Configuration Parameters

– Module (Page 1)

101 Contrast 0 (%) 117 Use Module RPM

On (1)

, O

ff (0) 102 Fast Loading Enabled

On (1), Off (0) 118 Use Module Charge Alt

On (1)

, O

ff (0) 103 All Warnings Latched

On (1)

, O

ff (0) 119 Disable CAN Speed Control

On (1)

, O

ff (0) 104 Lamp Test At S

tartup On (1)

, O

ff (0) 120 CT Position Gen (0), Load(1)

105 Power Save Mode E

nable On (1)

, O

ff (0) 121 Gen

erator Voltage Display On (1)

, O

ff (0) 106 Deep Sleep Mode Enable

On (1)

, O

ff (0) 122 Mains Voltage Display On

(1)

, O

ff (0) 107 Protected Start Enable

On (1)

, O

ff (0) 123 Generator Frequency

Display On (1)

, O

ff (0) 108 Event Log Display F

ormat On (1)

, O

ff (0) 124 Mains Frequency Display

On (1), Off (0)

109 Power Up Mode

0 (Power Up Mode)

125 Current Display

On

(1), Off (0) 110 DTC String Enable

On (1)

, O

ff (0) 126 kW Display On (1), Off (0)

111 RESERVED

127 kVAr Display

On (1), Off (0)

112

Pin Protect

ed

Maintenance Reset

On (1), Off (0)

128 kVA Display On (1), Off (0)

113 Stop Button Cooldown

On (1)

, O

ff

(0) 129 pf Display On (1), Off (0)

114 Use Module Oil Pressure

On (1)

, O

ff (0) 130 kWh Display

On (1), Off (0)

115 Use Module Coolant Temp

On (1)

, O

ff (0) 131 kVArh Display

On (1), Off (0)

116 Use Module Engine Hours

On (1)

, O

ff (0) 132 kVAh Display

On

(1), Off (0)

Configuration Parameters

– CAN Application (Page 2)

201 CAN

Alternative Engine Speed

On (1), Off (0)

203 CAN ECU Data Fail Action

0 (Action) 202 CAN ECU Data Fail Enable

On (1), Off (0)

204 CAN ECU Data Fail Delay

0 s

Configuration

Parameters

– Digital Inputs (Page 3)

301 Digital Input A Source

0 (Input Source)

302 Digital Input A Polarity

0 (Polarity) 303 Digital Input A Action (If Source = User Config)

0 (Action) 304 Digital Input A Arming (If Source = User Config)

0 (Arming) 305 Digital Input A Activation Delay (If Source = User Config)

0 s 306 Digital Input B Source

0 (Input Source)

307 Digital Input B Polarity

0 (Polarity) 308 Digital Input B Action (If Source = User Config)

0 (Action) 309 Digital Input B Arming (If Source = User Config)

0 (Arming) 310 Digital Input B Activation Delay (If Source = User Config)

0 s 311 Digital Input C Source

0 (Input Source)

312 Digital Input C Polarity

0 (Polarity) 313 Digital Input C Action (If Source = User Config)

0 (Action) 314 Digital Input C Arming (If Source = User Config)

0 (Arming) 315 Digital Input C Activation Delay (If Source = User Config)

0 s 316 Digital Input D Source

0 (Input Source)

317 Digital Input D Polarity 0 (Polarity) 318 Digital Input D Action (If Source = User Config)

0 (Action) 319 Digital Input D Arming (If Source = User Config)

0 (Arming) 320 Digital Input D Activation Delay (If Source = User Config)

0 s 321-330 RESERVED

331 Analogue

Input A (Set As Dig

ital)

Source 0 (Input Source)

332 Ana

logue Input A (Set As Digital)

Polarity 0 (Polarity) 333 Ana

logue Input A (Set As Digital)

Action (If Source = User Config)

0 (Action) 334 Analogue Input A (Set As Digital) Arming (If Source = User Config)

0 (Arming) 335 Analogue Input A (Set As Digital) Activation Delay (If Source = User Config)

0 s 336 Ana

logue Input B (Set As Digital)

Source 0 (Input Source)

337 Analogue Input B

(Set

As Digital) Polarity 0 (Polarity) 338 Ana

logue Input B (Set As Digital)

Action (If Source = User Config)

0 (Action) 339 Analogue Input B (Set As Digital

)

Arming (If Source = User Config)

0 (Arming) 340 Analogue Input B

(Set As Digital) Activation Delay (If Source = User Config)

0 s 341 Analogue Input C (Set As Digital) Source

0 (Input Source)

342 Analogue Input C (Set As Digital) Polarity

0 (Polarity) 343 Analogue Input C (Set As Digital) Action (If Source = User

Config) 0 (Action) 344 Analogue Input C (Set As Digital) Arming (If Source = User Config)

0 (Arming) 345 Analogue Input C (Set As Digital) Activation Delay (If Source = User Config)

0 s

Configuration Parameters

– Outputs (Page 4)

401 Digital Output

A

Source 0 (Output Source)

407 Digital Output

D

Source 0 (Output Source)

402 Digital Output

A Polarity 0 (Output Polarity)

408 Digital Output

D Polarity 0 (Output Polarity)

403 Digital Output

B

Source 0 (Output Source)

409 Digital Output E Source

0 (Output Source)

404 Digital Output

B Polarity 0 (Output Polarity)

410 Digital Output E Polarity

0 (Output Polarity)

405 Digital Output

C

Source 0 (Output Source)

411 Digital Output F Source

0 (Output Source)

406 Digital Output

C Polarity 0 (Output

Polarity) 412

Digital Output

F Polarity 0 (Output Polarity)

Pressure Sensor List

Temperature Senor List

Percentage Sensor List

Index Type Index Type Index Type 0 Not used 0 Not U

sed 0 Not U

sed 1 Dig C

losed for A

larm 1 Dig Closed for A

larm 1 Dig

Closed for A

larm 2 Dig O

pen for A

larm 2 Dig Open for A

larm 2 Dig Open for A

larm 3 VDO 5 Bar 3

VDO 120 °C 3

VDO Ohm

(10-180) 4 VDO 10 Bar 4

Datcon H

igh 4 VDO T

ube (90-0) 5 Dat

con 5 Bar 5 Datcon Low 5

US Ohm

(240-33) 6 Datcon 10 B

ar 6 Murphy 6 GM Ohm (0-

90) 7 Datcon 7 Bar 7

Cummins 7 GM O

hm (0-30) 8 Murphy 7 Bar 8 PT

100 8 Ford (73-10) 9 CMB812 9 Veglia 9 User D

efined 10 Veglia 10 Beru 11 User D

efined 11 User D

efined

Configuration Parameters

– Timers (Page 5)

501 Mains Transient Delay

510 Return Delay

519 Delayed Load Output 2

502 Start Delay 511 Cooling Time

520 Delayed Load Output 3

503 Preheat Timer

512 ETS Solenoid Hold

521 Delayed Load Output 4

504 Crank Time 513 Failed To Stop Delay

522 Power Save Mode Delay

505 Crank Rest

Time 514 Generator Transient Delay

523 Deep Sleep Mode Delay

506 Smoke Limiting

515 Transfer Time

524 Page Timer 507

Smoke Limiting

Off 516 Breaker Trip

Pulse 525 Cooling Time at Idle

508 Safety On Delay

517 Breaker Close Pulse

509 Warm Up Time

518 Delayed Load Output

1 Configuration Parameters

– Generator (Page 6)

601 Alternator Fitted

On (1), Off (0)

620 Over Frequency Warning Enable

On (1), Off (0)

602 Alternator Poles 0 621 Over Frequency Warning Return

0.0 Hz 603 Under Voltage Shutdown

Enable On (1), Off (0)

622 Over Frequency Warning Trip

0.0 Hz 604 Under Voltage

Trip Shutdown

0 V 623 Over Frequency Shutdown Enable

On (1), Off (0)

605 Under Voltage

Warning Enable

On (1), Off (0)

624 Over Frequency Shutdown Trip

0.0 Hz 606 Under

Voltage Warning Trip

0 V 625 AC System 0 (AC

System) 607 RESERVED

626 CT Primary 0 A 608 Loading Voltage

0 V 627 Full Load Rating

0 A 609 Over Voltage Warning Enable

On (1), Off (0)

628 Immediate Over Current Enable

On (1), Off (0)

610 Over Voltage Warning Return 0 V 629

Delayed Over Current Alarm

Enable

On (1), Off (0)

611 Over Voltage Warning Trip

0 V 630 Delayed Over Current Alarm Action

0 (Action) 612 Over Voltage Shutdown Trip

0 V 631 Over Current Delay Time

0 s

613

Under Frequency Shutdown

Enable

On (1), Off (0)

632 Over Current Trip 0 %

614 Under Frequency Shutdown Trip

0.0 Hz 633 kW Rating 0 kW

615

Under Frequency Warning

Enable

On (1), Off (0)

634 Over kW Protection Enable On (1), Off (0)

616 Under Frequency Warning Trip

0.0 Hz 635 Over kW Protection Action

0 (Action) 617 RESERVED

636 Over kW Protection Trip

0 % 618 Loading Frequency

0.0 Hz 637 Over kW Protection Trip Delay

0 s 619 Nominal Frequency

0.0 Hz 638* Enable CT Support

On (1), Off (0)

Configuration Parameters

– Mains

(Page 7) 701 AC System 0 (

AC System) 709 O

ver Voltage Level

Trip 0 V 702 Mains Failure Detection

On (1), Off (0)

710 U

nder Frequency Enable

On (1), Off (0)

703 Immediate Mains Dropout

On (1), Off (0)

711 U

nder Frequency

Trip 0.0 Hz

704 U

nder Voltage

Enable On (1), Off (0

) 712 U

nder Frequency Return

0.0 H

z 705 U

nder Voltage Level

0 V 713 O

ver Frequency Enable

On (1), Off (0)

706 U

nder Voltage Return

0 V 714 O

ver Frequency Return

0 Hz

707 O

ver Voltage Enable

On (1), Off (0

) 715 O

ver Frequency

Trip 0.0 Hz

708 O

ver Voltage Return

0 V Configuration Parameters

– Engine (Page 8)

801 Start Attempts

0

817 Low Battery Voltage

Return 0.0 V 802 Over Speed Overshoot

0 % 818 Low Ba

ttery Voltage

Delay 0:00:00 803

Over Speed Delay

0 s 819 High Battery

Voltage Enable On (1)

, O

ff (0)

804

Gas Choke Timer

(Gas Engine Only)

0 s

82 0 High Battery Voltage Return 0.0 V

805

Gas On Delay

(Gas Engine Only)

0 s

82 1 High Battery Voltage Trip 0.0 V

806

Gas Ignition Off Delay

(Gas Engine Only)

0 s 82 2

High Battery

Voltage Warning

Delay

0 s

807

Crank Disconnect On Oil

Pressure Enable

On (1), Off (0)

823 Charge Alt Shutdown Enable On (1), Off (0)

808

Check Oil Pressure Prior To

Starting

On (1), Off (0)

824 Charge Alt Shutdown Trip 0.0 V

809 Crank Disconnect On Oil

0.00 Bar 825 Charge Alt Shutdown Delay

0 s 810 Crank Disconnect On Frequency

0.0 Hz 826 Charge Alt Warning Enable

On (1), Off (0)

811

Crank Disconnect On Engine

Speed

0 RPM 827 Charge Alt Warning Trip 0.0 V

812 Under Speed Enable

On (1), O

ff (0) 828 Charge Alt Warning Delay

0 s 813 Under Speed Trip

0 RPM 829 Low Battery Start Arming

On (1), Off (0)

814 Over Speed Trip

0 RPM 830 Low Battery Start Threshold

0.0 V 815 Low Battery Voltage

Enable On (1

), O

ff (0) 831 Low Battery Start Delay

0 s 816 Low

Battery Voltage

Trip 0.0 V 832 Low Battery Start Run Time

0 s

Sensor Type AC System

Digital Input Alarm

Arming

Power Up Mode

Index Type Index Type Index Arming Index Mode 0 None 0 2 Phase 3 Wire (L1

-

L2) 0 Always 0 Stop 1 Digital Input 1 2 Phase 3

Wire (L1-L3) 1 From Safety On

1

Manual 2 Percentage Sensor

2

3 Phase 3 Wire

2

From Starting

2

Auto 3 Pressure

Sensor 3 3 Phase 4 Wire

3

Never 4 Temperature Sensor

4

3 Phase 4 Wire (Delta)

5 Single Phase 2 Wire

Digital Input Polarity

Output Polarity

Alarm Action

Index Polarity Index Polarity Index Action 0 Close to Activate

0

Energise 0 Electrical Trip

1

Open to Activate

1 De-

Energise 1 Shutdown 2 Warning

Configuration Parameters

– Analogue Inputs (Page 9)

901 Analogue Input A

Senor

Type 0 (Sensor Type)

902 Analogue Input A Sensor Selection

0 (Pressure Sen

s

or List)

903 Low Oil Pressure

Enable On (1)

, O

ff (0) 904 Low Oil Pressure Trip

0

Bar 905 Oil Pressure Sender O

pen Circuit On (1)

, O

ff (0) 906 Analogue Input B

Senor

Type 0 (Sensor Type)

907 Analogue Input B Sensor Selection

0 (Temperature

Sensor List)

908 High Engine Temperature

Trip 0.00 °C 909 Temperature Sender O

pen Circuit On (1)

, O

ff (0) 910 Analogue Input C Sensor Usage

Flexible Sensor

(1)

, Fuel Level

Sensor

(0) 911 Analogue Input C

Senor

Type 0 (Sensor Type)

912 Analogue Input C Sensor Selection

0 (Pressure /

Temp

erature /

Percentage Sen

s

or List)

913 Flexible Sensor C Arming

0 (Arming) 914 Flexible Sensor C Low

Alarm Action 0 (Action) 915 Flexible Sensor C

Low

Alarm Trip 0 % / Bar / °C

916 RESERVED

917 Flexible Sensor C

Low Pre-Alarm Enable

On (1)

, O

ff (0) 918 Flexible Sensor C

Low Pre-Alarm Trip 0 % / Bar / °C

919 Flexible Sensor C

Low Pre-Alarm Return

0 % / Bar / °C

920 RESERVED

921 Flexible Sensor C

High Pre-Alarm Enable

On (1)

, O

ff (0) 922 Flexible Se

nsor C High Pre

-

Alarm Return

0 % / Bar / °C

923 Flexible Sensor C

High Pre-Alarm Trip 0 % / Bar / °C

924-925 RESERVED

926 Flexible Sensor C

High Alarm Action

0 (Action) 927 Flexible Sensor C

High Alarm Trip

0 % / Bar / °C

928-929 RESERVED

930 Fuel Sensor C

Low Shutdown Enable

On (1)

, O

ff (0) 931 Fuel Sensor C

Low Shutdown Trip

0 % 932 Fuel Sensor C

Low

Shutdown Delay 0 s 933 Fuel Sensor C

Low Pre-Alarm Enable

On (1)

, O

ff (0) 934 Fuel Sensor C

Low Pre-Alarm Trip 0 % 935 Fuel Sensor C

Low Pre-Alarm Return

0 % 936 Fuel Sensor C

Low

Pre-Alarm Delay 0 s 937 Fuel

Sensor C

High Pre-Alarm Enable

On (1)

, O

ff (0) 938 Fuel Sensor C

High Pre-Alarm Return

0 % 939 Fuel Sensor C

High Pre-Alarm Trip 0 % 940 Fuel Sensor C

High Pre Alarm Delay

0 s 941 RESERVED

942 Fuel Sensor C

High Alarm

Action 0 (Action) 943 Fuel Sensor C

High Alarm Trip

0 % 944 Fuel Sensor C

High Alarm Delay

0 s

Configuration Parameters

– Scheduler (Page 10)

1001 Enable Scheduler

On (1), Off (0)

1002 Schedule Run

On or

Off Load On (1), Off (0)

1003 Scheduler

Period Weekly(0), Monthly(1)

1004, 1008, 1012, 1016, 1020, 1024, 1028,

1032 Start Time (Entry 1-8) 0:00:00 1005, 1009, 1013, 1017, 1021, 1025, 1029,

1033 Day (Entry 1-8) 0 (1=Monday)

1006, 1010, 1014, 1018, 1022, 1026, 1030,

1034 Week (Entry 1-8) 1, 2,

3 or 4 1007, 1011, 1015, 1019, 1023, 1027, 1031,

1035 Duration (Entry 1-8) 0 s

Configuration Parameters

– Time (Page 11)

1101 Time of Day

0:00:00 1104

Day of Month

1-31

1102 Day of Week

0 (1=Monday)

1105 Month of Y

ear 1-12 1103 Week of Year

1-52 1106 Year 0-99

Configuration Parameters

– Maintenance Alarms (Page 12)

1201 Oil Maintenance Alarm Enable On (1), Off (0) 1206

Air

Maintenance Alarm

Engine

Hours

0 h

1202 Oil

Maintenance Alarm

Action 0 (Action) 1207 Fuel

Maintenance Alarm Enable

On (1), Off (0)

1203

Oil

Maintenance Alarm

Engine

Hours

0 h 1208 Fuel Maintenance Alarm Action 0 (Action)

1204 Air Maintenance Alarm Enable On (1), Off (0) 1209

Fuel

Maintenance Alarm

Engine

Hours

0 h

1205 Air

Maintenance Alarm

Action 0 (Action)

x Functionality in all DSE4510 & DSE4520 variants

. x Functionality in all DSE4520 variants

. x Functionality in DSE4510 & DSE4520 current sensing variants only

x

Functionality in DSE4510 & DSE4520 RT & RTH variants only

. x* Functionality in DSE4510 &

DSE4520 RT & RTH variants only with version 1.6.71 and later.

Configuration Parameters

– Alternate Configuration (Page 20)

2001 Default Configuration On (1), Off (0) 2028

Delayed Over Current Alarm

Action

0 (Action)

2002 Enable Configuration

On (1), Off (0)

2029 Over Current Delay

00:00:00 2003 CAN Alternative Engine Speed

On (1), Off (0)

2030 Over Current Trip

0 % 2004 Under Voltage Shutdown Enable

On (1), Off (0)

2031 Generator kW Rating

0 kW 2005 Under Voltage Shutdown Trip

0 V 2032 Overload Protection Enable

On (1), Off (0)

2006 Under Voltage Warning Enable

On (1), Off (0)

2033 Overload Protection Action

0 (Action) 2007 Under Voltage Warning Trip

0 V 2034 Overload Protection Trip

0 %

2008 Loading Voltage 0 V 2035

Overload Protection Trip

Delay

0 s

2009 Over Voltage Warning Enable

On (1), Off (0)

2036 AC System 0 (AC system)

2010 Over Voltage Warning Return

0 V 2037 Mains Failure Detection

On (1), Off (0)

2011 Over Voltage Warning Trip

0 V 2038 Immediate Mains Dropout

On (1), Off (0)

2012 Over Voltage Trip

0 V 2039 Mains Under Voltage Enable

On (1), Off (0)

2013

Under Frequency Shutdown

Enable

On (1), Off (0)

2040 Mains Under Voltage Trip 0 V

2014 Under Frequency Shutdown Trip

0.0 Hz 2041 Mains Under Voltage Return

0 V

2015

Under Frequency Warning

Enable

On (1), Off (0)

2042 Mains Over Voltage Enable On (1), Off (0)

2016 Under Frequency Warning Trip

0.0 Hz 2043 Mains Over Voltage Return

0 V 2017 Loading Frequency

0.0 Hz 2044 Mains Over Voltage Trip

0 V

2018 Nominal Frequency 0.0 Hz 2045

Mains Under Frequency

Enable

On (1), Off (0)

2019 Over Frequency Warning Enable

On (1), Off (0)

2046 Mains Under Frequency Trip

0.0 Hz

2020 Over Frequency Warning Return 0.0 Hz 2047

Mains Under

Frequency

Return

0.0 Hz

2021 Over Frequency Warning Trip

0.0 Hz 2048 Mains Over Frequency Enable

On (1), Off (0)

2022

Over Frequency Shutdown

Enable

On (1), Off (0)

2049 Mains Over Frequency Return 0.0 Hz

2023 Over Frequency Shutdown Trip

0.0 Hz 2050 Mains Over Frequency Trip

0.0 Hz

2024 CT Primary 0 A 2051

Under Speed Shutdown

Enable

On (1), Off (0)

2025 Full Load Rating

0 A 2052 Under Speed Shutdown Trip

0 RPM 2026 Immediate Over Current

On (1), Off (0)

2053 Over Speed Shutdown Trip

0

RPM 2027 Delayed Over Current Alarm

On (1), Off (0)

Output Sources

0

Not Used 33 Fuel Relay 66 Flexible Sender

C

High

Alarm 1 Air Flap Relay

34

Gas Choke On

67

Flexible Sender

C

Low

Pre-Alarm 2 Audible Alarm

35

Gas Ignition 68 Flexible Sender

C

Low

Alarm 3 Battery Over Volts Warning

36

Generator Available

69

RESERVED 4 Battery Under Volts Warning

37

Generator Over Voltage Shutdown

70

RESERVED

5 CAN ECU Data Fail 38

Generator Under Voltage

Shutdown

71

RESERVED

6 CAN ECU Error

39

kW Overload Alarm

72

RESERVED 7 CAN ECU Fail

40

Over Current Immediate Warning

73

Fuel Sender

High

Alarm 8 CAN ECU Power

41

Delayed Over Current Trip Alarm

74

Fuel Sender

High

Alarm

9

CAN ECU Stop 42

High Coolant Temp

erature

Shutdown

75

Fuel Sender Low Pre-Alarm

10 Charge Alternator Shutdown

43

Low Oil Pressure

Shutdown 76 Fuel Sender

Low

Alarm 11 Charge Alternator Warning

44

Mains High Frequency

77

Delayed Load Output 1

12

Close Gen Output

45

Mains High Voltage

78

Delayed Load Output 2

13

Close Gen Output Pulse

46

Mains Low Frequency

79

Delayed Load Output 3

14

Close Mains Output

47

Mains Low Voltage

80

Delayed Load Output 4

15

Close Mains Output Pulse

48

Oil Pressure

Sender

Open Circuit

81

Air Filter Maintenance Output

16

Combined Mains Failure

49

Open Gen Output 82 Oil Filter Maintenance Output

17

Common Alarm

50

Open Gen Output Pulse

83

Fuel Filter Maintenance Output

18

Common Electrical Trip

51

Open Mains Output

84

System In

Stop Mode 19 Common Shutdown

52

Open Mains Output Pulse

85

System In

Auto

Mode 20 Common Warning

53

Over Frequency Shutdown

86

System In Manual

Mode 21 Cooling Down

54

Over Speed Shutdown

87

RESERVED 22 Dig

ital Input A 55 Preheat During Preheat Timer

88

Analogue Input A (

Digital) 23

Dig

ital Input B 56 Preheat Until End Of

Crank 89 Analogue Input B (Digital

) 24 Dig

ital Input C 57 Preheat Until End Of Safety Timer

90

Analogue Input C (Digital

) 25 Dig

ital Input D 58 Preheat Until End Of Warming

91

RESERVED 26 RESERVED 59 Smoke Limiting

92

RESERVED 27 RESERVED 60 Start

Relay 93 RESERVED 28 RESERVED 61 Temp

erature Sender Open Circuit

94

RESERVED 29 Emergency Stop

62

Under Frequency Shutdown

95

Over Speed Overshoot

30

Energise To Stop

63

Under Speed Shutdown

96

Over Frequency Overshoot

31

Fail To Start

64

Waiting For

Manual Restore

97

Display Heater Fitted and Active

32

Fail To Stop 65 Flexible Sender

C

High

Alarm

Input Sources

0

User Configured

9

External Panel Lock

18

Simulate Stop Button

1

Alarm Mute 10 Generator Load Inhibit

19

Simulate Auto Button

2

Alarm

Reset 11 Lamp Test 20 Simulate Start Button

3

Alternative Configuration

12

Low Fuel Level Switch

21

Smoke Limiting

4

Auto Restore Inhibit

13

Mains Load Inhibit

22

Close Generator Open Mains 5 Auto Start Inhibit

14

Oil Pressure Switch

23

Close

Mains

Open

Generator 6 Auxiliary Mains Fail

15

Remote Start Off Load

24

Maintenance Reset Oil

7

Coolant Temperature Switch

16

Remote Start On Load

25

Maintenance Reset Air

8 Emergency Stop 17

Simulate Mains

Available

26 Maintenance Reset Fuel

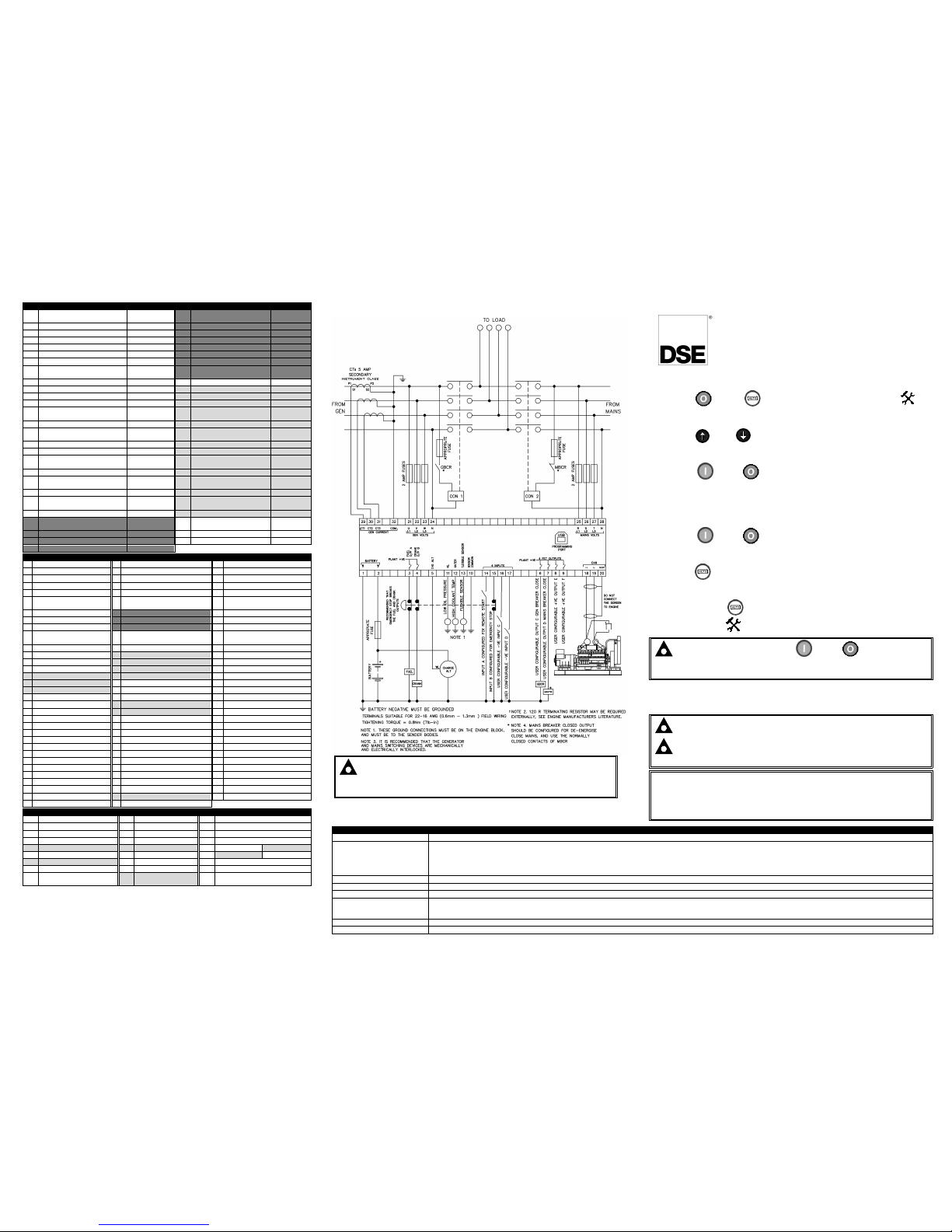

TYPICAL WIRING DIAGRAM

NOTE: A larger version of the typical wiring diagram is included in

the products operator manual. Refer to DSE Publication:

057-171 DSE4510 & DSE4520 Operators Manual

053-157 Issue 2

DEEP SEA ELECTRONICS PLC

DSE4510 & DSE4520 Installation Instructions

Applicable to module version 1.4.46 and upwards.

EDITING A PARAMETER

• Press the (

-

) and () buttons together to enter the editor

mode.

• Press the (up) or (down) navigation buttons to cycle through the

front panel editor in increments of 100.

• Press the (

+

) or ( - ) navigation buttons to cycle through the front

panel editor in increments of 1.

• W hen viewing the parameter to be edited, press the()

button and the value

begins to flash.

• Press the (

+

) or ( - ) navigation buttons to adjust the value to the

required setting.

• Press the () button the save the current value, the value ceases

flashing.

• Press and hold the ()

button to save and exit the editor, the

configuration icon is removed from the display.

NOTE: Pressing and holding the ( + ) or ( - ) buttons will

give auto-repeat functionality. Values can be changed qu ickly by holding

the navigation buttons for a prolonged period of time.

DIMENSIONS

PANEL CUTOUT

TERMINALS

140

mm x 113 mm x 43 mm

(5.5” x 4.4” x 1.7”)

118 mm x 92 mm

(4.6” x 3.6”)

Tightening Torque:

0.5 Nm (

4.5 lb-in)

Conductor Size:

0.5 mm² to 2.5 mm²

(AWG 24 to AWG 10)

NOTE: Terminals 8, 9, 25, 26, 27 & 28 are not fitt ed to DSE4510

NOTE: Terminals 29, 30, 31 & 32 are fitted to DSE4510 & D SE4520

current sensing variants only

Deep Sea Electronics PLC

Tel: +44 (0)1723 890099

Fax: +44 (0)1723 893303

Email: sales@deepseaplc.com

Web: www.deepseaplc.com

Deep Sea Electronics Inc

Tel: +1 (815) 316-8706

Fax: +1 (815) 316-8708

Email: sales@deepseausa.com

Web: www.deepseausa.com

REQUIREMENTS FOR UL CERT IFICATION

Specification

Description

Screw Terminal Tightening Torque

•

4.5 lb-in (0.5 Nm)

Conductors •

Terminals suitable for connection of conductor size 12 AWG – 26 AWG (0.5 mm² to 2.0 mm²).

• Conductor protection must be provided in accordance with NFPA 70, Article 240

• Low voltage circuits (35 V or less) must be supplied from the engine starting battery or an isolated secondary circuit.

• The communication, sensor, and/or battery derived circuit conductors shall be separated and secured to maintain at least ¼” (6 mm) separation from the generator and mains connected circuit

conductors unless all conductors are rated 600 V or greater.

Current Inputs

•

Must be connected through UL Listed or Recognized isolating current transformers with the secondary rating of 5 A max.

Communication Circuits

•

Must be connected to communication circuits of UL Listed equipment

DC

Output Pilot Duty

•

0.5 A

Mounting •

Suitable for use in type 1 Enclosure Type rating with surrounding air temperature -22 ºF to +158 ºF (-30 ºC to +70 ºC)

• Suitable for pollution degree 3 environments when voltage sensing inputs do not exceed 300 V. When used to monitor voltages over 300 V device to be install in an unventilated or filtered ventilation

enclosure to maintain a pollution degree 2 environment.

Operating Temperature

•

-22 ºF to +158 ºF (-30 ºC to +70 ºC)

Storage Temperature

•

-40 ºF to +176 ºF (-40 ºC to +80 ºC)

4510/4520

Loading...

Loading...