UDL500

Wiring & Installation

Instructions

V17/01/08

Wiring & Installation Instructions UDL500

© Copyright 2008 by deister electronic GmbH

All rights reserved. No part of this publication may be reproduced, stored in a retrieval

system, or transmitted, in any form or by any means, electronic, mechanical, photocopying,

recording, or otherwise, without prior written permission of deister electronic GmbH.

deister electronic GmbH reserves the right to make changes to any and all parts of this

documentation without obligation to notify any person or entity of such changes.

January 2008 SK/IO/BF

deister electronic GmbH

Hermann-Bahlsen Str. 11

30890 Barsinghausen

Germany

Phone: +49 (0) 51 05 - 51 61 11

Fax: +49 (0) 51 05 - 51 62 17

E-Mail: info@deister-gmbh.de

Web: www.deister.com

2 deister electronic GmbH 30890 Barsinghausen Germany V17/01/08

Wiring & Installation Instructions UDL500

Content

1. Technical Data............................................................4

2. Connectors...................................................................5

2.1 Installation note..................................................................................................5

2.2 Pin assignment UDL500.......................................................................................6

2.3 UDL500: RS485 interface....................................................................................6

2.4 UDL500: Control digital output via hardware trigger..............................................7

2.5 UDL500: Control digital output via software trigger................................................8

3. RS485 interface...........................................................9

4. Mechanical dimensions.............................................10

4.1 UDL500 housing...............................................................................................10

5. Transmission protocol...............................................11

6. Mounting...................................................................11

6.1 Mast/Tube mounting.........................................................................................11

6.2 Extended mast holding device LRM2 ..................................................................13

6.3 Wall mounting with link holder LRM1..................................................................14

6.4 Fixing link holder LRM1.....................................................................................14

6.5 Function principle and environmental influences...................................................15

6.6 Radiation pattern of the transmitting antenna.......................................................16

7. Configuration software.............................................20

7.1 SNG3 interface converter..................................................................................20

7.2 Configuration...................................................................................................21

7.3 Parameters.......................................................................................................22

7.3.1 Basic Setup..............................................................................................22

7.3.2 Frequency Setup......................................................................................24

7.3.3 Mode Control..........................................................................................25

7.3.4 Trigger....................................................................................................27

7.3.5 Selection Settings.....................................................................................28

7.3.6 Selection Mask.........................................................................................29

7.3.7 Prog data................................................................................................30

7.4 LEDs and Beeper...............................................................................................30

8. Portal application with DCU1 Data Control Unit......31

9. Accessories of the UHF product family......................32

10. Regulatory Notices..................................................33

10.1 Europe...........................................................................................................33

10.2 FCC Digital Device Limitations.........................................................................33

10.3 FCC Notice....................................................................................................34

10.4 FCC Radiation Exposure Statement...................................................................34

10.5 Industry Canada.............................................................................................34

V17/01/08 deister electronic GmbH 30890 Barsinghausen Germany 3

Wiring & Installation Instructions UDL500

1. Technical Data

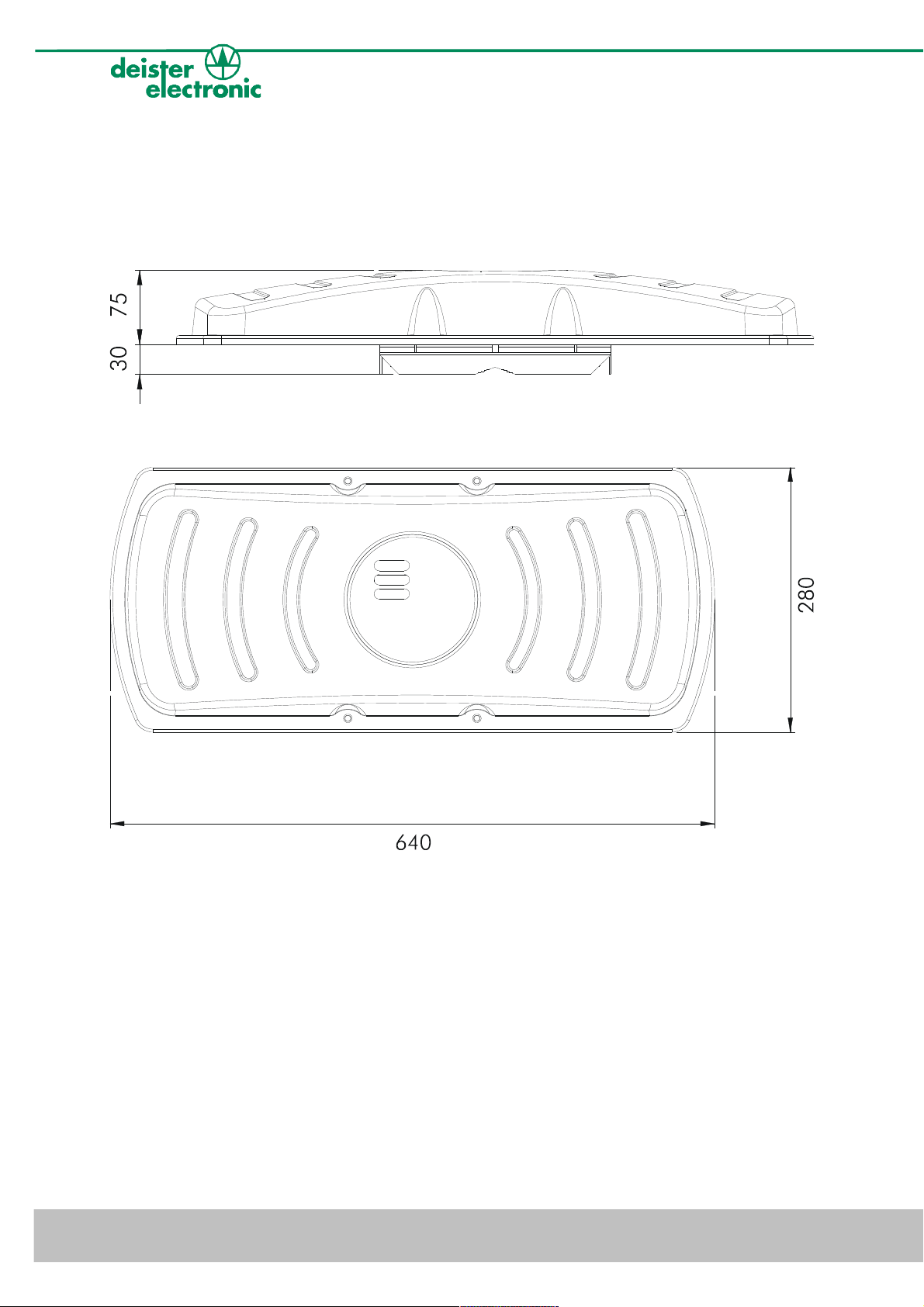

Dimensions (mm): 640 x 280 x 75

Housing material: ABS/PMMA, ALUMINUM, V2A

Color: silver

Protection class: IP65

Operating temperature: -20 ... +70°C

Storing temperature: -40 ... +85°C

Relative humidity: 5% ... 95% non condensing

Voltage supply: 10 ... 30V/DC

Power consumption: 10W (during operation)

2W (standby)

Transmission frequency: 865 – 868MHz (EU)

902 – 928MHz (USA)

Writing-/reading distance: up to 5m, depending on type of transponder

and the local environment

Antennas: 2 patch antennas (transmitting and receiving antennas)

Polarization: circular

Radiated output power: 2W ERP (ETSI EN 302 208) or 4W EIRP

(FCC Part 15), configurable in 10 steps

Transponder protocol: ISO 18000-6 Type C

EPC Class1 Gen2

optional:

ATMEL ATA 5590 (TAGIDU),

EM 4022, 4222, 4422

Trigger Input: 8 ... 36V/DC

Digital Output: 6 ... 32V/DC (I<500mA)

32 ... 48V/DC (I<300mA)

Interface: RS485

Anticollision: high-speed detection for multiple tag identification

Operating modes: single reader (stand alone), portal mode (up to 4

readers can be connected to the DCU1)

Acoustical indicator: beeper

Optical indicator: 3 LEDs (yellow, green, red)

Conformity:

Human exposure EN 50364

EMC EN 301 489

air interface (EU) EN 302 208 (listen before talk)

4 deister electronic GmbH 30890 Barsinghausen Germany V17/01/08

Wiring & Installation Instructions UDL500

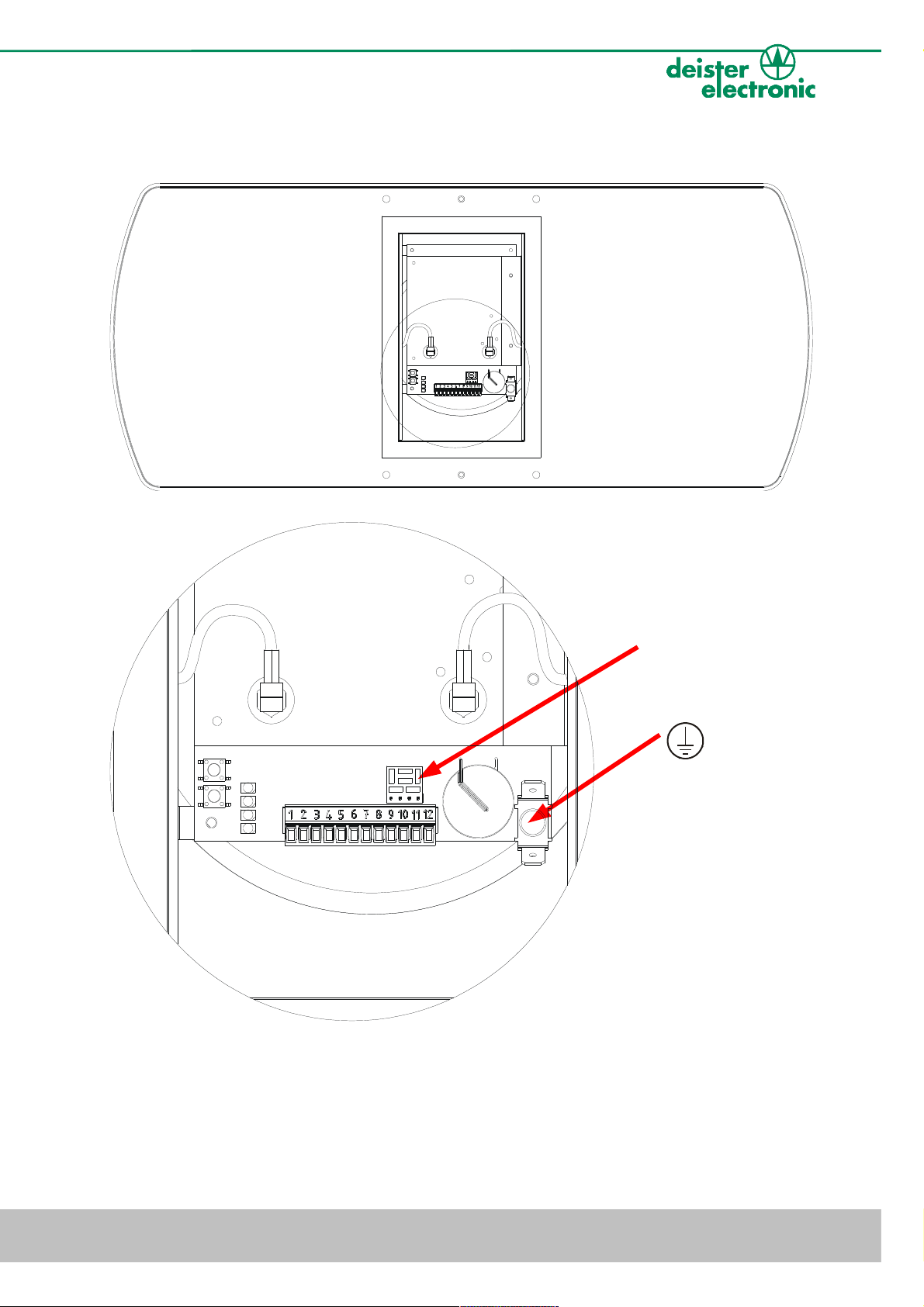

2. Connectors

RS485

termination

resistor

(terminator)

Tab connector

for grounding

2.1 Installation note

Attention:

It is important to take care that the marked tab connector is connected to the supplied

cable plug. The device always needs to be professionally grounded using a yellow/green

flexible line with a minimum profile of 0.75mm².

V17/01/08 deister electronic GmbH 30890 Barsinghausen Germany 5

Wiring & Installation Instructions UDL500

Attention:

The procedures and working activities described in this

document are intended to be performed by technical

professionals only.

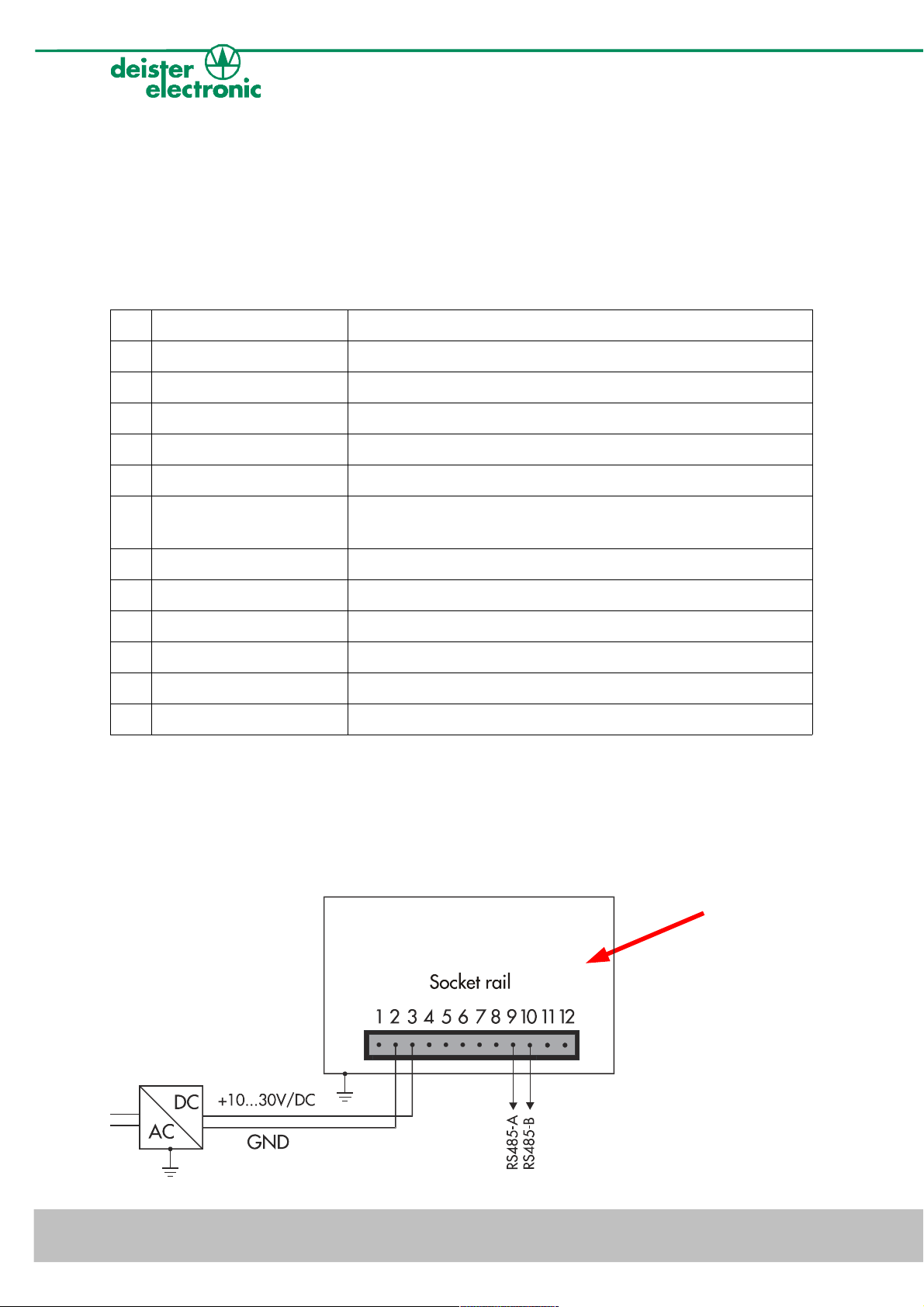

2.2 Pin assignment UDL500

Pin Name Function

1 – not connected

2 GND ground

3 +10 ... 30V/DC voltage supply +10 ... 30V/DC

4 OUT

5 OUT digital output voltage, max. +48V/DC, I<300mA

6 OUT

7 – not connected

8 – not connected

9 RS 485-A RS485 interface, data line A

10 RS 485-B RS485 interface, data line B

11 IN - external ground for trigger input

12 IN + external voltage supply for trigger input, max. +36V/DC

Table 1: pin assingment UDL500

GND

VCC

external ground for digital output

external voltage supply for digital output, max. +48V/DC,

I<300mA

2.3 UDL500: RS485 interface

Installation note: We recommend professional grounding of the device (see 2.1

Installation note).

UDL500 housing

6 deister electronic GmbH 30890 Barsinghausen Germany V17/01/08

Wiring & Installation Instructions UDL500

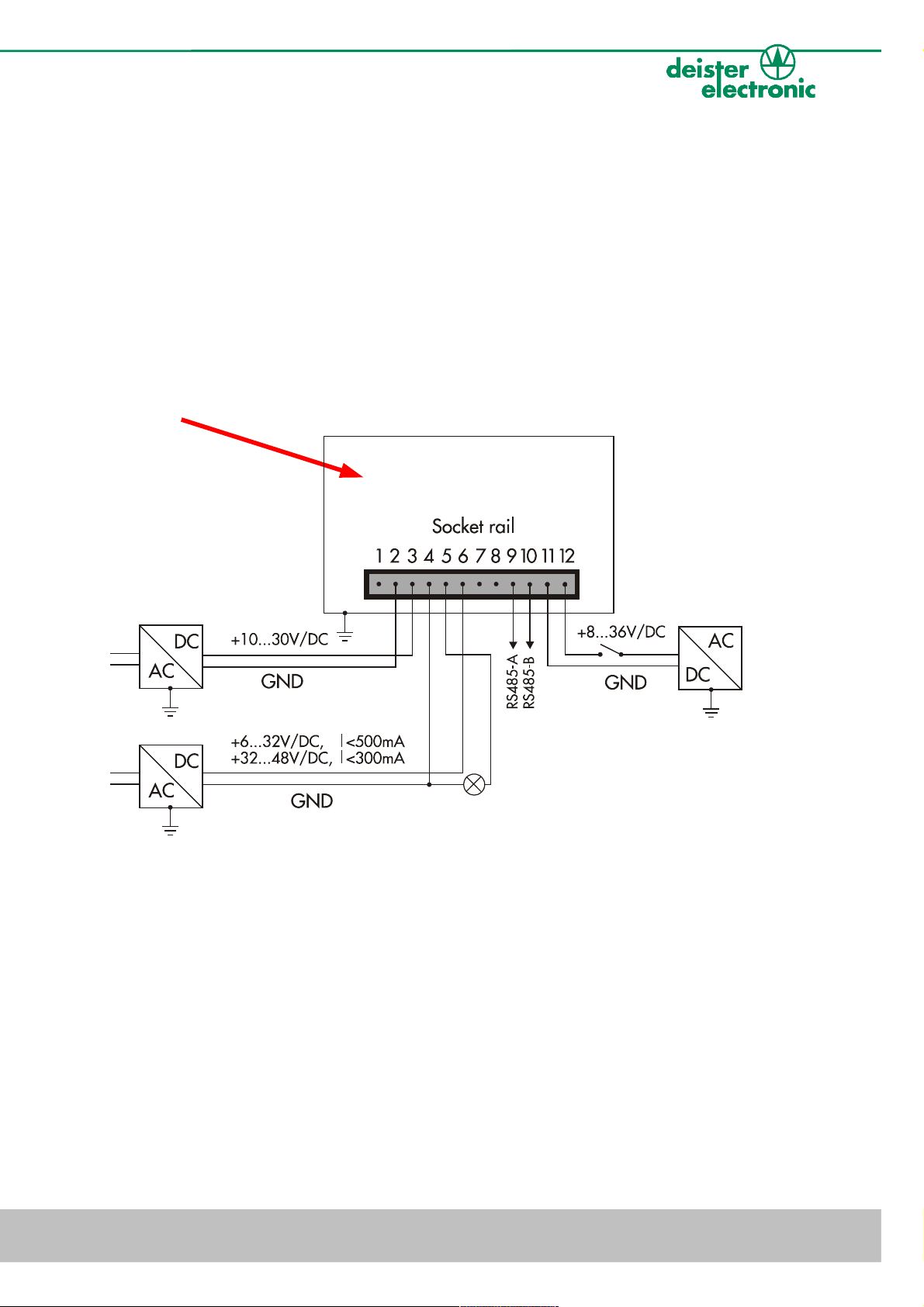

2.4 UDL500: Control digital output via hardware trigger

Installation notes: We recommend professional grounding of the device (see 2.1

Installation note). Output OUT and Input IN are potential-free. Take care that the

grounding will be sufficient (use second tab connector)!

The potential-free input IN may be used to control the reader by a hardware trigger (e.g.

tip switch). The control of the potential-free output OUT can be configured within the

software. For this the reader has to be operated in trigger mode.

In the following example of circuits, the output OUT has not been potential isolated:

UDL500 housing

V17/01/08 deister electronic GmbH 30890 Barsinghausen Germany 7

Wiring & Installation Instructions UDL500

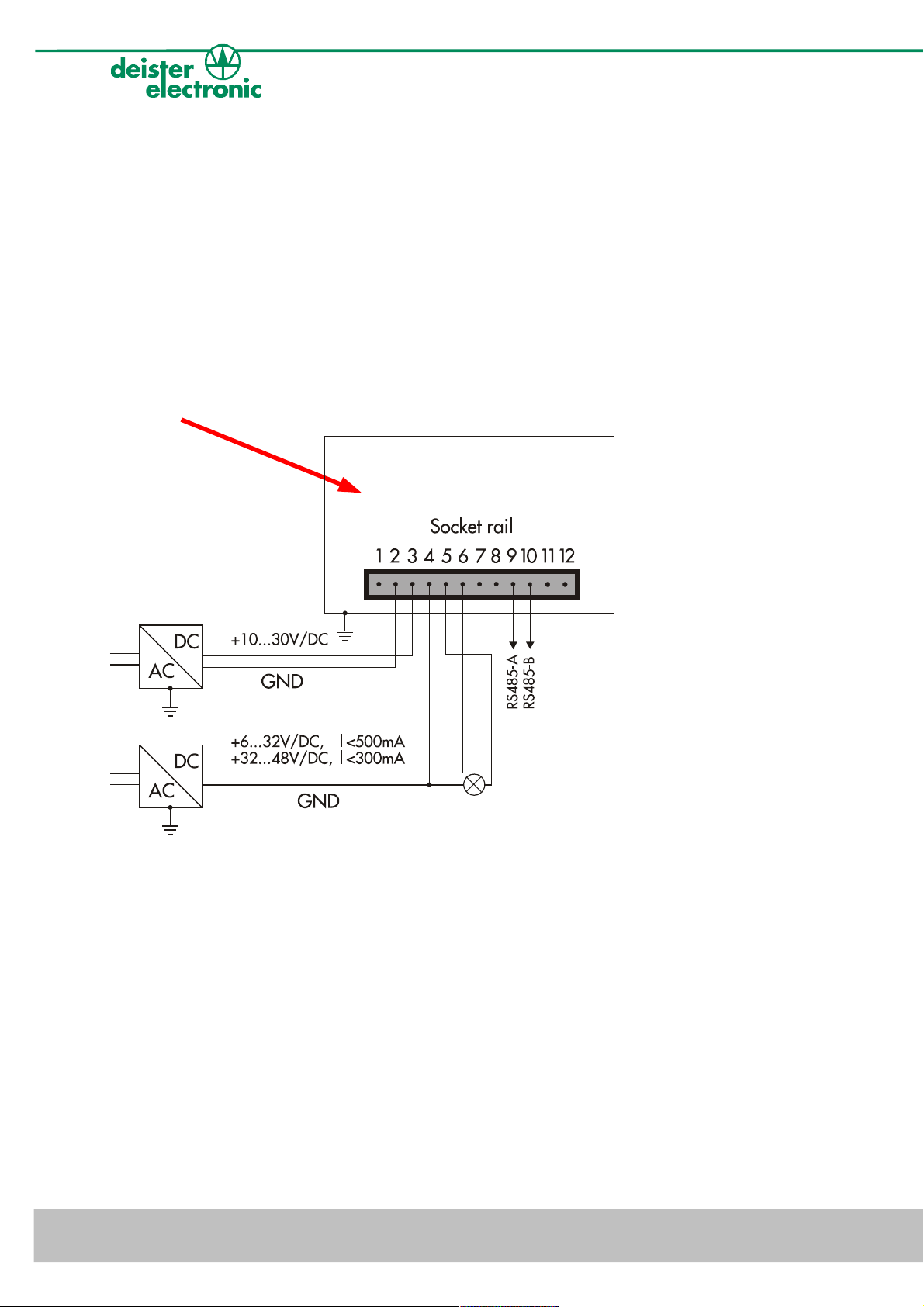

2.5 UDL500: Control digital output via software trigger

Installation notes: We recommend professional grounding of the device (see 2.1

Installation note). Output OUT is potential-free. Take care that the grounding will be

sufficient (use second tab connector)!

The reader can be controlled by a trigger signal via software. Therefore, it is not necessary

to use the potential-free input IN. The control of the potential-free OUT can be configured

within the software. For this the reader has to be operated in trigger mode.

In the following example of circuits the output has not been potential isolated:

UDL500 housing

8 deister electronic GmbH 30890 Barsinghausen Germany V17/01/08

Wiring & Installation Instructions UDL500

3. RS485 interface

Most RS485-buses require termination resistors across the conductor pair. The need for

termination has to be checked for each installation. Especially for high data rates, steep

edges or long cables termination resistors are absolutely mandatory. Only both ends of the

main cable, i.e. at the first and the last device, require termination resistors, additional

resistors excessively load the drivers. The resistor value matches the cable´s differential

mode characteristic impedance (in most cases 100 ... 120Ω).

Attention!

This termination resistor (Terminator, 120Ω) has been factory built-in into

all UDL500 and has to be removed if necessary (see chapter 2).

At the RS485-bus you need a controller with fail-safe biasing meaning a pull-up and a

pull-down resistor on the cable. The fail-safe biasing provides a known-state, in which

there is no active driver on the bus. Therefore this is absolutely mandatory regardless of

data rates and length of cables.

Technical data (for baud rates up to 100kBps):

Max. bus length: 1200m (4000 feet)

Max. stub length: because of reflections stubs should be kept as

short as possible; exceptions allow a length up

to 5m (16 feet)

Recommendation for the cable: twisted pair, cable-cross section at least

0.22mm2 (AWG 24) differential-mode

characteristic impedance 100 ... 120Ω

V17/01/08 deister electronic GmbH 30890 Barsinghausen Germany 9

4. Mechanical dimensions

4.1 UDL500 housing

All dimensions in mm:

Wiring & Installation Instructions UDL500

10 deister electronic GmbH 30890 Barsinghausen Germany V17/01/08

Wiring & Installation Instructions UDL500

5. Transmission protocol

The RS485 interface is being operated with 8 data bits, 1 stop bit and no parity bit. The

transmission rate can be adjusted to 9600, 19200, 38400 or 115200 baud.

The reader works with the “deBus” protocol. For details refer to document “UDL/UDK

deBus Protocol”.

6. Mounting

The back of the reader is prepared for mounting on masts and tubes. For mounting on

masts or ceilings,deister electronic provides the link holder LRM1 as an ideal supplement

(optional, art. nr. 6103.000).

6.1 Mast/Tube mounting

For mounting on masts/tubes the back of the reader is prepared in the way, that alignment

of the reader around its vertical or horizontal axis is possible. The jagged pipe guidings on

the back guarantee a safe tube mounting with a 360° justification round the tube and a

safe mounting of the reader as well.

V17/01/08 deister electronic GmbH 30890 Barsinghausen Germany 11

Loading...

Loading...