Page 1

HV1000 PULSER

OPERATION MANUAL

SERIAL NUMBER:

------

DATE:

---------

Directed Energy, Inc.

2301 Research Blvd., Ste. 105

Fort Collins, Colorado 80526

970/493-1901 FAX 970/493-1903

Page 2

DEI HVlOOO PULSER

REV B

r-

i

I

TABLE OF CONTENTS

1. 0 GENERAL DESCRIPTION ................................ 3

2. 0 SPECIFICATIONS ..................................... 4

2 .1 Maximum Duty Cycles ................................ 5

2. 2 Pulse Droop ........................................ 5

3 . 0 SAFETY ............................................. 6

3.1 Operating Safety Summary ........................... 6

3.2 Servicing Safety Summary ........................... 7

4.0 OPERATING CONSIDERATIONS ........................... 8

4.1 Output ............................................. 8

4.2 Pulse Risetime and Falltime ........................ 8

4. 3 Impedance Matching ................................. 8

4 . 4 Trigger Input ...................................... 8

4. 5 High Voltage Input ................................. 9

4. 6 Maximum Duty Cycle ................................. 9

5.0 PREPARATION FOR USE ............................... 10

5 .1 General ........................................... 10

5.2 Initial Inspection ................................ 10

5. 3 Electrical Installation ........................... 10

5.4 Mechanical Installation ........................... 10

5.5 Electrical Check .................................. 10

6.0 OPERATING INSTRUCTIONS ............................ 12

6 . 1 Power- Up Procedures ............................... 12

6.2 Power-Down Procedures ............................. 12

7 . 0 EXAMPLE WAVEFORMS ................................. 14

7 .1 50 Ohm Resistive Load ............................. 14

7.2 Inductive Load (Step-Up Transformer) .............. 15

7 .3 Capacitive Load ................................... 15

7. 4 Current Source .................................... 16

8 . 0 TROUBLESHOOTING ................................... 1 7

8.1 Troubleshooting Procedures ........................ 17

8. 2 Factory Service ................................... 18

9 . 0 SYSTEM FAILURE MODES .............................. 19

9.1 Over-Current Failure .............................. 19

9. 2 Over-Voltage Failure .............................. 19

10. 0 WARRANTY ......................................... 20

11.0 APPENDIX A - Schematics .......................... 21

1

Page 3

DEI HVl000 PULSER

********** WARNING **********

SAFE OPERATING PROCEDURES AND PROPER USE OF THE

EQUIPMENT ARE THE RESPONSIBILITY OF THE USER OF

THIS SYSTEM.

Directed Energy, Inc (DEI) provides information

on its products and associated hazards, but it

assumes no responsibility for the after-sale

operation and safety practices.

ALL PERSONNEL WHO WORK WITH OR ARE EXPOSED TO

THIS EQUIPMENT MUST TAKE PRECAUTIONS TO PROTECT

THEMSELVES AGAINST POSSIBLE SERIOUS AND/OR

FATAL BODILY INJURY. DO NOT PERFORM INTERNAL

REPAIR OR ADJUSTMENTS UNLESS ANOTHER PERSON

CAPABLE OF RENDERING FIRST AID AND

RESUSCITATION IS PRESENT.

2

REV B

Page 4

DEI HVlOOO PULSER

REV B

1.0 GENERAL DESCRIPI'ION

The HVlOOO Pulser is a high voltage pulse generator

designed to be operated into a load impedance of 50 ohms.

The HVlOOO is designed as an instrument for lab

experiments, calibration, component testing, beam

steering, gating PMTs and MCPs, and other applications

that require very fast and clean high speed pulses, or

incorporated into an OEM system.

The HVlOOO utilizes a patented state-of-the-art high-speed

power MOSFET as the high voltage switch, incorporated into

a low impedance configuration featuring a multi-layer

stripline-style output bus.

The HVlOOO requires an external high voltage DC supply

(950V maximum), and an input trigger. The unit is

available in either positive or negative polarities. The

polarity of the DC power supply must be the same as the

polarity of the HVlOOO (i.e. a positive-polarity HVlOOO

requires a positive polarity DC power supply; a

negative-polarity HVlOOO requires a negative polarity DC

power supply).

3

Page 5

DEI HVl000 PULSER

REV B

2.0 SPECIFICATIONS

(All Measurements into 50 Ohms)

INPUT HIGH VOLTAGE

Maximum Value .............•.......•.......•.... 950 volts DC

Minimum Value .••.•.........................•.•. 0 volts DC

Input High Voltage Connector ...........•..•.... Type N,

Side Panel

OUTPUT HIGH VOLTAGE

Maximum Value ........•.........•..•.••••...... 850 volts DC

Minimum Value ..........•....•............•..... 0 volts DC

Maximum Current ....•........................... 1 7 amperes

Means of adjustment .....•. Controlled by Input High Voltage

Output High Voltage Connector .......•..•....... Type BNC,

Side Panel

TRIGGER

Trigger Source ...•....••...................•... External

Trigger Input •............•.......•..•......... +5V +/-lV,

Into 50 ohms

Trigger Rise Time .......•.••............•...... <6ns

Minimum Trigger Pulse Width .......•..•..••..... 55ns

Maximum Trigger Pulse Width ....•........•..•... l0us

Input Trigger Connector ...•.......•......•.•... Type BNC,

Side Panel

OUTPUT PULSE ELECTRICAL CHARACTERISTICS

Pulse Rise Time (Negative Polarity) ..•..••..... 6ns 850V

(10%-90%)

Pulse Rise Time (Positive Polarity) ..•.••.....• l0ns 850V

(10%-90%)

Pulse Width .......•..•....•••..••..•.•...••••.. 55ns to lOus,

Controlled by Input Trigger

Pulse Recurrence Frequency •.••..• Single Shot to 1MHz, 5MHz

burst, controlled by input

trigger

Over /undershoot . ......................................... <5%

Jitter ...•.....•••.....•.•..••.....••...• <lO0ps shot-to-shot

Delay Between Trigger and Output Pulse •.•.••....•...... <40ns

Thermal Drift ..•.••...•.•••..•.•. Approx 500ps to lns over

ambient to 5o

0

c

GENERAL

Input AC Power ••.•...•......••.•. 110/220 VAC, 50/60Hz, Cord

provided

Dimensions .•.••..••.....••...•... 8.32" L x 4.22" W x 1.72" D

Weight. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Approx. 3. 5 lbs.

4

Page 6

DEI HVlOO0 PULSER

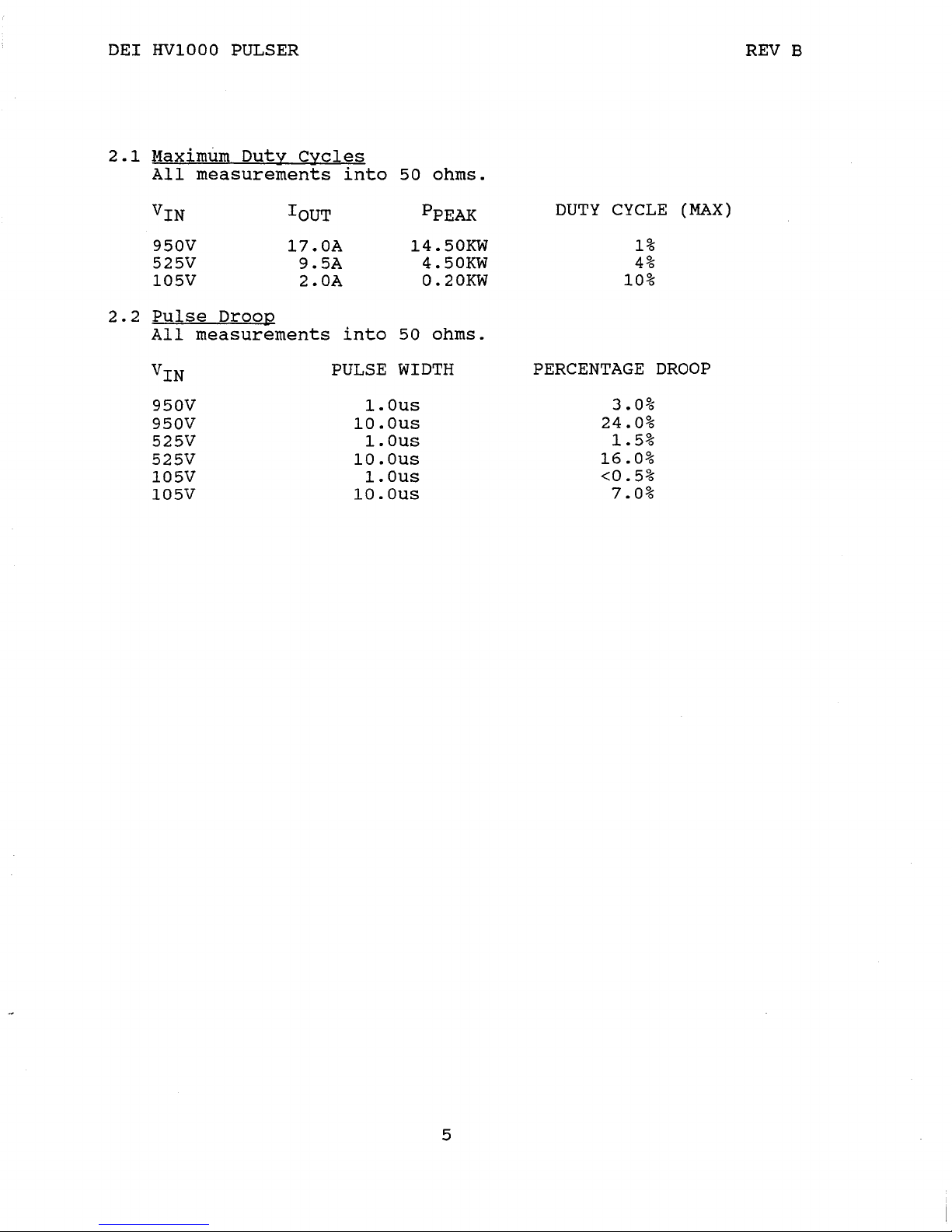

2.1

Maximum Duty Cycles

All measurements into

REV B

50 ohms.

VIN IoUT

950V

525V

17.0A

9.5A

105V 2.0A

2.2

Pulse Droog

All measurements into 50 ohms.

VIN

950V

950V

525V

525V

105V

105V

PULSE WIDTH

l.0us

10.ous

1.ous

10.ous

1.ous

10.0us

PPEAK

14.50KW

4.50KW

0.20KW

DUTY CYCLE

(MAX)

1%

4%

10%

PERCENTAGE DROOP

3.0%

24.0%

1.5%

16.0%

<0.5%

7.0%

5

Page 7

DEI HVl000 PULSER

REV B

3.0 SAFETY

The high voltage nature of this device dictates the use of

caution when operating or servicing this equipment. The

following is a summary of general safety precautions that

must be observed during all phases of operation and repair

of the HVl000 Pulser.

3.1 Operating Safety Summary

The safety information contained in this summary is for

both operating and servicing personnel. Specific warnings

may be found throughout this manual, but may not appear in

this summary.

3.1.1 Power Source

The HVl000 is designed to operate from a power source that

will not apply more than 220 volts between the supply

conductors or between either supply conductor and ground.

A protective grounding connection by way of the grounding

conductor in the AC power cord is essential.

3.1.2 Grounding

The HVl000 is grounded through the grounding conductor of

the AC power cord. To avoid electrical shock, plug the

HVlOOO into a properly wired receptacle before making

connection to any input or output connectors. Use only a

power cord that is in good condition.

3.1.3 Cover Removal

To avoid personal injury, do not remove the cover. Do not

operate the HVlOOO while the cover is removed. The cover

does not contain a safety interlock!

3.1.4 General Operating Precautions

Do not remove the input or output cables while the pulser

is in operation. Never short-circuit the high voltage

output of the pulse generator. Failure to observe these

precautions can result in potential electric shock to

personnel, arcing, and damage to the connectors and

system.

The top cover of the pulse generator is not safety

interlocked. Extreme caution should be exercised when

removing the cover.

6

Page 8

DEI HVlOOO PULSER

REV B

Any pulsed power system is capable of random triggering

via transients. Therefore when the pulse generator is

turned on, or high voltage is present in the chassis,

assume it is possible to get a pulse on the output

connector.

3.2 Servicing Safety Summary

The HVlOOO contains dangerous voltages and stored energy.

DEI strongly recommends that all repairs and adjustments

be performed by factory qualified personnel. DEI will not

be responsible for personal injury or damage to the pulser

that occurs during repair by any party other than the

factory.

3.2.1 Servicing Procedure

Do not perform internal repair or adjustments unless

another person capable of rendering first aid and

resuscitation is present.

3.2.2 Internal Energy Storage

The HVlOOO contains capacitors that are used as energy

storage elements. When charged, these capacitors contain

in excess of 1.5 joules of stored energy. This is

sufficient energy to cause serious injury. Assure that the

AC power cord is disconnected from the pulser, and that

the capacitor bank is fully discharged and a shorting

strap installed before any repairs or adjustments are

attempted. Verify with a voltmeter that all circuits are

de-energized before servicing. The voltmeter used to make

these measurements must be certified for use at lOOOVDC

and 220VAC or greater. Dangerous voltages, floating ground

planes and energy storage exist at several locations in

the HVlOOO. Touching connections and/or components could

result in serious injury.

7

Page 9

'

DEI HVl000 PULSER

4.0 OPERATING CONSIDERATIONS

4.1 Output

REV B

The HVl000 is designed to operate into a load whose

characteristic impedance is 50 ohms. An unterminated or

improperly terminated output will cause excessive

aberrations on the output waveform and could possibly

damage the pulser. To ensure this does not occur, observe

the following precautions:

- Use good quality 50 ohm coaxial cable and connectors;

- Make all external connections tight and as short as

possible;

- Use good quality attenuators and/or loads. If using an

attenuator, DEI recommends the Weinschel Engineering

model 45-40-33. Small attenuators will not work

correctly and can be harmed by the HVl000;

- Use terminators or impedance-matching devices to avoid

reflections;

- Ensure that all external cables and hardware have

adequate voltage and power ratings;

- Be extremely careful not to short the output of the

pulser to ground, as this can cause damage to the

pulser.

The HVl000 can be used to drive capacitive, inductive and

resistive loads other than 50 ohms. Please consult the

factory for further applications information.

4.2 Pulse Risetime and Falltime

The physical and electrical characteristics of the cable

transmitting the pulse determine the characteristic

impedance, velocity of propagation and the amount of

signal loss. Several feet of cable can attenuate high

frequency information in a pulse with a fast rise time. It

is therefore important to keep these cables as short as is

practical. For optimum performance, DEI recommends

interconnecting cable lengths of 8

11

or less. When signal

comparison measurements or time difference determinations

are made, the two signals from the test device should

travel through coaxial cables with identical less and time

delay characteristics.

4.3 Impedance Matching

If a pulse travels down a transmission line and encounters

a mismatch, a reflection is generated and sent back along

the line to the source. The amplitude and polarity of the

reflection are determined by the impedance mismatch. If

the reflected signal returns before the output pulse ends,

it adds or subtracts from the amplitude of the pulse. This

will distort the pulse shape and amplitude.

4.4 Trigger Input

An input trigger of +5V +/-lV into 50 ohms with a risetime

8

Page 10

DEI HVl000 PULSER

REV B

of <6ns is required to gate on the HVl000. Departure from

these values can result in a loss of performance. These

trigger requirements are met by any high quality low

voltage pulse generator. The trigger should be set to +5V

+/-lV into 50 ohms before the trigger cable is attached to

the HVl000 trigger input. The input trigger is

transformer-coupled into a DS0026 CMOS Clock Driver which

does not appear resistive to the input pulse generator.

For this reason, the input trigger amplitude should be set

using a 50 ohm load (e.g. a 50 ohm scope input) before

connecting it to the HVl000. If the trigger input is

greater than +5V into 50 ohms, pulse stretching can occur.

4.5 High Voltage Input

The HVl000 is rated at a maximum input voltage of 950VDC.

Proper precautions should be taken by the user to ensure

that the maximum voltage is not exceeded. The polarity of

the DC power supply must be the same as the polarity of

the HVl000 (i.e. a positive-polarity HVl000 requires a

positive polarity DC power supply; a negative-polarity

HVl000 requires a negative polarity DC power supply).

4.6 Maximum Duty Cycle

The case of the HVl000 (specifically the bottom panel) is

used as the heat sink for the power circuitry. Therefore

the case can get hot! Use caution when handling the HVl000

after operation. The duty cycle percentages shown in TABLE

2.1 are limited by the cooling capabilities of the HVl000.

Higher duty cycles can be obtained by forced air cooling

of the enclosure, or for very high power applications

(>lKw), bolting the HVl000 to a water or air cooled heat

sink.

9

Page 11

DEI HVl000 PULSER

5.0 PREPARATION FOR USE

5.1 General

REV B

After unpacking, initial inspection and preliminary

electrical check procedures should be performed to assure

that the unit is in good working order. If it is

determined that the unit is damaged, the carrier should be

notified immediately. Repair problems should be directed

to the service department, Directed Energy, Inc. (DEI),

Fort Collins, Colorado. Telephone: (303) 493-1901.

5.2 Initial Inspection

1. Inspect unit for exterior mechanical damage.

2. Inspect power input cord and input power module for

obvious signs of damage.

3. Remove top cover retaining screws. Inspect components

and printed circuit board for damage.

5.3 Electrical Installation

Standard units are shipped ready for use with a nominal

110 VAC input. The unit can be configured for 220VAC input

from the factory.

5.3.1 Input Power Cord

The input power cord terminates externally in a

three-prong polarized plug. The unit chassis is wired to

the plug through the line cord, and therefore, the

insertion of the plug into a compatible receptacle, hooked

up to a grounded input, will automatically ground the

unit. The unit should not be operated without a grounded

AC input!

5.4 Mechanical Installation

As received, the unit is ready for bench use. If

necessary, the unit can be bolted to an external heat sink

for additional cooling (see Section 4.6 above) using the

mounting flanges.

The HVl000 is extremely rugged, and can be mounted to

other equipment, hardware or benches using the mounting

flanges. Physical orientation is not critical.

5.5 Electrical Check

Before proceeding, please review the precautions in

Section 3.

5.5.1 Power-Up

The unit should be powered up using the following

procedures:

1. Ensure that the high voltage power supply is turned

off, and all controls set to zero volts.

10

Page 12

DEI HVl000 PULSER

REV B

2. Before connecting the pulse generator to the HVl000,

set up the pulse generator output to deliver a 5V

pulse (+/-lV) into 50 ohms, with a rep rate of

approximately 5KHz, and a pulse width of 200-S00ns.

3. Plug the power cord into the AC power input. The red

indicator light should turn on, indicating that the

HVl000 is operational. If this does not occur, unplug

the unit from the AC power, and refer to the

Troubleshooting Section of this manual.

4. Connect the cable from the high voltage power supply to

the N connector of the HVl000 labeled "HV IN, 950V

MAX".

5. Connect the pulse generator to the BNC connector of the

HVl000 labeled "TRIGGER INPUT".

6. Connect an appropriate load to the BNC connector of the

HVl000 labeled "OUTPUT".

7. Monitor the voltage across the load, utilizing an

appropriate attenuator.

8. Turn ON the high voltage power supply. Slowly increase

the power supply to l00VDC. The HVl000 should

produce an output pulse of approximately 95V, with a

pulse width and pulse recurrence frequency following

that of the incoming trigger.

9. If there is no output from the HVl000, or the output is

severely distorted, set the output voltage of the high

voltage power supply to zero and turn off the high

voltage power supply. Leave the HVl000 connected to the

AC input without high voltage and with all connectors

in place for approximately one minute to bleed off the

stored energy, then disconnect the AC power to the unit

and refer to the Troubleshooting Section of this

manual.

11

Page 13

DEI HVlOOO PULSER

REV B

6.0 OPERATING INSTRUCTIONS

This section provides basic operating instructions for the

HVlOOO. Additional application information may be found in

Section 7.0.

WARNING

1. To avoid personal injury, do not remove the cover.

Do not operate the HVlOOO while the cover is

removed. The cover does not contain a safety

interlock!

2. Do not remove the input or output cables while the

pulser is in operation. Never short-circuit the

high voltage output of the pulse generator. Failure

to observe these precautions can result in

potential electric shock to personnel, arcing, and

damage to the connectors and system.

3. The top cover of the pulse generator is not safety

interlocked. Extreme caution should be exercised

when removing the cover.

4. Pulsed power systems are capable of random

triggering via transients and therefore when the

pulse generator is turned on, or high voltage is

present in the chassis, assume it is possible to

get a pulse on the output connector.

6.1 Power-Up Procedures

The unit should be powered up using the procedures

detailed in Section 5.5.1. When this is accomplished, the

pulser can be adjusted for the particular application

through the following procedure:

1. Monitoring the output of the HVlOOO on an oscilloscope

utilizing an appropriate attenuator, set the output

amplitude of the HVlOOO to the desired level by

adjusting the high voltage power supply.

2. Set the output pulse width and pulse recurrence

frequency by varying the controls of the input pulse

generator. The output pulse width should be set by

monitoring the output of the HVlOOO. The output high

voltage will follow the input trigger, but will not

replicate in time the exact duration of the input

trigger due to the system propagation delay.

6.2 Power-Down Procedures

1. Set the output voltage of the high voltage power supply

to zero and turn off the high voltage power supply.

12

Page 14

DEI HVlOOO PULSER REV B

2 Leave the HVlOOO connected to the AC input without high

voltage and with all connectors in place for

approximately one minute to bleed off the stored

energy.

3. Disconnect the AC power to the unit.

13

Page 15

DEI HVlO00 PULSER

REV B

7.0 EXAMPLE WAVEFORMS

7.1 50 Ohm Resistive Load

Input Voltage=l0SV, Pulse Width=S00ns, Pulse Recurrence

Frequency=lMHz, Load=50 ohms:

Input Voltage=950V, Pulse Width=lO0ns, Pulse Recurrence

Frequency=4.5MHz (Burst Mode), Load=50 ohms:

14

Page 16

DEI HVl000 PULSER

REV B

7.2 Inductive Load (Step-Up Transformer)

Input Voltage=950V, Pulse Width=200ns, Pulse Recurrence

Frequency=500Hz, Oscilloscope Scale=l000V/DIV, Load=l000

ohm in secondary:

7.3 Capacitive Load

Input Voltage=150V, Oscilloscope Scale=SA/DIV, Load=0.lmF,

lKV Ceramic Capacitor, Traces show Voltage and Current:

15

Page 17

DEI HVl000 PULSER

7.4 Current Source

Input Voltage=575V, Pulse Width=400ns, Oscilloscope

Scale=l0A/DIV, Load=5 ohms:

REV B

16

Page 18

DEI HVl000 PULSER

REV B

8.0 TROUBLESHOOTING

WARNING

The HVl000 contains capacitors that are used as energy

storage elements. When charged, these capacitors contain

in excess of 1.5 joules of stored energy. This is

sufficient energy to cause serious injury. Assure that the

AC power cord is disconnected from the pulser, and that

the capacitor bank is fully discharged and a shorting

strap installed before any repairs or adjustments are

attempted. Verify with a voltmeter that all circuits are

de-energized before servicing. The voltmeter used to make

these measurements must be certified for use at l000VDC

and 220VAC or greater. Dangerous voltages, floating ground

planes and energy storage exist at several locations in

the HVl000. Touching connections or components could

result in serious injury.

8.1 Troubleshooting Procedures

Before attempting to service or troubleshoot the HVl000,

review the servicing safety summary in Section 3.0.

The power MOSFET utilized in the HVl000 is mounted

underneath the printed circuit board, and utilizes the

case as a heat sink. In the unlikely event that the MOSFET

need be replaced, it is highly recommended that the unit

be returned to the factory for servicing.

The table below summarizes potential problems and their

solutions. If these recommendations do not resolve the

problem, DEI customer service can be contacted for further

assistance.

SYMPTOM

1. Red LED does not

illuminate

2. No output pulse.

17

SOLUTIONS

-AC power not plugged in.

-Fuse(s) are blown. See fuse

replacement instructions

in Section 8.1.1.

-No input trigger.

-Input trigger voltage too

low.

-Input trigger pulse width

too short. Increase width.

-Input trigger frequency too

high. Reduce frequency.

-No input high voltage.

Check HV supply and

connections.

-Output not connected

correctly. Check all cables

and connections.

Page 19

DEI HVl000 PULSER

8.1.1 Fuses

REV B

-Pulser is damaged. Contact

DEI customer service.

To avoid fire hazard or damage to the pulser, use only 3A

fast blow fuses (Littlefuse #312003 or equivalent). Fuse

replacement should be performed by qualified personnel

only. Assure that the AC power cord is disconnected from

the pulser, and that the capacitor bank is fully

discharged and a shorting strap installed before fuse

replacement is attempted. Verify with a voltmeter that all

circuits are de-energized before servicing. The voltmeter

used to make these measurements must be certified for use

at l000VDC and 220VAC or greater.

The fuses are located in the corner of the printed circuit

board, adjacent to the power entry module.

8.2 Factory Service

If the procedures above fail to resolve an operational

problem, please contact the factory for further

assistance:

DIRECTED ENERGY, INC.

2301 RESEARCH BLVD

SUITE 105

FORT COLLINS, CO 80526

(303) 493-1901

FAX (303) 493-1903

18

Page 20

DEI HVlOOO PULSER

REV B

9.0 SYSTEM FAILURE MODES

The HVlOOO pulse generator is capable of generating large

amplitude current pulses with very fast rise and fall

times. There is no over-current or over-voltage protection

circuitry, and it is the user's responsibility to assure

that the interconnect cables and load do not create

transients, over-current or over-voltage conditions that

could damage the pulse generator. FAILURE TO DO SO VOIDS

THE WARRANTY.

9.1 Over-Current Failure

When the output is shorted, the HVlOOO can deliver up to

200A of current (depending on cabling, HV power supply

setting, etc.). A current pulse of this magnitude is far

in excess of the generator's maximum specification, and

may cause damage to the pulse generator, load and/or

associated cabling.

The output can be shorted by allowing the two output leads

to touch each other, the "hot" lead to contact ground,

load arcing, or a shorted load.

9.2 Over-Voltaoe Failure

One may incorrectly assume that the voltage across the

MOSFET switching device could never exceed the 950V

maximum input high. voltage. It is possible to create

voltages in excess of 950V by driving an open cable or by

generating L di/dt spikes.

From transmission line theory it is known that a voltage

pulse launched onto an open cable will cause the voltage

to reflect back down the cable and double in amplitude.

This voltage doubling will over-voltage the MOSFET and

lead to pulse generator failure. Turning on the pulse

generator with the load disconnected or opening the load

while the pulse generator is operating may cause it to

fail due to this voltage doubling effect.

L di/dt spikes are created when current flowing through an

inductor is interrupted (i.e. current is turned off). The

amplitude of the resultant voltage spike is defined by the

formula:

V = L di/dt,

where Lis the circuit inductance, di is the current value

at turn off and dt is the time it takes for the current to

get to zero (i.e. fall time). By monitoring the voltage

output of the pulse generator, the user can measure L

di/dt voltage spikes. With this measurement, the user can

determine the actual voltage across the MOSFET switching

device, with the formula:

19

Page 21

DEI HVl000 PULSER REV B

where

Vmax = [L di/dt] + Vsupply

peak of the negative-going spike;

panel meter voltage;

L di/dt =

Vsupply =

Vmax

= 950 volts.

Any time the test setup (e.g. interconnect cables and/or

load resistance) is changed, it will be necessary to again

verify that Vmax is no greater than 950 volts.

10 . 0 WARRANTY

Directed Energy, Inc. (DEI) warrants all parts of

equipment of its manufacture to be free from defects

caused by faulty material or poor workmanship. Directed

Energy, Inc's obligation is limited under the warranty to

repair or replacement of products in kind. Returns must be

accompanied by a Directed Energy, Inc. return

authorization number and conform to standard conditions

for adjustment. The aforesaid warranty shall expire twelve

(12) months following the day of shipment from Directed

Energy, Inc's plant~ The foregoing states the entire

warranty extended by Directed Energy, Inc. No other

warranty, expressed or implied, is made and, specifically,

Directed Energy, Inc. makes no warranty of merchantability

or fitness for any purpose. In no case shall Directed

Energy, Inc. be liable for any special or consequential

damages. Authorization must be obtained prior to return of

defective items.

20

Page 22

DEI HVlOOO PULSER

REV B

APPENDIX A

SCHEMATICS

21

Page 23

REVI EC DESCRIPTION

DATE I BY ICHK(:1 ENG

SIGNAL TRANSFORMER

PART # 14A-2.5-36

01 I - I ORIGINAL ISSUE

A2

COMPONENT UPDATES

A3

HVX UPDATES, NEW TITLE

3L 21}911 RS I GK

7 /26J91I RS I GK

CONN. Tl

FLOATING + 15V POWER SUPPLY

7

I

I

I

H

N

G

1N4002 (4)

0

100V@1A

i--

-

--

C13

(--

C1

__L C2

J 1000uf J 0.47uf

35V 50V

1 1

-- -- --

VRl

LM342-1

-

7

C3

T O.luf

'Q 50V

1 '

L

7

_J

3019

POT CORE 3C8 OR 387

R3

0.01

--

TI

5K 4W • ••

__j 1 OK!l/2 2W

1 GATE DRIVE

3.3

C14

3.3

C7 C11

I

I

l

I

I

I

I

L

R10

51

100

D~-~8

c

5

0.01

.01

1 1

/

Ul

DS0026

0.01

C15

0.01

C16

0.01

1

R4

~

~

l~

I

~

3.3

nr I I

3.3

-- -- -- -- -- -- --

L2 TRIGGER

"9

c12

0.47

1

01

IRFD9120

I

R13

02

, 680

IRFD110

D5 I

1 N4744

I

J

7o = EARTH GROUND

_ D6 Rl 1 K T2

I

D7

E R12

J

'7 l = FLOATING GROUND

• = OFF-CARD

•• = HVX ONLY

3019 1811 'Q

L

~

POT CORE 3CB OR 3~ __ __ POT CORE 3C8 ::J

NOTICE

THIS DOCUMENT CONTAINS PROPRlnARY INFORMATION OF

DIRECTED ENERGY, INC. AND JS NOT TO BE TRANS-

MITTED, USED OR DISCLOSED TO ANYONE OR PARTY.

OR TO BE USED AS THE BASIS fOR THE MANUFACTURE

OR SALE OF ANY ARTICLE WITHOUT THE WRITTEN

PERMISSION or DIRECTED ENERGY, INC.

!HIGH VOLTAGE-

SWITCH

5.1M 2W •

GATE

-<>--

SG2

I

0

7

I

3019 POT CORE l

3C8 OR 387

20 EA

O.Oluf

I

I

28 EA I

0.1uf

I

0

I

L

v' 1

OUTPUT

I

______ _J

CONTRACT NO.

DRAWN DATE

CADEC SERVICES 2/5/90 I TITLE

CHECK

RO. SHERWOOD 2/12/90

DESIGN

DESIGN ACTIVITY SIZE

A

CUSTOMER

SCALE

31/EDEI

HVI 000/HVX NEGATIVE

PULSE MODULE

SCHEMATIC

FCSM NO. I OWG NO.

6040-0002

RELEASE DATE

SHEET

REV

A3

OF 1

Loading...

Loading...