Page 1

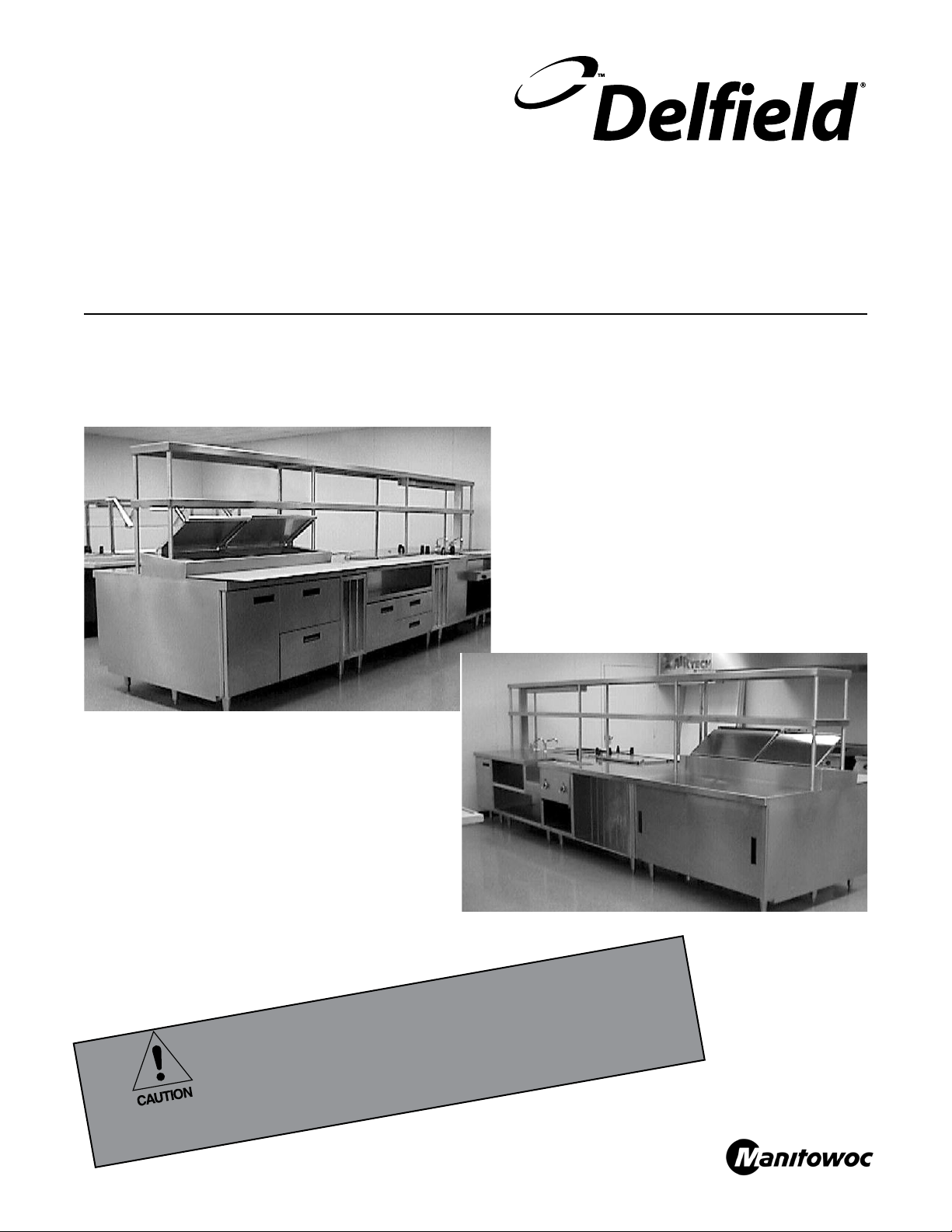

Component Crafted Custom Equipment - Line Ups

Service, Installation and Care Manual

Please read this manual completely before attempting to install or operate this equipment! Notify carrier

of damage! Inspect all components immediately.

IMPORTANT INFORMATION

READ BEFORE USE

PLEASE SAVE THESE INSTRUCTIONS!

Effective July 2010

Page 2

Component Crafted Custom Equipment - Line Ups Service and Installation Manual

Important Warning And Safety Information

WARNING Read This Manual Thoroughly Before Operating, Installing, Or Performing

Maintenance On The Equipment.

WARNING Failure To Follow Instructions In This Manual Can Cause Property Damage,

Injury Or Death.

WARNING Do Not Store Or Use Gasoline Or Other Flammable Vapors Or Liquids In The

Vicinity Of This Or Any Other Appliance.

WARNING Unless All Cover And Access Panels Are In Place And Properly Secured, Do

Not Operate This Equipment.

WARNING Do Not Clean With Water Jet.

CAUTION Observe the following:

Minimum clearances must be maintained from all walls and combustible

•

materials.

Keep the equipment area free and clear of combustible material.

•

Adequate clearance for air openings.

•

Operate equipment only on the type of electricity indicated on the

•

specification plate.

Retain this manual for future reference.

•

2

For customer service, call (800) 733-8829 or (800) 733-8948, Fax (989) 773-3210, www.delfield.com

Page 3

Component Crafted Custom Equipment - Line Ups Service and Installation Manual

Contents Receiving The Equipment

Receiving The Equipment .....................................................3

Tools And Supplies Required ................................................4

Maintenance ......................................................................4-5

Mark7 Fasteners ...................................................................6

Checking The Utility Rough-In ..............................................7

Splining Overview .................................................................7

Assembly And Installation ....................................................8

Curb-Mount Installation ........................................................8

Attachment Methods .............................................................9

Power Supply Information ....................................................9

Toe Plate Installation ...........................................................10

Counter Protector Installation .............................................11

Overshelf Installation ..........................................................11

Finished Back Panel Installation ..........................................12

Tray Slide Installation ..........................................................12

Standard Labor Guidelines ..................................................13

Standard Warranty ..............................................................14

Additional 4 Year Warranty .................................................15

Although most Delfield equipment is shipped crated, care

should be taken so the equipment is not damaged during

unloading and movement into the building.

Upon receipt of the shipment, be sure all items are included

and are undamaged. If there is damage, see the section on

“filing Freight Claims” for information on claims procedures.

All Delfield Custom Systems line-ups have been assembled

at the factory before shipment. Each unit is marked with the

work order number, item number and serial number. The

unit item number is identical to that marked on the sales

presentation drawing. Use these numbers as a guide during

installation.

Bolts, screws and other accessories needed for fastening

units together are in an envelope located inside one of the

units. The unit is marked with a note attached to the front.

©2010 The Delfield Company. All rights reserved.

Reproduction without written permission is prohibited.

SERIAL #

MODEL #

INSTALLATION DATE:

Receiving And Inspecting The Equipment

Even though most equipment is shipped crated, care should

be taken during unloading so the equipment is not damaged

while being moved into the building.

1. Visually inspect the exterior of the package and skid or

container. Any damage should be noted and reported to

the delivering carrier immediately.

2. If damaged, open and inspect the contents with the

carrier.

3. In the event that the exterior is not damaged, yet upon

opening, there is concealed damage to the equipment

notify the carrier. Notification should be made verbally

as well as in written form.

4. Request an inspection by the shipping company of the

damaged equipment. This should be done within 10

days from receipt of the equipment.

5. Check the lower portion of the unit to be sure legs or

casters are not bent.

6. Also open the compressor compartment housing and

visually inspect the refrigeration package. Be sure lines

are secure and base is still intact.

7. Freight carriers can supply the necessary damage forms

upon request.

8. Retain all crating material until an inspection has been

made or waived.

Uncrating the Equipment

First cut and remove the banding from around the crate.

Remove the front of the crate material, use of some tools will

be required. If the unit is on legs remove the top of the crate

as well and lift the unit off the skid. If the unit is on casters it

can be "rolled" off the skid.

For customer service, call (800) 733-8829 or (800) 733-8948, Fax (989) 773-3210, www.delfield.com

3

Page 4

Component Crafted Custom Equipment - Line Ups Service and Installation Manual

W ARE

Tools And Supplies Required

A steel hammer and a block of wood can be used to make

Units represented in this manual are for indoor use only.

The following tools are either required or will

make the installation easier:

A scissor jack to lift and hold heavy units off the floor so

1)

that legs can be adjusted, allowing the proper leveling of

the units.

A level is needed to assist in the leveling of each unit

2)

from front to back and left to right. A 2’ (61cm) level is a

must; a 4’ (122cm) level is also desirable.

Two 6’ (183cm) pipe clamps are useful in pulling

3)

equipment tightly together while fasteners are installed.

This results in a better spline.

Vise grips will hold backsplash bars together as they are

4)

being bolted together.

Maintenance

5)

minor alterations of the stainless steel along the seam

between two units, in order to perfect the seam. This is

used after the units are splined.

A rubber mallet.

6)

A socket set.

7)

Phillips, hex head and straight blade screwdrivers.

8)

7/16” (1.1cm), 9/16” (1.4cm) and 1/2” (1.3cm) open end

9)

wrenches.

Silicone sealant; Dow Corning #732 is ideal.

10)

Stainless Steel Care and Cleaning

To prevent discoloration of rust on stainless steel several

important steps need to be taken. First, we need to understand

the properties of stainless steel. Stainless steel contains 70-80%

iron which will rust. It also contains 12-30% chromium which

forms an invisible passive film over the steels surface which

acts as a shield against corrosion. As long as the protective

layer is intact, the metal is still stainless. If the film is broken

or contaminated, outside elements can begin to breakdown the

steel and begin to form rust of discoloration.

Proper cleaning of stainless steel requires soft cloths or plastic

scouring pads.

NEVER USE STEEL PADS, WIRE BRUSHES OR

SCRAPERS!

Cleaning solutions need to be alkaline based or non-chloride

cleaners. Any cleaner containing chlorides will damage

the protective film of the stainless steel. Chlorides are also

commonly found in hard water, salts, and household and

industrial cleaners. If cleaners containing chlorides are used be

sure to rinse repeatedly and dry thoroughly upon completion.

Routine cleaning of stainless steel can be done with soap and

water. Extreme stains or grease should be cleaned with a nonabrasive cleaner and plastic scrub pad. It is always good to

rub with the grain of the steel. There are also stainless steel

cleaners available which can restore and preserve the finish of

the steels protective layer.

Early signs of stainless steel breakdown can consist of small

pits and cracks. If this has begun, clean thoroughly and start to

apply stainless steel cleaners in attempt to restore the passivity

of the steel.

Never use an acid based cleaning solution!

Many food products have an acidic content which

can deteriorate the finish. Be sure to clean the

stainless steel surfaces of ALL food products.

Common items include, tomatoes, peppers and

other vegetables.

The power must be turned off and disconnected

whenever performing maintenance or repair

functions.

The interior of heated storage cabinets will be hot

for some time after the power is turned off. Avoid

touching the interior walls and heater ducts with

bare hands or arms until you are certain the unit

has cooled. The use of gloves is recommended.

Do not use a water jet, hose or pressure washer

on these units. The water will damage the

components.

4

For customer service, call (800) 733-8829 or (800) 733-8948, Fax (989) 773-3210, www.delfield.com

Page 5

Maintenance, continued

Component Crafted Custom Equipment - Line Ups Service and Installation Manual

Cleaning the Condenser Coil

The condenser coil requires regular cleaning, recommended is

every 90 days. In some instances though you may find that

there is a large amount of debris and dust or grease accumulated

prior to the 90 day time frame. In these cases the condenser coil

should be cleaned every 30 days.

If the build up on the coil consists of only light dust and debris

the condenser coil can be cleaned with a simple brush, heavier

dust build up may require a vacuum or even compressed air to

blow through the condenser coil.

If heavy grease is present there are de-greasing agents available

for refrigeration use and specifically for the condenser coils.

The condenser coil may require a spray with the de-greasing

agent and then blown through with compressed air.

Failure to maintain a clean condenser coil can initially cause high

temperatures and excessive run times, continuous operation

with dirty or clogged condenser coils can result in compressor

failures. Neglecting the condenser coil cleaning procedures will

void any warranties associated with the compressor or cost to

replace the compressor.

Never use a high pressure water wash for this cleaning

procedure as water can damage the electrical components

located near or at the condenser coil.

Drain Maintenance

Each refrigerated unit has a drain located inside the unit

which removes the condensation from the evaporator coil and

evaporates it at an external condensate evaporator pan. Each

drain can become loose or disconnected from moving or

bumping the drain. If you notice excessive water accumulation

on the inside of the unit be sure the drain tube is connected from

the evaporator housing to the condensate evaporator drain pan.

If water is collected underneath the unit you may want to check

the condensate evaporator drain tube to be sure it is still located

inside the drain pan. The leveling of the unit is important as the

units are designed to drain properly when on a level surface,

if your floor is not level this can also cause drain problems.

Be sure all drain lines are free of obstructions, typically food

product is found blocking drain lines causing water to back up

and overflow the drain pans.

Gasket Maintenance

Gaskets require regular cleaning to prevent mold and mildew

build up and also to keep the elasticity of the gasket. Gasket

cleaning can be done with the use of warm soapy water. Avoid

full strength cleaning products on gaskets as this can cause

them to become brittle and prevent proper seals. Also, never

use sharp tools or knives to scrape or clean the gasket which

could possibly tear the gasket and rip the bellows.

Gaskets can easily be replaced and do not require the use of

tools or authorized service persons. The gaskets are “Dart”

style and can be pulled out of the grove in the door and new

gaskets can be “pressed” back into place.

Doors/Hinges

Over time and with heavy use doors and the hinges may become

loose. If it is noticed that the door is beginning to sag, it may

become necessary to tighten the screws that mount the hinge

brackets to the frame of the unit. If the doors are loose or

sagging this can cause the hinge to pull out of the frame which

may damage both the doors and the door hinges. In some

cases this can require qualified service agents or maintenance

personnel.

For customer service, call (800) 733-8829 or (800) 733-8948, Fax (989) 773-3210, www.delfield.com

5

Page 6

Component Crafted Custom Equipment - Line Ups Service and Installation Manual

Mark 7 Fasteners

Part# 6320019

5/16-18 x .75 Screw — Used in

caster and leg attachment.

Part# 9321353

#10 x .50 Screw — Used in attachment of coil

assembly, food wells and panel attachment.

Part# 9321355

#10-32 x .50 Screw — Used on pan cover

hinges and electric raceways.

Part# 9321361

#6-32 x .75 Screw — Used on control panels

and sneeze guard brackets.

Part# 9321068

#10 x .87 Screw — Used on door

hinges and drawer fronts.

Part# 9321043

1/4-20 x .75 Screw — Used on

shelf supports and compressor hold

downs.

(Used On Delfield Mark 7 Line Ups)

Part# 9321244

5/32 x .50 Pop steel rivet

— Used on bars and

base assemblies.

Part# 9321067

#10 x 1.75 Screw —

Used on door hinges

and refrigerator base

assembly.

Part# 3234450

1/8 x .50 Pop stainless

steel rivet — Used on food

wells.

Part# 9321119

#14 x 3/4” Lag type hex head screw

— Used for splining units together.

Part# 9321137

#8-32 Shoulder screw —Mates to part# 9321184

Part# 9321401

1/4-20 Locking nut — Used as spot stud retainer.

Part# 9321374

Salad pan cover hinge pin — Used on pan

cover hinges and electrical raceways.

Part# 9321131

#10 x .50 Screw — Used on coil drain

pan.

Part# 9321338

1/4-20 x .37 Stainless steel spot stud — Used

on spot stud applications.

Part# 9321247

#10-32 x .37 Screw — Used on fan motors.

Part# 9321041

Acorn nut — Used on pan covers.

Part# 9321146

1/4-20 x 1.00 Screw — Used in

attachment of tray slides.

Part# 9321147

1/4-20 3-Prong tee nut — Mates to part

# 9321146. Used in attachment of tray

slides.

6

For customer service, call (800) 733-8829 or (800) 733-8948, Fax (989) 773-3210, www.delfield.com

Part# 9321184

#8-32 Threaded insert — Mates to

part# 9321137. Requires special gun for

installation.

Part# 9321114

#14 x 1 1/4” Lag type hexhead

screw — Used on counter protector

installation

Page 7

Component Crafted Custom Equipment - Line Ups Service and Installation Manual

Checking The Utility Rough-In

Plumbing, electrical and ventilation provisions must be made

in floors, walls or ceilings before the installation can begin.

Utilities should be roughed-in and surfaces finished before

the equipment is delivered.

Before moving equipment into place, double-check all utility

rough-in dimensions and locations against the presentation

drawing to insure accuracy. Check wall to wall dimensions to

make sure there will be enough clearance.

When connecting the equipment to utilities,

all plumbing, electrical and ventilation

installation must meet local codes. This work

should normally be done by contractors who

are familiar with the codes and are licensed,

if required in your area.

Splining Overview

Delfield’s Component Crafted Custom Equipment, back bar

systems, chef islands and waitress stations are designed for

easy alignment. Each unit has a 12-gauge spline bar on each

end of the top. Match the front nosing and the backsplash,

if any, and attach screws (provided by Delfield) thru the

prepunched holes in the interior of the unit. Tighten the screws

so the units are securely joined. At this point it is optional to add

a bead of silicone for a closed, tight seam.

Plumbers, electricians and refrigeration installers should

work at the same time as the equipment installers, if possible.

NOTE: This will allow them proper access to their work before

it is obstructed by the equipment.

Full disconnection from wiring mains according to all

applicable codes must be provided at the time of installation

For any counter requiring a water hookup the water pressure

must be 20-80psi (138-552kPa).

With units securely fastened, they can be assembled away from

the wall, and then slid into place.

In most cases, units are fastened together in two places: on

the nosing and the backsplash. Cafeteria lines replace the

backsplash with a second nosing.

Your Custom Systems line-up has been preassembled at the factory to ensure proper

fit. As the line-up was dis-assembled for

shipping, a yellow sticker was placed on each

unit indicating the location and direction in

which fasteners are to be re-installed.

Prepunched holes for joining equipment

For customer service, call (800) 733-8829 or (800) 733-8948, Fax (989) 773-3210, www.delfield.com

7

Page 8

Component Crafted Custom Equipment - Line Ups Service and Installation Manual

ST PE S

CAUTION

Assembly And Installation

Be sure all electrical power to this equipment,

or units already in place, has been disconnected

before starting to assemble the line-up.

Starting points for an installation vary, depending on the

building layout and the type of equipment included in the

line-up. A good place to start assembling the line-up is where

the equipment will tie-in to an end wall or to other equipment.

If your line-up contains an equipment stand, it will need

connections to ventilation duct work and therefore would be

a good place to begin. Or you might begin with the heaviest

unit, thereby reducing the amount of weight that must be

moved around during installation.

Leveling

After determining the starting point, the first unit must be

leveled at its work height. Check your drawings for the

correct work height. Standard work height is 36” (91.4cm)

but depending on the installation it may be lower or higher.

The work height is the distance from the finished floor to the

stainless steel top. Level the unit by turning the adjustable

bullet feet on the legs. Set the level on the unit length wise

first, and level the unit end to end. Next, place the level front

to back and level the unit again. A longer level will be more

accurate, if you can obtain one.

Units that are 72” (178cm) or longer will have six legs. On

these units, adjust the two center legs’ feet up until they no

longer touch the floor. Adjust the four outside legs to level the

unit as described previously. After the outside legs are set and

the unit is level, unscrew the center legs’ feet until they rest

firmly on the floor.

Unit alignment procedure

1) Pull the next unit into position and level as

described in the previous section at its work

height. Clean the spline bars of all dust, oils,

packing materials, residue or other foreign

matter, in order to ensure a good seal between

the units.

2) Pull the units together, inserting the screws

into the matching holes in the adjacent unit

(see photo on page 5). Draw the units tightly

together with #14 x 3/4” lag type hex head

sheet metal screws. A bead of NSF listed

silicone can be added for a closed, tight

seam.

Realigning damaged joints

Delfield’s splining process is designed to achieve a hairline

joint. Your equipment line-up was pre-assembled and fitted

together at the factory to ensure a perfect seam.

Although stainless steel is a very hard material, it is also

malleable. During shipment damage may occur, leaving the

splines out of alignment when the units are brought together.

Inspect all seams carefully. If high spots are found along a

seam, place a hardwood block over the spot and strike the

block several times with a heavy hammer.

Never strike the stainless steel directly with

the hammer or any other heavy object! This

will permanently damage the finish of your

equipment.

Curb-Mount Installation

The same fasteners used in a standard leg-mount installation

are in a curb-mount installation.

Before you begin to install the line-up, it is essential

that the curb is perfectly level. All electrical, water, drain

and refrigeration lines must be pre-plumbed. Condensate

evaporators are not recommended for curb installations

using remote units. Installation should begin at one end of

the line-up.

Connections should be made one unit at a time, as the

units are installed. If the curb has imperfections, it may be

necessary to use wood or metal shims to achieve level units.

Reconnections and final connection should be checked by a certified technician.

8

For customer service, call (800) 733-8829 or (800) 733-8948, Fax (989) 773-3210, www.delfield.com

Lifting and placement of these heavy units can be

difficult and even dangerous job. Never attempt

to lift or move these units by yourself. The use of

mechanical lift will make the job much easier.

Page 9

Component Crafted Custom Equipment - Line Ups Service and Installation Manual

SEAM BETWEEN

UNITS

NOSING

DOOR

OPENING

Remote refrigerated bases fastening method

CAUTION

Attachment Methods

Non-refrigerated bases (shelving units)

The alignment of shelving units, whether open shelf, hinged

or sliding door or drawer base, is achieved with screws. 1”

(2.5cm) diameter holes are located at the top of the interior

sides to allow the unit to be fastened to the adjacent unit

with #14 x 3/4” lag type hex head sheet metal screws. A

yellow sticker will indicate where the units are to be fastened

together.

Refrigerated bases

If a refrigerated base does not have a

condensate evaporator supplied, you must

connect the condensate line to a suitable drain.

Otherwise, water will collect on the floor,

causing a potentially hazardous situation.

As with non-refrigerated bases (shelving units), refrigerated

bases use screws. The location for fastening two units

together is in the machine compartment (behind the louver

panel) on self-contained units. Use #14 x 1.25” hex head

screws.

small stainless steel strap is used under the front nosing to

join the units (see illustration at right), fastened with Phillips

truss head sheet metal screws.

Equipment stands

Equipment stands are fastened to other line-up units in two

places. First, look for a pre-drilled hole in the mullion end.

This hole is located approximately 2” (5.1cm) from the front

and 1.5” (3.8cm) down from the top. Use 1/4”-20 x 2” slotted

truss head machine screws in this hole. Next, check behind

the backsplash. A 1” (2.5cm) diameter hole is located 1”

(2.5cm) in from the edge and 1.5” (3.8cm) down from the top

of the side. Use a #14 x 1.25” hex head sheet metal screw to

secure this spline.

Two remote refrigerated units present a problem, however,

because there is no access to the bare stainless steel side.

These must be splined behind the units at the backsplash,

using 1/4”-20 x 3/4” hex head bolts in combination with 1/4”

medium lock washers and 1/4”-20 hex nuts. In the front, a

Reconnections and final connection should be checked by a certified technician.

Power Supply Information

Electrical requirements may vary based on the many different

models which comprise custom line ups. Check the ratings listed

on the serial tag (example at bottom right) for requirements.

It is common for the controls for more than one appliance to be

combined in a single enclosure. Be aware that more than one

circuit will be supplying power to the enclosure. Disconnect all

power supplies before proceeding with the re-assembly of the

control enclosure.

Under these circumstances the conduits and knockouts are

numbered as well as the conductors. To re-assemble controls

of this nature connect all conduits to the knockout of the

same number. Connect all conductors to the like numbered

termination in the control enclosure.

With the main switches and/or controls turned OFF, turn on all

circuits. Check for the correct power at the supply conductor

termination before operating the appliance.

CAUTION

THIS PRODUCT HAS TWO POWER SUPPLY CORDS WITH

DIFFERENT RATINGS. EACH CORD REQUIRES AN INDIVIDUAL

BRANCH CIRCUIT

CORD PLUG RATING CIRCUIT AMPACITY

1 NEMA X-XXP XXX VOLT, XX AMP XX

2 NEMA Z-ZZP ZZZ VOLT, ZZ AMP ZZ

THIS PRODUCT HAS TWO POWER SUPPLY CORDS. CONNECT

EACH PLUG TO A RECEPTACLE THAT IS CONNECTED TO AN

INDIVIDUAL BRANCH CIRCUIT. UNPLUG ALL CORDS BEFORE

MOVING OR SERVICING THIS APPLIANCE

CAUTION

For customer service, call (800) 733-8829 or (800) 733-8948, Fax (989) 773-3210, www.delfield.com

9

Page 10

Component Crafted Custom Equipment - Line Ups Service and Installation Manual

Toe Plate Installation

Install the toe plate by hooking it over the top of the galvanized

bracket at the bottom of the unit. The toe plate then drops

down and fits under the galvanized bracket without the use of

fasteners (see photo at right). The toe plate will stay in place

but can also be easily removed for cleaning under the units.

Toe plate installation.

10

Avoid using cleaning products containing chlorine on the Plexiglas panels of your counter

protectors. It can cause cracking of the Plexiglas.

For customer service, call (800) 733-8829 or (800) 733-8948, Fax (989) 773-3210, www.delfield.com

Page 11

Component Crafted Custom Equipment - Line Ups Service and Installation Manual

Overshelf And Counter Protector Installation

Install the tubular legs of the overshelf over the bushings. A

#8 x 3/8” Phillips oval head sheet metal screw serves as a set

screw to hold the overshelf legs securely against the bushing.

If two overshelves are mounted adjacent to each other, they will

have a spline joint similar to those found on base units. Use

1/4”-20 x 3/4” hex head bolts in combination with 1/4” medium

lock washers and 1/4”-20 hex nuts to secure the overshelves.

Overshelves with heat lamps or other electrical accessories will

have a two-piece channel provided at one end for an electrical

raceway. The cover can be removed to allow wiring of accessory

items (see photo 1).

Overshelves wider than 14” (35.6cm) have 6” (15.2cm) wide

channel under the shelf for added support. Overshelves come

equipped with a 6” (15.2cm) wide channel under the shelf for

added support. There are two channels on units wider than

18” (45.7cm).

Ensure that all hardware is tightened securely.

Overshelves are to be used as shelves only and should not be used

in any other way. Counter protectors are to be used as food and

counter protection only and should not be used in any other way.

Photo 1: Overshelf vertical electrical raceway.

Photo 2: Overshelf support/raceway.

For customer service, call (800) 733-8829 or (800) 733-8948, Fax (989) 773-3210, www.delfield.com

11

Page 12

Component Crafted Custom Equipment - Line Ups Service and Installation Manual

Finished Back Panel Installation

Depending on the length of the panel, more than one person

may be required. If the unit is on casters, secure the brake so

the unit does not move. Align the panel at both ends of the unit,

inserting the top in the channel as show in the photo at right.

Push the panel to the top of the channel. After it is inserted in

the channel, lower the panel toward the unit fitting it into the

groove at the bottom. The panel will fit securely; no fasteners

are needed.

Tray Slide Installation

There are two styles of tray slides that may be provided with a

Delfield Component Crafted Custom Equipment line-up: Threebar tubular and solid-V Type.

Three-bar tubular tray slides

Tubular tray slides are attached to the provided brackets by the

use of the screws located on the underside of the brackets.

When splines are necessary, 0.87” (2.2cm) diameter rods are

inserted into one end of the tubing. The matching tubing from

the adjacent tray slide is then slipped over the rod to achieve the

spline. Set screws are used on the underside of the tubing to

hold the joint together.

Solid-V type tray slides

Solid-V type tray slides are provided with channels on

approximately 48” (121.9cm) centers. The brackets are fastened

to these channels using #6-32 x .75 screws. If two solid-V type

tray slides are mounted adjacent to each other, both ends will

be finished, requiring no spline process.

Night Switch Operation

For any counter equipped with a night switch. Turn on main

power switches on all units controlled by night switch. To

begin operation of affected units turn night switch ON. To stop

operation turn night switch OFF.

Mounting on finished back panels

Finished back panels have 1/4”-20 tee nuts inserted into the

back of the panel. Fasten the tray slide brackets to the finished

back panels of the equipment, matching a 1/4”-20 x 1” hex head

machine screw with each tee nut in the back panel.

12

The night switch does not disconnect the unit from

the main power. Disconnect each unit from the

main power before performing any maintenance

or service function.

For customer service, call (800) 733-8829 or (800) 733-8948, Fax (989) 773-3210, www.delfield.com

Page 13

Component Crafted Custom Equipment - Line Ups Service and Installation Manual

Standard Labor Guidelines To Repair Or Replace Parts 0n Delfield Equipment

Advice and recommendations given by Delfield Service Technicians do not constitute or guarantee any special coverage.

• A maximum of 1-hour is allowed to

• A maximum of 1-hour is allowed for

• A maximum

• Overtime, installation/start-up, normal control adjustments, general maintenance, glass breakage, freight damage, and/or

correcting and end-user installation error will not be reimbursed under warranty unless pre-approved with a Service Work

Authorization from Delfield. You must submit the number with the service claim.

LABOR OF 1-HOUR IS ALLOWED TO REPLACE:

• Thermostat • Contactor/Relay

• Infinite Switch • Transformer

• Door Jamb Switch • Evaporator/Condenser Fan Motor and Blade

• Solenoid Coil • Circulating Fan Motor and Blade

• Hi-limit/Thermal Protector Switch • Microprocessor Control

• Fan Delay/Defrost Termination Switch • Water Level Sensor/Probe

• Compressor Start Components and Overload Protector • Door Hinges, Locks, and Gaskets

• Defrost Timer • Condensate Element

• Thermometer • Springs/Lowerator

• Gear Box

LABOR OF 2 HOURS TO REPLACE:

• Drawer Tracks/Cartridges • Defrost Element

• Pressure Control • Heating Element

• Solenoid Valve • Locate/Repair Leak

travel distance of 100 miles round trip and 2-hours will be reimbursed.

diagnose a defective component.

retrieval of parts not in stock.

LABOR OF 3 HOURS TO REPLACE:

• EPR or CPR Valve • Condenser or Evaporator Coil

• Expansion Valve

LABOR OF 4 HOURS TO REPLACE

• Compressor

This includes recovery of refrigerant and leak check.

$55.00(USD) maximum reimbursement for refrigerant recovery (includes recovery machine, pump, torch, oil, flux, minor fit-

tings, solder, brazing rod, nitrogen, or similar fees.)

REFRIGERANTS

• R22 A maximum of $4.00(USD)/lb. or 25¢(USD)/oz. will be reimbursed.

• R134A A maximum of $5.00(USD)/lb. or 31¢(USD)/oz. will be reimbursed.

• R404A A maximum of $15.00(USD)/lb. or $1.00(USD)/oz. will be reimbursed.

For customer service, call (800) 733-8829 or (800) 733-8948, Fax (989) 773-3210, www.delfield.com

13

Page 14

Component Crafted Custom Equipment - Line Ups Service and Installation Manual

Standard One Year Warranty (One Year Parts, 90 Days Labor.)

The Delfield Company (“Delfield”) warrants to the Original Purchaser of

the Delfield product (herein called the “Unit”) that such Unit, and all

parts thereof, will be free from defects in material and workmanship

under normal use and service for a period of one (1) year from the date

of shipment of the Unit to the Original Purchaser or, if the Original

Purchaser returns the warranty card completely filled out including the

date of installation within thirty (30) days of receipt of the Unit, one (1)

year from the date of installation. During this one year warranty period,

Delfield will repair or replace any defective part or portion there of returned

to Delfield by the Original Purchaser which Delfield determines was

defective due to faulty material or workmanship. The Original purchaser

will pay all labor, crating, freight and related costs incurred in the removal

of the Unit of defective component and shipment to Delfield, except that

during a period of either ninety (90) days from the date of shipment of

the Unit to the Original Purchaser or, if the Original Purchaser returns

the warranty card completely filled out including the date of installation

within thirty (30) days of receipt of the Unit, ninety (90) days from the

date of installation Delfield will pay all related labor costs. Delfield will

pay the return costs if the Unit or part thereof was defective.

The term “Original Purchaser” as used herein means that person, firm,

association, or corporation for whom the Unit was originally installed.

This warranty does not apply to any Unit or part thereof that has been

subjected to misuse, neglect, alteration, or accident, such as accidental

damage to the exterior finish, operated contrary to the recommendations

specified by Delfield; or repaired or altered by anyone other than Delfield

in any way so as to, in Delfield’s sole judgement, affect its quality or

efficiency. This warranty does not apply to any Unit that has been moved

from the location where it was originally installed. This warranty also

does not cover the refrigerator drier or the light bulbs used in the Unit.

The warranty is subject to the user’s normal maintenance and care

responsibility as set forth in the Service and Installation Manual, such

as cleaning the condenser coil, and is in lieu of all other obligations

of Delfield. Delfield neither assumes, nor authorizes any other person

to assume for Delfield, any other liability in connection with Delfield’s

products.

Removal or defacement of the original Serial Number or Model Number

from any Unit shall be deemed to release Delfield from all obligations

hereunder or any other obligations, express or implied.

Parts furnished by suppliers to Delfield are guaranteed by Delfield only

to the extent of the original manufacturer’s express warranty to Delfield.

Failure of the Original Purchaser to receive such manufacturer’s express

warranty to Delfield. Failure of the Original Purchaser to receive such

manufacturers warranty shall in no way create any warranty, expressed

or implied, or any other obligation or liability on Delfield’s part in respect

thereof.

IF THE CUSTOMER IS USING A PART THAT RESULTS IN A VOIDED

WARRANTY AND A DELFIELD AUTHORIZED REPRESENTATIVE

TRAVELS TO THE INSTALLATION ADDRESS TO PERFORM WARRANTY

SERVICE, THE SERVICE REPRESENTATIVE WILL ADVISE CUSTOMER

THE WARRANTY IS VOID. SUCH SERVICE CALLS WILL BE BILLED

TO CUSTOMER AT THE AUTHORIZED SERVICE CENTER’S THEN

APPLICABLE TIME AND MATERIALS RATES. CONSIDER: CUSTOMER

MAY INITIATE A SERVICE AGREEMENT WITHOUT PARTS COVERAGE.

If shipment of a replacement part is requested prior to the arrival in the

Delfield factory of the part claimed to be defective, the Original Purchaser

must accept delivery of the replacement part of a C.O.D. basis, with credit

being issued after the part has been received and inspected at Delfield’s

plant and determined by Delfield to be within this warranty.

Under no condition does this warranty give the Original Purchaser the

right to replace the defective Unit with a complete Unit of the same

manufacturer or of another make. Unless authorized by Delfield in

writing, this warranty does not permit the replacement of any part,

including the motor-compressor, to be made with the part of another

make or manufacturer.

No claims can be made under this warranty for spoilage of any products

for any reason, including system failure.

The installation contractor shall be responsible for building access,

entrance and field conditions to insure sufficient clearance to allow any

hood(s), vent’s), or Unit’s) if necessary, to be brought into the building.

Delfield will not be responsible for structural changes or damages

incurred during installation of the Unit or any exhaust system.

Delfield shall not be liable in any manner for any default or delay in

performance hereunder caused by or resulting from any contingency

beyond Delfield’s control, including, but not limited to, war, governmental

restrictions or restraints, strike, lockouts, injunctions, fire, flood, acts of

nature, short or reduced supply of raw materials, or discontinuance of

the parts by the original part manufacturer.

Except as provided in any Additional Four Year Protection Plan, if

applicable, and the Service Labor Contract, if applicable, the foregoing

is exclusive and in lieu of all other warranties, whether written or

oral, express or implied. This warranty supersedes and excludes any

prior oral or written representations or warranties. Delfield expressly

disclaims any implied warranties of merchantability, fitness for a

particular purpose of compliance with any law, treaty, rule or regulation

relating to the discharge of substances into the environment. The sole

and exclusive remedies of any person relating to the Unit, and the full

liability of Delfield for any breach of this warranty, will be as provided

in this warranty.

Other than this Delfield Standard One Year Limited Warranty, any applicable

Delfield Additional Four Year Protection Plan or applicable Delfield Service

Labor Contract, the Original Purchaser agrees and acknowledges that no

other warranties are offered or provided in connection with or for the unit

or any other part thereof.

In no event will Delfield be liable for special, incidental or consequential

damages, or for damages in the nature of penalties.

IF DURING THE WARRANTY PERIOD, CUSTOMER USES A PART FOR

THIS DELFIELD EQUIPMENT OTHER THAN AN UNMODIFIED NEW OR

RECYCLED PART PURCHASED DIRECTLY FROM DELFIELD OR ANY OF

ITS AUTHORIZED SERVICE CENTERS AND/OR THE PART BEING USED

IS MODIFIED FROM ITS ORIGINAL CONFIGURATION, THIS WARRANTY

WILL BE VOID. FURTHER, DELFIELD AND ITS AFFILIATES WILL NOT

BE LIABLE FOR ANY CLAIMS DAMAGES OR EXPENSES INCURRED BY

THE CUSTOMER WHICH ARISE DIRECTLY OR INDIRECTLY, IN WHOLE

OR IN PART, DUE TO THE INSTALLATION OF ANY MODIFIED PART AND/

OR PART RECEIVED FROM AN UNAUTHORIZED SERVICE CENTER. If

the warranty becomes void, Customer may purchase from Delfield, if

available, a Service Agreement or service at the then current time and

materials rate.

For more information on Delfield warranty’s log on and check out the

service section of our web site at www.delfield.com.

14

For customer service, call (800) 733-8829 or (800) 733-8948, Fax (989) 773-3210, www.delfield.com

Page 15

Component Crafted Custom Equipment - Line Ups Service and Installation Manual

Additional Four Year Protection Plan (For Motor-Compressor Only)

Installation

Delfield Model# Serial # Date

General Conditions

Delfield shall not be liable in any manner for any default or delay in

performance hereunder caused by or resulting from any contingency

beyond Delfield’s control, including, but not limited to, war,

In addition to the Standard One Year Warranty on the MotorCompressor contained in the above listed Delfield product (the

“Unit”), The Delfield Company (“Delfield”) also agrees to repair, or

exchange with similar or interchangeable parts in design and capacity

at Delfield’s option, the defective Motor-Compressor contained in the

Unit (the “Motor-Compressor), or any part thereof, for the Original

Purchaser only, at any time during the four (4) years following the

initial one (1) year period commencing on the date of installation for the

Original Purchaser. Failure of the Original Purchaser to register the

registration card containing the Original Purchasers name, address,

date of installation, model number and serial number of the Unit

containing the Motor-Compressor within 30 days from the date of

installation shall void this warranty. This additional warranty is only

available if the Motor-Compressor is inoperative due to defects in

material or factory workmanship, as determined by Delfield in its sole

judgement and discretion. The Original Purchaser shall be responsible

for returning the defective Motor-Compressor to Delfield prepaid, F.O.B.

at the address shown on the back cover of this manual.

The term “Original Purchaser” as used herein means that person, firm,

association, or corporation for whom the Unit was originally installed.

The term “Motor-Compressor” as used herein does not include unit

base, air or water cooled condenser, receiver, electrical accessories

such as relay, capacitors, refrigerant controls, or condenser fan/motor

assembly. This warranty does not cover labor charges incidental to

the replacement of parts. This warranty further does not include

any equipment to which said condensing unit is connected, such as

cooling coils, temperature controls or refrigerant metering devices.

This warranty shall be void if the Motor-Compressor, in Delfield’s

sole judgement, has been subjected to misuse, neglect, alteration or

accident, operated contrary to the recommendations specified by the

Unit manufacturer, repaired or altered by anyone other than Delfield

in any way so as, in Delfield’s sole judgment, to affect its quality or

efficiency or if the serial number has been altered, defaced or removed.

This Warranty does not apply to a Motor-Compressor in any Unit that

has been moved from the location where it was originally installed.

The addition of methyl chloride to the condensing unit or refrigeration

system shall void this warranty.

governmental restrictions or restraints, strike, lockouts, injunctions,

fire, flood, acts of nature, short or reduced supply of raw materials,

or discontinuance of any part or the Motor-Compressor by the unit

manufacturer.

Replacement of a defective Motor-Compressor is limited to one (1)

Motor-Compressor by us during the four (4) year period. Delfield

shall replace the Motor-Compressor at no charge.

This warranty does not give the Original Purchaser of the Motor-

Compressor the right to purchase a complete replacement Motor-

Compressor of the same make or of another make. It further does

not permit the replacement to be made with a Motor-Compressor

of another kind unless authorized by Delfield. In the event Delfield

authorizes the Original Purchaser to purchase a replacement Motor-

Compressor locally, only the wholesale cost of the Motor-Compressor

is refundable.

Expressly excluded from this warranty are damages resulting from

spoilage of goods.

Except as provided in any applicable Standard One Year Limited

Warranty or applicable Service Labor Contract, the foregoing is

exclusive and in lieu of all other warranties, whether written or

oral, express or implied. This Warranty supersedes and excludes

any prior oral or written representations or warranties. Delfield

expressly disclaims any implied warranties of merchantability,

fitness for a particular purpose or compliance with any law, treaty,

rule or regulation relating to the Motor-Compressor, and the full

liability of Delfield for any breach of this warranty, will be as

provided in this warranty.

Other than any applicable Delfield Standard One year Limited

Warranty, this Delfield Additional Four Year Protection Plan and any

applicable Delfield Service Labor Contract, the Original Purchaser

agrees and acknowledges that no other warranties are offered or

provided in connection with or for the Motor-Compressor or any

part thereof.

In no event will Delfield be liable for special, incidental or consequential

damages, or for damages in the nature of penalties.

For customer service, call (800) 733-8829 or (800) 733-8948, Fax (989) 773-3210, www.delfield.com

15

Page 16

Mt. Pleasant, MI

Covington, TN

Thank you for choosing Delfield!

Help is a phone call away. Help our team of professional, courteous

customer service reps by having your model number and serial number

available at the time of your call (800) 733-8829.

Model: ____________________ S/N: ___________________

Installation Date: ____________

For a list of Delfield’s authorized parts depots,

visit our website at www.delfield.com.

980 S. Isabella Rd., Mt. Pleasant, MI 48858, U.S.A. • (989) 773-7981 or (800) 733-8829 • Fax (989) 773-3210 • www.delfield.com

Delfield reserves the right to make changes in design or specifications without prior notice. ©2010 The Delfield Company. All rights reserved. Printed in the U.S.A.

DMLineUp 07/10

Loading...

Loading...