de Gier GW10TGA, GW40HC, GW30L, GW20, GW20TGA Installation Manual

...

GW Installation manual

Standard Winch Rack drive HB series HC series

GW10 GW10L GW10TGA GW40HB GW40HC

GW20 GW30L GW20TGA GW80HB GW80HC

GW30 GW40L GW100HB GW125HC

GW40 GW150HC

GW60

GW80

GW100

GW110S

GW150S

P.INS.GW.01.EN

Version 1 – 2015 / 09 / 06

De Gier B.V., Westlandseweg 9, 2291 PG WATERINGEN, THE NETHERLANDS, Tel. +31 (0)174 292089, Fax +31 (0)174 295644, E-mail: sales@degier.nl

www.degier.eu

Version 1 – 2014 / 06 / 11

2

INSTALLATION MANUAL

Declaration of incorporation

Declaration of incorporation in accordance with the European Machinery Directive 2006/42/EC, Annex II,

No. 1B

DE GIER B.V.

WESTLANDSEWEG 9

NL-2291 PG WATERINGEN

THE NETHERLANDS

We hereby declare that pursuant to article 2G the following partly completed machines are exclusively intended to

be integrated into or mounted in another machine or piece of equipment:

Motor: GW10 / GW20 / GW30 / GW40 / GW80 / GW100 / GW110S / GW150S / GW40HB / GW80HB /

GW100HB / GW40HC / GW80HC / GW125HC / GW150HC / GW10L / GW30L / GW40L /

GW10TGA / GW20TGA

The specic technical documents pursuant to annex VII B have been drawn up and shall be sent on request by

post to the national authorities.

This partly completed machine is compliant with the provisions of the following European directives:

European Machinery Directive 2006/42/EC

European EMC Directive 2004/108/EC

The following harmonised standards (or parts of these standards) have been applied:

EN ISO 12100-1, -2: 04/2004

Safety of machinery: Basic terms, general design principles

EN ISO 14121-1:12/2007

Safety of machinery: Risk assessments

EN 60204-1:06/2007

Safety of machinery: Machinery electrical equipment

EN 60034-5:09/2007

Rotating electrical machines (only electric motors)

This partly completed machine may only be commissioned if it has been established that the machine into which

this partly completed machine needs to be built satises the provisions of the machinery directive.

Authorised compiler of the technical documents:

Rob Sandberg

Director General of De Gier B.V.

Wateringen, 14-10-2014

De Gier B.V., Westlandseweg 9, 2291 PG WATERINGEN, THE NETHERLANDS, Tel. +31 (0)174 292089, Fax +31 (0)174 295644, E-mail: sales@degier.nl

www.degier.eu

Version 1 – 2014 / 06 / 11

3

INSTALLATION MANUAL

Contents

Declaration of incorporation 2

Contents

3

Dimensions 4

Technical specications 5

1 Explanation of symbols and safety instructions 6

2 Product name 8

3 Instructions for use 8

4 Installation 10

5 Electrical connection and commissioning 16

6 Use 18

7 Inspection and maintenance 18

8 Dismounting 19

9 Troubleshooting 20

10 Spare parts and parts replacement 21

11 Disposal 21

12 Warranty 21

Glossary 22

Appendix:

Wiring diagram for 400 V three-phase supply 23

Wiring diagram for 230 V single-phase supply 24

Thank you

for choosing an electric motor gearbox from De Gier Drive Systems’ GW series.

Please pay careful attention to the information in the installation manual during installation and set-up. If you have

any questions or come across problems, please do not hesitate to contact us.

Our service number is: +31 174 - 29 20 89

Or by e-mail: sales@degier.nl

De Gier Drive Systems

De Gier B.V., Westlandseweg 9, 2291 PG WATERINGEN, THE NETHERLANDS, Tel. +31 (0)174 292089, Fax +31 (0)174 295644, E-mail: sales@degier.nl

www.degier.eu

Version 1 – 2014 / 06 / 11

4

INSTALLATION MANUAL

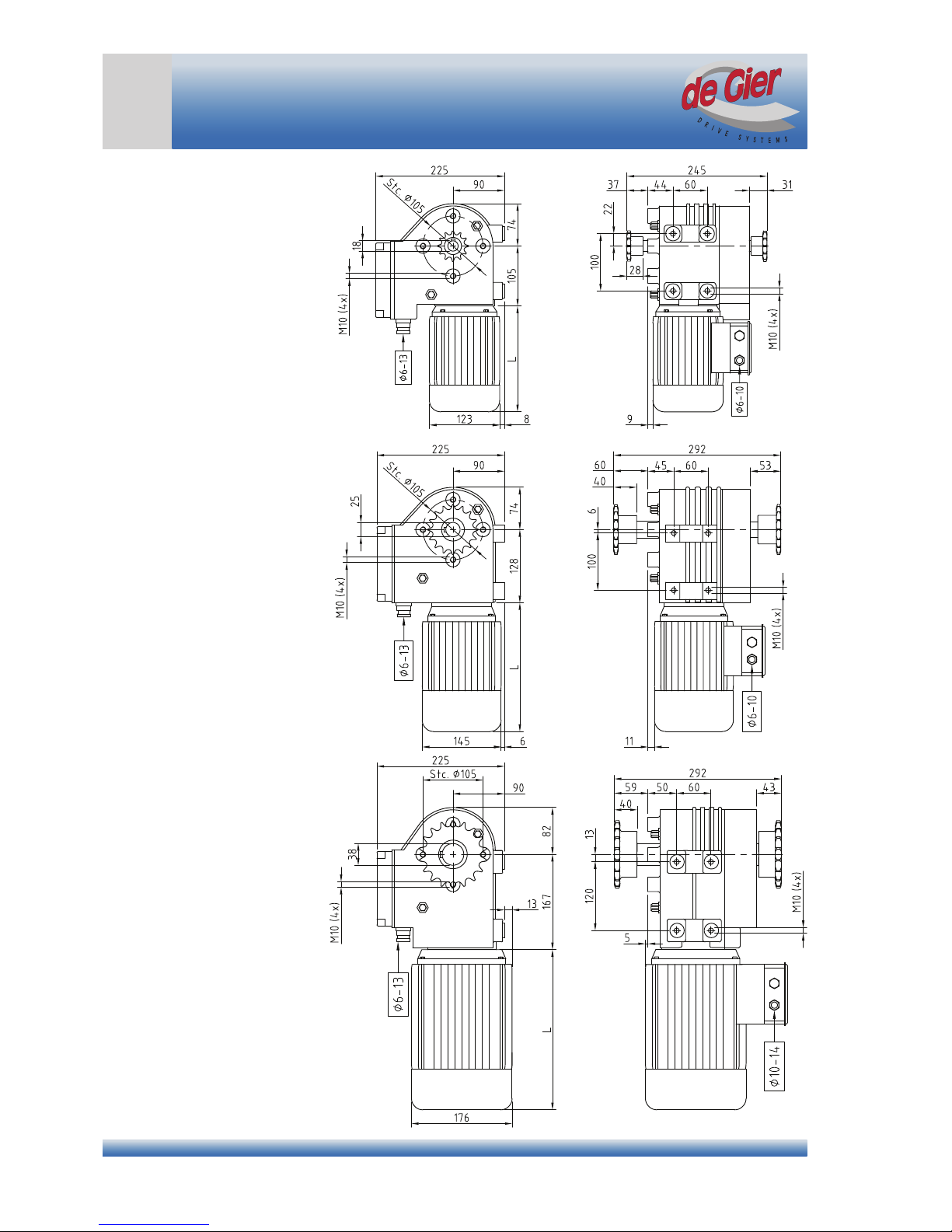

Dimensions

GW10

GW20 - GW30

GW40 - GW150

De Gier B.V., Westlandseweg 9, 2291 PG WATERINGEN, THE NETHERLANDS, Tel. +31 (0)174 292089, Fax +31 (0)174 295644, E-mail: sales@degier.nl

www.degier.eu

Version 1 – 2014 / 06 / 11

5

INSTALLATION MANUAL

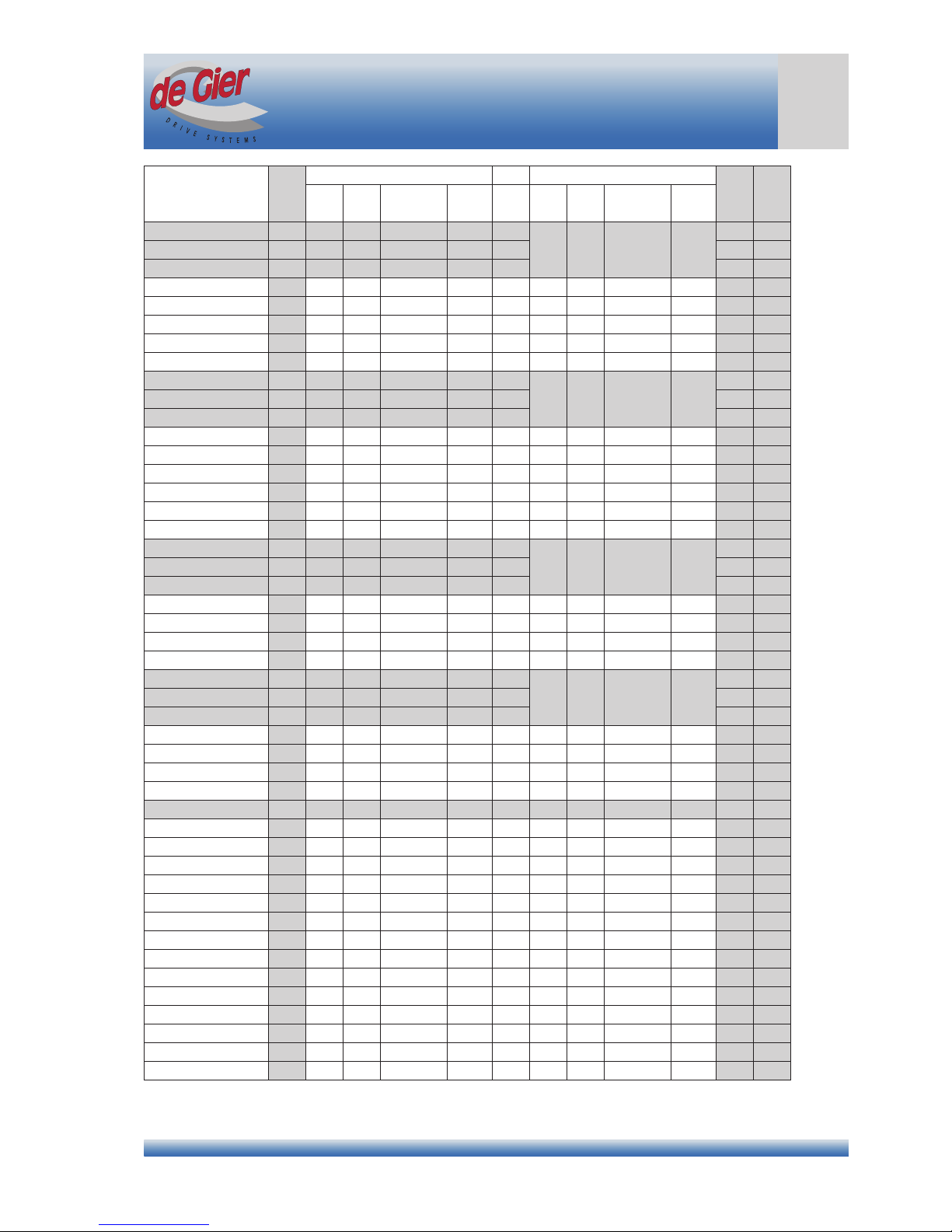

Technical specications

Description

T

50 Hz 60 Hz

L m

n P U I n P U I

[Nm] [rpm] [kW] [V] [A] [rpm] [kW] [V] [A] [mm] [kg]

P.GW10.230.13. *1 100 1,3 0,09 230 (~1) 1,3 / -

*2 *2 *2 *2

191 20

P.GW10.230.26. *1 100 2,6 0,18 230 (~1) 1,6 / - 191 23

P.GW10.230.52. *1 100 5,2 0,18 230 (~1) 1,5 / - 191 23

P.GW10.400.13. *1 100 1,3 0,09 230/400 (~3) 0,9/0,5 1,6 0,11 277/480 (3~) 0,9/0,5 191 20

P.GW10.400.26. *1 100 2,6 0,09 230/400 (~3) 0,7/0,4 3,1 0,11 277/480 (3~) 0,7/0,4 168 20

P.GW10.400.52. *1 100 5,2 0,18 230/400 (~3) 1,0/0,6 6,3 0,22 277/480 (3~) 1,0/0,6 191 23

P.GW10.400.150. *1 100 15 0,37 230/400 (~3) 1,7/1,0 18 0,44 277/480 (3~) 1,7/1,0 220 34

P.GW10.400.300. *1 100 30 0,75 230/400 (~3) 3,5/2,0 36 0,90 277/480 (3~) 3,5/2,0 220 34

P.GW20.230.13. *1 200 1,3 0,18 230 (~1) 1,6 / -

*2 *2 *2 *2

191 23

P.GW20.230.26. *1 200 2,6 0,37 230 (~1) 3,2 / - 220 28

P.GW20.230.52. *1 200 5,2 0,37 230 (~1) 3,6 / - 220 28

P.GW20.400.13. *1 200 1,3 0,18 230/400 (~3) 1,2/0,7 1,6 0,22 277/480 (3~) 1,2/0,7 191 23

P.GW20.400.26. *1 200 2,6 0,18 230/400 (~3) 1,2/0,7 3,1 0,22 277/480 (3~) 1,2/0,7 191 23

P.GW20.400.52. *1 200 5,2 0,37 230/400 (~3) 1,7/1,0 6,3 0,44 277/480 (3~) 1,7/1,0 20 28

P.GW20.400.80. *1 200 8 0,37 230/400 (~3) 1,7/1,0 9,6 0,44 277/480 (3~) 1,7/1,0 220 34

P.GW20.400.150. *1 200 15 0,75 230/400 (~3) 3,5/2,0 18 0,90 277/480 (3~) 3,5/2,0 242 34

P.GW20.400.300. *1 200 30 1,5 230/400 (~3) 5,9/3,4 36 1,8 277/480 (3~) 5,9/3,4 242 34

P.GW30.230.13. *1 300 1,3 0,37 230 (~1) 3,2 / -

*2 *2 *2 *2

220 25

P.GW30.230.26. *1 300 2,6 0,37 230 (~1) 3,2 / - 220 28

P.GW30.230.52. *1 300 5,2 0,56 230 (~1) 4,5 / - 220 28

P.GW30.400.13. *1 300 1,3 0,18 230/400 (~3) 1,2/0,7 1,6 0,22 277/480 (3~) 1,2/0,7 191 23

P.GW30.400.26. *1 300 2,6 0,25 230/400 (~3) 1,4/0,8 3,1 0,33 277/480 (3~) 1,4/0,8 220 25

P.GW30.400.52. *1 300 5,2 0,37 230/400 (~3) 1,7/1,0 6,3 0,44 277/480 (3~) 1,7/1,0 220 28

P.GW30.400.150. *1 300 15 1,1 230/400 (~3) 5,4/3,1 18 1,3 277/480 (3~) 5,4/3,1 242 34

P.GW40.230.13. *1 400 1,3 0,37 230 (~1) 3,2 / -

*2 *2 *2 *2

220 28

P.GW40.230.26. *1 400 2,6 0,55 230 (~1) 4,8 / - 242 33

P.GW40.230.52. *1 400 5,2 0,75 230 (~1) 6,0 / - 242 34

P.GW40.400.13. *1 400 1,3 0,25 230/400 (~3) 1,4/0,8 1,6 0,33 277/480 (3~) 1,4/0,8 220 28

P.GW40.400.26. *1 400 2,6 0,37 230/400 (~3) 1,7/1,0 3,1 0,44 277/480 (3~) 1,7/1,0 220 30

P.GW40.400.52. *1 400 5,2 0,55 230/400 (~3) 2,8/1,6 6,3 0,65 277/480 (3~) 2,8/1,6 220 30

P.GW40.400.80. *1 400 8 0,75 230/400 (~3) 3,4/2,0 9,6 0,90 277/480 (3~) 3,4/2,0 242 34

P.GW60.230.52. *1 600 5,2 1,1 230 (~1) 9,5 / - *2 *2 *2 *2 242 34

P.GW60.400.52. *1 600 5,2 0,75 230/400 (~3) 3,5/2,0 6,3 1,13 277/480 (3~) 3,5/2,0 220 30

P.GW80.400.13. *1 800 1,3 0,37 230/400 (~3) 1,7/1,0 1,6 0,44 277/480 (3~) 1,7/1,0 220

30

P.GW80.400.26. *1 800 2,6 0,55 230/400 (~3) 2,6/1,5 3,1 0,66 277/480 (3~) 2,6/1,5 220 32

P.GW80.400.40. *1 800 4 0,75 230/400 (~3) 3,5/2,0 6,3 0,90 277/480 (3~) 3,5/2,0 242 39

P.GW100.400.26. *1 1000 2,6 0,75 230/400 (~3) 3,8/2,2 3,1 0,90 277/480 (3~) 3,8/2,2 242 39

P.GW110S.400.40. *1 1100 4 1,1 230/400 (~3) 5,4/3,1 4,8 1,3 277/480 (3~) 5,4/3,1 242 38

P.GW150S.400.40. *1 1500 4 1,5 230/400 (~3) 6,4/3,7 4,8 1,8 277/480 (3~) 6,4/3,7 280 40

P.GW40HB.400.26. *1 400 2,6 0,37 230/400 (~3) 1,7/1,0 3,1 0,44 277/480 (3~) 1,7/1,0 266 32

P.GW40HC.400.26. *1 400 2,6 0,37 230/400 (~3) 1,7/1,0 3,1 0,44 277/480 (3~) 1,7/1,0 220 30

P.GW80HB.400.26. *1 800 2,6 0,55 230/400 (~3) 2,6/1,5 3,1 0,66 277/480 (3~) 2,6/1,5 266 34

P.GW80HC.400.26. *1 800 2,6 0,55 230/400 (~3) 2,6/1,5 3,1 0,66 277/480 (3~) 2,6/1,5 218 32

P.GW100HB.400.26. *1 1000 2,6 0,75 230/400 (~3) 3,8/2,2 3,1 0,90 277/480 (3~) 3,8/2,2 298 38

P.GW125HC.400.26. *1 1250 2,6 0,88 230/400 (~3) 4,5/2,6 3,1 1,0 277/480 (3~) 4,5/2,6 238 38

P.GW150HC.400.26. *1 1500 2,6 1,1 230/400 (~3) 5,2/3,0 3,1 1,3 277/480 (3~) 5,2/3,0 242 40

*1) Depending on version, K = chain coupling, L = Winch, T = Rack drive

*2) Ask for the possibilities of both 60 Hz electric motors and dual voltage electric motors

De Gier B.V., Westlandseweg 9, 2291 PG WATERINGEN, THE NETHERLANDS, Tel. +31 (0)174 292089, Fax +31 (0)174 295644, E-mail: sales@degier.nl

www.degier.eu

Version 1 – 2014 / 06 / 11

6

INSTALLATION MANUAL

1. Explanation of symbols and safety instructions

This installation manual is part of the delivery of the electric motor gearbox and must be kept in the vicinity of the

motor gearbox.

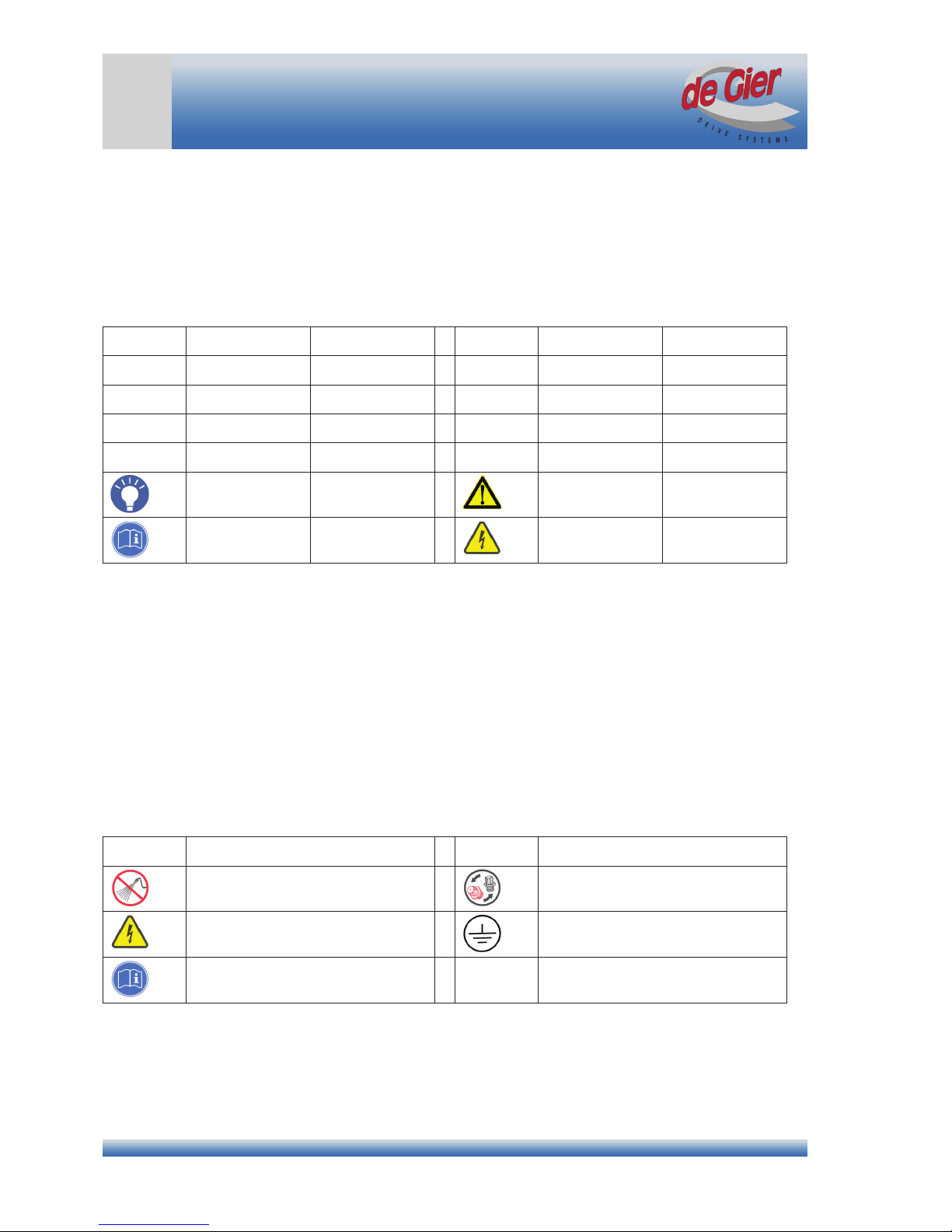

1.1 Explanation of symbols and instructions in this manual

Important procedures are emphasised in this user manual in a separate box with the initial lines printed in bold.

See below for an explanation of the various instructions you will encounter in this manual.

Symbol Meaning Unit Symbol Meaning Unit

T Torque Nm n Rotational speed rpm

P Power kW L Length mm

U Voltage V m Mass kg

I Current A

Tip - Hazard -

Note - Electrical hazard -

Instruction Explanation

Tip

Attention!

Caution!

Warning!

Risk of injury or death!

Gives the user suggestions and advice for carrying out specic tasks easily or more

practically.

Remarks with supplementary information for the user. These remarks draw the user’s

attention to potential problems.

Material damage can occur when the procedures are not followed carefully.

Serious injury to the user and/or serious damage to the product can occur if the

procedures are not followed carefully.

The user’s life is directly endangered.

1.2 Explanation of symbols on the motor gearbox

The following symbols are shown on the motor gearbox.

Symbol Meaning Symbol Meaning

Do not spray Fit the red vent plug

Electrically live parts PE connection point (earth)

Read the documentation

Explanation of symbols

De Gier B.V., Westlandseweg 9, 2291 PG WATERINGEN, THE NETHERLANDS, Tel. +31 (0)174 292089, Fax +31 (0)174 295644, E-mail: sales@degier.nl

www.degier.eu

Version 1 – 2014 / 06 / 11

7

INSTALLATION MANUAL

Safety instructions

1.3 General safety instructions

• Read the installation manual carefully and in full;

• Check that the delivery is complete before starting to install the motor gearbox;

• Strictly observe the step-by-step procedures set out in the installation manual;

• Observe all of the information in the installation manual, in particular all information relating to safety, use,

maintenance and servicing;

• Keep the installation manual in a safe place throughout the entire service life of the product;

• Switch off power to the motor gearbox before starting to work on the motor gearbox or in its immediate vicinity;

• Clean up the hazard area and leave it before switching the power back on;

• Improper installation, commissioning, maintenance etc. of the motor gearbox can lead to personal injury and/

or material damage due to the high torque of the motor gearbox;

• Operate the motor within its electrical ratings to avoid damage to the motor, drive train or other parts of the

system;

• Do not allow people to stand under or close to suspended loads;

• Never loosen screws, couplings or other parts while the drive train is under load;

• Also observe national legislation and guidelines regarding working conditions and safety.

1.4 General safety instructions

• Switch the power off before starting to work on the motor gearbox or the system and lock it out (for example,

with a padlock) to prevent it from being switched back on. This also applies to auxiliary circuits, such as limit

switches or standby heating. It is not sufcient to switch off the controller by selecting ‘stop’ or ‘0’. The motor

gearbox may also continue to operate in the «Stop» or «0» position in response to higher-level functions, such

as signals from wind or rain sensors;

• Attached or driven parts may have a shorter service life than the motor gearbox itself;

• With a three-phase supply, swapping two of the phases reverses the direction of rotation of the motor gearbox,

which can affect the operation of the limit switch mechanism;

• De Gier supplies motor gearboxes that are self-braking, but this function may not be effective under certain

conditions. We strongly recommend that for hoisting applications you use a motor gearbox equipped with a

mechanical brake and mount a fall-arrest brake on the driven shaft;

• With attached or driven components there is a risk of becoming trapped or injured. Amongst other things, the

safety distances set out in EN 349 and EN 13857 must be observed and suitable precautions must be taken,

such as safety devices or a dead-man vigilance system;

• The housing of the motor gearbox can reach temperatures above 60°C / 140°F. Fit a protective cover if

necessary, depending on the location of the motor gearbox;

• Despite careful planning and compliance with all regulations, some risks cannot be prevented.

1.5 Qualied staff

All activities described below must be performed by qualied staff. Qualied staff means persons who, based

upon their training, experience and/or education, have obtained sufcient knowledge of the applicable standards,

provisions, accident prevention regulations and operating conditions and are thus able to identify and avoid

potential hazards during relevant activities (for instance, installers recommended by De Gier). Approval by the

safety ofcer for the overall plant or system is always required before work may be carried out.

De Gier B.V., Westlandseweg 9, 2291 PG WATERINGEN, THE NETHERLANDS, Tel. +31 (0)174 292089, Fax +31 (0)174 295644, E-mail: sales@degier.nl

www.degier.eu

Version 1 – 2014 / 06 / 11

8

INSTALLATION MANUAL

2 Product name

2.1 Manufacturer

The address details of De Gier are set out below;

De Gier B.V.

Westlandseweg 9

NL-2291 PG Wateringen

The Netherlands

I : www.degier.eu

E : sales@degier.nl

T : +31 174 – 292 089

F : +31 174 – 295 644

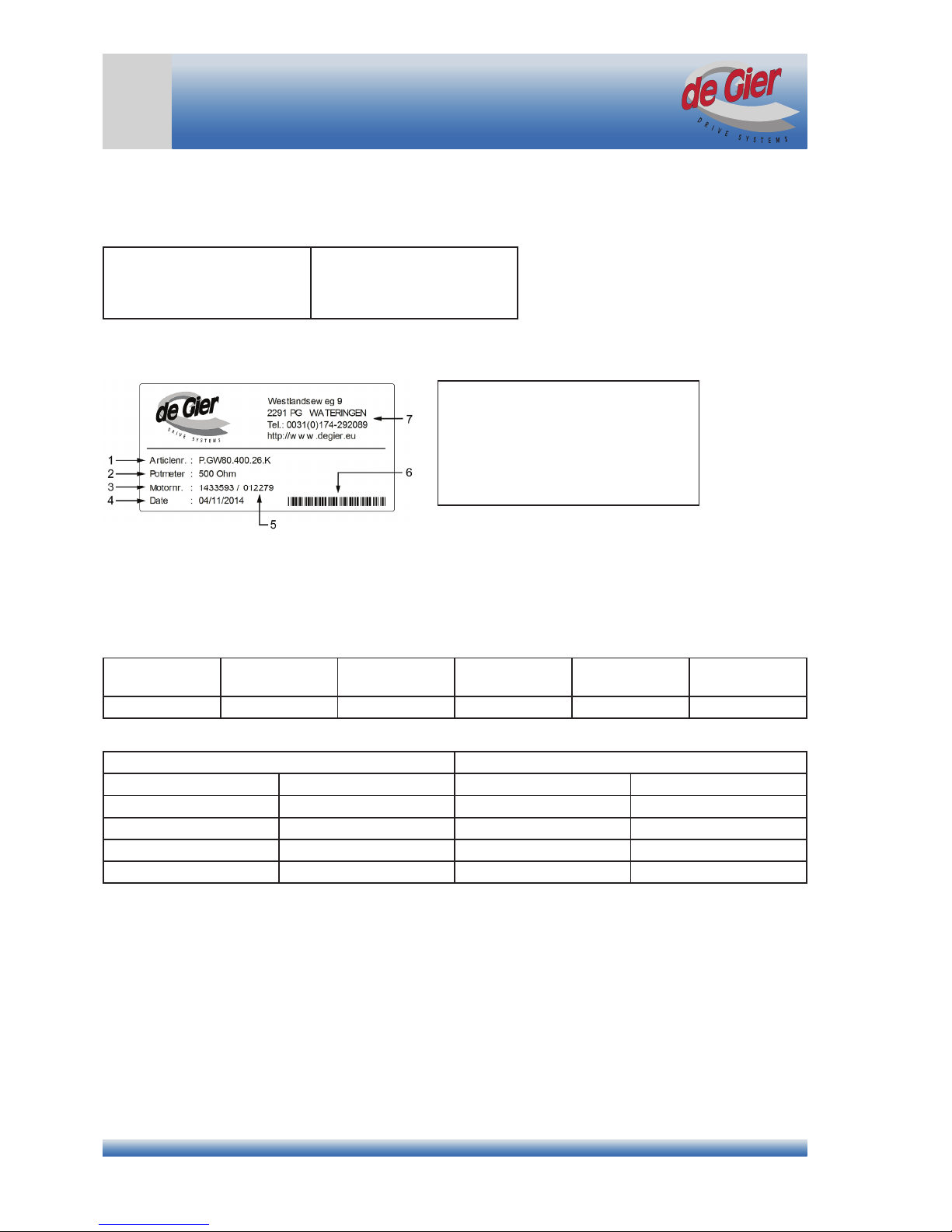

2.2 Rating plate

Let op! De prefab aandrijfassen van de U

2.3 Description

The structure of the item number on the above rating plate is set out below with an explanation of the possible

versions.

CODE SERIES TORQUE

[ x 10 Nm]

VOLTAGE

[V]

RPM

[ x 10-1 rpm]

VERSION

P GW 10 400 26 K

Possible versions Possible versions

K Chain coupling L1 Single cable drum

K100 1” Drive tube L2 Dual cable drum

K125 1,25” Drive tube LB Belt winch drum

K200 2” Drive tube T Toothed rack

L Winch drum Txxx Stroke length xxx mm

3. Instructions for Use

3.1 Intended use

GW motor gearboxes are intended for ventilation, screening and hoisting applications, such as:

• Ridge ventilation: linear-drive roof ventilation systems, for example in greenhouses, garden centres, ofce

buildings, halls, stables or polytunnels;

• Side ventilation: linear-drive side ventilation systems, for instance in greenhouses, facades, halls, or roll-up

curtains or plastic tarps for stables or greenhouses;

• Screening: for example, screens driven by cables or toothed racks in greenhouses or strip curtain systems;

• Hoisting applications: for example, growing tube or chrysanthemum (hoisting) heating. Only permitted with

fall-arrest brake protection.

Product name

1

2

3

4

5

6

7

Item number

Potentiometer resistance (optional)

Motor identication number

Production date

Serial number

De Gier barcode

De Gier address details

Example of an identication sticker

Loading...

Loading...