Page 1

International F5 and F15 Series

Service and Installation Manual

Please read this manual completely before attempting to install or operate this equipment!

Notify carrier of damage! Inspect all components immediately.

CAUTION

F5 and F15 SERIES

Drop-In and Serview Display Cases

Important Information

Read Before Use

Please Save These Instructions!

September 2013

Page 2

International F5 & F15 Series Service and Installation Manual

Important Warning And Safety Information

WARNING Read This Manual Thoroughly Before Operating, Installing, Or Performing Maintenance On The Equipment.

WARNING Failure To Follow Instructions In This Manual Can Cause Property Damage, Injury Or Death.

WARNING Do Not Store Or Use Gasoline Or Other Flammable Vapors Or Liquids In The Vicinity Of This Or Any Other

Appliance.

WARNING Unless All Cover And Access Panels Are In Place And Properly Secured, Do Not Operate This Equipment.

WARNING This Appliance Is Not Intended For Use By Persons Who Lack Experience Or Knowledge, Unless They Have

Been Given Supervision Or Instruction Concerning Use Of The Appliance By A Person Responsible For Their

Safety.

WARNING This Appliance Is Not To Be Played With.

WARNING Do Not Clean With Water Jet.

WARNING Do Not Use Electrical Appliances Inside The Food Storage Compartment Of This Appliance.

CAUTION Observe the following:

• Minimum clearances must be maintained from all walls and combustible materials.

• Keep the equipment area free and clear of combustible material.

• Allow adequate clearance for air openings.

• Operate equipment only on the type of electricity indicated on the specification plate.

• Unplug the unit before making any repairs.

• Retain this manual for future reference.

2

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

Page 3

International F5 & F15 Series Service and Installation Manual

Contents

Receiving & Inspecting Equipment ...................................................3

Serial Number Location ....................................................................4

Warranty Information.........................................................................4

Regulatory Certifications ...................................................................4

Specifications................................................................................ 5-6

Installation .................................................................................... 7-8

Shelf Installation ...............................................................................9

Display Lock Operation .....................................................................9

Operation ..........................................................................................9

Temperature Control Settings ..........................................................10

Pressure Control Settings ...............................................................10

Maintenance.............................................................................. 11-12

Condenser Air Flow ........................................................................13

Sliding Door ...................................................................................14

Replacement Parts .................................................................... 14-17

Wiring Diagram ...............................................................................18

Standard Labor Guidelines ..............................................................19

Receiving And Inspecting The Equipment

Even though most equipment is shipped crated, care should be

taken during unloading so the equipment is not damaged while

being moved into the building.

1. Visually inspect the exterior of the package and skid or

container. Any damage should be noted and reported to

the delivering carrier immediately.

2. If damaged, open and inspect the contents with the

carrier.

3. In the event that the exterior is not damaged, yet upon

opening, there is concealed damage to the equipment

notify the carrier. Notification should be made verbally as

well as in written form.

4. Request an inspection by the shipping company of the

damaged equipment. This should be done within 10 days

from receipt of the equipment.

5. Check the lower portion of the unit to be sure legs or

6. Also open the compressor compartment housing and

7. Freight carriers can supply the necessary damage forms

8. Retain all crating material until an inspection has been

Uncrating the Equipment

First cut and remove the banding from around the crate.

Remove the front of the crate material, use of some tools will

be required. If the unit is on legs remove the top of the crate

as well and lift the unit off the skid. If the unit is on casters it

can be "rolled" off the skid.

casters are not bent.

visually inspect the refrigeration package. Be sure lines

are secure and base is still intact.

upon request.

made or waived.

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

3

Page 4

International F5 & F15 Series Service and Installation Manual

Serial Number Location

The serial number on all self-contained F5 Series units is

located near the condensing unit. On all remote F5 Series

units the serial number is located on the drop-in frame.

The serial number on all self-contained F15 Series units is

located behind the compressor housing. On all remote F15

Series units the serial number is located behind the six inch

panel in the base.

Always have the serial number of your unit available when calling

for parts or service. A complete list of authorized Delfield parts

depots is available at www.delfield.com.

©2013 The Delfield Company. All rights reserved. Reproduction without

written permission is prohibited.

SERIAL #

MODEL #

INSTALLATION DATE:

Warranty Information

Visit http://www.delfield.com/minisite/service/warranty_info to:

• Register your product for warranty.

• Verify warranty information.

• View and download a copy of your warranty.

Regulatory Certifications

Models are certified by:

National Sanitation Foundation (NSF)

Technical Inspection Association

European Conformity

4

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

Page 5

International F5 & F15 Series Service and Installation Manual

Export F5 Series Specifications

24” (61cm) Deep Self-Contained Drop-In Refrigerated Display Cases

Model

F5MC48N-E 18.07/512 230-240/

F5SC48N-E 18.97/537 230-240/

F5PC48N-E 18.97/537 230-240/

F5MC72N-E 28.05/794 230-240/

F5SC72N-E 28.05/794 230-240/

F5PC72N-E 29.47/834 230-240/

30” (76.2cm) Deep Self-Contained Drop-In Refrigerated Display Cases

Model

F5MC48D-E 23.88/676 230-240/

F5SC48D-E 24.78/787 230-240/

F5PC48D-E 24.78/787 230-240/

F5MC72D-E 37.07/1050 230-240/

F5SC72D-E 37.07/1050 230-240/

F5PC72D-E 38.49/1090 230-240/

Storage

capacity FT3/L

Storage

capacity FT3/L

Volts/Hertz/

Phase Amps

6.0 25 1215 2970 1/2 32 N

50/1

6.0 25 1867 2970 1/2 32 N

50/1

6.0 25 1945 2970 1/2 32 N

50/1

6.0 40 1783 5821 3/4 48 N

50/1

6.0 40 2791 5821 3/4 48 N

50/1

6.0 40 2884 5821 3/4 48 N

50/1

Volts/Hertz/

Phase Amps

6.0 25 1282 2970 1/2 32 N

50/1

6.0 25 1934 2970 1/2 32 N

50/1

6.0 25 2012 2970 1/2 32 N

50/1

6.0 40 1870 5821 3/4 48 N

50/1

6.0 40 2878 5821 3/4 48 N

50/1

6.0 40 2971 5821 3/4 48 N

50/1

Max. Lamp

Watts

Max. Lamp

Watts

Cabinet Load

BTU/Hour

Cabinet Load

BTU/Hour

System

Capacity BTU/

Hour H.P.

System

Capacity BTU/

Hour H.P.

R404A Charge,

OZ. Temp Class

R404A Charge,

OZ. Temp Class

M = Mirror Back • P = Pass Thru • S = See Thru • C = Self-Contained • N = Narrow • D = Deep 30”

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

5

Page 6

International F5 & F15 Series Service and Installation Manual

Export F15 Series Specifications

24” (61cm) Deep Self-Contained Serview Refrigerated Display Cases

Shelf Capacity

Model

F15MC48N-E 18.78/17447

F15SC48N-E 21.05/19556

F15PC48N-E 21.05/19556

F15MC72N-E 29.28/27202

F15SC72N-E 32.58/30547

F15PC72N-E 32.88/30547

30” (76.2cm) Deep Self-Contained Serview Refrigerated Display Cases

Model

F15MC48D-E 18.78/17447

F15SC48D-E 21.05/19556

F15PC48D-E 21.05/19556

F15MC72D-E 29.28/27202

F15SC72D-E 32.58/30547

F15PC72D-E 32.88/30547

FT2/CM2

Display/Base

3.4/3159

3.4/3159

3.4/3159

7.9/7339

7.9/7339

7.9/7339

Shelf Capacity

FT2/CM2

Display/Base

3.4/3159

3.4/3159

3.4/3159

7.9/7339

7.9/7339

7.9/7339

Storage

Capacity FT3/L

Display/Base

18.07/512

9.11/258

18.97/537

9.11/2.58

18.97/537

9.11/258

28.05/794

18.10/513

29.47/834

18.10/513

29.47/834

18.10/513

Storage

Capacity FT3/L

Display/Base

23.88/676

9.11/258

24.78/787

9.11/258

24.78/787

9.11/258

37.07/1050

18.10/513

38.49/1090

18.10/513

38.49/1090

18.10/513

Volts/Hertz/

Phase Amps

230-240/

50/1

230-240/

50/1

230-240/

50/1

230-240/

50/1

230-240/

50/1

230-240/

50/1

Volts/Hertz/

Phase Amps

230-240/

50/1

230-240/

50/1

230-240/

50/1

230-240/

50/1

230-240/

50/1

230-240/

50/1

Max. Lamp

Watts

6.0 25 1569 8146 3/4 48 N

6.0 25 2221 8146 3/4 48 N

6.0 25 2299 8146 3/4 48 N

6.0 40 2361 9422 3/4 48 N

6.0 40 3369 9422 3/4 48 N

6.0 40 3462 9422 3/4 48 N

Max. Lamp

Watts

6.0 25 1636 8146 3/4 48 N

6.0 25 2288 8146 3/4 48 N

6.0 25 2366 8146 3/4 48 N

6.0 40 2448 9422 3/4 48 N

6.0 40 3456 9422 3/4 48 N

6.0 40 3549 9422 3/4 48 N

Cabinet Load

BTU/Hour

Cabinet Load

BTU/Hour

System

Capacity

BTU/Hour H.P.

System

Capacity

BTU/Hour H.P.

R404A

Charge,

OZ.

R404A

Charge,

OZ.

Temp

Class

Temp

Class

M = Mirror Back • P = Pass Thru • S = See Thru • C = Self-Contained • N = Narrow • D = Deep 30”

6

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

Page 7

International F5 & F15 Series Service and Installation Manual

CAUTION

Installation: Self-Contained F5 Series

Location

Units represented in this manual are for indoor use only. All

self-contained units were tested at the factory to assure proper

operation. The unit should not be installed directly next to high

heat generating equipment (ranges, griddles, etc.). Be sure the

location chosen has a counter strong enough to support the

total weight of the cabinet and contents. A fully loaded model

may weigh as much as 2,000 pounds! Reinforce the counter as

necessary to provide for maximum loading.

These units are installed by “dropping” them into the counter

from above. The counter cutout sizes are as follows:

48” wide units — 18.62" x 23.62" (47.3 cm x 60.0 cm)

72” wide units — 18.62" x 32.62" (47.3 cm x 82.9 cm)

Self-contained F5 Series units require airflow to the

compressor. Two louvers are provided with each unit and

should be installed as illustrated on page 13.

Unit is designed to maintain 36°F (2°C) to 40°F (4°C) interior

cabinet temperature at 55% or lower ambient relative humidity.

Plumbing

Self-contained models are standard with a condensate

evaporator. If, for some reason, a unit does not have a

condensate evaporator, or the evaporator fails, the unit’s

drain must have an outlet to an appropriate drainage area or

container.

Moisture collecting from improper drainage

can create a slippery surface on the floor

and a hazard to employees. It is the owner’s

responsibility to provide a container or outlet

for drainage.

Electrical connection

Refer to the amperage data on the specification pages, the

serial tag, your local code or the National Electrical Code to

be sure the unit is connected to the proper power source. A

protected circuit of the correct voltage and amperage must be

run for con nec tion of the line cord, or permanent connection

to the unit.

Self-contained units have an ON/OFF switch in the junction

box. Simply turn the switch to ON to begin operation.

The power switch should be turned to OFF and

the unit disconnected from the power source

whenever performing service or maintenance

functions.

Installation: Remote F5 Series

1.75"

(4cm)

Cutout

3.00" X 12.00" (8cm X 30cm)

Centered Front To Back

0.25" (0.6cm) From End

R

D

J

Front Of Unit

Typical Mechanical Access (Plan View)

3.75"

(10cm)

3.75"

(10cm)

All F5 Models

J= Junction Box

R= Refrigeration Lines,

0.25" Liquid,

C

0.37" Suction

D= 0.50" I.D. Drain

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

7

Page 8

International F5 & F15 Series Service and Installation Manual

CAUTION

Installation: Self-Contained F15 Series

Location

Units represented in this manual are for indoor use only. Be

sure the location chosen has a floor strong enough to support

the total weight of the cabinet and contents. A fully loaded model

may weigh as much as 3,000 pounds! Reinforce the floor as

necessary to provide for maximum loading.

For the most efficient refrigeration, be sure to provide good air

circulation inside and out. Don’t pack the refrigerator so full

that air cannot circulate. Be sure that the exterior of the unit has

access to ample air. Avoid hot corners and locations near stoves

and ovens.

Unit is designed to maintain 36°F (2°C) to 40°F (4°C) interior

cabinet temperature at 55% or lower ambient relative humidity.

Leveling

A level cabinet looks better and will perform better because

the drain pan will drain properly, the doors will line up with

the frames properly and the cabinet will not be subject to

undue strain. Units come standard with adjustable legs and

bullet feet to make leveling easier. If your unit has casters,

install in a stable condition with the front casters locked before

operating.

Plumbing

Self-contained models are standard with a condensate

evaporator. If your unit does not have a condensate evap o ra tor,

or the evaporator fails, the unit’s drain must have an outlet to an

appropriate drainage area or container.

Moisture collecting from improper drainage can

create a slippery surface on the floor and a hazard

to employees. It is the owner’s responsibility to

provide a container or outlet for drainage.

Electrical connection

Refer to the amperage data on the specification pages, the serial

tag, your local code or the National Electrical Code to be sure the

unit is connected to the proper power source. A protected circuit

of the correct voltage and amperage must be run for con nec tion

of the line cord, or permanent connection to the unit.

Self-contained units have an ON/OFF switch located directly

behind the louvered panel covering the compressor section.

Simply turn the switch to ON to begin operation.

The power switch should be turned to OFF and

the unit disconnected from the power source

whenever performing service or maintenance

functions.

Installation: Remote F15 Series

30.00"

76cm

1.75"

4cm

D

1.00"

2.5cm

R

D

J

Front Of Unit

Typical Mechanical Access (Plan View)

All F15 Models

3.75"

10cm

3.75"

10cm

J= Junction Box

R= Refrigeration Lines,

C

0.25" Liquid,

0.37" Suction

D= 0.50" I.D. Drain

8

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

Page 9

International F5 & F15 Series Service and Installation Manual

Shelf Installation Display Lock Operation

Display cases come with four epoxy coated wire shelves that

are adjustable in 3-3/4" increments.

Maximum weight for shelves is 75 pounds.

Overloading shelves can damage equipment or

CAUTION

cause bodily injury.

Operation

After turning the ON/OFF switch to ON the unit’s com pres sor

will begin operating. Delfield display cases are designed to

maintain an operational temperature of 36°F to 40°F (2°C to

4°C) in both the display (F5 and F15 Series) and storage areas

(F15 Series only).

Located on the operator side at the top right is an ON/OFF

switch for the display lights.

The display temperature control is located in the fan shroud. The

F15 base thermostat is located in the mechanical compartment.

Use the knob to adjust the temperature, adjustments should

be made gradually. Several small adjustments will be more

effective than one large adjustment. It may take an hour or

longer to realize the temperature change depending on the

application and location of the unit.

Continuous opening and closing of the doors will hinder the

unit’s ability to maintain operational tem per a tures.

If humidity is above 55%, condensation on the glass

will be present.

At the factory, the keys are taped to the display case. Follow the

directions below to lock and unlock the display case.

To lock: Line up key ridge with red dot.

Insert key and rotate one-half turn.

Remove key and push lock bolt in.

To open: Line up ridge with red dot.

Insert key and rotate key one-half turn.

Remove key.

F15 Refrigerated Base Evaporator Fan Operation

When the refrigerator is initially powered up or immediately

following a power outage the unit will begin cooling after a 3-6

minute delay. During normal operation the evaporator fan pulses

independently of the compressor as dictated by the controller

as follows:

1. During the cooling mode, compressor and evaporator fan

run simultaneously.

2. During the compressor off mode, evaporator fan pulses

three minutes on and three minutes off.

3. During an actual defrost event other than the off-cycle

defrost, compressor stays off but the evaporator fan runs

continuously.

Cooling Cycle Defrost Cycle

Compressor On Compressor Off Compressor Off

Evap Fan OnEvap Fan

X

Evap Fan OnEvap Fan

Off

Cycles On 3-Min,

Off 3-Min

Evap Fan OnEvap Fan

Off

Off

X

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

9

Page 10

International F5 & F15 Series Service and Installation Manual

Display Temperature Control Settings

The display temperature control is located on the evaporator

assembly on the ceiling of the display case. It is field

adjustable and does not require a service agent. The factory

setting is 2.5. Set toward 1 for higher temperatures and

toward 7 for lower temperatures.

Base Temperature Control Settings

The base temperature control is located in the machine

compartment. It is field adjustable and does not require a

service agent. The factory setting is 2.5. Set toward 1 for

higher temperatures and toward 7 for lower temperatures.

Please make small incremental adjustments if

a temperature adjustment is necessary. It may

take an hour or longer to realize the temperature

change depending on the application and location

of the unit.

Contact the service department at Delfield +1

(989) 773-7981 or your local service agent

for additional assistance. Delfield is not

responsible for charges incurred while adjusting

the thermostat.

Please make small incremental adjustments if

a temperature adjustment is necessary. It may

take an hour or longer to realize the temperature

change depending on the application and location

of the unit.

Contact the service department at Delfield +1

(989) 773-7981 or your local service agent

for additional assistance. Delfield is not

responsible for charges incurred while adjusting

the thermostat.

Pressure Control Settings

Low pressure cut in at 20 psi.

Low pressure cut out at 5 psi.

Differential setting of 15 psi.

10

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

Page 11

Maintenance

International F5 & F15 Series Service and Installation Manual

Door Gasket Maintenance

Door gaskets require regular cleaning to prevent mold and

mildew build up and also to retain the elasticity of the gasket.

Gasket cleaning can be done with the use of warm soapy water.

Avoid full strength cleaning products on gaskets as this can

cause them to become brittle and crack. Never use sharp tools

or knives to scrape or clean the gasket. Gaskets can be easily

replaced and do not require the use of tools or an authorized

service person. The gaskets are “Dart” style and can be pulled

out of the groove in the door and new gaskets can be “pressed”

back into place.

Drain Maintenance - Base

Each unit has a drain located inside the unit that removes

the condensation from the evaporator coil and routes it to an

external condensate evaporator pan. Each drain can become

loose or disconnected during normal use. If you notice water

accumulation on the inside of the unit be sure the drain tube

is connected to the evaporator drain pan. If water is collecting

underneath the unit make sure the end of the drain tube is in

the condensate evaporator in the machine compartment. The

leveling of the unit is important as the units are designed to

drain properly when level. Be sure all drain lines are free of

obstructions.

Caster Maintenance

Wipe casters with a damp cloth monthly to prevent corrosion.

The power switch must be turned to OFF and the

unit disconnected from the power source whenever

performing service, maintenance functions or

cleaning the refrigerated area.

Refrigerators

The interior and exterior can be cleaned using soap and warm

water. If this isn’t sufficient, try ammonia and water or a

nonabrasive liquid cleaner. When cleaning the exterior, always

rub with the “grain” of the stainless steel to avoid marring the

finish. Do not use an abrasive cleaner because it will scratch the

stainless steel and can damage the breaker strips and gaskets.

Stainless Steel Care and Cleaning

To prevent discoloration or rust on stainless steel several

important steps need to be taken. First, we need to understand

the properties of stainless steel. Stainless steel contains 7080% iron, which will rust. It also contains 12-30% chromium,

which forms an invisible passive film over the steel's surface,

which acts as a shield against corrosion. As long as the

protective layer is intact, the metal is still stainless. If the film

is broken or contaminated, outside elements can begin to

breakdown the steel and begin to form discoloration or rust.

Proper cleaning of stainless steel requires soft cloths or plastic

scouring pads.

NEVER USE STEEL PADS, WIRE BRUSHES OR SCRAPERS!

Cleaning solutions need to be alkaline based or non-chloride

cleaners. Any cleaner containing chlorides will damage

the protective film of the stainless steel. Chlorides are also

commonly found in hard water, salts, and household and

industrial cleaners. If cleaners containing chlorides are used be

sure to rinse repeatedly and dry thoroughly. Routine cleaning

of stainless steel can be done with soap and water. Extreme

stains or grease should be cleaned with a non-abrasive cleaner

and plastic scrub pad. Always rub with the grain of the steel.

There are stainless steel cleaners available which can restore

and preserve the finish of the steels protective layer. Early signs

of stainless steel breakdown are small pits and cracks. If this

has begun, clean thoroughly and start to apply stainless steel

cleaners in attempt to restore the passivity of the steel.

Never use an acid based cleaning solution! Many

food products have an acidic content, which can

CAUTION

deteriorate the finish. Be sure to clean the stainless

steel surfaces of ALL food products. Common items

include, tomatoes, peppers and other vegetables.

Do not throw items into the display case. Failure

to follow these recommendations could result in

damage to the interior or blower coil. Overloading,

restricting the airflow, and continuous opening and

closing of the doors will hamper the units ability to

maintain operational temperature.

Cleaning the Condenser Coil

In order to maintain proper refrigeration performance, the

condenser fins must be cleaned of dust, dirt and grease

regularly. It is recommended that this be done at least every

three months. If conditions are such that the condenser is totally

blocked in three months, the frequency of cleaning should be

increased. Clean the condenser with a vacuum cleaner or stiff

brush. If extremely dirty, a commercially available condenser

cleaner may be required.

Failure to maintain a clean condenser coil can initially cause high

temperatures and excessive run times. Continuous operation

with a dirty or clogged condenser coil can result in compressor

failure. Neglecting the condenser coil cleaning procedures will

void any warranties associated with the compressor and cost

to replace the compressor.

Never use a high-pressure water wash for this

cleaning procedure as water can damage the

CAUTION

electrical components located near or at the

condenser coil.

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

11

Page 12

International F5 & F15 Series Service and Installation Manual

Maintenance, continued

Doors/Hinges

Over time and with heavy use the doors hinges may become

loose. If this happens tighten the screws that mount the hinge

brackets to the frame of the unit. Loose or sagging doors can

cause the hinges to pull out of the frame, which may damage

both the doors and the hinges. In some cases this may require

qualified service agents or maintenance personnel to perform

repairs.

Do not place hot pans on/against the blue ABS liner.

Do not throw items into the storage area. Failure

to follow these recommendations could result in

damage to the interior of the cabinet or to the blower

coil. Overloading the storage area, restricting the

airflow, and continuous opening and closing of the

doors and drawers will hamper the units ability to

maintain operational temperature.

Preventing blower coil corrosion

To help prevent corrosion of the blower coil, store all acidic

items, such as pickles and tomatoes, in sealable containers.

Immediately wipe up all spills.

Cleaning the condensate evaporator (remote models only)

The stainless steel condensate evaporator pan should be

cleaned every six months. Use a vacuum cleaner or damp cloth

to remove dust that may have accumulated. This will prevent

corrosion of the stainless steel.

12

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

Page 13

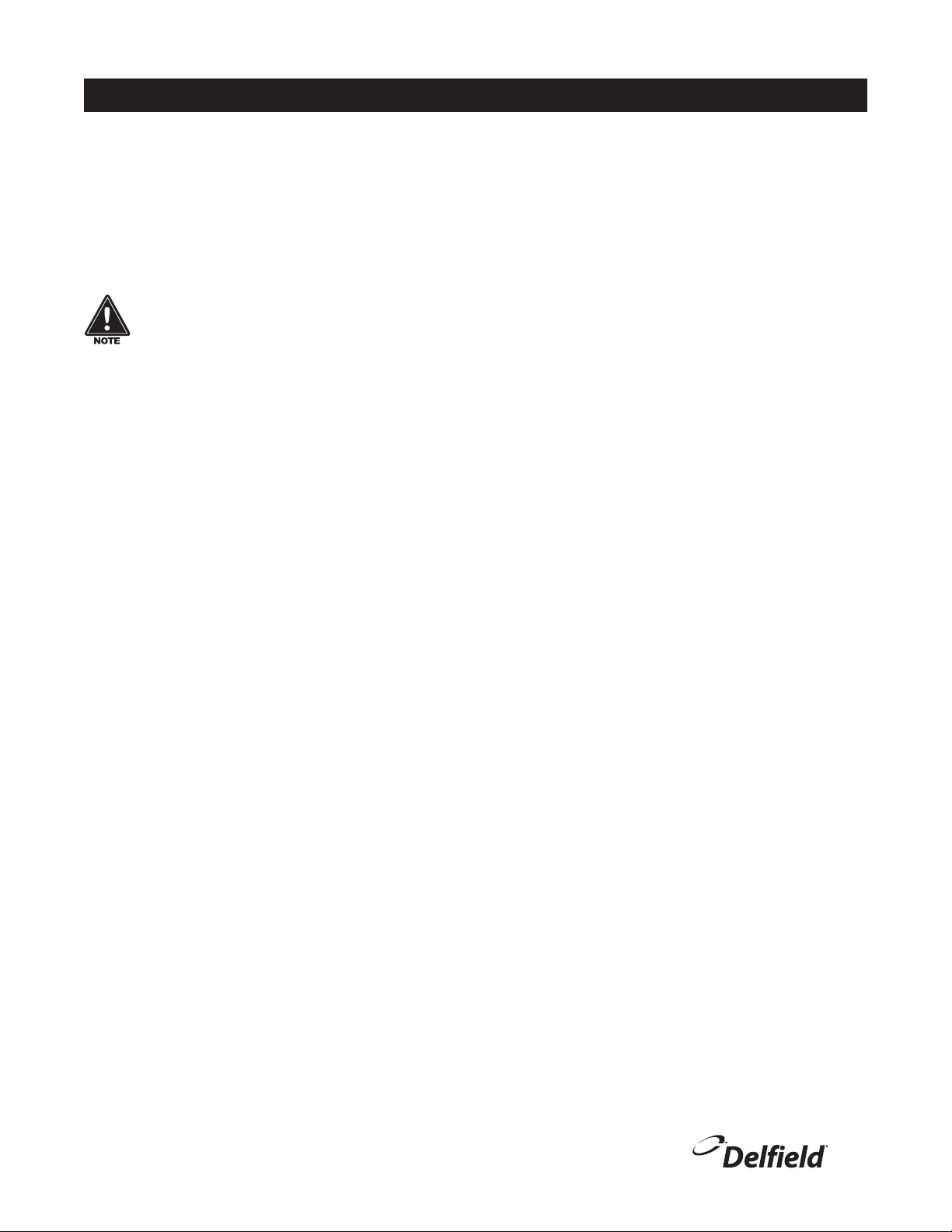

Condenser Air Flow: F5

International F5 & F15 Series Service and Installation Manual

F5 units are designed to be operated with two supplied louvered

panels for proper air flow. Failure to provide the proper air flow

will void the warranty. Louver cut-outs are 22" by 11" (55.9cm

by 27.9cm) typical. Cut-outs are to begin a maximum of

48" Wide Units Air Flow Detail

Discharge Air

Louver

Cond.

Louver

Fresh Air

4.00" (10.2cm) from the counter-top. Proper installation must

provide for air flow to and from the condensing unit. Install as

shown below.

72" Wide Units Air Flow Detail

An “air duct” should be constructed from the air-intake louver to the condenser. This is

recommended to prevent recirculation of discharge air.

Discharge air louver may be located further from fresh air louver or on the opposite side of

counter.

22.00"

56cm

11.00"

28cm

DisCharge

Air

22.00"

56cm

Louver

Cutout

12.00"

30cm

Minimum

Distance

Between

Louvers

Cond.

22.00"

56cm

Louver

Cutout

Fresh

Air

Duct

Top

View

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

13

Page 14

International F5 & F15 Series Service and Installation Manual

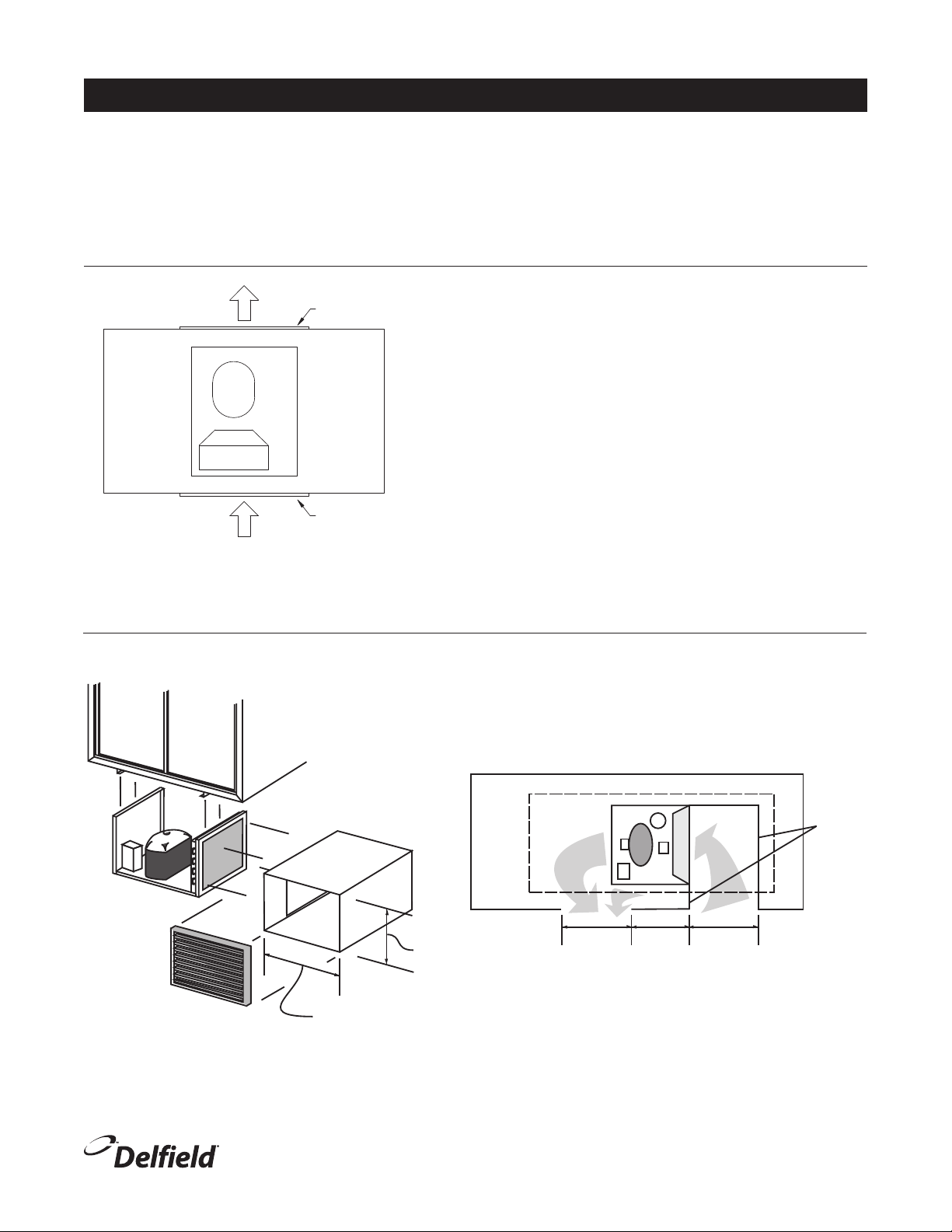

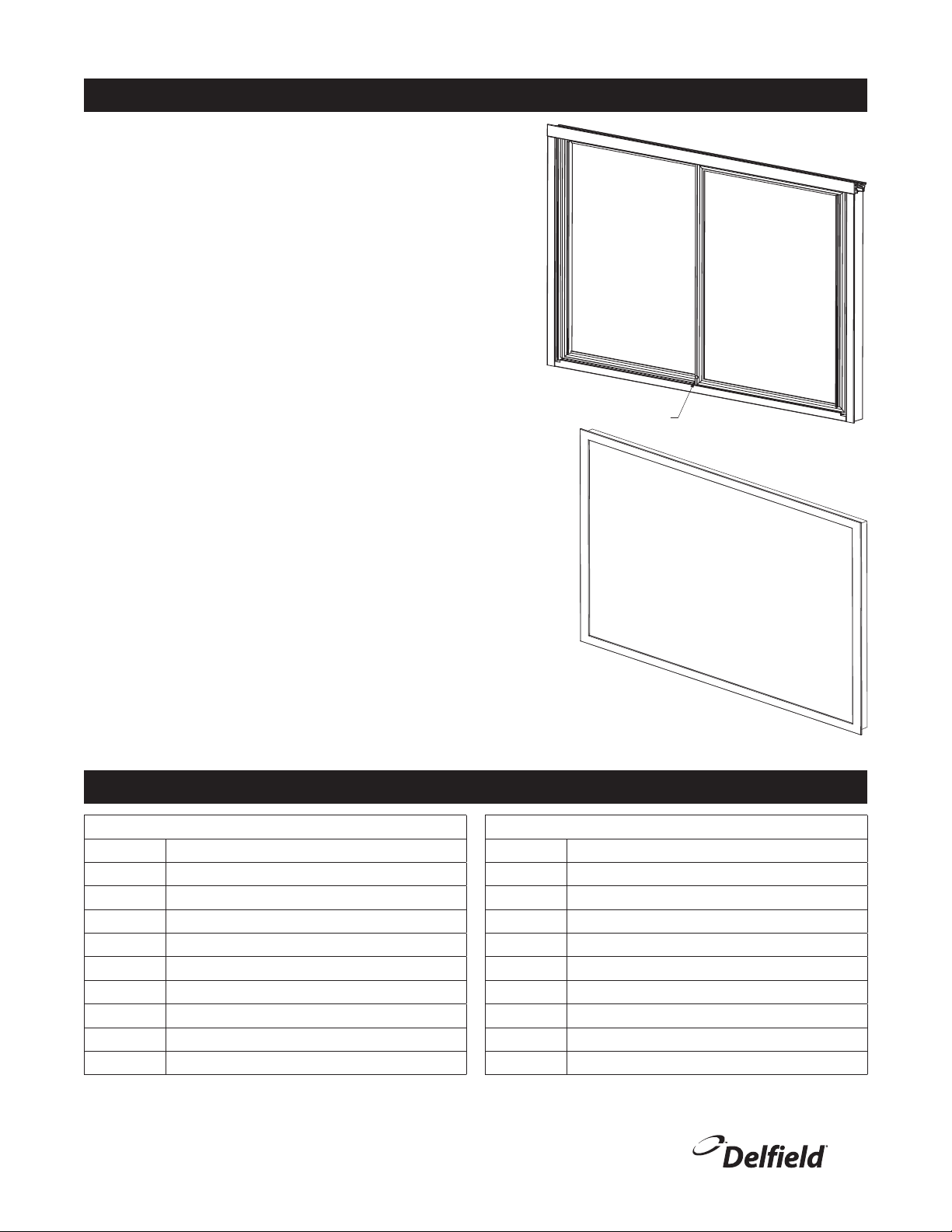

Standard With Door Lock

See-thru Panel

Sliding Door

All Delfield F5 Series and F15 Series display cases feature

a sliding door assembly. A typical sliding door assembly is

shown in the illustration at right.

Maintenance

Frequent, regular cleaning with a mild soap and water solution

will keep the tracks free of foreign matter and will insure many

years of service.

The glass may be cleaned with one of the many commercial

glass cleaners currently available.

If it becomes necessary to replace a sliding door as sem bly

or a glass panel, have your unit’s model and serial numbers

available when you call Delfield’s Service and Parts Department

at (800) 733-8829. Indicate that your unit has the sliding door

assembly when you call.

Sliding Door Removal

Open the door almost completely. Firmly grasp both sides of

the door. Lift the door up and move it until it enters a notch

and can be lifted higher. Tilt the bottom out without removing

the top. Use the top to gently return the spring to the closed

position. Remove the door from the top track.

Sliding Door Reinstall

There is a notch in the top inside corner of the door. Put the

spring in the door's notch and move the spring to the open

position. Put the top into the track and find the notch where the

door can be lifted higher. Set bottom of the door into the track.

Replacement Parts

48" Units

Part # Description

3234636 Bearing, roller, single

3234808 Gasket, bumper, 31 13/16"

3234809 Gasket, wiper strip, 30 3/8"

3234810 Spring, 17" gold

3234803 Track, bottom, 43 7/16"

3234800 Track top, 44 7/16"

3455397 See thru panel

3237549 Replacement lock, units 2007 and after

3233986 Replacement lock, units prior to 2007

72" Units

Part # Description

3234637 Bearing, roller, double

3234808 Gasket, bumper, 31 13/16"

3234809 Gasket, wiper strip, 30 3/8"

3233946 Spring, 30" gold

3234805 Track, bottom, 67 7/16"

3234802 Track top, 68 7/16"

3455399 See thru panel

3237549 Replacement lock, units 2007 and after

3233986 Replacement lock, units prior to 2007

Note: Pass-thru units have two sets of sliding display doors, see-through and mirror-back units have one set.

14

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

Page 15

International F5 & F15 Series Service and Installation Manual

Condensing Unit Assembly 1/2 H.P. F5 48" Models

5

4

3

2

1

6

Key Part Number Description

- 000-BN5-003O Assembly, 1/2HP Condenser, Med

1 3516554 Condenser fan blade

2 2160019 Condenser fan guard

3 2162721 Condenser fan motor, 230V

7

4 Danfoss

#117U5017 Start Capacitor

Danfoss

#117U6011 Start Relay

5 3527045 Compressor, SC12MLX, 220/50

6 000-998-0032 Hi pressure assembly, 13A, 220

7 3516322 Filter Drier

9

8

8 039-231-0031 Pan, Condensate

9 3516455 Condenser coil

Condensing Unit Assembly 3/4 H.P. F15 Models, F5 72" Models

2

1

4

3

Key Delfield Part # Description

- 000-BN5-003P Condensing Unit Assembly, 230-240V

1 026-C58-0032 Shroud, 3/4 HP condenser coil

2 2160019 Guard, fan, condenser, upright

3516433 Blade, fan 25º, 10”, CW, upright

5

2162721 Motor, fan, 230-240V

3 000-998-0032 Hi Pressure Assembly

4 3527010 Compressor, 3/4HP, 230-240V

5 3516322 Filter dryer, (2) inlet, .25”

6

7

6 3516360 Tank, receiver

7 3516456 Coil, condenser, 3/4 HP

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

15

Page 16

International F5 & F15 Series Service and Installation Manual

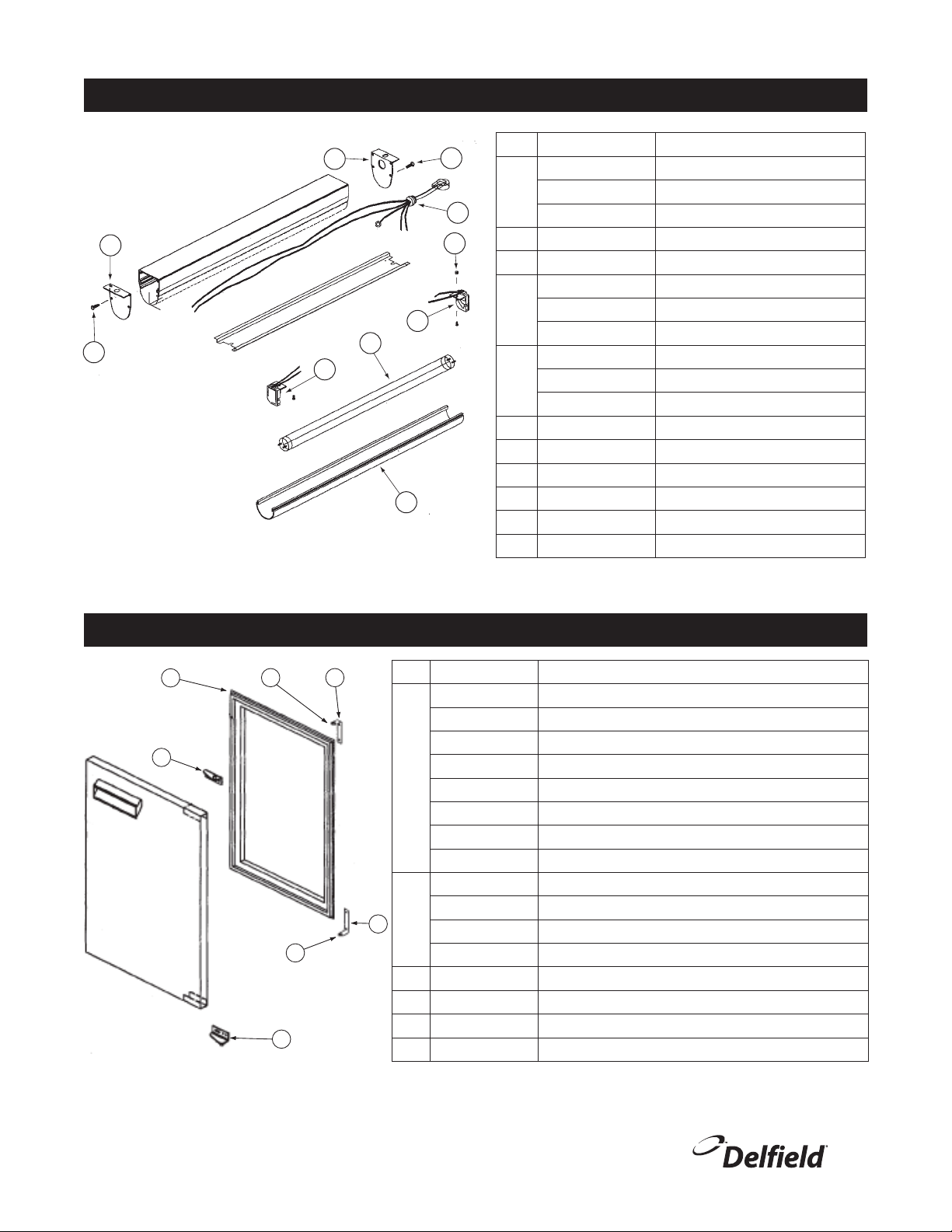

Fluorescent Light Fixture

1

7

8

2

9

5

7

4

6

3

Key Part# Description

- 000-406-0039 Complete assembly, 60"

000-406-0037 Complete assembly, 36”

000-406-0038 Complete assembly, 48”

1 313-146-0032 cap, end, top mtg, pigtail, -rem.

2 313-146-0033 cap, end, top mtg, blank, -rem.

3 376-A0M-0055 diffuser, fluor. light, 36”

376-A0M-0056 diffuser, fluor. light, 48"

376-A0M-0057 diffuser, fluor. light, 60"

4 2193907 lamp, fluorescent, 36”

2193908 lamp, fluorescent, 48”

2193909 lamp, fluorescent, 60"

5 2193939 lamp holder, left

6 2193940 lamp holder, right

7 9321266 screw, #8-32 x .50

8 2183613 pigtail, male, 3.5”, rem. ballast

9 9321010 nut, hex, starlock, s/s, #6-32

- 2194992 Ballast, rapid start 36” lamp

Base Door Assembly

1

3

5

5

2

4

Key Part# Description

- 000-187-0066 complete door assy., right, 19”, 18.75” x 25.72”

000-187-0067 complete door assy., left, 19”, 18.75” x 25.72”

000-187-0068 complete door assy., right, 24”, 23.75” x 25.72”

000-187-0069 complete door assy., left, 24”, 23.75” x 25.72”

000-187-006A complete door assy., right, 27”, 26.75” x 25.72”

000-187-006B complete door assy., left, 27”, 26.75” x 25.72”

000-187-006C complete door assy., right, 32”, 31.75” x 25.72”

000-187-006D complete door assy., left, 32”, 31.75” x 25.72”

1 1701183 gasket, door, 19”

1701184 gasket, door, 24”

4

1701185 gasket, door, 27”

1701186 gasket, door, 32”

3 3234072 hinge, door, top/LH, bottom/RH

4 3234073 hinge, door, top/RH, bottom/LH

5 3234391 hinge, cabinet, L-shaped

6 9321107 bushing, nylon, hinge pin

16

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

Page 17

International F5 & F15 Series Service and Installation Manual

F15 Base Evaporator Assembly Miscellaneous Replacement Parts

1

9

8

7

2

4

3

6

5

Key Part Number Description

- 000-248-0033 Coil Assembly, R404A, Ref

1 2160024 Guard, fan, 4.7"

2 2160025 Fan, axiel, 230V

3 3516095 Coil, evaporator

4 030-232-0003 Back, evaporator, enclosure

5 MCP00140 Expansion valve, 1/4, R-404a

6 030-233-0001 Side, coil, angled, Rt

7 000-BNH-0030 Drip pan, evaporator

8 030-234-0003 Front, coil

9 030-233-0002 Side, coil, angled, Lt

- 2184317 Harness, coil

- 2194808 Probe, Defrost, Danfoss, Control

- 2194809 Probe, Temp, Sensor, Danfoss

F15 Dual Pressure Control Assy.

Key Part Number Description

1 Varies per destination Dual pressure control

2 Varies per destination Control

- Varies per destination Rocker switch

1

2

Part Number Description

Display Cases

3516172 Blade, fan, Lexan, clear

031-264-0000

Bracket, fan motor, blower coil

3516090 Coil, evaporator, 48”

3516091 Coil, evaporator, 72”

2193942 Control, pressure, low

3516173 Fan Guard

2184063 Harness, elec., power to ballasts

2195301 Line Filter

2162692 Motor, fan, 240V

039-304-0030

000-BBO-0030

Pan, drip, evap coil, 42” with flat bottom

Pan, drip, evap coil, 42” w/ recessed drain

PMK00011 Pan, drip, evap coil, 72” with flat bottom

000-BBO-0032

Pan, drip, evap coil, 72” w/ recessed drain

MCP00142 Solenoid coil 240V

MCP00141 Solenoid valve, 240V

MCP00158 Solenoid valve connector

2194400 Switch, rocker, 240V

3516135 Thermometer, hanging, 4”

2194536 Thermostat, in-39.5D/out-22.5D

3516084 Valve, expansion, 1/2 ton, R404A

F15 Base

Varies per

Cord/plug assembly

destination

3234645 Leg, 6” with mount plate (4 used on 48” —

6 used on 72”)

356-303-0031

Louver, 18”, 17.94 x 26.34

Mirror Glass

3455418 Mirror, glass, top, 72”

Shelving & Misc. Parts — Serview Bases

3234290 Shelf support, plastic, plug 1”

3977984 Shelf, wire, 19” door, 14.38 x 25.25

3977998 Shelf, wire, 24” door, 19.38 x 25.25

3978014 Shelf, wire, 27” door, 22.56 x 25.25

3977983 Shelf, wire, 32” door, 27.38 x 25.25

9321132 Stud, wall side, for shelf support, 1/4x1.50

9321040 Stud, coil side, for shelf support

Shelving for Mirror Back Display Cases

3977993 Shelf, wire, 15.75” x 43.25” (M)

3978061 Shelf, wire, 15.75” x 67.25” (M)

3978025 Shelf, wire, 21.75” x 43.25” (M)

3978062 Shelf, wire, 21.75” x 67.25” (M)

Shelving for See Thru & Pass Thru Display Cases

3978026 Shelf, wire, 17.75” x 43.25” (S&P)

3978063 Shelf, wire, 17.75” x 67.25” (S&P)

3978027 Shelf, wire, 23.75” x 43.25” (S&P)

3978064 Shelf, wire, 23.75” x 67.25” (S&P)

(M)=MirrorBack•(S&P)=SeeThru&PassThru

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

17

Page 18

International F5 & F15 Series Service and Installation Manual

N

Wiring Diagram: Self-Contained F5 & F15 Series

18

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

Page 19

International F5 & F15 Series Service and Installation Manual

Standard Labor Guidelines To Repair Or Replace Parts On Delfield Equipment

Advice and recommendations given by Delfield Service Technicians do not constitute or guarantee any special coverage.

• A maximum of 1-hour is allowed to diagnose a defective component.

• A maximum travel distance of 100 miles round trip and 2-hours will be reimbursed. Actual travel to be charged.

• Overtime, installation/start-up, normal control adjustments, general maintenance, glass breakage, freight damage, and/or correcting and

end-user installation error will not be reimbursed under warranty unless pre-approved with a Service Work Authorization from Delfield.

You must submit the number with the service claim.

• Actual repair time will be paid at or below guidline.

• Parts on the critcal stock list must be air freighted at the expense of the service agent.

Labor Up To 1-Hour Is Allowed To Replace

• Infinite Switch • Contactor/Relay

• Door Jamb Switch • Transformer

• Solenoid Coil • Evaporator/Condenser Fan Motor and Blade

• Hi-limit/Thermal Protector Switch • Circulating Fan Motor and Blade

• Fan Delay/Defrost Termination Switch • Digital Control

• Compressor Start Components and Overload Protector • Water Level Sensor/Probe

• Defrost Timer • Door Hinges, Locks, and Gaskets

• Thermostat • Condensate Element

• Thermometer • Springs/Lowerator

• Gear Motor

Labor Up To 2 Hours To Replace

• Drawer Tracks/Cartridges • Defrost Element

• Pressure Control • Heating Element

• Solenoid Valve • Locate/Repair Leak

Labor Up To3 Hours To Replace

• EPR or CPR Valve • Condenser or Evaporator Coil

• Expansion Valve • Cap Tube

Labor Up To 4 Hours To Replace

• Compressor

- This includes recovery of refrigerant and leak check.

- $55.00 maximum reimbursement for refrigerant recovery (includes recovery machine, pump, torch, oil, flux, minor fittings, solder,

brazing rod, nitrogen, or similar fees).

Refrigerants

• R22 A maximum of $4.00/lb. or 25¢/oz. will be reimbursed.

• R134A A maximum of $7.00/lb. or 44¢/oz. will be reimbursed.

• R404A A maximum of $16.00/lb. or $1.00/oz. will be reimbursed.

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.deleld.com

19

Page 20

Mt. Pleasant, MI

Covington, TN

Thank you for choosing Delfield!

Help is a phone call away. Help our team of professional, courteous customer

service reps by having your model number and serial number available at the time

of your call (800) 733-8829.

Model: _______________________ S/N: ______________________

Installation Date: _______________

For a list of Delfield’s authorized parts depots,

visit our website at www.delfield.com

Register your Deleld warranty

online. Go to www.deleld.com

under the service tab to complete.

980 S. Isabella Rd., Mt. Pleasant, MI 48858, U.S.A. • (989) 773-7981 or (800) 733-8829 • Fax (989) 773-3210 • www.deleld.com

Deleld reserves the right to make changes in design or specications without prior notice. ©2013 The Deleld Company. All rights reserved. Printed in the U.S.A.

DM5_15int 09/13

XXXXXXX

Loading...

Loading...