Page 1

DEIF A/S · Frisenborgvej 33 · DK-7800 Skive · Tel.: +45 9614 9614 · Fax: +45 9614 9615 · info@deif.com · www.deif.com

OPERATOR'S MANUAL

Protection and Power Management

PPM 300

Document no.: 4189340910D

Page 2

1. Introduction

PPM 300 Operator's manual 4189340910 UK

www.deif.com

Page 2 of 157

1.1

About the Operator's manual...........................................................................................................................................................................................................7

1.1.1 Intended users of the Operator's manual.....................................................................................................................................................................7

1.1.2 Software versions..........................................................................................................................................................................................................................7

1.1.3 Technical support..........................................................................................................................................................................................................................7

1.1.4 List of technical documentation for PPM 300...........................................................................................................................................................8

1.2 Warnings and safety................................................................................................................................................................................................................................9

1.2.1 Safety during installation and operation ......................................................................................................................................................................9

1.2.2

Automatic and remote-controlled starts........................................................................................................................................................................9

1.2.3

Switchboard control......................................................................................................................................................................................................................9

1.2.4

Controller power supply.........................................................................................................................................................................................................10

1.2.5

Factory settings ..........................................................................................................................................................................................................................10

1.2.6

Electrostatic discharge ..........................................................................................................................................................................................................10

1.2.7 Do not manually override active alarm actions.....................................................................................................................................................10

1.3

Legal information.....................................................................................................................................................................................................................................10

1.3.1 Third party equipment.............................................................................................................................................................................................................10

1.3.2 Warranty............................................................................................................................................................................................................................................11

1.3.3 Open source software.............................................................................................................................................................................................................11

1.3.4 Trademarks.....................................................................................................................................................................................................................................11

1.3.5 Copyright...........................................................................................................................................................................................................................................11

1.3.6 Disclaimer .......................................................................................................................................................................................................................................11

Overview of the system

2.

2.1 Overview..........................................................................................................................................................................................................................................................12

2.1.1 Operating the PPM 300 controllers ..............................................................................................................................................................................12

2.2 Operator messages................................................................................................................................................................................................................................13

2.2.1 Controller status texts..............................................................................................................................................................................................................13

2.2.2

Operator information messages......................................................................................................................................................................................17

3. Controller equipment

3.1

Display unit...................................................................................................................................................................................................................................................24

3.1.1

Introduction to the display unit..........................................................................................................................................................................................24

3.1.2

Display unit LEDs and push-buttons............................................................................................................................................................................25

3.1.3 GENSET controller LEDs and push-buttons..........................................................................................................................................................26

3.1.4 EMERGENCY genset controller LEDs and push-buttons............................................................................................................................28

3.1.5 SHAFT generator controller LEDs and push-buttons .....................................................................................................................................30

3.1.6 SHORE connection controller LEDs and push-buttons ................................................................................................................................32

3.1.7 BUS TIE breaker controller LEDs and push-buttons ......................................................................................................................................33

3.2

Controller rack............................................................................................................................................................................................................................................35

3.2.1

Rack LEDs.......................................................................................................................................................................................................................................35

3.2.2 PSM3.1 LEDs................................................................................................................................................................................................................................35

3.2.3 PCM3.1 LEDs................................................................................................................................................................................................................................36

Operating the system

4.

4.1 Introduction...................................................................................................................................................................................................................................................37

4.1.1 About the operator actions...................................................................................................................................................................................................37

4.2 GENSET controller basic actions..............................................................................................................................................................................................37

4.2.1

Introduction to operating the GENSET controllers.............................................................................................................................................37

4.2.2

Changing modes.........................................................................................................................................................................................................................37

4.2.3

Starting the genset.....................................................................................................................................................................................................................39

Page 3

4.2.4

PPM 300 Operator's manual 4189340910 UK

Stopping the genset..................................................................................................................................................................................................................39

4.2.5 Closing the genset breaker.................................................................................................................................................................................................40

4.2.6 Opening the genset breaker...............................................................................................................................................................................................40

4.2.7

Setting genset start and stop priority............................................................................................................................................................................41

4.3 EMERGENCY genset controller basic actions..............................................................................................................................................................41

4.3.1

Introduction to operating the EMERGENCY genset controller.................................................................................................................41

4.3.2

Changing modes.........................................................................................................................................................................................................................41

4.3.3

Starting the emergency genset........................................................................................................................................................................................43

4.3.4 Stopping the emergency genset......................................................................................................................................................................................43

4.3.5 Closing the emergency genset breaker.....................................................................................................................................................................44

4.3.6 Opening the emergency genset breaker...................................................................................................................................................................44

4.3.7 Closing the tie breaker............................................................................................................................................................................................................45

4.3.8 Opening the tie breaker..........................................................................................................................................................................................................46

4.3.9 Emergency genset test function......................................................................................................................................................................................47

4.4 SHAFT generator controller basic actions........................................................................................................................................................................47

4.4.1 Introduction to operating the SHAFT generator controller...........................................................................................................................47

4.4.2 Closing the shaft generator breaker.............................................................................................................................................................................48

4.4.3 Opening the shaft generator breaker...........................................................................................................................................................................49

4.5 SHORE connection controller basic actions..................................................................................................................................................................49

4.5.1 Introduction to operating the SHORE connection controller.......................................................................................................................49

4.5.2

Closing the shore connection breaker.........................................................................................................................................................................50

4.5.3

Opening the shore connection breaker......................................................................................................................................................................51

4.6 BUS TIE breaker controller basic actions..........................................................................................................................................................................51

4.6.1 Introduction to operating the BUS TIE breaker controller.............................................................................................................................51

4.6.2 Closing the bus tie breaker..................................................................................................................................................................................................51

4.6.3 Opening the bus tie breaker...............................................................................................................................................................................................52

5. Using the display unit

5.1 Introduction...................................................................................................................................................................................................................................................53

5.1.1 About the display unit..............................................................................................................................................................................................................53

5.1.2

About the status bar..................................................................................................................................................................................................................53

5.1.3

About the soft keys....................................................................................................................................................................................................................54

5.1.4

About the virtual keyboard...................................................................................................................................................................................................56

5.1.5 View help...........................................................................................................................................................................................................................................57

Log on

6.

6.1 Permissions..................................................................................................................................................................................................................................................58

6.1.1 About permissions......................................................................................................................................................................................................................58

6.2 Log on................................................................................................................................................................................................................................................................58

6.2.1 Log on to controller....................................................................................................................................................................................................................58

6.3

Log off................................................................................................................................................................................................................................................................59

6.3.1 Log off from controller.............................................................................................................................................................................................................59

6.4 Language.........................................................................................................................................................................................................................................................60

6.4.1 Change language.......................................................................................................................................................................................................................60

6.5

Reset...................................................................................................................................................................................................................................................................61

6.5.1 Reset display unit.......................................................................................................................................................................................................................61

6.6 User info...........................................................................................................................................................................................................................................................62

6.6.1 View user information..............................................................................................................................................................................................................62

www.deif.com Page 3 of 157

Page 4

7. Configure

PPM 300 Operator's manual 4189340910 UK

www.deif.com

Page 4 of 157

7.1

Introduction...................................................................................................................................................................................................................................................63

7.1.1 About configure............................................................................................................................................................................................................................63

7.2

Priority...............................................................................................................................................................................................................................................................63

7.2.1 View or configure priority.......................................................................................................................................................................................................63

7.3 Counters..........................................................................................................................................................................................................................................................64

7.3.1 View or configure counters..................................................................................................................................................................................................64

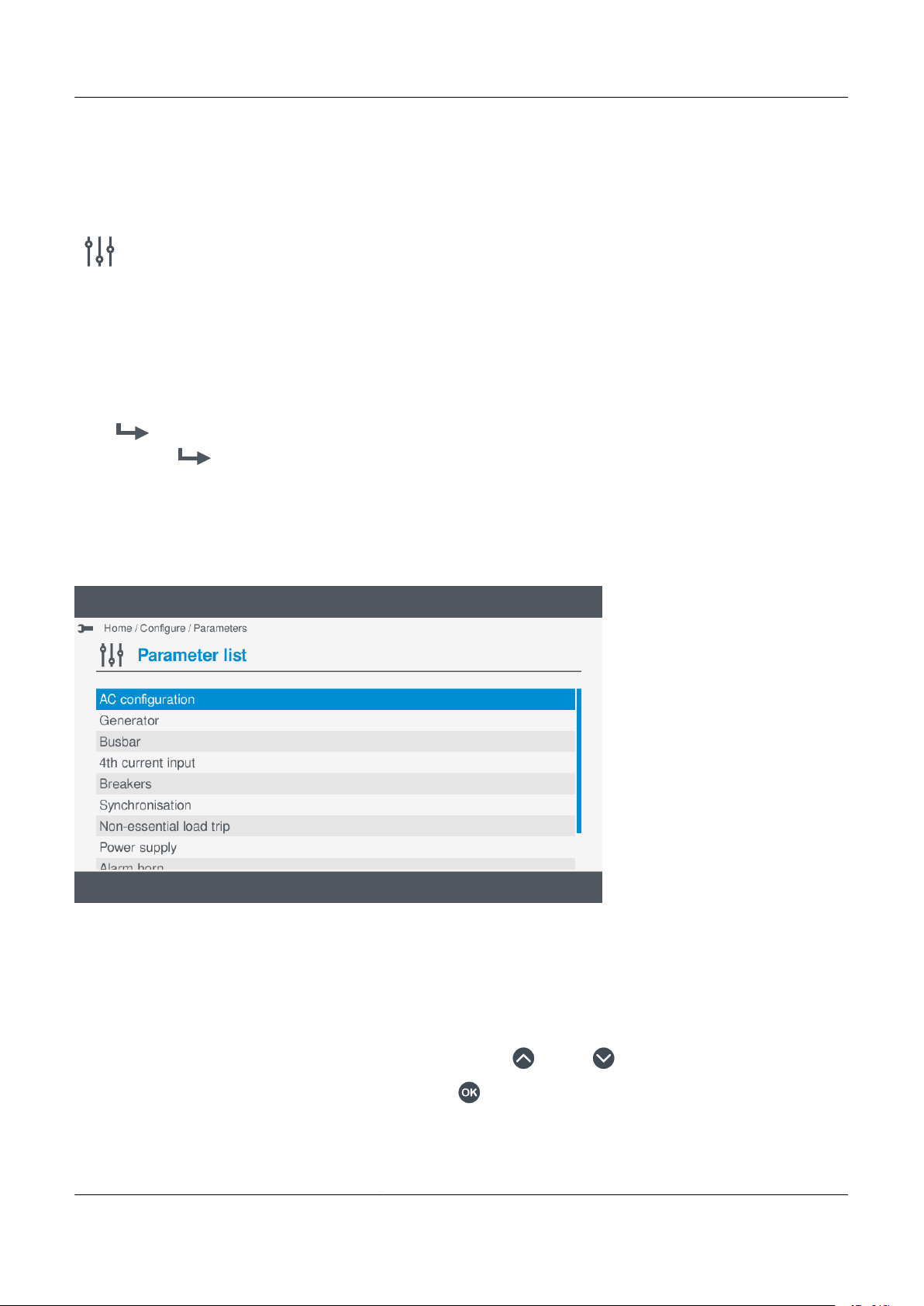

7.4 Parameters.....................................................................................................................................................................................................................................................68

7.4.1 View or configure parameters...........................................................................................................................................................................................68

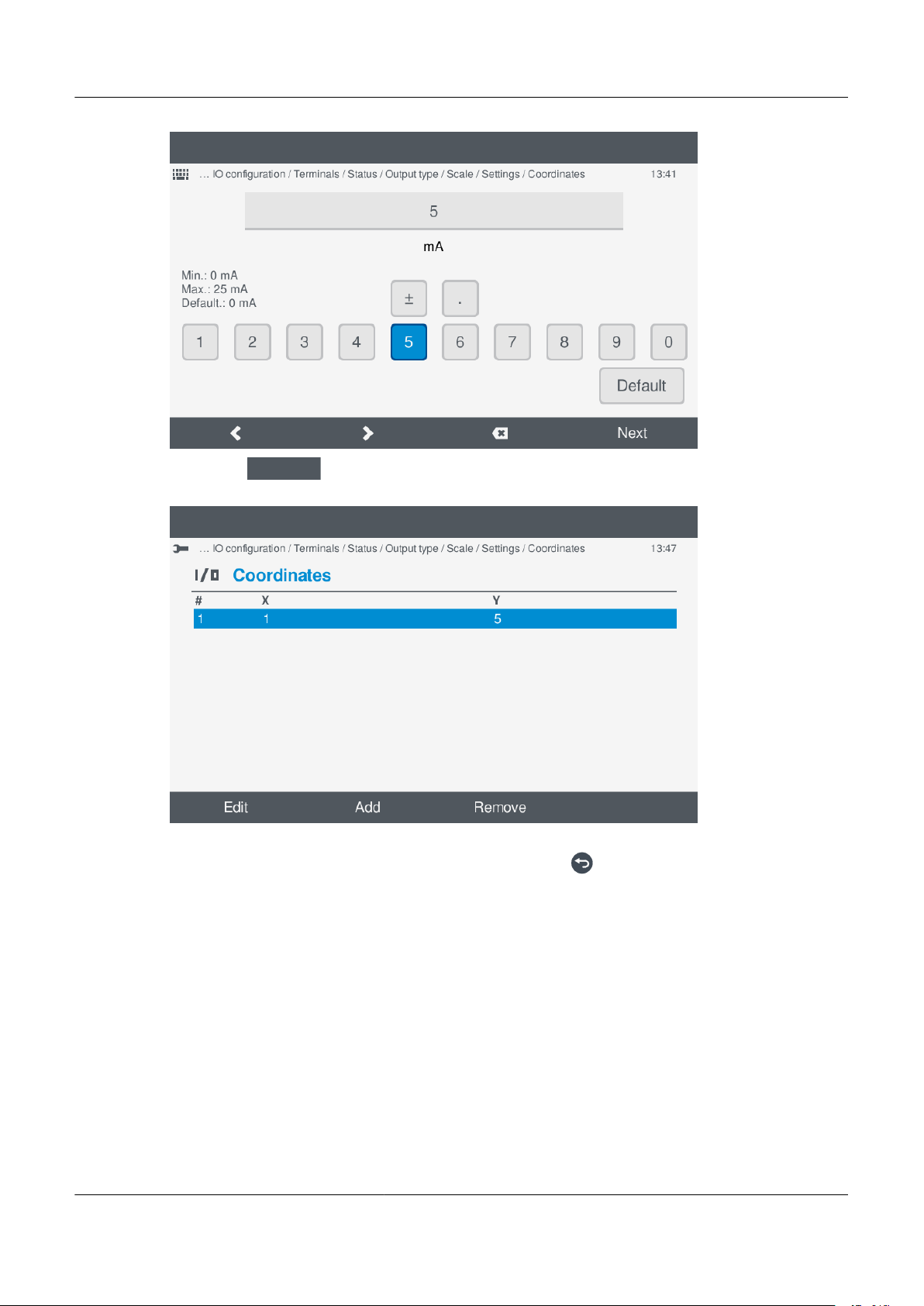

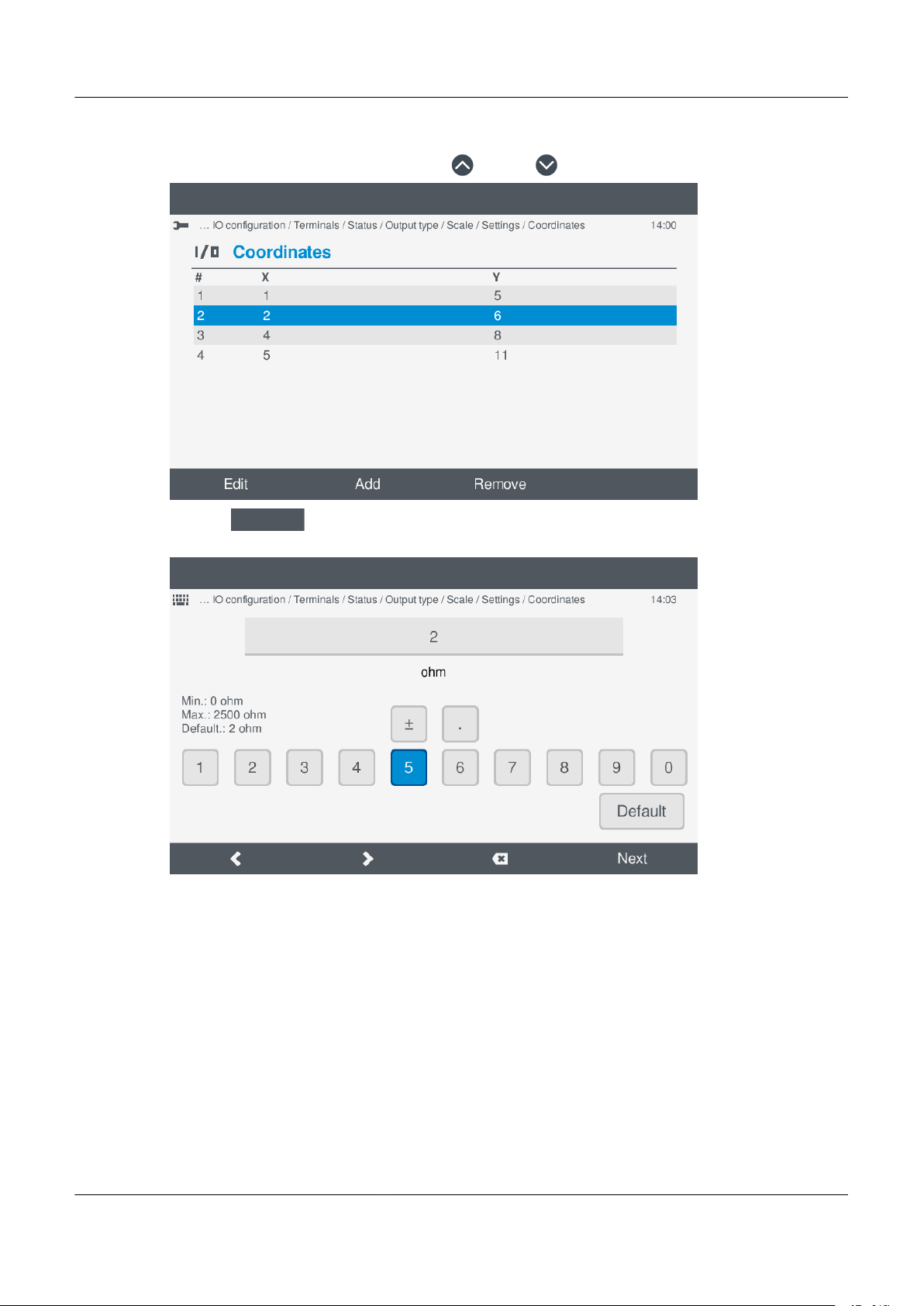

7.5 Input/output...................................................................................................................................................................................................................................................69

7.5.1 Configure Input/output.............................................................................................................................................................................................................69

7.5.2 Selecting a hardware module............................................................................................................................................................................................69

7.5.3

View or configure hardware module I/O terminals.............................................................................................................................................70

7.5.4

I/O terminal settings..................................................................................................................................................................................................................71

7.6

Digital input (DI)........................................................................................................................................................................................................................................72

7.6.1

Configure I/O name...................................................................................................................................................................................................................72

7.6.2

Configure function(s)................................................................................................................................................................................................................73

7.6.3 Configure alarm(s).....................................................................................................................................................................................................................73

7.7

Digital output (DO)..................................................................................................................................................................................................................................77

7.7.1 Configure I/O name...................................................................................................................................................................................................................77

7.7.2 View or configure I/O relay..................................................................................................................................................................................................77

7.7.3 Configure function(s)................................................................................................................................................................................................................78

7.7.4 Configure alarms.........................................................................................................................................................................................................................79

7.8

Analogue input (AI)................................................................................................................................................................................................................................80

7.8.1

Introduction to analogue inputs........................................................................................................................................................................................80

7.8.2

Configure Analogue input (AI)...........................................................................................................................................................................................81

7.8.3 Configure I/O name...................................................................................................................................................................................................................81

7.8.4 Configure function(s)................................................................................................................................................................................................................82

7.8.5 Configure alarm(s).....................................................................................................................................................................................................................85

7.8.6 View or configure sensor.......................................................................................................................................................................................................88

7.9

Analogue output (AO) / Pulse width modulation (PWM)....................................................................................................................................100

7.9.1

Configure Analogue output (AO)..................................................................................................................................................................................100

7.9.2 Configure I/O name................................................................................................................................................................................................................101

7.9.3 Configure function...................................................................................................................................................................................................................101

7.9.4 View or configure analogue output (AO) or pulse width modulation (PWM)...............................................................................104

Alarm

8.

8.1 Introduction................................................................................................................................................................................................................................................117

8.1.1 Alarm indication.........................................................................................................................................................................................................................117

8.1.2 About the alarm list.................................................................................................................................................................................................................118

8.1.3 Alarm symbols............................................................................................................................................................................................................................118

8.1.4 Alarm actions..............................................................................................................................................................................................................................120

8.1.5

Alarm notification......................................................................................................................................................................................................................120

8.2 Alarm actions...........................................................................................................................................................................................................................................121

8.2.1 View alarms..................................................................................................................................................................................................................................121

8.2.2 Operator actions.......................................................................................................................................................................................................................121

8.2.3 Silence horn.................................................................................................................................................................................................................................122

8.2.4 Acknowledge alarm(s)..........................................................................................................................................................................................................122

8.2.5

Reset latched alarm(s).........................................................................................................................................................................................................123

8.2.6

Shelve alarm(s).........................................................................................................................................................................................................................123

Page 5

8.2.7

PPM 300 Operator's manual 4189340910 UK

Out of service alarm(s)........................................................................................................................................................................................................124

9. Live data

9.1 Introduction................................................................................................................................................................................................................................................126

9.1.1 Live data.........................................................................................................................................................................................................................................126

9.2 Live data........................................................................................................................................................................................................................................................126

9.2.1 View the Live data...................................................................................................................................................................................................................126

9.2.2 Live data counters...................................................................................................................................................................................................................127

Tools

10.

10.1 Introduction................................................................................................................................................................................................................................................129

10.1.1 About tools....................................................................................................................................................................................................................................129

10.2 Communication......................................................................................................................................................................................................................................129

10.2.1 Configure communication..................................................................................................................................................................................................129

10.3 Advanced.....................................................................................................................................................................................................................................................131

10.3.1 About advanced........................................................................................................................................................................................................................131

10.4 Brightness...................................................................................................................................................................................................................................................132

10.4.1 About brightness menu.......................................................................................................................................................................................................132

10.4.2 View or configure brightness level setting.............................................................................................................................................................132

10.4.3 View or configure the brightness time setting.....................................................................................................................................................133

10.5 Permissions...............................................................................................................................................................................................................................................134

10.5.1 About permissions...................................................................................................................................................................................................................134

10.5.2 View groups.................................................................................................................................................................................................................................134

10.5.3

View users.....................................................................................................................................................................................................................................135

10.6 Controller type.........................................................................................................................................................................................................................................136

10.6.1 Prerequisites...............................................................................................................................................................................................................................136

10.6.2 Change controller type.........................................................................................................................................................................................................136

11. Log

11.1 Introduction................................................................................................................................................................................................................................................139

11.1.1 About the log...............................................................................................................................................................................................................................139

11.1.2 Log events.....................................................................................................................................................................................................................................139

11.2

Log.....................................................................................................................................................................................................................................................................140

11.2.1

Review log events...................................................................................................................................................................................................................140

Info

12.

12.1

Introduction................................................................................................................................................................................................................................................141

12.1.1

About info.......................................................................................................................................................................................................................................141

12.2 Production...................................................................................................................................................................................................................................................141

12.2.1 View the production info.....................................................................................................................................................................................................141

12.3

About...............................................................................................................................................................................................................................................................142

12.3.1

View about....................................................................................................................................................................................................................................142

13. Troubleshooting

13.1

Introduction................................................................................................................................................................................................................................................143

13.1.1

Finding the source of the problem...............................................................................................................................................................................143

13.2 Using SWBD control for troubleshooting.......................................................................................................................................................................143

13.2.1 Introduction to SWBD control.........................................................................................................................................................................................143

www.deif.com Page 5 of 157

Page 6

13.2.2

PPM 300 Operator's manual 4189340910 UK

www.deif.com

Page 6 of 157

Troubleshooting the system under SWBD control..........................................................................................................................................143

13.3 Troubleshooting alarms..................................................................................................................................................................................................................145

13.3.1 Troubleshooting alarms.......................................................................................................................................................................................................145

13.3.2 Troubleshooting analogue input sensor failures...............................................................................................................................................145

13.4

Engine.............................................................................................................................................................................................................................................................145

13.4.1

Start failure...................................................................................................................................................................................................................................145

13.4.2

Overspeed #................................................................................................................................................................................................................................146

13.5 Network and communication.....................................................................................................................................................................................................146

13.5.1

Ethernet redundancy broken...........................................................................................................................................................................................146

14. Maintenance

14.1

PCM3.1 internal battery...................................................................................................................................................................................................................148

14.1.1

Changing the battery.............................................................................................................................................................................................................148

15. End-of-life

15.1

Disposal of WEEE.................................................................................................................................................................................................................................150

15.1.1

Disposal of waste electrical and electronic equipment................................................................................................................................150

16. Glossary

16.1 Terms and abbreviations...............................................................................................................................................................................................................151

16.2 Units..................................................................................................................................................................................................................................................................154

16.3

Symbols.........................................................................................................................................................................................................................................................156

16.3.1 Symbols for notes....................................................................................................................................................................................................................156

16.3.2 Display unit symbols and push-buttons...................................................................................................................................................................156

Page 7

1. Introduction

PPM 300 Operator's manual 4189340910 UK

1.1 About the Operator's manual

1.1.1 Intended users of the Operator's manual

This is the operator's manual for DEIF's Protection and Power Management controller, PPM 300. The manual is for the

operator who uses the controller display unit. The manual includes an introduction to the display unit (LEDs, push-buttons

and screen), basic operator tasks, alarms, logs, more advanced operator tasks, and trouble shooting. The information in this

manual is simplified and general.

See the Designer's handbook for more detailed information and descriptions..

DANGER!

Read this manual before you operate the system. Failure to do this could result in personal injury and

damage to the equipment.

1.1.2 Software versions

The information in this document corresponds to the following software versions.

Table 1.1

Software Details Version

PCM APPL Controller application 1.0.4.x

DU APPL Display unit application 1.0.4.x

PICUS PC software 1.0.1.x

1.1.3

You can read about service and support options on the DEIF website, www.deif.com. You can also find contact details on the

DEIF website.

You have the following options if you need technical support:

• Help: The display unit includes context-sensitive help.

• Technical documentation: Download all the product technical documentation from the DEIF website:

www.deif.com/documentation

• Training: DEIF regularly offers training courses at the DEIF offices worldwide.

• Support: DEIF offers 24-hour support. See

you. You can also e-mail support@deif.com.

• Service: DEIF engineers can help with design, commissioning, operating and optimisation.

Software versions

Technical support

www.deif.com for contact details. There may be a DEIF subsidiary located near

www.deif.com Page 7 of 157

Page 8

1.1.4

PPM 300 Operator's manual 4189340910 UK

www.deif.com

Page 8 of 157

List of technical documentation for PPM 300

Document Contents

• System description and functions

• Technical specifications

Data sheet

Quick start guide

Designer's handbook

Installation instructions

Commissioning guidelines

• Each controller type

◦ Applications, hardware, functions and protections

• Hardware modules, display unit, and accessories

• Ordering information

• Mounting

• Connecting wiring

• PICUS (PC software)

◦ Download and install

◦ Controller configuration

• Display unit overview

• System principles

• AC configuration and nominal settings

• Protections and alarms

• Breakers, synchronisation and de-loading

• Regulation

• Power management

• Each controller type

◦ Principles, sequences, functions and protections

• Hardware characteristics and configuration

• PICUS (including permissions)

• CustomLogic

• Emulation

• Modbus

• Tools and materials

• Mounting

• Minimum wiring for each controller type

• Wiring for hardware module terminals

• Wiring for controller functions

• Wiring communication

• Wiring the display unit

• Tools, software and information required

• Controller, system and equipment checks

• Regulator tuning

• System testing

• Troubleshooting

Page 9

Document Contents

PPM 300 Operator's manual 4189340910 UK

• Controller equipment (push-buttons and LEDs)

• Operating the system

Operator's manual

PICUS manual Using PICUS and CustomLogic

Modbus tables

• Alarms and log

• Using the display unit

• Troubleshooting and maintenance

• Modbus address list

◦ PLC addresses

◦ Corresponding controller functions

• Descriptions for function codes, function groups

1.2 Warnings and safety

1.2.1 Safety during installation and operation

Installing and operating the equipment may require work with dangerous currents and voltages. The installation must only be

carried out by authorised personnel who understand the risks involved in working with electrical equipment.

DANGER!

Hazardous live currents and voltages. Do not touch any terminals, especially the AC measurement inputs

and the relay terminals. Touching the terminals could lead to injury or death.

1.2.2 Automatic and remote-controlled starts

The power management system automatically starts gensets when more power is needed. It can be difficult for an

inexperienced operator to predict which gensets will start. In addition, gensets can be started remotely (for example, by using

an Ethernet connection, or a digital input). To avoid personal injury, the genset design, the layout, and maintenance

procedures must take this into account.

1.2.3

The controllers are designed to normally run under power management system control. When switchboard control is

activated:

• If an alarm situation arises, and the alarm action requires a trip and/or shutdown, then the controller trips the breaker and/or

• The controller DOES NOT respond to a blackout.

• The controller DOES NOT provide any power management.

• The controller DOES NOT accept operator commands.

• The controller cannot and DOES NOT prevent any manual operator actions.

Switchboard control

shuts down the engine.

The switchboard design must therefore ensure that the system is sufficiently protected when the controller is under

switchboard control.

www.deif.com Page 9 of 157

Page 10

1.2.4

PPM 300 Operator's manual 4189340910 UK

www.deif.com

Page 10 of 157

If the controller has no power supply, it is OFF and does not provide any protection to the system. The controller cannot

enforce any trips, shutdowns or latches when it is off. The controller does not provide any control or power management. All

the controller relays de-energise.

The controller must have a reliable power supply, which must include a backup power supply. In addition, the switchboard

design must ensure that the system is sufficiently protected if the controller power supply fails.

Controller power supply

1.2.5 Factory settings

The controller is delivered pre-programmed from the factory with a set of default settings. These settings are based on typical

values and may not be correct for your system. You must therefore check all parameters before using the controller.

1.2.6 Electrostatic discharge

You must protect the equipment terminals from static discharge during handling, including installation and dismounting. Once

the equipment is correctly installed and the frame ground is connected, it is no longer necessary to protect the terminals from

static discharge.

1.2.7 Do not manually override active alarm actions

DANGER!

Do not use switchboard or manual control to override the alarm action of an active alarm.

An alarm may be active because it is latched, or because the alarm condition is still present. If the alarm action is manually

overridden, a latched alarm does not do its alarm action again. In this situation, the latched alarm does not provide protection.

Latched Over-current alarm example

The controller trips a breaker because of over-current. The operator then manually (that is, not using the controller)

closes the breaker while the Over-current alarm is still latched.

If another over-current situation arises, the controller does not trip the breaker again. The controller regards the

original Over-current latched alarm as still active, and does not provide protection.

1.3 Legal information

1.3.1 Third party equipment

DEIF takes no responsibility for the installation or operation of any third party equipment, including the genset. Contact the

genset company if you have any doubt about how to install or operate the genset.

Page 11

1.3.2

PPM 300 Operator's manual 4189340910 UK

Warranty

CAUTION

The rack may only be opened to remove, replace, and/or add a hardware module. The procedure in the Installation

instructions must be followed. If the rack is opened for any other reason, and/or the procedure is not followed, then

the warranty is void.

CAUTION

If the display unit is opened, then the warranty is void.

1.3.3 Open source software

This product contains open source software licensed under, for example, the GNU General Public License (GNU GPL) and

GNU Lesser Public License (GNU LGPL). The source code for this software can be obtained by contacting DEIF at

support@deif.com. DEIF reserves the right to charge for the cost of the service.

1.3.4 Trademarks

DEIF, power in control and the DEIF logo are trademarks of DEIF A/S.

Modbus is a registered trademark of Schneider Automation Inc.

Windows is a registered trademark of Microsoft Corporation in the United States and other countries.

All trademarks are the properties of their respective owners.

1.3.5 Copyright

© Copyright DEIF A/S 2016. All rights reserved.

1.3.6 Disclaimer

DEIF A/S reserves the right to change any of the contents of this document without prior notice.

The English version of this document always contains the most recent and up-to-date information about the product. DEIF

does not take responsibility for the accuracy of translations, and translations might not be updated at the same time as the

English document. If there is a discrepancy, the English version prevails.

www.deif.com Page 11 of 157

Page 12

2. Overview of the system

PPM 300 Operator's manual 4189340910 UK

www.deif.com

Page 12 of 157

2.1 Overview

2.1.1 Operating the PPM 300 controllers

The PPM 300 controllers ensure that the power required is available and that the system is protected for typical marine

applications.

Only qualified people may install and commission the controllers. After the controllers are installed and commissioned, they

are easy to operate.

Power management system (PMS) control

As far as possible, the controllers should all normally run under PMS control.

As far as possible, the GENSET controllers should all normally run in automatic mode (AUTO). In this mode, the PMS

automatically starts and stops gensets, according to the power requirements. The PMS also automatically closes and opens

the genset breakers to the busbar, to connect and disconnect the gensets as needed.

The SHAFT generator, SHORE connection and BUS TIE breaker controllers normally run under PMS control. For safety

reasons, these controllers will not normally automatically connect to a shaft generator or shore connection, or automatically

close a bus tie breaker. An operator action is needed to start these actions. Once the operator starts the action, the controller

automatically follows a pre-programmed sequence of actions.

The GENSET and EMERGENCY genset controllers can run in either AUTO or a semi-automatic (SEMI) mode. These are

both PMS modes. SEMI mode is a type of service mode. In SEMI mode, an operator action is needed to start or stop the

genset. An operator action is also needed to start the pre-programmed sequence to close or open the genset breaker to the

busbar.

Switchboard control

Each controller can also be put under switchboard control. The operator then manually controls the genset speeds and opens

and closes breakers. Switchboard control is useful for troubleshooting. It can also be useful in extreme circumstances if the

operator needs to override the control system. Under switchboard control, all the controller functions are disabled. However,

the controller protections are still active. The controller monitors the operation, and if an alarm condition arises, the controller

activates the alarm action.

Push-buttons and LEDs

The operator can use the display unit push-buttons to operate the system. This includes changing modes, selecting actions

to start pre-programmed sequences, changing genset priority, and silencing alarms. The push-buttons to start or stop the

genset, or close or open the breaker(s), are only active in SEMI mode.

The operator can look at the display unit LEDs to see the status of each part of the system.

Display unit screen *

The operator can monitor system operation on the display unit screen. The operator can also use the soft key buttons and

the display unit screen to log into the controller. The operator can then see the alarm lists and logs, and acknowledge and

unlatch alarms. The operator can also see or change the controller configuration.

PICUS *

PICUS - Power In Control Utility Software

Page 13

PICUS is the PC programming and monitoring tool, available from DEIF free of charge. The operator can connect a computer

PPM 300 Operator's manual 4189340910 UK

with PICUS to the controller by using a direct connection. The operator can then log into the controller. When the operator

logs on, they can use PICUS to monitor operation, send commands that correspond to the push-button actions, manage

alarms, and see or change the controller configuration. *

See the PICUS manual for more information about how to monitor and change the controller configuration using

PICUS.

* Both the display unit and PICUS are controlled by user level permissions which grant or restrict access to features of the

controller. Some features or functions may not be accessible to an operator depending upon the design of the controller

permissions.

2.2 Operator messages

2.2.1 Controller status texts

Table 2.1

Icon Notes

Status text Description

-

Alarm testing Enable alarm test parameter is enabled. ● ● ● ● ●

Blackout handling in remaining time

Blackout start blocked “Block blackout start” function is activated. ● ●

Controller types

Cannot read controller status. For

example, slow communication or a loss of

communication.

Displays the remaining time (in seconds)

before the emergency genset begins the

genset start procedure to solve a blackout.

GENSET controller

EMERGENCY genset controller

SHAFT generator controller

SHORE connection controller

BUS TIE breaker controller

● ● ● ● ●

● ●

www.deif.com Page 13 of 157

Page 14

Status text Description

PPM 300 Operator's manual 4189340910 UK

www.deif.com

Page 14 of 157

BTB in operation The bus tie breaker is closed. ●

Displays the remaining time (in seconds)

Busbar OK in remaining time

before the emergency genset begins the

emergency genset stop procedure after a

●

blackout is solved.

Cooldown - remaining

time

Displays the remaining time (in seconds)

for the genset cooldown.

● ●

There is no running detection of the

Crank off

genset during the genset start procedure,

● ●

and the crank is turned off.

Crank on

De-loading SCB /

SGB / BTB

The crank is activated in order to start the

genset.

The controller is busy de-loading the

external breaker to open the external

breaker.

● ●

● ● ● ● ●

The controller is busy de-loading the

De-loading GB

generator breaker to open the generator

● ●

breaker.

The controller is busy de-loading the shaft

De-loading SGB

generator breaker to open the shaft

●

generator breaker.

Dividing section

The controller is busy de-loading the bus

tie breaker to open the bus tie breaker.

Engine stopping The genset is being stopped. ● ●

Engine test remaining time

Displays the remaining time (in seconds)

that the EMERGENCY genset controller

engine test is still active for.

●

The shaft generator or shore connection is

Fixed power

running base load and the genset is

●

connected to the busbar.

Frequency regulation

The genset is running and is being

regulated using frequency regulation.

● ●

The genset frequency is too high and

Frequency too high

should be adjusted to a lower value. The

adjustment happens automatically if the

● ●

controller is under PMS control.

The genset frequency is too low and

Frequency too low

should be adjusted to a higher value. The

adjustment happens automatically if the

● ●

controller is under PMS control.

The emergency genset is operating in

Harbour operation

harbour operation and supplies power to

●

the busbar as the first priority genset.

Displays the remaining time (in seconds)

Idle run - remaining

time

that the genset is running before the

genset continues with the genset start or

● ●

stop procedure.

●

Page 15

Status text Description

PPM 300 Operator's manual 4189340910 UK

Load-dependent stop

blocked

Load sharing

Load sharing

(asymmetric)

LTO test - remaining

time

Non-connected stop in

- remaining time

Not ready for

operation

Parallel test remaining time

Precautionary standby

Ready for operation

SC in operation

SC in operation (base

load)

SC ready

SC ready for ship-toship supply

Secured mode active

SG in operation

Shown when the "Block load-dependent

stop" function is activated on the shaft

generator controller.

The gensets that are connected to the

busbar are sharing the load symmetrically

with each other.

The genset is sharing the load with

another genset as per asymmetric load

sharing parameters.

Displays the remaining time (in seconds)

that the EMERGENCY genset controller

load take over test is still active for.

Displays the remaining time (in seconds)

before a genset that is no longer

connected to the busbar starts the genset

stop procedure.

The controller is not under switchboard

control, but it is not ready for operation.

For gensets "Start enable" might not be

activated, or there are alarms (latched or

unacknowledged) blocking the ready

status.

Displays the remaining time (in seconds)

that the EMERGENCY genset controller

parallel test is still active for.

After a blackout is resolved the emergency

genset continues to run as a precaution

against a blackout reoccurring.

All operation conditions are met. Gensets

are ready to start and/or breakers are

ready to close.

A power supply from the shore connection

is available, and shore connection breaker

is closed.

A power supply from the shore connection

is available, and shore connection breaker

is closed. The base load parameter has

been activated.

A power supply from the shore connection

is available, and shore connection breaker

is open.

Ship-to-ship supply has been activated,

and shore connection breaker is open.

Secured mode has been activated to

ensure there is enough power if the

largest generator fails.

The shaft generator is producing power,

and shaft generator breaker is closed.

● ●

● ●

● ●

●

● ●

● ● ● ● ●

●

●

● ● ● ● ●

●

●

●

●

● ● ●

●

www.deif.com Page 15 of 157

Page 16

Status text Description

PPM 300 Operator's manual 4189340910 UK

www.deif.com

Page 16 of 157

SG in operation (base

load)

SG in PTH operation

The shaft generator is producing power,

and shaft generator breaker is closed. The

base load parameter is activated.

Power take home has been activated, and

shaft generator breaker is closed.

●

●

The shaft generator is not ready to provide

SG not ready

power to the busbar. There may be alarms

blocking the shaft generator breaker from

●

closing.

The shaft generator is ready to provide

SG ready

power to the busbar. The shaft generator

●

breaker may be closed.

SG ready for PTH

operation

SG running

Ship-to-ship active

Starting genset in remaining time

Start prepare remaining time

Stop coil activated remaining time

Stopping genset in remaining time

Power take home has been activated, and

shaft generator breaker is open.

The shaft generator is producing power,

and shaft generator breaker is open.

Ship-to-ship operation is active and the

shore connection breaker is closed.

Displays the remaining time (in seconds)

before the genset starts.

Displays the remaining time (in seconds)

for the genset to prepare to start.

Displays the remaining time (in seconds)

before the genset shuts down.

Displays the remaining time (in seconds)

before the genset stops.

●

●

●

● ●

● ●

● ●

● ●

The controller is under switchboard control

Switchboard control

and can only receive commands from the

switchboard. Power management is not

● ● ● ● ●

active.

The controller is busy synchronising the

Synchronising SCB /

SGB / BTB

busbar frequency and voltage across

busbar sections to close the external

● ● ● ● ●

breaker.

The controller is busy synchronising the

Synchronising GB

genset to the busbar frequency and

● ●

voltage to close the generator breaker.

The genset is busy synchronising the

Synchronising SGB

busbar frequency and voltage to close the

● ●

shaft generator breaker.

The controller is busy synchronising the

Synchronising TB

genset to the busbar frequency and

●

voltage to close the tie breaker.

Synchronising

sections

The two sections about to be connected

by a bus tie breaker are being

synchronised to close the bus tie breaker.

Waiting for software A software update is in progress. ● ● ● ● ●

●

Page 17

2.2.2

PPM 300 Operator's manual 4189340910 UK

Table 2.2 Controller types

Operator information messages

Icon Notes

GENSET controller

EMERGENCY genset controller

SHAFT generator controller

SHORE connection controller

BUS TIE breaker controller

Operator info Additional information

1st priority not

possible in SWBD

Alarm blocking BTB

close

Alarm blocking engine

start

Alarm blocking GB

close

Alarm blocking SCB

close

Alarm blocking SGB

close

Alarm blocking TB

close

Already first priority

Already selected

While the controller is under switchboard

controller, operator actions cannot be

performed from the controller interfaces.

A block alarm is active. Clear the alarm

before attempting to close the bus tie

breaker.

A block alarm is active. Clear the alarm

before attempting to start the genset.

A block alarm is active. Clear the alarm

before attempting to close the generator

breaker.

A block alarm is active. Clear the alarm

before attempting to close the shore

connection breaker.

A block alarm is active. Clear the alarm

before attempting to close the shaft

generator breaker.

A block alarm is active. Clear the alarm

before attempting to close the tie breaker.

Controller is already the first priority

controller.

The command has already been received.

The controller is busy synchronising the

breaker.

●

●

● ●

● ●

●

●

●

●

●

www.deif.com Page 17 of 157

Page 18

Operator info Additional information

PPM 300 Operator's manual 4189340910 UK

www.deif.com

Page 18 of 157

There is an overload present on the

Available power too

low

busbar the genset is connecting to.

Cancelling the Close breaker command

will cause a blackout.

Blackout start block

activated

Blackout start block

deactivated

Breaker already

closed

Breaker already

opened

BTB block not

possible in SWBD

The Block blackout start function is active. ● ● ● ● ●

The Block blackout start function is not

active.

The breaker is already closed and cannot

be closed again.

The breaker is already open and cannot

be opened again.

While the controller is under switchboard

controller, operator actions cannot be

performed from the controller interfaces.

The Block bus tie breaker close function is

BTB close blocked

active. A closed breaker will not open

automatically, and an open breaker cannot

be closed.

BTB close cancelled

BTB close not

possible in SWBD

BTB close unblocked

BTB open cancelled

BTB open not possible

in SWBD

The closing of Bus tie breaker has been

cancelled.

While the controller is under switchboard

controller, operator actions cannot be

performed from the controller interfaces.

The Block bus tie breaker close function is

not active.

The opening of Bus tie breaker has been

cancelled.

While the controller is under switchboard

controller, operator actions cannot be

performed from the controller interfaces.

The bus tie breaker cannot connect to a

Busbar A voltage/

frequency not OK

dead or unknown state busbar. The bus

tie breaker will not close until busbar state

is OK and known.

The bus tie breaker cannot connect to a

Busbar B voltage/

frequency not OK

dead or unknown state busbar. The bus

tie breaker will not close until busbar state

is OK and known.

The shaft generator cannot be connected

to a dead or unknown state busbar while it

Busbar V/Hz not OK

is in power take home mode. The shaft

generator breaker will not close until

busbar state is OK and known.

Engine already

running

Engine already

stopped

The engine is already running and cannot

be started again.

The engine has already stopped and

cannot be stopped again.

●

● ● ● ● ●

● ● ● ● ●

● ● ● ● ●

●

●

●

●

●

●

●

●

●

●

● ●

● ●

Page 19

Operator info Additional information

PPM 300 Operator's manual 4189340910 UK

Engine block not

possible in SWBD

While the controller is under switchboard

controller, operator actions cannot be

performed from the controller interfaces.

● ●

The command has already been received.

Engine is stopping

The controller is executing the engine stop

● ●

procedure.

Engine not ready

Engine start and

breaker close not

possible in SWBD

The genset cannot start. There might be

alarms blocking the ready status.

While the controller is under switchboard

controller, operator actions cannot be

performed from the controller interfaces.

● ●

●

The Block engine start function is active. A

Engine start blocked

running genset will not stop, and a

● ●

stopped genset cannot be started.

Engine start not

possible in SWBD

Engine start

unblocked

Engine stop not

possible in SWBD

Force all in section to

AUTO mode activated

Force all in section to

SEMI mode activated

Force all in section to

SWBD control

activated

Force all in section to

SWBD control

deactivated

GB block not possible

in SWBD

While the controller is under switchboard

controller, operator actions cannot be

performed from the controller interfaces.

The Block engine start function is not

active.

While the controller is under switchboard

controller, operator actions cannot be

performed from the controller interfaces.

The Force all controllers in section to

AUTO mode function is active.

The Force all controllers in section to

SEMI mode function is active.

The Force all controllers in section to

SWBD control function is active.

The Force all controllers in section to

SEMI mode function is not active.

While the controller is under switchboard

controller, operator actions cannot be

performed from the controller interfaces.

● ●

● ●

● ●

● ● ● ● ●

● ● ● ● ●

● ● ● ● ●

● ● ● ● ●

● ●

The Block generator breaker close

GB close blocked

function is active. A closed breaker will not

open automatically, and an open breaker

● ●

cannot be closed.

GB close cancelled - ● ●

GB close not possible

in SWBD

GB close unblocked

While the controller is under switchboard

controller, operator actions cannot be

performed from the controller interfaces.

The Block generator breaker close

function is not active.

●

● ●

GB is closed The Generator breaker is closed. ● ●

GB is de-loading

The Generator breaker is currently de-

loading.

● ●

www.deif.com Page 19 of 157

Page 20

Operator info Additional information

PPM 300 Operator's manual 4189340910 UK

www.deif.com

Page 20 of 157

GB is open The Generator breaker is open. ● ●

GB is synchronising The Generator breaker is synchronising. ● ●

GB open and stop not

possible in SWBD

GB open cancelled

GB open not possible

in SWBD

Harbour operation

activated

Harbour operation

deactivated

Load-dependent stop

block activated

Load-dependent stop

block deactivated

While the controller is under switchboard

controller, operator actions cannot be

●

performed from the controller interfaces.

Opening the Generator breaker has been

cancelled.

● ●

While the controller is under switchboard

controller, operator actions cannot be

● ●

performed from the controller interfaces.

Harbour operation has been activated. ●

Harbour operation has been deactivated. ●

The Block load-dependent stop function is

active.

The Block load-dependent stop function is

not active.

● ● ● ● ●

● ● ● ● ●

A shaft generator in power take home

Load on busbar too

high

mode cannot be connected to the busbar

because the additional load will cause a

blackout (overload on the busbar).

Load on SC too high

(Ship-to-ship)

Load on SG too high

(PTH)

The shore connection breaker will not

open because the load consumed by the

receiving ship is too high.

The shaft generator breaker will not open

because the load to drive the propeller is

too high.

It is not possible to change to SEMI or

Mode change locked

AUTO mode while the controller is under

● ●

switchboard control.