UDL5 – UHF mouse

Quick start manual

V27/09/07

UDL5 - UHF mouse · Quick start manual

© Copyright 2007 by deister electronic GmbH

All rights reserved. No part of this publication may be reproduced, stored in a retrieval

system, or transmitted, in any form or by any means, electronic, mechanical, photocopying,

recording, or otherwise, without prior written permission of deister electronic GmbH.

deister electronic GmbH reserves the right to make changes to any and all parts of this

documentation without obligation to notify any person or entity of such changes.

September 2007 SK

deister electronic GmbH

Hermann-Bahlsen Str. 11

30890 Barsinghausen

Germany

Phone: +49 (0) 51 05 - 51 61 11

Fax: +49 (0) 51 05 - 51 62 17

E-Mail: info@deister-gmbh.de

Web: www.deister.com

2

deister electronic GmbH 30890 Barsinghausen Germany V27/09/07

UDL5 - UHF mouse · Quick start manual

Content

1. UDL5 description.........................................................4

1.1 Components.......................................................................................................4

2. Mechanical Dimensions..............................................4

2.1 LEDs and Beeper.................................................................................................5

3. Configuration and setting...........................................5

3.1 Transmission protocol..........................................................................................5

4. Getting started............................................................6

4.1 Installing USB driver............................................................................................6

4.2 Installing RDemo...............................................................................................10

4.3 Get connection.................................................................................................10

4.4 Reading block data...........................................................................................14

4.5 Writing block data.............................................................................................15

4.6 EPC class1 gen2 tag functions............................................................................16

4.7 RDemo command builder..................................................................................16

5. EPC class1 gen2 memory organisation.....................17

V27/09/07 deister electronic GmbH 30890 Barsinghausen Germany

3

1. UDL5 description

1.1 Components

The UDL5 delivery contains:

• 1x UDL5 – UHF mouse

• 1x USB cable

• 1x CD with technical information and software

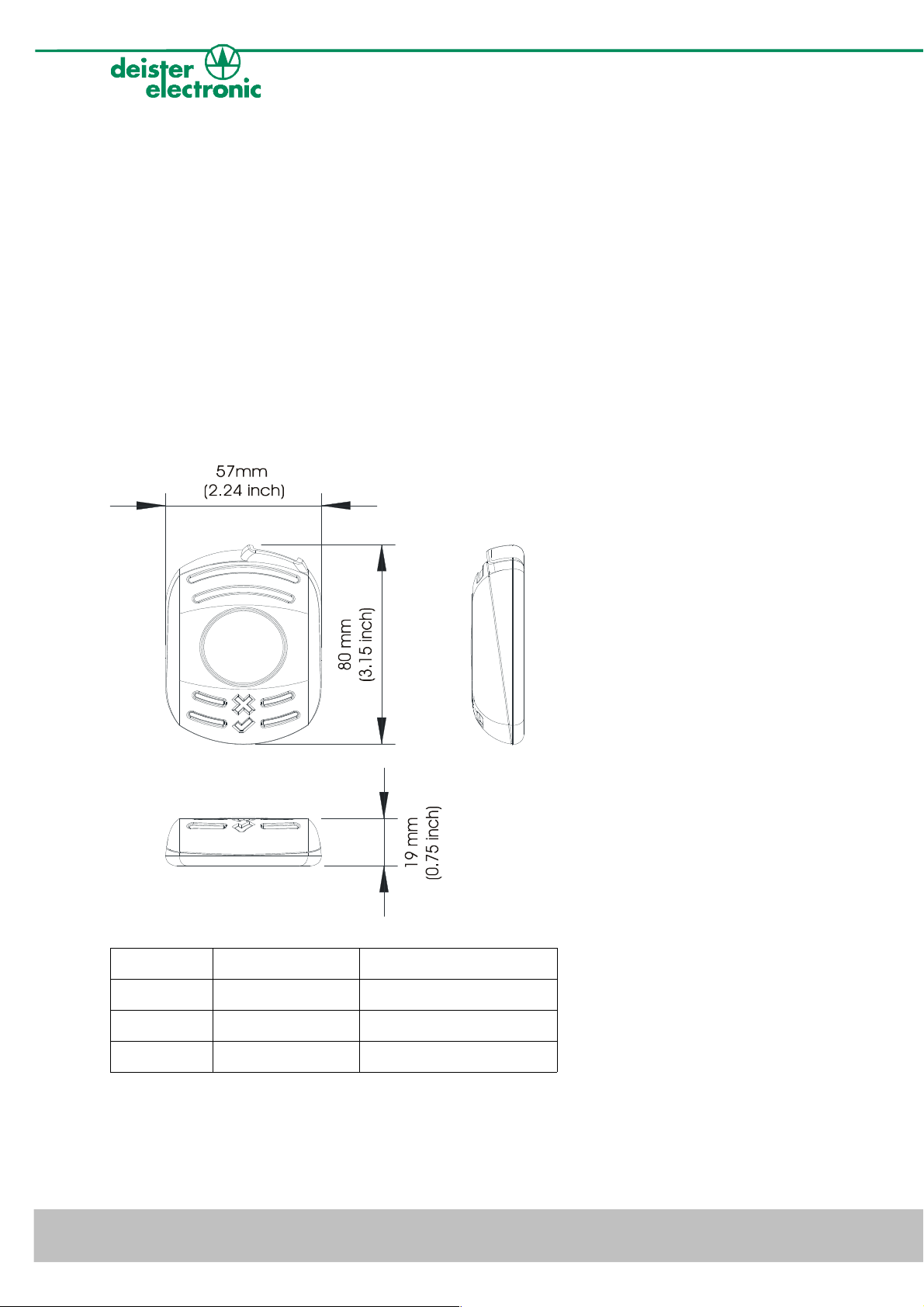

2. Mechanical Dimensions

All dimensions in mm (inch).

UDL5 - UHF mouse · Quick start manual

Symbol LED color Status

X red RF-field on/off

√ green reading/writing tags

blue power

Further explanation see next section 2.1 „LEDs and Beeper“.

4

deister electronic GmbH 30890 Barsinghausen Germany V27/09/07

UDL5 - UHF mouse · Quick start manual

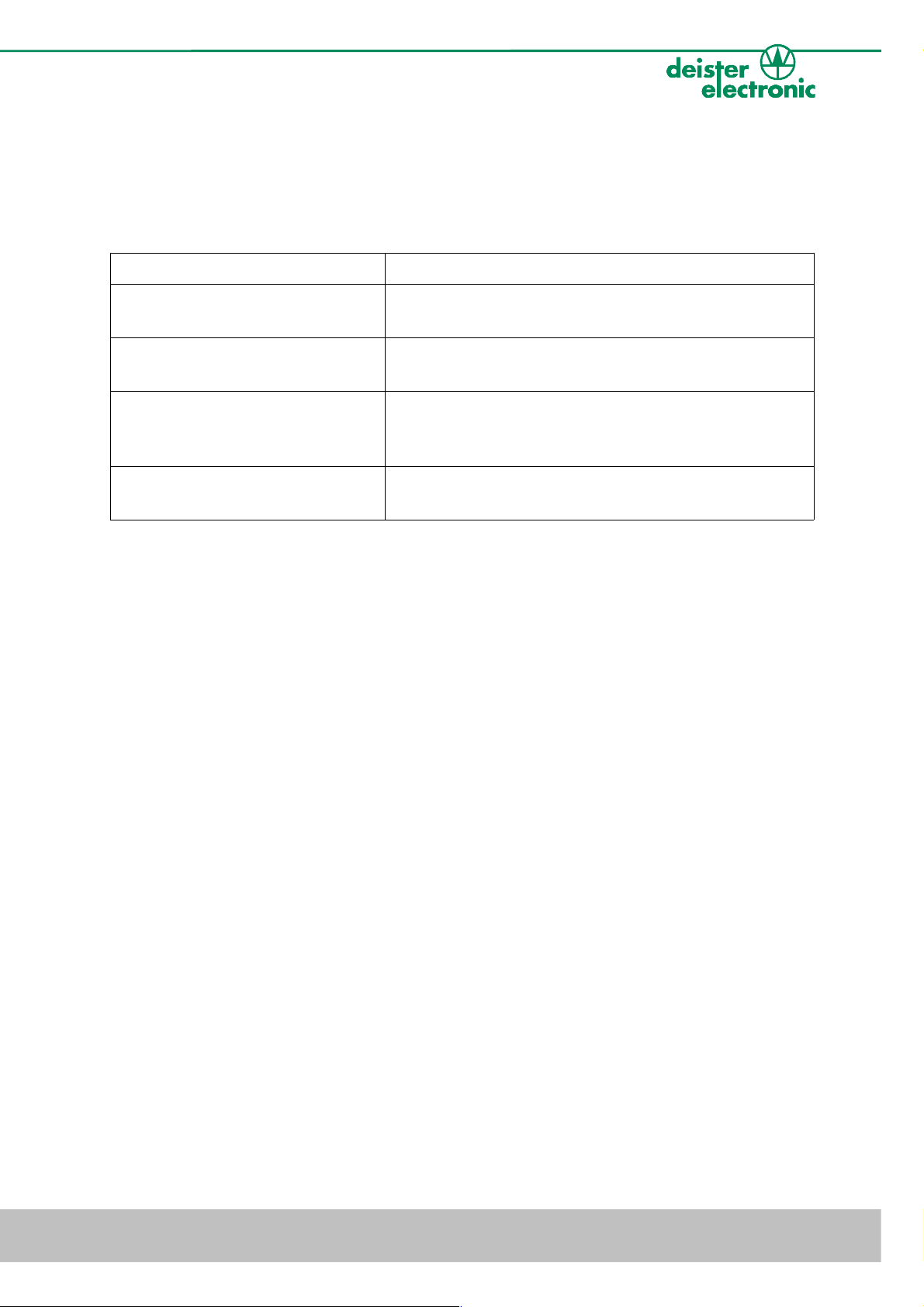

2.1 LEDs and Beeper

The device is equipped with three LEDs and one beeper to indicate the reader status. The

following table refers to the standard settings (device set in trigger mode).

LEDs Status UDL5

blue and red: on

green: off

blue: on

red and green: off

blue and green: on

red: off

beeper: on

blue, green and red: on reader carries out a reset, RF-field is switched off,

reader is ready to operate, RF-field is switched off

reader is ready to operate, RF-field is switched on,

reader is ready to read or write to transponder

reader is ready to operate, communication between

reader and tag (reading/writing)

reader is not ready to operate

3. Configuration and setting

Please note: This manual is considered to be prelimiary.

In the standard configuration the device is set in “Trigger Mode“. This means the device waits

for a “Trigger On“ command to switch the RF-field on and a „Trigger Off“ command to switch

the RF-field off. These software commands can be sent to the device using RDemo software (to

be found on the CD which is part of the UDL5 package).

The UDL5 in its current version is EPC class1 gen2 complicant only.

3.1 Transmission protocol

The communication of the UDL5 is based on the “deBus” protocol. For integration into userdefined applications please contact your local sales and service center (see end of document).

V27/09/07 deister electronic GmbH 30890 Barsinghausen Germany

5

UDL5 - UHF mouse · Quick start manual

4. Getting started

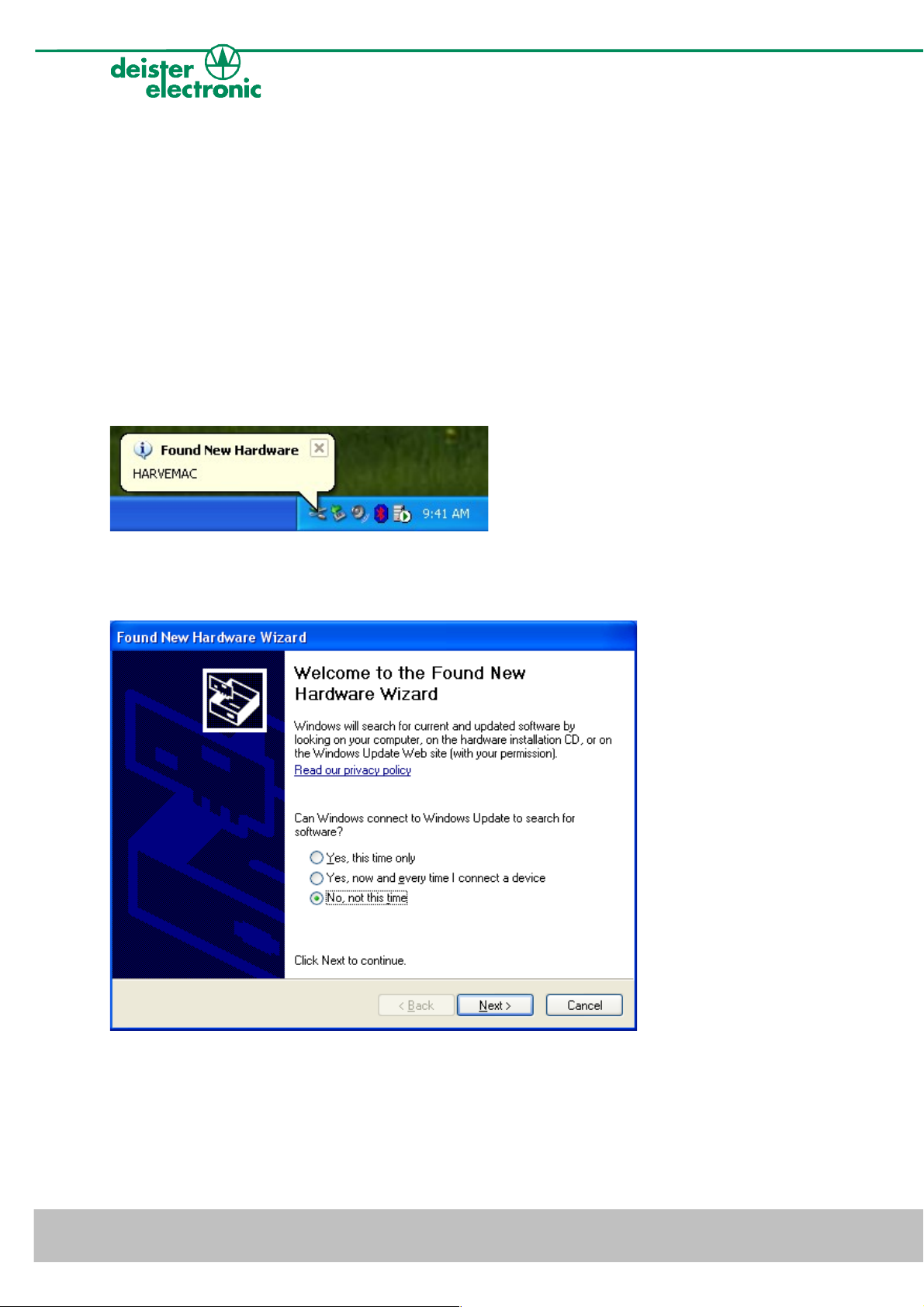

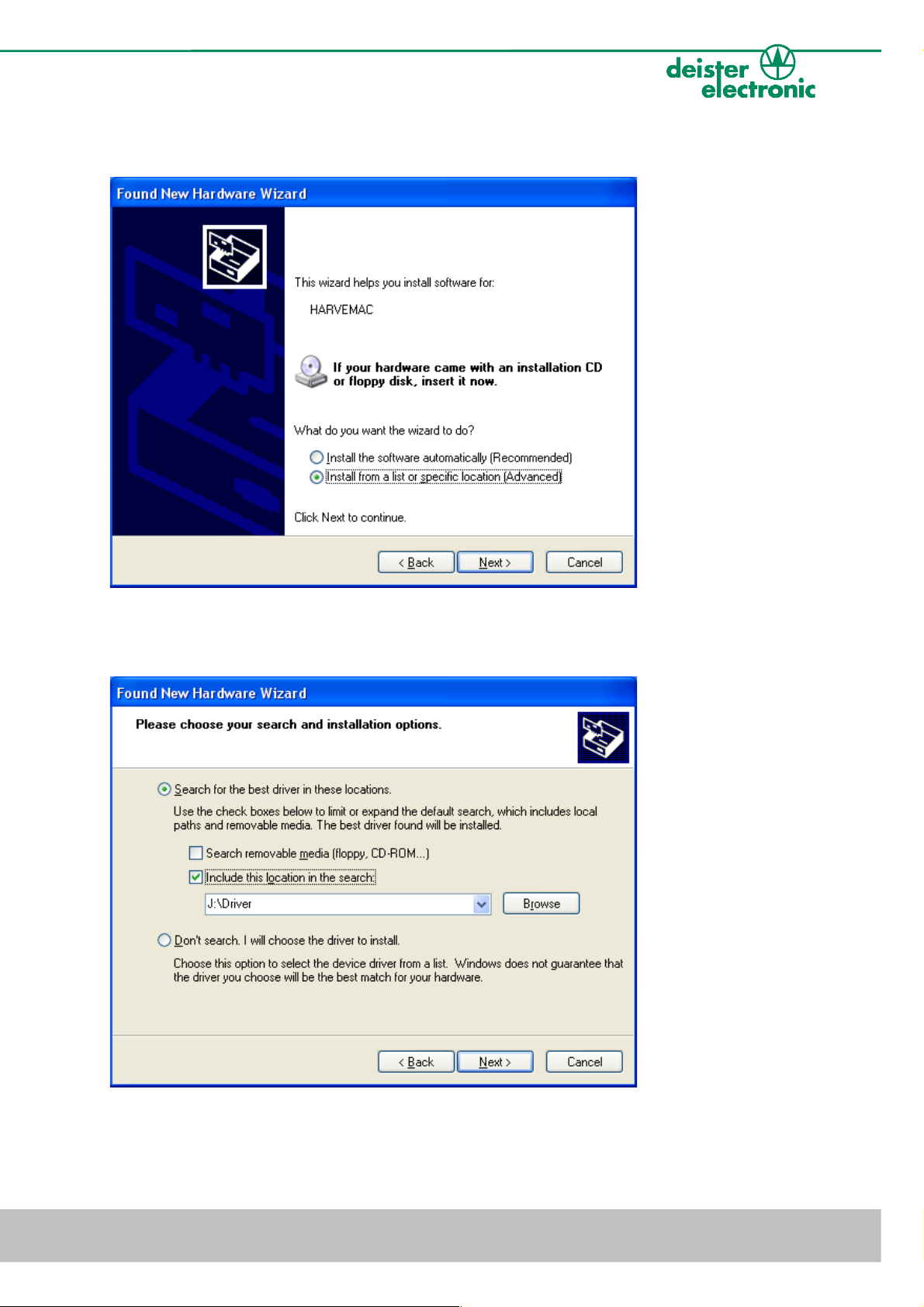

4.1 Installing USB driver

First the USB driver has to be installed. The following steps show how to install the driver

under Windows XP (Windows Vista is supported as well):

• Connect the UDL5 via USB cable to a spare USB Port at your Host/PC

(USB cable as part of delivery of UDL5).

• Windows XP indicates the new hardware with the message

“Found New Hardware: HARVEMAC“.

• The “Found New Hardware Wizard“ will now be started automatically.

Select “No, not this time“ and click “Next“.

If this procedure failed, the search for new hardware can be started manually by click on:

“Start“ -> “Settings“ -> “Control Panel“ -> “System“ -> “Hardware“ -> “Device

Manager“. Select the USB device, marked by a yellow question mark.

6

deister electronic GmbH 30890 Barsinghausen Germany V27/09/07

UDL5 - UHF mouse · Quick start manual

• Select “Install from a list or specific location (Advanced)“ and click “Next“.

• Select “Search for the best driver in these locations“. Enter path name into the combo-

box or browse to path using the “Browse“ button.

V27/09/07 deister electronic GmbH 30890 Barsinghausen Germany

7

UDL5 - UHF mouse · Quick start manual

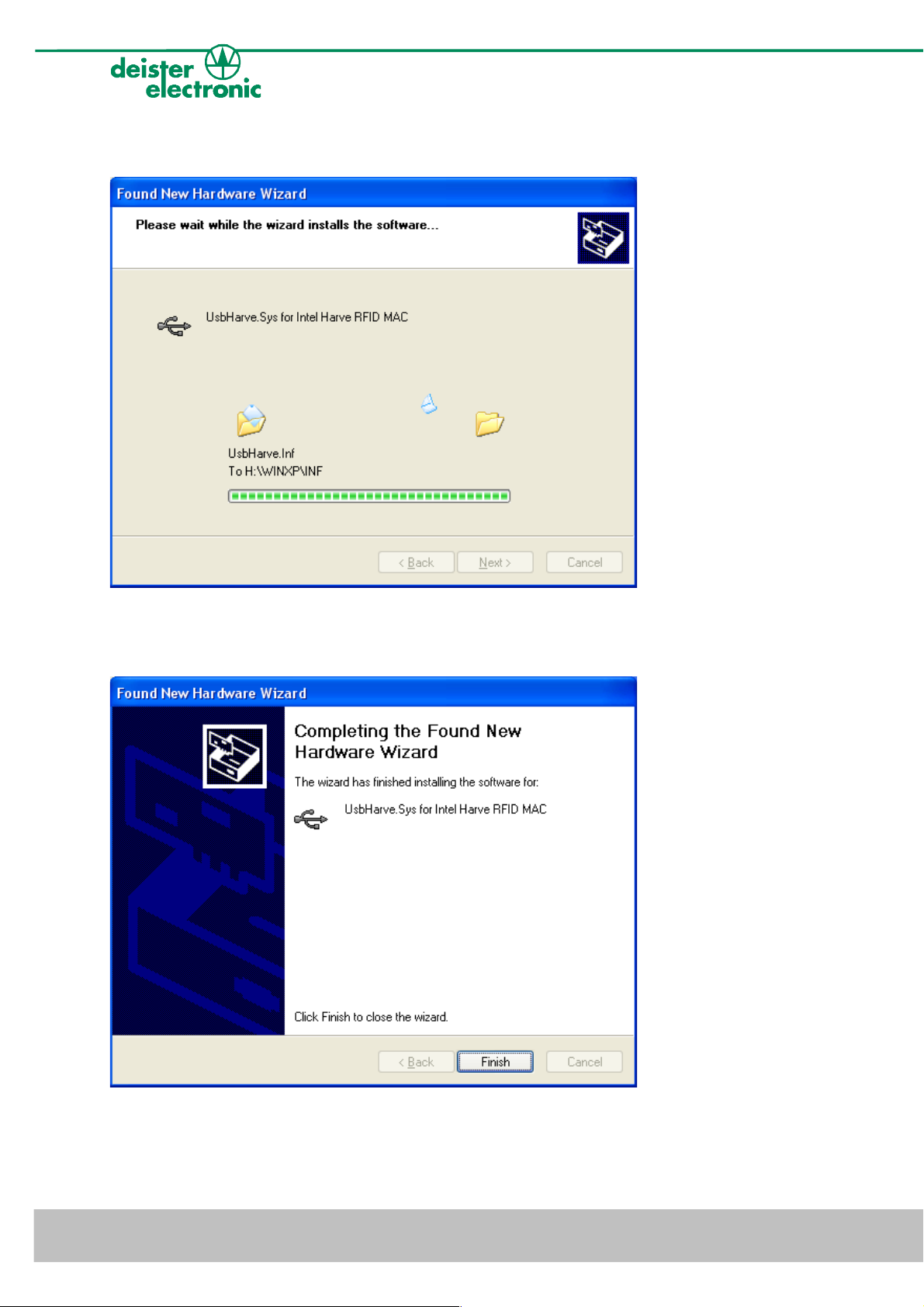

• The screen below will be shown while Windows XP copies the required files.

• The following message indicates a successful installation process. Click “Finish“ to

close the wizard. Now the UDL5 is successfully installed.

8

deister electronic GmbH 30890 Barsinghausen Germany V27/09/07

UDL5 - UHF mouse · Quick start manual

• After successful installation of the USB driver, the UDL5 is ready for use. The “Device

Manager“ indicates the UDL5 as an additional device named “UsbHarve.Sys for Intel

Harve RFID MAC“.

V27/09/07 deister electronic GmbH 30890 Barsinghausen Germany

9

UDL5 - UHF mouse · Quick start manual

4.2 Installing RDemo

The RDemo program can be found on the CD as part of the UDL5 package. For installation

proceed as follows:

• Start installing RDemo with double click on file or icon:

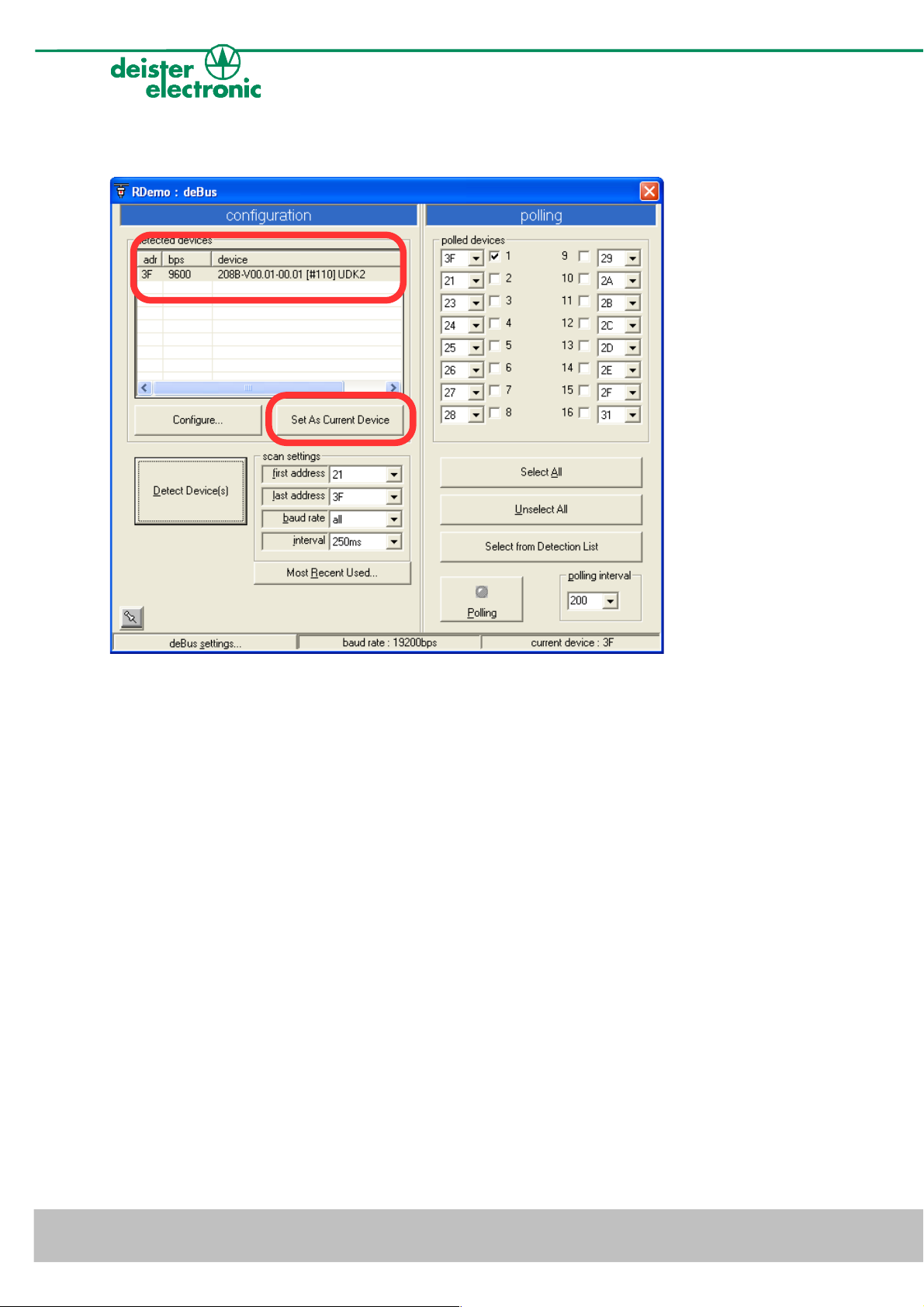

4.3 Get connection

• After successfull installation of RDemo start the program with double click

on file or icon:

• Select “Port“ -> “USB“.

10

deister electronic GmbH 30890 Barsinghausen Germany V27/09/07

UDL5 - UHF mouse · Quick start manual

• Click on button “deBus“.

• Select “baud rate: all“ and click “Detect Device(s)“.

• RDemo starts scanning for connected deBus devices.

V27/09/07 deister electronic GmbH 30890 Barsinghausen Germany

11

UDL5 - UHF mouse · Quick start manual

• After successful search the UDL5 will be shown as a detected device.

• Select the UDL5 with click on the left mouse button, then click “Set As Current Device“

and close the window.

12

deister electronic GmbH 30890 Barsinghausen Germany V27/09/07

UDL5 - UHF mouse · Quick start manual

• Click on the “Version“ button. A “version received“ message in the bottom state bar

indicates a successful version request of the UDL5.

• Click on the “Trigger On“ button in order to switch on the RF-field. Present an EPC

class1 gen2 tag in front of the reader and RDemo will display the tag read.

• Click on the „Trigger Off“ button in order to switch off the RF-field.

V27/09/07 deister electronic GmbH 30890 Barsinghausen Germany

13

UDL5 - UHF mouse · Quick start manual

4.4 Reading block data

The reading function “Transponder“ -> “Read“ can be used to read block data of an EPC

class1 gen2 transponder. To do so proceed as follows:

• Choose the tag type (please note: The current UDL5 version supports EPC class1 gen2

tags only), the serial number (EPC) of the tag to be read and one of the predefined

memory blocks.

• Click on the “Read!“ button and present the EPC class1 gen2 tag within the RF-field.

The block data will be shown in the „Transponder data“ window (see below).

For more details concerning EPC class1 gen2 tag memory organisation see section

5. “EPC class1 gen2 memory organisation“.

14

deister electronic GmbH 30890 Barsinghausen Germany V27/09/07

UDL5 - UHF mouse · Quick start manual

4.5 Writing block data

The writing function “Transponder“ -> “Write“ can be used to write block data to an EPC

class1 gen2 transponder. To do so proceed as follows:

• Choose a tag type (please note: The current UDL5 version supports EPC class1 gen2

tags only), the serial number (EPC) of the tag, a predefined memory section and the

data to be written.

• Click on the “Write!“ button and present the EPC class1 gen2 tag within the RF-field.

The block data will be shown in the “Monitor“ window. RDemo indicates successful

writing with a “write successful“ message (in the “Monitor“ bottom state bar, see

below).

For more details concerning EPC class1 gen2 tag memory organisation see section

5. “EPC class1 gen2 memory organisation“.

V27/09/07 deister electronic GmbH 30890 Barsinghausen Germany

15

UDL5 - UHF mouse · Quick start manual

4.6 EPC class1 gen2 tag functions

Additional tag functions like “Kill command“ and all others are not supported by the

current version of UDL5. Please consult the next sales and service center for details.

4.7 RDemo command builder

For sending a user-defined deBus command to the UDL5, the “Command Builder“ is a

useful tool.

• Go to “Special Functions“ and select “Command Builder“.

• Enter a user-defined deBus command string without dummy bytes, CRC and STOP

bytes and then click “send command“.

16

deister electronic GmbH 30890 Barsinghausen Germany V27/09/07

UDL5 - UHF mouse · Quick start manual

3 USER

[15:0]

… …

…

[N:N-15] [0:15] 192

2 TID

… … …

TID [15:0] [16:31] 129

TID [31:16] [0:15] 128

1 EPC

EPC [15:0]

… …

…

EPC [N:N-15] [32:47] 66

PC [15:0] [16:31] 65

CRC-16 [15:0] [0:15] 64

0 RESERVED

… … …

Access Password [15:0] [48:63] 3

Access Password [31:16] [32:47] 2

Kill Password [15:0] [16:31] 1

Kill Password [31:16] [0:15] 0

Bank No.

(decimal form)

Bank

Name

Block Memory Content

[MSB:LSB]

(decimal form)

Memory Bank

Addresses

[MSB:LSB] (decimal

form)

Block Address

(decimal form)

5. EPC class1 gen2 memory organisation

This paragraph refers to the document “EPCglobal™, Specification for RFID Air Interface”,

Version 1.0.9.

The tag memory is divided into four memory banks. Each memory bank consists of several

blocks, each block has the size of 2 bytes. The banks RESERVED, EPC and TID must always

be available, the USER bank is optional.

• RESERVED: Non-Volatile-Memory, this memory contains a 32 bit Kill Password and a

32 bit Access Password.

• EPC (Electronic Product Code): This bank contains the CRC-16 (cyclic redundancy

check), PC (Protocol Control) and EPC. The PC bits contain information about the tag,

e.g. length of the EPC. The EPC begins at block address 66 (dec), MSB first. In case of

a 96 bit EPC it has the size of 6 blocks.

• TID (Transponder Identification): The TID memory contains data about the

manufacturer. Tags may contain specific data within the TID memory, beginning at

block address 130 (dec), e.g. a tag serial number.

• USER: allows user specific data storage. The memory organisation is user-defined.

V27/09/07 deister electronic GmbH 30890 Barsinghausen Germany

17

UDL5 - UHF mouse · Quick start manual

6. Regulatory notices

6.1 Europe

Hereby, deister electronic GmbH declares, that this equipment - if used according to the

instructions - is in compliance with the essential requirements and other relevant provisions

of the RTTE Directive 1999/5/EC.

A full declaration of conformity can be requested at:

info@deister-gmbh.de

Approved for use in all European countries.

6.2 FCC Digital Device Limitations

Radio and Television Interference

This equipment has been tested and found to comply with the limits for a digital device,

pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses and can radiate radio frequency energy and,

if not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is

likely to cause harmful interference, in which case the user will be required to correct the

interference at his own expense.

This device complies with Part 15 of the FCC rules. Operation is subject to the following

two conditions: (1) This device may not cause harmful interference, and (2) this device

must accept any interference received, including interference that may cause undesired

operation.

In order to maintain compliance with FCC regulations, shielded cables must be used with

this equipment. Operation with non-approved equipment or unshielded cables is likely to

result in interference to radio and television reception.

Caution! Changes or modifications not expressly approved by the manufacturer could void

the user´s authority to operate this equipment.

18

deister electronic GmbH 30890 Barsinghausen Germany V27/09/07

UDL5 - UHF mouse · Quick start manual

Notes:

V27/09/07 deister electronic GmbH 30890 Barsinghausen Germany

19

Notes:

UDL5 - UHF mouse · Quick start manual

20

deister electronic GmbH 30890 Barsinghausen Germany V27/09/07

UDL5 - UHF mouse · Quick start manual

Notes:

V27/09/07 deister electronic GmbH 30890 Barsinghausen Germany

21

Germany:

deister electronic GmbH

Hermann-Bahlsen Str. 11

30890 Barsinghausen

Tel.: +49 (0) 51 05 - 51 61 11

Fax: +49 (0) 51 05 - 51 62 17

info@deister-gmbh.de

www.deister.com

deister worldwide

Belgium & Luxembourg:

deister electronic office

Business Park E 19

Battelsesteenweg 455/A

2800 Mechelen

Tel.: +32 (0) 15 - 28 09 68

Fax: +32 (0) 15 - 28 09 71

info@benelux.deister.com

France:

deister electronic france

101 rue Pierre Semard

92320 Chatillon

Tel.: +33 (0) 1 47 - 35 78 78

Fax: +33 (0) 1 47 - 35 92 59

info@deister.fr

Great Britain:

deister electronic (UK) Ltd.

Stapleton Way, Enterprise Park

Spalding, Lincolnshire

PE11 3YQ

Tel.: +44 (0) 1775 - 717100

Fax: +44 (0) 1775 - 717101

info@deister.co.uk

The Netherlands:

deister electronic office

Tolnasingel 3

2411 PV Bodegraven

Tel.: +31 (0) 1726 - 32970

Fax: +31 (0) 1726 - 32971

info@nl.deister.com

Canada:

deister electronic Inc.

1099 Kingston Road, Suite

212

Pickering, ON L1V 1B5

Tel.: +1 905 - 837 5666

Fax: +1 905 - 837 0777

info@deister-electronic.com

Japan:

deister electronic Japan, LTD.

Toshiba Hoshikawa Bldg. 4F

2-4 Kawabe-chô

Hodogaya-ku, Yokohama-shi

Kanagawa, 240-0001

Tel.: +81 (0) 45 340 1831

Fax: +81 (0) 45 340 1801

info@deister.jp

USA:

deister electronic USA Inc.

9303 Grant Avenue

Manassas, VA 20110

Tel.: +1 703 - 368 2739

Fax: +1 703 - 368 9791

info@deister.com

Loading...

Loading...