Page 1

™

Delfield

®

Specication Line

®

Installation, Use and Care Manual

Please read this manual completely before attempting to install or operate this equipment! Notify carrier

of damage! Inspect all components immediately.

Important Information

Please Save These Instructions!

*9291319*

Read Before Use

March 2013

Page 2

Deleld

Important Warning And Safety Information

WARNING Read This Manual Thoroughly Before Operating, Installing, Or Performing Maintenance On The Equipment.

WARNING Failure To Follow Instructions In This Manual Can Cause Property Damage, Injury Or Death.

WARNING Do Not Store Or Use Gasoline Or Other Flammable Vapors Or Liquids In The Vicinity Of This Or Any Other

Appliance.

WARNING Unless All Cover And Access Panels Are In Place And Properly Secured, Do Not Operate This Equipment.

WARNING This Appliance Is Not Intended For Use By Persons Who Lack Experience Or Knowledge, Unless They Have

Been Given Supervision Or Instruction Concerning Use Of The Appliance By A Person Responsible For Their

Safety.

WARNING This Appliance Is Not To Be Played With.

WARNING Do Not Clean With Water Jet.

WARNING Do Not Use Electrical Appliances Inside The Food Storage Compartment Of This Appliance.

CAUTION Observe the following:

• Minimum clearances must be maintained from all walls and combustible materials.

• Keep the equipment area free and clear of combustible material.

• Allow adequate clearance for air openings.

• Operate equipment only on the type of electricity indicated on the specification plate.

• Unplug the unit before making any repairs.

• Retain this manual for future reference.

2

Page 3

Specication Line

Contents

Receiving And Inspecting The Equipment ............................3

Serial Number .......................................................................4

Warranty Information ............................................................4

Model Numbers ....................................................................5

Introduction ..........................................................................6

Specifications .................................................................. 7-12

Installation .................................................................... 13-14

Heated Cabinet Operation ...................................................15

Electronic Temperature Control Operation .................... 16-17

Door Reversal Procedures ..................................................18

Maintenance .................................................................. 19-20

Wiring Diagrams ........................................................... 21-28

Compressor Diagrams ........................................................29

Replacement Parts ........................................................ 30-32

Standard Labor Guidelines ..................................................33

Notes ............................................................................ 34-35

Receiving And Inspecting The Equipment

Even though most equipment is shipped crated, care should be

taken during unloading so the equipment is not damaged while

being moved into the building.

1. Visually inspect the exterior of the package an skid or

container. Any damage should be noted and reported to the

delivering carrier immediately.

2. If damaged, open and inspect the contents with the carrier.

3. In the event that the exterior is not damaged, yet upon

opening, there is concealed damage to the equipment notify

the carrier. Notification should be made verbally as well as

in written form.

4. Request an inspection of the concealed equipment. This

should be done within 10 days from receipt of the equipment.

5. Check the lower portion of the unit to be sure legs or casters

are not bent.

6. Also open the compressor compartment housing and

7. Freight carriers can supply the necessary forms upon

8. Retain all crating material until an inspection has been made

Uncrating the Equipment

First cut and remove the banding from around the crate. Remove

the front of the crate material, use of some tools will be required.

If the unit is on legs remove the top of the crate as well and lift

the unit off the skid. If the unit is on casters it can be "rolled" off

the skid.

visually inspect the refrigeration package. Be sure lines are

secure and base is still intact.

request.

or waived.

3

Page 4

Deleld

Delfield

™

®

Serial Number Location

The serial number is on the identification plate that also

includes the model number. On refrigeration and freezer

units the identification plate is located inside the left most

door near the top front corner of the left interior wall. On

heated units, the identification plate is located in the shroud

area on the right side panel.

Always have the serial number of your unit available when

calling for parts or service. A complete list of authorized

Delfield parts depots can be found at www.delfield.com.

©2013 The Deleld Company. All rights reserved. Reproduction without written

permission is prohibited. “Deleld” is a registered trademark of The Deleld

Company.

Warranty Information

Visit http://www.delfield.com/minisite/service/warranty_info to:

• Register your product for warranty.

• Verify warranty information.

• View and download a copy of your warranty.

4

Page 5

Specication Line

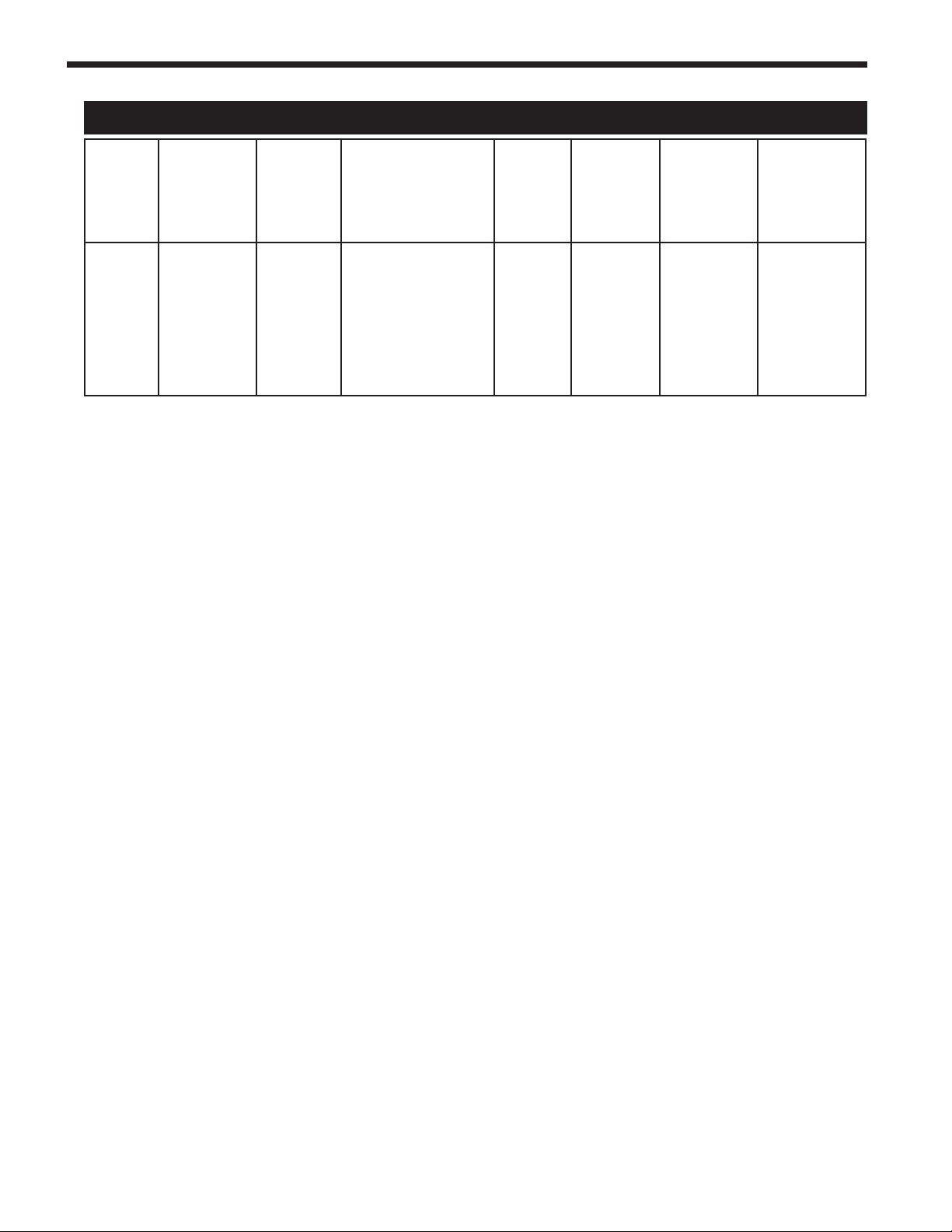

Model Numbers

Series

S=Specification

Line

Finish

S=Stainless interior &

exterior

A=Stainless exterior,

aluminum interior

M=Stainless front,

aluminum sides and

interior

Temp

R=Refrigerator

F=Freezer

H=Heated

D=Dual Temp

Configuration

None=Reach-in

PT=Pass Thru

RI=Roll-in

RT=Roll Thru

FF=Fish Drawers

RL=Refrigerator Left

FL=Freezer Left

TR=Top Refrigerator

BR=Bottom Refrigerator

TP=Top Refrigerator Pass Thru

BP=Bottom Refrigerator Pass Thru

RP=Refrigerator Left Pass Thru

FP=Freezer Left Pass Thru

Section

1=1 Section

2=2 Section

3=3 Section

Size

None=Standard

N=Narrow

S=Shallow

System

None=Standard

E=Export Voltage

R=Remote

Doors

S=Solid Full

SH=Solid Half

G=Hinged Glass Full

GH=Hinged Glass Half

SL=Sliding Glass Full

SLH=Sliding Glass Half

SLS=Sliding Solid Full

SLSH=Sliding Solid Half

D=Drawers

5

Page 6

Deleld

Introduction

Model numbers starting with the letters “SS” have a stainless

steel exterior and interior. Model numbers starting with the letters

“SA” have an aluminum interior and a stainless steel exterior.

Model numbers starting with the letters “SM” have an aluminum

interior and exterior with a stainless steel front and shroud. Door

gaskets are magnetic and mount to the door, snapping in place

and are removable without tools. Keyed door lock is mounted

in the door next to the handle.

Doors can be removed from the cabinet without the use of tools.

Each door has two edge mount, self-closing, cam lift style hinges.

Refrigeration System

All components are mounted to the exterior cabinet ceiling,

outside the food zone and are assembled as one-piece and can be

removed as one-piece. Environmentally friendly R404A refrigerant

is used. The system has the capability of maintaining between

33°F and 40°F (1°C and 4°C) in heavy use food service operations.

Refrigerant is metered using a highly responsive thermostatic

expansion valve. Systems are controlled using Delfield’s ACT

Electronic Temperature Control. It provides improved pull down

times, reducing compressor cycling and longer compressor life

with lower energy consumption. Control system uses adaptive

defrost to assure evaporator coil is free of ice and operating at

optimum efficiency. Evaporator condensate is eliminated using

an energy efficient hot gas system.

Freezer Refrigeration System

All components are mounted to the exterior cabinet ceiling,

outside the food zone and are assembled as one-piece and

can be removed as one-piece. Environmentally friendly R404A

refrigerant is used. The system has the capability of maintaining

between -5°F and 0°F (-21°C and -18°C) in heavy use food service

operations. Refrigerant is metered using a highly responsive

thermostatic expansion valve. System is controlled using

Delfield’s ACT Electronic Temperature Control, which provides

improved pull down times, reducing compressor cycling and

longer compressor life with lower energy consumption. Control

system uses adaptive defrost to assure evaporator coil is free of

ice and operating at optimum efficiency. Evaporator condensate

is eliminated using an energy efficient hot gas system.

Service Alert

During normal operation the evaporator fan may cycle

and/or pulse independently of the compressor. Consult

the service manual or contact Technical Support at

1-800-733-8829 if you are unsure of the proper function.

Dual Temperature Refrigeration/Freezer

Each compartment has its own separate refrigeration system.

Condensing units are located on top of the cabinet, outside the food

zone, behind the upper shroud. Evaporator coils are located inside

the cabinet mounted to the interior ceiling of each compartment.

Defrost is automatic. Condensate travels down a tube in the

cabinet sidewall to a receptacle mounted to the exterior bottom of

the cabinet where it evaporates with the aid of an electric heater.

Each compartment’s temperature is individually monitored and

controlled with Delfield's ACT Electronic Temperature Control. Two

exterior digital thermometers monitor temperature. Refrigerator

compartment maintains temperature between 33°F and 41°F (1°C

and 5°C). Freezer compartment maintains temperature between

-5°F and +5°F (-21°C and -15°C). Refrigerant is metered using

a highly responsive thermostatic expansion valve.

Power Switch

Select units are equipped with a power disconnect switch

located next to the energy saver switch and thermostat control

knob. Switch must be in the “on” position for the unit to

operate. On freezers, if the switch is turned off, then returned

to the on position, the unit will enter a defrost cycle and the

display will read “Def.”

Heating System

Heating system cabinets are designed to maintain temperatures

between 120°F and 200°F (49°C and 93°C). Heating elements

are helical shaped, with tubular fins. A circulating fan provides

uniform airflow in the cabinet. The entire heating system is

mounted to the exterior of the cabinet ceiling, outside the food

zone. It is assembled as one piece and can be removed as one

piece. An adjustable electronic thermostat controls temperature.

The system ON/OFF switch is located on the front exterior of

the cabinet.

6

Page 7

Specication Line

Specifications

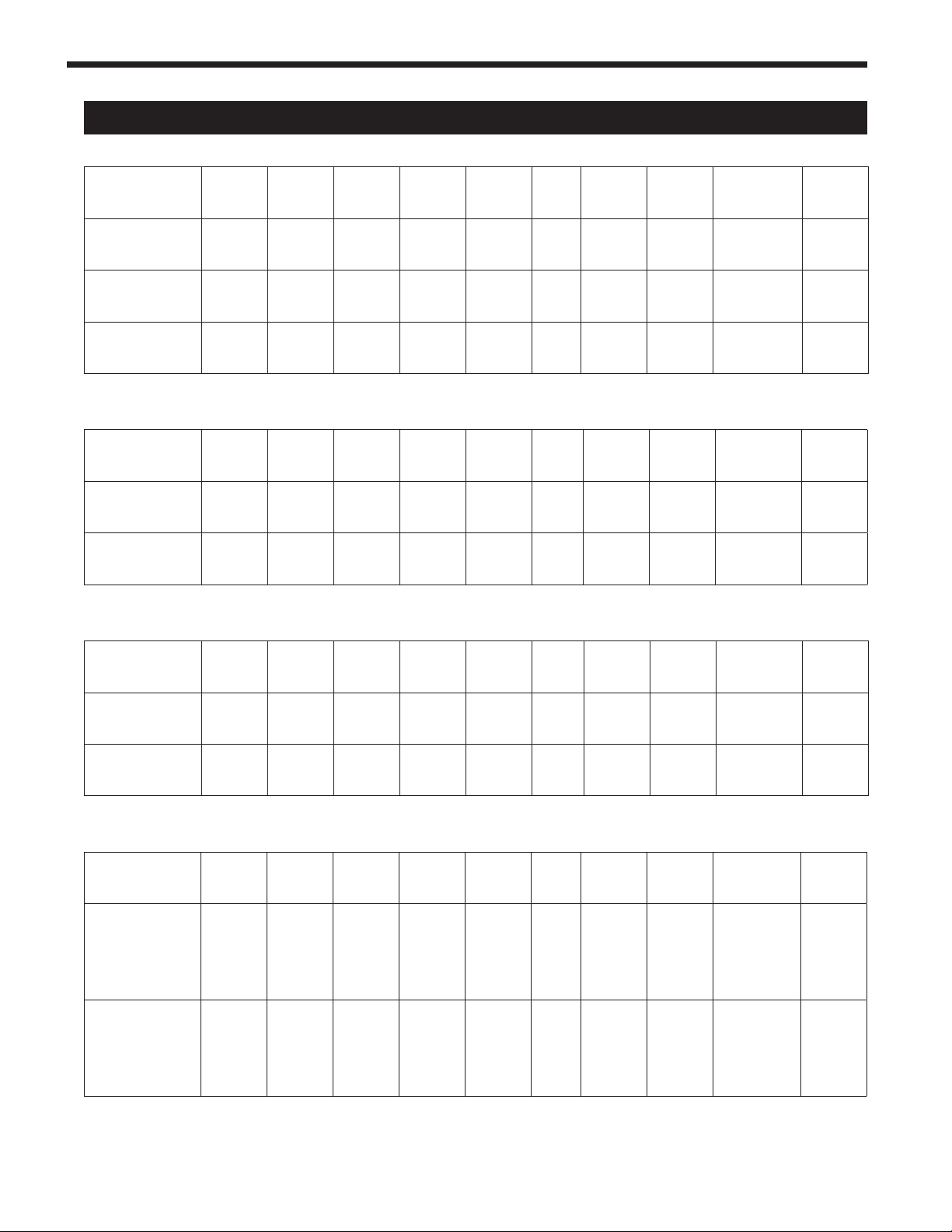

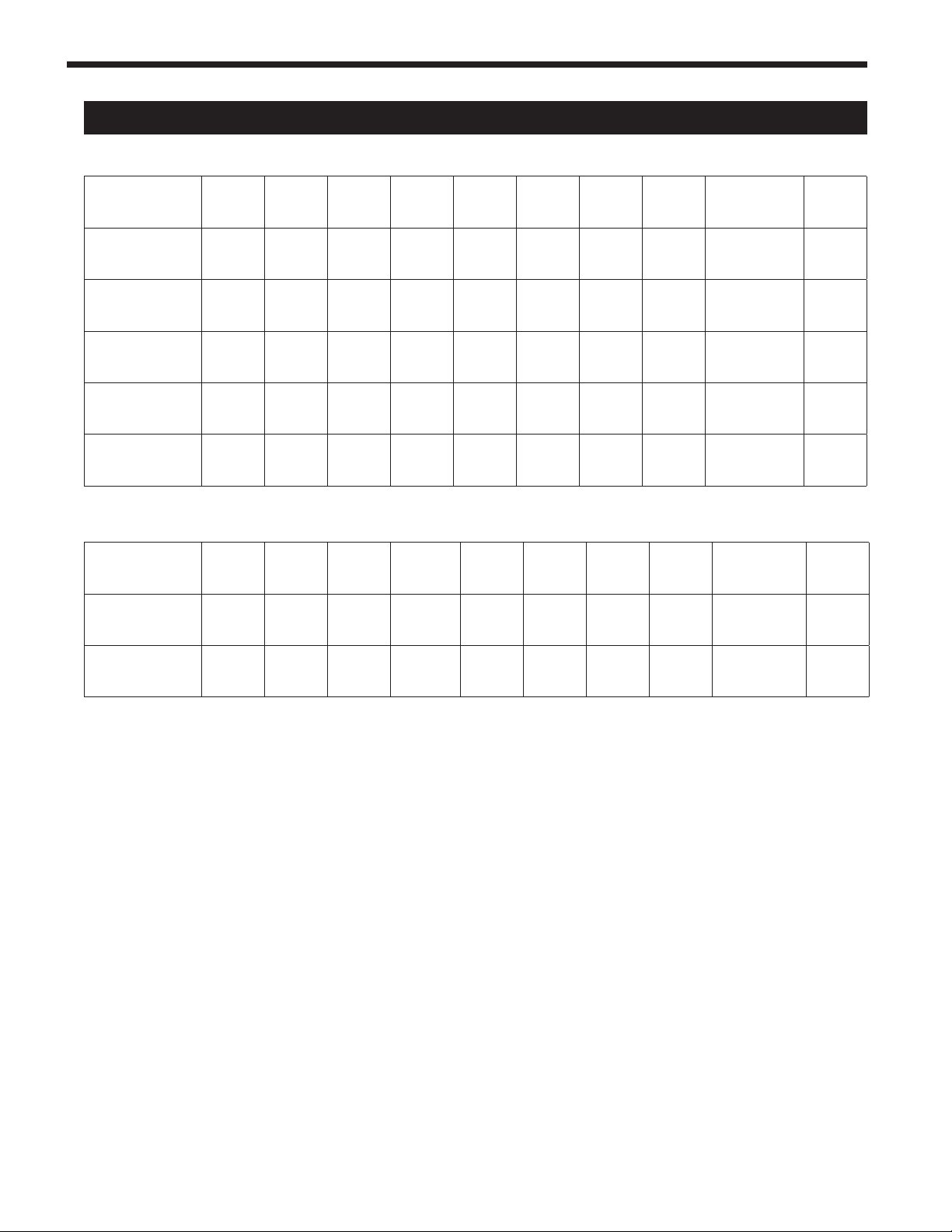

Reach-In Refrigerators - Hinged Doors - Standard Width & Depth

Model Voltage Amps

SSR1-S,SH,G,GH

115 6.0 24.96 12.81 3 1/4 2092 12.5 418lbs/190kg 5-15P

Volume

3

Ft

SAR1-S,SH,G,GH

SMR1-S,SH,G,GH

SSR2-S,SH,G,GH

115 9.5 51.92 27.54 6 1/3 3226 19 650lbs/295kg 5-15P

SAR2-S,SH,G,GH

SMR2-S,SH,G,GH

SSR3-S,SH,G,GH

115 14.5 78.89 42.47 9 1/2 5465 24 830lbs/376kg 5-20p

SAR3-S,SH,G,GH

SMR3-S,SH,G,GH

Reach-In Refrigerators - Hinged Doors - Narrow Width

Model Voltage Amps

SSR1N-S,SH,G,GH

115 6.0 20.97 10.59 3 1/4 2092 12.5 398lbs/181kg 5-15P

SAR1N-S,SH,G,GH

SMR1N-S,SH,G,GH

SSR2N-S,SH,G,GH

115 9.5 43.94 23.10 6 1/3 3226 19 588lbs/267kg 5-15P

SAR2N-S,SH,G,GH

SMR2N-S,SH,G,GH

Volume

3

Ft

Shelf

Capacity

2

Ft

Shelf

Capacity

2

Ft

No. Of

Shelves

No. Of

Shelves

H.P. BTU/HR

H.P. BTU/HR

R-404A

Charge

Oz.

R-404A

Charge

Oz.

Shipping

Weight

Shipping

Weight

NEMA

Plug

NEMA

Plug

Reach-In Refrigerators - Hinged Doors - Shallow Depth

Model Voltage Amps

SSR1S-S,SH,G,GH

115 6.0 18.25 12.81 3 1/4 2092 12.5 396lbs/180kg 5-15P

SAR1S-S,SH,G,GH

SMR1S-S,SH,G,GH

SSR2S-S,SH,G,GH

115 7.0 37.96 27.54 6 1/3 2488 12.5 586lbs/266kg 5-15P

SAR2S-S,SH,G,GH

SMR2S-S,SH,G,GH

Volume

3

Ft

Shelf

Capacity

2

Ft

Reach-In Refrigerators - Sliding Doors

Model Voltage Amps

SSR2-SLS,SLSH,

115 9.5 51.92 27.54 6 1/3 3226 19 670lbs/304kg 5-15P

SLG,SLGH

SAR2-SLS,SLSH,

SLG,SLGH

SMR2-SLS,SLSH,

SLG,SLGH

SSR2S-SLS,SLSH,

115 7.0 37.96 27.54 6 1/3 2488 12.5 670lbs/304kg 5-15P

SLG,SLGH

SAR2S-SLS,SLSH,

SLG,SLGH

SMR2S-SLS,SLSH,

SLG,SLGH

Volume

3

Ft

Shelf

Capacity

2

Ft

No. Of

Shelves

No. Of

Shelves

H.P. BTU/HR

H.P. BTU/HR

R-404A

Charge

Oz.

R-404A

Charge

Oz.

Shipping

Weight

Shipping

Weight

NEMA

Plug

NEMA

Plug

7

Page 8

Deleld

Specifications, continued

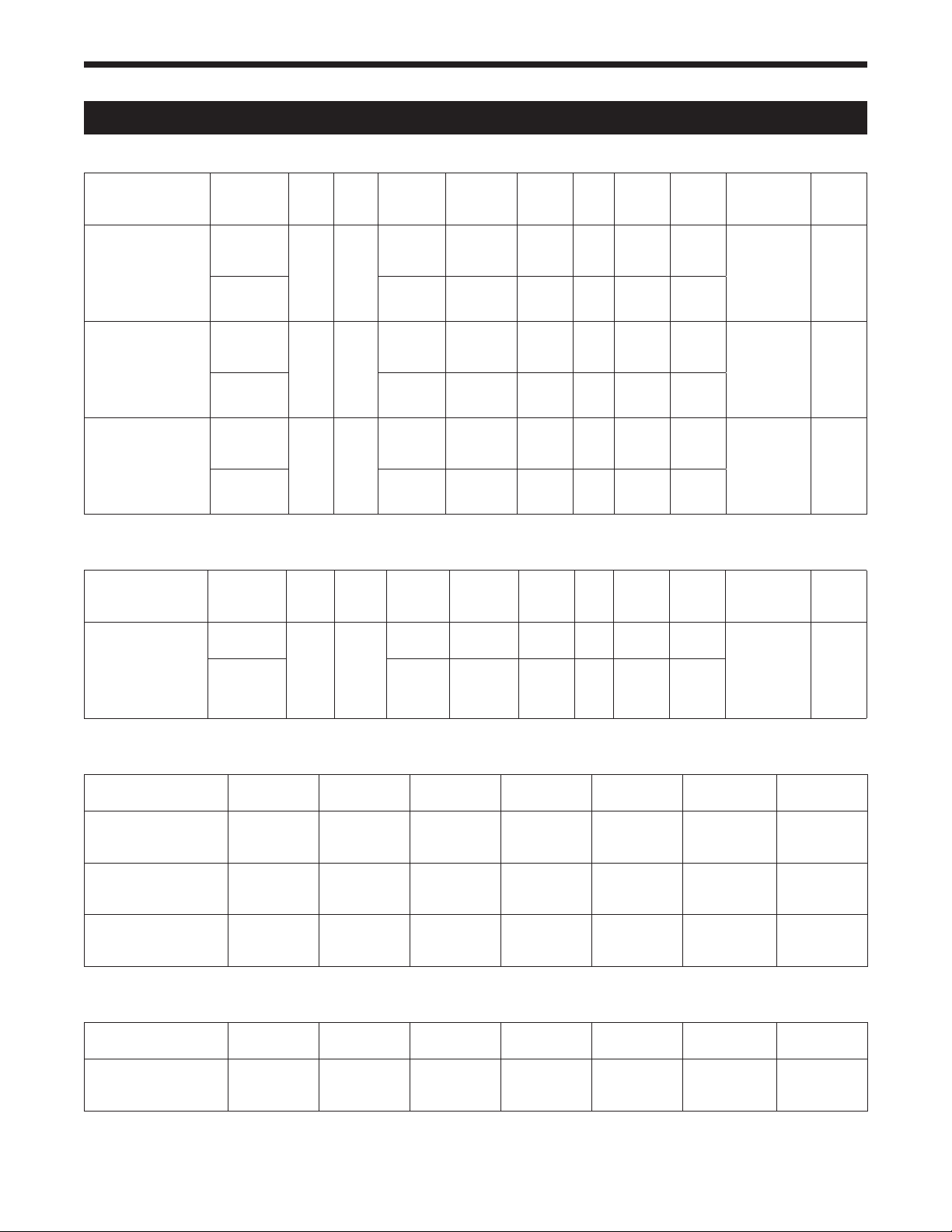

Reach-In Refrigerator/Freezer Combinations - Dual Temps - Hinged Doors - Standard Width & Depth

Model Section V Amps

SSDTR1-SH, GH,

Refrigerator 115 12.0 10.81 4.23 2 1/5 1543 11 525lbs/238kg 5-20P

SSDBR1-SH, GH,

SADTR1-SH, GH,

SADBR1-SH, GH,

SMDTR1-SH, GH,

Freezer 10.81 4.23 2 1/4 1260 12

SMDBR1-SH, GH

SSDRL2-S,SH,

Refrigerator 115 15.0 24.96 12.81 3 1/4 2092 12.5 730lbs/331kg 5-20P

SSDFL2-S,SH,

SADRL2-S,SH,

SADFL2-S,SH,

SMDRL2-S,SH,

Freezer 24.96 12.81 3 1/2 1516 12.5

SMDFL2-S,SH

SSDRL2-G,GH

Refrigerator 115/

SSDFL2-G,GH

SADRL2-G,GH

SADFL2-G,GH

SMDRL2-G,GH

Freezer 24.96 12.81 3 1/2 1923 12.5

SMDFL2-G,GH

208-

230

Volume

3

Ft

Shelf

Capacity

2

Ft

No. Of

Shelves

H.P. BTU/HR

8.0 24.96 12.81 3 1/4 2092 12.5 730lbs/331kg 14-20P

R-404A

Charge

Oz.

Shipping

Weight

NEMA

Plug

Pass-Thru Refrigerator/Freezer Combinations - Dual Temps - Hinged Doors - Standard Width & Depth

Model Section V Amps

SSDRP2-S,SH,

Refrigerator 115/

SSDFP2-S,SH

SADRP2-S,SH,

SADFP2-S,SH

Freezer 24.96 12.81 3 3/4 1923 12.5

SMDRP2-S,SH,

SMDFP2-S,SH

208-

230

Volume

3

Ft

Shelf

Capacity

2

Ft

No. Of

Shelves

H.P. BTU/HR

8.0 24.96 12.81 3 1/4 2092 12.5 730lbs/331kg 14-20P

R-404A

Charge

Oz.

Shipping

Weight

Reach-In Hot Food Cabinets - Hinged Doors - Standard Width & Depth

Model Voltage Amps Volume Ft

SSH1-S,SH,G,GH

SAH1-S,SH,G,GH

SMH1-S,SH,G,GH

SSH2-S,SH,G,GH

SAH2-S,SH,G,GH

SMH2-S,SH,G,GH

SSH3-S,SH,G,GH

SAH3-S,SH,G,GH

SMH3-S,SH,G,GH

Shelf Capacity

3

2

Ft

120/208-240 9.0 24.96 12.81 3 418lbs/190kg N/A

120/208-240 16.0 51.92 27.54 6 650lbs/295kg N/A

120/208-240 17.8 78.89 42.47 9 830lbs/376kg N/A

No. Of

Shelves

Shipping

Weight

NEMA

Plug

NEMA Plug

Reach-In Hot Food Cabinets - Hinged Doors - Narrow Width

Model Voltage Amps Volume Ft

SSH2N-S,SH

120/208-240 16.0 43.94 27.54 6 588lbs/267kg N/A

SAH2N-S,SH

SMH2N-S,SH

8

Shelf Capacity

3

2

Ft

No. Of

Shelves

Shipping

Weight

NEMA Plug

Page 9

Specication Line

Specifications, continued

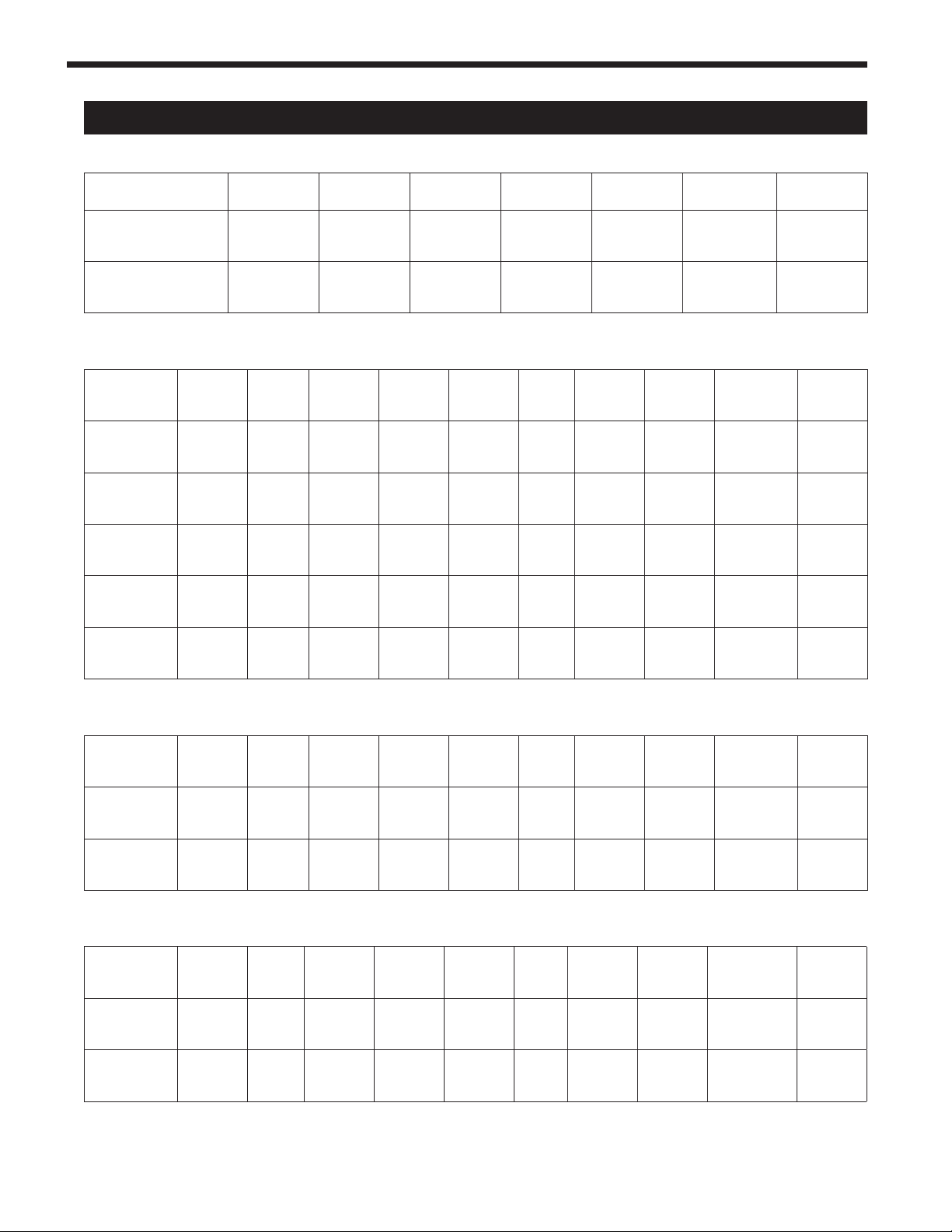

Pass-Thru Hot Food Cabinets - Hinged Doors - Standard Width & Depth

Shelf Capacity

Model Voltage Amps Volume Ft

SSHPT1-S,SH

120/208-240 9.0 26.96 12.81 3 398lbs/181kg N/A

SAHPT1-S,SH

SMHPT1-S,SH

SSHPT2-S,SH

120/208-240 16.0 51.92 27.54 6 650lbs/295kg N/A

SAHPT2-S,SH

SMHPT2-S,SH

Reach-In Freezers - Hinged Doors - Standard Width & Depth

Model Voltage Amps

SSF1-S,SH

115 9.0 24.96 12.81 3 1/2 1516 12.5 440lbs/200kg 5-15p

SAF1-S,SH

SMF1-S,SH

SSF1-G,GH

115 11.0 24.96 12.81 3 3/4 1923 12.5 440lbs/200kg 5-15p

SAF1-G,GH

SMF1-G,GH

SSF2-S,SH

115 14.3 51.92 27.54 6 3/4 2648 17 710lbs/322kg 5-20P

SAF2-S,SH

SMF2-S,SH

SSF2-G,GH

SAF2-G,GH

115/

208-230

SMF2-G,GH

SSF3-S,SH

SAF3-S,SH

115/

208-230

SMF3-S,SH

Volume

3

Ft

12.6 51.92 27.54 6 1 4793 30 710lbs/322kg N/A

12.6 78.89 42.47 9 1 4793 30 960lbs/435kg N/A

Shelf

Capacity

2

Ft

3

No. Of

Shelves

2

Ft

H.P. BTU/HR

No. Of

Shelves

R-404A

Charge

Oz.

Shipping

Weight

Shipping

Weight

NEMA Plug

NEMA

Plug

Reach-In Freezers - Hinged Doors - Narrow Width

Model Voltage Amps

SSF1N-S,SH

115 9.0 20.97 10.59 3 1/2 1516 12.5 408lbs/185kg 5-15p

SAF1N-S,SH

SMF1N-S,SH

SSF2N-S,SH

115 14.3 43.94 23.10 6 3/4 2648 17 680lbs/308kg 5-20P

SAF2N-S,SH

SMF2N-S,SH

Volume

3

Ft

Shelf

Capacity

2

Ft

Reach-In Freezers - Hinged Doors - Shallow Depth

Model Voltage Amps

SSF1S-S,SH

115 9.0 18.25 8.98 3 1/2 1516 12.5 406lbs/184kg 5-15p

SAF1S-S,SH

SMF1S-S,SH

SSF2S-S,SH

115 11.0 37.96 19.04 6 3/4 1923 12.5 676lbs/307kg 5-15P

SAF2S-S,SH

SMF2S-S,SH

Volume

3

Ft

Shelf

Capacity

2

Ft

No. Of

Shelves

No. Of

Shelves

H.P. BTU/HR

H.P. BTU/HR

R-404A

Charge

Oz.

R-404A

Charge

Oz.

Shipping

Weight

Shipping

Weight

NEMA

Plug

NEMA

Plug

9

Page 10

Deleld

Specifications, continued

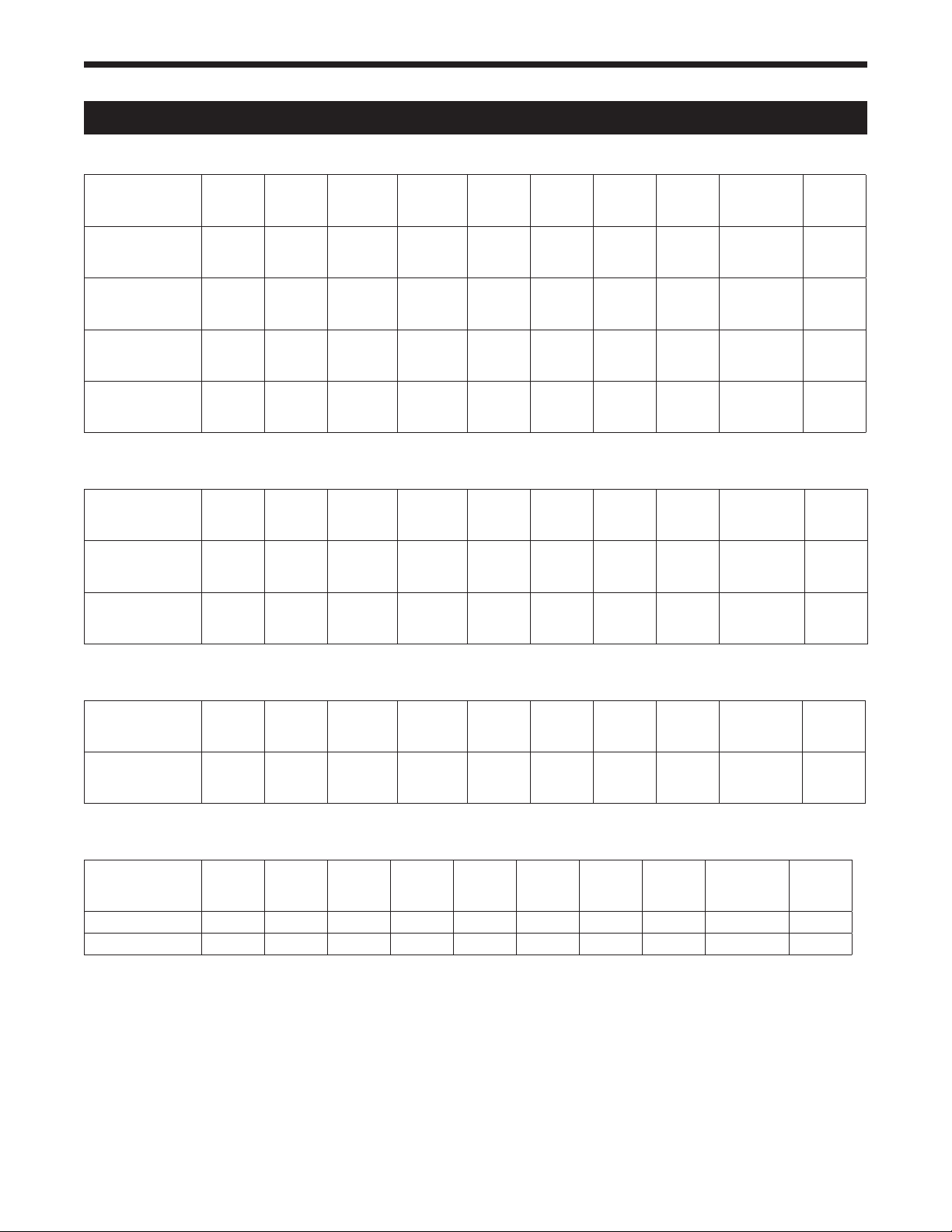

Pass-Thru Refrigerators - Hinged Doors - Standard Width

Model Voltage Amps

SSRPT1-S,SH

115 6.0 26.64 12.81 3 1/4 2092 12.5 455lbs/206kg 5-15P

Volume

3

Ft

SARPT1-S,SH

SMRPT1-S,SH

SSRPT1-G,GH

115 7.0 26.64 12.81 3 1/3 2488 12.5 455lbs/206kg 5-15P

SARPT1-G,GH

SMRPT1-G,GH

SSRPT2-S,SH

115 14.5 55.42 27.54 6 1/2 5465 24 700lbs/318kg 5-20P

SARPT2-S,SH

SMRPT2-S,SH

SSRPT2-G,GH

115 14.5 55.42 27.54 6 1/2 5465 24 700lbs/318kg 5-20P

SARPT2-G,GH

SMRPT2-G,GH

Pass-Thru Refrigerators - Hinged Doors - Shallow Depth

Model Voltage Amps

SSRPT1S-S,SH

115 6.0 18.25 8.98 3 1/3 2092 12.5 455lbs/206kg 5-15P

SARPT1S-S,SH

SMRPT1S-S,SH

SSRPT2S-S,SH

115 7.0 37.96 19.04 6 1/3 2488 12.5 700lbs/318kg 5-15P

SARPT2S-S,SH

SMRPT2S-S,SH

Volume

3

Ft

Shelf

Capacity

2

Ft

Shelf

Capacity

2

Ft

No. Of

Shelves

No. Of

Shelves

H.P. BTU/HR

H.P. BTU/HR

R-404A

Charge

Oz.

R-404A

Charge

Oz.

Shipping

Weight

Shipping

Weight

NEMA

Plug

NEMA

Plug

Pass-Thru Freezers - Hinged Doors - Standard Width

Model Voltage Amps

SSFPT1-S,SH

115 11.0 26.64 12.81 3 3/4 1923 12.5 672lbs/305kg 5-15p

SAFPT1-S,SH

SMFPT1-S,SH

Volume

3

Ft

Shelf

Capacity

2

Ft

No. Of

Shelves

H.P. BTU/HR

R-404A

Charge

Oz.

Shipping

Weight

Fish Drawer Reach-In - Four Fish Drawers Per Section

Model Voltage Amps

Volume

Ft

3

Shelf

Capacity

2

Ft

No. Of

Shelves

H.P. BTU/HR

SSRFF1 115 6.0 24.96 N/A N/A 1/4 2092 12.5 418lbs/190kg 5-15P

SSRFF2 115 9.5 51.92 N/A N/A 1/3 3226 19 650lbs/295kg 5-15P

R-404A

Charge

Oz.

Shipping

Weight

NEMA

NEMA

Plug

Plug

10

Page 11

Specication Line

Specifications, continued

Roll-In Refrigerators

Model Voltage Amps

SSRRI1-S

SARRI1-S

SMRRI1-S

SSRRI1-G

SARRI1-G

SMRRI1-G

SSRRI2-S

SARRI2-S

SMRRI2-S

SSRRI2-G

SARRI2-G

SMRRI2-G

SSRRI3-S

SARRI3-S

SMRRI3-S

115 6.0 36.15 N/A N/A 1/4 2092 12.5 476lbs/216kg 5-15P

115 7.0 36.15 N/A N/A 1/3 2488 12.5 476lbs/216kg 5-15P

115 9.5 76.34 N/A N/A 1/3 3226 19 768lbs/348kg 5-15P

115 14.5 76.34 N/A N/A 1/2 5465 24 768lbs/348kg 5-20P

115 14.5 113.28 N/A N/A 1/2 5465 24 1044lbs/4774kg 5-20p

Volume

3

Ft

Shelf

Capacity

2

Ft

No. Of

Shelves

H.P. BTU/HR

R-404A

Charge

Oz.

Shipping

Weight

NEMA

Plug

Roll-In Freezers

Model Voltage Amps

SSFRI1-S

SAFRI1-S

SMFRI1-S

SSFRI2-S

SAFRI2-S

SMFRI2-S

208-230

Volume

3

Ft

115 11.0 36.15 N/A N/A 3/4 1923 12.5 497lbs/225kg 5-15p

115/

12.6 76.34 N/A N/A 1 4793 30 824lbs/374kg N/A

Shelf

Capacity

Ft

No. Of

Shelves

2

H.P. BTU/HR

R-404A

Charge

Oz.

Shipping

Weight

NEMA

Plug

11

Page 12

Deleld

Specifications, continued

Hot Food Roll-Ins

Model Voltage Amps Volume Ft

SSHRI1-S,G

SAHRI1-S,G

SMHRI1-S,G

SSHRI2-S, G

SAHRI2-S, G

SMHRI2-S, G

SSHRI3-S, G 120/208-240 17.8 113.28 N/A N/A 1008lbs/457kg N/A

120/208-240 9.0 36.15 N/A N/A 459lbs/ 208kg N/A

120/208-240 16.0 76.34 N/A N/A 704lbs/ 319kg N/A

3

Shelf

Capacity Ft

Roll-Thru Refrigerators - Hinged Doors

Model Voltage Amps

SSRRT1-S

SARRT1-S

SMRRT1-S

SSRRT2-S

SARRT2-S

SMRRT2-S

Volume

Ft

115 7.0 38.58 N/A N/A 1/3 2488 12.5 514lbs/233kg 5-15P

115 14.5 79.74 N/A N/A 1/2 5465 24 776lbs/352kg 5-20P

3

Shelf

Capacity

2

Ft

No. Of

Shelves

H.P. BTU/HR

No. Of

2

Shelves

R-404A

Charge

Oz.

Shipping

Weight

Shipping

Weight

NEMA Plug

NEMA

Plug

Roll-Thru Hot Food Cabinets - Hinged Doors

Model Voltage Amps Volume Ft

SSHRT1-S

SAHRT1-S

SMHRT1-S

SSHRT2-S

SAHRT2-S

SMHRT2-S

SSHRT3-S

SAHRT3-S

120/208-240 9.0 38.58 N/A N/A 519lbs/

120/208-240 16.0 79.74 N/A N/A 836lbs/

120/208-240 17.8 120.90 N/A N/A 985lbs/

Shelf Capacity

3

2

Ft

No. Of

Shelves

Shipping

Weight

235kg

379kg

447kg

NEMA Plug

N/A

N/A

N/A

12

Page 13

Specication Line

Installation

Location

Cabinets represented in this manual are intended for indoor use

only. Be sure the location chosen has a floor strong enough to

support the total weight of the cabinet, 1000 pounds. per door

section. Reinforce the floor if necessary to provide for maximum

loading. For the most efficient operation, be sure to provide good

air circulation inside and out. The location should be selected so

that the power cord can be connected without any extensions.

Inside Unit

Take care not to block airflow to the fans or heating elements

and allow space along the front, back and sides.

Outside Unit

Be sure that the unit has access to ample air; avoid hot corners

and locations near stoves and ovens. Provide a minimum clearance

of 12” (30.5 cm) above the unit that is open to the front.

Due to the unique design of the One Door Dual Temp

units (ie: SSDTR1-SH), a 6" clearance is required at

the back of the unit to ensure proper operation.

Door Removal

The doors can be removed during installation if necessary.

Remove the door by opening the door to 90˚, lift it up and ease

it out of the hinge brackets

Stabilizing

It is very important that all legs are properly adjusted to keep

the cabinet level, evenly distribute the weight and to make sure

the unit will not rock, lean or be unstable.

Leg, Caster, Utility Base Installation

Some cabinets may weigh over 1000 pounds (450

kg). Use a lifting device capable of supporting the

unit when removing skid or installing legs, casters

WARNING

To install the legs, or casters refer to Figure 1. To install the utility

base, refer to Figure 2. Proceed as follows:

1. Remove unit from skid.

2. Raise unit to access leg/caster mounting holes on bottom

3. Attach the legs, casters or utility base to bottom of cabinet

or utility base.

of unit.

using hex head bolts.

Leveling

After the cabinet has been placed in the desired location, cabinets

with legs must be leveled. Level units from front to back and

from side to side. Leveling will insure proper door operation

and removal of condensate. Cabinets with casters must have

the caster brake set so the cabinet cannot move.

Figure 1. Leg or Caster Installation

Figure 2. Utility Base Installation

13

Page 14

Deleld

Installation, continued

Electrical Connection

Refer to the amperage data list in the SPECIFICATIONS

or the serial tag data and your local code or the

National Electrical Code to be sure the unit is

connected to the proper power source. A protected

circuit of the correct voltage and amperage must be

run for connection of the supply cord or permanent

connection to the unit. The power must be turned

off and disconnected whenever performing

maintenance or repair functions.

Permanently connected units must be connected

in accordance with NEC Article 422 Appliances,

C-Disconnecting means. It is the responsibility of

the end user to provide the disconnect means to

satisfy the authority having jurisdiction.

The power cords supplied with this equipment are three-pronged

plugs and must be connected to a three-pronged wall outlet for

proper grounding. Do not use an adapter to connect to a twopronged outlet. The three pronged-outlet provides a ground

connection which must be used to prevent a shock hazard.

Have the wall outlet checked by a qualified

electrician to be sure a proper ground is present

and that the outlet provides the correct voltage and

required amperage to match the rating plate.

Power Switch

Select units are equipped with a power disconnect switch located

next to the energy saver switch and thermostat control knob. Switch

must be in the “on” position for the unit to operate. On freezers, if

the switch is turned off, then returned to the on position, the unit

will enter a defrost cycle and the display will read “Def.”

Any power cord that is frayed or damaged should be replaced.

When disconnecting the unit from the power source, do not pull

on the wire. Firmly grip the plug and remove from outlet.

The plugs shown in Figure 3 are used on the various models.

Figure 3. Plug Congurations

14

Page 15

Specication Line

Heated Cabinet Operation

The Heated units have a POWER ON/OFF switch located behind

the flip up shroud at the front top of the unit for controlling power

to the unit and an electronic thermostat for setting the temperature. A circulating fan provides uniform airflow in the cabinet.

Power Up

1. Check that unit is properly connected to the power source.

2. Raise the shroud to access the controls.

3. Set the Main POWER ON/OFF switch, to the ON position.

4. Set the NIGHT switch to the ON position.

5. Adjust the electronic thermostat to the desired temperature.

6. Allow unit to warm-up before use.

The unit surface is very hot! Avoid direct contact

with skin; use appropriate protective apparel, such

as gloves.

Power Down

1. Turn the unit off daily by setting the NIGHT switch to the

OFF position

2. After use, allow unit to cool down.

3. If desired, set the Main POWER ON/OFF switch to the OFF

position.

4. Clean equipment as discussed in the MAINTENANCE section

of this manual.

15

Page 16

Deleld

Electronic Temperature Control Operation

These instructions are applicable to most models,

The electronic temperature control constantly monitors box

temperature as well as evaporator coil temperature to maintain

consistent product temperatures. The control also sends

temperature readings to the digital temperature display. The

control circuits continually self-check and if an error occurs,

the digital display will switch from temperature read-out to

error read-out, i.e. E1. Even when an error is displayed, the

refrigeration and controls system should continue to function,

however not at optimal performance. Whenever the display

has an error read-out, Delfield Service should be contacted.

At initial start-up or anytime power is disconnected, then

reconnected to the unit, the control will delay all operations for

a short time (up to 10 minutes.) While in this delay period, the

control initializes the control parameters and confirms that the

temperature sensors and circuits are operational. The digital

temperature display will not display temperature OR errors until

the self-check is complete and the control has switched on the

evaporator fan motor, compressor and condenser fan motor.

Regarding Freezers: After initializing, the control will

immediately enter a DEFROST mode and the display

will read DEF. The compressor and condenser fan

as well as the evaporator fan will remain off until

initialization defrost is complete. This initial defrost

cycle may take up to 15 minutes to complete, at which

time the freezing cycle will begin. The display will

continue to read DEF for an additional 30 minutes

before displaying temperature.

Refrigerator:

Whenever the refrigerator is plugged in, and the control has

completed initializing, the digital thermostat will display box

temperature. The temperature control will cycle the compressor,

evaporator fan motor and condenser fan motor to maintain box

temperature at the control setting. See evaporator fan matrix

for more information.

Refrigerator Defrost

The temperature control also monitors the evaporator temperature

and will turn off the compressor and condenser fan motor when

needed to allow accumulated frost on the evaporator to clear.

During this defrost cycle, the digital temperature display will

read dEF. After the defrost cycle is complete, the temperature

control will return to a normal cooling cycle, but the display

will continue to read dEF until the evaporator returns to normal

cooling temperatures (up to 15 minutes).

Power Switch

Select units are equipped with a power disconnect switch located

next to the energy saver switch and thermostat control knob. Switch

must be in the “on” position for the unit to operate. On freezers, if

the switch is turned off, then returned to the on position, the unit

will enter a defrost cycle and the display will read “Def.”

Energy Saver Switch

The energy saver switch is a rocker switch located next to the

thermostat knob that controls the amount of heat applied to the

door perimeter. The normal operating position for this switch is the

The control is located in the control box in the top of the unit

behind the hinged louvered front panel. Refrigerators are factory

set at mid-range to maintain about 38ºF (3ºC) box temperature.

Freezers are factory set at mid-range to maintain about 3ºF

(-18ºC) box temperature. To adjust for colder temperatures,

turn the knob clockwise. For warmer temperatures, turn the

knob counter-clockwise. Turn the knob fully counter-clockwise

to turn the refrigeration system off. Never turn the knob more

than 1 dial number and always allow 8 hours for temperature

stabilization before making any additional adjustments.

Temperature Alarm:

The alarm will flash "HI" or "LO" 90 minutes after the unit has

reached its alarm temperature point or after any power interruption

if the temperature is above or below the alarm set points.

Refrigerators are factory set at mid-range to maintain about 38ºF

(3ºC) box temperature. The high refrigerator temperature point

is 50°F (10°C). The low refrigerator temperature point is 25°F

(-4°C). Freezers are factory set at mid-range to maintain about 3ºF

(-18ºC) box temperature. The high freezer temperature point

is 20°F (-7°C). Freezers do not have a low temperature point.

ON position, providing the least heat. If excessive condensation

is observed on the door opening, press the energy saver switch

to the OFF position, to increase the amount of heat (red portion

of the rocker switch will be visible). Note: This feature is not

present on Dual Temperature models.

Freezer:

Whenever the freezer is plugged in, and the control has completed

initializing including the initial defrost cycle, the thermostat will

display box temperature. The temperature control will cycle the

compressor, evaporator fan motor and condenser fan motor to

maintain box temperature at the control setting. See evaporator

fan matrix for more information.

16

Page 17

Specication Line

Electronic Temperature Control Operation, continued

Freezer Automatic Defrost

The control also monitors compressor total running time and

will enter a defrost cycle after total compressor running time is

greater than 4-hours since the last defrost cycle OR if evaporator

coil temperature drops below -30ºF (-34ºC) (indicating excessive

frost on the coil.)

Freezer Manual Defrost

If a manual defrost is desired, simply unplug the unit for several

seconds, then plug unit back in. This will cause the control to

re-initialize and then enter a defrost cycle.

When the control enters the defrost mode, it switches off the

evaporator fan motor, compressor and condenser fan motor,

and switches on the defrost heater to warm the evaporator

coil. Thereby melting all frost accumulated during the previous

refrigeration cycle. The digital temperature display will now read

dEF. The control will continue the defrost cycle for a MINIMUM

of 8 minutes and a MAXIMUM of 30 minutes depending on the

amount of frost accumulated on the evaporator coil.

After the defrost cycle is complete, the control returns to a normal

refrigeration cycle, however the evaporator fan motor will not

switch on for 2 minutes AFTER the compressor and condenser

fan motor have begun operating. The digital temperature display

will continue to read dEF until the evaporator has returned to

normal freezing temperatures (up to 30 minutes).

Dual Temperature Refrigerator/Freezer Cabinets

These units combine both a refrigerator compartment and a

freezer compartment in the same cabinet. Each compartment has

its own separate refrigeration unit and Electronic Temperature

Control.

Regarding Single Section Dual Temperature Units:

After initializing, the both controls will immediately

enter a DEFROST mode and the displays will read

DEF. The compressor and condenser fan as well as

the evaporator fan will remain off until initialization

defrost is complete. This initial defrost cycle may

take up to 15 minutes to complete, at which time

the freezing cycle will begin. The displays will

continue to read DEF for an additional 30 minutes

before displaying temperature.

Service Alert

During normal operation the evaporator fan may cycle

and/or pulse independently of the compressor. Consult

the service manual or contact Technical Support at

1-800-733-8829 if you are unsure of the proper function.

Evaporator Fan Operation

Cooling Cycle Defrost Cycle

Compressor On Compressor Off Compressor Off

Evap Fan On Evap Fan Off Evap Fan On Evap Fan Off Evap Fan On Evap Fan Off

Refrigerator X Cycles On 3-Min, Off 3-Min X

Freezer X X X

Dual Temp

Refrigerator

Freezer X X X

X X X

17

Page 18

Deleld

Door Reversal Procedures

Only for Models Ordered With Re-Hinging Option.

The re-hinging option is only available on solid door models.

1. Lift front shroud if re-hinging the control side. If re-hinging

the rear side, the shroud must be removed.

2. Open door 90˚ and lift door straight up and off hinges.

3. Remove the metal screw covers on each door-side hinge

section by sliding it down and off.

4. Remove two outer screws that mount each hinge to door,

loosen the center screw, rotate hinge 180˚, reinstall outer

screws and retighten center screw. See Photos 1 and 2.

5. Remove lock strike assembly from the face frame, remove

screws from the opposite side of the face frame and install

the lock strike. Install the screws removed to fill the original

lock strike mounting holes.

6. Pry the plugs out of the hinge mounting holes on the side

opposite the current hinge locations and set them aside.

7. Pull the wires for the hinge switch out of the large hole and

remove the plastic caps and set them aside to re-use in

step 9. See Photo 3.

8. Remove the cabinet hinge screw covers by gently prying

them out with a small screwdriver.

Remove 2 outer screws

Loosen the center screw

Photo 1.

9. Remove all three screws from each hinge. Note that one

hinge has a hinge actuated switch to operate the lights.

Remove the wires from this switch and use the caps

removed in step 7 to cap the loose wires. See Photo 3.

Move this hinge to the opposite side of the face frame,

connect the switch wires and mount the hinge to face

frame, then mount the other hinge. Press the plugs

removed in step 6 into the screw holes from the original

hinge locations. Use a small amount of silicone sealant

under the lip of the cap if the fit of the plugs is not tight.

10. Remove the plastic cam from the hinges by pulling straight

up, then rotating the cam 180˚ and pushing back into the

hinge.

11. Remount the door and check for proper closure, gasket

seal, and light operation. Adjust hinges as needed. Once

adjustment is verified, remove the door, reinstall all hinge

screw covers and set the door back in place.

12. If additional plugs are needed due to loss or damage,

please contact Delfield Parts Department at (800) 7338821, extension 12801.

Photo 2. Rotate hinge 180º

Photo 3. Remove the caps and

reinstall them on the opposite

side switch wires

18

Page 19

Specication Line

Maintenance

Door Gasket Maintenance

Door gaskets require regular cleaning to prevent mold and

mildew build up and also to retain the elasticity of the gasket.

Gasket cleaning can be done with the use of warm soapy water.

Avoid full strength cleaning products on gaskets as this can

cause them to become brittle and crack. Never use sharp tools

or knives to scrape or clean the gasket. Gaskets can be easily

replaced and do not require the use of tools or an authorized

service person. The gaskets are “Dart” style and can be pulled

out of the groove in the door and new gaskets can be “pressed”

back into place.

Drain Maintenance - Base

Each unit has a drain located inside the unit that removes

the condensation from the evaporator coil and routes it to an

external condensate evaporator pan. Each drain can become

loose or disconnected during normal use. If you notice water

accumulation on the inside of the unit be sure the drain tube

is connected to the evaporator drain pan. If water is collecting

underneath the unit make sure the end of the drain tube is in

the condensate evaporator in the machine compartment. The

leveling of the unit is important as the units are designed to

drain properly when level. Be sure all drain lines are free of

obstructions.

Drawer Maintenance

Drawer Assembly Cleaning

The drawer assembly is designed to be cleaned easily. Both

drawer and tracks are removable without tools. The drawer

tracks are dishwasher safe or can be cleaned in a sink with

detergents and a soft bristle brush. Drawers and tracks should

be cleaned on a weekly basis.

Remove Drawers

Pull the drawer box out until it stops. Lift up on the drawer front

and pull the drawer box completely out. Using a soft bristle

brush, clean the track on the bottom of the drawer box. When

finished, it should be wiped clean of all food and debris.

Tracks

The drawer box assembly must be removed. Pull the drawer

tracks out until they hit a stop. Locate blue safety clips towards

the back of each drawer track. Blue safety clips have a tab on

the top. Push the tab back until it clicks. Lift up and pull the

drawer tracks all the way

out of the drawer cage.

The drawer tracks are

dishwasher safe or can

tab on top of

blue safety clip

and tracks should be cleaned on a weekly basis. Using a

soft bristle brush, wash the track making sure each roller is

thoroughly cleaned. The drawer cage should be cleaned with

a soft bristle brush, removing any food and debris gathered

on the bottom ledge. Once it’s cleaned thoroughly with a soft

be cleaned in a sink with

detergents and a soft

bristle brush. Drawers

bristle brush, wipe remaining debris clean with a soft towel.

Reassembly

Push the drawer tracks into the drawer cage. The blue safety

clip must remain pushed towards the back. Lift up and slide the

drawer track all the way into the drawer cage. The blue safety

clip will lock in place automatically. Once all tracks are replaced,

insert the drawer box. Rest the drawer box bottom track on the

front track roller. Then push the drawer back in place SLOWLY.

When the drawer box is about half way in you will hit a STOP.

You must lift the front of the drawer up approximately ½”

(1.3cm) to continue inward. Clean tracks as often as possible.

The cleaner the tracks are the better they will operate.

Caster Maintenance

Wipe casters with a damp cloth monthly to prevent corrosion.

The power switch must be turned to OFF and the

unit disconnected from the power source whenever

performing service, maintenance functions or

cleaning the refrigerated area.

Refrigerators and Freezers

The interior and exterior can be cleaned using soap and warm

water. If this isn’t sufficient, try ammonia and water or a

nonabrasive liquid cleaner. When cleaning the exterior, always

rub with the “grain” of the stainless steel to avoid marring the

finish. Do not use an abrasive cleaner because it will scratch the

stainless steel and can damage the breaker strips and gaskets.

Stainless Steel Care and Cleaning

To prevent discoloration or rust on stainless steel several

important steps need to be taken. First, we need to understand

the properties of stainless steel. Stainless steel contains 7080% iron, which will rust. It also contains 12-30% chromium,

which forms an invisible passive film over the steel’s surface,

which acts as a shield against corrosion. As long as the

protective layer is intact, the metal is still stainless. If the film

is broken or contaminated, outside elements can begin to

breakdown the steel and begin to form discoloration or rust.

Proper cleaning of stainless steel requires soft cloths or plastic

scouring pads.

NEVER USE STEEL PADS, WIRE BRUSHES OR SCRAPERS!

Cleaning solutions need to be alkaline based or non-chloride

cleaners. Any cleaner containing chlorides will damage

the protective film of the stainless steel. Chlorides are also

commonly found in hard water, salts, and household and

industrial cleaners. If cleaners containing chlorides are used be

sure to rinse repeatedly and dry thoroughly. Routine cleaning

of stainless steel can be done with soap and water. Extreme

stains or grease should be cleaned with a non-abrasive cleaner

and plastic scrub pad. Always rub with the grain of the steel.

There are stainless steel cleaners available which can restore

19

Page 20

Deleld

Maintenance, continued

and preserve the finish of the steels protective layer. Early signs

of stainless steel breakdown are small pits and cracks. If this

has begun, clean thoroughly and start to apply stainless steel

cleaners in attempt to restore the passivity of the steel.

Never use an acid based cleaning solution! Many

food products have an acidic content, which can

deteriorate the finish. Be sure to clean the stainless

steel surfaces of ALL food products. Common items

include, tomatoes, peppers and other vegetables.

Cleaning the Condenser Coil

In order to maintain proper refrigeration performance, the

condenser fins must be cleaned of dust, dirt and grease

regularly. It is recommended that this be done at least every

three months. If conditions are such that the condenser is totally

blocked in three months, the frequency of cleaning should be

increased. Clean the condenser with a vacuum cleaner or stiff

brush. If extremely dirty, a commercially available condenser

cleaner may be required.

Failure to maintain a clean condenser coil can initially cause high

temperatures and excessive run times. Continuous operation

with a dirty or clogged condenser coil can result in compressor

failure. Neglecting the condenser coil cleaning procedures will

void any warranties associated with the compressor and cost

to replace the compressor.

Immediately wipe up all spills.

Continuous opening and closing of the doors will hamper the

unit’s ability to maintain optimum refrigeration temperature.

Fluorescent Light Bulb Replacement

Delfield recommends that fluorescent light bulbs be recycled

rather than disposed of.

Never use a high-pressure water wash for this cleaning

procedure as water can damage the electrical

components located near or at the condenser coil.

Doors/Hinges

Over time and with heavy use doors the hinges may become

loose. If this happens tighten the screws that mount the hinge

brackets to the frame of the unit. Loose or sagging doors can

cause the hinges to pull out of the frame, which may damage

both the doors and the hinges. In some cases this may require

qualified service agents or maintenance personnel to perform

repairs.

Do not place hot pans on/against the grey ABS door

liner. Do not throw items into the storage area.

Failure to follow these recommendations could result

in damage to the interior of the cabinet or to the

blower coil. Overloading the storage area, restricting

the airflow, and continuous opening and closing of

the doors and drawers will hamper the units ability to

maintain operational temperature.

Preventing blower coil corrosion

To help prevent corrosion of the blower coil, store all acidic

items, such as pickles and tomatoes, in sealable containers.

20

Page 21

Specication Line

REVISIONS

INITIAL RELEASE1

REV DESCRIPTION DATE APPROVED

11"

8

1

2

"

L ENNIS

17-MAY-2011

ADDED L-2/3 DESIGNATION & H-4 FOR HEATER TERMINAL2

3 BROWN COMPRESSOR WIRE WAS BLACK (ON DIAGRAM ONLY )

26-MAY-2011

L ENNIS

REVISIONS

INITIAL RELEASE1

REV DESCRIPTION DATE APPROVED

11"

8

1

2

"

L ENNIS

02-MAY-2011

ADDED L-2/3 DESIGNATION & H-4 FOR HEATER TERMINAL2

17-MAY-2011

L ENNIS

26-MAY-2011

L ENNIS

BROWN COMPRESSOR WIRE WAS BLACK (ON DIAGRAM ONLY)3

Wiring Diagram Specification Line Refrigerators

S_R1, S_R1N, S_R1S, S_RPT1, S_RPT1S, S_RRI1, S_RRT1, SSRFF1 - Solid Doors

L1

2/3

SEE NAMEPLATE FOR MAXIMUM

TEMPERATURE

CONTROL

L

CONTROL

CIRCUIT

FAN RELAY

HEATER

RELAY

COMPRESSOR

RELAY

1.1,2,3 2.1,2,3 3.1,2,3

(IF USED)

LED DISPLAY

SENSOR

EVAP COIL

SWITCH

DOOR

SWITCH

9294455

LINE VOLTAGE

115/60/1

FUSE SIZE

N

5

F

6

H

4

C

1

CABINET AIR

SENSOR

M

EVAPORATOR FAN

M

COMPRESSOR

M

CONDENSOR FAN

DOOR FRAMEENERGY SAVER

HEATER

INCANDESCENT

LIGHT

NOTES:

N

1) USE COPPER CONDUCTORS ONLY

2) THIS UNIT MUST BE GROUNDED

3) UNIT SHOWN WITH COMPRESSOR

RUNNING AND DOORS CLOSED

CONTROL

BOX

P

RED

BLK

DOOR

HINGE

SWITCH

ENERGY SAVER

SWITCH

GREY

L

H

2LC1 3

4

TEMPERATURE

CONTROL

1.1,2,3 2.1,2,3 3.1,2,3

BLK

FRAME HEATERS

EVAPORATOR HOUSING

EVAP FAN

MOTOR

M

Y

DEFROST

HEATER

M

W

BLK

BRN

BLK

CONDENSER

FAN

BLK

W

INCANDESCENT

LIGHT

W

SPLICE

POWER BOX

10

11

12

START

13

WINDING

WINDING

RUN

14

COMPRESSOR

BLUE

SENSOR

SENSOR

EVAP COIL

CABINET AIR

W

W

WITH BLUE

STRIPES

W

F

5N6

W

LED DISPLAY

(IF USED)

W

START RELAY

START

CAPACITOR

COMPRESSOR

GROUND

MOTOR PROTECTOR

WIRE

NUT

PLUG

S_R1, S_R1N, S_R1S, S_RPT1, S_RRI1 - Glass Doors

L1

9294475

LINE VOLTAGE

115/60/1

SEE NAMEPLATE FOR MAXIMUM

FUSE SIZE

TEMPERATURE

CONTROL

L

N

CONTROL

CIRCUIT

2/3

FLUORESCENT

LAMP SWITCH

5

F

6

FAN RELAY

H

4

HEATER

RELAY

C

1

COMPRESSOR

RELAY

1.1,2,3 2.1,2,3 3.1,2,3

(IF USED)

LED DISPLAY

SENSOR

CABINET AIR

EVAP COIL

SENSOR

SWITCH

NOTES:

1) USE COPPER CONDUCTORS ONLY

2) THIS UNIT MUST BE GROUNDED

3) UNIT SHOWN WITH COMPRESSOR

RUNNING AND DOORS CLOSED

EVAPORATOR FAN

COMPRESSOR

CONDENSOR FAN

DOOR FRAMEENERGY SAVER

HEATER

FLUORESCENT

LAMP BALLAST

FLUORESCENT

LAMP

FLUORESCENT

N

LAMP

SWITCH

BLK

BLK

W

M

M

M

BLK

ENERGY SAVER

P

GREY

1.1,2,3 2.1,2,3 3.1,2,3

RED

FLUORESCENT LAMP ASSEMBLY

CONTROL

BOX

SWITCH

L

H

2LC1 3

4

TEMPERATURE

CONTROL

BLK

FRAME HEATERS

FLUORESCENT LIGHT

FLUORESCENT LAMP

F

5N6

W

BLUE

W

W

BLUE

EVAPORATOR HOUSING

EVAP FAN

MOTOR

M

Y

SENSOR

SENSOR

EVAP COIL

CABINET AIR

W

W

WITH BLUE

STRIPES

CONDENSER

FAN MOTOR

M

LED DISPLAY

(IF USED)

W

W

BLK

BRN

BLK

BLK

BALLAST

W

SPLICE

W

10

11

12

STAR

13

WINDING

WINDING

RUN

14

COMPRESSOR

POWER BOX

START RELAY

COMPRESSOR

GROUND

MOTOR PROTECTOR

START

CAPACITOR

PLUG

WIRE

NUT

21

Page 22

Deleld

REVISIONS

INITIAL RELEASE1

REV DESCRIPTION DATE APPROVED

11"

8

1

2

"

L ENNIS

02-MAY-2011

17-MAY-2011

L ENNIS

ADDED HEATER RELAY TO CONTROL & L-2/3 DESIGNATION2

BROWN COMPRESSOR WIRE WAS BLACK (ON DIAGRAM ONLY)3

26-MAY-2011

L ENNIS

REVISIONS

INITIAL RELEASE1

REV DESCRIPTION DATE APPROVED

11"

8

1

2

"

2 ADDED L-2/3 DESIGNATION & H-4 FOR HEATER TERMINAL

L ENNIS

17-MAY-2011

3 BROWN COMPRESSOR WIRE WAS BLACK (ON DIAGRAM ONLY )

26-MAY-2011

L ENNIS

Wiring Diagram Specification Line Refrigerators

S_R2, S_R2N, S_R2S, S_R2-SL, S_R2S-SL, S_RPT2S, S_RRI2, SSRFF2 - Solid Doors

L1

2/3

SEE NAMEPLATE FOR MAXIMUM

TEMPERATURE

CONTROL

L

CONTROL

CIRCUIT

FAN RELAY

HEATER

RELAY

COMPRESSOR

RELAY

1.1,2,3 2.1,2,3 3.1,2,3

(IF USED)

LED DISPLAY

SENSOR

EVAP COIL

SWITCH

DOOR

SWITCHES

9294454

LINE VOLTAGE

115/60/1

FUSE SIZE

N

5

F

6

H

4

C

1

CABINET AIR

SENSOR

M

EVAPORATOR FAN

M

COMPRESSOR

M

CONDENSOR FAN

DOOR FRAMEENERGY SAVER

HEATERS

INCANDESCENT

LIGHT

NOTES:

N

1) USE COPPER CONDUCTORS ONLY

2) THIS UNIT MUST BE GROUNDED

3) UNIT SHOWN WITH COMPRESSOR

RUNNING AND DOORS CLOSED

CONTROL

BOX

P

RED

BLK

DOOR

HINGE

SWITCHES

ENERGY SAVER

SWITCH

GREY

H

L

4

2LC1 3

TEMPERATURE

CONTROL

1.1,2,3 2.1,2,3 3.1,2,3

BLK

DOOR FRAME HEATERS

EVAPORATOR HOUSING

EVAP FAN

MOTOR

M

Y

DEFROST

HEATER

M

W

BLK

BRN

BLK

CONDENSER

FAN

BLK

W

INCANDESCENT

LIGHT

W

SPLICE

W

12

WINDING

RUN

POWER BOX

10

STAR

13

WINDING

14

COMPRESSOR

11

BLUE

SENSOR

SENSOR

EVAP COIL

CABINET AIR

W

W

WITH BLUE

STRIPES

W

F

5N6

W

LED DISPLAY

W

(IF USED)

START RELAY

START

CAPACITOR

COMPRESSOR

GROUND

MOTOR PROTECTOR

WIRE

NUT

PLUG

S_R2, S_R2N, S_R2S, S_R2-SL, S_R2S-SL - Glass Doors

BLK W

BLK

BLK

P

RED

FLUORESCENT LAMP ASSEMBLY

CONTROL

BOX

ENERGY SAVER

SWITCH

GREY

L

H

2LC1 3

4

TEMPERATURE

CONTROL

1.1,2,3 2.1,2,3 3.1,2,3

BLK

DOOR FRAME HEATERS

FLUORESCENT LIGHT

FLUORESCENT LAMP

F

5N6

W

BALLAST

BLUE

W

W

LED DISPLAY

(IF USED)

L1

9294476

LINE VOLTAGE

115/60/1

SEE NAMEPLATE FOR MAXIMUM

FUSE SIZE

TEMPERATURE

CONTROL

L

N

CONTROL

CIRCUIT

2/3

FLUORESCENT

LAMP SWITCHES

2) THIS UNIT MUST BE GROUNDED

5

F

6

FAN RELAY

H

4

HEATER

RELAY

C

1

COMPRESSOR

RELAY

1.1,2,3 2.1,2,3 3.1,2,3

(IF USED)

LED DISPLAY

SENSOR

CABINET AIR

EVAP COIL

SENSOR

SWITCH

NOTES:

1) USE COPPER CONDUCTORS ONLY

3) UNIT SHOWN WITH COMPRESSOR

RUNNING AND DOORS CLOSED

EVAPORATOR FAN

COMPRESSOR

CONDENSOR FAN

DOOR FRAMEENERGY SAVER

HEATERS

FLUORESCENT

LAMP BALLAST

FLUORESCENT

LAMP

FLUORESCENT

LAMP BALLAST

FLUORESCENT

LAMP

M

M

M

N

FLUORESCENT

LAMP

SWITCH

W

W

12

WINDING

RUN

FLUORESCENT LIGHT

BALLAST

RED

FLUORESCENT LAMP

FLUORESCENT LAMP ASSEMBLY

SPLICE

POWER BOX

10

11

STAR

13

WINDING

COMPRESSOR

GROUND

14

MOTOR PROTECTOR

COMPRESSOR

START RELAY

BLUE

START

CAPACITOR

WIRE

FLUORESCENT

BLUE

LAMP

SWITCH

EVAPORATOR HOUSING

EVAP FAN

MOTOR

M

Y

SENSOR

SENSOR

EVAP COIL

CABINET AIR

W

W

WITH BLUE

STRIPES

CONDENSER

FAN MOTOR

M

BLK

BLK

W

W

W

BLK

BRN

BLK

BLK

PLUG

NUT

22

Page 23

Specication Line

Wiring Diagram Specification Line Refrigerators

S_RPT2, S_RRT2, S_R3, S_RRI3 - Solid Doors

L1

POWER SWITCH

L

2/3

3 DOOR UNITS EMPLOY

3 LIGHT ASSEMBLIES

1.1,2,3 2.1,2,3 3.1,2,3

9294479

LINE VOLTAGE

115/60/1

SEE NAMEPLATE FOR MAXIMUM

FUSE SIZE

TEMPERATURE

CONTROL

N

CONTROL

CIRCUIT

5

F

6

FAN RELAY

H

4

HEATER

RELAY

C

1

COMPRESSOR

RELAY

(IF USED)

LED DISPLAY

SENSOR

EVAP COIL

SWITCH

DOOR

SWITCHES

CABINET AIR

SENSOR

M

EVAPORATOR FAN

M

COMPRESSOR

M

M

CONDENSOR FAN

3 DOOR UNITS EMPLOY

3 HEATER ASSEMBLIES

DOOR FRAMEENERGY SAVER

HEATERS

INCANDESCENT

LIGHT

NOTES:

N

1) USE COPPER CONDUCTORS ONLY

2) THIS UNIT MUST BE GROUNDED

3) UNIT SHOWN WITH COMPRESSOR

RUNNING AND DOORS CLOSED

CONTROL

BOX

P

RED

3 DOOR UNITS EMPLOY

3 DOOR SWITCHES

DOOR

HINGE

SWITCHES

BLK

POWER SWITCH

ENERGY SAVER

SWITCH

GREY

H

L

4

2LC1 3

TEMPERATURE

CONTROL

1.1,2,3 2.1,2,3 3.1,2,3

BLK

DOOR FRAME HEATERS

EVAPORATOR HOUSING

EVAP FAN

MOTOR

M

Y

W

BLK

BRN

M

CONDENSER

FAN MOTOR

W

INCANDESCENT

LIGHT

BLK

M

POWER BOX

W

SPLICE

W

MOTOR

MAIN WINDING

PROTECTOR

C

S

R

START

WINDING

1

1

2

2

N

BLK

N

L

L

COMPRESSOR

BLUE

SENSOR

SENSOR

EVAP COIL

CABINET AIR

W

W

WITH BLUE

STRIPES

W

F

5N6

W

W

LED DISPLAY

(IF USED)

3 DOOR UNITS EMPLOY

3 HEATER ASSEMBLIES

RUN CAPACITOR

2

5

1

4

START CAPACITOR

WIRE

NUT

PLUG

S_RPT2, S_RRI2, S_R3 - Glass Doors

L1

POWER SWITCH

3 DOOR UNITS EMPLOY

3 LIGHT ASSEMBLIES

9294480

LINE VOLTAGE

115/60/1

SEE NAMEPLATE FOR MAXIMUM

FUSE SIZE

TEMPERATURE

CONTROL

L

N

CONTROL

CIRCUIT

2/3

FLUORESCENT

LAMP SWITCHES

5

F

6

FAN RELAY

HEATER

RELAY

COMPRESSOR

RELAY

1.1,2,3 2.1,2,3 3.1,2,3

(IF USED)

LED DISPLAY

SWITCH

NOTES:

1) USE COPPER CONDUCTORS ONLY

2) THIS UNIT MUST BE GROUNDED

3) UNIT SHOWN WITH COMPRESSOR

RUNNING AND DOORS CLOSED

EVAP COIL

SENSOR

H

4

C

1

CABINET AIR

SENSOR

3 DOOR UNITS EMPLOY

3 HEATER ASSEMBLIES

EVAPORATOR FAN

CONDENSOR FAN

FLUORESCENT

LAMP BALLAST

FLUORESCENT

FLUORESCENT

LAMP BALLAST

FLUORESCENT

M

M

COMPRESSOR

M

M

DOOR FRAMEENERGY SAVER

HEATERS

LAMP

LAMP

N

FLUORESCENT

SWITCH

LAMP

BLK W

BLK

BLK

P

RED

FLUORESCENT LAMP ASSEMBLY

CONTROL

BOX

POWER SWITCH

ENERGY SAVER

SWITCH

GREY

H

L

4

2LC1 3

TEMPERATURE

CONTROL

1.1,2,3 2.1,2,3 3.1,2,3

BLK

DOOR FRAME HEATERS

FLUORESCENT LIGHT

FLUORESCENT LAMP

F

5N6

BALLAST

W

BLUE

EVAPORATOR HOUSING

BLUE

SENSOR

CABINET AIR

W

W

LED DISPLAY

(IF USED)

3 DOOR UNITS EMPLOY

3 HEATER ASSEMBLIES

W

Y

M

EVAP COIL

WITH BLUE

STRIPES

FLUORESCENT

LAMP

SWITCH

EVAP FAN

MOTOR

M

SENSOR

W

M

CONDENSER

FAN MOTOR

W

BLK

BRN

BLK

BLK

W

BLK

BLK

RED

W

FLUORESCENT LAMP ASSEMBLY

3 DOOR UNITS EMPLOY

3 LIGHT ASSEMBLIES

W

W

MOTOR

PROTECTOR

C

S

START

WINDING

1

1

2

2

N

N

L

L

FLUORESCENT LIGHT

BALLAST

FLUORESCENT LAMP

POWER BOX

SPLICE

MAIN WINDING

R

COMPRESSOR

RUN CAPACITOR

2

5

1

4

START CAPACITOR

BLUE

PLUG

WIRE

NUT

23

Page 24

Deleld

Wiring Diagram Specification Line Freezers

S_F1, S_F1N, S_F1S - Solid Doors

S_F1 - Glass Doors

24

Page 25

Specication Line

Wiring Diagram Specification Line Freezers

S_FPT1, S_FRI1 - Solid Doors

L1

POWER SWITCH

SEE NAMEPLATE FOR MAXIMUM

TEMPERATURE

CONTROL

L

CONTROL

CIRCUIT

3

FAN RELAY

HEATER RELAY

COMPRESSOR

RELAY

1.1,2,3 2.1,2,3 3.1,2,3

(IF USED)

LED DISPLAY

SENSOR

EVAP COIL

SWITCH

DOOR

SWITCH

9294108

LINE VOLTAGE

115/60/1

FUSE SIZE

N

5

F

6

H

4

C

1

CABINET AIR

SENSOR

M

EVAPORATOR FAN

DEFROST HEATER

M

COMPRESSOR

M

CONDENSOR FAN

DOOR FRAMEENERGY SAVER

HEATER

INCANDESCENT

LIGHT

NOTES:

N

1) USE COPPER CONDUCTORS ONLY

2) THIS UNIT MUST BE GROUNDED

3) UNIT SHOWN WITH COMPRESSOR

RUNNING AND DOORS CLOSED

CONTROL

BOX

P

RED

BLK

DOOR

HINGE

SWITCH

POWER SWITCH

ENERGY SAVER

SWITCH

GREY

H

L

4

2LC1 3

TEMPERATURE

CONTROL

1.1,2,3 2.1,2,3 3.1,2,3

BLK

FRAME HEATERS

EVAPORATOR HOUSING

EVAP FAN

MOTOR

M

Y

BLUE

SENSOR

SENSOR

EVAP COIL

CABINET AIR

W

W

WITH BLUE

STRIPES

W

F

5N6

W

LED DISPLAY

(IF USED)

W

M

CONDENSER

DEFROST

HEATER

W

BLK

BRN

BLK

FAN

BLK

HIGH TEMP

SWITCH

W

INCANDESCENT

LIGHT

LIMIT

PLUG

POWER BOX

WIRE

RUN CAPACITOR

2

1

NUT

W

SPLICE

W

MOTOR

MAIN WINDING

PROTECTOR

C

5

S

R

4

START CAPACITOR

COMPRESSOR

1

2

N

L

START

WINDING

1

2

N

L

S_F2, S_F2N, S_F2S - Solid Doors

LINE VOLTAGE

SEE NAMEPLATE FOR MAXIMUM

FUSE SIZE

TEMPERATURE

CONTROL

CONTROL

CIRCUIT

FAN RELAY

HEATER RELAY

COMPRESSOR

RELAY

(IF USED)

LED DISPLAY

SENSOR

EVAP COIL

SWITCH

DOOR

SWITCHES

9294124

115/60/1

N

5

F

6

H

4

C

1

CABINET AIR

SENSOR

M

EVAPORATOR FAN

DEFROST HEATER

M

COMPRESSOR

M

CONDENSOR FAN

DOOR FRAMEENERGY SAVER

HEATERS

INCANDESCENT

LIGHT

NOTES:

N

1) USE COPPER CONDUCTORS ONLY

2) THIS UNIT MUST BE GROUNDED

3) UNIT SHOWN WITH COMPRESSOR

RUNNING AND DOORS CLOSED

RED

DOOR

HINGE

SWITCHES

L1

POWER SWITCH

L

3

1.1,2,3 2.1,2,3 3.1,2,3

CONTROL

BOX

BLK

P

POWER SWITCH

ENERGY SAVER

SWITCH

GREY

H

L

4

2LC1 3

TEMPERATURE

CONTROL

1.1,2,3 2.1,2,3 3.1,2,3

BLK

DOOR FRAME HEATERS

EVAPORATOR HOUSING

EVAP FAN

MOTOR

M

Y

BLUE

SENSOR

CABINET AIR

W

F

5N6

W

LED DISPLAY

W

(IF USED)

DEFROST

SENSOR

EVAP COIL

W

W

WITH BLUE

STRIPES

M

CONDENSER

HEATER

W

BLK

BRN

BLK

FAN

BLK

HIGH TEMP

SWITCH

W

INCANDESCENT

LIGHT

LIMIT

PLUG

POWER BOX

WIRE

W

SPLICE

W

MOTOR

PROTECTOR

S

1

2

N

L

C

START

WINDING

1

2

N

L

MAIN WINDING

R

COMPRESSOR

5

4

START CAPACITOR

NUT

RUN CAPACITOR

2

1

25

Page 26

Deleld

Wiring Diagram Specification Line Freezers

S_F2 - Glass Doors

S_FRI2, S_F3 - Solid Doors

26

Page 27

Specication Line

Wiring Diagram Specification Line Refrigerator/Freezer Combinations

S_DTR1, S_DBR1 - Solid & Glass Doors

NOTES:

1) USE COPPER CONDUCTORS ONLY

2) THIS UNIT MUST BE GROUNDED

3) UNIT SHOWN WITH COMPRESSOR

RUNNING AND DOORS CLOSED

REFRIGERATORFREEZER

L1

CONDENSOR FAN

1.1,2,3 2.1,2,3 3.1,2,3

RELAY

SWITCH

COMPRESSOR

M

COMPRESSOR

C

1

HI-PRESSURE

M

CONDENSATE HEATER

HI-LIMIT

HEATER (REF & FRZ)

DOOR FRAME

INCANDESCENT

LIGHT

LED DISPLAY

SWITCH

DOOR

(IF USED)

EVAP COIL

SENSOR

CABINET AIR

SENSOR

DRAIN

HEATER

S_DRL2, S_DFL2 - Solid & Glass Doors

S_DRP2, S_DFP2 - Solid Doors

CONDENSOR FAN

1.1,2,3 2.1,2,3 3.1,2,3

COMPRESSOR

RELAY

SWITCH

COMPRESSOR

M

HEATER RELAY

C

1

HI-PRESSURE

M

4

H

3

HEATER RELAY

FAN RELAY

4

H

HI-LIMIT

DEFROST

HEATER

L

TEMPERATURE

CONTROL

CONTROL

CIRCUIT

5

N

6

F

INCANDESCENT

LIGHT

EVAPORATOR FAN

M

LED DISPLAY

(IF USED)

SWITCH

DOOR

EVAP COIL

SENSOR

CABINET AIR

SENSOR

3

L

TEMPERATURE

FAN RELAY

6

M

CONTROL

CONTROL

CIRCUIT

SEE NAMEPLATE FOR MAXIMUM

5

N

F

EVAPORATOR FAN

115/60/1 OR 220/50/1

LINE VOLTAGE

FUSE SIZE

L2-220V

N-115V

27

Page 28

Deleld

Wiring Diagram Specification Line Heated Models

S_H1, S_H2, S_HRI1, S_HRI2 - Solid & Glass Doors

S_H2N, S_HPT1, S_HPT2, S_HRT1, S_HRT2 - Solid Doors

S_H3, SSHRI3 - Solid & Glass Doors

S_HRT3 - Solid Doors

28

Page 29

Specication Line

Compressor Diagrams

Valve, EXP

Motor, fan,

evaporator

Blade, fan

Relay & Overload

Capacitor,

start

Compressor

Drier, filter

Motor, fan,

condensor

Guard, fan,

condenser

Fan delay, defrost limit

Coil, evaporator

Motor, fan,

evaporator

Blade, fan

Coil, evaporator

Blade, fan, condenser

Guard, fan, condenser

Coil, condenser

Compressor

Relay & Overload

Capacitor, start

Fan delay,

defrost limit

Coil, condenser

Valve, EXP

Switch

Control switch

Heater, defrost

Drier, filter

29

Page 30

Deleld

Replacement Parts

S_R1, S_R1N, S_R1S, S_RPT1, S_RPT1S, SSRFF1,

S_RRI1, S_DRL2, S_DFL2, S_DRP2, S_DFP2 - Solid Doors

S_R1, S_R1N, S_R1S, S_DRL2, S_DFL2 - Glass Doors

Part Number Description

2194792 Display, Blue, Danfoss

3516432 Blade, Fan, 25Deg, 8.75"

3517390 Blade, Fan, 5.56, CW, Lexan

3516204A Breaker, Vacuum

2194791 Cable, Display, 59

2194787 Capacitor, Start, 280MFD

3516427 Coil, Condenser, Large, Upright

3516437 Coil, Evap, Ref, 1DR

3526999 Comp, NF5.5CLX, 115V, 60HZ

3516444 Comp, Relay, Ovld, NF5.5CLX

2194811 Control, GDM, Danfoss, 115V

3516322 Drier, Filter, (2)Inlet

2160019 Guard, Fan, Wire

2162717 Motor, Fan, 9W, 115V, CW

2162715 Motor, Fan, Bay, 3/4ST

2190154 Switch, SPST, Rocker, 20A/125V

3516429 Valve, Therm EXP, W/O MOP

S_R2, S_R2N, S_R2-SL, SSRFF2, S_RRI2 - Solid Doors

S_R2, S_R2N, S_R2-SL - Glass Doors

Part Number Description

2194792 Display, Blue, Danfoss

3516433 Blade, Fan, 25

3516204A Breaker, Vacuum

2194791 Cable, Display, 59

2194788 Capacitor, Start, 320MFD

3517343 Coil, Condenser, Small

3517341 Coil, Evap, Sml Ref, 2dr, Up

3527000 Comp, NF7.0, 115V/60HZ

2194811 Control, GDM, Danfoss, 115V

3516322 Drier, Filter, (2)Inlet

2160019 Guard, Fan, Wire

2162750 Motor, Fan, Evap, PSC

2162716 Motor, Fan, Cond

3516438 Relay, Comp, Ovld, NF7CLX

2190154 Switch, SPST, Rocker, 20A/125V

3516429 Valve, Therm EXP, W/O MOP

S_R2S, S_R2S-SL, S_RRT1 - Solid Doors

S_R2S, S_R2S-SL, S_RPT1, S_RRI1 - Glass Doors

Part Number Description

2194792 Display, Blue, Danfoss

3516433 Blade, Fan, 25

3517390 Blade, Fan, 5.56, CW, Lexan

3516204A Breaker, Vacuum

2194791 Cable, Display, 59

2194788 Capacitor, Start, 320MFD

3516427 Coil, Condenser, Large

3516437 Coil, Evap, Ref, 1DR

3527000 Comp, NF7.0, 115V/60HZ

2194811 Control, GDM, Danfoss, 115V

3516322 Drier, Filter, (2)Inlet

2160019 Guard, Fan, Wire

2162716 Motor, Fan, 16W, 115V, CW

2162750 Motor, Fan, PSC

3516438 Relay, Comp, Ovld, NF7CLX

2190154 Switch, SPST, Rocker, 20A/125V

3516429 Valve, Therm EXP, W/O MOP

S_R3, S_RPT2, S_RPT2S, S_RRI3, S_RRT2 - Solid Doors

S_R3, S_RPT2, S_RRI2 - Glass Doors

Part Number Description

3516433 Blade, Fan, 25

3516204A Breaker, Vacuum

2194791 Cable, Display, 59

3516468 Capacitor, Start, Run, Assy

3517344 Coil, Condenser, Lrg 2dr

3517341 Coil, Evap, Sml Ref, 2dr, Up

3527016 Comp, SC15MLX.2, 115V/60HZ

2194811 Control, GDM, Danfoss, 115V

2194792 Display, Blue, Danfoss

3517345 Drier, Filter, 3/8", Danfoss

2160019 Guard, Fan, Wire

2162750 Motor, Fan, Evap, PSC

2162716 Motor, Fan, Cond

2190154 Switch, SPST, Rocker, 20A/125V

3516557 Valve, Thermal, Expansion

30

Page 31

Specication Line

Replacement Parts, continued

S_F1, S_F1N, S_F1S, S_DRL2, S_DFL2 - Solid Doors

S_DRL2, S_DFL2 - Glass Doors

Part Number Description

3516432 Blade, Fan, 25DEG, 8.75"

3517390 Blade, Fan, 5.56, CW, Lexan

3516204A Breaker, Vacuum

2194791 Cable, Display, 59

2194789 Capacitor, Start, 240MFD

3516427 Coil, Condenser, Large, Upright

3516436 Coil, Evap, Frz, 1DR

3527001 Comp, SC12CLX.2, 115/60HZ

2194812KT Control, Frz, Danfoss

2194792 Display, Blue, Danfoss

3516322 Drier, Filter, (2)Inlet

2160019 Guard, Fan, Wire

2194785 Htr, Def, 400W, 115V, 1DR

2194953 Limit, High Defrost

2162717 Motor, Fan, 9W, 115V, CW

2162715 Motor, Fan, Bay, 3/4ST

3516441 Relay, Comp, SC12CLX.2

2194959 Switch, SPDT, Rocker, Snap-in

3516588 Valve, Therm Exp, W/O MOP

S_F2, S_F2N - Solid Doors

Part Number Description

3516433 Blade, Fan, 25

3516204A Breaker, Vacuum

2194791 Cable, Display, 59

3516468 Capacitor, Start, Run, Assy

3517340 Coil, Evap, Sml FRZ, 2dr, Up

3527002 Comp, SC18CLX.2

2194812KT Control, Frz, Danfoss

2194792 Display, Blue, Danfoss

3516322 Drier, Filter, (2)Inlet

2160019 Guard, Fan, Wire

2194970 Heater, Defrost, 600W, 115V

2194953 Limit, High Defrost

2162750 Motor, Fan, PSC

2194959 Switch, SPDT, Rocker, Snap-in

2190154 Switch, SPST, Rocker, 20A/125V

3516557 Valve, Thermal, Expansion

S_FPT1, S_FRI1, S_F2S, S_DRP2, S_DFP2 - Solid Doors

S_F1 - Glass Doors

Part Number Description

3516433 Blade, Fan, 25

3517390 Blade, Fan, 5.56, CW, Lexan

3516204A Breaker, Vacuum

2194791

3516468 Capacitor, Start, Run, Assy

3516427 Coil, Condenser, Large

3516436 Coil, Evap, Frz, 1DR

3527002 Comp, SC18CLX.2

2194812KT Control, Frz, Danfoss

2194792

2160019 Guard, Fan, Wire

2194785 Htr, Def, 400W, 115V, 1DR

2194953 Limit, High Defrost

2162716 Motor, Fan, 16W, 115V, CW

2162750 Motor, Fan, PSC

2194959 Switch, SPDT, Rocker, Snap-in

2190154 Switch, SPST, Rocker, 20A/125V

Cable, Display, 59

Display, Blue, Danfoss

S_F3, S_FRI2 - Solid Doors

S_F2 - Glass Doors

Part Number Description

3516433 Blade, Fan, 25

3516204A Breaker, Vacuum

2194791 Cable, Display, 59

2194979 Capacitor, Run, 45 MFD

2194978 Capacitor, Start, 145-175

3517344 Coil, Condenser, Lrg 2dr

3517342 Coil, Evap, Lrg Frz, 2dr

3527017 Comp, AWA2460ZXD, 208V/60H

2194974 Contactor, 2 Pole, 120V

2194812KT Control, Frz, Danfoss

2194792 Display, Blue, Danfoss

2160019 Guard, Fan, Wire

2194970 Heater, Defrost, 600W, 115V

2194953 Limit, High Defrost

2162750 Motor, Fan, PSC

2194980 Relay, Potential, Start

2194959 Switch, SPDT, Rocker, Snap-in

3516557 Valve, Thermal, Expansion

31

Page 32

Deleld

Shelf Replacement Parts

S_DTR1, S_DBR1 - Solid & Glass Doors

Part Number Description

3516172 Blade, Fan, 5.56, CCW

3516432 Blade, Fan, 25deg, 8.75", CW

3516427 Coil, Condenser, Large, Upright

3516239 Coil, Evap, Refrig., RT, Spec

3516220 Coil, Evap, Frz, RT, Spec

3526999 Compressor, Frz., NF5.5CLX, 115V, 60Hz

3526997 Compressor, Ref., TF4CLX

3516443 Compressor Cover, Frz/Ref, Small, Danfoss

2194783-5KT Control, Frz, Danfoss, ETC1H, 115V

2194783-6KT Control, Ref, Danfoss, ETC1H, 115V

3516322 Drier, Filter, (2)inlet 1/4"

2160019 Guard, Fan, Wire

3516173 Guard, Plastic, Fan, 6

3978197 Guard, Wire, Evaporator

2194659 Heater, 115V-100W, 1A

2194670 Heater, 115V-305W, 3A

2194679 Heater, Drain, 120V-3.75W

2162717 Motor, Fan, 9W, 115V, CW

2162691 Motor, Fan, 115V, 50/60