DEI ES142 Install Manual

Dodge Engineering & Controls, Inc.

Toll Free (877) 334-2875 Fax: (978) 244-1422

ES142 Spring Return Electronic Actuators

b

a

e

EA0655R1

c

Figure 1. Parts of the ES142 Actuator.

Product Description

This installation instruction describes the steps for

direct-coupled mounting the ES142 series spring

return electronic actuator.

Product Numbers

ES142 (all versions)

Installation

a. Actuator

b. Shaft adapter

d

g

f

c. Position indicator

d. Shaft adapter locking

clip

e. Position indicator

adapter

h

f. Mounting bracket

(for dampe

g. Mounting screws

h. 3 mm hex wrench

rs)

Required Tools

• 10 mm (13/32 in. open end wrench or ratchet

• Drill

• 4 mm (5/32 in.) drill bit

• 3 mm hex wrench (provided)

• Phillips screwdriver

• Marker or pencil

Installation Conventions

Warning

Caution

Personal injury or loss of life may

occur if you do not perform a

procedure as specified.

Equipment damage or loss of data

may occur if you do not follow a

pro

edure as specified.

c

Expected Installation Time

30 minutes

Prerequisites

NOTE: The actuator is shipped from the factory

with a 5° preload on the spring. The

position of the indicator points to the 0°

position. When power is applied to the

actuator, the preload is released.

WARNING:

Do not open the actuator.

129-270 EAI/ES-1 DEI, Inc.

Installation

Dodge Engineering & Controls, Inc.

Toll Free (877) 334-2875 Fax: (978) 244-1422

ES142 Spring Return Electronic Actuators

1

Installation

90¡

2

Manual

Overide

EA1119R1

NOTE: The actuator can be mounted for clockwise or counterclockwi

Figure 2. Actuator Mounting Orientation.

d

>

77 mm

>3 in

5

4

a

90¡

2

Manual

Overide

se rotation of the damper shaft.

cc

c

c

b

6

6

3

>20 mm

<

77 mm

>3/4 in

<3 in

EA0656R1

NOTE: The shaft coupling and position indicator can be mounted on either side of the actuator.

Place the sha

129-270 EAI/ES-2 DEI, Inc.

ft adapter right next to the alignment mark keeping the mark visible.

Figure 3. Shaft Length and Proper Shaft Adapter Location.

4

SHAFT

ADAPTER

5

d

b

ALIGNMENT

MARK

90

6

a

e

cc

7

7

Dodge Engineering & Controls, Inc.

Toll Free (877) 334-2875 Fax: (978) 244-1422

Installation

ES142 Spring Return Electronic Actuators

OR

1

4

3

3

4

2

EA0289R2

OVERRIDE

MANUAL

OVERRIDE

MANUAL

EA0288R1

r bla

Place the actuator on the shaft with the dampe

des in the desired 0 position.

Tighten the middle screw so that the shaft is in the center of the shaft adapter opening.

Figure 4. Actuator Mounting.

1/2

1/2

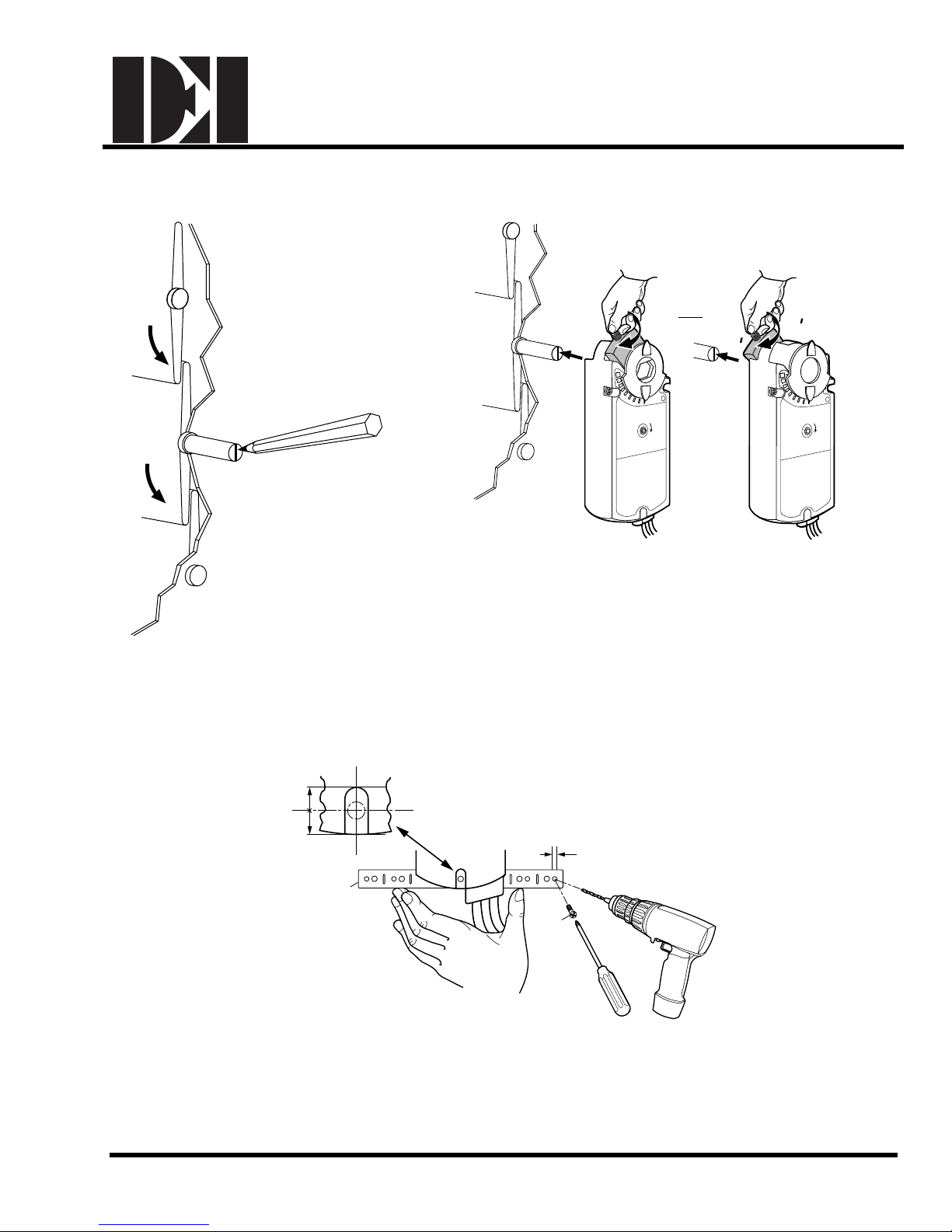

5

f

4 mm

5/32 in.

2 PLACES

Anti-rotation tab should be approximately in the center

129-270 EAI/ES-3 DEI, Inc.

g

EA0357R2

6

of the actuator anti-rotation slot.

Figure 5. Fasten the Mounting Bracket.

Dodge Engineering & Controls, Inc.

Toll Free (877) 334-2875 Fax: (978) 244-1422

Installation

ES142 Spring Return Electronic Actuators

NOTE: Keep the shaft in the ce

Manual Override

90˚

90˚

Manual

Override

GEAR TRAIN

LOCK PIN

EA0697R1

10 mm HEX

SOCKET

88 lb. - in.

(10Nm) TORQUE

10 mm HEX

SOCKET

88 lb. - in.

(10Nm) TORQUE

nter of the shaft adapter opening. Apply 7.5 lb-ft (10 Nm) torque maximum.

Figure 6. Fasten the Shaft Adapter to the Damper Shaft.

x 7-3/4 = 90˚

2

1

h

3 mm

Manual

Override

GEAR TRAIN

LOCK PIN

3

HOLD

5

90˚

7

Manual

Override

GEAR TRAIN

LOCK PIN

6

8

EA0374R3

Rotating

Turn the key in the direction of

the arrow on

the hand symbol.

CAUTION:

When you lock the gear train lock pin, be careful to turn only about 5 degree

click or meet slight resistance. Turning too far will strip the head of the lock pin. Once power is

restored, the actuator returns to automated control, without having to rotate the gear train lock pin.

129-270 EAI/ES-4 DEI, Inc.

4

Locking in place

Rotate the gear train

lock pin.

Figure 7. Manual Override.

Releasing when power is absent

Turn the key in the direction of the

arrow.

s until you hear a light

Dodge Engineering & Controls, Inc.

Toll Free (877) 334-2875 Fax: (978) 244-1422

ES142 Spring Return Electronic Actuators

Mechanical Range Adjustment –

Limiting Rotation (0 through 90°)

Make sure the actuator is in the zero position when

ng this adjustment. If making the adjustment

maki

before the actuator is in service, take into account the

5° preload. To release the preload, insert the 3 mm hex

key in the override opening and turn the key in the

direction of the arrow.

To line up the actuator at the desired angle of rotation,

begin by rem

Rotate adapter and insert at desired angle of rotation.

Return clam

applying signal.

If necessary, re-adjust adapter and restart.

oving the clamp from actuator.

p to secure the adapter. Test rotation by

Installation

1

2

3

EA0701R1

Figure 8.

The Angular Rotation is Adjustable between

0° and 90° at 5-degree Intervals.

5

Mounting for NEMA 2

See Figure 10 for acceptable NEMA 2 mounting

positions.

90

4

EA0660R1

Figure 9.

NEMA 2

<

90

˚

EA0692R1

Figure 10. Acceptable NEMA 2 Mounting Positions.

˚

90

<

˚

90

129-270 EAI/ES-5 DEI, Inc.

Dodge Engineering & Controls, Inc.

Toll Free (877) 334-2875 Fax: (978) 244-1422

ES142 Spring Return Electronic Actuators

DIP Switch Features

(ES142-M2 and ES142-M2-S Only)

Installation

Counterclockwise

Self-adapt feature

2 to 10 Vdc

Tandem Mount

Master

Figure 11. DIP Switch Settings.

After setting the 4th DIP switch for TM (tandem mount) on all actuators used in the

•

tandem ap

"M" on the 5th DIP switch.

• The rest of the actuators used in the applicatio

the 5th DIP switch.

• Connect all the 2 (black) Neutral wires a

• Connect all the 1 (red) Supply wires and connect them to the power supply.

• The Output Signal 9 (pink) wire identified as the Master actuator, needs to be

connected to all the Control Signal Wires 8 (gray) of the slave actuators used in the

tandem application.

plication, one actuator must be identified as the Master by selecting the

Operating

Voltage

Modulating Control

24 Vac/dc 9 VA/7W

2-Position and 3-Position Control

24 Vac/dc 8 VA/6W

120 Vac 9 VA

Power

Consumption

Clockwise

Self-Adapt Off

0 to 10 Vdc

Single Mount

Slave

n should have the "S" (slave) set on

nd connect them to the power supply.

129-270 EAI/ES-6 DEI, Inc.

Loading...

Loading...