Zia 6000 and 8000

series

Technical manual

Model: Zia 6000 and Zia 8000

Machine type: 9CND…

Revision 1.0, English

Reference: 5DTCNP20

The manufacturer of the machine is:

De Jong Duke

Postbus 190

3360 AD SLIEDRECHT

The Netherlands

Telephone +31 (0) 184 496767 www.dejongduke.nl

Fax: +31 (0) 184 416059 support@dejongduke.nl

2

Copyright © 2014, J.M. de Jong Duke automatenfabriek b.v.

All rights reserved.

Although this user manual has been put together with the utmost care, J.M. de

Jong Duke automatenfabriek b.v. accepts no liability for inaccuracies or

omissions. No liability is accepted for the consequences arising from operation of

the equipment in accordance with the information contained in these instructions.

J.M. de Jong Duke automatenfabriek b.v. reserves the right to alter specifications

at any time and without prior notification to the purchaser.

Preface

This technical manual is valid for the machine supplied by the manufacturer,

including the options installed by the manufacturer. The manufacturer accepts no

liability for any damage resulting from incorrect or improper use of the machine,

or resulting from modifications that have not been authorized by the

manufacturer.

This manual gives instructions for the operation and maintenance of the machine.

Moreover, it gives solutions to simple malfunctions that may occur. The

instructions in some paragraphs are meant only for persons who are trained in

the operation and maintenance of the machine.

Always use original parts from the manufacturer when the machine needs to be

repaired.

Carefully read this technical manual before you operate and/or repair the

machine.

Keep this manual in a safe place for possible later reference.

Only properly trained personnel may carry out repairs, install the machines or

transport the machines.

This manual cannot be regarded as a replacement for training and instruction, but

must be seen as an addition to the training, and as a reference work.

3

CONTENTS

1 SAFETY ............................................................................................... 6

1.1 SAFE USE .......................................................................................... 6

1.2 SAFETY RISKS ..................................................................................... 6

1.3 INSTALLATION..................................................................................... 6

1.4 MAINTENANCE .................................................................................... 6

1.5 EXTENDED DOWN TIME .......................................................................... 7

2 DESCRIPTION OF THE MACHINE ......................................................... 8

2.1 GENERAL........................................................................................... 8

2.2 THE FRONT OF THE MACHINE .................................................................... 8

2.3 OVERVIEW OF THE MACHINE INTERIOR ........................................................ 8

2.4 BACKSIDE OF THE MACHINE ..................................................................... 9

3 OPTIONS AND ACCESSORIES ............................................................ 10

3.1 BASE CABINET .................................................................................. 10

3.2 CUP DISPENSER ON FRONT .................................................................... 10

3.3 CUP DISPENSER ON RIGHT HAND SIDE ....................................................... 10

3.4 TABLE BETWEEN MACHINE AND CABINET .................................................... 10

3.5 COLD WATER UNIT IN BASE CABINET ......................................................... 11

3.6 WASTE GUIDE ................................................................................... 11

3.7 DRIP TRAY DRAIN. .............................................................................. 11

3.8 FRESH MILK SYSTEM............................................................................ 11

3.9 PAYMENT SYSTEMS ............................................................................. 12

3.10 MECHANICAL CONSUMPTION COUNTER ....................................................... 12

3.11 PUMP SET ........................................................................................ 12

4 TECHNICAL DATA .............................................................................. 13

4.1 TYPE PLATE ...................................................................................... 13

4.2 TECHNICAL SPECIFICATIONS .................................................................. 13

4.3 DIMENSIONS OF THE MACHINE ................................................................ 14

4.4 WATER SPECIFICATIONS ....................................................................... 15

4.5 MACHINE CONFIGURATIONS AND VARIATIONS .............................................. 15

4.6 NORMS AND STANDARDS ...................................................................... 15

5 FUNCTION OF THE COMPONENTS ..................................................... 16

5.1 HOT WATER SYSTEM ............................................................................ 16

5.2 SCHEMATIC DIAGRAM OF THE WATER SYSTEM .............................................. 17

5.3 INLET VALVE ..................................................................................... 18

5.4 PRESSURE REDUCER ............................................................................ 18

5.5 WATER FLOW METER/WATER COUNTER ...................................................... 20

5.6 PUMP ............................................................................................. 21

4

5.7 BOILER ........................................................................................... 23

5.8 POSITION OF VALVES IN THE HOT WATER SYSTEM .......................................... 26

5.9 2-WAY VALVE / OUTLET VALVE ................................................................ 28

5.10 3-WAY VALVE / BREWER VALVE ............................................................... 29

5.11 PRESSURE VALVE 2 BAR ....................................................................... 30

5.12 SAFETY PRESSURE VALVE 12 BAR ............................................................ 30

5.13 COEX

®

BREWING SYSTEM .................................................................... 31

5.14 REMOVAL OF THE COEX

®

BREWER ........................................................... 32

5.15 INSTALL THE BREWER .......................................................................... 33

5.16 BREWER CYCLE .................................................................................. 34

5.17 BREWER MOTOR AND MICRO SWITCH ........................................................ 36

5.18 UPPER PISTON .................................................................................. 37

5.19 CONTROLLING COFFEE/ESPRESSO PRESSURE SWITCH ..................................... 38

5.20 SEALS ............................................................................................ 40

5.21 REPLACE SEALS IN LOWER PISTON ........................................................... 41

5.22 MIXER ............................................................................................ 42

5.23 GRINDER ........................................................................................ 46

5.24 GRINDER IN DOOR .............................................................................. 47

5.25 REMOVING BEAN CANISTER AND GRINDER. ................................................. 47

5.26 GRINDING ADJUSTMENT. ...................................................................... 48

5.27 DEFAULT GRINDER SETTING ................................................................... 49

5.28 INGREDIENT CANISTERS ....................................................................... 50

6 ELECTRONIC HARDWARE .................................................................. 51

6.1 POWER SUPPLY .................................................................................. 52

6.2 CONTROL BOARD ............................................................................... 53

6.3 I/O BOARD ...................................................................................... 54

6.4 CONNECTORS ON THE IO BOARD ............................................................. 55

6.5 LVDS DISPLAY AND TOUCH SCREEN. ........................................................ 57

6.6 SPEAKER ......................................................................................... 57

6.7 CUP SENSOR .................................................................................... 58

6.8 ELECTRICAL SCHEMATICS ...................................................................... 59

7 SERVICE AND PROGRAMMING .......................................................... 61

MODE WITHOUT PASSWORD ........................................................................... 61

7.1 INSERTING SAFETY KEY ........................................................................ 61

7.2 FUNCTIONS WITHOUT PASSWORD ............................................................ 62

7.3 SERVICE MODE WITH PASSWORD ACCESS ................................................... 64

7.4 RECIPE SETTINGS ............................................................................... 65

7.5 BOILER TEMPERATURE ......................................................................... 68

5

7.6 CUP SENSOR .................................................................................... 69

7.7 LANGUAGE ....................................................................................... 69

7.8 PAYMENT SETTINGS ............................................................................ 70

7.9 SOFTWARE CONFIGURATIONS ................................................................. 71

7.10 LOAD PERMISSIONS ............................................................................ 72

7.11 CLOCK/TIME SETTINGS ........................................................................ 73

7.12 JUG SETTINGS ................................................................................... 74

7.13 IMAGES .......................................................................................... 75

7.14 TEST OUTPUTS .................................................................................. 76

7.15 SHOW ERROR LOG .............................................................................. 76

7.16 ERROR SETTINGS ............................................................................... 77

7.17 WATER FILTER SETTINGS ...................................................................... 78

7.18 RINSE ............................................................................................ 78

7.19 WEAKLY CLEANING CYCLE BREWER ........................................................... 78

7.20 SHOW PRODUCT COUNTERS ................................................................... 78

7.21 SOFTWARE INFORMATION ..................................................................... 78

7.22 SHOW EVA-DTS ............................................................................... 79

7.23 CHANGE THE SERIAL NUMBER ................................................................. 81

7.24 FAN TURN OFF DELAY ........................................................................... 81

7.25 EMPTY BOILER ................................................................................... 82

8 HOW TO DO ...................................................................................... 83

8.1 HOW TO LOAD A NEW CONFIGURATION FILE FROM AN USB STICK? ..................... 83

8.2 HOW TO LOAD A NEW FLASH(SWF) OR MOVEC ICEQ FILE FROM USB ................ 84

8.3 HOW TO GET AND LOAD A PERMISSION KEY ................................................. 85

9 WARNING, FAILURE AND ERROR MESSAGES .................................... 89

1 Safety

1.1 Safe use

Before using your coffee machine, please read the safety

instructions and all of the information in this manual first and

keep it for future reference.

Be careful! This machine serves hot drinks. Don’t reach

beneath the dispensing nozzles and hot water spout after

selection and during dispensing.

This appliance can be used by children aged 8 years and

above and persons with reduced physical, sensory or mental

capabilities or lack of experience and knowledge if they have

been given supervision or instruction concerning use of the

appliance in a safe way and they understand the hazards

involved. Children shall not play with the appliance. Cleaning

and user maintenance shall not be made by children without

supervision.

The machine may only be in locations where it can be

overseen by trained personnel.

1.2 Safety risks

The most important safety risks during maintenance of this

machine:

Moving parts inside the machine, beware of trapped fingers if

the service key is placed when the door is open.

Beware of hot parts and hot liquid inside the machine, even

after the power is disconnected.

1.3 Installation

Installation, transportation and adjustment of the machine

should only be carried out by properly trained service

personnel.

Check the appliance for transport damage. Do not connect a

damaged machine.

The machine is not suitable for outdoor use.

Do not install the machine in an area where a water jet or

similar device could be used.

Place the machine on a level surface in a hygienic dry room,

with a temperature between 5°C and 35°C. (40°F - 95°F)

Do not use an extension cord.

Only hose-sets according to IEC 61770 may be used for the

connection to the water supply.

1.4 Maintenance

Regular cleaning according to the user manual is needed to

ensure hygienic operation.

7

The appliance shall not be cleaned by a water jet.

Do not use water in or near the machine unless the

instructions explicitly give direction to do so.

Do not use aggressive cleaning products or abrasives to clean

(parts of) the machine.

1.5 Extended down time

If the machine will not be used for a longer period of time (for

example during the holidays) it is recommended to switch off

the water supply and the electricity. The main on/off switch

(see picture in chapter 2.3, point 2) is located at the inside of

the machine.

In areas where the temperature can fall below freezing, the

boilers must be emptied. (see chapter 7.25)

8

2 Description of the machine

2.1 General

The machine is a compact semi-automatic machine for the preparation and

vending of hot and optional cold drinks.

2.2 The front of the machine

The machine can be operated by using the touch panel on the door. By touching

one of the selection images on the screen, a product choice can be made.

Before pressing start, first a cup must be placed under the correct dispense

nozzle.

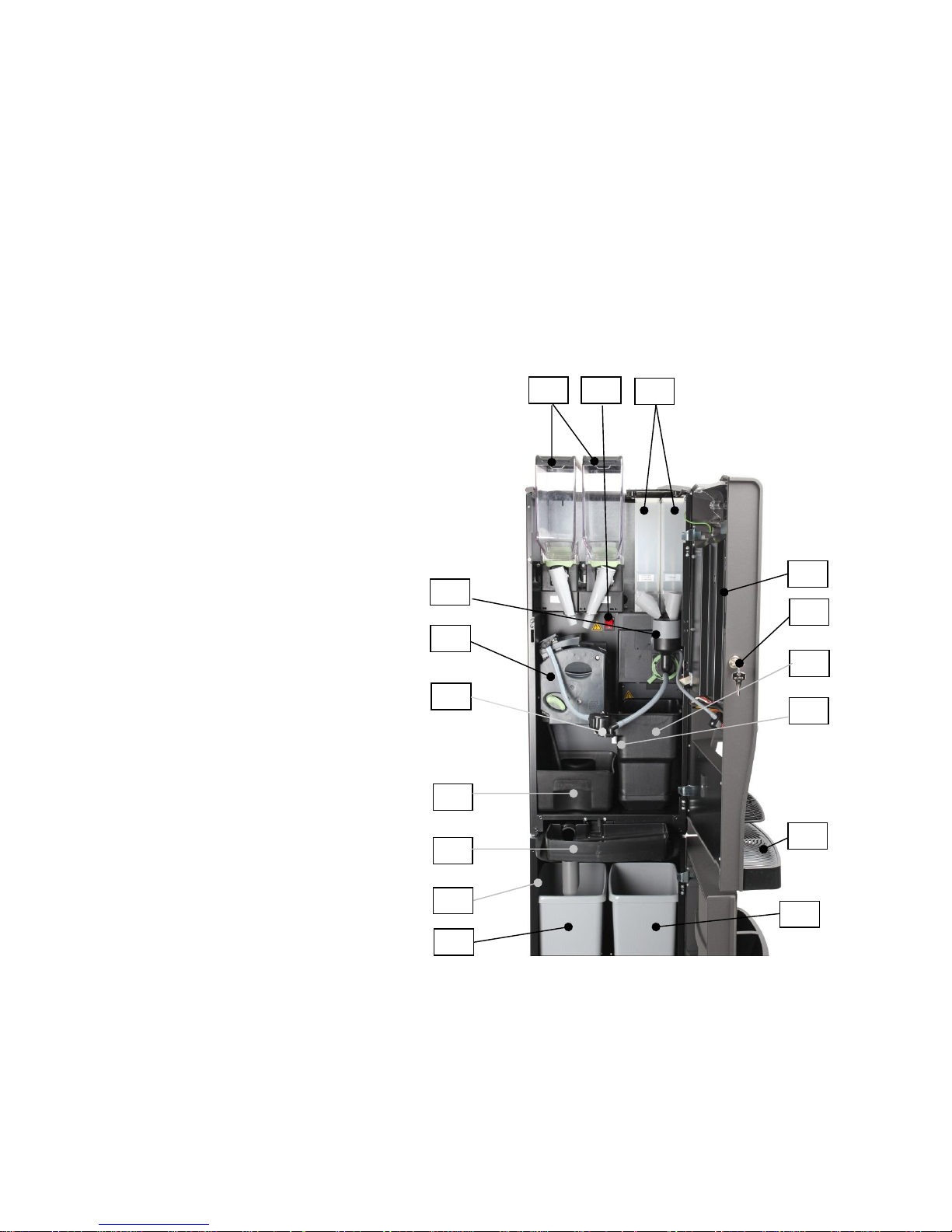

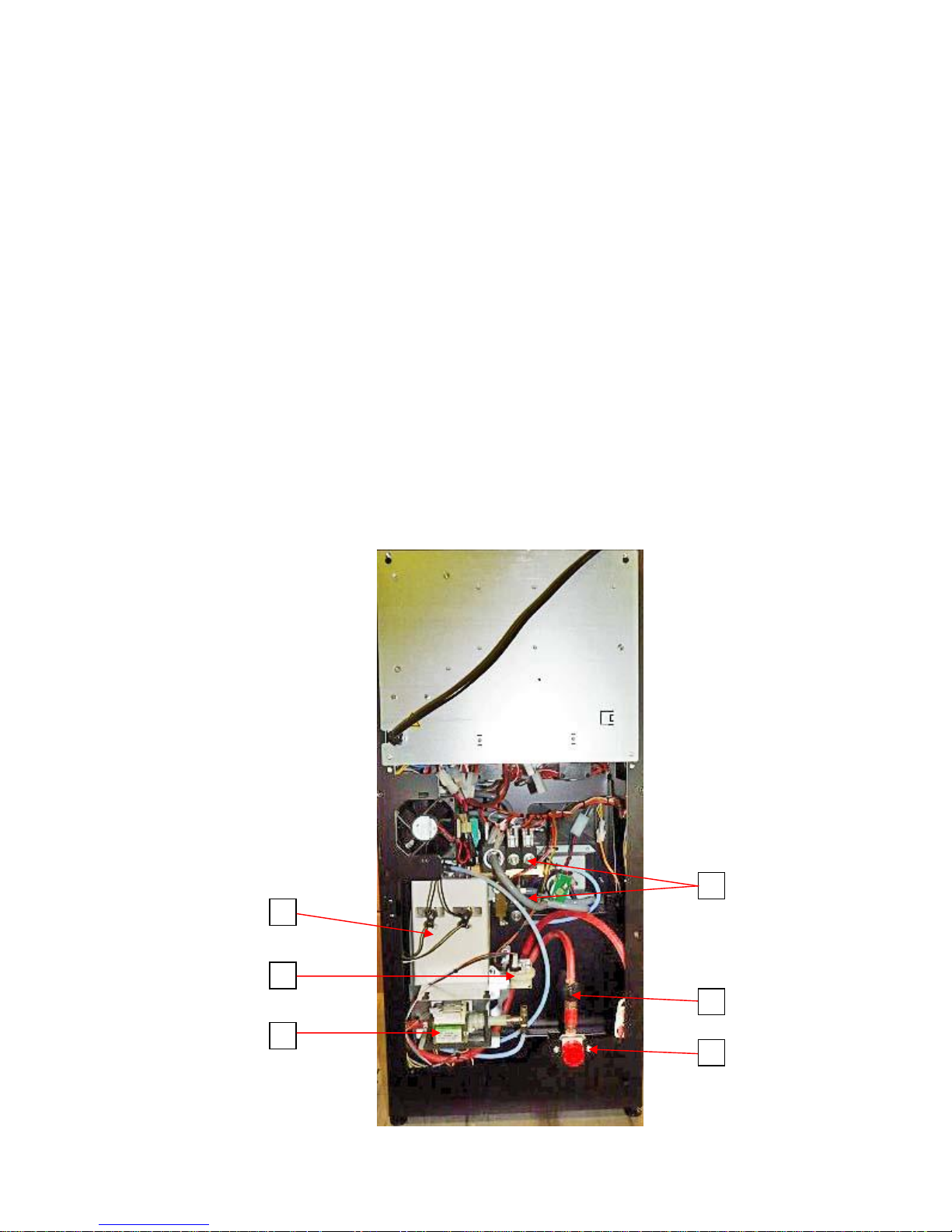

2.3 Overview of the machine interior

1. Bean canisters

2. On/off switch

3. Instant canisters

4. Door switch

5. Door lock

6. Waste guide (or Waste bucket)

7. External drip tray

8. Internal drip tray.

9. Dispensing nozzles

10. CoEx® brewer system

11. Mixing system

12. Base cabinet (Option)

13 Waste bucket sensor

14 Waste (residue) bucket

in base cabinet. (Option)

15 Waste (liquid) bucket

in base cabinet. (Option)

2 1 3 5 6

10

11

13

4

9

2.4 Backside of the machine

1 Water connection

2 Holes for water filter in

base cabinet. (optional)

3 Fan

4 Power cord

4 1 2

10

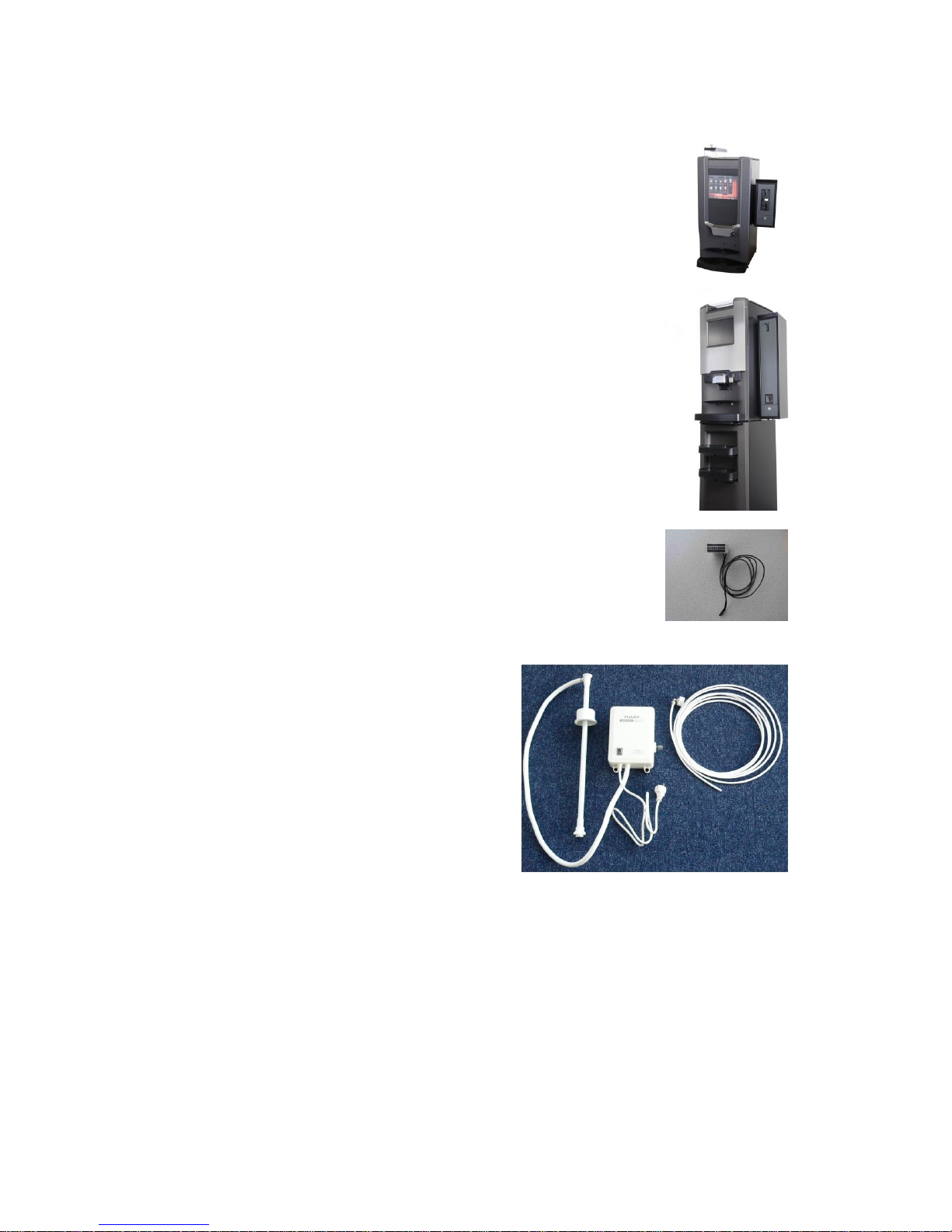

3 Options and accessories

The machine can be extended with several options. Some options can

interference or exclude other options.

3.1 Base cabinet

Part number 9OKNK1140 is a base cabinet with condimental trays.

Part number 9OKNK1110 is a base cabinet with closed front.

Dimensions base cabinet:

Height: 850 mm / 33.5 inch

Width: 360 mm / 14.2 inch

Depth: 510 mm / 20.0 inch

3.2 Cup dispenser on front

A Cup dispenser can be mounted on the front of the base cabinet

instead of an ingredient tray.

Part number 9BEB008 for cups 70mm diameter

Part number 9BEB010 for cups 80mm diameter

3.3 Cup dispenser on right hand side

Part number 9BEB007 for cups 70mm diameter

Part number 9BEB009 for cups 80mm diameter

3.4 Table between machine and cabinet

A table can be mounted in-between the base cabinet

and machine

Part number 9ETA003 table for 70mm cups

Part number 9ETA005 wide table for 70mm cups

Part number 9ETA007 table for 80mm cups

NOTE:

The drain from the drip tray to a bucket in the base

cabinet is not possible in combination with this option.

11

3.5 Cold water unit in base cabinet

A cold water unit for chilled water or a unit for

carbonated and chilled water can be installed in the

base cabinet.

Part number 9VKS019 chiller for chilled water.

Part number 9VKS017 chiller for chilled and

carbonated water.

3.6 Waste guide

The machine can be extended with a waste guide to the base

cabinet.

Part number 5KAF085

If this waste guide is installed, the error and warning

messages based on number of cycles needs to be switched off

(Set to not available) in the service menu.

(see chapter 7.16, error settings)

In this case the wires on the waste bucket sensor needs to be

electrical disconnected.

3.7 Drip tray drain.

The water from the drip tray can be drained to a large bucket in the base cabinet.

This drain is only available in combination with a base cabinet.

An extra sensor can be installed in the base cabinet for detecting a full bucket.

Part number 9AOV011

3.8 Fresh milk system.

It is possible to provide the machine with a fresh milk system.

This must be done in the factory, it is not possible to build a fresh milk system in

an existing machine.

For information, contact the manufacturer: support@dejongduke.nl

12

3.9 Payment systems

A Coin validator in a side unit.

A coin validator/acceptor communicating via the MDB protocol

can be connected to the control board.

B Change giver in a side unit.

A coin change giver, communicating via the MDB protocol,

can be connected to the control board.

C Card reader in a side unit.

A card reader or key payment system, communicating via the

MDB protocol, can be connected to the control board.

3.10 Mechanical consumption counter

A total product counter can be installed in the door and is

connected to the control board.

Part number 5ETL010

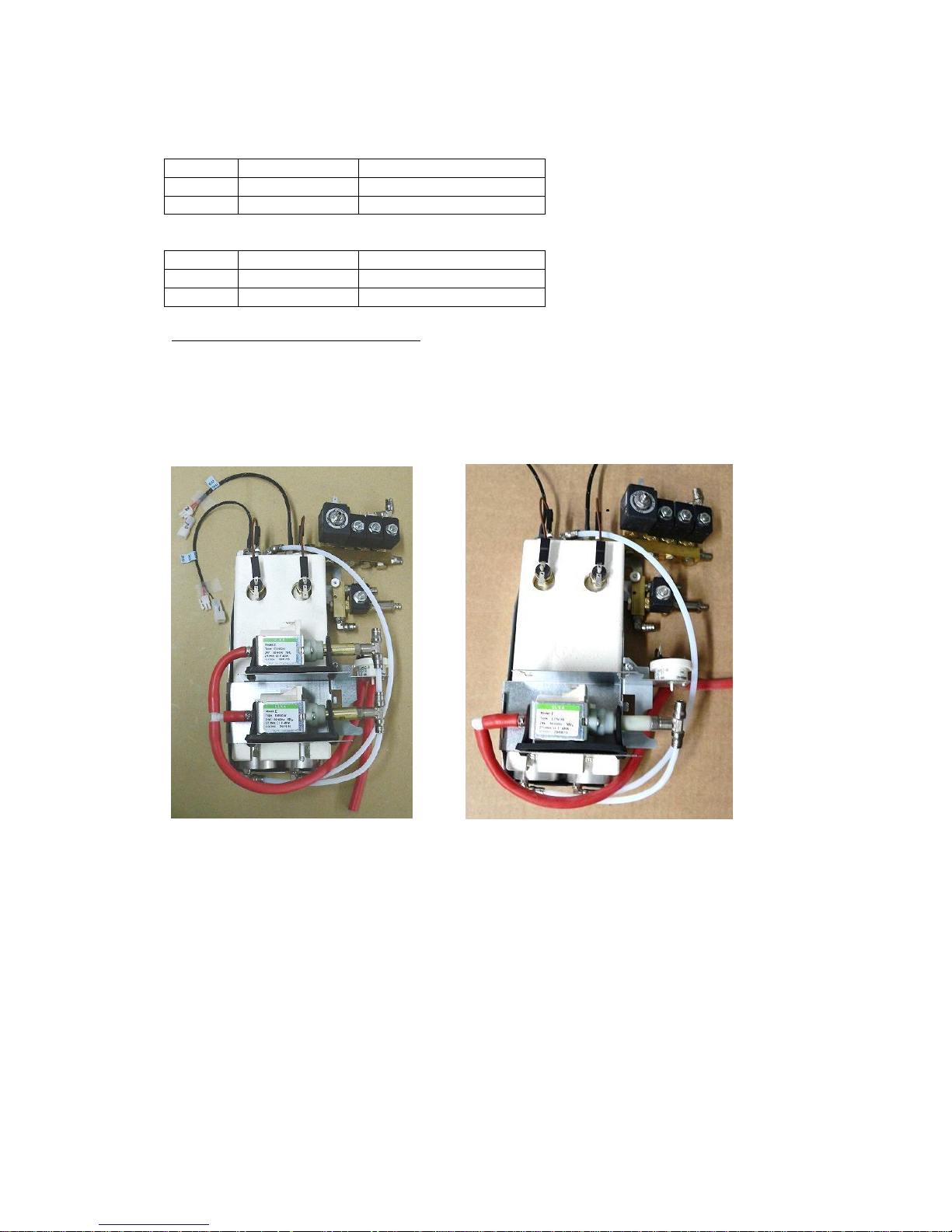

3.11 Pump set

The Machine can work in combination with a

pump set.

Part number of the 230V pump set complete:

9VIL018

13

4 Technical data

4.1 Type plate

The type plate is mounted at the inside of the machine, at the top left.

The type plate shows:

- Manufacturer

- Serial number

- Type/model specification

- Power connection

- Date of production

- Water connection

4.2 Technical specifications

Dimensions:

Width 360 mm / 14.2 inch

Depth 510 mm / 20.1 inch

Height :

- Standard machine: 795 mm / 31.3 inch

- With bean canister: 875 mm / 34.5 inch

- With increased bean canister: 1025 mm / 40.4 inch

Weight (empty): ±50 kg / 110 lbs

Electrical connection possibilities:

- 120 VAC, 60 Hz, 1.3 kW

- 220-240 VAC, 50-60 Hz, 2.9 kW

- 220-240 VAC, 50-60 Hz, 1.5-1.8 kW (limited power setting)

Water line pressure:

- Minimum 100 kPa (1 bar)

- Maximum 600 kPa (6 bar)

- Rated pressure: Water boiler 1.1 MPa (11 bar)/160 psi

Steam boiler 0.5 mPa (5 bar)/ 72 psi

Capacity waste bucket:

About 180 coffee consumptions.

Noise level:

- Standby: 0 dB(A).

- During delivering beverages using whole beans: < 63 dB(A).

Ambient temperature:

- Storage 5 - 50°C (40 - 120°F)

- Operating 5 - 35°C (40 - 95°F)

14

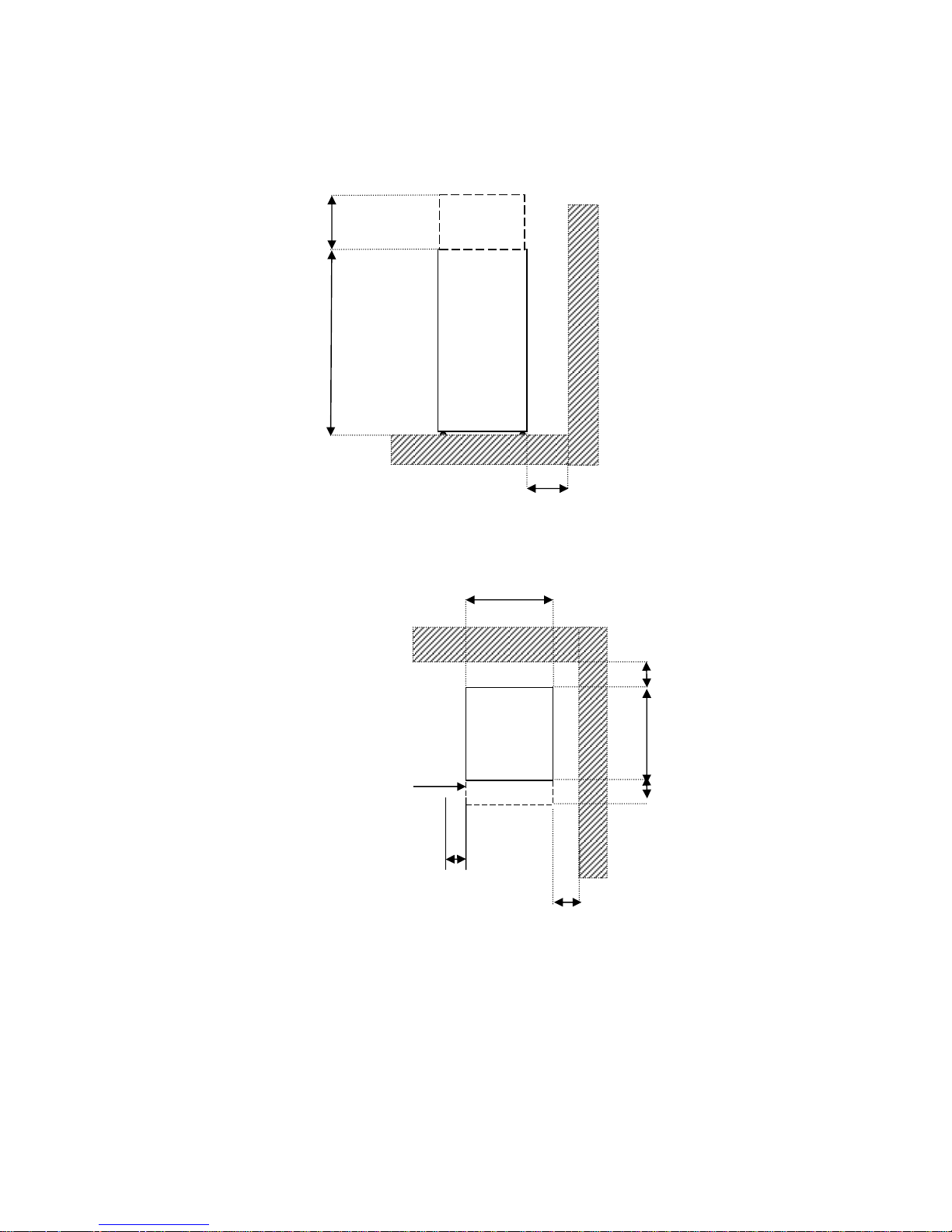

4.3 Dimensions of the machine

The machine can be extended with several options.

In the pictures below are the dimensions for a standard sized machine.

Door lock

Front view

Top view

795mm

31.3 inch

170mm

6.7 inch

295mm

11.6 inch

360mm

14.2 inch

170 mm

6.7 inch

160mm

6.3 inch

350mm

13.8 inch

80mm

3.2 inch

lid

door

50 mm

2 inch

15

4.4 Water specifications

Water line pressure: See chapter 4.2

The water flow rate from the mains should be minimal 2,5 liter per minute.

For an optimal operating of the coffee machine and an optimal coffee quality, the

water should be conform the following specifications:

- Hardness: 6-8 ºdH (German hardness) or11-14 °fH (French hardness)

- pH value: Minimal 6.5

Maximal 8.0

- Conductance: about 100S (micron Siemens) @ 20º C (68º F)

A water filter can be used if the water quality is not conform our specification.

The incoming water temperature may not be above 30ºC. (86ºF)

4.5 Machine configurations and variations

The machine can be equipped in different canister and product variations. The

specification number is always printed on the type plate. See the product

information sheets for detailed information.

www.dejongduke.nl

4.6 Norms and standards

The machine bears the CE marking and complies with the following

directives/regulations:

2006/42/EC Directive on machinery

2006/95/EC Low voltage directive

2004/108/EC Directive EMC

(EG) 1935/2004 Regulation on food contact materials

98/83/EG Directive on the quality of water

2011/65/EU Directive ROHS

The machine complies with the following standards:

IEC 60335-1 Safety of household and similar appliances

IEC 60335-2-75 Particular requirements for dispensing appliances and

vending machines

EN 61000-6-3 Radiated and conducted immunity up to 1 GHz

EN 61000-6-1 Radiated and conducted immunity up to 2.7 GHz

EN 61000-4-2 ESD

EN 61000-4-3 HF immunity

EN 61000-4-4 EFT

EN 61000-4-5 Surge

EN 61000-4-6 CDN/clamp injection

EN 61000-4-8 Power Magnetic filed

EN 61000-4-11 Dips and voltage fluctuations

EN 61000-3-2 Harmonic currents

EN 61000-3-3 Flicker

16

5 Function of the components

In the next paragraphs you find a detailed description of the several parts and

components in the machine.

Understanding of the function of the different components is essential for

maintaining the machines.

5.1 Hot water system

The water system is positioned at the back side of the machine and accessible

from the back.

If water and power are connected and the door is closed the water system start

filling the boilers automatically.

The water system consists out of the following main components:

1. Inlet valve

2. Pressure reducer

3. Flow meter

4. Vibration pump(s)

5. Boilers

6. Valves (outlet valves and pressure valves)

4

17

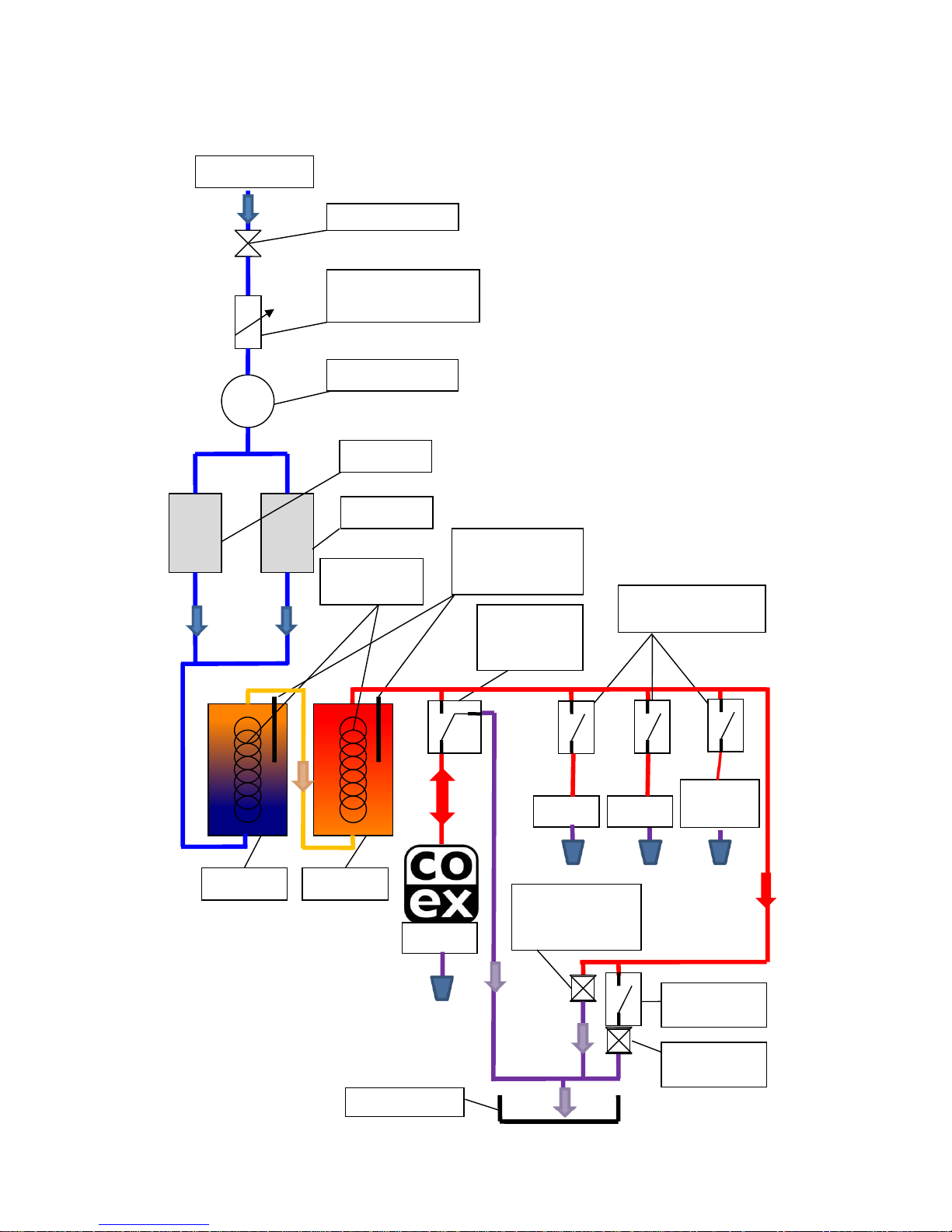

5.2 Schematic diagram of the water system

(standard 9CND machine, 2 mixers)

Mains water

Pressure

reducer 0,9 bar

C

Pump 1

Pressure

valve 2 bar

3-way

outlet

valve

Drip tray

Temperature

and level

sensor

Boiler with

heater

Mixer

Hot

water

2-way outlet

valve

Expansion

valve

Flow meter

Pump 2

Brewer

Mixer

2

1 2 1

2

1

2

1

2

1

Safety

pressure

valve 12 bar

Boiler 1

Boiler 2

18

5.3 Inlet valve

The inlet valve is controlled by the level sensor in the

boiler and is switched on during a dispense of hot water

to the brewer or mixer. The inlet valve is a 24V DC

valve. The inlet valve contains a backflow protection.

This backflow protection is preventing that water is

flowing back into the water supply.

Electrical connections/wire colors:

Number

Wire color

function

1

Orange

Common (+24V)

2

Orange-green

Output (0)

5.4 Pressure reducer

The pressure reducer reduces the water pressure to a stable pressure

independent from the inlet pressure from the mains water supply.

The required inlet pressure from the water supply is between 1,0 and 6 bar.

The pressure reducer is adjusted to an outlet pressure of about 0,8 - 0,9 bar

during an espresso cycle.

The input and output tube to the reducer must

be connected in the right direction, the reducer

works incorrectly in the reversed mode.

There is an arrow on the side of the reducer

indicating the correct water flow direction.

The reducer contains a backflow protection. This

backflow protection prevents the possibility that

water from the machine is flowing back into the

main water supply.

19

Procedure to adjust the pressure reducer:

1. Remove the lower back plate from the machine.

2. Remove the tube clamp and stop. (see picture)

3. Connect the manometer to the tube.

4. Pull out the knob to unlock the reducer.

5. Select an (double) espresso. Adjust the reducer by

turning the knob during the pump cycle of the espresso

selection. The manometer must show 0,8 - 0,9 bar during

an espresso cycle.

6. Lock the reducer by pushing the knob down towards it’s

own housing.

7. Disconnect the manometer and replace the tube clamp

and stop in the tube.

8. Replace the back plate on the machine.

9. Ready

Part number pressure reducer: 4MVL010

Looking from above: Turning clockwise = increase output pressure

Turning counter clockwise = decrease output pressure

20

IN

OUT

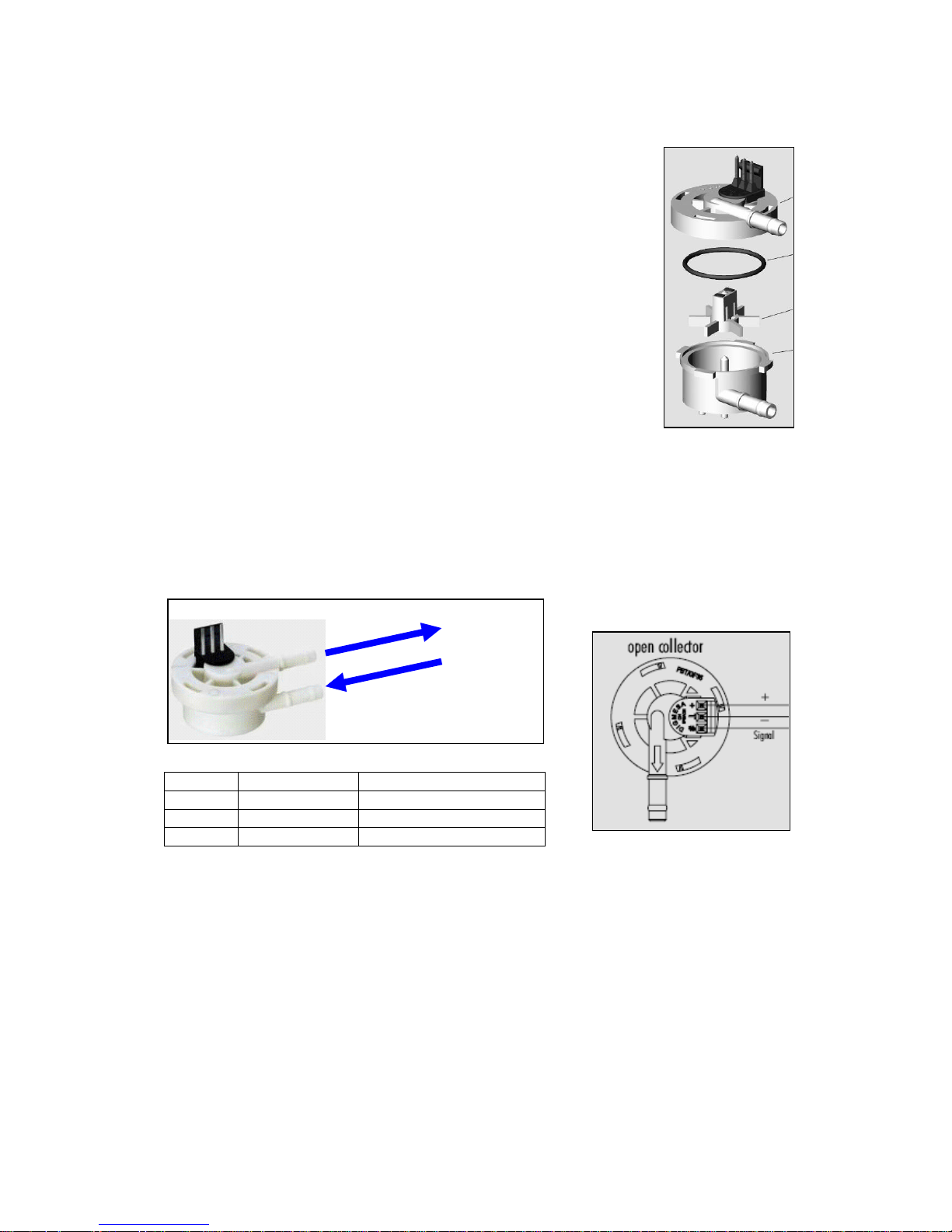

5.5 Water flow meter/water counter

The water flow meter measures the quantity of the water

flowing through the hot water pressure system.

Three functions are based on the water flow meter:

1. The water dosages for the consumptions are based on

quantity of the pulses generated by the flow meter.

2. During the start up procedure it is detected if water is flowing

into the system. If not, the machine will stop working and show

the error messages “start-up problem” and “no water

connected”

3. The amount of heating of the boiler is, besides the

measurement with the temperature probe, also based on the

quantity of incoming water.

The water flow meter is built in between the pressure reducer

and the pumps. It is a small turbine which produces electrical

pulses. Each 360º rotation produces 2 pulses in the sensor (Hall

element). The pulses are detected by the control system.

The tube to the water flow meter must be connected in the right position; the

flow meter cannot detect water in the reverse mode. There is a small arrow on

the water flow meter which shows the right direction.

The water flow meter is a 1.8 mm type.

Each pulse is about 0.8 ml of water.

Electrical connections/wire colors:

Number

Wire color

function

1

Red-white

Common (+)

2

Green-purple

Null (0)

3

Blue-black

Signal to the IO board

21

0

24V 0 24V

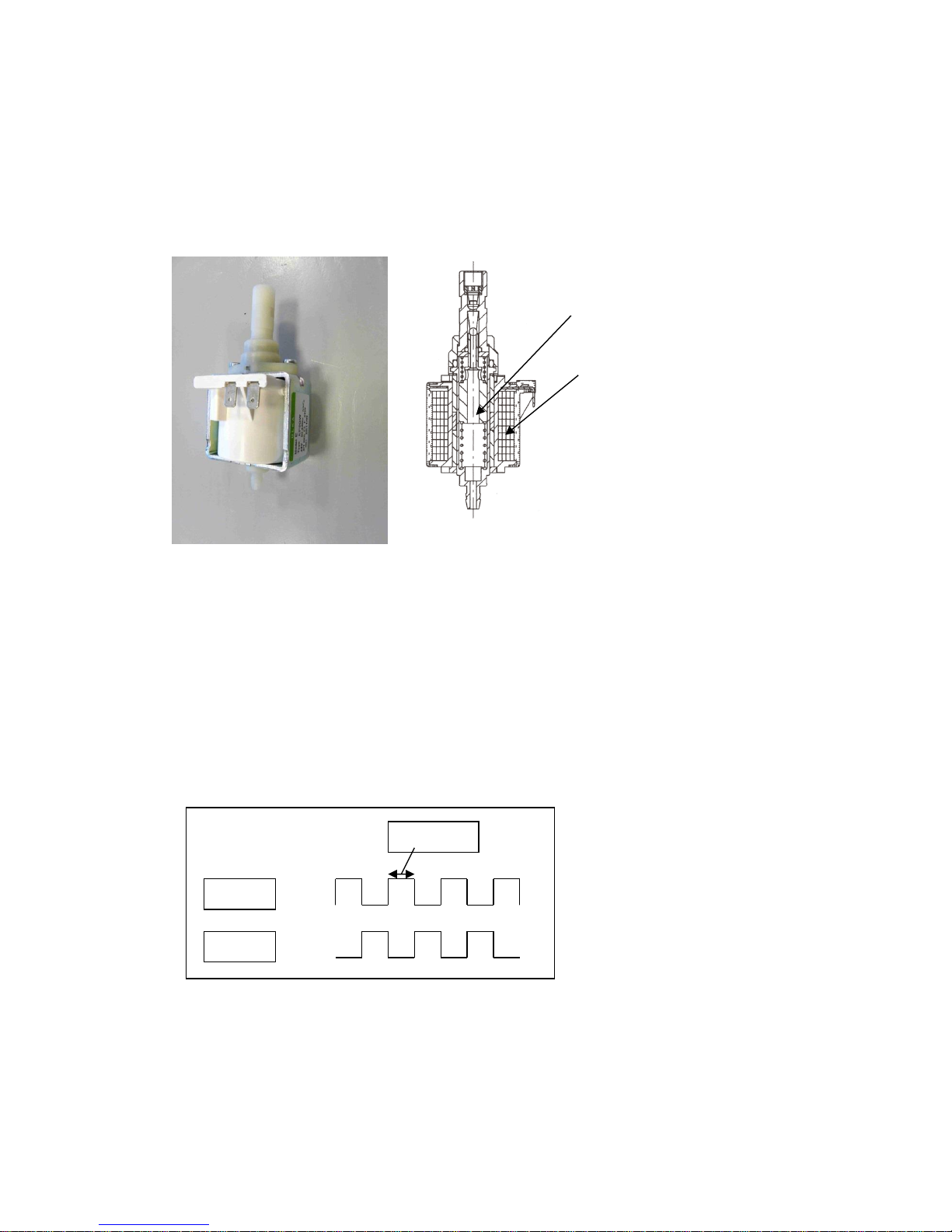

5.6 Pump

The pumps are generating the pressure and flow of the water.

The pumps increase the pressure to the required brewing pressure (1.5 till 10

bar).

The pump is a vibration pump. The plunger vibrates up and down, therewith a

pressure can be build-up.

The pump is a 24VAC pump, the electrical signal to the pump is a 24DC block

pulse.

The pressure can be adjusted by the electrical signal (pulse-width) to the pump.

A longer pulse gives a higher pressure because the plunger is lifted higher.

The maximum pulse width is 20. This figure can be set in the service program,

individual for every consumption.

Because of the high frequency of the pulses this electronic signal cannot be

measured with an ordinary volt meter.

The pulses for the two pumps runs out of phase so a stable high pressure is

offered to brew an espresso.

Pump 1

Pump 2

Pulswidth

plunger

coil

22

Electrical connections/wire colors:

Pump 1:

Number

Wire color

function

1

Grey-Blue

Common (+24V)

2

Yellow-Brown

Output (0)

Pump 2:

Number

Wire color

function

1

Black-Pink

Common (+24V)

2

Orange-White

Output (0)

Machines with one or two pumps:

- The Fresh brew version without a bean hopper (Zia 6000) has just 1 pump and

is brewing coffee on a low 1-4 bar pressure.

- The B2C espresso machine has 2 pumps, parallel connected and can brew

espresso on 8-10 Bar or coffee on a low pressure 1-4 bar.

The variation in pressure generates an excellent coffee or espresso flavor.

Part number pump: 4EMT027

2 pumps system (Zia 8000 series)

1 pump system (Zia 6000 series)

23

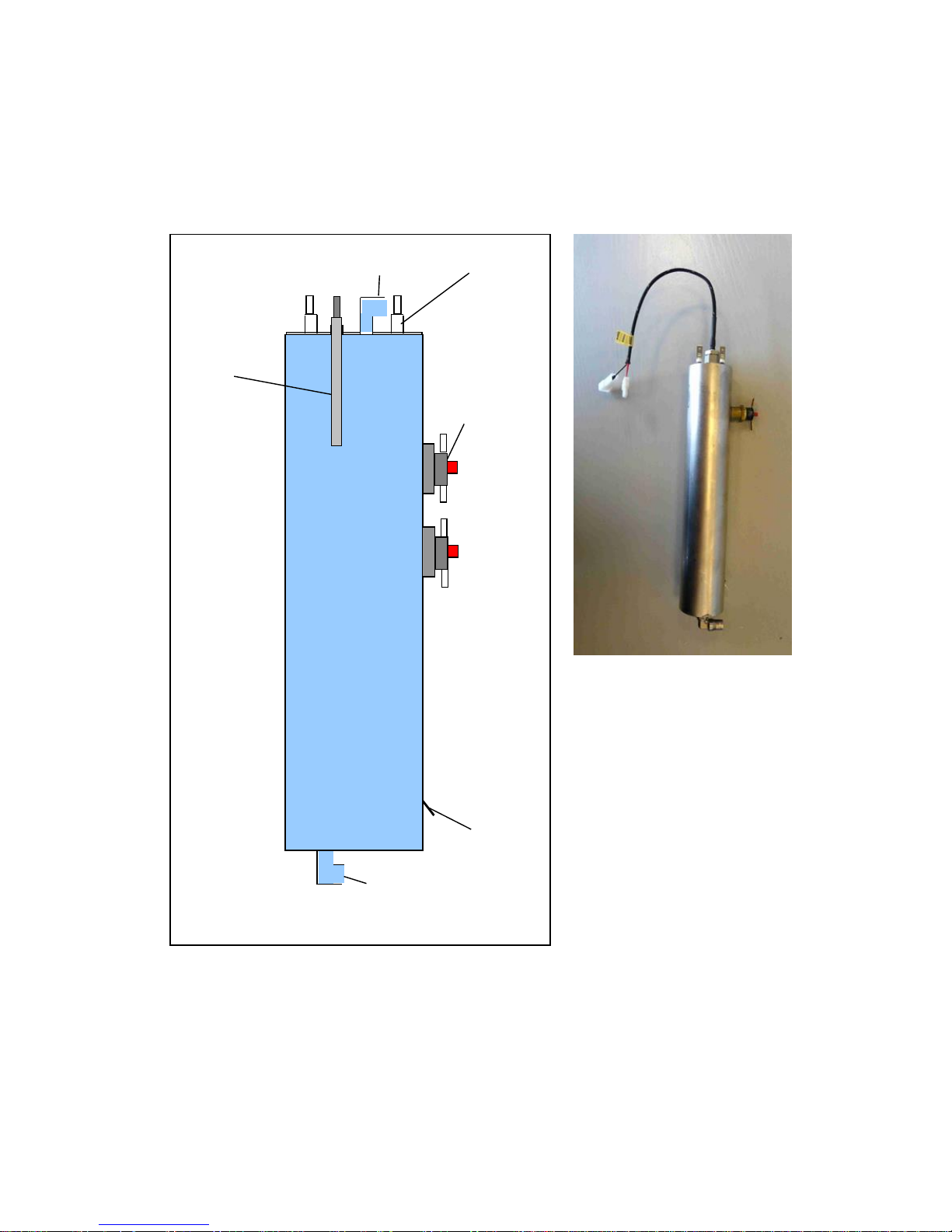

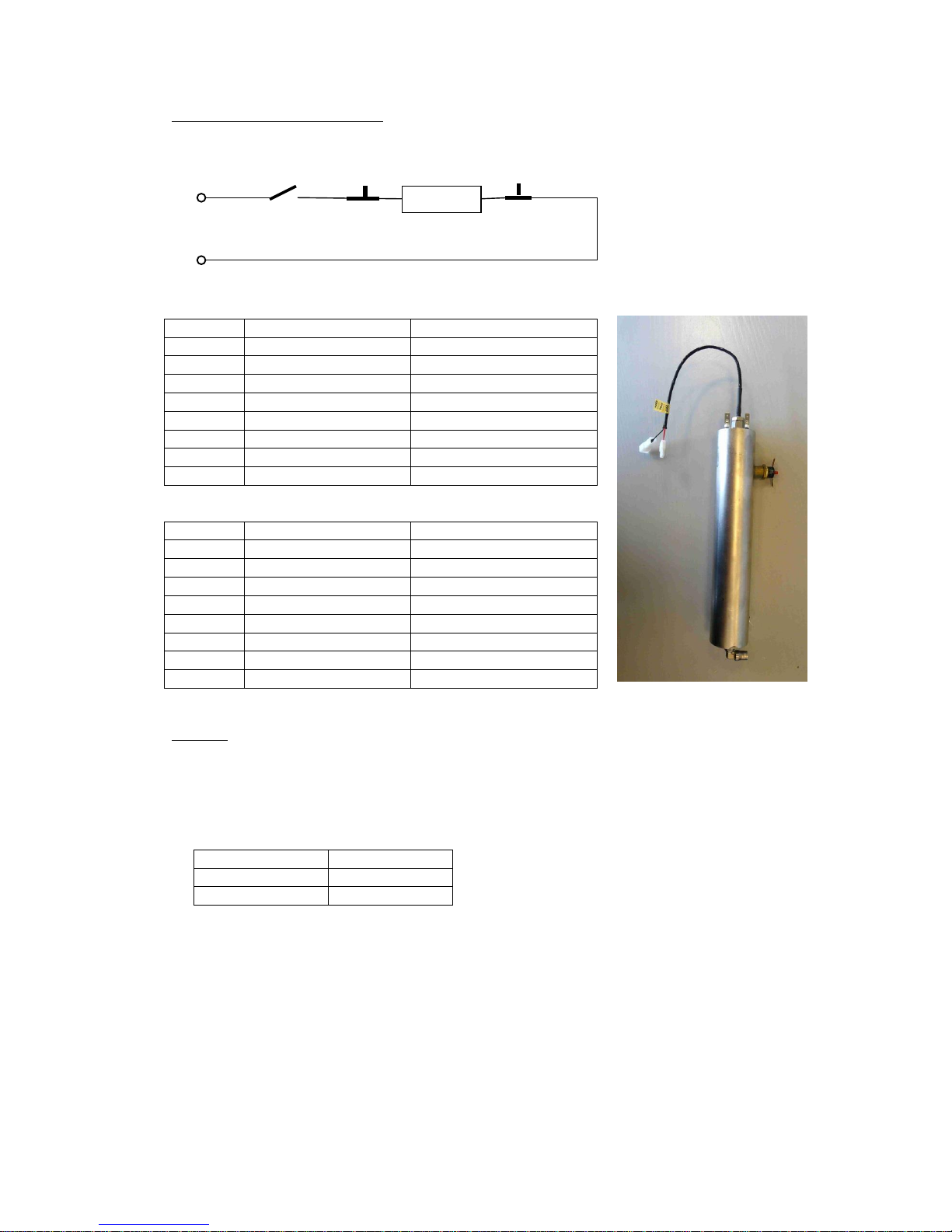

5.7 Boiler

The hot water is prepared in the boilers. The machine is equipped with two

boilers, made out of stainless steel.

The boilers are connected in serial; water from boiler 1 flows into boiler 2 and

from boiler 2 through outlet valves out of the hot water system.

The water inlet is in the bottom of the boiler, the outlet at the top.

Water inlet

Water outlet

Heater

Temperature

and level

sensor

Temperature

safety switch

(Clixon)

Ground

24

Electrical boiler connections:

Connections boiler 1

number

Wire color

function

1

Green-Purple

Temperature common

1

Pink

Temperature

2

Dark-red /Black

Level detection

3

Black

Heater phase

4

Blue

Heater neutral

5

Black

Temperature safety

6

Brown

Temperature safety

7

Yellow/grey

Earth boiler housing

Connections boiler 2

number

Wire color

function

1

Green-purple

Temperature common

1

White-pink

Temperature

2

Brown-black

Level detection

3

Black

Heater phase

4

Blue-white

Heater neutral

5

Black

Temperature safety

6

Brown-white

Temperature safety

7

Yellow/grey

Earth boiler housing

Heater:

The boiler has a 1,4 KW/240VAC heater or a 1,1KW/110VAC. The volume in the

boiler is 0,36 liter.

The boiler and heater are made of stainless steel. The heater is welded in the top

of the boiler.

The winding resistance of the heater is:

The heater is controlled by the control system. This is based on a combination of

detected temperature by the temperature sensor and the amount of incoming

water by the flow meter.

Heater

resistance

1400W 240VAC

39 - 40Ω

1100W 120VAC

12 – 13Ω

heater

Triac on

IOB

Temp.

safety

230VAC or

110VAC

1

3 4 6 7 2

5

Temp.

safety

25

Temperature safety / clixon:

The temperature safety switch is positioned on the side of the boiler. In the

housing is a bi-metal disk which switch if the device gets too hot.

This safety protects the heater against overheating if the control system does not

switch off the heater.

The temperature safety (normally closed contact) switches off at a temperature of

110ºC +/- 5ºC. The safety switches the current to the heater directly off if the

boiler is overheating. The clixon is resettable after cooling down by pressing the

pin by hand.

Temperature/Level sensor:

The sensor in the boiler is a combined level and temperature probe. The sensor is

isolated from the boiler housing with a plastic isolation clamped with two nuts

around the stainless steel sensor housing.

If replacement is needed the sensor needs to be replaced complete, including

nuts.

Temperature:

The temperature is detected by a thermistor mounted in the stainless steel

housing. The control system is controlling the temperature in the boiler based on

the resistance of the thermistor.

Resistance of the thermistor:

Resistance

Temperature

6.5 k

95ºC

100 k

25ºC

126.7 k

20ºC

The temperature is adjustable in the settings of the control system.

The optimal temperature setting is 90ºC in boiler 1 and 92 ºC in

boiler 2. If no consumptions are made, the temperature in boiler 2

will automatically raise in about 25 minutes to 98º. Herewith the

first consumption with a cold brewer is brewed with incoming water

on a higher temperature, compensating the colder brewer.

The control system contains some safeties and warnings based on

the detected value of the temperature sensor.

A too high temperature, too low temperature, shortcut or

disconnected sensor is detected by the control system.

- Disconnected temp. sensor is generated if the resistance is above 350 k.

- Shortcut temp. sensor is generated if the resistance is below 1 k

Reset

26

Level:

The level in the boiler is detected by the stainless steel housing of the sensor. The

boiler is connected to ground. On the housing is a positive signal from the control

system. If the sensor is in the water, current is able to pass through the water.

The control system is detecting the water level because of this current.

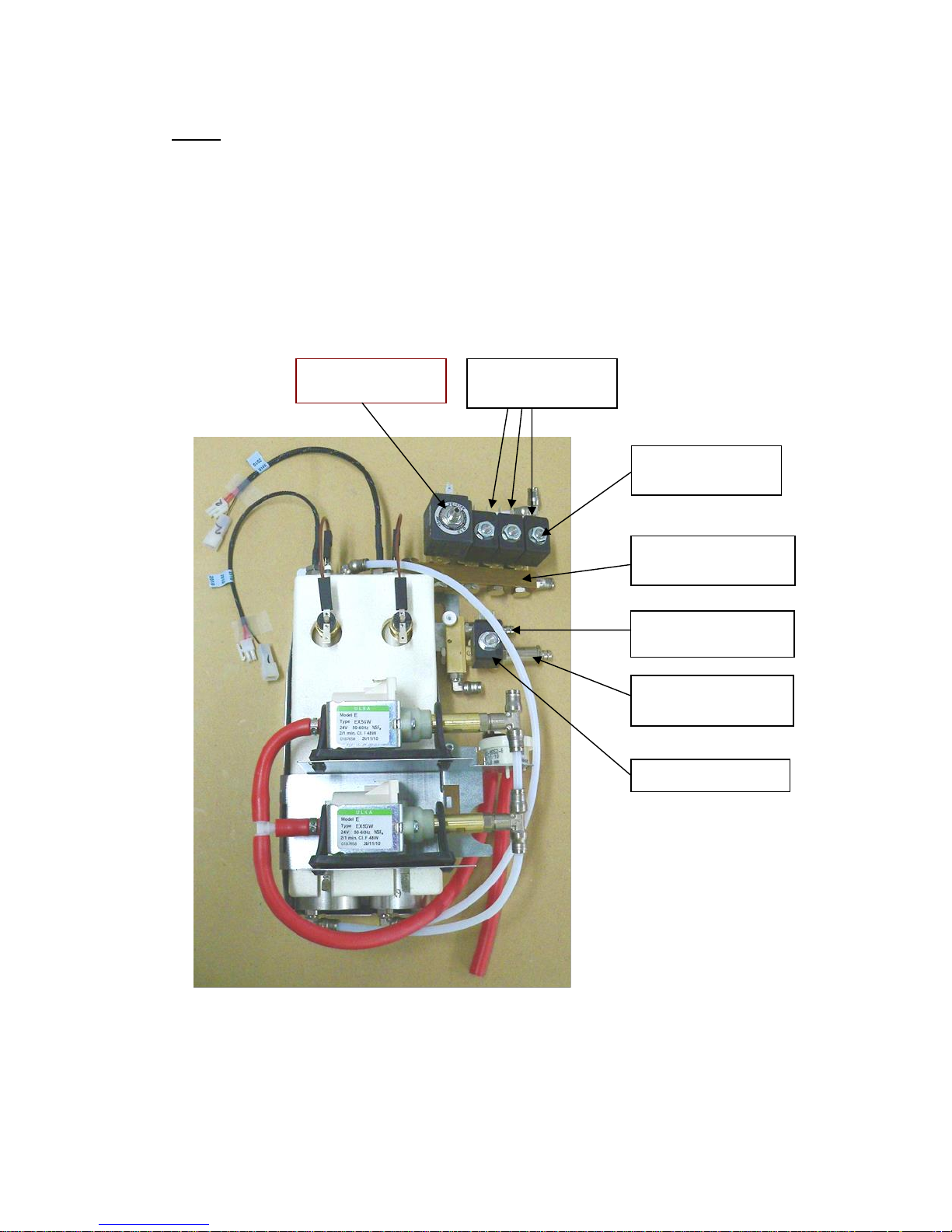

5.8 Position of valves in the hot water system

The manifold with valves is connected straight on the boiler with a bolt. This

connection is needed to keep the manifold with valves warm if the machine is not

used for a while.

Expansion valve

12-bar pressure

safety valve

2-bar pressure

valve

3-way coffee

valve

manifold

2-way hot water

outlet valve

2-way outlet

valve

27

The two way hot water outlet valve is equipped with a special disc

between valve and hose nozzle.

This disc has a very small hole (0.7mm) in the middle. All the water

must flow through this very small hole, causing the air in the water to

dissolve.

If this disc is not fitted, tea made with hot water will have a foam layer

and will not look appealing.

Part numbers:

- 2 way valve: 4EMV031

- O-ring: 4ROR015

- disc: 5MVL176

- cupper ring: 4BPR039

- Hose nozzle G1/8": 4MPF044

Mounting sequence: as shown in picture.

2-bar pressure

valve

12-bar pressure

safety valve

3-way coffee valve

2-way outlet valve

Hot water valve

28

1

2

1

2

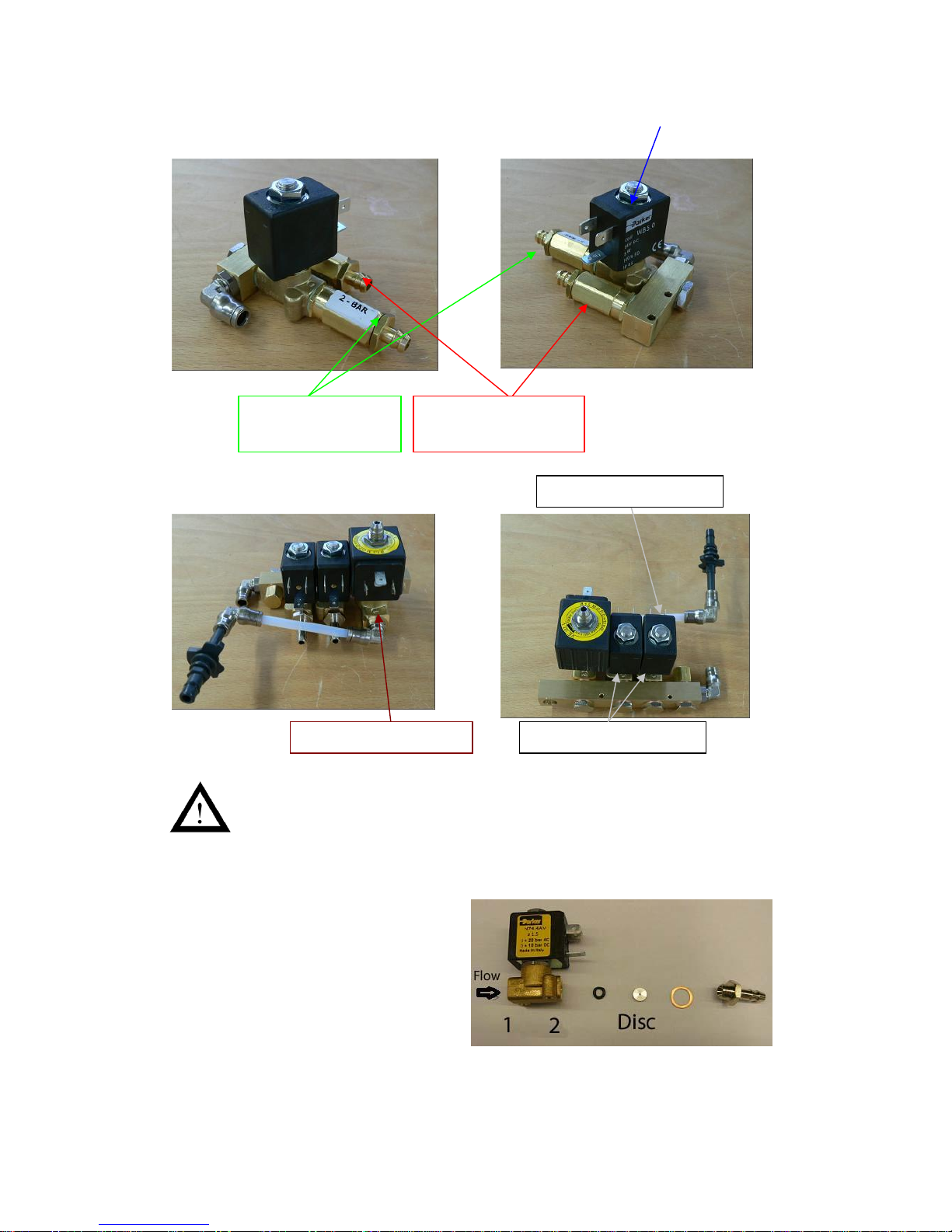

5.9 2-way valve / outlet valve

The two way valve is the outlet from the hot water system to a component.

The moveable plunger has an integral seat which, when the solenoid coil is

energized, moves off the valve (direct operated) orifice opening the valve.

When the coil is de-energized, a return spring repositions the plunger in the

original closing position on the valve, thus cutting off the flow of the fluid.

The valve is controlled by 24VDC from the IO-board.

Water connections:

Number

Function

Description

1

Input

Connected to manifold

2

Output

Connected to component

(Mixing system, hot water or 2-bar

valve)

Water flow in valve if coil de-energized: (no flow)

Water flow in valve if coil is energized:

The water connections on the valve are identified by numbers:

The water flow MUST BE from

number 1 to number 2!

1

2

29

3 2 1

5.10 3-way valve / brewer valve

The three way valve is the outlet from the hot water system to the CoEx® Brewer

(coffee valve) and has a channel from the brewer into the drip tray. Herewith the

coffee residue can flow back from the brewer into the waste bucket.

The function of the valve is based on a spring together with the system pressure

which is pressing the plunger on the valve-seat.

The valve is controlled by 24VDC

Water connections:

Number

Function

Description

1

Output

Connected to brewer

2

input

Connected to manifold

3

Drain

Drain to drip tray

Water flow in valve if coil de-energized:

Water flow in valve if coil energized position:

The water connections on the valve are identified by numbers.:

To drain

From Pump(s) T

3 2 1

1

To/from CoEx

®

brewer

30

5.11 Pressure valve 2 bar

The 2 bar pressure valve is a mechanical pressure valve. This valve automatic

opens if 2 bar pressure is reached.

This pressure valve can be switched off electronically by the 2-way expansion

valve, in front of this 2 bar valve. The 2-way expansion valve is switched off

during a vend cycle. If the system is in ‘standby’, the expansion valve is switched

on (open) if the heaters are switched on, so the maximum pressure in the system

during standby is 2 bar.

5.12 Safety pressure valve 12 bar

The 12 bar pressure valve is a mechanical pressure valve, in open line with the

water system after the pumps. The valve automatically opens if 12 bar pressure

is reached. Therefore the maximum pressure in the system can never be above

12 bar if this valve is functioning correctly.

Do not adjust the pressure valves in case of malfunction.

They are specially set to 2 or 12 bar, and cannot be set correctly

without special tools and knowledge.

In case of malfunction replace for a new one.

2 bar pressure valve

12 bar safety valve

31

5.13 CoEx

®

brewing system

The combined coffee and espresso brewer. The brewer is one of the most

important parts in the machine. The quality of the coffee depends very much on

the condition of the brewer. It is very important to keep the unit clean, also for a

good functionality.

Knob to remove

filter

Coffee funnel

(option)

Waste

wiper

Coffee

outlet

Espresso

outlet

Hand

grip

Fixation

knob

Cylinder

Coffee outlet

Espresso

outlet

Knob to remove

filter

Coffee funnel

Waste wiper

Water Inlet

Motor coupling

Cylinder

32

5.14 Removal of the CoEx

®

brewer

Removal of the brewer is necessary for performing maintenance.

Carry out the following procedure for removal of the brewer:

Open the door of the machine.

Remove the outlet tube from the brewer.

Push the green handle upwards and pull the brewer

out off the machine at the same time.

Ready.

A B C

33

5.15 Install the brewer

Carry out the following procedure to replace the

brewer:

Place the brewer in the bracket.

Push the brewer firmly in the machine till you hear

“click” and the green handle is turned downwards in its

home position.

Make sure that the green handle is in the

down position. When the brewer isn’t

installed correctly, the brewer can jump

out of the fitting during a cycle.

Replace the tube.

Check the function of the brewer by making a test drink. Place a cup under the

outlet.

34

5.16 Brewer cycle

Home position / Start position

After dosing the coffee the brewer start running. The

motor runs clockwise till closed position.

Closed position

The dosed coffee is pressed together between the

upper and lower piston.

After pressing the coffee together the water is dosed

through the piston, into the coffee cake and flows

through the filter screen out into the top and outlet of

the brewer.

The pressure from the piston on the coffee cake is

regulated by the adjustable current of the motor.

Open position

If enough water is dosed the brewer runs counter

clockwise to the open position.

Waste wipe

The brewer runs through, herewith the lower piston

moves to the top position. Now the brewer starts

running clockwise and the coffee cake is swiped from

the piston into the waste bucket.

35

Back to home

After swiping the coffee cake away, the brewer runs in

the clock wise direction to the home position.

Start/home position

The brewer is ready for a new cycle.

36

5.17 Brewer motor and micro switch

The brewer motor and micro switch are mounted on a bracket.

Specifications brewer motor:

- 24Vdc.

- No load: Speed 32 rpm, 0,10 A ± 0,05A

- Normal load: speed 25 rpm, 0,45A, 1,5 Nm.

- Stall: 1,8A ± 10%.

The motor is controlled in two directions, clockwise and counter clockwise. The

position of the brewer is controlled by the micro switch and timers in the control

system.

Electrical connections:

Number

Wire color

(motor loom)

Wire color main

loom)

function

1

Purple-red

Grey

Motor

2

Orange

Grey-white

Motor

3

Black

Purple-green (2x)

Micro switch

4

Blue

Grey-black

Micro switch

1 2 4

3

37

5.18 Upper piston

The upper piston is mounted in the top of the CoEx® brewer.

This upper piston is removable with the fixation knob on the top of the brewer.

To remove: Turn the knob clockwise

To fit on brewer: First place the complete upper piston in the right position, then

turn the know counter clockwise.

After replacing, check if the upper piston is correct fitted. If not correct

replaced, the brewer will stall during dispense.

The upper piston contains the filter,

restrictions and pressure switch. This part

switches mechanical to the coffee or

espresso outlet.

Upper piston.

38

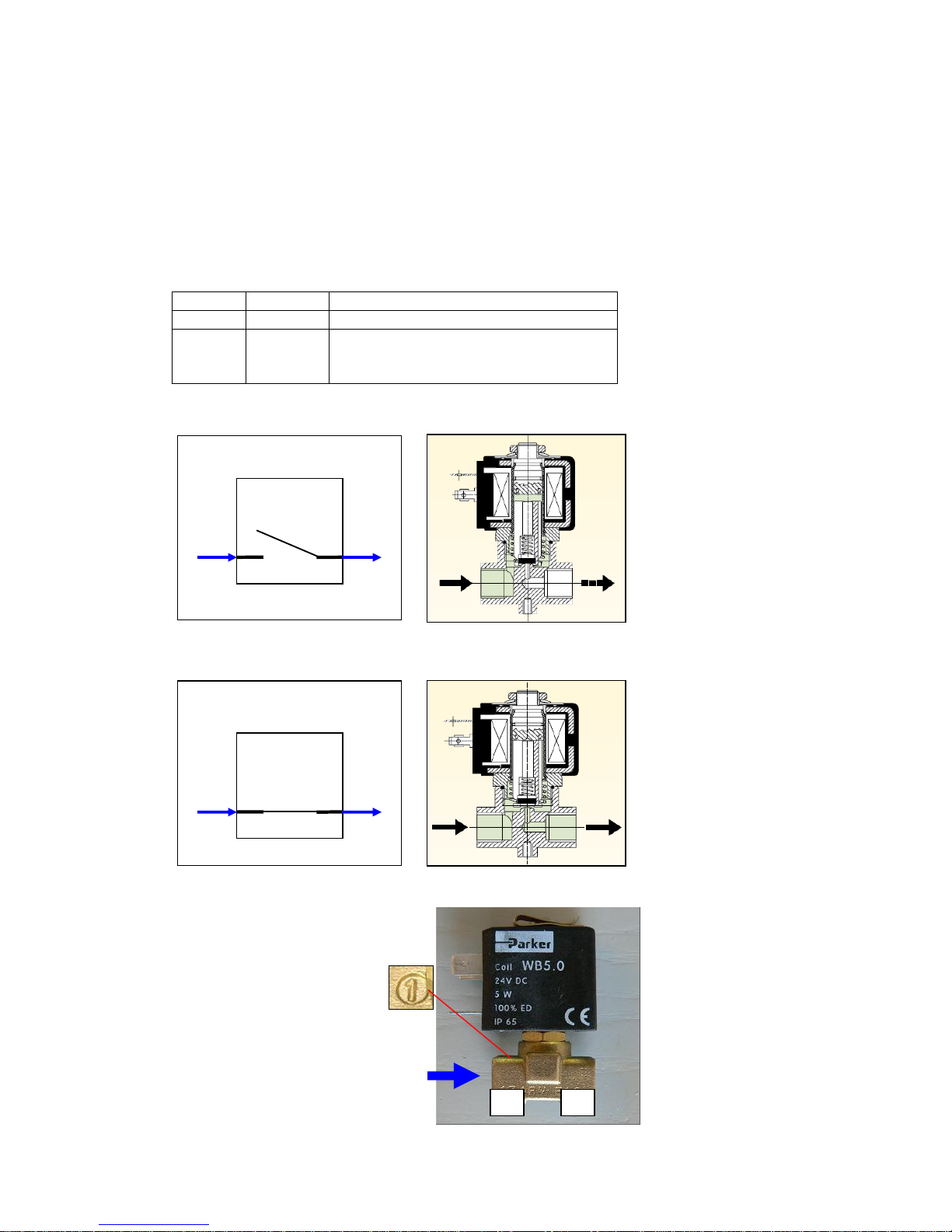

5.19 Controlling coffee/espresso pressure switch

With the unique patented system the CoEx®-brewer can make Coffee and

espresso consumptions in one brewing system. The pressure for coffee and

espresso is different, coffee is made with 3 - 4 bar pressure, espresso with 9 bar

pressure.

The volume of a consumption is easily changeable in the software settings in the

machine.

The duration time that the water is in contact with the coffee powder is a very

important factor in the performance of the brewer and is about the same for

coffee and espresso. The optimal water-coffee contact time is 15 - 25 seconds

To achieve this value a restriction in the system must be used. By the

combination of a higher pressure, lower volume and an equal coffee contact time

the flow for espresso must be much smaller than the flow for coffee. In the

following figures the solution for making these two beverages in one system is

shown.

39

Coffee cycle:

When coffee is chosen, the start flow is relative low

and will not activate the pressure switch. (Spring is

strong enough to keep pressure switch in coffee

position)

The coffee passes the primary restriction and can

then flow through the large coffee channel.

Espresso cycle:

When espresso is chosen, at first the flow is high

and will activate the pressure switch. (Spring is not

strong enough to keep pressure switch in Coffee

position)

The coffee channel is closed and the espresso is

forced through the secondary restriction, reducing

the flow and increasing the pressure to 9 bar.

This different pressure between coffee and espresso is only used in the B2C

espresso machines. (Zia 8000)

The CoEx® machines used as paperless fresh brew has no spring to switch

between coffee or espresso pressure. (Zia 6000)

The upper piston is marked with a colored dot:

Machine type

Dot Color

Hole sizes

Part number

B2C espresso

Yellow

1,5mm/0,3mm

6ZBR057

Paperless fresh brew

White

0,5mm

6ZBR091

dot

40

5.20 Seals

The brewer contains two pistons, the upper piston and lower piston.

There are three sealing responsible for the sealing of the pressure room: Two in

the lower piston and one in the upper piston. Hot water enters the cylinder

(through the lower piston) between the two sealing rings in the piston.

The mix of water and coffee powder will be filtered by the mesh in the upper

piston and then leave the cylinder.

The sealing in the upper piston and the lower sealing in the piston have to resist

the pressure of the hot water during the brewing process (10 bars).

As distinct from the most competitors this brewer is not equipped with o-ring

sealing, rings which seems an important malfunction factor. In the following

figure the impact of a coffee grain between the o-ring and the cylinder is shown.

The grain will stuck which will result in twisting of the ring and grooves in the

cylinder.

The shape of the selected u-cup ring avoids the grains scratching the cylinder.

The sealing consists of a

Teflon u-shaped ring filled with

silicon. Disadvantages of this

ring are the higher cost price

and the fact that the piston

must be divided into a lower

piston and a piston head to fix

it. The upper sealing in the

piston doesn’t have to resist

the high pressure but is only a

scraper.

Two different U-cup rings are used in the brewer:

The U-Cup ring in the upper piston has a blue color.

The U-cup ring in the lower piston has a red color.

41

5.21 Replace seals in lower piston

1. Needed tool: Screw driver

2. Unscrew the bolt in top of the brewer and

loosen the two other bolts 2 turns.

3. Remove waste wiper.

4. Push left and right housing sideward an pull

the cylinder with piston out of the brewer.

5. Replace parts and install in reversed order

remove

Loosen 2

turns

42

5.22 Mixer

The mixer consists of a mixer motor, to which a mixer blade and a

mixer house are connected.

The mixer is controlled by the control board and ensures a correct

mixing of the ingredients and the water.

Furthermore, the mixer whips air in de consumptions and forms a

crème layer. This will grade up the taste and the appearance of the

consumption.

Motor specification: 24VDC, 14.000 RPM.

In case of a blockage, a safety is actuated on the IO board and the message

“mixer blocked” is shown in the screen.

A restricted inlet diameter of the mixer house is used to create a nice flow in the

mixer bowl. The used black mixer house is a special made house with inlet

diameter for the pressure water system as used in the Zia 6000 an 8000 series.

43

Disassembling the mixing system:

1. Remove outlet pipes from the ingredient canisters.

2. Turn the bayonet catch counter clockwise (approx.

10º).

3. Remove the mixer house by pulling it towards you.

5. Pull the mixer blade towards you.

44

6. Turn the base plate further counterclockwise and

pull it towards you.

7. Ready

Assembling the mixing system:

1. Install the base plate.

2. Install the mixer blade.

Be sure that the arrow on the blade is at the flat side of the shaft.

45

3. Install the mixer house.

4. Turn the bayonet catch clockwise.

5. Install the outlet pipes on the ingredient canisters.

6. Ready.

46

Grinder

1 Grinder housing

2 Star shaft

3 Lower grinder disk

4 Upper grinder disk

5 Upper part of grinder

6 Grinding degree disk (setting

scale)

7 Worm gear

8 Powder outlet

9 Coffee beans

10 Ground coffee (coffee powder)

11 Motor / gear

12 Rubber / metal buffer

13 Visual check during service

5.23 Grinder

The grinder can been build in the door or on the base plate next to the other

ingredient canisters.

In the grinder the coffee beans are ground through two metal blades to fine

ground coffee.

These two blades in the grinder are mounted horizontally. The upper blade in the

grinder is a fixed blade and the lower blade is rotating, driven by a motor of

24VDC.

Grinder on canister plate grinder in door

By adjusting the upper grinder blade axially, the air gap between the two grinder

blades can be set very accurately. This air gap defines the grain size of the

ground coffee, what is known as the grinding degree.

The grinding degree setting is made manually on a worm gear. The powder

(ground coffee) is discharged into the powder outlet through four cams attached

evenly around the circumference of the star shaft.

47

5.24 Grinder in door

The grinder is mounted in a housing fixed with hinges in the cabinet. By opening

the door the grinder will rotate automatically and stay in the door.

The grinder can be moved above the brewer for making a test drink with coffee

from the grinder. In this case, unlock the grinder door with the green locking

handle and rotate the grinder above the brewer.

5.25 Removing bean canister and grinder.

- Pull at the green lever of the bean canister to close the canister.

- Lift the canister upwards and place it on a table.

- Pull the grinder upwards and lift it out the 4 position pins. (the motor stays

inside the machine)

Remove grinder:

48

5.26 Grinding adjustment.

For the adjustment of the grinder you can adjust the grinder blades inside the

machine without disassembling the grinder. The machine will give a finer grinding

by turning the screw counter clockwise and a coarse grained coffee by turning the

knob clockwise.

After adjusting the grinder, first take two consumptions, to get rid of the

old coffee in the grinder chute. After these two consumptions, check the

new grinder setting with taking a test consumption, checking crème

layer, taste etc.

finer

49

5.27 Default grinder setting

The grinder is default set as described

below:

1. Remove the upper part of the grinder

from the machine by pulling it

upwards.

2. Remove the black adjustment worm-

wheel by pulling the 2 pins outwards (1)

and at the same time lifting this wheel

upwards. (2)

3. Remove the upper grinder knife

together with the black gear ring by

rotating it counter clockwise.

4. Be sure there are no beans left on the

knifes and in the grinder housing.

Clean the knifes.

5. Replace the upper knife and turn it gently as far as possible clockwise, just till

the two knifes hit each other.

6. Mark the position of the upper knife

compared to a fixed point of the

housing.

Turn the upper-knife 2½ steps (1 step

is one pin position) counter clockwise.

1 1 2

50

7. Replace the black adjusting worm-wheel

8. Replace the grinder back in the black housing.

9. Test the result by taking consumptions.

Fine adjustments can be done by rotating the adjusting worm-wheel.

(see chapter 5.26, grinding adjustment.)

5.28 Ingredient canisters

The canisters can have a metal

auger or plastic auger.

The metal auger is used for instant

coffee, instant tea and leaf tea.

The plastic auger is used for the

other ingredients.

Special augers are available for

special ingredients or low gram

throws.

All canisters are driven by a 24VDC 120RPM motor.

51

6 Electronic hardware

Hardware MoVeC ICEQ

(Modular Vending Controller for Intelligent Connected Equipment)

The electrical system consists of the following main components:

Power supply board

IO board

Control board

Display board with touch screen

Inside machine

Inside door

Power supply

IO board

Control board

Touch screen

Controller

Cup sensor

Door switch

USB stick

Speaker

Display

Touch screen

52

6.1 Power supply

The power supply is located at the back plate of the machine behind the

ingredient canisters.

The mains voltage is connected to the power supply board.

For over voltage protection, the power supply has been equipped with a fuse.

The heating elements are directly connected to the mains, via the On/off

switch and the IO board. (see chapter 6.8, schematic 1)

The 5EPR078, a 120Watt power supply.

Connections on the power supply:

T1. Input 230V AC

T2. Output 24V DC

Fuse: 4A, 250V 5x20mm, slow. (T)

For the US:

Part number: 5EPR128

T1. Input 115V AC

T2. Output 24V DC

Fuse: 4A, 250V 5x20mm, slow (T)

53

6.2 Control board

The control board is located at the inside of the door. The control board controls

the operation of various components. The signals are send to the IO board. On

the control board you also find the connections for other PCB’s and payment

systems. The operating system, counters and settings are saved on the control

board.

Connections:

J1 IRDA Board

J2 Speaker

J3 mechanical counter

J4 USB

J5 USB

J6 Touch screen

J7 backlight

J10 Extension

J11 Display TTL

J12 IO board

J13 cable loom door (cup sensors, door switch, leds)

J14 Network connection

J15 MDB payment system

J16 USB

J17 Display LVDS

Part number control board: 5EPR140

J14

J12

J10

J7

J1

J5

J4

J3

J2

54

J13

6.3 I/O board

The IO board is controlled by the control board. The I/O board controls the

mechanical components such as dosing motors, boiler(s), brewer motor, mixers

and valves.

Part number: 5EPR132, 27 outputs and 2 heater outputs

J1,J2 Switching wires heater 1

J3,J4 Switching wires heater 2

J5 24Vdc input

J6 In and outputs

J8 Outputs

J9 In and outputs

J10 Outputs

J11 In and outputs

J12 Input potential-free contact

J13 Control board

J8

J9

J10

J11

J12

J4, J3

J2, J1

55

6.4 Connectors on the IO board

Connector

Component

Wiring color

J 1

Heating element 1

Blue

J 2

Heating element 1

Blue

J 3

Heating element 2

Blue/white

J 4

Heating element 2

Blue/white

J5-1

+24V DC supply

Red

J5-2

+24V DC supply

Red

J5-3

-

Black

J5-4

-

Black

J8-1

+24VDC (common)

Orange

J8-2

Valve brew/mix 1

Purple/white

J8-3

Ingredient motor 3

Blue/White

J8-4

Ingredient motor 4

White

J8-5

Brew/mix 1

Purple/Red

J8-6

Valve brew/mix 3

Orange/Brown

J8-7

Chilled water inlet valve

Black/Orange

J8-8

Ingredient motor 5

Blue/Green

J8-9

Ingredient motor 6

Purple/Black

J8-10

Mixer 2

Blue/purple

56

J9-1

+24V DC (common)

Orange

J9-2

Ingredient motor 1 coffee or grinder

Purple

J9-3

Ingredient motor 2 coffee or grinder

Brown/Red

J9-4

Brewer motor +

Gray/White

J9-5

Brewer motor -

Gray

J9-6

Brewer micro

Gray/Black

J9-7

Paper switch

Empty

J9-8

Common sensors

Green/Purple

J9-9

Drip tray detect

Black/Yellow

J9-10

Drip tray full detection

Yellow

J9-11

Drip tray common

Green/White

J9-12

Inlet valve open boiler

Red/Green

J9-13

Fan

Black/White

J9-14

Coffee valve

Yellow/White

J9-15

Valve hot water

Red/Blue

J9-16

Micro waste bucket

Yellow/Orange

J9-17

Tea brewer micro

Brown/Gray

J9-18

-

J9-19

Temp 1 common

Green/Purple

J9-20

Temperature 1

Pink

J9-21

Level detection 1

Red/Black

J9-22

Level detection 1 common

Yellow/Grey

J6-1

+24 volt DC (common)

Orange

J6-2

Pump 1 (common)

Gray/Blue

J6-3

Pump 2 (common)

Black/Pink

J6-4

Flow meter supply

Red/White

J6-5

Flow meter signal

Black/Blue

J6-6

Flow meter common

Green/Purple

J6-7

Level 2

Brown/Black

J6-8

Expansion valve

Blue/Yellow

J6-9

Pump 1

Yellow/Brown

J6-10

Pump 2

Orange/White

J6-11

-

J6-12

Temperature 2

Pink/White

J6-13

Temp 2 common

Green/Purple

J6-14

Level 2 common

Yellow/Grey

J10-1

+24 V DC (common)

Orange

J10-2

Output 23 Spare

Green/Red

J10-3

Output 24 spare

Green/Gray

J10-4

Carbonated water valve

Brown/Blue

J10-5

Output 26 Spare

Empty

J10-6

Brew/mix 4

Empty

J11-1

+24 V DC (common)

Orange

J11-2

Outlet arm

Purple/Yellow

J11-3

Micro switch cup splitter

Empty

J11-4

Micro switch outlet arm

Empty

J11-5

Cup splitter

Green/Pink

J11-6

Cup column mover

Orange/Blue

J11-7

Cups micro switch

Empty

J11-8

Common sensors

Empty

57

6.5 LVDS Display and touch screen.

Part numbers:

Display LVDS: 4EPR022

Touch screen: 6CSS053

Control board: 5EPR140

PCT controller: 4EPR023

PCT controller 4EPR023

6.6 Speaker

Part number: 4ELP001

58

6.7 Cup sensor

The cup sensor sense a cup on the cup stand. Maximum two cup sensors can be

connected in the machine. One for the right outlet and one for the center outlet.

A cup must be placed on the correct position on the cup stand before the start

button is green and the cycle can start.

The sensitivity of the sensor is adjustable, see chapter 7.6, cup sensor settings.

59

6.8 Electrical schematics

Electrical Diagram - MoVeC ICEQ - 9CND: 230Vac

Electrical Diagram - MoVeC ICEQ – Controller board - Zia

60

Electrical Diagram - MoVeC ICEQ - 9CND: IOB connector J6

Electrical Diagram - MoVeC ICEQ - 9CND: IOB connector J8, J9 en J10

61

Electrical Diagram - MoVeC ICEQ - 9CND: IOB connector J9

7 Service and programming

Mode without password

After opening the door the service mode

is shown in the screen.

This screen gives the options:

- Rinse (grey in picture)

- Weekly cleaning cycle brewer

- Show product counters

- Software information

Only buttons in light green color work.

Buttons who require a part of the machine to work will be in grey and will

not function as long as the service key is not placed.

The rinse cycle (grey in example picture) will only work if the service key

is inserted in the door.

(This key is in the machine for safety reasons. Conform CE no component

may run after opening the door, unless a safety key is placed)

7.1 Inserting safety key

Insert the safety key and turn this key a quarter turn

clockwise:

Inserting the service key gives electrical power to

components.

Be aware of the following:

62

• Possible moving parts inside the machine, beware of

trapped fingers if the service key is placed when the

door is open.

• Beware of hot parts and hot liquid inside the machine,

even after the power is disconnected.

7.2 Functions without password

Inserting of the safety key makes the rinse functions available for use.

(button color changes from grey to green)

Rinse:

The rinse cycle needs to be done daily.

A jug or bin needs to be installed under the

outlet nozzles before starting the rinse cycle.

Pressing the rinse button will start a rinse

cycle for mixers and brewer directly.

Weekly cleaning cycle:

The weekly cleaning cycle needs to be done

weekly. Pressing the weekly cleaning button

will show a new screen with instructions.

Follow the instructions and finish the whole

procedure to reset the cleaning counter.

If this cleaning cycle is not completed, an

error message will appear: “cleaning error”.

See chapter 7.16 for clearing this message.

Show product counters

Pressing free counters shows all the individual

counters, free vend.

Pressing paid counters shows all the

individual counters, paid vend.

63

Software information

This screen shows all types of software and

hardware information about the machine.

64

7.3 Service mode with password access

After opening the door the first level service

screen is shown.

Press the login button right at the top, a new

screen as shown here will pop up.

Enter the technician password and then press

the login button left under.

The available service menu items:

- Recipe settings

- Boiler temperature

- Cup sensor

- Select language

- Payment settings

- Software configurations

- Load permissions

- Clock/time settings

- Jug settings

- Images

- Test outputs

- show error log

- Error settings

- Water filter settings

- Rinse

- Weekly cleaning cycle brewer

- Show product counters

- Software information

- Show EVA-DTS

- Change serial number

- Fan turn off delay

- Empty boiler

65

7.4 Recipe settings

- Water/ingredient settings.

The water and ingredient dosage and other

timings can be adjusted per available recipe.

(see chapter 7.4.2 and 7.4.3 for detailed

explanation)

- Strength control %.

The max strength difference from the medium

dosage can be set.

The medium dosage is the set dosage in the

recipe settings of each individual consumption.

Example:

For coffee and tea (this are main products) 5

strength steps are possible.

If the main product strength is set to 10%:

Every step means 5% more or less product.

With this setting max 10% more or 10% less

product from the average dosage is possible.

For milk (creamer) and sugar 3 strength steps

are available.

If the strength% is set to 30:

Every step means 30% more or less product.

- Milk/Sugar available.

The milk or sugar option can be switched off. If

switched off, the milk/sugar selection will

disappear from the user menu.

- Selection available.

Every recipe can be available or not. If not

available is selected the selection is not

available in the user menu screen.

7.4.1 Water/ingredient settings

All available recipes are shown in the

water/ingredient settings menu.

Select the recipe you want to change.

66

7.4.2 EXAMPLE: (Fresh brew) Coffee recipe in a bean to cup machine

Coffee = The settings for the ingredient fresh

brew coffee.

Press coffee, this gives a new screen:

Delay = 0.0 means: Coffee is immediately

dosed in the brewer, no delay.

Duration = 2.5 means: The auger in the

coffee canister rotates for 2.5 seconds, giving

a certain amount of coffee in the brewer.

Speed = 100 means: The auger rotates

100% (= full speed. )

In “Sub high pressure” is it possible to set the

amount of water dosed in high pressure mode

to give a nice crème layer on top of the

coffee. Press sub high pressure to see the

water amount for this part of the recipe.

Water amount (in main recipe) = the basis

amount of water.

The water amount in the pressure boilers is

adjusted in pulses generated from the flow meter. 1 pulse ≈ 0,8 ml

Water amount 100 = about 80ml

This coffee selection in this example exist out of 140(main recipe) + 40 (sub high

pressure) = 180 pluses = 180 x 0,8 ≈ 144ml.

With the test button this recipe is dispensed in the service mode.

If there is also milk and sugar possible, the water amounts of milk and

sugar are also added to the main recipe water amount if a black coffee is

chosen.

Change a recipe setting:

1. Select the setting you want to change by

pressing the green button.

2. Enter the new value.

3. Press “Save” left under in the screen to

save the new setting.

67

7.4.3 EXAMPLE: Cappuccino recipe in a bean to cup machine

Beans = the duration time the grinder grinds

beans.

3.0 means a duration of 3 seconds for the grinder.

Subr topping = the recipe for topping in the

cappuccino.

- 1. Topping

0.5 in the first column means a delay of 0.5 (so

first there is water in the mixing bowl)

1.0 in the second column means a duration of 1.0

seconds for the milk powder motor.

- 2. topping

0.7 in the second column means a second topping

powder dosage of 0.7 seconds after a fixed, not

visible delay. (Normally this delay is 0.5 seconds)

- Water amount = 100: The amount of water dosed through the topping mixer.

100 = 100 pulses.

Delay for UI release: Delay time at the end of the consumption, to delay the

moment the machine is available for the next consumption. (also the “beep” at

the end of a selection is delayed)

Water amount = the amount of water dosed through the brewer.

If there is also sugar possible, the water amount of sugar is also added to

the main recipe water amount if a black coffee is chosen.

Change a recipe setting:

1. Select the setting you want to change by pressing the

green button.

2. Enter the new value.

3. Press “Save” to save the new setting.

68

7.4.4 Sub product milk and sugar

The sub products milk and sugar have their own

water and product settings.

In this example:

Delay = delay start dispensing product after start

recipe = 0,5 sec.

Duration = duration auger rotates, dispensing

product = 0,7 sec.

Speed = % of possible speed the auger rotates =

100%

7.5 Boiler temperature

Temperature setting gives the possibility to

change the desired boiler temperature.

The default settings:

Boiler 1: 90 = 90°C (194°F)

Boiler 2: 92 = 92°C (197°F)

Show boiler temperature will show the actual

temperature of the boilers in degrees Celsius or

degrees Fahrenheit.

Boiler 2 is default set to 92°C (197°F).

This value increases slowly automatically to 98°C (207°F) in about 20

minutes idle, to compensate a cold brewing system.

As soon as a consumption is taken, the temperature setting decreases to

the default 92°C.

After the consumption is taken, the sequence of slowly increasing the

boiler temperature in boiler 2 is starting again.

69

7.6 Cup sensor

Show cup sensor signal:

The signal of both sensors can be read

individually.

This way the visibility of a cup can be tested

also.

Cup sensor setting:

The sensitivity of the cup sensor is adjustable.

The value can be adjusted between 0 and 4000.

The value 0 means switched off. In this case the

machine works like there is no sensor.

A higher value means less sensitive. So for

detecting a transparent or dark colored cup the

value must be set low.

The default value is 100. This is the optimal

value and gives the best detection for the most

cup types.

If there are two cup sensors in the machine,

both are individual adjustable.

Sensor 1 = Middle sensor.

Sensor 2 = Right hand side sensor

Black cups or clear glass cups are not

detectable, we advise to switch off the

sensors if black cups or clear glass cups

are used.

7.7 Language

Select the required active language.

Depending on the configuration setup, a

language selection is available.

This chosen language is the default language for

the user screen and the service program.

DJD is the default English factory language.

70

7.8 Payment settings

With the payment settings menu the product

prices and the functions of the payment system

can be set.

Lnl

- Consumption prices:

To adjust the price for all available consumptions.

For each individual consumption type, 2 prices are

available: Pricelist 1 and pricelist 2.

- Free/paid vend

To set the machine in free vend or paid mode.

- Active price list

Activate the required price list.

- Multi vend

A payment system can run in multi vend or single

vend.

Multi vend means you can select more then 1

consumptions after each other. Your change or

card will be returned after pressing the return

button on change giver or card reader.

Singe vend means you always receive your change or card direct after dispensing

the consumption.

Overpay allowed

- Overpay allowed means that it is allowed to insert more money as the highest

consumption price.

Overpay not allowed means that it is not possible to insert more money as the

highest consumption price.

- MDB coin settings

The coin settings are adjustable in the software if they are set in the configuration

file loaded in the machine.

- MDB bill settings

The bill settings are adjustable in the software if they are set in the configuration

file loaded in the machine.

In clock/time settings (see chapter 7.11) it is possible to automatically

choose between pricelists and free or paid for a certain period of time.

71

7.9 Software configurations

- select active configuration:

Select the configuration file with which

the machine have to work.

The configuration file which is

currently active is in grey color,

all other inactive files are in

green.

- Delete configuration:

Delete a configuration file.

- Backup configuration:

This makes a copy of the active

configuration with all settings. This saved

file can be found back in the menu:

“Select active configuration”.

The back-up file name exists of the

original name added with an extension

year, month, day and time:

Example:

Original file name: 8124a00.mvq

Backup file name:

8124a00_1401121430.mvq

14 = year 2014

01 = month 01 (January)

12 = day 12

1430 = time 14.30

- Load configuration from USB:

Standard Device 0 is available (only if a

USB stick is placed)

It is possible to explore the maps

in the stick to find the needed

configuration file.

The new loaded file from the stick

is selected as active configuration

automatically.

- Save configuration to USB

This will save the current active file to the

USB stick.

72

7.10 Load permissions

In this menu the permissions, e.g. to show images on the screen of the machine,

can be loaded from an USB stick,

It is possible to explore the maps on the stick to find the needed permission file.

If the coffee machine is not configured for images, the standby images and

distributing images option can be enabled on the DJD coffee machine using the

following procedure.

Load Permissions Summary:

● Check if the correct software is installed on the coffee machine.

- MoVec ICEQ

Version:

3.40

or higher.

- Flash file

Version:

1.7

or higher.

- DJD software ID

Version:

4.0

or higher.

●

Collect coffee machine information: (visible in software information, chapter 7.2)

- Machine serial number

- CM-X300 serial number

●

Send coffee machine information to manufacturer.

●

Receive the permission key file from manufacturer

●

Load the permission key on coffee machine.

Note:

●

A permission key can be generated for one coffee machine or for multiple coffee

machines.

A detailed explanation how to do this can be found in chapter 8.3: How to get and

load a permission key

73

7.11 Clock/time settings

- Screen saver (delay) time

This is a delay time in minutes after the last

consumption.

After this delay, the standby image will appear.

If the time is set to 0, the standby image(s) will

never show-up in the screen.

- Set correct time

The actual date and time can be set in this menu.

The correct date and time is also important for

the correct timestamps in e.g. scheduler actions

and EVA-DTS messages.

- Select time zone

Select the correct time zone to enable automatic daylight saving settings and

network time protocol. (NTP)

- change scheduler actions

The following automatically actions can be set:

- Energy safe

- machine blocked.

- Switch to free vend

- Use other pricelist

- Machine off

Energy safe:

With the energy safe settings, the machine can

be switched to an energy safe mode during a

period of time. During this action the boiler

temperature drops to 65 °C.

After pressing a selection key, the machine will

first heat to the normal temperature, before the

machine is ready to give consumptions.

If the machine is not used for an hour the

machine will go back to the energy safe mode.

Machine blocked:

During this set time, the keys on the front panel

are blocked and not visible for the user. No

consumptions can be chosen. The boiler(s) stay

hot.

(The service mode is still working)

Switch to free vend.

A machine in pay mode can be switched to free

vend during the set time.

Use other pricelist.

In the set time the machine will switch to the other price list.

74

Machine off:

The machine is switched off during the set time. The

display is completely black.

The elements are switched off.

During this time the machine can only be activated in

the service mode.

Setting the times in the scheduler:

The scheduler has a start time for hour, minute and

day.

On the second page of each scheduled action (press

PgDwn), the associated stop times must be set.

(depending of the type of action)

- Optional the date, month or year can be set as well. (if not used, set

to 0)

- Set all the values to 0 to switch off an action in the machine.

- The value set in day, month and year must be 0 if the action is daily

required. In this case only the hour (and eventually minute) must

have a value greater then 0

7.12 Jug settings

Number of cycles:

- Preset 1 is used for the number of cycles in the 1

JUG selection.

- Preset 2 is used for the number of cycles in the

½ JUG selection.

- Preset 3 is not used.

Jug function without key.