Page 1

F13 Series

Service and Installation Manual

Please read this manual completely before attempting to install or operate this equipment!

Notify carrier of damage! Inspect all components immediately.

Ice Cream Cabinets

CAUTION

Important Information

Read Before Use

Please Save These Instructions!

February 2013

Page 2

F13 Series Ice Cream Cabinets Service and Installation Manual

Important Warning And Safety Information

WARNING Read This Manual Thoroughly Before Operating, Installing, Or Performing Maintenance On The Equipment.

WARNING Failure To Follow Instructions In This Manual Can Cause Property Damage, Injury Or Death.

WARNING Do Not Store Or Use Gasoline Or Other Flammable Vapors Or Liquids In The Vicinity Of This Or Any Other

Appliance.

WARNING Unless All Cover And Access Panels Are In Place And Properly Secured, Do Not Operate This Equipment.

WARNING This Appliance Is Not Intended For Use By Persons Who Lack Experience Or Knowledge, Unless They Have

Been Given Supervision Or Instruction Concerning Use Of The Appliance By A Person Responsible For Their

Safety.

WARNING This Appliance Is Not To Be Played With.

WARNING Do Not Clean With Water Jet.

WARNING Do Not Use Electrical Appliances Inside The Food Storage Compartment Of This Appliance.

CAUTION Observe the following:

• Minimum clearances must be maintained from all walls and combustible materials.

• Keep the equipment area free and clear of combustible material.

• Allow adequate clearance for air openings.

• Operate equipment only on the type of electricity indicated on the specification plate.

• Unplug the unit before making any repairs.

• Retain this manual for future reference.

2

For customer service, call (800) 733-8829, (800) 773-8821, (989) 773-7981, Fax (989) 773-3210, www.delfield.com

Page 3

CONTENTS

Receiving & Inspecting .........................................................3

Serial Number Location ........................................................4

Warranty Information ............................................................4

Regulatory Certifications .......................................................4

Specifications ........................................................................5

Refrigerant Charges .............................................................5

Installation ............................................................................6

Operation ..............................................................................6

Maintenance ..........................................................................7

Wiring Diagram .....................................................................8

Replacement Parts .......................................................... 9-10

Standard Labor Guidelines ..................................................11

F13 Series Ice Cream Cabinets Service and Installation Manual

RECEIVING AND INSPECTING THE EQUIPMENT

Even though most equipment is shipped crated, care should

be taken during unloading so the equipment is not damaged

while being moved into the building.

1. Visually inspect the exterior of the package and skid or

container. Any damage should be noted and reported to

the delivering carrier immediately.

2. If damaged, open and inspect the contents with the

carrier.

3. In the event that the exterior is not damaged, yet upon

opening, there is concealed damage to the equipment

notify the carrier. Notification should be made verbally

as well as in written form.

4. Request an inspection by the shipping company of the

damaged equipment. This should be done within 10

days from receipt of the equipment.

5. Check the lower portion of the unit to be sure legs or

casters are not bent.

6. Also open the machine compartment housing and

visually inspect the refrigeration package. Be sure lines

are secure and base is still intact.

7. Freight carriers can supply the necessary damage forms

upon request.

8. Retain all crating material until an inspection has been

made or waived.

Uncrating the Equipment

First cut and remove the banding from around the crate.

Remove the front of the crate material, use of some tools will

be required. If the unit is on legs remove the top of the crate

as well and lift the unit off the skid. If the unit is on casters it

can be "rolled" off the skid.

For customer service, call (800) 733-8829, (800) 773-8821, (989) 773-7981, Fax (989) 773-3210, www.delfield.com

3

Page 4

F13 Series Ice Cream Cabinets Service and Installation Manual

SERIAL NUMBER LOCATION

The serial number on self-contained units is located behind

the louver near the compressor. The serial number on remote

units is located in the mechanical area on the right side.

Always have the serial number of your unit available when

calling for parts or service.

©2013 The Delfield Company. All rights reserved. Reproduction without

written permission is prohibited. “Delfield” is a registered trademark of The

Delfield Company.

Warranty Information

Visit http://www.delfield.com/minisite/service/warranty_info to:

• Register your product for warranty.

• Verify warranty information.

• View and download a copy of your warranty.

Regulatory Certifications

Models are certified by:

National Sanitation Foundation (NSF)

Underwriters Laboratories (UL)

Underwriters Laboratories of Canada (ULC)

4

For customer service, call (800) 733-8829, (800) 773-8821, (989) 773-7981, Fax (989) 773-3210, www.delfield.com

Page 5

F13 Series Ice Cream Cabinets Service and Installation Manual

SPECIFICATIONS

MODEL GALLON NUMBER OF VOLTS/HERTZ BTU DESIGN BTU REF CHARGE SHIP

NUMBER CAPACITY COVERS H.P. PHASE AMPS LOAD SYS. CAP. OZ. WEIGHT

Self-Contained Low Temp, Ice Cream Cabinet

F13WC32 12 2 1/3 115/60/1 8.0 322 818 24 311 lbs/141 kg

F13WC44 24 4 1/3 115/60/1 8.0 506 983 24 380 lbs/173 kg

F13WC56 36 6 1/3 115/60/1 8.0 638 1073 24 408 lbs/185 kg

F13WC68 48 8 1/3 115/60/1 8.0 796 1160 24 475 lbs/216 kg

5-15P NEMA plug used on all lengths

MODEL GALLON NUMBER OF VOLTS/HERTZ BTU DESIGN EVAP. CAP. SHIP

NUMBER CAPACITY COVERS H.P. PHASE AMPS LOAD BTU/°TD WEIGHT

Remote Low Temp, Ice Cream Cabinet

F13WR24 12 2 N/A 115/60/1 1.5 322 27/29 195 lbs/89 kg

F13WR36 24 4 N/A 115/60/1 1.5 506 38/26 255 lbs/116 kg

F13WR48 36 6 N/A 115/60/1 1.5 638 46/23 295 lbs/134 kg

F13WR60 48 8 N/A 115/60/1 1.5 796 56/21 345 lbs/157 kg

*Recommended horsepower

MODEL GALLON NUMBER OF VOLTS/HERTZ BTU DESIGN LOAD BTU SYS. CAP. REF CHARGE SHIP

NUMBER CAPACITY COVERS H.P. PHASE AMPS FRZR./RAIL FRZR./RAIL OZ. WEIGHT

Self-Contained Low Temp, Ice Cream Cabinet With Syrup Rail

F13BC44 24 4 1/3 115/60/1 8.0 506/192 983/828 24 435 lbs/197 kg

F13BC56 36 6 1/3 115/60/1 8.0 638/250 1073/979 24 480 lbs/218 kg

F13BC72 48 8 1/2 115/60/1 10.0 796/307 1309/1174 40 540 lbs/245 kg

5-15P NEMA plug used on all lengths

MODEL GALLON NUMBER OF VOLTS/HERTZ BTU DESIGN LOAD BTU SYS. CAP. SHIP

NUMBER CAPACITY COVERS H.P. PHASE AMPS FRZR./RAIL FRZR./RAIL WEIGHT

Remote Low Temp, Ice Cream Cabinet With Syrup Rail

F13BR36 24 4 N/A 115/60/1 1.5 506/192 38/11 285 lbs/129 kg

F13BR48 36 6 N/A 115/60/1 1.5 638/250 46/14 340 lbs/154 kg

F13BR60 48 8 N/A 115/60/1 1.5 796/307 56/17 400 lbs/182 kg

STANDARD REFRIGERANT CHARGES

1/3 low — 1/3 H.P. 24 oz. 404A

1/2 low — 1/2 H.P. 40 oz. 404A

There may be exceptions on specific models.

Charge amount should match serial tag data.

For customer service, call (800) 733-8829, (800) 773-8821, (989) 773-7981, Fax (989) 773-3210, www.delfield.com

5

Page 6

F13 Series Ice Cream Cabinets Service and Installation Manual

INSTALLATION

Location

These units are for indoor use only. Be sure the location

chosen has a floor strong enough to support the total weight

of the cabinet and contents. Reinforce the floor if necessary to

provide for maximum loading.

For the most efficient refrigeration, be sure to provide good air

circulation inside and out.

Outside cabinet: Be sure that the unit has access to ample

air. It is suggested that the rear of the unit be no less than

two inches from any wall, partition or any other object which

will restrict exhaust air flow. Avoid hot corners and locations

near stoves and ovens.

Leveling

A level cabinet looks better and will perform better because the

cabinet will not be subject to undue strain.

Electrical connection

Refer to the amperage data on the serial tag and

your local code or the National Electrical Code to

be sure the unit is connected to the proper power

source. A protected circuit of the correct voltage

and amperage must be run for connection of the

line cord or permanent connection to the unit.

compressor section. Also located behind the louver panel in the

compressor section is the On/Off switch for the heater wires.

On the remote units the thermostat may be provided with an

OFF position which shuts off only the solenoid valve.

The power switch must be turned to the OFF

position and power disconnected whenever doing

the following:

1) Performing maintenance functions.

2) Cleaning the refrigerated cabinet area.

3) Performing service or repair functions.

Under no circumstances should the unit be

operated without the louvered panel in place!

If receptacles are to be mounted in the unit backsplash, the

power must be supplied from a separate electrical source and

installed in accordance with the national Electrical Code and

local electrical codes.

Self-contained models are provided with an a ON/OFF power

switch located directly behind the louvered panel of the

OPERATION

These units use a “cold wall” design — heat is removed

from the storage compartments through the liner walls.

Products next to or touching the walls of the compartment

will often be colder than items at the center of the

compartment. For best results, store items loosely and keep

them away from the side walls as much as possible.

The units are not designed to reduce temperature quickly.

When overloaded with warm items, it may take several

hours to return to normal temperature, Also, frequent or

continuous opening of the lids can affect the temperature in

the storage compartment.

Freezer compartments

Freezer compartments are designed to hold ice cream at 0°F to

5°F (-18°C to -15°C).

6

For customer service, call (800) 733-8829, (800) 773-8821, (989) 773-7981, Fax (989) 773-3210, www.delfield.com

Page 7

MAINTENANCE

Cleaning

The interior and exterior can be cleaned using soap and warm water.

If this is not sufficient, try ammonia and water or non-abrasive liquid

cleaner. When cleaning the exterior, always rub with the “grain” of

the stainless steel to avoid marring the finish. Do not use an abrasive

cleaner because it will scratch the stainless steel and plastic.

In order to maintain proper refrigeration performance, the condenser

fins must be cleaned of dust, dirt, and grease regularly. It is

recommended that this be done at least every three months. If

conditions are such that the condenser is totally blocked in three

months, the frequency of cleaning should be increased. Clean the

condenser with a vacuum cleaner or stiff brush. If extremely dirty, a

commercially available condenser cleaner may be required.

The compartment lids should be cleaned as required to maintain their

ability to seal properly. A bristle brush and solution of soap and water

should be all that is required to keep the lids clean. Do not use full

strength degreasing agents on the rubber parts as they can cause the

rubber to crack and become brittle.

Cleaning solutions need to be alkaline based or non-chloride

cleaners. Any cleaner containing chlorides will damage the

protective film of the stainless steel. Chlorides are also commonly

found in hard water, salts, and household and industrial cleaners. If

cleaners containing chlorides are used be sure to rinse repeatedly

and dry thoroughly upon completion. Routine cleaning of stainless

steel can be done with soap and water. Extreme stains or grease

should be cleaned with a non-abrasive cleaner and plastic scrub

pad. It is always good to rub with the grain of the steel. There

are also stainless steel cleaners available which can restore and

preserve the finish of the steels protective layer. Early signs of

stainless steel breakdown can consist of small pits and cracks. If

this has begun, clean thoroughly and start to apply stainless steel

cleaners in attempt to restore the passivity of the steel.

F13 Series Ice Cream Cabinets Service and Installation Manual

Expansion Valve Location

The expansion valve location for remote and self-contained models is

located in the machine compartment of the unit.

Pressure Control

The temperature on self contained units is controlled by an

adjustable pressure control located in the machine compartment.

An adjustable control has the word COLDER near the knob, with

an arrow to indicate the adjustment direction. These controls are

field adjustable and do not require a service agent. If you have

any questions, feel free to contact the Delfield Service

Department.

In attempting to adjust the pressure control, you can

do damage to your unit by accidentally adjusting

the differential. Please make small incremental

adjustments if a temperature adjustment is

necessary, please contact the service department at

Delfield (800) 733-8829 or your local service agent.

Delfield is not responsible for charges incurred

while having the pressure control adjusted.

Factory recommended low-pressure control settings for selfcontained models are as follows:

Cut in 27# — cut out 11#

EPR valve for syrup rail is set at 65#

Defrosting

These units do not have an automatic defrost system. Defrosting

must be done manually after 3/8” frost accumulation. To defrost, turn

the power switch to OFF. Allow the frost to melt and mop up with a

sponge or soft cloth. When the defrost is complete, turn the power

switch back to ON.

Do not use sharp utensils to scrape frost because they

can damage important refrigeration components and

scratch or dent the liner.

For customer service, call (800) 733-8829, (800) 773-8821, (989) 773-7981, Fax (989) 773-3210, www.delfield.com

7

Page 8

F13 Series Ice Cream Cabinets Service and Installation Manual

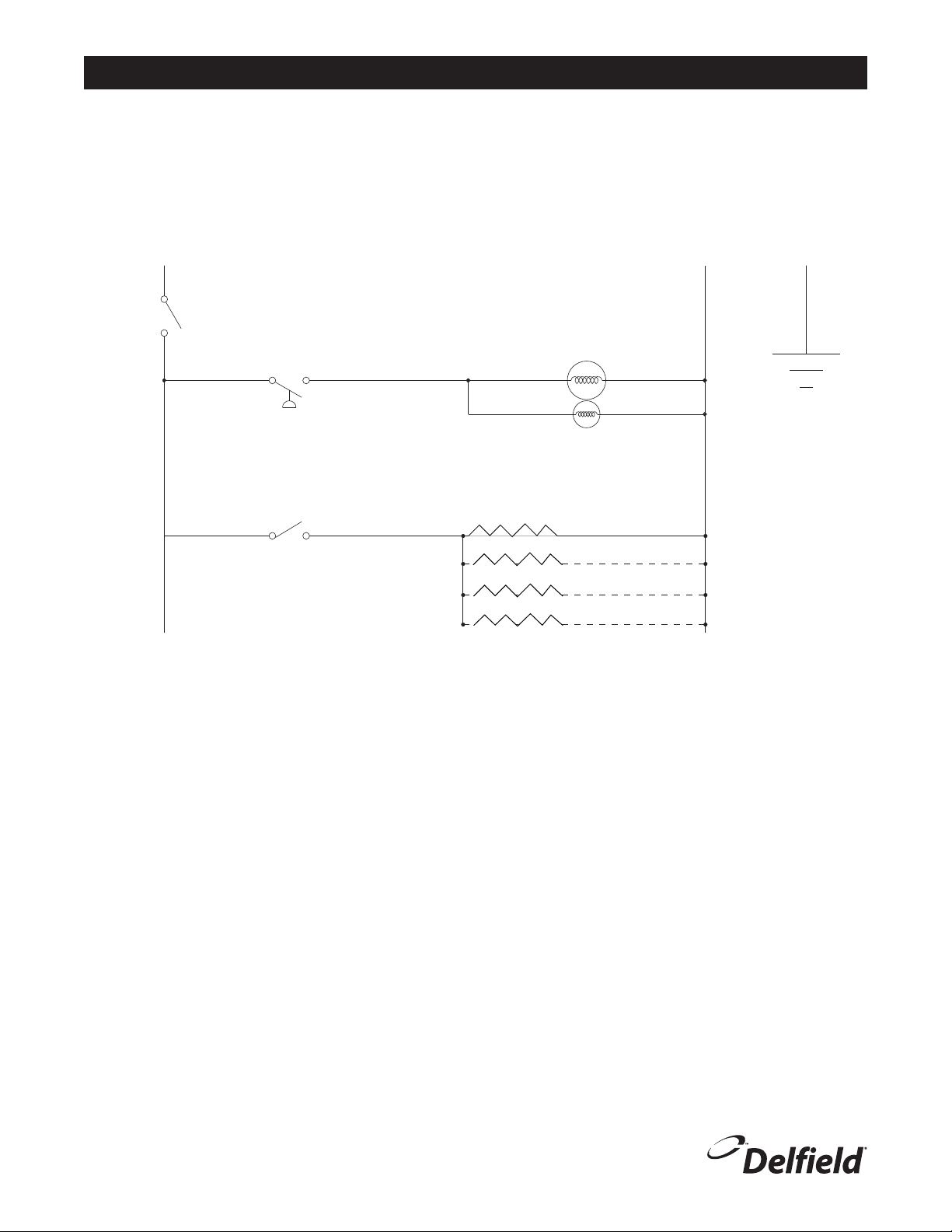

WIRING DIAGRAM: 13BC & WC SERIES

L1

ON/OFF

SWITCH

PRESSURE

CONTROL

ON/OFF

SWITCH

FOR HEATER WIRES

CONDENSING UNIT

HEATER WIRES AROUND

TOP OPENINGS

N

G

8

For customer service, call (800) 733-8829, (800) 773-8821, (989) 773-7981, Fax (989) 773-3210, www.delfield.com

Page 9

CONDENSING UNITS

F13 Series Ice Cream Cabinets Service and Installation Manual

7

See below for

8

part# on receiver tank

1

5

6

4

1/3 H.P. Condensing Units

DELFIELD COPELAND

KEY PART# PART# DESCRIPTION

1 3526749 AS13C1E-1AA-908 compressor

2 2194469 040-C411-83 relay, current

3 2194452 014-0038-04 capacitor, starting

4 2194462 071-C100-38 overload protector

5 — 050-0259-10 motor fan

6 — 066-C223-00 coil, condenser

7 — 083-0122-00 blade, fan

8 — 077-C221-03 receiver tank

Used on all F13WC units and on F13BC44 and F13BC56.

3526710 M4YL-0035-IAA-201 1/3 H.P. low condensing unit 404A

3

2

1/2 H.P. Condensing Units

DELFIELD COPELAND

KEY PART# PART# DESCRIPTION

3526711 FJAF-A050-IAA-201 1/2 H.P. low condensing unit 404A

1 3526760 RS43C1E-IAA-958 compressor

2 2194473 040-0102-00 relay, current

3 2194458 014-0008-57 capacitor, starting

4 2194466 071-0329-15 overload protector

5 — 050-0259-10 motor fan

6 — 066-0303-00 coil, condenser

7 — 083-0130-00 blade, fan

8 — 577-0346-02 receiver tank

Used on F13BC72 only.

For customer service, call (800) 733-8829, (800) 773-8821, (989) 773-7981, Fax (989) 773-3210, www.delfield.com

9

Page 10

F13 Series Ice Cream Cabinets Service and Installation Manual

REPLACEMENT PARTS LISTS

F13WR MODELS

REMOTE

Lid, large 3234188

Leg, 6” S/S, w/mount plate (4) 3234645

Valve, expansion, 1/4 Low, 404A 3516225

ON/OFF switch 2194099

F13WC MODELS

SELF-CONTAINED

Lid, large 3234188

Louver, 14” 356-303-0030

Leg, 6” S/S, w/mount plate (4) 3234645

Condensing unit, 1/3 H.P., Low 404A 3526710

Valve, expansion, 1/4 Low, 404A 3516225

Cord & plug 2183348

ON/OFF switch 2194099

F13BR MODELS

REMOTE

Lid, small 3234187

Pump, chocolate 3234113

Jar, syrup, white “poly” 3234100

Pump, regular syrup 3234114

Cover, lift, lid & spoon 3234051

Jar, crushed fruit 3234099

Leg, 6” S/S, w/mount plate (4) 3234645

Valve, expansion, 1/4 Low, 404A 3516225

ON/OFF switch 2194099

F13BC MODELS

SELF-CONTAINED

Lid, small 3234187

Pump, chocolate 3234113

Jar, syrup, white “poly” 3234100

Pump, regular syrup 3234114

Cover, lift, lid & spoon 3234051

Jar, crushed fruit 3234099

Louver, 14” 356-303-0030

Louver, 18” 356-303-0031

Leg, 6” S/S, w/mount plate (4) 3234645

Condensing unit, 1/3 H.P., Low 404A 3526710

Condensing unit, 1/2 H.P., Low 404A (72” only) 3526711

Valve, expansion, 1/4 Low, 404A 3516225

Valve, EPR 3/8 ODF, inlet/outlet 3516265

Control, low pressure 2193927

Cord & plug 2183348

ON/OFF switch 2194099

10

For customer service, call (800) 733-8829, (800) 773-8821, (989) 773-7981, Fax (989) 773-3210, www.delfield.com

Page 11

F13 Series Ice Cream Cabinets Service and Installation Manual

STANDARD LABOR GUIDELINES TO REPAIR OR REPLACE PARTS ON DELFIELD EQUIPMENT

Advice and recommendations given by Delfield Service Technicians do not constitute or guarantee any special coverage.

•Amaximumof1-hourisallowedtodiagnose a defective component.

•Amaximumof1-hourisallowedforretrieval of parts not in stock.

•Amaximumtravel distance of 100 miles round trip and 2-hours will be reimbursed.

•Overtime,installation/start-up,normalcontroladjustments,generalmaintenance,glassbreakage,freightdamage,and/or

correcting and end-user installation error will not be reimbursed under warranty unless pre-approved with a Service Work

Authorization from Delfield. You must submit the number with the service claim.

LABOR OF 1-HOUR IS ALLOWED TO REPLACE:

•Thermostat • Contactor/Relay

•Transformer • Evaporator/CondenserFanMotorandBlade

•SolenoidCoil • CirculatingFanMotorandBlade

•Hi-limit/ThermalProtectorSwitch • FanDelay/DefrostTerminationSwitch

•CompressorStartComponentsandOverloadProtector • DoorHinges,Locks,andGaskets

•DefrostTimer • CondensateElement

•Thermometer

LABOR OF 2 HOURS TO REPLACE:

•DefrostElement • PressureControl

•SolenoidValve • Locate/RepairLeak

LABOR OF 3 HOURS TO REPLACE:

•EPRorCPRValve • CondenserorEvaporatorCoil

•ExpansionValve

LABOR OF 4 HOURS TO REPLACE

•Compressor

This includes recovery of refrigerant and leak check.

$55.00 maximum reimbursement for refrigerant recovery (includes recovery machine, pump, torch, oil, flux, minor fittings,

solder, brazing rod, nitrogen, or similar fees.)

REFRIGERANTS

•R404AAmaximumof$12.00/lb.or75¢/oz.willbereimbursed.

For customer service, call (800) 733-8829, (800) 773-8821, (989) 773-7981, Fax (989) 773-3210, www.delfield.com

11

Page 12

Mt. Pleasant, MI

Covington, TN

Thank you for choosing Delfield!

Help is a phone call away. Help our team of professional, courteous customer

service reps by having your model number and serial number available at the time

of your call (800) 733-8829.

Model: _______________________ S/N: ______________________

Installation Date: _______________

For a list of Delfield’s authorized parts depots,

visit our website at www.delfield.com

Register your Delfield warranty online.

Go to www.delfield.com under the

service tab to complete.

™

®

Delfield

Delfield reserves the right to make changes in design or specifications without prior notice. ©2013 The Delfield Company. All rights reserved. Printed in the U.S.A.

980S.IsabellaRd.,Mt.Pleasant,MI48858,U.S.A.•(989)773-7981or(800)733-8829•Fax(989)773-3210•www.deleld.com

DM13 02/13

9291452

Loading...

Loading...