UDL120

Installation & Operating

Instructions

V08/07/09

#896068

UDL120

© Copyright 2009 by deister electronic GmbH

All rights reserved. No part of this publication may be reproduced, stored in a retrieval

system, or transmitted, in any form or by any means, electronic, mechanical, photocopying,

recording, or otherwise, without prior written permission of deister electronic GmbH.

deister electronic GmbH reserves the right to make changes to any and all parts of this

documentation without obligation to notify any person or entity of such changes.

Juli 2009 IO/PF/BF

deister electronic GmbH

Hermann-Bahlsen Str. 11

30890 Barsinghausen

Germany

Phone: +49 (0) 51 05 - 51 61 11

Fax: +49 (0) 51 05 - 51 62 17

E-Mail: info.de@deister.com

Web: www.deister.com

2 lo_udl120_io_en V08/07/09

UDL120

Contents

1. General.......................................................................4

2. Technical Data............................................................5

3. Mechanical Dimensions..............................................6

3.1 Dimensions UDL120 with steel sides......................................................................6

3.2 Dimensions UDL120 without steel sides.................................................................7

3.3 Picture UDL120...................................................................................................8

4. Wiring.........................................................................9

4.1 RS485................................................................................................................9

5. Mounting on Forklift.................................................10

5.1 Mounting of UDL120 with steel sides (Protection Set 1)..........................................10

5.1.1 Mounting steel sides.................................................................................10

5.1.2 Drilling Pattern for mounting steel sides.......................................................11

5.2 Mounting of UDL120 without steel sides..............................................................12

5.2.1 Drilling Pattern for direct mounting of UDL120............................................13

5.3 Mounting UDL120 onto steel sides......................................................................14

6. Function of LEDs........................................................15

7. Communication.........................................................15

7.1 Communication via deBus protocol (standard)......................................................15

7.2 Communication via Bluetooth™ (optional)...........................................................15

7.2.1 Connecting to Bluetooth™ module (pairing)................................................15

7.2.2 Configuration mode of Bluetooth™ module.................................................16

7.2.3 Transmitting power...................................................................................16

8. Accessories................................................................17

8.1 Basic principle of forklift application....................................................................17

9. Regulatory Notices....................................................18

V08/07/09 lo_udl120_io_en 3

UDL120

1. General

The UDL120 contains an integrated RFID antenna for contactless reading of transponders

fixed on storage racks. It has been designed for fast and faultless electronic recognition of

goods in transit (i.e. palettes) and is increasingly used within electronic inventory control

systems.

The reader can be mounted directly onto the fork carrier between the forks of a forklift.

Due to its flat mounting height (installation depth only 40 mm) any contact to the

transported goods will be avoided. Solid metal side cheeks (optionally available) prevent

the reader from being damaged by the transported goods and mounting on buffers

provides reasonable absorption of shocks and vibrations.

An ultrasonic sensor in the middle of the housing (optional) detects loading of the forks

and reports it to the control unit (terminal) of the forklift. This will initiate a reading process,

in which the transponder fixed to the storage rack is being read.

The reading result contains the defined storage position of the rack using the specific

transponder ident number and is instantly being reported to the terminal.

The communication between antenna and terminal can either be carried out via cable

using RS485 or wireless via Bluetooth™.

For power supply the reader requires a power connection directly at the fork carrier of the

lift mast (12...24 V/DC).

As this document is solely intended for application of the UDL120 on forklifts, the metal steel sides

(Protection Set 1) are included into all image presentations for reasons of clarity.

4 lo_udl120_io_en V08/07/09

UDL120

2. Technical Data

Dimensions (mm): 172 x 148 x 40

Weight: approx. 730 g (without steel sides)

approx. 1500 g (with steel sides)

Material: PA6, black (front of housing)

PMMA (back of housing)

steel (sides; PS1 optional)

Protection Class: IP 65

Operating Temperature: -25 °C...+50 °C

Storage Temperature: -40 °C...+85 °C

Voltage Supply: 12...24 V/DC via M8 (4-pole)

Power Consumption: 7 W (operating status) / 2.5 W (standby)

Transmission Frequency: 865-868 MHz (EU)

902-928 MHz (US)

Antenna:

Beam Width: 90°

Polarization: circular (LHCP)

Reading/Writing Distance: up to 1.5 m, depending on type of transponder

and environmental conditions

Radiated Transmit Power: max. 200 mW E.R.P. (ETSI EN 302 208),

330 mW E.I.R.P. (FCC Part.15), optional

Transponder Protocols: ISO 18000-6 C

EPC Class 1 Gen 2

Interfaces: RS485

Bluetooth™ Class 1 (optional)

Anticollision: simultaneous reading of several transponders

Reading Mode: Dense Reader Mode can be activated

Ultrasonic Sensor: range up to 70 cm distance

Signalling (optical): LEDs (yellow, green, red)

Conformity:

(Exposition of persons EN 50364

against EM fields)

EMV EN 301 489

Air interface (EU) EN 302 208 (DRM)

V08/07/09 lo_udl120_io_en 5

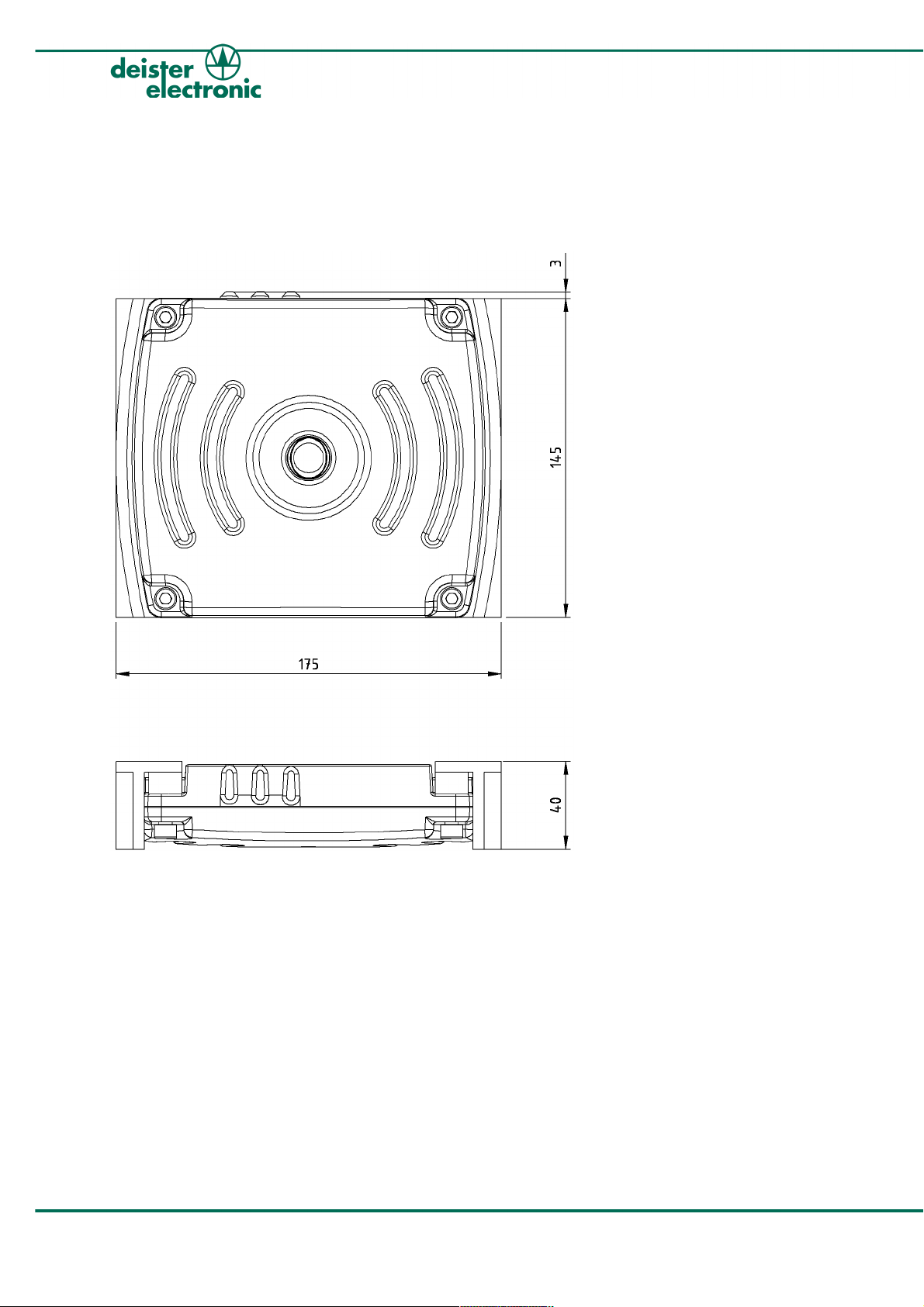

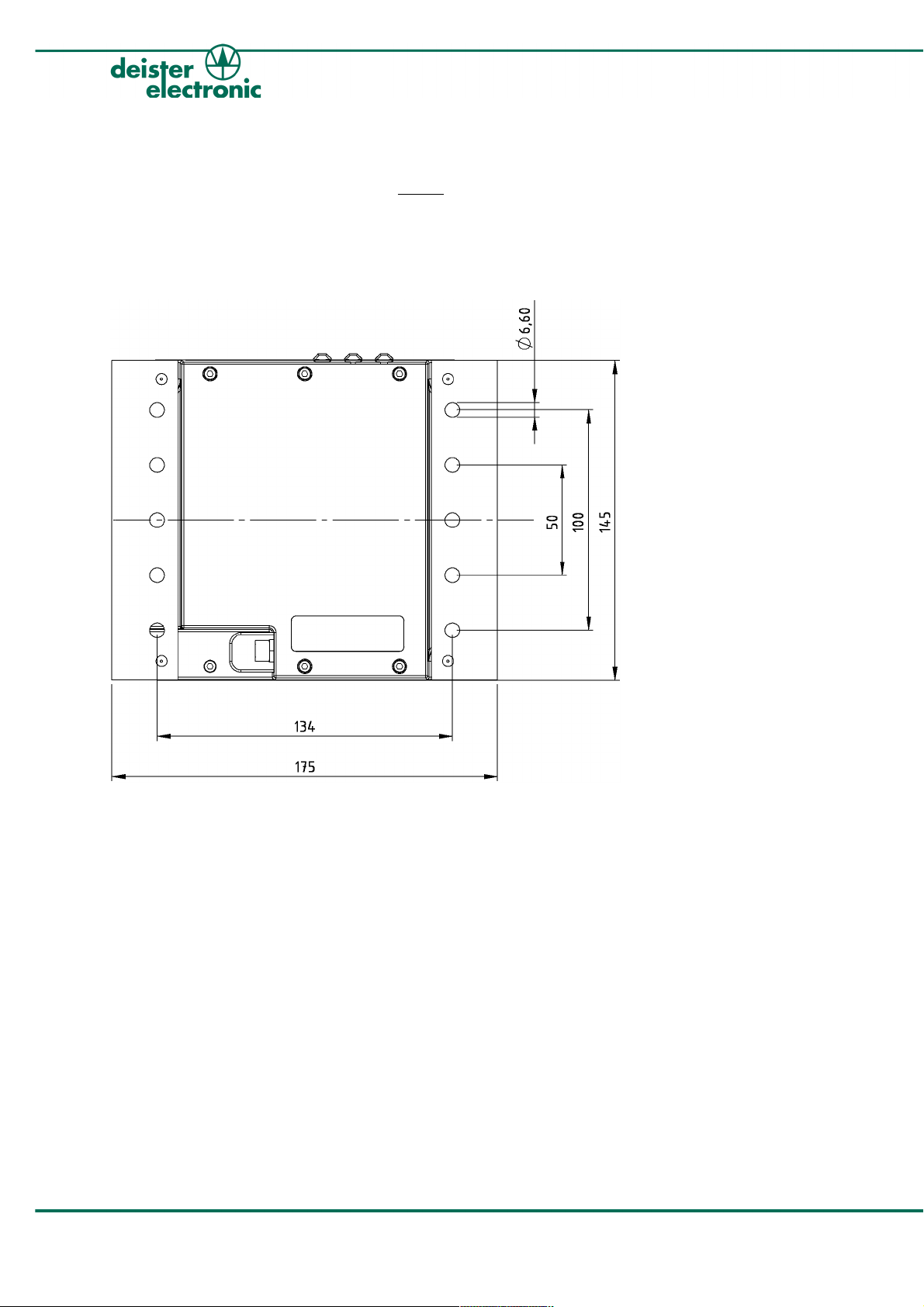

3. Mechanical Dimensions

(All dimensions in mm.)

3.1 Dimensions UDL120 with steel sides

UDL120

Figure 3.1.1: Mechanical Dimensions of UDL120 with steel sides

6 lo_udl120_io_en V08/07/09

UDL120

3.2 Dimensions UDL120 without steel sides

Figure 3.2.1: Mechanical Dimensions of UDL120 without steel sides

V08/07/09 lo_udl120_io_en 7

3.3 Picture UDL120

LED

LED

LED

red

green

yellow

UDL120

Ultrasonic sensor

Figure 3.3.1: Picture of UDL120 with LEDs and ultrasonic sensor

8 lo_udl120_io_en V08/07/09

UDL120

4. Wiring

4.1 RS485

The pin assignment for the voltage supply and data transfer via RS485 is as follows:

Figure 4.1.1: Pin assignment M8 connector (RS485)

pin assignment (M8): PIN 1: VCC (brown)

PIN 2: RS485 A (white) -->(optional*)

PIN 3: GND (blue)

PIN 4: RS485 B (black) -->(optional*)

* In case of communication solely via Bluetooth™ PIN 2 and 4 do not have to be assigned.

V08/07/09 lo_udl120_io_en 9

UDL120

5. Mounting on Forklift

5.1 Mounting of UDL120 with steel sides (Protection Set 1)

5.1.1 Mounting steel sides

The mounting of the two steel sides has to be carried out by the customer between the forks of the

fork carrier with 3 countersunk head screws (M6) on each side (drilling distances see per drawing):

Figure 5.1.1: Mounting UDL120 with steel sides (Protection Set 1)

10 lo_udl120_io_en V08/07/09

UDL120

5.1.2 Drilling Pattern for mounting steel sides

For the drilling pattern scale 1:1 see extra instruction leaflet inside the package.

Figure 5.1.2: Drilling Pattern for mounting steel sides to UDL120

V08/07/09 lo_udl120_io_en 11

5.2 Mounting of UDL120 without steel sides

UDL120

Figure 5.2.1: Mounting UDL120 without steel sides

12 lo_udl120_io_en V08/07/09

UDL120

5.2.1 Drilling Pattern for direct mounting of UDL120

For the drilling pattern scale 1:1 see extra instruction leaflet inside the package.

Figure 5.2.2: Drilling Pattern for direct mounting of UDL120

V08/07/09 lo_udl120_io_en 13

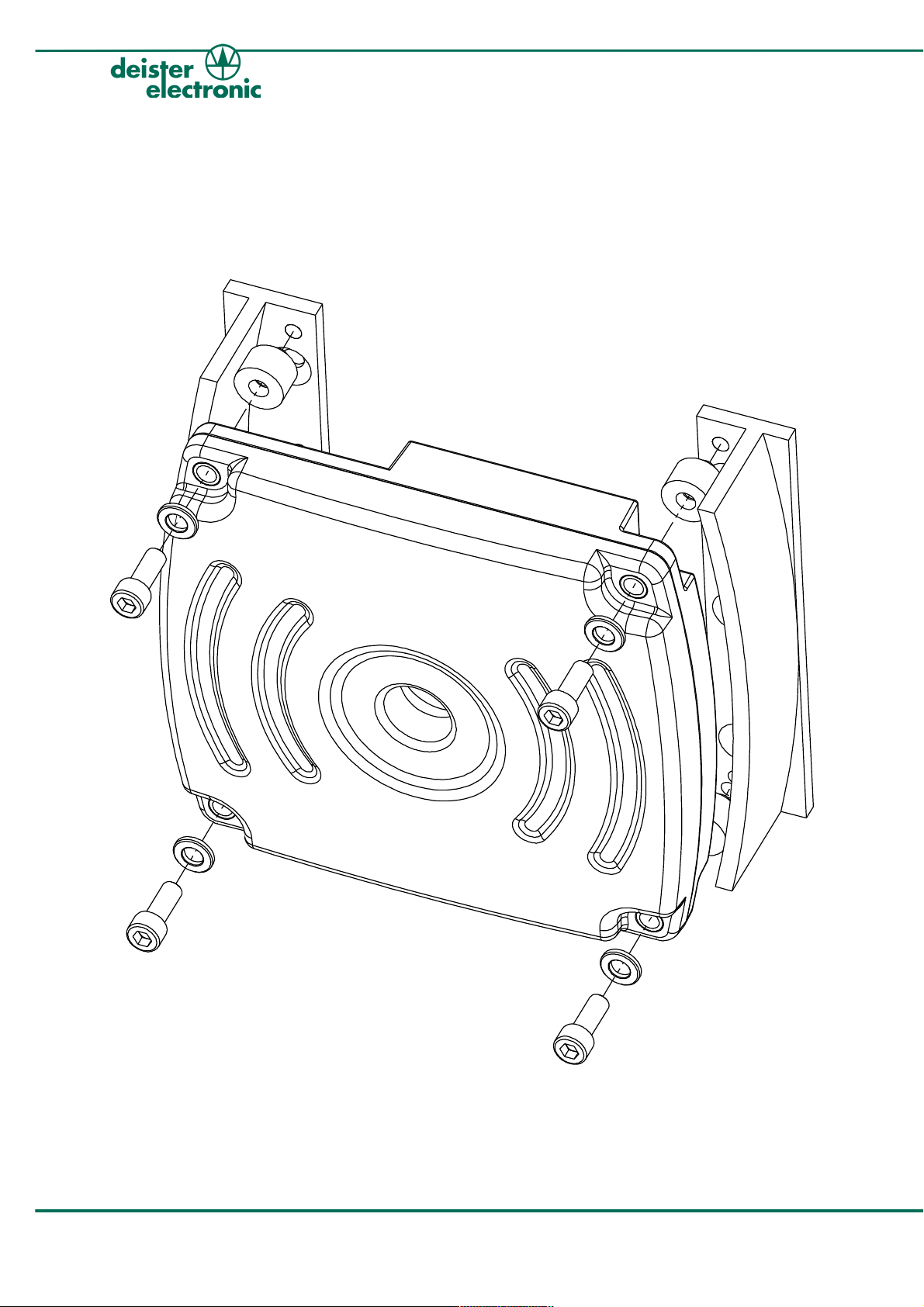

UDL120

5.3 Mounting UDL120 onto steel sides

Mounting of the reader onto the metal bracket has to be carried out using the 4 supplied

screws (DIN 912 cylinder head bolt, allen head screw) and the according washers.

For additional absorption of shocks and vibrations the reader has to be mounted onto the

steel sides using the four supplied buffers (see picture below):

Figure 5.3.1: Mounting UDL120 onto steel sides

14 lo_udl120_io_en V08/07/09

UDL120

6. Function of LEDs

The function of the three LEDs on top of the reader (see also 3.1 Picture) is as follows:

yellow LED is blinking: standard operating status in trigger mode;

device is ready to read;

RF field is switched off

yellow LED is permanently on: standard operating status; device is ready to read;

RF field is switched on

green LED shortly flashes: shows successful reading of a transponder

red LED is active: shows a general malfunction within the system

7. Communication

7.1 Communication via deBus protocol (standard)

The standard way of communication between UDL120 and Terminal (via CB2, CB1, SNG

etc.) is carried out using the deBus protocol on the RS485 bus.

7.2 Communication via Bluetooth™ (optional)

Contactless communication is carried out via Bluetooth™ with an Ezurio BISM2 module.

This module provides a virtual serial interface for communication with the reader using

the Bluetooth™ SPP (Serial Port Profile). The serial interface of the PC has to be

configured as follows:

Data rate: 115200 Baud

Data bits: 8

Stop bits: 1

Parity: none

7.2.1 Connecting to Bluetooth™ module (pairing)

A Bluetooth™ stick for the PC is needed, which contains SPP (Serial Port Profile). The

according Bluetooth™ module can be found by scanning all available Bluetooth™ devices.

The reader reports with „UDL120 #xxx“. The required PIN for the Bluetooth™ connection

is „0000“ (default setting). As long as the memory capacity of the Bluetooth™ module is

sufficient, the module stores the identification of the communication partner so that the

pairing process does not have to be repeated.

V08/07/09 lo_udl120_io_en 15

UDL120

7.2.2 Configuration mode of Bluetooth™ module

Configuration of the Bluetooth™ module takes place via Bluetooth™ interface. The

following parameters can be adjusted:

transmitting power of the Bluetooth™ module

The Bluetooth™ module needs to be switched into the configuration mode first in order to

change any of its settings. In order to do so, three consecutive quotation marks („!!!“) need to

be sent with a time difference of 100 ms between each other using the Bluetooth™ interface.

This can be done for example by help of the Windows program Hyperterminal, which can

access the Bluetooth™ module on the PC using the virtual serial interface.

In order to leave the configuration mode the following command

ATO<Enter>

needs to be sent to the module. After any configuration process a Reset is required.

7.2.3 Transmitting power

The Bluetooth™ module can be configured for a transmitting power between -27 dBm and

+6 dBm. The current transmitting power can be requested by using the following command

ATS541<Enter>

Configuration of the transmitting power is carried out using the command

ATS541?=m<Enter>

The parameter m can be configured with a value between -27 und +6. Changed settings

become active immediately but are only stored within the volatile memory. In case the

module can not be accessed any longer due to an incorrectly adjusted transmitting power,

the original value can be restored by switching the reader on and off.

If all changes of the settings are correct, the configuration has to be transferred into the

non-volatile memory by using the following command

AT&W<Enter>

16 lo_udl120_io_en V08/07/09

UDL120

8. Accessories

Further accessories such as necessary connection cables or peripheral devices (Connection

Box CB1, Connection Box CB2) are shortly explained in the following table and the chart

below will additionally illustrate the basic concept. For all peripheral devices mentioned below

there are separate Wiring and Installation Instructions available which can be obtained on

request from your local sales and service partner or directly at deister electronic GmbH.

CC1 Connection cable

M8 female connector 90° 4-pin with 3 m cable

Art.No. 09287.000

PS1 Protection Set 1

Art.No. 09286.000

CB1 Connection Box 1

Art.No. 09284.000

Steel sides for mounting the reader onto the fork

carriage; weight approx. 767 g

Interface converter;

converts data from Host/PC on the USB bus into

RS485 signals; serves as voltage supply for the

entire RFID system by being connected to a DC/DC

converter (see below)

CB2 Connection Box 2

(for up to 5 reader)

Art.No. 09285.000

Acts as RS485 hub;

serves as data transmitter from the Host/PC (via

CB1) and as voltage supply (from the CB1) for all

separately connected readers (see below)

Table 1: Accessories for UDL120

8.1 Basic principle of forklift application

RS485

UDL120

Terminal

(3rd Party)

USB

CB1

RS485RS485

CC1

CB2

UDLxxx

UDLxxx

UDLxxx

DC/DC converter

(3rd Party)

Figure 8.1.1: Basic principle of forklift application

24 V/DC

UDLxxx

V08/07/09 lo_udl120_io_en 17

UDL120

9. Regulatory Notices

Hereby, deister electronic GmbH declares that this equipment - if used according to the

instructions - is in compliance with the essential requirements and other relevant provisions

of the RTTE Directive 1999/5/EC.

A full declaration of conformity can be requested at:

info@deister-gmbh.de

Approved for use in all European countries.

FCC Digital Device Limitations

Radio and Television Interference

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may

cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference, in which case the user will be

required to correct the interference at his own expense.

This device complies with Part 15 of the FCC rules. Operation is subject to the following

two conditions: (1) This device may not cause harmful interference, and (2) this device

must accept any interference received, including interference that may cause undesired

operation.

In order to maintain compliance with FCC regulations, shielded cables must be used with

this equipment. Operation with non-approved equipment or unshielded cables is likely to

result in interference to radio and television reception.

Caution! Changes or modifications not expressly approved by the manufacturer could void

the user´s authority to operate this equipment.

18 lo_udl120_io_en V08/07/09

UDL120

FCC Notice

To comply with FCC Part 15 rules in the United States, the system must be professionally

installed to ensure compliance with the Part 15 certification. It is the responsibility of the

operator and professional installer to ensure that only certified systems are deployed in the

United States. The use of the system in any other combination (such as co-located

antennas transmitting the same information) is expressly forbidden.

FCC Radiation Exposure Statement

This equipment complies with the FCC radiation exposure limits set forth for an

uncontrolled environment. This equipment should be installed and operated with minimum

distance of 20 cm between the radiator and the human body.

Industry Canada

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

V08/07/09 lo_udl120_io_en 19

Germany

deister electronic GmbH

Hermann-Bahlsen Str. 11

30890 Barsinghausen

Tel.: +49 (0) 51 05 - 51 61 11

Fax: +49 (0) 51 05 - 51 62 17

info.de@deister.com

www.deister.com

deister worldwide

Benelux:

deister electronic office

Business Park E 19

Battelsesteenweg 455/A

2800 Mechelen

Tel.: +32 (0) 15 - 28 09 68

Fax: +32 (0) 15 - 28 09 71

info.be@deister.com

France:

deister electronic france

101 rue Pierre Semard

92320 Chatillon

Tel.: +33 (0) 1 47 - 35 78 78

Fax: +33 (0) 1 47 - 35 92 59

info.fr@deister.com

Great Britain:

deister electronic (UK) Ltd.

Stapleton Way, Enterprise Park

Spalding, Lincolnshire

PE11 3YQ

Tel.: +44 (0) 1775 - 717100

Fax: +44 (0) 1775 - 717101

info.uk@deister.com

Japan:

deister electronic Japan, LTD.

Toshiba Hoshikawa Bldg. 4F

2-4 Kawabe-chô

Hodogaya-ku, Yokohama-shi

Kanagawa, 240-0001

Tel.: +81 (0) 45 340 1831

Fax: +81 (0) 45 340 1801

info.jp@deister.com

USA:

Deister Electronics USA, Inc.

9303 Grant Avenue

Manassas, VA 20110

Tel.: +1 703 - 368 2739

Fax: +1 703 - 368 9791

info.us@deister.com

Loading...

Loading...