Deka G45, G75, G105 Service Manual

Table of Contents

age

P

INTRODUCTION ………………………………………………… 2

SECTION I - THEORY OF

OPERATION/BATTERY CONSTRUCTION …………………… 4

Discharging/Recharging Characteristics…………………… 4

Battery Ratings ……………………………………………… 4

Battery Voltage ……………………………………………… 4

Ampere Hour (AH) …………………………………………… 5

Kilowatt Hours (KWH) ……………………………………… 5

Positive Plate Capacity ……………………………………… 5

Specific Gravity ……………………………………………… 5

Specific Gravity During Recharge ………………………… 5

rid Casting ………………………………………………… 6

G

Apply Active Material………………………………………… 6

Curing and Drying …………………………………………… 6

Plate Formation ……………………………………………… 6

Wrapping Positive Plates …………………………………… 6

Assembling An Element …………………………………… 7

Finishing the Cell Assembly ………………………………… 7

Assembling into Trays ……………………………………… 8

Battery Finishing and Shipping……………………………… 8

SECTION II - BATTERY SAFETY ……………………………… 9

Hazardous Elements ………………………………………… 9

Wearing Protective Clothing………………………………… 9

Lifting Batteries ……………………………………………… 9

Using the Battery as a Counterbalance …………………… 9

CHARGING BATTERIES

Charging Areas — Proper Equipment …………………… 10

Charging Areas — Proper Ventilation …………………… 10

Connecting/Disconnecting Charger ……………………… 10

Sparks/Open Flames ……………………………………… 10

age

P

SECTION III - INSTALLATION AND USE (Cont.)

Operation of the Battery …………………………………… 13

Specific Gravity and On-Charge

Cell Voltage Temperature Correction……………………… 13

BATTERY CHARGING ………………………………………… 13

Basic Charging Facts ……………………………………… 13

Specific Gravity Temperature Correction ………………… 14

Charging Methods…………………………………………… 14

The Charging Process ……………………………………… 14

Improper Charging ………………………………………… 16

Charging Safety……………………………………………… 16

SECTION IV - BATTERY MAINTENANCE

AND TROUBLE SHOOTING …………………………………… 16

Reading Hydrometers and Thermometers ……………… 17

Using a Voltmeter …………………………………………… 17

Battery Inspection …………………………………………… 17

Adding Water/Adjust Electrolyte Levels…………………… 18

Battery Cleaning Wash Unit ……………………………… 18

Performing a Test Discharge ……………………………… 19

Correcting a Sulfated Battery ……………………………… 19

Procedure for Adjusting the

Specific Gravity of the Electrolyte of a Battery …………… 20

Storage Battery Troubleshooting Chart …………………… 21

Basic Rules for Battery Care and Maintenance ………… 23

SECTION V - VALVE REGULATED

LEAD-ACID BATTERIES ……………………………………… 24

Operation of a Gel Cell……………………………………… 24

Charging a Gel Cell ………………………………………… 24

Operating Instructions ……………………………………… 25

Maintenance Instructions…………………………………… 26

HANDLING ACID

Pouring Acid ………………………………………………… 10

Mixing Electrolyte …………………………………………… 10

First Aid for Acid Splash …………………………………… 10

Eye Wash and Emergency Shower Facilities …………… 11

Neutralizing Acid and Electrolyte ………………………… 11

Repairing Batteries ………………………………………… 12

SECTION III - INSTALLATION AND USE …………………… 12

Receiving a Battery ………………………………………… 12

Temporary Storage ………………………………………… 12

Placing a Wet Charged Battery in Service ……………… 12

Placing a Dry Charged Battery in Service ………………… 13

Cycling Characteristics……………………………………… 13

INTRODUCTION

Storage batteries do not store electrical energy, but convert electrical energy into chemical energy which is slowly accumulated as the

charge progresses. A battery in use is said to be on discharge.

During discharge, the chemical energy stored in the battery is converted into usable electrical energy.

A lead-acid motive power battery supplies direct current (DC)

power to electric lift trucks, tractors and pallet trucks. This type of

battery consists of a metal tray containing cells, connected in series.

These batteries come in a wide variety of shapes, sizes, voltages

and ampere-hour capacities.

Each cell in a motive power battery contains positive and negative

plates. All of the positive plates are joined in parallel to the positive

post and strap, to form a positive group. The negative plates also are

joined in parallel to the negative post and strap to form a negative

group. These groups are separated and insulated from one another

and they are immersed in a solution of sulfuric acid and water, called

electrolyte. These groups of plates, separators, posts and straps are

called an element and it is contained in an acid-proof plastic jar.

SECTION VI - BATTERY REPAIR

Repair or Replace …………………………………………… 27

Gas Purging ………………………………………………… 27

Removing Connectors ……………………………………… 27

Removing a Cell …………………………………………… 27

Removing an Element ……………………………………… 28

Reassembling the Battery ………………………………… 29

Using Sealing Compound ………………………………… 30

Attaching Intercell Connectors …………………………… 30

Replacing Acid and Charging ……………………………… 30

SECTION VII - SAFETY DATA SHEETS ………………… 31-48

GLOSSARY OF BATTERY TERMINOLOGY …………… 49-53

The cutaway illustration (Fig. A-1) shows the construction of an

East Penn battery cell. Each positive plate consists of a lead-alloy

grid structure which is filled with a paste of active material, made

from lead oxide. The active material is forced into the positive grid

structure during manufacturing and is held firmly to the grid by a system of vertical and horizontal glass fiber mats, which reinforce and

insulate the positive plate. A retainer and bottom shield encase each

positive plate and mat assembly to help prevent short circuits.

The negative plate also consists of a lead alloy grid structure that

is filled with active material. But because negative plates undergo

much less active material shedding, no reinforcing glass fiber mats

are needed. Separators provide insulation between the positive and

negative plates. The positive and negative plates are connected to

their respective posts by positive and negative straps.

A more detailed description of battery construction appears in

Section I.

2

Manufactured using the world’s most modern computer integrated manufacturing techniques…

COVER

Heat sealed with lead insert

bushing prevents leakage and

voltage-to-ground.

O-RING SEAL

Accomodates positive plate growth

without cover distortion and leakage.

POST

Special alloy for increased

strength and conductivity.

POST PLATE STRAP

Extra heavy to ensure a permanent

connection between posts and plates.

POSITIVE GRID

A non-porous lead alloy casting

designed for maximum current

carrying capacity, capable of many

years of dependable service.

Lead alloy is manufactured on-site

and undergoes rigid testing before,

during and after casting.

ACTIVE MATERIAL

Manufactured on-site to exacting

specifications and uniformly applied

under rigid laboratory control to

ensure maximum efficiency

throughout long battery life.

JAR

Molded of high impact-resistant

material to remain leak-free under

the roughest conditions.

BRIDGE

Provides firm element support

and ample sediment space.

BOTTOM SHIELD

Provides extra protection on bottom

of positive plate to prevent shorting

between plate and sediment.

STEEL TRAY

Heavy gauge with acid-resistant

protective coating. Steel covers

furnished as required.

VENT CAP

Quarter-turn bayonet style

simplifies watering and

inspection.

SEPARATOR GUARD

White color increases

visibility for fast electrolyte

check. Solid insulating guard

extends beneath the straps to

prevent shorting between the

plates and straps.

NEGATIVE PLATE

Engineered to complement

positive plate performance.

VERTICAL MAT

Laminated construction comprised of uniformly spaced,

fine glass tape that imbeds

into the active material.

Also features an inter-woven

glass fiber mat wrapped

vertically around the positive

plate ensuring optimum active

material retention.

HORIZONTAL MAT

Made of glass fibers with an

insoluble binder. Breaks up

gas bubbles and increases

positive plate insulation and

performance.

RETAINER

A high porosity perforated

envelope that encases positive

plates and glass mats to

prevent shorts and ensure

maximum performance and life.

SEPARATOR

Impervious to heat, acid and

corrosion, deep channeled,

microporous separators provide

insulation between positive and

negative plates while allowing

the free flow of electrolyte

throughout the cell.

ELECTROLYTE

In ample volume to ensure

top performance at all rates

of discharge.

Fig. A-1

3

SECTION I - THEORY OF OPERATION/BATTERY CONSTRUCTION OF LEAD ACID STORAGE BATTERIES

Theory of Operation

Discharging/Recharging

Characteristics

In a fully charged condition the active material in the positive

plate is lead peroxide (PbO

ative plates is sponge lead (Pb). The electrolyte has maximum

sulfuric acid content and its temperature corrected specific

gravity ranges should comply with the manufacturer’s recomme n ded fu l l char ge spe cifi c grav ity spe cifi cati ons

(See Table 1-1 ). (See Table 3-1 - shown on page 14 - Specific

ravity Temperature Corrections).

G

) and the active material in the neg-

2

Battery Type Range @ 77°F/25°C

Recommended Specific Gravity

Standard “D” Series 1.280 - 1.295

Maintenance Saver “M” Series 1.245 - 1-255

Max Powr “P” Series 1.320 - 1.330

Diesel Starting “DL/DLU” Series 1.245 - 1.255

Hydra Saver “H” Series 1.295 - 1.305

Table 1-1

When fully charged, each cell has a voltage of approximately

two (2) volts on open circuit. However, a cell may have a voltage from 2.12 to 2 .70 vo lts wh ile be ing ch arged. A cell

develops a voltage potential when two dissimilar metals are

immersed in a suitable electrolyte. The two metals used in leadacid cells are lead peroxide (PbO

the electrolyte is dilute sulfuric acid (H

of dissimilar metals and electrolyte results in a voltage potential

) and sponge lead (Pb), and

2

). This combination

2SO4

of nominally two (2) volts per cell and their potential ability to

deliver this voltage under varying load and for varying periods

of time.

When a battery is discharged, the internal components of each

cell undergo chemical changes (Figure I-1). During the discharge cycle, the composition of the positive plates changes

from lead peroxide (PbO

ative plates from sponge lead (Pb) to lead sulfate (PbSO

sulfate on both the positive and negative plates comes from the

) to lead sulfate (PbSO4) and the neg-

2

) The

4

sulfuric acid in the electrolyte solution combining chemically

with the active material of the plates. This chemical reaction

reduces the sulfuric acid content in the electrolyte. The specific

gravity of the electrolyte is reduced and approaches that of

water (1.100). Cell voltage decreases during the discharge

because the two (2) dissimilar metals (PbO

becoming more similar (PbSO

).

4

) and (Pb) are

2

Fig. I-1

Battery Ratings

During charging, the discharging reaction is reversed and the

chemical energy is restored. The lead sulfate on the positive

plates converts back to lead peroxide (PbO

fate on the negative plates converts back to sponge lead (Pb).

The released sulfate returns to the electrolyte solution, increasing the sulfuric acid content, which in turn increases the specific

gravity. When these electrochemical reactions are complete,

the cell is again fully charged.

During charging, hydrogen gas is formed on the negative plates

and oxygen is formed on the positive plates. This explosive gas

mixture is vented from the battery through the vent/filler caps.

THE WARNINGS (SHOWN ON PAGE 5) APPLY TO ALL

CELLS OR BATTERIES.

) and the lead sul-

2

A single lead-acid cell does not have sufficient power to handle

most requirements. However connecting a number of cells

together in series results in a battery capable of supplying higher power demands.

Battery Voltage

The number of cells is determined by the required nominal

operating voltage of the equipment. Since each cell has a nominal voltage of two (2) volts, a 36 volt industrial truck will require

an 18-cell battery (18 cells x 2 volts/cell = 36 volts).

4

SECTION I - THEORY OF OPERATION/BATTERY CONSTRUCTION OF LEAD ACID STORAGE BATTERIES (cont.)

M

anufactured by:

East Penn Manufacturing Co.

102 Deka Road,

Lyon Station, PA 19536

610-682-6361 USA

PROPOSITION 65 WARNING: Battery posts, terminals and related

a

ccessories contain lead and lead compounds, chemicals known

t

o the State of California to cause cancer and reproductive harm.

B

atteries also contain other chemicals known to the State of

California to cause cancer. WASH HANDS AFTER HANDLING.

W

ARNING: Risk of fire, explosion or burns. Do not disassemble

o

r incinerate. Not recommended for inverted use. Follow product

charging instructions. High Voltage: Risk of shock. Do not touch

uninsulated terminals or connectors.

K

eep Vent Caps Tightly in Place

Harmful if swallowed, inhaled, or in contact with skin.

A

cid causes severe skin burns and eye damage.

M

ay damage fertility or the unborn child if ingested

o

r inhaled.

M

ay cause harm to breast-fed children.

May cause cancer if ingested or inhaled.

C

auses skin irritation, serious eye damage.

Contact with internal components may cause

i

rritation or severe burns.

Causes damage to central nervous system, blood

and kidneys through prolonged or repeated

exposure if ingested or inhaled.

Irritating to eyes, respiratory system, and skin.

May form explosive air/gas mixture during charging.

Extremely flammable gas (hydrogen).

Explosive, fire, blast or projection hazard.

Obtain special instructions before use.

Do not handle until all safety precautions have

b

een read and understood.

Wash thoroughly after handling.

Do not eat drink or smoke when using this product.

Avoid contact during pregnancy/while nursing.

Wear protective gloves/protective clothing, eye

protection/face protection.

Use only outdoors or in a well-ventilated area.

Avoid contact with internal acid.

Do not breathe dust/fume/gas/mist/vapors/spray.

K

eep away from heat/sparks/open flames/hot

surfaces. No smoking.

I

F SWALLOWED OR CONSUMED: rinse mouth.

Do NOT induce vomiting. Call a poison center/

d

octor if you feel unwell.

IF ON CLOTHING OR SKIN (or hair): Remove/Take

o

ff immediately all contaminated clothing and wash

it before reuse. Rinse skin with water/shower.

I

F INHALED: Remove person to fresh air and keep

comfortable for breathing. Immediately call a

POISON CENTER or doctor/physician.

IF IN EYES: Rinse cautiously with water for several

minutes. Remove contact lenses, if present and

easy to do. Continue rinsing.

If exposed/concerned, or if you feel unwell seek

medical attention/advice.

Store locked up, in a well-ventilated area, in

accordance with local and national regulation.

Dispose of contents/container in accordance

with local and national regulation.

Keep out of reach of children.

Lead Acid

Battery

Electrolyte

(Sulfuric Acid)

DANGER

Contains: Lead, Sulfuric Acid (Electrolyte), Lead Compounds.

Danger

See P.23 for full warranty information.

HYDROGEN GAS FROM THE BATTERY OR CELL CAN

EXPLODE. DO NOT SMOKE, USE AN OPEN FLAME, OR

CREATE AN ARC OR SPARKS IN THE VICINITY OF INDIVIDUAL CELLS OR BATTERIES. VENTILATE WELL WHEN

IN AN ENCLOSED SPACE AND WHEN CHARGING.

THIS BATTERY OR INDIVIDUAL CELL CONTAINS SULFURIC ACID WHICH CAUSES SEVERE BURNS. DO NOT GET

IN EYES, ON SKIN OR ON CLOTHING. IN CASE OF CONTA C T, FL USH IMMED IATE LY W ITH CLEAN WATE R.

OBTAIN MEDICAL ATTENTION IF EYES ARE AFFECTED.

PERSONAL SAFETY EQUIPMENT IS RECOMMENDED

WHEN WORKING WITH BATTERIES AND SHOULD BE

USED IN ACCORDANCE WITH LOCAL REQUIREMENTS;

SA F ETY GLA SSES , G O GGL E S O R A FA C E S HIEL D.

RUBBER OR PLASTIC GLOVES AND A RUBBER OR PLASTIC APRON ARE ITEMS OFTEN USED IN THIS TYPE OF

WORK. EQUIPMENT WHICH WILL PROTECT THE EYES

FROM ACID SPLASHES IS THE MOST IMPORTANT SINCE

THE EYES CAN BE SERIOUSLY AFFECTED IN A VERY

SHORT TIME.

Ampere Hour (AH)

The elect rical c apabilit y of a stora ge ba ttery i s usually

expressed in ampere-hours. The ampere-hour capacity is the

number of ampere-hours which can be delivered under specified conditions of temperature, rate of discharge, and final

voltage. Basically, ampere-hours are determined by multiplying

the number of amperes which the battery will deliver by the

number of hours during which the current is flowing. Example:

100 amperes x 6 hours to 1.70 volts per cell = 600 amperehours (six hour rate). The size and number of plates which

make up the element then determine total cell or battery capacity. Due to the va riety of job require ments bat teries ar e

produced with many different sizes of cells.

Kilowatt Hours (KWH)

Battery capacity is also expressed in kilowatt-hours (KWH),

which is the product of ampere x time x average volts per cell

during discharge. Example: 100 amps x 6 hours x 1.930 average volts per cell = 1,158 watt hours ÷ 1000 = 1.158 KWH. For

an 18-cell battery, the capacity would be 1.158 x 18 = 20.84

KWH. Increasing or decreasing the size of the cells or the number of cells in the battery can vary the kilowatt-hour rating.

Positive Plate Capacity

Positive plate capacity is the ampere delivery for a fixed period

of time (usually six hours) for a particular size positive plate. A

Deka D100 type positive plate has the capability of delivering

16.66 amperes for six hours or 100 ampere hours (16.66 x 6 =

100 AH) to a final voltage of 1.70. Increasing or decreasing the

number of positive plates in the cell can vary this ampere-hour

rating or capacity. In the previous examples, the battery is an

8-cell, D100-13 plate unit. To determine the number of positive

1

plates in each cell, subtract one from the total number of plates

in the cell and divide by two. Example: 13 – 1 = 12 ÷ 2 = 6 positive plates per cell; 6 positive plates x 100 ampere-hours each =

600 AH. The use of a different type of positive plate, such as a

D75 or D125, will respectively decrease or increase the

ampere-hour capacity. The above ratings are based on an electrolyte temperature of 77°F/25°C with a full charge specific

gravity at battery nameplate rating.

Specific Gravity

The term specific gravity describes the ratio of the density of

electrolyte to the density of water. Electrolyte weighing 1.2

times as much as the same volume of water has a specific

gravity of 1.200. The full charge specific gravity of a cell is a

matter of design and depends on several factors. The specific

gravity must be high enough to contain the amount of sulfuric

acid necessary to meet the chemical needs of a cell. If the sulfuric acid content is too high, damage may result to the cell.

Since the acid content of the electrolyte decreases linearly as

the cell is discharged, the decrease in specific gravity is directly

proportionate to the amount of ampere-hours removed (refer to

Table 3-2, page 15).

The specific gravity at any point in the discharge indicates the

depth of discharge and can be translated into ampere-hours

removed. A cell having a full charge specific gravity of 1.290

and a final specific gravity of 1.140 will have a specific gravity

drop of 150 points. Example: Assume the specific gravity is

1.190 at the end of the discharge. That is 100 points specific

gravity below the full charge gravity; therefore, = 67% dis-

100

150

charged of rated capacity. Allow at least one

hour after end of discharge for the electrolyte to diffuse and give

a true reading corrected to 77°F/25°C.

The linear relation of specific gravity to state of discharge can

be used in tests to determine power consumption or capacity

required. Tests of this kind can be made to demonstrate that a

lift truck may require a larger capacity battery to do the job, and

can lead to the solution of a problem.

Specific Gravity During Recharge

The rise in specific gravity during recharge is not uniform or proportional to the amount charge returned in ampere-hours.

During the early part of the charge, there is no gassing action to

mix the electrolyte with the heavier acid being released from the

plates. The heavier sulfuric acid will lay on the bottom. A

hydrometer reading which draws electrolyte from the top of the

cell does not indicate the true specific gravity or actual state of

charge. During the gassing portion of the charge, the sulfuric

acid mixes, and the specific gravity rises rapidly to full charge

value.

5

SECTION I - THEORY OF OPERATION/BATTERY CONSTRUCTION OF LEAD ACID STORAGE BATTERIES (cont.)

Battery Construction

Grid Casting Positive and Negative Grids

A plate consists of a cast lead-alloy grid structure into which

lead oxide pastes are applied. Since lead by itself would be too

soft and flexible to make a grid, a certain amount of antimony is

added to the grid to prevent it from sagging or warping. The

grids are then cast by pouring the molten alloy into grid molds.

Negative

Grid

Positive

Grid

Fig. I-2

Due to the increased amount of chemical activity that takes place

on the positive grids during charging and discharging, positive

grids are more heavily constructed than negative grids (Fig. I-2).

Apply Active Material

After the gri ds have been cast , the lead oxid e pastes are

applied. The lead oxide applied to the negative grid contains an

expander to produce sponge lead. The positive plate contains a

putty-like mixture of lead, lead oxide, lead sulfate and water.

Because proper pasting is critical to battery performance, East

Penn uses highly sophisticated, computer-controlled pasting

machines to consistently apply paste to exact thicknesses and

weight.

Fig. I-3

and life. The formed plates become darker and are individually

inspected (Fig. I-4 and Fig. I-5) to be sure that each one is perfect. This is important because many other companies form

their plates in the battery, or in groups of cells, resulting in temperature variation between plates, and they can’t individually

inspect each one.

Fig. I-4

Curing and Drying

After the plates are pasted, they must be cured and dried in a

rigidly controlled environment. This securely binds the active

material to the grid and produces a smooth, uniform plate. The

active material, now highly porous, allows the electrolyte to

penetrate freely so it can produce maximum conductivity

between the paste and the grid for high cell efficiency. Because

the curing and drying process is so important to cell efficiency

and battery life, East Penn has invested in humidity and temperature-controlled curing ovens (Fig. I-3), which produce the

highest quality plates in the industry.

Plate Formation

The cured plates must now undergo a formation charge, which

transforms the previously inert material on the positive plates

into lead peroxide and the material on the negative plates into

sponge lead. The plates are lowered into a forming tank filled

with dilute sulfuric acid, then temporarily connected to a lead

bar, and given a computer-controlled forming charge. Individual

plate formation allows the entire row of plates to be formed at

uniform temperatures, which will enhance battery performance

Fig. I-5

Wrapping Positive Plates

The active material of positive plates (lead peroxide) is subject to

shedding as a cell goes through its normal discharge/recharge

cycle. The small particles that are shed settle to the bottom of

the cell. To keep the active material firmly on the positive plates,

6

SECTION I - THEORY OF OPERATION/BATTERY CONSTRUCTION OF LEAD ACID STORAGE BATTERIES (cont.)

plate, to the desired cell size. Both outside plates are negative,

therefore the number of plates per cell is always an odd number, with each cell having one more negative then positive

plate.

The separators used to insulate the positive plate from the negative plate are grooved on one side and flat on the other (Fig.

I-7). The grooved side faces the positive plate. The flat side

faces the negative plate because the sponge lead of the negative plate would expand if it faced into the grooved side. In

some cases, positive plates can be inserted into separator

sleeves, which are two separators joined at the sides.

hen assembling the stack of plates and separators into an

W

element, a post plate strap is welded onto the positive plate

lugs and another one is welded onto the negative plate lugs. At

the same time, positive and negative posts are welded onto the

proper plate straps. A perforated plastic moss shield is placed

on top of the assembled plates (Fig. I-8). The moss shield also

protects the tops of the plates and separators and permits the

gas bubbles to get up to the surface of the electrolyte.

Positive Plate Wrapped

Fig. I-6

they are “wrapped” with various retaining devices including glass

fiber mats, fiberglass tape and a retainer/bottom shield (Fig. I-6).

The positive plates are first wrapped with a vertical mat, which

consists of fiberglass tape and interwoven glass fibers. The

glass fibers imbed into the active material, strengthening in a

way similar to reinforcing rods in concrete. A horizontal glass

fiber mat is then wrapped around the plate to break up any gas

bubbles and increase the plate’s insulation. The wrapped plate

is then encased in a perforated plastic retainer envelope that

firmly holds the glass wraps in contact with the plate while

allowing the free flow of electrolyte to the plate. A bottom plate

boot is added to prevent the sediment in the sediment chamber

from contacting the bottom of the positive and negative plates

and shorting out the cell.

Assembling An Element

A group of positive and a group of negative plates are stacked

with separators, inserted between each positive and negative

Fig. I-8

Finishing the Cell Assembly

A finished cell consists of an element inserted into a high-impact

plastic jar with a cover (Fig. I-9). Before the element goes into

the jar, a sediment bridge is installed to give the element firm

support and provide a place for sediment to settle.

After the completed element is inserted into the jar, a high

impact plastic cover is placed on top and heat sealed onto the

jar. The cover’s positive and negative terminals have a lead post

bushing attached and are welded firmly to the element’s posts.

Fig. I-7

Each finished cell is air tested to ensure an air tight cover-to-jar

and post-to-bushing seal. The air test can also detect any leaks

in the high impact plastic jar.

7

SECTION I - THEORY OF OPERATION/BATTERY CONSTRUCTION OF LEAD ACID STORAGE BATTERIES (cont.)

Assembling into Trays

To create a battery, a specific amount of completed cells (element, jar and cover) are inserted into a steel tray. Spacer

material may be added between the cells and tray to assure a

tight assembly.

East Penn will assemble batteries with or without a hot asphalt

ba sed sealing compoun d that is pou red in the channel s

etween cells, per customer request. East Penn recommends

b

that sealing compound be used because it prevents dirt and

flushed electrolyte from draining between the cells and tray. This

internal build up of corrosive material over time could cause cell

or tray damage and result in voltage shorts to ground that

adversely effect lift truck electrical controls. Once all the jars

have been sealed into the tray, intercell connectors are attached

(Fig. I-10). Electrolyte is then added to the cells and the battery

is moved to the boosting room for a final charge.

Battery Finishing

and Shipping

After the boost charge, the battery is sent to the finishing line,

where cables and connectors are attached according to the

buyer’s layout specifications (Fig. I-11). The battery is then

weighed, thoroughly cleaned, and inspected. Actual battery service weight and the tray drawing number are stamped on the

steel tray, and all battery identification labels, warning labels,

plaques, and service stickers are affixed to the tray.

The finished batte ry is wrapped in plastic and pa lletized.

Shipping information and instructions are included with the battery before shipment and a “corrosive” label is attached to all wet

(containing electrolyte) shipments.

All East Penn employees are extremely proud of the products that

they produce. You can be assured that the highest quality materials and workmanship were used to manufacture your battery.

Fig. I-10

Fig. I-11

Fig. I-9

8

SECTION II — BATTERY SAFETY

Manufactured by:

East Penn Manufacturing Co.

102 Deka Road,

Lyon Station, PA 19536

610-682-6361 USA

PROPOSITION 65 WARNING: Battery posts, terminals and related

a

ccessories contain lead and lead compounds, chemicals known

to the State of California to cause cancer and reproductive harm.

Batteries also contain other chemicals known to the State of

C

alifornia to cause cancer. WASH HANDS AFTER HANDLING.

WARNING: Risk of fire, explosion or burns. Do not disassemble

or incinerate. Not recommended for inverted use. Follow product

c

harging instructions. High Voltage: Risk of shock. Do not touch

u

ninsulated terminals or connectors.

Keep Vent Caps Tightly in Place

Harmful if swallowed, inhaled, or in contact with skin.

A

cid causes severe skin burns and eye damage.

M

ay damage fertility or the unborn child if ingested

o

r inhaled.

M

ay cause harm to breast-fed children.

May cause cancer if ingested or inhaled.

C

auses skin irritation, serious eye damage.

Contact with internal components may cause

i

rritation or severe burns.

Causes damage to central nervous system, blood

and kidneys through prolonged or repeated

exposure if ingested or inhaled.

Irritating to eyes, respiratory system, and skin.

May form explosive air/gas mixture during charging.

Extremely flammable gas (hydrogen).

Explosive, fire, blast or projection hazard.

O

btain special instructions before use.

Do not handle until all safety precautions have

b

een read and understood.

Wash thoroughly after handling.

Do not eat drink or smoke when using this product.

A

void contact during pregnancy/while nursing.

Wear protective gloves/protective clothing, eye

protection/face protection.

Use only outdoors or in a well-ventilated area.

Avoid contact with internal acid.

Do not breathe dust/fume/gas/mist/vapors/spray.

K

eep away from heat/sparks/open flames/hot

surfaces. No smoking.

I

F SWALLOWED OR CONSUMED: rinse mouth.

Do NOT induce vomiting. Call a poison center/

d

octor if you feel unwell.

IF ON CLOTHING OR SKIN (or hair): Remove/Take

o

ff immediately all contaminated clothing and wash

it before reuse. Rinse skin with water/shower.

I

F INHALED: Remove person to fresh air and keep

comfortable for breathing. Immediately call a

POISON CENTER or doctor/physician.

IF IN EYES: Rinse cautiously with water for several

minutes. Remove contact lenses, if present and

easy to do. Continue rinsing.

If exposed/concerned, or if you feel unwell seek

medical attention/advice.

Store locked up, in a well-ventilated area, in

accordance with local and national regulation.

Dispose of contents/container in accordance

with local and national regulation.

Keep out of reach of children.

Lead Acid

Battery

Electrolyte

(

Sulfuric Acid)

DANGER

Contains: Lead, Sulfuric Acid (Electrolyte), Lead Compounds.

See P.23 for full warranty information.

Only trained and authorized personnel should change,

repair or charge batteries.

When used properly, a lead-acid motive power battery is a safe,

dependable source of electrical power. However, if proper care

and safety precautions aren’t exercised when handling a battery, it can be an extremely dangerous piece of equipment.

Wearing Protective Clothing

When working on or near batteries, always wear proper protective clothes including a face shield, safety glasses, long-sleeved

shirt, acid-resistant boots and gloves. Do not wear any metal

ewelry because it can short circuit a battery and become

j

extremely hot if it accidentally contacts exposed intercell connectors. Refer to detailed warnings, Section I, Page 5.

Lifting Batteries

hain hoists used to handle batteries should be equipped with

C

a non-metallic container or bucket to prevent the chains from

dangling and possibly causing a short by coming in contact with

exposed intercell connectors on the battery top. If no protection

is available, cover the battery with a non-conducting insulating

material such as plywood or heavy plastic.

There are four hazardous elements in a lead-acid battery: sulfuric acid, explosive gases, electricity, and weight.

Hazardous Elements

Sulfuric Acid: The electrolyte in a lead-acid storage battery

is a diluted solution of sulfuric acid and water. Although the acid

content in the solution is only about 37%, it’s still a strong corrosive agent and can burn skin and eyes and eat holes in many

types of fabric. (See Wearing Protective Clothing.)

Specific Gravity Reading % Acid Content by Weight

1.280 37.40

1.290 38.55

1.325 42.50

Explosive Gases: When a lead-acid battery is being

charged, it produces an explosive mixture of hydrogen and oxygen gases. Make sure that all vent caps are unclogged and

securely attached so that any gas is safely vented from the battery. Never smoke, use an open flame or create an arc or

sparks on or near a battery without first eliminating explosive

gases from the cells you’re working on. (See Gas Purging —

Section VI.)

Electricity: An electric shock hazard exists for persons who

contact live parts of batteries when the voltage is over 50 volts.

The higher the voltage, the greater the electric shock hazard. In

addition, metallic objects coming in contact with exposed cell

connectors will cause a short and can become very hot. Even

shorts involving a single cell can become hot enough to cause

severe burns.

Weight: The average lift truck battery weighs more than

2,000 pounds. Obviously it can cause serious injury if it isn’t

handled carefully during installation, removal or transport. Use

proper lifting equipment and techniques at all times.

Fig. II-1

Always use the proper lifting equipment to reduce the risk of

tray damage, shorting and possible injury. A wood insulated

battery lifting beam used with an overhead hoist is the safest

way to move a battery (Fig. II-1). An insulated lifting beam, with

hooks that fit properly into the lifting ears in the tray, can be

used with almost any type of overhead hoist. Be sure the lifting

hooks align perfectly with the battery lifting ears. Misaligned

hooks can cause battery lifting ear damage and could disengage while the battery is being lifted.

Using the Battery as a Counterbalance

In order for most lift trucks to operate safely, the battery is used to

counterbalance the carried load. Therefore, a new or different battery must fall within the recommended battery weight range. This

battery weight information is found on the nameplate of the truck. A

battery’s service weight is usually stamped on the tray near one of

the lifting holes. A battery that’s too heavy or too light can change

the truck’s center of gravity and cause it to be unstable. It’s the

user’s responsibility to be sure that this weight is in the proper

range.

9

SECTION II — BATTERY SAFETY (cont.)

CHARGING BATTERIES

Charging Areas — Proper Equipment

All plants should have designated charging areas, especially if they

hange batteries at the end of each shift.These areas should have

c

proper battery handling equipment including overhead hoists, lifting

beams, battery racks and cranes, and the area must be well ventilated.

A source of running water nearby is desirable and a water hose at

the filling operation is recommended.

Racks used in the charging area must be insulated to prevent any

sparking. The battery rack supports must also be suitably insulated

or made of non-conducting material.

The floors in battery and charging rooms should have an acid-resistant coating and be sloped toward a sump. They should always be

washed with clean water after an acid spill. The spill should be neutralized with a non-corrosive, water based neutralizing chemical that

is user safe and environmentally compliant.

Hand-operated fire extinguishes should be available in all charging

areas even if the areas are equipped with automatic sprinkler systems. For information on extinguisher class, size and mounting

locations, consult local fire authorities or your insurance carrier.

Charging Areas — Proper Ventilation

The charging area must be properly ventilated, either naturally or

with a ventilation system. When installing a ventilation system, a

number of factors must be considered, including the number and

size of batteries being charged at one time and the size, height and

air-tightness of the room

Ventilation is considered satisfactory if the hydrogen concentration

doesn’t exceed 2% in any one location. Concentrations of more

than 4% are explosive and dangerous. A number of instruments,

such as combustible gas indicators and flammable vapor indicators, are available for continuous automatic analysis of hydrogen

content in the air.

Always keep tray covers and truck compartment covers open when

charging a battery. This helps cool the battery and disperse the

gases.

Connecting/Disconnecting Charger

Always turn the charger OFF before connecting or disconnecting a

battery. Live leads can cause arcing and sparking, which could

cause an explosion if battery gases are present. In addition, the contact surfaces of the plugs or connectors will become pitted over time.

HANDLING ACID

Pouring Acid

Use a carboy tinter or safety siphon when removing acid from a

arboy container. The venting device in a carboy prevents splash-

c

ing. Carboys should be stored in a cool place away from direct

sunlight. (Note: Use proper eye protection, protective clothing and

equipment.)

Mixing Electrolyte

Mix electrolyte in a heat and acid-resistant container. Always pour

acid into water. Never pour water into acid because a violent chemical reaction can occur. Pour the acid slowly and stir the mixture so

the acid doesn’t settle on the bottom.

When using high specific gravity acid (above 1.400), take special

precautions because it can be extremely dangerous. (Note: Use

proper eye protection, protective clothing and equipment.)

Store acid and electrolyte solutions in covered containers made of

lead, glass or acid-resistant plastic. Keep the containers in a cool,

dry area away from direct sunlight.

Important - only the most experienced battery technicians

should be allowed access to sulfuric acid and allowed to add

acid for cell equalization purposes.

First Aid for Acid Splash

Eyes: Flush immediately with gently running water for at least

15 minutes, then see a doctor as quickly as possible. For contact

lens wearers, remove the lens before the eyes are flushed. A

buffering or neutralizing agent shouldn’t be used in the eyes without the approval of medical or safety personnel.

Skin: Wash affected area under running water and apply a

chemical burn treatment. Severe burns require immediate medical

attention.

Clothing: If large areas of clothing have been splashed or

soaked, the clothing must be removed and the acid must be neutralized with a non-corrosive, water based neutralizing chemical

that is user safe and environmentally compliant and then rinsed

under running water. If the clothing is rinsed quickly enough, the

chances of damage to the material are lessened.

Acid-resistant boots should always be checked before wearing to

be sure that there are no acid puddles inside.

Sparks, Open Flames

Because of the explosive gas mixtures generated while charging

batteries, anything that could ignite the gas, such as sparks,

open flames, an electrical arc, smoking, etc., must be prohibited

in the charging areas. To serve as a prominent reminde r,

“NO SMOKING” signs should be posted in all charging areas.

10

SECTION II — BATTERY SAFETY (cont.)

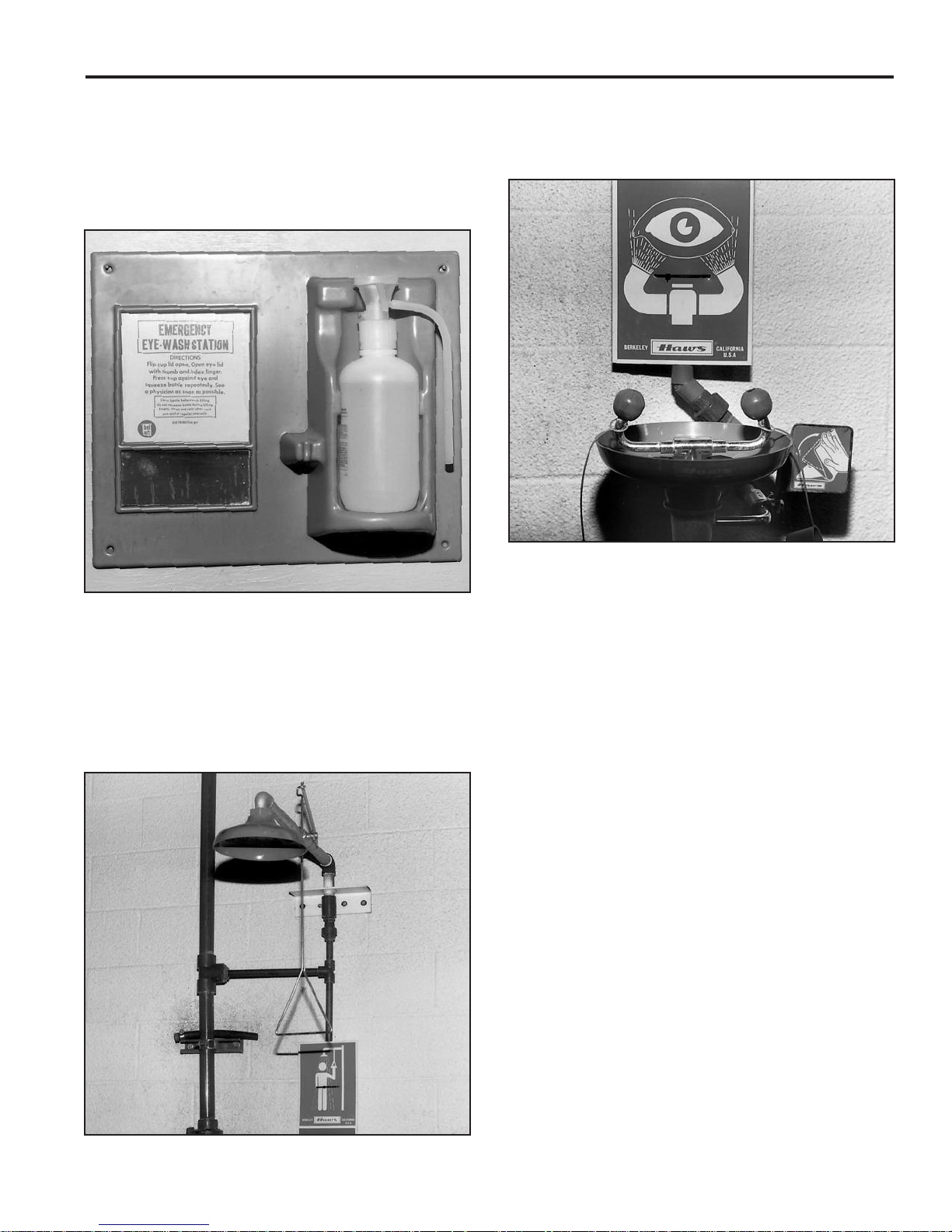

Eye Wash and Emergency Shower Facilities

Emergency eye wash and acid neutralization facilities should

be located in the immediate work area for easy access. The

three most popular types of eye wash and acid neutralizing

equipment are the chemical burn station, deluge shower, and

eye wash fountain.

2. A deluge shower (Fig. II-3) should be used where high spe-

cific gravity acid (above 1.400) is handled. The shower uses

a handle or foot treadle to turn on a powerful water stream

that can wash acid from skin and clothes.

Fig. II-2

1. A chemical burn station (Fig. II-2) is used in smaller bat-

tery charging and repair areas. The station consists of a

wall-mounted plastic squeeze bottle that contains a buffering solution for treating acid burns on skin, eyes and

clothing. This inexpensive equipment should be used only

where acid with a specific gravity lower than 1.400 is used.

A buffering or neutralizing agent shouldn’t be used in the

eyes without the approval of medical or safety personnel.

Fig. II-4

3. An eye wash fountain (Fig. II-4) should be used wherever

batteries and/or acid is handled, regardless of the acid’s

specific gravity. This device produces two streams of water

so that both eyes can be flushed simultaneously.

Neutralizing Acid and Electrolyte

For cleaning batteries, non-corrosive, water based battery

cleaning products are all that should be used. For user safety

and environmental regulatory compliance, the cleaning liquid

should contain no hazardous chemical ingredients. Even some

products labeled “Battery Cleaner” must be avoided because of

hazardous ingredients and damage to batteries and related

equipment.

Acid spills are common in battery rooms. When acid spills occur

it is critical to minimize:

1. Health and safety risk to personnel and the

environment.

2. Damage to batteries, equipment, and surrounding

surfaces.

3. Time to neutralize, absorb, and clean-up.

4. Disposal costs of waste materials.

5. Regulatory compliance risks and fines.

Fig. II-3

Neutralizing acid absorbers and spill kits have the performance

attributes required when dealing with acid spills. The ph neutral

dry and non-hazardous waste is easy to sweep-up and dispose

as non-hazardous waste.

11

SECTION II — BATTERY SAFETY (cont.)

1/4"

COVER VENT CAP IMPORTANT

Repairing Batteries

Keep in mind several safety points when repairing batteries:

1. Never work on a battery while on charge or discharge.

Always disconnect it from the charger or truck first.

2. Always remove vent caps before beginning work.

3. Always remove gas from all battery cells before beginning work (see Gas Purging — Section VI).

4. Use caution when melting sealing compound. Melted

compound is extremely hot and can cause severe

burns if not properly handled (see Sealing Compound

— Section VI).

SECTION III — INSTALLATION AND USE

Receiving a Battery

After receiving a battery, examine the crate and pallet for signs

of damage. If you see any wet spots, the battery may have

been tipped or damaged during transit. Be careful when handling a crate or packing material that’s contaminated with

spilled electrolyte. Chemical burns can result if skin or clothing

comes in contact with the spillage. Follow the precautions listed

under “Handling Acid” — Section II.

KEEP ELECTROLYTE LEVEL BELOW

FILLING WELL AS SHOWN

5. To prevent possible short circuits, use insulated tools

whenever you are working on a battery. If possible,

cover the terminals and connectors with an insulating

material such as plywood or heavy plastic, if the batte r y bei ng wo r ked on doe s not have inter cell

onnector and terminal shrouds installed.

c

For more detailed information on safety battery repair procedures, see Section VI — Battery Repair.

Temperature Effect on Specific Gravity

Temperature Loss of Specific Gravity

(Degrees Fahrenheit) Per Day

120 .004

100 .003

80 .001

50 .0005

a freshening charge (see “Placing a Wet Charged Battery in

Service”) should be given whenever the specific gravity falls

below 1.240 or every six weeks. If the average storage temperature is below 68°F (20°C), check the specific gravity at least

once every two months. If the temperature is above 68°F

(20°C), check it every month.

of New Batteries

Stored on Open Circuit

Maximum

Fig. III-1

Every cell should be inspected to be sure that the electrolyte

level is above the moss guard (Fig. III-1). If the electrolyte level

is slightly below the moss guard in any cell, it can be raised by

transferring a small amount of acid from higher level cells within

the battery by using a syringe or hydrometer.

If a large amount of liquid is required to raise the level, the cell

jar may be damaged. Inspect the packing material under the

tray for signs of leakage. All damaged components should be

inspected by your East Penn agent or representative.

Call your East Penn representative immediately. In the meantime, keep the damaged cell’s vent cap tightly in place and

protect the floor from acid leakage. Do not attempt to discharge

or charge the battery.

Temporary Storage

When it is fully charged and the electrolyte is at the proper

level, the battery can be stored for up to a year. It should be

stored in a cool, dry, well-ventilated area away from direct sunlight. If the battery must be stored for several months or longer,

Batteries in steel trays without covers should be covered with a

non-conductive material to protect them from dirt, moisture, etc.

A flat sheet of rigid plastic or plywood will work well. Do not

drape flexible plastic sheeting over batteries because it might

trap explosive gases underneath.

Note: If batteries must be stored for more than one year, consult the

manufacturer.

Placing a Wet Charged Battery in Service

Give a freshening charge to a new battery before putting it into

service. Charge the battery until the specific gravity and all cell

voltages have stabilized. The full charge specific gravity is

1.280 to 1.295 when temperature corrected to 77°F (25°C).

Ideally, the battery should be cool; less than 90°F (32°C), when

it’s installed in the vehicle. Check the manufacturer’s specifications for full charge specific gravity on high gravity battery

types.

When installing a battery, make sure that the battery compartment is clean, corrosion-free and the ventilation openings aren’t

obstructed or blocked off.

To lift the battery, use a lifting beam and an overhead hoist (see

“Lifting Batteries” — Section II). Set the battery securely in the

compartment and block it into position. Some vehicles have

adjustable clips for blocking the battery into place. The battery

should not be wedged tightly into the compartment because

clearance for expansion must be provided. However, clearance

can’t exceed 1/2” between the block or clip and the battery tray

(Fig. III-2).

12

SECTION III — INSTALLATION AND USE (cont.)

Operation of the Battery

There are several factors that effect the operation of the battery

concerning its ability to deliver capacity and life expectancy.

Many chemical reactions are effected by temperature, and this

is true of the reaction that occurs in a storage battery. The

chemical reaction of a lead-acid battery is slowed down by a

lowering of the electrolyte temperature that results in less

capacity. A battery that will deliver 100% of rated capacity at 77°

will only deliver 65% of rated capacity at 32°F. See Table 3-1,

F

for specific gravity and on charge cell voltage temperature correction.

Specific Gravity and On-Charge Cell Voltage

Temperature Correction

Fig. III-2

Be sure all vent caps are in place because electrolyte from

uncapped cells can corrode the tray and vehicle.

Placing a Dry Charged Battery in Service

Note: The activation of dry charged batteries is an involved process which should be handled by trained personnel. For a

thorough explanation, refer to East Penn’s “Procedure for

Activating Dry Charged Industrial Cells and Batteries,” which is

supplied with every dry charge battery.

A dry charged battery is a fully charged battery from which all

the electrolyte has been removed. Because it’s essential to

keep these batteries in the dry state until ready for use, they

should be stored in a cool, dry, low-humidity area with their vent

caps and protector cap and plugs tightly in place until ready for

use. When reactivated, install as described in “Placing a Wet

Charged Battery in Service.”

Cycling Characteristics

Every time a battery is discharged and then recharged it’s

called a cycle. An average battery lasts 1,500 to 1,800 cycles,

or 5 to 6 years. (Actual battery life depends on battery type, the

severity of use, and how the battery was maintained while in

service.)

EXCESSIVE HEAT will contribute greatly to reducing battery

life by corroding the positive grids and excessive gassing which

loosens active material in the plates, especially the positive

plate. Over charging is the most common contributing factor to

excessive temperatures and gassing in a battery. A properly

rated and matched charger will help to avoid the problem of

overcharging.

CONSISTENT UNDERCHARGING of a battery will gradually

run down the cells and result in one or more cells becoming

completely discharged before the others, and may become

reversed. Capacity and life expectancy are greatly reduced by

undercharging. Equalizing charges to return the cells to a normal condition should be part of a weekly maintenance schedule.

OVERDISCHARGING can also cause permanent damage to

the battery. Recharging is more difficult and more time consumin g . Oft en c ompl ete recha rge is not atta i ned and the

undercharged battery is placed into service. Consequently, it is

over discharged to a lower limit resulting in loss of capacity and

premature battery failure. Optimum battery life can be aided by

limiting the depth of discharge to 80% of its rated capacity.

A good battery maintenance program is necessary to protect

life expectancy and capacity of the battery. A more detailed discussion of battery maintenance can be found in Section IV of

this manual.

BATTERY CHARGING

As a battery discharges, the voltage normally drops slowly at

first and then more rapidly toward the end of the discharge.

Battery temperature, on the other hand, rises during discharge,

although the increase isn’t as high as it is during charging. The

amount of temperature increase depends on ambient temperature, ampere discharge rate, and the amount of heat dissipation

(which varies according to battery type).

To obtain maximum service life, batteries should be operated at

115°F (46°C) or lower, and they shouldn’t be discharged to

below 80% of rated capacity. Frequent over-discharging can

drastically shorten battery life.

One way to prevent over-discharging is to be sure that the

ampere-hour (A.H.) capacity rating of the battery is high enough

for the battery’s work load. The battery will over-discharge if its

workload exceeds its capacity. For heavy-duty applications, a

higher capacity battery — such as East Penn’s MAX POWR

battery — may solve frequent over-discharge problems. To

determine if a higher capacity battery is right for your needs,

contact your East Penn agent or representative.

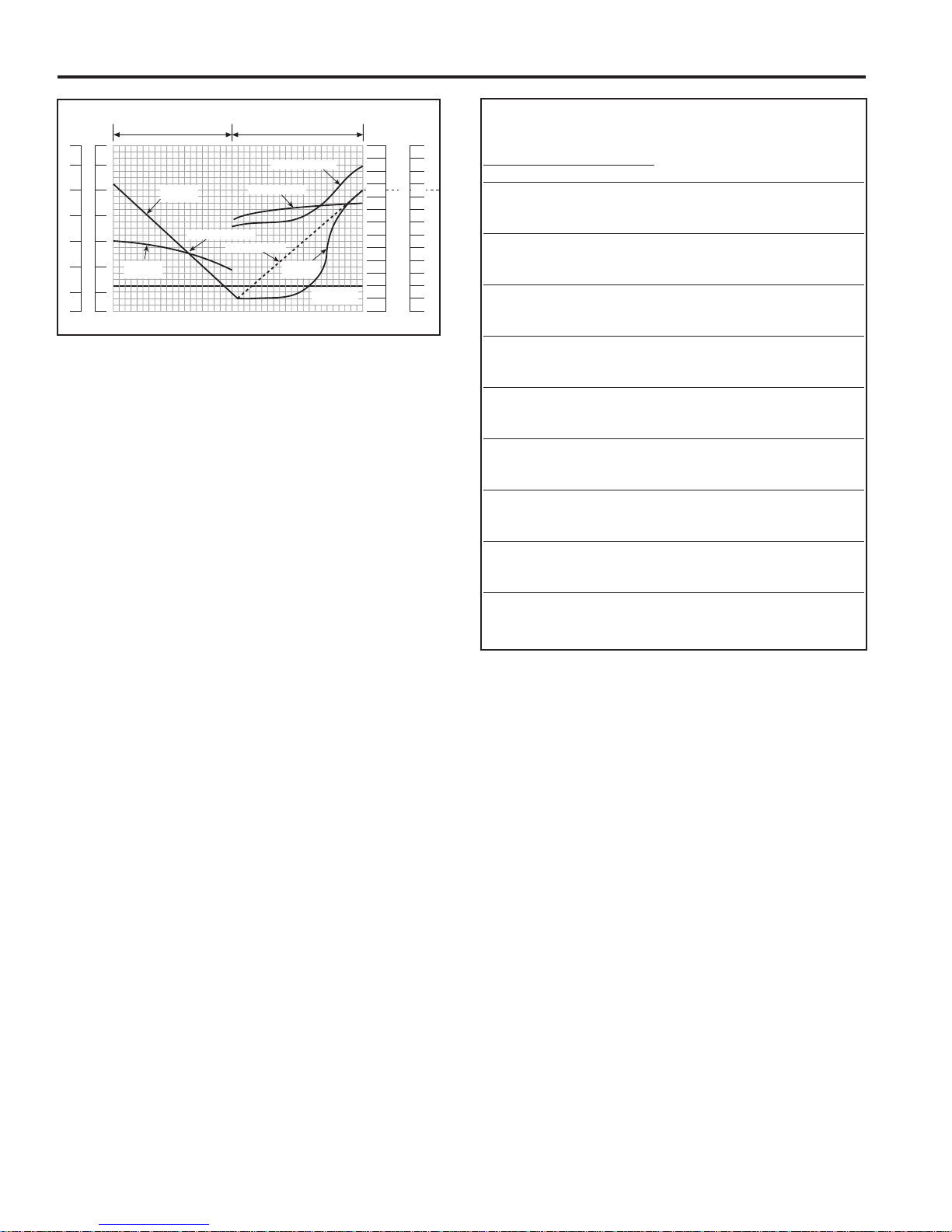

Basic Charging Facts

Proper charging is essential for maximum battery life. In general, the proper charging rate for lead-acid batteries is any rate

which doesn’t produce temperature higher than 115°F (46°C),

and any rate which doesn’t cause excessive gassing.

When a discharged battery is initially placed on charge, it draws

a current equal or close to the charger’s maximum output. As

the battery’s voltage rises, the charger output should adjust to

the changing voltage to assure a safe, efficient charging rate

during all stages of the charge.

With today’s automatic start/stop charges, under and overcharging are virtual ly e limin ated. These “sma rt” charg es h ave

computerized control units that can determine when a battery is

fully charged and then automatically terminate the charge cycle.

For example: The charger delivers a “maximum” start rate of 20

amps per 100 A.H. of rated capacity. As the voltage rises to 2.37

volts @ 77°F (25°C) per cell, the gassing voltage of the battery is

held constant until the charge rate tapers down to 5 amps per

13

SECTION III — INSTALLATION AND USE (cont.)

Typical Recharging Characteristics

TEMPERATURE

CELL VOLTS

2.80

2.60

2.40

2.20

2.00

1.80

1.60

140

120

100

80

60

4

0

2

0

%AMP. HOURS RETURNED

140

1

20

100

80

60

4

0

20

TIME

10

30

5

0

70

9

0

110

1

30

FULL CHARGE

DISCHARGE CHARGE

SPEC. GRAVITY

1.360

1

.340

1.320

1.300

1.260

1.240

1.220

1

.200

1.180

1.160

1.140

1

.120

1.100

1

.280

SPECIFIC

GRAVITY

VOL TS

PER CELL

A.H. DISCHARGED

A.H. RETURNED

TEMP ERA TURE

100%

DISCHARGE

SPECIFIC

GRAVITY

VOLTS PER CELL

Fig. III-3

100 A.H. This finish rate is held constant until the charger automatically shuts off. Charger start rates should not be more than

20 amps per 100 A.H. of rated capacity, and the finish rates not

less that 5 amps per 100 A.H. @ 2.60 V.P.C. (Fig. III-3).

The above requirements will return a discharged battery to full

recharge. See your East Penn representative for details.

Periodic inspection and adjustment of automatic charges

should be done by a qualified electrician.

Specific Gravity Temperature Correction

Specific gravity measurements are based on a cell temperature

of 77°F (25°C). In order to obtain an accurate specific gravity

measurement, the hydrometer reading must be adjusted based

on the temperature of the electrolyte. A good rule of thumb for

temperature correction is to add 4 points of specific gravity

(.004) for each 10 degrees Fahrenheit over 77°F and to subtract 4 points for each 10 degrees under 77°F.

Specific Gravity

Temperature Corrections

Electrolyte Specific On-Charge

Temperature Gravity Cell Voltage

Fahrenheit Celsius

Correction Correction

130 54 +.022 +.18

127 53 +.020 +.17

124 51 +.019 +.16

121 49 +.018 +.15

118 48 +.017 +.14

115 46 +.016 +.13

112 44 +.014 +.12

109 43 +.013 +.11

106 41 +.012 +.10

103 39 +.011 +.09

100 38 +.009 +.08

97 36 +.008 +.07

94 34 +.007 +.06

91 33 +.006 +.05

88 31 +.004 +.04

85 29 +.003 +.03

82 28 +.002 +.02

79 26 +.001 +.01

76 24 ——

73 23 -.002 -.01

70 21 -.003 -.02

67 19 -.004 -.03

64 18 -.005 -.04

61 16 -.006 -.05

58 14 -.008 -.06

55 13 -.009 -.07

52 11 -.010 -.08

Table 3-1

See table 3-1 — Specific Gravity Temperature Correction

Charging Methods

There are two important types of charge that are used for leadacid Industrial batteries: Standard Recharge (Cycle Charge)

and Equalizing Charge. (A third type of charge, the Freshening

Charge, is explained in “Placing a Wet Charged Battery in

Service”).

Standard Recharge — After a battery has undergone a normal

full shift and has been fully discharged to a recommended 80%

of rated capacity, it must undergo a complete, or standard,

recharge. Normally, a standard recharge is based on an 8-hour

charging cycle.

Equalizing Charge — Due to a slight difference in the construction of each battery cell, some cells take less charge than

others. An occasional equalizing charge will correct these cellto-cell imbalances and bring all cells up to the same capacity.

An equalizing charge is simply a 3-hour continuation of the

standard recharge at no more than the battery’s finish rate. A

minimum 3 amp per 100 A.H. equalize charge rate is necessary

to receive the full benefit of the equalize charge. A lower equalize charge rate will require a longer equalize charge period.

The best way to determine if the battery needs an equalizing

charge is to check the specific gravity readings for each cell. If

there is more than 0.020 specific gravity unit variation between

any two cells, the battery should be equalized. A good rule of

thumb is to equalize the battery once each week.

See table 3-2 — Specific Gravity vs. Percent Discharge

The Charging Process

During the charging process, the sulfate in the battery plates,

which accumulated during discharge, is driven back into the

electrolyte. This increases the specific gravity and brings the oncharge voltages up to 2.50-2.70 volts per cell, depending on the

age of the battery. (See “Discharging/Charging Characteristics”

in Section I).

As the battery approaches full charge, the charging rate must be

reduced to the battery’s finish rate. The finish rate is that current

which can be used safely on the battery anytime charging is

required, and which can be continued after the completion of the

charge without causing excessive gassing or high temperatures.

East Penn’s official finish rate in amps is equal to 5% of the amp

hour capacity at the 6 hour rate. The finish rate is on the nameplate of all East Penn batteries.

Normally, a battery will be properly charged if the charging

equipment is in good working condition and the battery is

“healthy”. A fully charged battery will have the following characteristics while on charge:

14

• Stable on charge battery voltage

• Gassing freely

• Charger current readings have leveled off

to finish rate

• Temperature-corrected specific gravity has

stopped rising

See table 3-1 for specific gravity temperature corrections.

SECTION III — INSTALLATION AND USE (cont.)

ELECTROLYTE SPECIFIC GRAVITY

VS. PERCENT DISCHARGE

GRAVITY

PERCENT DISCHARGED

020406080100

1.100

1.120

1.130

1.140

1.150

1.160

1.170

1.180

1.200

1.220

1.240

1.250

1.260

1.270

1.280

1.290

1

.300

D45 - D55

D35 - D65

D75 - D150

H80

H120

D110

M75

D160

D85 - D100

M85

D125

ELECTROLYTE SPECIFIC GRAVITY

VS. PERCENT DISCHARGE

G

RAVITY

PERCENT DISCHARGED

020406080100

1.100

1.120

1.130

1.140

1.150

1.160

1.170

1.180

1.200

1.220

1.240

1.250

1.260

1

.270

1

.280

1.290

1

.300

P49 - P60

P38 - P22

P82 - P165

P121

P170

1.310

1

.320

1

.325

P95 - P110

P140

D and M Series MAX POWR Series

Table 3-2

15

SECTION III — INSTALLATION AND USE (cont.)

Improper Charging

Improper charging reduces battery capacity and life.

Undercharging can cause residual sulfation to remain on plates,

educing cell performance. Sulfation also slowly occurs when

r

batteries are stored for months without receiving periodic freshening charges. The cells of a sulfated battery give low specific

gravity and voltage readings. It’s difficult to bring a heavily sulfated battery back to full charge and doing so will develop high

temperatures. (See “Correction of Sulfated Cells” — Section IV).

Undercharging also results in insufficient gassing, which creates

a high acid content at the bottom of the cell, eventually leading

to sulfation on the bottom part of the negative plates. This condition can be corrected by periodic equalizing charges.

Although all batteries are overcharged to an extent during every

charge cycle, severe overcharging results in excessive gassing

and very high battery temperatures — both of which are damaging to the battery. Battery temperatures should not exceed

115°F (25°C) during charging.

Excessive gassing occurs when a high charging rate is continued after the battery has been brought to its gassing voltage

(2.37 volts per cell nominal). A noticeable bubbling of electrolyte

can be seen, accompanied by high electrolyte temperature.

Because the gas is released from the electrolysis of water,

excessive gassing results in unusually high water usage. (See

the Troubleshooting Chart at the end of Section IV for additional

causes and remedies.)

For reduced maintenance and long, trouble-free battery life,

make sure all your batteries are properly charged. If you’re having trouble correcting any problems, contact your East Penn

agent or representative.

Charging Safety

There are several important safety precautions that should be

taken when charging a battery:

• Do not use open flames when checking the electrolyte

levels in storage batteries.

• Keep all open flames, sparks and matches away from

the charging area. DO NOT SMOKE around the charging

area.

• Only properly trained personnel should charge batteries.

• Before a battery is removed from a truck, or charged in a

ruck, the truck’s electrical circuit should be open, the

t

battery should be unplugged from the truck, and the

wheels should be chocked. (If removing the battery from

the truck, be sure to use proper lifting methods and

equipment.)

• The charger should be OFF before connecting it to the

battery.

• All mechanical connections on the battery and charger

should be tight. Loose connections can overheat and

cause arcing that could cause a gassing cell to explode,

or cables to become hot to the touch.

• Covers on battery trays should be kept open while

charging to promote cooling and allow gas to escape. If

the battery remains in the truck during charging, keep

the battery compartment cover and battery tray cover

open.

• Vent plugs should be kept firmly in place at all times to

minimize electrolyte spray when the battery gasses.

• The charger should be OFF before disconnecting the

battery.

• The charger connector shall not be plugged into the lift

truck connector under any circumstances.

SECTION IV — BATTERY MAINTENANCE AND TROUBLESHOOTING

Proper maintenance is essential to obtain long life and maximum efficiency from any Industrial battery. Carefully following a

scheduled maintenance routine will help increase battery performance and prolong service life.

One of the keys to an effective battery maintenance program is

to maintain an accurate records system of battery cycles and

maintenance/repair work for each battery. A records system is

particularly important for operations that use a large number of

batteries.

If you don’t already have one, these procedures should help

you create a reliable records system:

1. Assign a code/identification number to each battery and

charger. Use a multiple digit-system if you have several

different sizes or types of batteries. Prefixes or suffixes

can be used to identify batteries by size, voltage, shift,

lift truck, etc.

2. Designate a “pilot cell” for each battery. Record the specific gravity, voltage and temperature of the pilot cell

when the battery is first received and equalized, and

before and after each charge. The readings taken on

the pilot cell are considered to represent the specific

gravity, voltage and temperature of all the cells. Always

use the same cell for the pilot cell. The pilot cell

should be positioned near the center of the battery and

can be identified with a marking of some sort on the

intercell connector shroud or cell cover.

3. At least once each month, measure and compare the

specific gravity of all the cells. The readings should be

uniform from cell to cell. If the specific gravity readings

fall 20 points (0.20) below the nominal specific gravity

reading of 1.290, the electrolyte levels should be

checked and brought up to a uniform level before checking for a second time. If, at any time, the readings are 20

points (.020) greater than the nominal specific gravity

readings of 1.290, or the range of the on-charge cell

voltage readings is more than 0.15 volts, the battery

could be showing signs of cell failure. Contact your

authorized Deka Service Representative.

4. Remember to accurately record the number of cycles,

specific gravity, temperature and voltage readings; and

all maintenance and repair information for every battery.

THE DAILY BATTERY RECORD (Fig. IV-1) is an example of a basic record-keeping form. You should use a

form that best fits your operation’s individual needs. It is

also recommended that the identification number of the

charger used to charge the battery be recorded.

16

SECTION IV — BATTERY MAINTENANCE AND TROUBLESHOOTING (cont.)

DAILY BATTERY RECORD

Battery Number

Month Year

Total Cycles

Date

Specific Gravity

In Out

Operator

Wate r

Added

Repairs and Capacity Tests

(Date, Description and Results)

The correct hydrometer reading corresponds to an imaginary

line drawn across the side of the barrel at the lowest level of the

electrolyte. If the hydrometer has to be removed from the vent

hole, pinch the nozzle tightly or place a gloved finger against

the opening to prevent dripping.

To take the temperature reading, use the thermometer that’s

built into the hydrometer. If your hydrometer doesn’t have one,

insert a thermometer into the electrolyte of the cell. If the ther-

ometer doesn’t have specific gravity/temperature corrections

m

marked on it, refer to the temperature correction chart (Table 3-

1 — Section III). Always make sure the corrections on the float

thermometer agree with the chart in this service manual.

To obtain an accurate gravity measurement, it is important to

temperature correct the reading, as all specific gravity readings

should be corrected to a standard temperature of 77°F for proper comparison.

In addition to providing records of tests, repairs and individual

performance for each battery, accurate record keeping can also

reveal other helpful information:

• Specific gravity records taken at the beginning and

end of each cycle can pinpoint any irregularities in the

battery’s condition or in its operation. Readings taken

before recharging can indicate possible over-discharging and use in a low voltage condition, which eventually

can cause damage to lift truck electrical components

and shorten battery life.

• Maintenance and repair records can also point to bat-

tery abuse as well as help gauge individual battery

performance.

• Monthly and yearly records indicate the battery’s cycle

“age” and assist in controlling inventory and replacement

programs.

Fig. IV-1

Fig. IV-2

Using a Voltmeter

Using a voltmeter to measure open circuit voltage is usually a

faster and easier way to check a battery than measuring specific gravity with a hydrometer. A voltmeter is also used when

on-charge or on-discharge voltage readings are needed.

For individual cell voltage readings, place the positive lead of

the voltmeter on the positive terminal of the cell and the negative lead of the voltmeter on the negative terminal of the same

cell (Fig. IV-3).

After measuring the voltage of every cell, take the specific gravity readings of the cell with the highest open circuit voltage and

the cell with the lowest open circuit voltage. The specific gravity

readings should confirm the state of charge of both cells and

accurately pinpoint the difference between them. If the specific

gravity difference is greater than 20 points, a problem might

exist with one of the cells. Also, a cell may have internal problems if the open circuit voltage is more than 0.03 volts below

the average voltage of all the cells.

Reading Hydrometers and Thermometers

To take a specific gravity reading, remove the cell’s vent cap,

place the rubber hydrometer nozzle into the vent opening and

draw enough electrolyte into the barrel to permit the float to rise

freely. Hold the hydrometer at eye level as shown in (Fig. IV-2).

Battery Inspection

Batteries should be inspected periodically to avoid damage

resulting from previously undetected problems or improper

maintenance and operational procedures.

17

Loading...

Loading...