Page 1

Owner’s

Manual

SLIMLINE STAINELSS STEEL

BUILT-IN OVEN AND

HOB

600STS

CONTENTS

2 Introduction

2 Unpacking

2 Cupboard Design

2 Electrical Installation

3 Under-counter Installation

4 Hob Installation

5 Eyelevel Installation

5 The Control Panel

6 Thermofan Oven

7 Safety Advice

7 Ringer Timer

8 Solid Plates

9 Maintenance

10 Cleaning

11 Cleaning and Maintaining Stainless

Steel

13 Problem Check

13 Owner’s Responsibility

13 Service

14 Features

www.defy.co.za

Page 2

INTRODUCTION

Congratulations on the purchase of this quality product.

We trust that you will enjoy many years of trouble free use. Please read these instructions

carefully before using the oven and hob. This manual will provide you with information

on how to operate and care for your product in order that you gain the maximum benefit

from it.

UNPACKING

• Please ensure that packaging material is disposed of in a responsible manner.

• Plastic bags should be cut up to prevent children playing with them and accidentally

suffocating.

• Remove all packing from the oven cavity and position the accessories.

• If the appliance is damaged in any way, do not use it. Report the damage to your

dealer, who will take the necessary corrective action.

CUPBOARD DESIGN

• Cooking appliances generate considerable heat. The layout and materials of the

mounting cabinet should take account of the characteristics of the oven.

• Surfaces immediately adjacent to the oven should be able to withstand temperatures

of up to 100°C without delaminating or discolouring.

• Because the oven vents through the handle, overhanging doors and worktops above

the oven may be subjected to heat as well as condensation if very moist foods are

being cooked.

ELECTRICAL INSTALLATION

“This appliance must be earthed and the manufacturer and the seller do

not accept responsibility for any damage due to incorrect installation or

electrical connection.”

• This appliance should not be connected through an earth leakage system. Refer to

S.A.B.S. 0147.

• Place the oven on the floor in front of the aperture and make the electrical connection

before installing. This will ensure enough cable length for subsequent servicing.

Connection to the power supply must be carried out by a licensed electrician, who will

ensure that the oven is correctly connected and safely earthed. The rated current is printed

on the serial number label attached to the oven side trim.

The appliance must be connected to the mains through a double pole isolating switch

which has a minimum clearance between the contacts of 3 mm. in both poles.

A means for disconnection must be provided in the fixed wiring.

Hob to oven connection—Two 6 pin electrical plugs are used. (Refer to label on oven).

Page 3

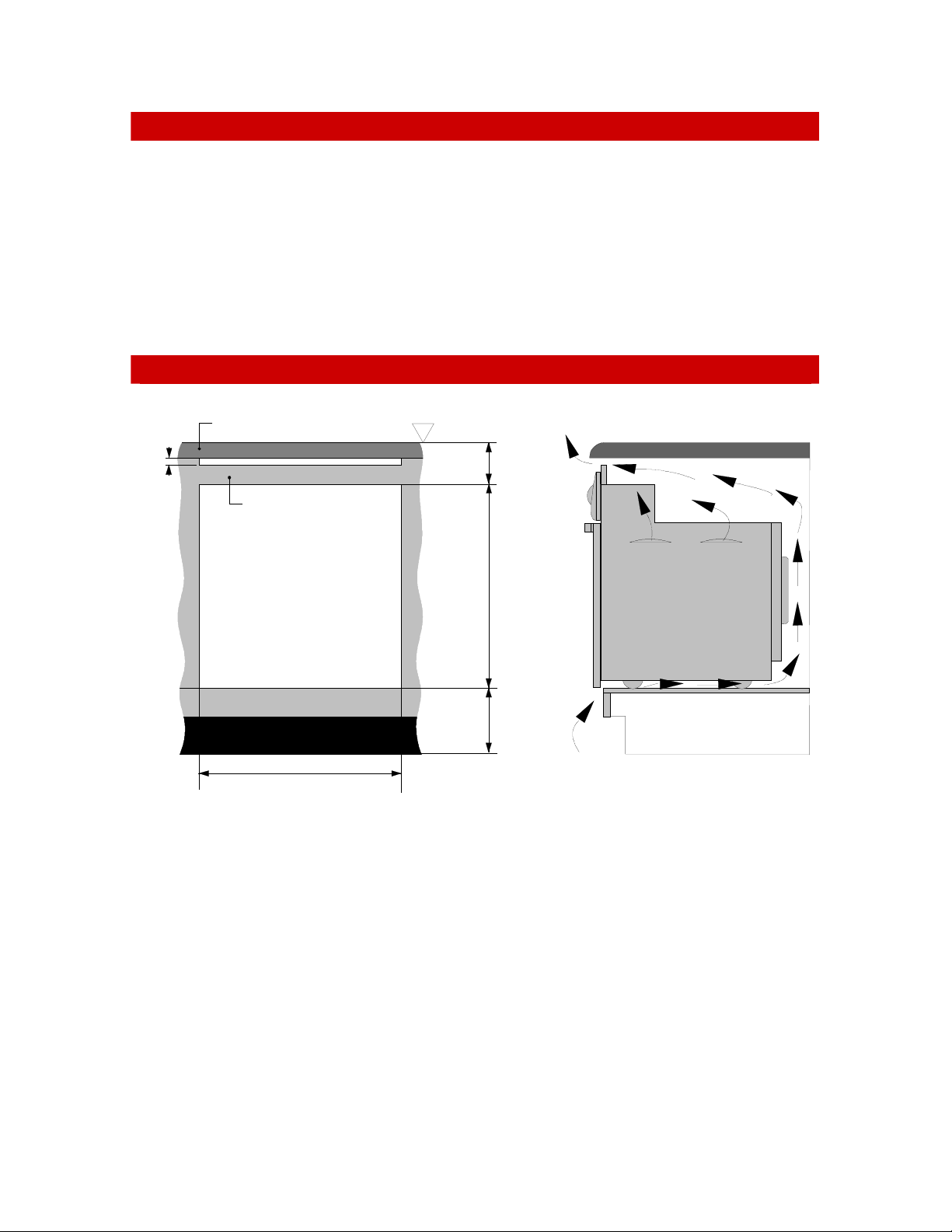

INSTALLATION

• Note: The oven cavity must vent through the front only. Avoid gaps between cavity

sides and the underside of the worktop.

• Insert the oven into the cupboard.

• Open the door to expose the fixing holes in the side trims.

• Secure the oven by 4 countersunk screws (fasteners are not supplied).

• The hob should be installed in a ventilated cupboard fitted with a sturdy worktop.

• Secure the hob using the fixing brackets provided.

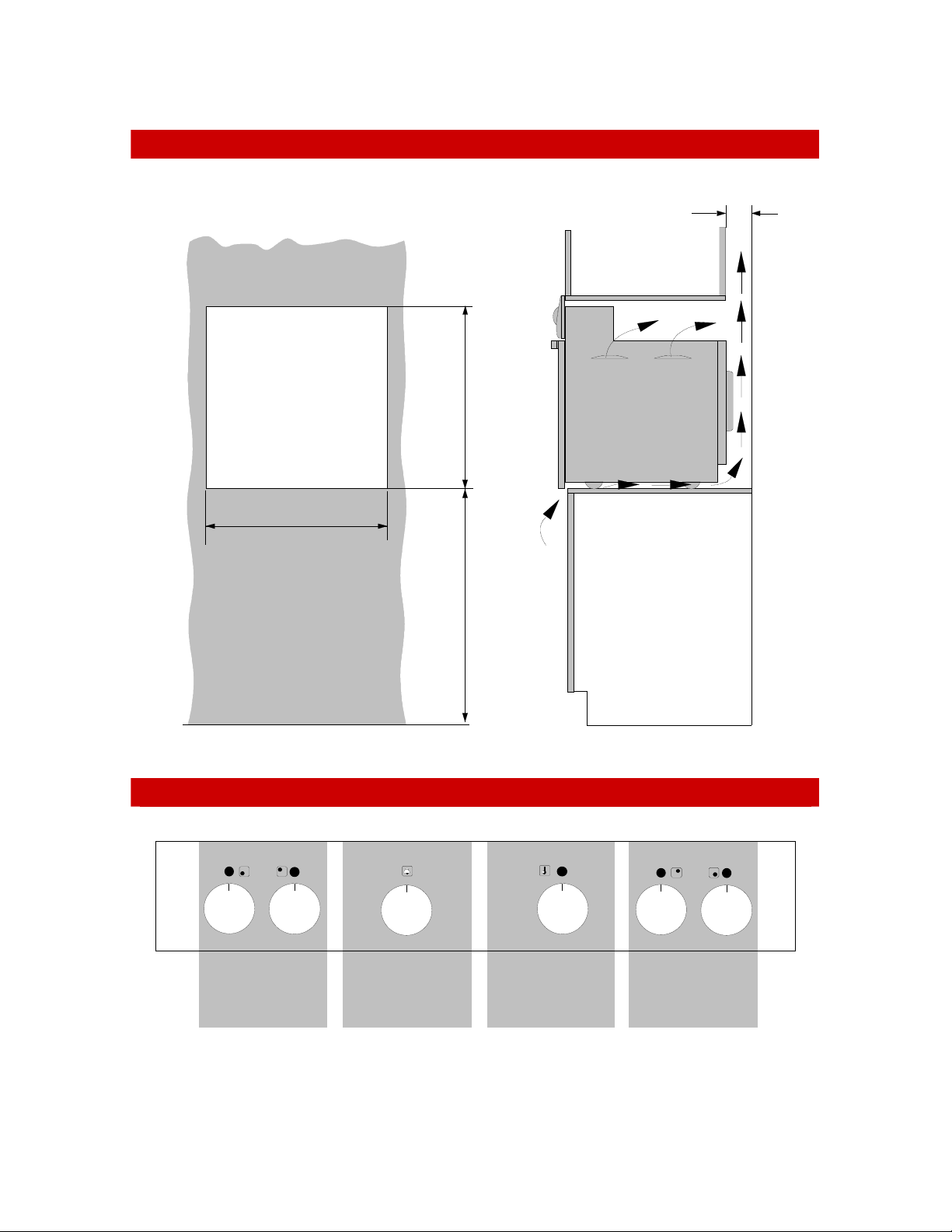

UNDER-COUNTER INSTALLATION

6

Vent

gap

at

front

only

Worktop

32mm - 48mm thick

Top filler piece

Aperture

590 H x 565 W x 570 D

900

Datum

100

590

Aperture

+_3

0

+_3

0

Typical section showing

ventilation requirements

+_3

565 Aperture

0

(210)

Floor

Page 4

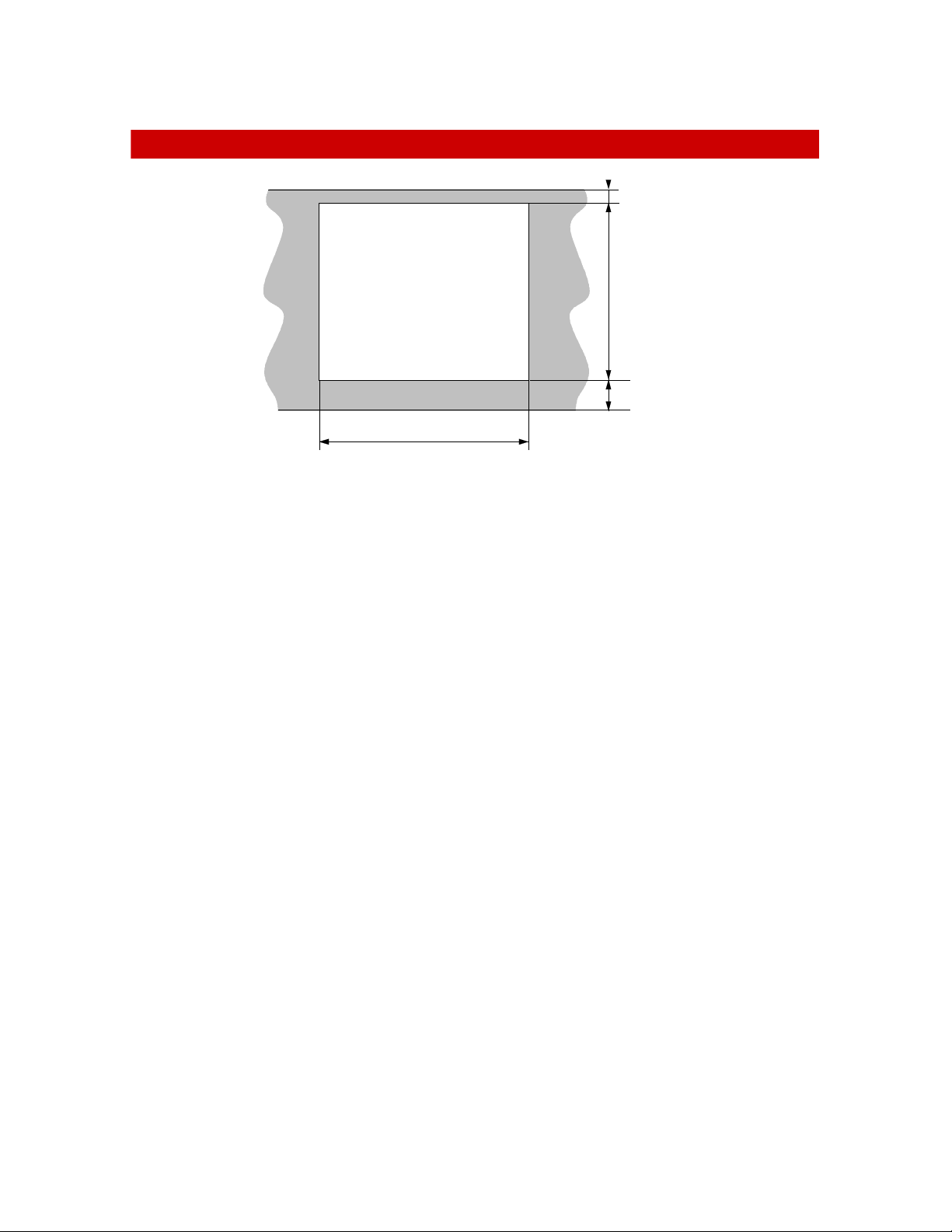

HOB INSTALLATION

( 35 )

48 5

+_3

0

Worktop front

56 0

NOTE

Defy Slimline undercounter ovens may be installed at eye level if so desired.

This will require the purchase of a wiring extension kit (part No. 061120) from the

nearest Defy Service Centre

+_3

0

80

+_3

0

Page 5

EYE-LEVEL INSTALLATION (optional)

+_3

Aperture

590 H x 565 W x 570 D

+_3

565

0

Aperture

590

0

Aperture

+_3

900

0

Above floor

level

Typical section showing

ventilation requirements

60

+_3

0

THE CONTROL PANEL

600 STS

Left front

and back

Plates

Ringer

timer

Floor

Oven

Thermo stat

Right back

and front

Plates

Page 6

THERMOFAN OVEN

Registered by Defy in 1978, Thermofan cooking differs from conventional cooking in

that it uses the principle of forced convection within the oven. The advantages are:

1. Both trays may be used at the same time.

2. Different dishes can be cooked simultaneously without flavour or aroma transfer.

Hence fish, meat and cakes can be baked at the same time.

3. The oven door may be opened any time for inspection purposes without risking a

flop.

4. By circulating hot air around the food, spit-roast chickens may be done without using

a rotisserie.

5. Cooking is done at slightly lower temperatures (10°C TO 20°C lower), saving

electricity and reducing splatter.

Cooking

• Set the oven thermostat to the required temperature.

• The indicator light will glow and remain on until the oven has reached the selected

temperature. When the indicator light switches off, the food should be placed in the

oven. During cooking the indicator light will cycle on and off as the oven thermostat

maintains the selected temperature

• After completion, the thermostat must be returned to 0.

Position 4 = T/fan bake

4

3

2

Position3 = Grill

Position 2 = T/Fan roasting.

Position 1 = T/Fan roasting ( large)

1

Baking guide

• Thermofan baking is done with the oven trays in position. An unused tray should be

kept in position to facilitate proper airflow.

• For small items the entire area of each tray may be utilised. Larger items should be

placed towards the front of each tray.

• All ovens extract a certain amount of moisture from the food being cooked. The much

greater capacity of the Thermofan oven allows more food to be cooked and thus more

moisture may be released. This is normal and not detrimental to the food or the oven.

• For professional results and perfect browning, open the oven door when half the

baking time has lapsed. Then turn the baking tins around so that the sides previously

facing the back of the oven now face the front.

Caution: Thermofan baking relies on good contact between the bottom of

the cake tin and the oven tray. Do not use spring form baking tins with a

raised bottom. The lack of contact will cause the bottom of the cake to be

underdone. These tins may be used on a wire shelf where no insulating air

space is created.

Page 7

Grilling

• The oven door must remain closed during grilling

• Use only a wire shelf when grilling as the intense heat could warp the baking trays.

• Set the oven thermostat to the grill position

• Pre-heat the roast pan and broiler for 5 minutes under the grill element to help seal the

meat.

• Place the food on the broiler and place this on a wire shelf near to the grill element.

• Monitor the grilling process to avoid burning the food.

• After completion, the thermostat must be returned to 0.

4

3

2

1

WARNING:

ACCESSIBLE PARTS MAY BECOME HOT WHEN GRILLING. ALWAYS USE OVEN GLOVES

WHEN HANDLING FOOD IN THE OVEN AND KEEP CHILDREN WELL AWAY FROM THE

PRODUCT WHEN IT IS IN USE.

recommended for

grilling

SAFETY ADVICE

• Only use the oven and hob for preparing food.

• Always keep children away from the product when it is in use.

• Do not leave hot fat or oil unattended. If overheating occurs, these could catch fire.

• Switch off the power at the wall switch in the event of a fault or when cleaning the

appliance.

• Do not store flammable items in the oven. If the oven is inadvertently switched on,

these could catch fire.

• Avoid spilling fruit juice, particularly citrus, on the oven as it could damage the

enamel.

• Always keep the oven door gasket clean as this will enable the door to seal properly.

Position 3 is

RINGER TIMER

• The ringer timer may be used for timing the cooking period. It does not switch off the

oven or the plates but gives an audible ring when the selected time period has elapsed.

• Turn the control knob to 60 minutes to wind up the mechanism.

• Return the knob to the desired period.

• When the time has elapsed, the timer will ring for a few seconds.

Page 8

SOLID PLATES

Red dot plates

• Plates featuring a red dot in the centre are high speed, high

wattage plates for increased performance

• For your safety these plates are fitted with thermal limiters.

Should a plate be accidentally switched on and left

unattended, the limiter will reduce the power output of the

plate and minimise the risk of overheating and the possibility

of fire.

Caring for Solid Plates

• Before using the plates for the first time, switch them on for about 4 minutes at the

highest setting. This allows the factory applied protective coating to burn in.

• To prevent blotchy discolouration and corrosion, moisture from spatters and spills

should be cleaned off immediately.

• To clean the plates, wipe them with a damp cloth or nylon pad. A little liquid

detergent may be used. Do not use metal scourers or sharp metal objects to clean the

plates.

• After cleaning, dry the plates by switching them on for a short while.

• To prevent rust, periodically apply some sewing machine oil or electrical hotplate

polish - available from Defy Service Centres. Extra attention is required in areas of

high humidity or in close proximity to the sea.

NOTE: THE WARRANTY DOES NOT COVER THE REPLACEMENT OR

REPAIR OF RUSTED OR CORRODED PLATES.

Recommendations

• Use only pots with a solid level base. An uneven base can prolong cooking times and

waste energy.

• Use pots with a base diameter slightly larger than the plate. This will ensure even heat

distribution and prevent spillage from dripping onto and staining the hot plate.

• Always cover the pot with a lid. This will conserve energy and minimise spillage.

• Thermal shock could damage the plates. Do not put cold pots on very hot plates.

Plate controls

• Select the heat level by turning the knob to the required

setting.

• You may select any setting, even between numbers.

• 1= low, 4 = medium and 8 = high.

• The plate indicator light will glow, when the plate is

switched on.

Page 9

MAINTENANCE

Lift-off oven door

• The oven door may be removed to improve access to the oven cavity and facilitate

cleaning.

• Open the door fully, turn the appropriate washers to lock the two hinges (see sketch)

and, using both hands, lift the door out as shown.

• After cleaning, refit in reverse order.

Removing the inner door glass.

• The glass may be removed for cleaning purposes

by removing the two screws which hold it in

place.

• It is now possible to clean the inside of the outer

glass if required.

• Wash the glass in hot soapy water, rinse and dry.

• Re-assemble by carefully locating the rubber seal

in the embossed groove before fitting the glass.

The glass is marked “THIS SIDE TOWARDS

OVEN”.

Re-fit the two securing screws.

Removing the side racks and shelves

• The side racks and shelves may be removed for

cleaning purposes.

• Remove the bottom bake element guard.

• Slide the shelf out fully against the shelf stop.

• Lift the shelf slightly and slide it out

• The side racks may be removed by pulling the

bottom stay slightly downwards thereby

dislodging it from the retainer at the bottom

centre. Lift the racks free of the retaining slots in

the oven wall.

• Replace in reverse order of disassembly.

Page 10

Oven light

The oven light is switched on by the oven thermostat and switches off when the

thermostat knob is returned to 0.

To replace a faulty light bulb, proceed as follows.

• Switch off the power at the wall switch to avoid the possibility of electric shock.

• Remove the light cover by unscrewing it in an anti-clockwise direction

• Unscrew the faulty bulb and fit a new 25 watt bulb rated for 300°C

Refit the light cover.

CLEANING

Cleaning the oven

• Switch off the electrical power supply before cleaning any part of the appliance.

• Open the oven door and allow the oven to cool down.

• Clean the oven with a damp, hot soapy cloth.

• It may be necessary to soak burnt soils with a liquid cleaner to soften them before

scrubbing them with a nylon brush or scouring sponge.

• Heavy soils on the bottom of the oven may require overnight soaking under a sponge

liberally sprinkled with household ammonia. The soil can then be removed the

following morning by washing normally.

• Do not use metal objects or steel wool to clean the oven.

• For your convenience, the shelves and side racks may be removed to improve access.

General cleaning

• Switch off the electrical power supply before cleaning any part of the appliance.

• Wipe down glass panels, cabinet, door, control knobs, trims and handles with a hot

soapy cloth.

• Use only liquid household cleaners and avoid abrasive powders, scouring pads and

caustic cleaners.

• Rinse and wipe down with a clean cloth.

Page 11

CLEANING AND MAINTAINING STAINLESS STEEL

Stainless steel is not adversely affected by normal household use but because of it’s

reputation for durability, it is sometimes assumed to be indestructible, and therefore

subjected to misuse or even abuse. Care should be taken to avoid such ‘abnormal use’.

Cleaning materials

DO USE

• A soft cloth or synthetic sponge.

• Soap, or mild household detergent (Handy Andy)

• Diluted ammonia in warm water.

• A nylon bristle brush.

• Cleaners labelled “Suitable for stainless steel”

]

DO NOT USE

• Acids

• Coarse abrasive cleaning powders.

• Metallic scourers, steel wool or metal scrapers.

• Wire brushes or emery paper.

• So called ‘silver cleaners’.

• Kitchen scourer/foam pads

Cleaning procedure

• Frequent cleaning is recommended rather than an occasional aggressive clean.

• Routine cleaning will preserve the corrosion resistance and appearance of the stainless

steel for many years.

• Clean the stainless steel as often as necessary (ie. when noticeably dull or dirty) and

use the simplest cleaning method that will effectively do the job.

• Use clean water, or a mild detergent solution applied with a soft cloth or sponge. Rinse

well and wipe dry.

ALWAYS WIPE

IN THE DIRECTION OF THE

BRUSHED TEXTURE ON THE

STAINLESS STEEL

Page 12

CONDITION ACTION NOTES AND

b

COMMENTS

Requires routine cleaning Mild detergent solution applied

with soft sponge or cloth. Rinse

and wipe dry.

Finger prints Pre-treat finger marks with

alcohol or an organic solvent.

Follow immediately with routine

cleaning

Wipe with a little baby oil and a

soft lint free cloth. Buff to shine

Stubborn stains and

discolouration

Grease and fat splatter. Wipe off excess with a soft cloth

Scratches on the brushed

finish.

Use a little Ceran cleaning paste.

(available from Defy Service

Centres)

Rinse and dry.

or paper towel. Use a water borne

degreasing agent (dishwashing

liquid). Follow up by routine

cleaning.

For slight scratches, use a nylon

pad loaded with an iron free

abrasive polishing compound.

Follow the direction of the

original texture. Follow up with

routine cleaning. For deep

scratches use a coarser abrasive

initially and follow up as for light

scratches,

If possible use warm to handhot water. A 5% addition of

ammonia is beneficial.

Minimize re-occurrence by

applying a wax or silicone

ased household polish to the

clean dry surface

Apply whenever necessary

Repeat several times rather

than resorting to a single

aggressive cleaning method

Deep scratches will be

difficult to remove

completely. Do not use steel

wool or metal scourers unless

they are made from stainless

steel.

It must be appreciated that some of the above suggested procedures will

alter the surface appearance of the treated area.

They should therefore only be applied with due consideration and care.

Page 13

PROBLEM CHECK

Before calling a service technician to assist with a problem, PLEASE

CHECK

THE MAINS DISTRIBUTION BOARD

THE WALL SWITCH

DO NOT ATTEMPT REPAIRS YOURSELF

Remember that you may be charged for a service call even during the warranty period if

the fault is due to or caused by any of the above.

OWNER’S RESPONSIBILITY

Since the following are not factory faults, they are the owner’s responsibility.

• Damage to exterior finish.

• Breakage of glass and other components.

• Replacement of the light bulb.

• Damage through improper installation or use of the appliance.

• Damage caused by moving the appliance.

• Rusted or corroded solid plates.

SERVICE

If you have followed the instructions and still have a problem, contact the nearest Defy

Service Centre. They will be able to advise you on any aspect of the product or send a

qualified technician to repair it.

Page 14

FEATURES

Under counter

Stainless steel cosmetics

Thermofan oven

Grill element

Ringer timer

Air vented “cool door”

Full glass door

Removable door

Removable inner door glass

Roast pan and broiler

Baking trays

Chromed wire shelf

Stainless steel hob with controls on oven

2 Red dot high speed plates and

2 standard plates

The Manufacturer strives for continuous improvements. For this reason, the text and

illustrations in this book are subject to change without notice.

Part Number 061 647

Loading...

Loading...