Page 1

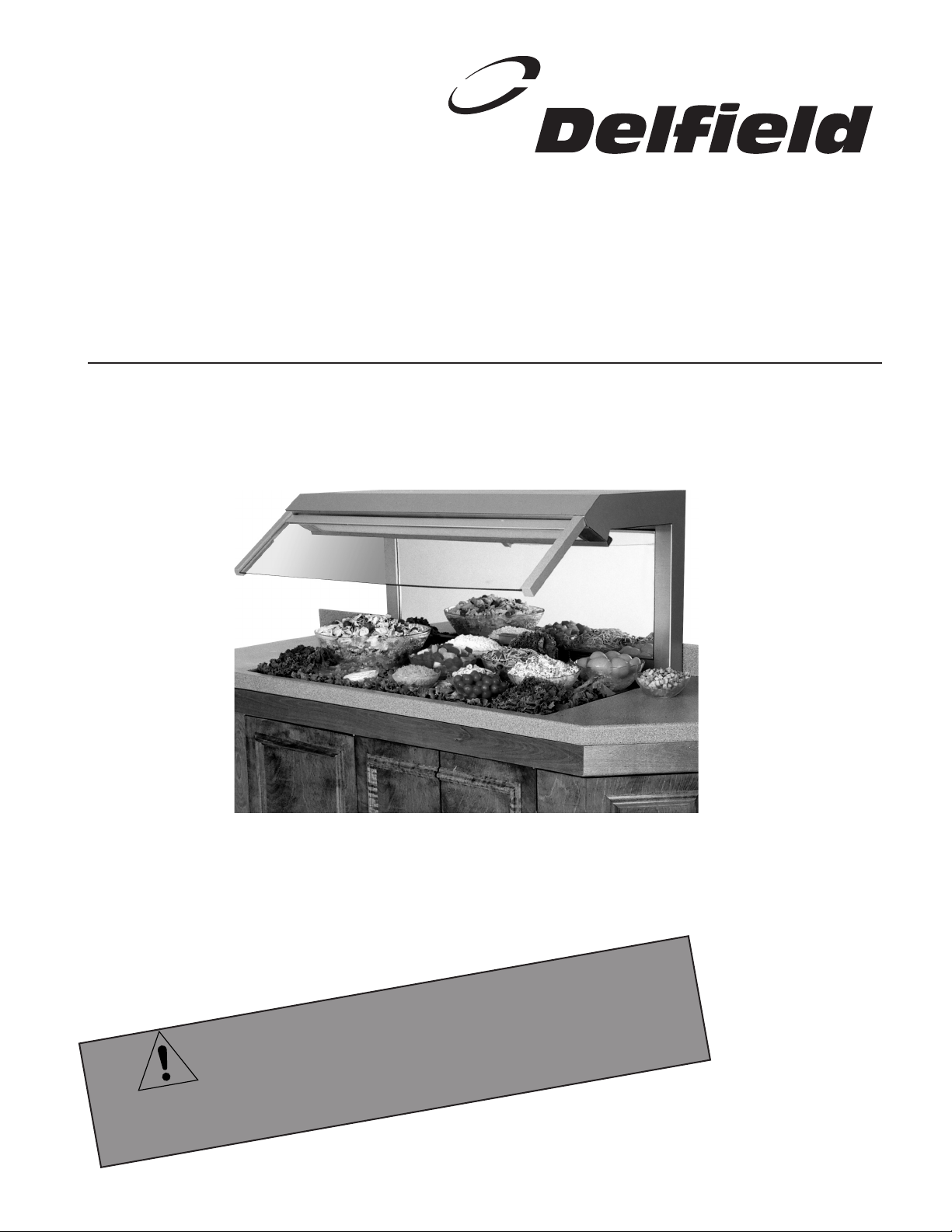

Nordic Zone™ Cold Food Bars

CAUTIO

N

Service, Installation and Care Manual

Please read this manual completely before attempting to install or operate this equipment! Notify carrier of

damage! Inspect all components immediately. See page 2.

IMPORTANT INFORMATION

READ BEFORE USE

PLEASE SAVE THESE INSTRUCTIONS!

August 2003

Page 2

Nordic Zone Salad Bar Service and Installation Manual

Nordic Zone Salad Bar Service and Installation Manual

3

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

CONTENTS

RECEIVING AND INSPECTING UNIT ................................................. 2

INSTALLATION.................................................................................. 3

ROUTINE MAINTENANCE ................................................................. 3

OPERATION ...................................................................................... 4

WIRING DIAGRAM............................................................................ 5

REPLACEMENT PARTS LIST............................................................. 5

FULL VIEW........................................................................................ 6

UNIT DETAILS................................................................................... 7

WALL MOUNT INSTALLATION.......................................................... 8

STANDARD WARRANTIES........................................................... 9-10

AUTHORIZED PARTS DEPOTS........................................................ 12

©2003 The Deleld Company. All rights reserved. Reproduction without written permission is prohibited. “Deleld” is a registered trademark of The Deleld Company.

SERIAL NUMBER LOCATION

The serial number on Nordic Zone series is located behind the hinge

doors afxed to the interior stainless side. On the two section model,

it will be the two interior sides in the center of the assembly.

Always have the serial number of your unit available when calling for

parts or service. A complete list of authorized Deleld parts depots is

shown on the back cover of this manual.

Refrigeration system is set up as a R-404a refrigerant.

Mechanical Data (dimensions for RT00012 (left side) and RT00013 (right side) combined

MODEL PRODUCT #OF # OF REMOTE REMOTE SHIP WEIGHT

NUMBER LENGTH HOLDING AREA DOORS LIGHT BULBS AMP HP BTU LBS.

NZ123 123.5” (313.69cm) 24” x 80.5” (60.69cm X 204.47cm) 4 (4) 48” 6 1.5 10,030 951

NZ207 207” (525.78cm) 24” x 124” (60.69 x 410 cm) 8 (8) 48” (2) 6 (2) 1 1/2 20,060 1600

RECEIVING AND INSPECTING THE EQUIPMENT

Units are shipped blanket wrapped.

Care should be taken during unloading so the equipment is not

damaged while being moved into the building.

1. Visually inspect the unit. Any damage should be noted and

reported to the delivering carrier immediately.

2. If damaged, open and inspect the unit with the carrier.

3. In the event that the unit is not damaged, yet upon opening,

there is concealed damage to the equipment notify the carrier.

Notification should be made verbally as well as in written

form.

4. Request an inspection by the shipping company of the

5. Also open the mechanical compartment housing and visually

6. Freight carriers can supply the necessary damage forms upon

damaged equipment. This should be done within 10 days

from receipt of the equipment.

inspect the control package. Be sure lines are secure and

base is still intact.

request.

2

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

Page 3

INSTALLATION

Nordic Zone Salad Bar Service and Installation Manual

In most instances, the salad bar units will arrive at the job site

uncrated, and caution must be taken not to damage any exterior

surfaces when moving into position. All internal components

including glass and mirrors will be shipped intact within the unit.

The area where the salad bar is to be located must be clean and the

oor level to assure a satisfactory installation.

In the appropriate location, units must be leveled with the nished

work height top of Corian® to be approximately 34” above nished

oor. Make sure units are level left to right as well as front to back.

The units are mounted on 6” high legs which can be adjusted up to 1”.

Corian® adhesive (supplied) is to be applied between Corian®

surfaces where they adjoin at center for proper moisture sealing.

Once the Corian® adhesive has been applied the units are ready to

be connected together where noted “spline here.” The locations are

directly behind the front nosing, below the upper front air diffuser,

and at the rear of the unit. Fasteners will be pre-installed within the

spline locations. Clean the units. Remove any excess silicone or

adhesive that may have squeezed out after splining units together.

With sufcient help (4-5) individuals, slowly push the connected units

“evenly” back to the wall at the rear. Make sure that all stubbed out

electrical, refrigeration lines, and plumbing lines clear the cabinet

structure. If not, make any necessary adjustments to clear these

components. Once the units are secure against the wall at the rear,

double check for level.

Locate and install Corian® rear and side splashes using adhesive

supplied. It may be necessary to trim pieces slightly to t.

REFRIGERATION INSTALLATION

If the condensing units are to be set on the roof of the building, it

must be mounted on beams supplied by the roong contractor or the

refrigeration contractor.

The condensing units must be a minimum of three feet apart to assure

proper air ow. Before the salad bar units arrive the refrigeration lines

must be installed from the condensing units down through the ceiling

and the rear wall and stubbed out per the drawing supplied to the

installer. The suction line should be 5/8 inch and the liquid line should

be 3/8 inch for most installations. The pipe insulation should be 1/2

inch wall thickness. A “p” trap must be installed at the lowest point

of the refrigeration lines. The electrical power supply must also be

stubbed through the rear wall.

The liquid line should be insulated if exposed to sunlight on roof

installations. All refrigeration lines must be secured to prevent

excessive vibrating or kinking of the copper tubing. Drain lines must

be installed to the drain stub on the bottom of the evaporator housing.

The drain must have proper slope to insure good drainage from the

evaporator pan. A minimum vacuum of 200 microns must be reached

before charging the units with R-404A refrigerant. The system must

be charged under a heat load with R-404A until the sight glass is clear.

Normal installations will require approximately 9lbs. of refrigerant for

each system.

All panels and covers must be installed in the proper locations and

the defrost timer must be set for the proper time. Defrost time for

normal installations should be 15 minutes every three hours and the

thermostat setting should be for 37º degrees box temperature.

NOTE: do not change setting of defrost timer or

thermostat. See page #4 for complete operation

instructions.

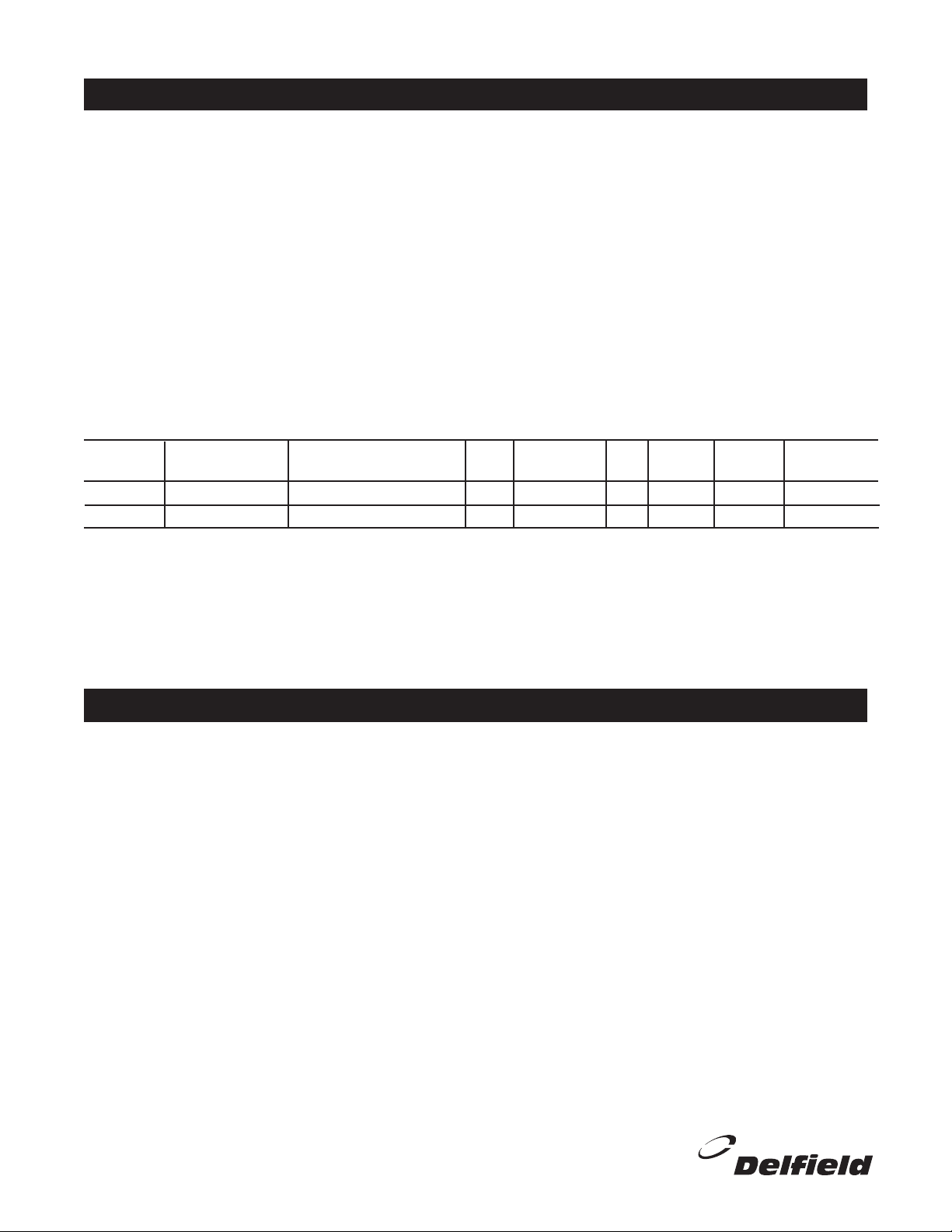

On/Off Switch located

behind the center

panel.

Thermostat located

behind the On/Off

switch panel.

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

3

Page 4

Nordic Zone Salad Bar Service and Installation Manual

Nordic Zone Salad Bar Service and Installation Manual

5

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

CAUTION

CLEANING INSTRUCTIONS

Daily cleaning of the interior and exterior of the unit is recommended.

All food must be removed from the interior before cleaning. Always

wear gloves and eye protection when handling cleaning solutions and

cleaning the salad bar.

GLASS: Use the mildest cleaning product available to clean glass

mirrors on the salad bar. Typically, soap and water, or ammonia will

clean the glass sufciently. If stronger solutions are required, be

sure to use products designed for use on glass. Cleaning products

designed for other materials will leave residue that is not removable.

DISINFECTING: If the interior surface requires disinfecting, use a

product that contains Alkyl Ammonium Chloride to kill germs.

GREASE REMOVAL: Your regular daily cleaner may not remove

grease, ngerprints or other oily deposits found on glass. In this

case, use a stronger degreasing cleaner with butoxyethanol. Apply

this cleaner with sponge or cloth. Remove with a squeegee. Reclean

as necessary if streaks appear from degreaser.

DEGREASERS CAN HARM YOU. ALWAYS WEAR PROTECTIVE

GLOVES AND EYE PROTECTION WHEN USING THESE MATERIALS.

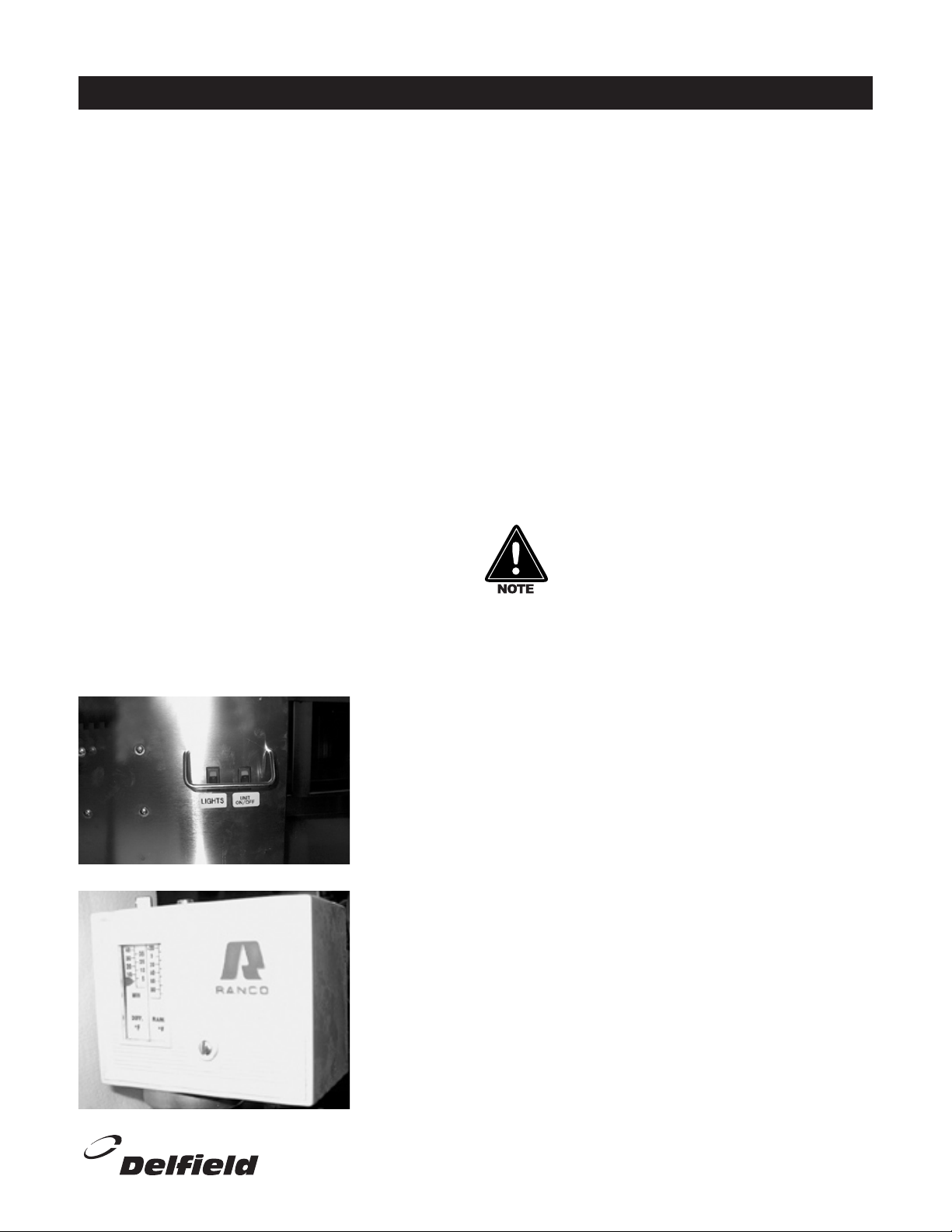

CLEANING REFRIGERATED PLATFORM: After removing all food

product and containers, lift the platform by grasping the front edge

and pulling up.

When lifting front edge take caution to ensure palms are down as

to not pinch ngers. See Figure-1 and Figure-2.

PLASTIC LAMINATE

In most cases, you only need to use a clean, damp nonabrasive

cotton cloth and a mild liquid detergent or household cleaner. Rinse

with clean water, using a clean, nonabrasive cotton cloth. Do not

ood the laminate, especially near seams since water can penetrate

and cause the substrate to swell. Dry the surface with a soft, clean,

non-abrasive cotton cloth.

DO NOT use abrasive cleaners, powders, steel wool, sandpaper,

or Scotch-Brite™ scouring pads. Use a trivet, insulated hot pad or

other protective device beneath all hot cookware, heat generating

appliances, or other heated objects.

®

CORIAN

There are three types of countertop nishes: matte,

semigloss and gloss. All Corian® sinks and bowls

have the matte nish. Soapy water or ammonia-based

cleaners will remove most dirt and stains from all

types of nishes. However, slightly different techniques must be

used to remove difcult stains, depending on the nish.

Preventing Heat Damage: to prevent heat damage, always use a hot

pad or a trivet with rubber feet to protect your Corian.

The platform is mounted on two pistons, located at

each end of the platform. Once raised, clean food debris

from the area, paying attention not to force food down

the drain of this area. This drain is easily clogged and

difcult to clean. Once food debris is cleaned out of the

area, use soap and water to wash the area and rinse. This will ow

down the drain. When cleaning is done, pull the platform down.

CABINET WOOD

To clean, gently wipe liquid spills up with a damp towel. If necessary

use with mild detergent.

Figure-1 Figure-2

4

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

Page 5

OPERATION

Nordic Zone Salad Bar Service and Installation Manual

Start Up Procedures

1) Turn main power toggle switch to the ON position

2) Turn the toggle switch labeled lights to the ON position

3) Allow the case to reach refrigerator temperatures before lling

with product.

Display area must be in down position for fans to run.

Shut Down Procedures

1) Turn the toggle switch labeled LIGHTS to the OFF position.

2) Turn the toggle switch labeled MAIN to the OFF position.

3) Remove product from the case and clean.

COPIES OF THIS INFORMATION ARE ATTACHED TO THE INSIDE CENTER DOORS ON THE SALAD BAR.

TO INSURE THE PROPER OPERATION OF THIS AIR SCREEN SALAD BAR, PLEASE OBSERVE THE FOLLOWING.

The master back door light switch controls the power to the salad bar. When turned on, the process of circulating cold air and cooling down the

cold plates will start. This must be done one hour prior to stocking the salad bar with any food items. (At pre-determined times throughout the

day, the unit will cycle itself into a defrost mode.) Turn on the overhead display lights and you are ready to go.

Listed below are some important steps that must be followed

to insure that the air screen salad bar unit is set up correctly.

Do not install plastic wrap on any areas except the solid surface

portion of the cooling plates. Be careful not to block the return

air vents at the front or extreme ends of the cooling plates.

The mirrored panels along the rear of the unit must be securely

in place with no air leaks between mirror panels or at the outside

ends.

Control Knobs and Switches: All control and switches are

labeled accordingly.

1. Never attempt to change the setting of the defrost timer

or thermostat. Adjustments are to be made by qualied

service technicians only. Defrost cycles are factory preset and should not require eld adjustments. In the event of a power loss to this unit,

timers will NOT need to be reset.

2. The toggle switch labeled lights are for the overhead display lights and can be operated as necessary. A master on/off switch is located in the

base area.

3. If the units are not keeping acceptable temperatures or performing properly an authorized service agent MUST BE contacted. Contact local

service company or Deleld Service direct at 800-733-8829.

4. When lifting front edge take caution to ensure palms are down as to not pinch ngers

- see photo to the right.

5. Cleaning under display area can be done by lifting front edge of display area - see photo above.

Consult service/maintenance manual for additional information.

PRIORITY:

All refrigerated Salad Bar items must

be at or below 40˚F prior to being

Do not allow the pewter bowls or kale garnish to block the airow from the louvered

areas at the inside back of the cooling plates. There must be a minimum of 3 inches

between the louvered panels and the pewter. Do not allow the pewter bowls or kale

garnish to block the return air vents at the front or extreme ends of the cooling plates.

placed onto the salad bar. Do not stack

the salad bar with warm product.

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

5

Page 6

Nordic Zone Salad Bar Service and Installation Manual

Nordic Zone Salad Bar Service and Installation Manual

7

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

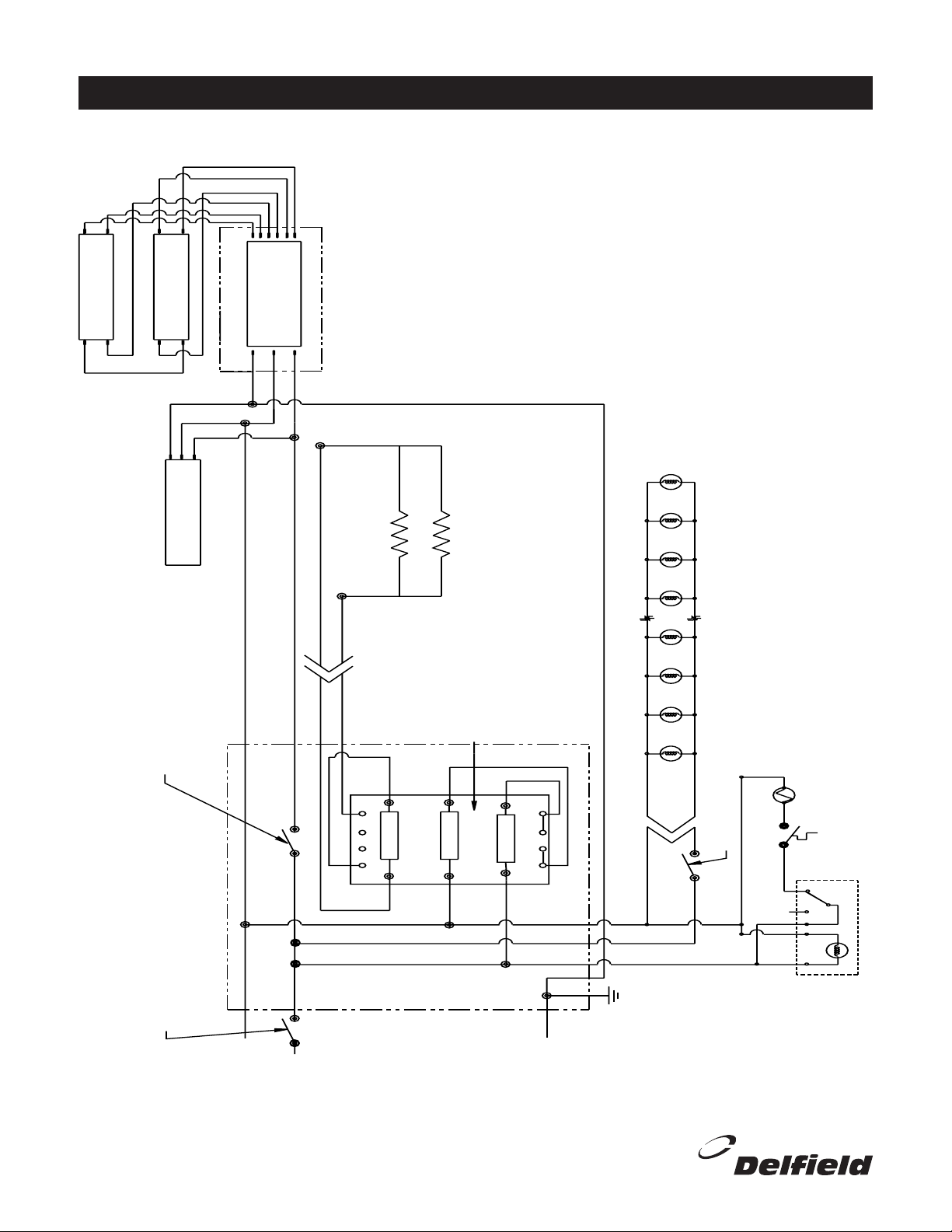

WIRING DIAGRAM 207”

NOTE: each 1/2 section of the

salad bar requires separate elec-

R

R

LAMP 1

Y

B

B

LAMP 2

Y

GREEN

WHITE

END LAMP

BLACK

Y

R

R

BALLAST, 120v INPUT, 227v OUTPUT

WHITE

GREEN

trical connections. This wiring

BBY

diagram represents a 1/2 section.

BLACK

RAIL FAN

HEATING ELEMENTS

RAIL FAN RAIL FANRAIL FAN RAIL FAN

(4) TO (8) FAN MOTORS

LIGHT ON/OFF SWITCH

WHITE

STAINLESS STEEL ENCLOSURE

MAIN ON/OFF SWITCH

NEUTRAL

BLACK

L1

BLUE

BLUE

RED

RED

X1 X2

BLUE

FUSE OFNM-15

XF

WHITE

RED

BLACK

120v TO 24v TRANSFORMER

BLACK

FUSE IKTK-R-5

WHITE

BLACK

FUSE IKTK-R-5

H4 H2 H3 H1

HF

H1

BLACK

GND

WHITE

WHITE

RAIL FAN RAIL FAN

BLACK

RAIL FAN

SOLENOID

THERMOSTAT

RED

5

4

1 2 3

FAN MOTOR

6

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

Page 7

Nordic Zone Salad Bar Service and Installation Manual

WIRING DIAGRAM 123” - NOTE: each 1/2 section of the salad bar requires separate electrical connections. This wiring diagram represents a 1/2 section.

R

R

LAMP 1

Y

B

Y

GREEN

LAMP 2

WHITE

B

BLACK

Y

R

R

BALLAST, 120v INPUT, 227v OUTPUT

WHITE

GREEN

BBY

BLACK

RAIL FAN

END LAMP

HEATING ELEMENTS

RAIL FAN RAIL FANRAIL FAN RAIL FAN

(4) TO (8) FAN MOTORS

LIGHT ON/OFF SWITCH

WHITE

STAINLESS STEEL ENCLOSURE

MAIN ON/OFF SWITCH

NEUTRAL

BLACK

L1

BLUE

BLUE

RED

RED

X1 X2

BLUE

FUSE OFNM-15

XF

WHITE

RED

BLACK

120v TO 24v TRANSFORMER

BLACK

FUSE IKTK-R-5

WHITE

BLACK

FUSE IKTK-R-5

H4 H2 H3 H1

HF

H1

BLACK

GND

WHITE

WHITE

RAIL FAN RAIL FAN

BLACK

RAIL FAN

SOLENOID

THERMOSTAT

RED

5

4

1 2 3

FAN MOTOR

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

7

Page 8

Nordic Zone Salad Bar Service and Installation Manual

Nordic Zone Salad Bar Service and Installation Manual

9

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

REPLACEMENT PARTS

LEFT and/or RIGHT HAND of 207” (each side)

Remote

PART NUMBER DESCRIPTION

323457 Control knob ring guard

2194620 Fan safety switch

RTP00013 34” Fluorescent bulb

RTP00034 UCM-8 Fluorescent bulb

RTP00012 2-Bulb uorescent bulb

3516222 Solenoid valve

5090025 Temperature control

6230110 Plastic insert

RTP00040 Alum hinge

3234645 6” leg

RTP00024 Limitron bussman fuse

RTP00022 Transformer

2190154 Rocker switch (lights, night power)

3234242 Plastic drain

2194345 Timer

3516151 Expansion valve

RTP00009 Evaporator coil

RTP00044 Mirror heater pad

3516172 Fan blade

3516173 Fan guard

2162691 Fan motor

ONE SIDE OF THE 123”

Remote

PART NUMBER DESCRIPTION

323457 Control knob ring guard

2194620 Fan safety switch

RTP00013 34” Fluorescent bulb

RTP00034 UCM-8 Fluorescent bulb

RTP00012 2-Bulb uorescent bulb

3516222 Solenoid valve

5090025 Temperature control

6230110 Plastic insert

RTP00040 Alum hinge

3234645 6” leg

RTP00024 Limitron bussman fuse

RTP00022 Transformer

2190154 Rocker switch (lights, night power)

3234242 Plastic drain

2194345 Timer

3516151 Expansion valve

RTP00010 Evaporator coil

RTP00044 Mirror heater pad

3516172 Fan blade

3516173 Fan guard

2162691 Fan motor

HEATED MIRROR ASSEMBLY

INSTALL .75” ABS STRIP

HANGER IS HOLLOW

74 - RT00034

ASSEMBLE ONTO BACKER

75 - RTP00017

78 - RT000324

AIRTECH FOAM INSULATION

SILICONE ALL

EDGES AFTER

ASSEMBLY

REMOVE BACKING

AND STICK TO

MIRROR BACK - 77

RTP00044

EDGE BAND SIDE

OF MIRRORS ONLY

76 - 3234037

8

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

Page 9

FULL VIEW 207”

Nordic Zone Salad Bar Service and Installation Manual

Switch and defrost locations

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

9

Page 10

Nordic Zone Salad Bar Service and Installation Manual

11

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

10.35"

10.35"

135°

32.3"

22"

20

"

20

"

123.5"

83.5"

102.8"

Nordic Zone Salad Bar Service and Installation Manual

FULL VIEW 123”

10

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

Page 11

LEG SCREW TOE PLATE TO UNIT

LEG RAIL

TOE PLATE BY OTHERS

Nordic Zone Salad Bar Service and Installation Manual

HOLE IN SIDE FOR SHARED

REFRIGERATION

SCREW TO CLEAT IF USED

OPTIONAL 1” CLEAT FOR STRENGTH

LAMINATE FRONT

1” CHROME HINGE

CLEAR TEMPERED GLASS

SNEEZE GUARD

1/2” GLASS STOP

6.12”

LEG RAIL

TOE PLATE BY OTHERS

TOE PLATE INSTALLATION DETAIL

LAMINATE TOP

POWDER COATED ARM

GLASS SNEEZE GUARD DETAIL

LAMINATE END

HOLE IN SHELF FOR

DRAIN/REF’G

LAMINATE

FRONT

BOLT SPLINERS

TOGETHER PRIOR TO

PUSHING AGAINST

WALL

ACCESS HOLE DETAIL

TOP

18 SPLINE

1” S/S SEAMS

REAR OF UPPER

STRUCTURE

REAR SPLINE DETAIL

BASE

SECTION VIEW

Sneeze shields to be “ip up” style and will be positioned to

meet NSF requirements (1/4” tempered glass)

NOTE: All return air chambers to be constructed of cleanable

approved materials.

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

11

Page 12

Nordic Zone Salad Bar Service and Installation Manual

Nordic Zone Salad Bar Service and Installation Manual

13

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

NSF Official Listing For Lighting System

12

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

Page 13

Nordic Zone Salad Bar Service and Installation Manual

STANDARD LABOR GUIDELINES TO REPAIR OR REPLACE PARTS ON DELFIELD EQUIPMENT

Advice and recommendations given by Delfield Service Technicians do not constitute or guarantee any special coverage.

• A maximum of 1-hour is allowed to diagnose a defective component.

• A maximum of 1-hour is allowed for retrieval of parts not in stock.

• A maximum travel distance of 100 miles round trip and 2-hours will be reimbursed.

• Overtime, installation/start-up, normal control adjustments, general maintenance, glass breakage, freight damage, and/or

correcting and end-user installation error will not be reimbursed under warranty unless pre-approved with a Service Work

Authorization from Delfield. You must submit the number with the service claim.

LABOR OF 1-HOUR IS ALLOWED TO REPLACE:

• Thermostat • Contactor/Relay

• Infinite Switch • Transformer

• Door Jamb Switch • Evaporator/Condenser Fan Motor and Blade

• Solenoid Coil • Circulating Fan Motor and Blade

• Hi-limit/Thermal Protector Switch • Microprocessor Control

• Fan Delay/Defrost Termination Switch • Water Level Sensor/Probe

• Compressor Start Components and Overload Protector • Door Hinges, Locks, and Gaskets

• Defrost Timer • Condensate Element

• Thermometer • Springs/Lowerator

• Gear Box

LABOR OF 2 HOURS TO REPLACE:

• Drawer Tracks/Cartridges • Defrost Element

• Pressure Control • Heating Element

• Solenoid Valve • Locate/Repair Leak

LABOR OF 3 HOURS TO REPLACE:

• EPR or CPR Valve • Condenser or Evaporator Coil

• Expansion Valve

LABOR OF 4 HOURS TO REPLACE

• Compressor

This includes recovery of refrigerant and leak check.

$35.00 maximum reimbursement for refrigerant recovery (includes recovery machine, pump, torch, oil, flux, minor fittings,

solder, brazing rod, nitrogen, or similar fees.)

REFRIGERANTS

• R22 A maximum of $4.00/lb. or 25¢/oz. will be reimbursed.

• R134A A maximum of $5.00/lb. or 31¢/oz. will be reimbursed.

• R404A A maximum of $12.00/lb. or 75¢/oz. will be reimbursed.

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

13

Page 14

Nordic Zone Salad Bar Service and Installation Manual

Nordic Zone Salad Bar Service and Installation Manual

15

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

STANDARD ONE YEAR WARRANT (One year parts, 90 days labor.)

The Deleld Company (“Deleld”) warrants to the Original Purchaser

of the Deleld product (herein called the “Unit”) that such Unit, and all

parts thereof, will be free from defects in material and workmanship

under normal use and service for a period of one (1) year from

the date of shipment of the Unit to the Original Purchaser or, if the

Original Purchaser returns the warranty card completely lled out

including the date of installation within thirty (30) days of receipt

of the Unit, one (1) year from the date of installation. During this

one year warranty period, Deleld will repair or replace any defective

part or portion there of returned to Deleld by the Original Purchaser

which Deleld determines was defective due to faulty material or

workmanship. The Original purchaser will pay all labor, crating, freight

and related costs incurred in the removal of the Unit of defective

component and shipment to Deleld, except that during a period of

either ninety (90) days from the date of shipment of the Unit to the

Original Purchaser or, if the Original Purchaser returns the warranty

card completely lled out including the date of installation within thirty

(30) days of receipt of the Unit, ninety (90) days from the date of

installation Deleld will pay all related labor costs. Deleld will pay the

return costs if the Unit or part thereof was defective.

The term “Original Purchaser” as used herein means that person, rm,

association, or corporation for whom the Unit was originally installed.

This warranty does not apply to any Unit or part thereof that has

been subjected to misuse, neglect, alteration, or accident, such as

accidental damage to the exterior nish, operated contrary to the

recommendations specied by Deleld; or repaired or altered by anyone

other than Deleld in any way so as to, in Deleld’s sole judgement,

affect its quality or efciency. This warranty does not apply to any Unit

that has been moved from the location where it was originally installed.

This warranty also does not cover the refrigerator drier or the light

bulbs used in the Unit. The warranty is subject to the user’s normal

maintenance and care responsibility as set forth in the Service and

Installation Manual, such as cleaning the condenser coil, and is in

lieu of all other obligations of Deleld. Deleld neither assumes, nor

authorizes any other person to assume for Deleld, any other liability

in connection with Deleld’s products.

basis, with credit being issued after the part has been received and

inspected at Deleld’s plant and determined by Deleld to be within this

warranty.

Under no condition does this warranty give the Original Purchaser the

right to replace the defective Unit with a complete Unit of the same

manufacturer or of another make. Unless authorized by Deleld in

writing, this warranty does not permit the replacement of any part,

including the motor-compressor, to be made with the part of another

make or manufacturer.

No claims can be made under this warranty for spoilage of any products

for any reason, including system failure.

The installation contractor shall be responsible for building access,

entrance and eld conditions to insure sufcient clearance to allow any

hood(s), vent(s), or Unit(s) if necessary, to be brought into the building.

Deleld will not be responsible for structural changes or damages

incurred during installation of the Unit or any exhaust system.

Deleld shall not be liable in any manner for any default or delay in

performance hereunder caused by or resulting from any contingency

beyond Deleld’s control, including, but not limited to, war,

governmental restrictions or restraints, strike, lockouts, injunctions,

re, ood, acts of nature, short or reduced supply of raw materials, or

discontinuance of the parts by the original part manufacturer.

Except as provided in any Additional Four Year Protection Plan,

if applicable, and the Service Labor Contract, if applicable, the

foregoing is exclusive and in lieu of all other warranties, whether

written or oral, express or implied. This warranty supersedes

and excludes any prior oral or written representations or

warranties. Deleld expressly disclaims any implied warranties

of merchantability, tness for a particular purpose of compliance

with any law, treaty, rule or regulation relating to the discharge of

substances into the environment. The sole and exclusive remedies

of any person relating to the Unit, and the full liability of Deleld for

any breach of this warranty, will be as provided in this warranty.

Removal or defacement of the original Serial Number or Model Number

from any Unit shall be deemed to release Deleld from all obligations

hereunder or any other obligations, express or implied.

Parts furnished by suppliers to Deleld are guaranteed by Deleld only

to the extent of the original manufacturer’s express warranty to Deleld.

Failure of the Original Purchaser to receive such manufacturer’s express

warranty to Deleld. Failure of the Original Purchaser to receive such

manufacturers warranty shall in no way create any warranty, expressed

or implied, or any other obligation or liability on Deleld’s part in respect

thereof.

IF THE CUSTOMER IS USING A PART THAT RESULTS IN A VOIDED

WARRANTY AND A DELFIELD AUTHORIZED REPRESENTATIVE

TRAVELS TO THE INSTALLATION ADDRESS TO PERFORM WARRANTY

SERVICE, THE SERVICE REPRESENTATIVE WILL ADVISE CUSTOMER

THE WARRANTY IS VOID. SUCH SERVICE CALLS WILL BE BILLED

TO CUSTOMER AT THE AUTHORIZED SERVICE CENTER’S THEN

APPLICABLE TIME AND MATERIALS RATES. CONSIDER: CUSTOMER

MAY INITIATE A SERVICE AGREEMENT WITHOUT PARTS COVERAGE.

If shipment of a replacement part is requested prior to the arrival in

the Deleld factory of the part claimed to be defective, the Original

Purchaser must accept delivery of the replacement part of a C.O.D.

14

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

Other than this Deleld Standard One Year Limited Warranty, any

applicable Deleld Additional Four Year Protection Plan or applicable

Deleld Service Labor Contract, the Original Purchaser agrees and

acknowledges that no other warranties are offered or provided in

connection with or for the unit or any other part thereof.

In no event will Deleld be liable for special, incidental or consequential

damages, or for damages in the nature of penalties.

IF DURING THE WARRANTY PERIOD, CUSTOMER USES A PART FOR

THIS DELFIELD EQUIPMENT OTHER THAN AN UNMODIFIED NEW

OR RECYCLED PART PURCHASED DIRECTLY FROM DELFIELD OR

ANY OF ITS AUTHORIZED SERVICE CENTERS AND/OR THE PART

BEING USED IS MODIFIED FROM ITS ORIGINAL CONFIGURATION,

THIS WARRANTY WILL BE VOID. FURTHER, DELFIELD AND ITS

AFFILIATES WILL NOT BE LIABLE FOR ANY CLAIMS DAMAGES OR

EXPENSES INCURRED BY THE CUSTOMER WHICH ARISE DIRECTLY

OR INDIRECTLY, IN WHOLE OR IN PART, DUE TO THE INSTALLATION

OF ANY MODIFIED PART AND/OR PART RECEIVED FROM AN

UNAUTHORIZED SERVICE CENTER. If the warranty becomes void,

Customer may purchase from Deleld, if available, a Service

Agreement or service at the then current time and materials rate.

For more information on Deleld warranty’s log on and check out the

service section of our web site at www.deleld.com.

Page 15

Nordic Zone Salad Bar Service and Installation Manual

ADDITIONAL FOUR YEAR PROTECTION PLAN (for Motor-Compressor only)

Installation

Deleld Model# Serial # Date

General Conditions

Deleld shall not be liable in any manner for any default or delay

in performance hereunder caused by or resulting from any

contingency beyond Deleld’s control, including, but not limited

In addition to the Standard One Year Warranty on the MotorCompressor contained in the above listed Deleld product (the

“Unit”), The Deleld Company (“Deleld”) also agrees to repair, or

exchange with similar or interchangeable parts in design and capacity

at Deleld’s option, the defective Motor-Compressor contained in the

Unit (the “Motor-Compressor), or any part thereof, for the Original

Purchaser only, at any time during the four (4) years following the

initial one (1) year period commencing on the date of installation for

the Original Purchaser. Failure of the Original Purchaser to register

the registration card containing the Original Purchasers name,

address, date of installation, model number and serial number of

the Unit containing the Motor-Compressor within 30 days from the

date of installation shall void this warranty. This additional warranty

is only available if the Motor-Compressor is inoperative due to defects

in material or factory workmanship, as determined by Deleld in

its sole judgement and discretion. The Original Purchaser shall be

responsible for returning the defective Motor-Compressor to Deleld

prepaid, F.O.B. at the address shown on the back cover of this manual.

The term “Original Purchaser” as used herein means that person, rm,

association, or corporation for whom the Unit was originally installed.

The term “Motor-Compressor” as used herein does not include unit

base, air or water cooled condenser, receiver, electrical accessories

such as relay, capacitors, refrigerant controls, or condenser fan/motor

assembly. This warranty does not cover labor charges incidental to

the replacement of parts. This warranty further does not include

any equipment to which said condensing unit is connected, such as

cooling coils, temperature controls or refrigerant metering devices.

This warranty shall be void if the Motor-Compressor, in Deleld’s

sole judgement, has been subjected to misuse, neglect, alteration

or accident, operated contrary to the recommendations specied

by the Unit manufacturer, repaired or altered by anyone other than

Deleld in any way so as, in Deleld’s sole judgment, to affect its

quality or efciency or if the serial number has been altered, defaced

or removed. This Warranty does not apply to a Motor-Compressor in

any Unit that has been moved from the location where it was originally

installed. The addition of methyl chloride to the condensing unit or

refrigeration system shall void this warranty.

to, war, governmental restrictions or restraints, strike, lockouts,

injunctions, re, ood, acts of nature, short or reduced supply

of raw materials, or discontinuance of any part or the Motor-

Compressor by the unit manufacturer.

Replacement of a defective Motor-Compressor is limited to one (1)

Motor-Compressor by us during the four (4) year period. Deleld

shall replace the Motor-Compressor at no charge.

This warranty does not give the Original Purchaser of the Motor-

Compressor the right to purchase a complete replacement Motor-

Compressor of the same make or of another make. It further does

not permit the replacement to be made with a Motor-Compressor

of another kind unless authorized by Deleld. In the event Deleld

authorizes the Original Purchaser to purchase a replacement

Motor-Compressor locally, only the wholesale cost of the Motor-

Compressor is refundable.

Expressly excluded from this warranty are damages resulting from

spoilage of goods.

Except as provided in any applicable Standard One Year Limited

Warranty or applicable Service Labor Contract, the foregoing

is exclusive and in lieu of all other warranties, whether written

or oral, express or implied. This Warranty supersedes and

excludes any prior oral or written representations or warranties.

Deleld expressly disclaims any implied warranties of

merchantability, tness for a particular purpose or compliance

with any law, treaty, rule or regulation relating to the Motor-

Compressor, and the full liability of Deleld for any breach of this

warranty, will be as provided in this warranty.

Other than any applicable Deleld Standard One year Limited

Warranty, this Deleld Additional Four Year Protection Plan and any

applicable Deleld Service Labor Contract, the Original Purchaser

agrees and acknowledges that no other warranties are offered or

provided in connection with or for the Motor-Compressor or any

part thereof.

In no event will Deleld be liable for special, incidental or

consequential damages, or for damages in the nature of penalties.

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

15

Page 16

Nordic Zone Salad Bar Service and Installation Manual

NOTES:

16

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

Page 17

980 S. Isabella Rd., Mt. Pleasant, MI 48804-0470, U.S.A. • (989) 773-7981 or (800) 733-8821 • Fax (800) 669-0619 • www.delfield.com

Delfield reserves the right to make changes in design or specifications without prior notice. 2003 The Delfield Company. All rights reserved. Printed in the U.S.A.

1336 Main Street

Buffalo, NY 14209

800.722.1252

716.884.7425

716. 884.0410 FAX

serves: CT, DC, DE, MA, MD, ME,

NH, NJ, NY, PA, RI, VA, VT, WV

3) Appliance Installation Service

15024 Staff Court

Gardena, CA 90248

1.800.531.1111

1.800.782.5747

Email: orders@pacparts.com

www.pacparts.com

serves: AZ, CA, HI, NV, OR

4) Pacific Coast Parts

2916 Sidco Drive

Nashville, TN 37204

615.726.0351

800.737.0351

615.259.4100 FAX

serves: TN, AL

14) T.M.A.

14450 Ewing Ave S. #100

Burnsville, MN 55306

800.422.2823

952.894.4427

952.894.2164 FAX

serves: IA, MN, MT, ND, SD, WI

5) Contract Ice

3909 St. Timothy Lane

St. Ann, MO 63074

800.972.7670

314.427.7477

314. 427.8190 FAX

serves: AR, IA, IL, KS,

KY, MO, NE, OK, TX, NM, LA

6) E.M.C.O. Sales & Distributors

2920 N.W. 109th Avenue

Miami, FL 33172

305 994.9994

305.994.9992 FAX

International parts depot

9) Global Parts and Supplies

2120 Solona St.

PO Box 14009

Fort Worth, TX 76117-0009

1.800.433.1804 toll free

1.800.272.7358 fax

serves: AR, LA, NM, OK, TX

7) Stove Parts Supply/GCS Service

9923 S.W. 178th St.

Vashon, WA 98070

888.872.2465

206-463-1772

206.463.4431 FAX

serves: AK, HI, ID, MT, OR, WA

12) Performance Refrigeration Parts

2200 Norcross Parkway, Suite 210

Atlanta, GA 30071

800.235.6516

770.446.6177

770.446.3157 FAX

serves: FL, GA, MS, NC, SC, VA

13) Southeastern Restaurant Ser vices

1816 West 26th Street

Erie, PA 16508-1149

800.332.3732

814.456.3732

814.452.4843 FAX

serves: MD, NJ, OH, PA, VA, WV

2) A.I.S. Commercial Parts & Service

1177 Kamato Road

Mississauga, Ontario L4W1X4

800.427.6668

800.361.7745 FAX

serves: Canada

8) Garland Group

980 South Isabella Road

Mt. Pleasant, MI 48858

800.733.8829

989.773.7981

989.773.3210 FAX

custom parts direct from Delfield

1) The Delfield Company

44792 Helm

Plymouth, MI 48170

888.828.4454

734.451.2043

734.451.3215 FAX

serves: MI, IN, WI, OH

11) MicroDine, Inc.

3000 S. Wyandot

Englewood, CO 80110

(800) 624-2117

(303) 7618861 FAX

serves: AZ, CO, KS, NE, NM, OK, UT, WY

10) Hawkins Commercial Appl. Serv.

NORTH

AMERICA

4

4

12

9

10

1

11

7

6

5

14

3

13

8

2

12

Delfield has 14 conveniently located Parts Depots to

ensure parts are handled promptly and accurately.

Delfield reserves the right to update or make changes

to this list without prior notice

Please call 1-800-733-8829 or check the web at www.delfield.com

for a list of the current Parts Depots.

AUTHORIZED PARTS DEPOTS

DMNZ 06/03

Loading...

Loading...