Deka Dominator Gel-Mate SVRLA G105, Dominator Gel-Mate SVRLA G45, Dominator SVRLA Gel-Mate G75 User Manual

WARNING: Risk of fire, explosion or burns. Do not disassemble or incinerate. Not recommended for inverted use.

Follow product charging instructions. High Voltage: Risk of shock. Do not touch uninsulated terminals or connectors.

Do Not Remove Vent Valves.

TM

Congratulations on your choice of a new Deka industrial battery. The SVRLA

line of Deka industrial batteries incorporates every feature required by today’s

user of electric industrial trucks. Designed with East Penn engineering technology

and built by master battery craftsmen according to strict quality assurance

guidelines, Deka industrial batteries are the finest available to meet today’s

material handling requirements. Deka precision construction provides new

equipment performance throughout a long life. This battery has been inspected

prior to shipment to ensure that it meets your specifications as ordered. By

following the operating and maintenance instructions, you will be ensuring

optimum life and performance of your new Deka industrial battery.

SEALED VALVE REGULATED LEAD-ACID

(SVRLA) GELLED ELECTROLYTE BATTERIES

STATE OF CHARGE VS. OPEN CIRCUIT

% Charge Open Circuit Voltage

100 …………… 2.15 – 2.18

75 ………………… 2.12

50 …………………2.07

25 …………………2.01

0 …………………1.97

OPERATING INSTRUCTIONS

WARNING: Charging shall be performed by using only the supplied on-board charger for gelmate. Only use an approved East Penn

charger with a sealed lead-acid gel battery charge curve profile.The valve-regulated vent should not be removed. Removal of the vent

will adversely affect the battery’s life and performance.The battery’s warranty will be void if these guidelines are not followed.

1. Upon receipt of the battery, if there are signs of rough handling,

or exposed electrolyte, or loose or missing vent(s), file a claim

with the carrier and advise your Deka representative.

2. Check the nameplate of your charger against the nameplate of the

battery to make sure they both show the same voltage and that

the six-hour ampere hour capacity of the battery falls within the

recharge range of the charger.

3. The “Battery Type Identification” shown on the battery (E, EO),

should match the “Battery Type Identification” specified on the

truck nameplate.

4. Make sure that the battery “SERVICE WEIGHT,” which is stamped

below the lifting hole in the steel tray, falls within the battery

weight range shown on the truck nameplate. East Penn

Manufacturing Co. cannot be responsible for determining that the

battery weight is sufficient to counterbalance your particular truck.

5. The battery should receive an equalizing charge prior to placing

the battery into service. The battery shall be charged by using the

supplied charger. The equalizing charge is complete when the

charger automatically terminates. No other charger should be

used unless approved by East Penn. Doing so will void the

warranty.

6. The battery shall be placed on charge at the end of the work shift

and the charge should continue until the charger terminates the

charge automatically. All vents should be unobstructed and

securely tightened. The steel tray cover or the truck compartment

should be kept open during the entire duration of charge.

7. Overcharging and undercharging a sealed gel electrolyte battery

will greatly affect the life of the battery.

8. Measuring the open circuit voltage provides a way to determine

the state of charge of the battery. The open circuit voltage shall be

taken with a voltmeter. Voltage measurements should be taken no

earlier than 4 hours on open circuit following a charge.

9. EPM recommends when lifting a battery that an insulated lifting

beam be used. Also, make certain that the lifting hooks are the

correct size and are properly aligned with the holes in the lifting

ears of the tray prior to hoisting a battery.

SEALED VALVE REGULATED LEAD-ACID (SVRLA) GELLED ELECTROLYTE BATTERIES

WARNING: Always wear safety glasses when working around batteries! Keep sparks and flames away! The valve regulated pressure relief

valve should never be removed or loosened!

1. The top of the battery should be kept clean and dry at all times.

Simply clean the top of the battery with a damp cloth. The valve

regulated vent and shroud shall remain on the battery at all times.

2. The cables and connectors should be inspected monthly for

exposed copper wires, frayed or cracked insulation, loose

connections, or pitted contacts, and repaired as required.

3. Be especially careful to keep metallic objects off the top of the

battery. Any metal touching two or more connectors may cause a

short circuit resulting in an arc or spark which ignite battery

gasses explosively.

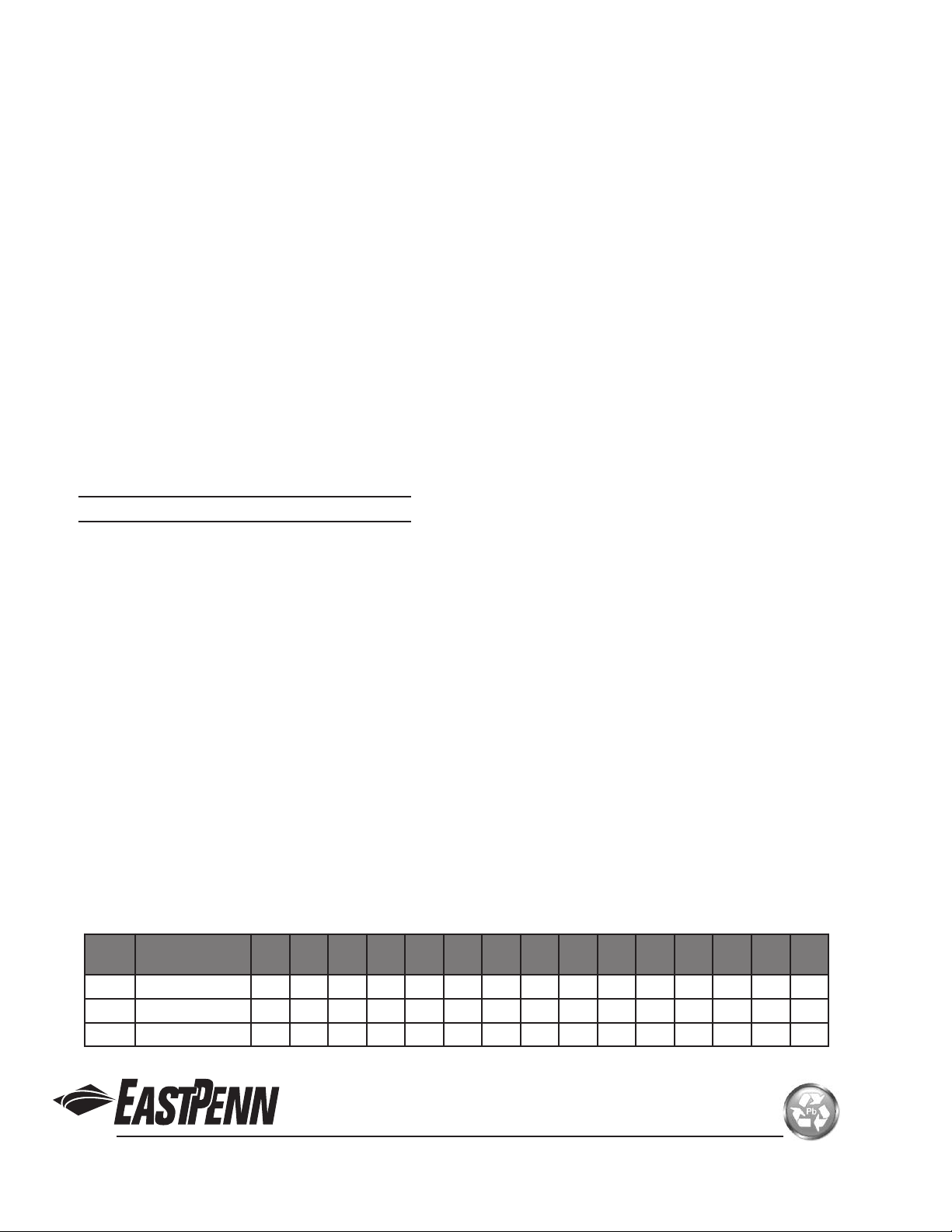

TYPE PLATES PER CELL 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33

G45 6 Hr A.H. Rating 90 135 180 225 270 315 360 405 –– –– –– –– –– –– ––

G75 6 Hr A.H. Rating 150 225 300 375 450 525 600 675 750 825 900 975 1050 1125 1200

G105 6 Hr A.H. Rating –– –– 420 525 630 735 840 945 –– –– –– –– –– –– ––

MAINTENANCE

4. The output rate and voltage of the charger should be checked

periodically. Make certain that the DC voltage and ampere hour

range of the charger match the nameplate information on the

battery.

5. Depending on the type of service, it will be necessary to give the

battery an equalizing charge every one to four weeks. Set the

charger to the equalize position.

East Penn Manufacturing Co. Lyon Station, PA 19536-0147 Phone: 610-682-6361 Fax: 610-682-4781 www.dekabatteries.com

E.P.M. Form No. 0700 2/16 © 2016 by EPM Printed in U.S.A.

All data subject to change without notice. No part of this document may be copied or

reproduced, electronically or mechanically, without written permission from the company.

Loading...

Loading...