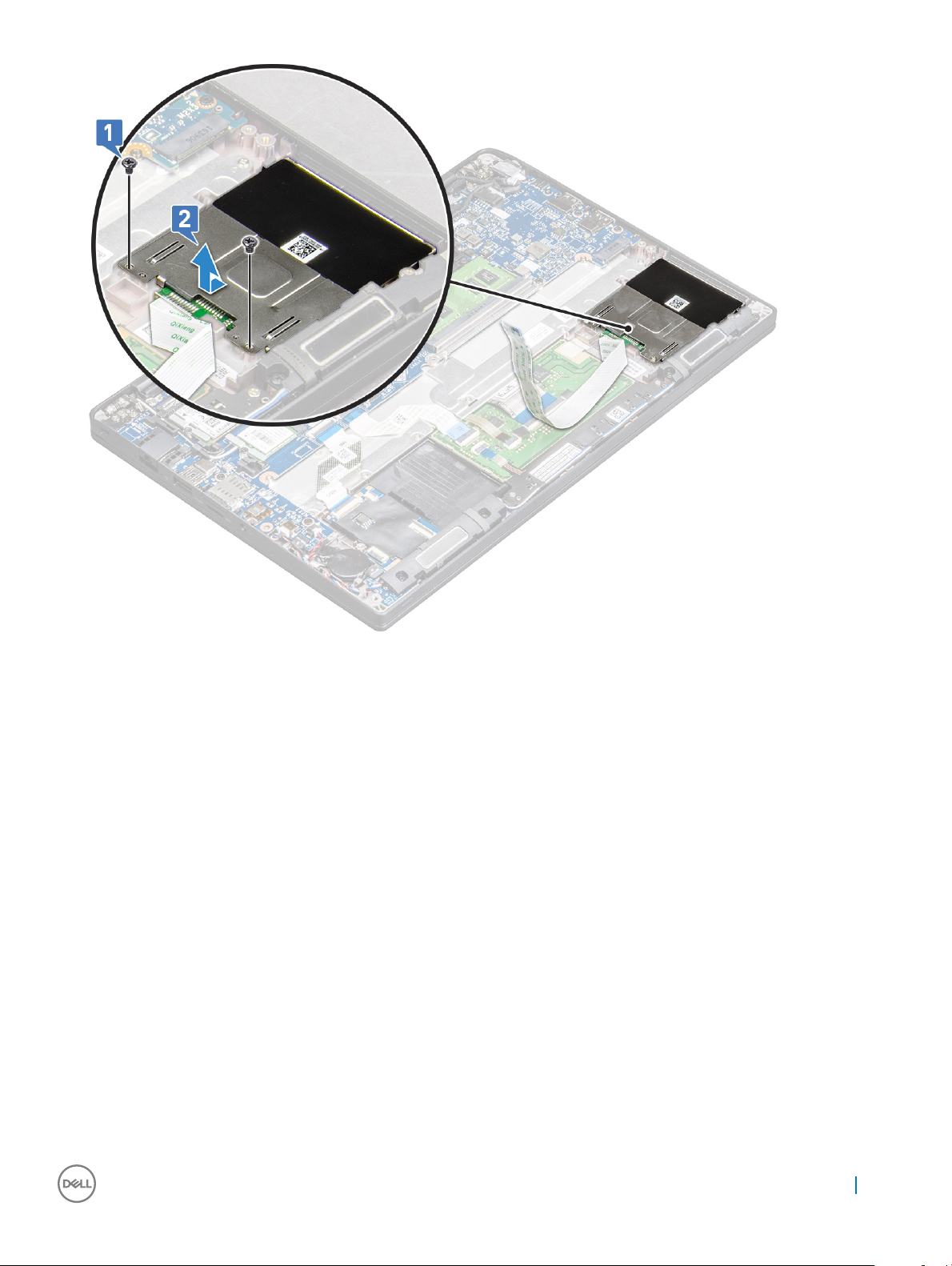

4 To remove the smart card cage:

: To identify the number of screws, see screw list

NOTE

a Remove the M2.0 x 3.0 screws (2) that secure the smart card cage to the computer [1].

b Slide and lift the smart card cage from the computer [2].

26

Removing and installing components

Page 27

Installing smart card cage

1 Slide the smart card cage into the slot to align with the tabs on the computer.

2 Tighten the M2.0 x 3.0 screws to secure the smart card cage to the computer.

3 Ax the smart card cable and connect it to the connector on the computer .

4 Install the:

a PCIe SSD card

b battery

c base cover

5 Follow the procedure in After working inside your computer.

Touchpad buttons board

Removing touchpad buttons board

1 Follow the procedure in Before working inside your computer.

2 Remove the:

a base cover

b battery

c speaker

Removing and installing components

27

Page 28

3 To disconnect the smart card cable:

a Disconnect the smart card cable [1].

b Lift the smart card cable that is axed to the computer [2] to reveal the touchpad buttons board cable.

c Remove the adhesive tape that secures the speaker cable to the touchpad panel [3].

4 To remove the touchpad buttons board:

a Disconnect the touchpad buttons board cable from the touchpad board [1].

NOTE

: The touchpad buttons board cable is below the smart card cable. Ensure to lift the latch, to release the

touchpad button board cable.

b Remove M2.0 x 2.5 screws (2) that secure the touchpad buttons board [2].

c Lift the touchpad buttons board from the computer [3].

28

Removing and installing components

Page 29

Installing touchpad buttons board

1 Insert the touchpad buttons board into the slot to align the tabs with the grooves on the computer.

2 Tighten the screws to secure the touchpad buttons board to the computer.

3 Connect the touchpad buttons board cable to the connector on the touchpad board.

4 Ax the smart card cable and connect it to the connector on the computer

5 Install the:

a speaker

b battery

c base cover

6 Follow the procedure in After working inside your computer.

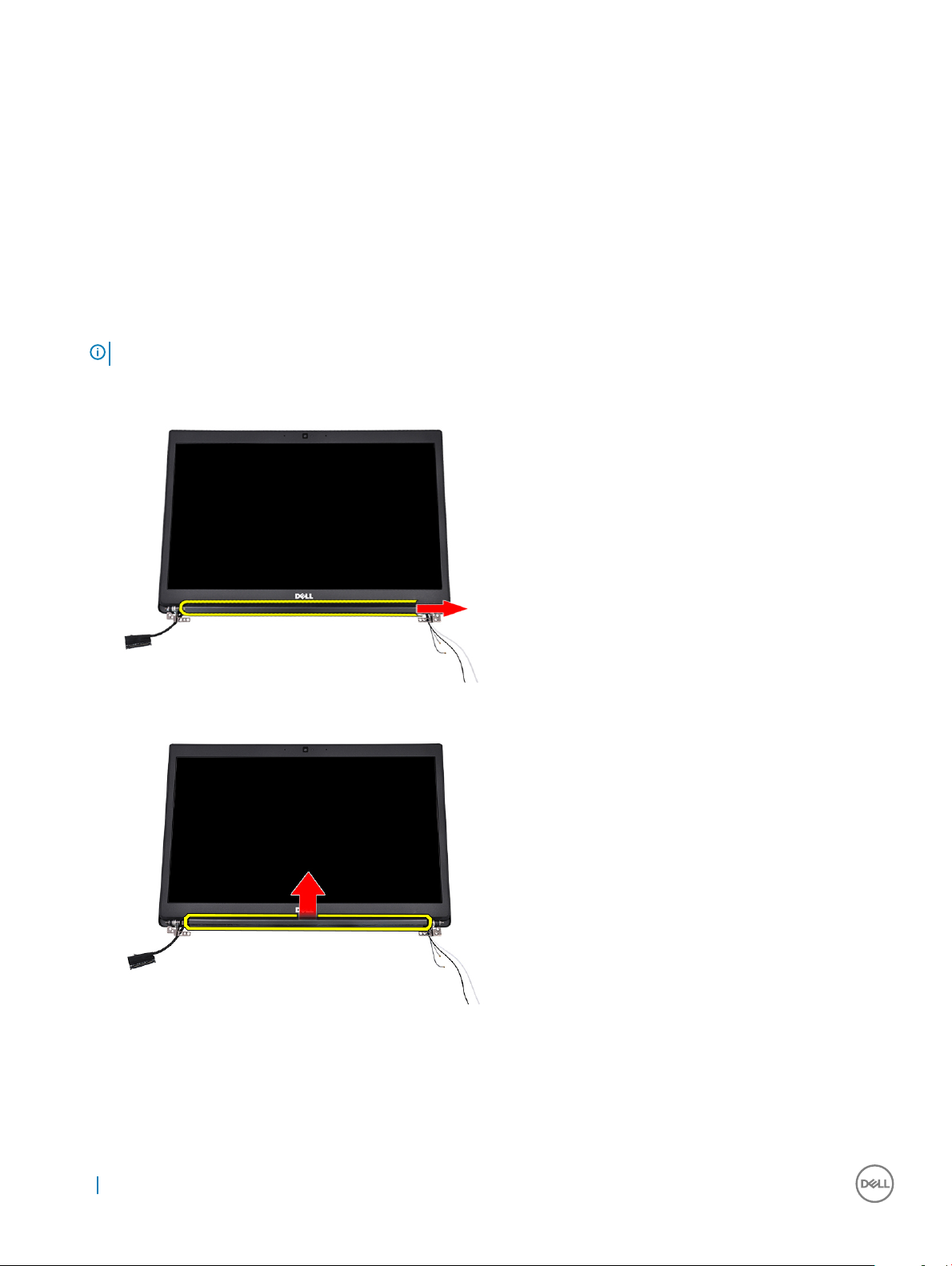

Display Assembly

Removing display assembly

1 Follow the procedure in Before working inside your computer.

2 Remove the:

a base cover

b battery

c WLAN card

Removing and installing components

29

Page 30

d WWAN card

NOTE: To identify the number of screws, see screw list

3 To remove the display assembly:

a Unroute the WLAN and WWAN cables from the routing channels [1].

b Remove the M2.0 x 5.0 screws that secures the eDP bracket [2].

c Lift the eDP bracket from the eDP cable [3].

d Disconnect the eDP cable from its connector on the system board [4].

NOTE: In touch-conguration system, you need to remove the touch display cable connected to its connector on the

system board.

e Remove the adhesive tape that secures the eDP cable [5].

NOTE: In touch-conguration system you will nd both eDP cable and touch display cable secured with adhesive

tape.

f Disconnect the cable from its connector on the system board [6].

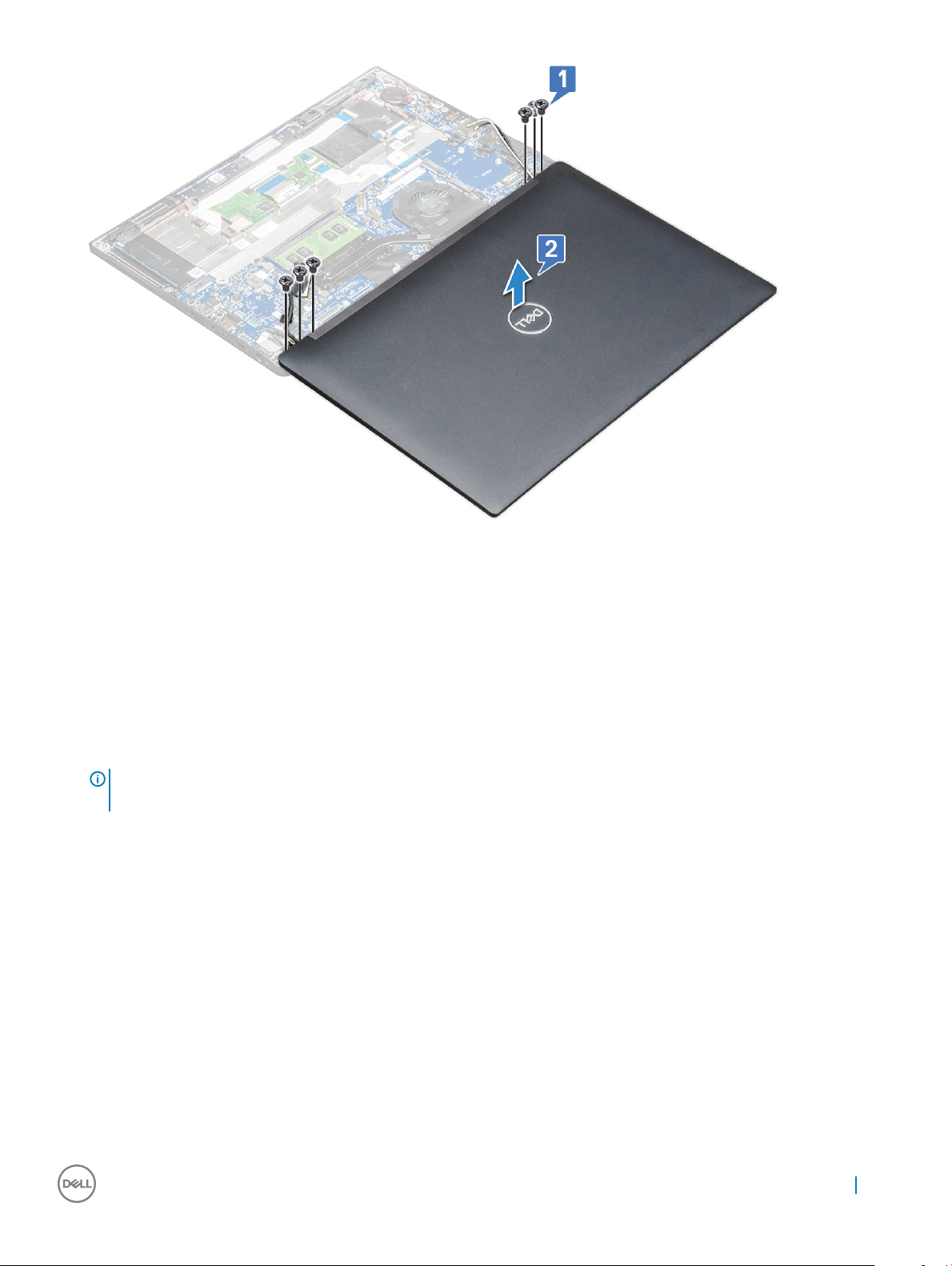

4 To remove the display assembly:

a Open the display of the computer and lay it on a at surface at 180 degree angle

b Remove the M2.5 x 4.0 screws (6) that secure the display hinge to the display assembly [1].

c Lift the display assembly from the computer [2].

30

Removing and installing components

Page 31

Installing display assembly

1 Place the base of the computer on a plane surface of a table and position it closer to the edge of the table.

2 Install the display assembly to align it with the display hinge holders on the system.

3 Holding the display assembly, tighten the M2.5 x 4.0 screws to secure the display hinges on the system display assembly with the

system unit.

4 Ax the tapes to secure the eDP cable (display cable).

For touch-conguration system you will see touch display cable, secure it with tapes along with the eDP cable.

5 Connect the eDP cable to the connector on the system board.

NOTE

: For touch-conguration system, connect the touch display cable to its connector on the system

board.

6 Install the eDP metal bracket on the eDP cable and tighten the M2.0 x 5.0 screws.

7 Route the WLAN and WWAN cables through the routing channels.

8 Install the:

a WLAN card

b WWAN card

c battery

d base cover

9 Follow the procedure in After working inside your computer.

Removing and installing components

31

Page 32

Display hinge cap

Removing display hinge Cap

1 Follow the procedure in Before working inside your computer.

2 Remove the:

a base cover

b battery

c WLAN card

d WWAN card

e display assembly

NOTE: To identify the number of screws, see screw list

3 Push the display hinge cap to the right.

4 Remove the display hinge cap.

Installing display hinge Cap

1 Insert the display hinge cap to the display assembly.

2 Push the display hinge cap to the left to secure it.

32

Removing and installing components

Page 33

3 Install the:

a display assembly

b WLAN card

c WWAN card

d battery

e base cover

4 Follow the procedure in After working inside your computer.

System board

Removing system board

1 Follow the procedure in Before working inside your computer.

1 If your computer is shipped with a WWAN card, then the removal of a blank SIM card tray is a requirement.

2 Remove the:

a SIM card

b base cover

c battery

d memory module

e PCle SSD

f WLAN card

g WWAN card

h heat sink assembly

2 To identify the screws, see screw list

3 To remove the memory module bracket:

a Remove the M2.0 x 3.0 screws (2) that secure memory module bracket to the system board [1].

b Lift the memory module bracket from the system board [2].

Removing and installing components

33

Page 34

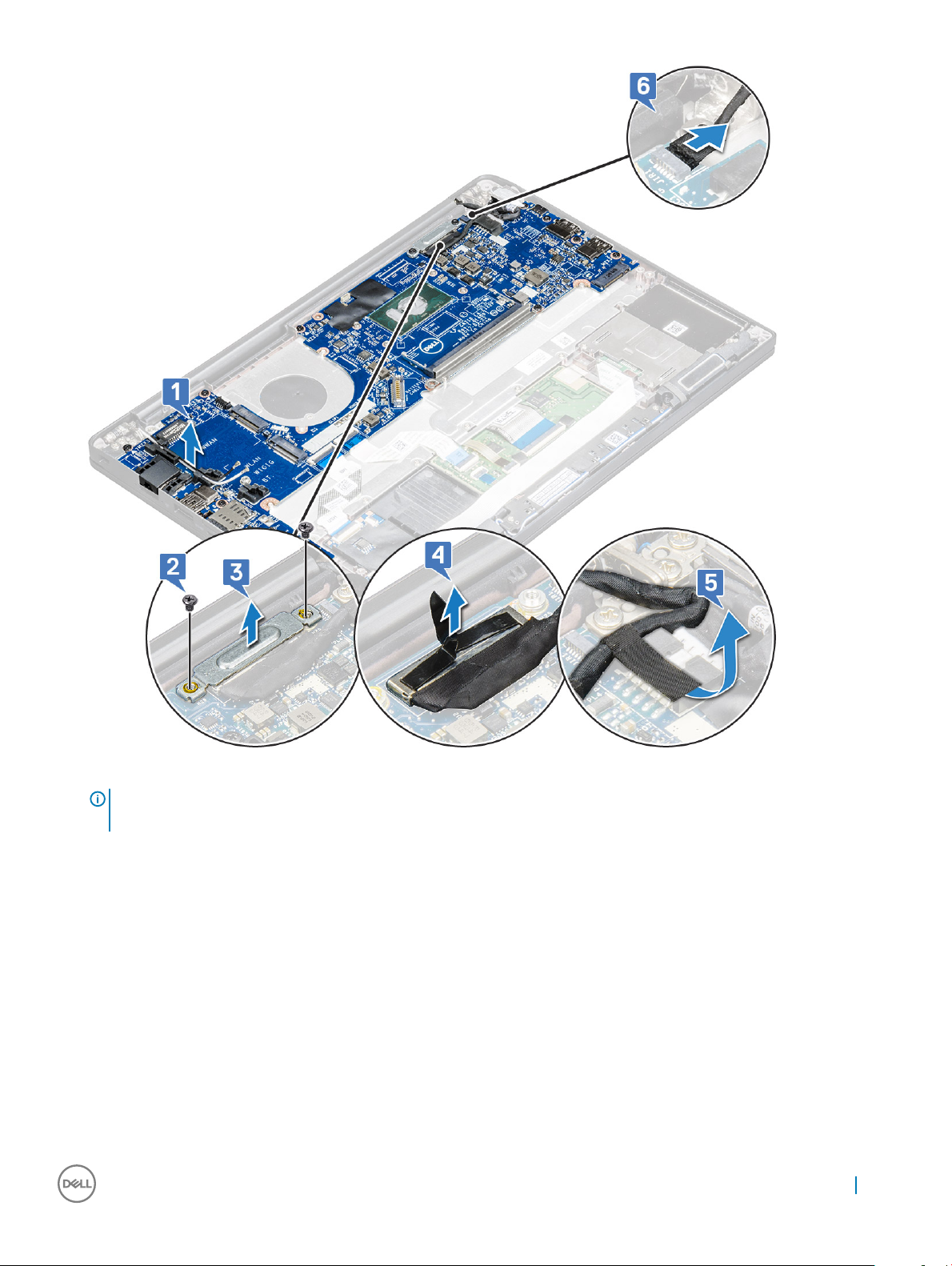

4 To disconnect the eDP cable:

a Un route the WLAN and WWAN cables from the routing channels [1].

b Remove the M2.0 x 3.0 screw (2) and lift the eDP cable bracket that secures to the system board [2,3].

c Disconnect the clip that secures the cable to the system board [4].

d Remove the adhesive tape that secures the eDP cable [5].

e Disconnect the eDP cable from the system board [6].

34

Removing and installing components

Page 35

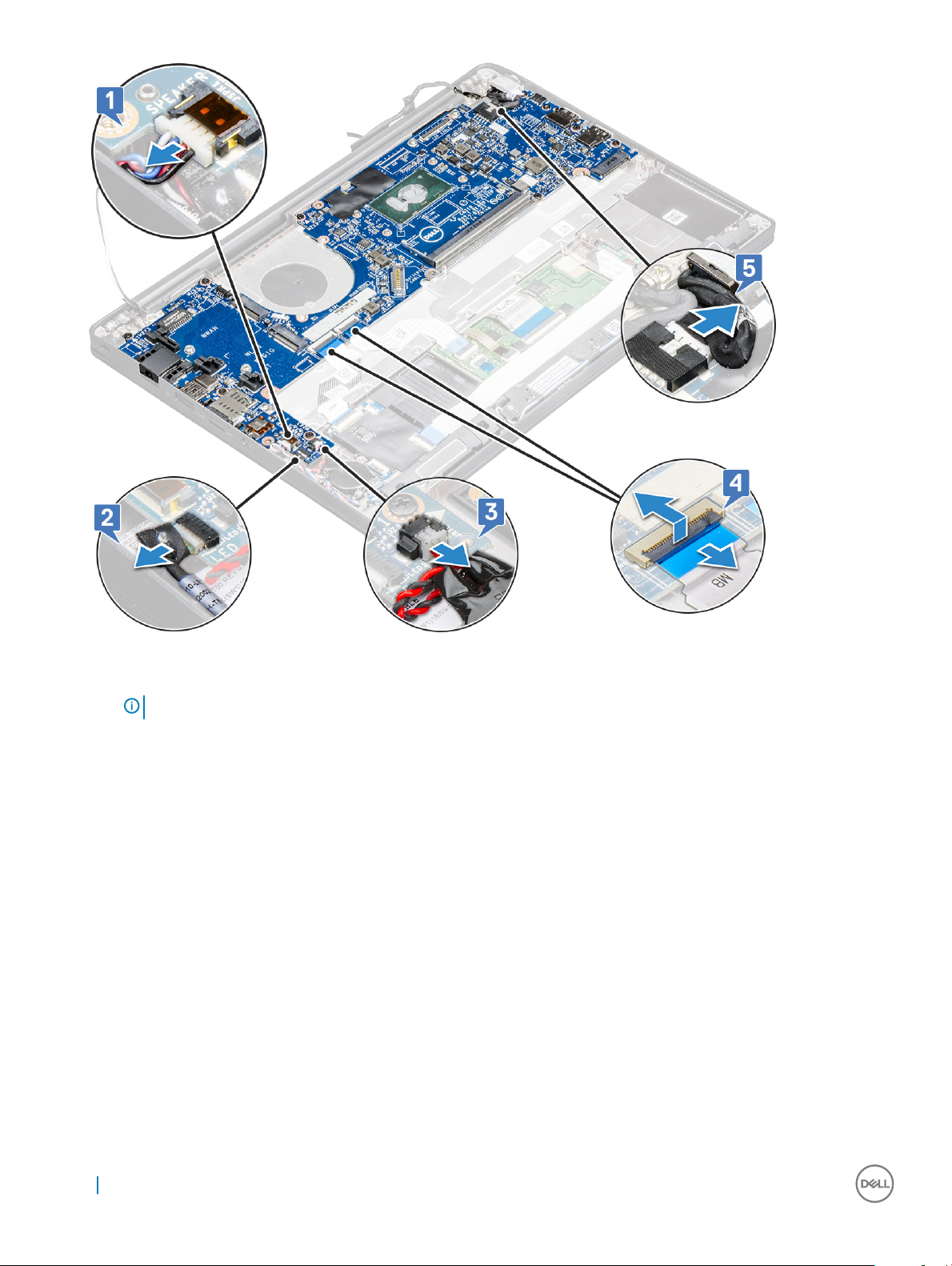

5 To disconnect the cables:

NOTE

: To disconnect the speaker, LED board, coin cell battery and the power connector port cables, use a plastic scribe to

release the cables from the connectors. Do not pull the cable as it may result in breakage

a speaker cable [1]

b LED board cable [2]

c coin cell battery cable [3]

d touchpad cable and USH board cable [4]

e power connector port [5]

Removing and installing components

35

Page 36

6 To remove the system board:

a Remove the M2.0x5.0 screws (8) that secure the USB Type-C bracket [1].

NOTE

: Image does not display the USB type-C bracket removal.

b Flip the system board, peel o the tapes securing the bracket and remove the USB Type-C port from the system board.

c Lift the system board away from the computer [2].

36

Removing and installing components

Page 37

Installing system board

1 Place the USB Type-C port along with the bracket in the slot on the system board.

2 Ax the tape to secure the Type-C port bracket.

3 Flip the system board and tighten the M2.0x5.0 screws to secure the USB type-C port.

4 Align the system board with the screw holders on the computer.

5 Tighten the M2.0 x 5.0 screws to secure the system board to the computer.

6 Connect the speaker, power connector, LED board, touchpad, and USH cables to the connectors on the system board.

7 Connect the eDP cable to the connector on the system board.

8 Place the metal bracket over the eDP cable and tighten the to secure it.

9 Remove the metal bracket from the memory module connectors of the system board that was removed.

10 Place the metal bracket over the memory module connectors and tighten the M2.0 x 3.0 screws to secure it to the computer.

: If your computer has a WWAN card, then SIM card tray installation is a requirement.

NOTE

11 Install the:

a coin cell battery

b heat sink

c WLAN card

d WWAN card

e SSD card

f memory module

g speaker

h battery

Removing and installing components

37

Page 38

i base cover

12 Follow the procedure in After working inside your computer.

Keyboard assembly

Removing keyboard assembly

NOTE: The keyboard and the keyboard tray together are called the keyboard assembly.

1 Follow the procedure in Before working inside your computer.

2 Remove:

a base cover

b battery

c memory module

d PCIe SSD

e WLAN card

f WWAN card

g heat sink assembly

h system board

3 Disconnect the cables from the palmrest end:

a touchpad and USH board cables [1]

b keyboard backlight cable [2]

c keyboard cable [3]

4 To remove the keyboard assembly:

38

Removing and installing components

Page 39

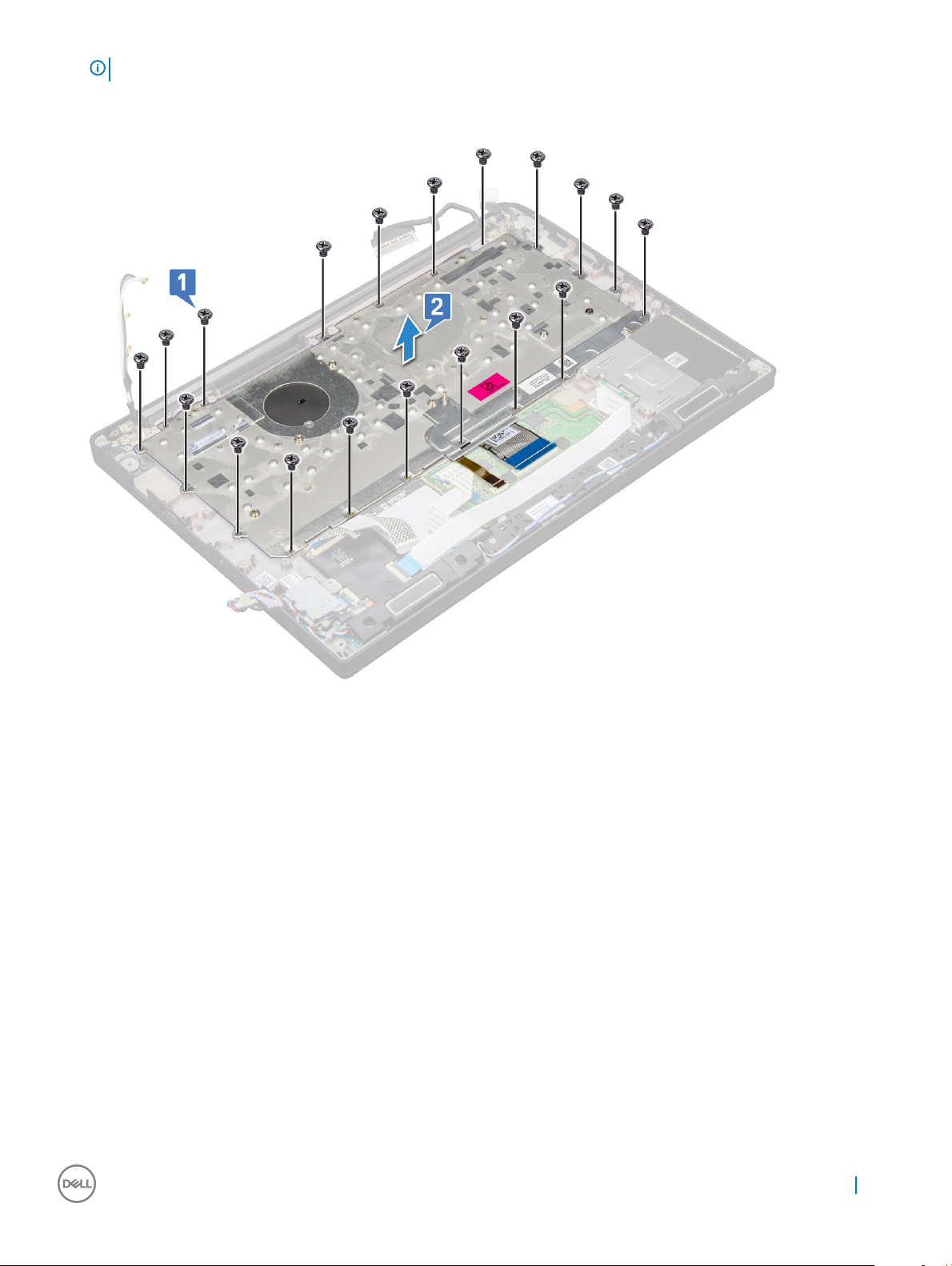

NOTE: To identify the screws, see screw list

a Remove the M2.0 x 2.5 screws (19) that secure the keyboard [1].

b Lift the keyboard assembly from the chassis [2].

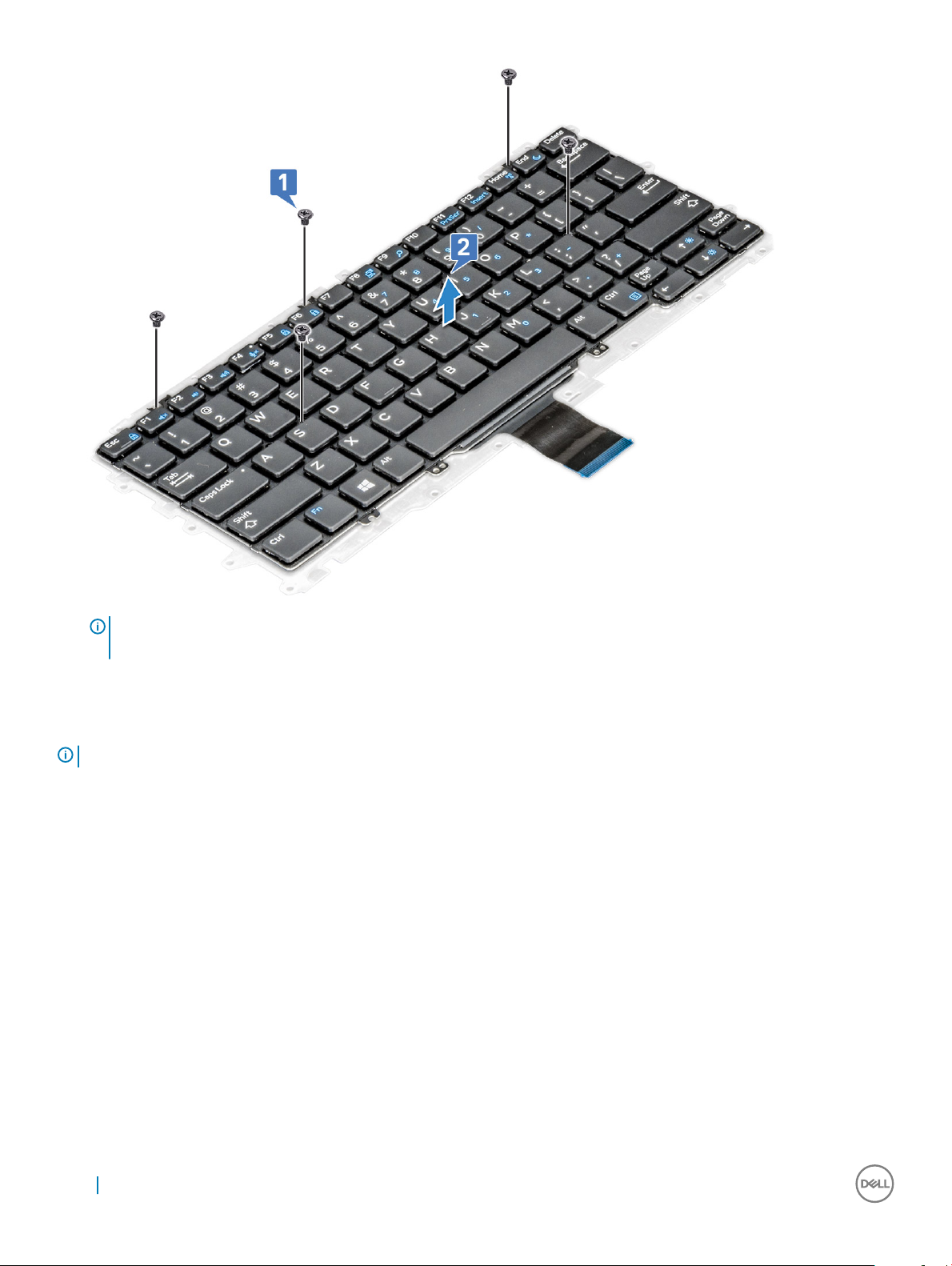

5 Remove the screws (5) that secures the keypad to the keyboard chassis and lift the keyboard [1,2].

Removing and installing components

39

Page 40

NOTE: Remove the keyboard chassis when you encounter malfunction in the keyboard, after validating with a working

laptop.

Installing keyboard assembly

: The keyboard and the keyboard tray together are called the keyboard assembly.

NOTE

1 Align the keyboard assembly with the screw holders on the computer.

2 Tighten the M2.0 x 2.5 screws that secure the keyboard to the chassis.

3 Connect the keyboard cable, keyboard backlight cable, touchpad cable cable to the connectors on the touchpad buttons board.

4 Install the:

a system board

b heat sink

c WLAN card

d WWAN card

e SSD card

f memory module

g battery

h base cover

5 Follow the procedure in After working inside your computer.

40

Removing and installing components

Page 41

Keyboard

Removing keyboard from keyboard tray

1 Follow the procedure in Before working inside your computer.

2 Remove the keyboard assembly

3 Remove the M2.0 x 2.0 screws that secure the keyboard to the keyboard assembly [1].

4 Lift the keyboard away from the keyboard tray [2].

Installing keyboard to keyboard tray

1 Align the keyboard with the screw holders on the keyboard tray.

2 Tighten the M2.0 x 2.0 screws to secure the keyboard to the keyboard tray.

3 Install the keyboard assembly.

Removing and installing components

41

Page 42

Palm rest

Replacing palm rest

1 Follow the procedure in Before working inside your computer.

2 Remove the:

a base cover

b battery

c memory module

d PCIe SSD

e WLAN card

f WWAN card

g power connector port

h heat sink assembly

i coin cell battery

j speaker

k display assembly

l system board

m keyboard

The component you are left with is the palm rest.

3 Replace the palm rest.

4 Install the:

a keyboard

b system board

c display assembly

42

Removing and installing components

Page 43

d speaker

e coin cell battery

f heatsink

g power connector port

h WLAN card

i WWAN card

j PCIe SSD

k memory

l battery

m base cover

5 Follow the procedure in After working inside your computer.

Removing and installing components 43

Page 44

Technology and components

This chapter details the technology and components available in the system.

Topics:

• USB features

• HDMI 1.4

USB features

Universal Serial Bus, or USB, was introduced in 1996. It dramatically simplied the connection between host computers and peripheral

devices like mice, keyboards, external drivers, and printers.

Let's take a quick look on the USB evolution referencing to the table below.

Table 2. USB evolution

Type Data Transfer Rate Category Introduction Year

USB 3.0/USB 3.1 Gen 1 5 Gbps Super Speed 2010

3

USB 2.0 480 Mbps High Speed 2000

USB 3.0/USB 3.1 Gen 1 (SuperSpeed USB)

For years, the USB 2.0 has been rmly entrenched as the de facto interface standard in the PC world with about 6 billion devices sold, and

yet the need for more speed grows by ever faster computing hardware and ever greater bandwidth demands. The USB 3.0/USB 3.1 Gen 1

nally has the answer to the consumers' demands with a theoretically 10 times faster than its predecessor. In a nutshell, USB 3.1 Gen 1

features are as follows:

• Higher transfer rates (up to 5 Gbps)

• Increased maximum bus power and increased device current draw to better accommodate power-hungry devices

• New power management features

• Full-duplex data transfers and support for new transfer types

• Backward USB 2.0 compatibility

• New connectors and cable

The topics below cover some of the most commonly asked questions regarding USB 3.0/USB 3.1 Gen 1.

Speed

Currently, there are 3 speed modes dened by the latest USB 3.0/USB 3.1 Gen 1 specication. They are Super-Speed, Hi-Speed and FullSpeed. The new SuperSpeed mode has a transfer rate of 4.8Gbps. While the specication retains Hi-Speed, and Full-Speed USB mode,

44 Technology and components

Page 45

commonly known as USB 2.0 and 1.1 respectively, the slower modes still operate at 480Mbps and 12Mbps respectively and are kept to

maintain backward compatibility.

USB 3.0/USB 3.1 Gen 1 achieves the much higher performance by the technical changes below:

• An additional physical bus that is added in parallel with the existing USB 2.0 bus (refer to the picture below).

• USB 2.0 previously had four wires (power, ground, and a pair for dierential data); USB 3.0/USB 3.1 Gen 1 adds four more for two pairs

of dierential signals (receive and transmit) for a combined total of eight connections in the connectors and cabling.

• USB 3.0/USB 3.1 Gen 1 utilizes the bidirectional data interface, rather than USB 2.0's half-duplex arrangement. This gives a 10-fold

increase in theoretical bandwidth.

With today's ever increasing demands placed on data transfers with high-denition video content, terabyte storage devices, high megapixel

count digital cameras etc., USB 2.0 may not be fast enough. Furthermore, no USB 2.0 connection could ever come close to the 480Mbps

theoretical maximum throughput, making data transfer at around 320Mbps (40MB/s) — the actual real-world maximum. Similarly, USB

3.0/USB 3.1 Gen 1 connections will never achieve 4.8Gbps. We will likely see a real-world maximum rate of 400MB/s with overheads. At this

speed, USB 3.0/USB 3.1 Gen 1 is a 10x improvement over USB 2.0.

Applications

USB 3.0/USB 3.1 Gen 1 opens up the laneways and provides more headroom for devices to deliver a better overall experience. Where USB

video was barely tolerable previously (both from a maximum resolution, latency, and video compression perspective), it's easy to imagine

that with 5-10 times the bandwidth available, USB video solutions should work that much better. Single-link DVI requires almost 2Gbps

throughput. Where 480Mbps was limiting, 5Gbps is more than promising. With its promised 4.8Gbps speed, the standard will nd its way

into some products that previously weren't USB territory, like external RAID storage systems.

Listed below are some of the available SuperSpeed USB 3.0/USB 3.1 Gen 1 products:

• External Desktop USB 3.0/USB 3.1 Gen 1 Hard Drives

• Portable USB 3.0/USB 3.1 Gen 1 Hard Drives

• USB 3.0/USB 3.1 Gen 1 Drive Docks & Adapters

• USB 3.0/USB 3.1 Gen 1 Flash Drives & Readers

• USB 3.0/USB 3.1 Gen 1 Solid-state Drives

• USB 3.0/USB 3.1 Gen 1 RAIDs

• Optical Media Drives

• Multimedia Devices

• Networking

• USB 3.0/USB 3.1 Gen 1 Adapter Cards & Hubs

Technology and components

45

Page 46

Compatibility

The good news is that USB 3.0/USB 3.1 Gen 1 has been carefully planned from the start to peacefully co-exist with USB 2.0. First of all,

while USB 3.0/USB 3.1 Gen 1 species new physical connections and thus new cables to take advantage of the higher speed capability of

the new protocol, the connector itself remains the same rectangular shape with the four USB 2.0 contacts in the exact same location as

before. Five new connections to carry receive and transmitted data independently are present on USB 3.0/USB 3.1 Gen 1 cables and only

come into contact when connected to a proper SuperSpeed USB connection.

Windows 8/10 will be bringing native support for USB 3.1 Gen 1 controllers. This is in contrast to previous versions of Windows, which

continue to require separate drivers for USB 3.0/USB 3.1 Gen 1 controllers.

Microsoft announced that Windows 7 would have USB 3.1 Gen 1 support, perhaps not on its immediate release, but in a subsequent Service

Pack or update. It is not out of the question to think that following a successful release of USB 3.0/USB 3.1 Gen 1 support in Windows 7,

SuperSpeed support would trickle down to Vista. Microsoft has conrmed this by stating that most of their partners share the opinion that

Vista should also support USB 3.0/USB 3.1 Gen 1.

Super-Speed support for Windows XP is unknown at this point. Given that XP is a seven-year-old operating system, the likelihood of this

happening is remote.

Thunderbolt over USB Type-C

Thunderbolt is a hardware interface that combines data, video, audio, and power in a single connection. Thunderbolt combines PCI Express

(PCIe) and DisplayPort (DP) into one serial signal, and additionally provides DC power, all in one cable. Thunderbolt 1 and Thunderbolt 2 use

the same connector [1] as miniDP (DisplayPort) to connect to peripherals, while Thunderbolt 3 uses a USB Type-C connector [2].

Figure 1. Thunderbolt 1 and Thunderbolt 3

1 Thunderbolt 1 and Thunderbolt 2 (using a miniDP connector)

2 Thunderbolt 3 (using a USB Type-C connector)

Thunderbolt 3 over USB Type-C

Thunderbolt 3 brings Thunderbolt to USB Type-C at speeds up to 40 Gbps, creating one compact port that does it all - delivering the

fastest, most versatile connection to any dock, display or data device like an external hard drive. Thunderbolt 3 uses a USB Type-C

connector/port to connect to supported peripherals.

1 Thunderbolt 3 uses USB Type-C connector and cables - It is compact and reversible

2 Thunderbolt 3 supports speed up to 40 Gbps

3 DisplayPort 1.2 – compatible with existing DisplayPort monitors, devices and cables

4 USB Power Delivery - Up to 130W on supported computers

46

Technology and components

Page 47

Key Features of Thunderbolt 3 over USB Type-C

1 Thunderbolt, USB, DisplayPort and power on USB Type-C on a single cable (features vary between dierent products)

2 USB Type-C connector and cables which are compact and reversible

3 Supports Thunderbolt Networking (*varies between dierent products)

4 Supports up to 4K displays

5 Up to 40 Gbps

NOTE: Data transfer speed may vary between dierent devices.

Thunderbolt Icons

Figure 2. Thunderbolt Iconography Variations

Advantages of Displayport over USB Type-C

• Full DisplayPort audio/video (A/V) performance (up to 4K at 60Hz)

• SuperSpeed USB (USB 3.1) data

• Reversible plug orientation and cable direction

• Backwards compatibility to VGA, DVI with adaptors

• Supports HDMI 2.0a and is backwards compatible with previous versions

HDMI 1.4

This topic explains the HDMI 1.4 and its features along with the advantages.

HDMI (High-Denition Multimedia Interface) is an industry-supported, uncompressed, all-digital audio/video interface. HDMI provides an

interface between any compatible digital audio/video source, such as a DVD player, or A/V receiver and a compatible digital audio and/or

video monitor, such as a digital TV (DTV). The intended applications for HDMI TVs, and DVD players. The primary advantage is cable

reduction and content protection provisions. HDMI supports standard, enhanced, or high-denition video, plus multichannel digital audio on

a single cable.

: The HDMI 1.4 will provide 5.1 channel audio support.

NOTE

HDMI 1.4 Features

• HDMI Ethernet Channel - Adds high-speed networking to an HDMI link, allowing users to take full advantage of their IP-enabled

devices without a separate Ethernet cable

• Audio Return Channel - Allows an HDMI-connected TV with a built-in tuner to send audio data "upstream" to a surround audio system,

eliminating the need for a separate audio cable

• 3D - Denes input/output protocols for major 3D video formats, paving the way for true 3D gaming and 3D home theater applications

Technology and components

47

Page 48

• Content Type - Real-time signaling of content types between display and source devices, enabling a TV to optimize picture settings

based on content type

• Additional Color Spaces - Adds support for additional color models used in digital photography and computer graphics

• 4K Support - Enables video resolutions far beyond 1080p, supporting next-generation displays that will rival the Digital Cinema systems

used in many commercial movie theaters

• HDMI Micro Connector - A new, smaller connector for phones and other portable devices, supporting video resolutions up to 1080p

• Automotive Connection System - New cables and connectors for automotive video systems, designed to meet the unique demands of

the motoring environment while delivering true HD quality

Advantages of HDMI

• Quality HDMI transfers uncompressed digital audio and video for the highest, crispest image quality.

• Low -cost HDMI provides the quality and functionality of a digital interface while also supporting uncompressed video formats in a

simple, cost-eective manner

• Audio HDMI supports multiple audio formats from standard stereo to multichannel surround sound

• HDMI combines video and multichannel audio into a single cable, eliminating the cost, complexity, and confusion of multiple cables

currently used in A/V systems

• HDMI supports communication between the video source (such as a DVD player) and the DTV, enabling new functionality

48 Technology and components

Page 49

System specications

Feature Specication

Chipset Intel KabyLake U & R (integrated with processor)

DRAM bus width 64-bit

Flash EPROM SPI 128 Mbits

PCIe bus 100 MHz

4

System specications

External Bus

Frequency

DMI 3.0—8GT/s

Processor specications

Feature

Types

Specication

• 7th Generation Intel Core up to i5 processors

• 8th Generation Intel Core up to i7 processors

Memory specications

Feature

Memory connector One DIMM slot

Memory capacity 4 GB and 16 GB

Memory type DDR4 2400 SDRAM operates at 2133 with Intel 7th Gen, DDR4 2400 SDRAM operates at 2400 with Intel 8th Gen

Minimum memory 4 GB

Maximum memory Up to 16 GB

Specication

Video specications

Feature

Type Integrated on system board

UMA controller

External display

support

Specication

• Intel HD Graphics 620 (GT2) - (7th Gen Intel® Core)

• Intel UHD Graphics 620 (GT2) - (8th Gen Intel® Core)

• HDMI 1.4

• Display Port over USB Type-C(optional Thunderbolt 3

System specications 49

Page 50

Feature Specication

NOTE: Supports one VGA, DisplayPort, HDMI through the docking station .

Audio specications

Feature Specication

Types Four-channel high-denition audio

Controller Realtek ALC3246

Stereo conversion 24-bit—analog-to-digital and digital-to-analog

Internal interface High-denition audio

External interface Microphone-in, stereo headphones, and headset combo connector

Speakers Two

Internal speaker

amplier

Volume controls Hot keys

2 W (RMS) per channel

Battery specications

Feature

Type

42 WHr (3–cell):

Length 200.5 mm (7.89 inches)

Width 95.9 mm (3.78 inches)

Height 5.7 mm (0.22 inch)

Weight 185.0 g (0.41 lb)

Voltage 11.4 VDC

60 WHr (4–cell):

Length 238 mm (9.37 inches)

Specication

• 3-cell Lithium Prismatic battery with ExpressCharge

• 4-cell Lithium Prismatic battery with ExpressCharge

Width 95.9 mm (3.78 inch)

Height 5.7 mm (0.22 inch)

Weight 270 g (0.6 lb)

Voltage 7.6 VDC

Life span 300 discharge per charge cycles

Temperature range

Operating

Non-operating - 20°C to 65°C (- 4°F to 149°F)

50 System specications

• Charge: 0°C to 50°C (32°F to 158°F)

• Discharge: 0°C to 70°C (32°F to 122°F)

Page 51

Feature Specication

Coin cell battery 3 V CR2032 lithium coin cell

AC adapter specications

Feature Specication

Type 65 W or 90 W 65W E5 for India

NOTE: The system is shipped with 65 W adapter and also supports 90 W adapter for fast charging.

Input voltage 100 V AC to 240 V AC

Input current—

maximum

Input frequency 50 Hz to 60 Hz

Output current 3.34 A (continuous) and 4.62 A (continuous)

Rated output

voltage

Weight 0.23 kg, 0.51 lbs (65W) and 0.32 kg, 0.77 lbs (90W)

Dimensions 22 x 66 x 106 mm (65 W) and 22 x 66 x 130 (90 W) or 0.87 x 2.60 x 4.17 inches (65 W) and 0.87 x 2.60 x 5.12

Temperature range

—Operating

Temperature range

—Non-Operating

1.7 A / 1.6 A

19.5 V DC

inches (90 W)

0°C to 40°C (32°F to 104°F)

–40°C to 70°C (–40°F to 158°F)

Touchpad specications

Feature

Active Area: Sensor-active area

X-axis 101.7mm (4.0 inch)

Specication

Y-axis 52mm (2.04 inch)

X/Y position

resolution

Multi-touch Congurable single nger and multi-nger gestures

X: 1048cpi; Y:984cpi

Port and connector specications

Feature

Audio Four-channel high denition audio, Realtek ALC3246 Controller, Stereo conversion: 24-bit (analog-to-digital and

Video HDMI 1.4

Specication

digital-to-analog), Internal Interface - high-denition audio codec, External Interface - microphone-in and stereo

headphones/speakers universal connector, Speakers: Power: 2X2 Wrms, Internal speaker amplier: 2 watt per

channel, Internal microphone: digital microphone (dual microphone with camera), No volume control buttons, only

support hot-key keyboard button

System specications 51

Page 52

Feature Specication

Network adapter One RJ-45 connector

USB

Memory card reader MicroSD 4.0 card reader and One 3042, One 2280 M.2 slots

Micro Subscriber

Identity Module

(uSIM) card

Docking port Security cable slot

Express Card None

AC adapter One

Smart card reader One (optional)

• One DisplayPort over USB Type-C (optional Thunderbolt 3)

• Type-C USB 3.1 Gen 1 Display port (optional Thunderbolt)

• Two USB 3.1 Gen1 ports - (one PowerShare capable)

External tray tied to WWAN hinge up

Communication specications

Features Specication

Network adapter 10/100/1000 Mb/s Ethernet (RJ-45)

Wireless No WLAN option, Qualcomm QCA61x4A 2x2 AC + Bluetooth 4.1 (non vPro), Qualcomm QCA6174A XR 2x2 AC +

Bluetooth 4.1 (non vPro), Intel Dual-Band Wireless-AC 8265 2x2 + Bluetooth 4.2 (non vPro), Mobile Broadband

Options (optional)

Mobile Broadband

Options (optional)

Qualcomm Snapdragon X7 LTE-A (DW5811e) for AT&T, Verizon & Sprint. (US); Qualcomm Snapdragon X7 LTE-A

(DW5811e) (EMEA/APJ/ROW); Qualcomm Snapdragon X7 HSPA + (DW5811e) (China/Indonesia/ India);

Qualcomm Snapdragon X7 LTE-A (DW5816e) (Japan/ANZ/India/South Korea/Taiwan)

Camera specications

Easy Remote Collaboration:

• Video conference online with an optional built-in camera

• Windows Hello feature can be enabled with IR Camera embedded

Table 3. Camera

Camera features 13 HD/FHD 13" FHD 13" FHD touch

Camera Type HD xed focus HD xed focus HD xed focus

IR Camera N/A Yes N/A

Sensor Type CMOS sensor technology CMOS sensor

Resolution: Motion Video Up to 1280x720 (0.92MP) Up to 1280x720

Resolution: Still Image Up to 1280 x 720 (0.92MP) Up to 1280 x 720

specications

technology

(0.92MP)

(0.92MP)

CMOS sensor

technology

Up to 1280x720

(0.92MP)

Up to 1280 x 720

(0.92MP)

52 System specications

Page 53

Imaging Rate Up to 30 frames per second Up to 30 frames per

second

Display

Table 4. 13.3" (16:9) AG FHD WLED 300 nits eDP 1.3 WVA

Feature Specication

Type FHD Anti-Glare

Luminance (typical) 300 nits

Dimensions (Active Area)

Native Resolution 1920 x 1080

Megapixels 2.07

Pixels per Inch (PPI) 166

Contrast Ratio (min) 600:1

Response Time (max) 35 msec rise/fall

Refresh Rate 60 Hz

Horizontal View Angle +/- 80 degrees

Vertical View Angle +/- 80 degrees

Pixel Pitch 0.153 mm

Power Consumption (maximum) 4.6 W

• Height: 165.08 mm

• Width: 293.47 mm

• Diagonal: 13.3 inch

Up to 30 frames per

second

Table 5. 13.3" (16:9) AG FHD Touch WLED 300 nits eDP 1.3 WVA

Feature Specication

Type FHD Anti-Smudge

Luminance (typical) 300 nits

Dimensions (Active Area)

Native Resolution 1920 x 1080

Megapixels 2.07

Pixels per Inch (PPI) 166

Contrast Ratio (min) 600:1

Response Time (max) 35msec rise/fall

Refresh Rate 60 Hz

Horizontal View Angle +/- 80 degrees

Vertical View Angle +/- 80 degrees

Pixel Pitch 0.153 mm

Power Consumption (maximum) 5.2 W

• Height:165.08 mm

• Width: 293.47 mm

• Diagonal: 13.3”

System specications 53

Page 54

Dimensions and Weight

Table 6. Dimensions

Dimensions Inches Millimeter

Width 12.00 304.80

Depth 8.19 207.95

Height (front, full ) for NT FHD and Touch FHD 0.64 16.33

Height (rear, full) for all congurations 0.66 16.86

Table 7. Weight

Starting weight Pounds Kilograms

2.59 1.17

Environmental specications

Temperature Specications

Operating 0°C to 35°C (32°F to 95°F)

Storage –40°C to 65°C (–40°F to 149°F)

Relative humidity

Specications

—maximum

Operating 10% to 90% (non-condensing)

Storage 5% to 95% (non-condensing)

Altitude—

Specications

maximum

Operating 0 to 3048 m (0 to 10,000 ft)

Storage 0 to 10668 m

54 System specications

Page 55

5

System setup

System setup enables you to manage your tablet hardware and specify BIOS level options. From the System setup, you can:

• Change the NVRAM settings after you add or remove hardware

• View the system hardware conguration

• Enable or disable integrated devices

• Set performance and power management thresholds

• Manage your computer security

Topics:

• Boot menu

• System setup options

Boot menu

Press <F12> when the Dell™ logo appears to initiate a one-time boot menu with a list of the valid boot devices for the system. Diagnostics

and BIOS Setup options are also included in this menu. The devices listed on the boot menu depend on the bootable devices in the system.

This menu is useful when you are attempting to boot to a particular device or to bring up the diagnostics for the system. Using the boot

menu does not make any changes to the boot order stored in the BIOS.

The options are:

• Legacy Boot:

• Internal HDD

• Onboard NIC

• UEFI Boot:

• Windows Boot Manager

• Other Options:

• BIOS Setup

• BIOS Flash Update

• Diagnostics

• Change Boot Mode Settings

Navigation keys

: For most of the System Setup options, changes that you make are recorded but do not take eect until you restart the

NOTE

system.

Keys Navigation

Up arrow Moves to the previous eld.

Down arrow Moves to the next eld.

Enter Selects a value in the selected eld (if applicable) or follow the link in the eld.

System setup 55

Page 56

Keys Navigation

Spacebar Expands or collapses a drop‐down list, if applicable.

Tab Moves to the next focus area.

NOTE: For the standard graphics browser only.

Esc Moves to the previous page until you view the main screen. Pressing Esc in the main screen displays a message

that prompts you to save any unsaved changes and restarts the system.

System setup options

NOTE: Depending on the tablet and its installed devices, the items listed in this section may or may not appear.

General screen options

This section lists the primary hardware features of your computer.

Option Description

System Information

Battery Information Displays the battery status and the type of AC adapter connected to the computer.

Boot Sequence

• System Information: Displays BIOS Version, Service Tag, Asset Tag, Ownership Tag, Ownership Date,

Manufacture Date, and the Express Service Code.

• Memory Information: Displays Memory Installed, Memory Available, Memory Speed, Memory Channels Mode,

Memory Technology, DIMM A Size, DIMM B Size.

• Processor Information: Displays Processor Type, Core Count, Processor ID, Current Clock Speed, Minimum

Clock Speed, Maximum Clock Speed, Processor L2 Cache, Processor L3 Cache, HT Capable, and 64-Bit

technology.

• Device Information: Displays Primary Hard Drive, MiniCard Device, ODD Device, Dock eSATA Device, LOM

MAC Address, Video Controller, Video BIOS Version, Video Memory, Panel Type, Native Resolution, Audio

Controller, Wi-Fi Device, WiGig Device, Cellular Device, Bluetooth Device.

Boot Sequence Allows you to change the order in which the computer attempts to nd an operating

system. The options are:

• Windows Boot Manager

By default, the options is checked.

Boot List Options Allows you to change the boot list option:

• Legacy

• UEFI (The option is enabled by default)

Advanced Boot

Options

UEFI Boot Path

SecurityOptions

56 System setup

Allows you the legacy option ROMs to load. By default, all the option are disabled.

• Enable Legacy Option ROMs

• Enable Attempt Legacy Boot

Allows you to control whether or not the system will prompt to the user to enter the Admin password, when a user

selects a UEFI boot path from the F12 boot Menu.

• Always, Except Internal HDD. This option is enabled by default.

Page 57

Option Description

• Always

• Never

NOTE: These options have no relevance if the Admin password is not set BIOS settings.

Date/Time Allows you to change the date and time.

Video screen options

Option Description

LCD Brightness Allows you to set the display brightness depending up on the power source (On Battery and On AC).

NOTE: The video setting will be visible only when a video card is installed into the system.

Security screen options

Option Description

Admin Password Allows you to set, change, or delete the administrator (admin) password.

NOTE: You must set the admin password before you set the system or hard drive password. Deleting the

admin password automatically deletes the system password and the hard drive password.

NOTE: Password changes take eect immediately.

By default, the drive will not have a password set.

System Password Allows you to set, change or delete the system password.

NOTE: Password changes take eect immediately.

By default, the drive will not have a password set.

Strong Password Allows you to enforce the option to always set strong passwords.

Default Setting: Enable Strong Password is not selected.

NOTE: If user interface is enabled, Admin and System passwords must contain at least one uppercase

character, one lowercase character and be at least 8 characters long.

Password

Conguration

Password Bypass Allows you to disable or enable the permission to bypass the System and the Internal hard drive password, when

Allows you to determine the minimum and maximum length of Administrator and System passwords.

they are set. The options are:

• Disabled. This option is selected by default.

• Reboot bypass

Password Change Allows you to enable or disable permission to the System and Hard Drive passwords when the admin password is

set.

Allow Non-Admin Password Changes This option is selected by default.

System setup 57

Page 58

Option Description

Non-Admin Setup

Changes

UEFI Capsule

Firmware Updates

TPM 2.0 Security Allows you to enable the Trusted Platform Module (TPM) during POST.

Allows you to determine whether changes to the setup options are allowed when an administrator password is set.

If disabled the setup options are locked by the admin password.

This option controls whether the system allows BIOS updates via UEFI capsule update packages.

Enable UEFI Capsule Firmware Updates option is selected by default.

NOTE: Disabling this option will block BIOS updates from services such as Microsoft Windows Update

and Linux Vendor Firmware Service (LVFS).

You can control whether the trusted platform module is visible to the operating system. The option is:

• TPM on This option is selected by default.

• Clear

• PPI Bypass for Enable Commands This option is selected by default.

• Attestation Enable. This option is selected by default.

• PPI Bypass for Disable Commands

• Key Storage Enable. This option is selected by default.

• SHA-256. This option is selected by default.

CAUTION: For the TPM upgrade/downgrade process, it is recommended to complete the process in an

AC power with AC adapter plugged into the computer. The upgrade/downgrade process without the AC

adapter plugged in might damage the computer or hard disk.

NOTE: Disabling this option does not change any settings you have made to the TPM, nor does it delete

or change any information or keys you may have stored in the TPM. Changes to this setting take eect

immediately.

Computrace (R) Allows you to activate or disable the optional Computrace Service from Absolute software. The options are:

• Deactivate

• Disable

• Activate

NOTE: The Activate and Disable options will permanently activate or disable the feature and no further

changes will be allowed

Default setting: Activate

OROM Keyboard

Access

Admin Setup

Lockout

Allows you to set an option to enter the Option ROM Conguration screens using hotkeys during boot. The options

are:

• Enabled. This option is selected by default.

• One Time Enable

• Disabled

Default setting: Enable

Allows you to prevent users from entering the setup when an Administrator password is set.

Enable Admin Setup Lockout This option is not selected by default.

Master Password

Lockout

58 System setup

Allows you to prevent users from entering the setup when an Master password is set. Hard disk passwords need to

be cleared before the setting can be changed.

Page 59

Option Description

Enable Master Password Lockout This option is not selected by default.

SSM Security

Mitigation

Allows you to enable or disable additional UEFI SMM Security Mitigation protections. The OS can use the feature

to help protect the secure environment created by virtualization based security.

SSM Security Mitigation This option is disabled by default.

Secure Boot

Option Description

Secure Boot Enable This option enables or disables the Secure Boot feature.

• Disabled

• Enabled

Default setting: Enabled.

Expert Key

Management

Custom Mode Key

Management

Allows you to manipulate the security key databases only if the system is in Custom Mode. The Enable Custom

Mode option is disabled by default.

Allows you to manage the security key databases only if the system is in Custom Mode .The options are:

• PK. This option is selected by default.

• KEK

• db

• dbx

NOTE: If you disable the Enable Custom Mode, all the changes made will be erased and the keys will

restore to default settings. Save to File will save the key to a user-selected le.

Intel software Guard Extensions

Option

Intel SGX Enable This option enables or disables to provide a secured environment for running code/storing sensitive information in

Enclave Memory

Size

Description

the context of the main OS. The options are:

• Disabled

• Enabled

• Software Controlled.This option is selected by default.

Allows you to reserve the memory size. The memory size can be set from 32 MB to 128 MB, these options are

disabled by default. The options are:

• 32 MB

• 64 MB

• 128 MB

System setup 59

Page 60

Performance screen options

Option Description

Multi Core Support This eld species whether the process has one or all cores enabled. The performance of some applications

improves with the additional cores. This option is enabled by default. Allows you to enable or disable multi-core

support for the processor.

• AllThis option is enabled by default.

• 1

• 2

• 3

Intel SpeedStep Allows you to enable or disable the Intel SpeedStep mode of the processor.

• Enable Intel SpeedStep

Default setting: The option is enabled.

C-States Control Allows you to enable or disable the additional processor sleep states.

• C states

Default setting: The option is enabled.

Intel TurboBoost Allows you to enable or disable the Intel TurboBoost mode of the processor.

• Enable Intel TurboBoost

Default setting: The option is enabled.

HyperThread

Control

Allows you to enable or disable the HyperThreading in the processor.

• Disabled

• EnabledThis option is enabled by default.

Power Management screen options

Option

AC Behavior Allows you to enable or disable the computer from turning on automatically when an AC adapter is connected.

Enable Intel Speed

Shift Technology

Description

Wake on AC This option is disabled by default.

Allows you to enable or disable the Intel speed Shift Technology support. Setting to enable option, allows the

operating system to automatically select the required processor performance.

Enable Intel Speed Shift Technology This option is enabled by default.

Auto On Time Allows you to set the time at which the computer must turn on automatically. The options are:

• Disabled This option is enabled by default.

• Every Day

60 System setup

Page 61

Option Description

• Weekdays

• Select Days

USB Wake Support Allows you to enable USB devices to wake the system from Standby.

NOTE: This feature is only functional when the AC power adapter is connected. If the AC power adapter

is removed during Standby, the system setup removes power from all the USB ports to conserve battery

power.

• Enable USB Wake Support

• Wake on Dell USB-C Dock The option is selected by default.

Wireless Radio

Control

Wake on WLAN Allows you to enable or disable the feature that powers on the computer from the O state when triggered by a

Block Sleep Allows you to block entering to sleep (S3 state) in OS environment. When enabled system wont go to sleep. Intel

Peak Shift Allows you to minimize the AC power consumption during the peak power times of day. After you enable this

Allows you to sense the connection of the system to a wired network and subsequently disable the selected

wireless radios (WLAN and/or WWAN)

Upon disconnection from the wired network, the selected wireless radios is re-enabled. By default none of the

option is enabled. The options are:

• Control WLAN radio

• Control WWAN radio

LAN signal.

• Disabled This option is selected by default.

• LAN Only

• WLAN Only

• LAN or WLAN

Rapid Start will be disabled automatically and OS Power option will be blank if it was set to Sleep (S3 state) . Block

Sleep (S3 State) option is disabled by default.

option, your system runs only in battery even if the AC is attached.

• Enable Peak ShiftThis option is not selected by default.

Advanced Battery

Charge

Conguration

Primary Battery

Charge

Conguration

This option enables you to maximize the battery health. By enabling this option, your system uses the standard