Page 1

INSTALLATION

INSTRUCTIONS

CONSOLE

Air conditioners

www.defy.co.za

SILHOUETTE CONSOLES

SPLIT CONSOLES

CURTAIN WALL CONSOLES

The Manufacturer strives for continuous improve-

ments. For this reason, the text and illustrations in

this book are subject to change without notice.

Part Number 059 044

Page 2

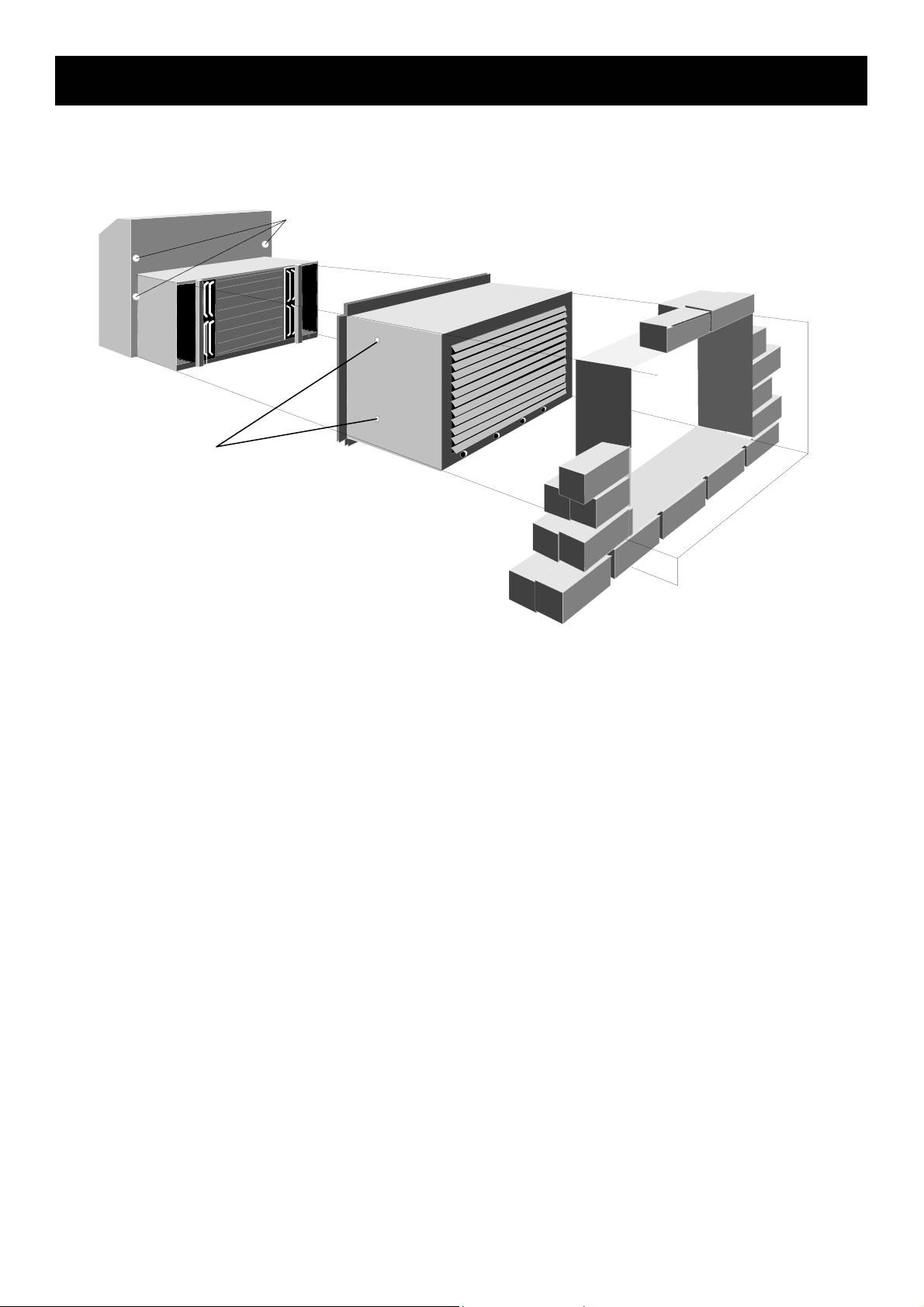

Installation notes.

To ensure optimum performance and customer satisfaction, please read these instructions

carefully.

All Defy Console type air-conditioners are tested and rated using the standard Defy wall

sleeve and louvre assembly. Units can safely operate up to 43

have been designed to produce the rated capacity at the lowest power consumption under

International Standard Rating conditions.(ISO5151) at 27°C DB, 19°C WB indoor and 35°

C DB, 24°C WB outdoor, at sea level and with a 230V 50Hz power supply.

To achieve this performance, the following should be noted:

• Smooth curved louvers are used to maximise the condenser airflow requirements.

• Air deflectors which guide the air leaving the unit away from the return air openings are fitted

onto the condenser coil to minimise hot air re-circulation.

• Open cell foam strips are fitted to the condenser end plates and fit tight up against the louvre.

These strips effectively prevent unwanted air from entering or leaving the compartments.

• To prevent rain water from entering via the wall sleeve, the bottom panel of the sleeve slants

outwards . Weep holes at the lower edge allow rainwater to drain away freely.

Architectural and aesthetic requirements often necessitate the use of non standard louver assemblies. As these could influence the performance of the units, we undertake to test, free of charge,

any proposed designs in our calorimeter facility

When specifying non standard louvers, please bear the following in mind:

Defy Appliances Limited, manufactures special wall sleeves wi thout louvers. This sleeve is shorter

than standard and thus minimises the gap between the condensing unit and the outside grille

Should the factory fitted foam strips not locate against the louver, insulated divider plates must be

fitted to prevent hot air re-circulation. It is also recommended to remove the side deflectors from

the condenser coil and reposition them directly behind the louvre.

Units installed with fl ush mounted louvers, need an insulated wall spacer collar to fill the gap between the indoor unit and the outside wall. In this instance part of the condensing section will protrude into the room. It is important therefore to insulate the condensing section and to ensure that

there are no gaps where heat and noise from the compressor and condenser could enter the room.

°C outdoor temperature. They

Page 3

Silhouette Console Installation instructions

550

220

310

CONSOLE UNIT

MOUNTING HOLES

900

720

390

MOUNTING HOLES

335

WALL SL EEV E

735

400

WALL APERTURE

745

100mm.

100

ABOVE FINISHE D

FLOOR LEVEL

(INDOOR)

405

PRIOR TO INSTALLATION

• Remove the filter assembly.

• Loosen the two screws at the bottom corners of the access cover and remove it.

• Loosen the two screws at either end of the fan deck.

• Disconnect the multi-plug and slide the fan deck out.

• Protect the deck against dust generated during the installation process.

• Secure the unit to the wall using at least four of the fixing holes provided. ( See sketch above )

• Ensure that the unit is properly and accurately fitted to the wall sleeve assembly.

• Should the factory fitted condenser coil foam seals not butt up to the louver assembly, insulated divider

plates must be fitted to prevent hot air re-circulation back into the condenser section.

• It is also advisable to remove the side deflectors from the condenser coil and fit them directly behind the

louvre.

ELECTRICAL CONNECTION

• Ensure that the supply voltage is 230V 50 Hz

• This unit must be earthed and installed in accordance with local municipal safety standards.

• If necessary, ensure that a qualified electrician replaces the mains cable.

Page 4

Split Console installation instructions

ELECTRICAL CONNECTIONS

• A 16A mains cable is connected to the indoor

unit.

• If this cable is too short, a qualified electrician

should replace it.

• An interconnecting cable complying with local

wiring codes, should be connected between the

indoor and outdoor units.

1. Connect the brown wire to terminal 1

2. Connect the blue wire to terminal 2

3. Connect the earth wire to the terminal marked

NOTE.

• An electrical isolator must be installed close to

the condensing unit.

• Ensure that the supply voltage is 230V 50 Hz.

• The unit must be earthed.

• Field wiring and connections must comply with

local codes.

• Only connect one unit to a circuit and use only

the recommended circuit breaker size.

• The evaporator and condenser must be con-

nected through the same circuit breaker.

• Please consult a qualified electrician.

INSTALLATION OF THE INDOOR UNIT.

• Select the most suitable position for uniform air

distribution, and one that requires the shortest interconnecting tubing and condensate drain pipe.

When the required interconnecting piping is longer

than 9m. an additional 20g/m of refrigerant should

be added. The maximum recommended pipe length

is 16 m. For longer lengths please refer to the pipe

sizing manuals.

• The unit must be installed at least 100mm above

floor level. Ensure that the return air outlet underneath the unit is not obstructed.

• The unit is supplied with 2 loose and two fixed

brackets for wall mounting. The brackets at the

rear may be removed and there are mounting holes

FIXING SCREW

SLIDING PLATE

DIRECTION OF MOVEMENT

MESH

MOUNTING HOLE

behind the fan assembly or optional mounting feet

are available for free standing installations, if wall

mounting is not a suitable option.

• Two openings are provided for the refrigerant piping and condensate drain tube. Both openings are on

the right hand side of the unit and cater for rear or bottom entry.

• The copper tube connections are situated behind the fan deck assembly. To remove the assembly please

proceed as follows:(a) Disconnect the unit from the electrical power supply.

(b) Remove the filter and the front access panel by removing the two screws at the bottom of the panel.

(c) Pull the 4 pin connector plug apart without unscrewing the electrical connections. Remove the four

screws securing the fan assembly and pull the assembly out carefully.

(d) The liquid and suction lines will now be visible. The copper tubes should be fitted with flare nuts

and stoppers.

(e) Measure and prepare the interconnecting piping prior to removing the stoppers. Ensure that the in-

terconnecting pipes are fully insulated. After connecting, insulate the fittings with non drip tape to

prevent sweating. NOTE: The unit has been pumped down after testing and only a small hold-

ing charge of R22 refrigerant will be in the indoor unit. Please take precautions when removing the stoppers.

(f)

Connect a 19mm (internal diameter) drain pipe to the drain connection. Insulate the drain pipe

where sweating could cause damage. Ensure the drain pipe is slanted to allow easy flow. Do not use

traps for the condensate drain.

(g)

For service and warranty purposes a duplicate serial sticker is located on the control panel door.

FIXED BRACKETS

WALL MOUNTED BRACKETS

Page 5

Installation of the Outdoor unit

• Ensure that the voltage is 230V 50Hz. Also check that the model and capacity matches those of the in-

door unit.

• Select a position for the outdoor unit which allows for the shortest possible unobstructed pipe length.

Ensure that the air intake and discharge are unobstructed and that there is enough room for servicing.

• Provide a concrete base or sturdy mounting plate and bolt the unit down using anti-vibration pads to

reduce vibration and noise.

• Due to the use of resilient, rubber compressor mountings, it is no longer necessary to remove the outer

cover and loosen the compressor mounting nuts.

• Two service valves are provided for ease of installation and servicing. They have gauge ports and

Schrader valves.

• Connect, evacuate and charge the unit in the following manner:-

(a) Connect the piping between the indoor and outdoor units. Use a drop of refrigerant oil when form-

ing the flares and ensure that they are without burrs and are of the correct shape and size.

(b) Connect the suction and discharge gauges to the gauge ports and evacuate the piping and the indoor

unit using a good vacuum pump.

(c) When a low vacuum has been achieved, close the valves and the gauge manifolds and fully open

the liquid and suction service valves with an allan key.

(d) Test for leaks before operating the unit.

NOTE:- The condensing unit has a full gas charge of R22 refrigerant which should be sufficient for a back-to-back installation with 1/4” and 1/2” copper tubing. When the required interconnecting piping is more than 9m, an additional 20g/m of refrigerant must be added.

(e) The additional refrigerant can be added either immediately after evacuation of the system or in va-

pour form when the unit is running.

(f) Start up of the unit: Set the thermostat to the coldest position with the fan on maximum and push

the Heating / Cooling button. A 2.5 to 3.0 minute time delay will be experienced before the compressor starts.

(g) Run the unit and observe the pressures and temperatures.

SERVICE TIP

• The condensing temperature should be approximately 16°C to 18°C higher than the outdoor ambient

temperature. The above should not be used as a charging method and is only a guide for new air-cooled

split systems and air-cooled units with clean condensers and an unrestricted airflow.

• Operate the unit using all functions i.e.; fan only, heating, cooling and at various fan speeds. Ensure

that the unit operates efficiently and quietly. Disconnect the gauges and check that all the screws that

were removed have been replaced.

• Advise the customer how to operate the unit and explain the various features.

Page 6

Electrical

Installation

INTERCONNECTING SPLIT EVAP. AND COND. WIRING DIAGRAM

WIRING FOR ELECTRONIC CONTROL

LIVE

HEAT

COMP

MAINS

CABLE

BROWN

PURPLE

WHITE / BROWN

GREEN / YELLO W

MAINS

CABLE

E

Y

/

N

E

SPLIT

E

R

G

COND.

CONNECT.

SPLIT

CABLE

CONDENSER

CONNECTING

CABLE

ELECTRO MECHANICAL SPLIT EVAPORATOR WIRING DIAGRAM PART NUMBER 059169

“This appliance must be earthed and

the manufacturer and the seller do not accept

responsibility for any damage due to

incorrect installation or electrical connection.”

INTER CONNECTING WIRING DIAGRAM FOR SPLIT EVAP AND CONDENSER SECTION

ELECTRO MECHANICAL CONTROLS

ELECTRONIC MODULE

X-FAN

NEUTRAL

BROWN

BLUE

BLUE

WHITE / BLUE

BLUE / BLAC K

BROWN

BLUE

W

O

L

L

GREEN / YELLOW

SILHOUETTE SPLIT EVAPORATOR / WIRING DIAGRAM

I-FAN HI

I-FAN MED

I-FAN H LOW

RED

BROWN

GREY

BLACK

L

BLUE

N

BLUE

GREEN / YELLOW

GREEN / YELLOW

L

N

GREEN / YELLOW

GREEN / YELLOW

WIRING TERM.

BROWN

BLUE

EARTH

GREEN / YELLOW

BLOCK

SELECTOR SWITCH T / STAT

L1 234 C4 L3 H6

EXT. FAN COMP.

BROWN

SPLIT

COND.

NEUTRAL

PURPLEBROWN

PURPLE

1 2

12

LIVE

WHITE / BROWN

BLUE

BLUE

BLUE

INT. FAN

HEAT EARTH

BLUE / BLACK

BLUE

WHITE / BR OW N

MED FAN SPEED LEAD

USE ON ELECTRONIC MODULE ONLY

BLACK BLACK

BLACK

GREY

RED

HEATER HEATER

HEATER

WHITE / BROWN

WHITE / BROWN

WHITE / BLUE

E

E

BLUE

N1

N1

N2

N2

BLUE

H

H

F

HI

MED MED

LO

E

N1

N2

H

HI

LO

E

N1

N2

H

F

WHITE / BRO WN

GREEN

GREEN/

YELLOW

YELLOW

BLACK

BLUE

RED

WHITE / BROWN

WHITE

WHITE /

BLUE

BLUE

GREEN / YELLO W

WHITE /

BLUE

GREEN / YELLOW

WHITE

WHITE (N)

HEATER

GREEN / YELLOW

BLUE

BROWN

BROWN

BROWN

EVAP.

GREEN / YELLOW

WHITE (N)

EVAP

FAN

FAN

MOTOR

MOTOR

EVAP.

FAN

CAP.

CAP

BROWN

WARNING: DISCONNECT THE UNIT FROM THE MAINS BEFORE SERVICING

WIRING FOR EXTERNAL

OVERLOAD COMPRESSOR

O / L

PURPLE

BLACK

C

CONNECTING

CABLE

GREEN / YELLOW

R

RED

S

YELLOW

COMPRESSOR

BLUE

BROWN

GREEN / YELLOW

GREEN / YELLOW

GREEN / YELLOW

BLUE

2

WHITE

1

PURPLE

SPLIT CONDENSER ELECTRICAL WIRING DIAGRAM

COND.

FAN

MOTOR

WHITE

C

R

S

RED

MUSTARD

PINK

BROWN

BLUE

FAN

CAP.

COMP.

CAP.

BLUE

PART No. 058407

Page 7

Curtain Wall Console Installation Instruction

95

810

WALL

SLEEVE

60

815

405

410

WALL

APERTURE

PRIOR TO INSTALLATION

• Remove Front Inlet Grille and store in a safe place.

• Remove both Filter Assemblies and store with the front inlet grille.

• Remove the two screws securing the Front Cover assembly to the Chassis Assembly.

• Remove the Front Cover assembly

• Two mounting holes, located on the Condenser Back Cover, are now exposed and clearly visible.

• Isolate the area and be sure not to contaminate the Electrical components with dust.

FILTER ASSEMBLY

FRONT INLET GRILLE

FRONT COVE R ASS EM BLY

ELECTRICAL CONNECTION

• Ensure that the supply voltage is 230V 50 Hz

• This unit must be earthed and installed in accordance with local municipal safety standards.

• If necessary, ensure that a qualified electrician replaces the mains cable.

Page 8

Defy branch

Sales

Phone Fax

Parts

Phone Fax

JOHANNESBURG

PRETORIA

BLOEMFONTEIN

DURBAN

CAPE TOWN

PORT ELIZABETH

NAMIBIA

BOTSWANA

SWAZILAND ( AGENT)

011 621 0200

——————

051 400 3900

031 460 9649

021 551 8314

041 401 6400

09264 61 216162

09267 306476

09268 518 6527

011 621 0399

——————

051 400 3950

031 460 9631

021 551 8228

041 401 6501

09264 61 216134

09267 359705

09268 518 4318

011 621 0200

012 377 0061

051 400 3900

031 460 9712

021 551 8314

041 401 6400

—————

—————

—————

011 621 0396

012 377 0398

051 400 3951

031 460 9988

021 551 8342

041 401 6499

—————

—————

—————

Warranty

Defy Appliances (“the C ompany”) warrants to the purchaser to whom the product was sol d by the dealer appointed by

the company to distribute its products (“authorized dealer”) and in respect of which no prior sale of the product was

made (“original purchaser”) that the Defy Air conditioning unit (“product”) sold with this certificate is free of defects

in material of workmanship under normal use and service for a period of 2 years from the date of purchase thereof.

The warranty period of 2 years for console air conditioners is subject to a signed service and maintenance agreement

between a Defy authorized contractor and the end user for the full warranty period. Without a service/maintenance

agreement the warranty period of 1 year applies. The warranty is subject to the following conditions:

1. This warrant y shall apply to the pr oduct, provided the prod uct is still own ed by the original pu rchaser and provided that it was pur chased in and is retained for use in the Republic of South Africa, Swaziland, Lesotho, Botswana and Namibia.

2. The Company undertakes to, within 2 years from date of the invoice issued to the original purchaser, through an

authorized dealer appointed by its regional office i n its discretion, replace or repair, free of charge, any parts of

the product, which may be faulty.

3. It is a condition of this warranty that the Company shall not be responsible for any transportation, labour, material

or any other cos ts no t s p ecified in the clauses contai ned herein.

4. The produ ct shall be serviced regular ly by an authorized dealer (which int ervals shall not exceed 6 months) and

failure to comply with this condition shall render the warrant null and void.

5. The Company shall not be responsible for damage to the product resulting from in correct voltage or fault in the

electrical power supply system, general misuse or abuse of t he product, failure to use the produ ct for the purpose

for which it was design ed, fire, fl ood, war, civil disturbances, strikes, lock outs, acts of God, acts of Government ,

or quasi-Government, or any other cause beyond the reasonable control of the Company.

6. The Company shall not accept any responsibility or liability (whether in contract and / or delict and / or otherwise), for any loss suffered by or damage of any ki nd caused to the original pur chase or any other person by or

due to failure of operation or malfunction of the product or for consequential damage of whatsoever nature,

whether such loss, damage or consequential damage was suffered by the original purchaser or any other person.

7. Should the product be worked on by anyon e oth er t han a Re gional Offi ce service represen tati ve or au th orised service dealer or be found to contain any component parts or accessories other than product component parts of accessories, this warranty will become null and void.

8. Th e defacement or removal of the nameplate and or serial number from the product will render the warranty null

and void.

9. The warranty does not apply to filters, external cables and plugs, nor to any parts where the length of life depends

on the amount of use and care given. Transport and handling damages are not covered by this warranty.

10. Save as set out in this warranty, no terms, conditions, provisions, representations or statements (wh ether express

or implied) shal l be of any force or effect whether mad e prior to, on, or subsequent to the date of ori ginal purchase, unless the same shall have been confirmed in writing by the Company.

11. The product has been designed for normal use. If the product is used for abnormal applications i.e. operation outside its design conditions, operation with restrictive louvers, which have not been approved by Defy Appliances

Ltd., extreme high or low temperatures, dusty and / or highly polluted areas or any other similar or related purpose, the warranty shall be rendered null and void.

Defy Appliances Ltd

PO Box 12004

Jacobs 4026

Loading...

Loading...