Page 1

WASHER-DRYER

WBD 1211

124970940

GB

INSTRUCTION BOOKLET

Page 2

Domestic Use

• This appliance is designed to be

operated by adults for domestic

purposes only.

It has to be used according to the

instructions contained in this

booklet.

• Never operate the machine if the

mains cable is damaged or the

control panel, worktop or base area

are damaged allowing internal

components to be accessible.

• Do not use the mains cable to pull

the plug out of the socket.

• Garments which have been in

contact with volatile petroleum

products should not be machine

washed. If volatile cleaning fluids

are used, care should be taken to

ensure that the fluid is removed

from the garment before placing in

the machine.

• Never tumble dry items that have

had contact with chemicals such as

dry cleaning fluid.These are of a

volatile nature and could cause an

explosion.

Only tumble dry items which have

been washed in water or require

airing.

• Plastic detergent dispensers should

not remain in the drum during the

drying cycle, as the plastic used is

not designed to withstand the heat.

If you wish to wash-through-to-dry

you should use the conventional

detergent dispenser drawer.

• Under no circumstances should you

attempt to repair the machine

yourself.Repairs carried out by

inexperienced persons may cause

injury or serious malfunctioning.

Contact the telephone number at

the back of this booklet. Always

insist on genuine Brandt spare

parts.

Child Safety

• Never leave children unattended

whilst the appliance is operating.

• Please check the machine drum

before loading because children or

pets could have climbed into the

machine.

• Keep all packaging material (e.g.

plastic film, polystyrene) well away

from children. Danger of suffocation.

• Keep all detergents in a safe place

out of children’s reach.

• When the appliance is to be

scrapped, cut off the power supply

cable and make the door lock

device unusable to prevent young

children from being trapped inside.

For the user

Safety Information

Please read these operating instructions carefully and pay particular attention to

the safety notes indicated in this page.We recommend that you keep this

instruction booklet for future reference and pass it on to any future owners.

These warnings have been provided in the interest of safety.You MUST read

them carefully before installing or using the appliance.

For the user

Tips for environmental protection

Disposal

Packaging materials

The materials marked with the symbol

are recyclable.

>PE< polyethylene

>PS< polystyrene

>PP< polypropylene

This means that they can be recycled

by disposing of them properly in

appropriate collection containers.

Machine

Use authorised disposal sites for your

old appliance. Help to keep your

country tidy!

To save water, energy and to help

protect the environment, we

recommend that you follow these tips:

• Normally soiled laundry may be

washed without prewashing in order

to save detergent, water and time

(the environment is protected too!).

• The machine works more

economically if it is fully loaded.

• With adequate pre-treatment, stains

and limited soiling can be removed;

the laundry can then be washed at a

lower temperature.

• Measure out detergent according to

the water hardness, the degree of

soiling and the quantity of laundry

being washed.

• The machine will consume less

energy if the laundry is adequately

spun before being dried.

Our contribution to the protection of the

environment: we use enviromentally

friendly paper.

Guide to using the Instruction Book

The following symbols will be found in the text to guide you throughout the

instructions:

Safety instructions

Hints and tips

Environmental information

Page 3

Maintenance and

Cleaning 26-29

Descaling 26

Door seal 26

External cleaning 26

Cleaning the detergent drawer 26

Cleaning the drawer recess 27

Cleaning the drain filter 27

Cleaning the water inlet filters 28

The dangers of freezing 28

Emergency emptying out 29

Something Not

Working 30-33

For the Installer 34

Safety Information 34

Technical

Specifications 35

Installation 36

Removing the transport safety

devices 36-37

Positioning 37

Levelling 37

Water inlet 38

Water drainage 39

Electrical connection 40-41

Building-in 41-43

For the User

Safety Information 2

Disposal 3

Tips for environmental

protection 3

Description of the

Appliance 5

Detergent dispenser drawer 5

The Control Panel 6-7

Operating Sequence 8-13

Washing only 8-10

Drying only 11-12

Washing & Drying 12-13

Washing Hints 14-15

Which detergent?.... 16

And in which form? 16

Quantity of detergent to be used 17

Fabric conditioners 17

Drying Hints 18-19

Washing Programmes 20-23

Drying Programmes 24

Wash Care Symbols 25

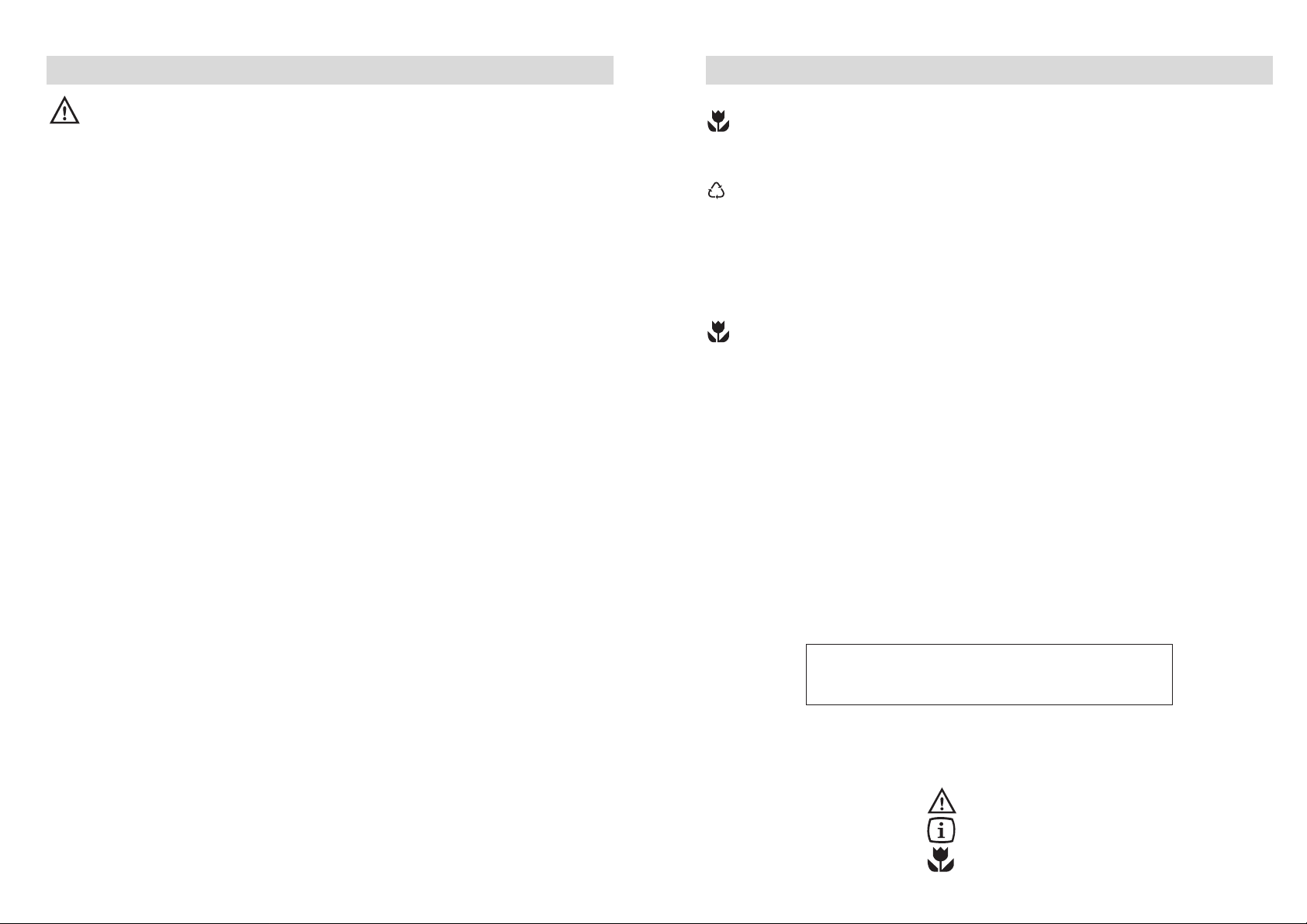

Contents Description of the Appliance

1 Detergent dispenser drawer

2 Programme chart

3 Control panel

4 Door handle

5 Drain filter

6 Adjustable feet

Detergent dispenser drawer

Prewash detergent

Main wash detergent

Fabric softener

IMPORTANT : PLEASE READ THE INSTRUCTION BOOK BEFORE USING THIS APPLIANCE

WBD 1211

13

2

4

5

6

QUICK

WASH

650

1200

Programme chart

P0239S

Page 4

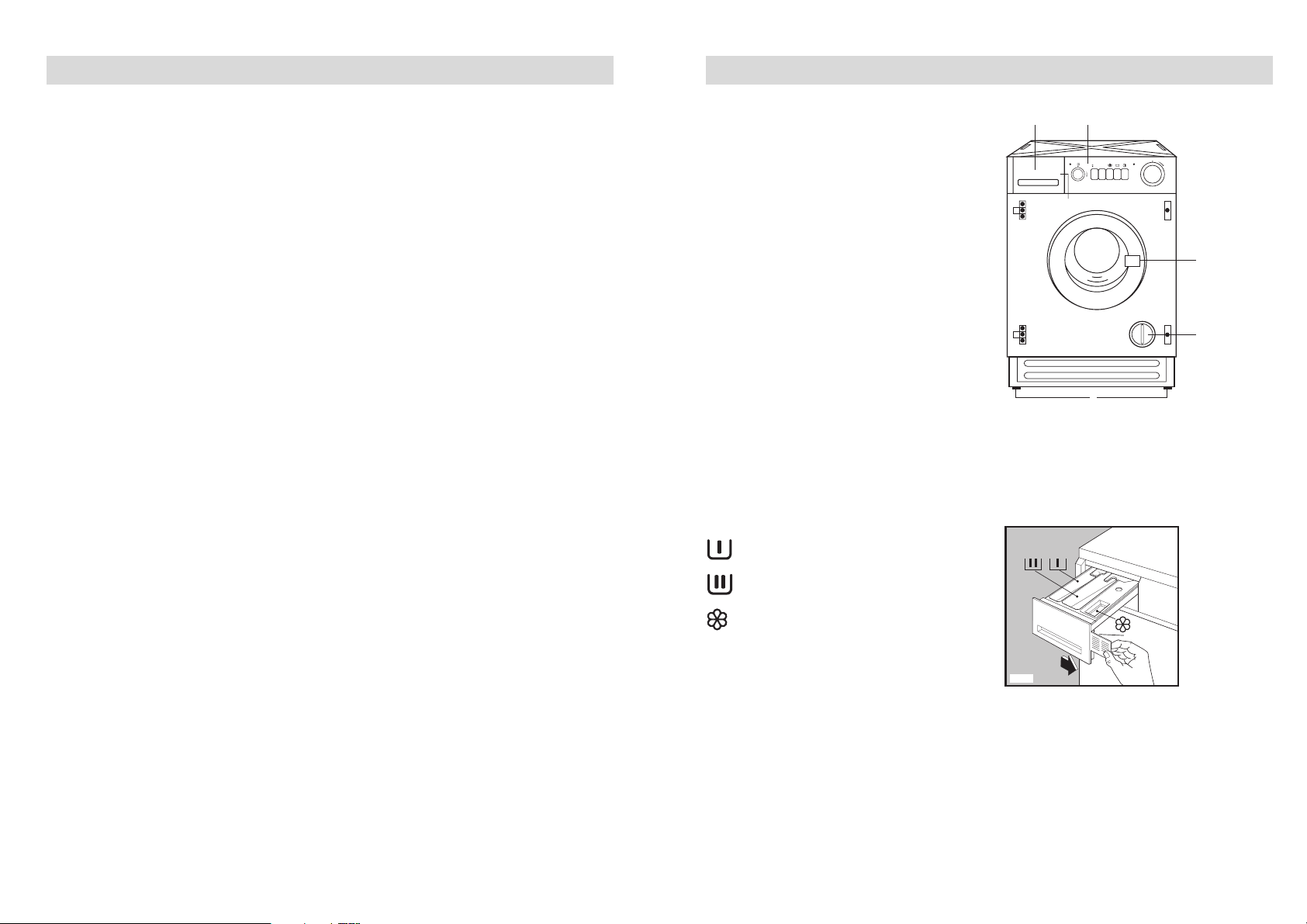

The Control Panel

12345678910

QUICK

WASH

650

1200

WBD 1211

1 Detergent dispenser drawer

2 Drying indicator light

This light illuminates when the

machine is drying.

3 Drying time selector dial

Graduated up to 120 mins for cottons

and synthetics, this dial allows you to

select the desired drying time

according to the type and quantity of

laundry and the required degree of

dryness:

- Red sector for cottons

- Grey sector for synthetics

Turn the dial clockwise only.

Depress the dial to pop it out.

Cooling phase

To allow the laundry to cool down, a

cooling phase starts automatically 10

minutes before the end of drying and

this phase must in no circumstances

be reduced or interrupted.

4 Spin speed reduction

button

By depressing this button the spin

speed is reduced as follows:

- cotton & linen: from 1200 rpm to

650 rpm;

- synthetics, delicates and

programme “1”: from 650 rpm to

450 rpm.

- wool: from 1000 rpm to 650 rpm.

Important!

In order to save energy and to avoid

too long drying times we suggest not

to reduce the spin speed when you

wash and dry automatically.

5 Quick wash button

By depressing this button on

programmes 2, 3, 4 and 5 the wash

time is reduced.

This is suitable only for garments which

are lightly soiled.

6 Super Rinse button

By depressing this button on

programmes for cottons and linens the

machine will perform the rinses with

high water level.

This is recommended for people who

are allergic to detergents and in areas

where the water is very soft.

650

1200

7 Anti-Crease button

Press this button to make the machine

stop with water in the drum after the

cotton, synthetic or delicate wash

cycles.

This prevents any creasing which may

occur if the clothes are left damp in the

drum.When it is convenient for you to

empty the machine, simply press this

button again so that the machine can

proceed to drain and spin, or turn the

dial to the drain programme “ ”.

If this button is not activated, the

washing programmes will end with a

spin.

Important!

This button is not compatible with the

automatic washing & drying

programme.

8 ON/OFF button

By depressing this button the machine

starts operating.

When depressing it again, the machine

stops.

The push button is provided with a

child-proof safety lock.Move the small

slider placed in the middle of the

button downwards to lock the button in

the «off» position.

9 Mains-on light

This light will illuminate when the

machine starts working and goes out

when the ON/OFF button is depressed

again to switch the machine off.

10 Programme selector dial

With the programme selector dial

you choose the desired washing and

drying programme.

Turn it clockwise.

Depress the dial to pop it out.

Before setting the dial to any position

the machine must be switched off by

depressing the ON/OFF button.

The Control Panel

Page 5

Operating Sequence

Washing only

Before the first wash, we recommend

that you run a cotton cycle at 60°C,

without any laundry in the machine, to

remove any manufactur ing residue

from the drum and tub.

Pour 1/2 a measure of detergent into

the main wash compartment of

the dispenser drawer and start the

machine.

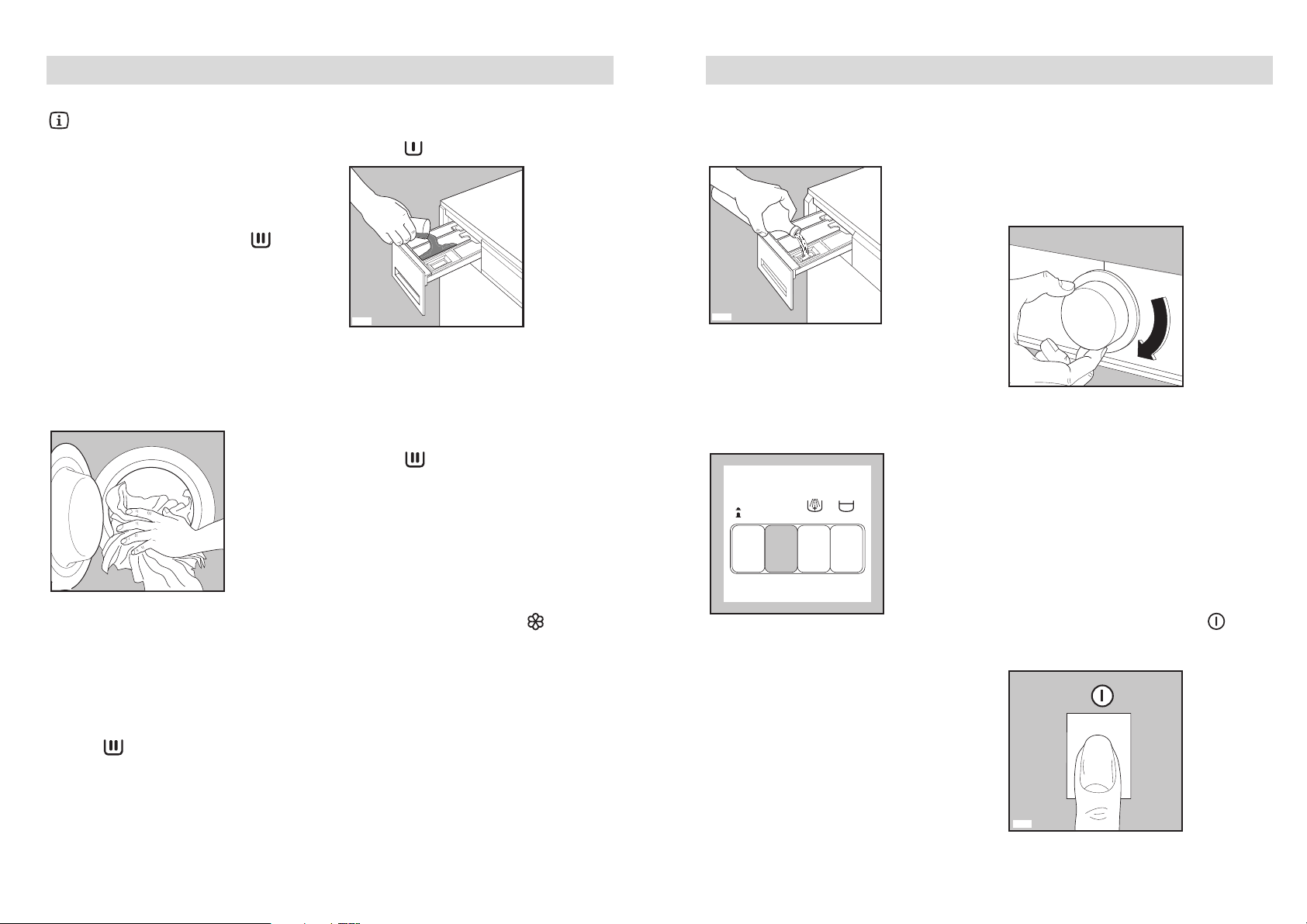

1. Load the laundry

Open the door by pulling the door

handle outwards.

Place the laundry in the drum, one

item at a time, shaking them out as

much as possible.Close the door.

2. Measure out the detergent

Pull out the dispenser drawer until it

stops.

Measure out the amount of detergent

required and pour it into the main

wash compartment marked with the

symbol .

P0004

If you wish to carry out the prewash,

pour detergent into the compartment

marked .

Important

If using concentrated powder or liquid

detergents, a programme without

prewash must be selected.

Pour liquid detergent into the

dispenser drawer compartment

marked just before starting the

programme or use the special

dispenser to be placed directly in the

drum.

3. Measure out the liquid

additive

If required, pour fabric softener into

the compartment marked (the

amount used must not exceed the

“MAX” mark in the drawer).

When using thick concentrated fabric

softeners we recommend you dilute

the concentrate with water to ensure

trouble-free dispensing.

If using starch powder dissolve

according to manufacturer’s

instructions.

P0006

Close the drawer gently to avoid te

fabric conditioner entering de machine

prematurely.

4. Select the required

option(s)

Depress SPIN REDUCTION and/or

QUICK WASH and/or SUPER RINSE

or RINSE HOLD button, if required

QUICK

WASH

650

1200

P0005

5. Select the required

programme

Turn the programme selector dial

clockwise to the programme 2 or 1 if

you want to perform a prewash before

the main wash.

6. Start the machine

Before starting up the machine check

that:

• the appliance is plugged in;

• the water supply taps are turned on;

• the drain hose is correctly and

securely positioned;

• the door and the detergent

dispenser drawer are

closed.

Depress the ON/OFF button : the

mains-on light will illuminate and the

machine starts operating.

P0045

P0379

2

Operating Sequence

Page 6

7. At the end of the

programme

The machine stops automatically.

If you have depressed the ANTI-

CREASE button, the machine will

stop with the water left in the tub, to

prevent the fabric from creasing.To

drain the water and spin, release the

same button.To drain only, select

programme “ ”.

The door is controlled by a safety

device which releases 2 minutes after

the end of the programme.

Switch the machine off by depressing

the ON/OFF button again.The mainson light goes out.

Remove the laundry.

Turn the dr um by hand to make sure it

is completely empty, so as to avoid

any forgotten items being damaged in

a subsequent wash (e.g. shr inking) or

their colour running into a load of

whites.

Release any buttons which have been

pressed.

Turn the water taps off and unplug the

machine.

Leave the door ajar to air the

machine.

Operating Sequence Operating Sequence

Drying only

You have for example just machinewashed and spun at 1200 rpm 4.5 kg

(10 lb) of laundry.

They are cotton fabrics of medium

weight which you want to iron as soon

as they are dry.

Switch off the machine.

Then remove the laundry from the

appliance and divide the items to

obtain two loads of approx.2.25 kg

(5 lb) each.

1. Load the laundry

Open the door by pulling the catch

outward.

Load the items one at a time and

close the door.

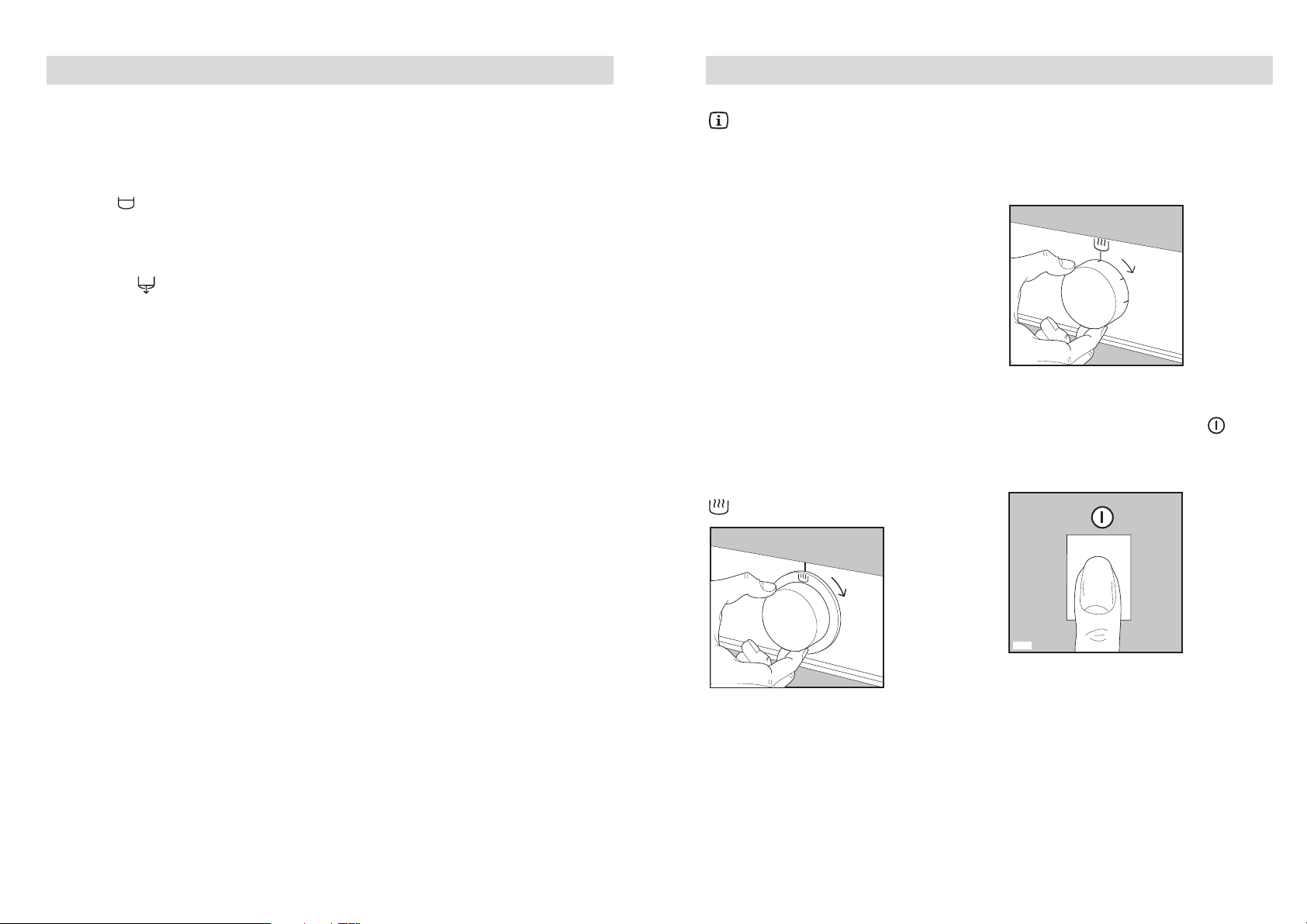

2. Select the programme

Turn the programme selector dial

clockwise to the drying programme

for cotton.

P0803S

3. Select the required time

Following indications given in the

programme chart on page 24, turn the

drying time selector dial clockwise to

the 60 mins setting in the red sector.

4. Start the machine

Depress the ON/OFF button , the

mains-on light and drying light will

illuminate and the machine starts

operating.

P0045

M0031a

60

90

Page 7

4. Select the required option

Depress QUICK WASH button, if

required.

5. Select the required time

Following indications given in the

programme chart on page 24, turn the

time selector dial clockwise to the 40

mins setting in the grey sector.

M0031b

40

60

QUICK

WASH

650

1200

6. Start the machine

Depress the ON/OFF button : the

mains-on light comes on and the

machine starts operating.

7. At the end of the programme

The machine stops automatically and

the drying light goes out.

The door is controlled by a safety

device which releases 2 minutes after

the end of the programme.

Switch the machine off by depressing

the ON/OFF button again, the mainson light goes out.

If the laundry is still too damp, select

a further brief dr ying time, bearing in

mind that during the last 10 minutes

the appliance carries out a cooling

and anticrease phase.

When the programme has finished

you are advised to unplug the

appliance and turn off the water taps.

P0045

Operating Sequence

5. At the end of the

programme

The machine stops automatically and

the drying light goes out.

The door is controlled by a safety

device which releases 2 minutes after

the end of the programme.

Switch the machine off by depressing

the ON/OFF button again, the mainson light goes out.

If the laundry is still too damp, select

a further brief dr ying time, bearing in

mind that during the last 10 minutes

the appliance carries out a cooling

and anticrease phase.

When the programme has finished

you are advised to unplug the

appliance and turn off the water taps.

Washing & Drying

You intend to wash and dry

automatically 1 kg (2.2 lb) of mixed

fabrics which have to be ironed.

Proceed as follows:

1. Load the laundry

Open the door by pulling the catch

outward.

Load the items one at a time and

close the door.

2. Measure out the detergent

and fabric softener

Pull out the dispenser drawer until it

stops.

Measure out the amount of detergent

required and pour it into the main

wash compartment .

If required, pour fabric softener into

the compartment marked (the

amount used must not exceed the “MAX”

mark in the drawer).

Close the drawer gently.

3. Select the required

programme

Turn the programme selector dial

clockwise to programme 5.

5

P0673S

Operating Sequence

Page 8

• Only wool marked “Pure New Wool washable, preshrunk” can be

washed in the machine using the

wool programme; other types of

wool should be washed by hand or

dry cleaned.

• If you have used the machine to

wash, rinse or spin only non-colour

fast garments, there may be dye left

in the sump.To ensure any

subsequent wash is not

contaminated with the dye, select

and carry out a rinse and spin

programme, without any garments,

to ensure that any dye is removed

from the sump.

Removing stains

Stubborn stains may not be removed

by just water and detergent.It is

therefore advisable to treat them prior

to washing.

Blood: treat fresh stains with cold

water.For dried stains, soak overnight

in water with a special detergent then

rub in the soap and water.

Oil based paint: moisten with

benzine stain remover, lay the

garment on a soft cloth and dab the

stain; treat several times.

Dried grease stains: moisten with

turpentine, lay the garment on a soft

surface and dab the stain with the

fingertips and a cotton cloth.

Rust: oxalic acid dissolved in hot

water or a rust removing product used

cold. Be careful with rust stains which

are not recent since the cellulose

structure will already have been

damaged and the fabric tends to hole.

Mould stains: treat with bleach, rinse

well (whites and fast coloureds only).

Grass: soap lightly and treat with

bleach (whites and fast coloureds

only).

Ball point pen and glue: moisten

with acetone (*), lay the garment on a

soft cloth and dab the stain.

Lipstick: moisten with acetone as

above, then treat stains with

methylated spirits. Remove any

residual marks from white fabrics with

bleach.

Red wine: soak in water and

detergent, rinse and treat with acetic

or citric acid, then rinse.Treat any

residual marks with bleach.

Ink: depending on the type of ink,

moisten the fabric first with acetone

(*), then with acetic acid; treat any

residual marks on white fabrics with

bleach and then rinse thoroughly.

Tar stains: first treat with stain

remover, methylated spirits or

benzine, then rub with detergent

paste.

(*) do not use acetone on artificial

silk.

Washing Hints

Do NOT overload the machine.

Recommended loads are indicated in

the programme charts.

General rules:

Cotton, linen: dr um full but not too

tightly packed;

Synthetics: drum no more than half

full;

Delicate fabrics and woollens:drum

no more than one third full.

The average weights of the most

common items are listed below as a

guide:

Sheet 700-1000 g

Pillow case 100-200 g

Tablecloth 400-500 g

Serviette 50-100 g

Tea towel 70-120 g

Linen hand towel 100-150 g

Towelling hand towel 150-250 g

Towelling bath towel 700-1000 g

Bath robe 1000-1500 g

Man’s shirt 200-300 g

Apron 150-200 g

• Load the laundry loosely alternating

large items with small ones.

• Sort the laundr y according to the

type of fabric, colour-fastness and

how dirty it is.

• Avoid washing unhemmed or torn

items as they may unravel.

• Before washing, empty all

pockets of small objects which

may have been left inside (coins,

keys, screws etc). as these could

damage the drain pump.

• When washing curtains, remove the

hooks.

• Close poppers and zips and fasten

loose buttons.

• It is essential to wash new coloured

items separately when washing for

the first time.

• When washing fabrics requiring

different wash temperatures

together, always select the lowest

temperature.

• White items should not be washed

with coloured items.

• Very small items (handkerchiefs,

ribbons, socks etc) should be

washed in a washing bag or a pillow

case as it is possible for such items

to slip down between the tub and

the drum.

• Some stains such as fruit, wine,

grass, rust etc. are difficult to

remove and should be treated

before washing with specific

products, which can be found in

most household shops. In some

cases it may help to soak the stain

before washing with a special presoak product or biological detergent.

Washing Hints Washing Hints

Page 9

Which detergent?....

To ensure you obtain the best wash

results from your appliance, it is

important to use the right detergent in

your everyday wash, and only

detergents recommended for use in

automatic machines.

To maintain the appearance of your

clothes and household textiles and to

make them last longer you should use

different types of detergent for

different washes, whether for whites,

colours or delicates.

WHITES

You can use a biological product

designed to provide excellent cleaning

and stain removal even at low

temperatures or a non biological

detergent, which does not contain

enzymes

.

COLOUREDS

For coloured items you should use a

detergent which is designed to clean

while maintaining the original colour.

DELICATE ITEMS

When washing delicates such as

woollens, you should use a product

which is specially designed to care for

fine fabrics.

LAUNDRY BLEACH

For additional stain removal you may

wish to use a Gentle Bleach product

which is used in addition to your

chosen detergent.

And in which form?

Not only are there different types of

detergent, but they are also available

in different forms.Whether you chose

a powder or liquid in traditional or

compact form is to own personal

choice.

TRADITIONAL POWDERS

Pour the powder directly into the

dispenser drawer. Do not spr inkle

powder onto clothes in the machine

drum.

TRADITIONAL LIQUIDS

Liquid can be placed in the main

wash compartment of the detergent

drawer marked with the symbol .

Start the machine immediately upon

placing the detergent in the dispenser

drawer.

Alternatively the detergent is

measured into the specially designed

dosing device* which should be

placed on top of the laundry, and at

the back of the machine drum.

COMPACT POWDERS AND

LIQUIDS

Compact detergents (or concentrates

as they are also known) are available

in liquid or powder form, and generally

require a smaller dosage. Follow the

manufacturer’s instr uctions to ensure

the most economical usage. Pour the

detergent directly into the dispenser

drawer, or alter natively measure the

detergent into the specially designed

dosing device* which should be

placed on top of the laundry, and at

the back of the machine drum.

* If you use a dosing device, please

ensure the dosing device/ball is

removed before carrying out a

drying programme.

Quantity of detergent to be

used

The quantity of detergent will depend

on the type of fabric, load size,

degree of soiling and hardness of the

water used.

Water hardness is classified in socalled “degrees” of hardness.

Information on hardness of water in

your area can be obtained from

your water supply company or from

your local authority.

Follow the product manufacturers’

instructions on quantities to be used.

Use less detergent if:

– you are washing small loads,

– the laundr y is lightly soiled,

– large amounts of foam form during

washing.

FABRIC CONDITIONERS

These are ideal for improving

‘softness’, and also reduce static cling

on synthetics and make ironing

easier.

The liquid fabric softener should be

poured into the compartment marked

with the symbol .

Follow the manufacturer’s dosage

instructions and never exceed the

MAX level.

Washing Hints Washing Hints

Page 10

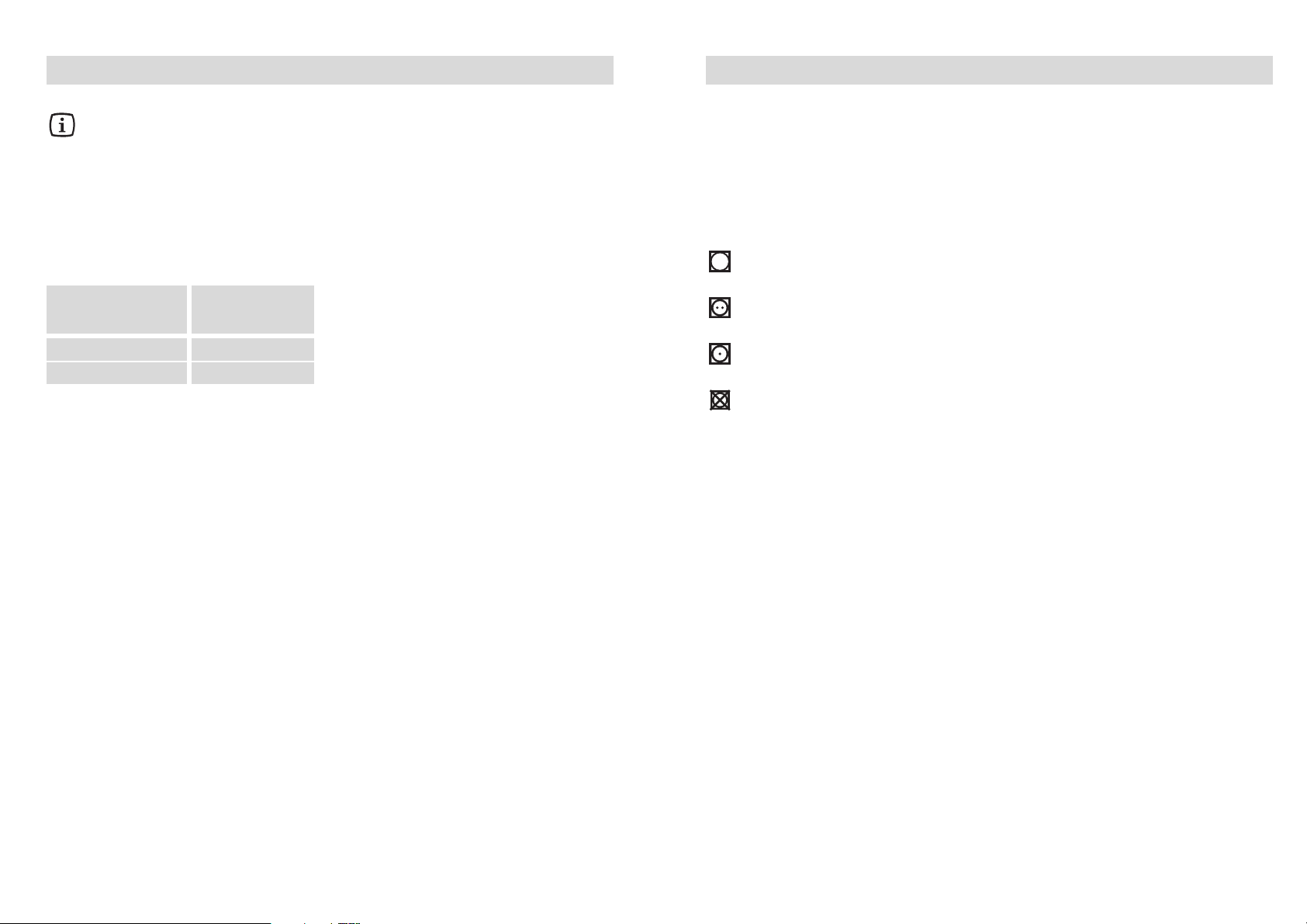

Drying symbols on garment

labels

Always look at the garment label to

check whether garments can be

machine dried.

The following symbols refer to

drying:

Machine drying is usually

possible

Normal drying (nor mal

temperature)

Gentle drying (reduced

temperature)

Do not machine dry

Duration of the drying cycle

The drying time can vary

according to

• the final spin speed;

• the required degree of drying;

• the type of laundry;

• the size of load.

The usual drying times are

indicated in the programme chart.

As you become more familiar with

the appliance, you will discover the

drying times that best suit your

needs according to the various

type of fabric. It is a good idea to

make a note of these times.

Fibre residue

After drying fluffy fabrics, such as new

towels, it is advisable to perfor m a

gentle rinse to be sure that any

residue that may remain in the tub is

completely removed and does not

stick to garments dried afterwards.

After each drying cycle the filter

should be checked and cleaned.

Additional drying

Should the laundry still be too wet at

the end of the programme, set

another short dr ying cycle.

Warning! To prevent the formation

of creases or shrinking of fabrics,

avoid excessive drying.

Drying Hints

Drying Hints

As a dryer, the machine works on the

condensation principle.

Therefore, the water tap must be

open and the drain hose must drain

water into a sink or into the drain

pipe, even during the drying cycle.

Load

Warning:

Loads of washed laundry

exceeding these values must be

divided before being dried,

otherwise poor results will be

obtained.

Garments not suitable for

drying

• Particularly delicate items such as

synthetic curtains, woollen and silk,

garments with metal inserts, nylon

stockings, bulky garments such as

anoraks, bedcovers, quilts, sleeping

bags and duvets must not be

machine dried.

• Garments padded with foam-rubber

or materials similar to foam-rubber

must not be machine dried; they

represent a fire hazard.

• Also, fabrics containing residues of

setting lotions or hair sprays, nail

solvents or similar solutions must

not be machine dried in order to

avoid the formation of harmful

vapours.

Drying Hints

Sort of laundry

max. load

(dry weight)

2.25 kgCottons-Linen

1.5 kgMixed fabrics

Page 11

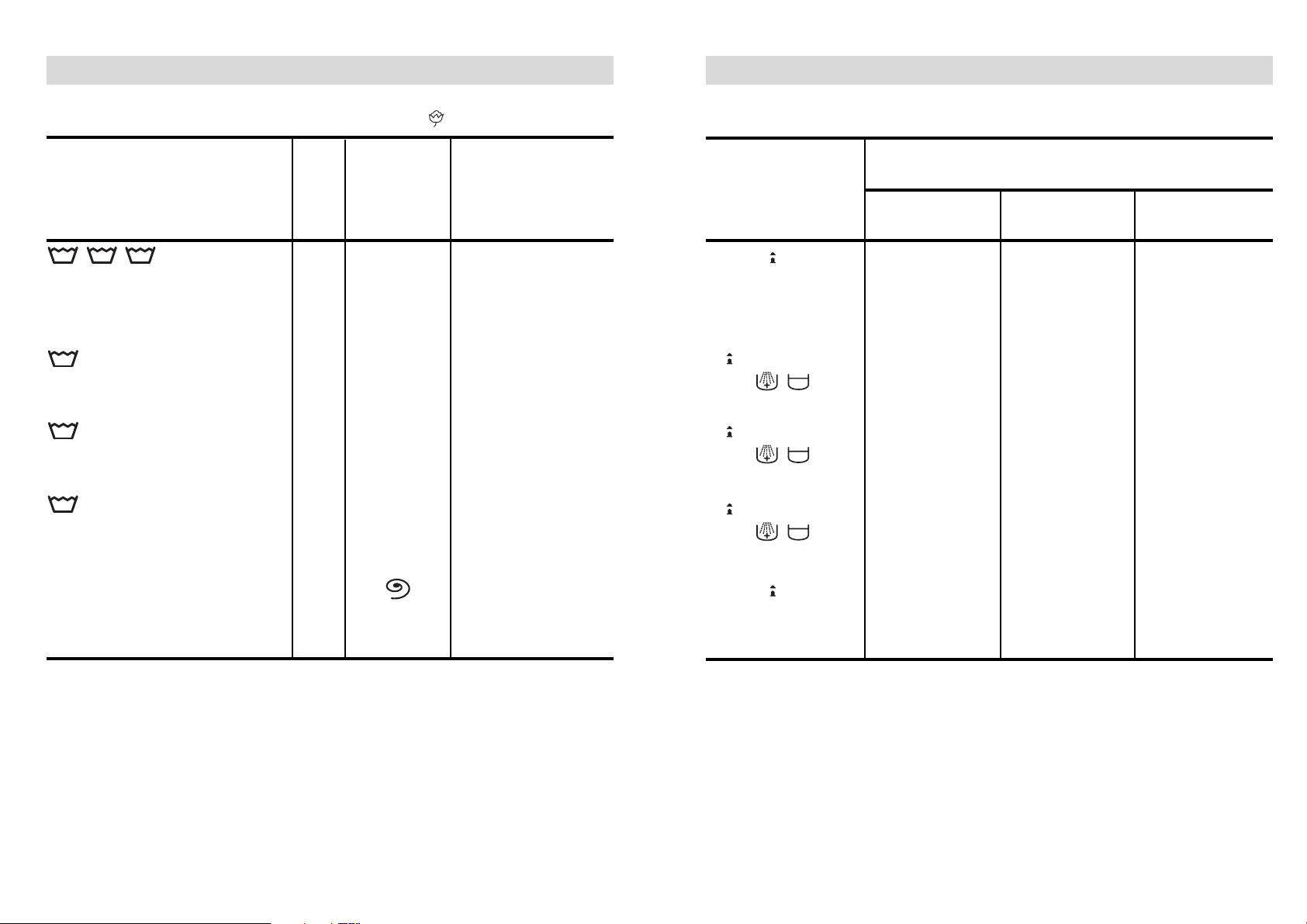

Programme T able

Programme T able

Washing programmes for cotton and linen

Type

of laundry,

care symbol

Max

load

Programme/

temperature

Programme

description

Whites and

Coloureds,

heavy soiled,

for

example sheets, household linen,

underwear, towels

Whites, normally soiled, for

example, household linen, towels,

sheets

Fast coloureds, normally

soiled, table-cloths, shirts,

blouses, underwear

Fast coloureds, normally

soiled

shirts, blouses, underwear

Cottons/linen to be spun

40

60

95

95

60

40

Prewash at 40°C

Short spin at 650 r pm

Wash at 95°C

3 rinses

Long spin at 1200 rpm

Wash at 60°C

3 rinses

Long spin at 1200 rpm

Wash at 40°C

3 rinses

Long spin at 1200 rpm

Long spin at 1200 rpm

1

40°

2

95°

3

60°

4

40°

LONG SPIN

4.5 kg

4.5 kg

4.5 kg

4.5 kg

4.5 kg

In compliance with EC directive 92/75, the consumption figures indicated on the

energy label refer to the 60°C wash programme for cotton (programme “3”) with

cold water filling.

Water filling:30°-40° programmes: cold water filling

50°-60° programmes: hot and cold filling

60°-95° programme: hot water filling

Additional functions

Consumptions*

Energy

kWh

Water

lt

Duration

min.

* The consumption data shown on this chart is to be considered purely indicative,

as it may vary depending on the quantity and type of laundry, on the inlet water

temperature and on the ambient temperature.It refers to the highest temperature

for each wash programme.

QUICK WASH

QUICK WASH

QUICK WASH

650

1200

650

1200

650

1200

650

1200

650

1200

1.85

1.5

0.8

0.65

-

82

68

65

65

-

135

115

110

95

10

Page 12

* The consumption data shown on this chart is to be considered purely indicative, as it may vary

depending on the quantity and type of laundry, on the inlet water temperature and on the

ambient temperature.

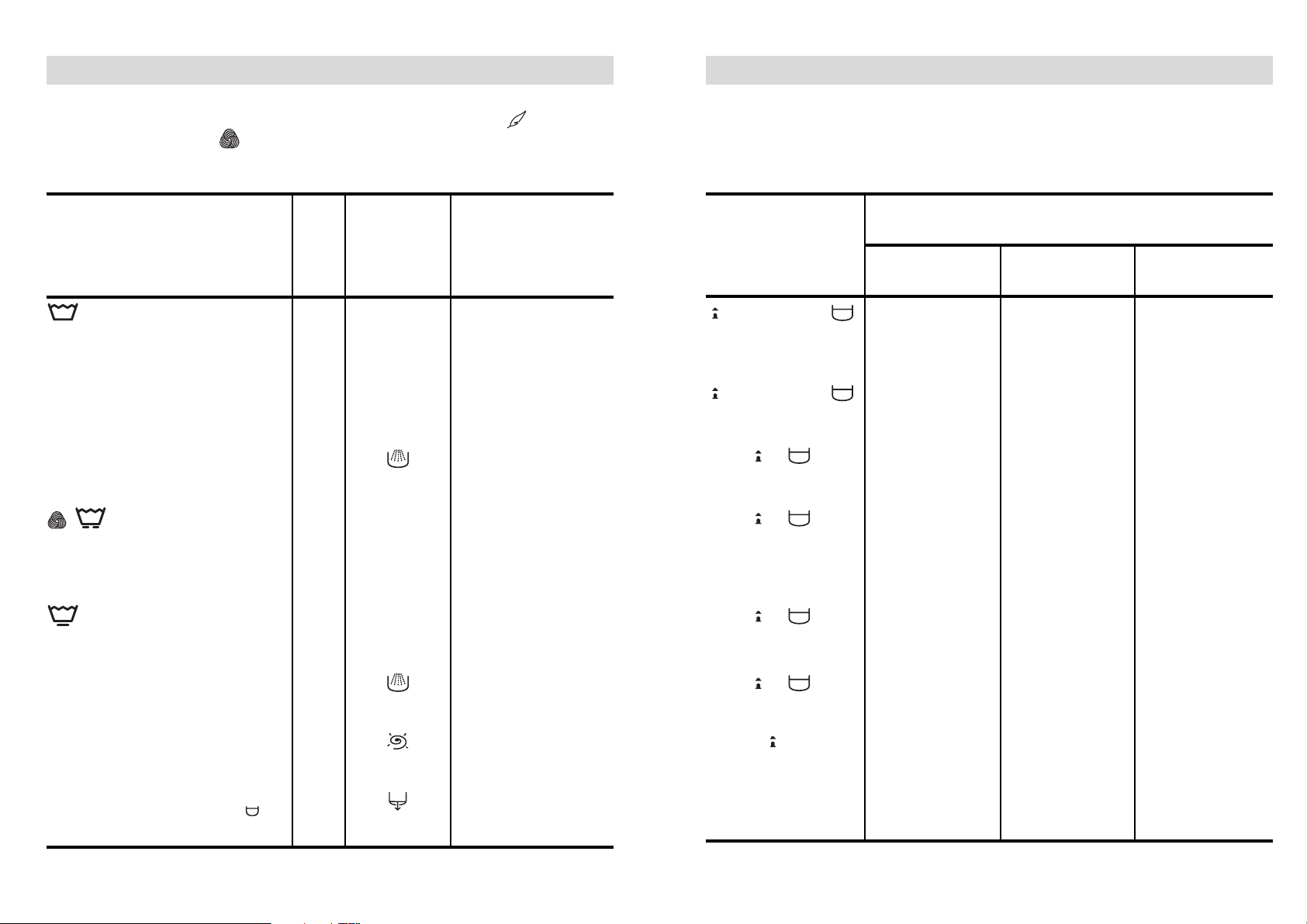

Programme T able

Programme T able

Washing programmes for synthetics, mixed fabrics ,

delicates and wool

Important: When the automatic NON-STOP washing plus drying programme is

used for synthetics, there is a short spin at 900 rpm before drying starts.

Type

of laundry,

care symbol

Max

load

Programme/

temperature

Programme

description

Mixed fabrics normally

soiled

underwear, shirts, blouses

30° Synthetics and mixed

fabrics, lightly soiled

Synthetics, mixed fabrics to be

rinsed

Wool

Special programme for garments

bearing the “Pure new wool, nonshrink, machine washable” label

Delicates, for example

curtains

Delicates and wool

to be rinsed

Synthetics, delicates and wool

to be spun

Synthetics, delicates and wool

washed with the anti-crease

option (stop with water in tub)

40

40

50

Wash at 50°C

3 rinses

Short spin at 650 r pm

Wash at 30°C

3 rinses

Short spin at 650 r pm

3 rinses

Short spin at 650 r pm

Wash at 40°C

3 rinses

Short spin at 1000 rpm

Wash at 40°C

3 rinses

Short spin at 650 rpm

3 rinses

Short spin at 650 r pm

Short spin at 650 r pm

Draining of the water

of the last rinse

5

50°

6

30°

RINSES, COLD

7

40°

8

40°

RINSES, COLD

SHORT SPIN

DRAIN

2 kg

2 kg

2 kg

1 kg

2 kg

2 kg

2 kg

Additional functions

Consumptions*

Energy

kWh

Water

lt

Duration

min.

QUICK WASH

QUICK WASH

650

1200

650

1200

650

1200

650

1200

650

1200

650

1200

650

1200

0.5

0.45

0.02

0.55

0.6

0.02

-

-

60

65

50

65

65

50

-

-

70

40

25

55

55

25

5

1.5

Page 13

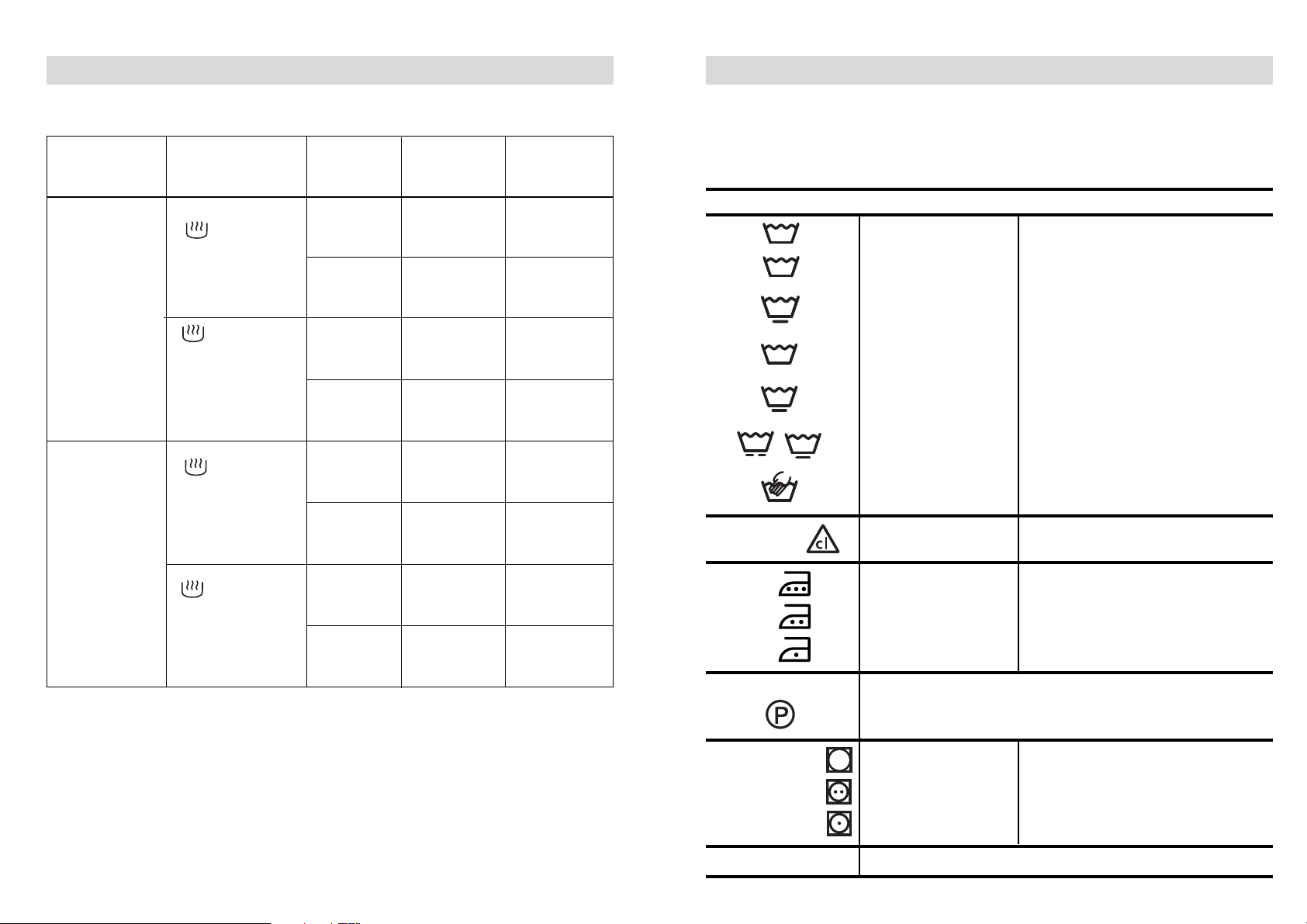

Programme T able Wash Care Symbols

Wash care labels inside garments recommend how to launder your clothes with

the best results.The care labelling code is in line with care labelling used in the

rest of Europe.The symbols used make it easy to select the correct programme

on your washing machine.

30

40

40

40

50

60

95

Normal (Maximum)

Normal (Maximum)

Reduced (Medium)

Normal (Maximum)

Reduced (Medium)

Much Reduced

(Minimum)

Hand wash only

White Cotton or Linen

Cotton, Linen or Viscose

Colourfast at 60°C

Nylon, Polyester/Cotton, Viscose,

Cotton/Acrylic mixtures

Cotton, Linen or Viscose

Colourfast at 40°C but not 60°C

Acrylics, Acetate, Triacetate, Wool

mixes, Polyester/wool blends.

Wool, wool mixtures, Silks,

microfibres

Do not machine wash

WASHING SYMBOL WASH ACTION FABRIC

BLEACHING

Chlorine bleach

may be used

IRONING

Hot iron

Warm iron

Cool iron

Cotton, Linen, Viscose

Polyester mixtures, Wool

Acrylic, Nylon, Polyester

DRY CLEANING

May be dry cleaned. Other letters and/or a bar beneath the

circle will indicate the required process to the dry cleaner

TUMBLE DRYING

May be tumble dried

with high heat setting

with low heat setting

X

A cross through any symbol means «DO NOT»

(*) The STORE DRY drying programme for cotton is the reference programme for

the Energy Label data, in compliance with standard EEC 92/75.

Degree of

drying

Drying time

mins

Spin speedMax. load

Programme/

Type of fabric

Store dry (*)

Suitable for

items to put

away without

ironing

red sector

Cotton and linen

(towels, T-shirts,

bathrobes)

grey sector

Synthetics and

mixed fabrics

(jumpers, blouses,

underwear,

household linen)

2.25 kg 1200 85-95

1.5 kg 1200 55-65

1.5 kg

900

650

90-100

105-115

1 kg

900

650

55-65

75-85

Iron dry

Suitable for

ironing

red sector

Cotton and linen

(sheets,

tablecloths, shirts,

etc.)

grey sector

Synthetics and

mixed fabrics

(shirts, blouses,

household linen)

2.25 kg 1200 60-70

1.5 kg 1200 40-50

1.5 kg

900

650

70-80

80-90

1 kg

900

650

40-45

60-70

Drying Programmes

Page 14

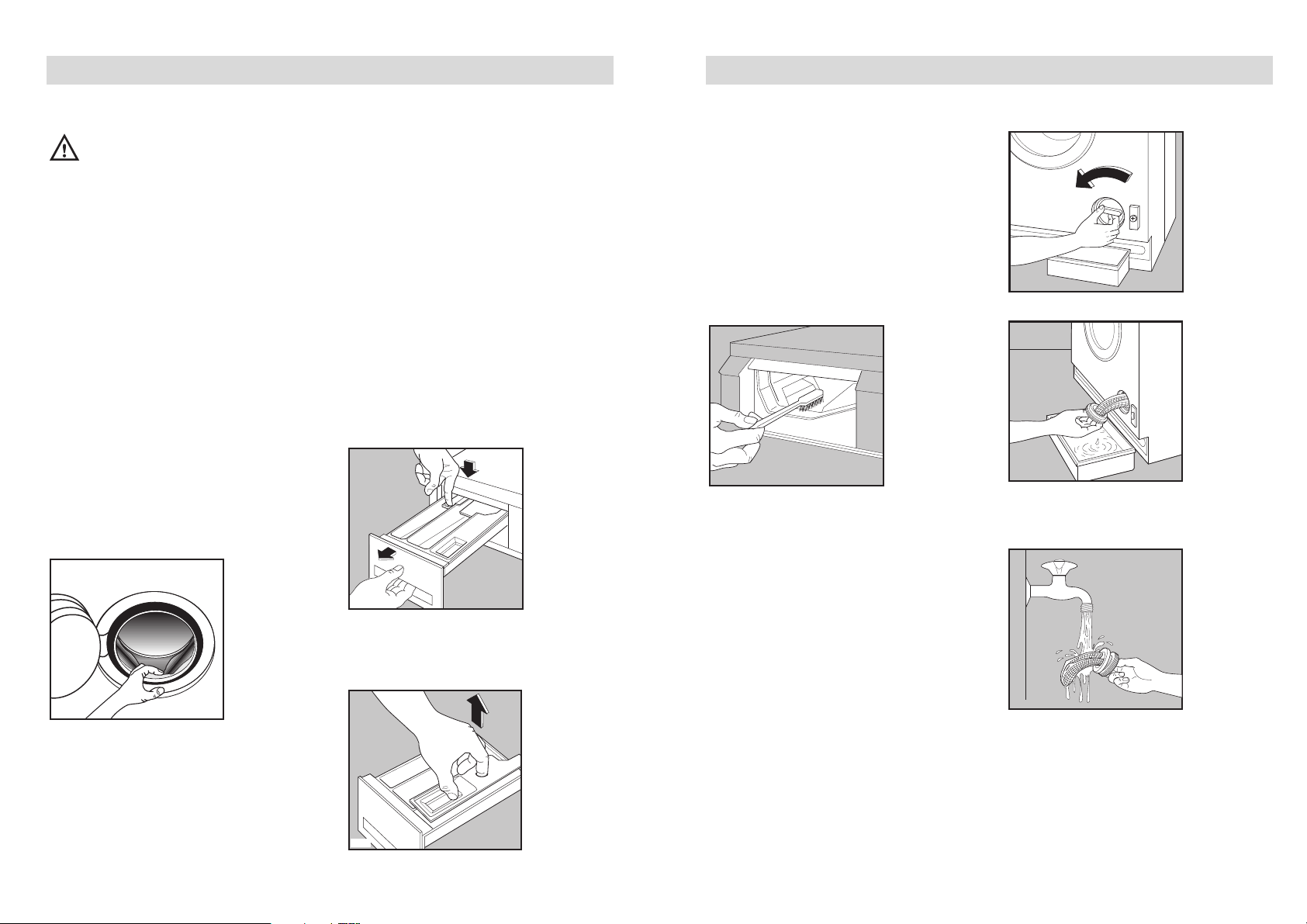

Maintenance and Cleaning Maintenance and Cleaning

Before any maintenance or

cleaning is carried out you

must DISCONNECT the

appliance from the electricity

supply.

Descaling

The water we use normally contains

lime. It is a good idea to periodically

use a water softening powder in the

machine. Do this separately from any

laundry washing, and according to the

softening powder manufacturer's

instructions.This will help to prevent

the formation of lime deposits.

Door seal

Check from time to time the door seal

and eliminate eventual possible

objects that could be trapped in the

fold.

Rust forming could be possible, if

items such as paper clips, buttons,

nails, etc. are not removed after a

long time.

P1050

External cleaning

Clean the exterior cabinet of the

appliance with soap and water only,

and then dry thoroughly.

Do not use methylated spirits,

solvents or similar products.

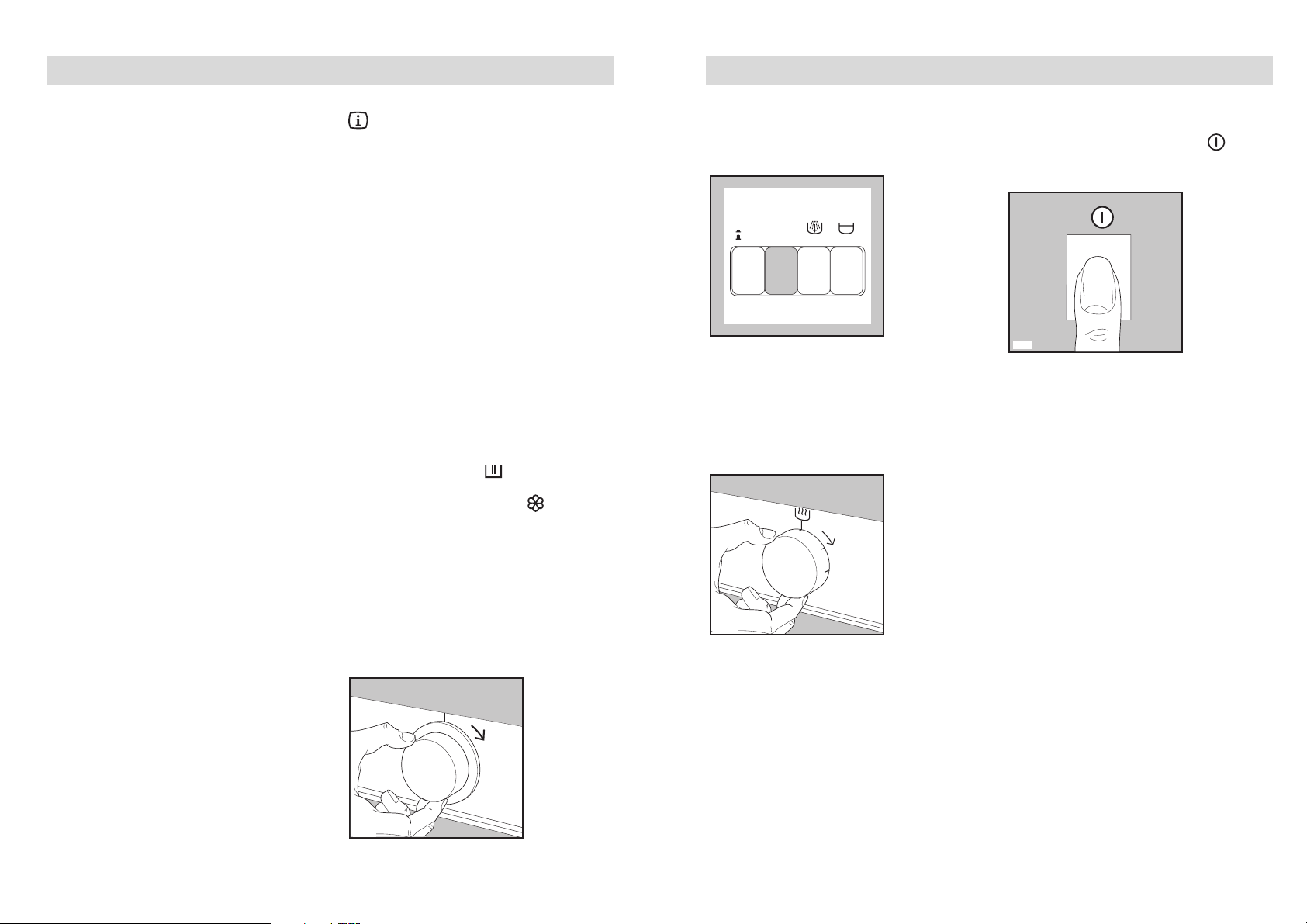

Cleaning the detergent

drawer

From time to time the washing powder

and additive dispenser drawer should

be cleaned.

Remove the drawer by pressing the

catch downwards and by pulling it out.

Flush it out under a tap, to remove

any traces of accumulated powder.

To facilitate cleaning, the top part of

the additive compartment can be

removed.

P0009

P0010

Cleaning the drawer

recess

Having removed the drawer, use a

small brush to clean the recess,

ensuring that all washing powder

residue is removed from the upper

and lower part of the recess.

Replace the drawer and run the rinse

programme without any clothes in the

drum.

Cleaning the drain filter

A clean filter is important for the

correct functioning of the machine,

and should therefore be cleaned at

regular intervals.

P0038

Unscrew and remove the filter.

Clean carefully under a fast running

tap.

Refit the filter, screwing it fully in.

P0040

P0039

P0037

Page 15

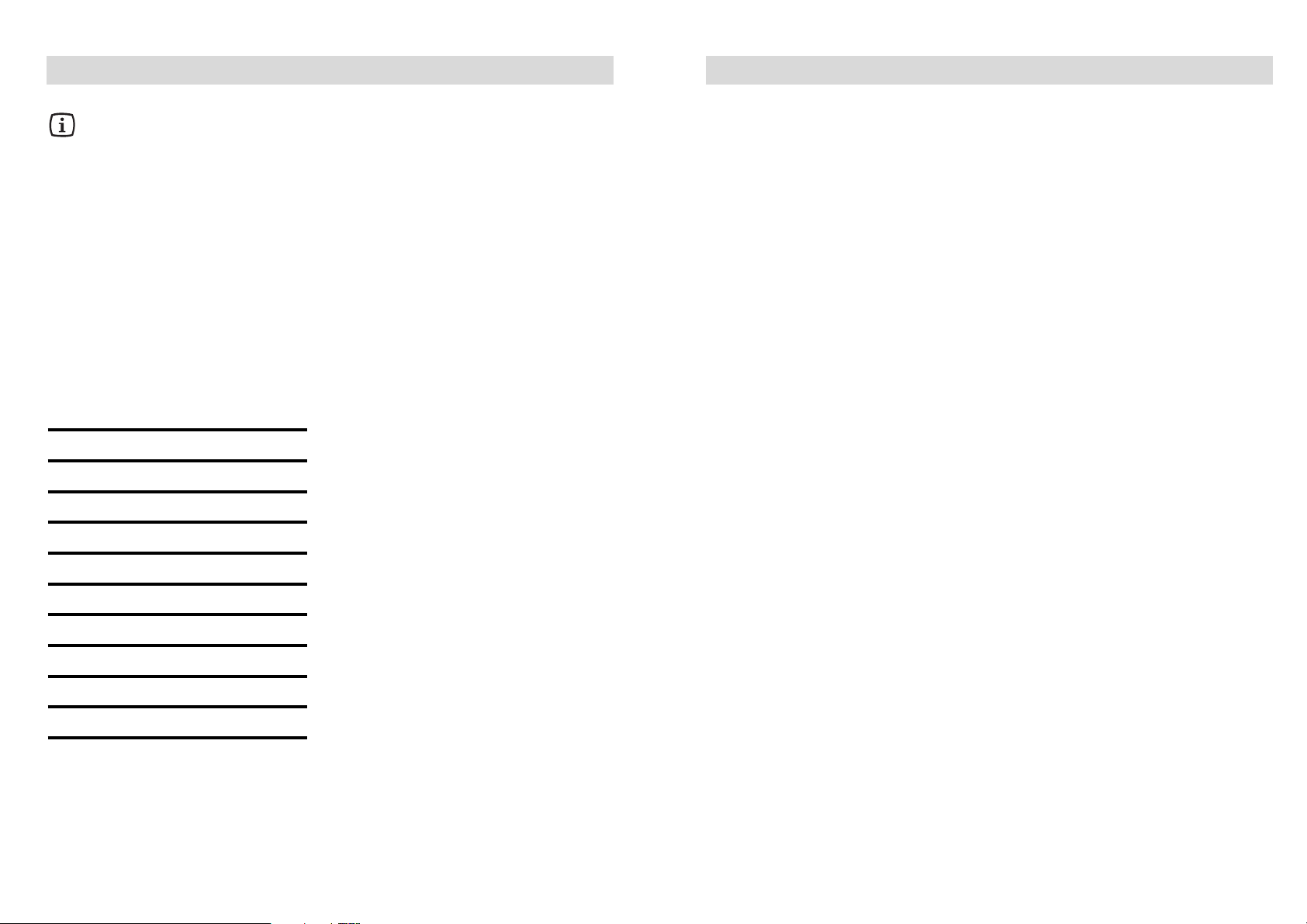

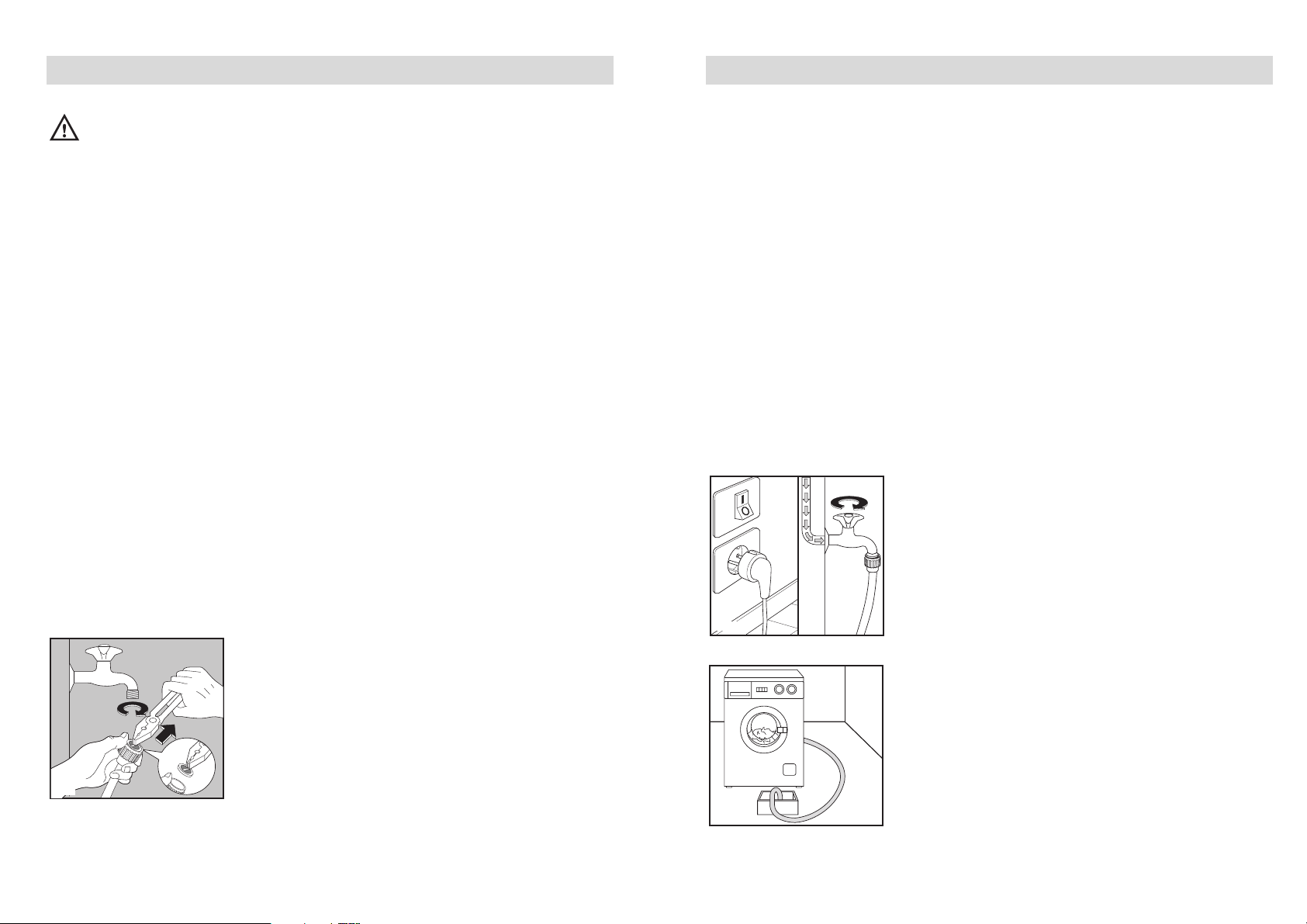

Emergency emptying out

If the water is not discharged (drain

pump is blocked, filter or drain pipe is

clogged), proceed as follows to empty

out the machine:

• pull out the plug from the power

socket;

• close the water taps;

• if necessary, wait until the water has

cooled down;

• place a bowl on the floor;

• put the drain hose end into the bowl

and let the water come out.When

the bowl is full, hook the hose back

up and empty the bowl. Repeat the

procedure until water stops flowing

out.

P1071

ON

OFF

P 1070

Should it not be possible to have

access to the drain hose or pipe

because, for example, the appliance

is built in the kitchen furniture, slightly

loosen the drain filter after placing a

bowl on the floor, to let the water

come out slowly.

At the end screw the filter again.

Warning

When the appliance is in use and

depending on the programme

selected there can be hot water in the

filter.Never remove the filter during

a wash cycle, (unless it is absolutely

necessary - see “Emergency

emptying out”), always wait until the

appliance has finished the cycle, and

is empty. When replacing the filter,

ensure it is securely retightened so as

to stop leaks and young children

being able to remove it.

Cleaning the water inlet

filters

If your water is very hard or contains

traces of lime deposit, the water inlet

filters may become clogged.

It is therefore a good idea to clean

them from time to time.

Turn off the water taps. Unscrew the

water inlet hoses. Clean the filters

using a hard bristle brush. Tighten up

the inlet hoses.

P0041

The dangers of freezing

If the machine is exposed to

temperatures below 0°C, certain

precautions should be taken.

• Turn off the water taps.

• Unscrew the inlet hoses.

• Unhook the drain hose from the rear

support and position the end of this

hose and that of the inlet hoses in a

bowl.

• Run the draining programme.

• Disconnect the appliance.

• Screw the inlet hoses and reposition

the drain hose.

When you intend to start the machine

up again, make sure that the room

temperature is above 0°C.

Maintenance and Cleaning Maintenance and Cleaning

Page 16

Something Not Working Something Not Working

Certain problems are due to lack of simple maintenance or oversights, which can

be solved easily without calling out a service agent. Before you call, please carry

out the checks listed below.

You can find the Brandt Service telephone number at the back of this booklet.

Symptom Possible causes

• The machine does not

start:

• The door has not been closed.

• The plug is not properly inserted in

the power socket.

• There is no current at the socket.

• The main fuse or the fuse in the

plug has blown.

• The selector dial is not correctly

positioned.

• The ON/OFF button has not been

depressed.

• The machine does not fill:

• The water taps are closed.

• The filters in the inlet hoses are

blocked.

Refer to paragraph “Cleaning the

water inlet filters”.

• The inlet hoses may be squashed or

kinked.

• The door has not been closed.

• The machine fills then

empties immediately:

• The end of the drain hose is too low

(see “ water drainage”in “Installation

instructions”).

• The drain hose may be squashed or

kinked.

• The ANTI-CREASE option has

been selected.

• The drain filter may be blocked.

(Please refer to “Maintenance”:

Emergency emptying out).

• The drain hose extension is not

correct. Follow the instructions for

connecting to the waste.

• The drainage system pipes are

blocked.

• The wash load is unbalanced:

redistribute the clothes inside the

drum to allow the machine to spin.

• There is water on the floor:

• Too much detergent or unsuitable

detergent has been used (creates

too much foam).

• Check whether there are any leaks

from one of the inlet hoses fittings. It

is not always easy to see this as the

water runs down the hose; check to

see if it is damp.

• The drain hose may be damaged or

not securely positioned.

• The detergent dispenser drawer or

recess is clogged.

• The drainage system pipes are

blocked.

• The drain filter has not been

properly screwed on after cleaning.

• Unsatisfactory washing

results:

• Too little detergent or unsuitable

detergent has been used. An

insufficient amount of detergent

leaves the laundry looking grey and

causes lime scale to form.

• Stubborn stains have not been

treated prior to washing.

• The correct wash programme has

not been selected.

• Too much laundry has been placed

in the drum.

• The machine does not

empty and/or does not

spin:

• The machine vibrates when

spinning or is noisy:

• The internal packing has not been

removed.

• The machine is in contact with the

wall or furniture.

• The machine is not level.

• The washing load is badly

distributed in the drum.

• Maybe there is very little laundry in

the drum.

• The door will not open:

• The programme is still running.

• The door lock has not yet released.

• Water in the tub.

Page 17

• Spinning starts late or the

machine does not spin:

• The electronic unbalance detection

device has cut in because the

laundry is not evenly distributed in

the drum.The laundr y is

redistributed by reverse rotation of

the drum.This may happen several

times before the unbalance

disappears and normal spinning can

resume. If, after 10 minutes, the

laundry is still not evenly distributed

in the drum, the machine will not

spin. In this case, redistribute the

load manually and select the spin

programme.

• The machine makes an

unusual noise:

• The machine is fitted with a new

type of motor which makes an

unusual whistling noise, different

from the noise made by traditional

motors.This new motor ensures a

softer start and more even

distribution of the laundry in the

drum when spinning, as well as

increased stability of the machine.

• No water is visible in the

drum:

• Machines based on modern

technology operate very

economically using very little water

without affecting performance.

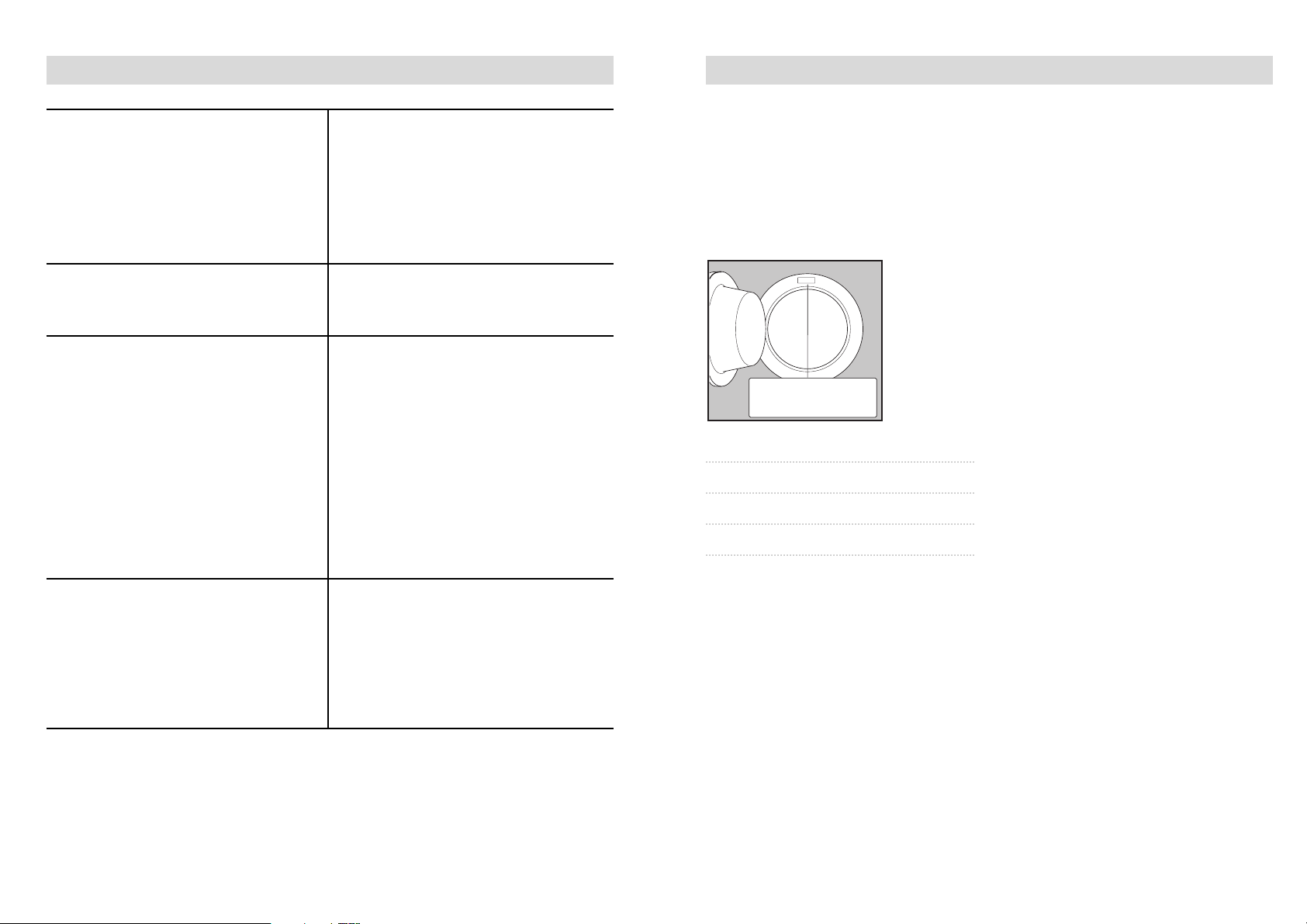

If after the above checks, there is still

a fault, please call 0870 600 1301.

When you call please make sure you

give the model and serial number of

the appliance.

This information can be found on the

rating plate (see picture).

Mod. ..........

Prod. No. ...........

Ser. No. .........

Mod.

..........

Ser.

P0042

• The machine does not dry

or does not dry properly

• The drying time has not been

selected

• The water taps are not turned on

• The drain filter is clogged

• The machine is overloaded

• The selected drying time or sector

are not suitable for the laundry

Something Not Working Something Not Working

Page 18

Safety Information

• When unpacking the appliance,

check that it is not damaged. If in

doubt, do not install it and contact

the Service Agent.

• This appliance is heavy. Care

should be taken when moving it.

• It is dangerous to alter the

specifications or attempt to modify

this product in any way.

• All packing and transit bolts must be

removed before use. Serious

damage can occur to the product

and to property if this is not adhered

to.See relevant section in

instructions.

• Any plumbing work required to

install this appliance should be

carried out by a qualified plumber or

competent person.

• Any electrical work required to

install this appliance should be

carried out by a qualified electrician

or competent person.

• Check that the domestic electrical

installation can take the maximum

load required (see “Technical

Specifications”), also taking into

account any other appliances in

use.

• Adaptors and extension cables must

not be used. Risk of fire!

• Care must be taken to ensure that

the appliance does not stand on the

electrical supply cable.

• If the machine is situated on a

carpeted floor, please adjust the

feet in order to allow air to circulate

freely.

• Should the appliance electrical

supply cable need to be replaced,

this should be carried out by our

Service Agent.

For the installer Technical Specifications

DIMENSIONS Height 82 cm

Width 60 cm

Depth 54 cm

POWER SUPPLY VOLT A GE 230-240 V/50 Hz

TOTAL POWER ABSORBED 2550 W (13A)

WATER PRESSURE Minimum (hot) 0.35 bar (3.5 N/cm2)

Minimum (cold) 0.48 bar (4.8 N/cm2)

Maximum 7.60 bar (76 N/cm2)

Washing Drying

MAXIMUM RECOMMENDED Cotton, linen 4.5 kg 2.25 kg

LOAD Synthetics 2.5 kg 1.50 kg

Delicate fabrics 2.5 kg Wool 1 kg -

SPIN SPEED Maximum 1200 r pm

This appliance complies with the following E.E.C. Directives:

- 73/23 EEC of 19.2.73 (Low Voltage Directive) and subsequent

modifications;

- 89/336 EEC of 3.5.89 (Electromagnetic Compatibility Directive) and

subsequent modifications.

Page 19

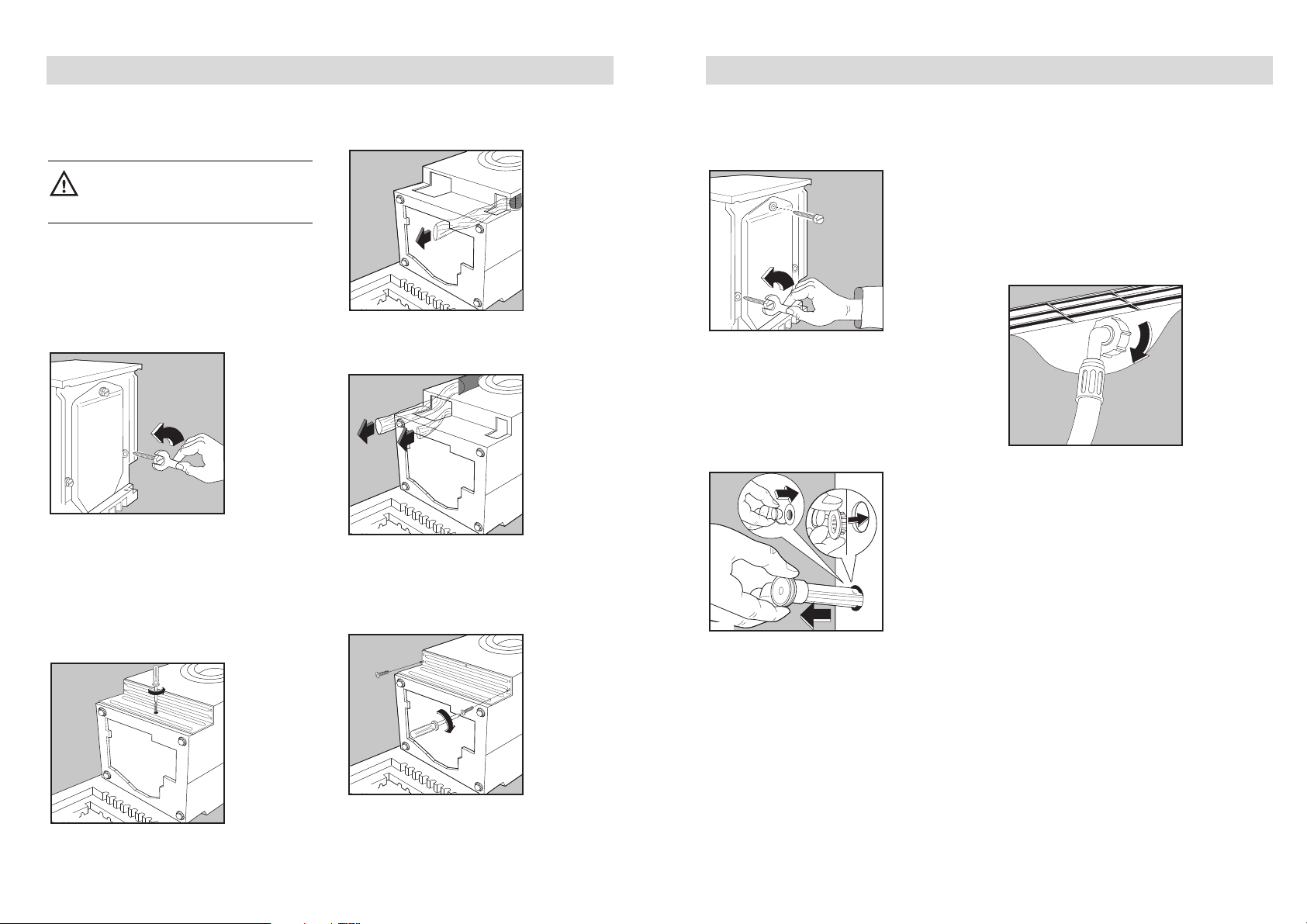

Removing the transport

safety devices

All transit bolts and packing

must be removed before using

the appliance.

You are advised to keep all the

transport safety devices for re-use

in case the machine is to be

transported again.

1. Using a spanner unscrew and

remove the rear right bolt.

2. Lay the machine gently on its

back, making sure that the hoses

are not squashed.

3. Remove the polystyrene base and

take off the bottom panel by

unscrewing the central screw.

P0457

P0255

4. Carefully slide out the right

polythene bag.

5. Repeat the operation for the left and

central polythene bag.

6. Re-fit the bottom panel using the 4

screws supplied with the door

hinges (in the plastic bag) and the

previously removed screw.

P0453

P0016

P0015

7. Set the machine upright and

remove the two remaining bolts

from the back.

8. Pull out the three plastic spacers

from the holes into which the bolts

were fitted.

9. Plug the open holes with the plugs

which are supplied with the

instruction booklet.

P0020

P0256

Positioning

Before positioning the machine in its

definitive place, rotate the inlet hoses

at the back of the appliance in order

to suit the water supply system.To do

this: loose the ring nuts, position the

hoses and tighten the ring nuts again

to prevent leaks.

Install the machine on a flat hard

floor.

Make sure that air circulation around

the machine is not impeded by

carpets, rugs etc. Check that the

machine does not touch the wall or

other kitchen units.

Never place cardboard, wood or

similar materials under the machine to

compensate for any unevenness in

the floor.

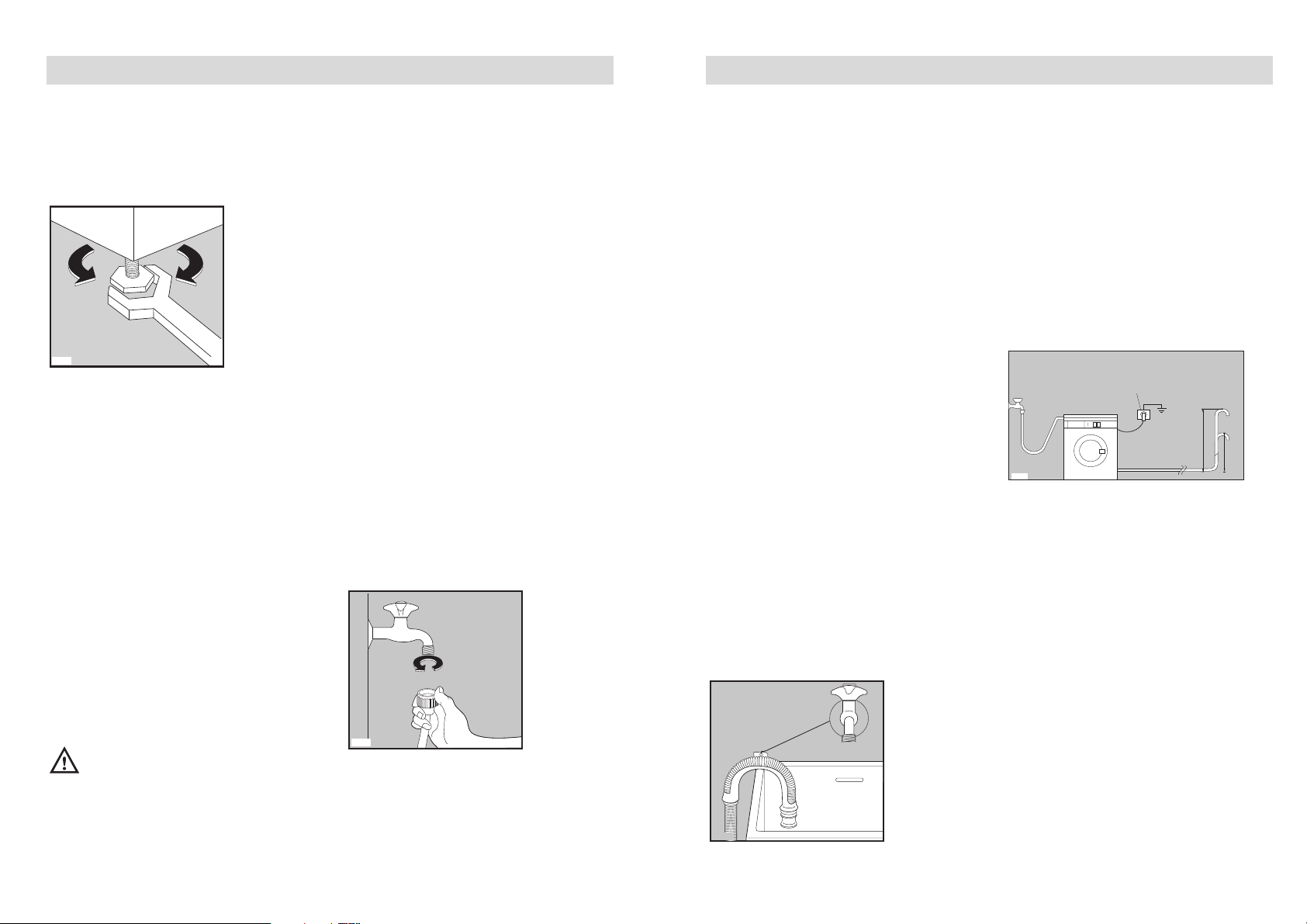

Levelling

Level the washing machine by raising

or lowering the feet.The feet may be

tight to adjust as they incorporate a

self locking nut, but the machine

MUST be level.

P0021

Installation

Installation

Page 20

Installation should comply with local

water authority and building

regulations’ requirements.

The appliance must be given a

separate cold water supply and not be

connected to a mixer tap, a single

outlet water heater or a booster pump.

A minimum water pressure of 0.48 bar

is required for safe operation of the

appliance.

The inlet hoses must not be

lengthened. If they are too short and

you do not wish to move the taps, you

will have to purchase new, longer

hoses specially designed for this type

of use.

Water drainage

The end of the drain hose can be

positioned in three ways:

Hooked over the edge of a sink

using the plastic U-piece supplied

with the machine. In this case, make

sure the end cannot come unhooked

when the machine is emptying.

This could be done by tying it to the

tap with a piece of string or attaching

it to the wall.

P0022

In a sink drain pipe branch.This

branch must be above the trap so that

the bend is at least 60 cm above the

ground.

Directly into a drain pipe at a

height of not less than 60 cm and not

more than 90 cm.

The end of the drain hose must

always be ventilated, i.e.the inside

diameter of the drain pipe must be

larger than the outside diameter of the

drain hose.

The drain hose must not be kinked.

Run it along the floor; only the par t

near the drainage point must be

raised.

The drain hose may be extended to a

maximum of 4 metres. An additional

drain hose and joining piece is

available from our Service Agent.

Important

Before connecting up the machine to

new pipework or to pipework that has

not been used for some time, run off a

reasonable amount of water to flush

out any debris that may have

collected in the pipes.

P1039

3 pin

Max. 90 cm.(35.4")

Min.60 cm.

(23.6")

Installation

Any necessary adjustment can be

made with a spanner.Accurate

levelling prevents vibration, noise and

displacement of the machine during

operation.

Some vibration is inevitable,

especially if mounted on a wooden

floor.

Sprung wooden floors are particularly

susceptible to vibration. For advice,

consult a builder. If possible, always

place the machine on a solid floor.

Special conditions

If the floor is carpeted or covered with

crumbly or soft material, insert a rigid

support base under the feet to prevent

noise, vibration or displacement.The

base should protrude a few

centimetres beyond the edges of the

machine.

Warning

The machine should NOT be

placed on deep pile carpeting.

P1051

Note

Please ensure that when the

appliance is installed it is easily

accessible for the engineer in the

event of a breakdown.

Water inlet

The appliance has two inlet hoses,

hot and cold, with female 3/4” BSP

thread connectors. If this connection

is not compatible with the plumbing of

the existing installation, a variety of

connectors are available from good

hardware stores and plumbers

merchants to suit most domestic

plumbing. Any alteration to your

existing plumbing must be carried out

by a competent person, or qualified

plumber.

The inlets on the back of the

appliance are colour coded, blue for

cold and red for hot.

Connect the water inlet hoses to taps

with a 3/4” thread.

If only a cold water supply is

available, connect the two hoses to a

cold water outlet by means of a «Y»

connection piece.

P1088

Installation

Page 21

Permanent connection

In the case of permanent connection

it is necessary that you install a

double pole switch between the

appliance and the electricity supply

(mains), with a minimum gap of 3mm

between the switch contacts and of a

type suitable for the required load in

compliance with the current electrical

regulations.

The switch must not break the yellow

and green earth cable at any point.

IMPORTANT!

The power supply cable must be

easily accessible after installing the

appliance.

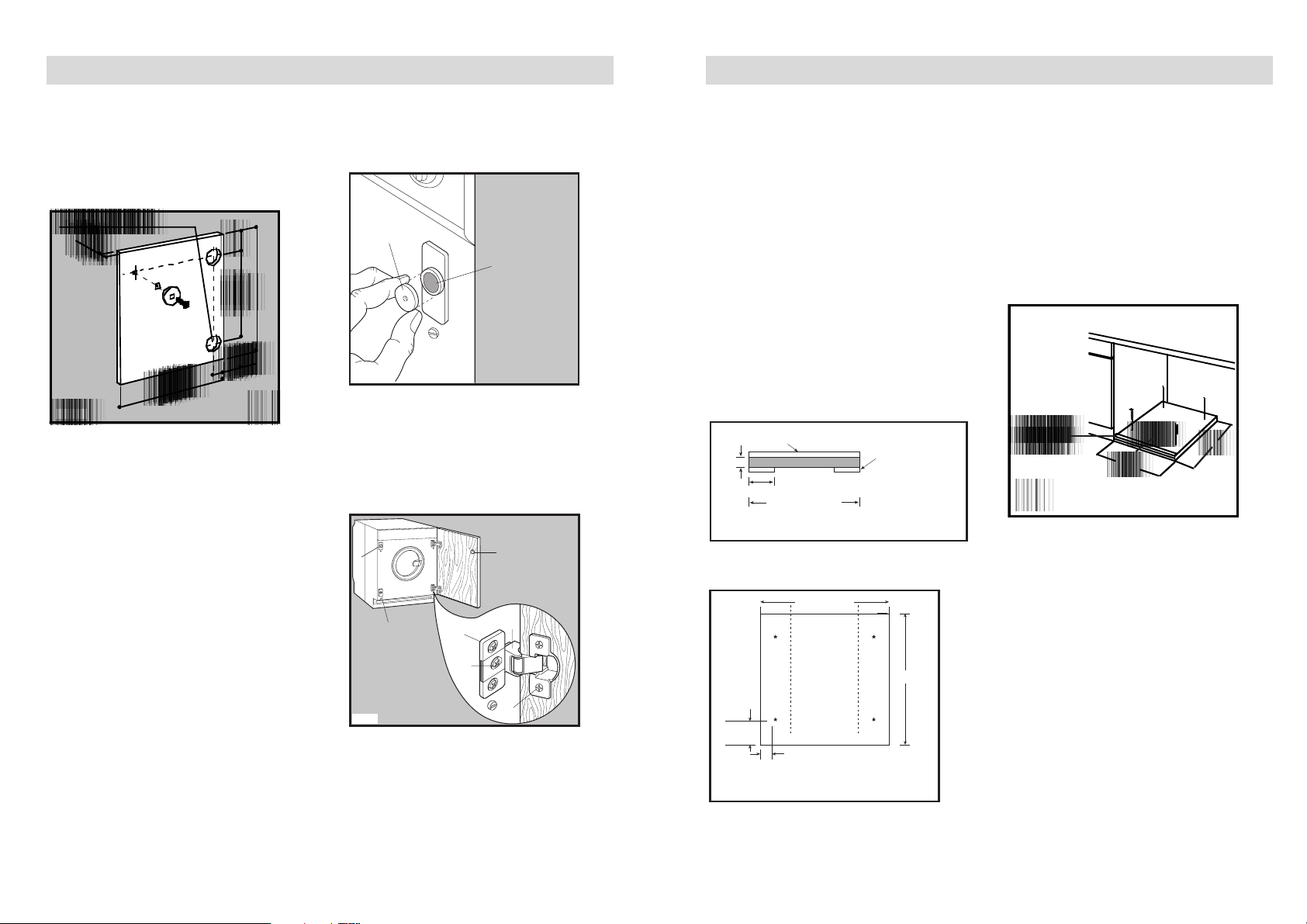

Building-in

This appliance has been designed to

be built into the kitchen furniture.

The recess should have the

dimensions shown in picture A.

P0965

820 min

600 min.

600

596

416

176,5

818

541

195

490

160

120

90

8

515

165

A

Preparation and assembly of

the door

The machine is originally prearranged for the assembly of a door

opening from right to left.

In this case it is sufficient to screw in

the hinges (1) and the countermagnet (6) provided with the

appliance, at the right level (Fig.B).

a) Door

The dimensions of the door should

be:

- width 595-598 mm

- thickness 16-22 mm

The height (C-Fig. C) depends on the

height of the adjacent furniture's base.

b) Hinges

To mount the hinges it is necessary to

drill two holes (dia. 35 mm, depth 12.514 mm depending on the depth of door

furniture) on the inner side of the door.

The distance between the holes hobs

fixing centres must be 416 mm.

The distance (B) from upper edge of

the door to the centre of the hole

depends on the adjacent furniture's

dimensions.

4

1

2

3

6

1

2

3

P0982

7

B

5

Installation

Electrical connection

Any electrical work required to install

this appliance should be carried out

by a qualified electrician or competent

person.

WARNING:THIS APPLIANCE

MUST BE EARTHED.

The manufacturer declines

any liability should this safety

measure not be observed.

Before switching on, make sure the

electricity supply voltage is the same

as that indicated on the appliance’s

rating plate.The rating plate is located

at the top of the rim of the open door.

The appliance is supplied with a

13amp plug fitted.

In the event of having to change the

fuse in the plug supplied, a 13amp

ASTA approved (BS1363 A) fuse must

be used.

Should the plug need to be replaced

for any reason, proceed as described

below.

Mod. ..........

Prod. No. ...........

Ser. No. .........

Mod.

..........

Ser.

P0042

The wires in the mains lead are

coloured in accordance with the

following code:

Green and Yellow - Earth

Blue - Neutral

Brown - Live

The wire coloured green and yellow

must be connected to the terminal

marked with the letter «E» or by the

earth symbol or coloured green

and yellow.

The wire coloured blue must be

connected to the terminal marked

«N» or coloured black.

The wire coloured brown must be

connected to the terminal marked «L»

or coloured red.

Upon completion there must be no

cut, or stray strands of wire present

and the cord clamp must be secure

over the outer sheath.

WARNING:

A cut off plug inserted into a

13 amp socket is a serious

safety (shock) hazard.

Ensure that the cut off plug is

disposed of safely.

GREEN & YELLOW

BROWN

CORD CLAMP

BLUE

13A

P1041

E

N

L

Installation

Page 22

Recommendations regarding

the construction and fitting of

a base when the installation

requires an integrated

appliance to be raised

Where the appliance has been raised by

mounting onto a wooden base provided

by the installer.The material used to

construct the base should have a non

slip surface, be water repellent and if

possible be one solid piece.

If it is not possible to use one solid

piece, due to the additional height

required, ensure that any additional

strips of timber are glued and screwed

to the underside of the base (see Fig. F).

Drill four fixing holes (see Fig.G)

600-605 mm

50 mm

Front edge

Top view

95 mm

490 mm

G

600-605 mm

Front view

5 mm Hardwood strip

Additional pieces of

timber should run

from front to back

100 mm

40 mm

F

Position the base into the recess with its

front edge as far forward as the

adjoining plinth line will allow. The

reason for placing the base in this

position is to allow a small strip of

beading to be fitted in front of the

appliance feet.

Fix the base firmly to the floor using four

appropriate countersunk screws (see

Fig. H).

With the appliance installed adjust all

four feet ensuring the machine is stable,

and a clearance of approximately 5 mm

is left between the top of the machine

and the underside of the worktop.

A final check for stability should be

carried out with the machine on spin

with a load, this will identify the need for

any further fine adjustment to the feet.

A strip of beading approximately

605 mm W, x 5 mm H, x 25 mm D must

be screwed down into the base directly

in front of the machine’s feet, this will

provide additional security.

If required an additional door magnet,

part number 1242394-00/3 and disc,

part number 1242393-00/5 are available

from spare parts.

Installation

The required dimensions are given in

the picture C.

The hinges will be fixed to the door by

means of screws for wood (2-Fig.B)

supplied with the appliance.

c) Mounting the door

Fix the hinges (1) to the machine by

means of the M 5x9 screws (3-Fig. B).

The hinges can be adjusted to

compensate for possible uneven

thickness of the door.

To align the door perfectly it is

necessary to loosen the screw (3-Fig.

B), adjust the door and tighten the

screw again.

d) Counter-magnet (6)

The appliance is pre-arranged for a

magnetic closure of the door.To

enable a correct operation of this

device, it is necessary to screw the

counter-magnet (6) (steel disk +

rubber ring) into the inner side of the

door.

Its position must correspond to the

magnet (4) on the appliance (see

picture D).

If the door has to be opened from left

to right, invert the position of the

plates (7), the magnet (4) and the

plates (5) (Fig. B and E). Mount the

countermagnet (6) and the hinges (1)

as previously described.

4

6

5

1

2

3

7

E

P0983

P0984

6

4

D

Installation

Page 23

After

After

-Sales Ser

-Sales Ser

vice

vice

● Congratulations on the purchase of your appliance, which

has been manufactured to the highest specification, and

should give you many years of use.

● Your appliance is guaranteed for all electrical failures and

mechanical failures for a period of twelve months from the

date of purchase, providing the appliance has been

installed and used in accordance with the instructions.

Please retain your receipt as proof of purchase.

● This warranty is only valid for domestic users and not where

the appliance is used for commercial purposes.

● This warranty does not affect your statutory rights.

● In the unlikely event of there being a problem, please call

0870 600 1301 where trained staff are available to advise

or book a service call to one of our authorised ser vice

agents. It will help to be prepared when calling by having

the model number of the appliance ready - this can be

found on the rating plate.

BRANDT UK LIMITED

INTEC FOUR

WADE ROAD

BASINGSTOKE

HANTS RG24 SNE

tel.: 0870 600 1301

fax.: 01256 34 6877

Loading...

Loading...