DEI DTS-1600A Datasheet

DTS-1600A

Dielectric Test

System

The use of Pulse Width Modulated

(PWM) types of adjustable speed

drives (ASD) in the electric motor industry has caused an increased incidence of premature wire insulation failure. The DTS-1600A is an integrated

test system designed to test the failure

behavior of insulation by simulating,

under controlled and accelerated conditions, the electrical and ther mal

stresses that characterize PWM

(inverter) motor controllers.

The DTS-1600A test system is designed to vary and monitor the electrical and thermal test parameters for up

to five samples simultaneously, including voltage, current, pulse width, frequency, voltage rate-of-rise time, duty

cycle and temperature. The control

and monitoring of these parameters

allows the user to study the insulation

failure mechanisms common to PWM

applications. This data can then be

used in the development of new motor

designs and insulation that will overcome these failure modes.

Compared to testing with an inverter,

the DTS-1600A can reduce the test

time from days per sample to minutes

per sample (time-to-failure with the

DTS-1600A is typically 1,000 times

faster than with an inverter), dramatically reducing research and development time for new insulating materials.

Equally important, full control over the

electrical and thermal test parameters

provides a reproducible test environ-

The Pulse Of The Future

Directed Energy, Inc.

• 2401 Research Blvd., Suite 108 • Fort Collins, CO 80526

TEL: 970-493-1901 • FAX: 970-493-1903 • EMAIL: deiinfo@directedenergy.com • Internet: http://www.directedenergy.com

• 5-Channel 3,200V Pulsed Test

System for Accelerated Breakdown

Testing of Motorettes, Twisted-Pair

and Dielectric Materials

• Variable Output Voltage, Pulse Rate-

of-Rise Time, Frequency, Duty Cycle

and Temperature

• Graphical User Interface and

Computer Control and Logging Of

Test and Oven Parameters

DTS-1600A Dielectric Test System

OPERATIONAL OVERVIEW

The DTS-1600A is designed to meet the testing

requirements of magnet wire manufacturers, motor designers and manufacturers, and manufacturers of varnish and insulating materials.

The DTS-1600A will test up to five samples

(twisted pairs, motorettes or dielectric material)

simultaneously. The samples are installed in the

oven to facilitate testing at controlled and elevated temperatures. The test parameters are controlled and monitored through the control computer. Each channel can be individually enabled

or disabled, and programmed for current trip

threshold and voltage rise and fall time. The pulse

frequency, pulse width, amplitude (voltage) and

oven temperature are shared by all five channels.

The system can simultaneously pulse five capacitive samples of 50pF (a typical twisted pair) per

sample or three samples of 350pF each (a typical

motorette) at 20KHz frequency at ±1600V (3200V

peak-to-peak) in bipolar mode. (Higher capacitance loads can be driven at derated voltage and/

or frequency.) It can also drive an inductive load,

such as a motor stator, of 3mH at up to 3.5µs

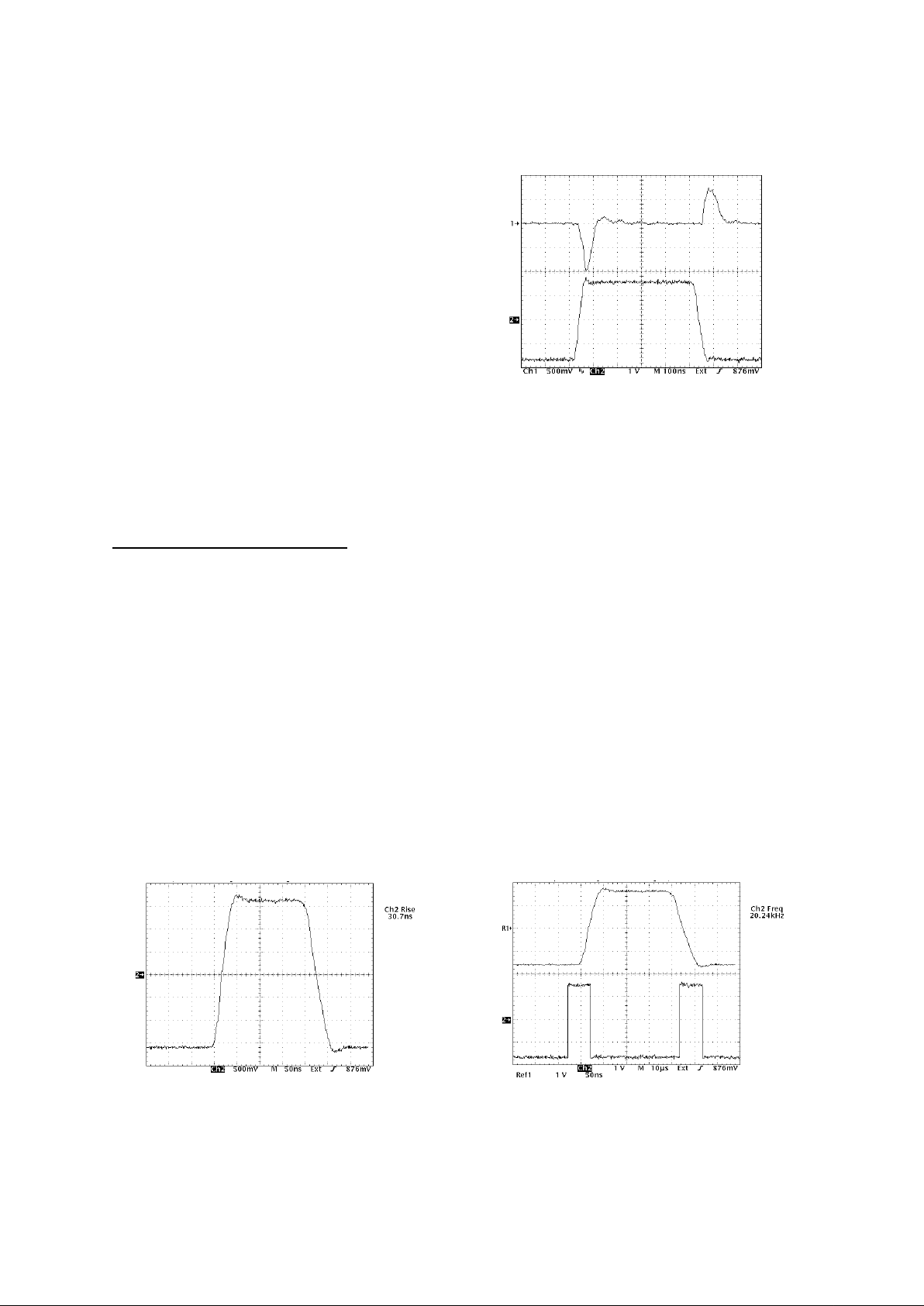

pulse width and 1600V (typical oper a tin g par ameters) in unipolar mode. Typical output wave forms

are shown in Figures 1, 2 and 3.

When a sample under test fails (the charging current exceeds the current threshold, indicating the

sample has shorted or arced), the channel is disabled, and the failure information is logged to a

text file and displayed on the Graphical User Interface (GUI) monitor. In addition to the parameters displayed and controlled through the GUI display, each channel has current and voltage monitor outputs that can be monitored using an oscilloscope or digitizer for real-time data acquisition

of the voltage and current profiles for each sample during operation.

The DTS-1600A is controlled by its control computer and GUI, which provides the interface be-

ment in which time-to-failure is repeatable within

statistically allowable differences. For all practical

purposes, inverters do not offer this capability.

In addition, the DTS-1600A offers other advantages over testing using an inverter. These advantages include:

• Capable of testing up to 5 samples simultaneously.

• User-controlled, variab le vo ltag e, curr ent trippoint, pulse width, frequency, duty cycle, voltage rise and fall time and sample temperature.

• Computer control and logging of the test parameters and failure data.

The DTS-1600A was developed in collaboration

with the U.S. Electrical Motors Division of Emerson Electric, utilizing a patented test technique

developed by USEM

(1)

.

(1) Licensed under US Patent

#5,648,725 and Copyright of the Emerson Electric Company, 1996

Figure 1

Typical rise time (~31ns) on fastest rise time setting, driving

a twisted pair (~50pF), ±1600V

Figure 2

Typical current (top trace) and voltage (bottom trace) wave-

forms, driving a twisted pair (~50pF), ±1600V

Figure 3

Typical voltage waveform (top trace) at 20KHz repetition

rate (bottom trace), driving a twisted pair (~50pF), ±1600V

Loading...

Loading...