Page 1

1

PRO-TC

Temperature Controller

This quad channel thermocouple con-

troller is ideal for numerous industrial

temperature applications. It accepts di-

rect sensor input from all common ther-

mocouple types.

One of the key features of this controller

is its ability to average the inputs across

2, 3 or 4 temperature channels, and use

this averaged value for a display source

or for setpoint activation.

Contents

1 - Specications .............................. 2

2 - Front Panel & Display ................. 3

3 - Wiring .......................................... 5

4 - Dimensions & Installation .......... 8

5 - Data Sources ............................. 10

6 - Input Setup & Calibration ........ 13

7 - Setpoint Setup .......................... 20

8 - Setpoint Direct Access .............. 23

9 - Reset PIN Numbers / View

Firmware Version ...................... 23

A - Appendix A - Serial Modes ....... 24

Order Codes

PRO-TC

-HV

85–265V AC / 95–370V DC

-LV

15–48V AC / 10–72V DC

Options

-R2

2 x relay outputs

-R4

4 x relay outputs

-A 1 x mA/V analog output

-S2R 1 x RS232 (RJ11 terminal)

-S4S 1 x RS485 (screw terminal)

PRO-TC-MAN-19V01 (0306) Copyright © 2019 Dene Instruments

Page 2

2

1

SPECIFICATIONS

Input

Sensor input Thermocouple types J, K,

R, T or N

Power supply HV (85–265V AC/95–

370V DC) or LV (15–48V AC/10–72V DC)

Temperature units Degrees C or F

Processing rate 10Hz

Resolution 0.1°C

Zero dri ±40nV/°C

Span dri ±20ppm/°C FS max

Non-linearity 1°C max

Input noise 160nVp-p typical at 1Hz

output rate

Noise rejection 50/60Hz

Output rate Fixed 10Hz averaged per

channel

Features Fully scalable. Window pro-

grammable over any range within the

controller's full-scale range

Comm Port

Number of serial ports None or 1

Serial port options Isolated RS232 (RJ

terminal) or RS485 (screw terminal)

Output mode Custom ASCII, Modbus

RTU slave, or Ranger A (5 updates/sec)

Data rate: 1200–115k2 baud

Parity: Odd, even or none

OPTIONAL

Programming

Front panel buttons Up, Down, P (Prog/

Enter), plus 2 Menu buttons (F)

Security Input and setpoint setups

are independently accessible and PIN

protected

Relay Output

OPTIONAL

Display

Number of relay outputs None, 2, or 4

Relay output type 5A form A (3A 240V

AC max or 3A 30V DC max)

Analog Output

Analog output type 1 x Isolated 16 bit

4–20mA / 0–10V (selectable)

PRO-TC-MAN-19V01 (0306) Copyright © 2019 Dene Instruments

OPTIONAL

Display type LED display, 5 buttons

LED indicators 6 setpoint indicator LED's

Digits 1 row of 6 digits, 13mm (0.5"), 14

segment alphanumeric LED

Display range 0.1 to 99999.9

Page 3

3

Construction

Casing Panel mount case

48 x 96 x 120mm (1.89 x 3.78 x 4.72")

Panel cutout 45 x 92mm (1.77 x 3.62")

Ingress protection rating IP65 dust/

splash proof (face only)

Dimensions (H x W x D)

2

FRONT PANEL & DISPLAY

2.1 - Front panel

SPX

The SP LED's are used to

indicate active setpoints.

This button is used to ac-

cess the Input Setup & Calibra-

tion menu (Section 6).

This button is used to save

your settings and advance to the next step in the setup process.

48mm

(1.89")

96mm (3.78")

This button is typically used to scroll through options or increase values in the

setup menu. Pressing this button from the main display will allow you to view/reset

the Peak value

This button is typically used to scroll through options or decrease values in the

, or to view the current input values for channels 1–4 (see 2.3).

setup menu. Pressing this button from the main display will allow you to view/reset

the Valley value, or to view the current channel average value (see 2.3).

This button is used to access the Setpoint Setup menu (Section 7) and the Set-

point Direct Access menu (Section 8).

PRO-TC-MAN-19V01 (0306) Copyright © 2019 Dene Instruments

Page 4

4

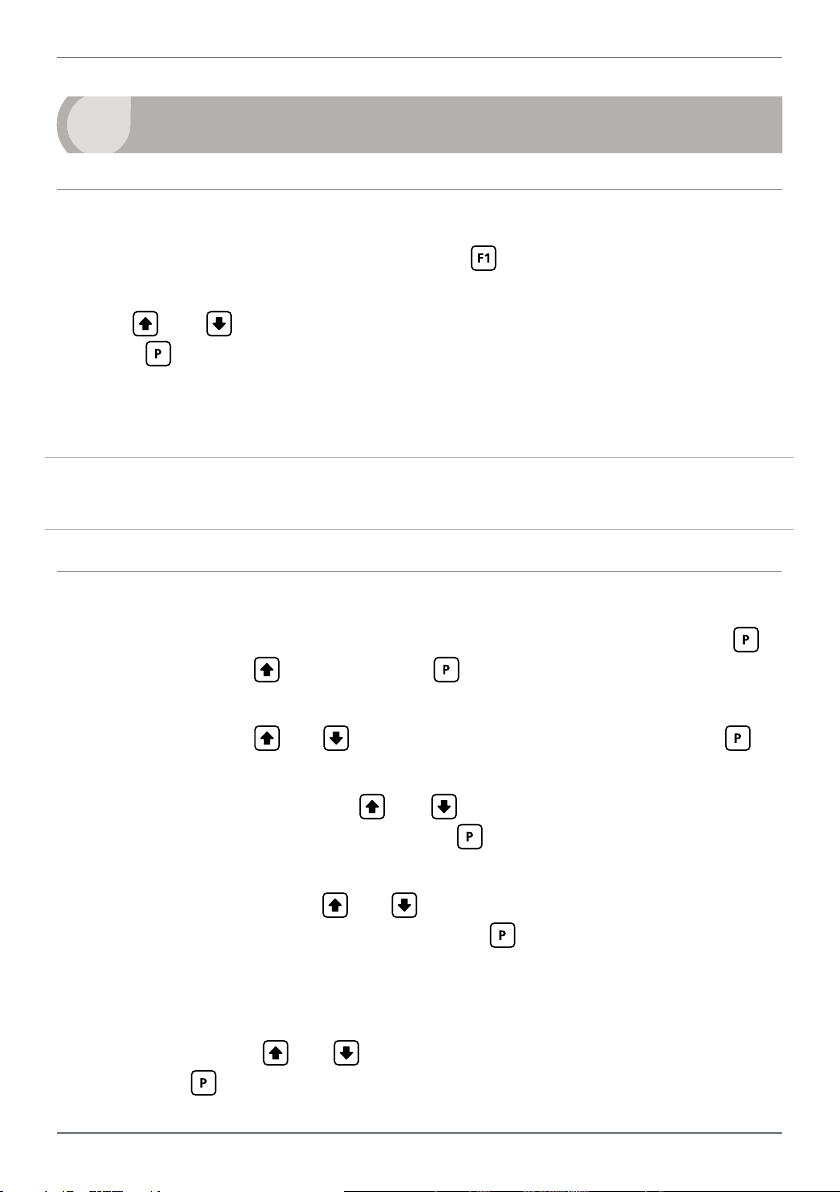

2.2 - Display brightness

To adjust the display brightness, press the and buttons together from the

main display. BRI appears and toggles with the current setting. Use the and

buttons to adjust the LED backlight, and then press to nish.

2.3 - Up and down button shortcuts

Pressing the and buttons from the main operational display allows instant

access to a number of values held in the controller's memory. These variables will ap-

pear in the order shown in the table below, and will cycle continuously at each press

of the or button.

Press

at any time to return to normal operating mode. PEAK and VALLEY may be

reset to zero by pressing the and buttons at the same time while the variable

is being displayed.

Up and down button shortcuts

PEAK The maximum measured value since the instrument was turned on or reset

(see 5.5)

TEMP 1 Current input value for channel 1

TEMP 2 Current input value for channel 2

TEMP 3 Current input value for channel 3

TEMP 4 Current input value for channel 4

VALLEY The minimum measured value since the instrument was turned on or reset

(see 5.5)

AVETMP Average temperature value (see 5.4A)

PRO-TC-MAN-19V01 (0306) Copyright © 2019 Dene Instruments

Page 5

5

SP2 SP1

SP3SP4 SP1SP2

3

WIRING

3.1 - Pinouts

A C

D

B

Key

3.1A Relay Output (see 3.3)

3.1B Serial Port (see 3.5)

3.1C Analog Output (see 3.4)

3.1D Analog Input (see 3.2)

3.1E Function Pins (see 3.6)

3.1F Power Supply HV/LV

E

F

3.2 - Analog input

See 3.1D

Wire the analog input module as shown, referring to the

product label. The unit accepts input from up to four ther-

mocouple sensors. (To use less than four sensors, select

your number of sensors in 6.2D.)

(see 3.7)

Note that you must start wiring from channel 1. (I.e. For 2 channels, use CH1–2, not CH3–4).

3.3 - Relay outputs

See 3.1A

If your controller has relay

outputs tted, wire them as

shown. Relays can be pro-

grammed to operate within

the total span range of the

controller.

–R2

–R4

PRO-TC-MAN-19V01 (0306) Copyright © 2019 Dene Instruments

Page 6

6

+mA

Pk/Val Tes tHold

3.4 - Analog output

See 3.1C

If your controller has analog output tted, wire it as shown for either

voltage (0–10V) or current (4–20mA).

3.5 - Serial port

N/C

-S2R

SGND

+5V DC (option)

RXD

See 3.1B

If your controller has serial port tted, wire it as shown

in the applicable diagram. (S2R: RS232, RJ11 terminal,

S4S: RS485, screw terminal).

3.6 - Function pins

See 3.1E

TXD

N/C

-A

–V+V–mA

-S4S

D -D +

SGND

Connect external switches as shown to enable

a function to be executed when its switch is

activated.

› Pk/Val Resets the peak and valley readings

› Hold Holds the current display value

› Tes t Resets the meter

Note that if you have activated the multiplex feature by setting your analog output

source to MPX in 6.6B, then the 'Pk/Val' and 'Hold' pins will not perform the func-

tions described above. (See 5.4C for more information.)

PRO-TC-MAN-19V01 (0306) Copyright © 2019 Dene Instruments

COM

Page 7

7

3.7 - Power supply

See 3.1F

DO NOT attempt to wire your controller while the power is on. NEVER connect your

low voltage controller to mains power.

Wire your controller for low or high voltage power supply, as show in the diagrams

below. Check the label on the unit against the colour of the connector:

› Orange =

High voltage (85–265V AC,

95–370V DC)

› Black =

Low voltage (15–48V AC,

High

voltage

(HV)

+DC

Live

AC

−DC

Neutral

AC

Low

voltage

(LV)

+DC

Live

AC

−DC

Neutral

AC

10–72V DC)

HV power

supply

LV power

supply

Once you have completed the wiring process it is safe to switch on your power

supply. Ensure that your display is functioning before you proceed.

PRO-TC-MAN-19V01 (0306) Copyright © 2019 Dene Instruments

Page 8

8

120

39

155mm (6.10") minimum depth required behind panel

4

DIMENSIONS & INSTALLATION

4.1 - Case dimensions

mm (0.16")

4

96

mm

92mm

(3.78")

(3.62")

mm (4.72")

mm (1.54")

Cabling

Allowance

155mm (6.10") minimum depth required behind panel

120 mm (4.72") 39mm (1.54")

mm (0.16")

4

mm

45mm

48

(1.89")

(1.77")

PRO-TC-MAN-19V01 (0306) Copyright © 2019 Dene Instruments

Cabling

Allowance

Page 9

4.2 - Installation instructions

Panel Meter Faceplate

Panel Cutout

9

A Prepare the Panel Cutout to

92 x 45mm ±.5 (3.62 x 1.77" ±.02),

as shown below.

Allow at least 155mm (6.10")

depth behind the panel to accommodate the meter body, protruding connectors and cabling.

B Remove the Mounting Clips from

the meter back.

Panel

Gasket

Mounting

Clips

Screws

C Slide the Panel Gasket over the

rear of the unit to the back of the

Meter Faceplate.

D From the front of the panel, insert

the meter into the Panel Cutout.

Holding the unit in place, engage

the Mounting Clips so that the tabs

snap into place over the notches on

the case.

E To achieve a proper seal, tighten

the Screws evenly until the unit sits

rmly against the panel. Do not

over-tighten the screws.

92mm ±.5

(3.62″ ±.02)

45mm ±.5

(1.77″ ±.02)

PRO-TC-MAN-19V01 (0306) Copyright © 2019 Dene Instruments

Page 10

10

5

DATA SOURCES

5.1 - Available data sources

The table below shows the data sources that are available for the various controller

outputs. See 5.2–5.5 for more information.

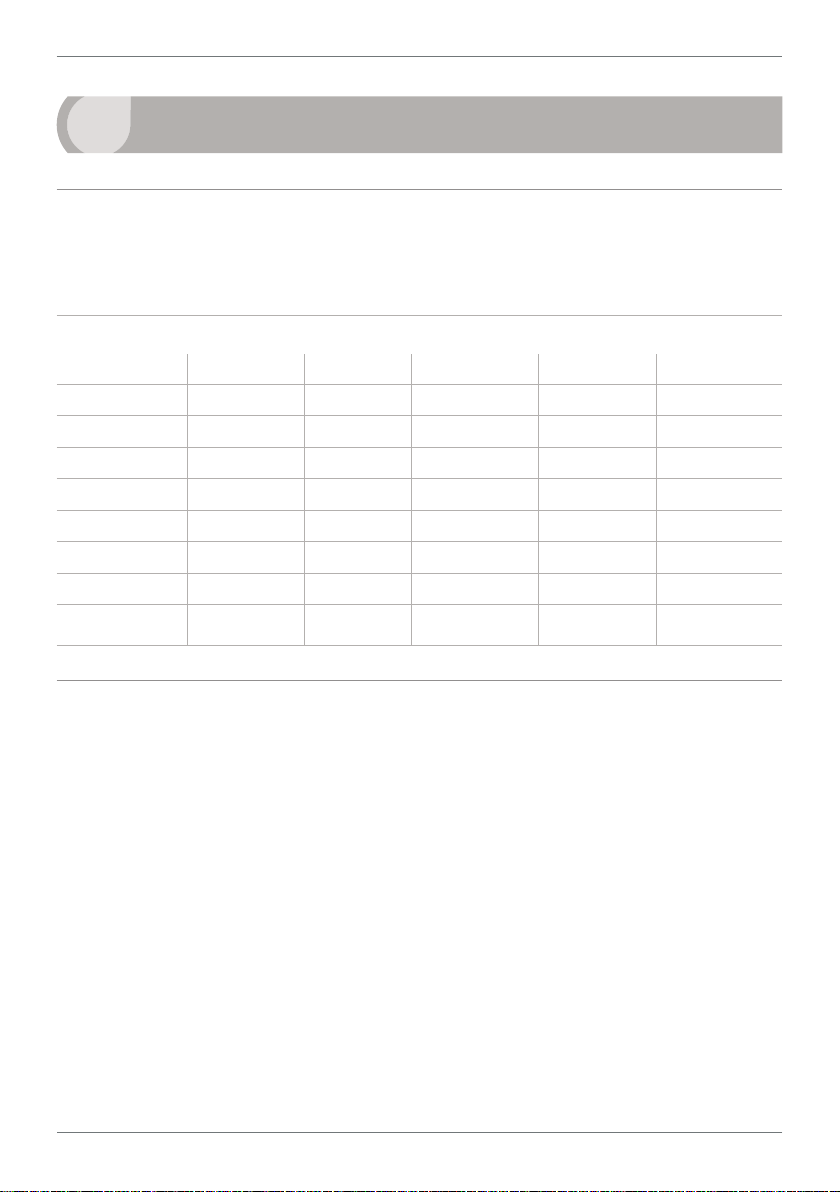

Display SP Analog O/P Serial O/P Peak/Valley

DISP

AUTO

TEMP 1–4

AVETMP

MAXTMP

MINTMP

MPX

PEAK

VALLEY

5.2 - Display

The data source for the Display determines what will be displayed on the screen

when the controller is in normal operating mode - you can set this in 6.3B.

Most of the available data sources can be selected (see 5.1). You can also select

'AUTO', which will cause the display to cycle continuously through the four

temperature input channels.

While 'Display' has its own data source, it can also be used as a data source - for a

setpoint, the analog output, the serial output, or the peak and valley values. This will

essentially mirror the display data source to the selected output, allowing the cycling

'AUTO' feature to be used with other outputs, if desired.

PRO-TC-MAN-19V01 (0306) Copyright © 2019 Dene Instruments

Page 11

11

5.3 - Temp 1 – Temp 4

An individual temperature channel can be used as a data source by selecting TEMP 1,

TEMP 2, TEMP 3 or TEMP 4. Individual temperature channels can be used as a data

source for any kind of controller output (see 5.1).

5.4 - Multi channel data sources

For multi channel functions to operate correctly, you must specify how many chan-

nels are to be included in the sample range (see 6.3G: 'Number of Channels for Multi

Channel Functions').

Note that the controller will assign channels sequentially if you select less than 4. I.e. Selecting 2 CH

will use channels 1–2; 3 CH will use channels 1–3. 4 CH will use channels 1–4.

A Average Temperature

The Average Temperature (rendered on your LED display as 'AVETMP') is a cal-

culated value, created by averaging 2, 3 or 4 of the thermocouple input chan-

nels, as selected in 'Number of Channels for Multi Channel Functions' (6.3G).

This value can be used as the default view for the operational display, or as a

data source for analog output, serial output, setpoint control, or the peak and

valley values. The AVETMP value can also be viewed via the

main display (see 2.3).

button on the

B Max/Min Temperature

Max Temperature (MAXTMP) and Min Temperature (MINTMP) are the maxi-

mum and minimum instantaneous temperatures, taken over the number of

channels selected in 'Number of Channels for Multi Channel Functions' (6.3G).

For example, if you selected 3 CH in 6.3G, then the controller will sample channels 1–3 continually to maintain up-to-date MAXTMP and MINTMP values. If

CH1=60.5, CH2=60.8 and CH3=60.6, then the MAXTMP value at that point in

time will be 60.8, and the MINTMP value will be 60.5.

The MAXTMP or MINTMP value can be used as the default view for the op-

erational display, or as a data source for analog output, serial output, setpoint

control, or the peak and valley values.

PRO-TC-MAN-19V01 (0306) Copyright © 2019 Dene Instruments

Page 12

12

C Multiplexing

The Multiplex (MPX) feature was designed for PLC interface, and allows the

PLC to determine, via the controller's 'Pk/Val' and 'Hold' function pins (see 3.6),

which temperature channel will be used as a data source for the analog output.

To activate this feature, your analog output data source must be set to MPX

(see 6.6B). When you activate MPX, the default functions of the 'Pk/Val' and

'Hold' pins will be deactivated, and the pins will be used to determine which

temperature channel is used for the analog output, as shown in the table below.

Channel Pk/Val Hold

TEMP 1

TEMP 2

TEMP 3

TEMP 4

OFF OFF

ON OFF

OFF ON

ON ON

Note that when changing the 'Pk/Val' or 'Hold' pins in MPX mode, you need to

allow a settling time of at least 0.5 seconds before reading the analog output

current.

5.5 - Peak & Valley

Peak and Valley are the maximum and minimum values measured since the instrument was turned on or reset. (These values dier from MAXTMP and MINTMP, in

that they will hold the maximum and minimum values until they are reset.)

The Peak and Valley data source can be set (in 6.3F), to a range of options as shown

in table 5.1.

Peak and Valley can be viewed from the front panel using shortcut keys (see 2.3),

or appear continually on the main display (if you set one of these variables as your

display data source). They can also be reset via the front panel (2.3), the rear pins

(3.6), or by restarting the controller.

While 'Peak' and 'Valley' have their own data source, they can also be used as data

sources - for the display, analog output, serial output, or setpoint control.

PRO-TC-MAN-19V01 (0306) Copyright © 2019 Dene Instruments

Page 13

13

6

INPUT SETUP & CALIBRATION

6.1 - Enter F1 PIN number

A Enter the calibration mode by pressing the button.

_ _ _ ENTER F1 PIN NUMBER scrolls across the display and toggles with 0. Use

the

press . If the correct PIN is entered, setup is started at 6.2.

If an incorrect PIN number is entered, _ _ _ INCORRECT PIN – ACCESS DENIED

scrolls across the display and it returns to normal operating mode.

You will have the opportunity to change your PIN number at the end of this section

(6.8). If you have forgotten your PIN number, see Section 9.

and buttons to enter your security code (factory default 1). Then

6.2 - Input setup

A _ _ _ INPUT SETUP scrolls across the display and toggles with SKIP. Press to

skip to 6.3, or the button and then to ENTER input setup.

B _ _ _ MAINS FREQUENCY scrolls across the display and toggles with the current

selection. Use the

C _ _ _ SENSOR TYPE scrolls across the display and toggles with the currently

selected sensor type. Use the

TYPE, T TYPE or N TYPE, and then press .

D _ _ _ NUMBER OF SENSORS scrolls across the display and toggles with the

current selection. Use the

perature channels are connected. Then press .

Channels are assigned sequentially. I.e. Selecting 2 CH will use channels 1–2; 3 CH will use channels 1–3, etc. See 3.2 for wiring.

E _ _ _ TEMPERATURE SCALE scrolls across the display and toggles with the cur-

rent scale. Use the and buttons to select DEG C (°C) or DEG F (°F), and

then press .

and buttons to select 50HZ or 60HZ, and press .

and buttons to select J TYPE, K TYPE, R

and buttons to select how many of the 4 tem-

PRO-TC-MAN-19V01 (0306) Copyright © 2019 Dene Instruments

Page 14

14

Input signal in counts

Sampling

F _ _ _ AVERAGING SAMPLES scrolls across the display and toggles with the cur-

rent averaging. Using the and buttons, alter the number of input samples

that the controller will average, and then press .

This feature allows signal averaging

of each individual input channel, to

optimise stable measurement. (This is

dierent from Multi-Channel Averaging,

as explained in 5.4A.)

If the change in input exceeds the averaging window value it will not average, ensuring fast response when there are large

dierences between readings.

Increasing the number of AVERAGING

SAMPLES will stabilise measurement, but

it will also slow down response rates.

Input exceeds

averaging window

Number

of samples

Averaging window

in displayed counts

G _ _ _ AVERAGING WINDOW scrolls across the display and toggles with the cur-

rently selected signal averaging window value. Using the and buttons,

alter the signal averaging window. Then press .

If your input signal contains large noise spikes, you can increase the size of the averaging window to ensure that these are still averaged. However, increasing the window size too far will reduce the ability of the controller to respond quickly to real changes in input signal. Setting AV-

ERAGING WINDOW to 0 will give continuous averaging as per the selected averaging samples.

6.3 - Display setup

A _ _ _ DISPLAY SETUP scrolls across the display and toggles with SKIP. Press

to skip to 6.4, or the button and then to ENTER display setup.

B _ _ _ DISPLAY SOURCE scrolls across the display and toggles with the currently

selected display source. Use the

TEMP 1, TEMP 2, TEMP 3, TEMP 4, AVETMP, MAXTMP, MINTMP, PEAK, or

VALLEY. Then press .

¨ If you selected AUTO, continue to 6.3C now.

¨ If you selected something else, skip to 6.3D now.

Note that your options in this step will be limited by the 'Number of Sensors' selected in 6.2D.

For more information about display data sources, see 5.2.

In Auto mode, the main display constantly cycles through all available input channels (I.e. TEMP

1, followed by the current value for that channel, then TEMP 2, TEMP 3 etc).

PRO-TC-MAN-19V01 (0306) Copyright © 2019 Dene Instruments

and buttons to choose between: AUTO,

Page 15

15

C _ _ _ DISPLAY TIME IN SECONDS scrolls across and toggles with the current

selection. This setting is only used for AUTO display (see 6.3B), and is the pause

time between variables as they cycle on the display. Use the and buttons

to adjust this value as required, and then press .

D _ _ _ UNITS scrolls across the display and toggles with the current setting. Use

and buttons to select either YES or NO, and then press .

the

E _ _ _ RESOLUTION scrolls across the display and toggles with the currently se-

lected resolution. Use the

and then press

.

and buttons to choose between 1DEG and 0.1,

F _ _ _ PEAK/VALLEY SOURCE scrolls across the display and toggles with the

currently selected peak and valley source. Use the

and buttons to select:

DISP, TEMP 1, TEMP 2, TEMP 3, TEMP 4, AVETMP, MAXTMP or MINTMP, and

then press .

Note that your options in this step will be limited by the 'Number of Sensors' selected in 6.2D.

Additionally, if your display source (6.3B) is set to either 'PEAK' or 'VALLEY', then 'DISP' will not

appear as an option, as this would create a circular reference.

For more information about Peak/Valley data sources, see 5.5.

G _ _ _ NUMBER OF CHANNELS FOR MULTI CHANNEL FUNCTIONS scrolls

across and toggles with the number of channels to be included in multi channel

calculations, including the AVETMP, MINTMP and MAXTMP values. Use the

and buttons to select: NONE, 2 CH, 3 CH or 4 CH, and then press .

Note that your options in this step will be limited by the 'Number of Sensors' selected in 6.2D.

For more information about multi-channel data sources, see 5.4.

6.4 - Clock setup

A _ _ _ CLOCK SETUP scrolls across the display and toggles with SKIP. If you do

not wish to congure your clock now, press to skip to 6.5.

Otherwise, press the

time.

B _ _ _ HOURS scrolls across the display and toggles with the current selection.

Use the

and buttons to adjust the hour (from 0 to 23), and press .

button and then to ENTER and set the date and

PRO-TC-MAN-19V01 (0306) Copyright © 2019 Dene Instruments

Page 16

16

The controller's internal clock uses 24 hour time; you cannot select a.m. or p.m.

C _ _ _ MINUTES scrolls across the display and toggles with the current selection.

Use the and buttons to adjust the minutes (from 0 to 59), and press .

Aer pressing the seconds timer will be reset to zero, and will immediately begin counting.

D _ _ _ DATE scrolls across the display and toggles with the current selection. Use

the and buttons to adjust the date (from 1 to 31), and press .

E _ _ _ MONTH scrolls across the display and toggles with the current selection.

Use the

and buttons to select a month (from JAN to DEC), and press .

F _ _ _ YEAR scrolls across the display and toggles with the current selection. Use

and buttons to adjust the display to the current year, and press .

the

6.5 - Calibration

When calibration is complete, you will be directed back to the start of the calibration

menu (6.5A). To proceed to 6.6, you must select SKIP at 6.5A.

A _ _ _ CALIBRATE scrolls across the display and toggles with SKIP. Press

now

to skip to 6.6, or use the and buttons to select a channel to calibrate

(TEMP 1, TEMP 2, TEMP 3 or TEMP 4), and then press .

The number of channels available for calibration are determined in 6.2D (Number of Sensors).

B _ _ _ APPLY LOW TEMPERATURE – – – –ENTER LOW DISPLAY VALUE scrolls

across the display, and the currently selected low display value appears. Apply

the required low level temperature to the meter, and wait a moment for the

signal to stabilise. Then use the and buttons to set the required low level

display value, and press to accept.

C _ _ _ APPLY HIGH TEMPERATURE – – – –ENTER HIGH DISPLAY VALUE scrolls

across the display, and the currently selected high display value appears. Apply

the required high level temperature to the meter, and wait a moment for the

signal to stabilise. Then use the

and buttons to set the required high level

display value, and press to accept.

D If calibration was successful, you will be directed back to 6.5A to select a new

PRO-TC-MAN-19V01 (0306) Copyright © 2019 Dene Instruments

Page 17

17

channel to calibrate. (To enter step 6.6, you must select SKIP at 6.5A.)

If calibration fails, _ _ _ CALIBRATION FAILED will scroll across the display twice,

and then you will be directed back to 6.5A to try calibrating again.

The most likely cause of this message is that the controller has not detected any change in input

signal during the calibration process. Check your signal and connections, and then repeat the

calibration procedure.

6.6 - Analog output setup

N.B. All new units are calibrated before shipping. Recalibration is only necessary if settings

are wiped or the unit's accuracy requires verication aer a long period of use. e.g. 1 year.

A _ _ _ ANALOG OUTPUT SETUP scrolls across the display and toggles with SKIP.

If your controller does not have analog output installed, (or you do not wish to

congure your analog output now), press to skip to 6.7.

Otherwise, press the

button and then to ENTER analog output setup.

B _ _ _ DATA SOURCE FOR ANALOG O/P scrolls across the display and toggles

with the current analog output data source. Use the

and buttons to

select an option from: DISP, TEMP 1, TEMP 2, TEMP 3, TEMP 4, AVETMP,

MAXTMP, MINTMP, PEAK, VALLEY or MPX (multiplex). Then press .

Note that your options in this step will be limited by the 'Number of Sensors' selected in 6.2D.

See Section 5 for more information on analog output data sources, with specic reference to

5.4C for the MPX (multiplex) feature.

C _ _ _ LOW SCALE VALUE FOR ANALOG O/P scrolls across the display and tog-

gles with the currently selected low scale display value. Use the and but-

tons and buttons to enter your cal low position, and then press .

D _ _ _ HIGH SCALE VALUE FOR ANALOG O/P scrolls across the display and

toggles with the currently selected high scale display value. Use the

and

buttons to enter your cal high position, and then press .

E _ _ _ CALIBRATE ANALOG O/P? scrolls across and toggles with SKIP. Press

now to skip analog output calibration, or the button and then to ENTER.

¨ If you selected ENTER, continue to 6.6F now.

¨ If you selected SKIP, skip to 6.7 now.

PRO-TC-MAN-19V01 (0306) Copyright © 2019 Dene Instruments

Page 18

18

F _ _ _ CAL LOW ANALOG O/P scrolls across the display and toggles with a cali-

bration number shown in internal units (around -16000). Before proceeding,

connect a mA or volt meter across the analog output connector (see 3.4). Press

the or buttons until the multimeter displays your target low output, then

Press .

G _ _ _ CAL HIGH ANALOG O/P scrolls across the display and toggles with a

calibration number shown in internal units (around 30000). Press the

or

buttons until the multimeter displays your target high output, then press .

Factory analog output calibration is precisely set before shipping this instrument, and should not be adjusted unless advised by the manufacturer.

6.7 - Serial setup

Refer to Appendix A for more information on serial modes and registers.

A _ _ _ SERIAL SETUP scrolls across the display and toggles with SKIP. If your

controller does not have a serial port installed, (or you do not wish to congure

your serial options now), please press

Otherwise, press the

button and then to ENTER serial setup.

to skip to 6.8.

B _ _ _ SERIAL MODE scrolls across the display and toggles with the current serial

mode. Use the

and buttons to choose between: ASCII (custom), MOD-

BUS (RTU), or RNGR A (Ranger A). Then press .

¨ If you selected ASCII or MODBUS, skip to 6.9D now.

¨ If you selected RNGR A, continue to 6.9C now.

ASCII is a simple, custom protocol that allows connection to various PC conguration tools.

(This is dierent from the Modbus ASCII protocol.) See A.1 for more information.

MODBUS (RTU) is an industry standard RTU slave mode that allows connection to a wide range

of devices, such as PC’s or PLC’s. See A.2 for more information.

RNGR A is a continuous output, used to drive instruments in the Rinstrum™ range. See A.3 for

more information.

C _ _ _ SERIAL DATA SOURCE scrolls across the display and toggles with the

PRO-TC-MAN-19V01 (0306) Copyright © 2019 Dene Instruments

Page 19

19

currently selected serial data source. Using the and buttons, select: DISP,

TEMP 1, TEMP 2, TEMP 3, TEMP 4, AVETMP, MAXTMP, MINTMP, PEAK, or

VALLEY, and then press .

Note that your options in this step will be limited by the 'Number of Sensors' selected in 6.2D.

See Section 5 for more information about serial data sources.

D _ _ _ BAUD RATE scrolls across the display and toggles with the current se-

lection. Use the and buttons to select one of: 1200, 2400, 4800, 9600,

19200, 38400, 57600 or 115200. Then press .

E _ _ _ PARITY scrolls across the display and toggles with the currently selected

parity. Using the

and buttons, select: NONE, ODD or EVEN, and then

press .

F _ _ _ SERIAL ADDRESS scrolls across the display and toggles with the currently

selected serial address. Use the

and buttons to alter the serial address,

and then press .

The serial address parameter is used to identify a particular device when it is used with other

devices in a system. (It applies particularly to MODBUS mode when used on an RS485 serial

network.) The serial address of the controller must be set to match the serial address dened

in the master device.

6.8 - Edit F1 PIN number

A _ _ _ EDIT F1 PIN NUMBER scrolls across the display and toggles with SKIP.

Press to skip and return to the operational display, or the button and

then to ENTER and change your PIN number.

B _ _ _ ENTER NEW F1 PIN NUMBER scrolls across the display and toggles with

the current PIN (default 1). Using the

number. Then press to exit to the operational display.

and buttons, enter your new F1 PIN

PRO-TC-MAN-19V01 (0306) Copyright © 2019 Dene Instruments

Page 20

20

7

Your controller will allow conguration of up to 6 setpoints, however full

functionality is only supported when relay output hardware is installed.

(Setpoints with no corresponding relay output hardware may be used as simple LED

indicators, if desired. In this case, features requiring relay output functionality will

continue to appear in the setup menu, but will be ignored by the controller.)

SETPOINT SETUP

7.1 - Enter F2 PIN number

A Enter setpoint setup mode by pressing and holding the button for 3 seconds.

_ _ _ ENTER F2 PIN NUMBER scrolls across the display and toggles with 0. Use

the

press . If the correct PIN is entered, setup is started at 7.2.

If an incorrect PIN number is entered, _ _ _ INCORRECT PIN – ACCESS DENIED

scrolls across the display and it returns to normal operating mode.

You will have the opportunity to change your PIN number at the end of this section

(7.3). If you have forgotten your PIN number, see Section 9.

and buttons to enter your security code (factory default 1). Then

7.2 - Setpoint setup

A _ _ _ EDIT SETPOINT scrolls across the display and toggles with SKIP. Press

now to skip to 7.3, or use the and buttons to select a setpoint to edit,

and then press .

B _ _ _ SP VALUE scrolls across the display and toggles with the current value for

the selected setpoint. Using the

which the selected setpoint will activate, and then press .

PRO-TC-MAN-19V01 (0306) Copyright © 2019 Dene Instruments

and buttons, adjust the display value at

Page 21

21

Energised Above

Energised Above

C The step that you proceed to now will depend on which setpoint you are editing

(selected in 7.2A):

¨ If you are currently editing SP 1, skip to 7.2E now.

¨ If you are currently editing SP 2–6, continue to 7.2D now.

D _ _ _ TRACK SP1 scrolls across the display and toggles with the tracking setting

for the selected setpoint. Using the

and buttons, select OFF or ON, and

then press .

¨ If you selected OFF, continue to 7.2E now.

¨ If you selected ON, skip to 7.2F now.

A setpoint with TRACK SP1 enabled will track the setpoint value of SP 1, with the setpoint

value of the tracking setpoint becoming an oset value.

E _ _ _ SP SOURCE scrolls across the display and toggles with the activation source

for the selected setpoint. Use the and buttons to select an option from:

DISP, TEMP 1, TEMP 2, TEMP 3, TEMP 4, AVETMP, MAXTMP, MINTMP, PEAK,

or VALLEY, and then press .

Note that your options in this step will be limited by the 'Number of Sensors' selected in 6.2D.

See Section 5 for more information on setpoint data sources.

F _ _ _ SP ACTIVATION scrolls across the display and toggles with the current ac-

tivation for the selected setpoint. Using the and buttons, select the relay

activation to operate ABOVE or BELOW the setpoint value, and then press .

ABOVE: Relay turns on above the setpoint value and o below it. BELOW: Relay turns on below

the setpoint value and o above it.

G _ _ _ SP TYPE scrolls across the display and toggles with the hysteresis type for

the selected setpoint. Using the and buttons, select either ALARM or

CNTRL (control), and then press .

ALARM - SETPOINT VALUE controls setpoint

activation point. HYSTERESIS VALUE controls

setpoint deactivation point.

Hysteresis

band

Energised Below

Hysteresis

band

CNTRL - SETPOINT VALUE controls setpoint

deactivation point. HYSTERESIS VALUE con-

trols setpoint reactivation point.

Hysteresis

band

PRO-TC-MAN-19V01 (0306) Copyright © 2019 Dene Instruments

Hysteresis

band

Energised Below

Page 22

22

H _ _ _ HYSTERESIS VALUE scrolls across the display and toggles with the hyster-

esis value for the selected setpoint. Use the and buttons to adjust this

value if required, and then press .

The HYSTERESIS VALUE denes the separation band between setpoint activation and deacti-

vation, and will operate as per the SP TYPE setting selected in 7.2G.

I _ _ _ MAKE DELAY scrolls across the display and toggles with the current make

delay time for the selected setpoint. This is the time delay between setpoint ac-

tivation, and when the relay turns on. Adjust this value in 0.1 second increments

using the and buttons, and then press .

J _ _ _ USER ACCESS? scrolls across the display and toggles with the direct access

permission setting for the selected setpoint. Use the

and to select either

OFF or ON, and then press .

When enabled, this option allows the selected setpoint's value to be edited directly aer pressing the button, without needing to enter a PIN number or go through all of the other options. Each setpoint can individually have this option enabled or disabled. See Section 8.

K _ _ _ EDIT SETPOINT scrolls across the display and toggles with SKIP. You are

now back at 7.2A. To edit another setpoint, follow the instructions from 7.2A–K

again. If you do not wish to edit another setpoint, press now to skip to 7.3.

7.3 - Edit F2 PIN number

A _ _ _ EDIT F2 PIN NUMBER scrolls across the display and toggles with SKIP.

Press to skip and return to the operational display, or the button and

then to ENTER and change your PIN number.

B _ _ _ ENTER NEW F2 PIN NUMBER scrolls across the display and toggles with

the current PIN (default 1). Using the

number. Then press to exit to the operational display.

PRO-TC-MAN-19V01 (0306) Copyright © 2019 Dene Instruments

and buttons, enter your new F2 PIN

Page 23

23

8

When this feature is enabled, the selected setpoint will be editable via the

button without entering a PIN.

If none of the setpoints have their direct access option enabled in 7.2J then this

feature will be disabled and the

A Begin by pressing the

B The name of the rst access-enabled setpoint will appear on the display and

toggle with the current value for that setpoint. Using the

adjust the selected value. Then press to accept and continue.

C The name of the next access-enabled setpoint will appear on the display, along

with its setpoint value. Repeat step 8B. The direct access menu will proceed

through all access-enabled setpoints in this fashion. Pressing

bled setpoint will exit and return to the operational display.

9

SETPOINT DIRECT ACCESS

button will not respond to a short button press.

button for less than 3 seconds.

and buttons,

for the last ena-

RESET PIN NUMBERS / VIEW FIRMWARE VERSION

If you have forgotten your PIN number(s), follow the procedure below to reset both

the F1 and F2 PINs to their factory default of 1.

This procedure will also allow you to view the current soware installed on your

controller, which may be required for support purposes.

A Press

execute and you may need several tries to get it right.)

B A message will appear on the display, with details of the unit's current soware

conguration (Product Name, Firmware Version, and Macro Version). At the

end, you will see – ALL PIN NUMBERS RESET TO 1.

C Reset the default PIN numbers if required by following the instructions in 6.8

and 7.3, entering ‘1’ whenever you are prompted for your current PIN.

, and at the same time. (This key combination can be dicult to

PRO-TC-MAN-19V01 (0306) Copyright © 2019 Dene Instruments

Page 24

24

A

APPENDIX A - SERIAL MODES

A.1 - Custom ASCII mode

Custom ASCII is a simple, custom protocol that allows connection to various PC con-

guration tools. ('Custom ASCII' diers from the 'Modbus (ASCII)' protocol used by

some devices.) Custom ASCII command strings must be constructed in this order:

<Start> <Controller Address> <Read/Write Command> <Register Address>

<Separator Character> <Data Value> <Message Terminator>

Start - Use 'S' for the start character of a command string (not case sensitive). This

must be the rst character in the string.

Controller Address - Use an ASCII number from '1' to '255' for the controller address.

If the character following the start character is not an ASCII number, then address '0' is assumed. All controllers respond to address '0'.

Read/Write Command - Use ASCII 'R' for read, 'U' for unformatted read, or 'W' for

write (not case sensitive). Any other character aborts the operation.

In Custom ASCII mode, data is normally read as formatted data (which includes decimals and

any text characters that may be selected to show units). However it is also possible to read unformatted data by using a 'U' in the read command. There is no unformatted write command,

as when writing to xed point registers, any decimal point and text characters are ignored.

Register Address - The register address for the read/write operation will be an ASCII

number from '1' to '65535'. This character must be specied for a write com-

mand, but may be omitted for a read command, (in which case the controller

will respond with the data value currently on the display).

Separator Character - The separator character can be either a space or a comma,

and is used to separate the register address from the data value.

Data Value - Must be an ASCII number. The absolute limits for this number are

–

1000000 to +1000000, but note that not all registers will accept this range.

Message Terminator - This is the last character, and must be either a '$' (dollar) or

an '*' (asterisk). Neither of these characters should be used elsewhere in the

PRO-TC-MAN-19V01 (0306) Copyright © 2019 Dene Instruments

Page 25

25

message string. If '$' is used, a 50ms minimum delay is inserted before a reply is

sent. If '*' is used, a 2ms minimum delay is inserted before a reply is sent.

Custom ASCII Read/Write Examples

Example Description

SR$ Read display value from all controllers, 50ms delay.

S15R$ Read display value from controller address 15, 50ms delay.

S3U40* Read unformatted data in channel 4 from controller address 3, 2ms delay.

–

S2W2 –10000$ Write

SWT CHAN_1$ Write ASCII text string Chan_1 to channel 1 text register, 50ms delay.

10000 to the display register of controller address 2, 50ms delay.

Custom ASCII Registers - Active for models with relay output installed

8 Bit Unsigned

Address Function

8207 Baudrate

8211 Serial address

8215 Serial mode

16 Bit Unsigned

Address Function

4181–

4184

4197–

4200

Note: Address 16543 is a read/write null

terminated text string, into which you can

write your own identication text (up to 62

characters).

Hysteresis (SP1=4181, SP2=4182,

SP3 =4183, SP4=4184)

Make delay (SP1=4197,

SP2=4198, SP 3=4199, SP4=4200)

32 Bit Signed

Address Function

7 Temperature CH 1

17 Temperature CH 2

19 Temperature CH 3

21 Temperature CH 4

39 Average temperature

57 Peak

59 Valley

111 Setpoint 1

113 Setpoint 2

115 Setpoint 3

117 Setpoint 4

239 Alarm status

381 D/A scale low value

405 D/A scale high value

Controller Response - Aer the controller has completed a read or write instruction,

it responds by sending a carriage return/line feed (CR/LF) back to the host. If

the instruction was a read command, the CR/LF follows the last character in the

PRO-TC-MAN-19V01 (0306) Copyright © 2019 Dene Instruments

Page 26

26

ASCII string. If it was a write command, CR/LF is the only response sent back.

The host must wait for this before sending further commands to the controller.

If the controller encounters an error, it will respond with a null (0x00) CR/LF.

A.2 - Modbus (RTU) mode

Modbus (RTU) is an industry standard RTU slave mode that allows connection to a

wide range of devices. Modbus registers are all holding registers, and should be ac-

cessed via function codes 3 and 6.

Register addresses are displayed in the Modicon™ 5-digit addressing format. I.e.

Register 65=400065 (subtract 1 for direct addressing).

Modbus (RTU) Registers - Active for models with relay output installed

8 Bit Unsigned

Address Function

408207 Baudrate

408211 Serial address

408215 Serial mode

16 Bit Unsigned

Address Function

404181–

404184

404197–

404200

Note: Address 416543 is a read/write null terminated text string, into which you can write

your own identication text (up to 62 characters). This is accessed using a standard Modbus

read/write command for holding registers, where each 16 bit register holds 2 x ASCII string

characters in sequence.

Hysteresis (SP1=404181, SP2=

404182, SP3=404183, SP4=

404184)

Make delay (SP1=404197, SP2=

404198, SP3=404199, SP4=

404200)

32 Bit Signed (2 x 16 Bit)

LSW MSW Function

400007 400008 Temperature CH 1

400017 400018 Temperature CH 2

400019 400020 Temperature CH 3

400021 400022 Temperature CH 4

400039 400040 Average temperature

400057 400058 Peak

400059 400060 Valley

40 0111 400112 Setpoint 1

400113 400114 Setpoint 2

400115 400116 Setpoint 3

400117 400118 Setpoint 4

400239 400240 Alarm status

40587 40588 D/A scale low value

40591 40592 D/A scale high value

PRO-TC-MAN-19V01 (0306) Copyright © 2019 Dene Instruments

Page 27

27

A.3 - Ranger A mode

Ranger A is a continuous output, used to drive remote displays and other instru-

ments in the Rinstrum™ range. (Ranger is a trade name belonging to Rinstrum Pty

Ltd.) Ranger A output strings are constructed as shown:

<Start> <Sign> <Output Value> <Status> <End>

Start - STX character (ASCII 02)

Sign - Output value sign (space for + and dash for -)

Output Value - Seven character ASCII string containing the current output value and

decimal point. (If there is no decimal point, then the rst character is a space.

Leading zero blanking applies.)

Status - Single character output value status. 'U'=Under, 'O'=Over, 'E'=Error.

End - ETX character (ASCII 03)

PRO-TC-MAN-19V01 (0306) Copyright © 2019 Dene Instruments

Page 28

De ne Instruments

New Zealand

(Head O ce)

Auckland 0632, New Zealand

Auckland 0661, New Zealand

Ph

Fax

www.de neinstruments.com

10B Vega Place, Rosedale,

PO Box 245 Westpark Village,

: +64 (9) 835 1550

: +64 (9) 835 1250

sales@de neinstruments.co.nz

PRO-TC MV3.4 Document Revision Code: PRO-TC-MAN-18V01 Date Code: 180410

United States (Dallas, TX)

Ph: (214) 926 4950

sales@de neinstruments.com

www.de neinstruments.com

Loading...

Loading...