Ghost Gunner 2

Operator’s Manual

An open source project by Defense Distributed

1 - Safety .................................................................................................................................................1

2 - Overview ...........................................................................................................................................2

3 - Unboxing .......................................................................................................................................... 3

3.1 - Packing List 4

4 - Software ............................................................................................................................................5

4.1.1 - Installing DDcut 5

4.1.2 - Using DDcut 5

4.1.3 - Inspecting .dd Files for Malicious Content 6

4.2 - Grbl 7

4.3 - Creating .dd Files 7

4.3.1 - Creating YAML Files 7

4.3.2 - Creating G-code 9

4.3.3 - Creating 3D Printable Jigs 9

4.1 - DDcut 5

5 - Hardware .........................................................................................................................................10

5.1 - Referencing the Machine 10

5.2 - Understanding the Work Coordinate System 10

5.3 - Spindle Operation 11

5.3.1 - Spindle g-code 12

5.4 - Installing a Work Piece 12

5.5 - Installing/Changing Tools 13

5.6 - Using the Probe 14

5.7 - Electrical Overview 15

6 - Maintenance ....................................................................................................................................17

6.1 - Removing Chip Accumulation: 17

6.2 - Protection from Rust 17

6.3 - Leveling X Axis 18

6.3.1 - Unbinding X Axis 18

6.4 - Resolving a Tripped Limit Switch 19

7 - FAQ ..................................................................................................................................................20

8 - RMA Policy .....................................................................................................................................22

9 - Specications ...................................................................................................................................23

Appendix A: Supported G-Code Commands ........................................................................................24

Appendix B: YAML Formatting ...........................................................................................................26

Appendix C: Individual Axis Labels .....................................................................................................27

Rev: A0609

1 - Safety

Ignorance is dangerous. Read and understand this manual prior to using Ghost Gunner.

The following precautionary statements are used throughout this manual:

Danger: Indicates a hazardous situation that will result in death or serious injury.

Warning: Indicates a hazardous situation that could result in death or serious injury.

Caution: Indicates a hazardous situation that could result in minor or moderate injury.

Notice: Indicates information considered important but not hazard related.

Warning: Crush hazard. Ghost Gunner’s gantry and table move with sufcient force to cut metal, and can

crush, pinch and tear body parts. Do not reach into Ghost Gunner except as indicated, AND only when

the machine is at a complete stop.

Warning: Extremely sharp rotating cutter inside. Secure spindle with wrench prior to servicing cutting

tool, following the procedure outlined in this manual.

Caution: Ghost Gunner is computer controlled and can start automatically whenever the USB cable is

powered. Keep hands away from all pinch points and cutting surfaces at all times, except as outlined in

this manual.

Caution: Never use a dropped, visibly damaged, dull, or suspect cutting tool, as it could shatter. End

mills are extremely brittle and should be discarded if dropped, as micro fractures could cause a latent

failure while the tool is in motion. Damaged tools can shatter into projectiles without warning.

Caution: The magnetic front entry guard is only intended to contain aluminum chips, and is not designed

to contain an improperly secured work piece or shattered end mill.

Caution: Always wear eye and ear protection when operating Ghost Gunner. Do not wear rings, watches,

necklaces, loose clothing, or long hair down while operating Ghost Gunner. Wear gloves when handling

parts and cleaning aluminum chips, but not while operating the machine.

Caution: Ghost Gunner does not have a dedicated hardware emergency stop button. Unplugging either

the USB or power cable will immediately stop Ghost Gunner. The software emergency stop button will

only work if Ghost Gunner has a valid USB connection to the host and the host processes the emergency

stop command. Due to the indeterminacy of modern operating systems, the software emergency stop

button is not guaranteed to stop Ghost Gunner in a reasonable time period, or at all if Ghost Gunner isn’t

enumerated as a USB device and communicating with the host software.

Caution: Ghost Gunner’s spindle and stepper motors generate considerable heat during operation and

remain hot for several minutes after unplugging. Prolonged contact with these components could result

in minor burn injuries.

Notice: Ghost Gunner is not a consumer device. It is the user’s responsibility to operate Ghost Gunner

per OSHA 1910.212 - Milling Machine, ANSI B11.8-1983, and OSHA 3067, as amended.

1

2 - Overview

Ghost Gunner is an open source CNC machine designed to machine aluminum objects. Where 3D printers

additively manufacture objects by depositing material in layers, Ghost Gunner subtractively manufactures objects

by cutting away material. Subtractive manufacturing is difcult because the machine must accurately determine

where a part is - without crashing into it - and remain rigid enough to physically cut away material with specic

geometry and tools.

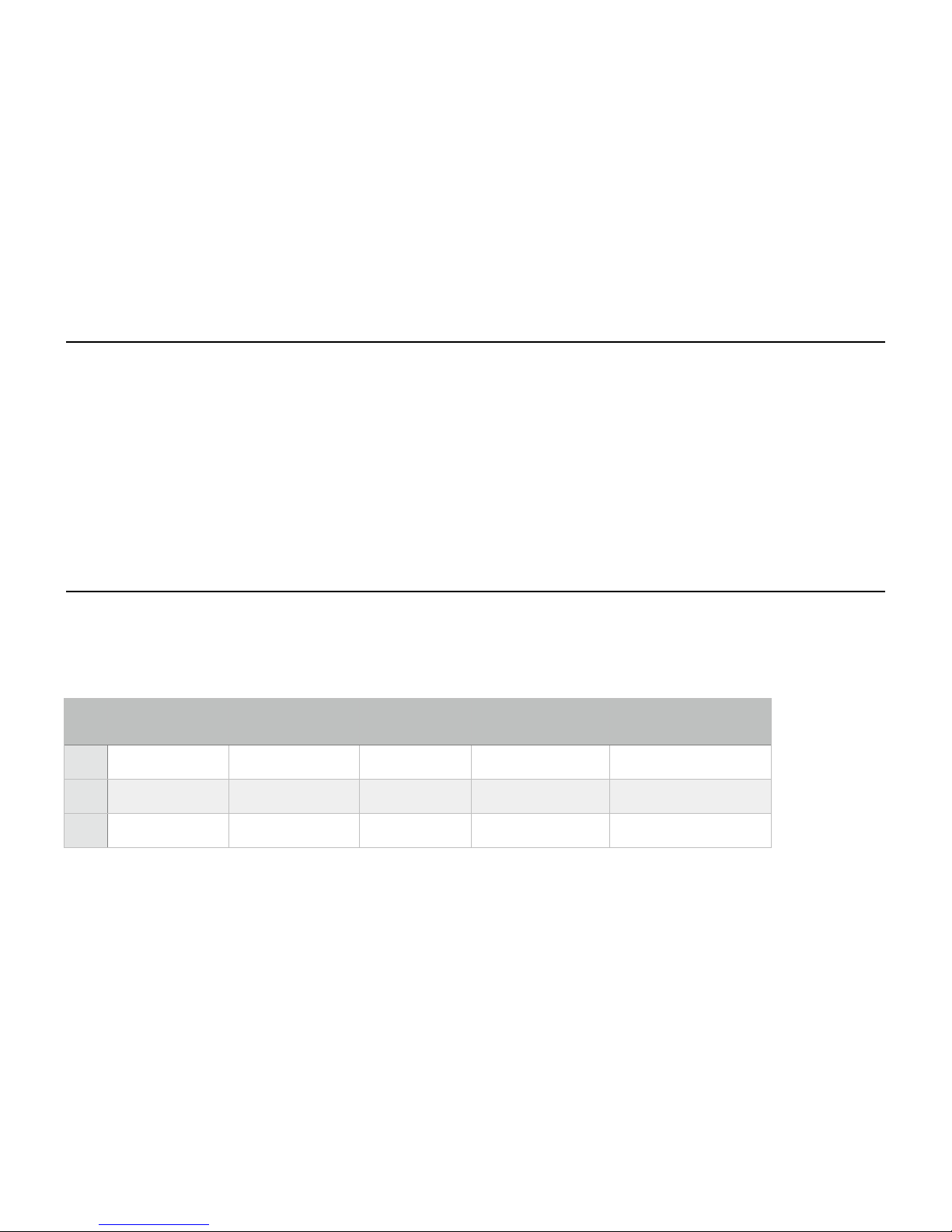

The following table highlights difculties inherent to subtractive manufacturing:

Additive Manufacturing

Difculty

Part Mounting Not required Vice, expensive jigs

Initial Geometry Not required Required to prevent crashing Programmed into .dd le

Part Probing Not required Separate probe

Machine Rigidity Not required Heavy frame Unibody exoskeleton

Cutting Tools Not required Various collet systems

Tool Path Creation Simple, Automated Extensive cutting knowledge

File Distribution Universal ‘.stl’ format Job/setup-specic ‘g-code’ Distributable ‘.dd’ le

(3D Printing)

Subtractive Manufacturing

(Traditional)

Subtractive Manufacturing

(Ghost Gunner w/ .dd le)

3D printable jigs

Contained within .dd le

Cutting tool used as probe

Programmed into .dd le

ER-11 collet system

Step-by-step setup

Extensive cutting knowledge

Programmed into .dd le

Ghost Gunner grew from the hope that experienced machinists might create and share ‘.dd’ les with a wider

layman community, which could replicate distributed .dd parts with minimal prior knowledge. This ecosystem

mirrors 3D printing’s ‘.stl’ le format: some community members possess the knowledge to create .stl les, yet

any community member with a 3D printer can create objects.

Why did we bother with difcult, subtractive CNC manufacturing? 3D printing is great for prototyping, but Ghost

Gunner creates objects equivalent to those traditionally available only through regulated commerce. Ghost

Gunner fullls the promise 3D printing dreams of tomorrow, today: easily building useful products in the privacy

of your own home, free from government intervention. Defense Distributed (DD) envisions a vibrant artisan

manufacturing community fueled by experienced members’ .dd creations.

Ghost Gunner’s design goal is to enable individuals to manufacture aluminum rearm receivers, with initial

support for the venerable AR-15 lower receiver. 3D printable jigs allow Ghost Gunner to mill nearly any aluminum

shape that can t within the machine’s build envelope. We leave the machine’s wider manufacturing direction to its

community.

Ghost Gunner strikes a balance between affordability, rigidity and usability, and is cheaper than most DIY CNC

kits. We believe Ghost Gunner is the most capable machine in its class, particularly since it includes many high

end features, including limit switches, electronic probing, and a custom-designed PWM-controlled BLDC spindle.

While Ghost Gunner is capable of manufacturing small run aluminum parts, please remember that Ghost Gunner

is not a high-end CNC mill.

We spent countless hours developing the Ghost Gunner concept. We want you to succeed in yours, so please don’t

hesitate to contact us with any questions, complaints of freedback at support@ghostgunner.net. Thank you for

supporting our experimental work, and helping to protect and advance the Second Amendment!

-Defense Distributed, February 2017

2

3 - Unboxing

Remove Ghost Gunner and all accessories from the shipping container. Keep the box for future transportation

needs; protecting a 50 pound steel box is difcult without specic packaging.

Notice: Do not lift Ghost

Gunner by the external

stepper motors. Applying

excessive force to the

stepper motors could

damage Ghost Gunner’s

linear accuracy and/or

electrical wiring. Lift

Ghost Gunner only via the

reinforced 1/4” side plates

or the machine bottom.

Place Ghost Gunner on a smooth surface in a shop environment conducive to stray aluminum chips. Ghost Gunner

must operate in the upright position to prevent chip ingress to sensitive linear components.

Connect Ghost Gunner to a grounded power outlet, then plug Ghost Gunner into a computer with the included

USB cable. Place the host computer some feet from Ghost Gunner to prevent stray chip entry.

Warning: To ensure continued safe operation, Ghost Gunner must connect to earth ground via a three-pronged

IEC power cord connected to a properly grounded outlet. Defeating the ground protection prong on the included

power cable poses an electrocution hazard. In the unlikely event that aluminum chips bridge the input line to the

chassis, a properly grounded Ghost Gunner will prevent the outer metal

enclosure from energizing by tripping an upstream Ground Fault Circuit Interrupt (GFCI), circuit

breaker, or fuse.

Notice: Ghost Gunner produces audible noises when powered and connected to a USB host. This is

normal behavior. See FAQ: “Why does Ghost Gunner make noise when the USB cable is plugged in?”

Notice: You may connect the power and USB cables in any order.

3

3.1 - Packing List

Part Quantity Reference

Ghost Gunner CNC 1

6’ three prong power cable 2

6’ USB A-B cable

DD USB drive

17mm wrench 1

12mm wrench 1

3mm ball-end allen wrench

5/16" hex allen wrench

ER11 collet nut

1

1

1

1

1

1

1 9

1 10

1 11

1 12

3 14

1

1

3

4

5

6

7

8

9

5

6

4

3

7

9

8

DD recommends the purchase of our jigs, lowers, frames, and tooling for an optimal experience: https://ghostgunner.net/

e following additional items are required to manufacture an 80% lower receiver:

Part Quantity

Mil-spec AR-15 lower receiver jig (four pieces) 1

1

*Receivers with non-mil-spec trigger guards - that are otherwise mil-spec - work if they don’t contact the T-slot.

4

4 - Software

Ghost Gunner’s embedded 328p microcontroller requires the open source Arduino driver for proper enumeration.

The simplest method to install the required driver is to run the “install.bat” le included with Ghost Gunner. An

alternate method to obtain the driver is to download and install Arduino IDE 1.0.5 or later: http://www.arduino.cc/en/

Main/Software

Once the driver is installed, Ghost Gunner is supported in three software environments:

Software

DDcut

Grbl

Operating

System

MacOS/

Windows

XP/7/8*

MacOS/

Linux/

Windows

Ease-of-Use Description

Automated ‘.dd’ les guide the user through the manufacturing process,

Simple

Advanced

including step-by-step instructions with illustrations to setup the part and

tools in the machine.

Manual ‘g-code’ les are created by experienced users, using concepts not

completely described herein. Finished code is packaged into .dd les for

distribution to other users, for use with DDcut.

*Linux support is in development, but not released as of 6/1/2016.

4.1 - DDcut

DDcut replaces arduous CNC concepts with step-by-step setup instructions and automated milling code. DDcut’s

simple software interface is solely designed to interpret ‘.dd’ les, allowing users to create predened objects

without part-specic manufacturing knowledge. DDcut doesn’t generate .dd les. See “4.3 - Creating .dd Files”for

le format requirements.

To simplify part replication, DDcut intentionally lacks many features:

Lacking Feature Rationale

No g-code command entry line Automated .dd les don’t require manual code entry

No manual jog/spindle control Automated .dd les don’t require manual code entry

No machine coordinate visibility Users don’t need to understand concept

No tool path visualizer Users don’t need to understand concept

4.1.1 - Installing DDcut

DDcut runs as a standalone Windows executable. No installation is required.

4.1.2 - Using DDcut

1. Launch DDcut.exe from the included USB ash drive and select a .dd le to manufacture. DD’s AR15.dd le

enables Ghost Gunner to manufacture mil-spec 80% AR-15 lower receivers. The AR15.dd le ships with Ghost

Gunner, and may soon be available - along with other .dd les - at ghostgunner.net.

Notice: DD recommends only running .dd les from trusted, veried sources. See “4.1.3 - Inspecting .dd

Files for Malicious Content” for more information.

2. If the selected .dd le contains 3D-printable jigs, DDcut prompts whether to export .stl les for printing. Ghost

Gunner ships with jigs for mil-spec AR-15 lower receivers; printing additional jigs isn’t required. See “4.3.4 Creating 3D Printable Jigs” for more information.

3. Follow onscreen instructions as required to manufacture the specied .dd part. DDcut automatically performs

probing and cutting operations as dened by the .dd le.

5

4.1.3 - Inspecting .dd Files for Malicious Content

Similar to software viruses, unknown .dd les can recongure Ghost Gunner to destroy itself. Such is the nature

of open source hardware/software. Before running .dd les on Ghost Gunner, DD recommends simulating the

g-code contained within suspect .dd les (e.g. with OpenSCAM, G-code Optimizer, etc). See “4.3 - Creating .dd

Files” for specics on obtaining g-code from within a .dd le.

Watch out for ‘$’ commands that reprogram Ghost Gunner’s behavior, including the following:

Command Example Behavior

$X $X

Allows gantry movement without homing, potentially crashing machine

$Nx=command $N0=$X

$n=x $23=0

Congures a command that runs each time Ghost Gunner connects to the host.

Modies Grbl conguration settings, changing machine behavior

The following commands are considered safe

Command Example Behavior

$H $H

$$ $$

$# $#

$G $G

$I $I

$Nn $N1

$C $C

? ?

homes the machine along Z, then XY axes

Displays Grbl settings

Displays probe, work coordinates and offsets

Displays parser state

Displays build info

Displays stored g-code that runs at startup (should return empty)

Modal g-code status

Displays current status

See “Appendix A: Supported G-Code Commands” for a complete programming reference!

Notice: To restore Ghost Gunner’s default settings, launch DDcut and run ‘DefaultGGSettings.dd’.

Hash functions ensure a le isn’t modied in transit, assuming the hash publisher is trusted. DD maintains a .dd

le hash list at https://ghostgunner.net/hash

Users wanting only to manufacture shipped .dd files can stop reading the manual here.

End of Manual Quick Start

6

4.2 - Grbl

Machinists and designers rejoice: Ghost Gunner uses the (excellent) open source Grbl motion controller, and

is 100% hardware and software compatible with that ecosystem’s many product offerings. Grbl allows Ghost

Gunner to operate as a standard CNC machine, accepting g-code from most CAM post-processors. Rather than

introducing another generic CNC controller, DD recommends using GrblController or GrblPanel to send gcode to

Ghost Gunner.

‘Grbl’ is often confused with, but isn’t:

-GrblController/GrblPanel: GUIs that send g-code to Grbl.

-grblshield (aka ‘gshield’): a hardware board that moves stepper motors.

-GrBLDC: a hardware board that controls brushless DC motors.

Grbl users must thoroughly understand the operating principals outlined in this manual. Ghost Gunner has no

brain and is entirely capable of destroying itself when programmed incorrectly. Numerous safeguards exist to

prevent damage, but in the spirit of open source development, those features can be easily modied or disabled.

Ghost Gunner will happily plunge a stationary end mill into a work piece at 30 ipm.

4.3 - Creating .dd Files

The .dd le format simplies part sharing amongst users. A .dd le is simply a .zip archive with the le extension

changed (for user clarity). A special “manifest.yml” le denes how the le contents are displayed to the user via

a series of step-by-step instructions (see “4.3.1 - Creating YAML Files”). A properly designed .dd le houses all

manufacturing les and user instructions required to make the contained part:

Housed File Type Purpose Required Format

Pictures

G-code

3D Printable Jigs

Part Model

Guide Files

Manifest

Display visual setup .BMP, .JPG

Automate machine cutting code Any ASCII text (extension irrelevant)

Create jigs, if needed .STL is most common (extension irrelevant)

Allow user to modify part/CAM g-code Any model le (extension irrelevant)

Supplemental instructions to user,

typically PDF.

Denes le presentation order to user. manifest.yml (lower case)*

Any le (extension irrelevant)

*File names are case sensitive inside .zip archives.

Once all les are created (as described in detail below), compress all items into a .zip container, change the le

extension from ‘.zip’ to ‘.dd’, and verify the le works as desired in DDcut.

4.3.1 - Creating YAML Files

A root-level “manifest.yml” le denes how DDcut presents each le to the user. The yaml le is editable in a

standard text editor, allowing experienced machinists to create .dd les without also requiring a programming

background. DD recommends Notepad++ for formatting assistance.

Folders within the .dd le are accessed with forward slashes: MyCodeFolder/MyAwesomeFile.txt

Folder and le names within .dd containers are cAsE SeNsItIvE.

Debug tip: Comment out ‘step_gcode’ commands from manifest.yml to verify the text and images display as

intended without actually milling the part.

7

The manifest.yml le contains the following building blocks:

Syntax* Description Example (user text)**

“- job_name: “

“job_text: “

“model_les: “

“guide_les: “

“job_steps: “

A ‘job’ contains all information required to

create a part. Most .dd les make a single

part, and thus contain a single ‘job’

Additional text shown when user selects a job

(optional) One or more les used to:

-create a 3D printed jig, and/or

-model the part

If called, the user can optionally save all les

to a user-specied directory, then 3D print

and/or modify

(optional) One or more les used to provide

supplemental information. If called, the user

can optionally save all les to a user-specied

directory, then access directly

A single list of step-by-step instructions

presented to the user to manufacture a part

- job_name: Mill AR15

#At least one job step

- job_name: Mill M16

#At least one job step

job_text: Manufacture AR15

model_les:

- stl/left_jig.stl

- stl/right_jig.stl

- stl/part.ipt

guide_les:

- PDF/lower_build.pdf

job_steps:

- step_name: Verify Empty

step_text: Is GG Empty?

step_image: IMAGE/1-Empty.

bmp step_gcode: Code/01_

Home.txt

- step_name: Home step_

text: Install nuts.

“step_name: “

“step_text: “

“step_image: “

“step_gcode: “

“timeout: “

“reset: “

“pause: “

Title text summarizing step action

Bulk text shown to the user during the step.

(ASCII text)

(optional) Path to image le displayed to user

during the step. (.BMP or .JPG)

(optional) Path to g-code le that executes

AFTER the user sees ‘step_image’/’step_text’,

then presses next

(optional, step must also contain ‘step_gcode’)

Seconds DDcut waits before returning an

error each time Ghost Gunner acknowledges a

command. Default is 40 seconds.

(optional, step must also contain ‘step_gcode’)

After the step completes, Ghost Gunner: False:

doesn’t reset (default)

True: resets, unreferencing the axes

(optional, step must also contain ‘step_gcode’)

When ‘step_gcode’ nishes executing:

False: DDcut automatically progresses to the

next step (default)

True: User must press next to progress to the

next step

- step_name: Verify Empty

step_text: Why was I

only created to destroy?

step_image: IMAGE/1A-Empty.bmp

step_gcode: Code/01_Home.txt

timeout: 80

reset: true

pause: true

*Note trailing spaces

**Examples assume the .dd le has root-level folders ‘stl’, ‘PDF’, ‘Code’, & ‘IMAGE’.

See “Appendix B: YAML Formatting” for complete formatting instructions

8

Example .dd File:

- job_name: Beer Bottle Opener

job_text: Manufacture an 80% Defense Distributed beer bottle opener.

job_steps:

- step_name: Verify Empty

step_text: Is GG Empty? Verify nothing is installed.

step_image: 01_Empty.jpg

step_gcode: 01_Home.nc

- step_name: Step2#This step doesn’t show a picture or execute code.

step_text: This step only displays this text (it’s so meta).

guide_les: #le save prompt at job beginning regardless of order

- exampleGuide1.pdf

model_les: #le save prompt at job beginning regardless of order

- exampleModel1.stl

4.3.2 - Creating G-code

Appendix A lists all g-code commands supported by Ghost Gunner.

Some CAM programs generate g-code that moves the cutting tool row-by-row across the part, raising and

lowering the Z axis as needed, but otherwise paying no heed to actual part geometry. These programs are suitable for

cutting wood and plastic, but do not fare well when cutting metal. DD recommends generating g-code only with CAM

programs that cut along part geometry with uniform radial engagement.

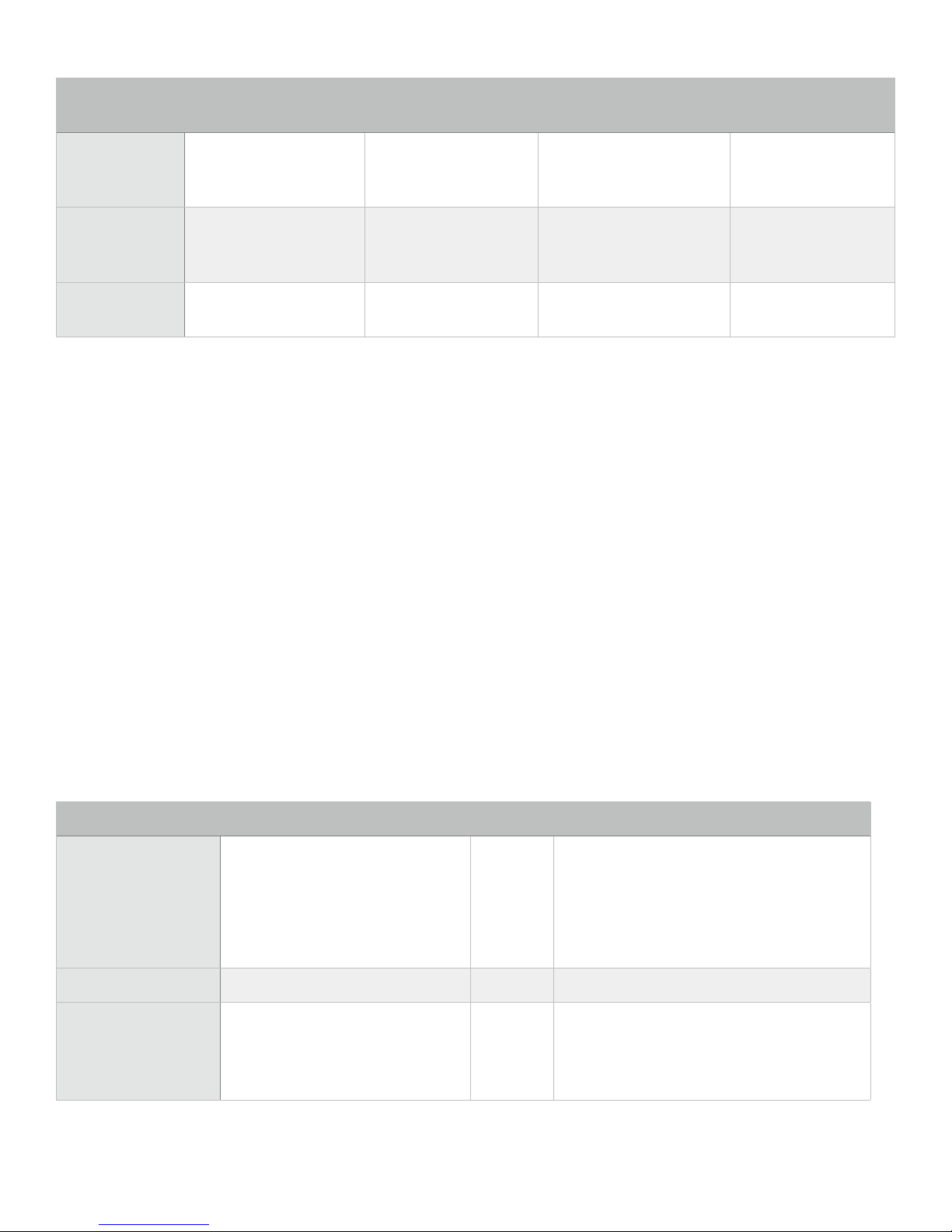

The following recommended starting parameters cut 7075-T6 aluminum:

Rough Slot Plunge Drill Finish Pocket

Revolutions per Minute 10,000 10,000 6,500 10,000 10,000

Method

Feed rate (mm/min), or

Ramp angle (°)

Depth of Cut (mm) 3.175 - 2.5 3.0 3.8

Step over (mm) 0.375 - - 0.200 0.300

Trochoidal

Climb

Helical

Climb

750 75 2.5 380 380

Peck Conventional

Trochoidal

Climb

25.4 mm equals 1 inch

4.3.3 - Creating 3D Printable Jigs

Distributing subtractively-manufactured designs is traditionally difcult due to the various xtures, clamping tools,

and/or vices required for each design and available to each user. 3D printing attempts to overcome these obstacles

by enabling each user to reliably reproduce the exact jigs used to secure a particular part, even if that part isn’t

rectangular. 3D printed jigs abstract alignment concepts from the user, enabling automated machine alignment to the

part.

3D printed jigs must hold the work piece rigid to prevent cutting vibration. Plastics are weak when tensioned,

torqued, or sheared, but remain rigid when compressed. Thus, jigs should attempt to contact as much surface area

as possible between the part and T-slot. Apply compression with bolts, but make sure neither the bolts nor the T- slot

contact the part if using the integral probe; see “5.6 - Using the Probe”.

9

5 - Hardware

Ghost Gunner is a three-axis desktop subtractive manufacturing machine primarily designed to cut aluminum and

other soft, non-ferrous metals. The machine can also cut plastic, wood, and other soft materials. Ghost Gunner is

not designed to cut steel, titanium, or other hard metals. Skilled machinists attempting to cut hard metals must use

small cutters to prevent overloading Ghost Gunner’s limited power, torque and rigidity limits. Ghost Gunner lacks a

lubrication system, which is required when cutting most hard metals.

Ghost Gunner’s unibody steel exoskeleton increases rigidity per unit weight, but Ghost Gunner is certainly less

rigid than an 800 pound industrial machine. Understanding that Ghost Gunner - like all CNC machines - will ex

proportional to an applied load is paramount to understanding its ultimate cutting abilities. While an 8000 pound

machine might 3” inch face aluminum at 0.150” DOC, Ghost Gunner would require several passes with a much smaller

cutter and less DOC to achieve the same task. As a hobbyist CNC machine, Ghost Gunner’s part throughput is less

critical than cost.

5.1 - Referencing the Machine

Ghost Gunner prohibits motion until the machine is referenced (a.k.a ‘homed’) to a limit switch on each axis. Software

limits are then used to prevent out-of-bounds motion that could damage the machine. Tools 3” or less can remain

installed while referencing. Remove tools over 3” before homing, as they won’t clear the T-slot plate. Parts can remain

installed while referencing as long as they don’t interfere with the fully retracted tool.

‘$H’ initiates the referencing routine, which rst retracts Z, then simultaneously moves the T-slot plate up and the

spindle right. Each axis is them pulled 1 mm from its limit switch. Grbl operates all three axes in negative space (i.e.

quadrant III operation). Once referenced, the software origin (0,0,0) is at the machine’s bottom (X+), right (Y

+), and rear (Z+). However, since the limit switches are located at X-/Y+/Z+, the machine position immediately after

homing is (-74,-1, -1).

5.2 - Understanding the Work Coordinate System

Ghost Gunner is designed to cut holes much deeper than most hobbyist CNC machines. Ghost Gunner uses a horizontal

spindle to prevent chip accumulation in deep pockets. The horizontal spindle also increases 3D printed jig rigidity. All

three axes operate in negative coordinate space and follow standard right hand rule nomenclature:

Absolute Range

(mm)

Axis

Z

-60.5 <= Z <= 0 -60.5 <= Z <= -0.2 Z = 0 ...tool away ...tool away

Y

-140 <= Y <= 0 -140 <= Y <= -0.2 Y = 0 ...tool right ...tool right

X

-75 <= X <= 0 -74.8 <= X <= 0 X = -75 ...T-slot down ...tool up

*Maintain a gap to prevent accidental limit switch tripping.

The gure at right shows physical axes movement. The Y & Z axes

physically move in the same direction as seen by the part. However, the

X axis physically moves in the opposite direction than is seen by the part.

The direction shown in the gure at right is the physical direction the T-slot

will move.

Appendix C contains larger labels that attach to the machine.

Recommended

Range* (mm)

Limit Switch

Location (mm)

Positive command

physically moves...

Positive command (as

seen by part) moves...

10

5.3 - Spindle Operation

Ghost Gunner’s custom-designed spindle operates between 4,000 and 10,000 rpm via a closed-loop current- limited

PWM signal. Spindle speed is constant unless the cutting bit is loaded beyond Ghost Gunner’s torque and/ or power

capabilities. Typical mechanical cutting power and torque curves are shown below:

Observation Rationale

Ghost Gunner has considerably less power and

torque than professional CNC machines

Ghost Gunner’s optimal speed is 7,000-9,000 rpm Maximum power delivered at 9,000 rpm

Cutting below 4,000 rpm isn’t recommended Cutting torque decreases below 4,000 rpm

Ghost Gunner rapidly loses cutting power and torque

above 9,000 rpm

Set spindle speed to 10,000 rpm to mill aluminum,

but assume speed is 9,000 rpm for speed calculations

Spindle won’t rotate below 2,800 rpm Motor doesn’t turn

Professional machines deliver kW+ cutting

power and foot-pound+ cutting torque

Back-EMF = Vin at 10,400 rpm, at which

point no additional energy enters the system.

Cutting torque rapidly drops above 9,300 rpm

The spindle requires a ve minute warmup period at full speed to warm the bearings prior to cutting. Attempting

to mill before the spindle is warm could trip Ghost Gunner’s overcurrent circuitry, as the spindle itself consumes

signicant power until reaching operating temperature. The following example code properly warms the spindle:

M3 S5000 (start motor)

G4 P1 (pause 1 second for speed)

S10000 (set motor full speed)

G4 P300 (wait 5 minutes. Note timeout period requirements)

Caution: The spindle operates at elevated temperatures and remains hot long after operation ceases. Do

not directly touch the spindle subassembly for at least 15 minutes following any cutting operation.

11

5.3.1 - Spindle g-code

Ghost Gunner supports the following spindle g-code commands:

Command Example Behavior

M3 M3

M4 M4

M5 M5

Sn S10000

Full scale spindle speed/direction changes can trip Ghost Gunner’s overcurrent protection circuitry. For example,

an instantaneous request to stop a spindle operating at 10,000 rpm requires the controller to short all three phases out,

generating a massive overcurrent condition. Ghost Gunner will lose reference if the X/Y/Z axes are moving when an

overcurrent condition occurs. The following example code limits current when stopping the spindle:

M3 (Turn spindle CW. Spindle won’t spin until ‘S’ is set)

S5000 (Run spindle at half speed)

G4 P1 (Pause for one second to allow spindle to speed up)

S10000 (Run spindle at full speed)

G4 P2 (Wait for spindle to reach full speed before cutting)

S5000 (Slow down spindle)

G4 P1 (Pause for one second to allow spindle to slow down)

S0 (Set spindle to 0 rpm)

M5 (Stop spindle)

Rotate spindle clockwise

Rotate spindle counterclockwise

Stop spindle

Run spindle at speed 0 <= n <= 10000

(Cutting code)

5.4 - Installing a Work Piece

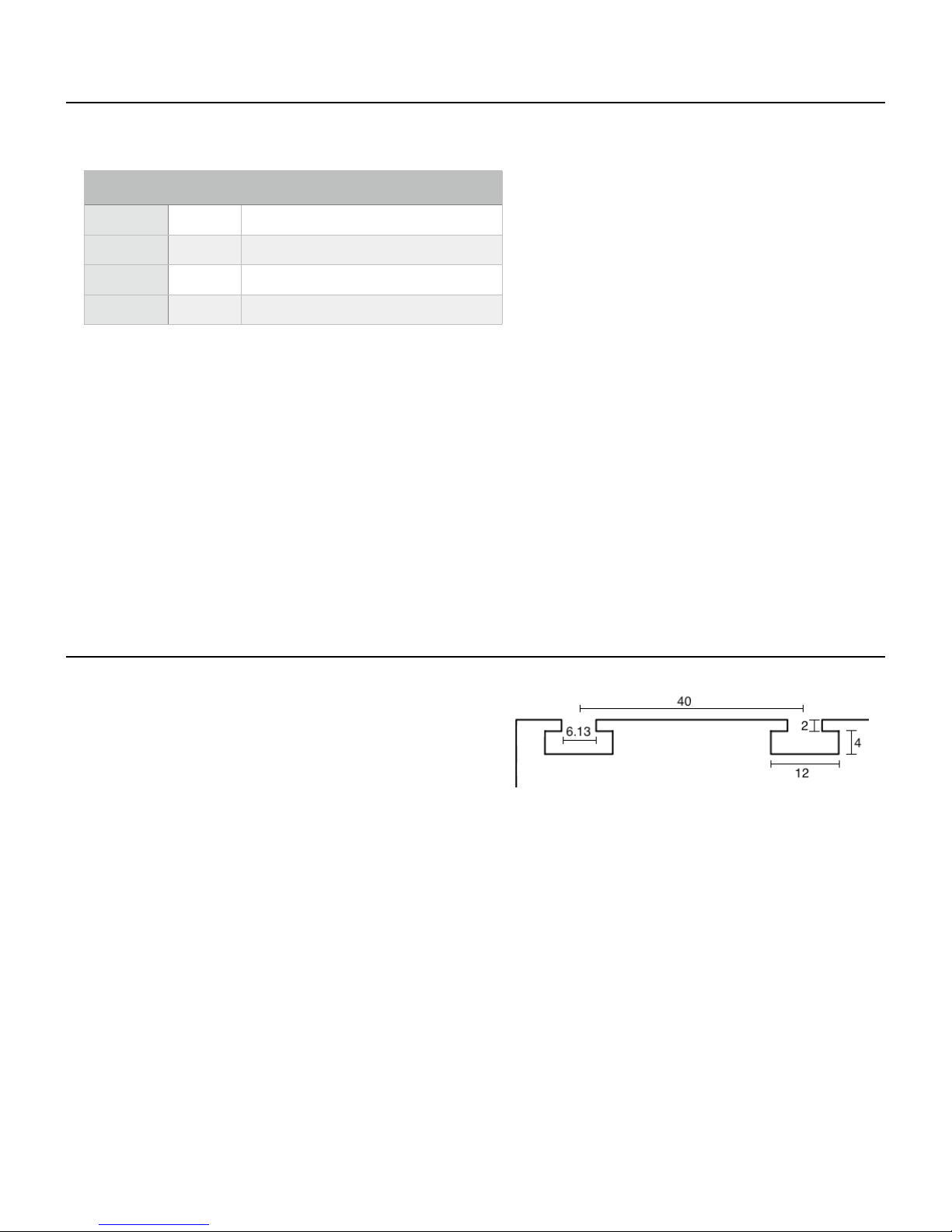

Ghost Gunner’s mounting plate consists of two T-slot rails

spaced 40mm apart. The T slot rail dimensions are compatible

with industry standard 20mm T-nuts. DD recommends at

least three mounting points when possible to reduce chatter.

Two mounting points are acceptable if the mounting jig has

sufcient width and an alignment groove, to prevent part

walking during milling.

Each T-slot rail has an opening on the left side to accept

T-nuts. Insert T-nuts bump-side down (shown at right).

Caution: Loose work pieces are projectiles when

struck by a high speed end mill. Ensure your

work piece is securely fastened prior to milling.

Notice: Loose work pieces dull end mills.

12

5.5 - Installing/Changing Tools

Ghost Gunner accepts industry standard ER11 collets.

Follow these instructions to change tools:

A). Remove the work piece, if required.

B). Center the Y axis and plunge the Z axis.

Example code:

G90 (absolute position)

G21 (mm units)

G53 G0 Z-1 (Retract Z)

G53 G0 X-1 (Move table down)

G53 G0 Y-70 (Center Y axis)

G53 G0 Z-60 (Plunge Z axis)

C). Place a 13 mm wrench onto the spindle’s spanner slot. Due to the spindle’s low torque, holding the wrench

in place prevents spinning if accidentally enabled.

Caution: If the spindle enables while the 13mm wrench is installed - but not retained in hand - then the

wrench could become a projectile.

D). Place a 17mm wrench onto the collet nut.

E). While holding the 13mm wrench stationary, force the 17mm wrench counterclockwise, thus loosening the

collet nut. Apply the force from one tool to the other, not directly into the spindle’s mechanical frame. The nut

will initially loosen, then tighten again. Keep turning the collet nut counterclockwise until it loosens again.

F). Remove the existing tool.

G). Remove the collet nut and verify the collet is clean. Aluminum chips inside the collet reduce gripping force

and increase runout.

H). If the replacement tool diameter differs from the existing tool, push the collet at an angle to remove it from

the nut, then press the new collet into the nut until it clicks.

I). Screw the collet nut a few turns onto the spindle, then insert the new tool into the collet. If the tool’s shank is

greater than 1”, slide the tool in as far as possible. Don’t fully insert a tool if the shank is less than 1”, as the

collet is only designed to crimp a solid cylindrical surface.

J). Tighten the collet by holding the 13mm wrench stationary while turning the 17mm wrench clockwise. Keep

tightening the nut until it is VERY tight. The ER11 collet is sufciently tight at 30 foot pounds of applied

torque, but unless you have a torque wrench, this number is useless; it is difcult to over tighten the collet nut.

Loose nuts allow the tool to walk while milling, which will ruin your work piece, your tool, and possibly your

machine.

K). Remove the 17mm wrench, then remove the 13mm wrench.

13

5.6 - Using the Probe

Ghost Gunner includes a built-in probe to zero the part to the machine. To use the probe, connect the red cable to the part,

then mount the part to the T-slot with an electrically isolated jig. The probe won’t work if the part electrically contacts the

T-slot plate, hence the use of 3D printable mounting jigs. Jigs included with Ghost Gunner properly isolate an AR lower

from Ghost Gunner; mounting bolts are isolated from the part and the part doesn’t electrically contact the T-slot.

The probe command returns X/Y/Z coordinates when the (grounded) tool contacts the (5 V) part. Ghost Gunner supports

G38.2 probing (probe toward workpiece, stop on contact, error if no contact). G38.3/4/5 isn’t supported.

Example probing code:

S3000 (spindle set to 3000 rpm)

M3 (turn spindle clockwise)

G91 (relative movement)

G21 (mm units)

G38.2 Y-10 F40 (probe Y axis up to -10 mm at 40 mm/min)

(Grbl returns X/Y/Z position)

G10 L20 P2 Y2.5 (zero Y axis to tool center, assuming 5 mm diameter)

The last line merits further explanation:

Command As used in example General Description General Syntax

G10 Set Work Coordinate System Set Work Coordinate System G10

P2 Use WCS G55* P1 through P6 correspond to WCS

G54 through G59, respectively

Y2.5 A 5mm tool contacts the part 2.5

mm from tool center (sign changes

depending on probe direction)

L20 Set current position of Y axis of

WCS G55 to 2.5 mm

One or more axes to set (X/Y/Z).

Only called axes are set

Set current position of specied axis

of specied WCS to specied value.

*Work coordinates are persistent until explicitly changed, even aer power-cycling.

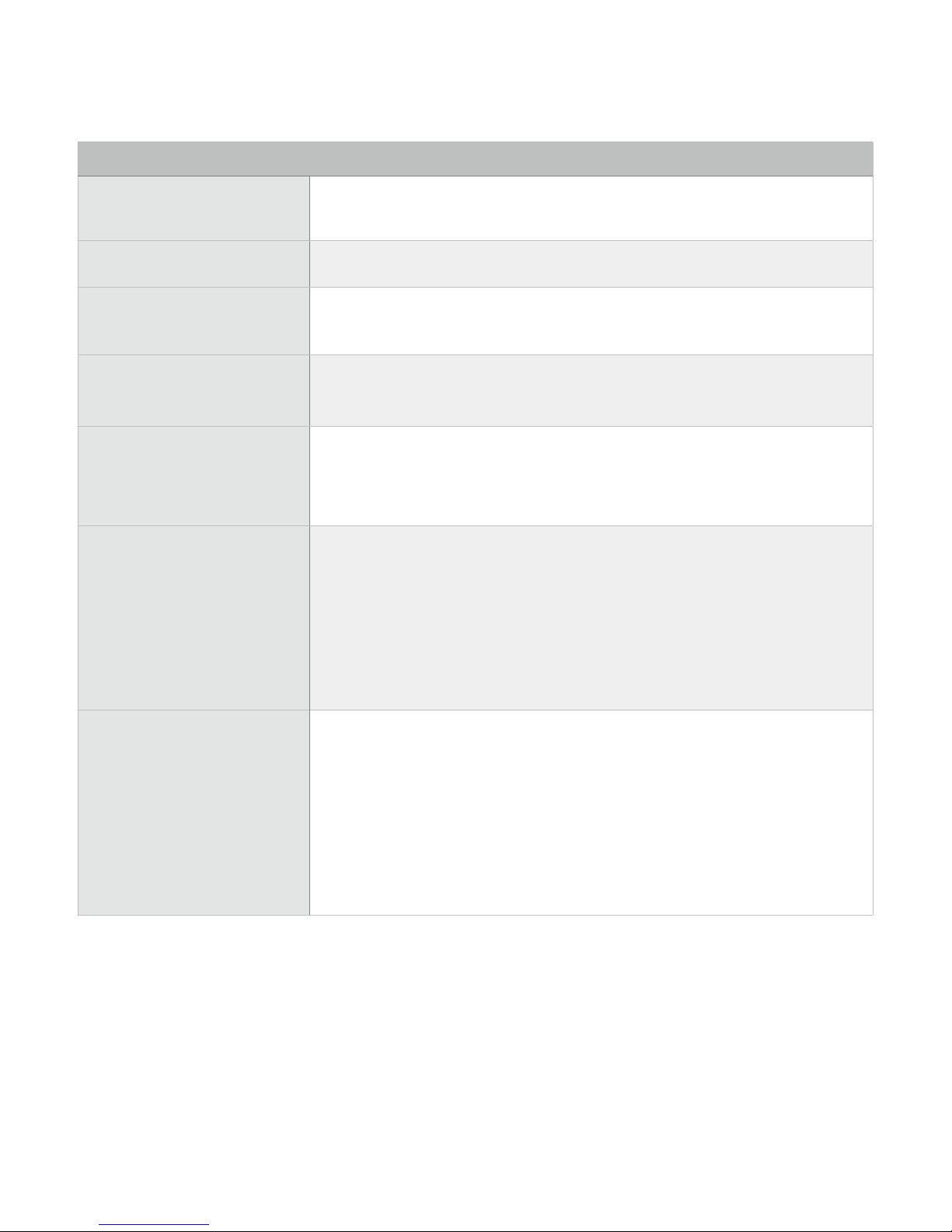

e following table summarizes potential probing outcomes:

Probe cable status when

probe command issued

Connected to part and

isolated from T-slot

Disconnected from part

and oating.

Shorted to T-slot (due to

chips, mounting, etc)

Result Hardware Outcome Software Outcome

Probed correctly Tool contacts part and stops Correct zero

determined

Tool contact with part

undetected (probe

remains high)

Ground short

detected

Tool stalls or mills into part

until reaching user-specied

maximum probing distance

No movement occurs Error, probe is shorted

Error, probe didn’t

contact part.

Reset required

to ground.

Reset required

Pn

1<=n<=6

Xn and/or Yn and/or Zn

n is a positive or negative

number within machine limits

L20

V

part-to-T-slot

4.5 to 5.5 V

0 V

0 V

Connected to part and

isolated from T-slot, but

tool too far from part

Connected to part and

isolated from T-slot, but

spindle rpm too fast

Tool never contacts

part

Tool contact time to

part insufcient to

trip probe.

*Measuring the voltage between the part and T-slot can uncover setup issues.

Tool moves to user-specied

maximum probing distance

Tool cuts aluminum until

either tripping or reaching

user-specied maximum

probing distance

Error, probe didn’t

contact part.

Reset required

Incorrect zero

determined (if probe

trips), or error (if

probe never trips)

4.5 to 5.5 V

4.5 to 5.5 V

14

e spindle must rotate while probing. A stationary tool’s contact radius isn’t constant because stationary tools

aren’t cylindrical. However, the probe circuit won’t trip if the spindle rotates too fast, due to a 110 kHz low pass lter that

prevents false tripping. Most metal cutting tools probe best around 3000 rpm. ere’s typically no advantage to probing at

higher rpm, except that anodized (aluminum oxide) part surfaces aren’t conductive, and thus the probe must tear through

that thin layer to contact the conductive aluminum below (dull tools will take longer). DD recommends lightly sanding

away anodization at each contact surface prior to probing.

e spindle is turning too fast if the end mill eats into an aluminum part before the probe trips; a properly

congured probe is sensitive enough to only microscopically cut the part before tripping. In fact, when properly

congured, repeated probing in the same location doesn’t introduce appreciable zero dri. Use the equations below to

determine maximum probing rpm:

CalculationE quationE xample* at 10000 rpm Example* at 3000 rpm

Tool Contact

Percentage

Contact

Percentage

per Tooth

Single Tooth

Contact Time

Minimum

contact time

Single Tooth Contact Time > 50us?N oY es

met?

*Example uses the Destiny Viper 0.250” end mill (included with Ghost Gunner).

It goes without saying, but the probe does not work on nonconductive parts. Traditional X/Y/Z touch-off methods

are of course supported - paper snagging, roller gauges, etc - but they’re not automated. One possible nonmetallic

probing method is to connect the probe cable to adhesive aluminum tape mounted on three surfaces (X/Y/Z). We leave

these implementations to the traditional machinist, as Ghost Gunner’s primary focus is automated aluminum machining.

DD advises creators to distribute aluminum parts to casual users, as the probe functionality is a vital simplication tool

to inexperienced users.

5.7 - Electrical Overview

Ghost Gunner contains the following power rails:

Rail Source Subsystems powered

24 V Wall-powered AC->DC converter Stepper motors, BLDC spindle motor, cooling fan

5 V USB host Limit switches, 328p uC, all I/O logic, motion control signals, probe

Ghost Gunner immediately ceases all motion if either rail is unpowered (i.e. the USB and/or power cables are

disconnected). e machine loses zero if move commands are sent while the 24 V rail is unpowered; the

soware-calculated position will update, but the motors won’t actually move. e host doesn’t know whether the 24 V rail

is powered. Ghost Gunner’s hardware can detect whether 24 V is present (via 328p pin A4), but that feature isn’t presently

implemented in soware.

Notice: To prevent crashing due to lost steps, immediately unplug the USB cable if move commands are

issued while the 24 V rail is unpowered. Reference Ghost Gunner prior to resuming movement.

15

Ghost Gunner contains three current-limiting circuits:

System

Monitored

Spindle Limits RMS

Steppers Motors are current

24 V Rail Short circuit (di/dt)

Reasons

Monitored

current! Prevents

overheating

controlled devices

Overcurrent (Imax)

Method Result Reset Required if

Current Limit Hit?

Spindle PWM

reduced

Controlled

by precision

reference circuit

Rail temporarily

disabled

Spindle slows down

until within current

limit

Steppers pull

constant current

24 V rail hiccups*

No

No

Ye s

As a safety feature, the following events will temporarily disable the 24 V rail:

-Aluminum chips short the 24 V rail to ground (the entire 24 V system is guarded from chips)

-Spindle stalls due to incorrect programming or incorrectly installed work piece

-Spindle starts or stops too quickly (see “5.3.1 - Spindle g-code” for proper coding technique)

-The cutting tool is dull/broken.

Notice: If the spindle stalls for any reason during a cutting operation, immediately stop milling by

unplugging the USB cable and assume the machine is no longer referenced.

*When overcurrent events occur, the 24 V rail turns off due to overcurrent, remains off for several seconds,

then turns back on. The cycle repeats if the overcurrent condition persists. If the overcurrent event is due to

spindle inrush current, either set the spindle speed to 0 rpm (‘S0’), or unplug the USB cable.

During an overcurrent event:

-the fan stops spinning

-the spindle stops spinning (if spinning)

-stepper motors stop moving (if moving)

Ghost Gunner is controlled by three PCBs:

PCB Function Firmware More Information

328p Uno-R3

compatible

microcontroller,

running Grbl

gShield (GG1 only) -Drives X/Y/Z stepper motors n/a github.com/synthetos/grblShield/wiki

GrBLDC -Drives spindle BLDC motor

-Communicates with host

-Interprets g-code

-Plans stepper motion

-Responds to probe

-Responds to limit switches

-Sends stepper pulses to gShield

-Generates spindle PWM signal

-Filters probe noise

-Filters limit switch noise

-Isolates gShield noise from 328p

-Fan/probe/limit connections

Custom

Grbl 1.0c

fork

n/a defdist.org

github.com/grbl/grbl

16

6 - Maintenance

Like most industrial machinery, Ghost Gunner requires periodic maintenance. With proper care, Ghost Gunner

should remain operational for many years. Some maintenance requires axes realignment to ensure the machine is

square. Ghost Gunner might not operate correctly if the machine isn’t properly aligned.

6.1 - Removing Chip Accumulation:

Routine vacuuming is the most important preventative maintenance. If allowed to accumulate, chips can work

past guards and then contact the sensitive linear rails and ball screws, reducing bearing life. Chips rapidly

accumulate while cutting; aluminum chips occupy approximately 15 times more space than the uncut solid. !

To simplify cleanup, Ghost Gunner lacks a lower panel. After milling, temporarily move the machine to another

location, then vacuum up aluminum chips. Vacuum inside the machine via the front entry access. Once most

chips are removed, tilt Ghost Gunner left to gain additional vacuuming access. The goal is to vacuum away as

many chips as possible to prevent contamination into sensitive components.

Notice: Do not use compressed air to clean Ghost Gunner. Ghost Gunner’s sensitive components are

gravity-sealed from aluminum chips. Blowing air into Ghost Gunner will force chips past the sealed

areas into sensitive components, decreasing Ghost Gunner’s useful life. !

Notice: Inverting Ghost Gunner prior to cleaning could allow chips to bypass gravity seals and contact

sensitive components. Thoroughly vacuum Ghost Gunner prior to inverting, shipping, or servicing.

6.2 - Protection from Rust

Ghost Gunner incorporates aluminum, steel, and stainless steel parts:

Material Protection Method Example Parts

Aluminum Inherent, aluminum corrodes to

stronger aluminum oxide

Stainless steel Chromium passivation Spindle

Powder coated steel Coating prevents oxygen from

contacting steel

Chrome plated steel Chromium passivation Shafts, ball screws

Black oxide bolts Oil-impregnated conversion coating Bolts

Chromoly steel None Y ange bearing housings

A few steel parts are unprotected from oxidation and will develop cosmetic rust if stored in a humid environment.

Parts with surface rust treatments will also oxidize if said treatment is compromised. As with other industrial

machinery, periodically applying a thin layer of oil will prevent cosmetic surface rust. Operate Ghost Gunner in a

climate controlled environment and prevent sudden temperature changes to reduce water condensate exposure.

Shaft Supports NEMA

mounts T-slot

Bearings

Enclosure

Plates

Spindle outer tube

17

6.3 - Leveling X Axis

The X axis is driven by two stepper motors and can unlevel when the machine is crashed hard; one stepper loses

steps, but not the other. The following example routine veries the X axis is level:

Command Description

G90 G21 G55

G53 G0 Y-70 X0

G53 G0 Z-60

G53 Y-0.5

G91 G0 X-0.1

G10 L20 P2 X0

G91 G0 X+3

G53 G90 G0 Y-140

G91 G0 X-0.1

$#

X axis leveling is required if X exceeds ± 0.1 mm.

Absolute mm movement in WCS G55

Position X & Y for 1/4” end mill installation

Plunge Z, then install 1/4” end mill

Move Y axis to machine right

Place a sheet of paper between tool and T-slot

Move X stage towards tool (relative)

(Repeat command until paper snags)

Zero X

Move X away from table (to prevent crash if unleveled)

Move Y axis to machine left

Move X stage towards tool (relative)

(Repeat command until paper snags)

Display WCS.

Adjustment not required if -0.1 <= X <= 0.1 mm

If X>0.1 mm (e.g. X = 0.5 mm):

Unplug the power cable, then rotate the left ball screw until the tool barely snags the paper. The left ballscrew is

accessed by slightly tilting Ghost Gunner. Verify the X axis is level by rerunning the above routine.

If X<-0.1 mm (e.g. X = -0.5 mm):

Move the Y axis right (‘G53 G0 Y-0.5’), unplug the power cable, then rotate the right ball screw until the tool

barely snags the paper. The right ballscrew is accessed by slightly tilting Ghost Gunner. Verify the X axis is level by

rerunning the above routine.

Notice: The Y & Z axes only use one stepper motor; leveling isn’t required on these axes.

6.3.1 - Unbinding X Axis

The X axis can bind if enough steps are lost during a crash, or if the machine is dropped or bent. If the axis binds:

A). Unplug the power.

B). Turn the X ball screws until they rotate smoothly. Smooth rotation should occur when the T-slot is

perpendicular to the X shafts.

C). Perform the “Leveling X Axis” procedure

If binding persists, contact DD for further guidance, or to create an RMA.

18

6.4 - Resolving a Tripped Limit Switch

Ghost Gunner enters an alarm state when a limit switch trips, preventing all movement, including referencing.

Tripped limit switches typically indicate something catastrophic occurred.

This procedure isn’t required on machines running the latest Ghost Gunner rmware. The latest rmware automatically

clears limit switch issues. We recommend upgrading your rmware rather than performing the steps outlined below.

To manually resolve a tripped limit switch:

Command Description

Determine which limit switch is tripped.*

Ctrl-x

$X

$20=0

Ctrl-x

$X

G91

G21

G0 X+1

or G0 Y-1

or G0 Z-1

Ctrl-x

$20=1

Ctrl-x

$H

Soft reset Grbl (ASCII code 24), or unplug and reconnect USB

Unlock Ghost Gunner**

Disable Soft Limits***

Soft reset Grbl (ASCII code 24), or unplug and reconnect USB

Unlock Ghost Gunner

Relative Movement

mm (Units)

Move away from limit switch on tripped axis. Moving an axis

closer to a tripped limit switch will destroy it.

Soft reset Grbl (ASCII code 24)****

Enable Soft Limits

Soft reset Grbl (ASCII code 24), or unplug and reconnect USB

Home machine.

*An LED on each limit switch illuminates when tripped. Limit switches are located:

Limit Switch Mounting Location Switch Contacts LED Visible

X

Y

Z

Enclosure

(behind right X ballscrew)

Y plate

(bottom right)

Y plate (rear

center)

**Allows movement without referencing. The machine remains unlocked for the remainder of the session.

***Soft limits prevent positive absolute movement (outside quadrant III), even when the machine is unlocked.

****Another reset is required because limit switches activate both when pressed AND when their state changes.

X plate

(front right corner)

Enclosure

(right side)

Z ballscrew mount

(rear)

Between T-slot and right

inner chip cover

Between gantry and right

inner enclosure

Above spindle when viewed at a

low angle

19

7 - FAQ

Q: Why does Ghost Gunner make noise when the USB cable is plugged in?

The stepper motors that position the X/Y/Z axes use microstepping to increase positioning resolution.

Microstepping uses two high current PWM waveforms to place the motor between two discrete phases. PWM

waveforms are variable frequency square waves. Square waves are mathematically innite sinusoidal sums,

resulting in audible noise.

Q: Why won’t the X stage move?

See “6.3.1 - Unbinding X Axis”.

Q: Why does Ghost Gunner keep starting and stopping?

If the machine is running known-good g-code, verify the tool isn’t worn out. As the parts wear, more energy is

required to perform the same cutting task. See “5.7 - Electrical Overview” for more information on how a dull

tool can trip the overcurrent safety feature. With proper care, the consumable end mill and drill that ship with

Ghost Gunner should manufacture numerous parts, but will eventually require replacement.

Q: Why did Ghost Gunner crash into the part while probing?

See “5.6 - Using the Probe” to verify the probe is properly connected.

Q: Why won’t Ghost Gunner respond to motion commands?

Make sure the power cable is plugged in and the fan is spinning. If Ghost Gunner still doesn’t move, see “6.4 Resolving a Tripped Limit Switch”.

Q: Why won’t Ghost Gunner work?

In the spirit of open source, DD encourages users to diagnose, troubleshoot and improve the machine as a

community. To obtain service, contact DD as described in our “RMA Policy” or email us at support@ghostgunner.net.

Q: Why does spindle motor pitch change during warmup?

Bearings are conceptually simple, but are actually quite complicated. Ghost Gunner’s spindle uses heavily

preloaded, press-t angular contact bearings to reduce runout. When the spindle is cold, non-uniform grease

viscosity and metal constriction intermittently combine to require more power than Ghost Gunner’s current-limited

PWM feedback loop is programmed to deliver. As the bearings heat, the metal expands and grease

viscosity decreases, thus decreasing power lost as friction. Human ears are incredibly sensitive to pitch changes,

but assuming the spindle is used within specication, the actual RPM value changes very little (less than 5%).

Q: How is spindle power measured?

Most manufacturers list their machine’s peak power consumption, which occurs only when power is rst applied

to a stationary motor. This gure is typically MUCH higher than the motor’s actual rated continuous power

consumption. For example, a certain ‘300 W’ spindle used in other machines overheats in under 15 minutes if

continuously loaded to 75 W using a dynamometer. Ghost Gunner’s specied power is the continuous cutting

energy transferable to the work piece, as measured by a dynamometer.

Q: Why are there two X stepper motors?

Ghost Gunner’s horizontal spindle conguration doesn’t allow a single, central linear X drive; the screw would

punch through the build platform. Placing a single drive screw at one edge reduces the other edge’s rigidity.

Thus, two ball screws are required (one at each edge).

Q: Why are there two stepper motors sticking outside the machine?

Ghost Gunner’s mechanical rigidity is derived from its compact, single-piece enclosure. Increasing the enclosure

dimensions (to encompass the Y & Z stepper motors) exponentially decreases overall rigidity. Note these motors

aren’t handles and are easily damaged. Also note the pinch points on either side of the Y (rear) stepper.

20

Q: Are non-conductive jigs required to mill parts?

To use the probe, the mounting method must not allow the part to conduct to the aluminum T-slot. 3D printed jigs are

easy to design and can secure nearly any part geometry, allowing probe use and distribution within .dd les.

Q: Why are all specications metric? This is America!

The metric system is nearly universally adopted because it’s better, namely when converting between units (e.g.

1000 mg = 1 g = 0.001 kg). But Ghost Gunner supports the Imperial system, too, via ‘G20’. To pay

homage to Eugene Stoner, Jim Sullivan, and Bob Fremont, the AR15.dd le is written in Imperial inches.

Q: Where is Ghost Gunner’s serial number?

Serial numbers permit government surveillance and abuse. Ghost Gunner doesn’t have a serial number, but it does contain certain universal identifying marks that we may use to verify a particular machine was of our manufacture.

Q: Just how open source is Ghost Gunner?

CC0 1.0 Universal (CC0 1.0) 2015 - 2017 Defense Distributed

All design les and models by Defense Distributed are licensed under Creative Commons Zero, which means you can

copy, modify, distribute and use the les for free, including for commercial purposes, without asking permission from or

providing attribution to Defense Distributed.

-The Product is provided “as is,” without warranty of any kind.

Incorporated hardware and software is sub-licensed under the terms of separate licenses, including:

-328p Uno Driver, Copyright 2012 Blacklabel Development, Inc.

-zlib and minizip

-Grbl(tm) v1.0 fork

Copyright (c) 2012-2014 Sungeun K. Jeon

Grbl v1.0 is free software: you can redistribute it and/or modify it under the terms of the GNU General Public

License as published by the Free Software Foundation, either version 3 of the License, or (at your option) any

later version.

Grbl v1.0 is distributed in the hope that it will be useful, but WITHOUT ANY WARRANTY; without even the

implied warranty of MERCHANTABILITY or FITNESS FOR A PARTICULAR PURPOSE. See the GNU

General Public License for more details.

You should have received a copy of the GNU General Public License along with Grbl v1.0.

If not, see <http://www.gnu.org/licenses/>.

A full list of hardware and software sub-licenses is available on the USB ash drive that ships with Ghost Gunner.

Q: Ghost Gunner is open source. Where can I nd ______?

DD makes every effort to publish content into the public domain. The US Government illegally asserts prepublication

approval authority over technical data it claims is directly related to “defense articles” as dened by the International

Trafc in Arms Regulations. DD distributes such content as is legally permitted. At present, DD can only send rearms-related .dd les to veried customers who are US persons.

Q: How is Ghost Gunner Assembled?

Meticulous assembly instructions are available at ghostgunner.net. DD advises against disassembling Ghost Gunner

unless required; proper axes alignment requires considerable time and effort.

Q: What’s the difference between a ‘jig’ and a ‘xture’?

As it pertains to metalworking:

-Fixtures hold parts stationary to allow cutting via moving tools.

-Jigs hold parts, but must also somehow mechanically guide cutting tools (e.g. via a lever, alignment race, etc).

However, the terms are used nearly synonymously in industry, with a prevalence towards ‘jig’. Thus, Ghost

Gunner (incorrectly) uses the term ‘jig’.

21

8 - RMA Policy

This RMA Policy applies to all customer requests for Return Merchandise Authorization (RMA), and is in

addition to those found in the Ghost Gunner Terms and Conditions of Sale (Terms of Sale). The Terms of Sale

take precedence and supersede this RMA Policy.

DD may modify this RMA Policy at its sole discretion from time to time. The most recent RMA Policy is

available at: Ghostgunner.net/terms/rma-policy.html

DD will not accept any product for service or repair without prior authorization, as evidenced by an RMA

Number. To receive an RMA Number, a Customer must:

-Request an RMA Application Form by emailing support@ghostgunner.net, and

-Fully complete the RMA Application Form to receive an RMA Number, and

-Include the completed RMA Application Form with all returned product, and

-Write the RMA Number on the outside of all shipping containers used to return product.

Non-functional/defective peripherals are considered separate items and are treated as a separate RMA. Customer

must only send nonfunctional products as described in the RMA Application Form used to create the RMA

Number. Do not return functional peripherals unless requested by DD.

An RMA Number is valid for sixty (60) days from issuance, at which time said RMA Number expires and is void;

DD must receive the returned product under said RMA Number within this sixty (60) day period.

DD IS NOT OBLIGATED TO ACCEPT ANY RETURNED PRODUCT not in compliance with DD’s RMA

Policy. SUCH PRODUCT MAY BE returned to CUSTOMER freight collect.

DO NOT SEND FIREARMS TO DD. DD is not licensed to accept rearms sent via courier, per 18 U.S.C.

922(a)(3) and 922(a)(1)(A). DD will legally dispose any received rearms.

DD products are sold without warranty. DD charges a at $200 Service Charge that covers all parts and labor

required to replace materials deemed defective through normal use. DD may, at its discretion and on a case-bycase

basis, offer to waive some or all incurred Service Charges. RMA repair work is not warrantied.

DD’s RMA Department will notify Customer prior to charging more than the Service Charge and will provide

Customer with an estimate regarding the cost of such service. DD reserves the right to charge the Customer for

parts, labor, and shipping expenses if DD determines that:

-Consumable components returned with product require replacement, or

-The cause for RMA was: misuse, abuse, alteration, improper installation, incorrect repair, negligence in

use, improper handling, or inadequate protection during transportation by any party other than DD, or

-The customer intensionally misrepresented information on the RMA Application Form to make it appear

that the product required RMA due to normal use, or

-No defect is found.

If no defect is found, DD will attempt to contact the Customer to obtain additional information to reproduce the

defect. If DD is unable to obtain further Customer information to reproduce the defect, DD will assume the

product is operating correctly and will return it without additional testing.

DD expects to ship serviced or repaired products within thirty (30) business days of receipt (Turn Around Time).

This Turn Around Time is an estimate; failure to repair or replace the product within Turn Around Time does not

breach this RMA Policy.

DD shall not be liable for any delay in performance directly or indirectly caused by or resulting from acts of

nature, re, ood, accident, riot, war, government intervention, embargoes, strikes, labor difculties, equipment

failure, late deliveries by suppliers, or other difculties which are beyond the control and without the fault or

gross negligence of DD.

22

9 - Specications

Parameter Value Unit Note

X/Y/Z travel 75/180/60.5 mm -

X/Y/Z table size 125/270/95 mm Larger X and Z dimensions possible depending on part geometry

Spindle Cutting Power 115 W Irms limited

Spindle speed 3000-10000 rpm Variable

Input Voltage 90-250 Vac -

Input Frequency 45-70 Hz Sinusoidal

Weight 23 Kg ~51 pounds

Shipping Weight 25 Kg ~55 pounds

T-slot spacing 40 mm Center-to-center

Table T-slots 2 QTY Compatible with 20 mm T-nuts

Collet system ER11 - Accepts tools up to 8 mm

Operating temperature 0-40 °C To prevent overheating

Relative Humidity 0-50 % To reduce oxidation

Max linear velocity 28 mm/s Simultaneous X/Y/Z Traverse

Max single-axis velocity 16 mm/s Software-limited

5 V current (max) 95 mA Can plug into unpowered hubs

24 V current (max) 185 W For 10 minutes

24 V current (continuous) 160 W -

23

Appendix A: Supported G-Code Commands

Supported g-code command summary (less used commands in gray):

Command Example Name Summary

Fn F10

G0 G0 X-2 Y-1

G1 G1 X-2 F1

G2

G3

G4 G4 P2

G10 L2 G10 P2 L2 X1

G10 L20 G10 P2 L20 X1

G17 G17

G18 G18

G19 G19

search online CW Arc Arc at specied Feed Rate in specied plane

search online CCW Arc Arc at specied Feed Rate in specied plane

Feed Rate Set maximum velocity on speed-limited commands. Unit = G20/21

Rapid Move Move as fast as possible in a straight line to the specied point

Linear Move Move at specied Feed Rate in a straight line to the specied point

Dwell Pause for specied period (seconds)

Set WCS point

Set WCS point

Set XY Plane Sets arc plane to XY

Set XZ Plane Sets arc plane to XZ

Set YZ Plane Sets arc plane to YZ

P1:P6 indicates which WCS - G54:G59 - to modify, respectively.

Set specied WCS axes to specied value based on machine

absolute origin, without movement (current position ignored).

Example sets WCS G55’s X axis 1 unit from machine absolute zero

P1:P6 indicates which WCS - G54:G59 - to modify, respectively.

Set specied WCS axes so current position becomes specied value,

without movement. Use to set WCS based on probed result.

Example sets current X position to 1 in WCS G55

G20 G20

G21 G21

G28 G28 Z-1

G28.1 G28.1

G30 G30 Z-1

G30.1 G30.1

G38.2 G38.2 X-2 F5

G53 G53 G0 X-2

G54

G55

G56

G57

G58

G59

G55 X-2

Unit = inch Set units to inches. Persists until G21 is called, or reset.

Unit = mm Set units to mm. Persists until G20 is called, default on reset.

Move to G28.1

via axes

Store nal G28

position

Move to G30.1

via axes

Store nal G30

position

Probe Probe towards part, stop on contact, error if no contact

Use Machine

origin

Work Offsets

‘WCS’

Move to specied position (in current WCS), then move to absolute

position stored in G28.1.

Example moves to Z-1 in the current WCS, then moves to G28.1

Store the current absolute position, for use by G28

Move to specied position (in current WCS), then move to absolute

position stored in G30.1

Example moves to Z-1 in the current WCS, then moves to G30.1

Store the current absolute position, for use by G30

Move in machine coordinates, regardless of active WCS.

G53 only applies to code on the same line (not persistent)

Work offsets dene an origin in relation to absolute machine zero.

Work offsets are persistent,

Use the origin dened in the specied work coordinate system

(persistent). See ‘G10’ to dene the origin. Example moves 2 units

from origin dened by WCS G55

24

Command Example Name Summary

G90 G90 X-2

G91 G91 X-2

G92 G92 X0Y0Z1

G92.1 G92.1

G93 G93

G94 G94

M3 M3

M4 M4 S5000

M5 M5

M8 M8

M9 M9

Absolute Move

Relative Move

Coordinate

Offset

Clear Offset Clear previously set G92 coordinate offset.

Minutes/Unit F interpreted as inverse feed rate

Units/Minute F interpreted as feed rate

Spindle CW Spin spindle CW at specied speed

Spindle CCW Spin spindle CCW at specied speed

Stop Spindle Stop the spindle, as specied in “Spindle Operation”

Enable Coolant Ghost Gunner supports coolant, but no system is installed

Disable Coolant Ghost Gunner supports coolant, but no system is installed

Move relative to current WCS. Example moves 2 units from origin

Move relative to current position. Example moves X axis 2 units

Source of epic misery, do not use; use WCS instead.

Set active WCS position as specied (without movement).

Modies all WCS axes to match calculated offset.

Unspecied axes aren’t modied.

Not stored in EEPROM, cleared when reset.

Example sets active WCS origin Z+1 from current position and

modies all WCS axes to match calculated offset.

M30 M30

M100 Un M100 X10

M101 Vm M101 X1

Sn S5000

End End program.

Before calling M30, stop spindle as per “Spindle Operation”

Verify

Remaining

Travel

Verify Delta

Between Points

Spindle Speed Set the spindle speed, as specied in “Spindle Operation”

(Supported in DDcut only)

Verify at least n distance is available on U axis between last probe

point and absolute machine limit. Alarm if n exceeds available

distance on U axis. Error if no probe has occurred.

M100 disregards unit mode; all arguments are in mm

(Supported in DDcut only)

Verify distance between the two most recent G38.2 probe results is

less than m along axis V. Alarm if calculated delta exceeds m.

Error if less than two previous probe operations have occurred.

M101 disregards unit mode; all arguments are in mm.

More Grbl-specic command information:

http://www.shapeoko.com/wiki/index.php/G-Code !

Grbl attempts to follow LinuxCNC’s g-code syntax and methodologies:

http://linuxcnc.org/docs/html/gcode/gcode.html !

Grbl conguration commands:

https://github.com/grbl/grbl/wiki/Conguring-Grbl-v0.9

25

Appendix B: YAML Formatting

YAML is a new-line-separated, space-delimited format:

Description Example

Subsequent lines are Children

if space-indented further than

the Parent line

Text following the pound

symbol (‘#’) is a Comment

Strings are simple text

data. Indicate a new line

with “\n”

Arrays are groups of named values

Lists are a group of

values indicated with a

“- “

(Note a space follows the dash)

List and Array items may

have String, Array, or List

Children

Parent:

Child:

NotChild:

#Comment

This is a string\nThis is on a new line

red: (value)

green: (value)

blue: (value)

- (value)

- (value)

- (value)

name1: this is a string value\nthis text is on a new line

name2: #a comment is placed here

child1: (value)

child2: (value)

child3: (value)

name3:

- (value)

- (value)

- (value)

Children of String, Array and

List items are allowed.

Lists of lists aren’t allowed

- this is a string value\nthis text is on a new line

- child1: (value)

child2: (value)

child3: (value)

#note a list of lists is never used in the manifest

- - (value)

- (value)

- (value)

26

Appendix C: Individual Axis Labels

Section “5.2 - Understanding the Work Coordinate System” creates an axis movement reference. If desired, cut

out these larger labels and tape them to Ghost Gunner.

Y-170 mm

Gantry Left

Z-60.5 mm

Towards Part

- Y +

- Z +

Y-1 mm

Gantry Lef

Z-1 mm

Away from part

t

X-75 mm

(T Slot Up)

Top of Machine Back of Machine Left of Machine

Physical T-slot Movement

X-0

( T Slot Down)

- X +

27

28

Loading...

Loading...