Page 1

Dell PowerEdge M1000e Enclosure

Owner's Manual

Regulatory Model: BMX01

Page 2

Notes, Cautions, and Warnings

NOTE: A NOTE indicates important information that helps you make better use of your computer.

CAUTION: A CAUTION indicates either potential damage to hardware or loss of data and tells you how to avoid the

problem.

WARNING: A WARNING indicates a potential for property damage, personal injury, or death.

Information in this publication is subject to change without notice.

© 2012 Dell Inc. All rights reserved.

Reproduction of these materials in any manner whatsoever without the written permission of Dell Inc. is strictly forbidden.

Trademarks used in this text:

PowerConnect

Inc.

Intel

is a registered trademark and

Microsoft

®

,

Pentium

®

,

™

,

OpenManage

Windows

®

,

Xeon

®

,

™

, the Dell logo,

Dell

™

,

EqualLogic

®

®

,

and

Core

AMD Opteron

Windows Server

Dell Precision

™

,

Compellent

®

are registered trademarks of Intel Corporation in the U.S. and other countries.

Celeron

™

,

AMD Phenom

®

,

Internet Explorer

or registered trademarks of Microsoft Corporation in the United States and/or other countries.

Enterprise Linux® are registered trademarks of Red Hat, Inc. in the United States and/or other countries. Novell® and SUSE® are

registered trademarks of Novell Inc. in the United States and other countries. Oracle® is a registered trademark of Oracle Corporation

and/or its affiliates. Citrix®, Xen®, XenServer® and XenMotion® are either registered trademarks or trademarks of Citrix Systems, Inc. in

the United States and/or other countries. VMware®, Virtual SMP®, vMotion®, vCenter® and vSphere® are registered trademarks or

trademarks of VMware, Inc. in the United States or other countries. IBM® is a registered trademark of International Business Machines

Corporation.

Other trademarks and trade names may be used in this publication to refer to either the entities claiming the marks and names or their

products. Dell Inc. disclaims any proprietary interest in trademarks and trade names other than its own.

™

™

®

,

KACE

and

,

™

MS-DOS

,

™

OptiPlex

™

,

FlexAddress

AMD Sempron

®

,

Windows Vista

™

,

Latitude

,

PowerEdge

™

,

Force10

™

are trademarks of Advanced Micro Devices, Inc.

®

and

™

,

™

Red Hat

PowerVault

and

Vostro

Active Directory

®

and

™

™

,

are trademarks of Dell

®

are either trademarks

®

Red Hat

AMD

®

2012 - 04

Rev. A01

Page 3

Contents

Notes, Cautions, and Warnings...................................................................................................2

1 About Your System......................................................................................................................7

System Overview......................................................................................................................................................7

System Control-Panel Features................................................................................................................................9

LCD Module............................................................................................................................................................10

LCD Module Features.......................................................................................................................................11

Using The LCD Module Menus.........................................................................................................................12

Configuration Wizard..............................................................................................................................................12

Back-Panel Features..............................................................................................................................................13

Power Supply Indicators..................................................................................................................................14

Fan Module Indicators.....................................................................................................................................15

Avocent iKVM Analog Switch Module (Optional)...................................................................................................16

Avocent Analog iKVM Switch Module Features And Indicators.....................................................................17

CMC Module...........................................................................................................................................................18

CMC Module Features......................................................................................................................................18

CMC Fail-Safe Mode........................................................................................................................................19

Daisy-Chain CMC Network Connection...........................................................................................................20

System Messages...................................................................................................................................................21

Other Information You May Need...........................................................................................................................21

2 Initial System Configuration....................................................................................................23

Before You Begin....................................................................................................................................................23

Initial Setup Sequence............................................................................................................................................23

Initial CMC Network Configuration.........................................................................................................................23

Configuring The CMC Using The LCD Configuration Wizard............................................................................24

Configuring The CMC Using A Management Station And CLI.........................................................................24

Logging In To The CMC Using The Web-Based Interface......................................................................................25

Adding And Managing CMC Users.........................................................................................................................26

Configuring iDRAC Networking Using The Web-Based Interface.........................................................................26

Setting The First Boot Device For Servers..............................................................................................................27

Configuring And Managing Power.........................................................................................................................27

Installing Or Updating The CMC Firmware.............................................................................................................27

Downloading The CMC Firmware....................................................................................................................28

Updating The CMC Firmware Using The Web-Based Interface......................................................................28

Updating The CMC Firmware Using RACADM.................................................................................................28

Configuring The Optional iKVM Switch Module.....................................................................................................29

Page 4

Updating The iKVM Firmware..........................................................................................................................29

Tiering The Avocent iKVM Switch From A Digital KVM Switch.......................................................................29

Tiering The Avocent iKVM Switch From An Analog KVM Switch....................................................................29

Configuring The Analog Switch........................................................................................................................30

Resynchronizing The Server List At The Remote Client Workstation..............................................................31

Viewing And Selecting Servers........................................................................................................................31

FlexAddress............................................................................................................................................................32

FlexAddress Plus....................................................................................................................................................32

3 Configuring The I/O Modules..................................................................................................33

Network Information...............................................................................................................................................33

I/O Connectivity.......................................................................................................................................................33

General I/O Module Configuration Guidelines.................................................................................................33

Fabric A............................................................................................................................................................33

Fabric B............................................................................................................................................................34

Fabric C............................................................................................................................................................34

Port Auto-Disablement in Quad-Port Network Daughter Card (Dell PowerEdge M710HD Only)...........................34

Mezzanine Cards....................................................................................................................................................35

PowerEdge M610x Only...................................................................................................................................35

Full-Height Blades............................................................................................................................................35

Half-Height Blades...........................................................................................................................................35

Quarter-Height Blades.....................................................................................................................................37

I/O Module Port Mapping—Full-Height Blades.....................................................................................................37

Standard LOM (Dual-Port) Mapping................................................................................................................37

Dual-Port Mezzanine Cards.............................................................................................................................37

Quad-Port Mezzanine Cards............................................................................................................................42

I/O Module Port Mapping─Half-Height Blades......................................................................................................43

Standard LOM (Dual-Port) and Network Daughter Card (Quad-Port) Mapping..............................................43

Dual-Port Mezzanine Cards.............................................................................................................................44

Quad-Port Mezzanine Cards ...........................................................................................................................45

I/O Module Port Mapping—Quarter-Height Blades...............................................................................................46

Standard LOM (Dual-Port) Mapping................................................................................................................46

Dual-Port Mezzanine Cards.............................................................................................................................47

Quad-Port Mezzanine Cards............................................................................................................................50

I/O Modules—Switches.........................................................................................................................................51

Configuring A Switch Module Network Ethernet Port Using The Web-Based Interface................................51

Mellanox M4001F/M4001Q Infiniband Switch I/O Module...............................................................................51

Dell PowerConnect KR 8024-k Switch..............................................................................................................52

Dell PowerConnect M8428-k 10 Gb Converged Network Switch....................................................................53

Mellanox M2401G DDR Infiniband Switch I/O Module....................................................................................54

Mellanox M3601Q QDR Infiniband Switch I/O Module....................................................................................55

Cisco Catalyst Ethernet Switch I/O Modules...................................................................................................56

Page 5

Dell PowerConnect M6348 1 Gb Ethernet Switch I/O Module.........................................................................57

Dell PowerConnect M6220 Ethernet Switch I/O Module.................................................................................58

Dell PowerConnect M8024 10 Gb Ethernet Switch I/O Module.......................................................................59

Dell 8/4 Gbps FC SAN Module..........................................................................................................................60

I/O Modules—Pass-Through .................................................................................................................................61

Dell 4 Gbps Fibre Channel Pass-Through Module...........................................................................................61

Dell 10 GbE KR Pass-Through I/O Module........................................................................................................63

Dell 10 Gb Ethernet Pass-Through Module II...................................................................................................64

10/100/1000 Mb Ethernet Pass-Through I/O Module........................................................................................64

Brocade M4424 SAN I/O Module.....................................................................................................................65

Brocade M5424 FC8 I/O Module.......................................................................................................................67

4 Installing Enclosure Components...........................................................................................71

Recommended Tools..............................................................................................................................................71

Removing And Installing A Blade...........................................................................................................................71

Removing A Blade............................................................................................................................................71

Installing A Blade.............................................................................................................................................73

Removing And Installing A Sleeve..........................................................................................................................73

Removing The Sleeve.......................................................................................................................................73

Installing The Sleeve........................................................................................................................................74

Power Supply Modules...........................................................................................................................................74

Power Supply Blanks.......................................................................................................................................75

Removing A Power Supply Module..................................................................................................................75

Installing a Power Supply Module...................................................................................................................77

Fan Modules...........................................................................................................................................................77

Removing A Fan Module..................................................................................................................................78

Installing a Fan Module....................................................................................................................................78

CMC Module...........................................................................................................................................................79

Removing A CMC Module................................................................................................................................79

Installing A CMC Module.................................................................................................................................79

iKVM Module..........................................................................................................................................................81

Removing An iKVM Module.............................................................................................................................81

Installing An iKVM Module...............................................................................................................................81

I/O Modules............................................................................................................................................................82

Removing An I/O Module.................................................................................................................................82

Installing An I/O Module...................................................................................................................................83

Enclosure Bezel......................................................................................................................................................83

Removing The Enclosure Bezel........................................................................................................................83

Installing The Enclosure Bezel.........................................................................................................................84

Enclosure Midplane................................................................................................................................................84

Removing The Front Module Cage Assembly And Midplane...........................................................................84

Installing The Midplane And Front Module Cage Assembly............................................................................86

Page 6

Enclosure Control Panel Assembly.........................................................................................................................87

Removing The Control Panel............................................................................................................................87

Installing The Control Panel.............................................................................................................................88

LCD Module............................................................................................................................................................88

Removing The LCD Module..............................................................................................................................88

Installing The LCD Module...............................................................................................................................89

5 Troubleshooting The Enclosure..............................................................................................91

Safety First—For You and Your System..................................................................................................................91

Responding to a Systems Management Alert Message........................................................................................91

Troubleshooting A Damaged Enclosure.................................................................................................................91

Troubleshooting Enclosure Components................................................................................................................91

Troubleshooting A Wet Enclosure...................................................................................................................92

Troubleshooting Power Supply Modules.........................................................................................................92

Troubleshooting Fan Modules..........................................................................................................................93

Troubleshooting The iKVM Module.................................................................................................................93

Troubleshooting I/O Modules...........................................................................................................................93

6 Technical Specifications.........................................................................................................95

Enclosure Specifications........................................................................................................................................95

I/O Module Specifications......................................................................................................................................96

7 Getting Help................................................................................................................................99

Contacting Dell.......................................................................................................................................................99

Page 7

1

About Your System

System Overview

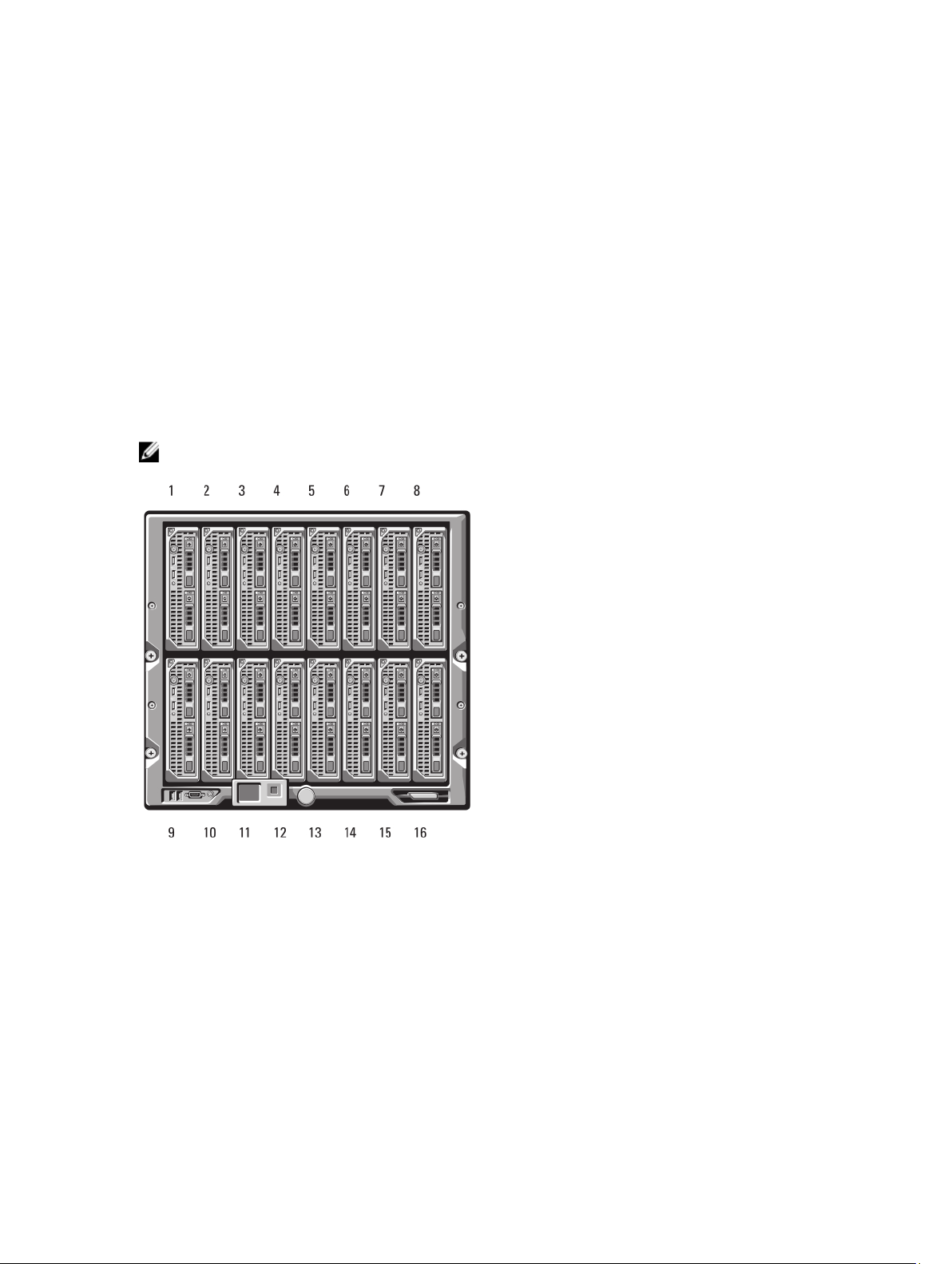

Your system can include up to 16 half-height blades (server modules), eight full-height blades, eight sleeves with

quarter-height blades, or a mix of the three blade types. To function as a system, a blade or sleeve is inserted into an

enclosure (chassis) that supports power supplies, fan modules, a Chassis Management Controller (CMC) module, and at

least one I/O module for external network connectivity. The power supplies, fans, CMC, optional iKVM module, and I/O

modules are shared resources of the blades in the PowerEdge M1000e enclosure.

NOTE: To ensure proper operation and cooling, all bays in the enclosure must be populated at all times with either

a module or with a blank.

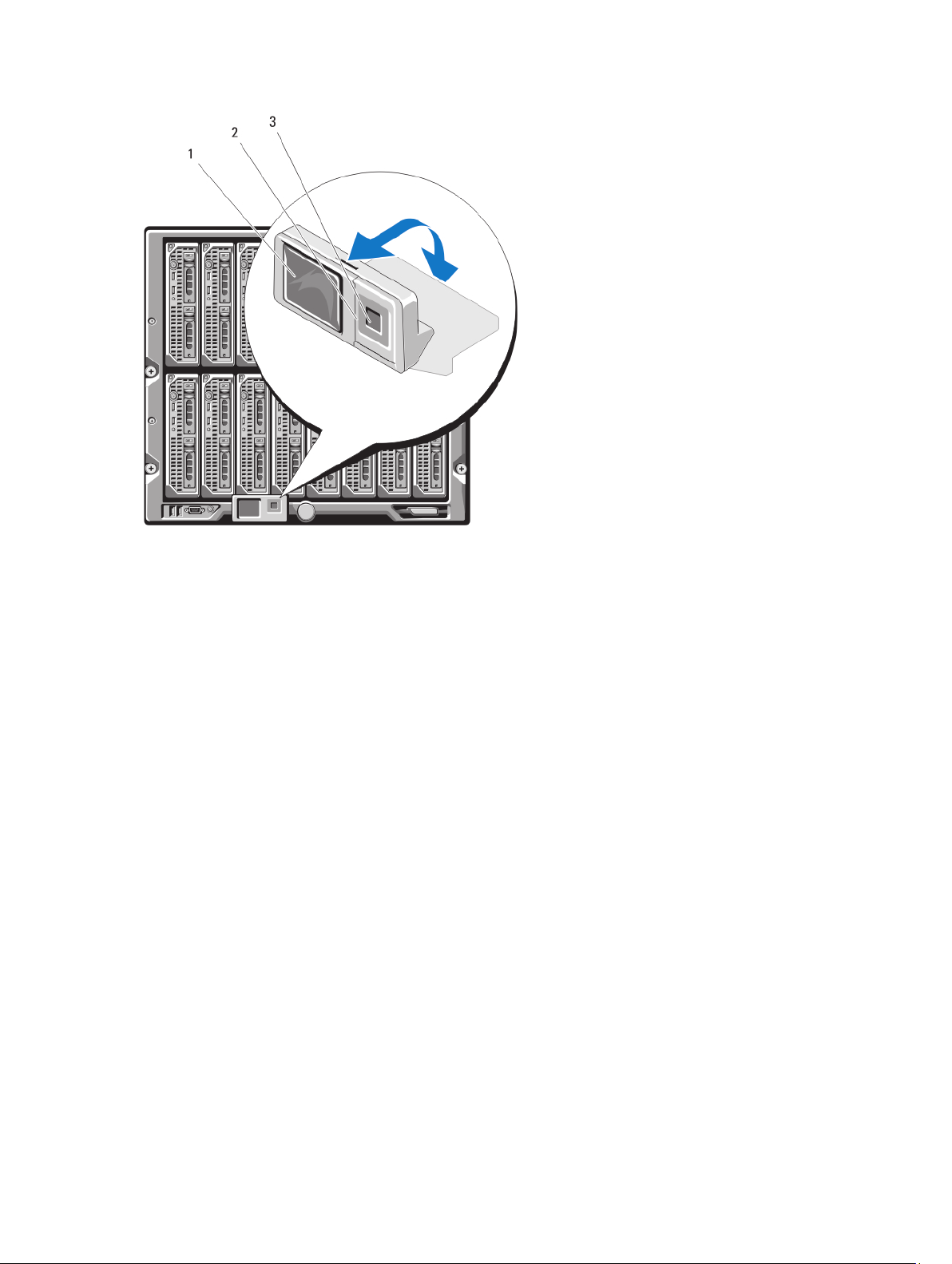

Figure 1. Blade Numbering – Half-Height Blades

7

Page 8

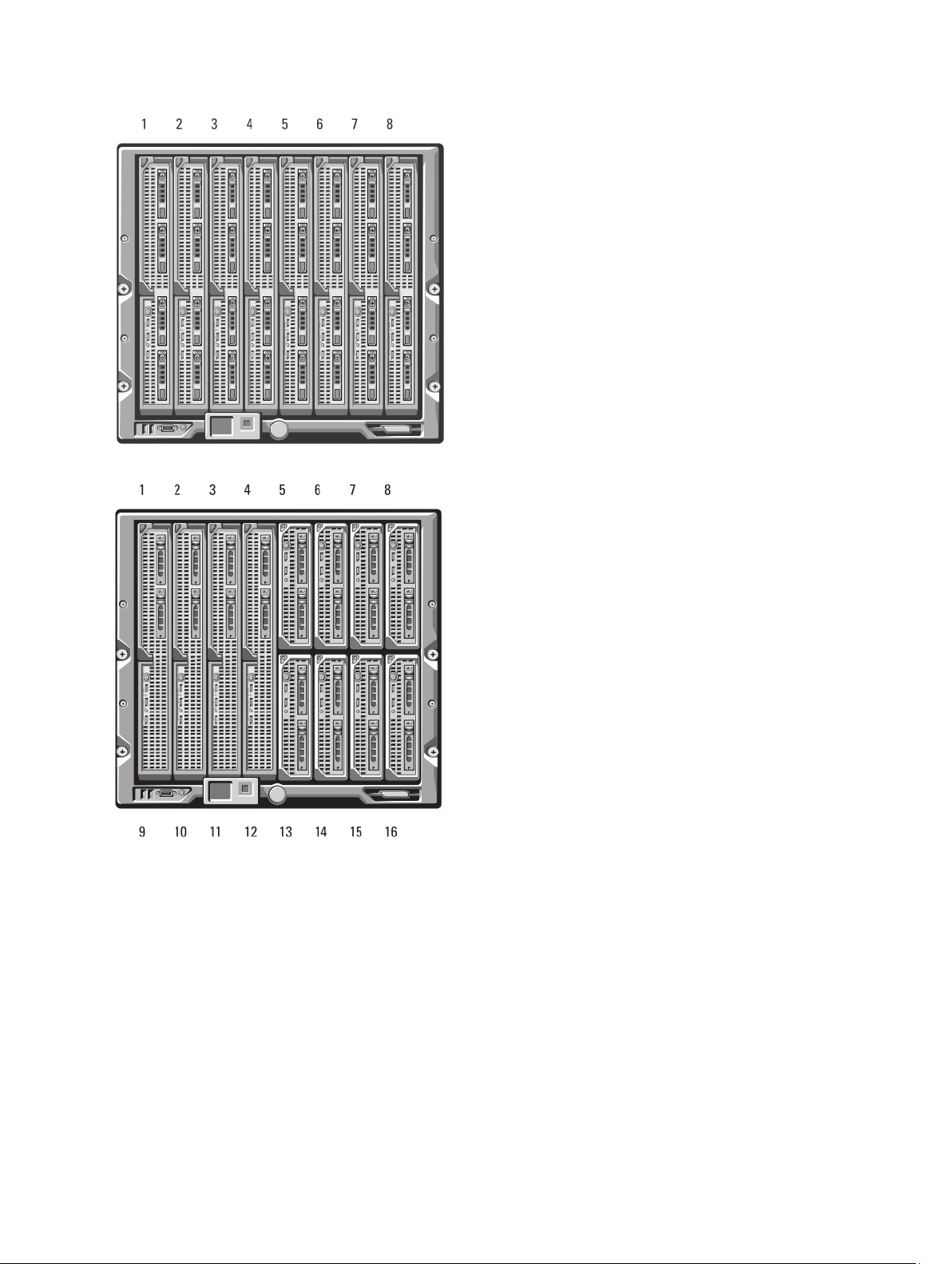

Figure 2. Blade Numbering – Full Height Blades

Figure 3. Blade Numbering – Mixed Full-Height and Half-Height Blades

8

Page 9

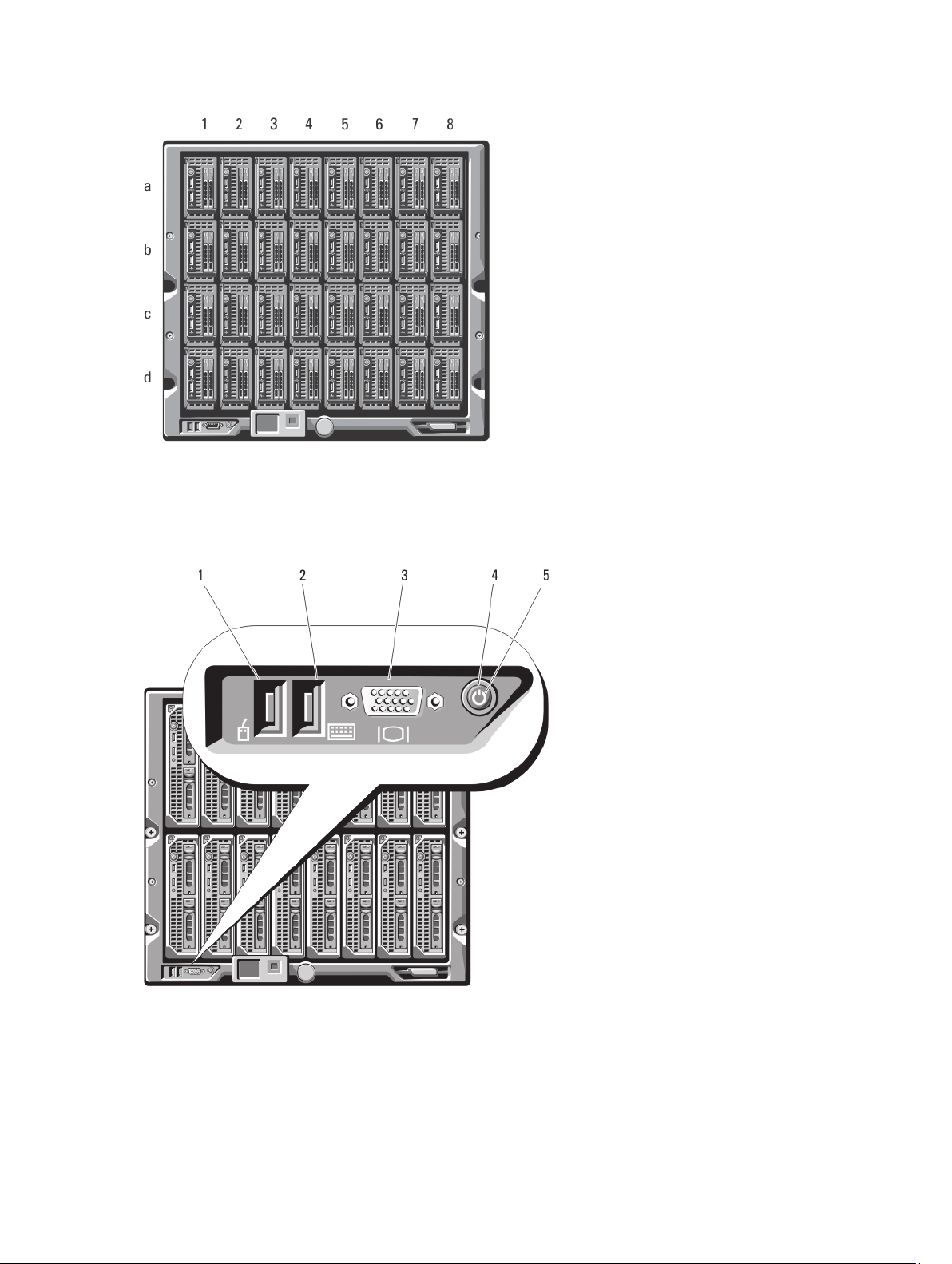

Figure 4. Blade Numbering – Quarter Height Blades

System Control-Panel Features

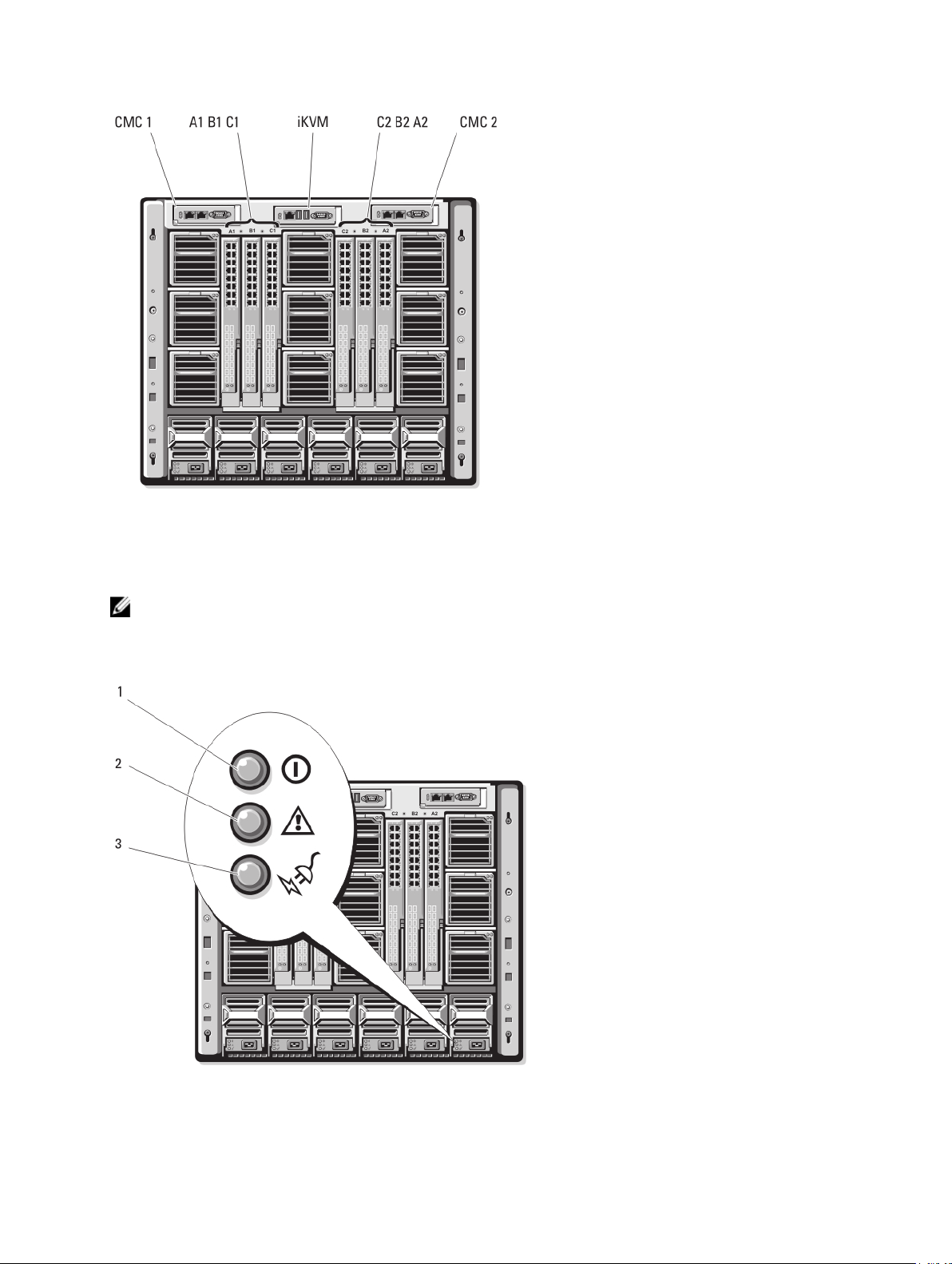

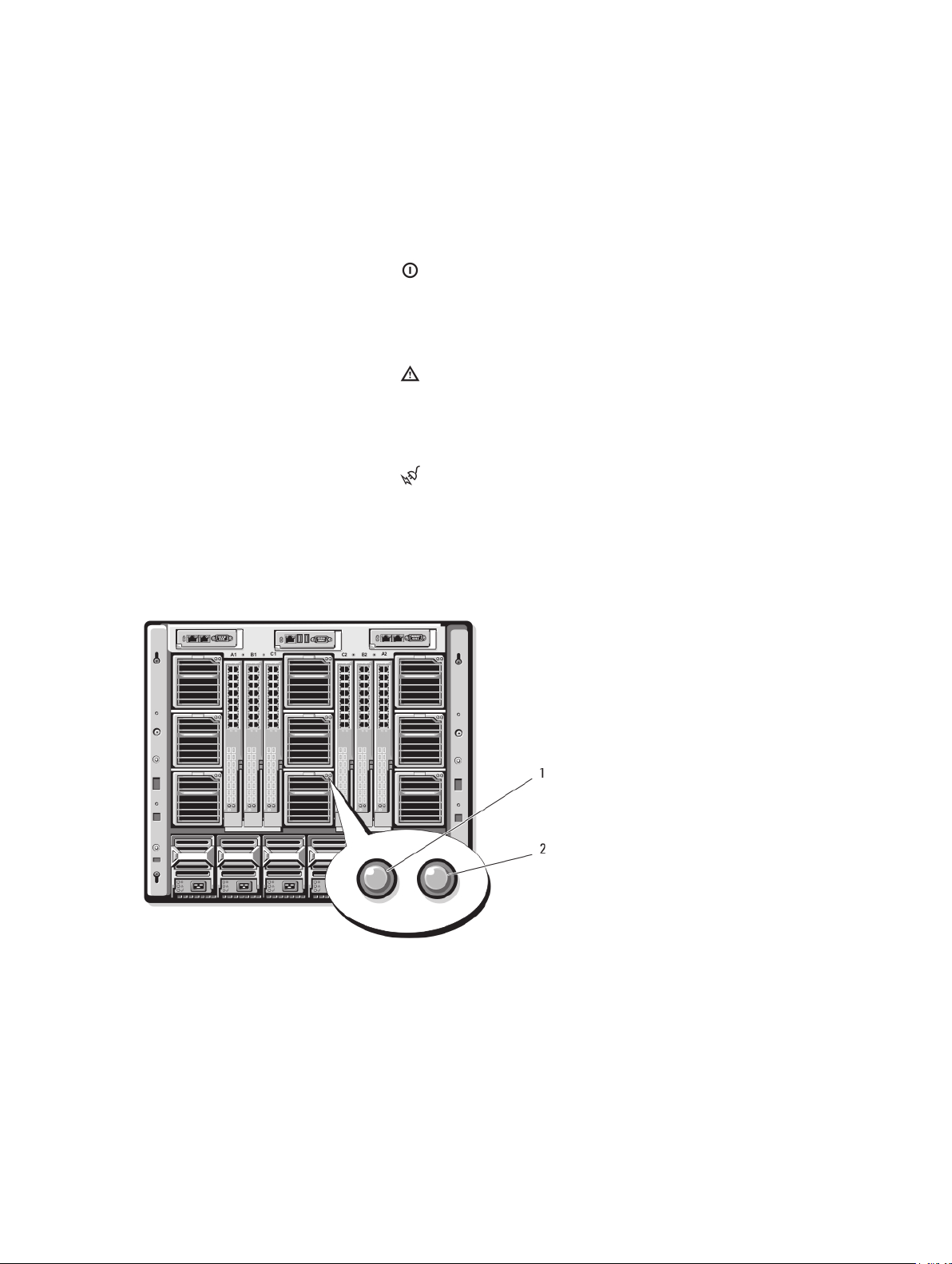

Figure 5. Control-Panel Features

1. USB port (mouse only)

2. USB port (keyboard only)

3. video connector

9

Page 10

4. system power button

5. system power indicator

Control Panel

Features

System power

button

System power

indicator

USB ports for

keyboard and

mouse

Video connector

Description

Turns the system on and off. Press to turn on the system. Press and hold 10 seconds to turn off

the system.

NOTE: The system power button controls power to all of the blades and I/O modules in the

enclosure.

Icon

Indicators

Icon

Description Functional if an optional iKVM module is installed and front panel ports are

Icon

Off System does not have power.

Green System power is on.

enabled (default setting) in the CMC interface.

NOTE: These ports do not support USB storage devices. Only connect USB

storage devices to the USB ports on the front panel of the blade.

Description Functional if an optional iKVM module is installed and front panel ports are

enabled (default setting) in the CMC interface.

LCD Module

The LCD module provides an initial configuration/deployment wizard, as well as easy access to infrastructure and blade

information, and error reporting.

10

Page 11

Figure 6. LCD Display

1. LCD screen

2. scroll buttons (4)

3. selection ("check") button

LCD Module Features

The primary function of the LCD module is to provide real-time information on the health and status of the modules in the

enclosure.

LCD module features include:

• A deployment setup wizard that allows you to configure the CMC module’s network settings during initial system

set up.

• Menus to configure the iDRAC in each blade.

• Status information screens for each blade.

• Status information screens for the modules installed in the back of the enclosure, including the I/O modules,

fans, CMC, iKVM, and power supplies.

• A Network Summary screen listing the IP addresses of all components in the system.

• Real time power consumption statistics, including high and low values, and average power consumption.

• Ambient temperature values.

• AC power information.

• Critical failure alerts and warnings.

11

Page 12

Using The LCD Module Menus

Key Action

Left and right arrows Move between screens.

Up or down arrow Move to the previous or next option on a screen.

Center button Select and save an item and move to the next screen.

Main Menu

The Main Menu options include links to the LCD Setup Menu, Server Menu, and Enclosure Menu.

LCD Setup Menu

You can change the default language and start-up screen for the LCD menu screens using this menu.

Server Menu

From the Server Menu dialog box, you can highlight each blade in the enclosure using the arrow keys, and view its

status.

• A blade that is turned off or booting is designated by a gray rectangle. An active blade is indicated by a green

rectangle. If a blade has errors, this condition is indicated by an amber rectangle.

• To select a blade, highlight it and press the center button. A dialog box displays the iDRAC IP address of the

blade and any errors present.

Enclosure Menu

The Enclosure Menu includes options for Module Status, Enclosure Status, and Network Summary.

• In the Module Status dialog box, you can highlight each component in the enclosure and view its status.

– A module that is turned off or booting is designated by a gray rectangle. An active module is indicated

by a green rectangle. If a module has errors, it is indicated by an amber rectangle.

– If a module is selected, a dialog box displays the current status of the module and any errors present.

• In the Enclosure Status dialog box, you can view the enclosure status, any error conditions, and power

consumption statistics.

• The Network Summary screen lists the IP addresses for the CMC and iDRAC in each blade, and other

components in the enclosure.

Configuration Wizard

The CMC is preset for Dynamic Host Configuration Protocol (DHCP). To use a static IP address, you must toggle the CMC

setting from DHCP to a static address by either running the LCD configuration wizard, or by using a management station

and CLI commands. For more information, see the CMC documentation at support.dell.com/manuals.

To set up a network using the LCD configuration wizard:

1. If you have not already done so, press the chassis power button to turn it on.

The LCD screen displays a series of initialization screens as it turns on. When it is ready, the Language Setup

screen is displayed.

2. Select a language from the options in the dialog box.

The following message is displayed on the enclosure screen: Configure Enclosure?

3. Press the center button to continue to the CMC Network Settings screen.

12

Page 13

4. Configure the CMC network settings for your network environment:

– Network speed

– Duplex mode

– Network mode (DHCP or static)

– Static IP address, subnet mask, and gateway values (if static mode was selected)

– DNS settings

5. If required, configure the iDRAC network settings. For more information about iDRAC, see the iDRAC User’s Guide

at

support.dell.com/manuals.

NOTE: The configuration wizard automatically configures each blade’s iDRAC internal network interface if you do

not choose to manually configure the iDRAC settings.

NOTE: You cannot set a static IP address for the iDRAC using the LCD configuration wizard. To set a static IP

address, use the CMC web-based interface or Remote Access Controller Administrator (RACADM).

6. Review the settings on the Network Summary screen:

– If the settings are correct, press the center button to close the configuration wizard and return to the Main

Menu.

– If the settings are not correct, use the left arrow key to return to the screen for that setting and correct it.

After you complete the configuration wizard, the CMC is available on your network.

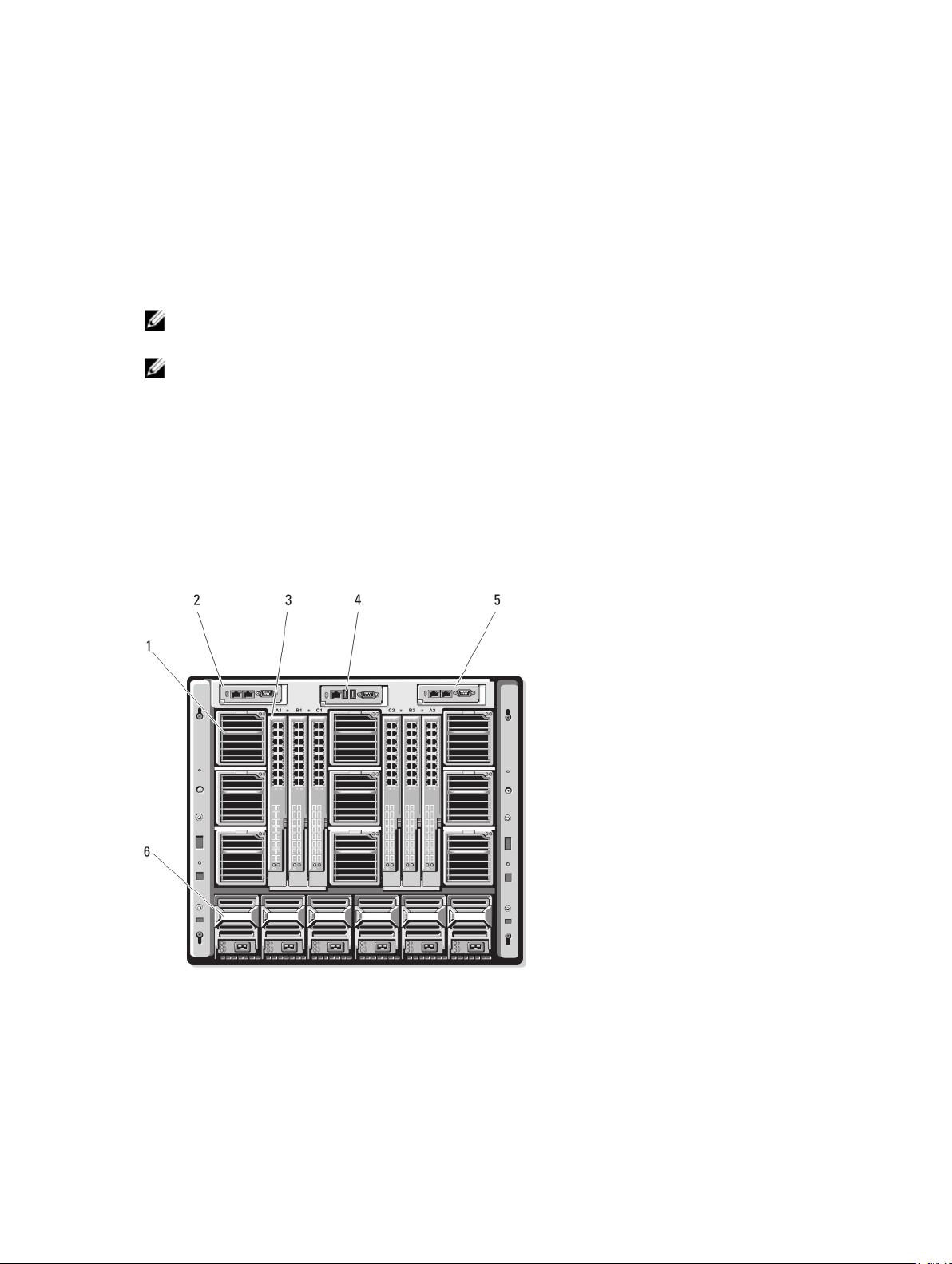

Back-Panel Features

Figure 7. Back-Panel Features

fan modules (9)

1.

2. primary CMC module

3. I/O modules (6)

4. optional iKVM module

5. secondary CMC module

6. power supplies (6)

13

Page 14

Figure 8. Back-Panel Module Bay Numbering

Power Supply Indicators

NOTE: The power supplies must be connected to a Power Distribution Unit (PDU), not directly to an electrical

outlet.

• The power supplies require a 100 V to 240 V power source.

• A 2700 W power supply provides 1350 W input power, if connected to a 110 V AC power source (optional).

Figure 9. Power Supply Indicators

14

Page 15

1. DC power output indicator

2. power supply fault indicator

3. AC power indicator

The indicators provide the following information:

Indicator Description

DC power output indicator

Power supply fault

indicator

AC power source present

indicator

Fan Module Indicators

Icon

Description Green indicates that the power supply is operational and providing DC

power to the system.

Icon

Description Amber indicates a problem with the power supply, which can result from

either a failed power supply or a failed fan within the power supply.

Icon

Description Green indicates that a valid AC source is connected to the power supply

and is operational.

Figure 10. Fan Module Indicators

1. fan power indicator

2. fan fault indicator

The indicators provide the following information:

15

Page 16

Indicator Description

Fan power indicator

Fan fault indicator

Solid Green The fan is receiving DC power and working properly.

Off The fan has failed.

Amber The fan is in a fault condition.

Avocent iKVM Analog Switch Module (Optional)

• Local iKVM access can be remotely disabled on a per blade basis, using the blade’s iDRAC interface (access is

enabled by default).

NOTE: By default (enabled), a console session to a given blade is available for both the iDRAC interface and iKVM

(users connected to a blade's console using iDRAC and the iKVM see the same video and are able to type

commands). If not required, sharing can be disabled using the iDRAC console interface.

• One VGA connector. The iKVM supports a video display resolution range from 640 x 480 at 60 Hz up to 1280 x

1024 x 65,000 colors (non-interlaced) at 75 Hz.

• Two USB ports for keyboard and mouse.

NOTE: The iKVM USB ports do not support storage devices.

• RJ-45 Analog Console Interface (ACI) port for tiering with Dell and Avocent analog KVM and KVM over IP

switches with Analog Rack Interface (ARI) ports.

NOTE: Although the ACI port is an RJ-45 connector and uses Cat5 (or better) cabling, it is not an Ethernet network

interface port. It is only used for connection to external KVM switches with ARI ports, and does not support native

KVM over IP.

• The iKVM can also be accessed from the front of the enclosure, providing front or rear panel KVM functionality,

but not at the same time. For enhanced security, front panel access can be disabled using the CMC’s interface.

NOTE: Connecting a keyboard, video, and mouse to the enclosure front panel disables video output to the iKVM

back panel port. It does not interrupt iDRAC video and console redirection.

• You can use the iKVM to access the CMC console directly, using RACADM or using the web-based interface.

For more information, see Using the iKVM Module in the CMC User’s Guide at support.dell.com/manuals.

16

Page 17

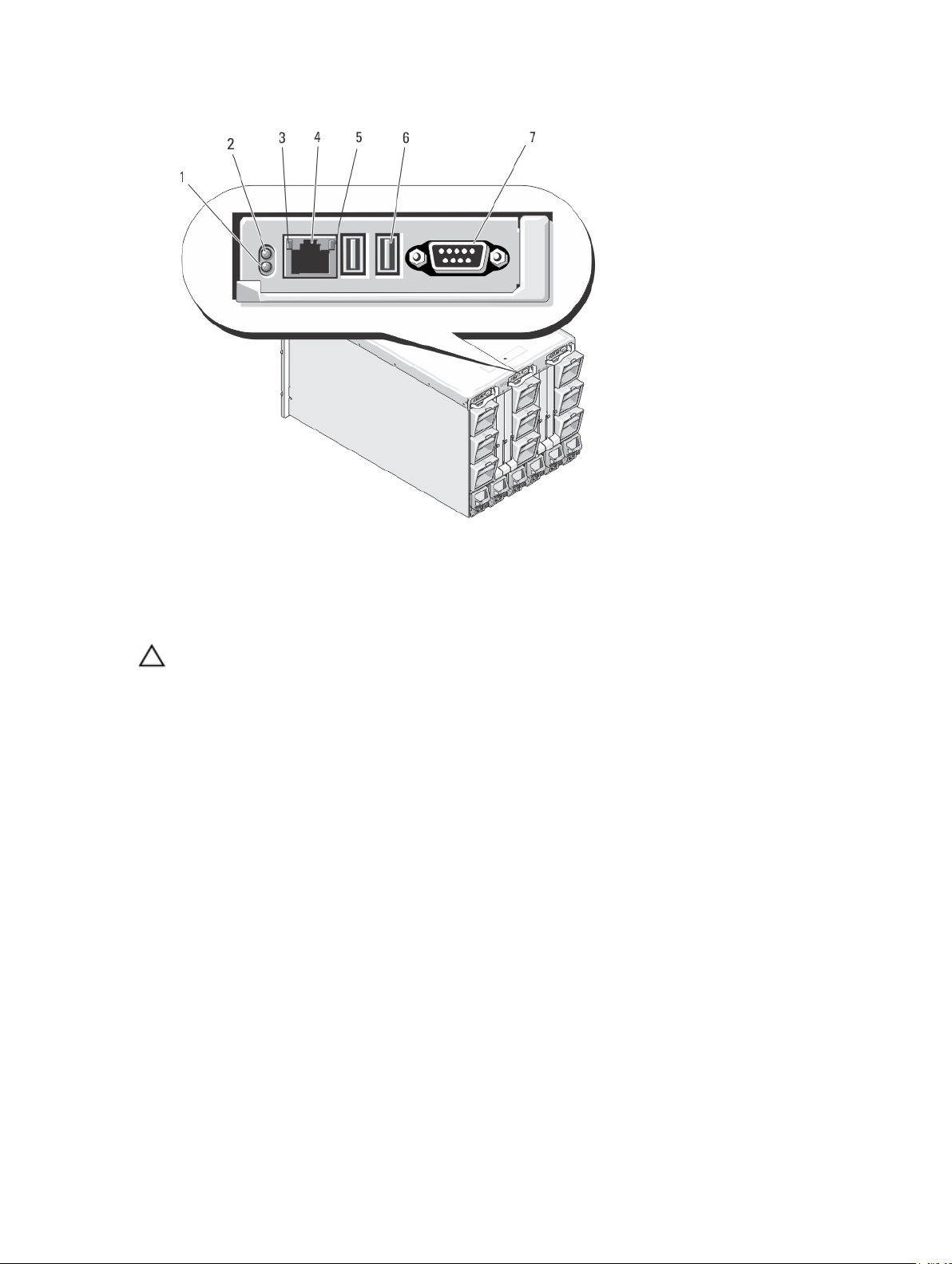

Figure 11. Avocent iKVM Switch Module

1. status/identification indicator

2. power indicator

3. link indicator

CAUTION: Do not connect the ACI port to a LAN

device such as a network hub. Doing so may result in

equipment damage.

4. Analog Console Interface (ACI) port (for tiering

connection only)

5. activity indicator

6. USB connectors (2) for keyboard and mouse

7. video connector

Avocent Analog iKVM Switch Module Features And Indicators

Module Feature Description

Power indicator

Status/Identification

indicator

USB connectors Allows a keyboard and mouse to be connected to the system.

Video connector Allows a monitor to be connected to the system.

Off iKVM switch does not have power.

Green iKVM switch has power.

Green flashing Firmware upgrade in progress.

Blue blinking iKVM module is being identified.

Amber flashing System fault or error condition.

ACI port Allows connection of one or more servers to a Dell console switch with an Analog Rack

Interface (ARI) port, such as an external digital or analog switch.

17

Page 18

Module Feature Description

Link indicator

Activity indicator

CMC Module

Off The ACI is not connected to the external switch.

Green The ACI is connected to the external switch.

Off Data is not being sent or received.

Amber blinking Data is being sent or received.

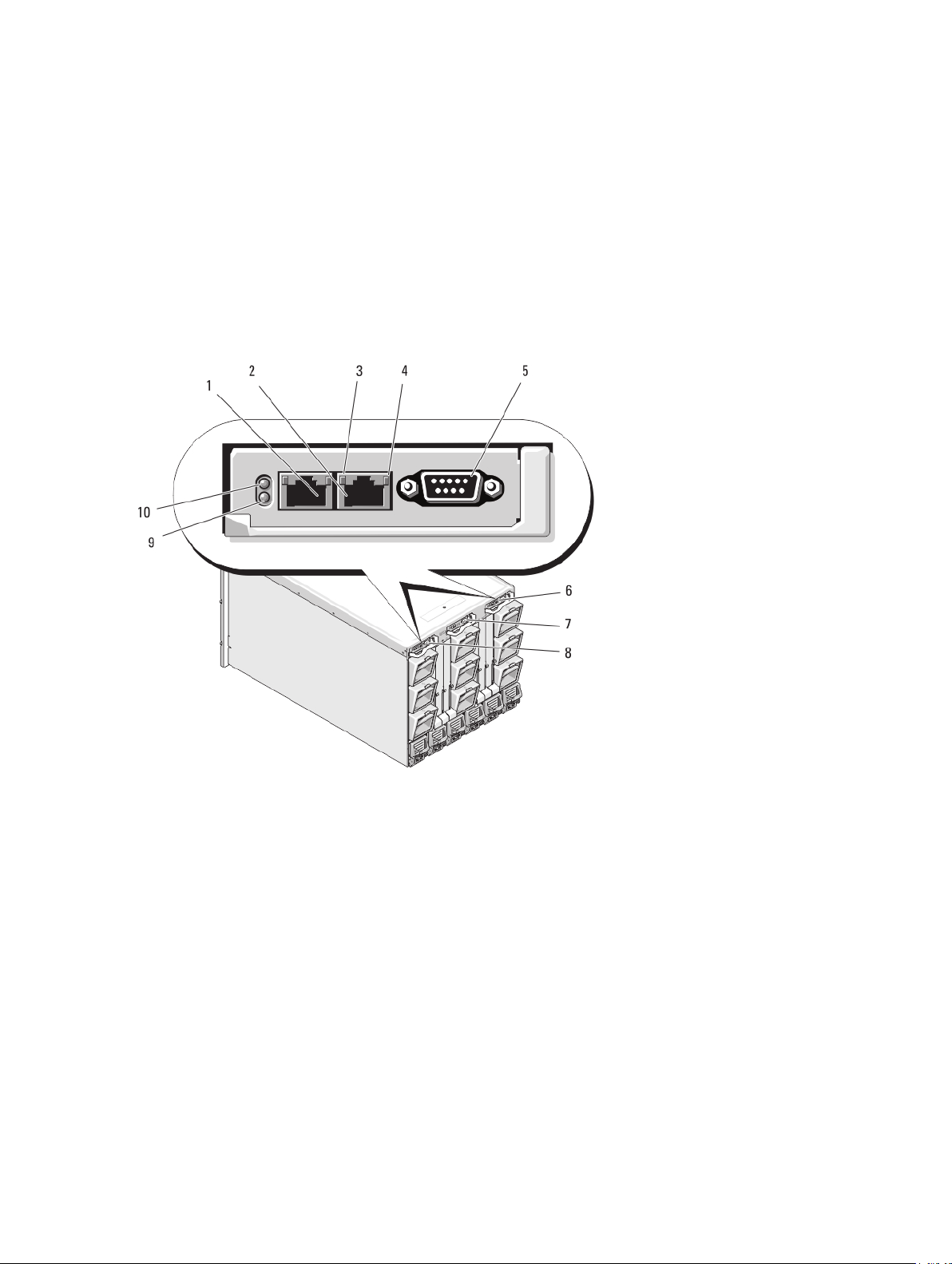

Figure 12. CMC Module Features

1 Ethernet connector Gb1 2 Ethernet connector STK ("stack") - used for daisy-

chaining CMCs in separate enclosures

3 link indicator 4 activity indicator

5 DB-9 serial connector for local configuration 6 optional secondary CMC (CMC 2)

7 optional iKVM module 8 primary CMC (CMC 1)

9 blue status/identification indicator 10 power indicator

CMC Module Features

The CMC provides the following multiple systems management functions for your modular server:

• Enclosure-level real-time automatic power and thermal management.

18

Page 19

– Monitors system power requirements and supports the optional Dynamic Power Supply Engagement

(DPSE) mode. The DPSE mode improves power efficiency by allowing the CMC to dynamically place

power supplies in standby mode, depending on the load and redundancy requirements.

– Reports real-time power consumption, which includes logging high and low points with a time stamp.

– Supports setting an optional enclosure Maximum Power Limit, which either alerts or takes actions, such

as throttling server modules and/or preventing the power up of new blades to keep the enclosure under

the defined maximum power limit.

– Monitors and automatically controls cooling fans based on actual ambient and internal temperature

measurements.

– Provides comprehensive enclosure inventory and status/error reporting.

• CMC fail-safe mode. For more information, see CMC Fail-Safe Mode.

• The CMC provides a mechanism for centralized configuration of the following:

– The enclosure’s network and security settings

– Power redundancy and power ceiling settings

– I/O switches and iDRAC network settings

– First boot device on the server blades

– Checks I/O fabric consistency between the I/O modules and blades and disables components if

necessary to protect the system hardware

– User access security

NOTE: It is recommended that you isolate chassis management from the data network. Dell cannot support or

guarantee uptime of a chassis that is improperly integrated into your environment. Due to the potential of traffic on

the data network, the management interfaces on the internal management network can be saturated by traffic

intended for servers. This results in CMC and iDRAC communication delays. These delays may cause

unpredictable chassis behavior, such as CMC displaying iDRAC as offline even when it is up and running, which in

turn causes other unwanted behavior. If physically isolating the management network is impractical, the other

option is to separate CMC and iDRAC traffic to a separate VLAN. The CMC and individual iDRAC network interfaces

can be configured to use a VLAN with the racadm setniccfg command. For more information, see the

Management Controller Administrator Reference Guide

at support.dell.com/manuals.

Dell Chassis

CMC Fail-Safe Mode

Similar to the failover protection offered by the redundant CMC, the M1000e enclosure enables the fail-safe mode to

protect the blades and I/O modules from failures. The fail-safe mode is enabled when no CMC is in control of the

chassis. During the CMC failover period or during a single CMC management loss:

• you cannot turn on newly installed blades

• existing blades cannot be accessed remotely

• chassis cooling fans run at 100% for thermal protection of the components

• blade performance reduces to limit power consumption until management of the CMC is restored

The following are some of the conditions that can result in CMC management loss:

Condition Description

CMC removal Chassis management resumes after replacing CMC, or after failover to standby CMC.

CMC network cable

removal or network

connection loss

Chassis management resumes after the chassis fails over to the standby CMC. Network

failover is only enabled in redundant CMC mode.

19

Page 20

Condition Description

CMC reset Chassis management resumes after the CMC reboots or chassis fails over to the standby

CMC.

CMC failover command

issued

CMC firmware update Chassis management resumes after the CMC reboots or chassis fails over to the standby

CMC error detection and

correction

NOTE: You can configure the enclosure with a single CMC or with redundant CMCs. In redundant CMC

configurations, if the primary CMC loses communication with the enclosure or the management network, the

standby CMC takes over chassis management.

Chassis management resumes after the chassis fails over to the standby CMC.

CMC. It is recommended that you update the standby CMC first so that there is only one

failover event. For more information on updating the CMC firmware, see the CMC User's

Guide at support.dell.com/manuals.

Chassis management resumes after the CMC resets or chassis fails over to the standby

CMC.

Daisy-Chain CMC Network Connection

Each CMC has two RJ-45 Ethernet ports, labeled GB (the uplink port) and STK (the stacking or cable consolidation port).

With basic cabling, you can connect the GB port to the management network and leave the STK port unused.

CAUTION: Connecting the STK port to the management network can have unpredictable results. Cabling GB and

STK to the same network (broadcast domain) can cause a broadcast storm.

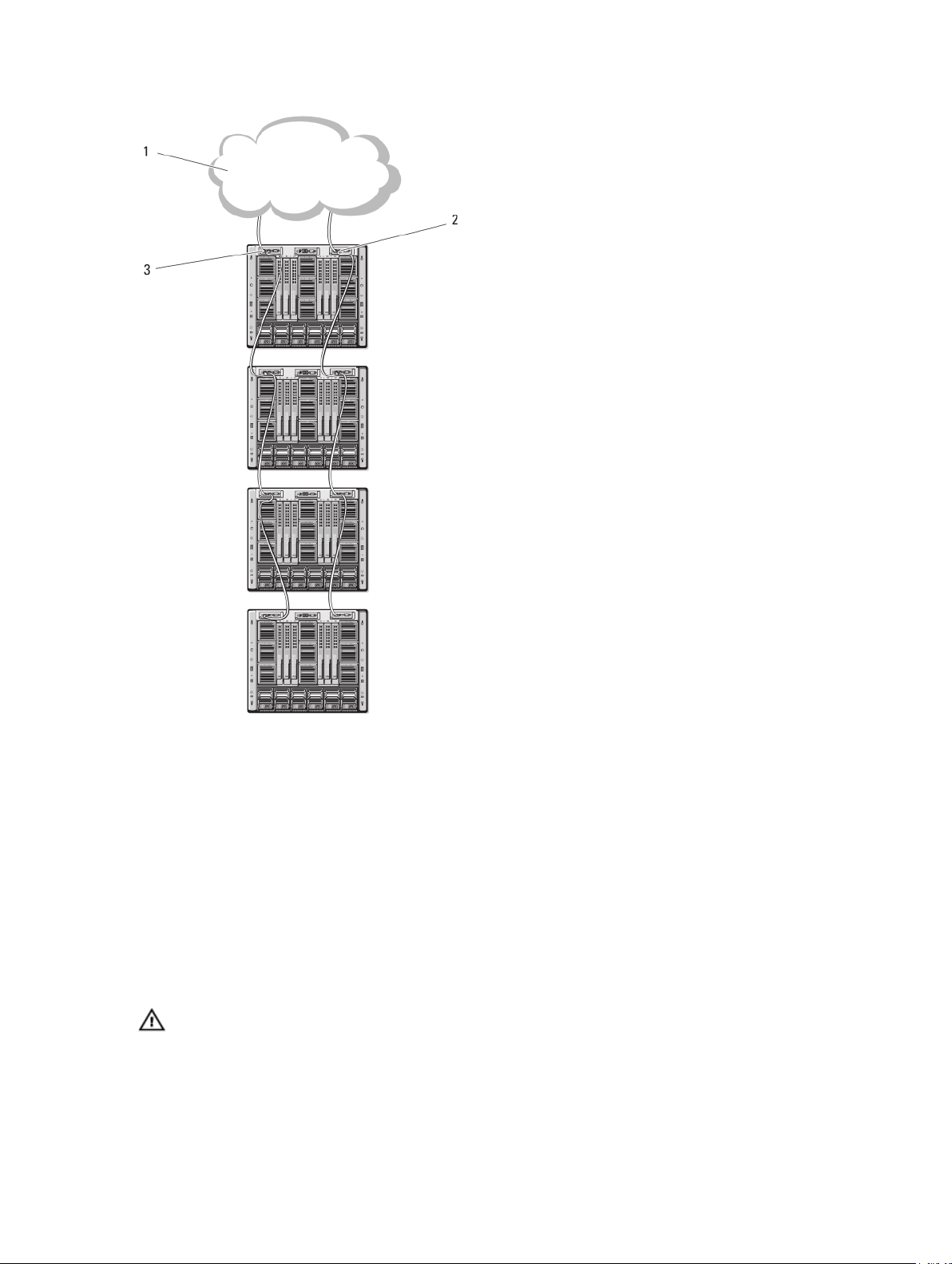

If you have multiple chassis in a rack, you can reduce the number of connections to the management network by daisychaining up to four chassis together. If each of the four chassis contains a redundant CMC, by daisy-chaining you can

reduce the number of management network connections required from eight to two. If each chassis has only one CMC,

you can reduce the connections required from four to one.

When daisy-chaining chassis together, GB is the uplink port and STK is the stacking (cable consolidation) port. Connect

the GB ports to the management network or to the STK port of the CMC in a chassis that is closer to the network. You

must connect the STK port only to a GB port further from the chain or network.

Create separate chains for the CMCs in the active CMC slot and the second CMC slot.

NOTE: At least one CMC must be installed for the system to power up. If a second, optional CMC module is

installed, failover protection and hot-swap replacement is available. See the latest CMC User's Guide at

support.dell.com/manuals for complete instructions on how to set up and operate the CMC module.

The following figure illustrates the arrangement of cables for four daisy-chained chassis, each with active and standby

CMCs.

20

Page 21

Figure 13. CMC Daisy-Chaining

1. management network

2. secondary CMC

3. primary CMC

System Messages

System messages related to the blades in the enclosure may appear on the monitor screen to notify you of a possible

problem with a blade. For a detailed listing of these error messages, including possible causes and solutions, see the

blade documentation.

Other Information You May Need

WARNING: See the safety and regulatory information that shipped with your system. Warranty information may be

included within this document or as a separate document.

• The

Getting Started Guide

specifications.

provides an overview of system features, setting up your system, and technical

21

Page 22

• The blade Owner's Manual provides information about the blade features and describes how to troubleshoot the

blade and install or replace the blade's components.

• The Dell CMC User’s Guide provides information on installing, configuring, and using the CMC.

• Dell systems management application documentation provides information about installing and using the

systems management software.

• For the full name of an abbreviation or acronym used in this document, see the Glossary at support.dell.com/

manuals.

• Any media that ships with your system that provides documentation and tools for configuring and managing your

system, including those pertaining to the operating system, system management software, system updates, and

system components that you purchased with your system.

NOTE: Always check for updates on support.dell.com/manuals and read the updates first because they often

supersede information in other documents.

22

Page 23

Initial System Configuration

Before You Begin

CAUTION: The enclosure power supplies must be connected to a Type B or permanently-connected PDU and not

directly to an electrical outlet. The power supplies require a 100 V to 120 V or 200 V to 240 V power source. You can

select only one AC power input, as the system does not operate at both ranges simultaneously.

If your network uses static addressing, you need the IP address, subnet mask, and gateway to configure the CMC and

other modules in the enclosure.

Initial Setup Sequence

NOTE: Follow the instructions on the enclosure chassis and remove the blades and power supplies before lifting

and installing the system. Reinstall the blades and power supplies after you install the chassis in the rack.

1. Unpack the enclosure and install it in a rack.

For more information, see the

CAUTION: Do not turn on the blades (server modules) until you have configured the switch modules.

2. Connect the power supply units to a PDU.

Getting Started Guide

and

Rack Installation Guide

at support.dell.com/manuals.

2

3. If an optional iKVM module is installed, connect the keyboard, video, and mouse to the enclosure control panel or

to the iKVM module.

NOTE: Connecting a keyboard, video, and mouse to the enclosure control panel disables video output to the iKVM

back panel port.

4. Press the power button on the enclosure control panel.

5. Configure the CMC network settings.

The LCD configuration wizard allows you to quickly configure the CMC and iDRAC management interfaces and

manage the enclosure remotely. You can also use a management station and the RACADM CLI to configure the

CMC.

6. Configure the I/O modules to allow proper network or storage management or paths.

7. After the Ethernet and fibre channel switches are configured, you can turn on your server blades. This allows time

for the Ethernet switch to boot and allow PXI\UNDI traffic for all blade modules.

Initial CMC Network Configuration

The CMC is preset for DHCP. To use a static IP address, you must toggle the CMC setting from DHCP to a static address

by either running the LCD configuration wizard, or by using a management station and CLI commands.

If toggled to use a static address, the CMC IP address defaults to the standard IP address settings of 192.168.0.120,

255.255.255.0, and gateway of 192.168.0.1. You can change this address to an IP address of your choice.

23

Page 24

Configuring The CMC Using The LCD Configuration Wizard

When you first boot your system, the screen on the LCD module directs you to configure the CMC network settings.

NOTE: The option to configure the enclosure using the LCD configuration wizard is only available until the CMC

default password is changed or when the LCD configuration wizard is complete. Thereafter, use the RACADM CLI

or the web-based GUI to change the CMC settings.

NOTE: The serial null modem cable for the CMC is an option. You can access the CLI using the 17th blade feature

on the embedded iKVM module. Blade number 17 is a direct local connection to the CMC.

1. Choose a language from the options in the dialog box.

2. Start the LCD configuration wizard.

3. Configure the CMC network settings for your network environment.

– Network speed

– Duplex mode

– Protocol (IPv4 and/or IPv6)

– Network mode (DHCP or static)

– Static IP address, subnet mask, and gateway values (if static mode was selected)

– DNS setting, including a registered CMC name, (if DHCP mode was selected)

NOTE: The CMC external management network mode is set by default to DHCP. To use a static IP address, you

must change the setting using the LCD configuration wizard.

4. If required, configure the iDRAC network setting for DHCP mode.

NOTE: You cannot set a static IP address for the iDRAC using the LCD configuration wizard. To set the static IP

address, use the web-based interface.

5. Review the settings on the Network Summary screen:

– If the settings are correct, press the center button to close the configuration wizard and return to the Main

Menu.

– If the settings are not correct, use the left-arrow key to return to the screen for that setting and make the

appropriate changes.

The Network Summary screen lists the IP addresses for the CMC and the iDRAC network settings.

After you complete the LCD configuration wizard, you can access the CMC on the network using the web-based CMC

interface or text-based interfaces such as a serial console, Telnet, or SSH.

NOTE: If you want to use static addresses rather than DHCP to access the iDRACs, you must configure them using

the CMC web-based interface or CLI.

Configuring The CMC Using A Management Station And CLI

The LCD configuration wizard is the quickest way to initially configure the CMC network settings. However, you can also

use a management station and a local connection to access the CMC.

There are two ways to create a local connection to the CMC:

• The CMC Console, using the optional iKVM. Press <Prnt Scrn> and select blade number 17.

• Serial connection, using an optional null modem cable (115200 bps, 8 data bits, no parity, 1 stop bit, and no flow

control).

24

Page 25

Once you have established a connection to the CMC, you can complete the initial CMC network configuration.

1. Log in to the CMC.

The default user name is root and the default password is calvin.

2. Type getniccfg and press <Enter> to view the current CMC network parameters.

3. Configure the CMC network settings:

– To set a static IP address, type

setniccfg -s <IP address><network mask><gateway>

and press <Enter>.

– To configure the CMC to obtain an IP address using DHCP, type

setniccfg -d

and press <Enter>.

The new network settings are activated in a few seconds after configuring the network.

Logging In To The CMC Using The Web-Based Interface

1. Open a supported web browser window.

For current information on supported web browsers, see the CMC User’s Guide at support.dell.com/manuals.

2. Log in to the CMC.

– If the CMC is accessed using a specific IP address, type the following URL in the Address field, and then

press <Enter>.

https://<CMC IP address>

The default IP address for the CMC is 192.168.0.120. If the default HTTPS port number (port 443) has been

changed, type:

https://<CMC IP address>:<port number>

where

<CMC IP address>

– If you access the CMC using a registered DNS name, type the CMC’s name:

https://<CMC name>

By default, the CMC name on the DNS server is cmc-<service tag>

The CMC Login page is displayed.

is the IP address for the CMC and

<port number>

is the HTTPS port number.

NOTE: The default CMC user name is root, and the password is calvin. The root account is the default

administrative account that ships with the CMC. For added security, you must change the default password of the

root account during initial setup.

NOTE: The CMC does not support extended ASCII characters, such as ß, å, é, ü, or other characters used primarily

in non-English languages.

NOTE: You cannot log in to the web-based interface with different user names in multiple browser windows on a

single workstation.

You can log in as either a CMC user or as Directory Service user in Microsoft Active Directory or Lightweight

Directory Access Protocol Services (LDAP).

3. In the Username field, type your user name:

– CMC user name: <user name>

– Active Directory user name: <domain>\<user name>

25

Page 26

– LDAP user name: <user name>

NOTE: This field is case sensitive.

4. In the Password field, type your CMC user password or Active Directory user password.

NOTE: This field is case-sensitive.

Adding And Managing CMC Users

From the Users and User Configuration pages in the web-based interface, you can view information about CMC users,

add a new user, and change settings for an existing user.

NOTE: For added security, it is highly recommended that you change the default password of the root (User 1)

account. The root account is the default administrative account that ships with the CMC.

To change the default password for the root account, click User ID 1 to open the User Configuration page. Help for that

page is available through the Help link at the top right corner of the page.

NOTE: You must have User Configuration Administrator privileges to perform the following steps.

1. Log in to the web-based interface.

2. Select Chassis in the system tree.

3. Click the Network/Security tab, and then click the Users sub-tab.

The Users page is displayed, listing each user’s user ID, login state, user name, and CMC privilege, including those

of the root user. User IDs available for configuration have no user information displayed.

4. Click an available user ID number. The User Configuration page is displayed.

To refresh the contents of the Users page, click Refresh. To print the contents of the Users page, click Print.

5. Select general settings for the users.

For details on user groups and privileges, see the CMC User’s Guide at support.dell.com/manuals.

6. Assign the user to a CMC user group.

You can customize the privileges settings for the user by using the check boxes. After you have selected a CMC

Group or made Custom user privilege selections, click Apply Changes to save the settings.

When you select a user privilege setting from the CMC Group drop-down menu, the enabled privileges (shown as

checked boxes in the list) are displayed according to the pre-defined settings for that group.

Configuring iDRAC Networking Using The Web-Based Interface

Follow this procedure to configure the iDRAC in the LCD configuration wizard.

NOTE: If you did not configure the iDRAC using the LCD configuration wizard, iDRAC is disabled until you configure

it using the web-based interface.

NOTE: You must have Chassis Configuration Administrator privileges to set up iDRAC network settings from the

CMC.

NOTE: The default CMC user name is root and the default password is calvin.

1. Log in to the web-based interface.

2. Click the plus (+) symbol next to Chassis in the left column, then click Servers.

3. Click Setup → Deploy.

4. Select the protocol for the iDRAC setting (IPv4 and/or IPv6).

5. Under Enable Lan, select the check box next to the server to enable LAN for iDRAC.

26

Page 27

6. Under Enable IPMI over LAN, select or clear the check box next to the server to enable or disable IPMI over LAN.

7. Under DHCP Enabled, select or clear the check box next to the server to enable or disable DHCP for iDRAC.

8. If DHCP is disabled, enter the static IP address, netmask, and default gateway for the iDRAC.

9. Click Apply at the bottom of the page.

Setting The First Boot Device For Servers

The First Boot Device page allows you to specify the boot device for each blade. You can set the default boot device and

also set a one-time boot device. This allows you to boot using a special image to perform tasks such as running

diagnostics or reinstalling an operating system.

To set the first boot device for some or all servers in the chassis:

1. Log in to the CMC web-based interface.

2. Click Servers in the system tree and then click Setup → Deploy First Boot Device. A list of servers is displayed, one

per row.

3. Select the boot device you want to use for each server from the list box.

4. If you want the server to boot from the selected device every time it boots, clear the Boot Once check box for the

server.

If you want the server to boot from the selected device only on the next boot cycle, select the Boot Once check box

for the server.

5. Click Apply.

Configuring And Managing Power

You can use the web-based and RACADM interfaces to manage and configure power controls on the CMC, as outlined

in the following sections. For more information on the various power management options, see the CMC User’s Guide at

support.dell.com/manuals.

The CMC’s power management service optimizes power consumption for the entire chassis (the chassis, servers, I/O

modules, iKVM, CMC, and PSUs) and re-allocates power to different modules based on the demand.

NOTE: To perform power management actions, you must have Chassis Control Administrator privileges.

1. Log in to the CMC web-based interface.

2. Select Chassis in the system tree.

3. Click the Power Management tab. The Power Budget Status page is displayed.

4. Click the Configuration sub-tab. The Budget/Redundancy Configuration page is displayed.

5. Configure the power budget and redundancy settings based on the components in the enclosure and your needs.

6. Click Apply to save your changes.

Installing Or Updating The CMC Firmware

NOTE: It is normal for some or all of the fan units to spin at 100 percent during CMC or iDRAC firmware updates on

a server.

NOTE: In a redundant CMC configuration, care must be taken to update CMC firmware on both modules. Failure to

do so may cause unexpected behavior during a CMC failover or failback. Use the following procedure for

redundant CMC deployments.

27

Page 28

1. Locate the secondary or standby CMC by using the RACADM getsysinfo command, or by using the Chassis

Summary page in the web-based interface. Visually, the status indicator is solid blue on the primary or active CMC

module and off on the standby or secondary CMC.

2. Update the firmware on the standby CMC first, using the web-based interface or RACADM.

3. Verify that the secondary or standby CMC’s firmware is at the requested level with the getsysinfo command or

using the web-based interface.

4. After the standby CMC has rebooted, update the firmware on the active or primary CMC. Allow 10 minutes for the

standby CMC to boot.

5. Verify that the active or primary CMC firmware is at the requested level using the getsysinfo command or using

the web-based interface.

6. Once both CMCs are updated to the same firmware revision, use the cmcchangeover command to reset the

CMC in the left slot as primary.

Downloading The CMC Firmware

Before beginning the firmware update, download the latest firmware version from support.dell.com, and save it to your

local system. The following software components are included with your CMC firmware package:

• Compiled CMC firmware code and data

• Web-based interface, JPEG, and other user interface data files

• Default configuration files

Use the Firmware Update page to update the CMC firmware to the latest revision. When you run the firmware update,

the update retains the current CMC settings.

NOTE: The firmware update, by default, retains the current CMC settings. During the update process, you have the

option to reset the CMC configuration settings back to the factory default settings.

Updating The CMC Firmware Using The Web-Based Interface

1. Log in to the web-based interface.

2. Click Chassis in the system tree.

3. Click the Update tab. The Updatable Components page is displayed.

4. On the Updatable Components page, click the CMC name. The Firmware Update page is displayed.

5. In the Value field, type the path on your management station or shared network where the firmware image file

resides, or click

NOTE: The default CMC firmware image name is firmimg.cmc and this filename must not be changed. Ensure that

you keep different firmware revisions separated as the file name always remains the same.

6. Click Update. A dialog box prompts to confirm the action.

7. Click Yes to continue. The firmware transfer process begins and the status displays the message Firmware

Update in Progress

Interface page to log in again.

Browse to navigate to the file location.

. After the CMC update is complete, the CMC is reset and you must refresh the User

Updating The CMC Firmware Using RACADM

1. Open a CMC command line console and log in.

2. Type:

racadm fwupdate -g -u - a <TFTP server IP address> -d <filepath> -m <cmcactive|cmc-standby>

28

Page 29

For complete instructions on how to configure and operate the CMC module, see the latest CMC User's Guide at

support.dell.com/manuals.

Configuring The Optional iKVM Switch Module

Updating The iKVM Firmware

NOTE: The iKVM resets and becomes temporarily unavailable after the firmware has been uploaded successfully.

1. Log in to the CMC web-based interface.

2. Select Chassis in the system tree.

3. Click the Update tab. The Updatable Components page is displayed.

4. Click the iKVM name. The Firmware Update page is displayed.

5. In the Value field, type the path on your management station or shared network where the firmware image file

resides, or click

NOTE: The default iKVM firmware image name is ikvm.bin. However, the iKVM firmware image name can be

renamed. If you are unable to locate ikvm.bin, verify if another user has renamed the file.

6. Click Update. A dialog box prompts you to confirm the action.

7. Click Yes to continue.

When the update is complete, the iKVM resets.

Browse to navigate to the file location.

Tiering The Avocent iKVM Switch From A Digital KVM Switch

The iKVM module may also be tiered from a digital KVM switch such as the Dell 2161DS-2 or 4161DS, or a supported

Avocent digital KVM switch. Many switches may be tiered without the need for a Server Interface Pod (SIP).

The cabling requirements for various external digital KVM switches are as follows:

• Dell PowerConnect 2161DS, 4161DS, 2161DS-2, 2321DS (version 1.3.40.0 or later) or Avocent DSR x02x (except

1024), x03x (version 3.6 or later): Seamless tiering using ACI port and Cat 5 cable

• Avocent DSR 800, x16x, x010, 1024: Avocent USB SIP (DSRIQ-USB) with Cat 5 cable

To tier the iKVM module from a Dell 2161DS, 180AS, or 2160AS console switch:

•

If the switch does not require a SIP to connect to the iKVM

port on the iKVM module. Connect the other end of this cable to the ARI port on the external switch.

•

If the switch requires a USB SIP

cable to the SIP. Connect the other end of this cable to the ARI port on the external switch.

Once the KVM switch is connected, the server modules are displayed in OSCAR.

NOTE: You must also re-synchronize the server list from the Remote Console Switch software to view the list of

blades.

, connect an Avocent USB SIP to the iKVM, then connect a Cat 5 (or newer)

, connect a Cat 5 (or newer) cable to the RJ-45 ACI

Tiering The Avocent iKVM Switch From An Analog KVM Switch

The Avocent iKVM switch can be tiered from analog KVM switches such as the Dell 2160AS and 180AS, as well as many

Avocent analog KVM switches. Many switches may be tiered without the need for a SIP.

The cabling requirements for specific external switches are as follows:

29

Page 30

• Dell PowerConnect 180AS, 2160AS (version 1.0.3.2 or later) or Avocent Autoview 2020, 2030 (version 1.6.0.4 or

later): Seamless tiering using ACI port and Cat 5 cable

• Avocent Autoview 1400, 1500, 2000, 1415, 1515, 2015u: Avocent USB SIP (DSRIQ-USB) required with Cat 5 cable

Before connecting the iKVM switch to a supported analog switch, you must set the display in slot order, and set the

Screen Delay Time to 1 or more seconds:

1. Press <Prnt Scrn> to launch the iKVM Switch OSCAR.

2. Click Setup → Menu. The Menu dialog box is displayed.

3. Select Slot to display servers numerically by slot number.

4. Set a screen delay time of at least 1 second.

5. Click OK.

Setting the Screen Delay time to 1 second allows you to soft switch to a server without launching OSCAR.

NOTE: Soft switching allows you to switch servers using a hot key sequence. To soft switch to a server, press

<Prnt Scrn> and type the first few characters of its name or number. If you have a Delay Time set and you press

the key sequences before that time has elapsed, OSCAR does not display.

Configuring The Analog Switch

1. Press <Prnt Scrn> to launch the iKVM Switch OSCAR.

2. Click Setup → Devices → Device Modify.

3. Select the 16-port option to match the number of blades in your system.

4. Click OK to exit OSCAR.

5. Press <Prnt Scrn> to verify that the settings have taken effect. The slot number of the blade to which the iKVM

switch is now attached must be expanded to display each of the slot locations of the blades in the system. For

instance, if the iKVM switch is attached to slot 1, it must be displayed as 01-01 to 01-16.

6. Connect the Avocent iKVM switch to a supported analog switch:

If the switch does not require a SIP to connect to the iKVM

on the iKVM module. Connect the other end of this cable to the ARI port on the external switch.

If the analog switch requires a USB SIP

cable to the SIP. Connect the other end of this cable to the ARI port on the external switch.

7. Connect both the analog switch and the system to an appropriate power source.

8. Turn on the system.

9. Turn on the external analog switch.

NOTE: If the external analog switch is powered up before the system, it may result in only one blade being

displayed in the analog switch OSCAR, instead of 16. If this behavior occurs, shut down and restart the switch so

that the entire complement of blades is recognized.

NOTE: In addition to the steps outlined above, some external analog switches may require you to perform

additional steps to ensure that the iKVM switch blades are displayed in the external analog switch OSCAR. For

more information, see the external analog switch documentation.

, connect an Avocent USB SIP to the iKVM, then connect a Cat 5 (or newer)

, connect a Cat 5 (or newer) cable to the RJ-45 ACI port

30

Page 31

Resynchronizing The Server List At The Remote Client Workstation

Once the iKVM module is connected, the blades are displayed in OSCAR. You must re-synchronize the servers on any

remote workstation to ensure that the blades are available to any remote users connected to the console switch through

the Remote Console Switch software.

NOTE: This procedure only re-synchronizes one remote client workstation. With multiple client workstations, save

the re-synchronized local database and load it into the other client workstations to ensure consistency.

To re-synchronize the server listing:

1. Click Resync in the Server category of the Management panel. The resync wizard launches.

2. Click Next. A warning message is displayed indicating that the database will be updated to match the current

configuration of the console switch. Your current local database names will be overwritten with the switch names.

To include unpowered SIPs in the re-synchronization, select the

3. Click Next. A Polling Remote Console Switch message box is displayed with a progress bar indicating that the

switch information is being retrieved.

4. If no changes were detected in the appliance, a completion dialog box is displayed with this information. If server

changes were detected, then the Detected Changes dialog box is displayed.

5. Click Next to update the database.

If a cascade switch was detected, the Enter Cascade Switch Information dialog box is displayed.

6. Select the type of switch connected to the appliance from the drop-down list. If the type you are looking for is not

available, you can add it by clicking

7. Click Next. The completion dialog box is displayed.

Add.

Include Offline SIPs check box.

8. Click Finish to exit.

9. Start up the analog switch and the system.

Viewing And Selecting Servers

Use the OSCAR Main dialog box to view, configure, and manage servers in the M1000e enclosure through the iKVM. You

can view the servers by name or by slot. The slot number is the chassis slot number the server occupies. The Slot

column indicates the slot number in which a server is installed.

NOTE: Server names and slot numbers are assigned by the CMC.

NOTE: If you have enabled access to the CMC though the iKVM, an additional option, Dell CMC Console, is

displayed.

To access the Main dialog box, press <Prnt Scrn> launch the iKVM Switch OSCAR. The Main dialog box is displayed.

or

If a password has been assigned, the Password dialog box is displayed. Type your password and click OK. The Main

dialog box is displayed.

To toggle between quarter-height blades installed in a sleeve:

1. Press <Prnt Scrn> to launch the iKVM Switch OSCAR.

2. Select the slot where the sleeve and blade is installed and press <Enter> to exit OSCAR.

3. Press <Scroll Lock> twice to toggle between the quarter-height blades installed in the sleeve.

31

Page 32

FlexAddress

The FlexAddress feature allows server modules to replace the factory assigned World Wide Name and Media Access

Control (WWN/MAC) network IDs with WWN/MAC IDs provided by the chassis. FlexAddress is delivered on a Secure

Digital (SD) card that must be inserted into the CMC to provide the chassis-assigned WWN/MAC IDs.

Every server module is assigned unique WWN and MAC IDs as part of the manufacturing process. Before the

FlexAddress feature was introduced, if you had to replace one server module with another, the WWN/MAC IDs would

change and Ethernet network management tools and SAN resources would need to be reconfigured to be aware of the

new server module.

FlexAddress allows the CMC to assign WWN/MAC IDs to a particular slot and override the factory IDs. If the server

module is replaced, the slot-based WWN/MAC ID remains the same. This feature eliminates the need to reconfigure

Ethernet network management tools and SAN resources for a new server module.

Additionally, the override action only occurs when a server module is inserted in a FlexAddress enabled chassis; no

permanent changes are made to the server module. If a server module is moved to a chassis that does not support

FlexAddress, the factory assigned WWN/MAC IDs are used.

Prior to installing FlexAddress, you can determine the range of MAC addresses contained on a FlexAddress feature card

by inserting the SD card into an USB Memory Card Reader and viewing the file pwwn_mac.xml. This clear text XML file

on the SD card contains an XML tag mac_start, which is the first starting hex MAC address that will be used for this

unique MAC address range. The mac_count tag is the total number of MAC addresses that the SD card allocates. The

total MAC range allocated can be determined by:

<mac_start> + 0xCF (208 - 1) = mac_end

For example:

(starting_mac)00188BFFDCFA + 0xCF = (ending_mac)00188BFFDDC9

NOTE: To prevent modifying any of the contents accidentally, you must lock the SD card prior to inserting in the

USB "Memory Card Reader". You must then unlock the SD card before inserting it into the CMC.

For more information on the FlexAddress feature, see the following resources:

• The CMC Secure Digital (SD) Card Technical Specification document at support.dell.com/manuals

• The Help link in the CMC web interface

• The FlexAddress information in the CMC User’s Guide at support.dell.com/manuals

FlexAddress Plus

FlexAddress Plus expands the number of MAC addresses to 3136 from the original FlexAddress pool of 208.

FlexAddress Plus is provided on the FlexAddress Plus Secure Digital (SD) card along with the FlexAddress feature.

NOTE: The SD card labeled FlexAddress only contains FlexAddress and the card labeled FlexAddress Plus contains

FlexAddress and FlexAddress Plus. The card must be inserted into the CMC to activate the feature.

32

Page 33

Configuring The I/O Modules

Network Information

You can configure your I/O switch modules using:

• CMC web-based interface.

NOTE: The default IP address for the CMC is 192.168.0.120.

• CMC CLI using serial console redirection.

• Direct access to the I/O module serial port (if supported).

• I/O module default IP address (if supported).

I/O Connectivity

The enclosure supports three layers of I/O fabric, selectable between combinations of Ethernet, fibre-channel, and

Infiniband modules. You can install up to six hot-swappable I/O modules in the enclosure, including fibre channel

switches, fibre-channel pass-throughs, Infiniband switches, Ethernet switches, and Ethernet pass-through modules.

General I/O Module Configuration Guidelines

3

• If an I/O module is installed in Fabric B or Fabric C, at least one blade must have a matching mezzanine card

installed to support data flow to that I/O module.

• If a blade has an optional mezzanine card installed in a Fabric B or Fabric C card slot, at least one corresponding

I/O module must be installed to support data flow to that fabric.

• Modules may be installed in Fabrics B and C independently (you do not need to install modules in Fabric B

before installing modules in the Fabric C slots).

• Slots A1 and A2 only support Ethernet I/O modules. This fabric type is hardset to Ethernet for these slots and

cannot support fibre channel, Infiniband, or other fabric type modules.

• Fabrics A, B, and C can support Ethernet fabric-type modules.

• To enable switch configuration prior to blade imaging, I/O modules are allowed to power-up before a blade is

inserted in the enclosure.

Fabric A

Fabric A is a redundant Gb Ethernet fabric, supporting I/O module slots A1 and A2. The integrated Ethernet controllers in

each blade dictate Fabric A as an Ethernet-only fabric.

NOTE: Fabric A supports KR (10 Gbps standard).

NOTE: Modules designed specifically for Fabric B or Fabric C cannot be installed in slots A1 or A2, as indicated by

the color-coded labeling on the faceplate of each module.

33

Page 34

Fabric B

Fabric B is a 1 to 40 Gb/sec redundant fabric, supporting I/O module slots B1 and B2. Fabric B currently supports 1 Gb or

10 Gb Ethernet, DDR/QDR Infiniband, and 4 Gbps or 8 Gbps fibre channel modules. Additional fabric types may be

supported in the future.

NOTE: Fabric B supports up to 16 Gbps fibre channel, Infiniband FDR (14 Gbps standard), and KR (10 Gbps

standard).

To communicate with an I/O module in the Fabric B slots, a blade must have a matching mezzanine card installed in a

Fabric B mezzanine card location.

Modules designed for Fabric A may also be installed in the Fabric B slots.

Fabric C

Fabric C is a 1 to 40 Gb/sec redundant fabric, supporting I/O module slots C1 and C2. Fabric C currently supports 1 Gb or

10 Gb Ethernet, DDR/QDR Infiniband, and 4 Gbps or 8 Gbps fibre channel modules. Additional fabric types may be

supported in the future.

NOTE: Fabric C supports up to 16 Gbps fibre channel, Infiniband FDR (14 Gbps standard), and KR (10 Gbps

standard).

To communicate with an I/O module in the Fabric C slots, a blade must have a matching mezzanine card installed in a

Fabric C mezzanine card location.

Modules designed for Fabric A may also be installed in the Fabric C slots.

Port Auto-Disablement in Quad-Port Network Daughter Card (Dell PowerEdge M710HD Only)

Systems installed with quad-port Network Daughter Card support a Port Auto-Disablement feature. This feature disables

the third (NIC3) and fourth (NIC4) ports of a quad-port network daughter card during system boot, if the corresponding

I/O module installed in the chassis Fabric A slots does not support quad-port mapping. This behavior is limited to Fabric

A slots only and is automatically enabled or disabled depending on the type of I/O module installed.

NOTE: A quad-port network daughter card must be used with a 48-port switch module (32 internal ports) for all the

ports to be active.

NOTE: LOM firmware updates are applied only to the enabled ports on a quad-port network daughter card.