Page 1

Shelleymatic

®

by Deleld

Dispensing Models

Service and Installation Manual

Please read this manual completely before attempting to install or operate this equipment! Notify carrier of damage! Inspect all

components immediately.

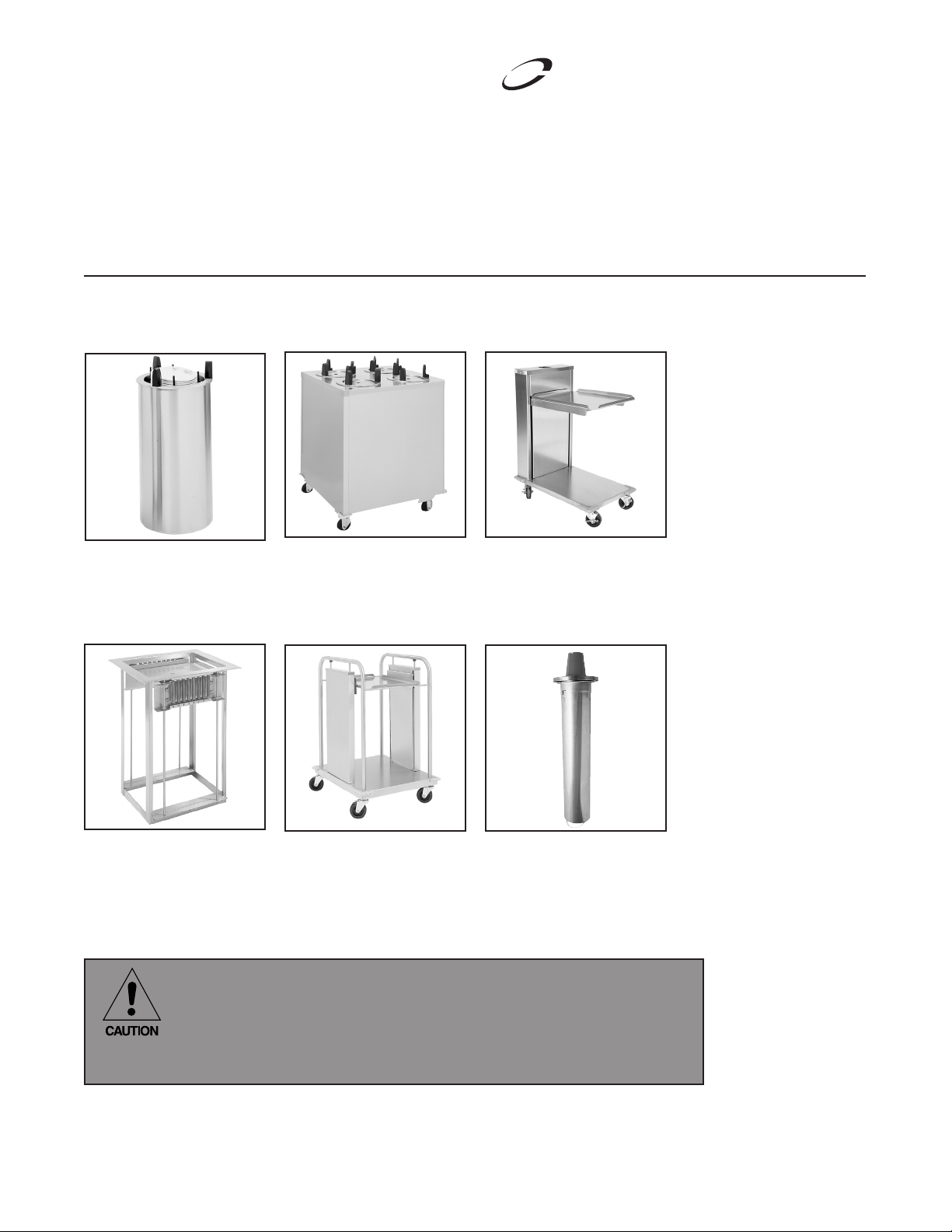

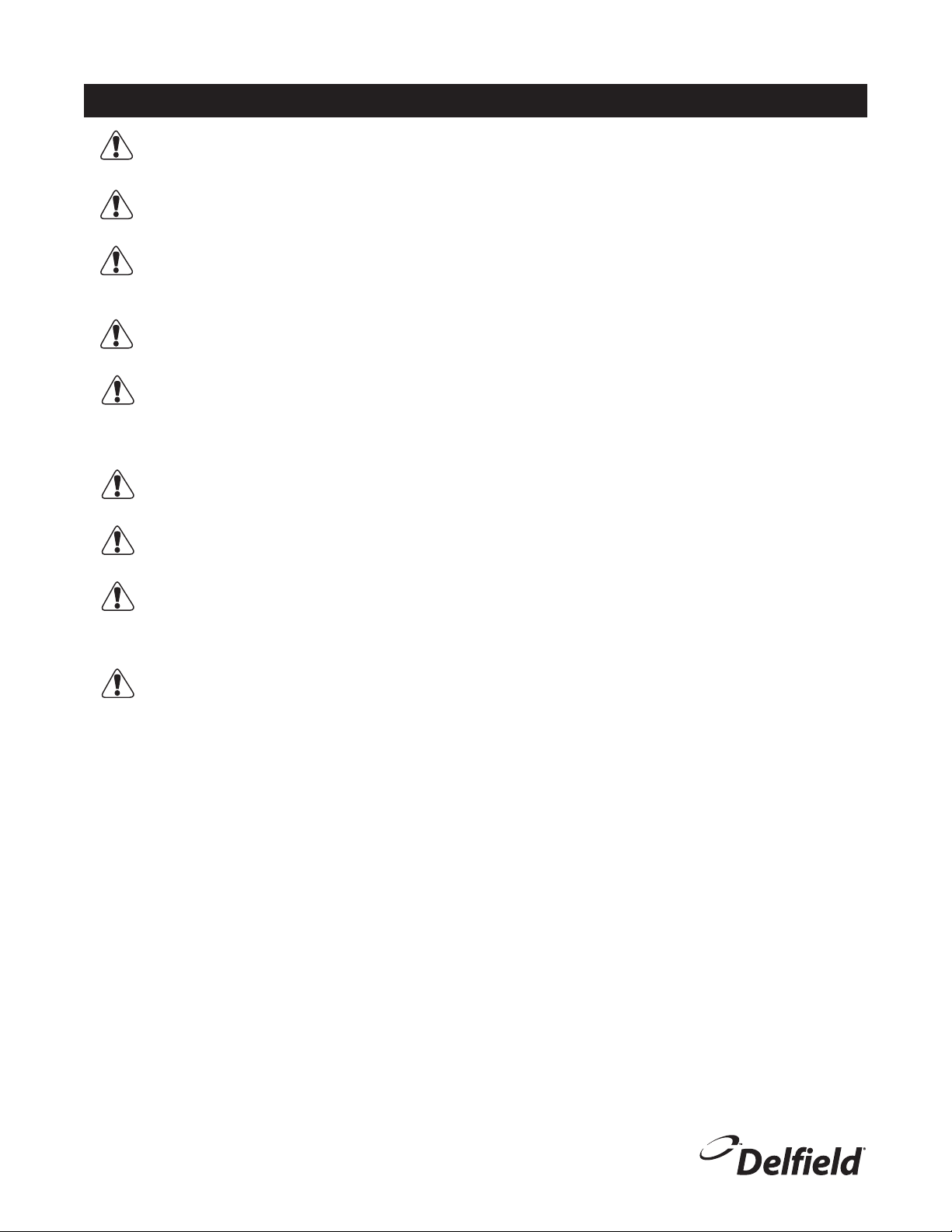

DIS

Drop-In Dish Dispensers

LT

Drop-In Tray Dispensers

CAB

Mobile Enclosed Dish

Dispensers

TT

Mobile Tray/Rack

Dispensers

Mobile Cantilever Tray/

CT

Rack Dispensers

CD

Disposable Cup

Dispensers

Important information

Also in this

manual:

ND

SB

T

T-H

T2

FT2-SN

Please save these instructions!

Read before use

March 2013

Page 2

Dispensing Models Service and Installation Manual

Important Warning And Safety Information

WARNING Read This Manual Thoroughly Before Operating, Installing, Or Performing Maintenance On The Equipment.

WARNING Failure To Follow Instructions In This Manual Can Cause Property Damage, Injury Or Death.

WARNING Do Not Store Or Use Gasoline Or Other Flammable Vapors Or Liquids In The Vicinity Of This Or Any Other

Appliance.

WARNING Unless All Cover And Access Panels Are In Place And Properly Secured, Do Not Operate This Equipment.

WARNING This Appliance Is Not Intended For Use By Persons Who Lack Experience Or Knowledge, Unless They Have

Been Given Supervision Or Instruction Concerning Use Of The Appliance By A Person Responsible For Their

Safety.

WARNING This Appliance Is Not To Be Played With.

WARNING Do Not Clean With Water Jet.

WARNING Do Not Use Electrical Appliances Inside The Food Storage Compartment Of This Appliance.

CAUTION Observe the following:

• Minimum clearances must be maintained from all walls and combustible materials.

• Keep the equipment area free and clear of combustible material.

• Allow adequate clearance for air openings.

• Operate equipment only on the type of electricity indicated on the specification plate.

• Unplug the unit before making any repairs.

• Retain this manual for future reference.

2

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

Page 3

Contents

Receiving & Inspecting Equipment ...........................................3

Serial Number Location ............................................................. 4

Warranty Information ................................................................. 4

Regulatory Certifications ............................................................ 4

Specifications ..........................................................................5-8

Installation ................................................................................. 9

Operation .............................................................................10-11

Adjusting Self-Leveling Dispenser ......................................12-13

Maintenance ............................................................................. 14

Troubleshooting Reference Chart ............................................15

Wiring Diagrams ...................................................................... 16

Replacement Parts List .......................................................17-18

Dispensing Models Service and Installation Manual

Standard Labor Guidelines ......................................................19

Receiving And Inspecting The Equipment

Even though most equipment is shipped crated, care should

be taken during unloading so the equipment is not damaged

while being moved into the building.

1. Visually inspect the exterior of the package and skid or

container. Any damage should be noted and reported to

the delivering carrier immediately.

2. If damaged, open and inspect the contents with the

carrier.

3. In the event that the exterior is not damaged, yet upon

opening, there is concealed damage to the equipment

notify the carrier. Notification should be made verbally

as well as in written form.

4. Request an inspection by the shipping company of the

damaged equipment. This should be done within 10

days from receipt of the equipment.

5. Check the lower portion of the unit to be sure the casters

6. Retain all crating material until an inspection has been

Uncrating the Equipment

First cut and remove the banding from around the crate.

Remove the front of the crate material, use of some tools will

be required. If the unit is on legs remove the top of the crate

as well and lift the unit off the skid. If the unit is on casters it

can be rolled off the skid.

are not bent.

made or waived.

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

3

Page 4

Dispensing Models Service and Installation Manual

Serial Number Location

Dish Dispensers: The serial number is located on the

dispenser housing.

Tray & Rack Dispensers: The serial number is located on the

back of the unit or the underside of the flange.

Always have the serial number of your unit available when calling

for parts or service.

©2013 The Delfield Company. All rights reserved. Reproduction without written

permission is prohibited. “Delfield” & “Shelleymatic” are registered trademarks of

The Delfield Company.

Warranty Information

Visit http://www.delfield.com/minisite/service/warranty_info to:

• Register your product for warranty.

• Verify warranty information.

• View and download a copy of your warranty.

Regulatory Certifications

All models are certified by:

National Sanitation Foundation (NSF)

Electrical models are also certified by:

Underwriters Laboratories (UL)

Underwriters Laboratories of Canada (ULC)

4

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

Page 5

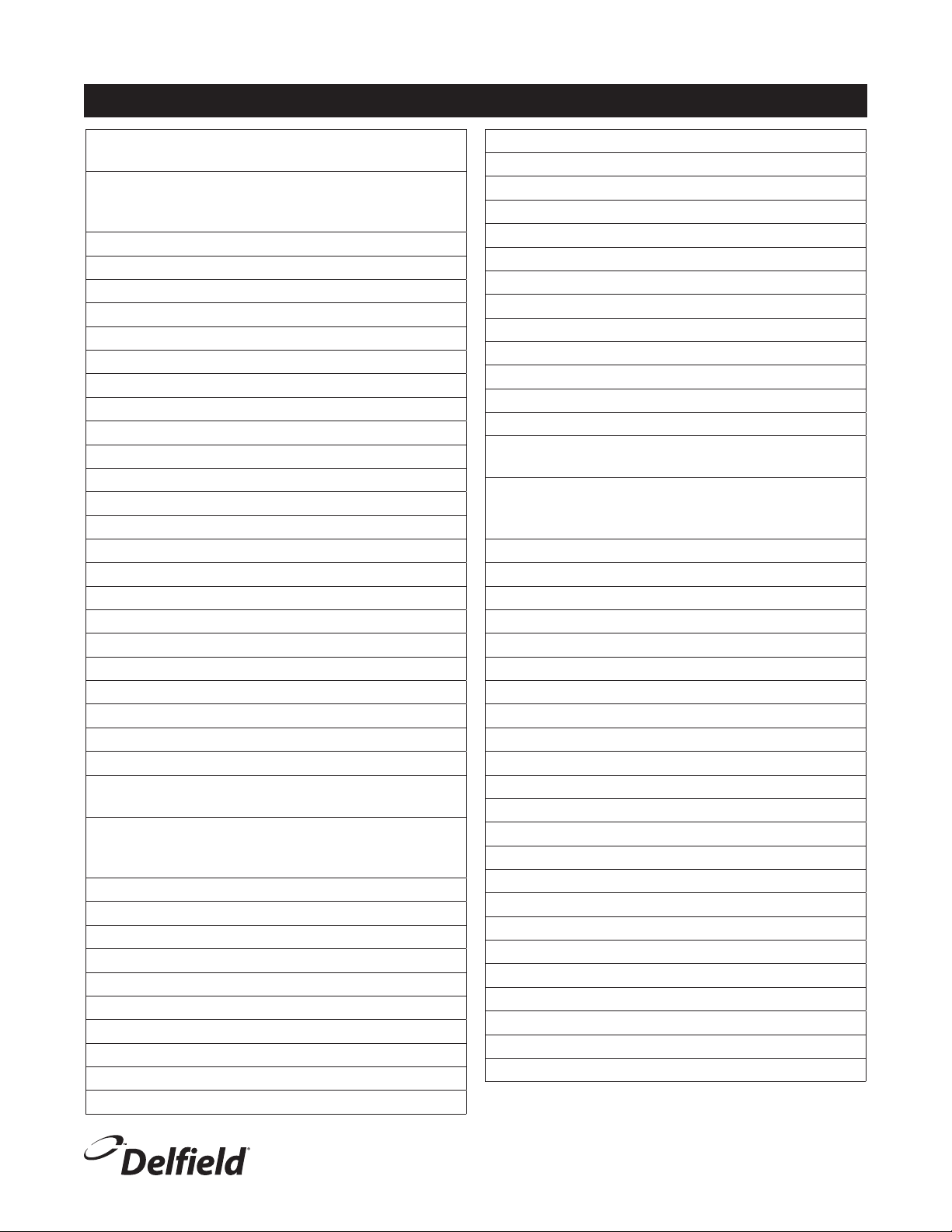

Specifications

Dish Dispensers — Mobile Two Stack

Max.

Dish

Model

CAB2-500 5.00” N/A N/A N/A

CAB2-575 5.75” N/A N/A N/A

CAB2-650 6.50” N/A N/A N/A

CAB2-725 7.25” N/A N/A N/A

CAB2-813 8.12” N/A N/A N/A

CAB2-913 9.12” N/A N/A N/A

CAB2-1013 10.12” N/A N/A N/A

CAB2-1200 12.00” N/A N/A N/A

CAB2-1450 14.50” N/A N/A N/A

CAB2-500ET 5.00” 120 11.0 5-20P

CAB2-575ET 5.75” 120 11.0 5-20P

CAB2-650ET 6.50” 120 11.0 5-20P

CAB2-725ET 7.25” 120 11.0 5-20P

CAB2-813ET 8.12” 120 11.0 5-20P

CAB2-913ET 9.12” 120 11.0 5-20P

CAB2-1013ET 10.12” 120 11.0 5-20P

CAB2-1200ET 12.00” 120 11.0 5-20P

CAB2-1450ET 14.50” 120 11.0 5-20P

CAB2-813QT 8.12” 120 11.0 5-20P

CAB2-913QT 9.12” 120 11.0 5-20P

CAB2-1013QT 10.12” 120 11.0 5-20P

CAB2-1200QT 12.00” 120 11.0 5-20P

CAB2-1450QT 14.50” 120 11.0 5-20P

Dish Dispensers — Mobile Three Stack

Model

CAB3-500 5.00” N/A N/A N/A

CAB3-575 5.75” N/A N/A N/A

CAB3-650 6.50” N/A N/A N/A

CAB3-725 7.25” N/A N/A N/A

CAB3-813 8.12” N/A N/A N/A

CAB3-913 9.12” N/A N/A N/A

CAB3-1013 10.12” N/A N/A N/A

CAB3-1200 12.00” N/A N/A N/A

CAB3-1450 14.50” N/A N/A N/A

CAB3-500ET 5.00” 208 10.6 6-20P

Diameter

Max.

Dish

Diameter

Voltage

(60hz,

1Ph) Amps

Voltage

(60hz,

1Ph) Amps

Nema

Plug

Nema

Plug

Dispensing Models Service and Installation Manual

CAB3-575ET 5.75” 208 10.6 6-20P

CAB3-650ET 6.50” 208 10.6 6-20P

CAB3-725ET 7.25” 208 10.6 6-20P

CAB3-813ET 8.12” 208 10.6 6-20P

CAB3-913ET 9.12” 208 10.6 6-20P

CAB3-1013ET 10.12” 208 10.6 6-20P

CAB3-1200ET 12.00” 208 10.6 6-20P

CAB3-1450ET 14.50” 208 10.6 6-20P

CAB3-813QT 8.12” 208 10.6 6-20P

CAB3-913QT 9.12” 208 10.6 6-20P

CAB3-1013QT 10.12” 208 10.6 6-20P

CAB3-1200QT 12.00” 208 10.6 6-20P

CAB3-1450QT 14.50” 208 10.6 6-20P

Dish Dispensers — Mobile Four Stack

Max.

Dish

Model

CAB4-500 5.00” N/A N/A N/A

CAB4-575 5.75” N/A N/A N/A

CAB4-650 6.50” N/A N/A N/A

CAB4-725 7.25” N/A N/A N/A

CAB4-813 8.12” N/A N/A N/A

CAB4-913 9.12” N/A N/A N/A

CAB4-1013 10.12” N/A N/A N/A

CAB4-1200 12.00” N/A N/A N/A

CAB4-1450 14.50” N/A N/A N/A

CAB4-500ET 5.00” 208 14.2 6-20P

CAB4-575ET 5.75” 208 14.2 6-20P

CAB4-650ET 6.50” 208 14.2 6-20P

CAB4-725ET 7.25” 208 14.2 6-20P

CAB4-813ET 8.12” 208 14.2 6-20P

CAB4-913ET 9.12” 208 14.2 6-20P

CAB4-1013ET 10.12” 208 14.2 6-20P

CAB4-1200ET 12.00” 208 14.2 6-20P

CAB4-1450ET 14.50” 208 14.2 6-20P

CAB4-813QT 8.12” 208 14.2 6-20P

CAB4-913QT 9.12” 208 14.2 6-20P

CAB4-1013QT 10.12” 208 14.2 6-20P

CAB4-1200QT 12.00” 208 14.2 6-20P

CAB4-1450QT 14.50” 208 14.2 6-20P

Diameter

Voltage

(60hz,

1Ph) Amps

Nema

Plug

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

5

Page 6

Dispensing Models Service and Installation Manual

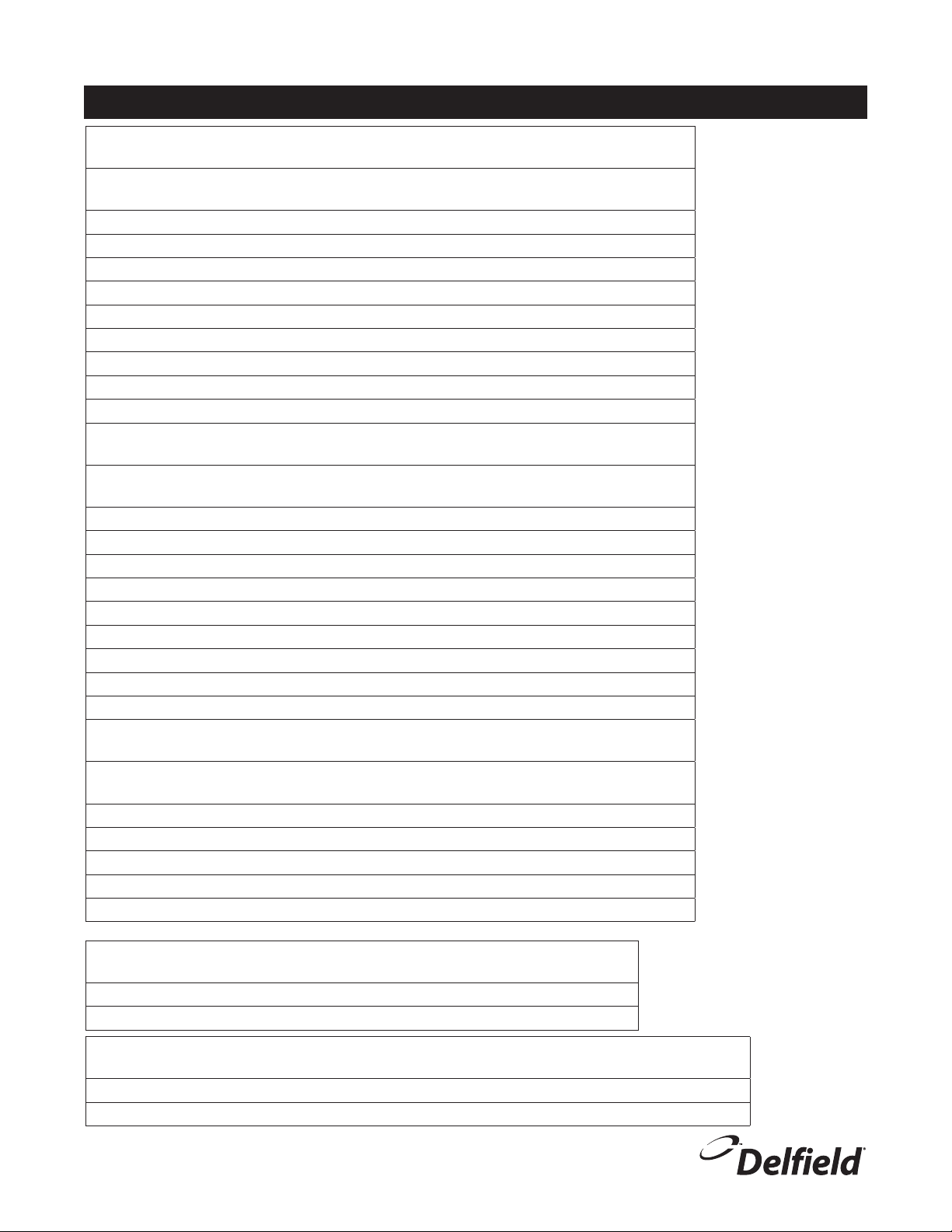

Specifications

Dish Dispensers — Drop-In

Flange

Model

DIS-500 8.37” 7.75” 5.00” N/A N/A N/A

DIS-575 9.12” 8.50” 5.75” N/A N/A N/A

DIS-650 9.87” 9.25” 6.50” N/A N/A N/A

DIS-725 10.62” 10.00” 7.25” N/A N/A N/A

DIS-813 11.50” 10.87” 8.12” N/A N/A N/A

DIS-913 12.50” 11.87” 9.12” N/A N/A N/A

DIS-1013 13.50” 12.87” 10.12” N/A N/A N/A

DIS-1200 15.37” 14.75” 12.00” N/A N/A N/A

DIS-1450 17.88” 17.25” 14.50” N/A N/A N/A

Dish Dispensers — Drop-In/Heated

Model

DIS-500-ET 8.37” 7.75” 5.00” 120 5.5 5-15P

DIS-575-ET 9.12” 8.50” 5.75” 120 5.5 5-15P

DIS-650-ET 9.87” 9.25” 6.50” 120 5.5 5-15P

DIS-725-ET 10.62” 10.00” 7.25” 120 5.5 5-15P

DIS-813-ET 11.50” 10.87” 8.12” 120 5.5 5-15P

DIS-913-ET 12.50” 11.87” 9.12” 120 5.5 5-15P

DIS-1013-ET 13.50” 12.87” 10.12” 120 5.5 5-15P

DIS-1200-ET 15.37” 14.75” 12.00” 120 5.5 5-15P

DIS-1450-ET 17.88” 17.25” 14.50” 120 5.5 5-15P

Diameter

Flange

Diameter

Cutout

Diameter

Cutout

Diameter

Dish

Diameter

Dish

Diameter

Voltage

(60Hz, 1Ph) Amps

Voltage

(60Hz, 1Ph) Amps

Nema

Plug

Nema

Plug

Dish Dispensers — Drop-In/Heated/Quick Temp

Flange

Model

DIS-813-QT 11.50” 10.87” 8.12” 120 5.5 5-15P

DIS-913-QT 12.50” 11.87” 9.12” 120 5.5 5-15P

DIS-1013-QT 13.50” 12.87” 10.12” 120 5.5 5-15P

DIS-1200-QT 15.37” 14.75” 12.00” 120 5.5 5-15P

DIS-1450-QT 17.88” 17.25” 14.50” 120 5.5 5-15P

Disposable Cup Dispensers

Model Flange Diameter Cutout Diameter Dish Diameter

CD 7.38” 5.12” 2.50”-4.63”

Bread Dispensers

Model Flange Diameter Cutout Diameter Bread Dimension Ship Weight

SB-1 6.50” X 6.50” 5.87” X 5.87" 5.25” X 5.25” 15lbs (7kg)

6

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

Diameter

Cutout

Diameter

Dish

Diameter

Voltage

(60Hz, 1Ph) Amps

Nema

Plug

Page 7

Dispensing Models Service and Installation Manual

Specifications, continued

Mobile Cantilevered Tray and Rack Dispensers

Maximum

Model

CT-1216 12” x 16” 106lbs/48kg CT-1622 16” x 22” 159lbs/72kg

CT-1221 12” x 21” 132lbs/60kg CT-1826 18” x 26” 165lbs/75kg

CT-1418 14” x 18” 145lbs/66kg CT-2020 20” x 21” 168lbs/76kg

CT-1422 14” x 22” 145lbs/66kg

Napkin Dispensers

Model Cutout Dimension Napkin Dimension Ship Weight

ND-45 5.62” X 7.00” 4.00” X 5.37” 12lbs (5kg)

ND-47 5.87” X 8.75” 4.25” X 7.12” 12lbs (5kg)

ND-48 6.12” X 9.62” 4.50” X 8.00” 12lbs (5kg)

ND-57 6.75” X 8.62” 5.12” X 7.00” 12lbs (5kg)

ND-59 6.37” X 10.37” 4.75” X 8.75” 12lbs (5kg)

ND-67 8.5” X 8.75” 6.87” X 7.12” 12lbs (5kg)

Tray Size Ship Weight Model

Maximum

Tray Size Ship Weight

Mobile Enclosed Tray And Rack Dispensers

Model Maximum Tray Size Ship Weight

T-1014 10" x 15" (25.4cm x 38.1cm) 150lbs/68kg

T-1216 12" x 16" (30.5cm x 40.6cm) 153lbs/69kg

T-1221 12" x 21" (30.5cm x 53.3cm) 162lbs/74kg

T-1418 14" x 18" (35.6cm x 45.7cm) 153lbs/69kg

T-1422 14" x 22" (35.6cm x 55.9cm) 162lbs/74kg

T-1622 16" x 22" (40.6cm x 55.9cm) 177lbs/80kg

T-1826 18" x 26" (45.7cm x 66.0cm) 210lbs/95kg

T-2020 20" x 21" (50.8cm x 53.3cm) 175lbs/79kg

T2-1014 10" x 15" (25.4cm x 38.1cm) 177lbs/80kg

T2-1216 12" x 16" (30.5cm x 40.6cm) 177lbs/80kg

T2-1221 12" x 21" (30.5cm x 53.3cm) 185lbs/84kg

Heated Mobile Enclosed Tray And Rack Dispensers

Model Capacity Amp Ship Weight Nema Plug

T-1221H 12.00” X 21.00” 6.34 127lbs (58kg) 5-15p

T-1418H 14.00” X 18.00” 6.34 155lbs (70kg) 5-15p

T-1422H 14.00” X 22.00” 12.7 155lbs (70kg) 5-20p

T-1826H 18.00” X 26.00” 12.7 195lbs (88kg) 5-20p

T-2020H 20.00” X 21.00” 12.7 185lbs (84kg) 5-20p

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

7

Page 8

Dispensing Models Service and Installation Manual

Specifications, continued

Two Stack, Heated Mobile Enclosed Tray And Rack Dispensers

T2-1221H 12.00” X 21.00” 12.7 185 5-20p

Mobile Open Frame Tray And Rack Dispensers

Model Maximum Tray Size Ship Weight

TT-1014 11”x15” 102lbs (46kg)

TT-1216 12”x16” 102lbs (46kg)

TT-1221 12”x21” 105lbs (48kg)

TT-1418 14”x18” 102lbs (46kg)

TT-1422 14”x22” 105lbs (48kg)

TT-1622 16”x22” 106lbs (48kg)

TT-1826 18”x26” 111lbs (50kg)

TT-2020 20”x21” 111lbs (50kg)

Two Stack, Mobile Open Frame Tray And Rack Dispensers

TT2-1014 11”x15” 113lbs (51kg)

TT2-1216 12”x16” 165lbs (75kg)

TT2-1221 12”x21” 163lbs (74kg)

TT2-1418 14”x18” 165lbs (75kg)

TT2-1422 14”x22” 163lbs (74kg)

TT2-1622 16”x22” 170lbs (77kg)

TT2-1826 18”x26” 179lbs (81kg)

TT2-2020 20”x21” 179lbs (81kg)

Two Stack, Mobile Open Frame Tray And Rack Dispensers With

Silverware Bin And Napkin Dispensers

Model Maximum Tray Size Ship Weight

FT2-SN-1216 12.00” X 16.00” 289lbs (131kg)

FT2-SN-1418 14.00” X 18.00” 298lbs (131kg)

FT2-SN-1622 16.00” X 22.00” 306lbs (139kg)

Tray/Rack Dispensers

Model Cutout Size Model Cutout Size

LT-1014 11.75” X 21.00” LT-1826 27.75” X 24.00”

LT-1216 17.75” X 18.00” LT-2020 22.75” X 26.00”

LT-1221 22.75” X 18.00” LT2-1014 23.75” X 21.00”

LT-1418 19.75” X 20.00” LT2-1216 27.75” X 22.00”

LT-1422 23.75” X 20.00” LT2-1221 27.75” X 27.00”

LT-1622 23.75” X 22.00”

8

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

Page 9

DARNGE

Installation: Dish Dispensers

Dispensing Models Service and Installation Manual

Location

Dish dispensers are intended for indoor use only. Drop-in

units require a counter cutout of a specific size for proper

fit. Refer to specification data for the proper dimensions.

Heated units must have minimum 1” (2.5cm) air

gap between the bottom of the dispensing tube and

any surface or objects below. Make sure the tube

will have proper clearance when installing it into a

counter or another piece of equipment.

Stabilizing

CAB models are supplied with casters for your convenience, for

ease of cleaning underneath and mobility.

The unit must be installed in a stable condition with

the front wheels locked. Locking the front casters

after installation is the owner’s and operator’s

responsibility.

Electrical Connection

All heated DIS and CAB models are tested at the factory to

assure proper operation.

Refer to the amperage data, the serial tag, your local or the

National Electrical Code to be sure the unit is connected to the

proper power source. A protected circuit of the correct voltage

and amperage must run for connection of the line cord.

DIS models plug into a wall receptacle when used as drop-in

models; if they are grouped together in a CAB model, all of the

individual DIS power cords are plugged into the receptacle in the

CAB cabinet. The master power cord on CAB models plugs into

a wall receptacle.

The unit must be disconnected from the power

source whenever performing service or maintenance

functions.

Installation: Napkin/Cup Dispensers

Dispensers are intended for indoor use only. Napkin and cup

units require a counter cutout of a specific size for proper fit.

Refer to specification data for the proper dimensions.

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

9

Page 10

Dispensing Models Service and Installation Manual

AR

AR

Tube

Frame

Carrier

Bracket

Springs

H

= High Tension Spring

M

= Medium Tension Spring

L

= Low Tension Spring

Typical example of spring placement.

Note that each of the three sections

has the same number and type of

springs and that the springs are

installed in the same order in each

section.

Operation Dish Dispensers

Field adjustment

The dispensing height may be adjusted, by following these

instructions in order:

Always wear safety glasses when adjusting

your dispenser. Springs under tension may

W ARE

D

1) Lock brakes on mobile units before beginning.

2) Unload the dispenser. Remove dispensers from the unit

3) There are minimum of six springs per dispenser. When

recoil when released.

If adjusting a heated model, unplug the unit. Allow

the unit to cool completely before handling.

NGE

by grasping the black plastic guide posts and lifting the

dispenser completely out of the unit.

adjusting, make sure each section has the same number

and size of springs connected to the tube and make sure the

springs are attached in the same order in each section (see

diagram 1). This will prevent the load of dishes from binding.

spring at a time, unhooking the bottom loop out of the carrier

bracket first, the unhooking the top loop from the tube frame.

(see diagram 2). Remove as many springs as necessary.

6) If level is appropriate, return tube to cart or counter. If

spring adjustment does not position carrier properly, repeat

procedure trying different springs. If this does not work,

a different set of springs may be required. To order call

Delfield’s Parts and Service Department.

Spring Requirements

Spring Tension

Model

Light Medium Heavy

DIS-500, 575, 650 3 3 0

DIS-725 0 6 0

DIS-813 3 3 3

DIS-913 3 6 3

DIS-1013 6 6 3

DIS-1200 6 6 6

DIS-1450 6 6 6

(diagram 1)

4) If the dispensing

height is too low, add

springs or replace

current springs with

higher tension springs

(springs with higher

tension may be

ordered from Delfield’s

Parts and Service

Department). Gently

engage one spring at

a time by hooking

the top loop of

Dish dispenser spring attachments

(diagram 2)

the spring into the bracket on the tube frame. Then hook

the bottom loop of the spring into the carrier bracket (see

diagram 2). Add as many springs as necessary.

5) If the dishes are resting too high in the unit, remove springs

or replace current springs with lower tension springs

(springs with lower tension may be ordered from Delfield’s

Parts and Service Department). Gently disengage one

10

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

Loading instructions

After adjusting for dispensing height, you are ready to load

your dishes.

Only load a manageable stack of dishes at a time —

approximately 4” (10.2cm) to 5” (12.7cm). Each DIS model

dispensing tube will accommodate a 26” (66cm) stack of plates

or bowls.

Keep fingers clear from the edge of

the opening

D

NGE

If the stack is over the guide posts and is bottomed out, it is

full. If stack is over guide posts and not bottomed out (the

stack will bounce up and down), adjust the springs. See “Field

adjustment” instructions.

Temperature adjustment – ET & QT models only

ET (even-temp) models have either a 400 or 700 watt

heating element and an adjustable thermostat. The factory

setting for thermostat is “A” which gives an operating

temperature of about 165°F (74°C) and effective plate

temperatures of between 110°F (43°C) to 120°F (49°C)

after about two to three hours of pre-warming.

QT (quick-temp) models have a 700 watt heating element

and an adjustable thermostat. The factory setting for

thermostat is “E” which gives an operating temperature

of about 205°F (96°C) and effective plate temperatures of

between 130°F (54°C) to 150°F (66°C) after about two to

three hours of pre-warming.

(Continued on the next page.)

Page 11

DARNGE

Operation: Dish Dispensers, continued

The thermostat is located on the bottom of the unit near

the fan motor. Use the following directions to adjust.

Unplug the unit and allow the unit to cool

completely before handling.

1) Lock brakes on mobile units before beginning.

2) Unload the dispenser. Remove dispensers from the unit

by grasping the black plastic guide posts and lifting the

dispenser completely out of the unit. It is not necessary to

remove the steel jacket from the dispensing tube.

3) Turn the unit on its side.

4) Remove filter from

bottom of unit. It

is not necessary

to remove the

perforated screen.

The screen has

access holes in it to

allow adjustment

of the thermostat.

The screen is

shown removed in

Location of thermostat adjustment screw

diagram 3 to show

the location of the thermostat adjustment screw only.

5) Use a small screw-driver to reach the adjustment screw

located under the perforated screen (see diagram 3). Turn

the screw to the desired setting based on the “thermostat

settings chart” shown below.

6) Reattach the filter before operating the unit again.

(diagram 3)

Dispensing Models Service and Installation Manual

Heated Unit Thermostat Settings

Temperature Setting Operating Temperature

A

B

C

D

E

165°F/ 74°C

175°F/ 79°C

185°F/ 85°C

195°F/ 91°C

205°F/ 96°C

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

11

Page 12

Dispensing Models Service and Installation Manual

CAUTION

Adjusting Self-Leveling Dispensers, Models FT2, TT & LT

Tools Needed: One small flat head screw driver;

One Phillips head screw driver

1. Always wear safety glasses when adjusting your dispenser.

Also, lock brakes on mobile units before beginning.

2. Unload dispenser and remove stainless steel load tray by

lifting straight up and set it aside (see fig. 1). For Models LT

skip to step #6.

(figure 1) Sample unit

3. Use small regular screw driver to loosen each retainer

mounted on stainless steel rod at top of each elevator

housing.

4. To remove

elevator housing,

lift housing

straight up to

clear the stud on

unit base. Then

gently swing the

bottom of the

housing towards

the inside of the

unit and pull

housing out of

the unit (see fig.

2). Lay housing

on flat surface.

5. Use Phillips head

screw driver to remove

front panel on the

elevator housing (see

fig. 3).

6. If carrier is riding

too high, you need

to remove springs.

With carrier all the

way to the top, gently

disengage one spring

at a time, unhooking

bottom loop out of

(figure 3) Remove front panel

carrier bracket (see fig.

4). Remove as many

springs as necessary.

If carrier is riding too

low, you need to add

springs. With carrier

all the way to the top,

gently engage one

spring at a time by

hooking bottom loop

of spring into carrier

bracket. Add as many

springs as necessary.

7. When finished, put

(figure 4) Remove or add springs

elevator housing back in unit (except on models LT) and

put stainless steel load tray back on elevator housings.

Load unit to test dispensing level. If spring adjustment

does not position carrier properly, repeat procedure #6

trying different springs. If this does not work, a different

set of springs may be required. To order, call The Delfield

Parts and Service Department.

8. If level is appropriate, put front panels back on and

tighten retainer.

Dispenser should not be operated with front

panels off elevator housing.

NOTE: When adjusting the elevators make sure each have the

same number and size of springs connected to the carrier on

both sides. This will prevent the load tray from binding.

12

(figure 2) Remove elevator housing

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

Page 13

Dispensing Models Service and Installation Manual

CAUTION

Adjusting Self-Leveling Dispensers, Model CT

Tools Needed: One small flat head screw driver;

One Phillips head screw driver

1. Always wear safety glasses when adjusting your dispenser.

Also, lock brakes on mobile units before beginning.

2. Unload dispenser.

3. Use screw driver to remove

two screws, one on each

side of the elevator housing.

4. Remove cover and slide

front panel off.

5. If carrier is riding too

high, you need to remove

springs. With carrier all

the way to the top, gently

disengage one spring at a

time, unhooking bottom

loop out of carrier bracket.

Remove as many springs

as necessary.

If carrier is riding too low,

you need to add springs.

With carrier all the way to

the top, gently engage one

spring at a time by hooking

bottom loop of spring into

carrier bracket. Add as

many springs as necessary.

6. Load unit to test dispensing level. If spring adjustment

does not position carrier properly, repeat step #5 trying

different springs. If this does not work, a different set of

springs may be required. To order, call The Delfield Parts

and Service Department.

7. If level is appropriate, replace front panel and cover.

Secure with screws.

Dispenser should not be operated with front panel

off elevator housing.

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

13

Page 14

Dispensing Models Service and Installation Manual

AR

DARNGE

Maintenance

Dish Dispensers

Heated units must be disconnected from the main

power source and allowed to cool down before

D

Lift the dispenser out of the counter or CAB cart by grasping

the black dish guides and lifting straight up and out. Remove

any debris that may be in the assembly with a damp cloth.

Clean the stainless steel by using a soft cloth, soap and warm

water. If this is not sufficient, try ammonia and water or a nonabrasive liquid cleaner. Rub with the grain of the stainless steel

to avoid marring the finish. When cleaning is completed, insert

the dispenser assembly back into the counter or CAB cart.

The bottom rails on the CAB cart should be cleaned occasionally.

They may be accessed most easily through the bottom of the

unit.

cleaning. Cords on DIS models used as drop-ins

NGE

into a counter or into another piece of equipment

are directly connected to the power source. On CAB

units there is a cord from each individual DIS tube

to a central receptacle on the cart and a separate

cord from that receptacle to the main power

source. Never hose down units with water.

Do not use abrasive cleaner because it will scratch

the stainless steel and plastic.

Mobile & Built In Dispensers

The interior and exterior can be cleaned using soap and swarm

water. If this is not sufficient, try ammonia and water or a nonabrasive liquid cleaner. When cleaning the exterior, always

rub with the “grain” of the stainless steel to avoid marring the

finish. Do not use an abrasive cleaner because it will scratch

the stainless steel and plastic.

14

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

Page 15

Dispensing Models Service and Installation Manual

Troubleshooting Reference Chart: Heated Dish Dispensers

Problem Possible Cause Solutions

Power cord disconnected Check power source to unit and receptacle at the

underside of the cabinet. Reset GFCI receptacle

GFCI tripped

position

No Heat

Not Hot Enough

Too Hot

Noisy

Disconnected ON/OFF switch or ON/OFF switch in

the OFF position

Defective heating element Replace element

Air circulating fan defective or blocked Replace motor, or remove blockage from fan

Unit plugged into incorrect voltage Check voltage supply and compare to unit’s voltage

Thermostat set too low Adjust thermostat to a higher setting

Air circulating fan partially blocked Remove blockage

Not waiting long enough for pre-heating 90 minutes is a good average pre-heat on DIS

Thermostat set too high Adjust thermostat to a lower setting

Thermostat defective Replace thermostat

Defective air circulating motor Replace motor

Obstruction at air circulating motor Free obstruction

Replace ON/OFF switch; turn ON/OFF switch to on

position

rating

models

Loose fan blade Tighten blade

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

15

Page 16

Dispensing Models Service and Installation Manual

Motor

Cord &

Plug

Thermostat Limit

Heater

Wiring Diagram: DIS Models & T-H Models

Cord &

Plug

On/off

Switch

Thermostat Limit

Motor

Heater

Wiring Diagram: CAB Models

DIS

DIS

CAB Models Contain

Several DIS Units Wired Together

DIS

DIS

16

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

Page 17

Replacement Parts List

Models DIS

All units

6230314 Filter, air, 6” diameter (DDS)

6230244 Guide post

6150201 Spring, heavy tension

6150203 Spring, light tension

6150202 Spring, medium tension

500 units

6200121 Spinning head

6970011 Wire head

575 units

6200122 Spinning head

6970012 Wire head

650 units

6200123 Spinning head

6970013 Wire head

725 units

6200124 Spinning head

6970014 Wire head

813 units

6200125 Spinning head

6970015 Wire head

913 units

6200126 Spinning head

6970016 Wire head

1013 units

6200127 Spinning head

6970017 Wire head

1200 units

6200128 Spinning head

6970018 Wire head

1450 units

6200129 Spinning head

6970026 Wire head

Dispensing Models Service and Installation Manual

Model DIS-ET, DIS-QT

All units

6190085 Cord with plug, NEMA 5-15P 5’

6230314 Filter, air, 6” diameter

6230244 Guide post

6160024 Motor, 115V 50-60Hz

6150201 Spring, heavy tension

6150203 Spring, light tension

6150202 Spring, medium tension

6190180 Switch, high-limit, 245°F

2190154 Switch rocker

6190181

T-stat, automatic 165°F - 205°F

500/ 575/ 650/ 725 ET units

6160008 Fan blade, 3” diameter

6190250 Heating element, 120V/327W

000-BHM-0030

Heating module

813/ 913/ 1013/ 1200/ 1450 ET & QT

units

6160007 Fan blade, 4” dia, ET &QT

6190269

000-BHM-0031

Htg element, 120V/700W,

Heating module, ET & QT models

ET &

Model CAB, CAB-ET,

CAB-QT

All units

3234180 Caster, 4” with brake

6190085 Cord with plug, NEMA 5-15P 5’

6230314 Filter, air, 6” diameter

6230244 Guide post

6160024 Motor, 115V 50-60Hz

6150203 Spring, light tension

6150202 Spring, medium tension

6190180 Switch, high-limit, 245°F

2190154 Switch rocker

6190181 T-stat, automatic 165°F - 205°F

500/ 575/ 650/ 725 ET units

6160008 Fan blade, 3” diameter

6190250 Heating element, 120V/327W

000-BHM-0030

Heating module

813/ 913/ 1013/ 1200/ 1450 ET & QT

units

6160007 Fan blade, 4” dia, ET &QT models

6190269

000-BHM-0031

Htg element, 120V/700W,

Heating module, ET & QT models

CAB2-ET & CAB2-QT units

2183347 Cord with plug, NEMA 5-20P 9’

CAB3-ET, CAB4-ET, CAB3-QT, CAB4-QT

units

6190079 Cord with plug, NEMA 6-20P 9’

Model SB

6150024 Dish spring

Model ND

ND-45

QT

223-BGA-0030

6150203 Extension spring

313-B38-0030 Head

ND-47

223-BGA-0031

6150203 Extension spring

313-B38-0031 Head

ND-48

223-BGA-0032

6150203 Extension spring

313-B38-0032 Head

ND-57

223-BGA-0033 Cover

6150203 Extension spring

313-B38-0033 Head

ND-59

223-BGA-0034 Cover

6150203 Extension spring

313-B38-0034 Head

ND-67

223-BGA-0035 Cover

6150203 Extension spring

313-B38-0035 Head

Cover

Cover

Cover

ET &

QT

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

17

Page 18

Dispensing Models Service and Installation Manual

Replacement Parts List, continued

Model CT Series

6230068 Bearing

6230170 Bumper, corner, small

3234180 Caster, 4”

6150206 Extension spring

CT-1216

000-BLD-0030 Carrier assembly, 12.50 x 16.50

CT-1221

000-BLD-0031 Carrier assembly, 12.50 x 21.50

CT-1418

000-BLD-0032 Carrier assembly, 14.56 x 18.56

CT-1422

000-BLD-0033 Carrier assembly, 14.50 x 22.50

CT-1622

000-BLD-0034 Carrier assembly, 16.56 x 22.56

CT-1826

000-BLD-0035 Carrier 18.56 x 26.56

CT-2020

000-BLD-0036 Carrier assembly, 20.56 x 21.56

Model FT2-SN All units

6320007 Bearing

6230218 Caster, 4”

6230170 Corner bumper

000-546-0038 Elevator assembly, large

6150203 Extension spring .16

6150202 Extension spring .28

6150201 Extension spring .58

6230024 Silverware container, Plastic

3234052 Silverware container, S/S

FT2-SN-1216

372-395-0030

Carrier 1216

FT2-SN-1418

372-395-0032

Carrier, 1418

FT2-SN-1622

372-395-0035

Carrier 1622

Model T & T2 Series

T-1014, All T2 Models

6320007

3234180

6150201

T-1216 through T-2020

6320007

3234180

6150202

Bearing, 0.50”ID

Caster, 4”, Swivel, with Break

Spring, Extension, 0.58lbs/In

Bearing, 0.50”ID

Caster, 4”, Swivel, with Break

Spring, Extension, 0.28lbs/In

Model T-H & T2-H Series

All Models

6320007

6160007

3234180

6190269

6160024

6190180

2190154

6190181

Bearing, 0.50”ID

Blade, Fan 4”Dia, Alum

Caster, 4”, Plate, Swivel, Break

Element, Heating, 120V/700W

Motor, 115V, 50/60Hz

Switch, Hi-limit, 245F

Switch, Rocker, 20A/125V, 15A/250V

Thermostat

T-1221H, T-1418H

2183348

Cord Assembly, 14/3 W/Nema 5-15P

T-1422H, T-1826H, T-2020H, T2-1221H

2183347

Cord Assembly, 12/3 W/Nema 5-20P

All T-H Models

6150202

Spring, Extension, 0.28lbs/in

T2-1221H

6150201

Spring, Extension, 0.58lbs/in

Model TT Series

All Models

6320007

6230218

6150201

Bearing, 0.50”ID

Caster, 4”, Stem, Swivel Break

Spring, Extension, 0.58lbs/in

18

Model LT & LT2 Series

LT-1014, All LT2 Models

6320007

6150201

LT-1216 through LT-2020

6320007

6150202

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

Bearing, 0.50”ID

Spring, Extension, 0.58lbs/in

Bearing, 0.50”ID

Spring, Extension, 0.28lbs/in

Page 19

Dispensing Models Service and Installation Manual

Standard Labor Guidelines To Repair Or Replace Parts On Delfield Equipment

Advice and recommendations given by Delfield Service Technicians do not constitute or guarantee any special coverage.

•Amaximumof1-hourisallowedtodiagnose a defective component.

•Amaximumof1-hourisallowedforretrieval of parts not in stock.

•Amaximumtravel distance of 100 miles round trip and 2-hours will be reimbursed.

•Overtime,installation/start-up,normalcontroladjustments,generalmaintenance,glassbreakage,freightdamage,and/or

correcting and end-user installation error will not be reimbursed under warranty unless pre-approved with a Service Work

Authorization from Delfield. You must submit the number with the service claim.

LABOR OF 1-HOUR IS ALLOWED TO REPLACE:

•Thermostat

•Transformer

•CirculatingFanMotorandBlade

•Hi-limit/ThermalProtectorSwitch

•Springs/Lowerator

LABOR OF 2 HOURS TO REPLACE:

•HeatingElement

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

19

Page 20

™

®

Delfield

Mt. Pleasant, MI Covington, TN

Thank you for choosing Delfield!

Help is a phone call away. Help our team of professional, courteous customer

service reps by having your model number and serial number available at the time

of your call (800) 733-8829.

Model: _______________________ S/N: ______________________

Installation Date: _______________

For a list of Delfield’s authorized parts depots,

visit our website at www.delfield.com

Register your Deleld warranty

online. Go to www.deleld.com

under the service tab to complete.

™

®

Delfield

980 S. Isabella Rd., Mt. Pleasant, MI 48858, U.S.A. • (989) 773-7981 or (800) 733-8829 • Fax (989) 773-3210 • www.deleld.com

Deleld reserves the right to make changes in design or specications without prior notice. ©2013 The Deleld Company. All rights reserved. Printed in the U.S.A.

DMDISH 03/13

9291468

Loading...

Loading...