Delfield N, N6, N10, N14, NDF Service Manual

...

Shelleymatic

®

by Delfield

Milk, Ice Cream and Milk & Ice Cream Dispensers

Service and Installation Manual

Please read this manual completely before attempting to install or operate this equipment! Notify carrier of damage! Inspect all

components immediately. See page 2.

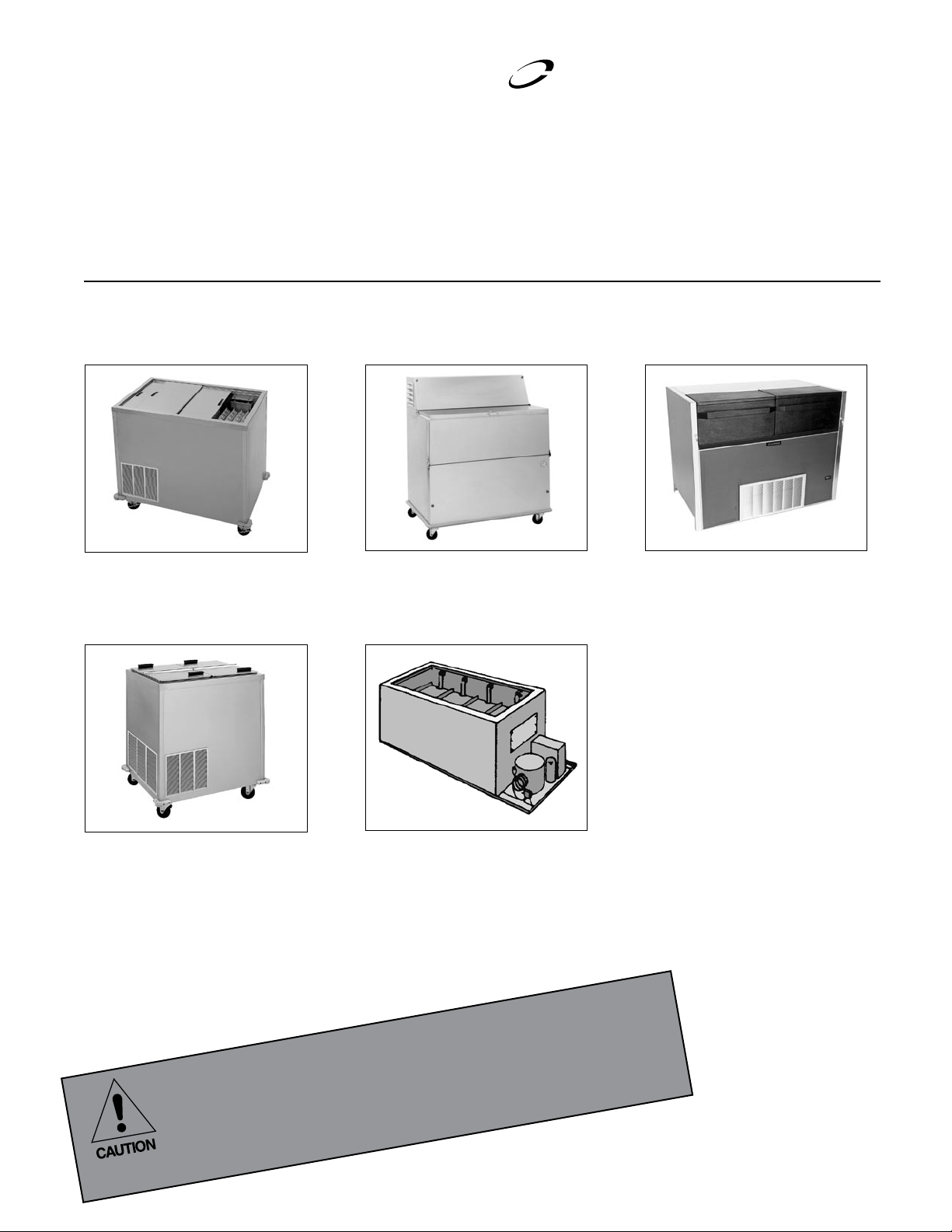

N, N6/N10/N14

Free-standing milk or

beverage dispensers

NSCF, SCF

Free-standing ice cream

dispensers and milk & ice

cream dispensers

NDF

Free-standing milk or

beverage dispensers

MF, MFSC, FF,

FFSC, RFF, RFFSC

Built-in milk or beverage,

ice cream, and milk & ice cream

dispensers

NLFAC

Free-standing milk or beverage

dispensers with air curtain

IMPORTANT INFORMATION

PLEASE SAVE THESE INSTRUCTIONS!

READ BEFORE USE

August 2010

Milk, Ice Cream & Milk & Ice Cream Dispensers Service and Installation Manual

Contents

Serial Number Location .............................................................2

Receiving and Inspecting Equipment ........................................2

Specifications .............................................................................3

Installation ...............................................................................4-5

Operation ....................................................................................6

Maintenance ...............................................................................7

Wiring Diagram ..........................................................................8

Replacement Parts ................................................................9-16

Standard Labor Guidelines ......................................................17

Standard Warranties ...........................................................18-19

©2010 The Delfield Company. All rights reserved. Reproduction without

written permission is prohibited. “Delfield” and “Shelleymatic” are registered

trademarks of The Delfield Company.

Serial Number Location

Serial number tag locations

MF/MFSC, FF/FFSC and RFF/RFFSC — on the end above the

refrigeration system.

N, N6/N10/N14, and SCF — rear of the unit above the louver.

NDF — Front right hand corner under the lid.

NLFAC — at the rear of the unit by the power cord.

Always have the serial number of your unit available when calling

for parts or service. A complete list of authorized Delfield parts

depots is available at www.delfield.com.

The units represented in this manual are for indoor use only.

Receiving and Inspecting the Equipment

Even though most equipment is shipped crated, care should

be taken during unloading so the equipment is not damaged

while being moved into the building.

1. Visually inspect the exterior of the package and skid or

container. Any damage should be noted and reported to

the delivering carrier immediately.

2. If damaged, open and inspect the contents with the

carrier.

3. In the event that the exterior is not damaged, yet upon

opening, there is concealed damage to the equipment

notify the carrier. Notification should be made verbally

as well as in written form.

4. Request an inspection by the shipping company of the

damaged equipment. This should be done within 10

days from receipt of the equipment.

5. Check the lower portion of the unit to be sure casters are

not bent.

6. Also open the compressor compartment housing and

7. Freight carriers can supply the necessary damage forms

8. Retain all crating material until an inspection has been

Uncrating the Equipment

First cut and remove the banding from around the crate.

Remove the front of the crate material, use of some tools will

be required. If the unit is on legs remove the top of the crate

as well and lift the unit off the skid. If the unit is on casters it

can be rolled off the skid.

visually inspect the refrigeration package. Be sure lines

are secure and base is still intact.

upon request.

made or waived.

2

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

Milk, Ice Cream & Milk & Ice Cream Dispensers Service and Installation Manual

Specifications

Model H.P. Loading/Dispensing Length Depth Height Weight (lbs) Amps (115V) NEMA Plug BTU Load Evap BTU/TD BTU Capacity Ref/Charge

Self-contained free-standing milk or beverage dispensers

N-520

N-860

N-1200

N-1530

N6-1313-34

N6-1313-36

N10-1313-34

N10-1313-36

N14-1313-34

N14-1313-36

Self-contained free-standing milk or beverage dispensers

NDF-12

NDF-18

Self-contained free-standing milk or beverage dispensers with air curtain (BTU is with lids closed.)

NLFAC-8

NLFAC-12

NLFAC-16

Self-contained free-standing milk and ice cream dispensers

NSCF-48

Self-contained free-standing ice cream dispensers

SCF-32

SCF-48

Model H.P. Cutout Dim. (L x D) L x D x H Weight (lbs) Amps (115V) NEMA Plug BTU Load Evap BTU/TD BTU Capacity Ref/Charge

Self-contained built-in milk or beverage dispensers *a 2.87” space is required between each cutout

MFSC-2020

MFSC-2821

MFSC-31

MFSC-44

MFSC-57

Remote built-in milk or beverage dispensers *a 2.87” space is required between each cutout

MF-2020

MF-2821

MF-31

MF-44

MF-57

Remote built-in ice cream dispensers *a 2.87” space is required between each cutout

FF-3324

FF-2

Self-contained built-in ice cream dispensers *a 2.87” space is required between each cutout

FFSC-3324

FFSC-2

Self-contained built-in milk & ice cream dispensers *a 2.87” space is required between each cutout

RFFSC-103

Remote built-in milk & ice cream dispensers *a 2.87” space is required between each cutout

RFF-103

1/4 sliding top lids 29” x 28” x 36” 327 5.0 5-15P 189 33/31º 1035 134a/16oz

1/4 sliding top lids 42” x 28” x 36” 392 5.0 5-15P 259 42/28º 1167 134a/16oz

1/4 sliding top lids 55” x 28” x 36” 462 5.0 5-15P 328 51/25º 1273 134a/16oz

1/4 sliding top lids 68” x 28” x 36” 532 5.0 5-15P 398 60/23º 1360 134a/16oz

1/4 sliding top lids 36” x 32” x 34” 382 5.0 5-15P 245 42/28º 1167 134a/16oz

1/4 sliding top lids 36” x 32” x 36” 402 5.0 5-15P 245 42/28º 1167 134a/16oz

1/4 sliding top lids 54.5” x 32” x 34” 545 5.0 5-15P 353 55/24º 1315 134a/16oz

1/4 sliding top lids 54.5” x 32” x 36” 565 5.0 5-15P 353 55/24º 1315 134a/16oz

1/4 sliding top lids 73” x 32” x 34” 650 5.0 5-15P 455 68/21º 1422 134a/16oz

1/4 sliding top lids 73” x 32” x 36” 670 5.0 5-15P 455 68/21º 1422 134a/16oz

1/4 drop front & flip top lids 35.88” x 33.38” x 57” 365 5.0 5-15P 687 49/25º 1204 134a/16oz

1/3 drop front & flip top lids 49.88” x 33.38” x 57” 430 7.0 5-15P 898 60/27º 1585 134a/24oz

1/3 hinged lids w/air curtain 40” x 32” x 42.50” 401 7.0 5-15P 668 140/16º 2184 134a/24oz

1/2 hinged lids w/air curtain 54” x 32” x 42.50” 491 9.0 5-15P 859 140/21º 2885 134a/32oz

1/2 hinged lids w/air curtain 68” x 32” x 42.50” 583 11.0 5-15P 1050 140/23º 3193 134a/32oz

1/4 hinged top lids 48” x 28” x 37” 390 7.1 5-15P 139(ref)

1/4 hinged top lids 32.5” x 28” x 37” 334 7.1 5-15P 709 51/18º 915 404A/16oz

1/3 hinged top lids 48” x 28” x 37” 414 8.0 5-15P 1043 69/19º 1350 404A/24oz

1/4 (1) 25.25” x 22.25” 43.25” x 26.25” x 28.25” 303 5.0 5-15P 304 51/24º 1223 134a/16oz

1/4 (1) 10.75” x 21” 28.5” x 26.25” x 28.25” 267 5.0 5-15P 264 45/26º 1166 134a/16oz

1/4 (2) 10.75” x 21”* 42” x 26.25” x 28.25” 306 5.0 5-15P 296 50/24º 1212 134a/16oz

1/4 (3) 10.75” x 21”* 55.5” x 26.25” x 28.25” 413 5.0 5-15P 408 64/21º 1346 134a/16oz

1/4 (4) 10.75” x 21”* 69” x 26.25” x 28.25” 461 5.0 5-15P 519 79/18º 1447 134a/16oz

N/A (1) 25.25” x 22.25” 29.25” x 26.25” x 28.25” 240 N/A N/A 304 51/24º N/A 134a/N/A

N/A (1) 10.75” x 21” 14.5” x 26.25” x 28.25” 197 N/A N/A 264 45/26º N/A 134a/N/A

N/A (2)10.75” x 21”* 28” x 26.25” x 28.25” 238 N/A N/A 296 50/24º N/A 134a/N/A

N/A (3)10.75” x 21”* 41.5” x 26.25” x 28.25” 312 N/A N/A 408 64/21º N/A 134a/N/A

N/A (4) 10.75” x 21”* 55” x 26.25” x 28.25” 335 N/A N/A 519 79/18º N/A 134a/N/A

N/A (1) 10.75” x 21” 14.5” x 26.25” x 28” 215 N/A N/A 434 35/22º N/A 404A/N/A

N/A (2)10.75” x 21”* 28” x 26.25” x 28” 290 N/A N/A 709 51/18º N/A 404A/N/A

1/4 (1) 10.75” x 21” 28.5” x 26.25” x 28.25” 308 7.1 5-15P 434 35/22º 763 404A/16oz

1/3 (2) 10.75” x 21”* 42” x 26.25” x 28.25” 408 8.0 5-15P 709 51/18º 915 404A/24oz

1/4 (2) 10.75” x 21”* 42” x 26.25” x 28.25” 428 7.1 5-15P 139(ref)

N/A (2) 10.75” x 21” 28” x 26.25” x 28” 310 N/A N/A 139(ref)

414(frz)

414(frz)

414(frz)

37/43º(ref)

37/21º(frz)

37/43º(ref)

37/21º(frz)

37/43º(ref)

37/21º(frz)

1596(ref)

796(frz)

1596 (ref)

796(frz)

N/A 404A/N/A

404A/16oz

404A/16oz

404A/16oz

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

3

Milk, Ice Cream & Milk & Ice Cream Dispensers Service and Installation Manual

Installation

Location

These units are intended for indoor use only. Be sure the location

chosen has a floor strong enough to support the total weight of

the cabinet and contents. Units in this product line can weigh as

much as 1500 pounds when it is fully stocked. Reinforce the

floor as necessary to provide for maximum loading.

For the most efficient refrigeration, be sure to provide good air

circulation inside and out.

Inside cabinet: Do not pack unit so full that air cannot circulate.

Take care not to block air flow to the fans and allow space along

sides.

Outside cabinet: Be sure that the unit has access to ample

air. Avoid hot corners and locations near stoves and ovens. It

is recommended that the rear of the unit be no less than two

inches from any wall, partition or any other object which will

restrict exhaust air flow.

Leveling

A level cabinet looks better and will perform better because

the cabinet will not be subject to unnecessary strain due to

doors not properly lining up with door frames.

Some models have casters for ease of cleaning underneath and

for mobility. It is important that the unit be installed in a stable

condition with the front casters locked before operating. Locking

the front casters after installation is the operator’s responsibility.

Electrical connection

A standard self-contained unit is provided with a power cord

and three-prong grounded plug.

The unit should be plugged into a receptacle with its own

circuit protection that matches the amperage of the plug.

Refer to the amperage data on page three or the

serial tag data and your local code or the National

Electrical Code to be sure the unit is connected

to the proper power source. A protected circuit of

the correct voltage and amperage must be run for

connection to the unit.

The power supply must be disconnected

whenever performing maintenance or repairing

the equipment!

Built-in units

All self-contained units (MFSC, FFSC and RFFSC) are tested at

the factory to assure proper operation. The unit should not be

installed directly next to high heat generating equipment (ranges,

griddles, etc.).

These units are built into the counter from below and must be

supported from the bottom. The counter cut-out sizes and power

supply requirements are shown in the specifications on page

three. All refrigerators have drains located in the bottom of the

tank. An appropriate drainage area or container must be provided

by the customer. Be sure to place the unit so the pressure control,

located near the compressor, can be reached.

For installation of remote units (MF, FF and RFF), consult a

refrigeration service company to connect refrigeration lines to the

remote condensing unit.

Self-contained refrigerated units (MFSC, FFSC and

RFFSC) require air flow to the compressor. A louver

is provided and must be installed in the counter in

front of the condenser. An equal size opening at the

rear of the cabinet must also be provided to allow

warm air to escape. Failure to do so will void all

product warranties.

Free standing units

All self-contained units (N, N6/10/14, NDF, NLFAC, SCF and

NSCF) are tested at the factory to assure proper operation. The

unit should not be installed directly next to high heat generating

equipment (ranges, griddles, etc.).

These units are free standing, either on legs or casters. The

power supply requirements are shown on page three. All free

standing units have drains located in the bottom of the tank.

An appropriate drainage area or container must be provided by

the customer.

Do not place the unit against a wall or any object that will block

air circulation through the condensing unit. If the unit must

be placed against a wall, leave a minimum of 2” of space for

air flow.

The unit must never be operated without the

louvered panel in place.

4

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

Milk, Ice Cream & Milk & Ice Cream Dispensers Service and Installation Manual

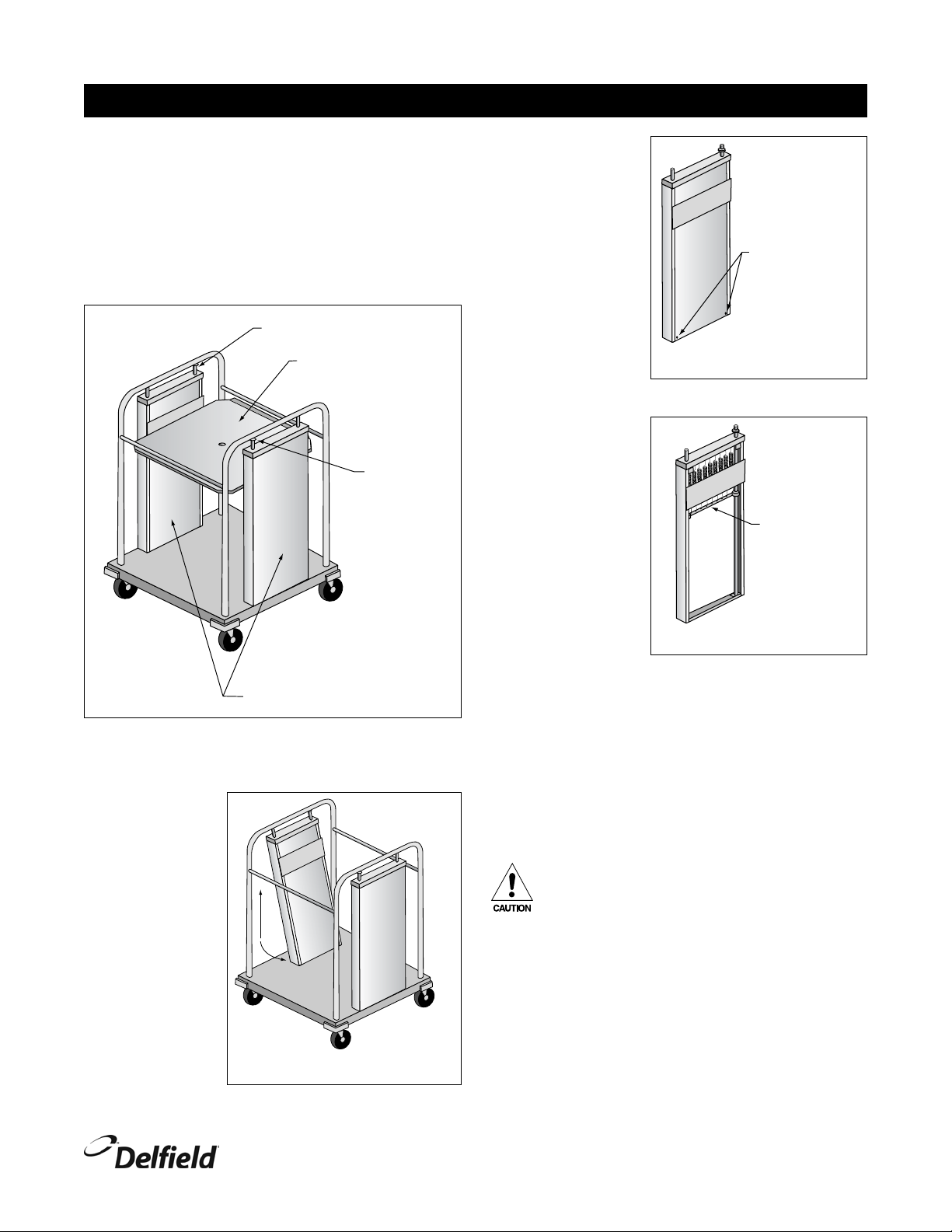

RETAINER

LOAD TRAY

ELEVATOR HOUSINGS

RETAINER

REMOVE SCREWS,

SLIDE COVER OFF

REMOVE OR

ADD SPRINGS

AS NEEDED

Installation Continued

How to adjust self-leveling dispenser

Tools Needed: One small flat head screw driver; One Phillips

head screw driver.

1. Always wear safety glasses when adjusting your dispenser.

Also, lock brakes on mobile units before beginning.

2. Unload dispenser and remove stainless steel load tray by

lifting straight up and set it aside (see figure 1).

(Figure 1) Sample unit

3. Use small regular screw driver to loosen each retainer

mounted on stainless steel rod at top of each elevator

housing.

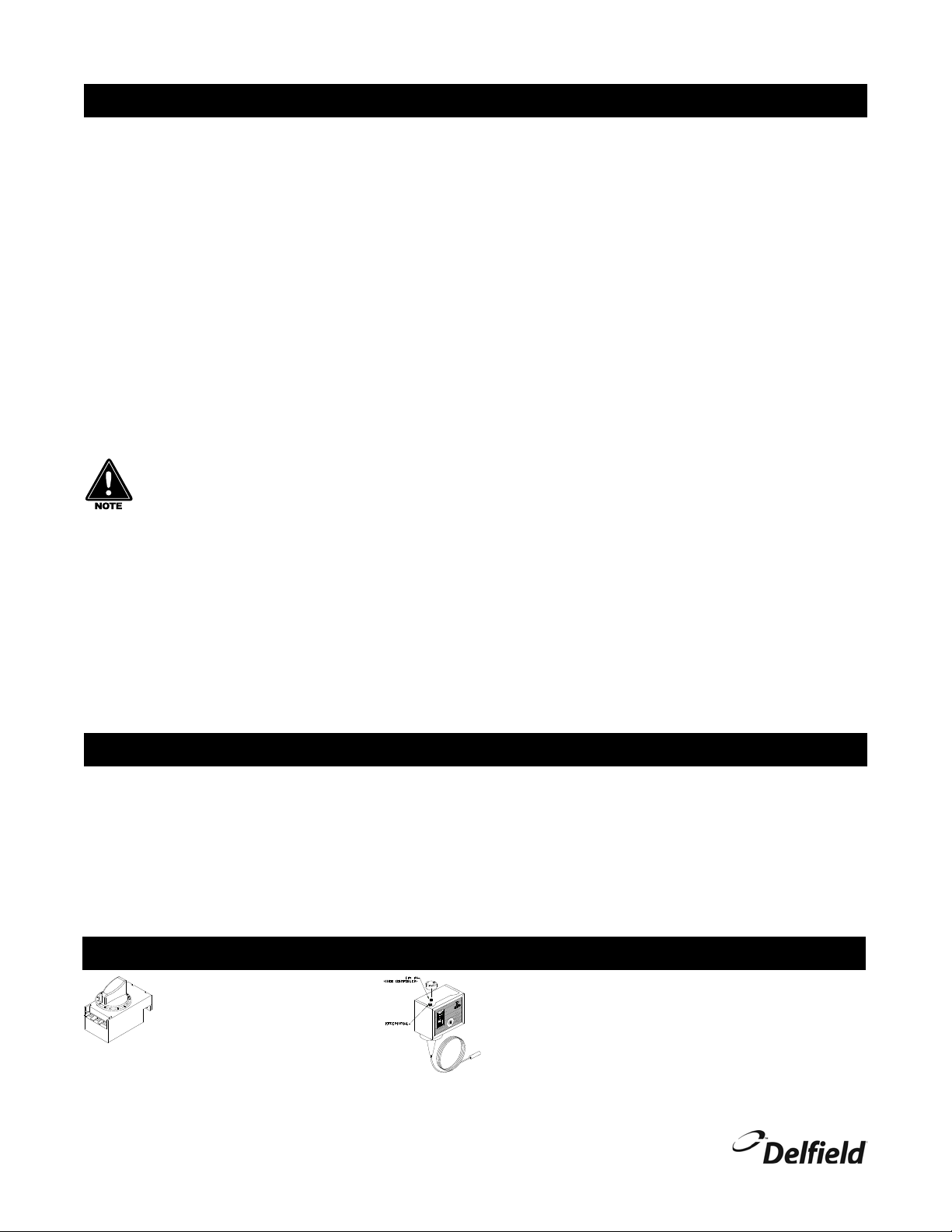

4. To remove elevator

housing, lift

housing straight

up to clear the

stud on unit base.

Then gently swing

the bottom of the

housing towards

the inside of the

unit and pull

housing out of the

unit (see figure 2).

Lay housing on

flat surface.

5. Use Phillips head

screw driver to

remove front panel

on the elevator

housing (see figure

3).

6. If carrier is riding

too high, you need

to remove springs.

With carrier all the

way to the top, gently

disengage one spring

at a time, unhooking

(Figure 3) Remove front panel

bottom loop out of

carrier bracket (see

figure 4). Remove

as many springs as

necessary.

If carrier is riding too

low, you need to add

springs. With carrier

all the way to the top,

gently engage one

spring at a time by

hooking bottom loop

of spring into carrier

bracket. Add as many

(Figure 4) Remove or add springs

springs as necessary.

7. When finished, put elevator housing back in unit and put

stainless steel load tray back on elevator housings. Load

unit to test dispensing level. If spring adjustment does

not position carrier properly, repeat procedure #6 trying

different springs. If this does not work, a different set

of springs may be required. To order, call The Delfield

Company Parts and Service Department at 800.733.8829

8. If level is appropriate, put front panels back on and

tighten retainer.

CAUTION: Dispenser should not be operated

with front panels off elevator housing.

When adjusting the elevators make sure each have the

NOTE:

same number and size of springs connected to the carrier on

both sides. This will prevent the load tray from binding.

(Figure 2) Remove elevator housing

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

5

Milk, Ice Cream & Milk & Ice Cream Dispensers Service and Installation Manual

Operation: N, N6/10/14, NDF, NLFAC, MF & MFSC Series

N, N6/10/14, NDF, NLFAC and MFSC Series milk dispensers

are set at the factory to maintain temperatures between 36°F

and 40°F. No further adjustment should be necessary. To begin

operation on self-contained models, plug the electrical supply

cord into a receptacle with the correct voltage. Remote models

will require a connection to a separate refrigeration system.

Loading: N, MF & MFSC Series

To load, place a complete layer of cartons or bottles standing

upright on the load tray. Then place a divider tray on top of

this layer, then another layer of cartons or bottles on this tray,

then another tray and another layer, etc. As each additional

tray is loaded, the elevators gradually lower. The last layer

may be placed on top without the use of another tray. When

loading the average tall half pint bottles, four layers may be

loaded into each compartment standing upright and the fifth

layer laying down.

It is very important to use the divider trays

provided between each successive layer of

contents to assure the correct balance of the

load and the proper action of the elevating

mechanism.

Wire racks, when used, should be loaded completely. When

placing one rack on top of the other, be sure the stacking lugs

are properly aligned.

Loading: N6/10/14 Series

These cabinets are designed to dispense 13” x 13” x 11” high

(maximum dimensions) dairy cases. Place one case loaded

with milk on the carrier and then place a second case loaded

with milk on top of the first case. Press down on the cases

leaning them toward the retaining bracket located under the

top lid track, then gradually release pressure on the cases

so that the top edge of the case engages with the retaining

bracket.

The elevating mechanism is designed to keep the contents

several inches below the top of the cabinet when fully loaded.

This distance serves two purposes:

A. It keeps the top layer of milk completely refrigerated even

when the lids are removed.

B. It insures that the lids will operate without striking the

contents as successive layers are added.

Loading: NDF Series

These cabinets are designed to dispense 13” x 13” x 11” high

(maximum dimensions) dairy cases. They do not have a selfleveling mechanism. Simply place the cases on top of each

other inside the cabinet through the wide opening in the top

and front.

Loading: NLFAC Series

These cabinets are designed to dispense 13” x 13” x 11” high

(maximum dimensions) dairy cases. Model NLFAC-8 holds

eight cases; four on the bottom and four on the top. Model

NLFAC-12 holds twelve cases; six on the bottom and six on

the top. Model NLFAC-16 holds sixteen cases, eight on the

bottom and eight on the top.

Milk cases are loaded through the wide opening in the top and

front of the unit. Fold the hinged lids up and back and rest

them on the top. The cabinet interior has self-locating guides

installed to make loading easy.

Operation: FFSC, RFFSC, SCF & NSCF series

FFSC and SCF Series ice cream dispensers are set at the

factory to maintain temperatures between -5°F and 0°F. RFFSC

and NSCF Series combination milk and ice cream dispensers

are set at the factory to maintain temperatures between 36°F

and 40°F for refrigerated product and between -5°F and 0°F for

frozen product. Each combination unit is constructed with two

tanks and separate controls. No further adjustments should be

necessary. To begin operation plug the electrical supply cord

into a receptacle with the correct voltage.

Loading

To load, place two layers of ice cream on the load tray, then a

tray, two additional layers of ice cream, then another tray, etc.

Do not stack ice cream above the frost line on the interior of

the freezer. See the instructions for the MF units (above) for

loading the refrigerated portion of the combination units.

Temperature Control

NLFAC Thermostat Control

Set the thermostat toward 1 for

higher temperatures and toward

7 for lower temperatures. The

refrigerator factory setting is 4

and maintains 38ºF (3ºC) in the

box.

6

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

Low Pressure Control, Remaining Self Contained Models

If it is necessary to adjust the temperature, turn the knob

clockwise as indicated on the control. Make adjustments

gradually. It may take an hour to realize the temperature

change. Milk or beverage dispenser factory settings are 17ºF

differential, 34ºF cut in, and 17ºF cut out. Milk and ice cream

dispenser factory settings are 25ºF differential, 30ºF cut in, and

5ºF cut out.

Loading...

Loading...