DRAFT

Model 7900

DRAFT

Installation Guide

NOTE: This product is intended for installation by a professional installer only!

Any attempt to install this product by any person other than a trained professional

may result in severe damage to a vehicle’s electrical system and components.

© 2006 Directed Electronics, Vista, CA

N5501V 10-06

DRAFT

Bitwriter®, Code Hopping™, Doubleguard®, ESP™, FailSafe®, Ghost Switch™, Learn Routine™, Nite-

DRAFT

Lite®, Nuisance Prevention® Circuitry, Revenger®, Silent Mode™, Soft Chirp®, Stinger®, Valet®,

Vehicle Recovery System®, VRS®, and Warn Away® are all Trademarks or Registered Trademarks of

Directed Electronics.

The Bitwriter® (p/n 998T)

requires chip version 2.2 or

newer to program this unit.

New Software Compatibility for

103T Keypad

This unit now has software that

allows arming with entry delay when

used in conjunction with the optional

103T Keypad. Refer to the 103T

Owner’s Guide for details.

2 © 2005 Directed Electronics—all rights reserved

DRAFT

table of contents

DRAFT

what is included . . . . . . . . . . . . . . . . . . . . . . . . . . .4

warning! safety first . . . . . . . . . . . . . . . . . . . . . . . .4

installation points to remember . . . . . . . . . . . . . . .5

before beginning the installation . . . . . . . . . . . . . 5

after the installation . . . . . . . . . . . . . . . . . . . . .5

deciding on component locations . . . . . . . . . . . . . .6

locations for the siren . . . . . . . . . . . . . . . . . . . . 6

locations for the control module . . . . . . . . . . . . . 6

locations for stinger doubleguard shock sensor . . .7

mounting the antenna . . . . . . . . . . . . . . . . . . . . 7

locations for valet/program switch . . . . . . . . . . . . 8

locations for the status LED . . . . . . . . . . . . . . . .8

finding the wires you need . . . . . . . . . . . . . . . . . . .9

locations for the optional starter kill relay . . . . . .9

locations for the relay satellite . . . . . . . . . . . . . . 9

obtaining constant 12V . . . . . . . . . . . . . . . . . . .9

finding the 12V switched ignition wire . . . . . . . . 10

finding the starter wire . . . . . . . . . . . . . . . . . . 10

finding the tachometer wire . . . . . . . . . . . . . . . 11

finding the accessory wire . . . . . . . . . . . . . . . . 11

finding the wait-to-start bulb wire for diesels . . . 11

finding a (+) parking light wire . . . . . . . . . . . . . 12

finding the door pin switch circuit . . . . . . . . . . . 12

making your wiring connections . . . . . . . . . . . . . .13

primary harness (H1), 12-pin connector . . . . . . . .14

auxiliary harness (H2), 6-pin connector . . . . . . . . .14

door lock harness, 3-pin connector . . . . . . . . . . . .15

remote start ribbon harness, wiring diagram . . . . .15

heavy gauge inline connector key switch interface .16

remote start harness (H3), 5-pin connector . . . . . .16

horn, channel 6 (H4), 2-pin connector . . . . . . . . .16

relay satellite wire connection guide . . . . . . . . . . .23

remote start secondary harness (H3) wire . . . . . . . . .

connection guide . . . . . . . . . . . . . . . . . . . . . . . . . 24

horn, channel 6 harness (H4) wire connection guide 26

neutral safety switch interface . . . . . . . . . . . . . . . 26

testing the neutral safety switch . . . . . . . . . . . . 27

bypassing GM vehicle anti-theft systems (VATS) . . . 29

1995 and newer vehicle anti-theft systems . . . . . . . .

(immobilizers) . . . . . . . . . . . . . . . . . . . . . . . . . . .30

passlock I and passlock II (PL-1 and PL-2) . . . . . 30

passkey III (PK-3), transponder-based systems . . 30

plug-in LED and valet/program switch . . . . . . . . . .31

programmer interface, 3-pin black plug . . . . . . . . .31

shock sensor harness, 4-pin connector . . . . . . . . . .32

tach learning . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

programming jumpers . . . . . . . . . . . . . . . . . . . . . .33

tach threshold on/off . . . . . . . . . . . . . . . . . . . . 33

light flash (+)/(-) . . . . . . . . . . . . . . . . . . . . . . 33

transmitter/receiver learn routine™ . . . . . . . . . . . .34

standard configuration . . . . . . . . . . . . . . . . . . . 36

remote control diagram . . . . . . . . . . . . . . . . . . . . .37

standard mode configuration . . . . . . . . . . . . . . . . .38

multi-level security arming . . . . . . . . . . . . . . . . . .39

system features learn routine . . . . . . . . . . . . . . . .40

feature menus . . . . . . . . . . . . . . . . . . . . . . . . . . .42

menu #1 - basic features . . . . . . . . . . . . . . . . . 42

menu #2 - advanced features. . . . . . . . . . . . . . . 43

menu #3 - remote start options . . . . . . . . . . . . . 44

feature descriptions . . . . . . . . . . . . . . . . . . . . . . .45

menu #1 - basic features . . . . . . . . . . . . . . . . . 45

menu #2 - advanced features. . . . . . . . . . . . . . . 46

menu #3 - remote start options . . . . . . . . . . . . . 49

valet mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

rear defogger control . . . . . . . . . . . . . . . . . . . . . .51

timer mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

table of zones . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

shutdown diagnostics . . . . . . . . . . . . . . . . . . . . . .53

to perform shutdown diagnostics . . . . . . . . . . . . 53

long term event history . . . . . . . . . . . . . . . . . . . .54

safety check . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . .55

alarm troubleshooting . . . . . . . . . . . . . . . . . . . 55

remote start troubleshooting . . . . . . . . . . . . . . . 56

wiring quick reference guide . . . . . . . . . . . . . . . . . 58

relay satellite wiring quick reference guide . . . . . .59

© 2005 Directed Electronics—all rights reserved 3

DRAFT

what is included

DRAFT

■ The control module ■ The plug-in status LED

■ A Responder receiver/antenna ■ The plug-in Valet/Program switch

■ One 2-way Color Remote Control P/N 7541V ■ A hood pinswitch

■ A Stinger Doubleguard shock sensor ■ A toggle (override) switch

■ A 514N Neosiren ■ One Remote Control car charger

warning! safety first

The following safety warnings must be observed at all times:

■ Due to the complexity of this system, installation of this product must only be performed by an authorized

Directed Electronics dealer.

■ When properly installed, this system can start the vehicle via a command signal from the remote control

transmitter. Therefore, never operate the system in an area that does not have adequate ventilation. The

following precautions are the sole responsibility of the user; however, authorized Directed Electronics dealers

should make the following recommendations to all users of this system:

1. Never operate the system in an enclosed or partially enclosed area without ventilation (such as a

garage).

2. When parking in an enclosed or partially enclosed area or when having the vehicle serviced, the remote

start system must be disabled using the installed toggle switch.

3. It is the user's sole responsibility to properly handle and keep out of reach from children all remote

control transmitters to assure that the system does not unintentionally remote start the vehicle.

4. THE USER MUST INSTALL A CARBON MONOXIDE DETECTOR IN OR ABOUT THE LIVING AREA ADJACENT

TO THE VEHICLE. ALL DOORS LEADING FROM ADJACENT LIVING AREAS TO THE ENCLOSED OR PARTIALLY

ENCLOSED VEHICLE STORAGE AREA MUST AT ALL TIMES REMAIN CLOSED.

■ Use of this product in a manner contrary to its intended mode of operation may result in property damage,

personal injury, or death. Except when performing the Safety Check outlined in this installation guide, (1)

Never remotely start the vehicle with the vehicle in gear, and (2) Never remotely start the vehicle with the

keys in the ignition. The user will be responsible for having the neutral safety feature of the vehicle periodi-

cally checked, wherein the vehicle must not remotely start while the car is in gear. This testing should be

performed by an authorized Directed Electronics dealer in accordance with the Safety Check outlined in this

product installation guide. If the vehicle starts in gear, cease remote start operation immediately and consult

with the user to fix the problem immediately.

4 © 2005 Directed Electronics—all rights reserved

DRAFT

fcc/id notice

DRAFT

This device complies with Part 15 of FCC rules. Operation is subject to the following two conditions: (1)

This device may not cause harmful interference, and (2) This device must accept any interference received,

including interference that may cause undesirable operation.

Changes or modifications not expressly approved by the party responsible for compliance could void the user's

authority to operate this device.

caution

This product is designed for fuel injected, automatic transmission vehicles only. Use of this product in a standard

transmission vehicle is dangerous and contrary the product's intended use.

© 2005 Directed Electronics—all rights reserved 5

DRAFT

■ After the remote start module has been installed, test the remote start module in accordance with the

DRAFT

Safety Check outlined in this installation guide. If the vehicle starts when performing the Neutral Safety

Shutdown Circuit test, the remote start unit has not been properly installed. The remote start module must

be removed or properly reinstalled so that the vehicle does not start in gear. All installations must be per-

formed by an authorized Directed Electronics dealer. OPERATION OF THE REMOTE START MODULE IF THE

VEHICLE STARTS IN GEAR IS CONTRARY TO ITS INTENDED MODE OF OPERATION. OPERATING THE REMOTE

START SYSTEM UNDER THESE CONDITIONS MAY RESULT IN PROPERTY DAMAGE OR PERSONAL INJURY.

IMMEDIATELY CEASE THE USE OF THE UNIT AND REPAIR OR DISCONNECT THE INSTALLED REMOTE START

MODULE. DIRECTED ELECTRONICS, INC. WILL NOT BE HELD RESPONSIBLE OR PAY FOR INSTALLATION OR

REINSTALLATION COSTS.

installation points to remember

IMPORTANT! This product is designed for fuel-injected, automatic transmission vehicles only.

Installing it in a standard transmission vehicle is dangerous and is contrary to its intended use.

before beginning the installation

■ Please read this entire installation guide before beginning the installation. The installation of this remote

start system requires interfacing with many of the vehicle’s systems. Many new vehicles use low-voltage or

multiplexed systems that can be damaged by low resistance testing devices, such as test lights and logic

probes (computer safe test lights). Test all circuits with a high quality digital multi-meter before making con-

nections.

■ Do not disconnect the battery if the vehicle has an anti-theft-coded radio. If equipped with an air bag,

avoid disconnecting the battery if possible. Many airbag systems will display a diagnostic code through their

warning lights after they lose power. Disconnecting the battery requires this code to be erased, which can

require a trip to the dealer.

■ Check with the customer on status LED location.

■ Remove the domelight fuse. This prevents accidentally draining the battery.

■ Roll down a window to avoid being locked out of the car.

after the installation

■ Test all functions. The “Using Your System” section of the Owner's Guide is very helpful when testing.

■ When testing, don’t forget that this system is equipped with Nuisance Prevention® Circuitry (NPC). NPC can

bypass trigger zones, making them appear to stop working. See the Nuisance Prevention® Circuitry section.

■ Review and complete the Safety Check section of this guide prior to the vehicle reassembly.

6 © 2005 Directed Electronics—all rights reserved

DRAFT

deciding on component locations

DRAFT

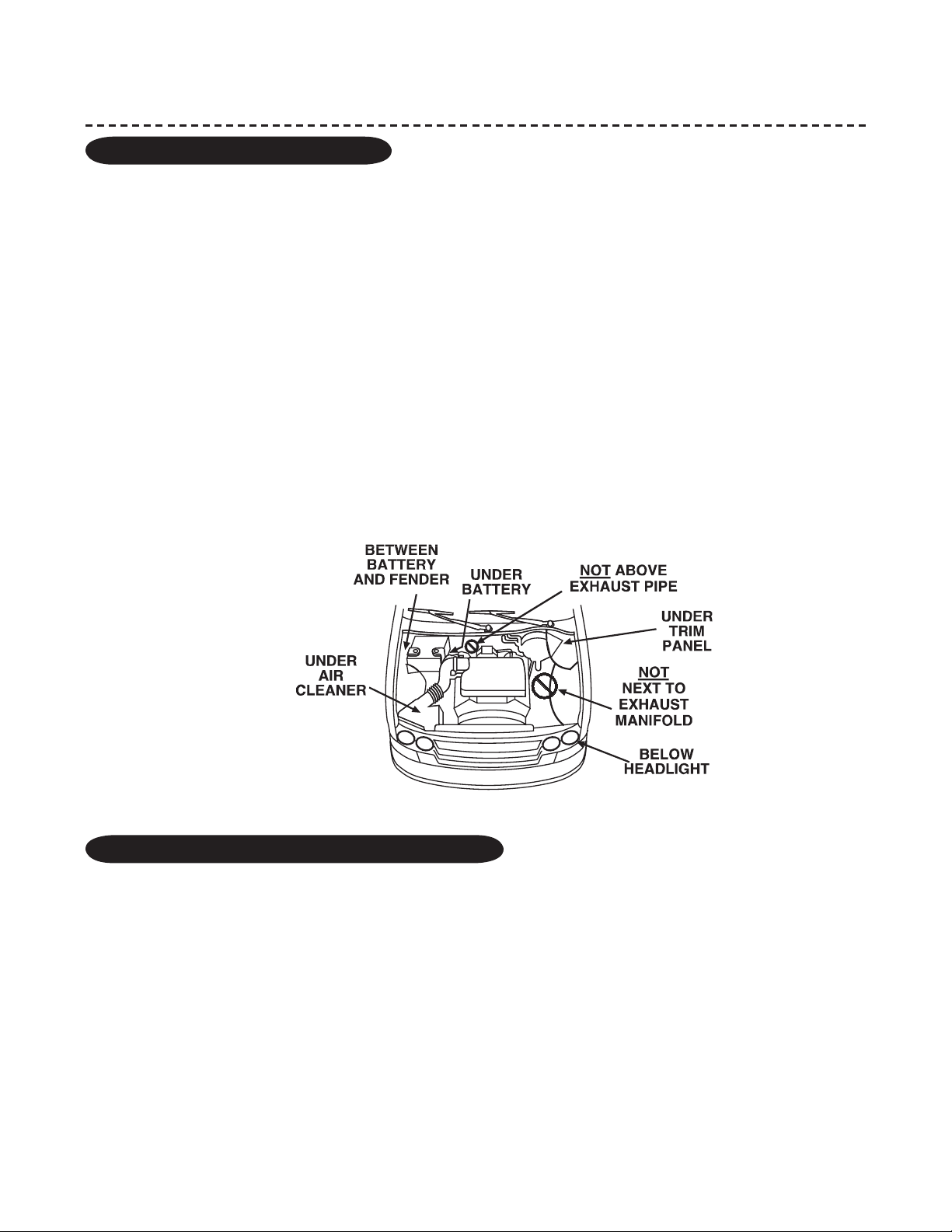

locations for the siren

Some things to remember about mounting the siren:

■ Keep it away from heat sources, such as radiators, exhaust manifolds, turbochargers, and heat shields.

■ Mount it where a thief cannot easily disconnect it, whether the hood is open or shut. Both the siren and its

wires should be difficult to find. This usually in volves disguising the wire to look like a factory harness.

■ We recommend against grounding the siren to its mounting screws. Instead, we recommend running both

the red and black wires into the passenger compartment and grounding to one common point for all devices.

After all, both wires are the same length and come already bonded together. Whenever possible, conceal your

wires in the factory har ness es or in the same style loom as the factory.

■ When possible, place the siren on the same side of the vehicle as the control module, where its wires will

reach the control module’s wires without extending them. Always run the wires through the center of a

grommet, never through bare metal!

■ Point the siren down so water does not collect in it.

locations for the control module

Some things to remember about where to mount the control module:

■ Never put the control module in the engine compartment!

■ The first step in hot-wiring a vehicle is removing the driver's side under-dash panel to access the starter

and ignition wires. If the control module is placed just behind the driver's side dash it can easily be discon-

nected.

■ When mounting the control module, try to find a secure location that will not require you to extend the har-

nesses’ wires (they are 1.5 meters long). Keep it away from the heater core (or any other heat sources) and

any obvious leaks.

■ Some good control module locations are: Above the glove box, inside the center console, above the under-

© 2005 Directed Electronics—all rights reserved 7

DRAFT

dash fuse box, or above the radio.

DRAFT

mounting the antenna

The antenna position should be discussed with the vehicle’s owner prior to installation, since the antenna may

be visible to the vehicle’s operator. The best location for the antenna is centered high on either the front or

rear windshield. For optimal range, the antenna should be mounted horizontally. It can be mounted vertically

but range will be diminished. Metallic window tint can also affect range, so this should be a consideration when

determining the mounting location.

After determining the best mounting location, follow these steps:

1. Clean the mounting area with a quality glass cleaner or alcohol to remove any dirt or residue.

3. Mount the antenna using the supplied double-sided tape.

4. Route the antenna cable to the control module and plug it into the antenna connector.

IMPORTANT! To achieve the best possible range, DO NOT leave the antenna cable bundled under the

dash. Always extend the cable full length during installation, regardless of the antenna mounting

location.

locations for stinger doubleguard shock sensor

Some things to remember about where to mount the shock sensor:

■ Never put the Stinger® in the engine compartment!

■ Find a spot close to the control module so that the wires do not need to be extended. Keep it away from the

heater core (or any other heat sources) and any obvious leaks.

How the Stinger® is mounted is the most important factor in its performance. We recommend two meth-

ods:

■ Using double-sided tape or hook-and-loop fastener to mount to a trim panel or an air duct,

or

■ Wire-tying to a wire harness.

If mounting the sensor where it cannot be easily reached for adjustment, hook-and-loop fastening tape (such as

Velcro) is recommended for ease of removal for future adjustments.

NOTE: In many vehicles, tying the sensor to a steering column or screwing it to metal will result in

poor sensitivity, especially at the rear of the vehicle.

8 © 2005 Directed Electronics—all rights reserved

DRAFT

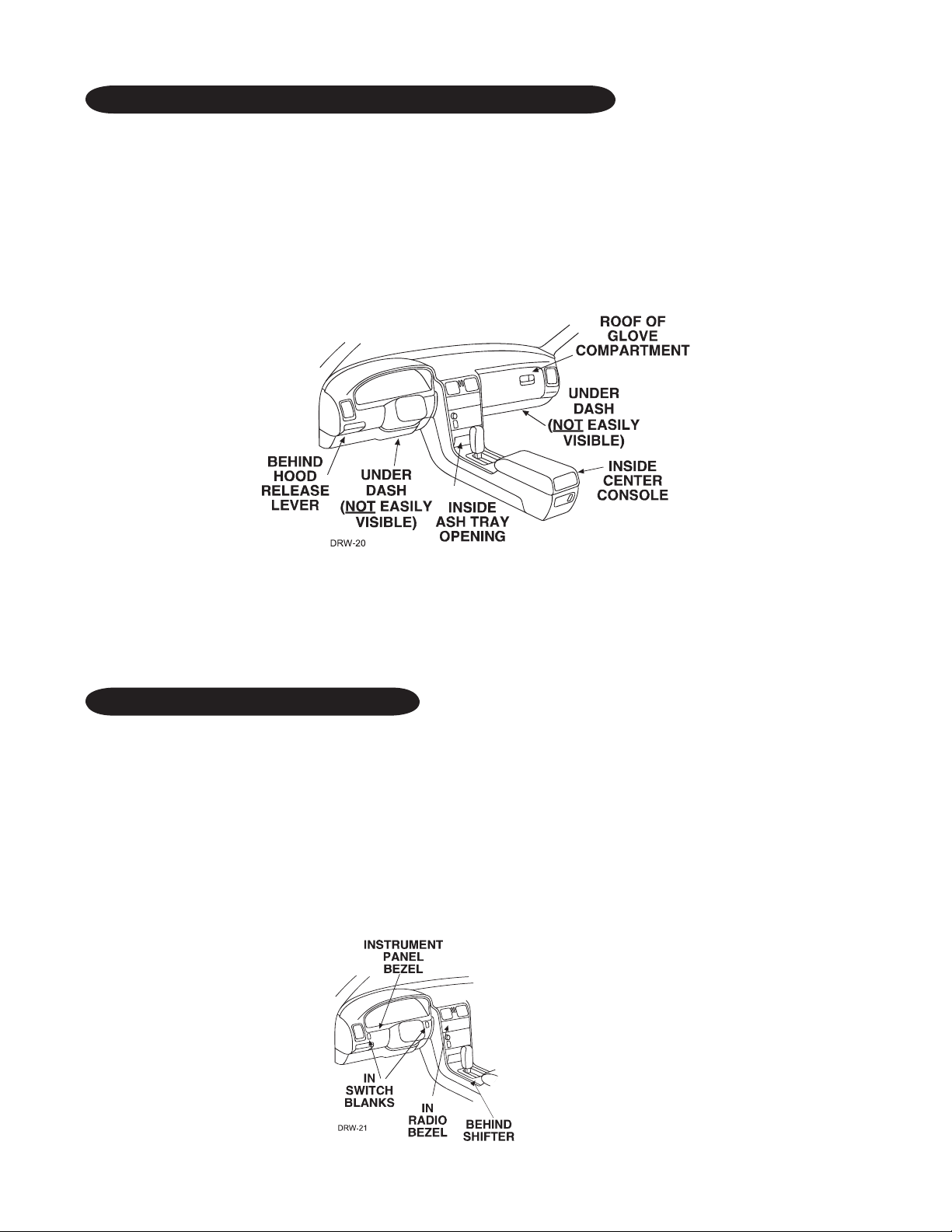

locations for valet/program switch

DRAFT

IMPORTANT! When the vehicle is delivered, please show the user where this switch is lo cat ed and

how to disarm the system with it.

Ensure that the location you pick for the switch has sufficient clearance to the rear. The switch should be well

hidden. It should be placed so pas sen gers or stored items (such as in a glove box or center console) cannot

accidentally hit it. The switch fits into a

9

/32-inch hole.

This system has Remote Valet. The user can enter and exit Valet Mode without having to reach the Valet/Program

switch. This feature was introduced so that switch location was less critical in day-to-day use. As long as the

Valet/Program switch can be reached to disarm without a transmitter, easy access is not important.

locations for the status LED

Things to remember when po si tion ing the Status LED:

■ It should be visible from both sides and the rear of the vehicle, if possible.

■ It needs at least

■ It is easiest to remove a small panel, such as a switch blank or a dash bezel, before drilling a

hole.

■ Use quick-disconnects near the LED wires if the panel is re mov able. This lets me chan ics or other installers

remove the pan el with out cut ting the wires.

1

/2-inch clearance to the rear.

9

/32-inch

© 2005 Directed Electronics—all rights reserved 9

DRAFT

locations for the optional starter kill relay

DRAFT

If optional starter kill relay or its connections are immediately visible upon removal of the under-dash panel, they

can easily be bypassed. Always make the relay and its con nec tions difficult to discern from the factory wiring!

Exposed yellow butt connectors do not look like factory parts, and will not fool anyone! For this reason, routing

the optional starter kill wires away from the steering column is recommended.

locations for the relay satellite

The relay satellite wiring carries large amounts of current. The wires should not be extended and should be cut

to the minimum length necessary. Since the relay satellite is functioning as the ignition switch in the vehicle, it

is often convenient to mount the relay satellite close to the main ignition switch harness.

finding the wires you need

Now that you have decided where each component will be located, you’re going to find the wires in the car that

the security system will be connected to.

IMPORTANT! Do not use a 12V test light or logic probe (computer safe test light) to find these

wires! Use a digital multimeter for all testing.

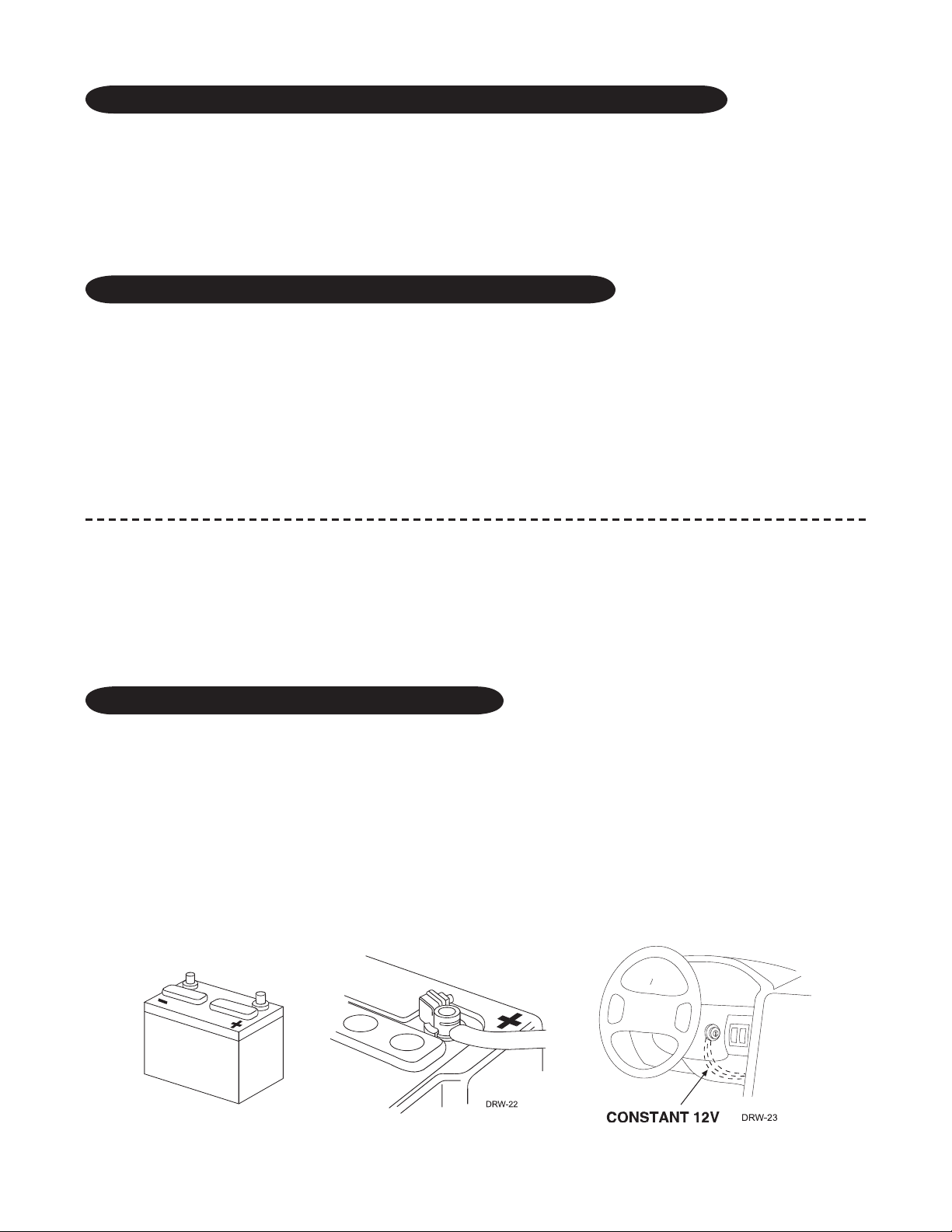

obtaining constant 12V

We recommend two possible sources for 12V constant: the (+) terminal of the battery, or the constant supply to

the ignition switch. Always install a fuse within 12 inches of this connection. If the fuse also will be powering

other circuits such as door locks, fuse accordingly.

IMPORTANT! Do not remove the fuse holder on the red wire. It ensures that the control module

has its own fuse, of the proper value, regardless of how many accessories are added to the main power

feed.

10 © 2005 Directed Electronics—all rights reserved

DRAFT

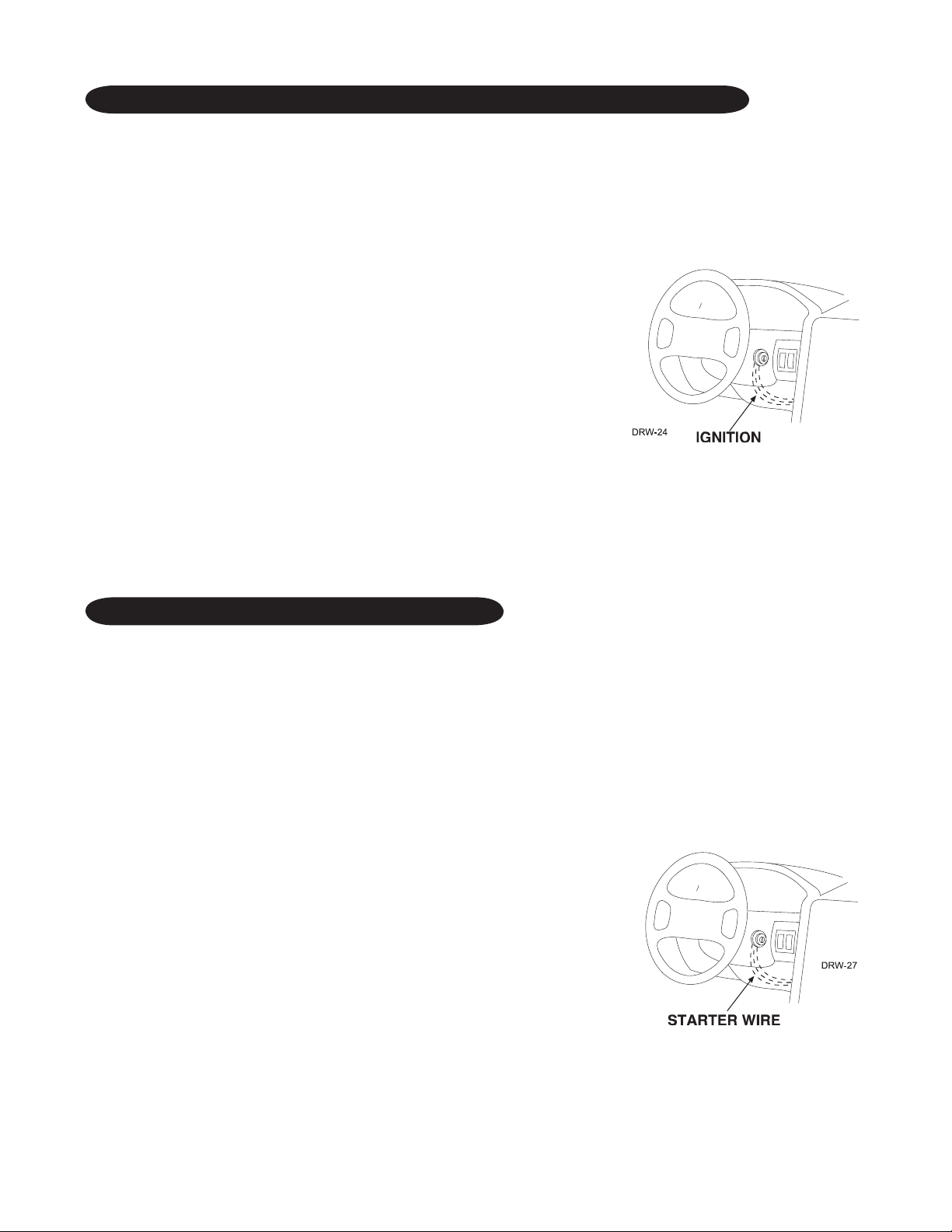

finding the 12V switched ignition wire

DRAFT

The ignition wire is powered when the key is in the run or start position. This is because the ignition wire powers

the ignition system (spark plugs, coil) as well as the fuel delivery system (fuel pump, fuel injection computer).

Accessory wires lose power when the key is in the start position to make more current avail able to the starter

motor.

How to find (+)12V ignition with your multimeter:

1. Set to DCV or DC voltage (12V or 20V is fine).

2. Attach the (-) probe of the meter to chassis ground.

3. Probe the wire you suspect of being the ignition wire. The steering

column harness or ig ni tion switch harness is an excellent place to find

this wire.

4. Turn the ignition key switch to the run position. If your meter reads (+)12V,

go to the next step. If it doesn’t, probe another wire.

5. Now turn the key to the start po si tion. The meter display should stay

steady, not drop ping by more than a few tenths of a volt. If it drops close to or all the way to zero, go back

to Step 3. If it stays steady at (+)12V, you have found an ig ni tion wire.

finding the starter wire

The starter wire provides 12V directly to the starter or to a relay controlling the starter. In some vehicles, it is

necessary to power a cold start circuit. A cold start circuit will test exactly like a starter circuit, but it does not

control the starter. Instead, the cold start circuit is used to prime the fuel injection system for starting when

the vehicle is cold.

How to find the starter wire with your multimeter:

1. Set to DCV or DC voltage (12V or 20V is fine).

2. Attach the (-) probe of the meter to chassis ground.

3. Probe the wire you suspect of being the starter wire. The steering

column is an ex cel lent place to find this wire. Re mem ber you do not

need to interrupt the starter at the same point you test it. Hiding your

optional starter kill relay and con nec tions is always rec om mend ed.

4. Turn the ignition key switch to the start position. Make sure the car

is not in gear! If your meter reads (+)12V, go to the next step. If it

doesn’t, probe another wire.

5. Cut the wire you suspect of being the starter wire.

6. Attempt to start the car. If the starter engages, reconnect it and go back to Step 3. If the starter does not

© 2005 Directed Electronics—all rights reserved 11

DRAFT

turn over, you have the right wire.

DRAFT

finding the accessory wire

An accessory wire will show +12V when the key is in the accessory and run positions. It will not show +12V

during the cranking cycle. There will often be more than one accessory wire in the ignition harness. The correct

accessory wire will power the vehicle's climate control system. Some vehicles may have separate wires for the blower

motor and the air conditioning compressor. In such cases, it will be necessary to add a relay to power the second

accessory wire.

finding the tachometer wire

To test for a tachometer wire, a multimeter capable of testing AC voltage must be used. The tachometer wire will

show between 1V and 6V AC. In multi-coil ignition systems, the system can learn individual coil wires. Individual

coil wires in a multi-coil ignition system will register lower amounts of AC voltage. Also, if necessary, the system

can use a fuel injector control wire for engine speed sensing. Common locations for a tachometer wire are the

ignition coil itself, the back of the gauges, engine computers, and automatic transmission computers.

IMPORTANT! Do not test tachometer wires using a test light or logic probe (computer safe test light)!

This will damage the vehicle.

How to find a tachometer wire with your multimeter:

1. Set to ACV or AC voltage (12V or 20V is fine).

2. Attach the (-) probe of the meter to chassis ground.

3. Start and run the vehicle.

4. Probe the wire you suspect of being the tachometer wire with the red probe of the meter.

5. If this is the correct wire the meter will read between 1V and 6V.

finding the wait-to-start bulb wire for diesels

In diesel vehicles it is necessary to interface with the wire that turns on the WAIT TO START light in the dash-

board. This wire illuminates the bulb until the vehicle’s glow plugs are properly heated. When the light goes out

the vehicle can be started. This wire is always available at the connector leading to the bulb in the dashboard.

It can also be found at the Engine Control Module (ECM) in many vehicles.

To test and determine the polarity of this wire:

1. Set your multimeter to DCV or DC voltage (12 or 20V is fine).

2. Attach the (+) probe of the meter to (+)12V.

3. Probe the wire that you suspect leads to the bulb with the (-) probe of the meter.

4. Turn the ignition switch to the ON position.

5. If the meter indicates 12 volts until the light goes out you have isolated the correct wire and the wire's

12 © 2005 Directed Electronics—all rights reserved

DRAFT

polarity is negative (ground while the bulb is on).

DRAFT

6. If the meter reads zero volts until the light goes out and then reads 12 volts, you have isolated the correct

wire and the wire's polarity is positive.

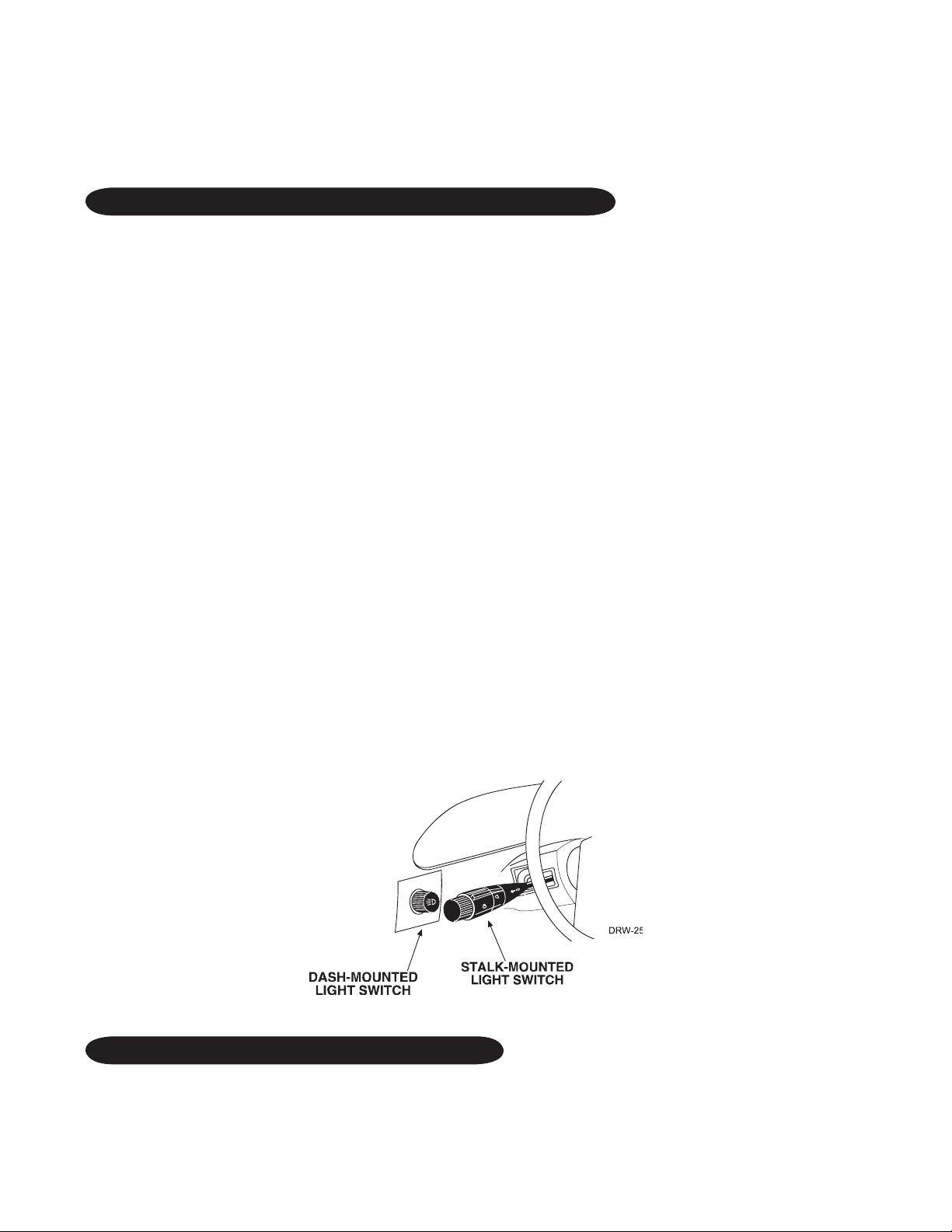

finding a (+) parking light wire

The (+) parking light wire is often found near the switch. Many cars have the switch built into the turn signal

lever, and in these cars the parking light wire can be found in the steering column. The same wire is often avail-

able in the kick panel or running board.

NOTE: Many Toyotas, as well as many other Asian vehicles, send a (-) signal from the switch to a

relay. The relay then sends (+)12V to the bulbs. Whenever you have difficulty finding a (+) parking

light wire near the switch, simply test the wires at any switch or control panel which is lit by the

instrument panel lighting. Remember, you need a (+) parking light wire that does not vary with

the dimmer setting.

How to find a (+) parking light flash wire with your multimeter:

1. Set to DCV or DC voltage (12V or 20V is fine).

2. Attach the (-) probe of the meter to chassis ground.

3. Probe the wire you suspect of being the parking light wire. Usually, the area near the headlight/park ing light

switch is an excellent area to start, as is the kick panel.

4. Turn on the parking lights. If your meter shows (+)12V, turn off the parking lights and make sure it goes back

to zero.

5. If it does return to zero, turn the parking lights back on and, using the dash light dim mer con trol, turn the

brightness of the dash lights up and down. If the meter changes more than a volt when using the dimmer,

look for an oth er wire. If it stays relatively close to (+)12V, you have found your parking light wire.

finding the door pin switch circuit

The best places to find the door switch wire are:

■ At the pin switch: When testing at the pin switch, check the wire to ensure that it “sees” all the doors. Often,

the passenger switch will cover all the doors even if the driver’s switch will not.

© 2005 Directed Electronics—all rights reserved 13

DRAFT

■ At the dome light: This may not be your best choice if the vehicle has delayed domelight supervision, but it

DRAFT

will work in many Hondas, or any vehicle with completely diode-isolated pin switches.

Once you have determined the wire color, the easiest place to connect to the wire is often at the kick panel,

at the windshield pillar, or in the running board. When an easy location is not available, running a wire to the

domelight itself is often the best solution.

How to find a door pin switch trigger wire with your multimeter:

1. Set to DCV or DC voltage (12V or 20V is fine).

2. In most Fords, fasten the (-) probe of the meter to chassis ground. In most other cars, fasten the (+) probe

of your meter to (+)12V con stant.

3. Probe the wire you suspect of being the door trigger wire. If the meter reads (+)12V when any door

is opened, you have found a trigger wire.

NOTE: Make sure the wire you use “sees” all the doors! Some newer GM vehicles lack standardtype pin switches. The dome light in these vehicles is turned on when the door handle is lifted.

These usually have a blue/white or white wire coming out of the door into the kick panel which

will provide a (-) trigger for all doors. Some GM vehicles (some Cavaliers, Grand Ams, etc.) have a

yellow wire coming out of the door which provides a (+) door trigger.

making your wiring connections

Before making your connections, plan how your wires will be routed through the vehicle. For instance, the red

12V constant input and the orange ground-when-armed output (for the optional starter kill relay) will often be

routed together to the ignition switch harness. In order to keep the wiring neat and make it harder to find, you

may wish to wrap these wires together in electrical tape or conceal them in tubing similar to what the manu-

facturer used.

There are two acceptable ways of making a wire connection - solder con nec tions and crimp connectors. When

properly performed, either type of connection is reliable and trouble-free. Regardless of whether you solder your

connections or you use mechanical-type crimp-on connections, ensure that all connections are mechanically

sound and that they are insulated.

Cheap electrical tape, especially when poorly applied, is not a reliable insulator. It often falls off in hot weather.

Use good-quality electrical tape or heat shrink.

■ Never twist-and-tape the wires together without soldering.

■ Never use “fuse taps”, as they can damage fuse box terminals.

If you use tapping connectors such as 3M T-Taps (not to be confused with Scotch-Locks), avoid using them in

higher-current applications (constant 12V, ground, etc.). Some tapping connectors are inferior in quality and

14 © 2005 Directed Electronics—all rights reserved

DRAFT

should be avoided.

DRAFT

primary harness (H1), 12-pin connector

H1/1

______

______

______

______

______

______

______

______

______

______

______

H1/2

H1/3

H1/4

H1/5

H1/6

H1/7

H1/8

H1/9

H1/10

H1/11

H1/12

______

RED/WHITE (-) 200 mA CHANNEL 2 VALIDITY OUTPUT

RED (+) CONSTANT POWER INPUT

BROWN (+) SIREN OUTPUT

EMPTY NOT USED

BLACK (-) CHASSIS GROUND INPUT

VIOLET (+) DOOR TRIGGER INPUT, ZONE 3

BLUE (-) MULTIPLEXED INPUT, ZONE 4

GREEN (-) DOOR TRIGGER INPUT, ZONE 3

BLACK/WHITE (-) 200 mA DOMELIGHT SUPERVISION OUTPUT

WHITE/BLUE (-) REMOTE START ACTIVATION INPUT

WHITE (+)/(-) SELECTABLE LIGHT FLASH OUTPUT

ORANGE (-) 500 mA ARMED OUTPUT

auxiliary harness (H2), 6-pin connector

H2/1

______

______

______

______

______

© 2005 Directed Electronics—all rights reserved 15

H2/2

H2/3

H2/4

H2/5

H2/6

______

LIGHT BLUE (-) SECOND UNLOCK OUTPUT

WHITE/BLACK (-) CHANNEL 5 OUTPUT

VIOLET/BLACK (-) CHANNEL 4 OUTPUT

GREEN/WHITE (-) FACTORY ALARM REARM

GRAY/BLACK (-) WAIT TO START INPUT

LIGHT GREEN/BLACK (-) FACTORY ALARM DISARM

DRAFT

door lock harness, 3-pin connector

DRAFT

1

______

______

______

2

3

Note: Refer to TechTip 1041 for wiring information.

LIGHT BLUE (+) LOCK (-) UNLOCK OUTPUT

EMPTY NOT USED

GREEN (-) LOCK (+) UNLOCK OUTPUT

remote start ribbon harness, wiring diagram

1

______

2

______

3

______

4

______

5

______

PINK/WHITE 200 mA (-) PROGRAMMABLE IGN2/ACC2 RELAY TURN ON

YELLOW (+) IGNITION INPUT TO ALARM

PINK (-) 200 mA IGNITION RELAY TURN-ON

ORANGE (-) 200 mA ACCESSORY RELAY TURN-ON

PURPLE (-) 200 mA STARTER RELAY TURN-ON

______

______

This ribbon harness connects to the relay satellite.

16 © 2005 Directed Electronics—all rights reserved

6

7

ORANGE/BLACK (-) ANTIGRIND/GROUND WHEN ARMED OUTPUT

BLUE (-) 200 mA STATUS OUTPUT

DRAFT

heavy gauge inline connector

DRAFT

key switch interface

1

______

______

______

______

______

______

______

______

2

3

4

5

6

7

8

PURPLE (+) STARTER OUTPUT TO STARTER (STARTER SIDE)

GREEN STARTER INPUT FROM IGNITION (KEY SIDE)

RED (+) HIGH CURRENT 12V INPUT

ORANGE (+) OUTPUT TO ACCESSORY CIRCUIT

PINK (+) OUTPUT TO PRIMARY IGNITION CIRCUIT

RED (+) (30A) HIGH CURRENT 12V INPUT

PINK/WHITE (+) OUTPUT TO SECOND IGNITION CIRCUIT

RED/WHITE (+) (30A) HIGH CURRENT 12V INPUT

remote start harness (H3), 5-pin connector

H3/1

______

______

______

______

H3/2

H3/3

H3/4

H3/5

______

BLACK/WHITE (-) NEUTRAL SAFETY SWITCH INPUT

VIOLET/WHITE TACHOMETER INPUT WIRE

BROWN (+) BRAKE SHUTDOWN WIRE

GRAY (-) HOOD PINSWITCH INPUT, ZONE 1

BLUE/WHITE (-) 200 mA 2ND STATUS/REAR DEFOGGER- LATCHED/PULSED

horn, channel 6 (H4), 2-pin connector

H4/1

______

H4/2

______

ORANGE/BLACK CHANNEL 6 OUTPUT

BROWN (-) 200mA HORN

© 2005 Directed Electronics—all rights reserved 17

DRAFT

primary harness (H1) wire connection guide

DRAFT

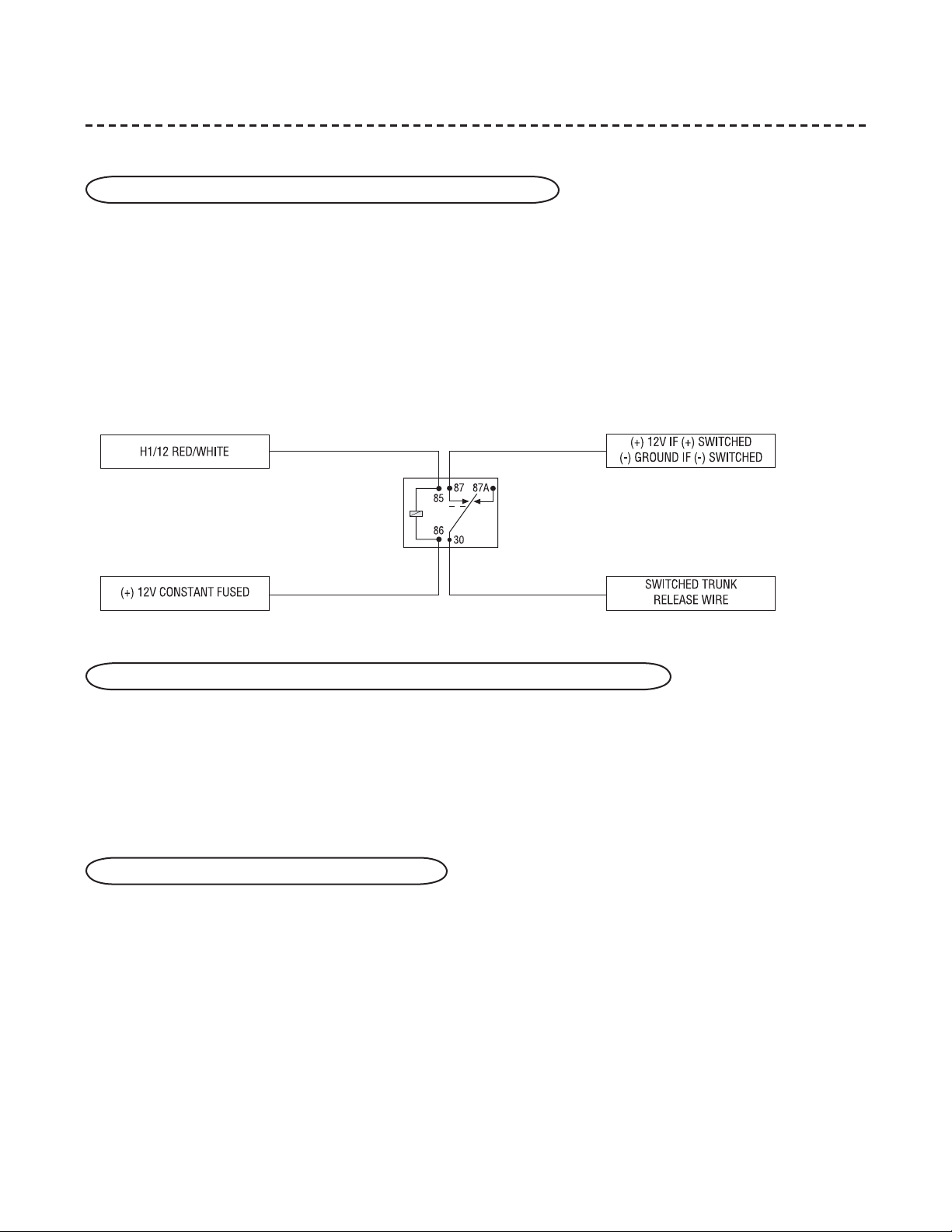

H1/1 RED/WHITE channel 2, 200mA (-) output

When the system receives the code controlling Channel 2, for longer than 1.5 seconds, the red/white wire will

supply an output as long as the transmission continues. This is often used to operate a trunk/hatch release or

other relay-driven function.

IMPORTANT! Never use this wire to drive anything but a relay or a low-current input! The transistorized output can only supply 200 mA of current. Connecting directly to a solenoid, motor, or other

high-current device will cause it to fail.

H1/2 RED (+)12V constant power input

Before connecting this wire, remove the supplied fuse. Connect to the battery positive terminal or the constant

12V supply to the ignition switch.

NOTE: Always use a fuse within 12 inches of the point you obtain (+)12V. Do not use the 15A fuse

in the harness for this purpose. This fuse protects the module itself.

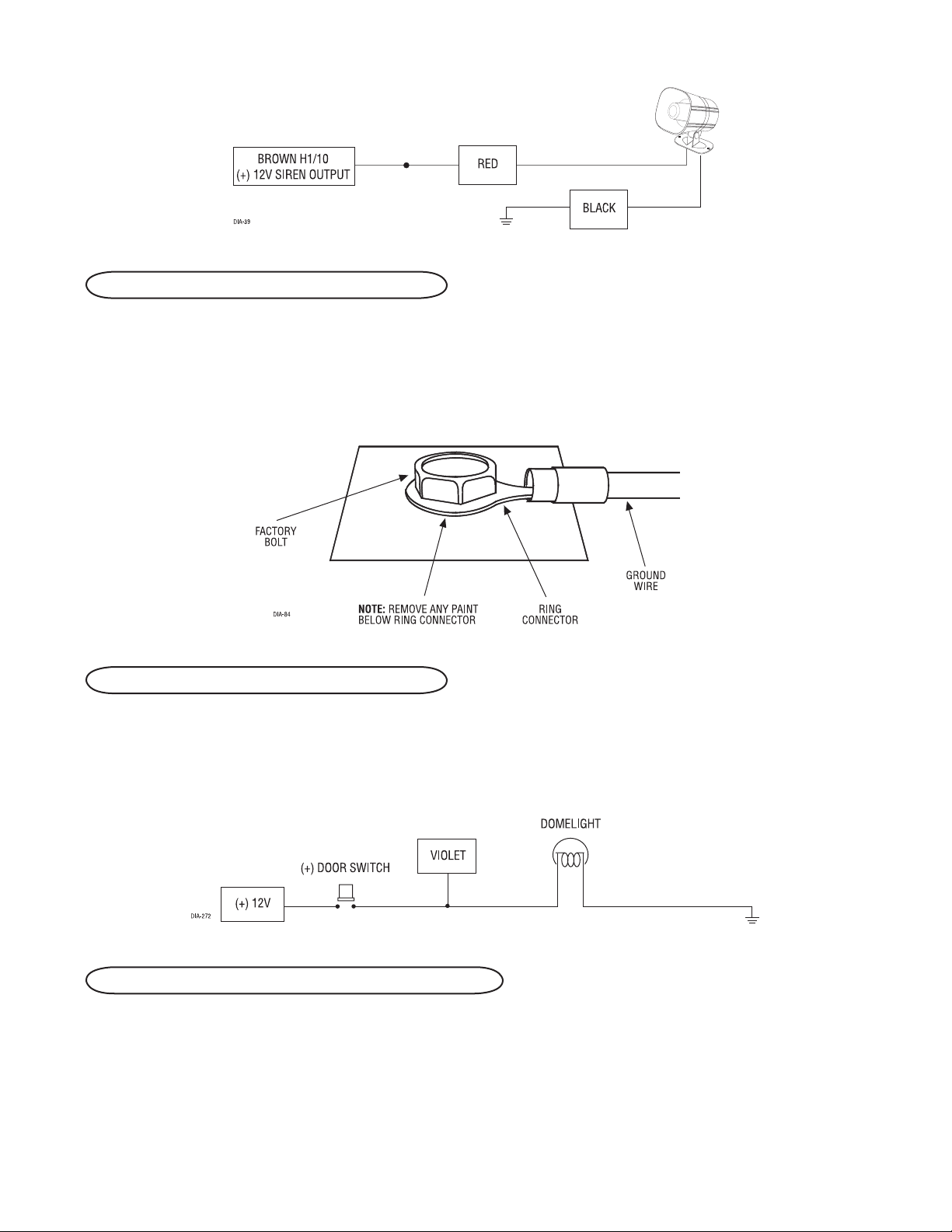

H1/3 BROWN (+) siren output

Connect this to the red wire of the siren. Connect the black wire of the siren to (-) chassis ground, preferably at

the same point you connected the control module’s black ground wire. See Features Description section for horn

output.

18 © 2005 Directed Electronics—all rights reserved

DRAFT

H1/5 BLACK (-) chassis ground connection

DRAFT

Remove any paint and connect this wire to bare metal, preferably with a factory bolt rather than your own screw.

(Screws tend to either strip or loosen with time.) We recommend grounding all your components, including the

siren, to the same point in the vehicle.

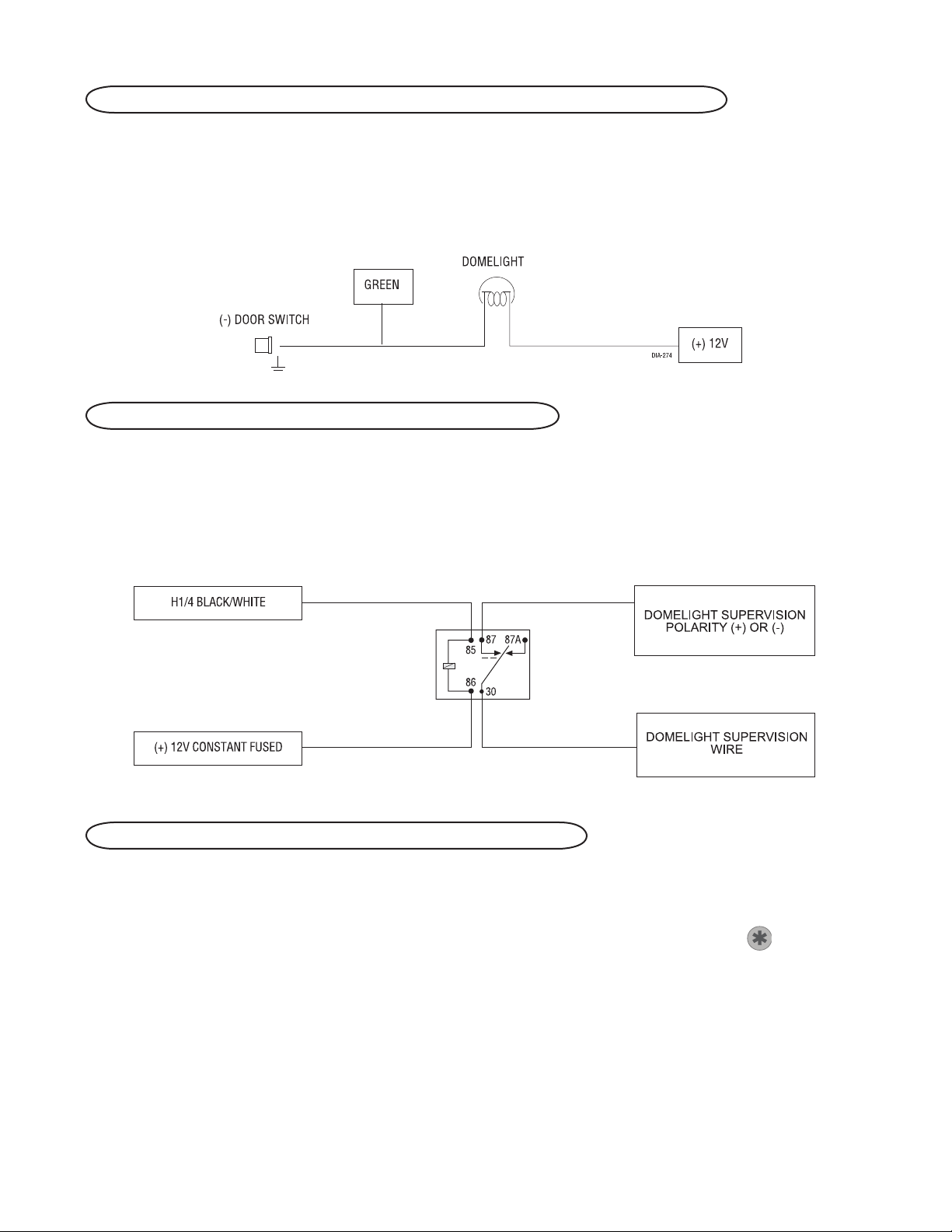

H1/6 VIOLET (+) door trigger input, zone 3

This wire is used in vehicles that have a positive (+) switched dome light circuit. Connect the violet wire to a wire

that shows (+)12V when any door is opened, and ground when the door is closed. This wire will report Zone 3.

H1/7 BLUE (-) multiplex input, zone 4

Inputs shorter than 0.8 seconds will trigger the Warn Away response, while inputs longer than 0.8 seconds will

trigger the full alarm sequence. If installing an optional Directed Electronics dual stage sensor, connect both the

blue and the green wires of the optional sensor to this input. This wire will report Zone 4.

© 2005 Directed Electronics—all rights reserved 19

DRAFT

H1/8 GREEN (-) door trigger input, zone 3

DRAFT

Most vehicles use negative door trigger circuits. Connect the green wire to a wire which shows ground when any

door is opened. In vehicles with factory delays on the domelight circuit, there is usually a wire that is unaffected

by the delay circuitry. This wire will report Zone 3.

H1/9 BLACK/WHITE (-) 200 mA domelight supervision output

Connect this wire to the optional domelight supervision relay as shown below:

IMPORTANT! This output is only intended to drive a relay. It cannot be connected directly to the

domelight circuit, as the output cannot support the current draw of one or more light bulbs.

H1/10 WHITE/BLUE remote start (-) activation input

This input comes from the factory set to 2 activation pulses. This means that it is necessary to have 2 consecu-

tive ground pulses on the white/blue wire for the remote start to activate or to deactivate. The same holds true

for the remote control activation when set to a two pulse setting it is necessary to press the

for the remote start to activate or deactivate.

NOTE: The number of activation inputs can be programmed to 1 or 2 pulses. This setting affects

both the input wire and the remote control when operating the remote starter.

20 © 2005 Directed Electronics—all rights reserved

button twice

Loading...

Loading...